Process for producing yeast from waste beer yeast liquid

A technology for waste beer yeast and yeast essence, which is applied to the technical field of preparing yeast essence from waste beer yeast liquid, can solve the problems of long preparation period, poor seasoning effect, etc., and achieves improved yield, short production process time, delicious and mellow taste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] best practice

[0010] The specific embodiment of the present invention is given in detail by the following examples.

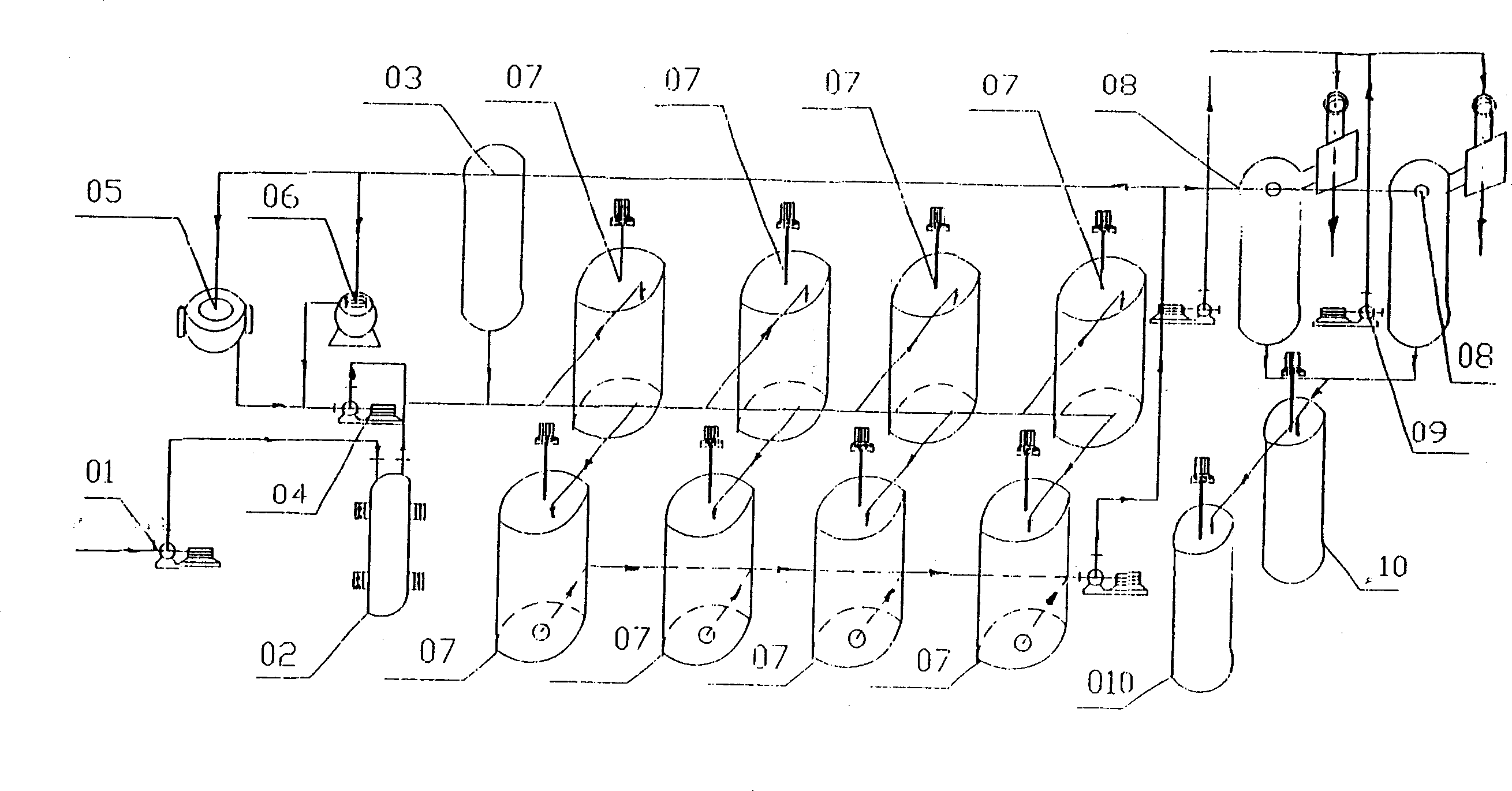

[0011] According to a process method of the present invention for preparing yeast essence by using waste beer yeast liquid, the process flow is as follows: raise the temperature of the waste yeast liquid to 50-55°C and keep it warm for a period of time, and strictly adjust the pH value to 5.5-6.5 , add salt, potassium dihydrogen phosphate, magnesium chloride, promote cell wall breaking and autolysis, heat preservation and stirring, then add enzyme preparation, continue heat preservation for 25-30 hours to completely dissolve the cells, and the nutrients such as amino acids and nucleotides in the cells will be released. It will dissolve into the solution, and after centrifugation, concentration and sterilization, yeast essence can be obtained.

[0012] More specifically, the present invention utilizes beer waste yeast liquid to prepare the technical me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com