Method for preparing peptone by utilizing fish processing wastes

A technology for preparing peptone and leftovers, applied in the field of preparing peptone, can solve the problems of low ammonia nitrogen content, protein thermal denaturation, precise control, etc., and achieve the effect of complete amino acid composition, small protein molecular weight, and amino acid composition retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

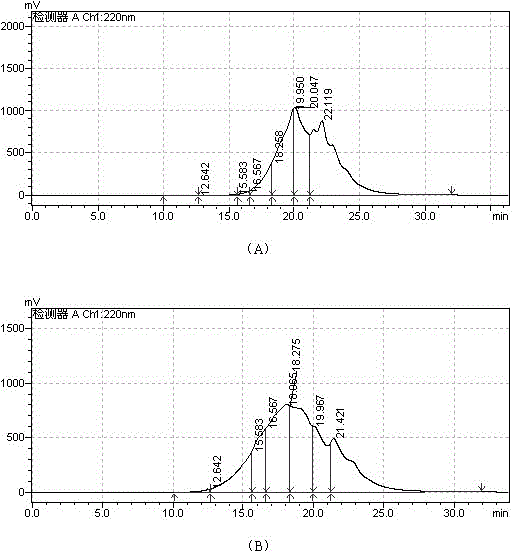

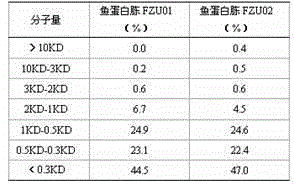

[0021] Get 100 kilograms of small miscellaneous fish, grind it with a meat grinder, add 300 liters of No. 60 solvent oil and degrease it for 3 times to obtain degreased surimi pulp. Add 400L of water and adjust the pH with 10% acetic acid solution to make the final pH 3.5. A two-step enzymatic hydrolysis process is adopted. The first step of enzymatic hydrolysis uses papain, the amount of enzyme added is 0.8%, the pH value is adjusted to 3.0, the reaction temperature is 40°C, and the enzymatic hydrolysis time is 8 hours; the second step of enzymatic hydrolysis uses trypsin, and the amount of enzyme added is 0.7 %, adjust the pH value to 4.5, the reaction temperature is 40°C, and the enzymolysis time is 12 hours. The enzymolysis solution was detected by SEC-HPLC, and the molecular weight of the protein was more than 90% lower than 3000Kda (the SEC-HPLC analysis spectrum is as follows figure 1 As shown in A, the molecular weight distribution results are shown in Table 1 fish p...

Embodiment 2

[0023] Take 100 kg of surimi processing scraps (including fish head, fish skin, fish bones, fish tendon and fish tail, etc.), grind them with a meat grinder, add 300 liters of No. 60 solvent oil for degreasing treatment 3 times, and obtain defatted fish Mineral pulp. Add 400L of water, adjust the pH with 1N hydrochloric acid solution, and make the final pH reach 3.5. Add 1.0% protease (pepsin, trypsin, papain, subtilisin or cathepsin, etc.), 35 ℃, under the condition of full stirring, enzymatic hydrolysis for 6h. The enzymolysis solution was detected by SEC-HPLC, and the molecular weight of the protein was more than 90% lower than 3000Kda (the SEC-HPLC analysis spectrum is as follows figure 1 As shown in B, the molecular weight distribution results are shown in Table 1 fish peptone FZU02), and the enzyme reaction was terminated. The enzymatic hydrolysis product is centrifuged and separated by a high-speed continuous centrifuge, and the supernatant is collected, that is, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com