Production method of collagen membrane

A collagen film and production method technology, applied in the development field of environment-friendly packaging film, can solve the problems of decreased mechanical strength of the film, hindering the interaction of collagen, etc., and achieve the effects of increasing added value, inhibiting expansion, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

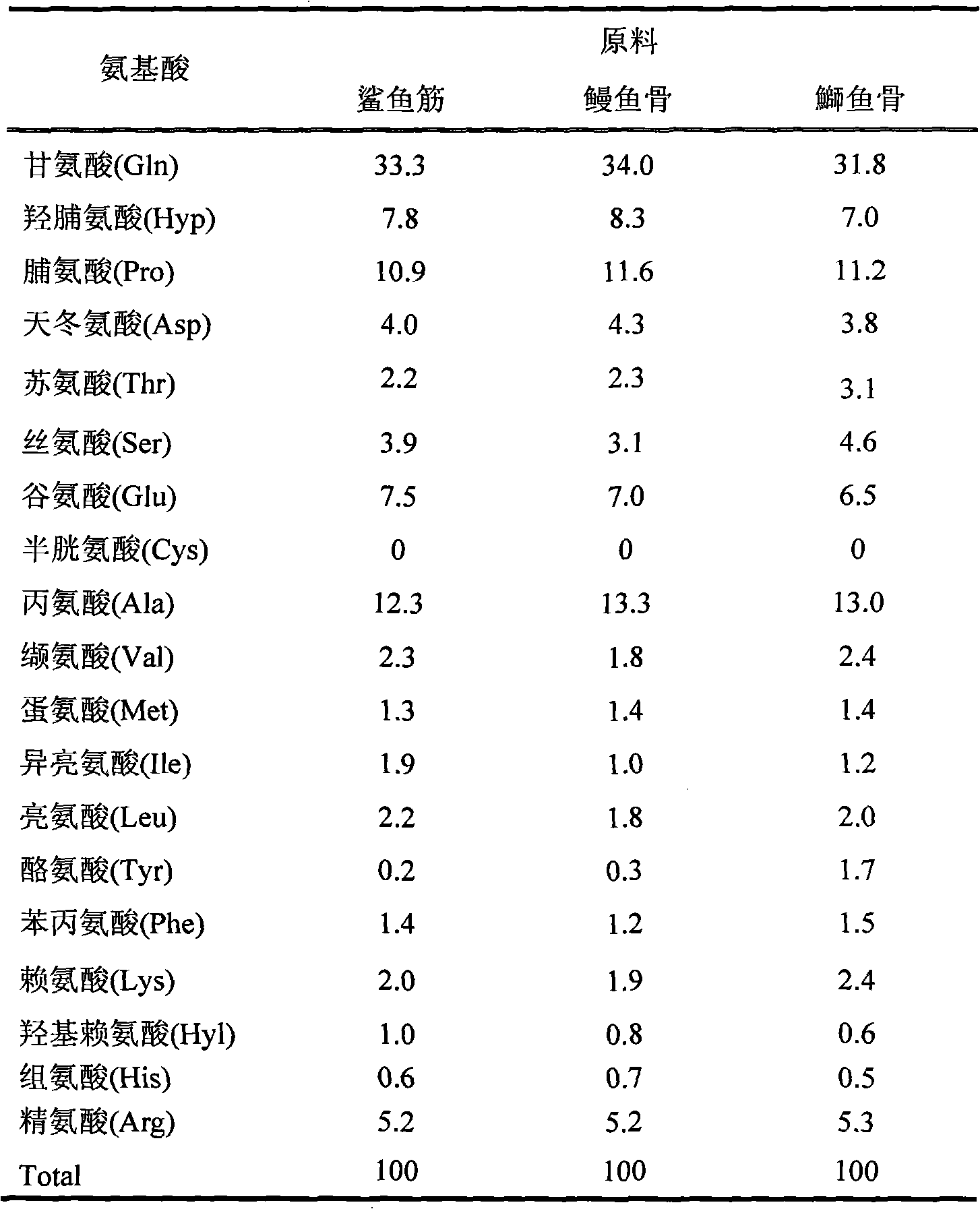

Embodiment 1

[0023] 1. Extraction of crude collagen: take 1kg of eel bone and put it in 5L of 0.05M NaOH-25% alcohol-1.5%H 2 o 2 solution, stirred and soaked at 10°C for 1 day, stirred and rinsed with clean water until neutral; then stirred and soaked with 7.5L of 0.05M hydrochloric acid for 3 hours, rinsed to neutral, filtered, and crushed the filter residue to prepare crude collagen.

[0024] 2. Preparation of membrane solution: add 120ml of distilled water to 40g of crushed crude collagen, extract at 100°C for 1 hour, filter with gauze, remove insoluble impurities from the filtrate by centrifugation, and use distilled water to prepare the obtained supernatant into protein The content is 2%, the glycerol content is 0.8%, and the edible film liquid is prepared after defoaming by a defoaming machine.

[0025] 3. Preparation of protein film: evenly pour 4g of the prepared film solution into a 5cm×5cm silicone resin frame (1.6kg / m 2 ), dried in a constant temperature and humidity chamber ...

Embodiment 2

[0027] 1. Extraction of crude collagen: take 1kg of shark tendon and put it in 3L of 0.05M NaOH-25% alcohol-1.5%H 2 o 2 After stirring and immersing in the solution for 1 day at 20° C., stirring and rinsing with clean water until neutral, filtering, and crushing the filter residue to prepare crude collagen.

[0028] 2. Preparation of membrane solution: add 120ml of distilled water to 40g of crushed crude collagen, extract at 80°C for 6 hours, filter with gauze, remove insoluble impurities by centrifugation of the filtrate, and use distilled water to prepare the obtained supernatant into protein The content is 3%, the glycerol content is 0.6%, and the edible film liquid is prepared after defoaming by a defoaming machine.

[0029] 3. Preparation of protein film: the preparation method is the same as in Example 1. The thickness, mechanical strength, light transmittance and other indicators of the prepared protein film were measured, and the results are shown in Table 2.

Embodiment 3

[0031] 1. Extraction of crude collagen: take 1kg yellowtail fish bone and put it in 5L of 0.05M NaOH-25% alcohol-1.5% H 2 o 2 In the solution, after stirring and soaking at 4°C for 1 day, stir and rinse with water until neutral; then stir and soak with 10L of 0.05M citric acid for 3 hours, rinse until neutral, filter, and crush the filter residue to prepare crude collagen protein.

[0032] 2. Preparation of membrane solution: add 120ml of distilled water to 40g of crushed crude collagen, extract at 60°C for 6 hours, filter with gauze, remove insoluble impurities by centrifuging the filtrate, and use distilled water to prepare the obtained supernatant into protein The content is 4%, and the glycerin content is 1.2%, and after being stirred evenly, the defoaming machine is used for defoaming to prepare an edible film liquid.

[0033] 3. Preparation of protein film: the preparation method is the same as in Example 1. The thickness, mechanical strength, light transmittance and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com