Milling cutter dynamic cutting force model construction and verification method under vibration effect

A verification method and cutting force technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as only considering the impact of cutting force and milling vibration, and achieve the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

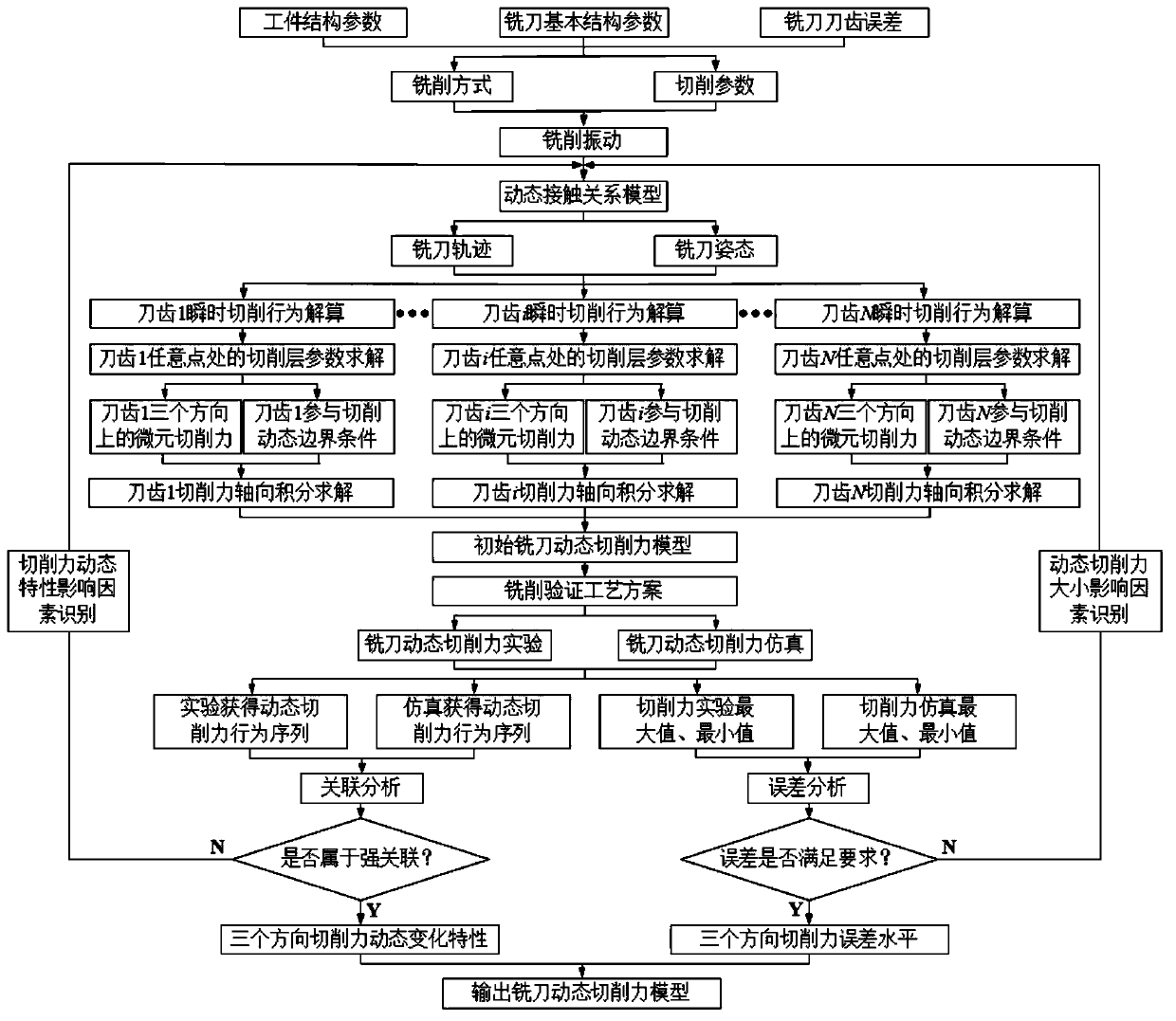

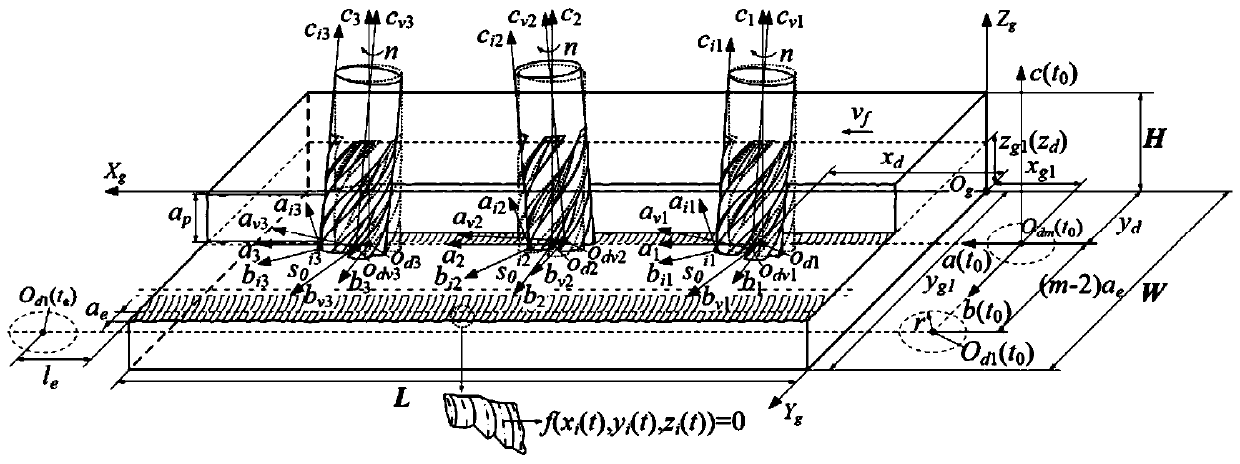

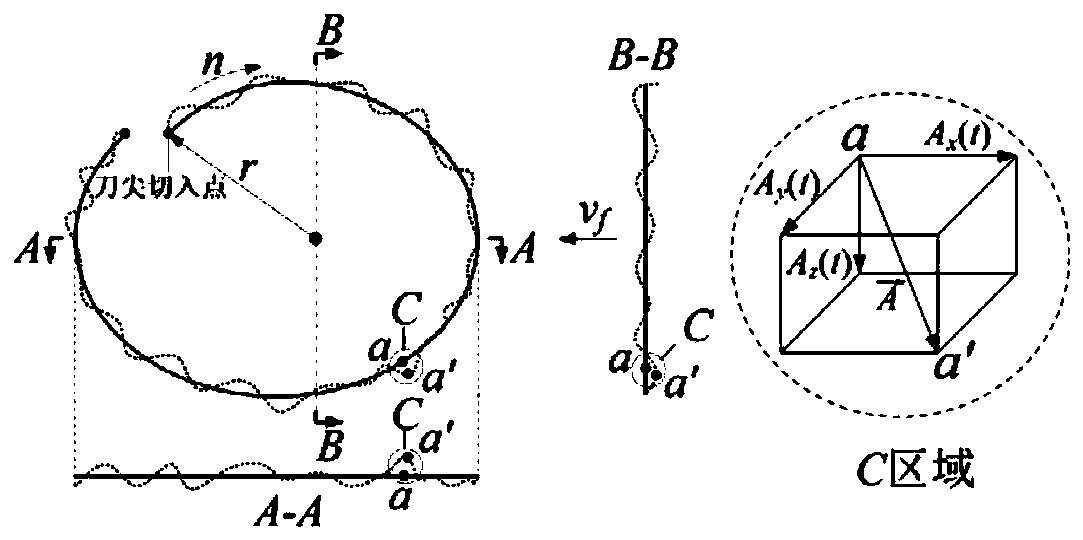

[0064] Specific implementation mode 1, a dynamic cutting force model construction and verification method for milling cutters under the action of vibration, such as figure 1 As shown, where N represents the number of teeth of the milling cutter, the process of milling titanium alloy by the end mill is analyzed, and the model of the instantaneous contact relationship of the milling cutter under the action of vibration is established; according to the contact relationship of the milling titanium alloy cutter, the actual cutting motion trajectory of the milling cutter is calculated and attitude; build a milling cutter structure model, divide the cutting edge into micro-elements, characterize the spatial position of the cutting edge, and determine the single-tooth cutting boundary conditions; according to the trajectory and attitude, establish the instantaneous cutting layer parameter model of the cutter tooth under the action of vibration, and construct the instantaneous cutting ed...

specific Embodiment approach 2

[0126] Vibration Variation Characteristics of Milling Titanium Alloy

[0127] (1) The experiment was carried out on a three-axis milling machining center (VDL-1000E), using the milling method of down milling, the spindle speed n was 1290r / min, and the feed rate was v f It is 573mm / min. Vibration is tested by DHDAS5922 dynamic signal test system.

[0128] Acquisition of vibration acceleration signals such as Figure 4 shown.

[0129] In the figure, T 1 , T 2 , T 3 and T 4 They are idling, initial stage of cut-in, smooth cutting and cut-out idling stage.

[0130] (2) Taking the vibration signal in the cutting speed direction obtained in the experiment as an example, use matlab to perform noise reduction processing on the vibration acceleration signal, and perform sine function fitting on the vibration acceleration signal after noise reduction, and the specific fitting results Such as Figure 5 and Figure 6 shown.

[0131] Equation fitting is performed on the vibratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com