Biological method for extracting grease from flat almond

A technology for oil extraction and biology, applied in the direction of oil/fat production, fat production, fermentation, etc., can solve the problems of low extraction efficiency, increased cost, and limited industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

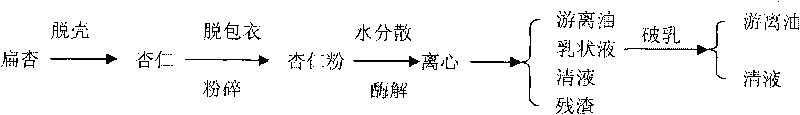

[0018] Such as figure 1 As shown, the flat almonds are crushed by a dry method with a pulverizer, the particle size is between 10-150 mesh, preferably 10-60 mesh, and the tissue cells of the flat almond raw material are destroyed. Mix the crushed flat almond powder and water in a mass ratio of 1:4, adjust the pH to 6.5, and the temperature to 50°C, add 0.1% neutral protease in the quality of the flat almond powder, and stir for 2 hours for enzymatic hydrolysis; then cool down to 40°C, then adjust the pH to 7.5, add 0.1% alkaline protease in the mass of flat almond powder, and then stir for 2 hours to obtain the enzymolysis solution; centrifuge the enzymolysis solution at 3500-4000r / min for 10min, To obtain free oil, emulsion, hydrolyzate and almond residue, add lipopeptide biological demulsifier accounting for 0.1% of the emulsion volume to the obtained emulsion, and after demulsification, centrifuge again at 3500-4000r / min for 10min to obtain free oil Combine the free oil ob...

Embodiment 2

[0020] Such as figure 1 As shown, the flat almonds are crushed by a dry method with a pulverizer, the particle size is between 10-150 mesh, preferably 10-60 mesh, and the tissue cells of the flat almond raw material are destroyed. Mix the crushed flat almonds and water with a mass ratio of 1:8, adjust the pH to 7.0, and the temperature is 50°C, add 0.5% neutral protease of the quality of flat almond powder, stir for 4 hours; then cool down to 40°C, adjust the pH to 8.0, add alkaline protease with 0.5% mass of flat almond powder, and then stir for 3 hours to obtain the enzymolysis solution; centrifuge the enzymolysis solution at 3500-4000r / min for 10min, then top-down Obtain free oil, emulsion, hydrolyzate and almond residue, add lipopeptide biological demulsifier accounting for 0.3% of the emulsion volume to the obtained emulsion, after demulsification, centrifuge again at 3500-4000r / min for 10min to obtain free oil; combine The free oil obtained by secondary centrifugation c...

Embodiment 3

[0022] Such as figure 1 As shown, the flat almonds are crushed by a dry method with a pulverizer, the particle size is between 10-150 mesh, preferably 10-60 mesh, and the tissue cells of the flat almond raw material are destroyed. Mix the crushed flat almonds and water with a mass ratio of 1:10, adjust the pH to 7.5, and the temperature is 50°C, add 1.0% of the mass of flat almond powder with neutral protease, and perform enzymatic hydrolysis for 6 hours; then lower the temperature to 40 ℃, adjust the pH to 8.5, add almond powder mass 1.0% alkaline protease, and then stir for 6 hours for enzymolysis to obtain an enzymolysis solution. After centrifuging the enzymatic solution at 3500-4000r / min for 10 minutes, free oil, emulsion, hydrolyzate and almond residue are obtained from top to bottom, and the obtained emulsion is added with a lipopeptide biodemulsifier accounting for 0.5% of the emulsion volume, After demulsification, centrifuge again at 3500-4000r / min for 10 minutes to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com