Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

84 results about "Cutting force model" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

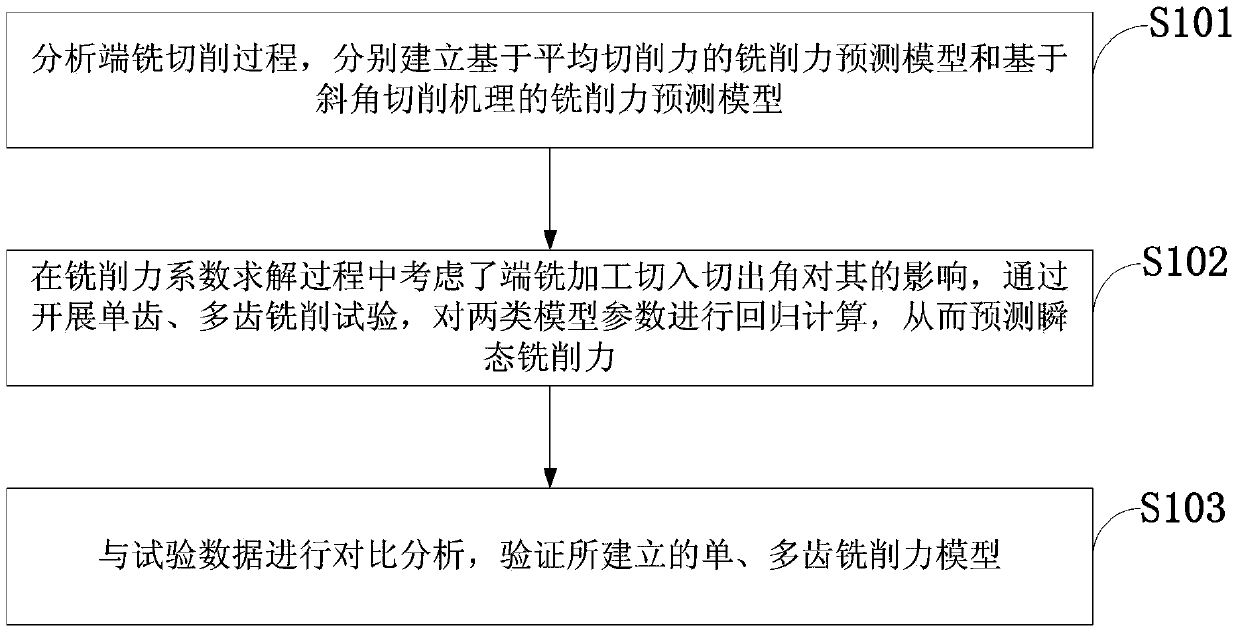

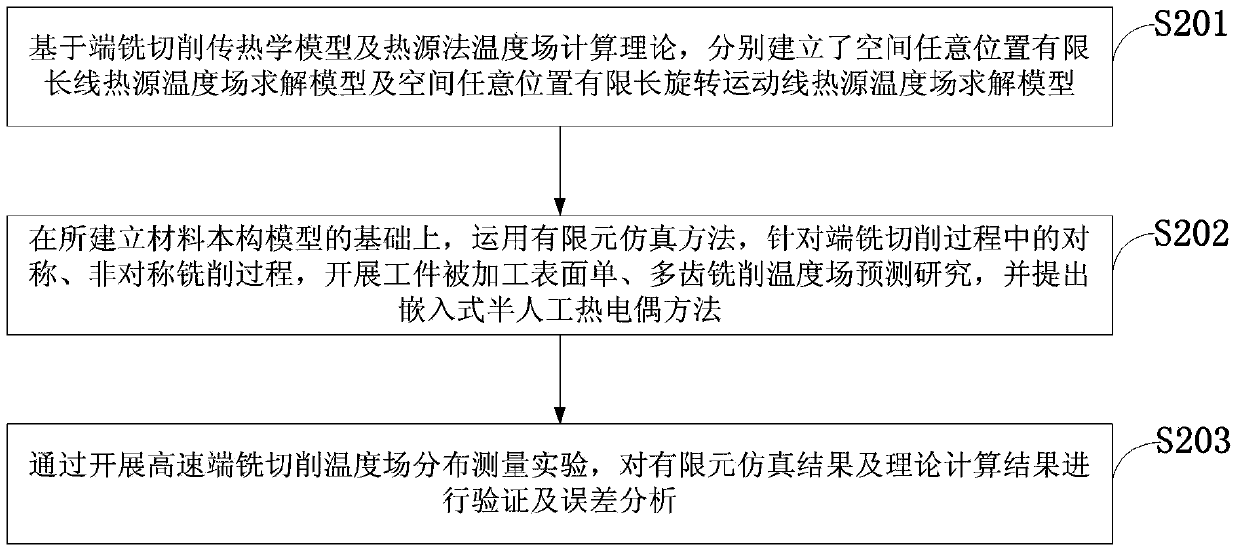

Method of cutting force prediction and temperature prediction for end-milling cutting

ActiveCN104268343ASimple methodEasy to operateSpecial data processing applicationsMethod developmentCutting force model

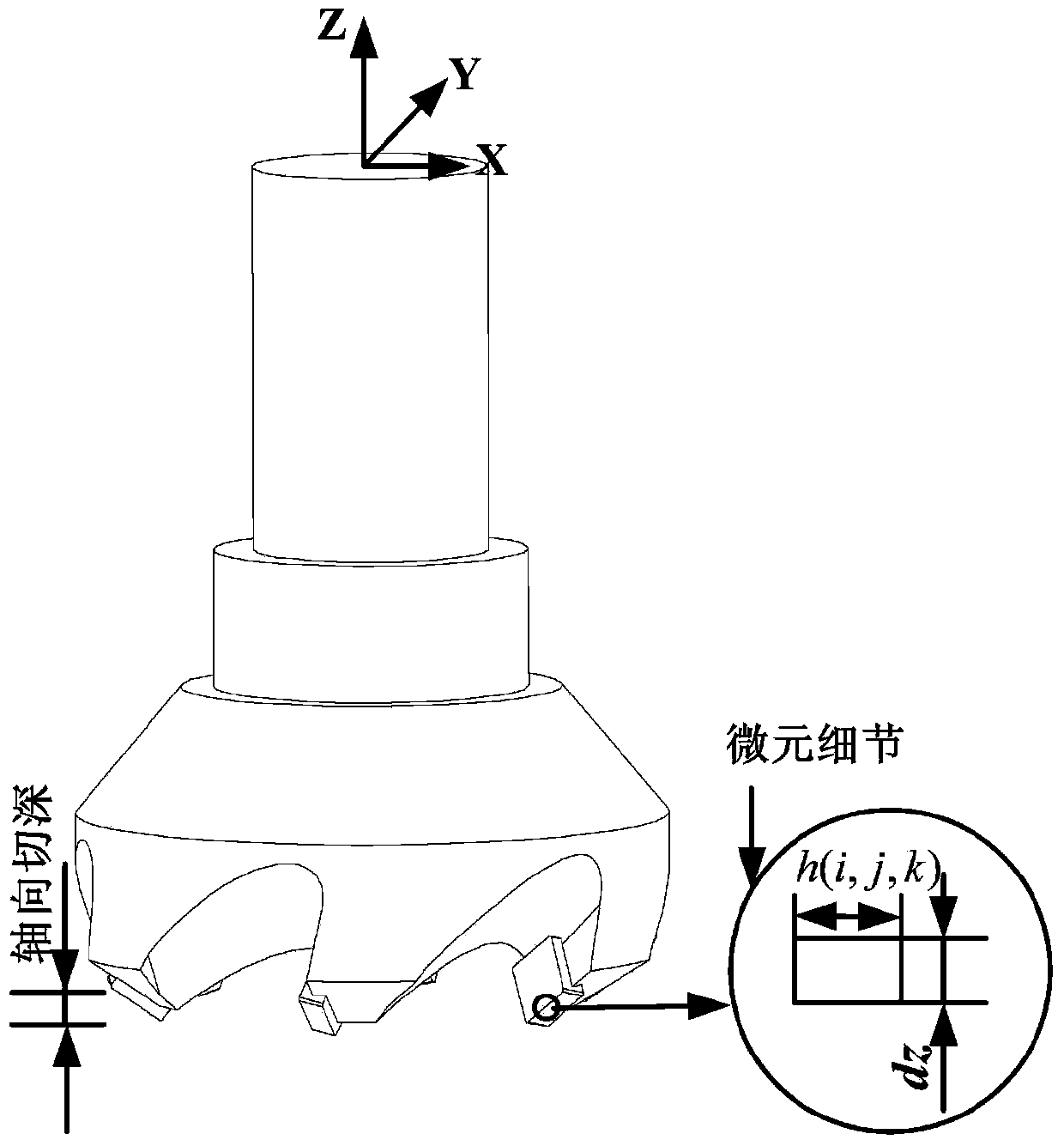

The invention discloses a method of cutting force prediction and temperature prediction for end-milling cutting, the method development of the cutting force prediction is based on a milling forces prediction model of average cutting forces and a milling forces prediction model of bevel angle cutting mechanism and is characterized by performing regression calculating on the two model parameters, predicting transient cutting force, performing comparative analysis with test data, and verifying established single-tooth and multi-teeth cutting force models; the method of cutting force temperature prediction establishes a temperature field solution model of a limited long-line heat source of space optional positions and a temperature field solution model of a limited long-rotation movement line heat source of space optional positions; by means of a limited element simulation method, an embedding semi-artificial thermocouple method is put forward, and by carrying out high speed end-milling cutting temperature field distribution measurement, verification and error analysis are performed on a limited element simulation result and a theoretical calculation result. The method of the cutting force prediction and the temperature prediction of the end-milling cutting has the advantages that the method is simple, operation is easy, reference foundation is provided for end-milling cutting technology, and the method is more beneficial to production.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

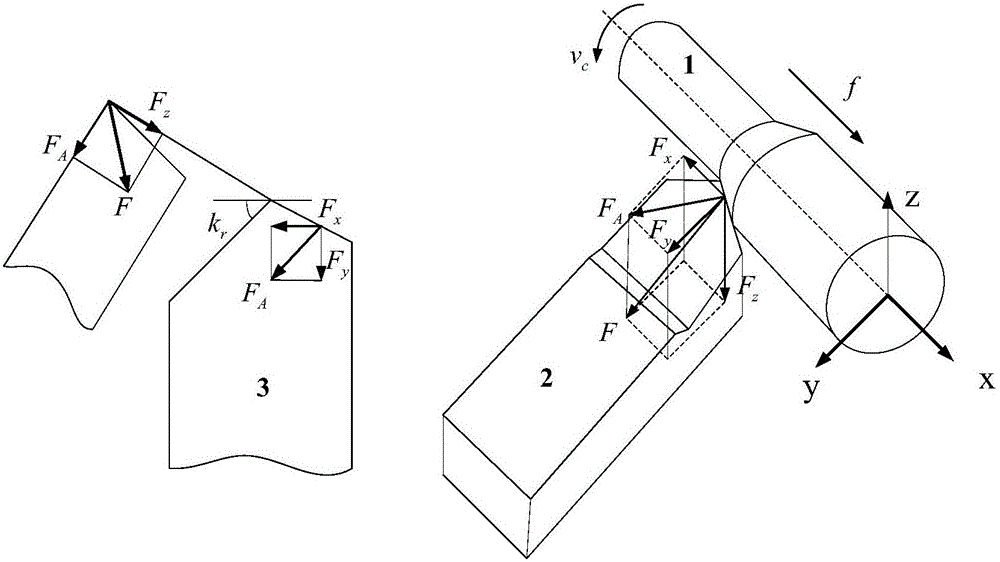

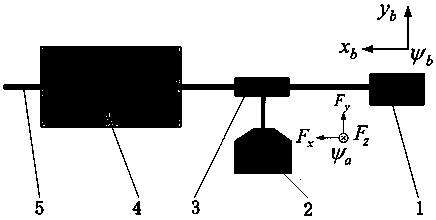

Turning force prediction method based on cutting-tool angle and cutting amount parametric variation

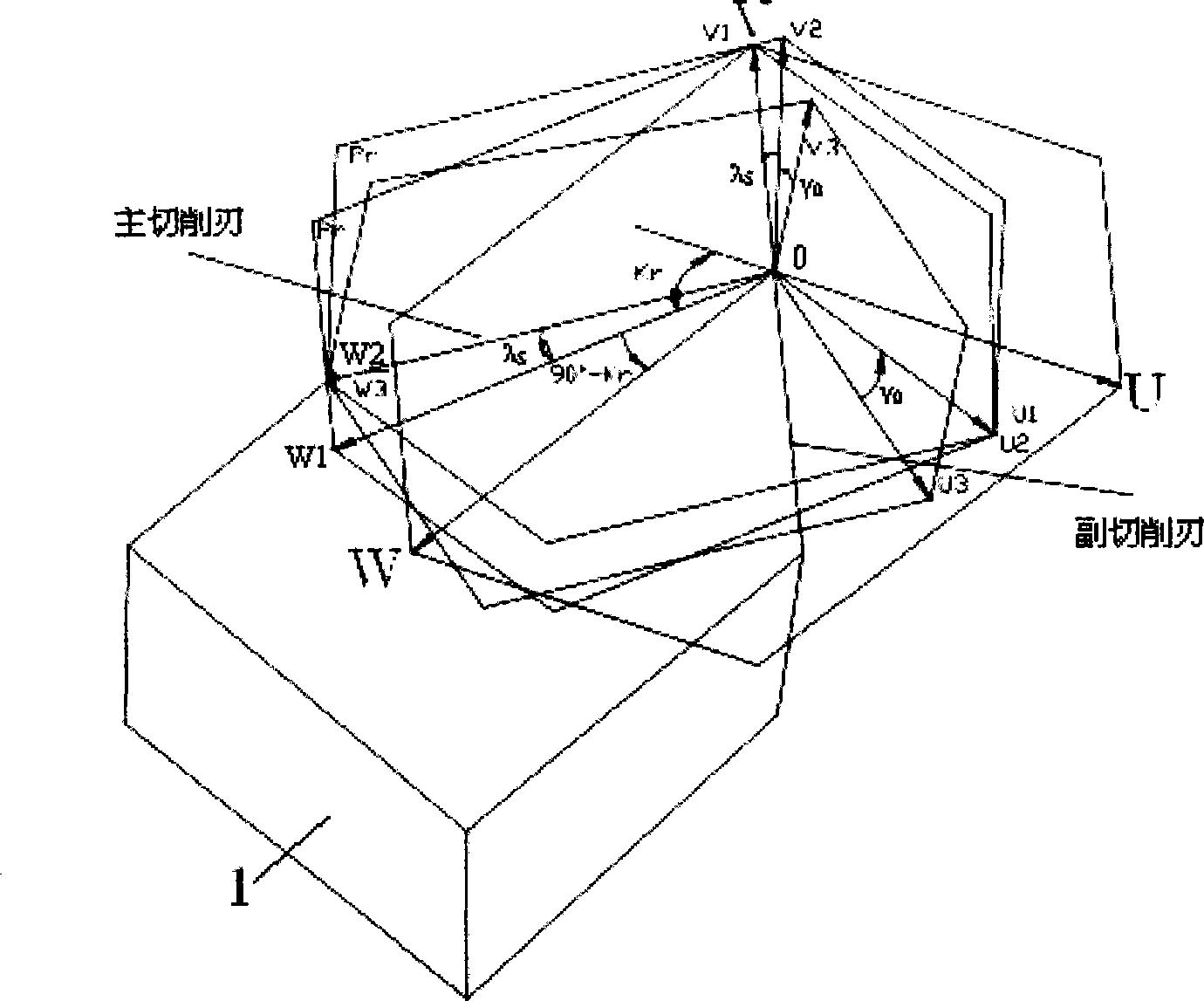

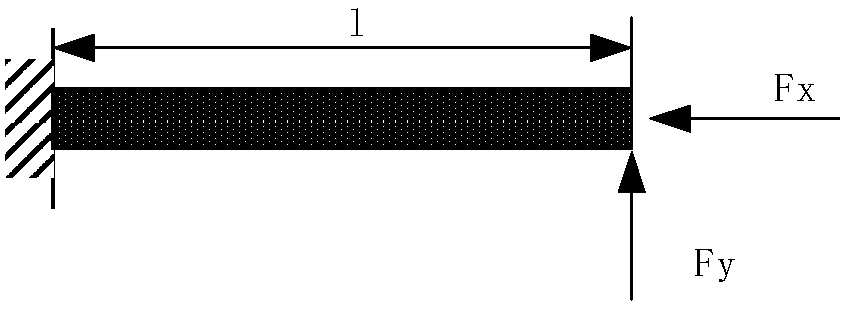

InactiveCN101412196AMeasurement/indication equipmentsMeasurement of force componentsEngineeringCutting force model

The invention discloses a method for predicting a turning force based on cutter angle and parameter variation of cutting data. The method comprises the following steps: using a dynamometer to measure a cutting force distributed along a coordinate axis of a coordinate system in one-time turning, calculating a three-way turning force coefficient of the cutting force in a converted coordinate system through converting the coordinate system, and calculating and obtaining the predicted turning force according to the factor of the cutting force, so as to achieve prediction of a three-way turning force for processing work pieces made from the same material and having the same heat treating state under the same cutting and lubricating conditions of the cutters made from the same material at any cutter angle parameter and cutting data parameter. The method for predicting the turning force needs little workload for cutting experiments, and the obtained cutting force models have wider application application, have predicting precision meeting actual demand, and are convenient to popularize and apply.

Owner:XIAN UNIV OF TECH

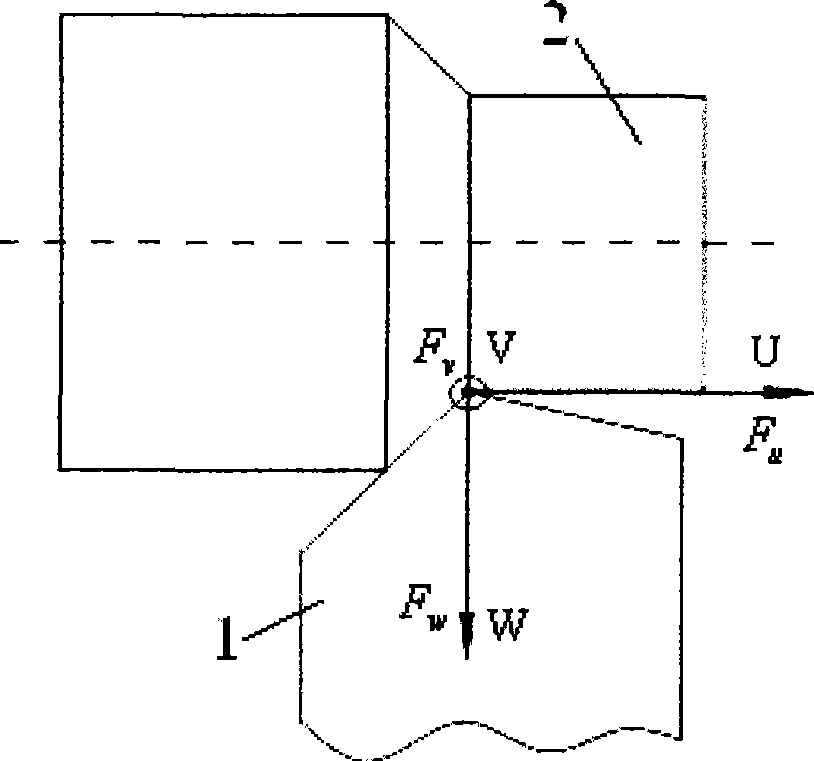

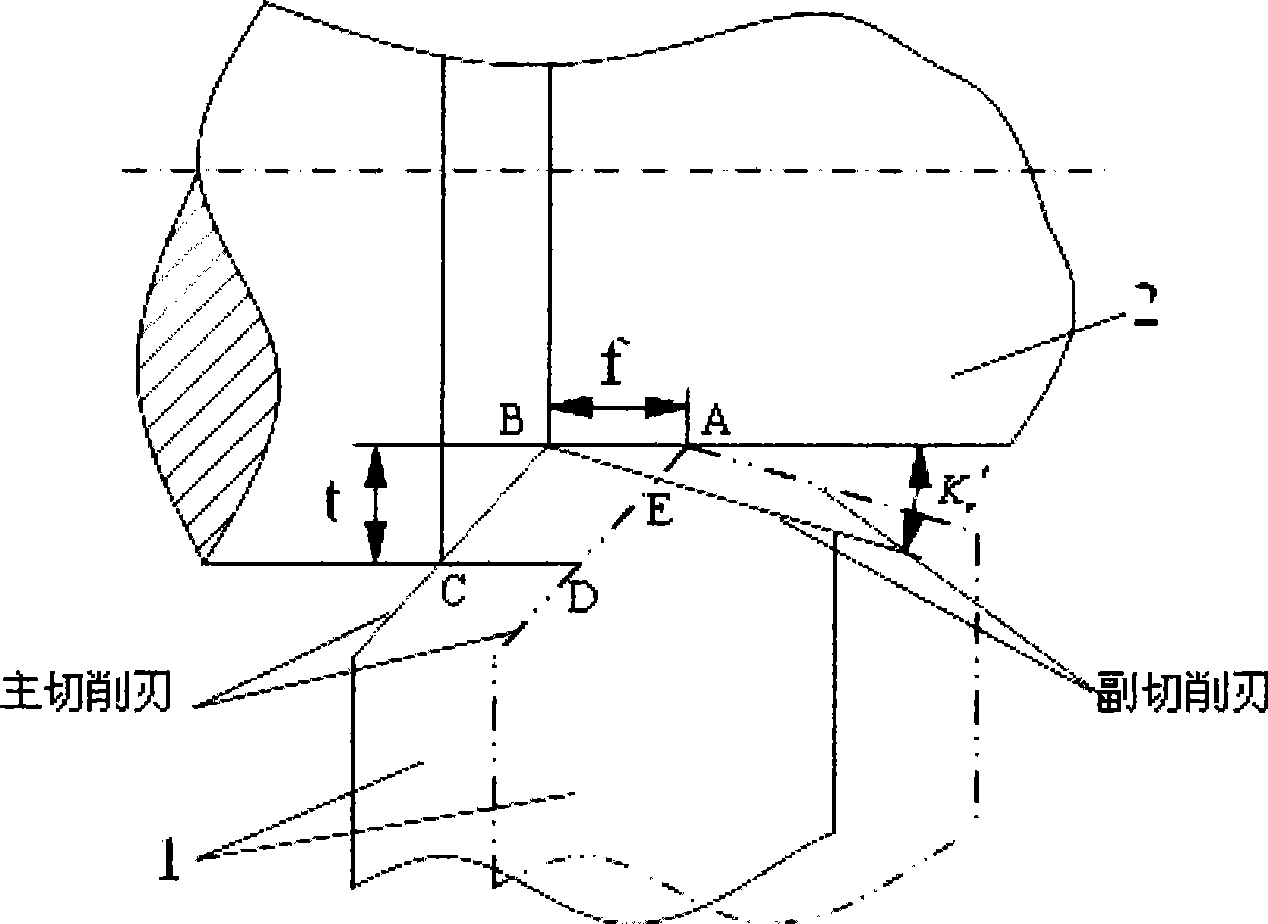

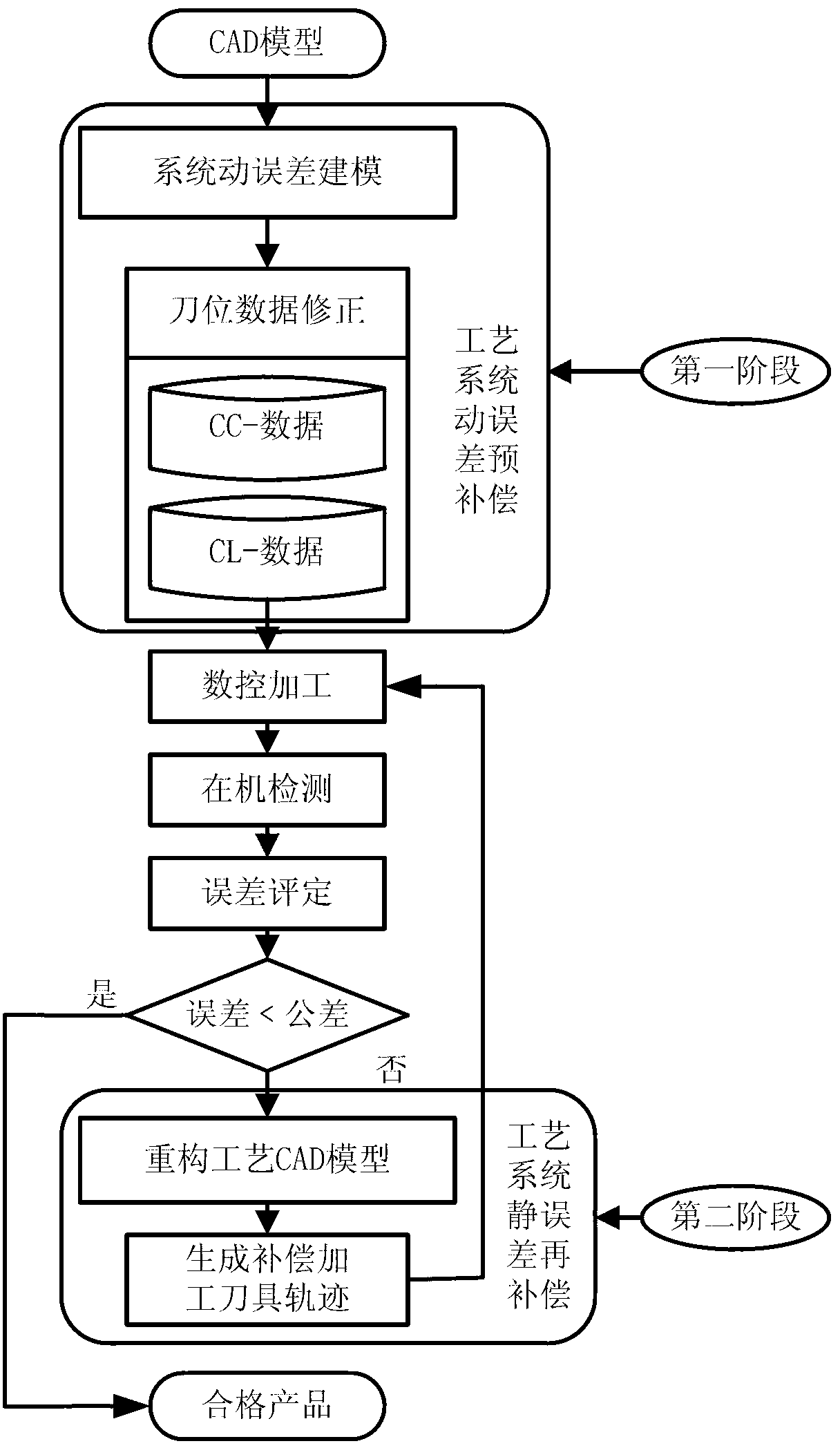

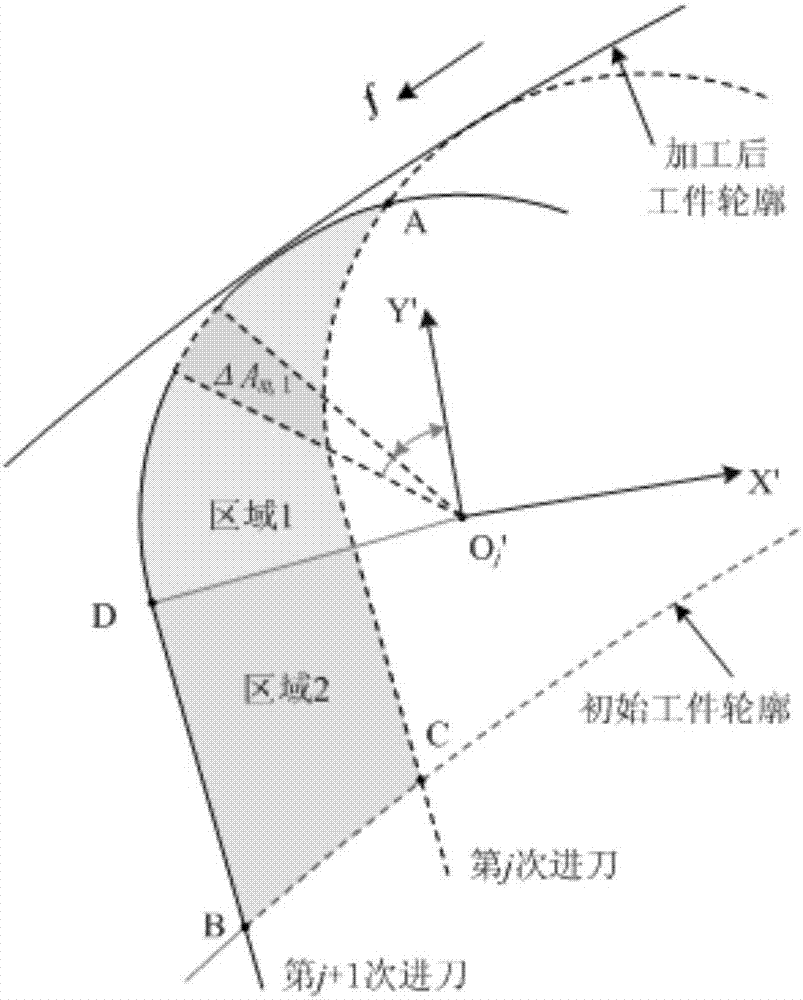

In-process evaluation based complex spatial surface error feedback compensating method

ActiveCN103218475AAvoid repeated positioning errorsReduce handlingSpecial data processing applicationsComputer Aided DesignCutter location

The invention discloses an in-process evaluation based complex spatial surface error feedback compensating method. The method comprises the following steps of processing a complex surface cutting force module through a ball-end cutter, performing dynamic compensation for a target cutter location point for workpiece pre-processing; performing in-process detection for the pre-processed workpiece to obtain geometrical information of an actual contour; evaluating error for the pre-processed workpiece through a contour degree error evaluation model; when the contour error is greater than tolerance, determining a compensation point position U1 corresponding to each contact point; guiding the compensation point position corresponding to each contact point to three-dimensional CAD (Computer-Aided Design) to obtain a compensating process contour to generate a compensating processing tool track; and performing static compensation and processing for the pre-processed workpiece and finishing the flow. Under the premise of ensuring the processing precision of part surface, the processing precision of the part is detected in process without investing fund to purchase more detection devices, so that the conveying and loading time of workpieces is shortened.

Owner:TIANJIN SAIXIANG TECH

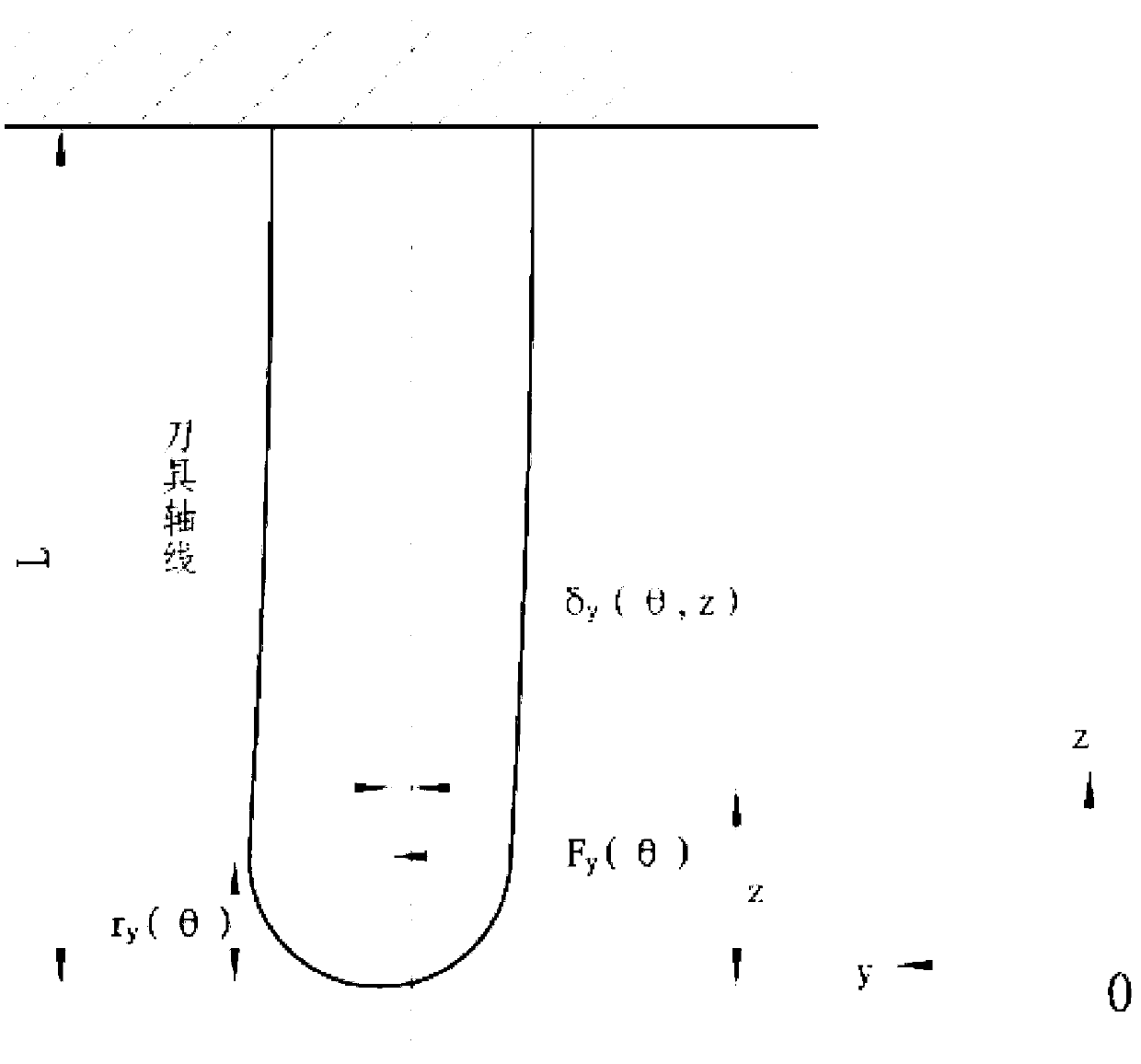

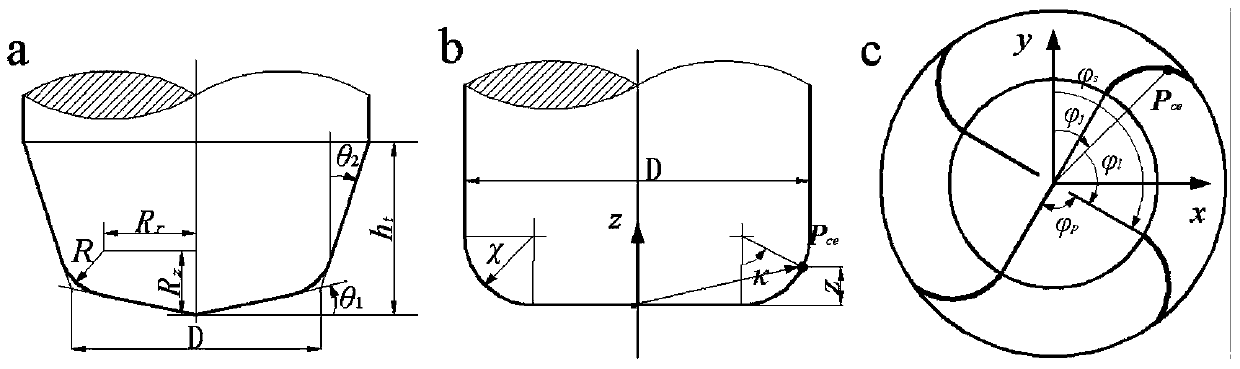

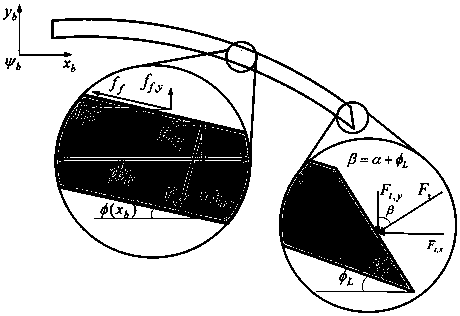

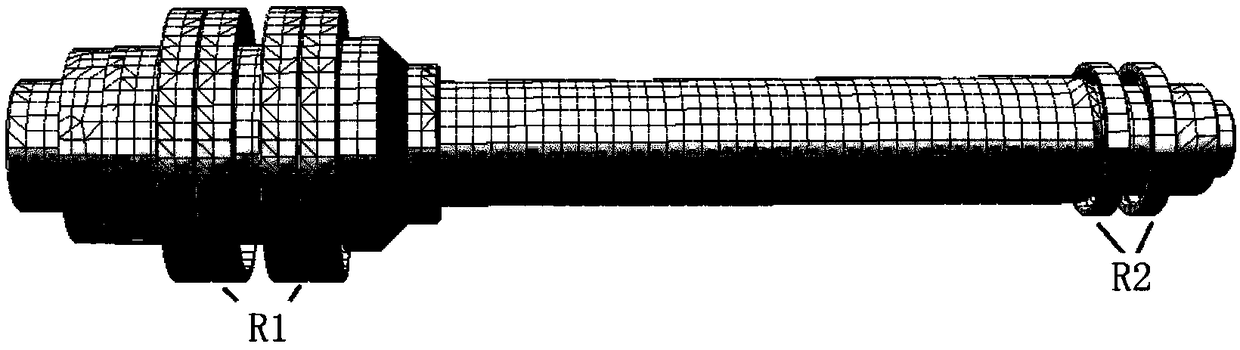

Tool deflection modeling method for multi-axis machining system

ActiveCN104182631AVariation law of accurate deviationThe compliance model is accurateProgramme controlComputer controlDrive shaftEngineering

The invention discloses a tool deflection modeling method for a multi-axis machining system. The tool deflection modeling method includes establishing a new non-deformable cutting thickness model, and a cutting force prediction model of arc-tool variable-posture milling by the vector method; establishing a flexibility model of a machine transmission shaft by the equivalent column method and a comprehensive flexibility model of the machining system by force ellipsoid method and coordinate system transformation; finally utilizing the cutting force model in the process of variable-posture machining and the flexibility model at the tail end of the multi-axis machining system to obtain a tool deflection model. In the tool deflection modeling method, the non-deformable cutting thickness model of a new tool cutting blade and the comprehensive flexibility model of the multi-axis machining system are used to obtain a more accurate tool deflection change law during machining, so that the tool postures during multi-axis machining and machining parameters such as feed speed and spindle revolving speed are optimized, tool deflection is controlled, and quality of machined surfaces of workpiece is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

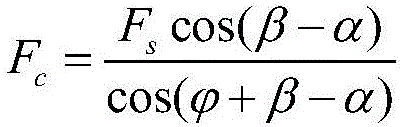

Building method of carbon fiber composite material cutting model

The invention belongs to the field of carbon fiber composite material cutting and processing researching, and relates to a building method of a carbon fiber composite material cutting model. The building method comprises the steps that firstly, a bidirectionally matrix-constrained single-fiber cut-off model is built, wherein the fiber deformation characteristics are described in three segments through the boundary condition difference in the fiber length direction according to the differences of the fiber stress and the borne matrix constraining action of the model in the fiber direction, the first segment starts from the top end to a cutting edge contact point, the second segment starts from the cutting edge contact point to a cutting plane, and the third segment starts from the cutting plane to a certain point far away from a processing surface; secondly, a contact model and a single-fiber compression-shearing model for a cutting edge and fibers are built; lastly, a composite material cutting force model is built. According to the method, fiber breakage, resin interface crack and the extruding action of a rear cutter surface on the fibers can be represented, a quantitative relation between the cutting force and processing parameters in composite material cutting and processing can be obtained, and an experimental basis is provided for actual cutter design and technological parameter establishment.

Owner:DALIAN UNIV OF TECH

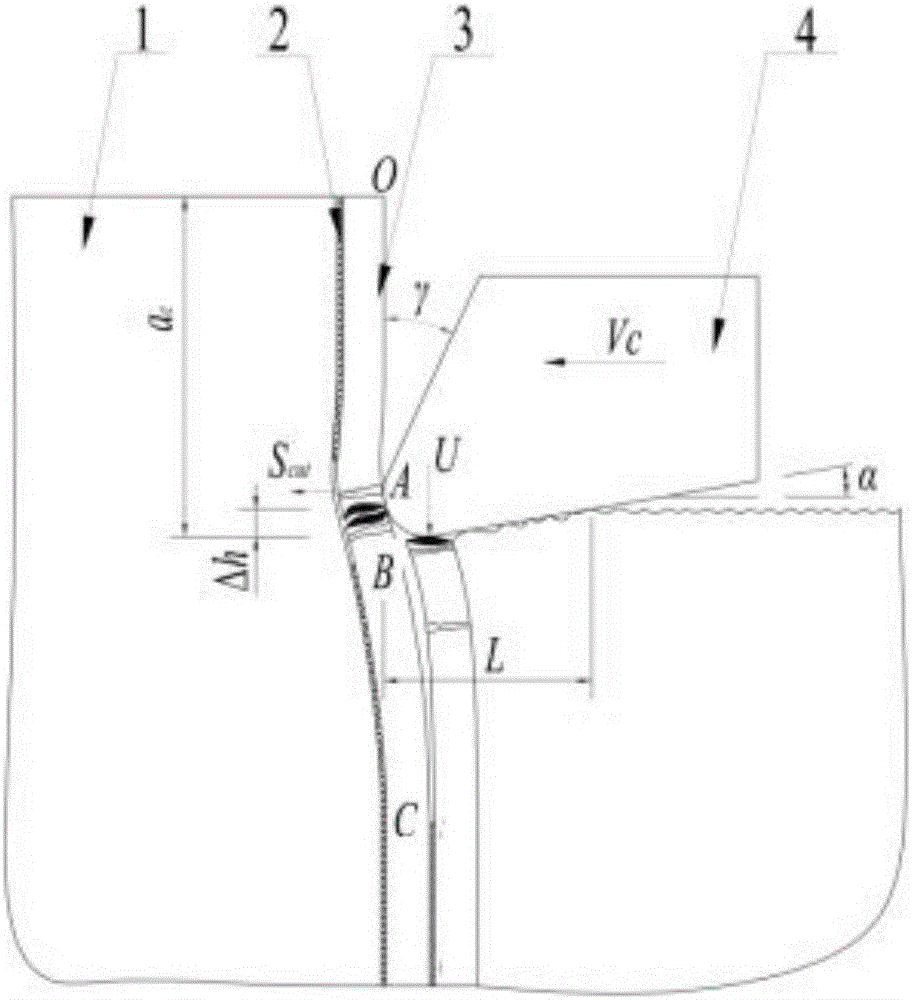

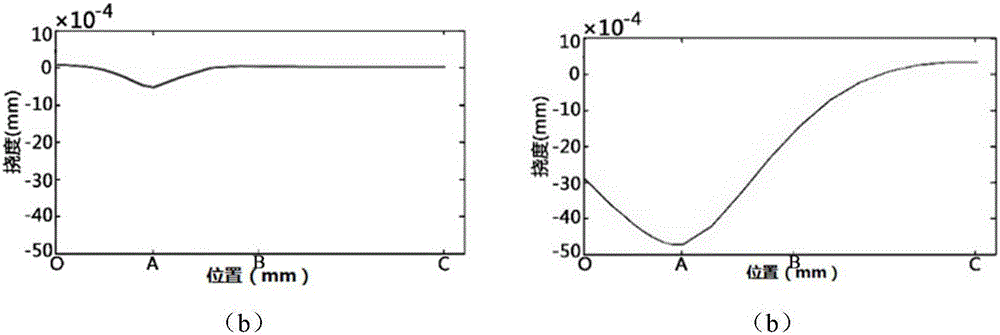

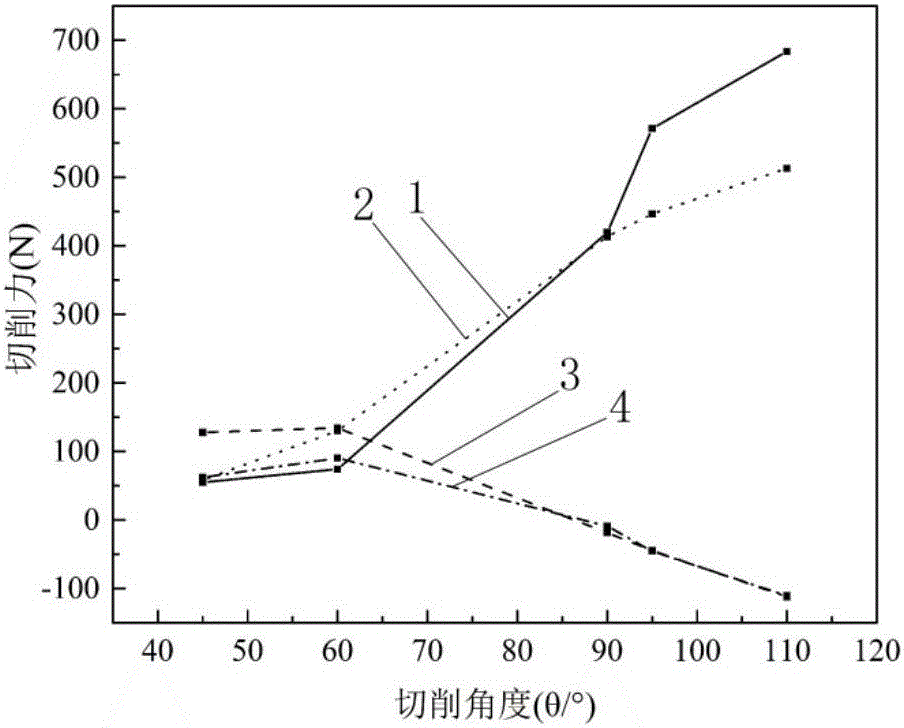

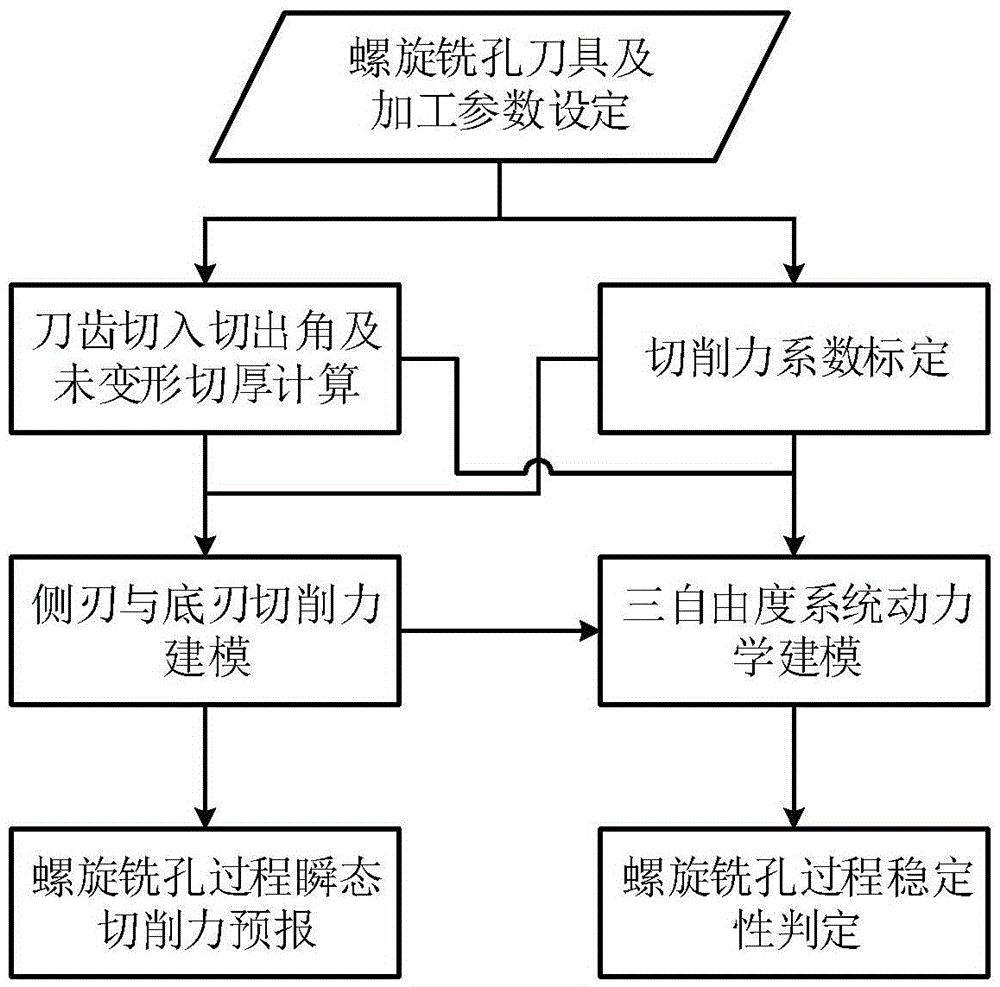

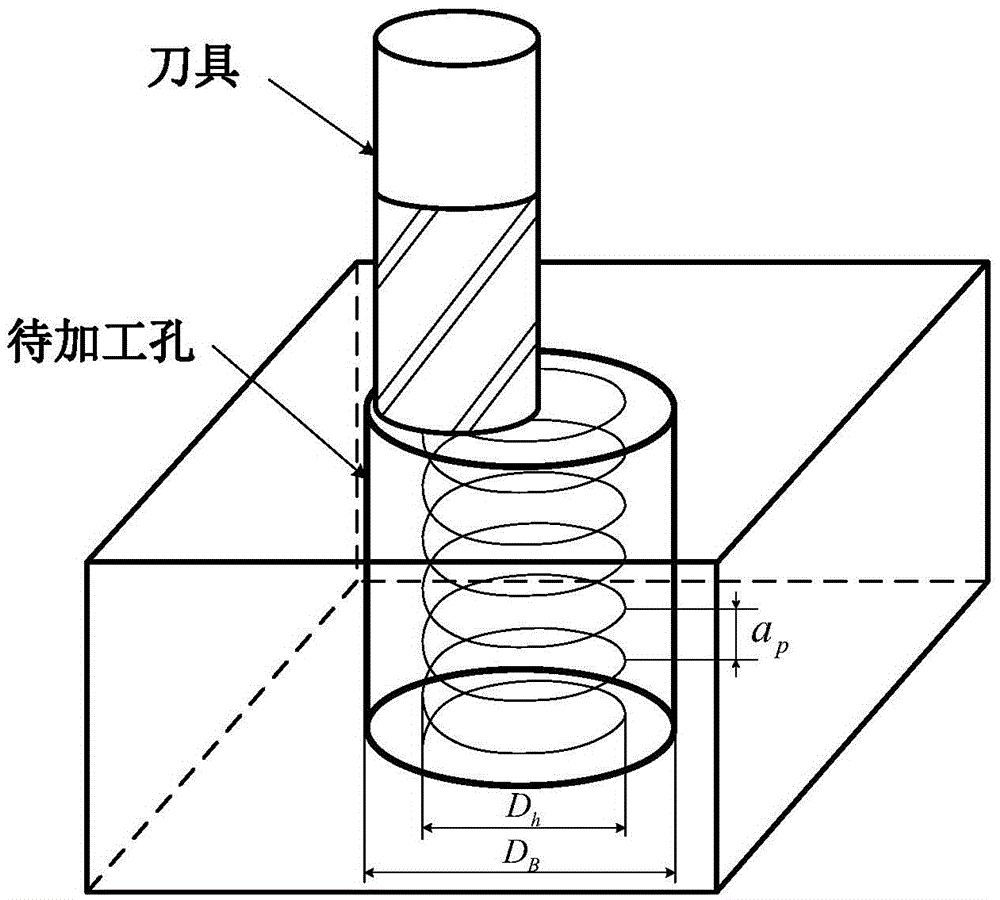

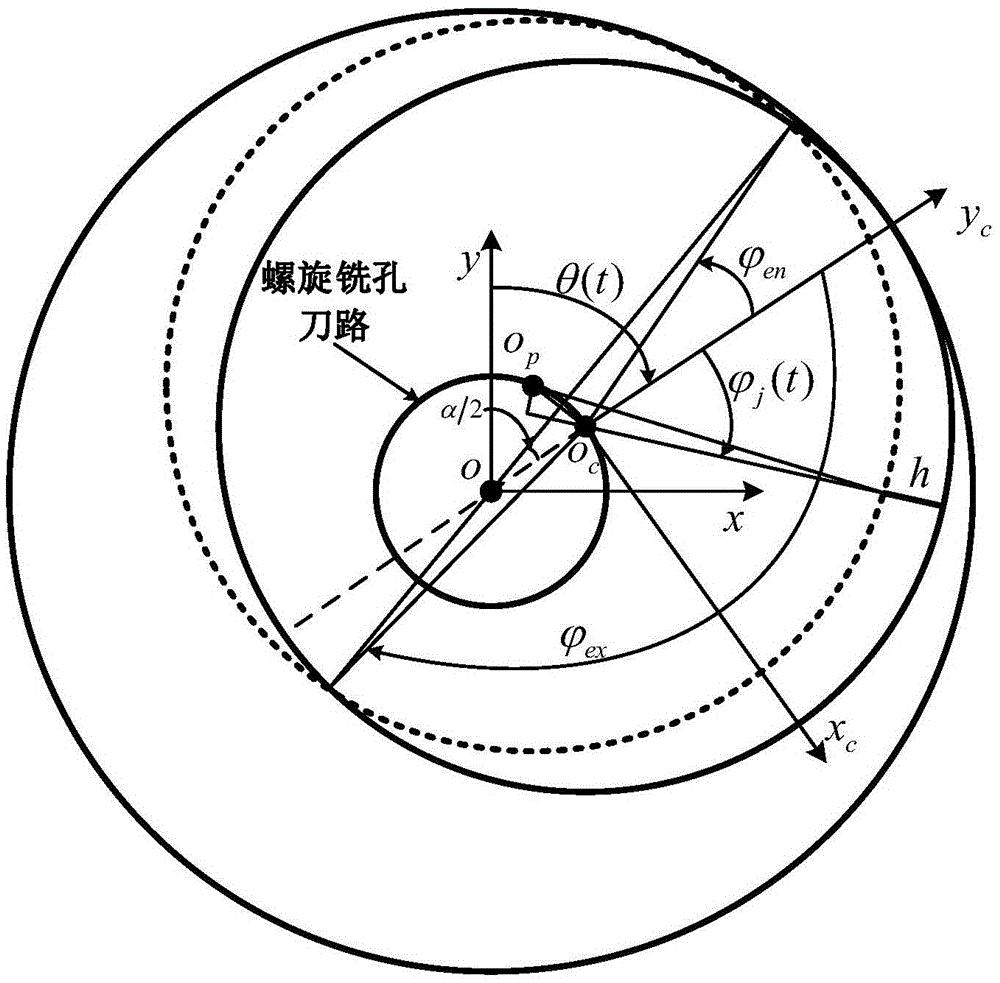

Method for cutting force forecasting and stability judging in spiral hole milling process

The invention provides a method for cutting force forecasting and stability judging in the spiral hole milling process. The method comprises the following steps that a tool and machining parameters are selected according to the size of a hole to be machined, and a spiral milling tool path is generated; assumption is carried out based on a tool tooth track arc, and the analytic calculation expression of the tool tooth cut-in and cut-out angle and non-deformation cutting thickness is obtained according to the tool geometric position relation between adjacent tool positions; side edge and bottom edge cutting force coefficients are obtained through triaxis single-tooth milling experiment calibration and triaxis inserting milling experiment calibration; the obtained parameters are substituted into a binary cutting force model to obtain side edge cutting force and bottom edge cutting force through calculation, and the side edge cutting force and the bottom edge cutting force are added to achieve precise forecasting of instant cutting force in the spiral hole milling process; and a three-freedom-degree milling kinetic equation comprehensively considering the milling tool structure mode coupling effect and the dynamic cutting thickness regeneration effect is built, and the stability of the machining process is judged based on a numerical integration method. The accuracy of cutting force forecasting and stability judging in the spiral hole milling process is improved.

Owner:SHANGHAI JIAO TONG UNIV

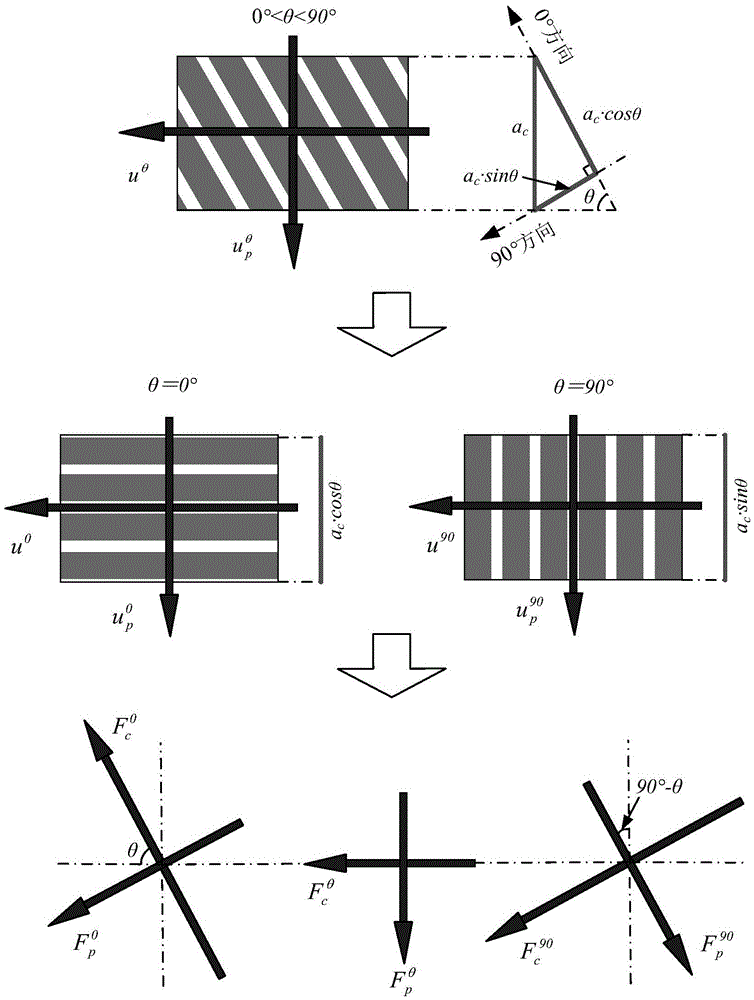

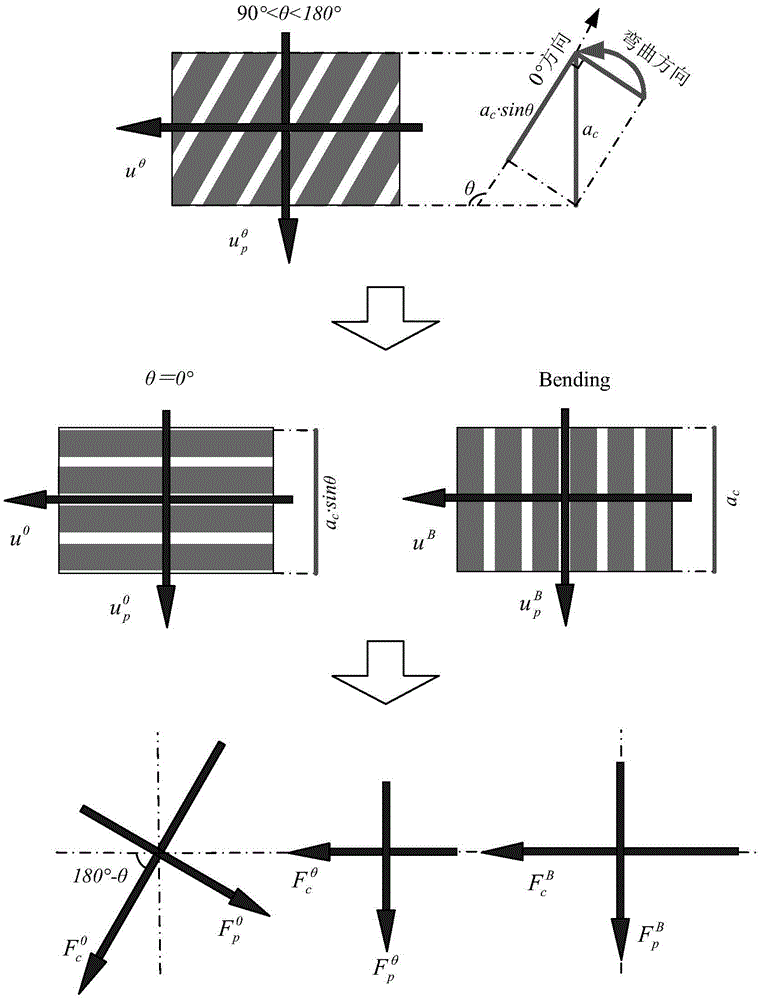

Carbon fiber reinforced composite material unidirectional laminate two-dimensional cutting force modeling method

InactiveCN105678026AImprove forecast accuracyCutting Process OptimizationGeometric CADSpecial data processing applicationsCutting force modelCarbon fiber reinforced composite

The invention discloses a carbon fiber reinforced composite material unidirectional laminate two-dimensional cutting force modeling method.A cutting force model under any fiber direction angle can be obtained according to a directionality cutting ratio so that the two-dimensional cutting force model can predict two-dimensional cutting force under different fiber direction angles.The method comprises the following steps that fiber direction angles theta are 0 degree, 90 degrees and 135 degrees respectively for performing carbon fiber reinforced composite material unidirectional laminate two-dimensional cutting experiments to obtain basic data for modeling; according to the basic data obtained through the cutting experiments when the theta is 0 degree and 90 degrees, a two-dimensional cutting force model of the carbon fiber reinforced composite material unidirectional laminate under any direction angle along fiber is built; according to the basic data obtained by the cutting experiments when the theta is 0 degree and 135 degrees, a two-dimensional cutting force model of the carbon fiber reinforced composite material unidirectional laminate under any direction angle opposite to fiber is built.According to the carbon fiber reinforced composite material unidirectional laminate two-dimensional cutting force modeling method, influences of a cutting mechanism and anisotropism are considered, the prediction precision of the obtained two-dimensional cutting force model is higher, and the method can be used for designing and manufacturing a cutting tool for carbon fiber reinforced materials and determining cutting technological paths and parameters.

Owner:SHANGHAI JIAO TONG UNIV

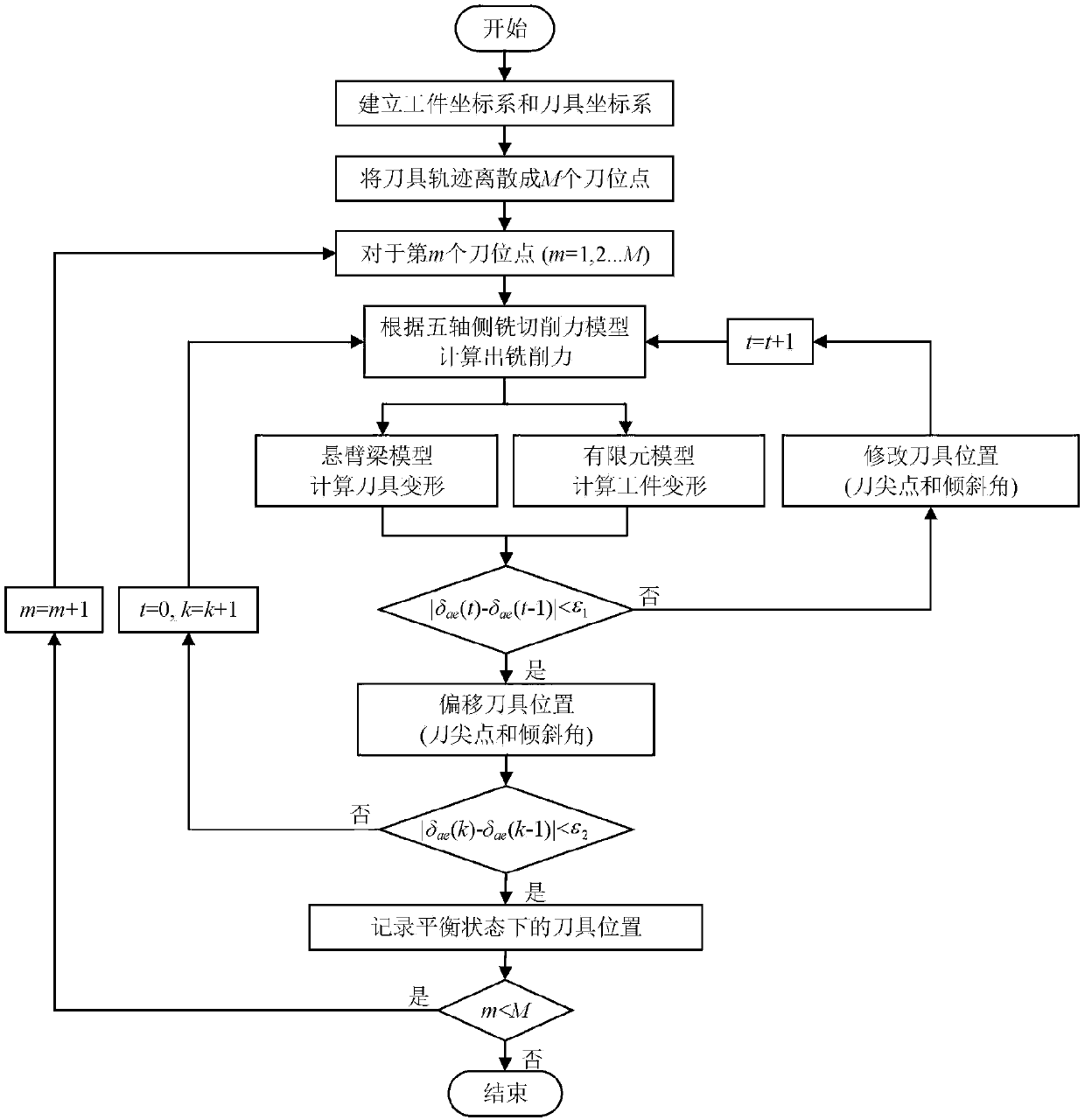

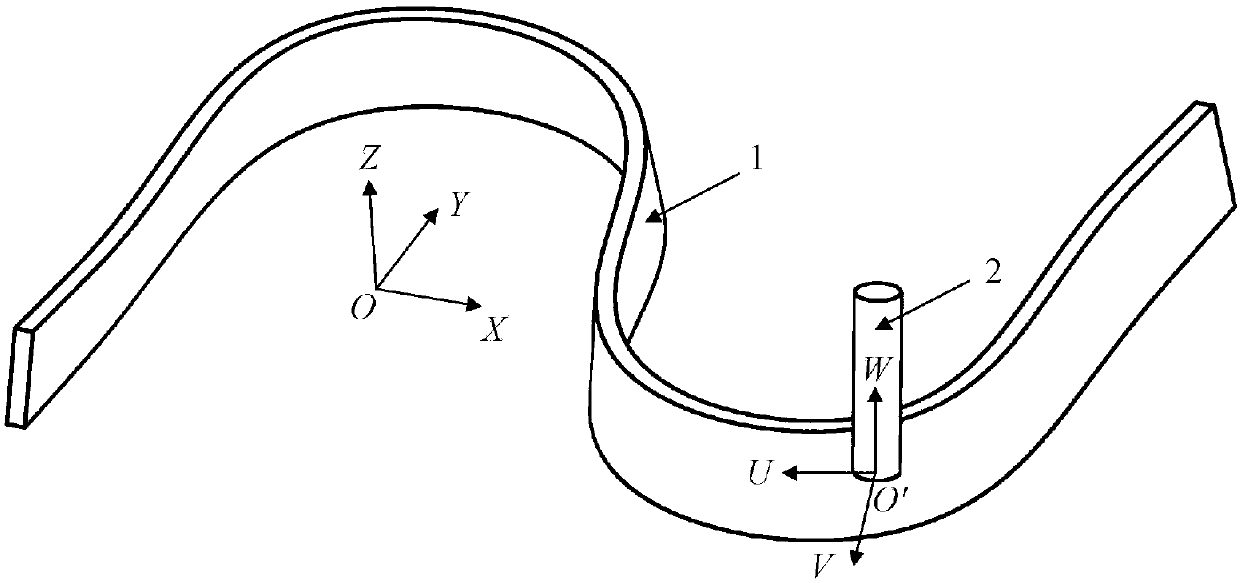

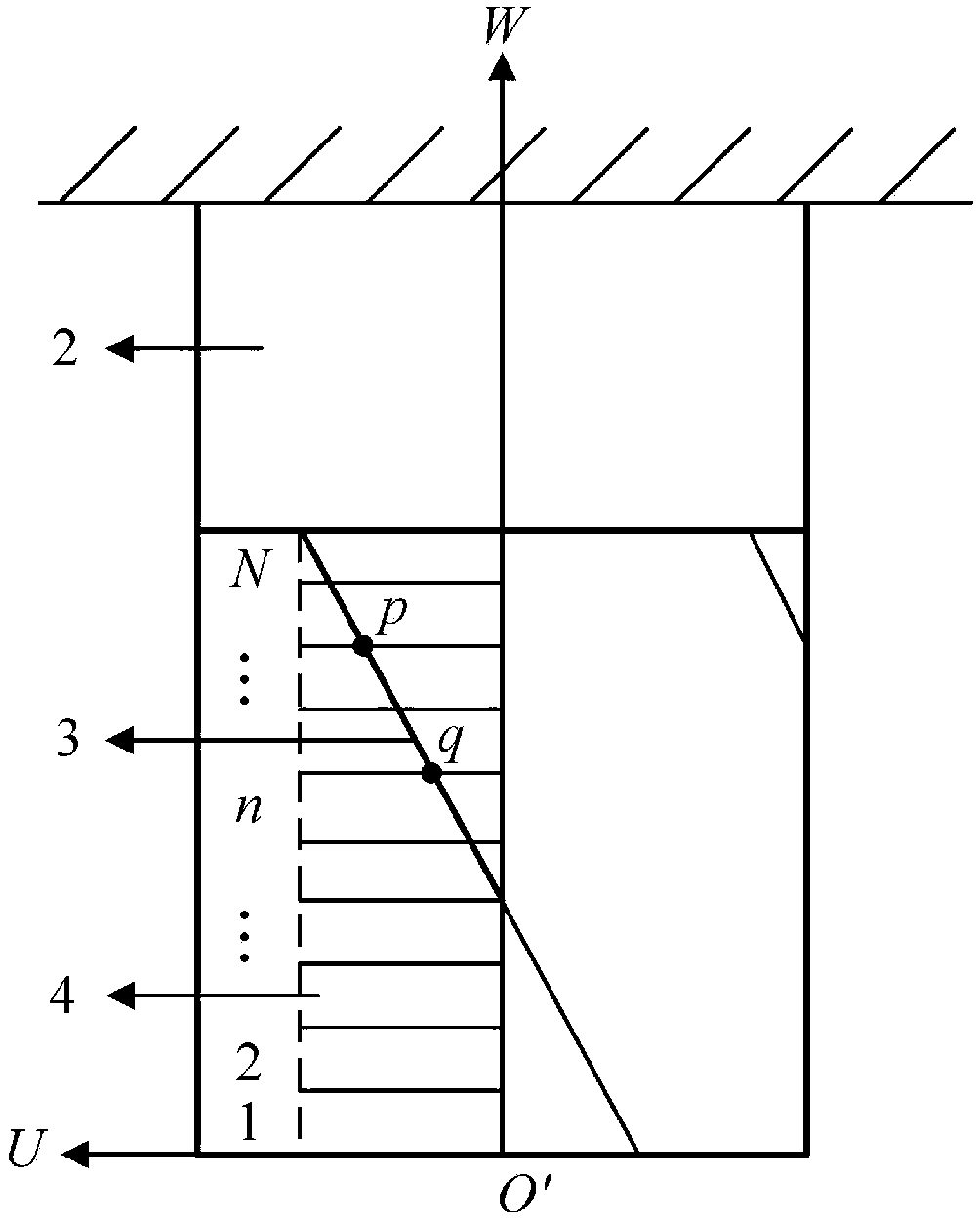

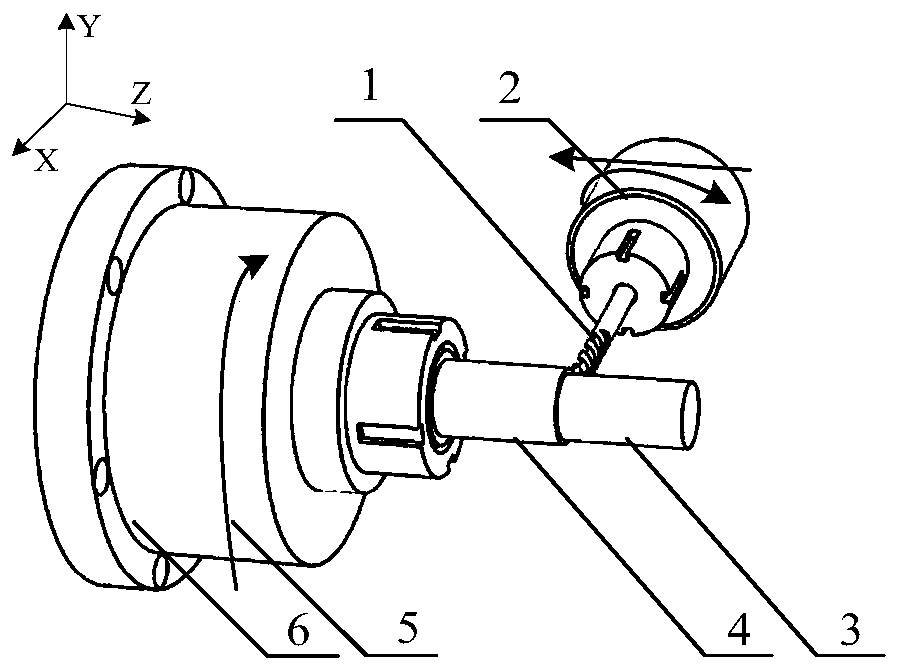

Five-axis side milling processing tool and workpiece deformation error compensation method

ActiveCN107942936AThe calculation result is accurateProgramme controlComputer controlCantilevered beamElement model

The invention provides a five-axis side milling processing tool and workpiece deformation error compensation method. The method comprises a step of calculating milling force based on a five-axis sidemilling cutting force model and then using a cantilever beam model and a finite element model to calculate the deformation of a tool and a workpiece, a step of solving a deformation error under a cutting balance state by using an iterative algorithm with the consideration of the feedback influence of tool and workpiece deformation on milling force in a machining process, a step of modifying the position of a tool tip and the inclination angle of a tool shaft at a current tool position according to the principle of mirror image, inputting an updated tool position into the cutting force model and recording a tool position in a balance state after iterative calculation, and a step of traversing the above process for each tool position point and obtaining a compensated tool path. According tothe method, the reduction of the deformation error caused by the cutting force in a five-axis side milling processing process is facilitated, and the method plays an important role in improving the machining accuracy of parts. The method is applicable to the compensation of a deformation error in the five-axis side milling processing of an aerospace thin-wall workpiece by using a ball-end millingcutter or a round nose milling cutter.

Owner:TSINGHUA UNIV

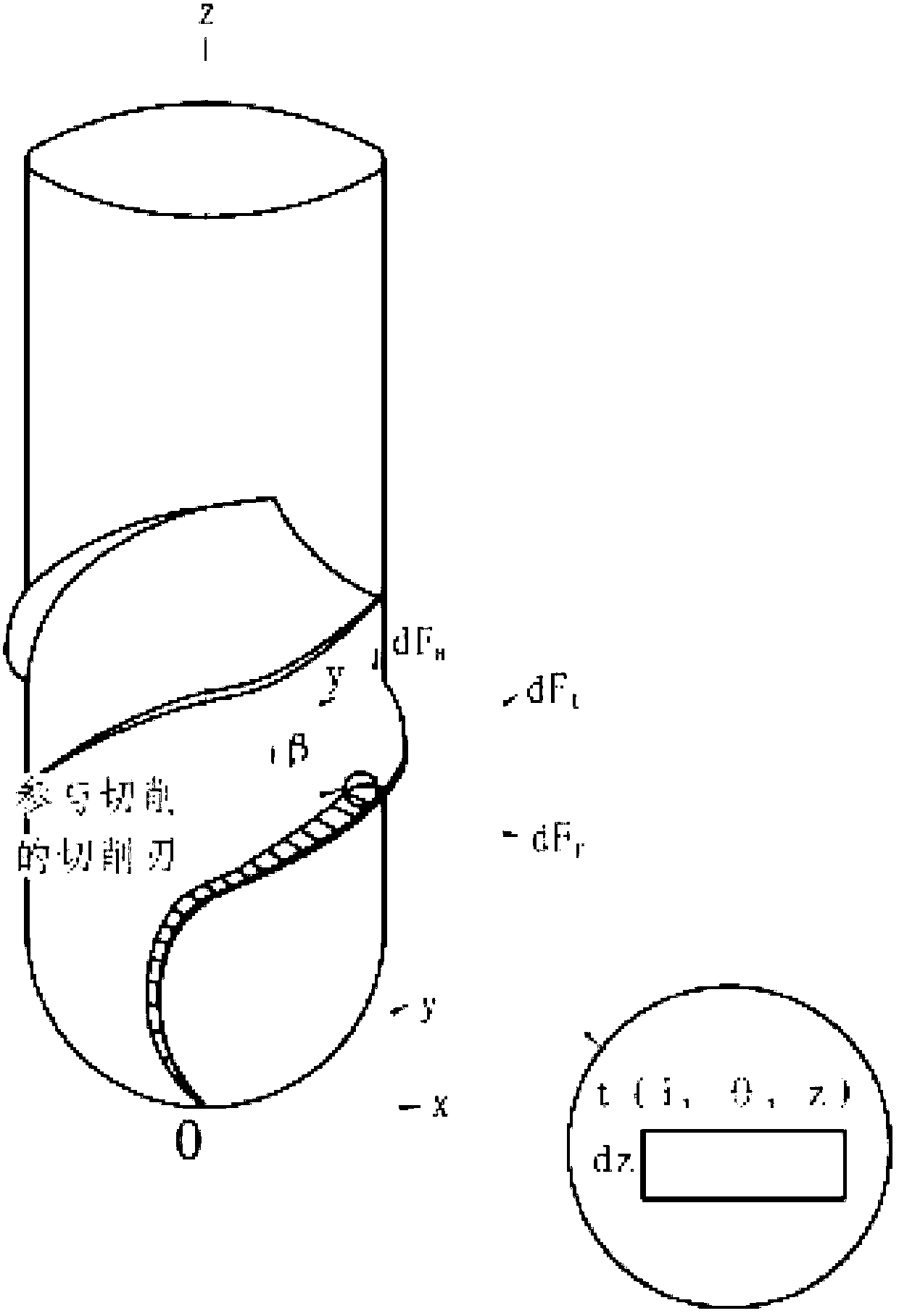

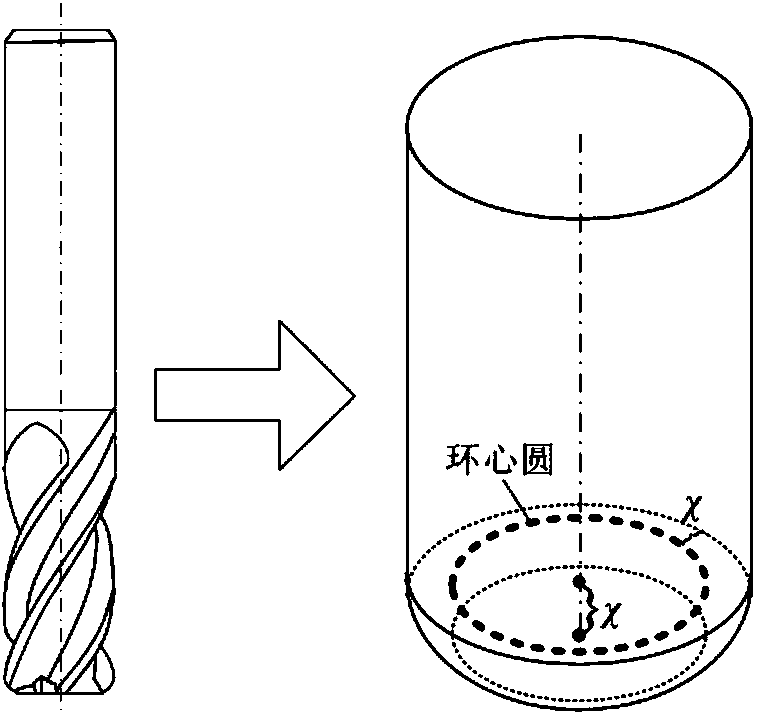

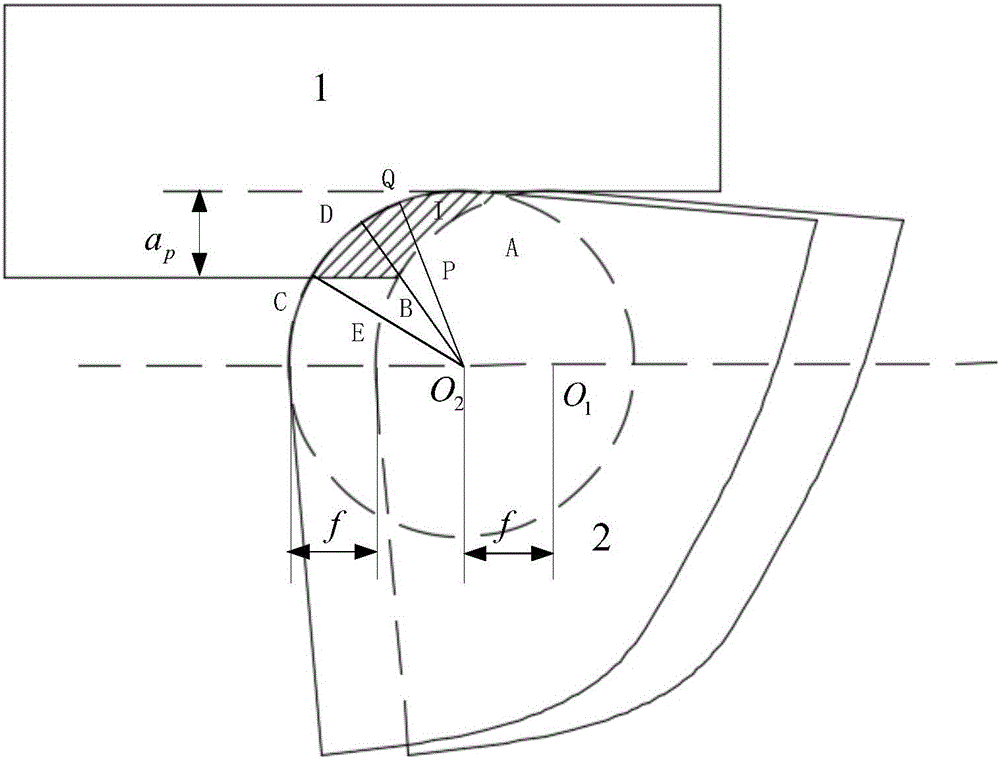

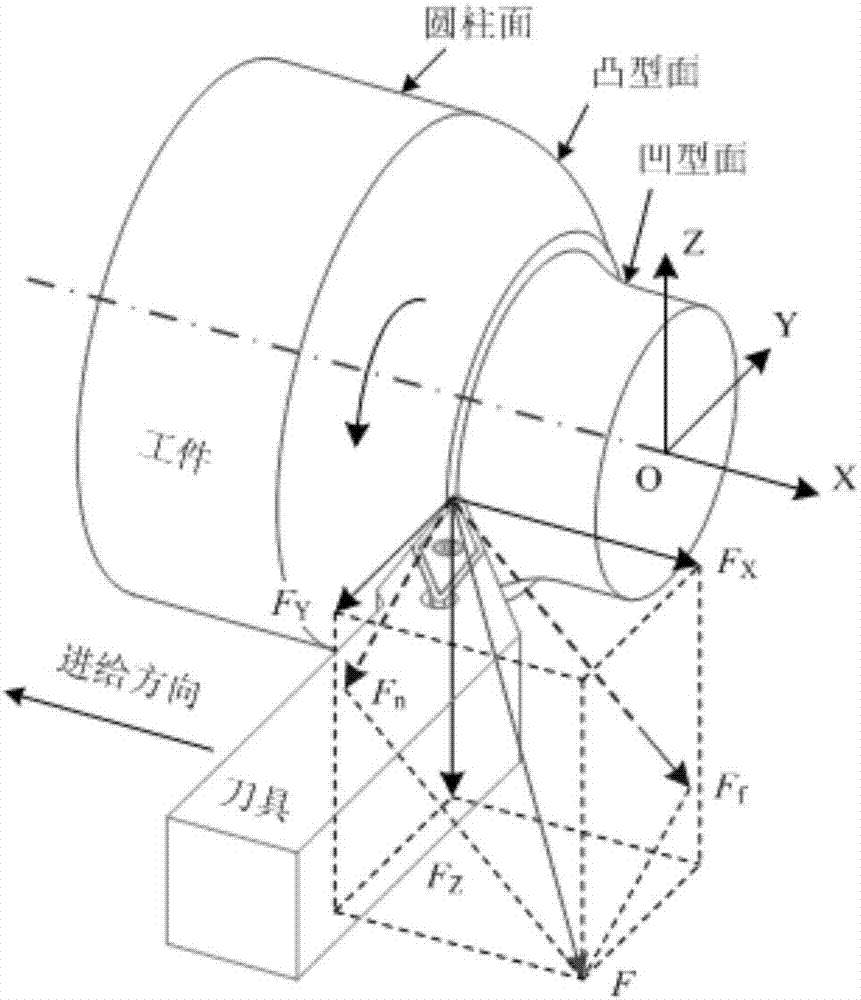

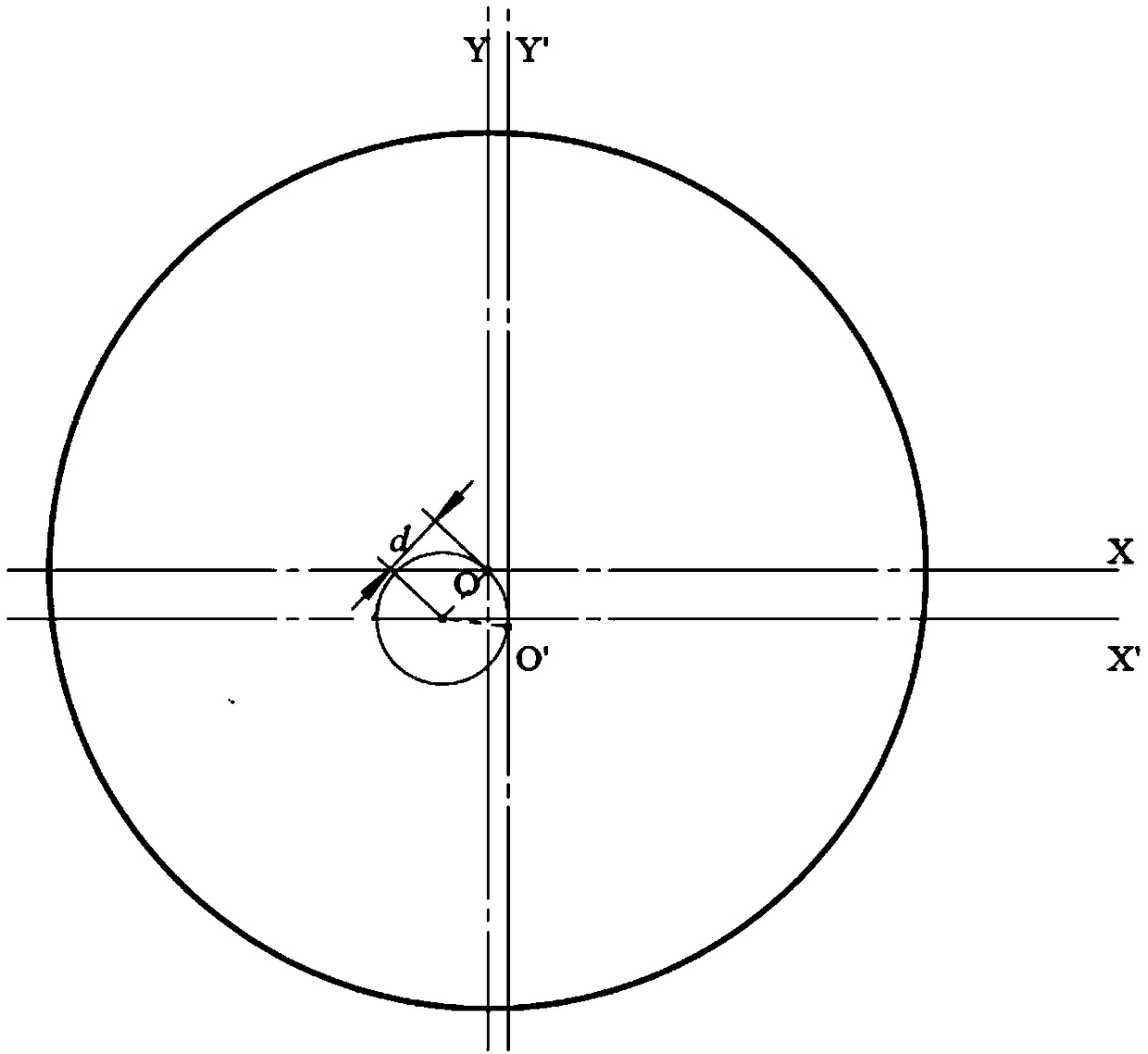

Prediction model for turn-milling machining spatial spiral trochoid motion trail and an instantaneous cutting force

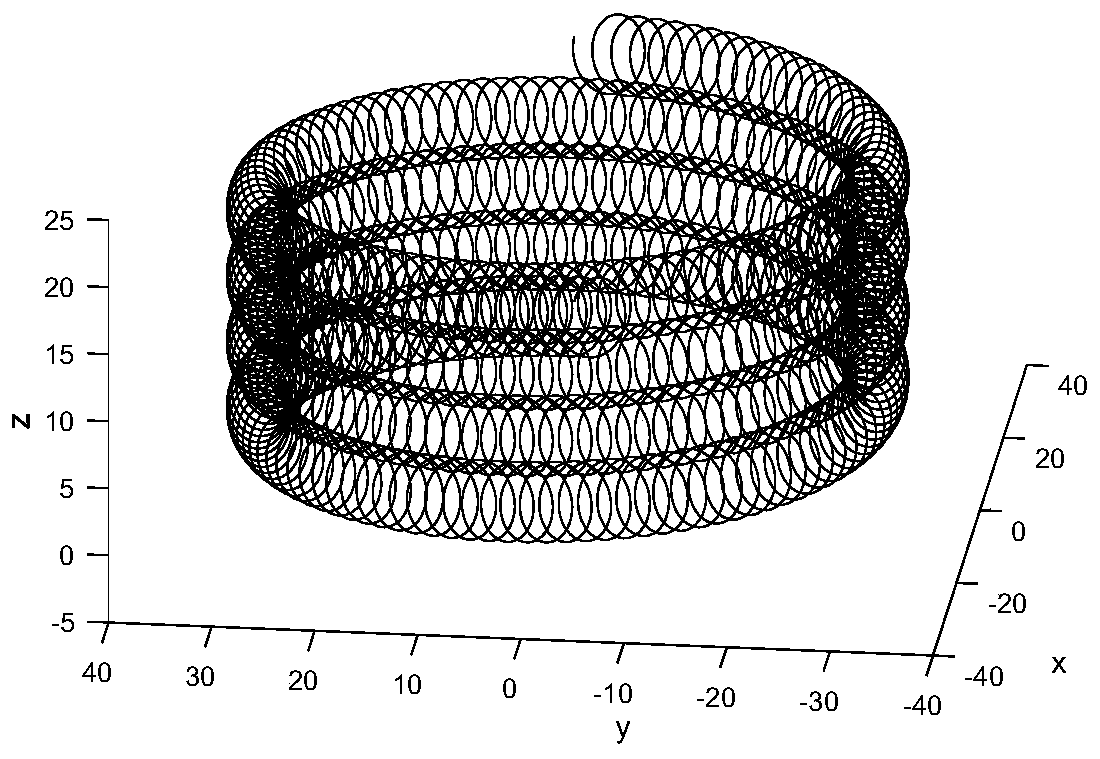

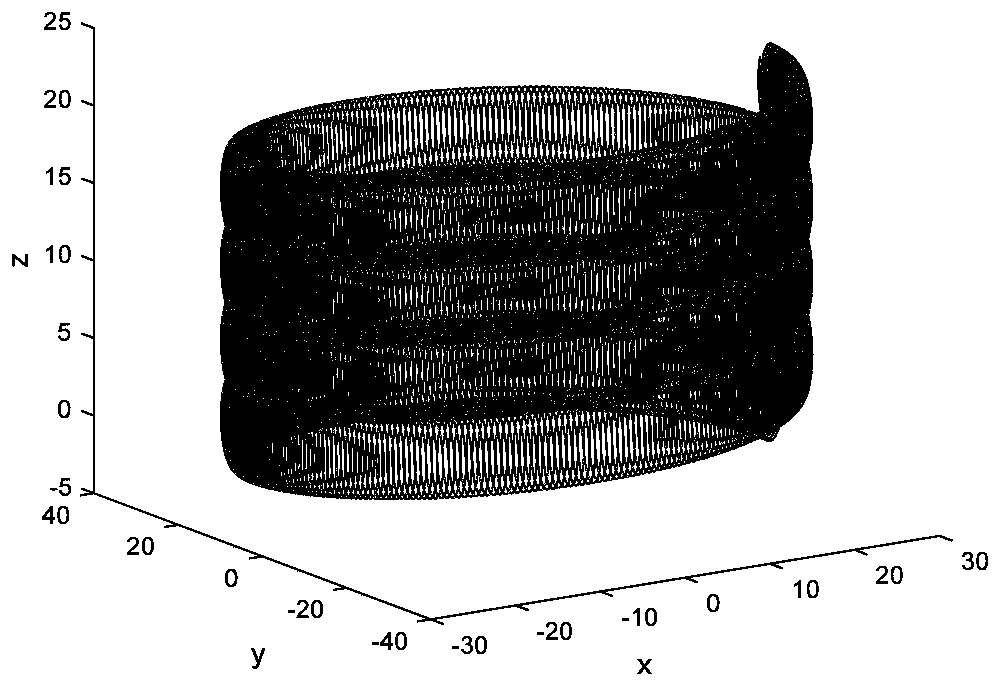

ActiveCN110262397ASolve inaccurateAccurate calculationProgramme controlComputer controlTracking modelCutting force model

The invention discloses a prediction model for a turning and milling spatial spiral trochoid motion trail and an instantaneous cutting force, and belongs to the technical field of machining and manufacturing. The establishment process of the instantaneous cutting force prediction model is as follows: firstly, establishing a tool coordinate system and a workpiece coordinate system, secondly, establishing a space spiral trochoid motion track model; thirdly, establishing a single-tooth circumferential blade cutting angle and cutting angle model; fourthly, establishing a model of the cutting thickness and the cutting width of the single-tooth circumferential edge; and finally, establishing a theoretical orthogonal turn milling instantaneous cutting force model. The method can truly reflect the cutting motion track of the tool nose, and solves the problem of the motion track of the turn milling combined machining tool tooth.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

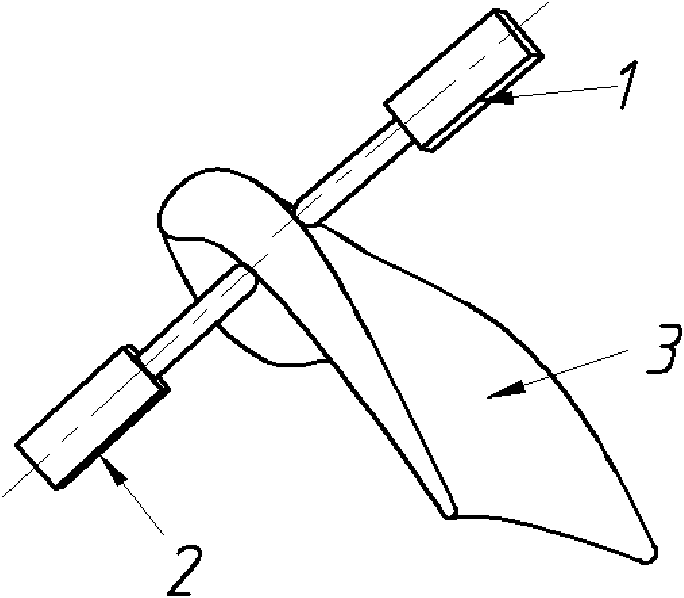

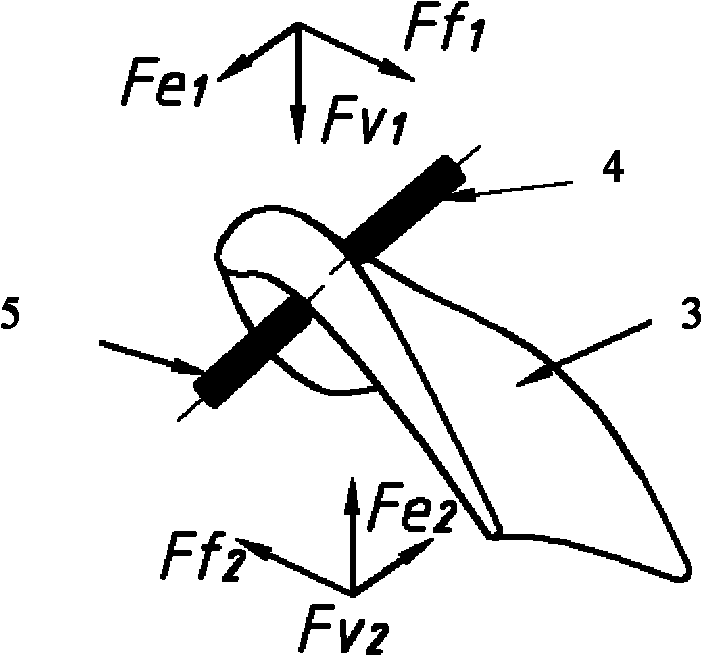

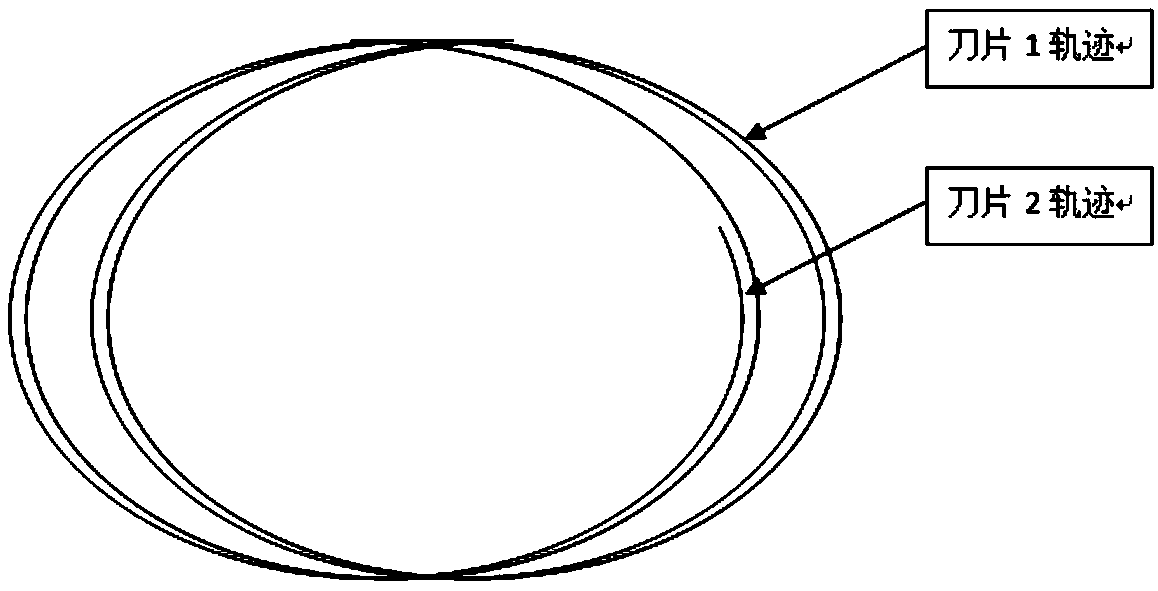

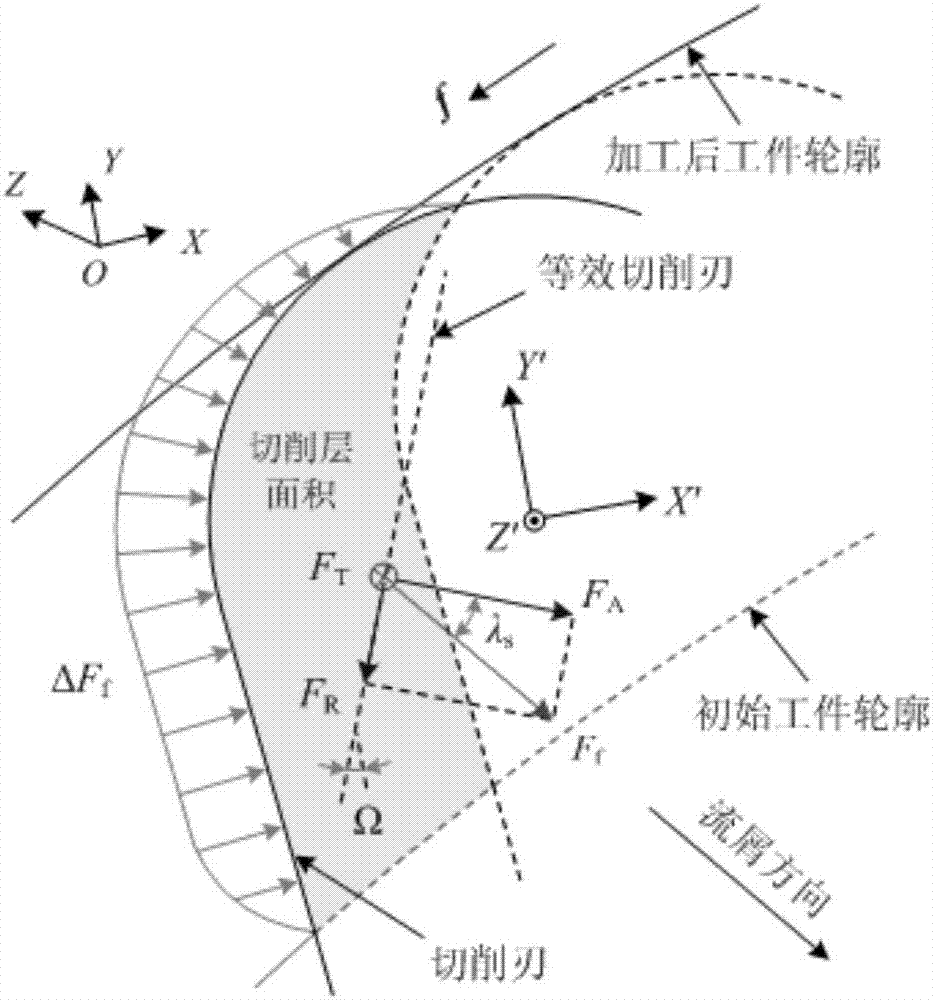

Cutter path generating method for double blade head processing of turbine long blade profile

InactiveCN102096391AImprove processing efficiencyReduce distortionNumerical controlCutter locationCutting force model

The invention discloses a cutter path generating method for double blade head processing of a turbine long blade profile. The method comprises the following steps: firstly establishing a corresponding mathematical relation between cutting force and cutter shaft inclinations during blade processing so as to obtain a cutting force model of the blade processing; then acquiring section moulded line data of a blade, and determining the range of cutter location control point data of double blades in the section moulded lines of the blade, wherein the cutter location control point data comprise the step length between cutter location control points, the number of the cutter location control points and the cutter shaft inclination of a cutter at each corresponding cutter location control point; and finally determining the final offset effect of the cutting force. In the invention, the double blade head can simultaneously process parts, and the processing efficiency is obviously improved compared with a single blade by reasonably scheduling the processing technique on the parts; and besides, the double blade processing can ensure the cutting force to be greatly offset, thus the processing deformation of the parts is obviously reduced.

Owner:XI AN JIAOTONG UNIV

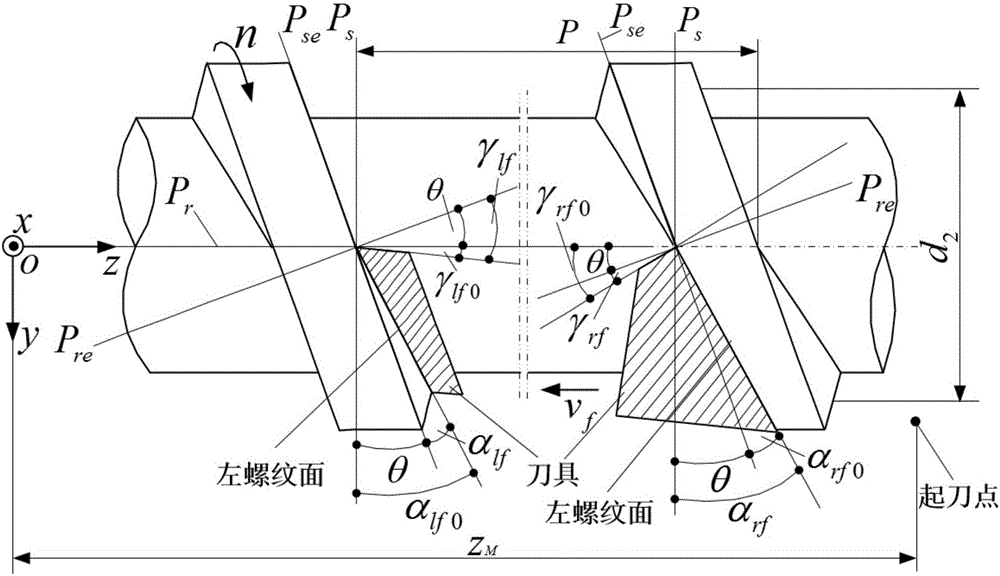

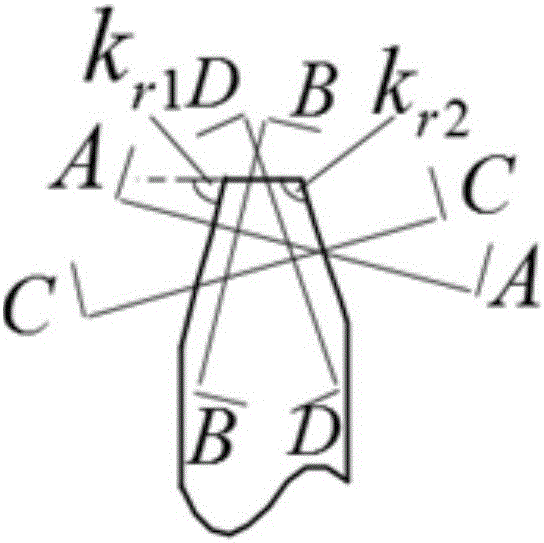

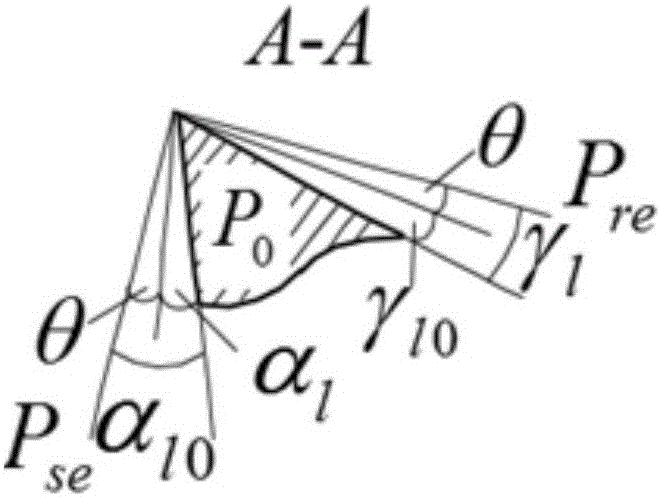

Trapezoidal external thread turning instant cutting force model building and experimental testing method

InactiveCN105787194AEfficient processingSolve the problem of ambiguityGeometric CADSpecial data processing applicationsExperimental testingExperimental methods

The invention relates to a cutting force model building and experimental testing method, in particular to a trapezoidal external thread turning instant cutting force model building and experimental testing method.The problem that according to an existing instant main cutting force study method, the influence mechanism of tool nose cutting motion track changes and tool cutting edge inclination changes on instant cutting force in the coarse-pitch thread turning process cannot be revealed is solved.The trapezoidal external thread turning instant cutting force model building and experimental testing method specifically comprises a tool nose cutting motion track under the vibration action, the instant cutting postures of a left cutting edge and a right cutting edge of a tool under the vibration action, instant cutting layer parameters of the left cutting edge and the right cutting edge of the tool, the instant cutting force of the left cutting edge and the right cutting edge of the tool, a coarse-pitch trapezoidal external thread turning experimental method and the instant cutting force of the left cutting edge and the right cutting edge of the tool during turning of a trapezoidal external thread with the thread pitch of 16 mm.The influence mechanism of the tool nose cutting motion track changes and the tool cutting edge inclination changes on instant cutting force in the coarse-pitch thread turning process is revealed.

Owner:HARBIN UNIV OF SCI & TECH

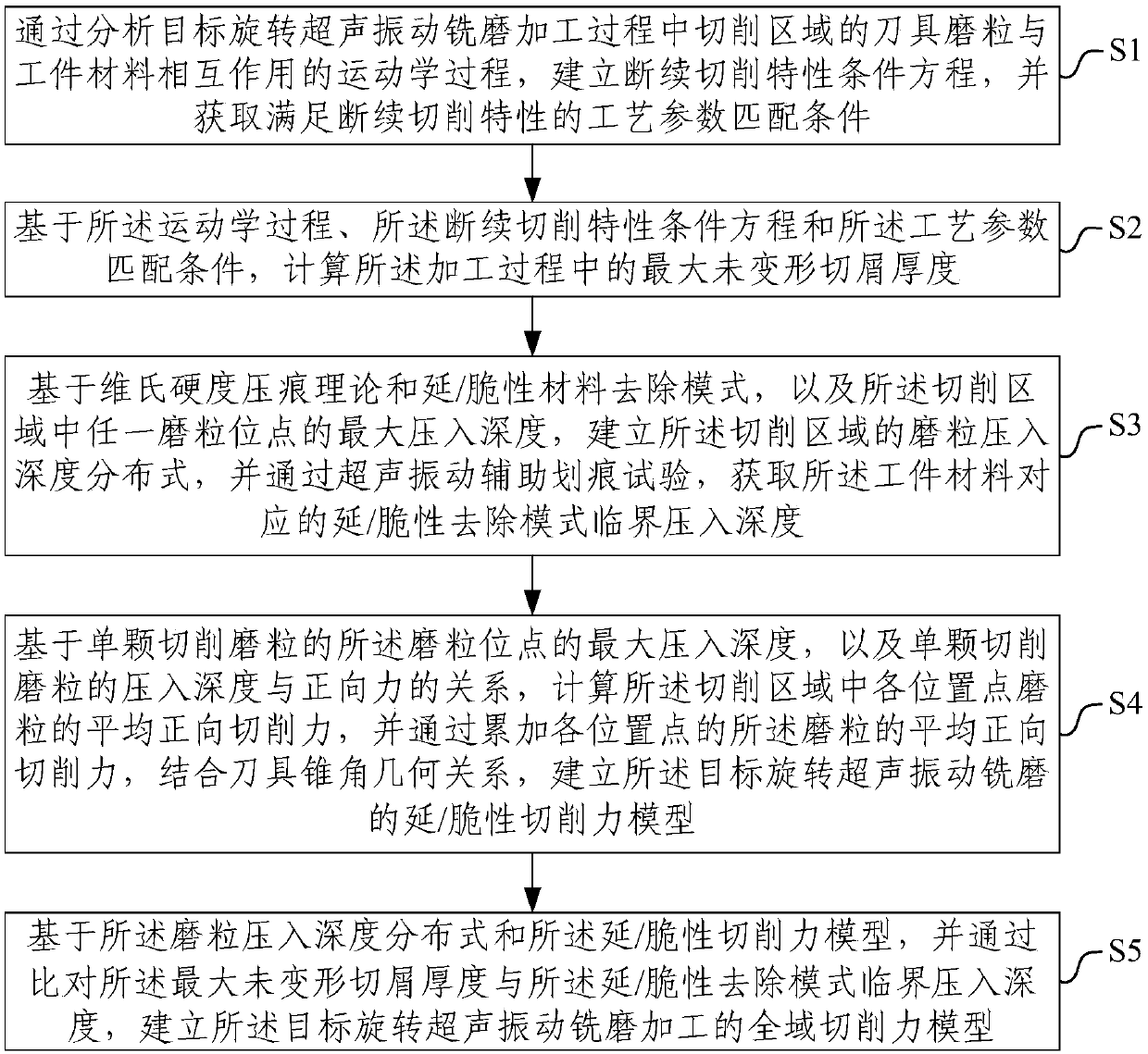

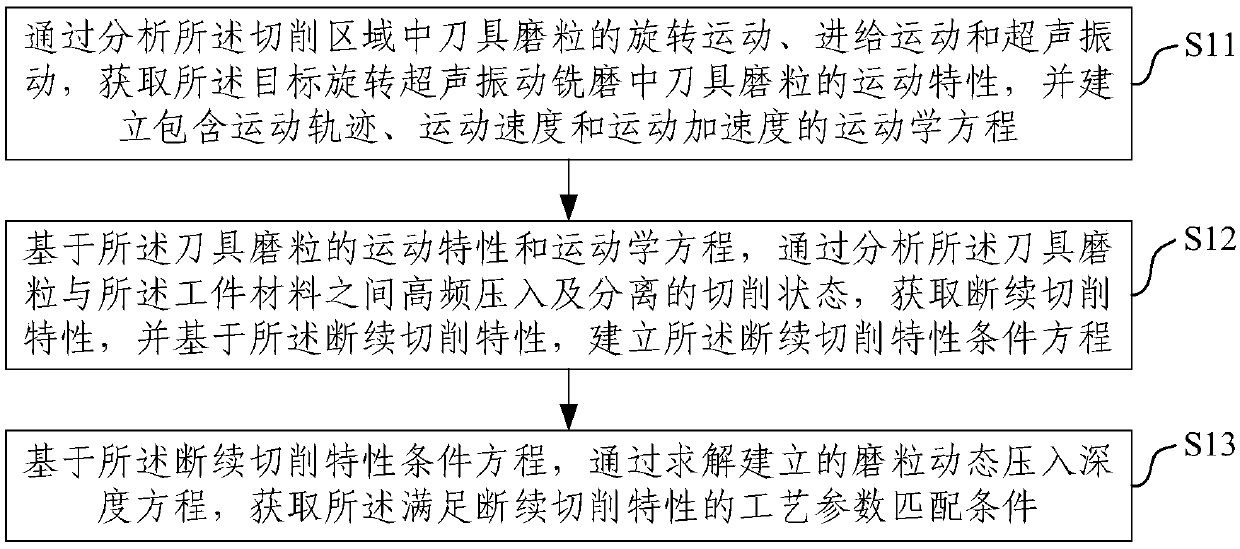

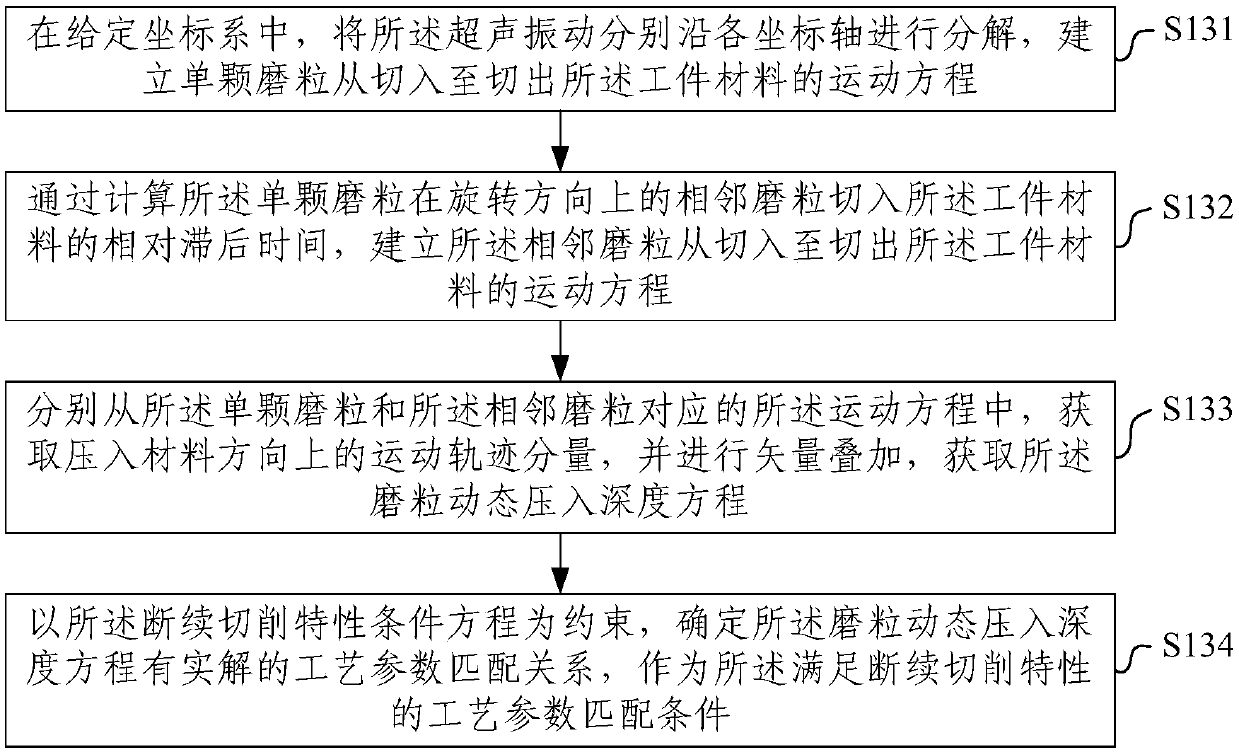

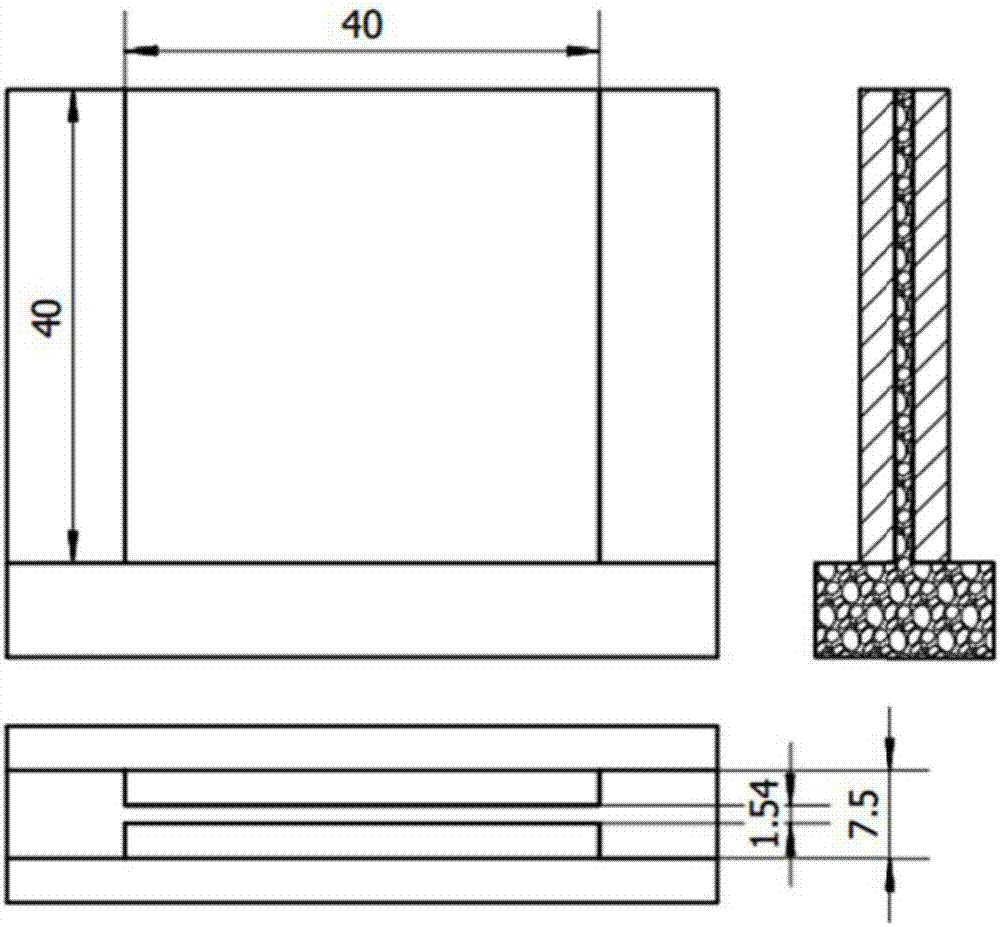

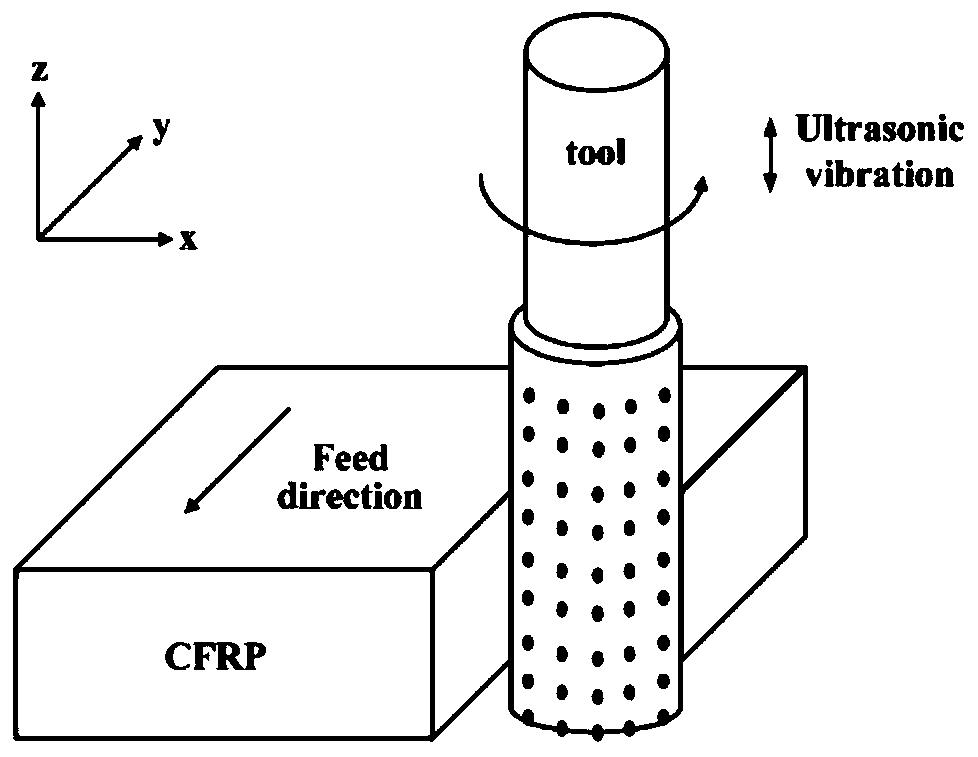

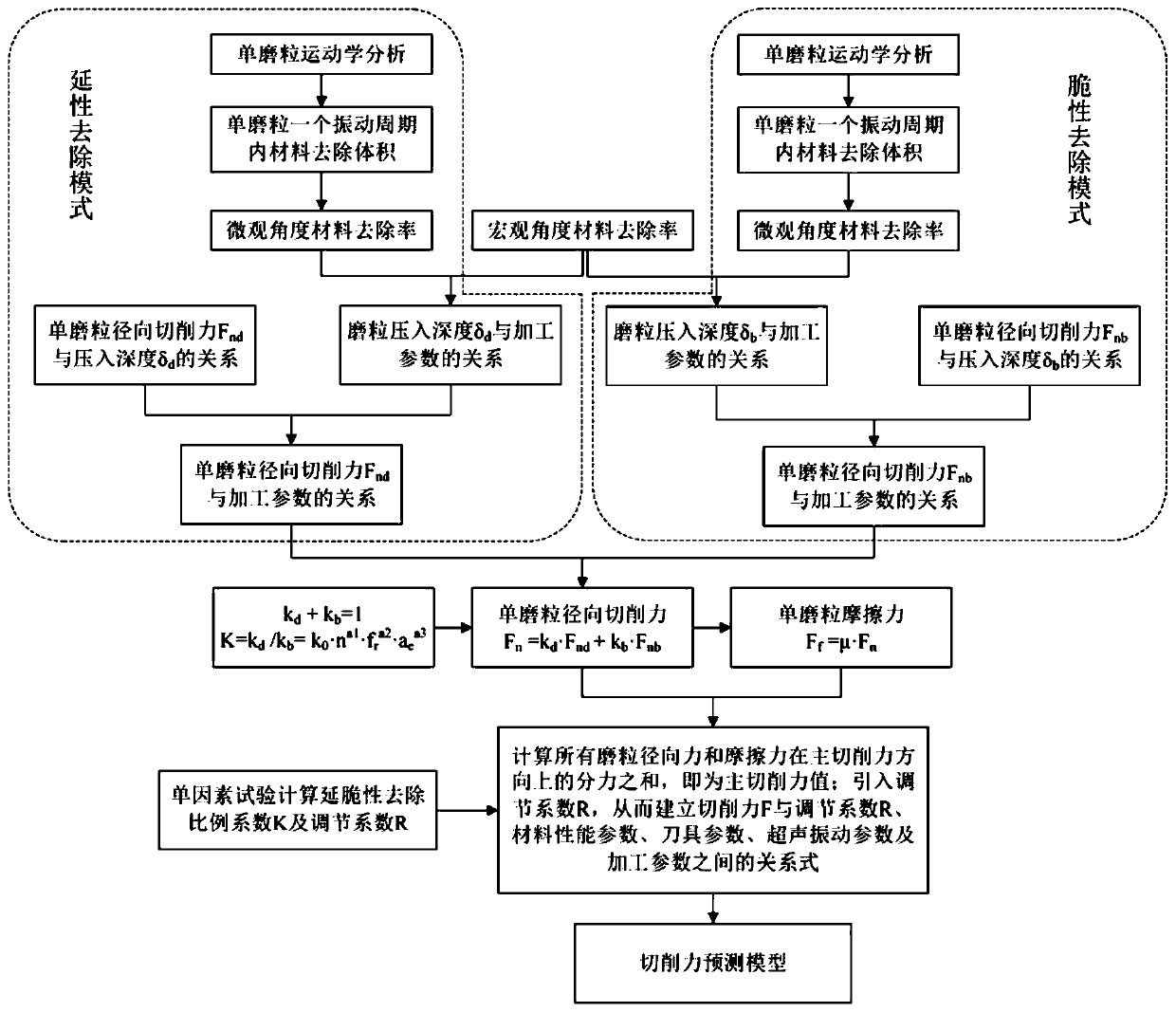

Method and device of full-domain cutting force modeling in rotary ultrasonic vibration milling

The invention provides a method and a device of full-domain cutting force model in rotary ultrasonic vibration milling. By carrying out the kinematics analysis between a tool abrasive grain and a workpiece material interaction in the machining process, a technology parameter matching relation meeting the vibration separation of a cutting area is obtained, and a condition equation of an intermittent cutting characteristic is established; and according to an ultrasonic vibration auxiliary scratch test, critical press-in depth of ductility or brittleness removal mode changing of a material is obtained, the abrasive particle press-in depth distribution relation of the cutting area is established, the abrasive grain loads of different positions of the cutting area are accumulated, and ductilityor brittleness cutting force model is obtained correspondingly, the models are fused according to the critical press-in depth and the maximum cutting thickness, and the rotary ultrasonic vibration machining whole-domain cutting force model is obtained. According to the device, the rotary ultrasonic vibration machining characteristic and a removing mechanism can be more comprehensively reflected,so that the cutting force prediction and the technology optimization of the actual machining can be effectively guided.

Owner:BEIHANG UNIV

Method for compensating cutting error of hard-brittle material thin-walled component

ActiveCN107272580AProgramme controlComputer controlNumerical controlFinite element analysis software

The invention provides a method for compensating a cutting error of a hard-brittle material thin-walled component. The method comprises the steps of firstly building a cutting force model for cutting a material of the thin-walled component, then calculating a cutting force according to the actual radial cutting depth, solving the deformation of each discrete position in finite element analysis software by taking the actual cutting force as a load value, and finally generating a numerical control program with error compensation by taking the deformation as an error compensation value. Compared with the existing thin-walled component machining error compensation method, the method provided by the invention is higher in compensation accuracy and higher in calculation efficiency.

Owner:DALIAN UNIV OF TECH

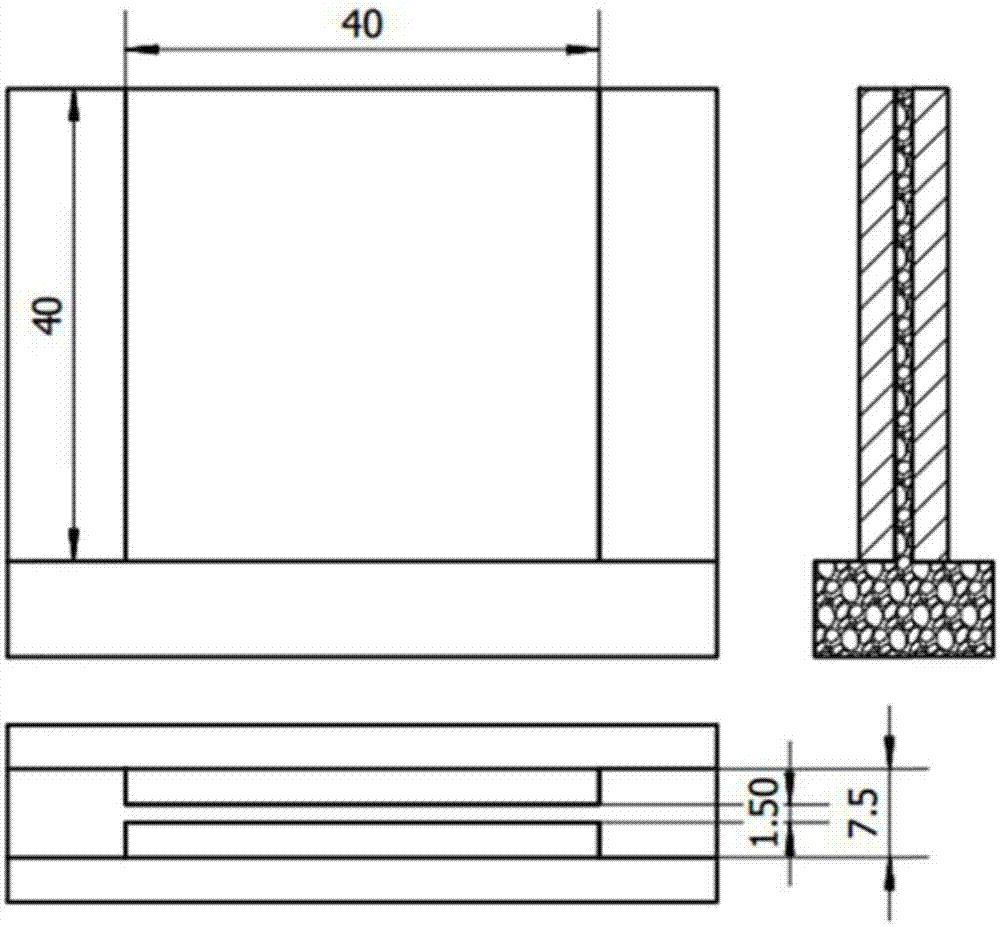

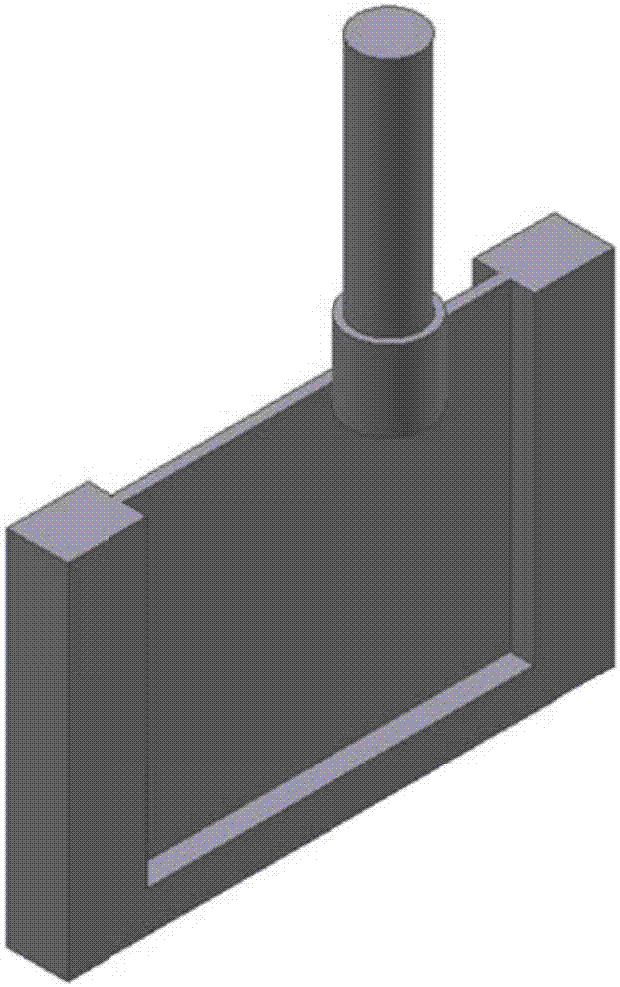

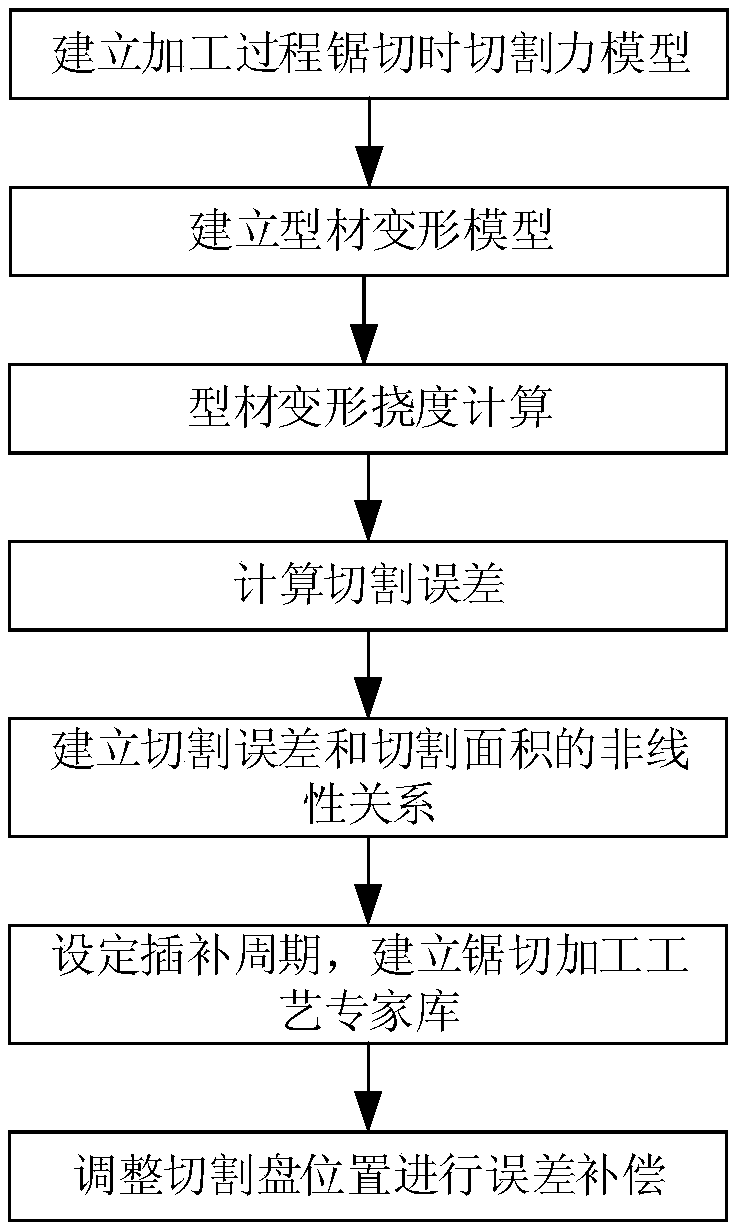

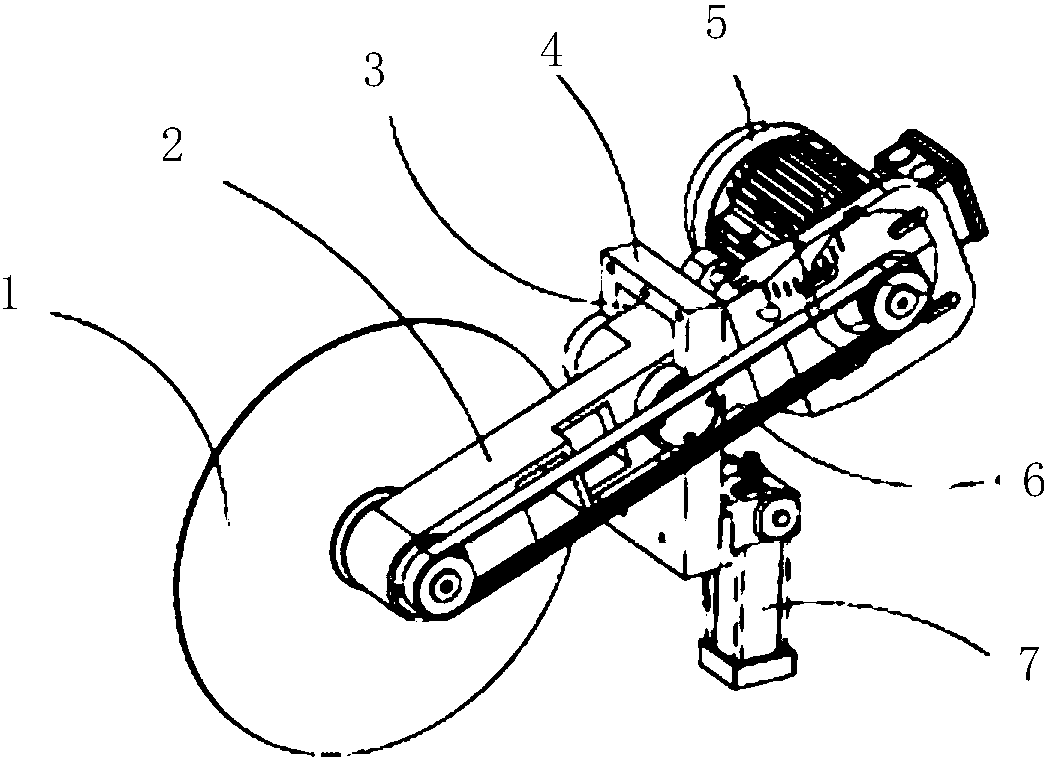

Length compensation method of saw cutting of section bars through cutting machine

ActiveCN108519759AOptimizing cutting force errorOptimizing Thermal Distortion ErrorsProgramme controlComputer controlEngineeringCutting force model

The present invention discloses a length compensation method of saw cutting of section bars through a cutting machine. The method comprises the following steps of: S1, establishing a cutting force model when sew cutting is performed in a processing process; S2, establishing a section aluminum deformation model; S3, setting an interpolation period, and establishing a saw cutting processing technology expert database according to known section aluminum information, cutting errors and cutting areas; and S4, performing cutting track planning according to the saw cutting processing technology expert database to perform error compensation of the position of a cutting disc and complete processing. The method effectively improves the processing accuracy and improves the processing quality.

Owner:佛山金皇宇企业孵化器有限公司 +1

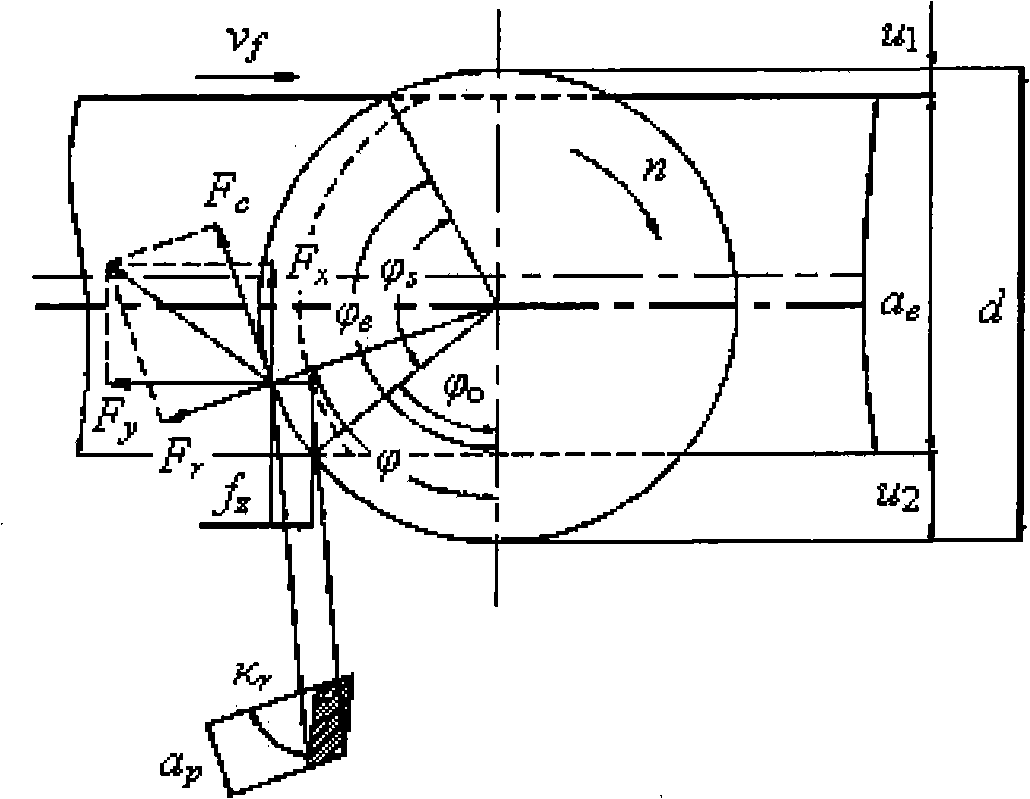

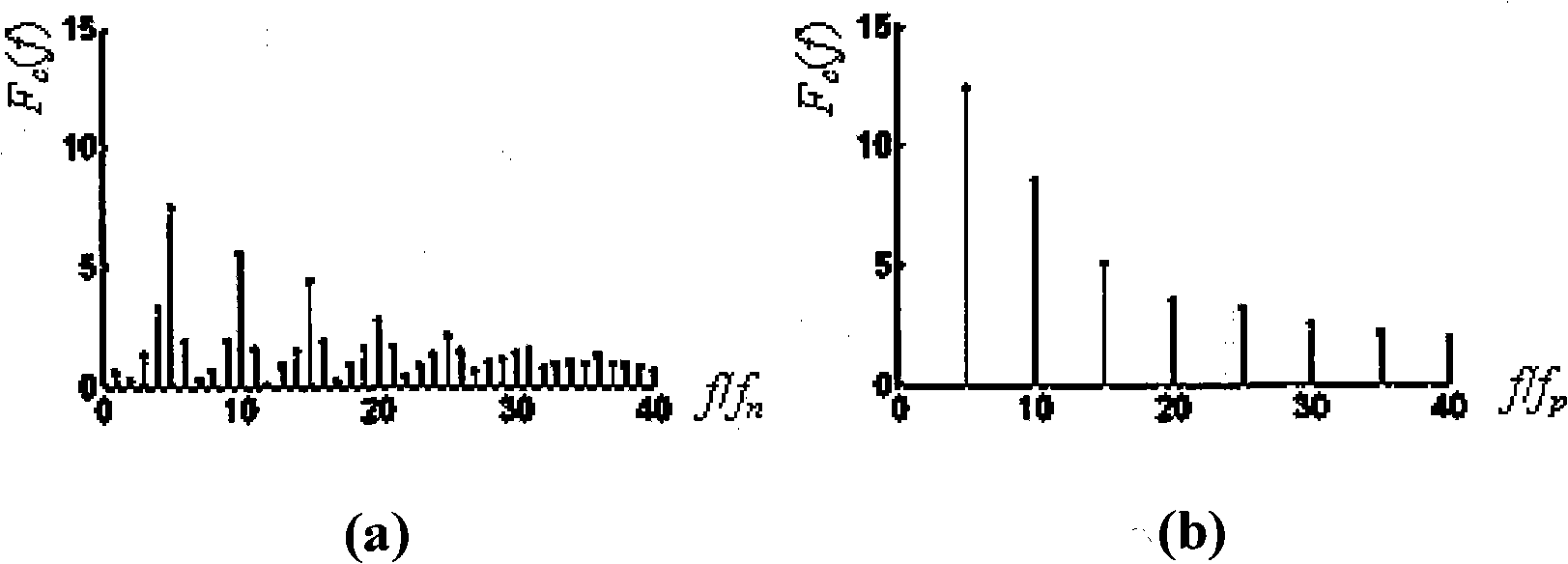

Damping balance high-speed milling tool and design method thereof

InactiveCN102120273AHigh quality machined surfaceReduce vibrationMilling cuttersDynamic balanceCutting force model

The invention discloses a damping balance high-speed milling tool and a design method thereof. The excitation energy during high-speed milling of the tool is concentrated; if the number of teeth of the tool is improperly selected, the excitation frequency approaches the natural frequency of the milling tool, thus relatively strong vibration appears, and the requirements of high-efficiency and high-speed cutting processing cannot be met. The method disclosed by the invention comprises the following steps of: (1) establishing a multi-tooth dynamic cutting force model of the high-speed milling tool based on a single-tooth dynamic cutting force model; (2) establishing a multi-tooth cutting dynamic cutting force spectrum model; (3) establishing a cutting stability evaluation model of the high-speed milling tool; (4) analyzing influence of the tool tooth distribution on the dynamic cutting force spectrum, and optimizing the tooth pitch of the high-speed milling tool; and (5) under the constraint conditions of the structural strength of the high-speed milling tool, analyzing the dynamic balance precision of the milling tool, and implementing the optimal design of the tool tooth distribution and a scraps containing groove by use of the behavior modeling technology so as to meet the requirements for the milling tool safety and dynamic balance precision and obtain a high-speed milling tool design scheme meeting the damping requirements. The method disclosed by the invention is used for designing the damping balance high-speed milling tool.

Owner:HARBIN UNIV OF SCI & TECH

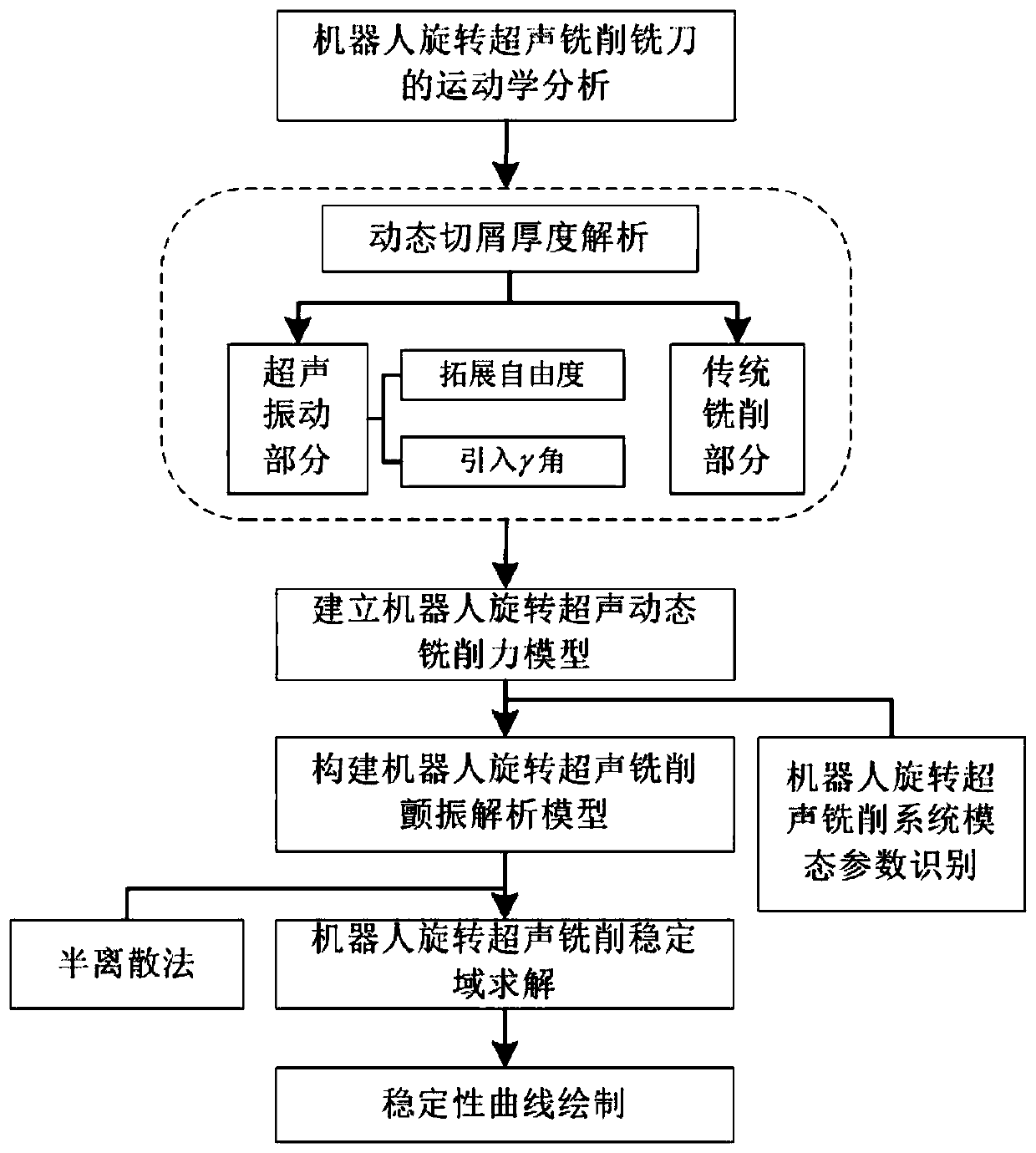

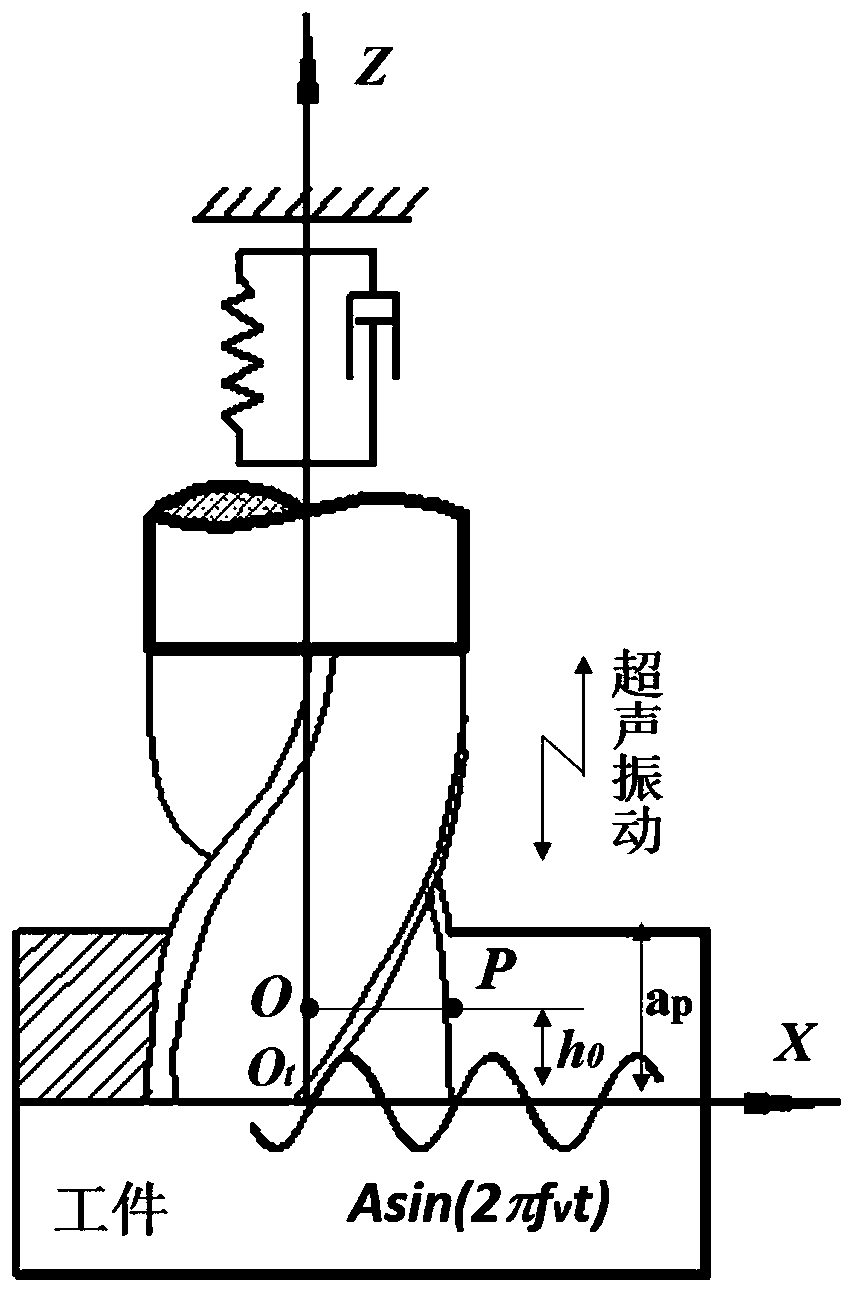

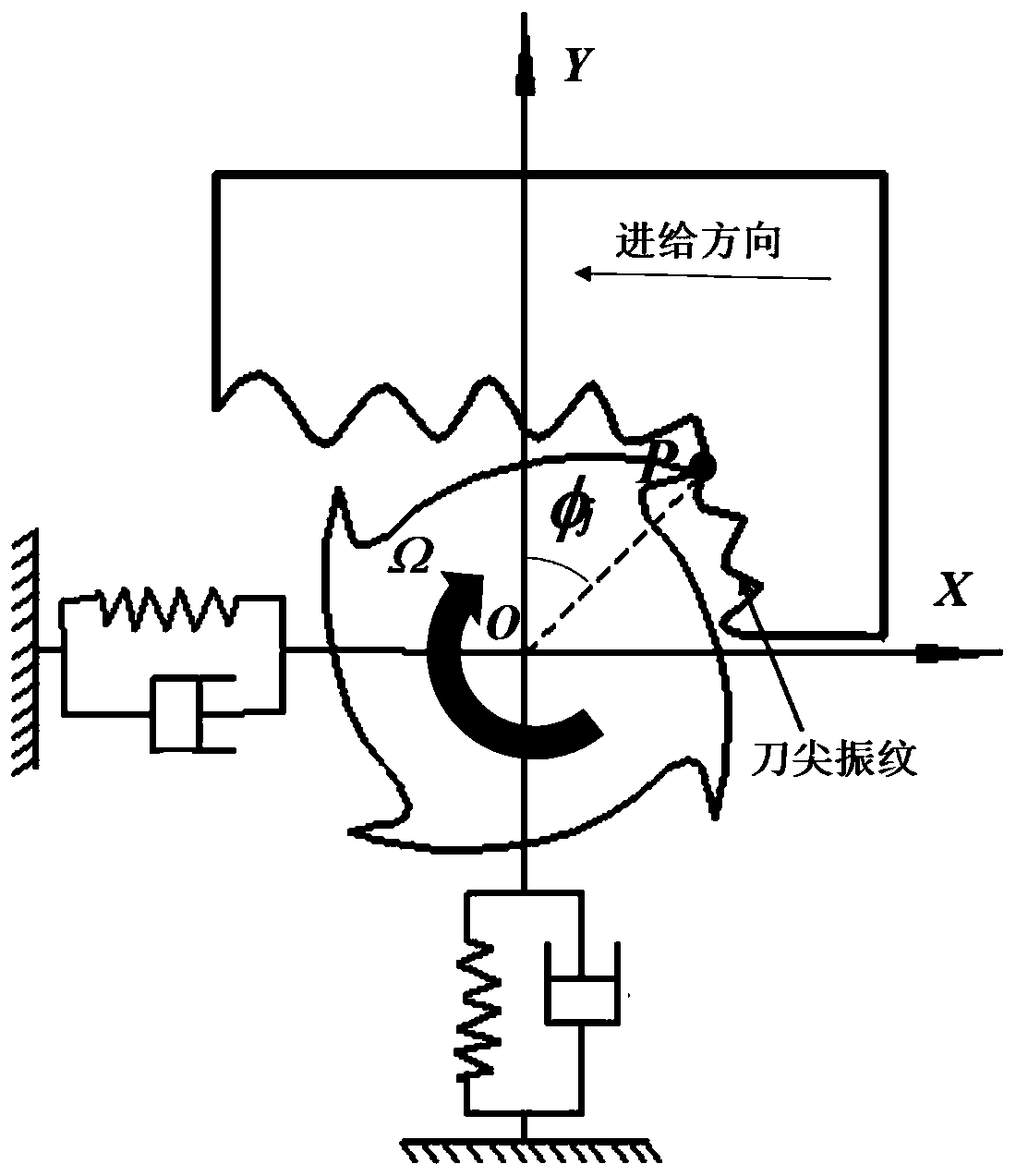

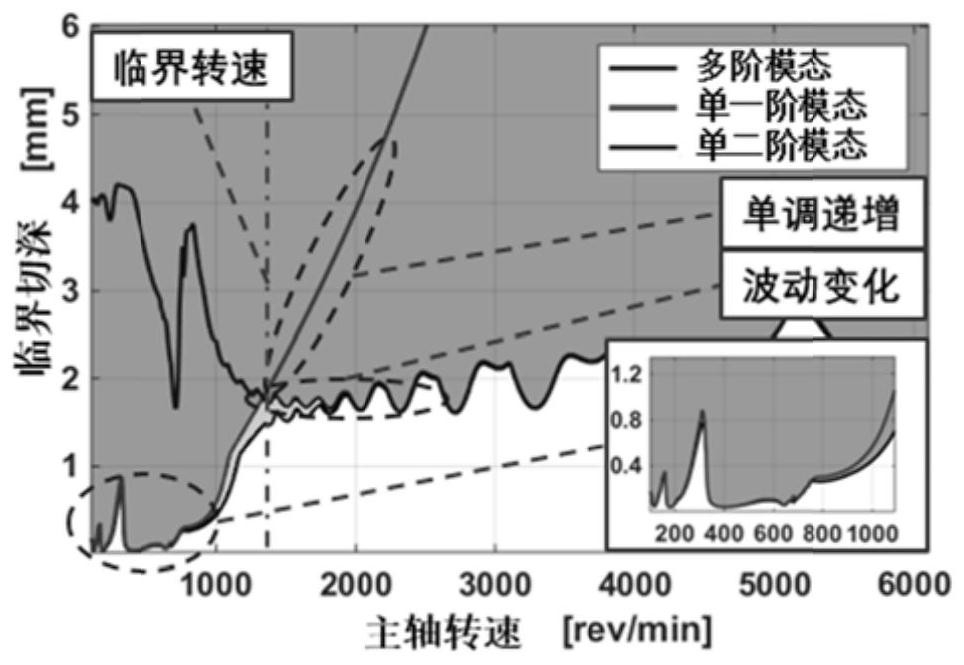

Method for expanding milling stability range of robot

ActiveCN109909806AIncrease stability domainGood at suppressing chatterProgramme-controlled manipulatorMeasurement/indication equipmentsEngineeringCutting force model

The invention discloses a method for expanding a milling stability range of a robot. The method for expanding the milling stability range of the robot comprises the following steps: step 1, establishing a dynamic chip thickness model of rotary ultrasonic milling of the robot; step 2, establishing a dynamic cutting force model of the rotary ultrasonic milling of the robot; step 3, establishing a milling stability range analytical model of the rotary ultrasonic milling of the robot; step 4, solving the rotary ultrasonic milling stability range of the robot; and step 5, drawing a flutter stability curve of the rotary ultrasonic milling of the robot and realizing stability range predication. According to the method for expanding the milling stability range of the robot, a rotary ultrasonic technology is combined with robot milling, so that the stability range of the milling machining of the robot is greatly expanded, and a great flutter suppression effect is achieved; and meanwhile, underthe condition of rotary ultrasonic milling machining of the robot, a three-dimensional stability analysis method for a common end mill is disclosed, and stability analysis is enabled to be much meet the actual working condition of milling.

Owner:NANJING UNIV OF SCI & TECH

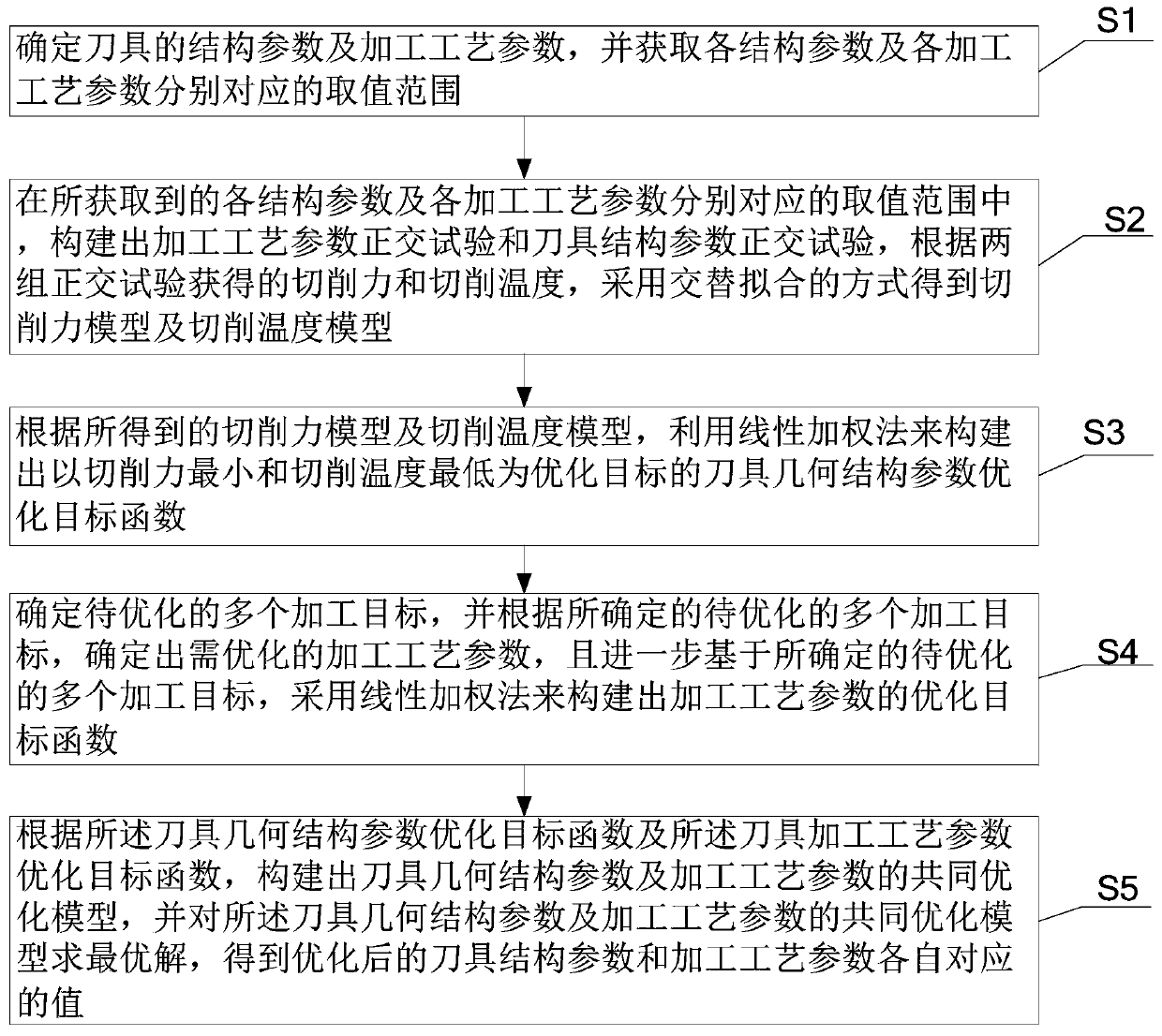

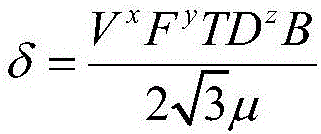

Method for jointly optimizing tool geometry parameters and machining process parameters

ActiveCN109839895AExcellent structureExcellent processabilityNumerical controlCutting force modelProcess engineering

The invention provides a method for jointly optimizing tool geometry parameters and machining process parameters. The method comprises the steps that structural parameters of a tool, machining processparameters and respective ranges of values are determined; the orthogonal test of the machining process parameters and the orthogonal test of the structural parameters of the tool are constructed inrespective ranges of values; a cutting force model and a cutting temperature model are acquired according to the cutting force data and cutting temperature data acquired by two orthogonal tests; according to the cutting force model and the cutting temperature model, the optimization objective function of the geometry structural parameters of the tool is constructed; according to a machining targetto be optimized, the machining process parameters to be optimized are determined, and the optimization objective function of the machining process parameter is constructed; and according to the abovetwo optimization objective functions, a common optimization model is constructed, and the optimal solution is acquired to acquire corresponding values of the optimized tool structural parameters andmachining process parameters. According to the invention, each machining target in the actual machining process is comprehensively considered, and the optimal tool structural parameters and machiningprocess parameters are acquired.

Owner:WENZHOU UNIVERSITY

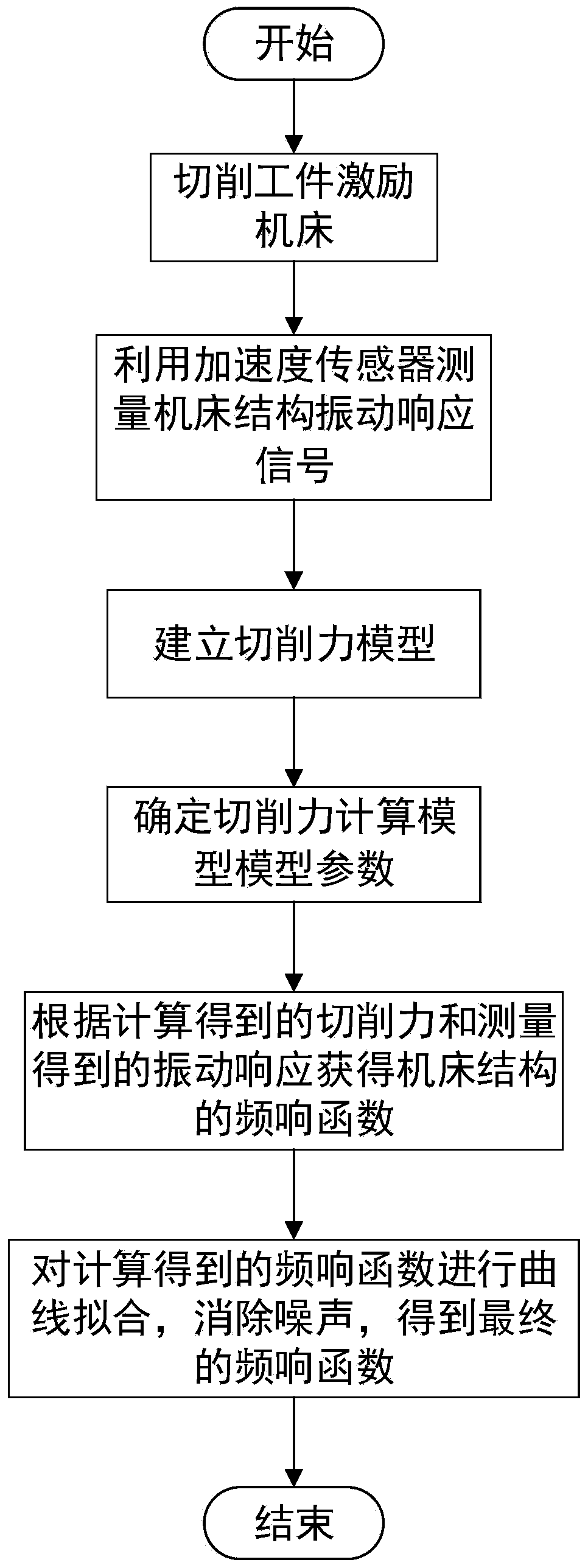

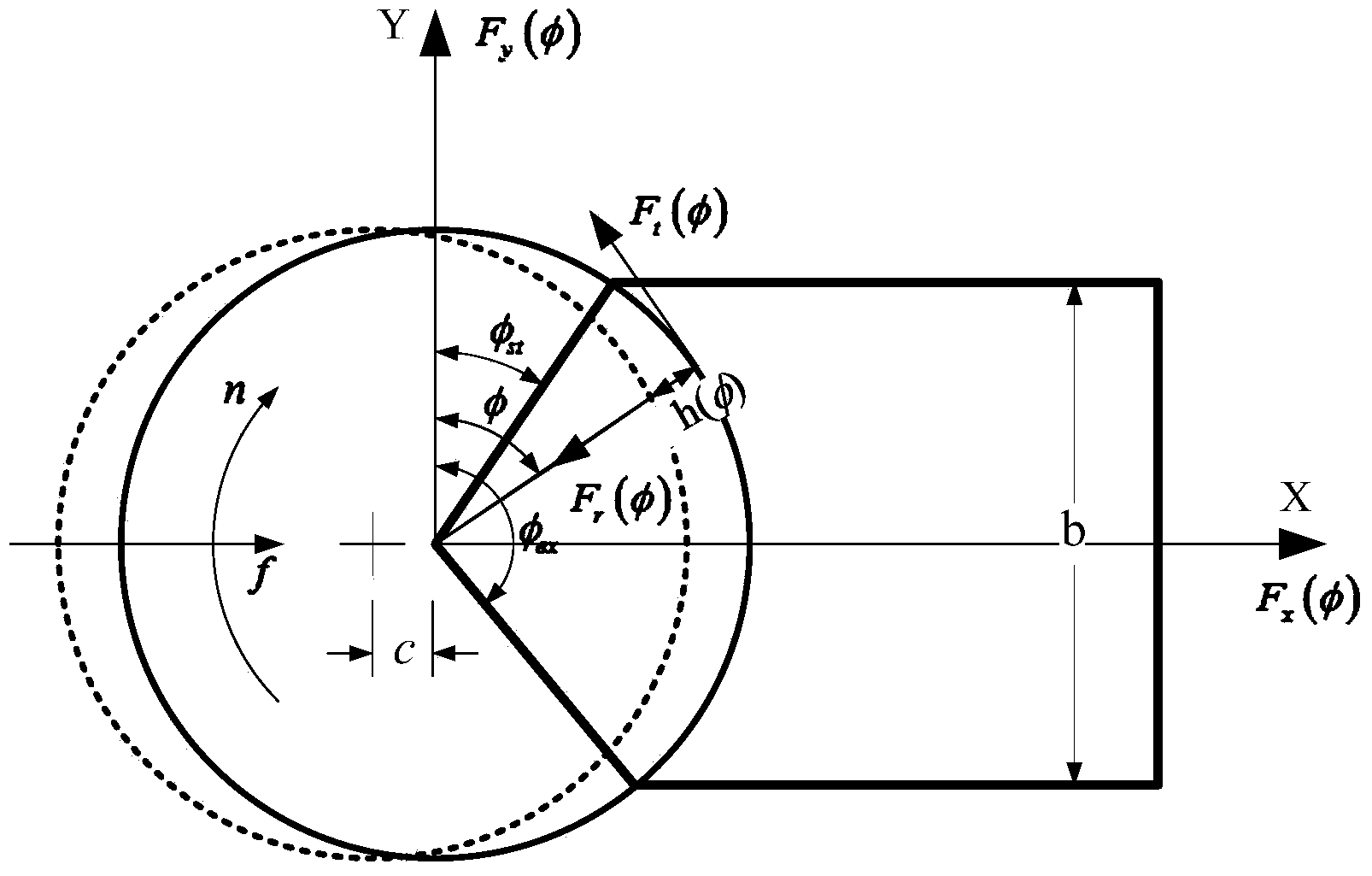

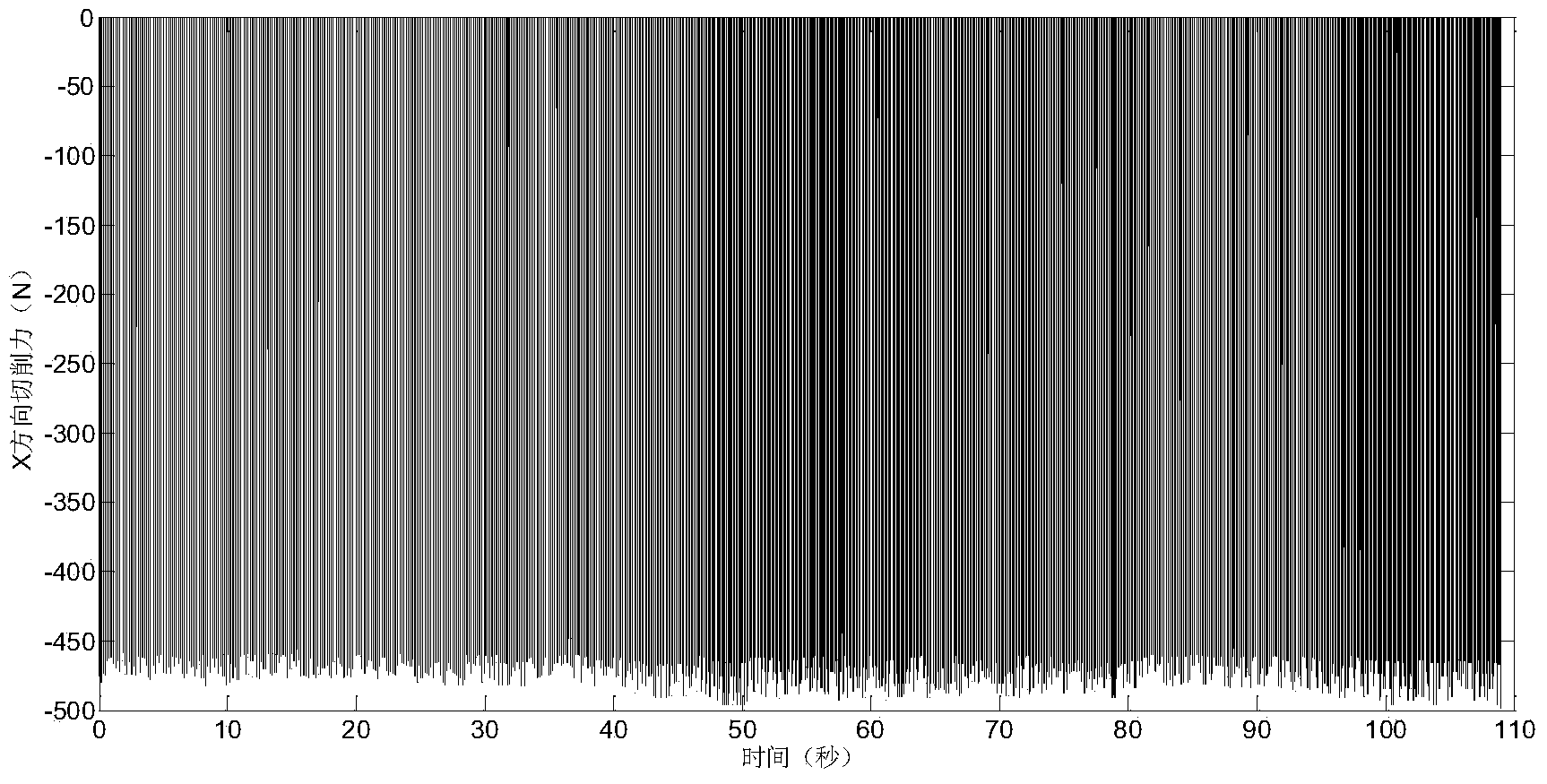

Method for acquiring frequency response function of numerically-controlled machine tool based on cutting excitation

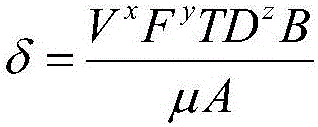

The invention discloses a method for acquiring a frequency response function of a numerically-controlled machine tool based on cutting excitation. The method includes the steps that a machine tool structure is excited through random cutting force generated in a machine tool cutting project; vibration response signals of the position where the frequency response function needs to be acquired are measured through a sensor; a cutting force model is established, and the cutting force model is modified through a modification function according to the influence of the rotating speed change on the cutting force; coefficients in the cutting force calculation model are determined, and the modification function is fit according to experiments; the frequency response function of the machine tool structure is acquired according to the cutting force acquired through calculation and vibration response acquired through measurement, curve fitting is conducted on the frequency response function acquired through calculation, noise is eliminated, and then the final frequency response function is acquired. According to the method, dynamic characteristics of the machine tool with an accurate and reliable recognition result in an operating state can be acquired, and the optimization design of the machine tool structure and state monitoring of the machine tool can be conducted through the acquired frequency response function.

Owner:HUAZHONG UNIV OF SCI & TECH

Cutter abrasion monitoring method based on cutting force model

ActiveCN106002488ASimple calculationThe result is accurateMeasurement/indication equipmentsCutting force modelTool wear

The invention discloses a cutter abrasion monitoring method based on a cutting force model. The cutter abrasion monitoring method is used for conducting real-time online monitoring on the abrasion loss of a cutting tool. The cutter abrasion monitoring method is characterized by comprising the steps that 1, cutting force caused by chip forming under the action of a sharp cutter in the cutting process is calculated by means of a non-equant shearing region model; 2, plowing force caused by cutting edge roundness in the cutting process is calculated; 3, cutter cutting force is obtained according to the determined cutting force under the action of the sharp cutter and the determined plowing force caused by cutting edge roundness; 4, a cutter abrasion monitoring model is established according to the obtained cutter cutting force, and therefore real-time monitoring on cutter abrasion is achieved. By means of the cutter abrasion monitoring method based on the cutting force model, the cutter abrasion state can be accurately represented, monitoring on the cutter abrasion can be achieved by monitoring the cutting force, and therefore real-time online and accurate monitoring of the cutter abrasion is achieved.

Owner:太仓鑫祥金属制品有限公司 +1

A method for predicting the milling force of end face milling cutter combined with SVM

ActiveCN109543329ASmall amount of calculationReduced simulation timeDesign optimisation/simulationSpecial data processing applicationsMicro structureMilling cutter

The invention relates to a method for predicting the milling force of an end face milling cutter combined with SVM, which relates to an ultra-precision machining technology. The simulation parametersof different cutting depth and different radial feed back are designed, and the geometric model is established. The round corners are arranged at the cutting edge position of the insert, and the insert only takes the tip part which is in contact with the workpiece, so that the mesh can combine the shape of the micro-structure on the insert. After getting the simulation value, the mixed kernel function SVM algorithm is used to fit the simulation value. the tool tip kinematics model is computed. According to the kinematics model, At that current phase angle, the cut forces of each insert are calculated by substituting the cutting force model into the cutting force model. The cutting forces are divided into three directions: axial force, radial force and tangential force, which are convertedinto tool axial force Fz, feed direction force Fy and perpendicular feed direction force Fx, and the cutting forces are directly superposed and solved.

Owner:XIAMEN UNIV +1

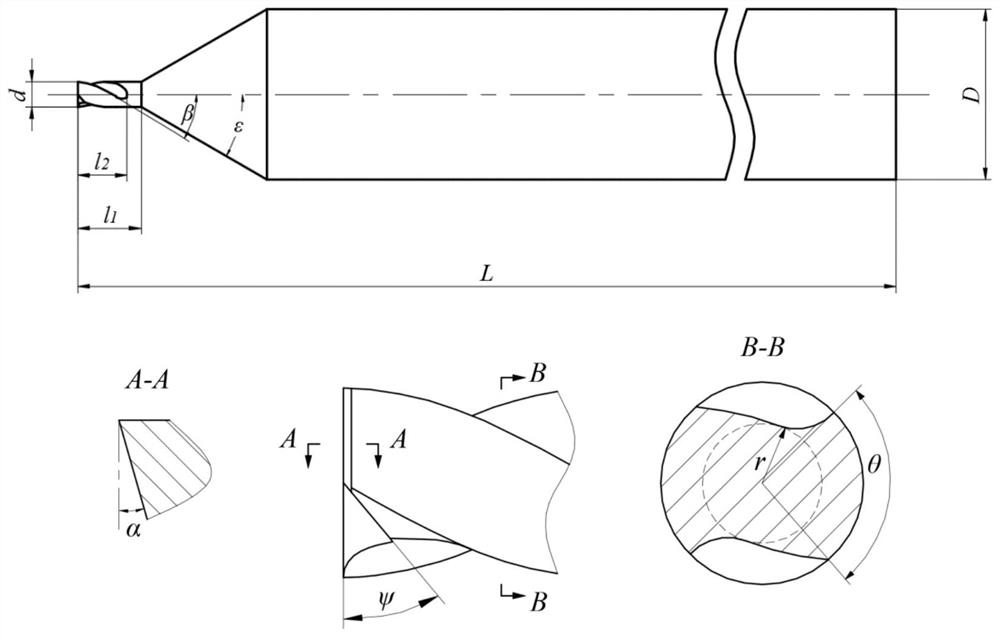

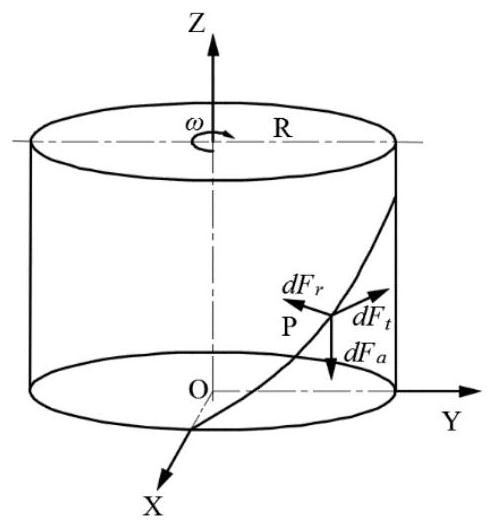

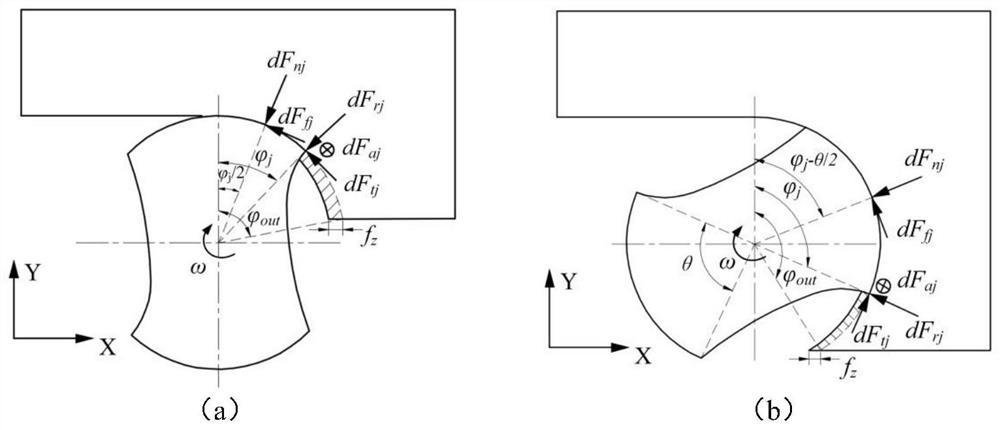

Modeling method for cutting force of micro PCD milling cutter without side edge relief angle

PendingCN113536543AImprove processing efficiencyImprove processing qualityDesign optimisation/simulationCAD numerical modellingMilling cutterRectangular coordinates

The invention belongs to the technical field of micro cutter machining, and provides a side-edge-relief-angle-free micro PCD milling cutter cutting force modeling method which mainly comprises the steps: S1, establishing a cutter coordinate system; s2, defining an infinitesimal radial force dFrj, an infinitesimal tangential force dFtj and an infinitesimal axial force dFaj of a point P on the cutting edge of the cutter at any moment and a radial grinding force dFnj and a tangential grinding force dFfj of a rear cutter surface; s3, determining a cut-in angle and a cut-out angle of a milling cutter; s4, establishing infinitesimal cutting force expressions of the milling cutter in the X, Y and Z directions under the rectangular coordinate system; s5, determining the contact state of the cutting edge and the workpiece; s6, obtaining cutting force models of the milling cutter in the X, Y and Z directions through numerical integration. The model can predict the cutting force of the milling cutter under different main shaft rotating speeds, feeding speeds and radial cutting depths, and then the main shaft rotating speeds, the feeding speeds and the radial cutting depths can be optimized, so that the purposes of reducing cutter abrasion and improving the machining efficiency and the machining quality are achieved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

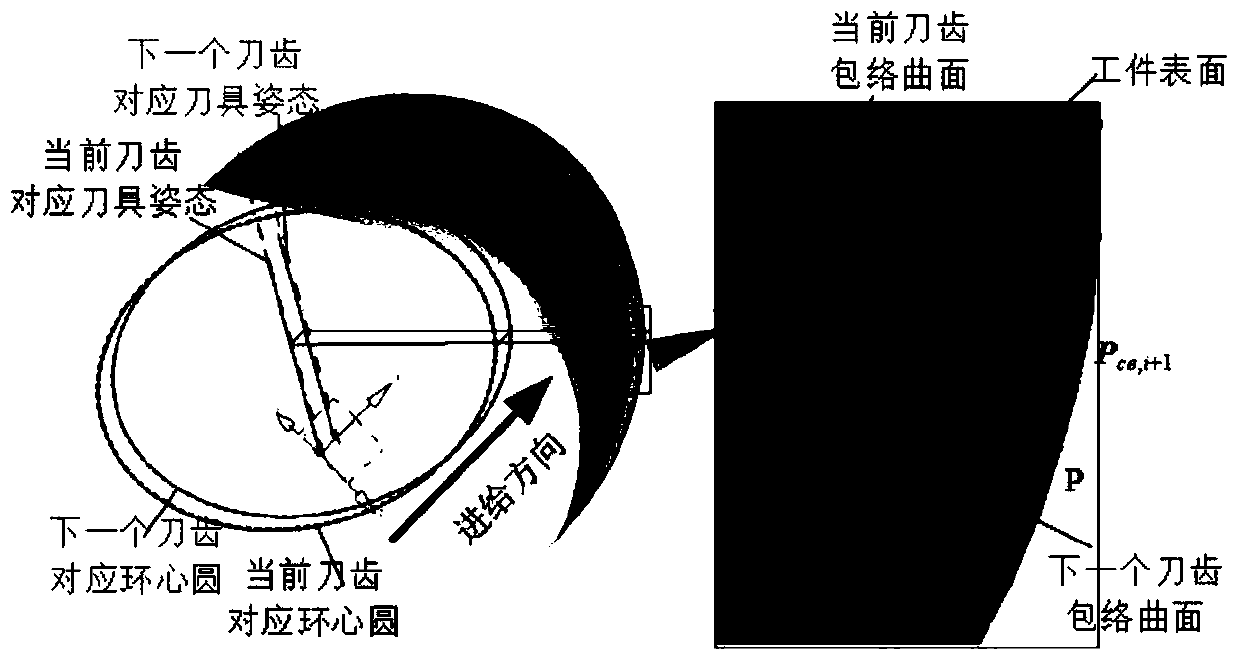

Thin-walled workpiece cutter back-off deformation error prediction model building method and application thereof

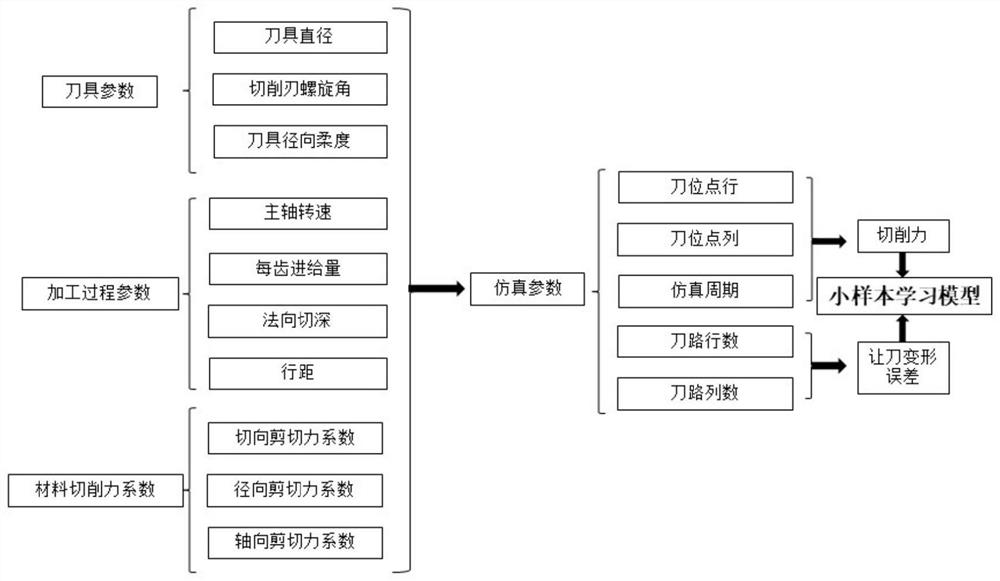

PendingCN112668227AGuaranteed training effectGuaranteed credibilityDesign optimisation/simulationNeural architecturesData setAlgorithm

The invention discloses a thin-walled workpiece cutter back-off deformation error prediction model building method and application thereof, and belongs to the field of machining error prediction, and the method comprises the steps: building a cutting force model through a finite element analysis method, and taking cutter parameters, machining process parameters and material cutting force parameters of an actual production line under different machining conditions as the input of the cutting force model; outputting cutting force and cutter back-off deformation errors corresponding to each group of parameters to obtain a training data set; obtaining cutting force and corresponding cutter back-off deformation errors of multiple sets of machining sites, and obtaining a test data set; adding a data enhancement module between an input layer and a first hidden layer of the neural network, and establishing a small sample learning model for predicting a cutter relieving deformation error according to the cutting force; and training and testing the small sample learning model by using the training data set and the test data set respectively to obtain a thin-walled workpiece cutter back-off deformation error prediction model. The prediction precision of the cutter back-off deformation error in the thin-walled workpiece machining process can be improved.

Owner:HUAZHONG UNIV OF SCI & TECH

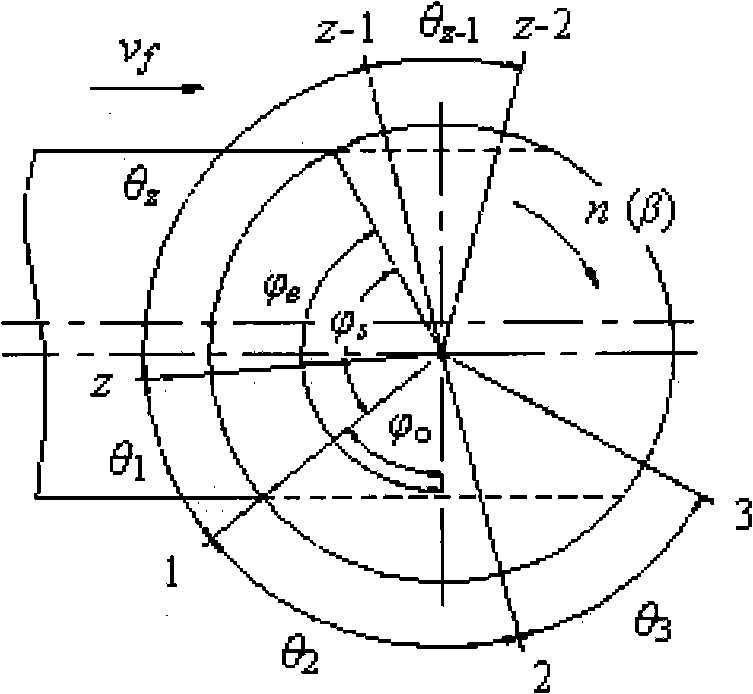

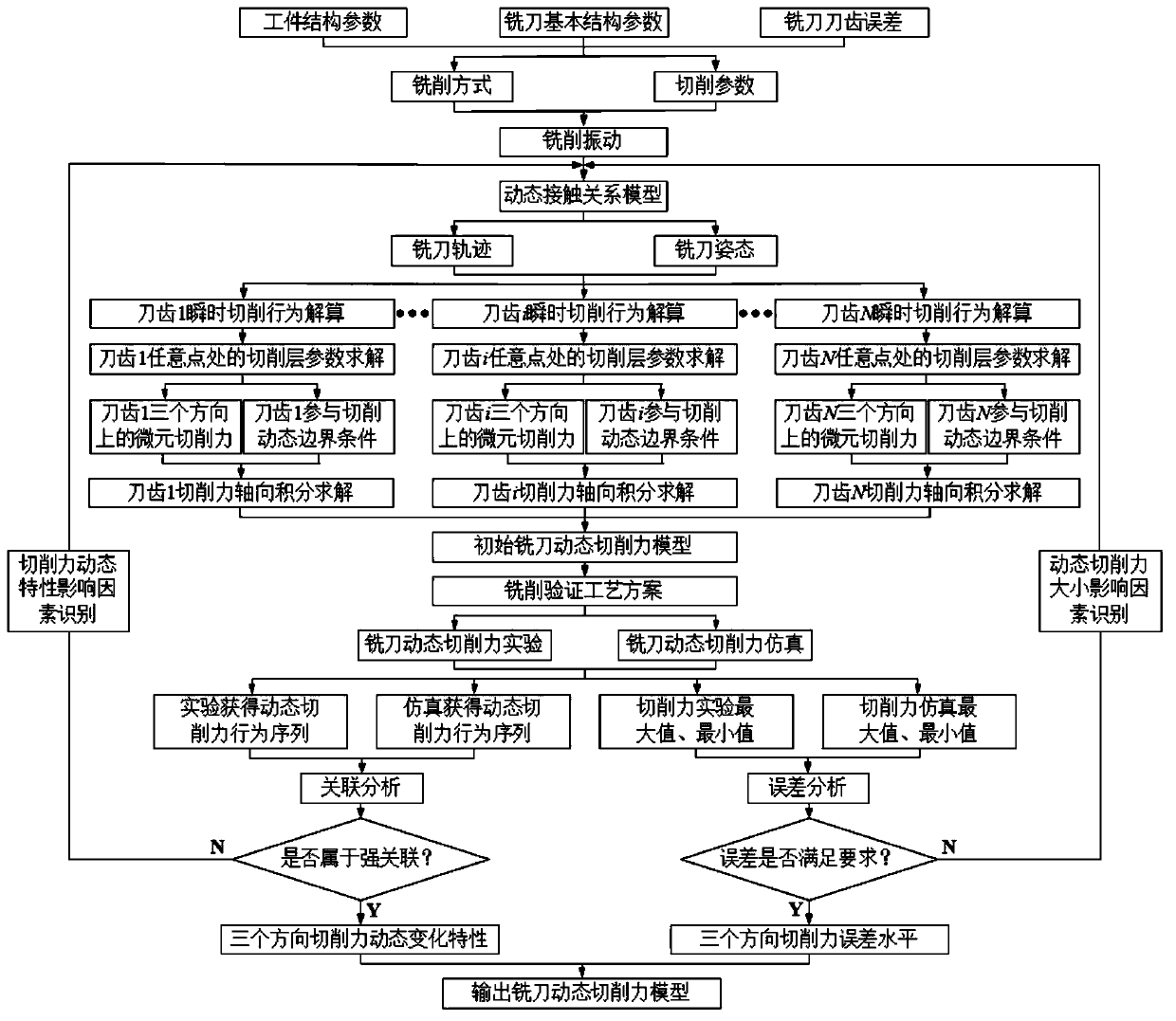

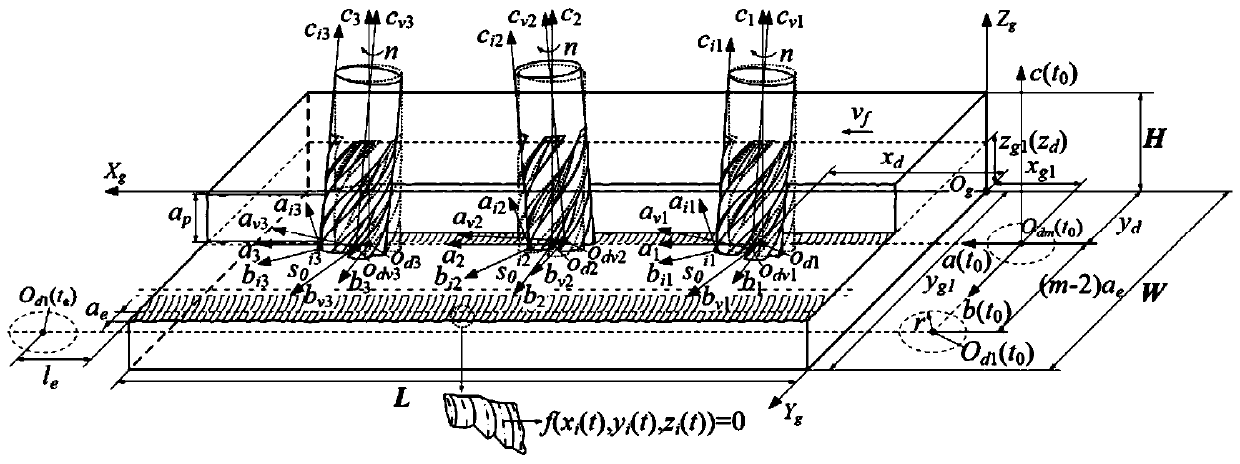

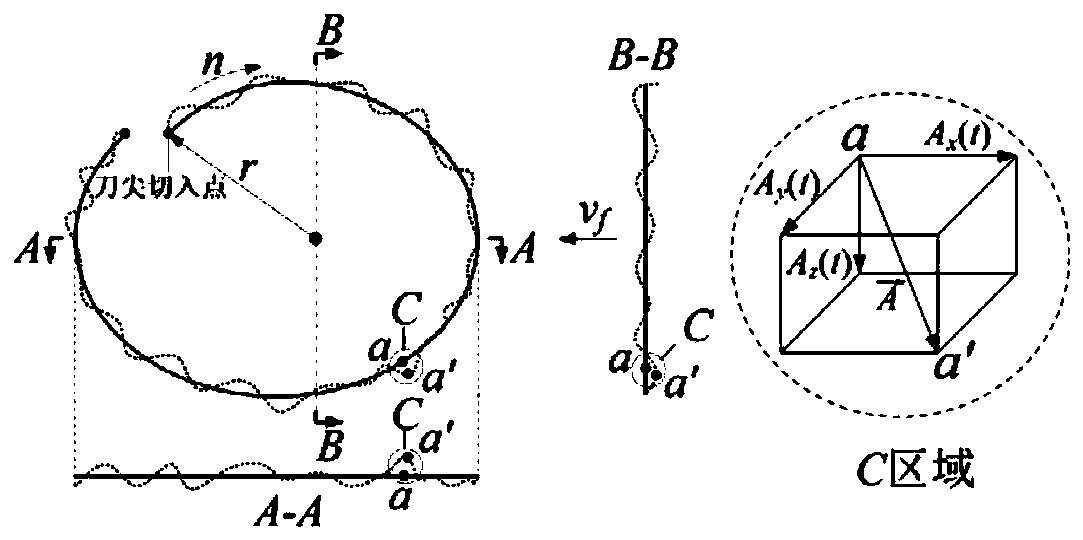

Milling cutter dynamic cutting force model construction and verification method under vibration effect

ActiveCN110032794AGuaranteed reliabilityRevealing Dynamic ChangesGeometric CADDesign optimisation/simulationValidation methodsMilling cutter

The invention discloses a milling cutter dynamic cutting force model construction and verification method under a vibration effect, which belongs to the technical field of milling cutters and aims tosolve the problems that the existing research on cutting force modeling cannot reveal the distribution and change characteristics of the cutter tooth milling infinitesimal instantaneous cutting force,cannot reveal the relation between cutter teeth and cutter teeth and cannot accurately reflect the dynamic change process of the cutting force. The method comprises the steps of a solving the instantaneous cutting behavior of the milling cutter; b, solving a single-tooth cutting boundary condition under the vibration effect; step c, establishing and calculating a milling cutter tooth instantaneous cutting layer parameter model; d, establishing an instantaneous cutting force model of the cutter teeth of the milling cutter and solving; and e, completing construction and verification of the milling cutter dynamic cutting force model. According to the dynamic cutting force model construction and verification method for the milling cutter under the vibration effect, the dynamic cutting force model capable of accurately reflecting the dynamic change of the cutting force in the cutting process can be constructed, and triple verification is carried out on the dynamic cutting force predictionmodel.

Owner:HARBIN UNIV OF SCI & TECH

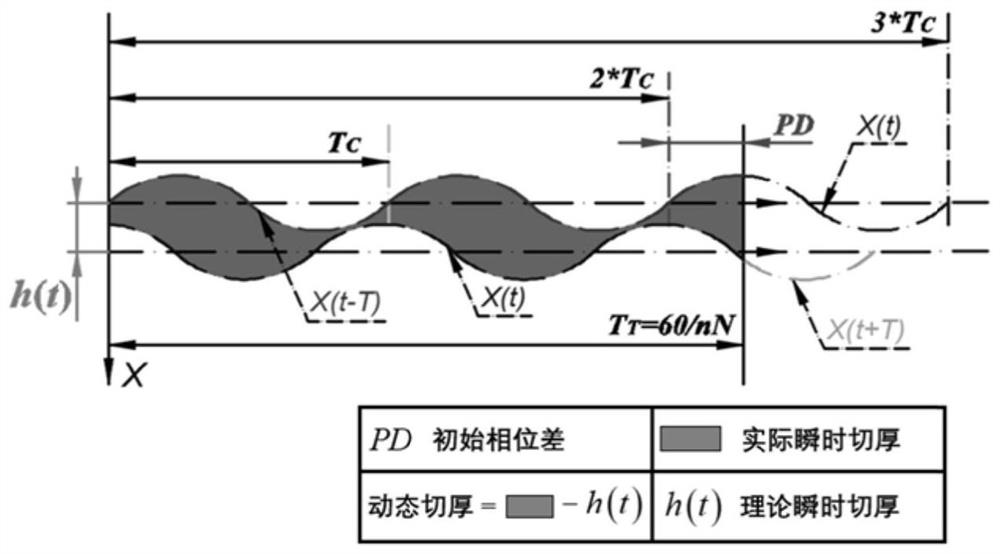

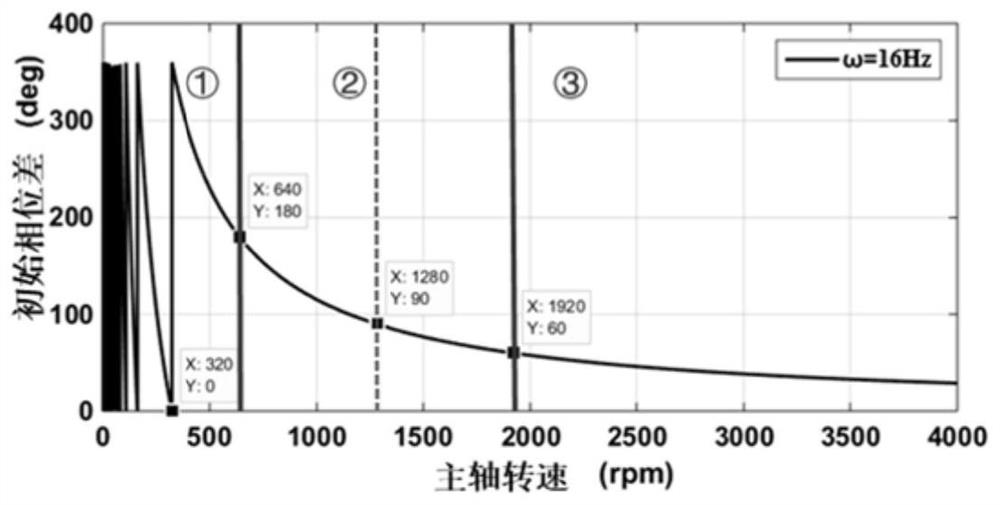

Robot milling flutter prediction and main modal analysis method

PendingCN112069664AShorten operation timePrecise positioningDesign optimisation/simulationSpecial data processing applicationsClassical mechanicsEngineering

The invention belongs to the technical field related to robot milling, and discloses a robot milling chatter prediction and main modal analysis method, which comprises the following steps: (1) constructing a dynamic cutting force model considering a regeneration chatter effect, and combining the dynamic cutting force model with a robot dynamic model considering a modal coupling effect to obtain adynamic cutting force model considering a regeneration chatter effect; carrying out modal space quality normalization conversion to obtain a final kinetic model; (2) analyzing the change of the dynamic cutting thickness of the robot along with the rotating speed under different modes according to the kinetic model, determining a mode influence factor, and judging the dominant mode of the milling flutter stability of the robot under a certain working condition by adopting the mode influence factor so as to provide a mode selection basis for predicting the milling stability of the robot, whereinthe modal influence factor is the phase difference of two times of blade ripples. According to the invention, operation data is saved, and the stability prediction efficiency is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Diamond cutter abrasion monitoring method based on cutting force model

ActiveCN106002487ASimple calculationThe result is accurateMeasurement/indication equipmentsEngineeringCutting force model

The invention discloses a diamond cutter abrasion monitoring method based on a cutting force model. The diamond cutter abrasion monitoring method is used for conducting real-time online monitoring on the abrasion loss of a cutting tool. The diamond cutter abrasion monitoring method is characterized by comprising the steps that 1, cutting force caused by chip forming under the action of a sharp diamond cutter in the cutting process is calculated by means of a non-equant shearing region model; 2, plowing force caused by cutting edge roundness in the cutting process is calculated; 3, diamond cutter cutting force is obtained according to the determined cutting force under the action of the sharp diamond cutter and the determined plowing force caused by cutting edge roundness; 4, a diamond cutter abrasion monitoring model is established according to the obtained diamond cutter cutting force, and therefore real-time monitoring on diamond cutter abrasion is achieved. By means of the diamond cutter abrasion monitoring method based on the cutting force model, the diamond cutter abrasion state can be accurately represented, monitoring on the diamond cutter abrasion can be achieved by monitoring the cutting force, and therefore real-time online and accurate monitoring of the diamond cutter abrasion is achieved.

Owner:途研(苏州)精密机械科技有限公司

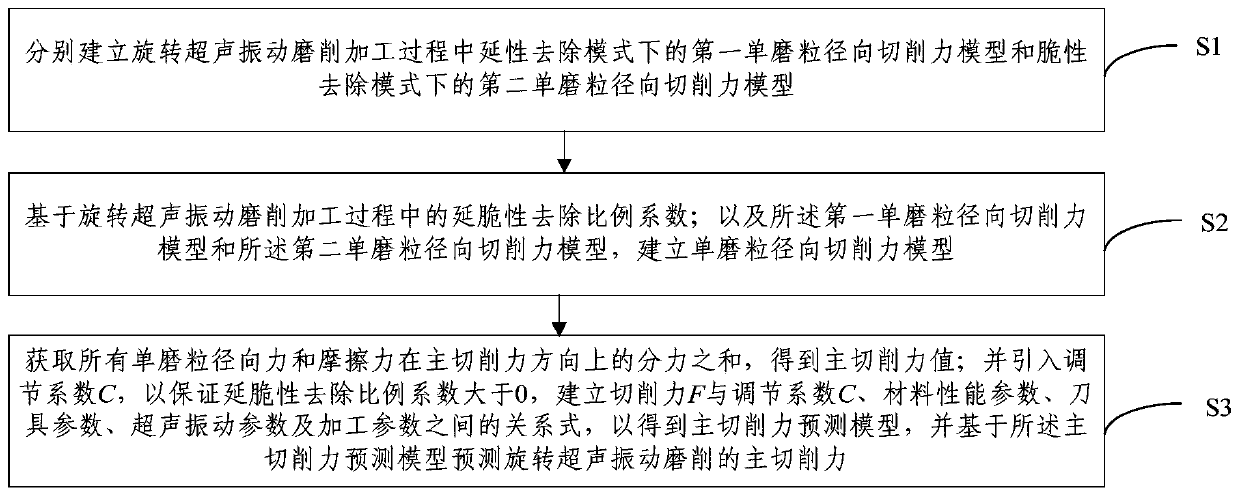

Rotary ultrasonic vibration grinding cutting force prediction method

ActiveCN110281087AIn line with the actual cutting processForecastingDesign optimisation/simulationCutting force modelUltrasonic vibration

The embodiment of the invention provides a rotary ultrasonic vibration grinding cutting force prediction method. The rotary ultrasonic vibration grinding cutting force prediction method comprises the following steps that a first single abrasive particle radial cutting force model in a plastic flow removal mode and a second single abrasive particle radial cutting force model in a brittle fracture removal mode are established correspondingly, by combining a ductile-brittle removal proportion coefficient, a single abrasive particle radial cutting force model is obtained; the condition that a workpiece undergoes combined action of single abrasive particle radial force and friction force in the rotary ultrasonic vibration grinding machining process is considered, and the sum of the component force of radial force of all abrasive particles and the friction force in the main cutting force direction is calculated, so that a main cutting force value is obtained; and finally, an adjusting coefficient C is introduced to be used for ensuring that the ductile-brittle removal proportion coefficient is greater than zero, so that a relational expression between cutting force F and the adjusting coefficient C, material performance parameters, tool parameters, ultrasonic vibration parameters and machining parameters is established. The provided cutting force prediction method more conforms to an actual machining process, and the prediction precision of the rotary ultrasonic vibration grinding cutting force can be improved.

Owner:BEIHANG UNIV

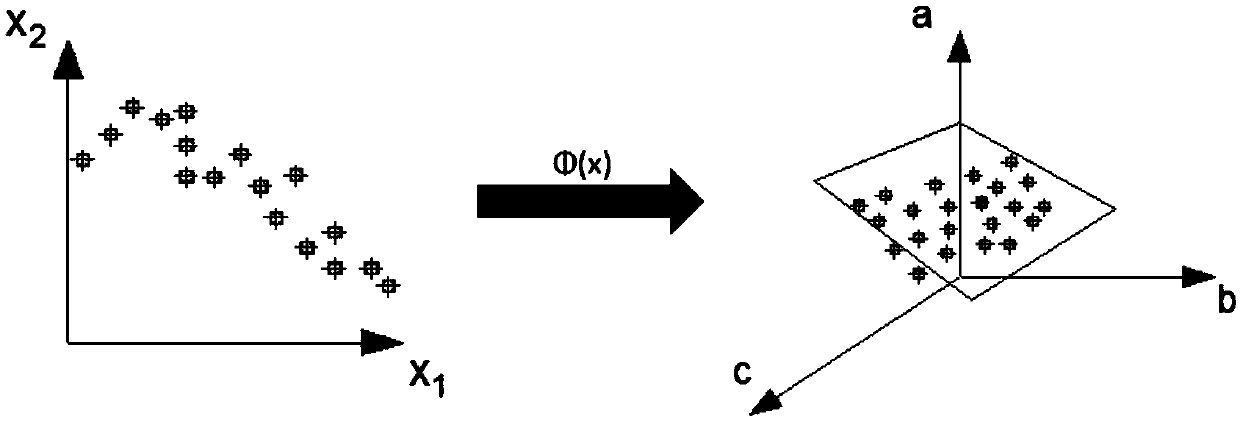

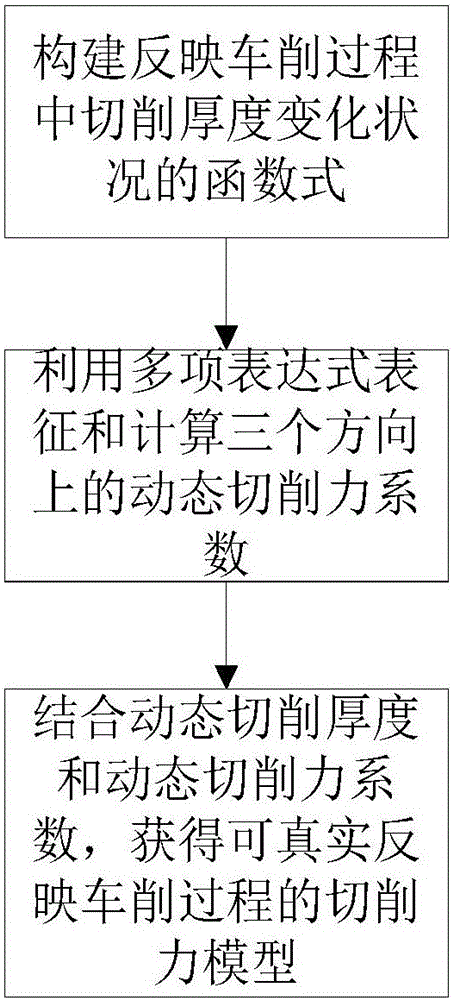

Cutting force modeling method suitable for high-speed turning process of difficult machining material

InactiveCN105930654AComprehensive responseAccurate responseSpecial data processing applicationsInformaticsCutting force modelEngineering

The invention belongs to the technical field associated with metal turning machining, and discloses a cutting force modeling method suitable for a high-speed turning process of a difficult machining material. The cutting force modeling method comprises the following steps: (i) constructing an expression to reflect a cutting thickness change situation in a whole turning process; (ii) aiming at the cutting force, independently representing and calculating a corresponding dynamic cutting force coefficient along cutting, radial and axial directions; and (iii) combining with the obtained dynamic cutting thickness and the obtained dynamic cutting force coefficient, establishing a cutting force model which can truly reflect the high-speed turning process of the difficult machining material. Through the cutting force modeling method, the cutting force in the integral high-speed turning process can be more comprehensively and accurately predicted, the cutting process is efficiently controlled at a high quality, and targeted technical guidance is provided.

Owner:HUAZHONG UNIV OF SCI & TECH

Mechanical and bending deformation modeling method for flexible needle penetration into soft tissue

ActiveCN107808698ASolve the problem of the square of the first derivativeMedical simulationDesign optimisation/simulationNeedle penetrationDeformation modeling

The invention provides a mechanical and bending deformation modeling method for flexible needle penetration into the soft tissue. The method comprises: step one, establishing a clamping friction forcemodel; step two, establishing a cutting force model; step three, establishing a tissue resistance model; and step four, according to an established mechanical model, obtaining lateral component forces of all forces and carrying out summation, and introducing the lateral joint force into a large deformation theory to calculate bending deformation of a flexible needle. According to the method provided by the invention, the influences of relates factors like the supporting friction force and the tissue resistance friction force are taken into consideration and the large deformation theory conforming to the actual situation of the bending deformation of the flexible needle is selected, so that the mechanical and bending deformation model of the flexible needle is perfected.

Owner:HARBIN UNIV OF SCI & TECH

Method for controlling cutting force mutation in curve turning machining

ActiveCN107085412ASmooth changeAvoid Parsing Difficult ProblemsProgramme controlComputer controlEngineeringCutting force model

The invention discloses a method for controlling a cutting force mutation in curve turning machining. The method comprises the steps of adopting a B-spline curve method to perform parameterized processing on a cutting edge and a workpiece contour curve, establishing a unified computing model containing key geometric parameters, analyzing constrained relationships between coefficients of a cutting force model and a force vector, a speed vector and a chip flow vector, proposing a cutting force model coefficient calibration method, further determining cutting force model coefficients, judging a position where mutation of the cutting force occurs during the actual curve machining process by means of the established cutting force model, and further adjusting a feed amount of a cutter at the cutting force mutation position so that variation of the cutting force tends to be stable at the position. Compared with the application of a linear cutting modeling technology at present, the method provided by the invention can complete the curve turning machining efficiently.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

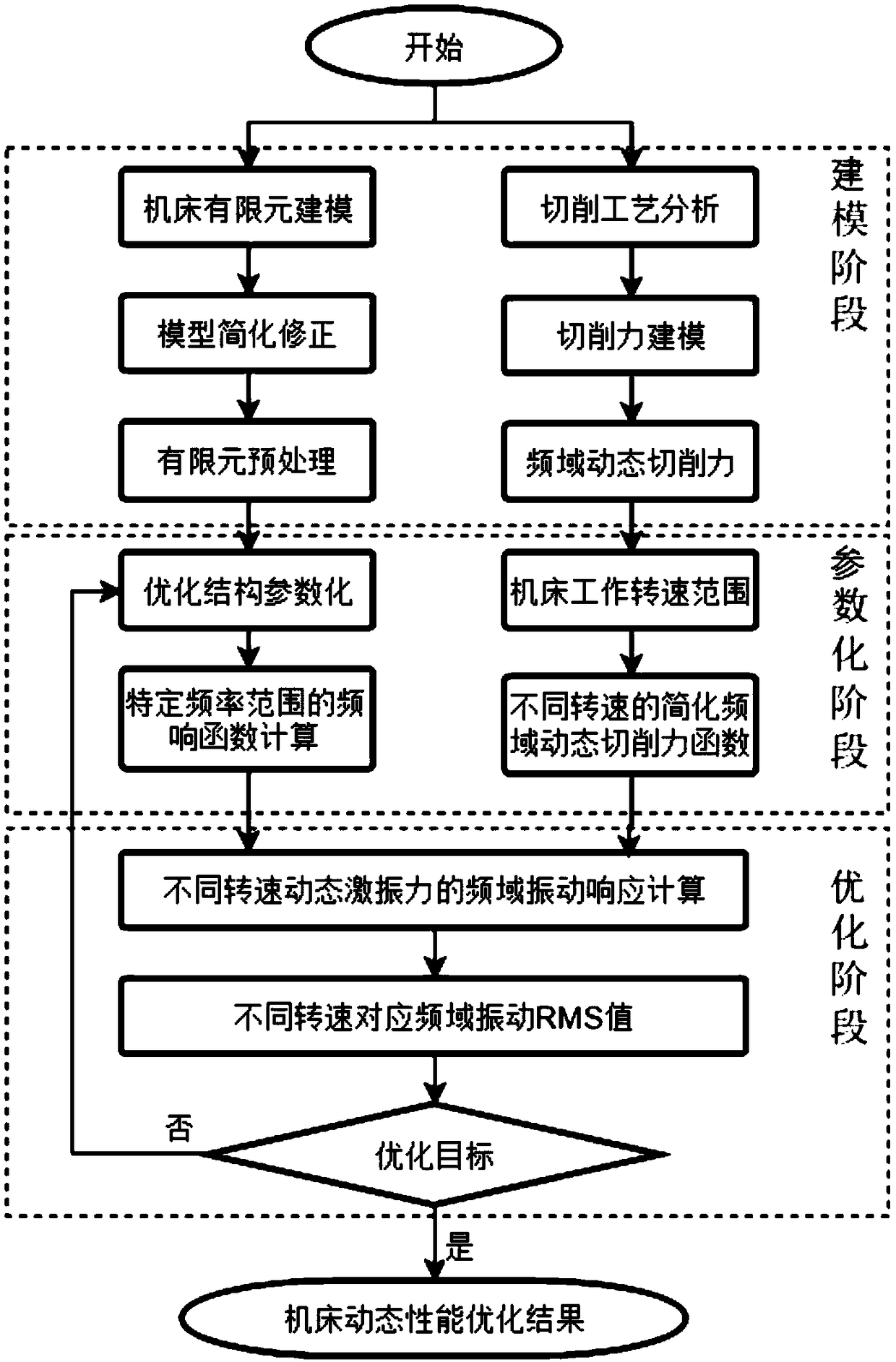

Precision machine tool dynamic performance optimization method based on frequency response calculation

InactiveCN108733899AImprove dynamic characteristicsImprove machining accuracyGeometric CADDesign optimisation/simulationFeature DimensionEngineering

The invention relates to a precision machine tool dynamic performance optimization method based on frequency response calculation. The method comprises the following steps: establishing models of structural parts of a machine tool in three-dimensional designing software, and establishing a frequency-domain dynamic cutting force model; selecting structural feature dimensions that need to be optimized as optimization input parameters, so as to obtain frequency response functions of key parts of the machine tool under initial parameter conditions; simplifying frequency-domain dynamic cutting forces, and obtaining a simplified calculation equation, so as to achieve a calculation solution of frequency responses under a dynamic excitation force; calculating a dynamic cutting force under each rotation speed condition within a selected rotation speed range, further carrying out frequency response function response calculation to obtain vibration responses in sensitive directions of the machinetool at each rotation speed, and obtaining RMS values of vibration response functions through the discretization mode; and carrying out loop optimization calculation by using a vibration RMS within acertain rotation speed range as an optimization target and structural parameters as optimization variables, and finally obtaining a dynamic performance optimization result of the machine tool or a key component structure of the machine tool when the RMS is reduced to a preset target.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com