Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

413 results about "Fish processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The term fish processing refers to the processes associated with fish and fish products between the time fish are caught or harvested, and the time the final product is delivered to the customer. Although the term refers specifically to fish, in practice it is extended to cover any aquatic organisms harvested for commercial purposes, whether caught in wild fisheries or harvested from aquaculture or fish farming.

Process engineering for extracting fishes processing offal fish oil by enzymolysis process

InactiveCN101248821ATake advantage ofHigh extraction rateEdible oils/fatsFood preparationNeutral proteaseHydrolysate

A process technology using enzymolysis method to extract leftover fish oil from fish processing comprises the following steps: preliminary treatment, in which the leftovers from the fish processing are cleaned and minced; protease hydrolysis, in which neutral protease and papain are hydrolyzed simultaneously; oil-water separation, in which hydrolysate is centrifugally filtered to remove residues, and filtrate undergoes oil-water separation via a centrifuge, thereby obtaining the fish oil and hydrolyzed protein; and fish oil refinement, in which refined fish oil can be obtained after the fish oil is degummed, depickled, decolored and deodorized. The leftovers from the fish processing can be hydrolyzed with the proteases to destroy the associative relation of protein and fat, thereby releasing axunge which undergoes oil-water separation by the tubular centrifuge to obtain the fish oil with high quality, and meanwhile, the protein therein can be fully utilized to produce hydrolyzed protein, so as to change wastes into valuables and synthetically and efficiently utilize the resources of the fish and the processing leftovers.

Owner:GUANGDONG OCEAN UNIVERSITY

Process for preparing micro-molecular fish scale collagen peptides

ActiveCN102154424AHigh yieldReduce the effect of enzyme activityPeptide preparation methodsFermentationFish processingCollagenan

The invention discloses a process for preparing micro-molecular fish scale collagen peptides and belongs to the technical field of biological extraction. The process comprises the following steps of: 1, pretreating fish scales, and removing impurities and fat on the surfaces of fish scales; 2, extracting fish scale collagen peptides by using a high-temperature sulfuric acid extraction method, wherein the extraction yield is over 95 percent; 3, purifying the extracting solution by adopting the process technology combining centrifugal separation and membrane separation to obtain macro-molecularfish scale collagen peptides of which the purity is over 90 percent; 4, hydrolyzing the macro-molecular fish scale collagen peptides by using protease, and performing enzymic inactivation to obtain the solution of micro-molecular fish scale collagen peptides of which the purity is more than 90 percent and the relative molecular weight is less than 1.5kD; and 5, spray-drying and quickly drying thesolution of collagen peptides to obtain the finished product of micro-molecular fish scale collagen peptides. The micro-molecular fish scale collagen peptides prepared by the process have the advantages of low cost, high yield, high purity and low molecular weight; moreover, in the process, the fish scales discarded in fish processing are fully utilized, and the wastes are changed into the valuables.

Owner:THIRD INST OF OCEANOGRAPHY STATE OCEANIC ADMINISTATION

Method for producing water-soluble fish protein organic fertilizer from fish

ActiveCN104892037AHigh nitrogen contentGood water solubilityAnimal corpse fertilisersClimate change adaptationHydrolysisProduced water

The invention belongs to the technical field of organic fertilizer production. In order to fully utilize nutrient substances in offal fish and leftovers generated after fish processing, the invention provides a method for producing a water-soluble fish protein organic fertilizer from fish, which comprises the following steps: raw material treatment, fermentation and enzyme hydrolysis, physical separation, water-soluble enzymolysis solution purification treatment, concentration, drying and packaging. The production method has the advantages of severe steps and scientific parameter setting, can prevent environmental pollution generated by fish leftovers, changes the waste leftovers into valuable substances, and can implement centralized collection and treatment on the leftovers generated by aquatic product processing enterprises.

Owner:荣成鸿德海洋生物科技有限公司

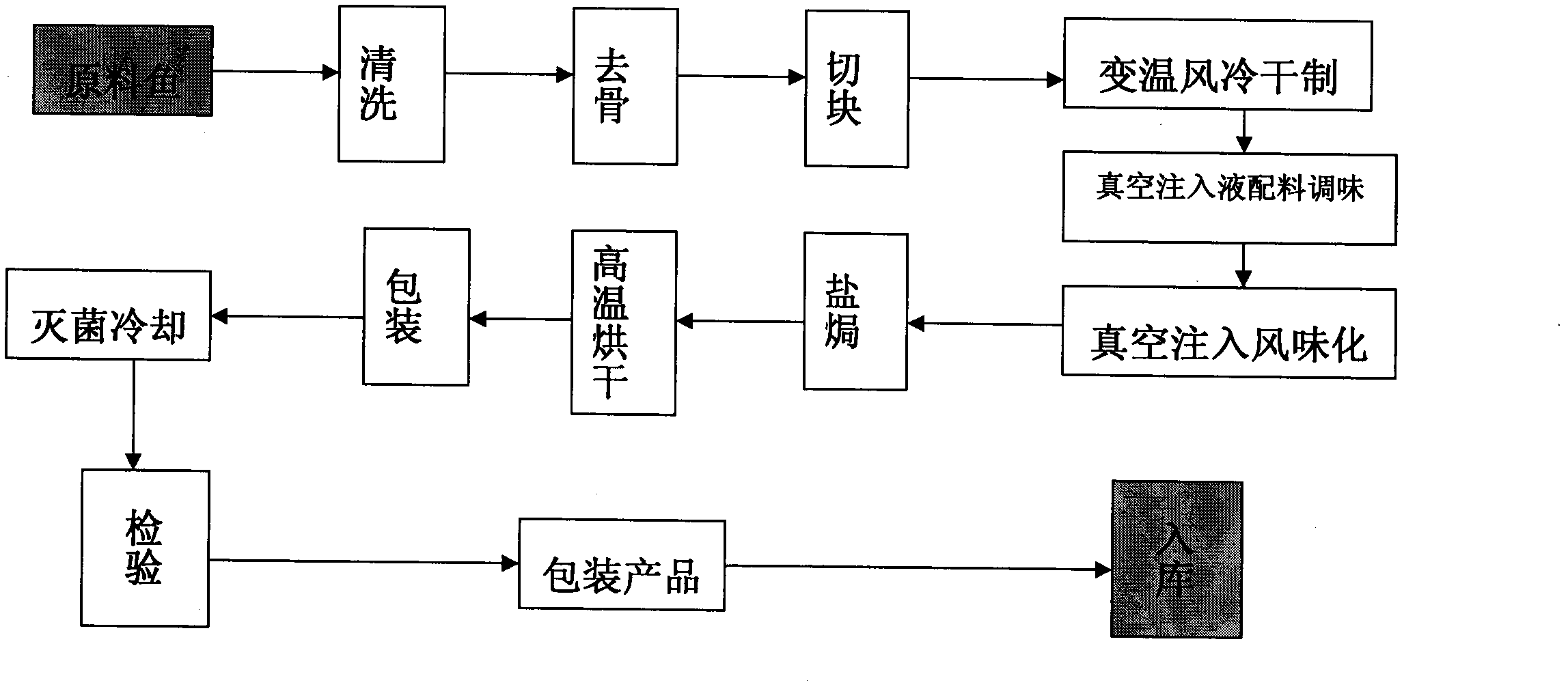

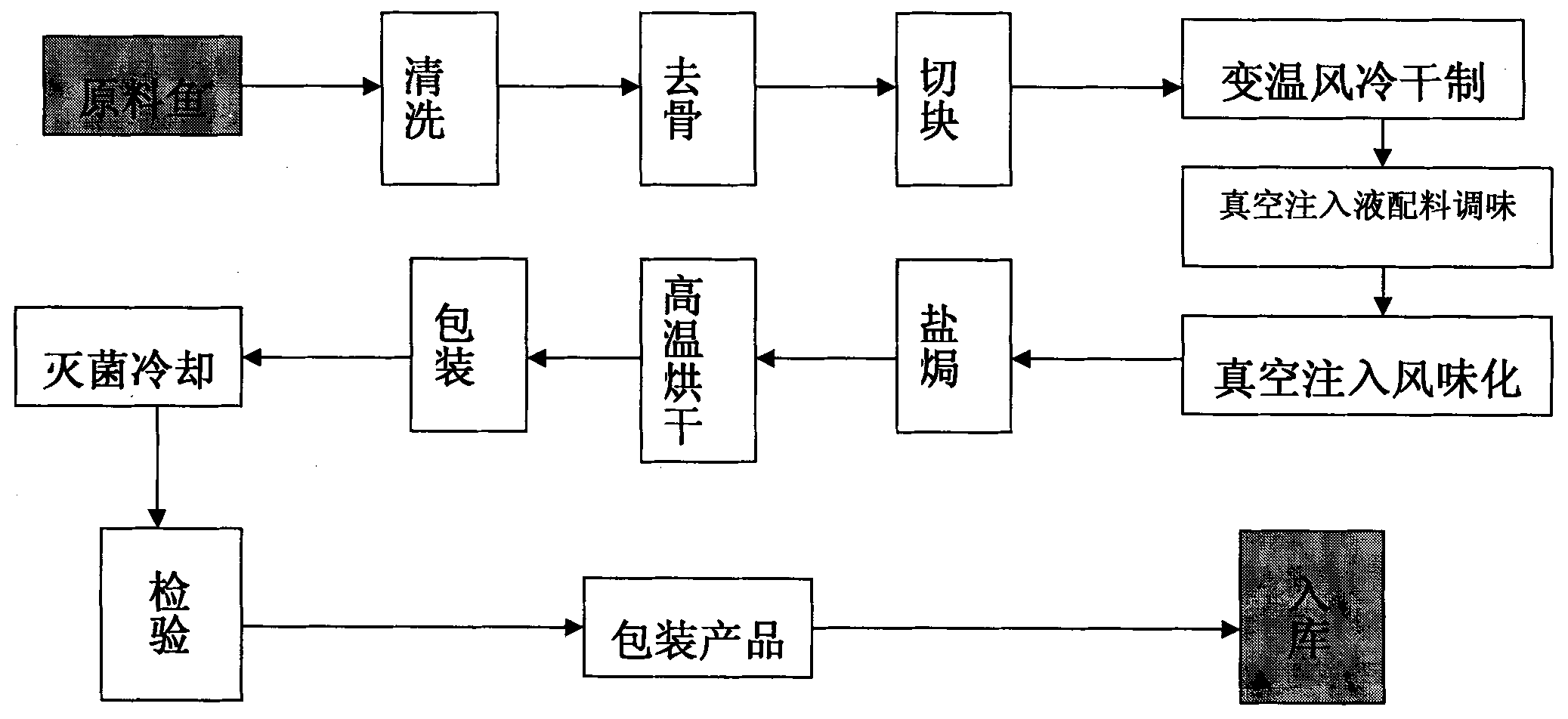

Instant salt baked fish processing method

InactiveCN101912126AImprove processing productivityImprove qualityFood preparationFlavorFish processing

The invention relates to an instant salt baked fish processing method, which comprises the following steps of: selecting raw material fish, cleaning, removing bones, cutting into blocks, drying through variable temperature air cooling, mixing and seasoning, injecting flavors in vacuum, performing salt baking, drying at high temperature, packaging, sterilizing and cooling, inspecting, packaging into a finished product, warehousing and other procedures. The instant salt baked fish has the advantages of high processing and production efficiency, good quality, long storage time, convenient eating, and delicious meat.

Owner:佛山六奇食品科技有限公司

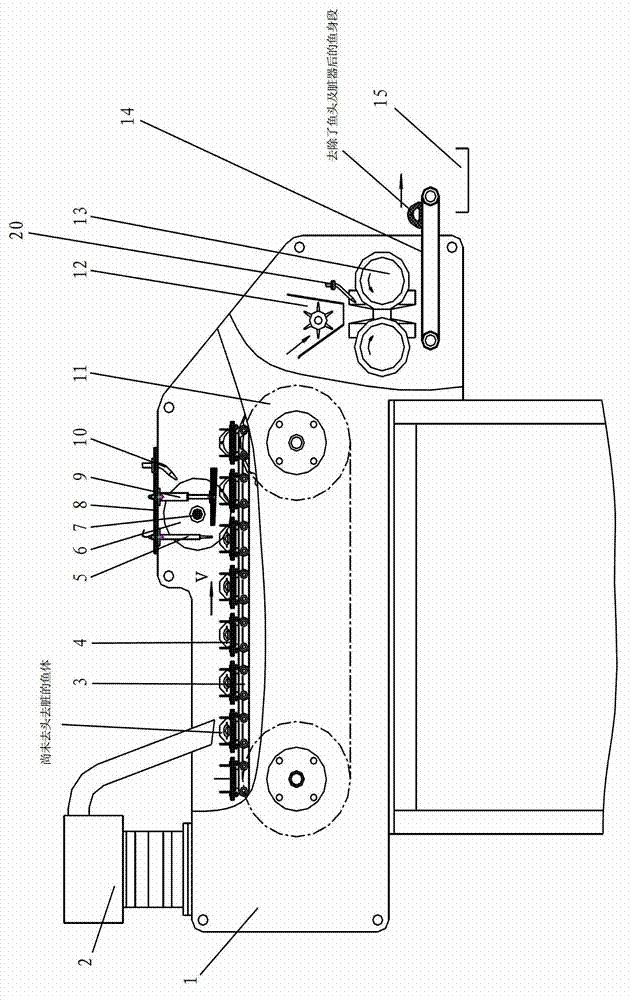

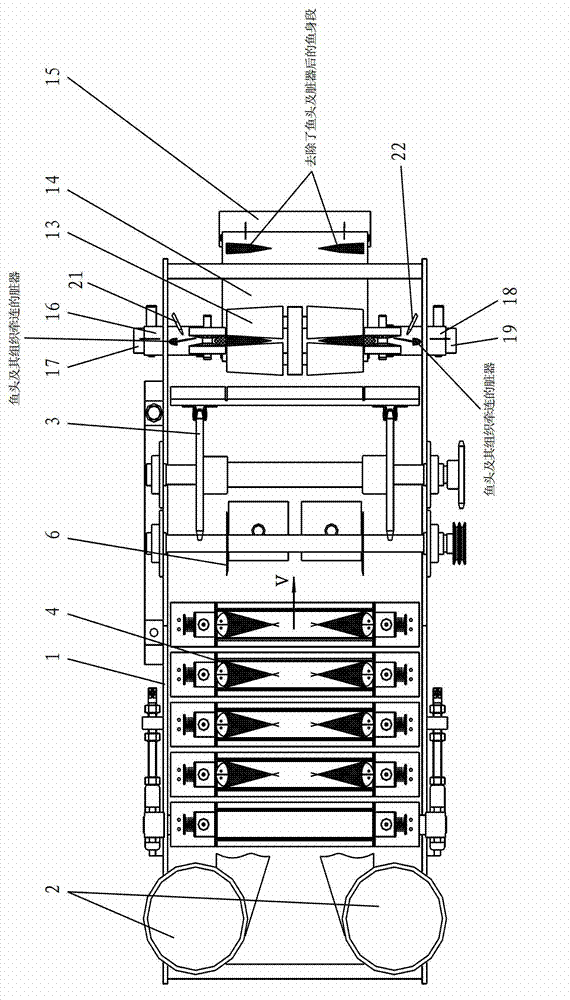

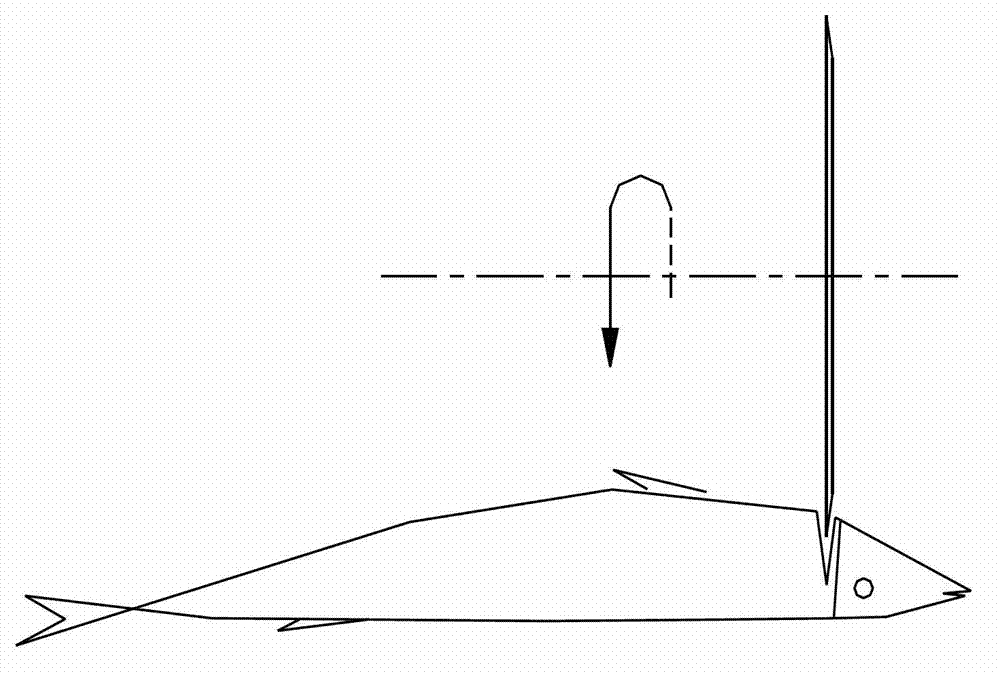

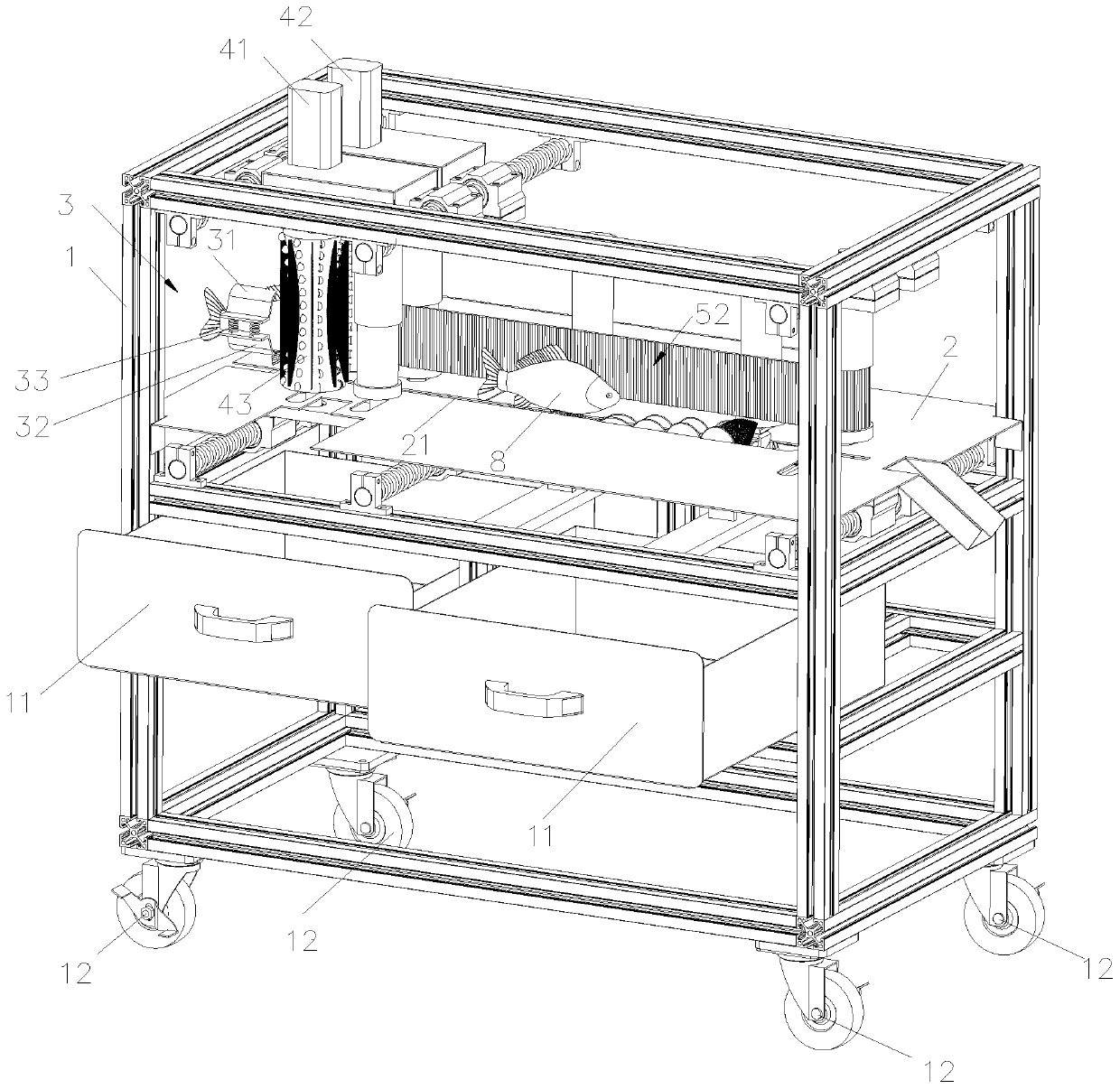

Machining method and machining equipment for removing heads and viscera of small fishes

InactiveCN102860346AReduce labor intensityImprove labor productivityFish processingThroatFish processing

The invention relates to a machining method and machining equipment for removing heads and viscera of small fishes and belongs to the field of fish processing. The machining method includes the followings steps of firstly, placing small fishes on a fish body conveying belt via a directional fish body feeder unit; secondly, placing the small fishes in distance-adjustable positioning grooves of the fish body conveying belt in a manner that the backs of the fish bodies face upwards and the bellies of the fish bodies face downwards, cutting off spines and peripherally connected muscular tissues via a disc cutter of a head cutting device while guaranteeing that the heads and the bodies of the backs of the fish bodies are cut off without cutting off flesh tissue of the bellies of the fish bodies and throat tissues connected with the viscera and the heads; thirdly, conveying the fish bodies not completely cut off and separated to a viscera remover device via a synchronous feeder, clamping and conveying the fish bodies, pulling and removing the heads, the viscera and connected throat tissues; and fourthly, conveying the fish bodies to a fish container, and feeding the heads and the viscera into other containers.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

Method for preparing fish protein powder without bitter and fishy smells

InactiveCN101347174AWide variety of sourcesAddress issues affecting its utilizationProtein composition from fishSide effectVacuum pack

A preparation method of a fish protein powder without bitter and fishy smell comprises the following technical process: low-value fish and fish processing leftovers are crushed, added with water, hydrolysis is controlled with protease by a pH-state method, and then enzyme is inactivated to obtain an enzymolytic protein liquid. The enzymolytic protein liquid is fermented by lactobacillus; the fermentation liquor is then sterilized, filtered, dried in spraying way and packaged in vacuum. The protein powder of the invention is prepared by utilizing the fish processing leftovers which has wide sources, thus providing a new approach for high-value utilizing the wastes from the fish preprocessing leftovers, and solving the problem that the utilization of the fish preprocessing leftovers is affected due to bitter and fishy substances from enzyme hydrolysate; and the preparation method of the invention is a biological enzymolysis method, which reduces the formation of bitter peptides by monitoring the enzymolysis process. The fish protein powder has the advantages of safe, effective, non-toxic and no side effects, and the fish protein powder also has rich nutritive materials, and can be developed as a food base material, thus having wide market prospect.

Owner:GUANGDONG OCEAN UNIVERSITY

Production method of collagen membrane

InactiveCN101942204AInhibit swellingLow mechanical strengthFlexible coversWrappersFishy odorNon collagenous protein

The invention discloses a method for producing a non-fishy smell collagen membrane by fish processing leftovers, such as fishbone, fish skin, fish scale, fish muscle and the like. The technical process comprises the following steps: removing non collagen, degreasing, removing fishy odor and deashing, stirring and the like to the fish processing leftovers, such as the fishbone, the fishskin, the fish scale, the fish muscle and the like; adding plasticizer in the collagen acquired by hot water extraction and centrifugal separation, stirring, defoaming, drying and the like to prepare the collagen membrane. The invention utilizes fish processing leftovers as main raw materials, and develops a new way for the comprehensive utilization and the product development of the fish processing leftovers; the prepared collagen membrane has good mechanical strength and transparency and no fishy odor, can replace parts of plastic packaging films, can be eaten together with the packaged food, and has good effects on reducing the waste emission of aquatic product processing enterprises, reducing the use of the plastic packaging film in food, and protecting the environment.

Owner:JIMEI UNIV

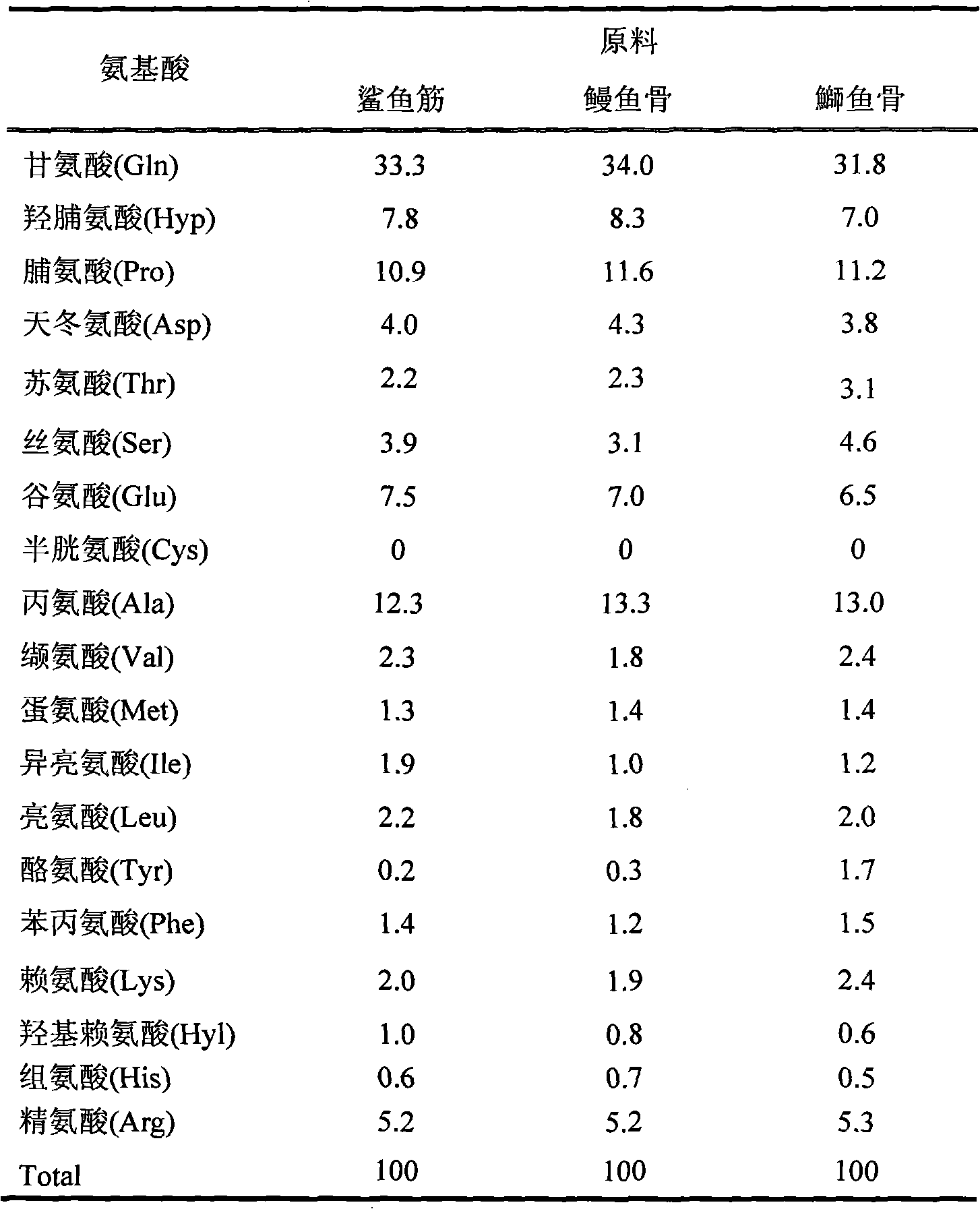

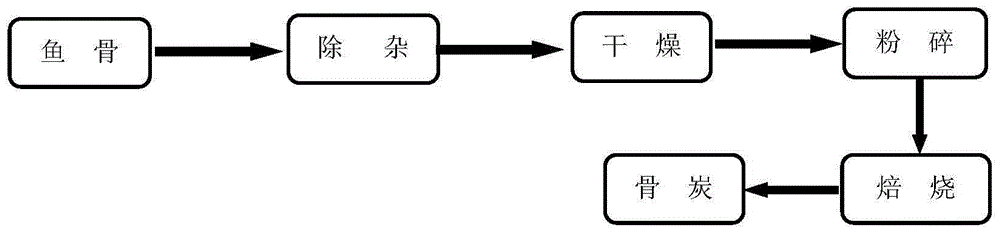

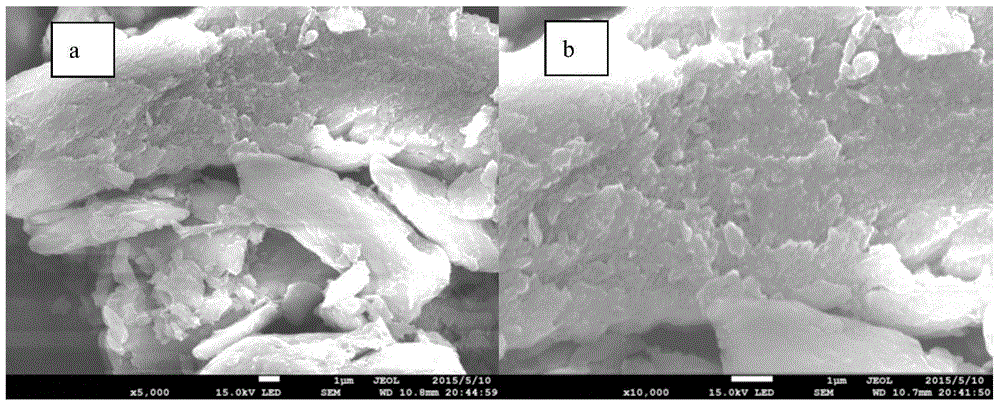

Fish bone charcoal adsorbent and preparation method and application thereof

InactiveCN104923159AIncrease capacityImprove adsorption capacityOther chemical processesWater/sewage treatment by sorptionSorbentFishing

The invention relates to fish bone charcoal adsorbent, a preparation method thereof and application to heavy metal waste water. The preparation method includes the following steps of 1 impurity removing, wherein an obtained fish bone raw material is stirred and scalded in water to remove impurities; 2 drying, wherein the fish bones are put into a drying oven to be dried after the impurities are removed; 3 pulverizing, wherein the dried fish bones are pulverized in a pulverizer, and obtained fish bone dust serves as an adsorbent raw material; 4 high-temperature roasting, wherein the prepared fish bone dust is roasted and carbonized at high temperature, naturally cooled to the room temperature and then taken out to obtain the fish bone charcoal adsorbent. The preparation method has the following advantages that fish processing waste is low in price and easy to obtain, as the fish processing waste is prepared into fish bone charcoal, the potential value of the fish processing waste can be developed further, and the environmental pollution caused by discarding the fishing processing waste can be effectively reduced. In addition, the prepared bone charcoal is high in stability and adsorbability, easy to regenerate after absorption and reusable.

Owner:WUHAN UNIV OF TECH

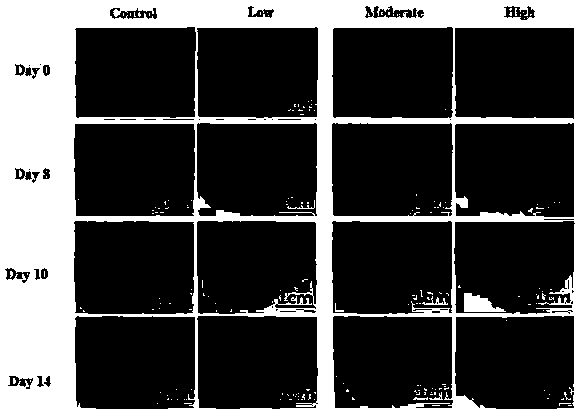

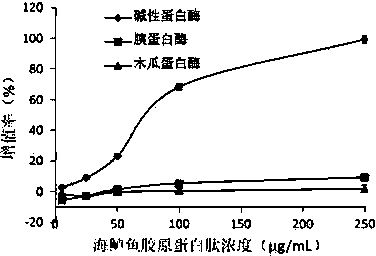

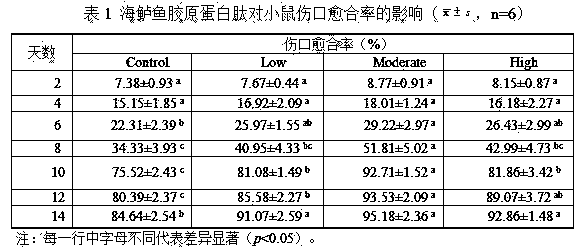

Enzyme preparation method of sea collagen peptide capable of promoting wound healing

ActiveCN104109705AEasy accessPromote healthy and sustainable developmentConnective tissue peptidesPeptide preparation methodsFreeze-dryingEngineering

The invention discloses an enzyme preparation method of sea collagen peptide capable of promoting the wound healing. The method comprises the following steps: (1) removing other proteins and impurities from by-products of orange rock-fish processing, opening the three-strand helical structure of collagen; (2) adding acid to extract the pre-treated collagen from the by-products of orange rock-fish processing, freeze-drying the obtained collagen, and saving the freeze-dried collagen as the substrate to prepare collagen peptide through enzymolysis in the next step; (3) adding water into the freeze-dried collagen to prepare a collagen solution, adding protease into the collagen solution to carry out enzymolysis so as to convert collagen into collagen peptide; (4) deactivating the enzyme, cooling; (5) removing the fishy smelling, decoloring; (6) subjecting the collagen peptide to centrifugation, saving the supernate for later use; (7) carrying out membrane separation to collect the collagen peptides with a molecular weight of 1000 to 3000 Da; (8) condensing the separated collagen peptides through rotation evaporation; (9) freeze-drying the condensed collagen peptide into powder. High bioactivity biological active peptide capable of healing the wounds is prepared from by-products of orange rock-fish processing through an enzyme method assisted by a membrane separation technology.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI +2

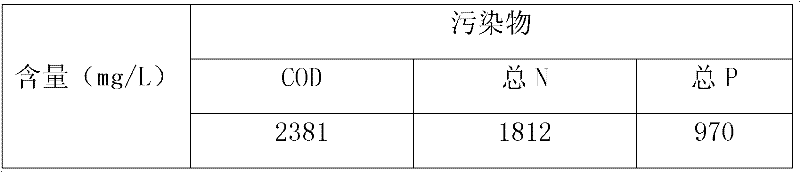

Treatment method of biogas slurry polluted by livestock and poultry breeding

InactiveCN102267787ASolve pollutionMeet emission standardsWaste water treatment from animal husbandryWaste based fuelIntensive treatmentTreatment effect

The invention discloses a method for treating biogas slurry contaminated by livestock and poultry breeding. It adopts the traditional pig-biogas-fish treatment mode of biogas slurry, and uses Bacillus preparation FB-1, photosynthetic bacteria preparation FP-1, lactic acid bacteria preparation FL-2, Five kinds of microbial preparations including nitrifying bacteria preparation FN-1 and denitrifying bacteria preparation FD-1, mycelium FC-2 of actinomycetes as microbial adsorbent and filter-feeding fish to strengthen the treatment of biogas slurry to improve the treatment effect, Improve conversion efficiency and realize resource utilization of biogas slurry nutrition. This method has low investment and operating costs, simple operation, good treatment effect, wide application range, and easy popularization in underdeveloped rural areas.

Owner:FUJIAN KEJIAQIMAI BIOENG

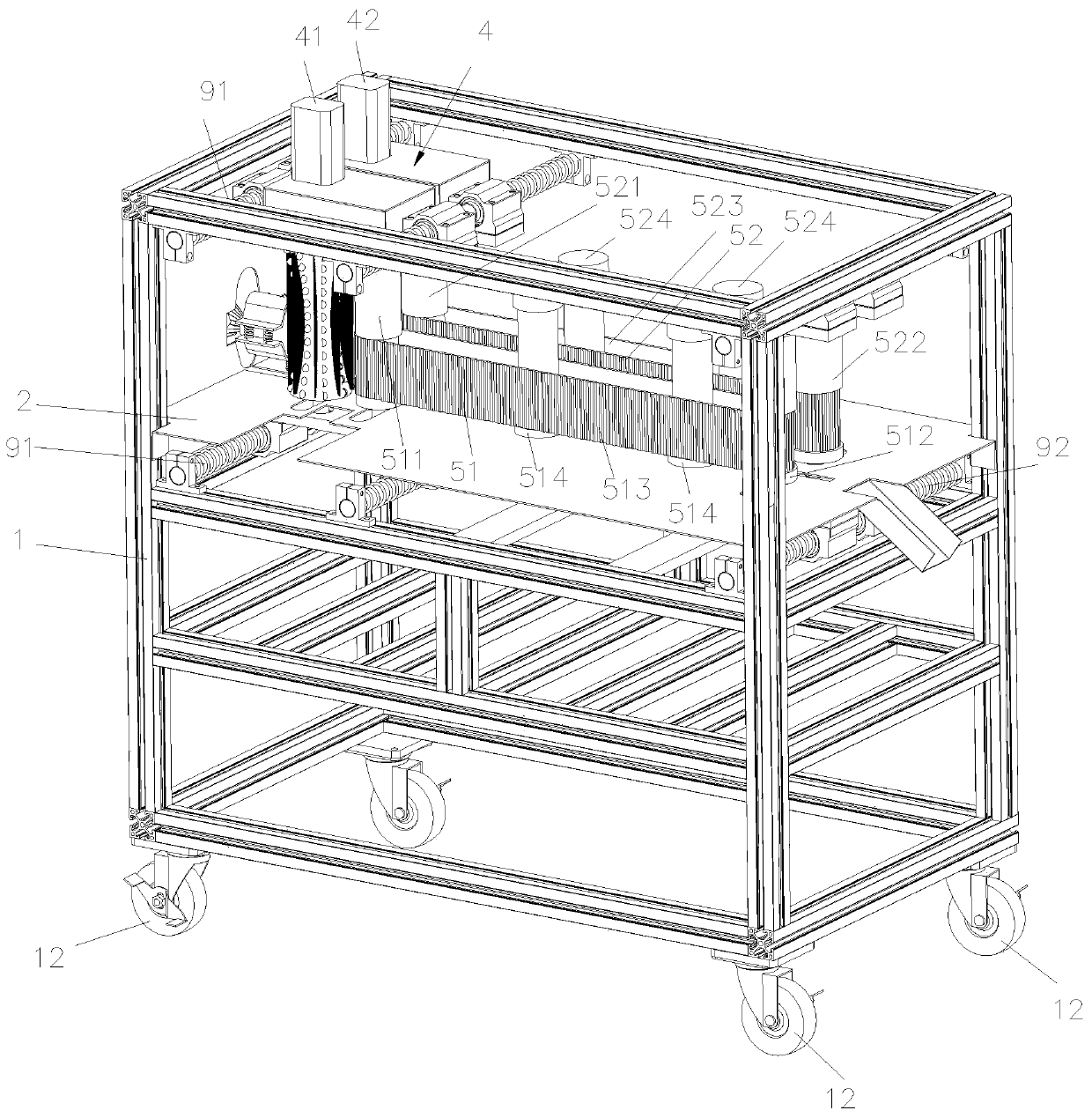

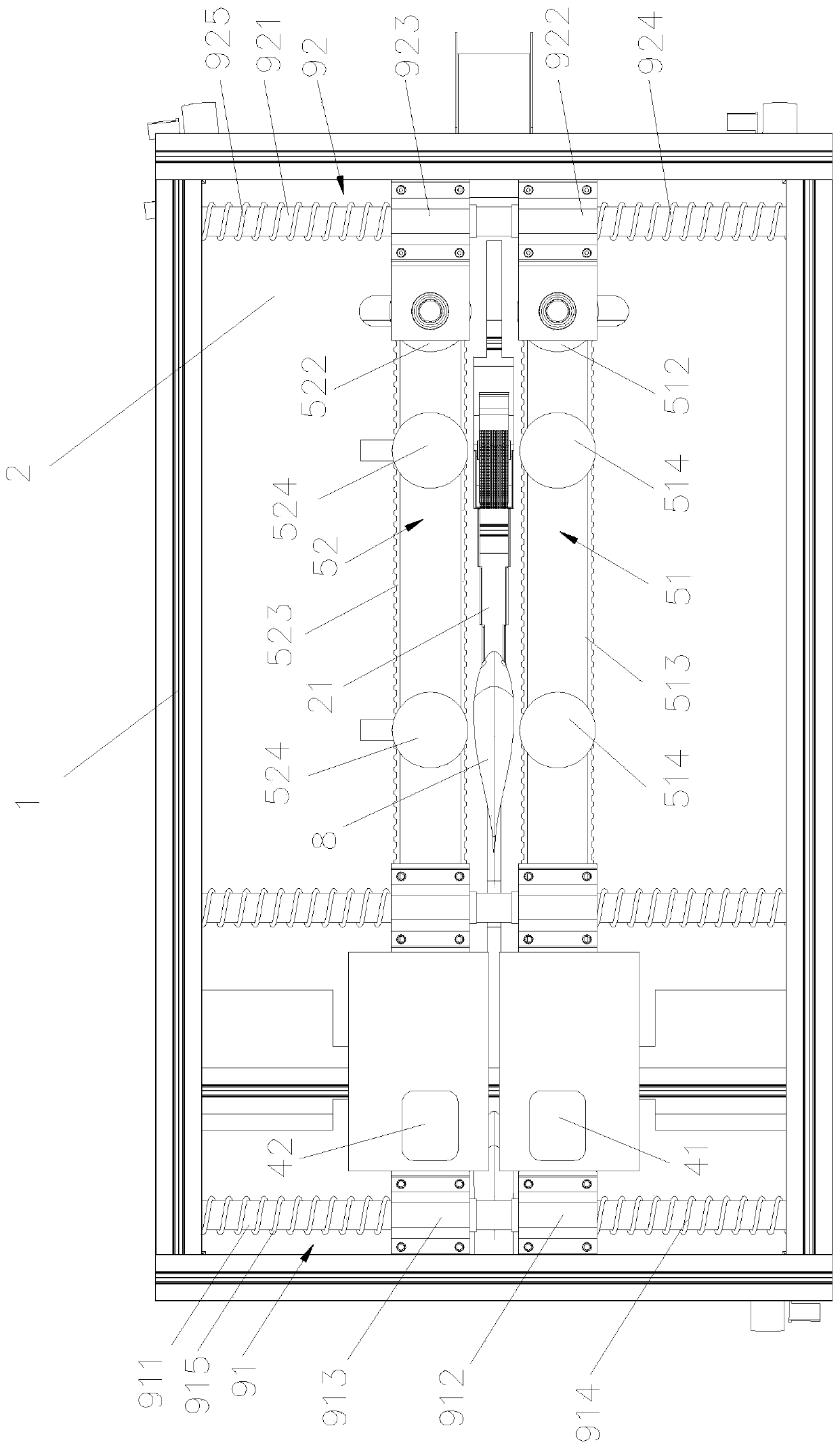

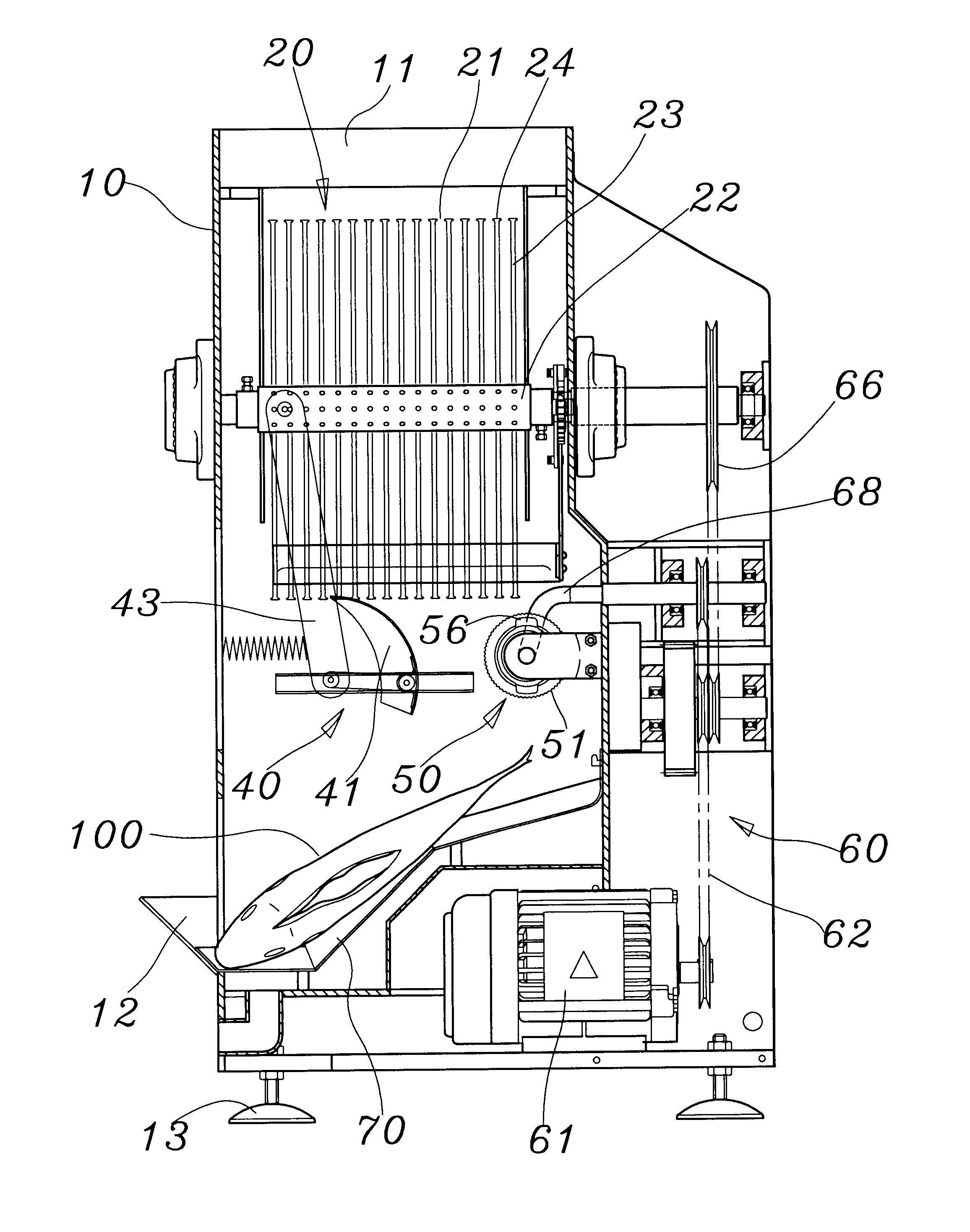

Automatic fish killing machine

InactiveCN110973219AHigh degree of mechanizationCompact structureFish washing/descalingFish work-tablesFish processingMechanical engineering

The invention relates to an automatic fish killing machine. The machine comprises a machine frame, a working table, and a clamping device, a descaling device, a conveying device, a belly cutting device and an evisceration device which are arranged on the working table, and the working table is provided with a working groove; the clamping device has a channel structure with openings in the front and back, the channel cross-sectional size of the clamping device is adjustable, and the opening direction of the clamping device is the same as the length extension direction of the working groove; thedescaling device includes a first power part, a second power part, and descaling rollers symmetrically arranged on both sides of the working groove; the conveying device includes a first conveying group, a second conveying group and a first transmission component; the belly cutting device includes a third power part and a saw blade; and the evisceration device includes a second transmission component and a scraper blade. The automatic fish killing machine has a compact structure and lower cost, improves the reasonable utilization rate of resources, is suitable for use by small and medium-sized merchants, and effectively improves the degree of mechanization of fish processing.

Owner:NINGDE NORMAL UNIV

Process for hydrolyzing fish processing leftover using emzyme preparation

InactiveCN1943365AIncrease added valueMeat/fish preservation using chemicalsFresh fishNeutral proteinase

A process for treating tailings of processing fish with the enzymes, such as one of or the combination of two more of the neutral proteinase,alkali protease,papainase,flavor protease and trypsinase. The hydrolysis process includes 7 steps as following, adjusting the substance concentration, high temperature denaturalization, cooling down and adjusting the pH to 8.0-9.5, heat preservation at 35-6deg.C for 30-50min, enzymolysis for 2-6hr, enzyme destroyed at 85-100deg.C for 10-30min, then it will be separated to get the hydrolysis product. Such product can be used in the food industry with fresh fish flavor. The added value of the fish processing tailings will be greatly improved and it will make sense to the aquaculture and the environment.

Owner:天津市诺奥科技发展股份有限公司

Liquor-marinated fish processing technology

The invention discloses a liquor-marinated fish processing technology which is characterized by comprising the following steps: (1) cleaning: fresh grass carps are taken and processed through removal of scales, heads, tails and internal organs, the thickness is within 1.5 cm, part of which the thickness is larger than 1.5 cm is lightly scratched by a knife, without damaging the skin, black films and bloodiness are cleaned, fish slices are uniform, and the optimal weight of the grass carp is less than 3 kg; (2) curing to deodorize: salt, cooking wine and curing material are weighed, one layer of curing material, salt and cooling wine is scattered on each layer of fish slice in curing, the quantity of salt on the bottom layer is small, while the quantity of salt on the top layer is large, the curing time is 7 days, and tank overturning every day is carried out once. The liquor-marinated fish has the characteristics of moderate taste, fresh meat, fragrant flavor and chewing feeling. The fish meat has the effects of invigorating stomach to remove coldness, boosting immunization, clearing away heat and toxic materials, preventing cancer, reducing blood fat, assisting resisting computer radiation, and whetting the appetite, is good to the physical fitness, and is suitable for being eaten by populations sitting in the office too long.

Owner:安徽绍峰实业有限责任公司

Fish processing method

InactiveCN101558886ASpeed up penetrationFull of nutritionFood preparationMeat/fish preservation by dryingDried fishFish processing

The invention provides a fish processing method, which is to use salts to pickle fish. The whole technological process of pickling is as follows: firstly, drying the fish at a temperature of less than 16 DEG C until the water content is between 28 and 32 weight percent; secondly, dividing common salts which account for 12 to 15 weight percent of dried fish into two parts, spreading one part of the common salts at the bottom of a pickling container, spreading the dried fish on a salt layer to form a layer one by one, and spreading the other part of the common salts on a fish layer and making the common salts completely cover fish bodies; thirdly, applying pressure on the common salt layer on the fish, wherein the pressure is between 0.1 and 0.2 kPa; and fourthly, placing the fish for 6 to 9 days in a room at the temperature of between 2 and 4 DEG C. Compared with the prior art, the fish processing method has simple processing technique, convenient operation and low equipment cost, and the processed salted fish has rich nutrition, proper salinity and long storage period. Moreover, the fish processing method overcomes the defects of heavy taste of the conventional salted fish, complex processing technique and containing of a nitrite composition, and simultaneously solves the problem of mutual contradiction of the taste and the storage period.

Owner:浙江舟富食品有限公司

Process for processing fishes cleanly in high quality

ActiveCN102160566AFull of nutritionHigh white qualityElectric current slaughtering/stunningFish processingFish processingSting fish

The invention belongs to the technical field of fish processing, and particularly relates to a process for processing fishes cleanly, which comprises the following steps of: stunning the fishes instantly, namely stunning live fishes by using rated voltage so as to allow the fishes to have heartbeat but lose memory or stunning the live fishes in a closed bag by using carbon dioxide; cutting fish gills off, namely allowing a knife to extend into the fish gills from water outlet edges of the fish gills on sides of fish cheeks to cut the fish gills on both sides off; performing bloodletting, namely hanging the fishes of which the fish gills are cut off in a mode of allowing fishtails to be upward and fish heads to be downward for bloodletting, so that fish blood flows out of fish mouths until the fish blood is discharged completely from fish gill cavities; washing, namely washing blood in fish mouth cavities cleanly by using pressurized water conveyed from the fish mouths, and washing dirt and mucus on surfaces of fish bodies cleanly; and drying, namely drying the water on the surfaces of the fish bodies by using a water absorption material. The process has the advantages that the fishes are stunned instantly, so the slaughter effect is good; the bloodletting is complete in a mode of cutting the fish gills off, so fish flesh is not polluted; and the fish bodies are hung upside down, the bloodletting is complete, and time and labor are saved, so the process is suitable for processing various fishes, particularly globefishes cleanly.

Owner:徐志敏

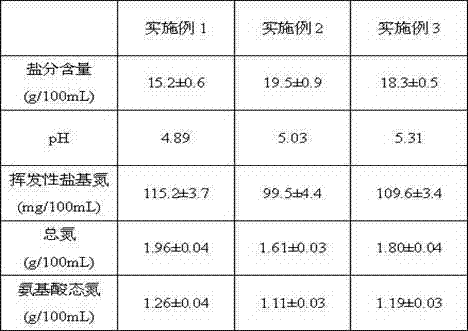

Rapid-brewing production method of low-salt fish sauce

The invention discloses a rapid-brewing production method of low-salt fish sauce, which comprises the steps of mixing fish viscera and soy sauce koji, and preparing into a fish viscera fermentation solution after the salt is added into the mixture for fermentation for a time at a low temperature; and then heating to dissolve the fish heads, the fish skins, the fish bones and the minced fish meal and the like with an acidic solution, after salting, cooling and pH regulating, mixing with the fish viscera fermentation solution for fermentation; and prepraring into the low-salt fish sauce after the steps that the fish meal without residues fermented to be mature is subject to after-maturation degreasing, heating and sterilization and filtering and the like. According to the invention, the fish viscera and the soy sauce koji are fermented at the low temperature, thereby not only inhibiting the growth and propagation of the spoilage microorganisms, but also fully utilizing the protease resource of the fish viscera; furthermore, an acidifying and heating and dissolving process is utilized to quickly dissolve collagen in a fish processing side-product, thereby being beneficial to reducing the fermentation time and having an effect on sterilizing the stale raw materials; and the combined after-maturation degreasing process is combined to further improve the flavor and quality of the fish sauce product.

Owner:JIMEI UNIV

A kind of processing technology of fish ball

The invention belongs to the field of food processing, in particular to a processing technology of fish balls. The technical solution adopted is: a processing technology of flavored fish balls, including the following technological process: selection of raw fish → pretreatment → meat picking → rinsing → dehydration → batching crushing → forming → boiling → cooling → packaging. The fish balls produced by the processing technology have a long fresh-keeping time and unique taste. And it can be processed and produced on a large scale.

Owner:胡林

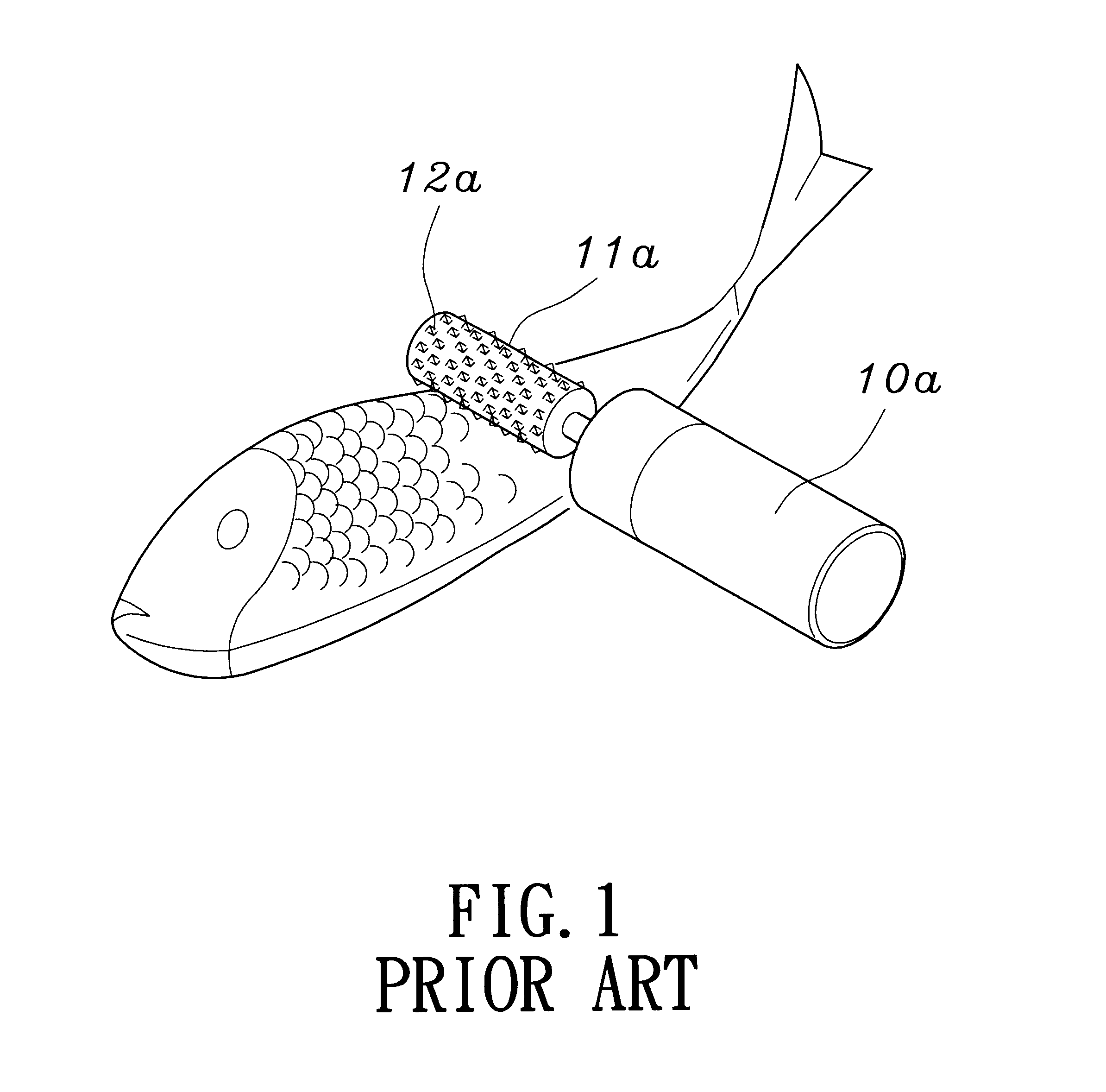

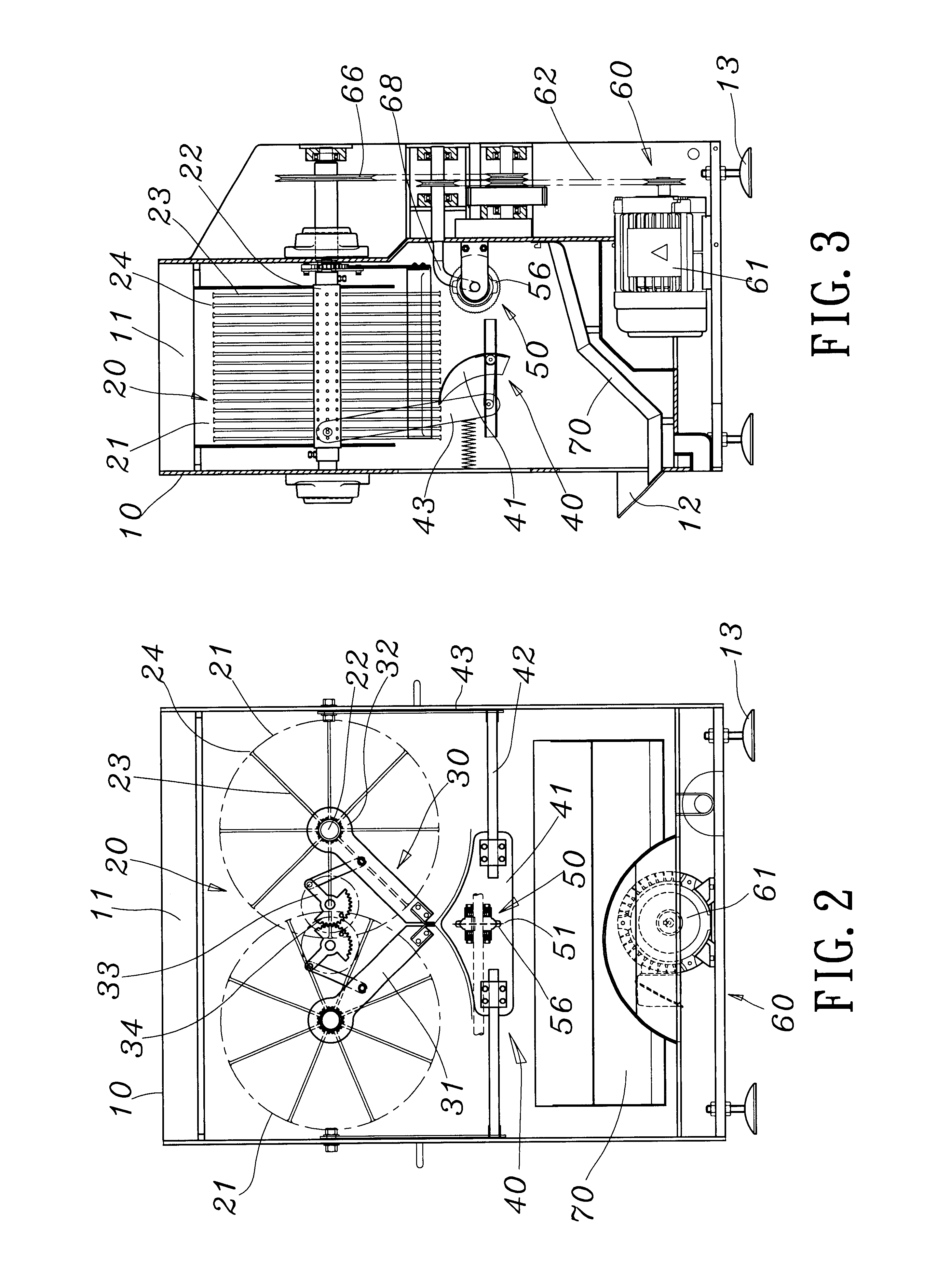

Fish processing apparatus

A fish processing apparatus includes a casing in which are respectively mounted a brushing unit, a clamping unit, a pushing unit, a cutting unit, and a driving unit. The brushing unit includes two scraping brushes that are mounted in a manner to overlap each other. Each scraping brush includes an axle on which are attached a plurality of flexible bristles respectively terminating in a scraping portion. The rotation of the scraping brushes removes the scales of the fish body. The clamping unit is mounted at a location between and below the two scraping brushes to receive the fish body, and the pushing unit is placed below the clamping unit to push the fish body toward the cutting unit that cuts the fish body and removes its viscera.

Owner:LI YU PIN

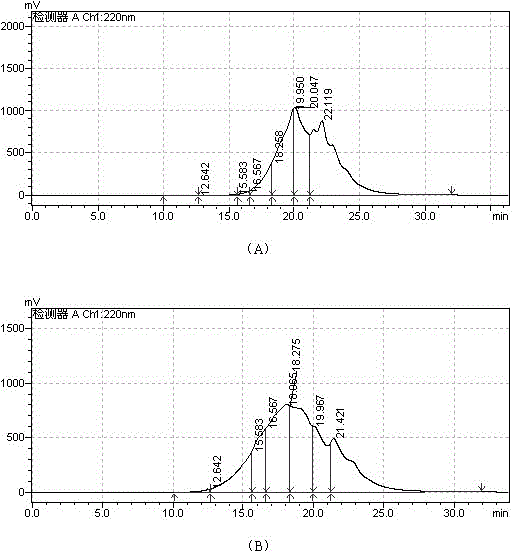

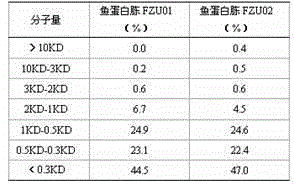

Method for preparing peptone by utilizing fish processing wastes

InactiveCN104313093ARich in compositionComposition remains intactFermentationBiotechnologyFood additive

The invention discloses a method for preparing peptone by utilizing fish processing wastes, belonging to the technical field of biology. The method is characterized in that the raw materials used for preparing peptone are fish processing wastes; the raw materials are minced and degreased to obtain minced fillet pulp; a certain amount of protease is added; protease enzymolysis procedures are controlled by applying size-exclusion high performance liquid chromatography (SEC-HPLC); membrane separation is further used for desalination and concentration, and the powder obtained after spray drying is fish peptone. The method has the beneficial effects that the fish processing wastes can be fully utilized by adopting the method to prepare high-quality fish peptone; the method has the advantages of retention of full amino acid composition, high content of amino nitrogen, low protein molecular weight, low ash content, and the like; the product can serve as health food, a nutrient enhancer, a food additive, a feed additive, a medium in the fermentation industry, and the like.

Owner:FUZHOU UNIV

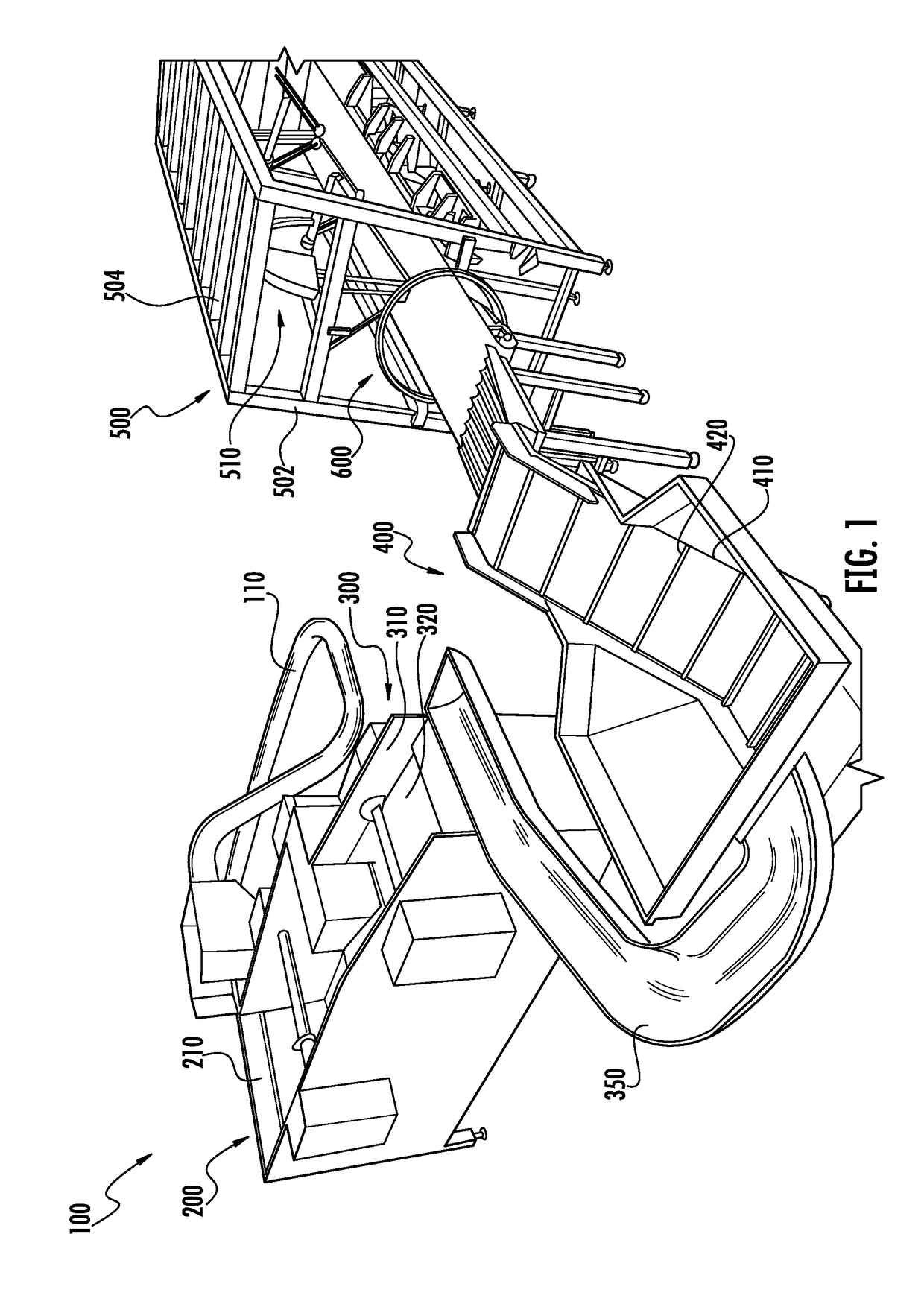

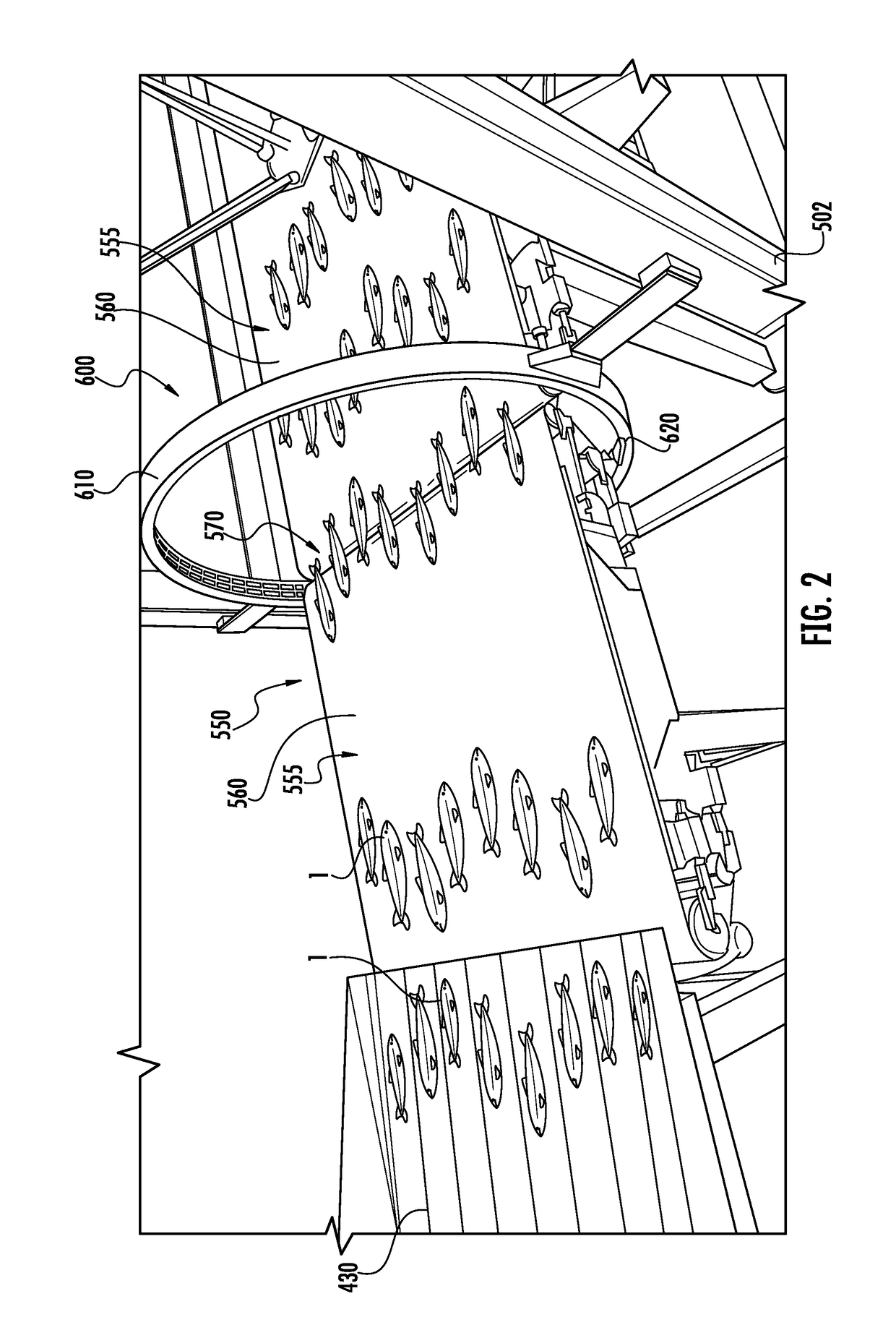

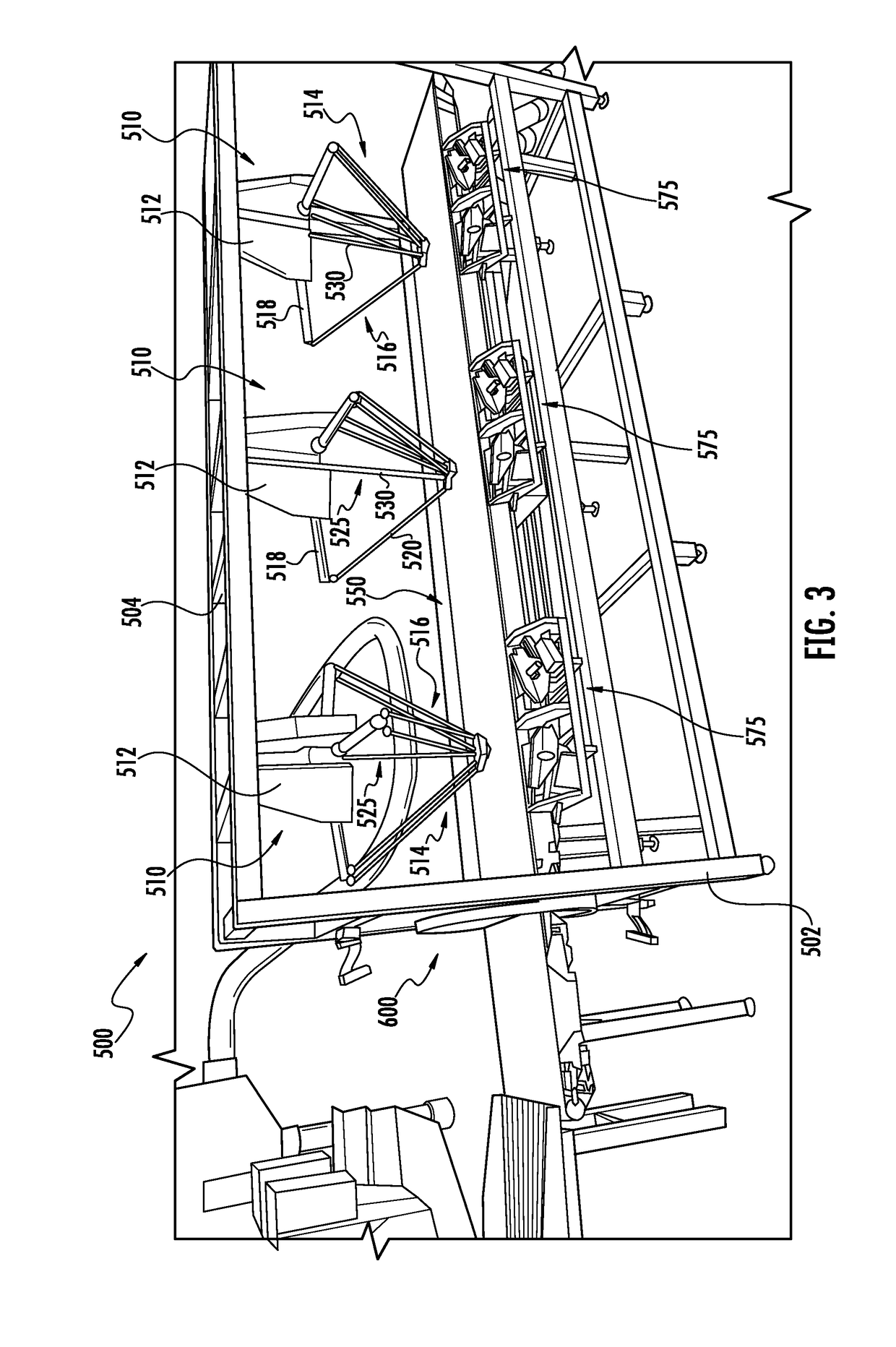

Live fish processing system, and associated methods

A fish handling unit for processing live fish is provided. Such fish handling unit includes an inspection system configured to inspect a plurality of live fish. A conveyor assembly transports the live fish to the inspection system. At least one robotic cell is in communication with the inspection system. The robotic cell has a controller configured to control operation thereof. An end effector is operably engaged with the robotic cell. The end effector interacts with the live fish moving along the conveyor assembly, based on information determined by the inspection system and received by the controller. The end effector may optionally be an integrated gripper and injection assembly capable of orientation and injection of the live fish. Associated devices and methods are also provided.

Owner:PHARMAQ

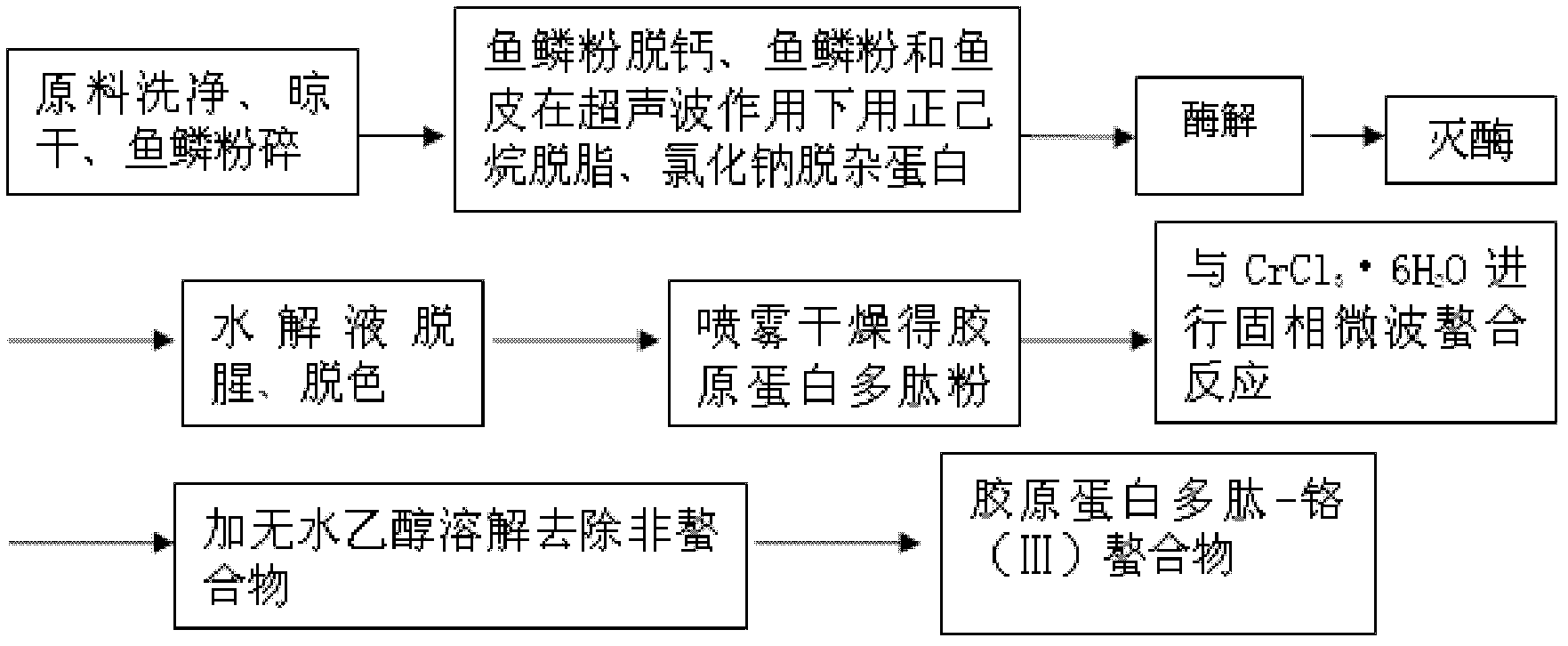

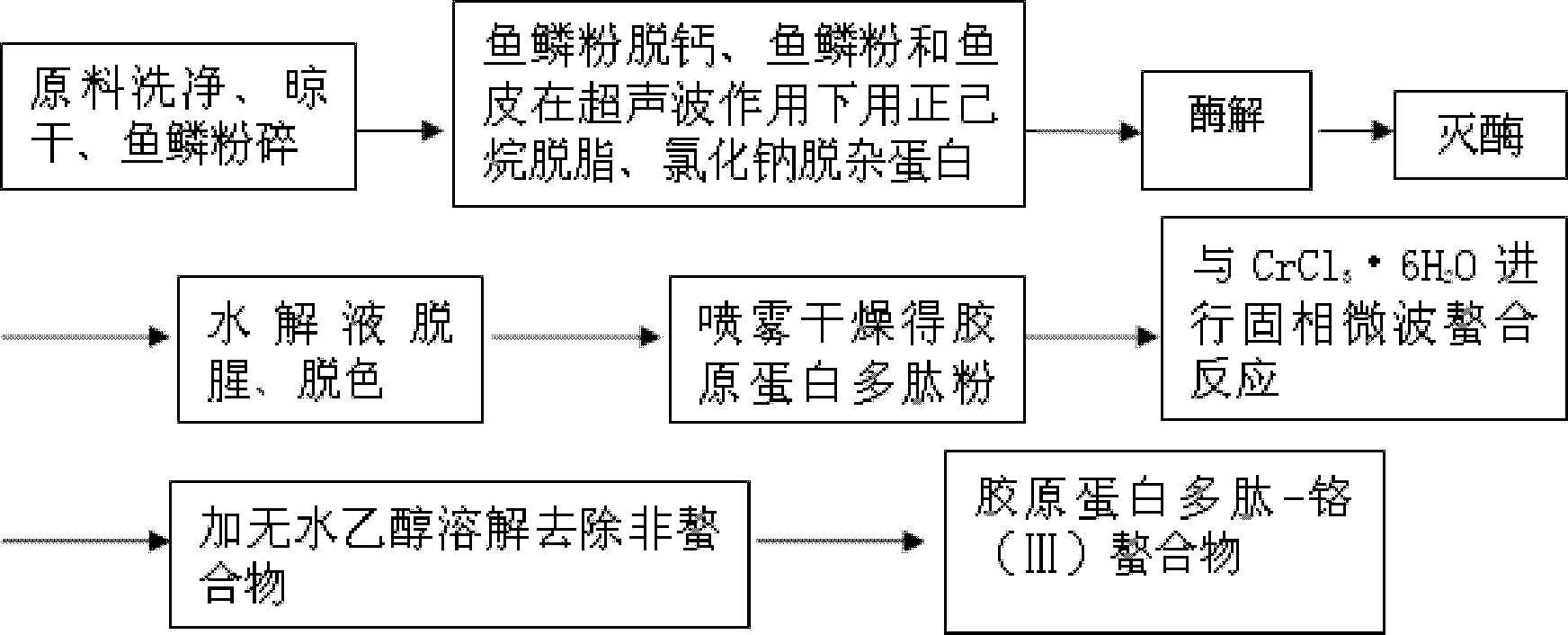

Method for processing red sea bream collagen polypeptide-chromium (III) chelate

ActiveCN102657338AShorten the timeImprove processing efficiencyFood preparationUltrasound - actionHydrolysate

The invention relates to a method for processing red sea bream collagen polypeptide-chromium (III) chelate. The method comprises the following steps: taking fish skin and fish scale of the red sea bream as raw materials, crushing the fish scale into fish scale powder, soaking the fish scale powder into lactic acid to decalcify, respectively degreasing the fish powder and the fish skin by using normal hexane under the ultrasonic action, and removing other protein from the fish powder and the fish skin under the ultrasonic-sodium chloride synergistic action; performing enzymolysis to the fish powder and the fish skin according to a certain ratio by using trypsin, deodorizing the hydrolysate by using active carbon powder to obtain collagen peptide solution and spray drying to prepare powder;crushing and mixing the collagen peptide powder and CrCl3.6H2O completely, performing microwave solid phase chelation reaction, dissolving by adding absolute ethanol to remove non-chelate, and dryingthe undissolved substance to obtain the collagen polypeptide-chromium (III) chelate. The preparation process of the collagen polypeptide-chromium (III) chelate is safe and pollution-free, so that effective and high-value utilization of the fish processing low-value byproducts or leftovers such as fish skin and fish scale is realized, the utilization ratio of the raw materials is high, the processing cost is low, and important social and economic significance is achieved.

Owner:河北保食健健康科技有限公司

Method for preparing collagen protein powder from fish scales

The invention discloses a method for preparing collagen protein powder from fish scales. The method comprises the following steps of: (1) deordorization, decalcification and washing treatment on the fish scales; (2) cryogenic grinding treatment on the fish scales; (3) steam explosion treatment on the fish scales; (4) enzyme hydrolysis of the fish scales; and (5) preparation of the collagen protein powder from the fish scales. The production method provided by the invention is simple, less in dosage of protease, low in production cost, short in processing cycle, mild in condition, high in utilization rate of equipment and easy to realize industrialized production, and can reach an average extraction rate of above 70%. The collagen protein content in the prepared collagen protein powder reaches above 95%, the in vitro digestibility of the powder reaches above 95%, and the problem of utilization of fish scales in fish processing is well solved, so that the additional value of leftovers in the processing of aquatic products increases, and the comprehensive utilization rate of freshwater fish is improved.

Owner:宜昌湘宜水产品有限公司

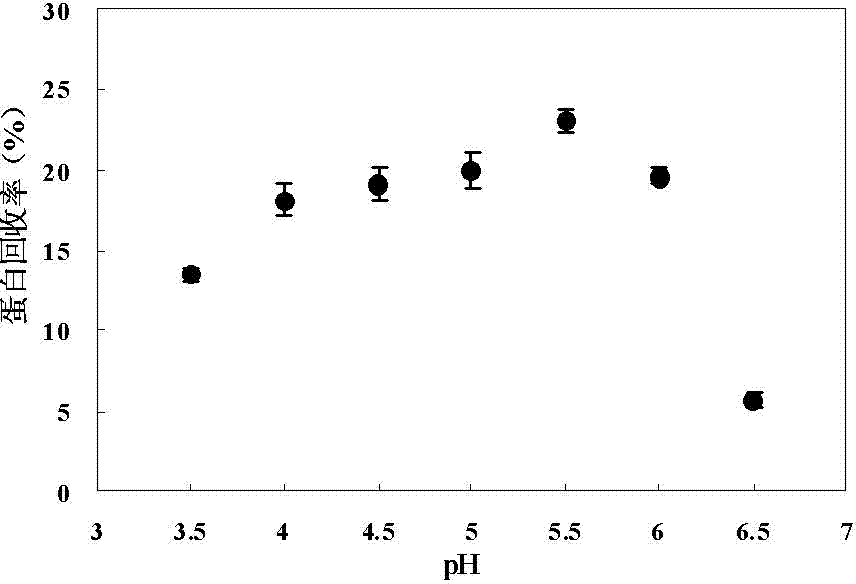

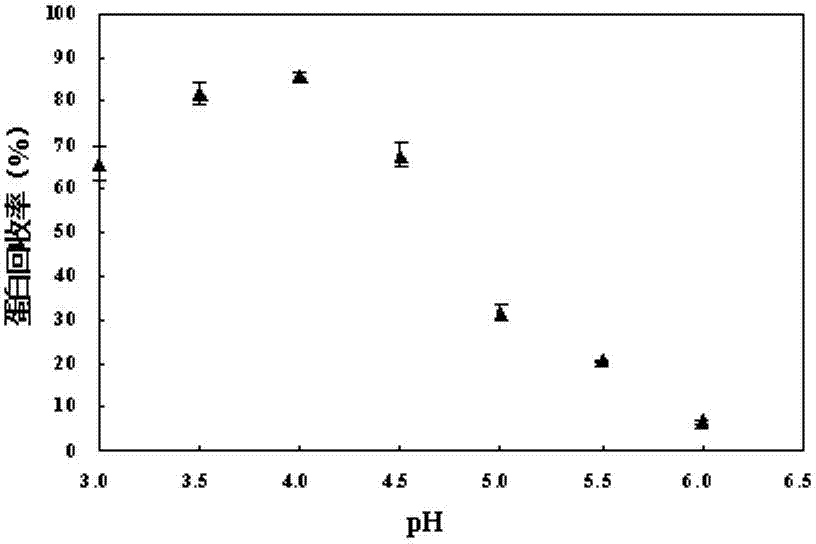

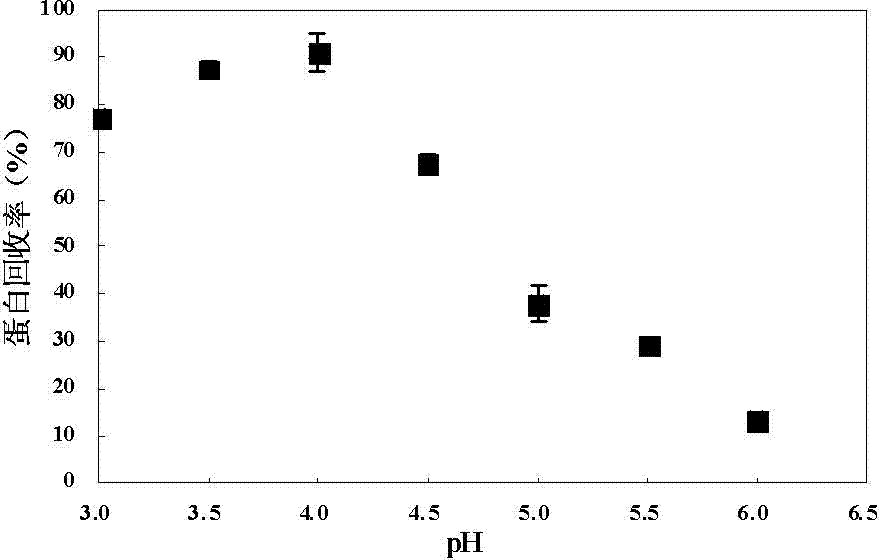

Method for recycling water-soluble proteins in minced fish rinsing water

ActiveCN102757491AIncrease ionic strengthImprove settlement performancePeptide preparation methodsAnimals/human peptidesCentrifugationEconomic benefits

The invention relates to a method for recycling water-soluble proteins in minced fish rinsing water, which is characterized by comprising the following steps: salt-process low-temperature degreasing: adding a certain amount of table salt (NaCl) into minced fish rinsing water, stirring to sufficiently dissolve the table salt, and standing until grease precipitates and floats up to the surface, wherein the temperature of the rinsing water is controlled at 10 DEG C below in the whole process; isoelectric point protein precipitation: adding acid to the obtained liquid to regulate the pH value to 4.0-5.0, and standing to sufficiently stratify; preliminary protein recycling: discharging the supernatant part of the obtained liquid out by using a pump, and collecting the understratum protein precipitation layer; and protein recycling by centrifugation. The recycled protein can be directly packaged into finished product for freezing storage, or spray-dried into protein powder. The method provided by the invention is simple and easy to implement and is efficient; and the method can greatly reduce environmental pollution caused by improper discharge of protein-rich rinsing water, enhance the economic benefit of the minced fish production enterprise, and implement efficient utilization of resources, thereby having important meaning for environment-friendly sustainable development in minced fish processing industry.

Owner:JIMEI UNIV

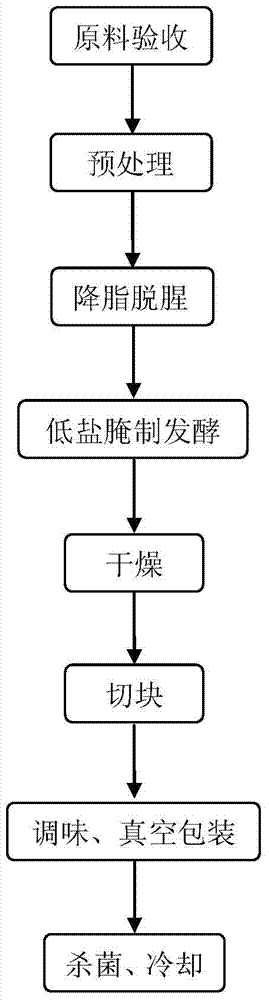

Method for improving flavor of liquor-marinated fish by utilizing biological flavor increasing technique

ActiveCN103932243AAchieving aroma enhancement by fermentationQuality improvementFood dryingFood preparationFish processingHigh fat

The invention discloses a method for improving flavor of liquor-marinated fish by utilizing a biological flavor increasing technique, belonging to the field of food processing and preservation. The method comprises the following steps: by taking fresh, alive or frozen freshwater fish as raw materials, pretreating, degreasing, deodorizing, pickling with low salt, fermenting, drying, slicing, carrying out seasoning and vacuum packaging, sterilizing and cooling, thereby preparing the instant liquor-marinated fish product with special flavor. According to the method, based on the traditional liquor-marinated fish processing technology, the earthy smell of freshwater fish is removed by utilizing a biological enzyme technique and a low-salt pickling and fermenting technique; the mellow flavor of the liquor-marinated fish is improved; leisure liquor-marinated fish food with low fat content and excellent flavor quality is produced; in the processing course, any chemical preservative is not added; the produced liquor-marinated fish is thick and mellow in flavor, and is stable in quality; due to the technique, the liquor-marinated fish production raw materials can also adopt high-fat fishes such as channel catfish; the production problems of difficulty of drying and dehydrating of high-fat fishes and serious oyster fat oxidation are solved; the liquor-marinated fish product quality and storage stability are improved; the industrialization production can be realized easily; the market prospect is wide.

Owner:JIANGNAN UNIV

Method for preparing fish oil ethyl ester from fish wastes

InactiveCN101376868AReduce pollutionIncrease added valueFatty acid esterificationPreparation by ester-hydroxy reactionOil and greaseFish oil

The invention relates to a method for preparing a fish oil ethyl ester by using fish leftovers. In the method, the fish leftovers during fish processing are used as materials and are cut, frozen, cracked and then extracted by using supercritical carbon dioxide ( SC-CO2), thus obtaining a liquid grease mixture; the mixture is decompressed by CO2 for realizing oil separation and obtaining the grease with a purity of 69 to 78 percent; then the grease is extracted by the SC-CO2 added with the ethanol with a concentration of 5 to 20 percent, thus obtaining the grease with a purity of 86 to 95 percent; then fish oil and absolute ethyl alcohol are reacted under a basic catalyst condition according to a proportion of 1 : 2 to 4; after the reaction, impurities like glycerol are removed through washing, thus obtaining the fish oil ethyl ester; then the fish oil ethyl ester is distilled by multi-grades of molecules, thus obtaining the fish oil ethyl ester with high purity. The method has the advantages of low operation temperature, high product extraction rate and purity, non-solvent vestigital, non-environment pollution, high separation efficiency and being easy for the continuous industrialization production.

Owner:RONGCHENG TAIXIANG FOOD

Method for extracting collagen from fish processing waste including skin, bones and scale

The invention discloses a method for extracting collagen from fish processing waste including skin, bones and scale. The method mainly comprises the following steps of: processing raw materials; hydrolyzing by using bromelin to remove non-fibrous proteins; washing with water; hydrolyzing residual collagen by using 537 acid prolease; filtering under normal pressure; performing freeze drying; and drying and storing. Keys points of the method lie in enzymolysis and purification of the collagen. A higher-purity product can be prepared from fish leftover collagen extracted with the method; and the product is white, does not have any peculiar smell, and has the average extraction rate of 38.9 percent and the purity of 99.67 percent.

Owner:NANTONG YOUPU PRESERVATIVE TECH

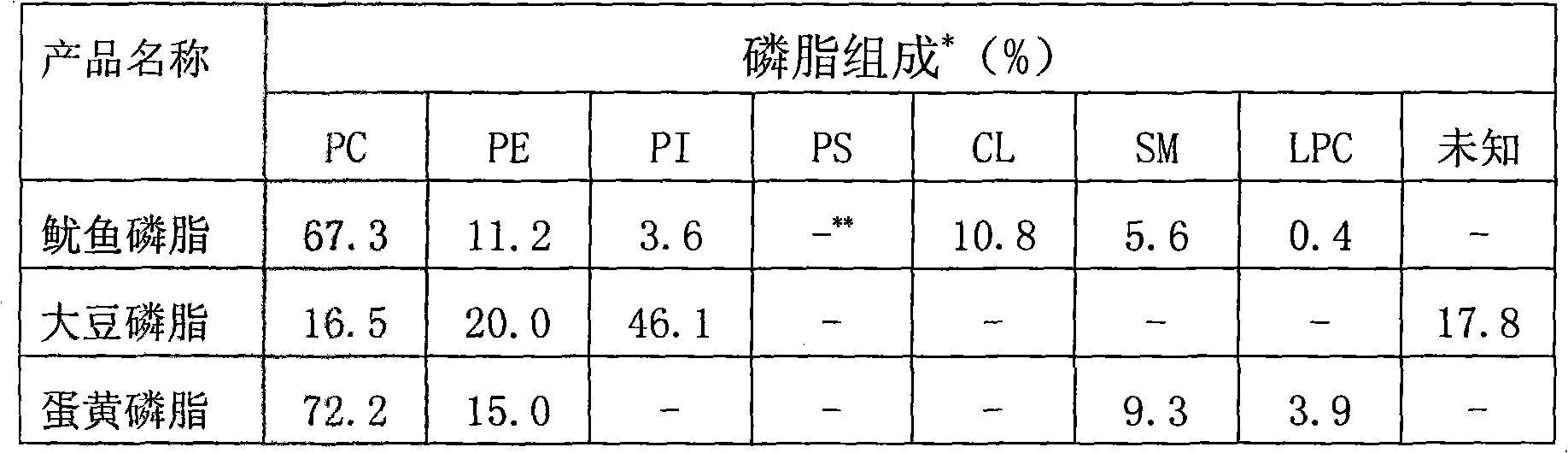

Method for extracting high-purity phospholipid from sleeve-fish-processing waste

InactiveCN101812087AHigh purityReduce dosagePhosphatide foodstuff compositionsBulk chemical productionProcess equipmentAutomatic control

The invention, which belongs to the technical field of substance extraction, relates to a method for extracting high-purity phospholipid from sleeve-fish-processing waste. Fresh sleeve-fish-processing waste is first dried until the moisture content is less than or equal to 3 percent, and is ground to 10 to 80 meshes; the preprocessed powdery material is then loaded into an extraction kettle, and after the air is removed, extracting solvent CO2 is injected to set pressure; the supercritical extraction and separation of the extraction system is regulated as three processes, i.e. extraction, primary separation and secondary separation, raffinate is taken out of the extraction kettle after triglycercide and cholesterol are separated and removed, ethanol which is 4 to 10 times the weight of the raffinate is added in the raffinate according to a weight ratio to dissolve the raffinate, clear solution is taken out and concentrated, and is then washed by acetone, the obtained solid substance is dissolved in ethanol and then mixed with water, and precipitate which is obtained by centrifugation is dried, so that sleeve-fish phospholipid is obtained. The method has the advantages of less organic solvent dosage, little environment pollution, simple processing equipment, easy operation, automatic control, stable product quality, low production cost, good quality and high purity.

Owner:QINGDAO HAIENCI BIOENG

Deep processing process for sleeve-fish

The invention relates to a deep processing process for sleeve-fish and belongs to the technical field of a sleeve-fish processing method. The process comprises the following steps of: 1, unfreezing; 2, sterilizing; 3, cooling; 4, flavouring; 5, pickling; 6, drying; 7, remoistening; 8, unfreezing; 9, flavouring; 10, canning and sealing; and 11, sterilizing. The process is simple and convenient and by the process, sleeve-fish tips, tentacles, sleeve-fish necks and sleeve-fish legs can be prepared into sleeve-fish foods with fresh tastes.

Owner:YANTAI YOUMEI FOODSTUFF

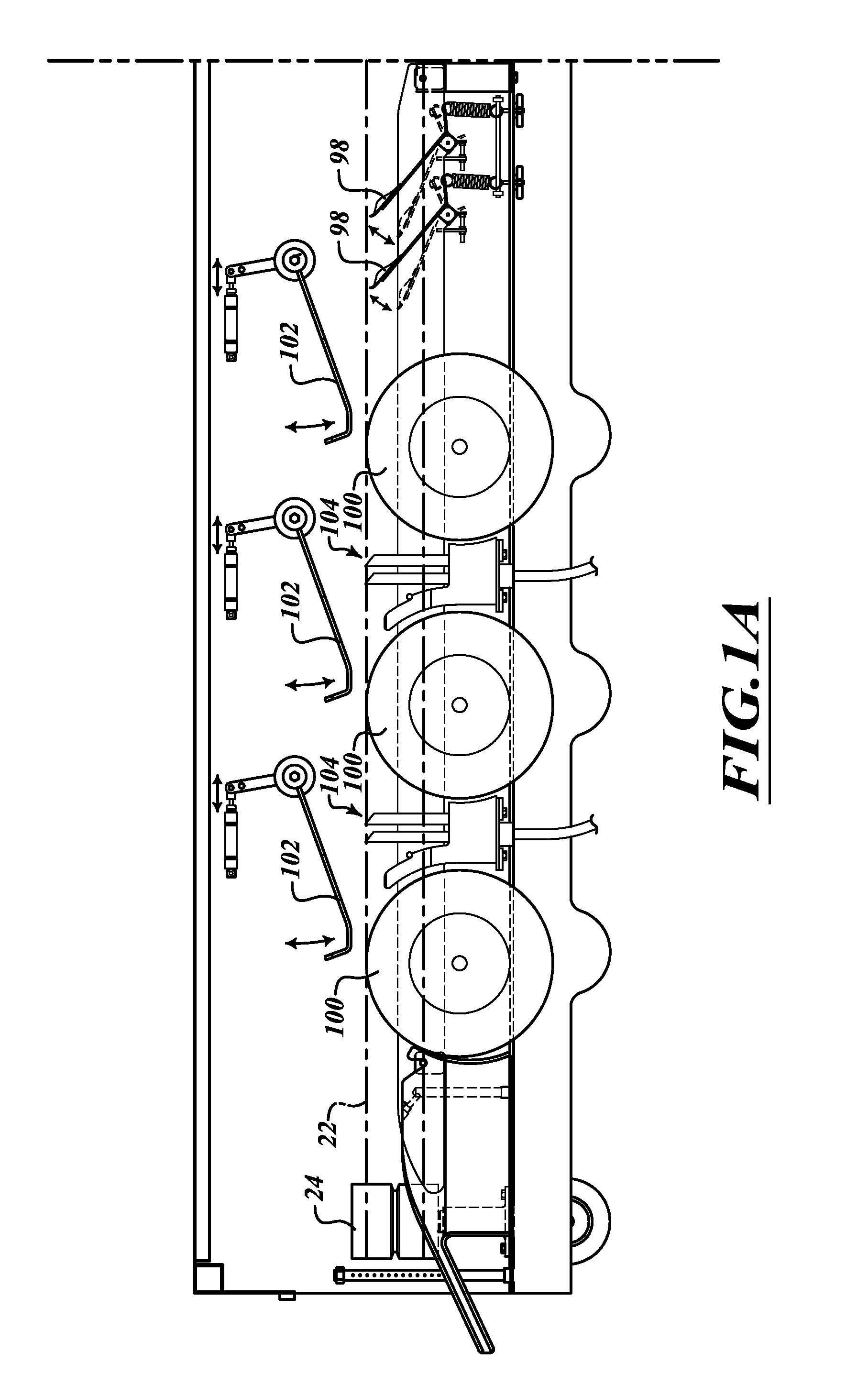

Fish processing system and method

ActiveUS8986077B1Efficient and reliable removalMinimal damageSlaughtering/stunningFish processingFish processingEngineering

Owner:RYCO EQUIP

Flavored recombined fish candy snack food and preparation method thereof

InactiveCN103948049AReduce fishy smellStay nourishedFood ingredientsFood preparationBiotechnologyNutrition

The invention provides a flavored recombined fish candy snack food and a preparation method thereof. The flavored recombined fish candy is a dehydrated snack food which is prepared by comprehensively utilizing fish processing leftover-minced fish or offal fish and scientifically adding textured soybean protein (TSP) by a recombination technique. The preparation method comprises the following steps: defreezing fish, selecting, rinsing, removing fishy smell by biofermentation, rinsing, steaming, separating fish fibers, adding TSP fibers, stir-frying while adding seasonings, adding an exogenous adhesive, mixing, spreading on a tray, forming, drying and packaging to obtain the finished product. The flavored recombined fish candy is a dried recombined fish snack food with the texture, chewiness and nutrition of natural fish fibers, conforms to the new diet concept of nutrition and good taste of consumers, solves the problem in comprehensive utilization of processing byproducts, creates higher economic value for the enterprise, and has practical instruction meanings for enhancing the aquatic product deep processing level.

Owner:FUJIAN AGRI & FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com