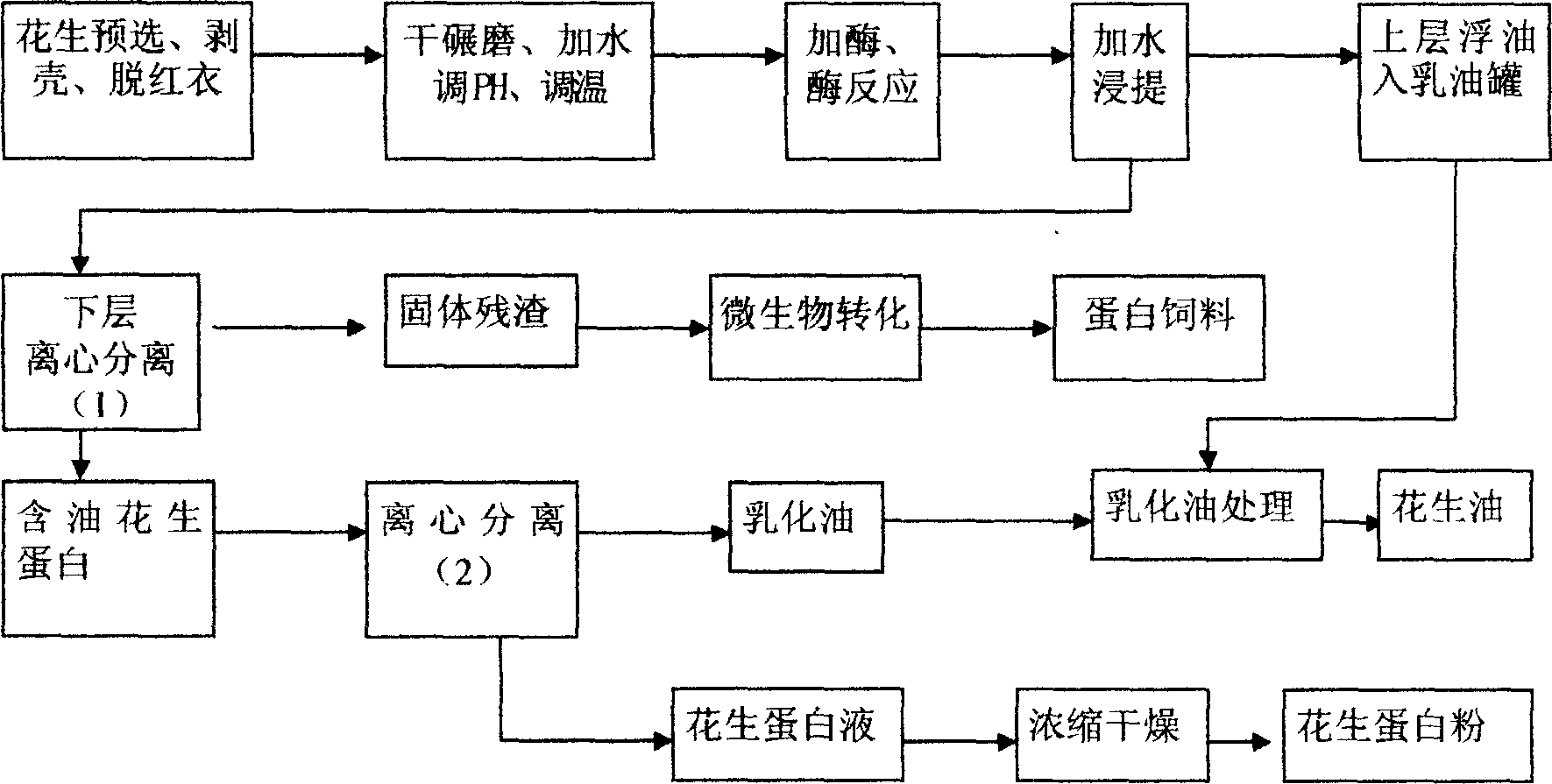

Peanut protein and fat enzyme extracting process

An enzymatic extraction and protein technology, which is applied in the field of peanut protein, can solve the problems of high oil content, large emulsified oil content, and inability to release oil in peanut protein powder, and achieves improved oil and protein yield, less adsorption, and oil content. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0011] Embodiment: First, the raw materials are pretreated: select peanuts without mildew, remove various impurities in the peanuts, peel the peanuts, and remove the red coat. Take the red-coated peanut kernels and dry-mill them with a superfine mill or calender, and the milling particle size is controlled at about 10 μm.

[0012] Preparation of enzyme preparation: the enzyme preparation, pectinase is from Aspergillus sp., neutral protease is from Bacillus subtilis (B.subtilis), and cellulase is from Trichodermaviride. It is produced by solid state or liquid submerged fermentation method, and the pure enzyme is obtained after the enzyme prepared by fermentation is purified.

[0013] Enzymolysis reaction: Put the dry-milled raw materials into a vertical leaching tank, add water for soaking according to a solid-liquid ratio of 1:3, adjust the pH to 6.8 with edible soda ash, and keep the material temperature at about 49°C, first add cellulase (add Enzyme amount 100U / g oil plant)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com