Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31 results about "Line heat source" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

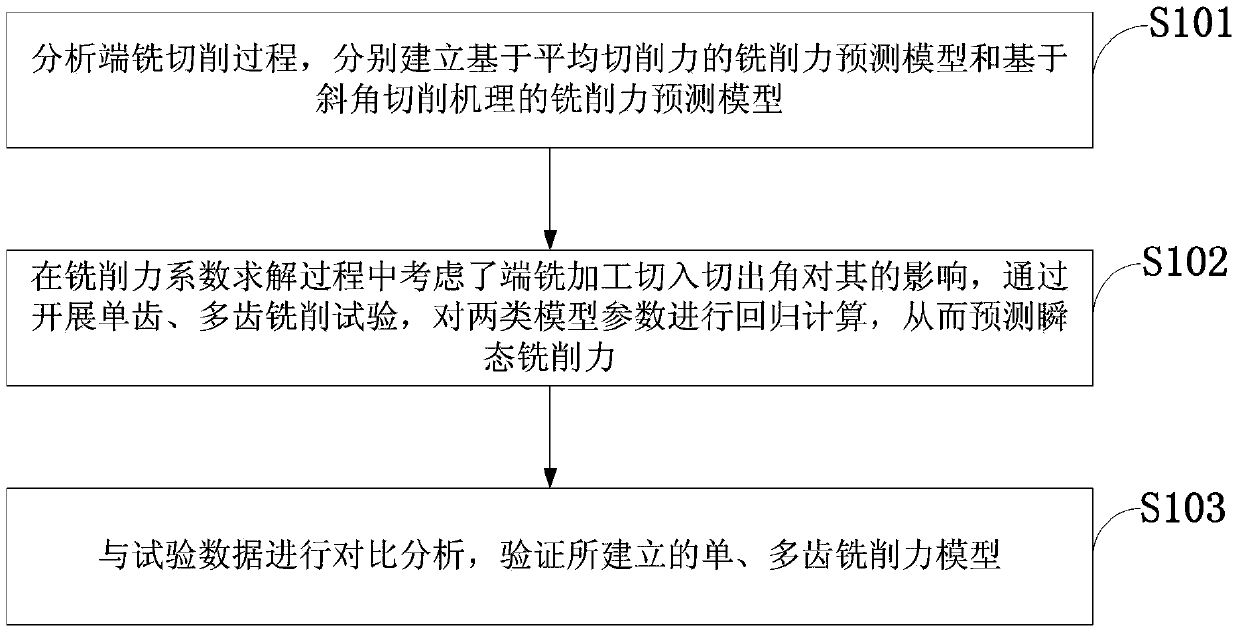

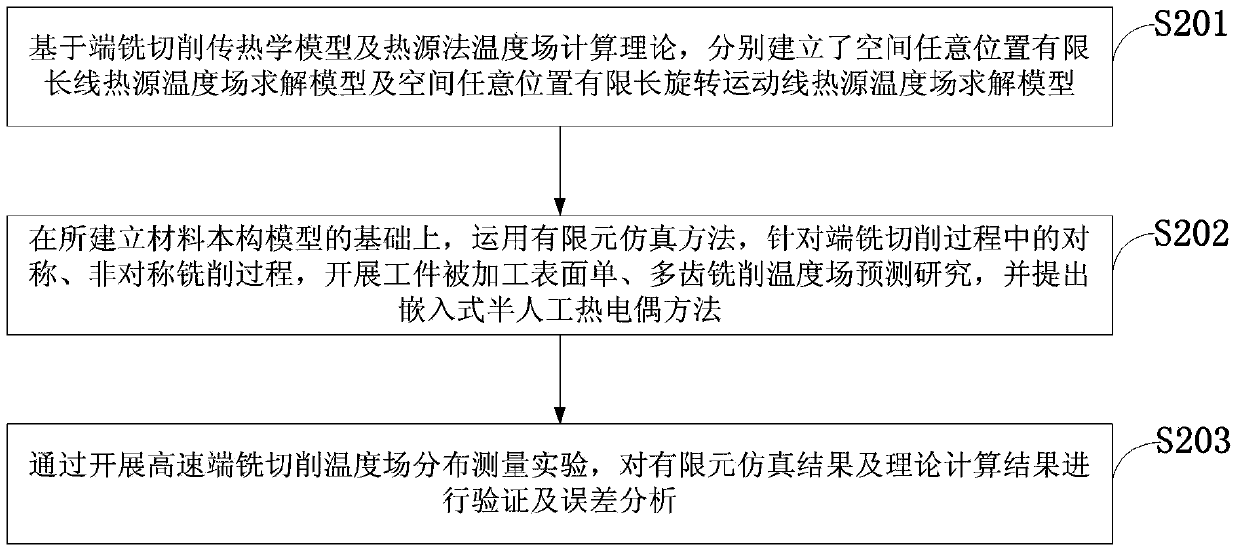

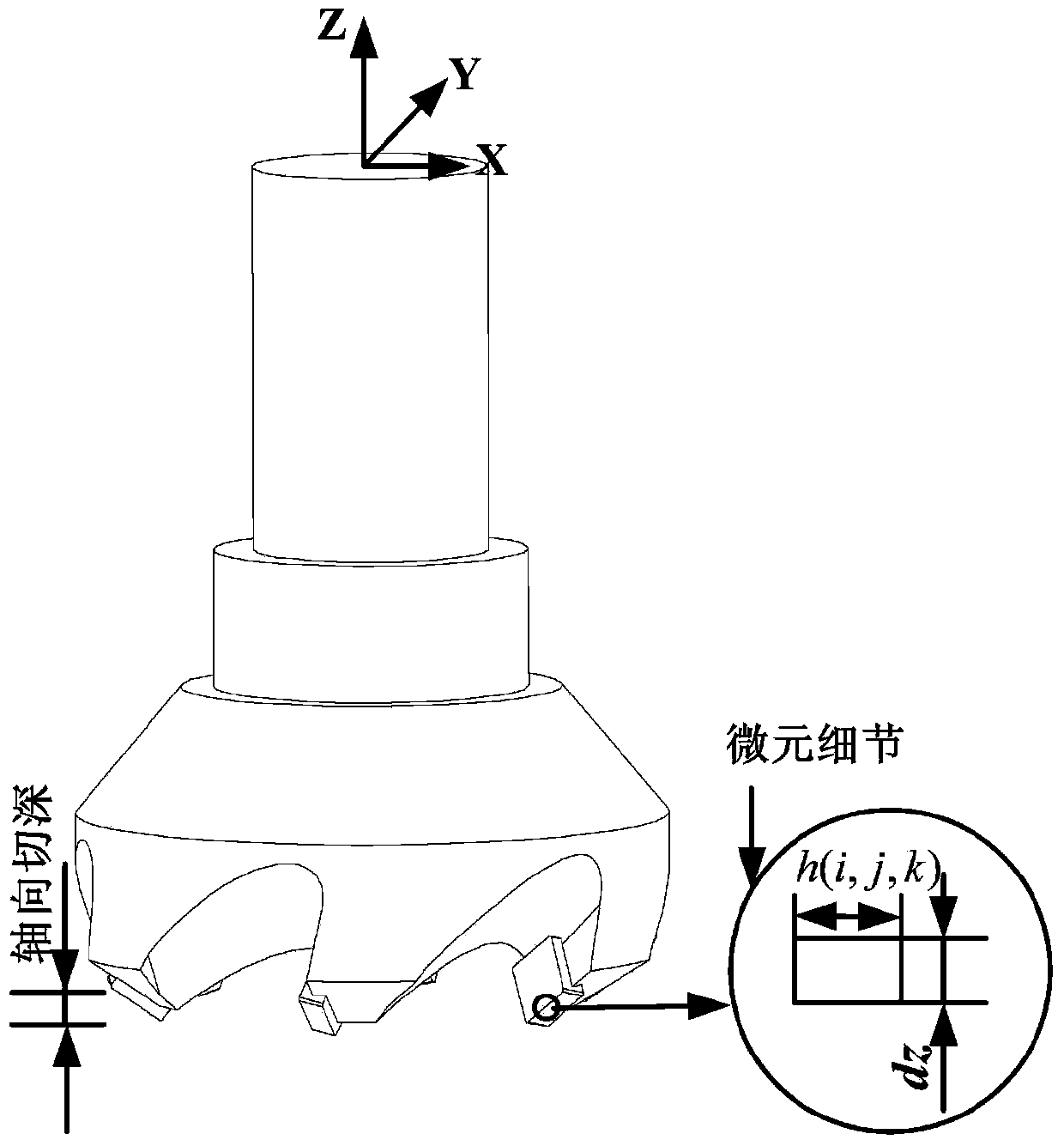

Method of cutting force prediction and temperature prediction for end-milling cutting

ActiveCN104268343ASimple methodEasy to operateSpecial data processing applicationsMethod developmentCutting force model

The invention discloses a method of cutting force prediction and temperature prediction for end-milling cutting, the method development of the cutting force prediction is based on a milling forces prediction model of average cutting forces and a milling forces prediction model of bevel angle cutting mechanism and is characterized by performing regression calculating on the two model parameters, predicting transient cutting force, performing comparative analysis with test data, and verifying established single-tooth and multi-teeth cutting force models; the method of cutting force temperature prediction establishes a temperature field solution model of a limited long-line heat source of space optional positions and a temperature field solution model of a limited long-rotation movement line heat source of space optional positions; by means of a limited element simulation method, an embedding semi-artificial thermocouple method is put forward, and by carrying out high speed end-milling cutting temperature field distribution measurement, verification and error analysis are performed on a limited element simulation result and a theoretical calculation result. The method of the cutting force prediction and the temperature prediction of the end-milling cutting has the advantages that the method is simple, operation is easy, reference foundation is provided for end-milling cutting technology, and the method is more beneficial to production.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

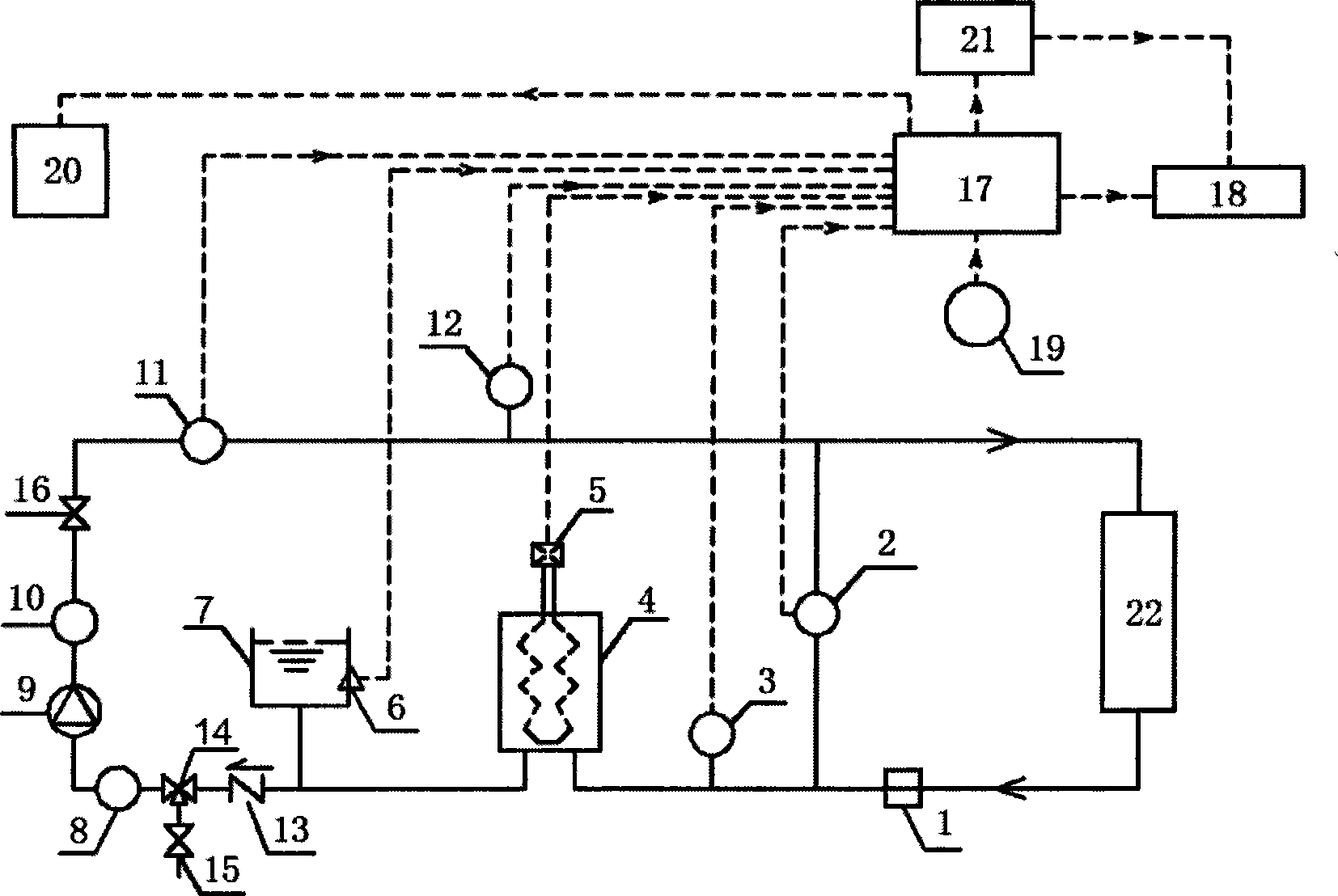

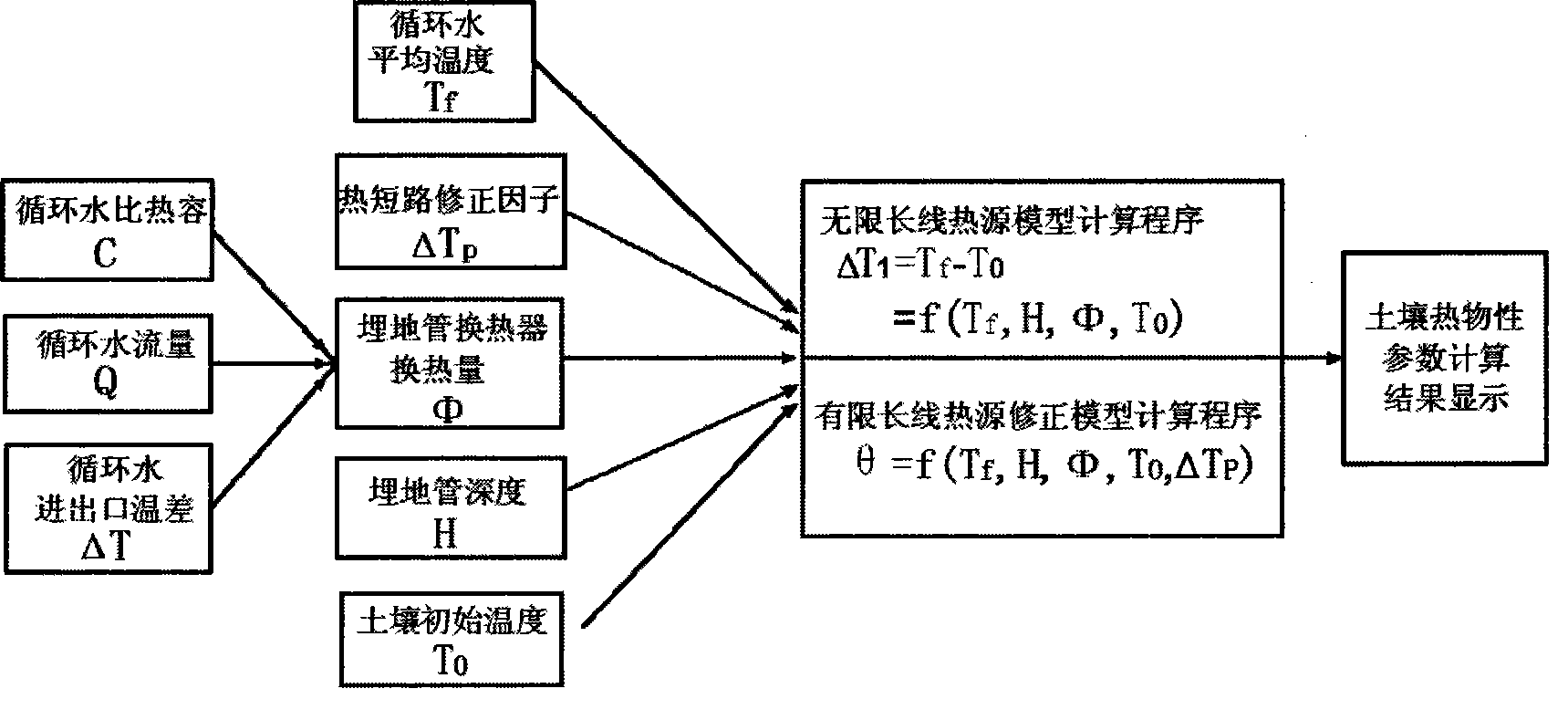

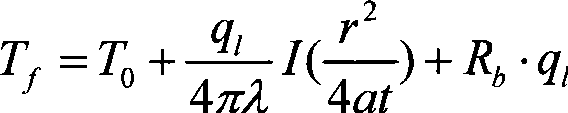

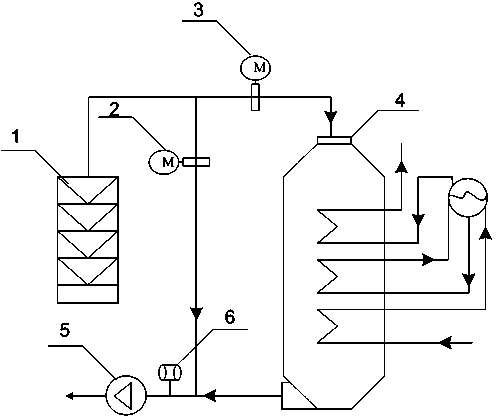

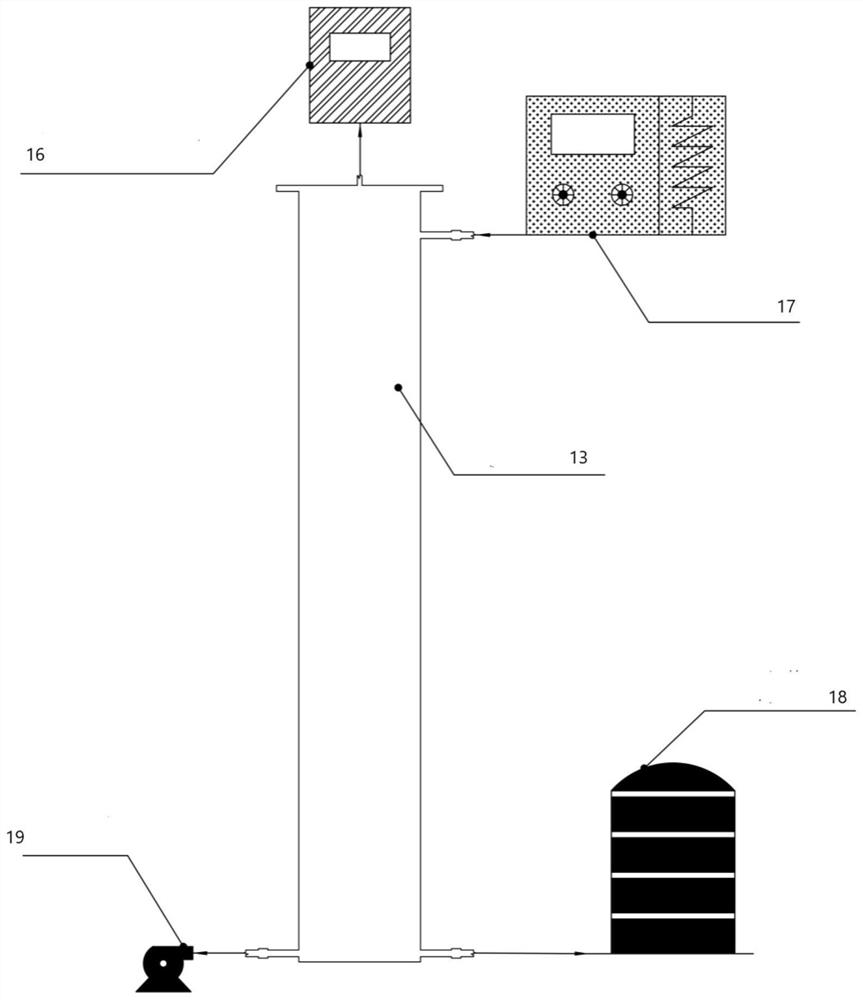

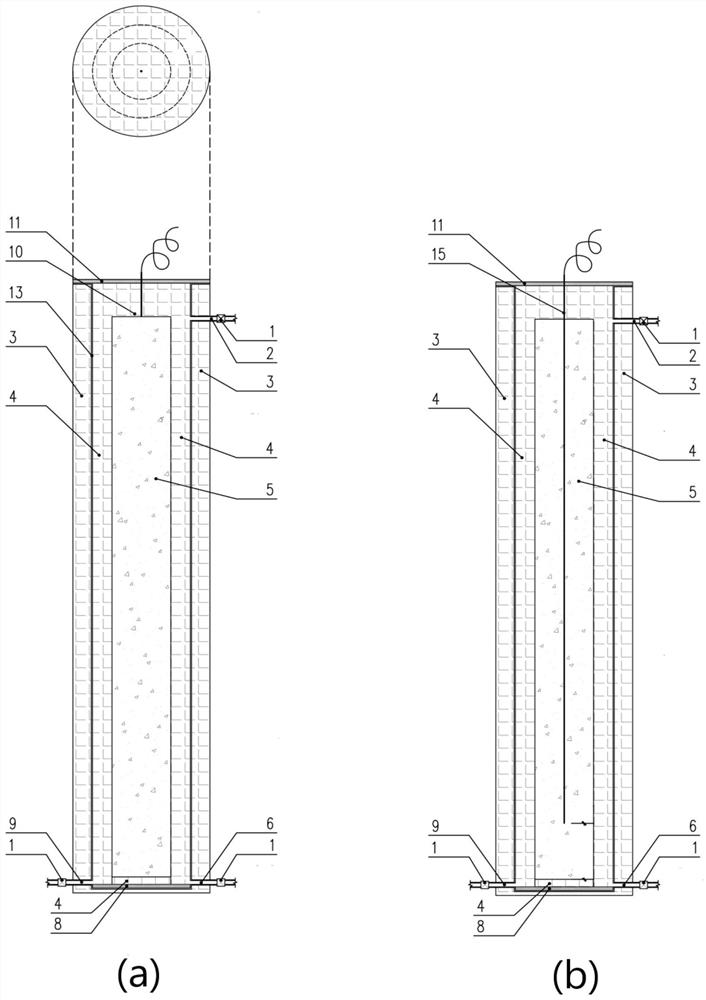

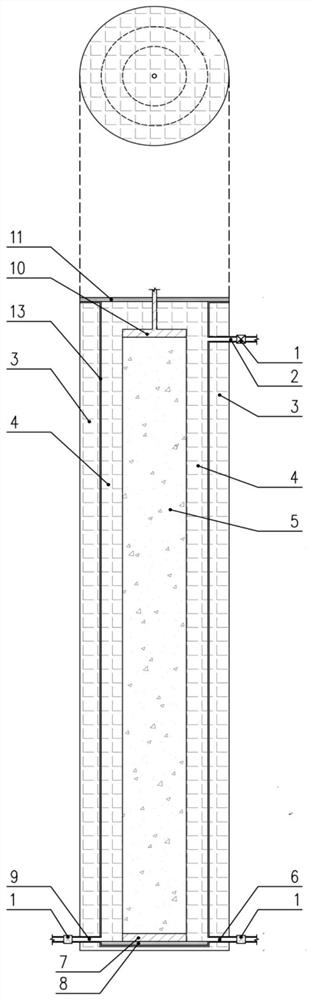

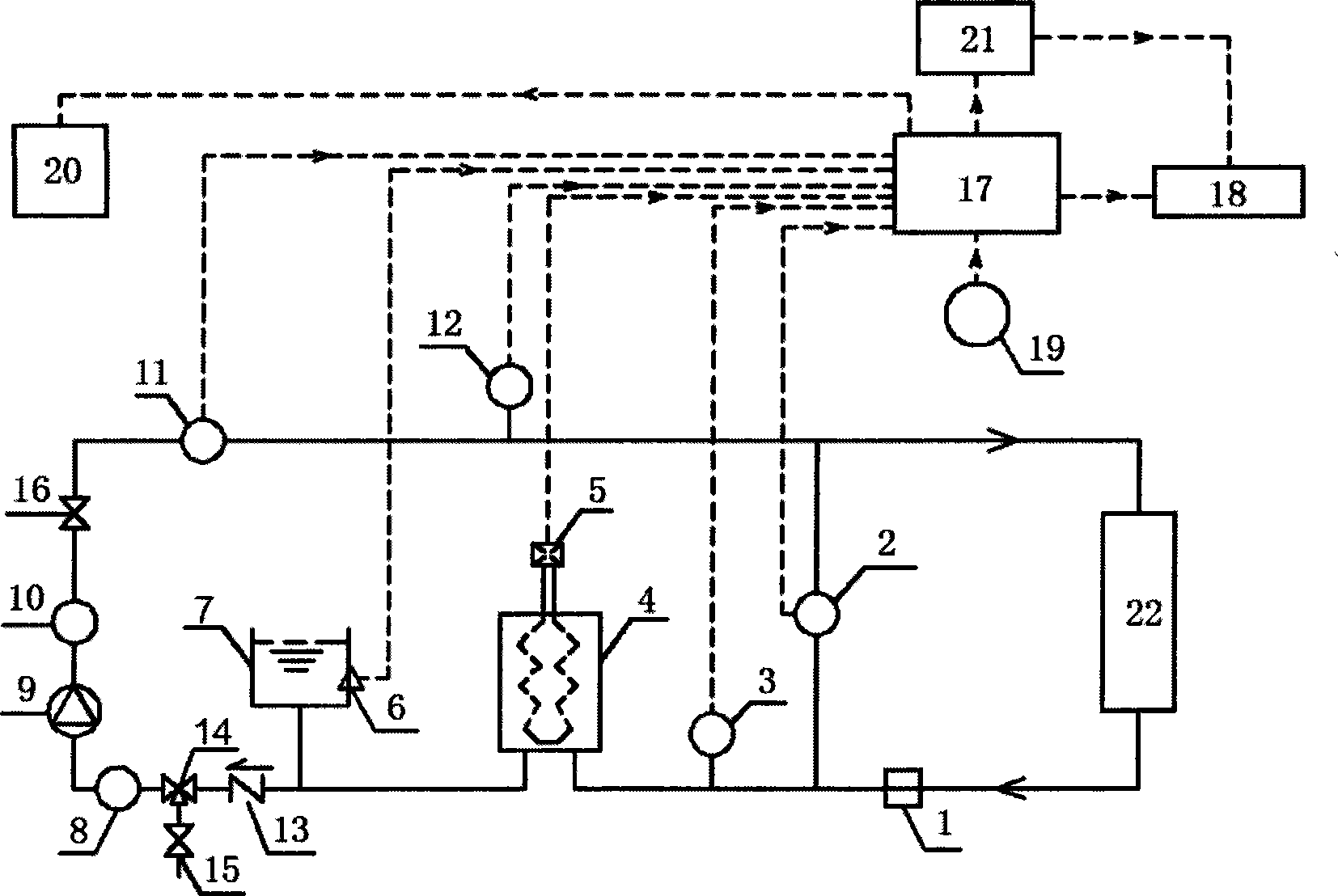

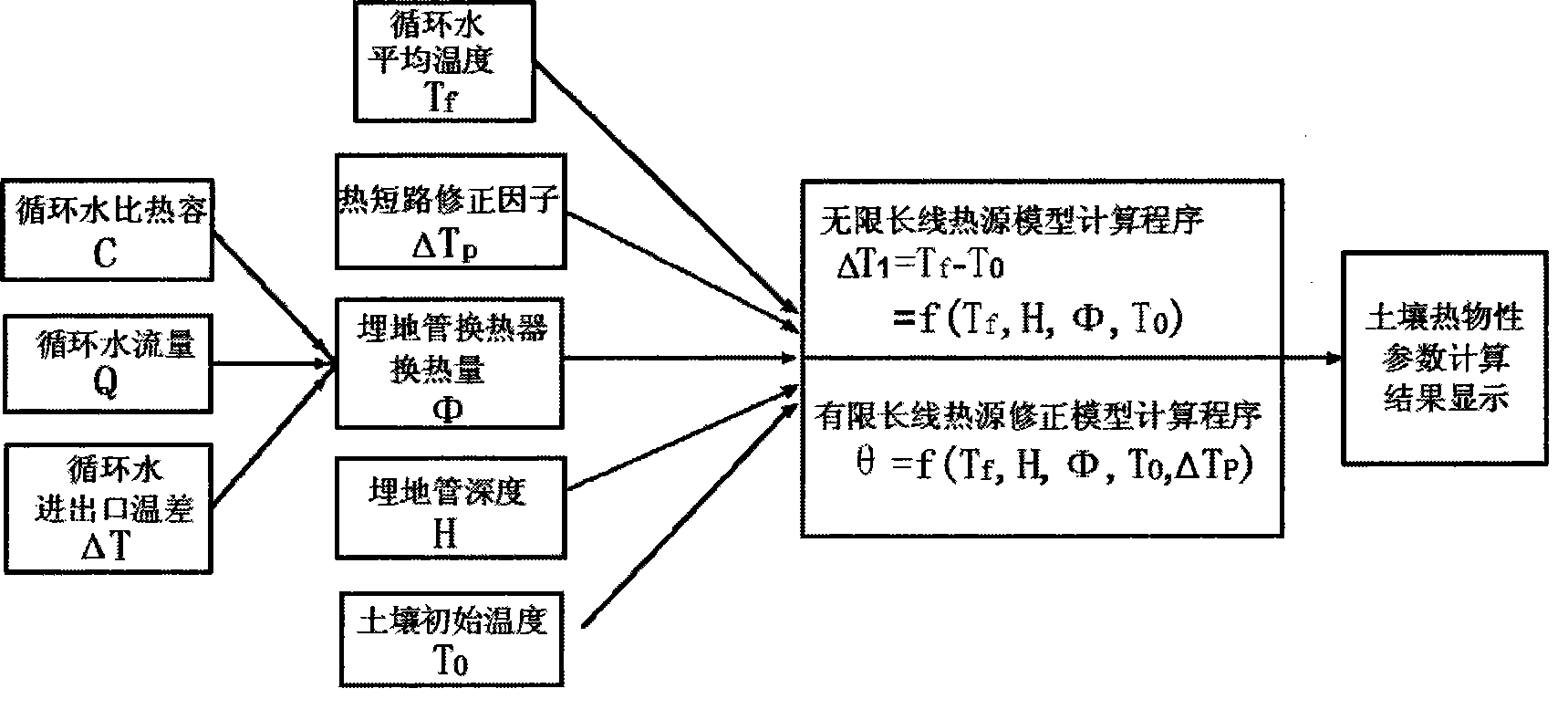

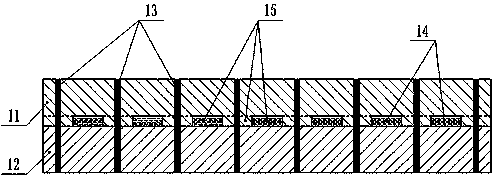

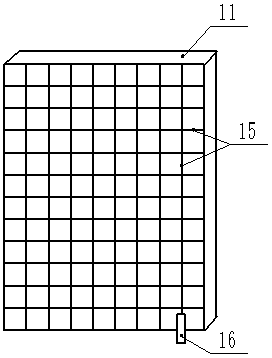

High precision soil thermophysical nature measurer for ground source heat pump

InactiveCN101393149ACompact structureWide range of test powerMaterial thermal conductivityMaterial heat developmentTest powerEngineering

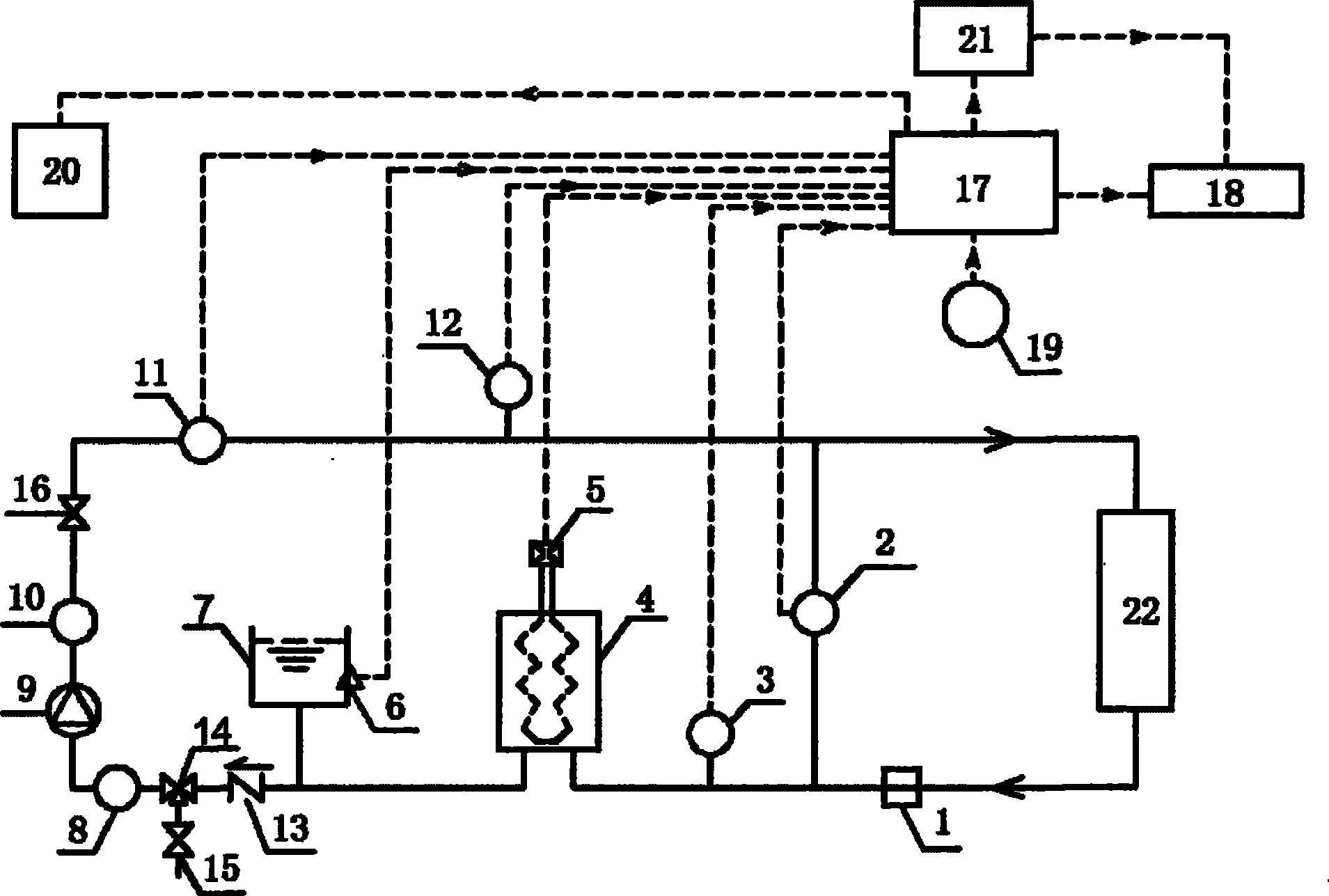

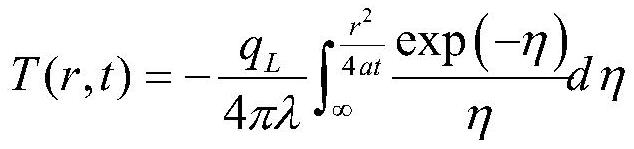

The invention relates to a high-precision soil thermophysical property tester for a ground source heat pump, and belongs to the technical field of energy-saving and air-conditioning. The tester consists of a filter, an electric heater, a water supplementing tank, a one way valve, a tee joint, a water circulating pump, a second ball valve and an electromagnetic flow meter which form a test pipeline. A data computation module computes soil thermophysical property parameters by adopting programs of an infinite line heat source model and a finite line heat source correcting model according to five parameters of average temperature of circulating water, initial temperature of soil, heat exchange amount of unit pipe length of a heat exchanger for an embedded pipe, flow rate of the circulating water and the depth of the embedded pipe. The tester can not only be applied to actual measurement of engineering, but also applied to researching the underground soil thermophysical property parameters when the ground source heat pump works for a long time. The tested computation result is in more accordance with the practical situation; and the tester has the advantages of compact structure, high test precision, wide test power range, high visibility degree, convenient operation and safe use.

Owner:SHANGHAI JIAO TONG UNIV +3

Line heat source

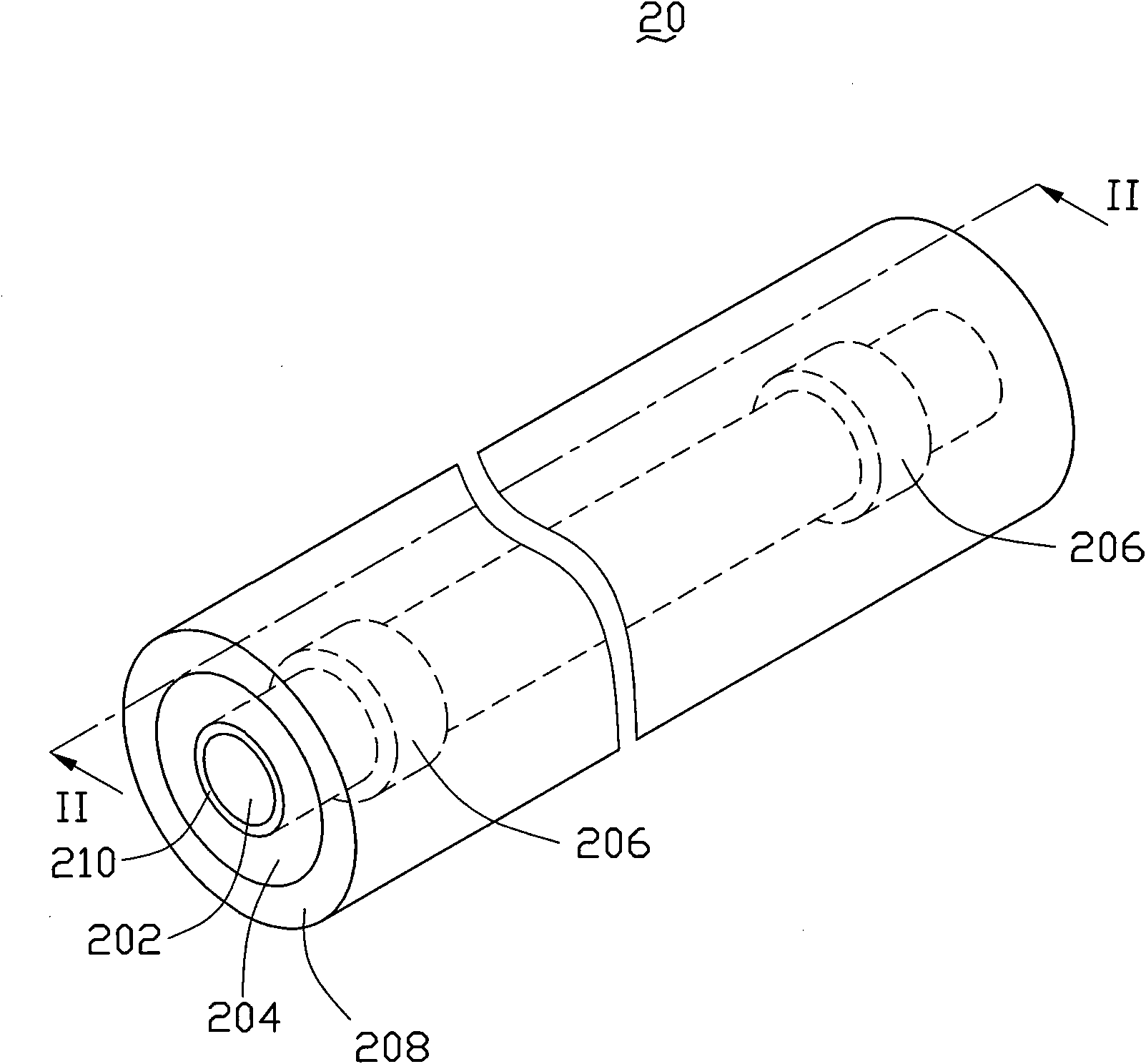

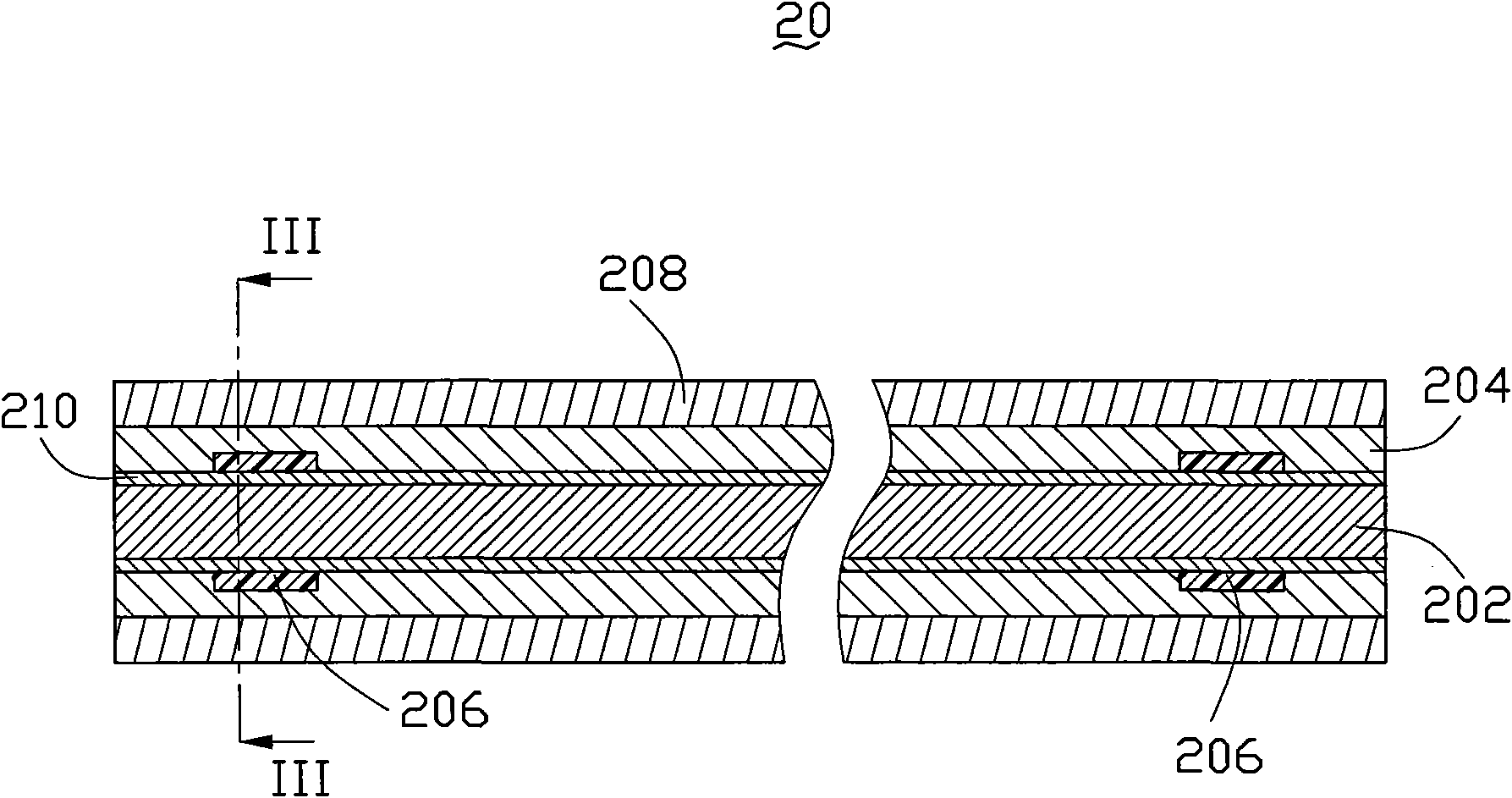

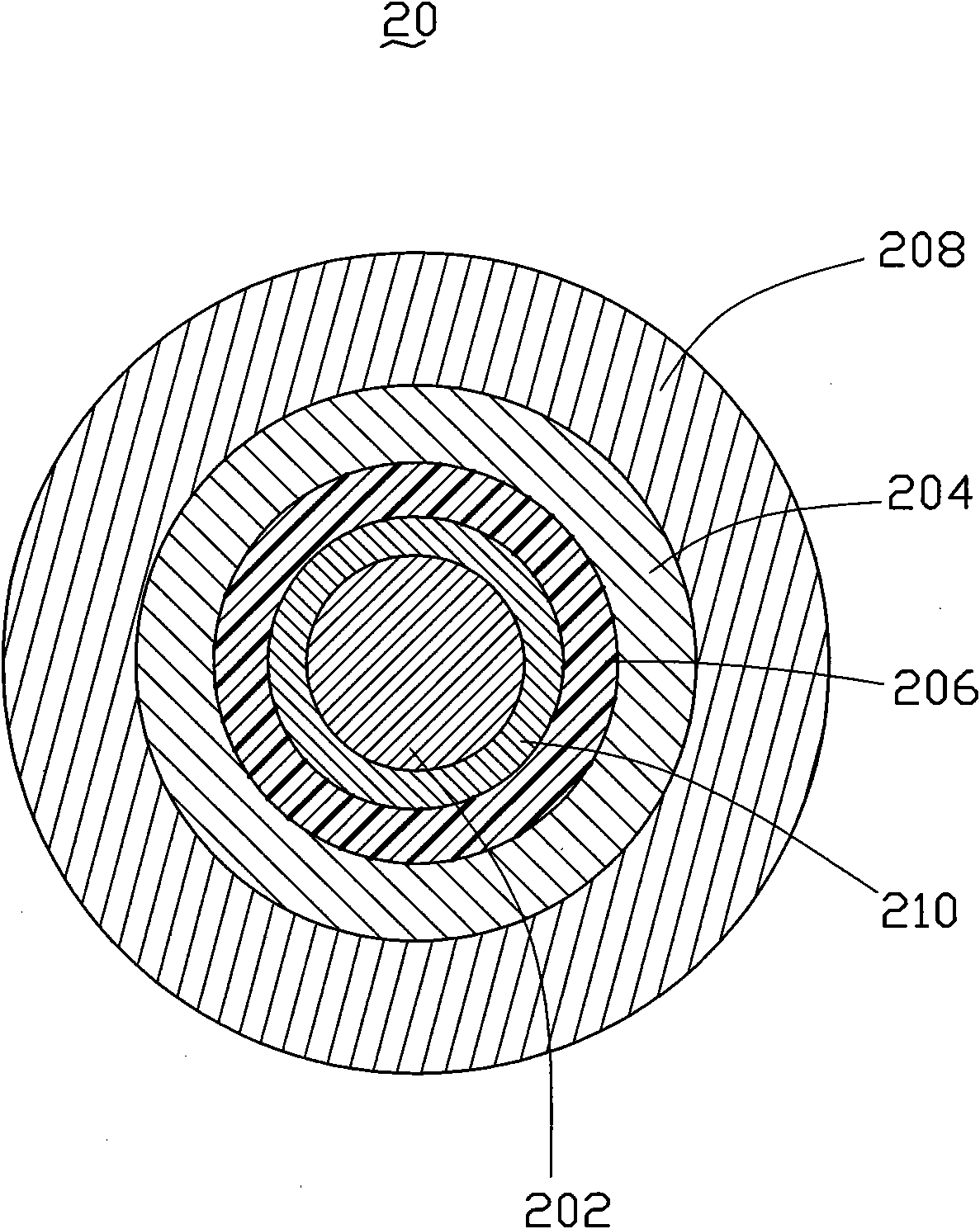

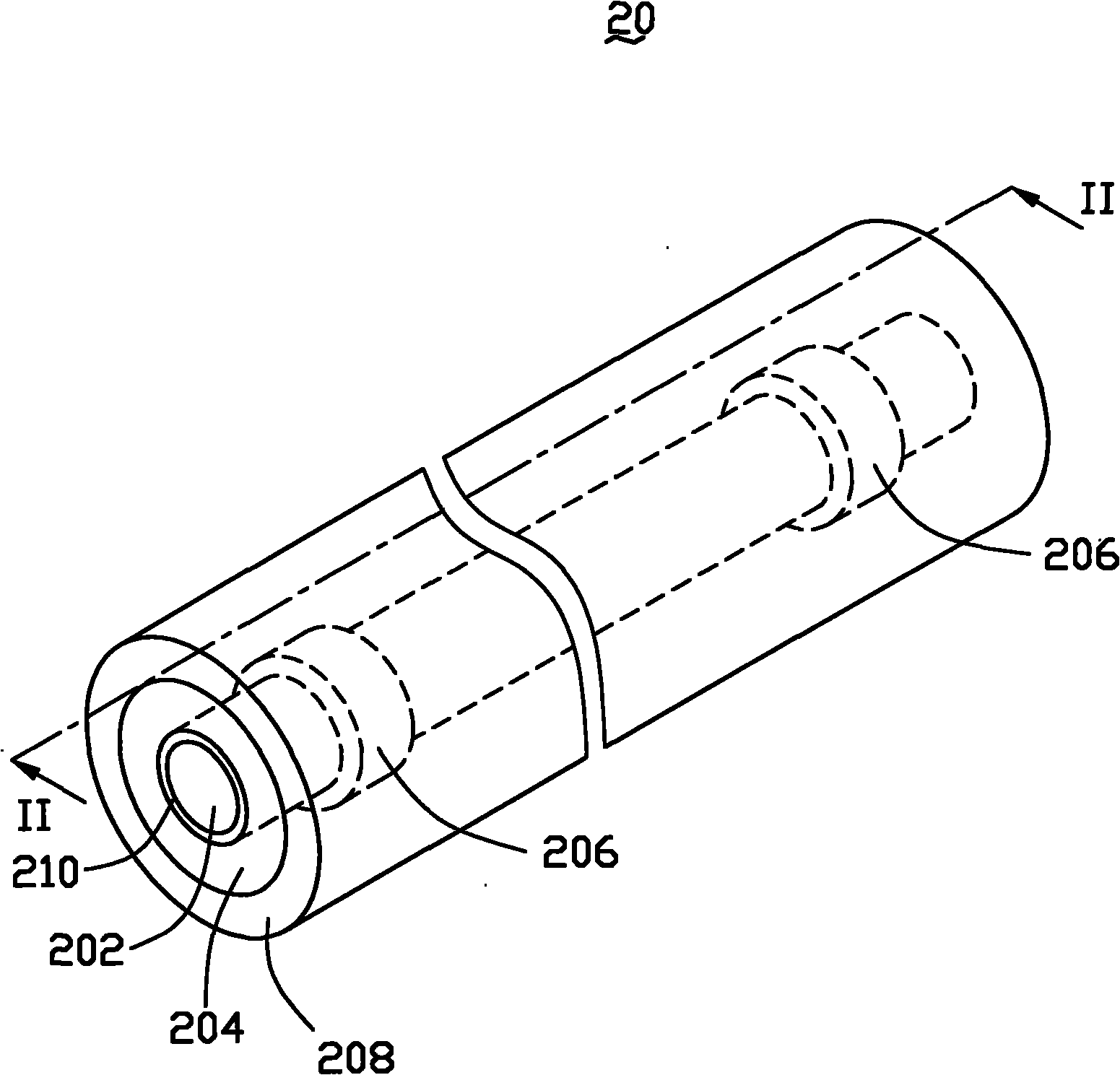

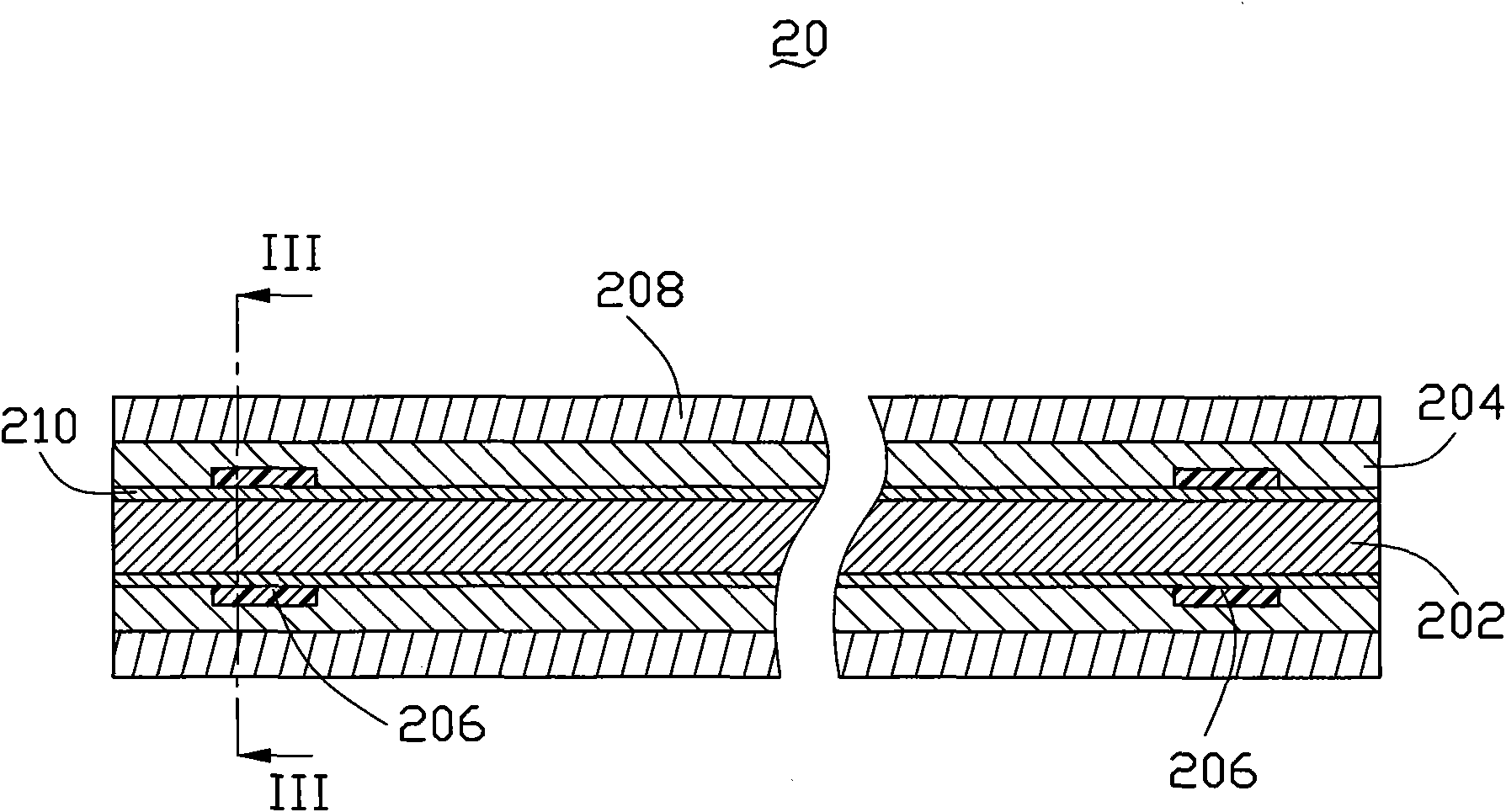

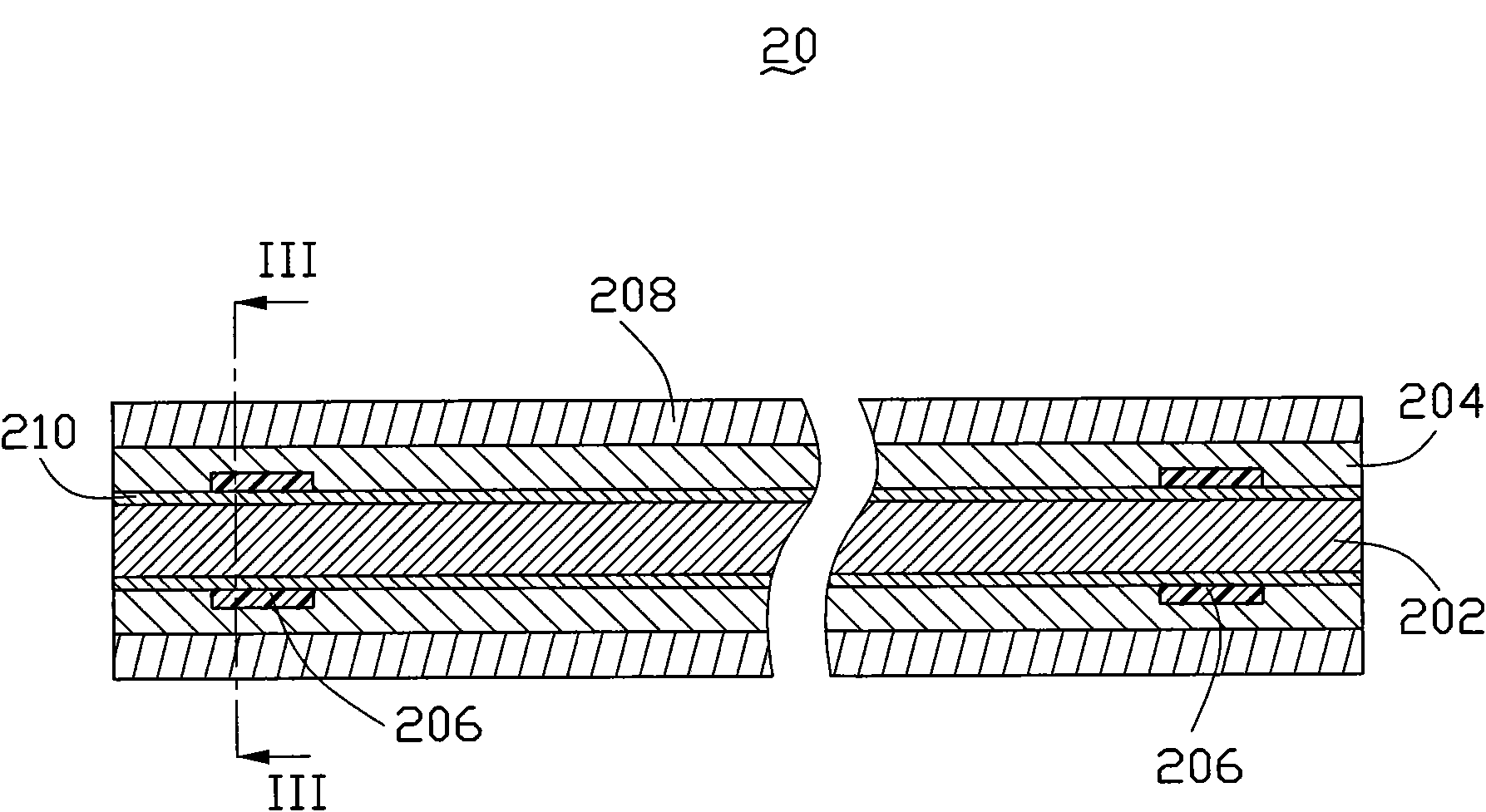

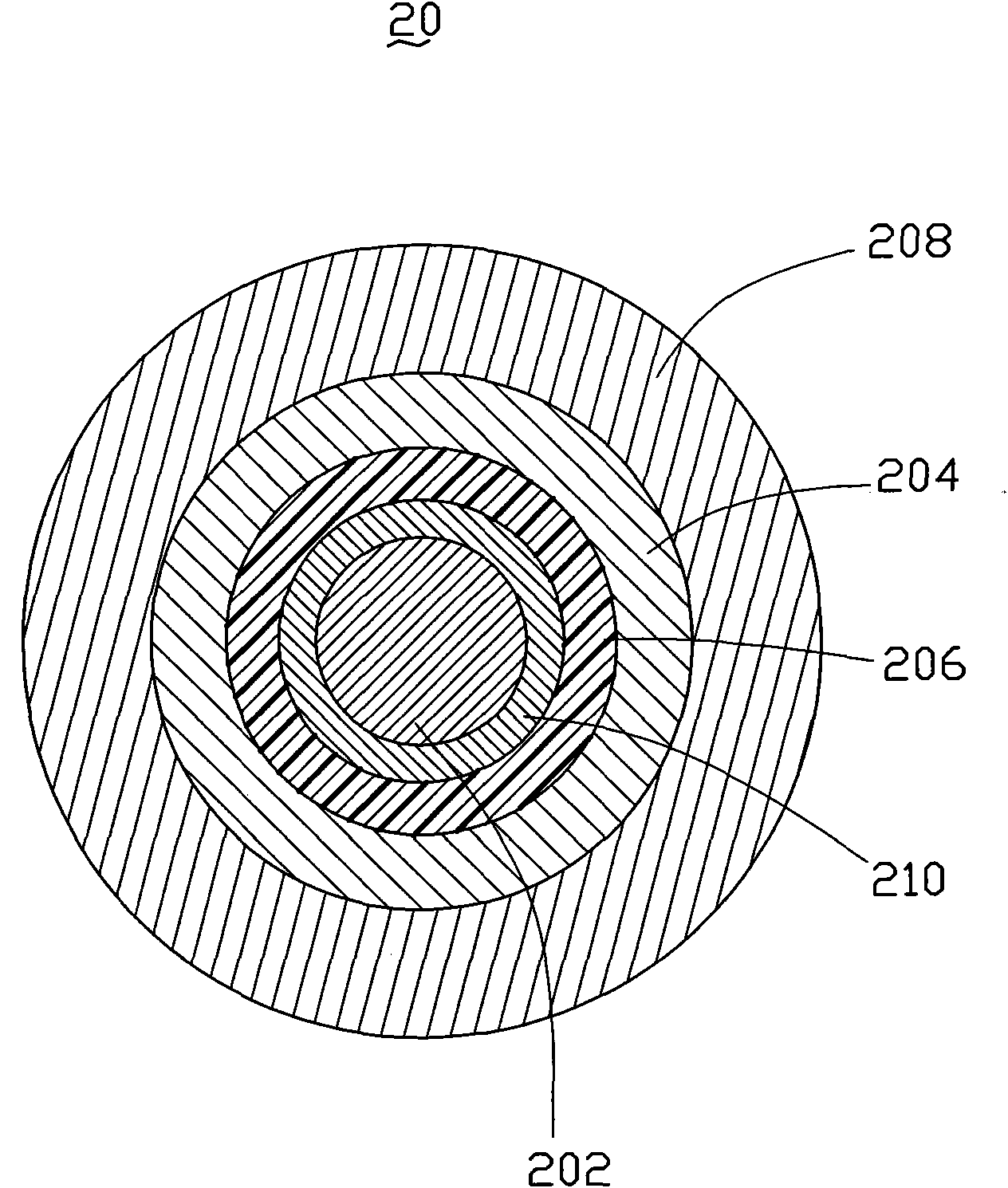

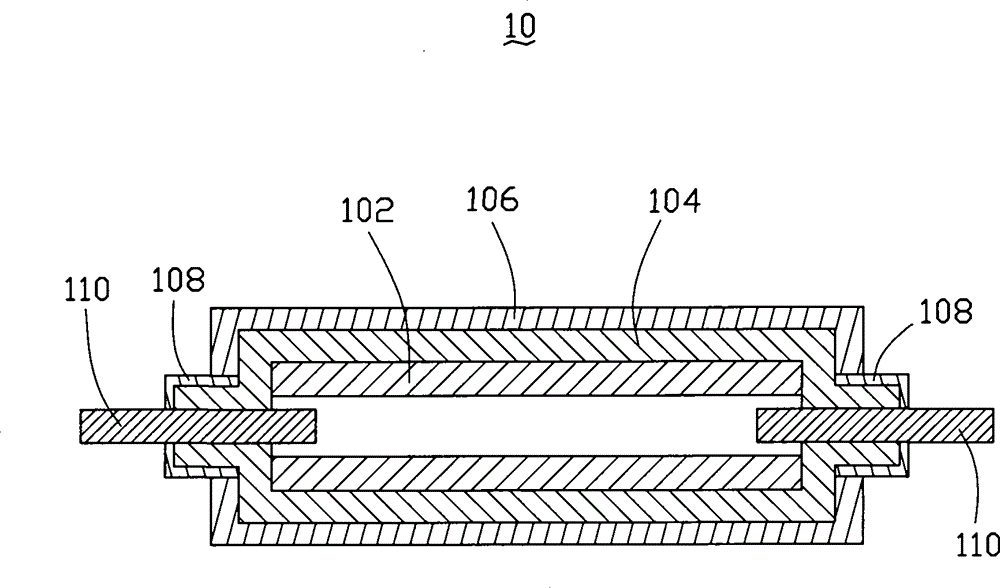

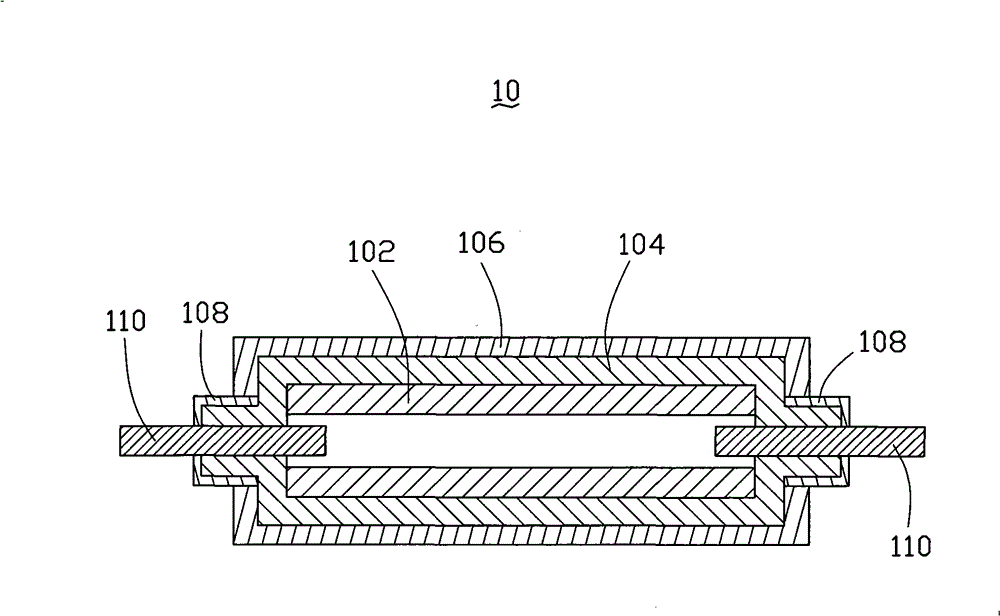

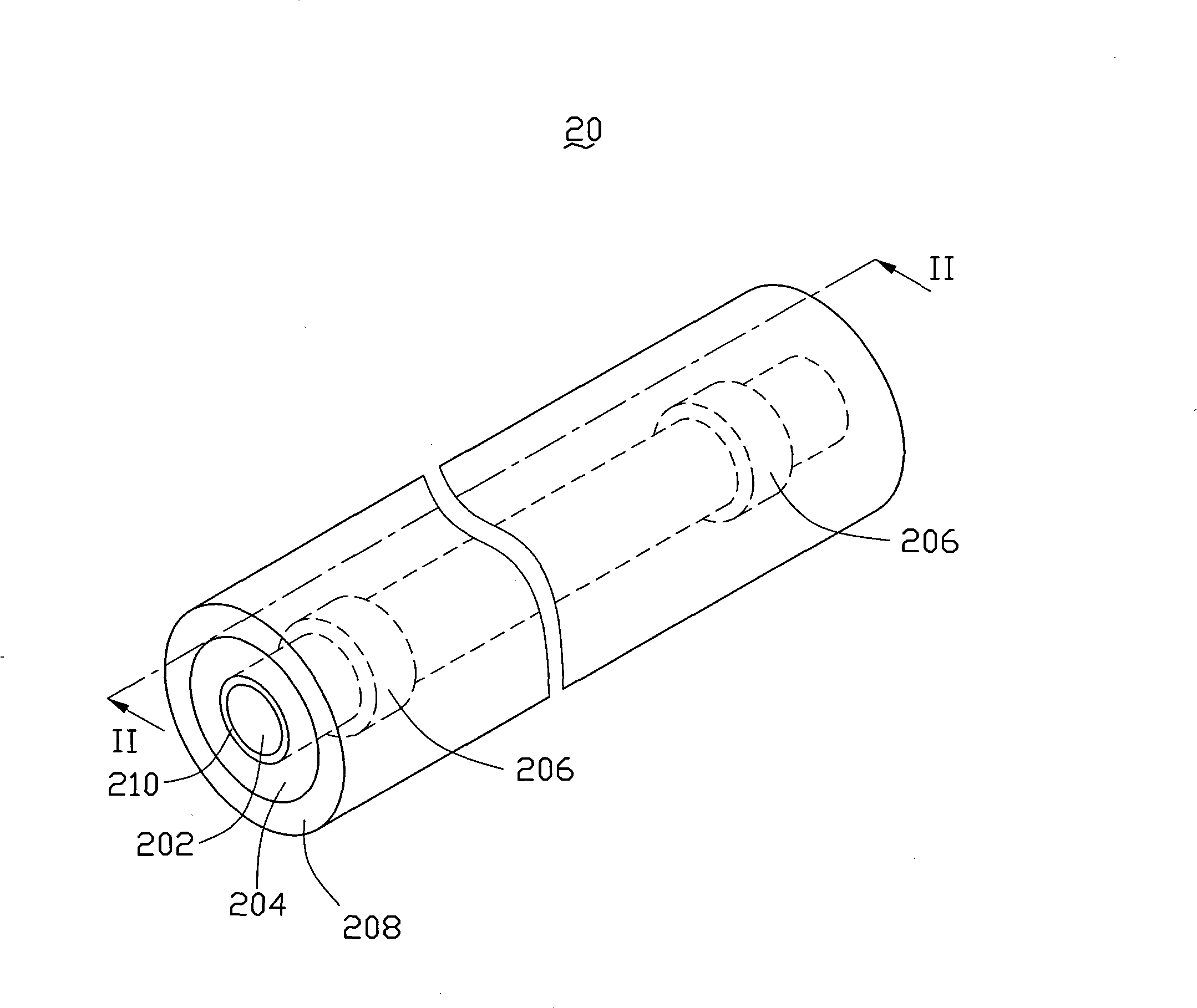

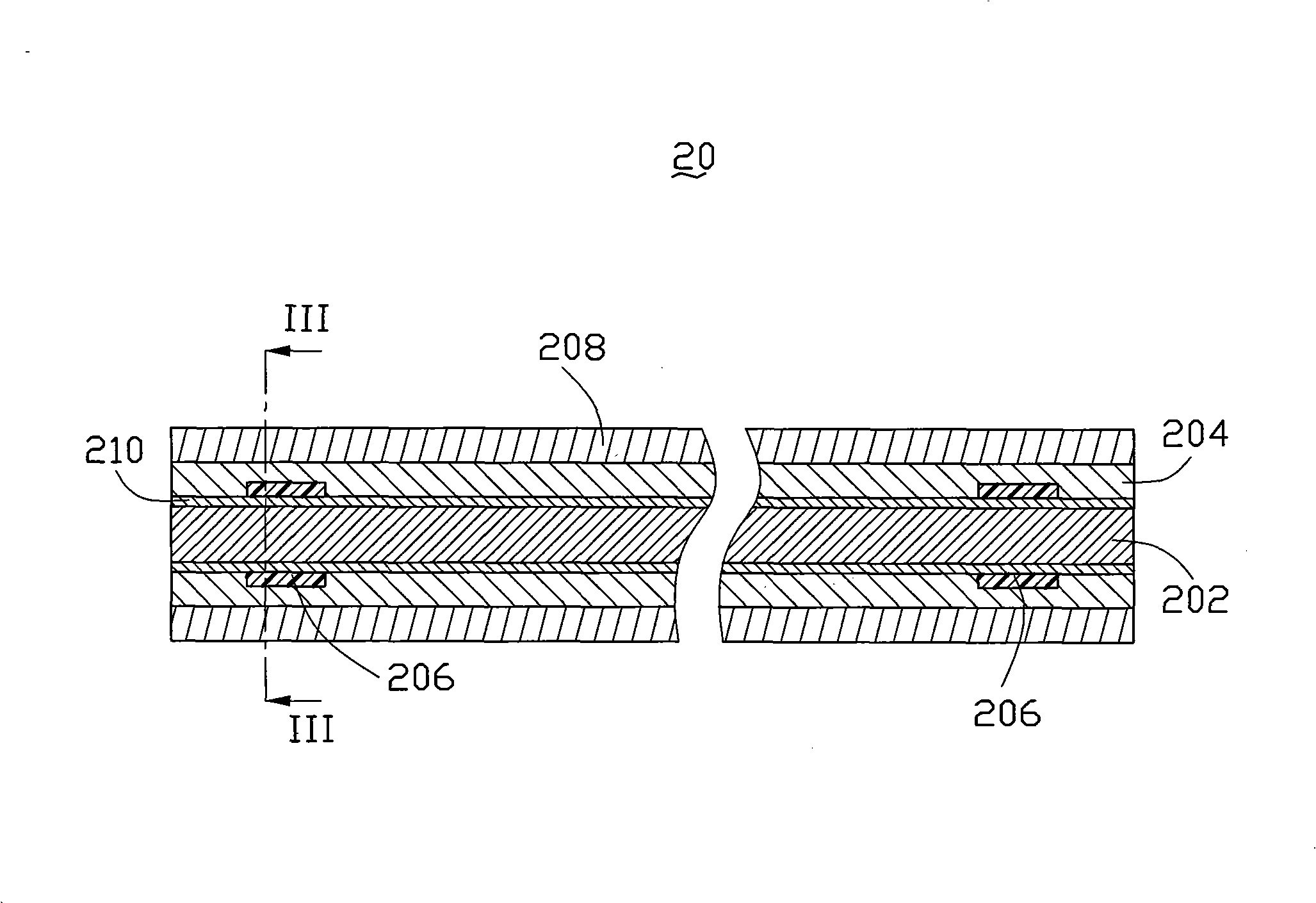

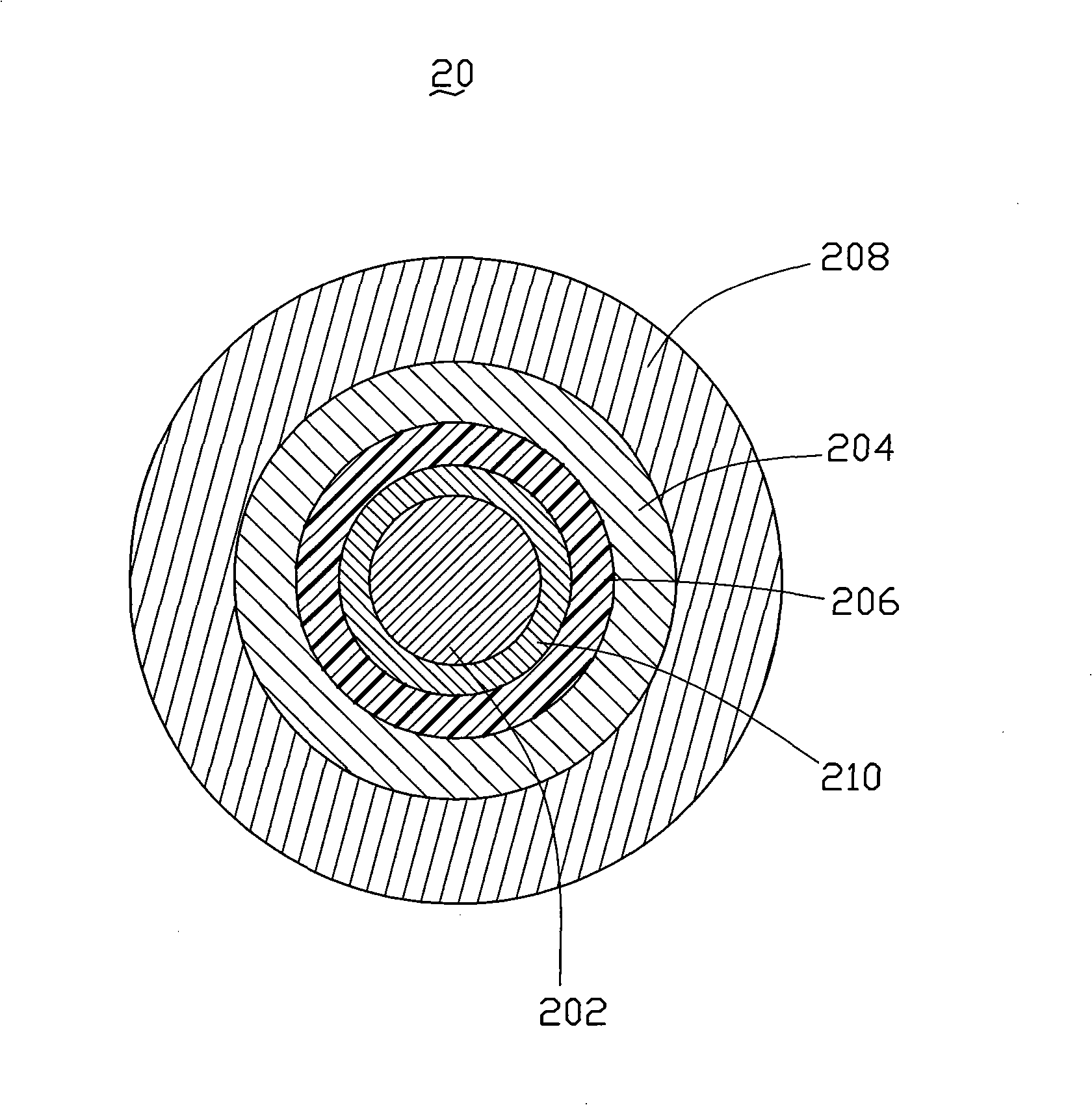

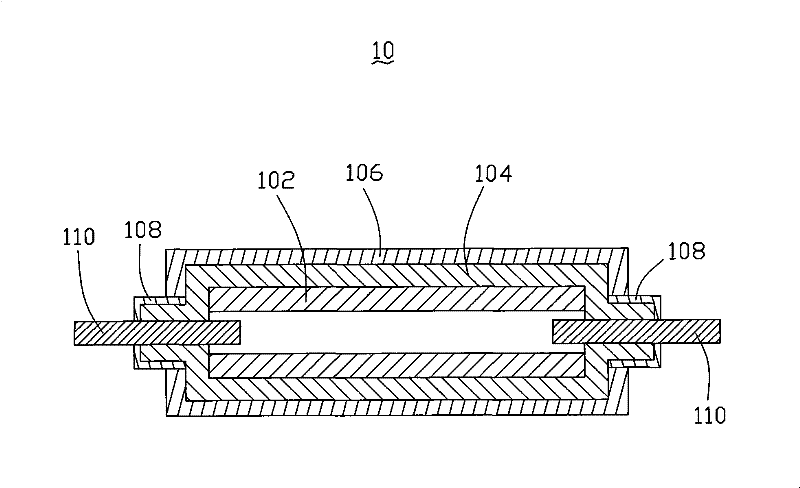

ActiveCN101610613AReduce weightEasy to useIndividual molecule manipulationHeating element shapesCarbon nanotubeNanometre

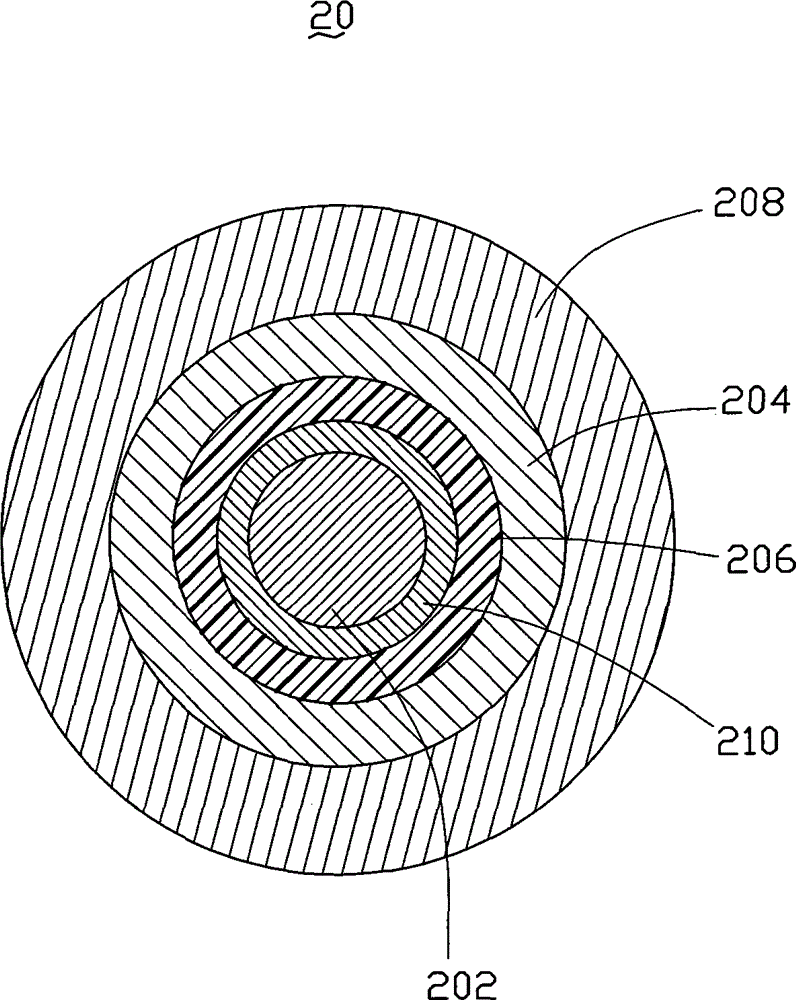

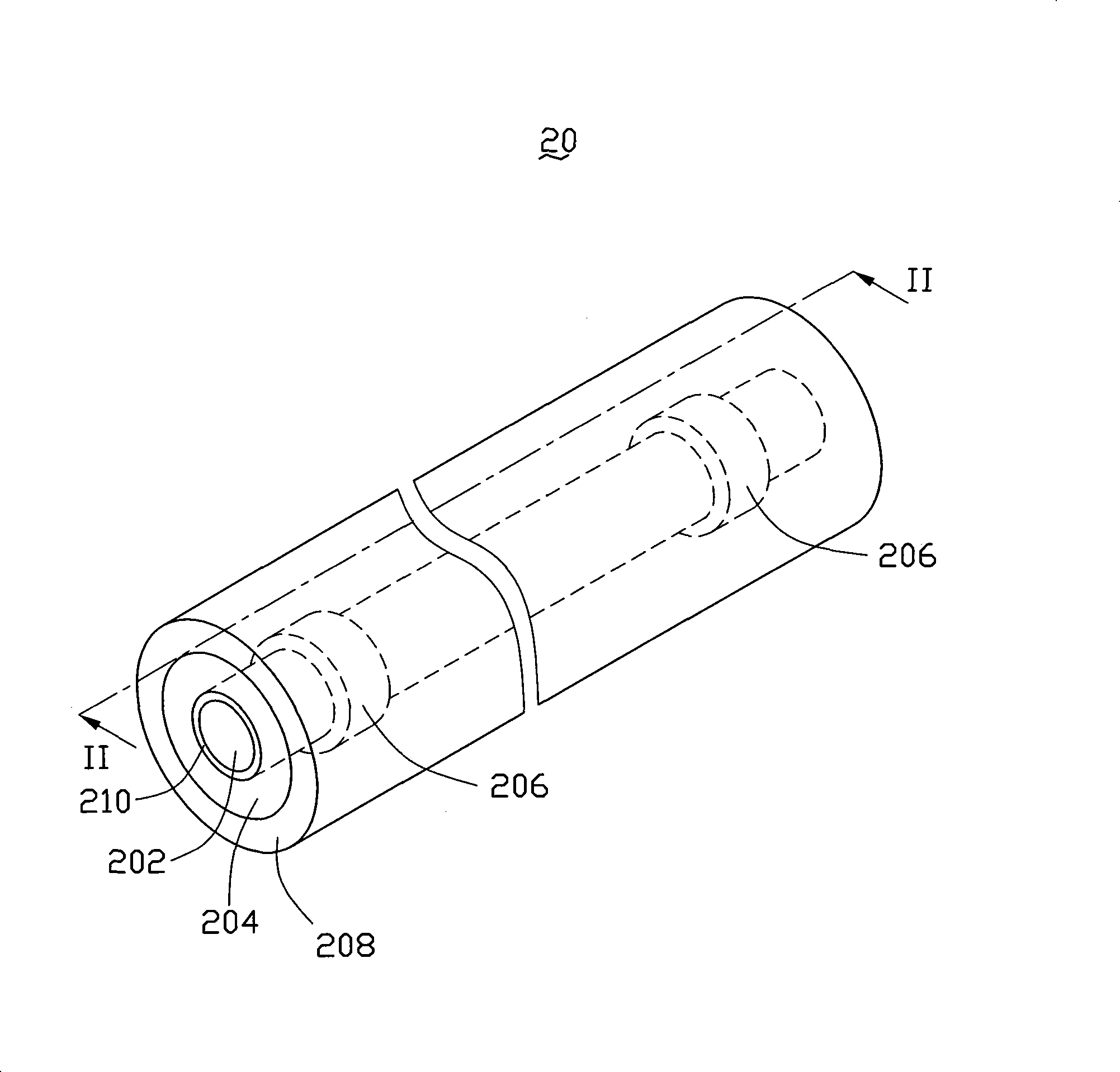

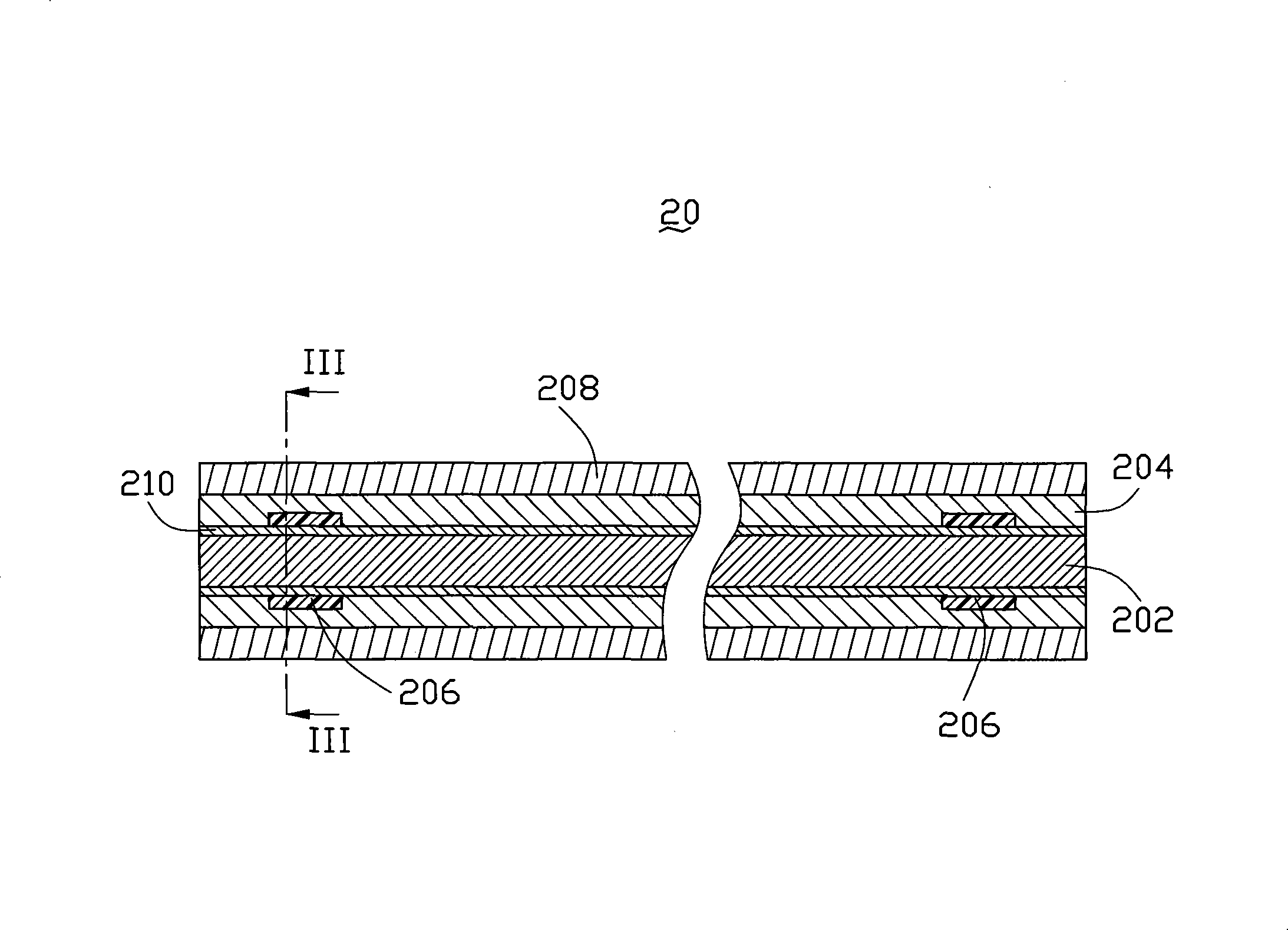

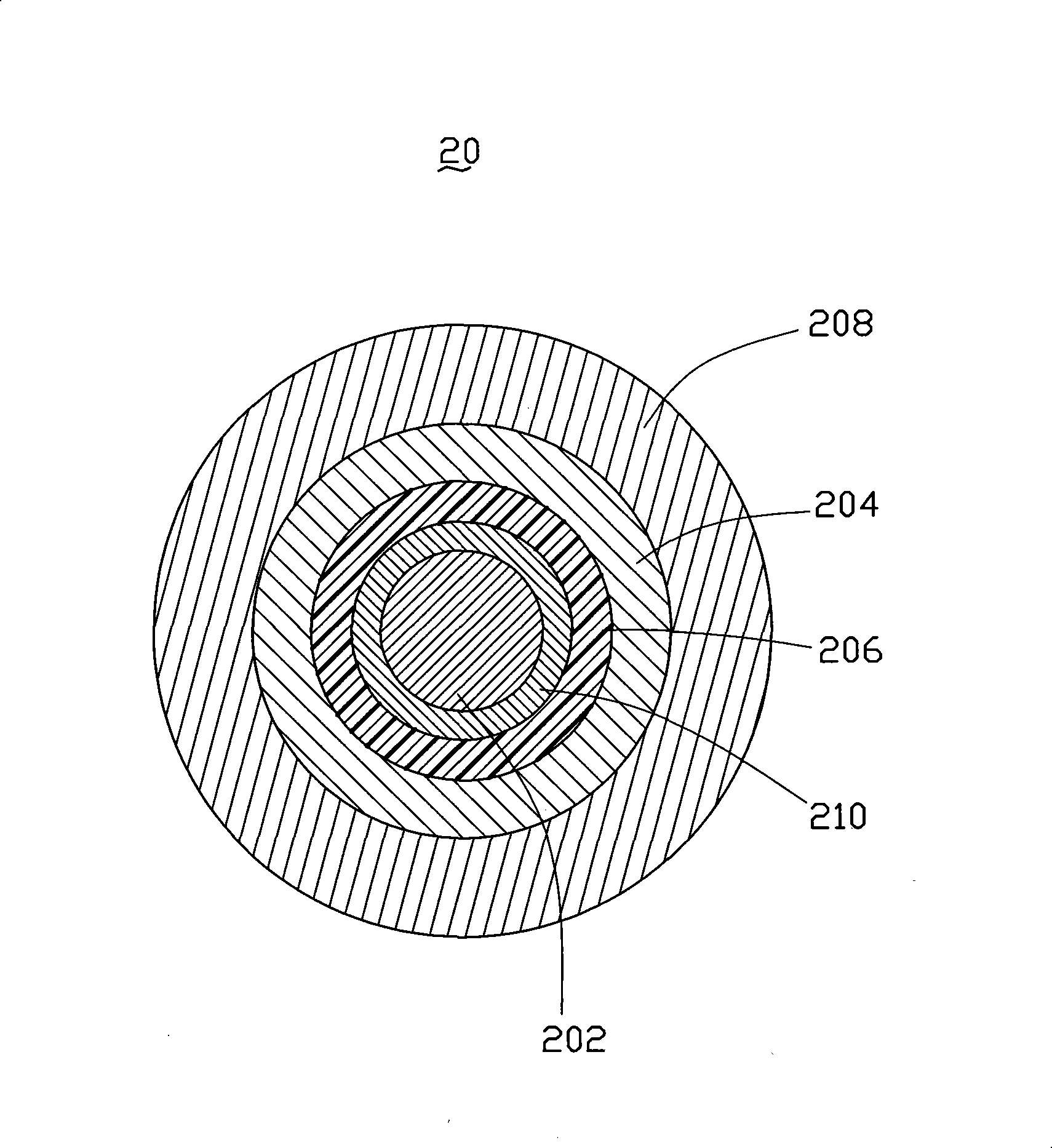

The invention relates to a line heat source, which comprises a linear support structure, a heating element arranged on the surface of the linear support structure and at least two electrodes arranged at intervals, the at least two electrodes are electrically connected with the heating element, wherein the heating element comprises at least one carbon nanotube film, and carbon nanotubes in the same carbon nanotube film are arranged by preferred orientation along the same direction.

Owner:TSINGHUA UNIV +1

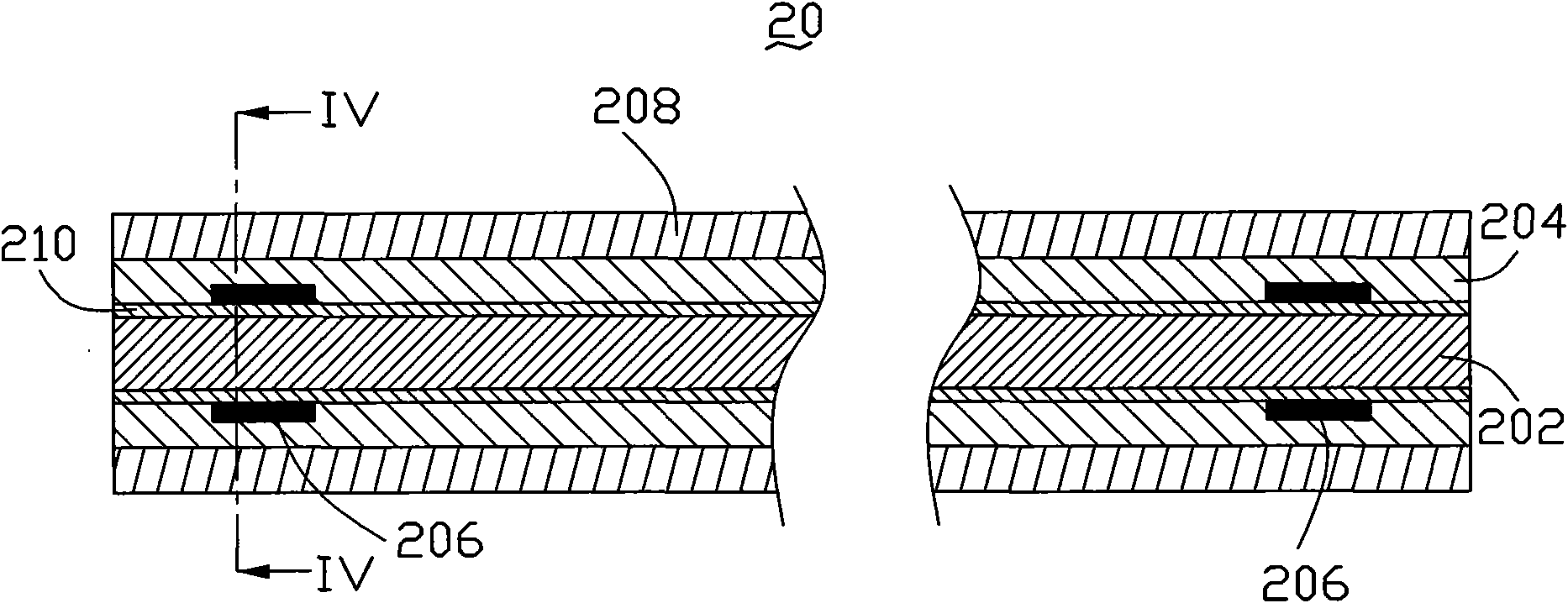

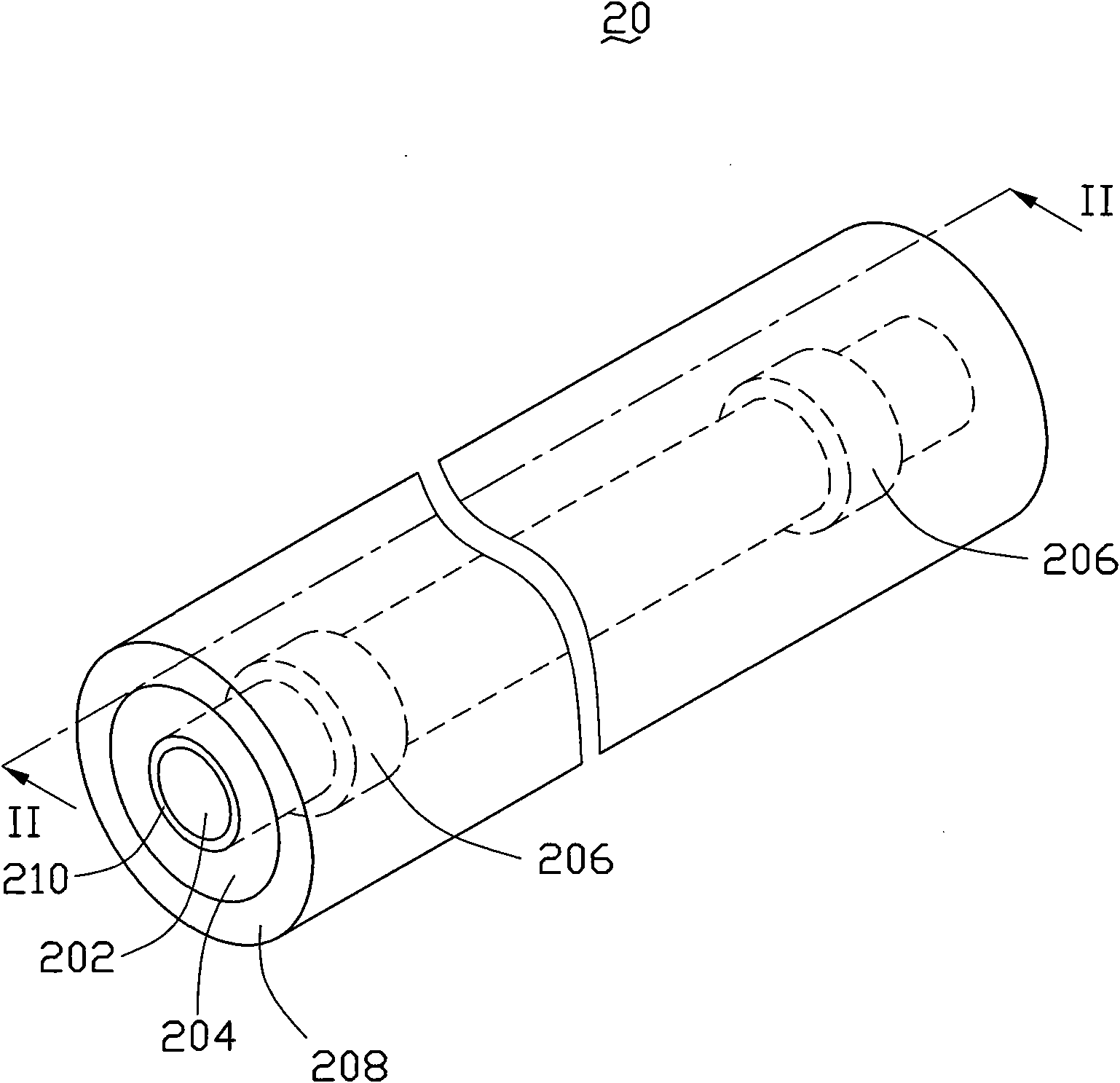

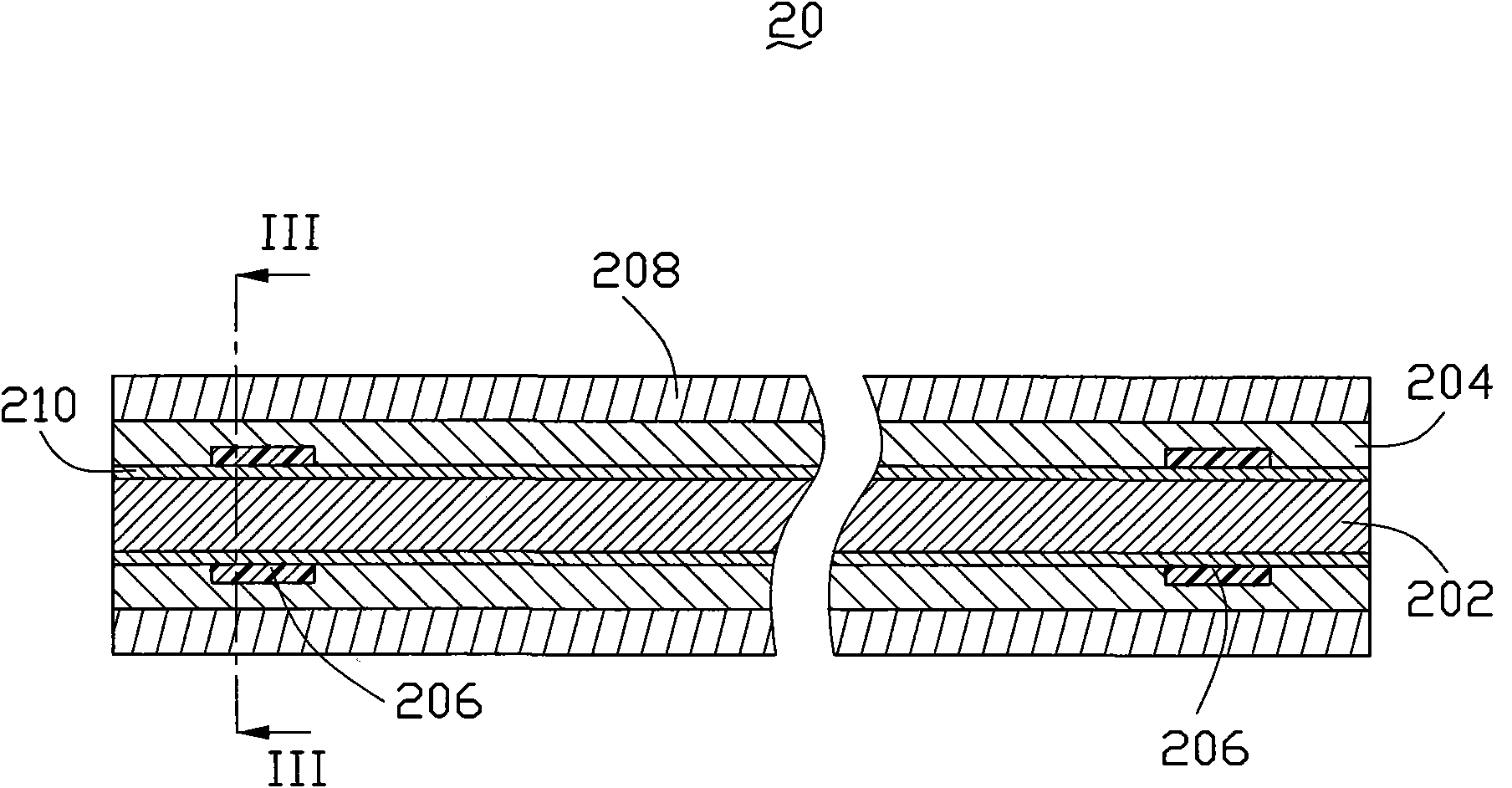

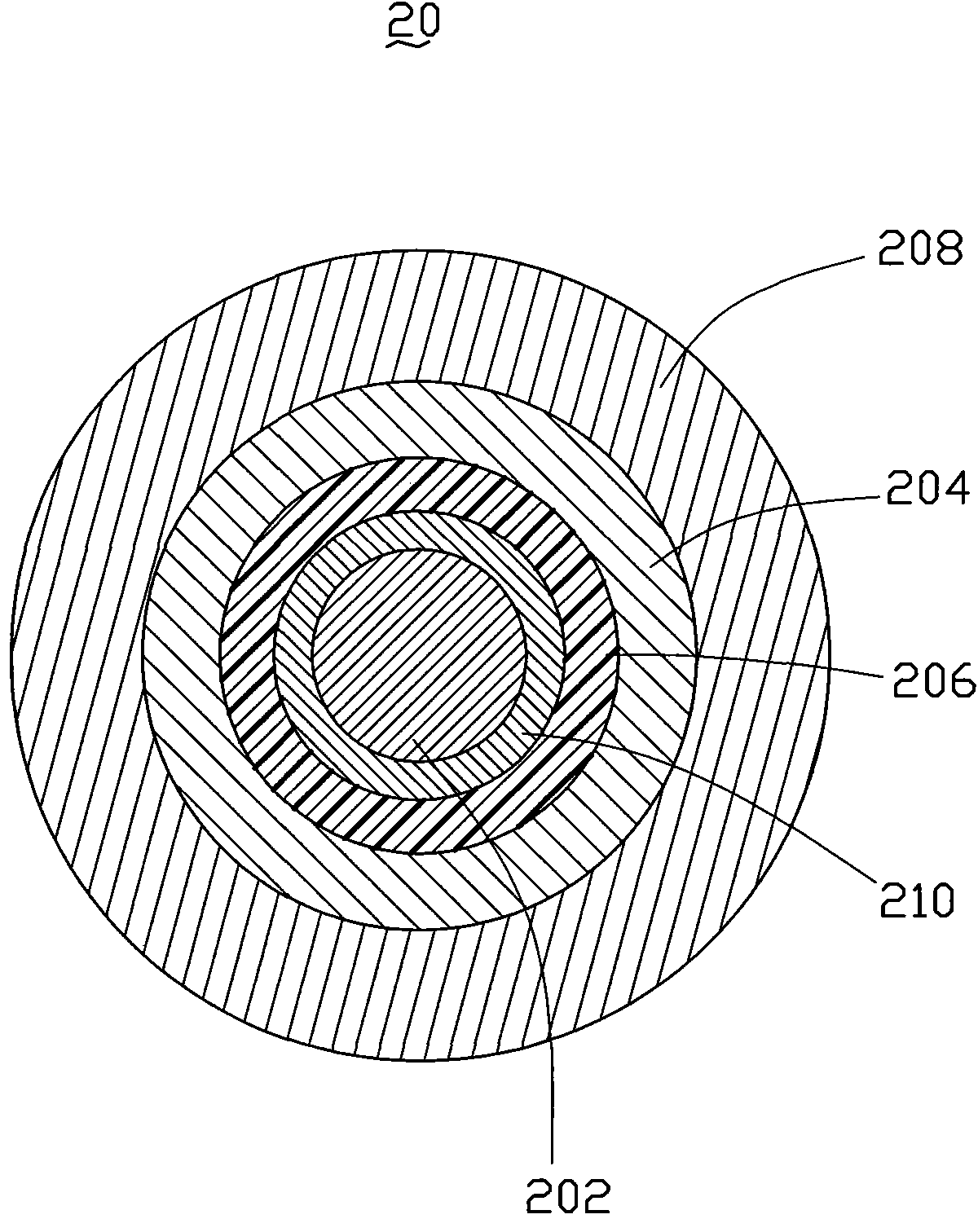

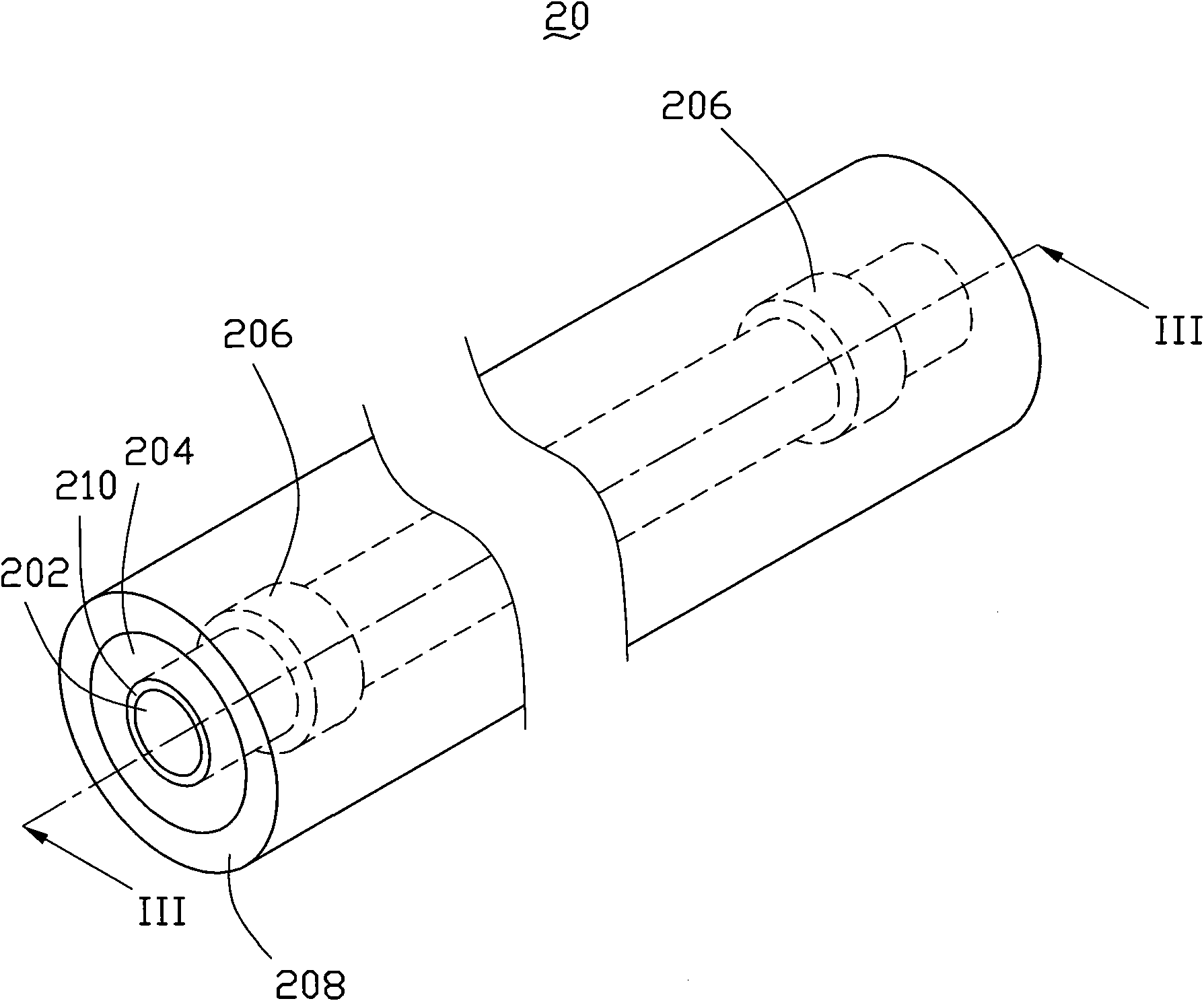

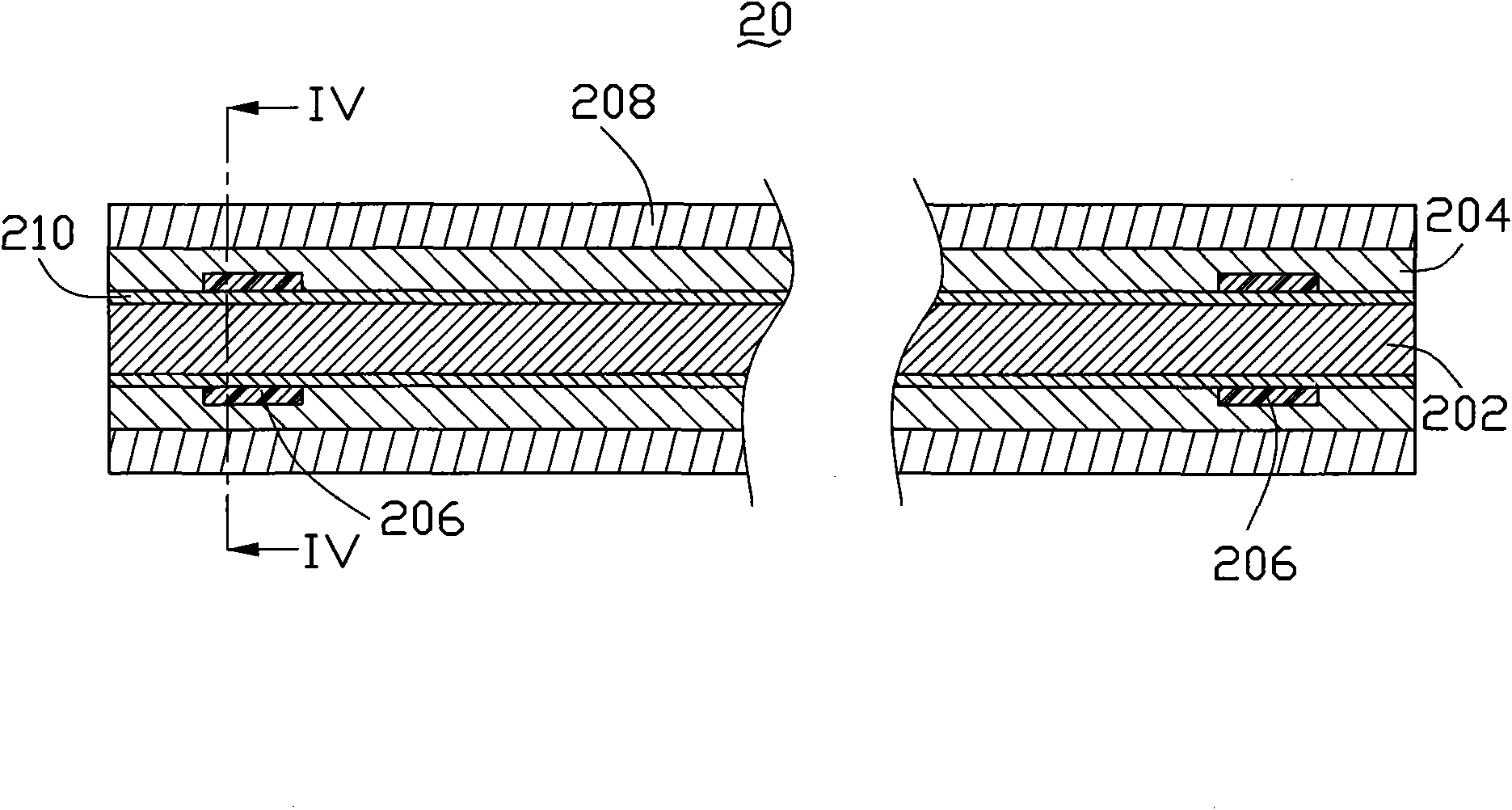

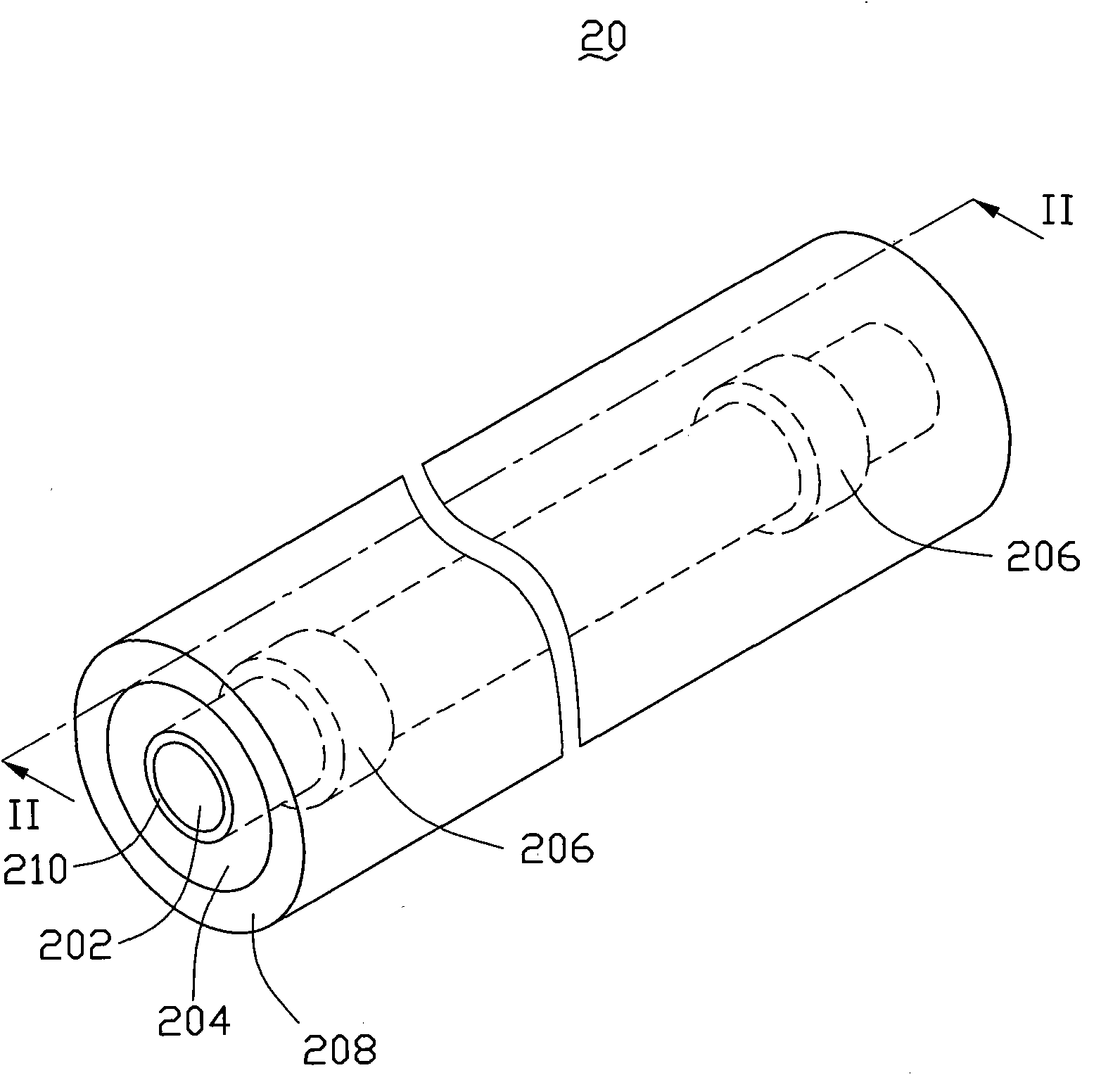

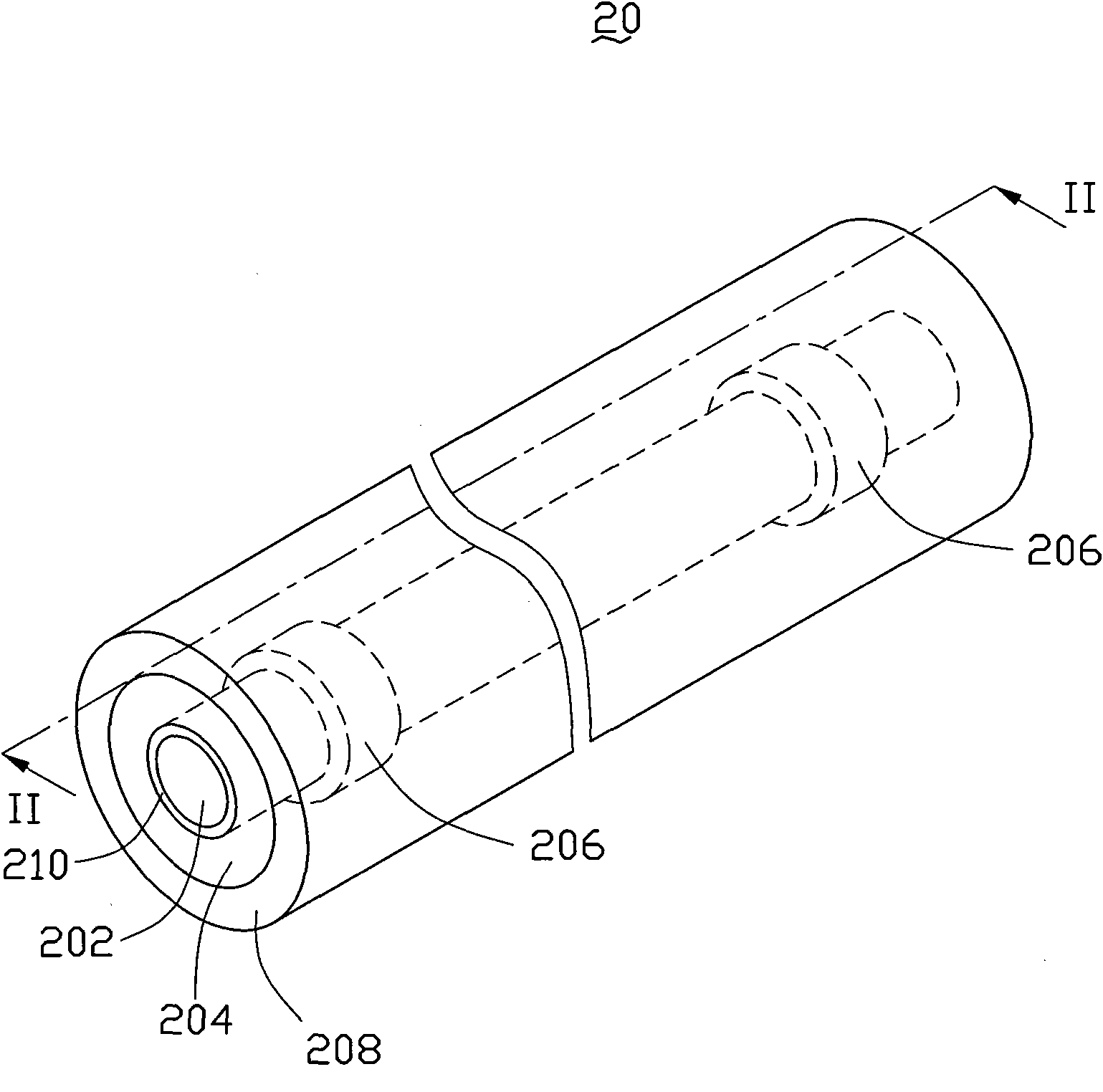

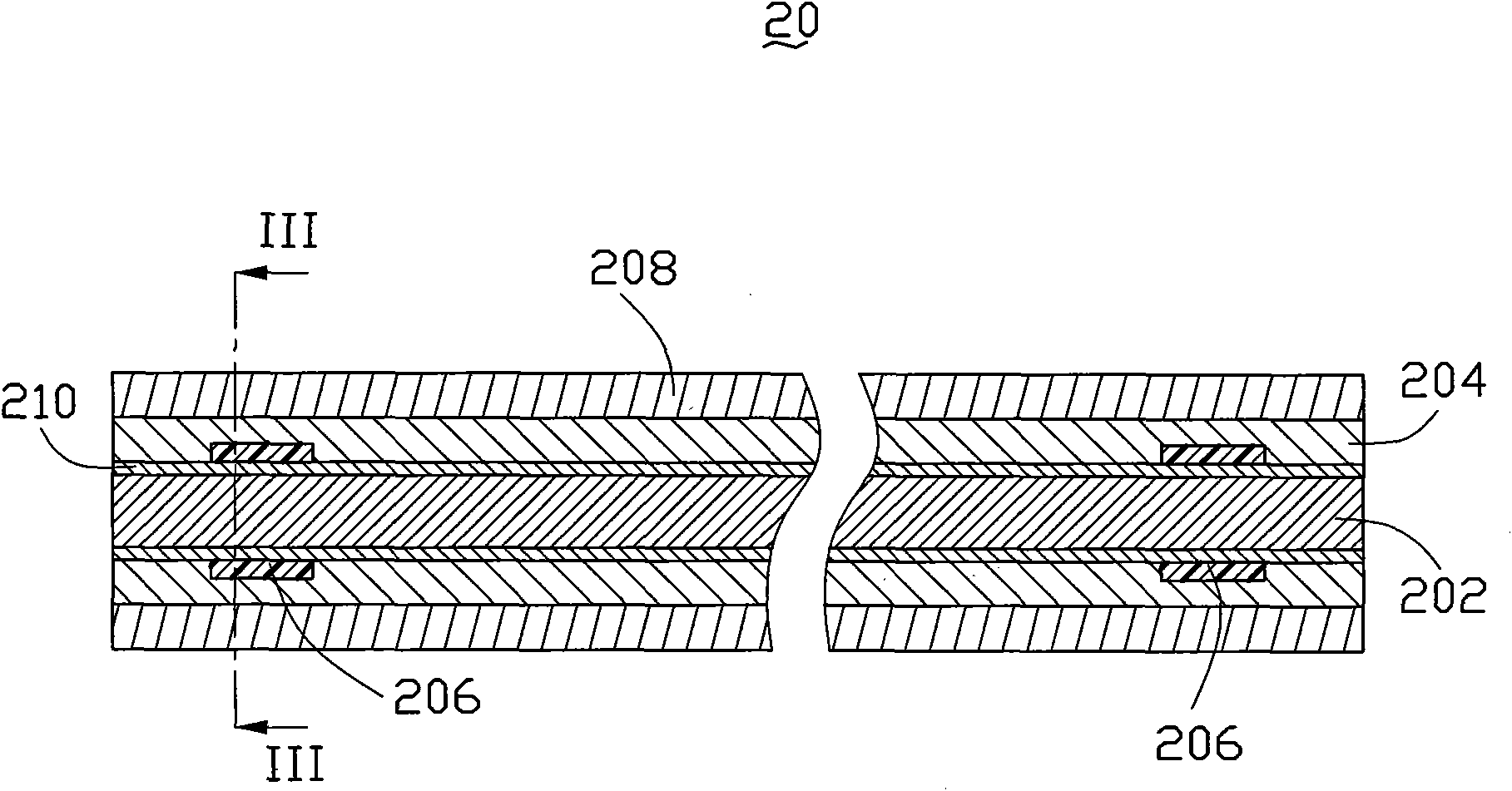

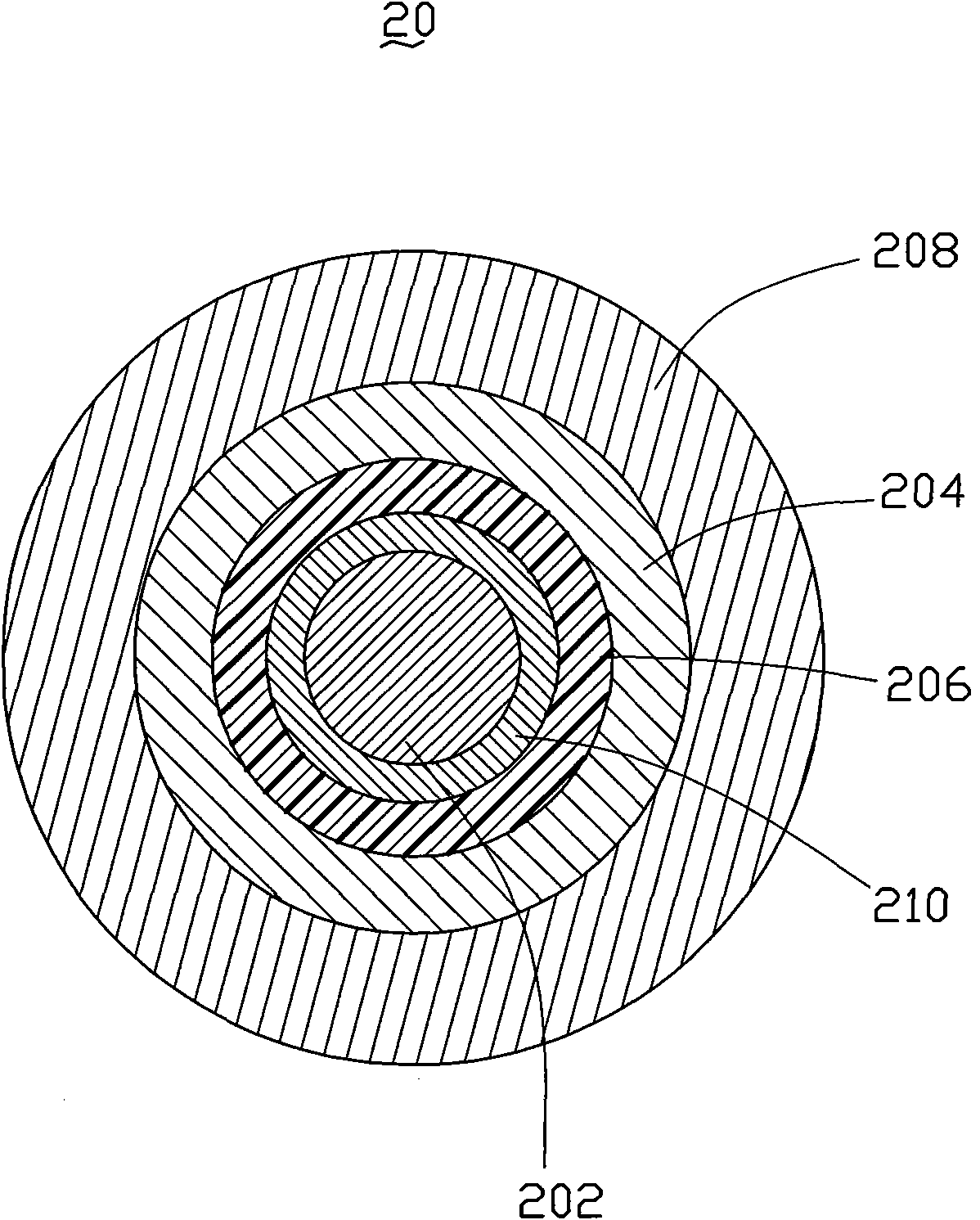

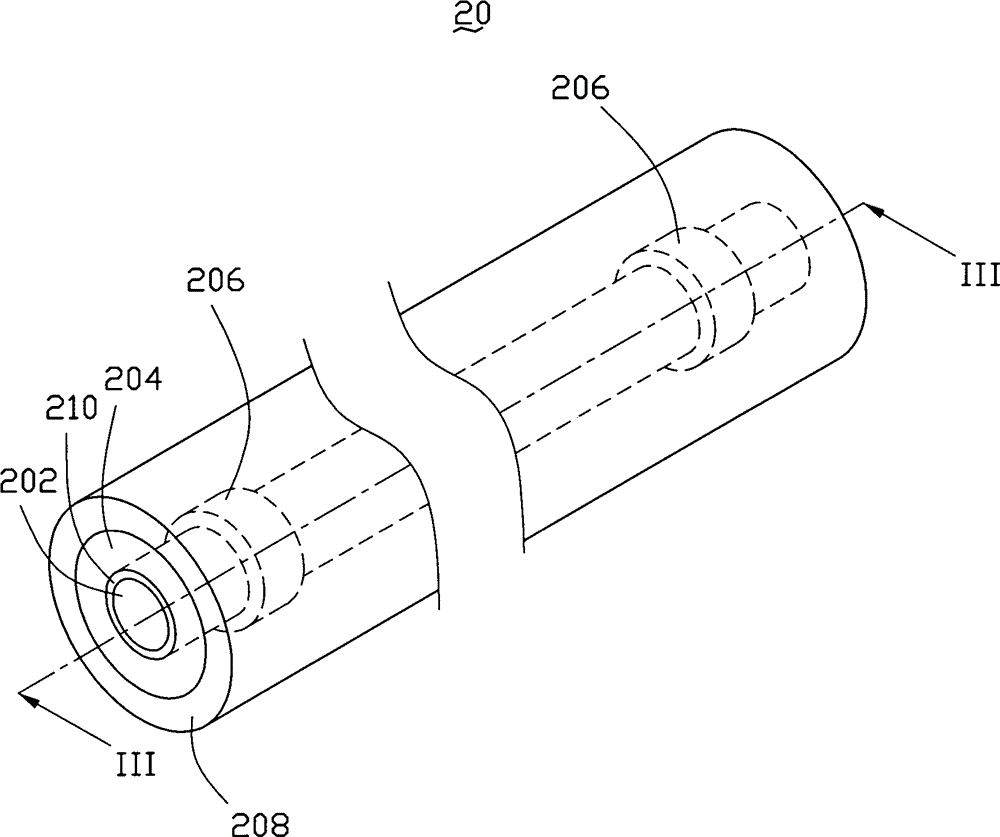

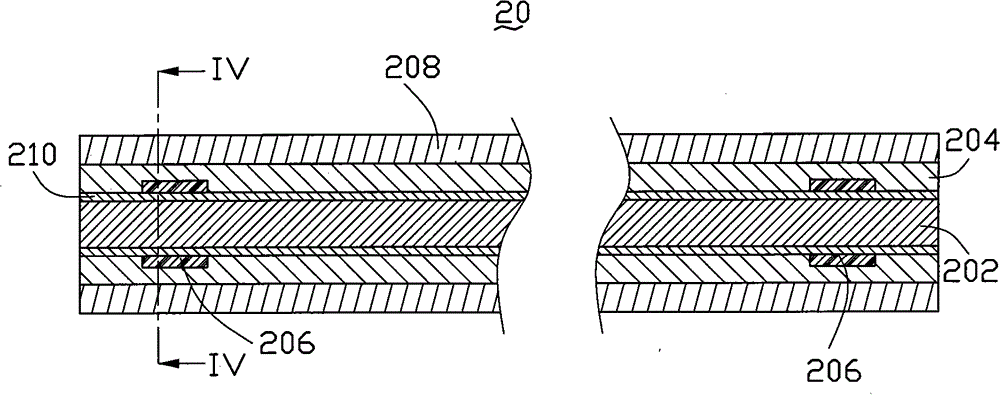

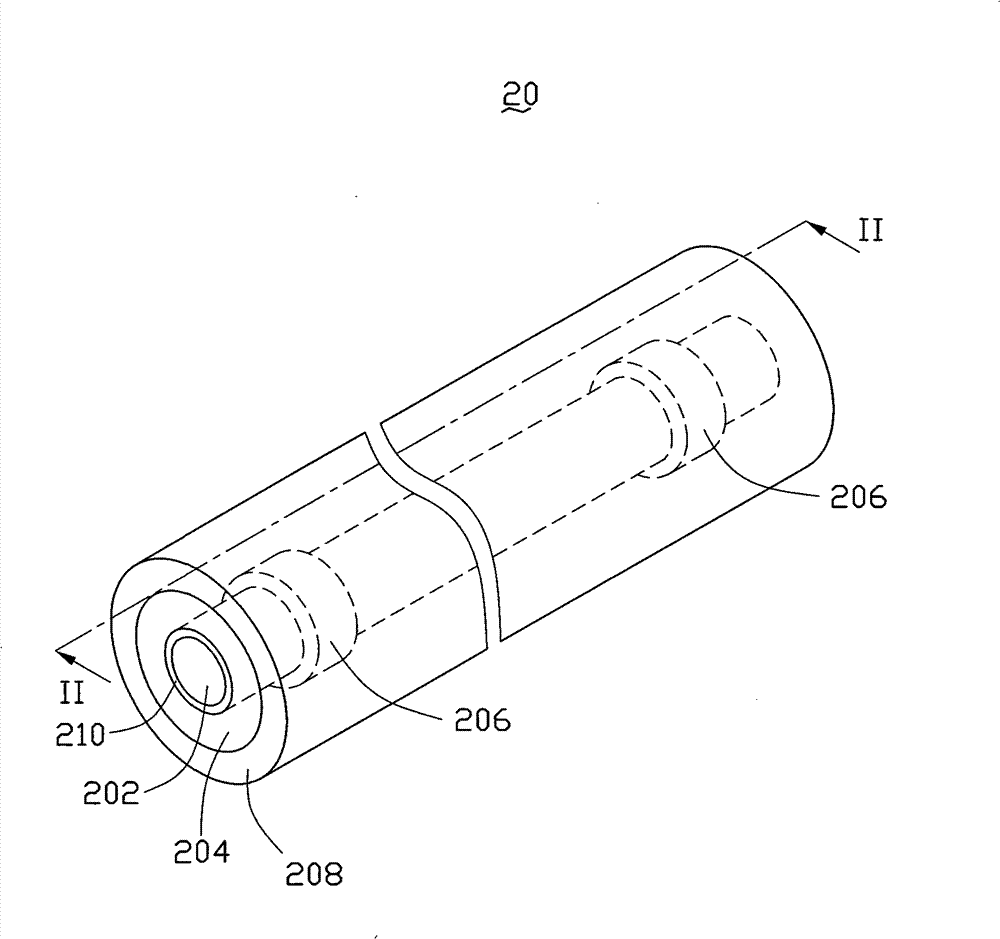

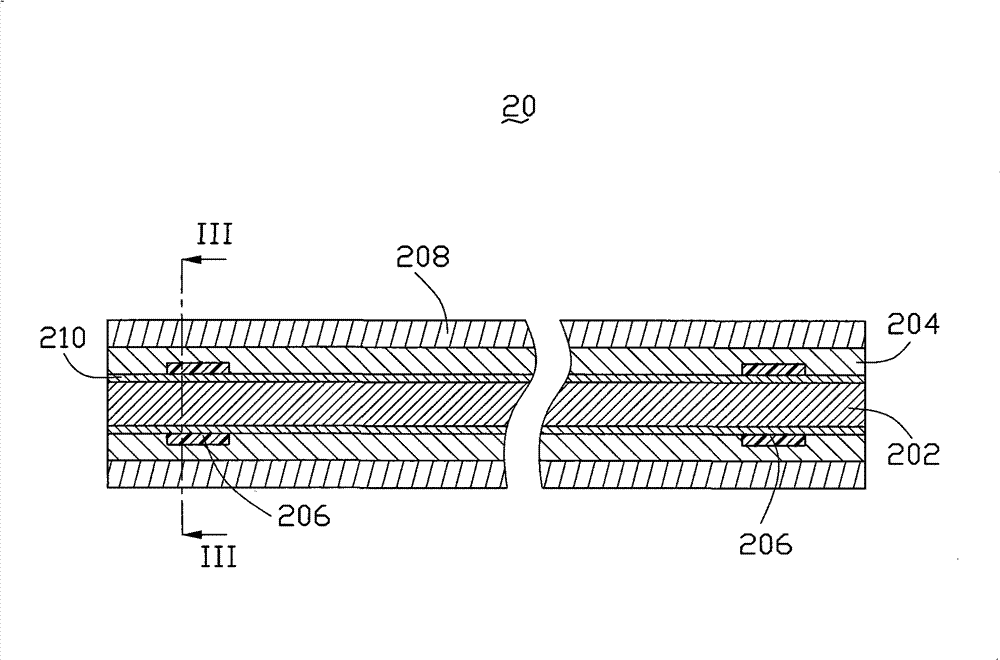

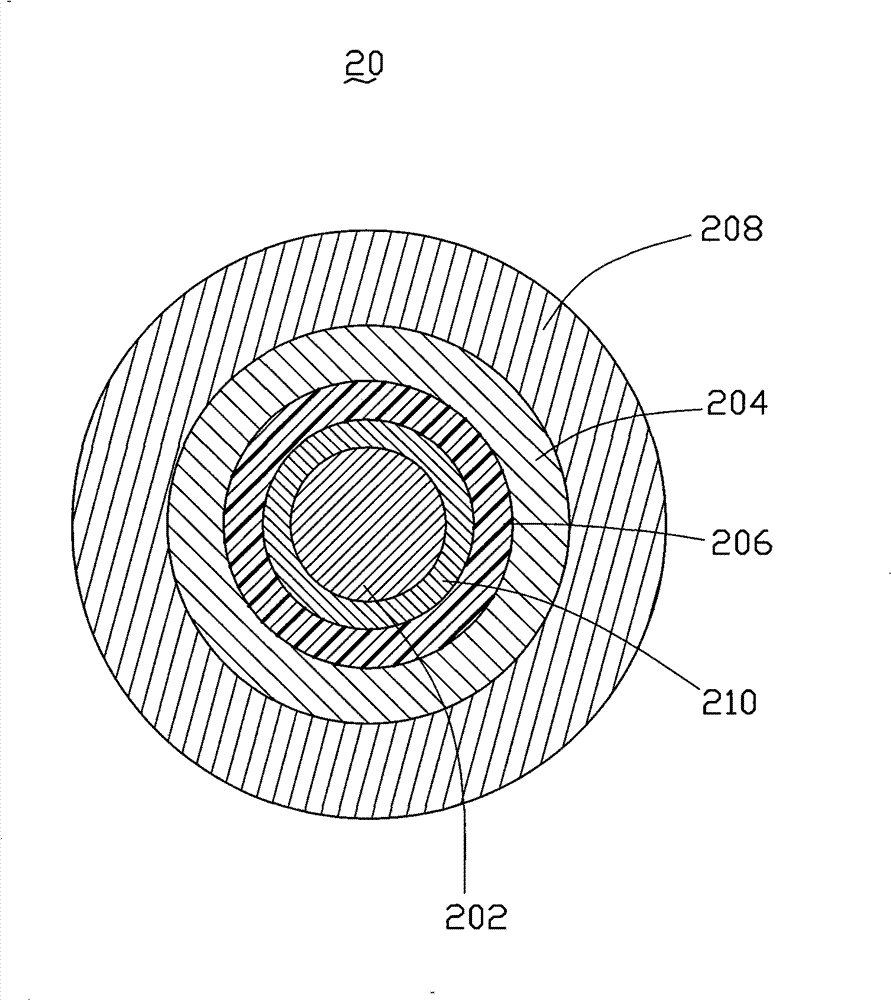

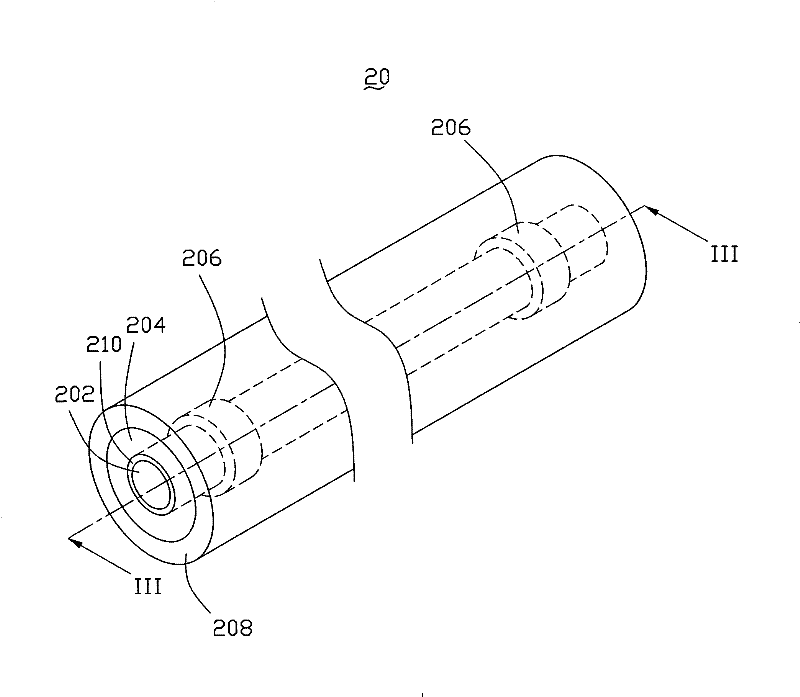

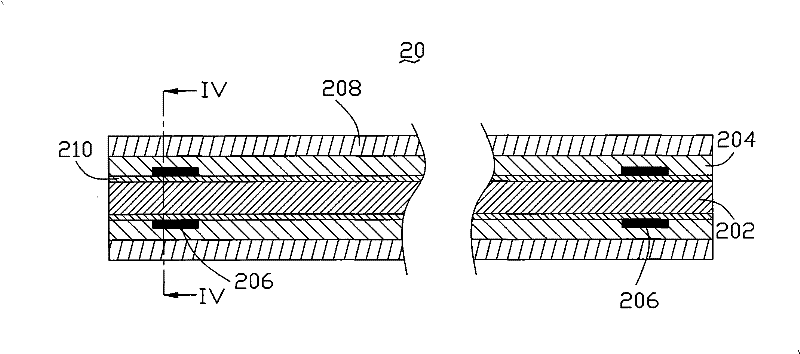

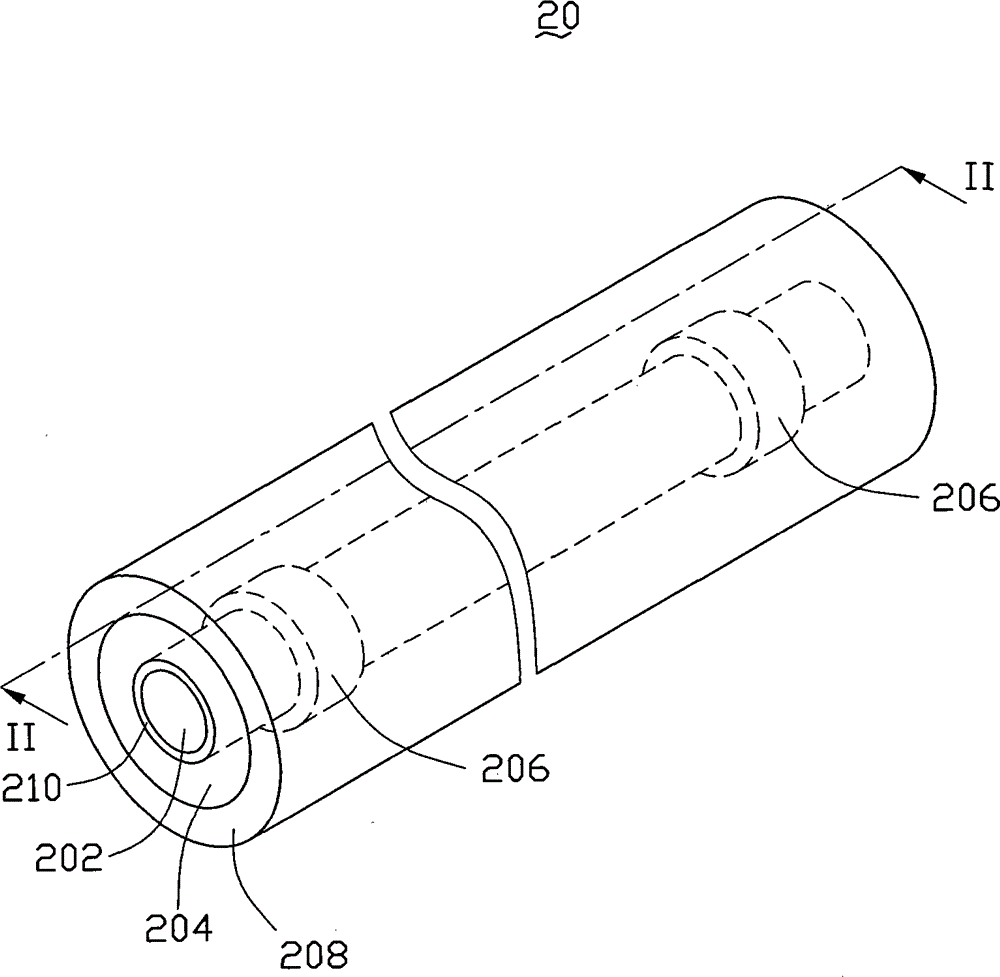

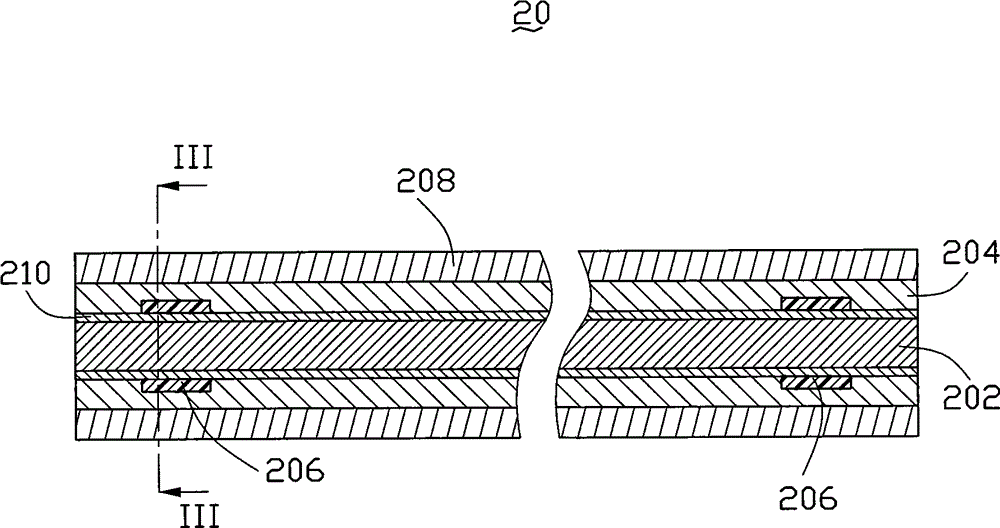

Line heat source

ActiveCN101868073AHigh mechanical strengthHigh mechanical toughnessIndividual molecule manipulationHeating element shapesElectricityNanometre

The invention relates to a line heat source comprising a line-shaped supporting structure, a heating element arranged at the surface of the line-shaped supporting structure and two electrodes, wherein the two electrodes are arranged at intervals and are electrically connected with the heating element, the heating element comprises at least one carbon nano pipe composite structure, the carbon nanopipe composite structure comprises a basal body and a carbon nano pipe membrane structure compounded in the basal body, and the carbon nano pipe membrane structure comprises a plurality of carbon nano pipes which are mutually wound. The line heat source can be used for manufacturing heating clothes, heating gloves or heating shoes with spontaneous heating, an electric heater, an infrared therapeutic apparatus, an electric room heater and the like and has extensive application range.

Owner:TSINGHUA UNIV +1

Line heat source

InactiveCN101868071AHigh mechanical strengthHigh mechanical toughnessIndividual molecule manipulationHeating element shapesElectricityLine heat source

The invention relates to a line heat source comprising a line-shaped supporting structure, a heating element arranged at the surface of the line-shaped supporting structure and two electrodes, wherein the two electrodes are arranged at intervals and are electrically connected with the heating element, the heating element comprises at least one carbon nano pipe composite structure, the carbon nano pipe composite structure comprises a basal body and a carbon nano pipe membrane structure compounded in the basal body, and the carbon nano pipe membrane structure comprises a plurality of carbon nano pipes which are optimally orientated and arranged along a fixed direction or different directions. The line heat source can be used for manufacturing heating clothes, heating gloves or heating shoes with spontaneous heating, an electric heater, an infrared therapeutic apparatus, an electric room heater and the like and has extensive application range.

Owner:TSINGHUA UNIV +1

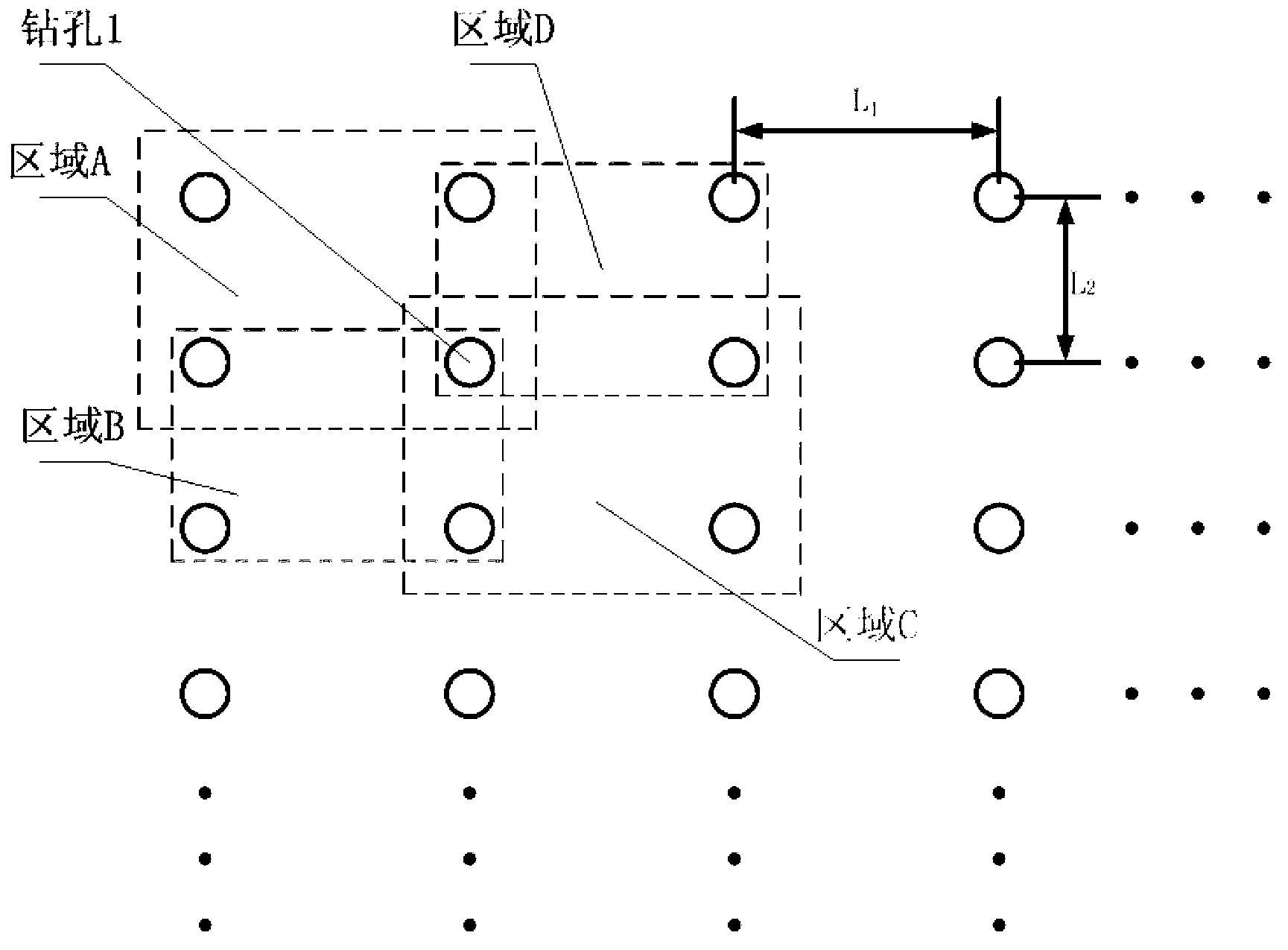

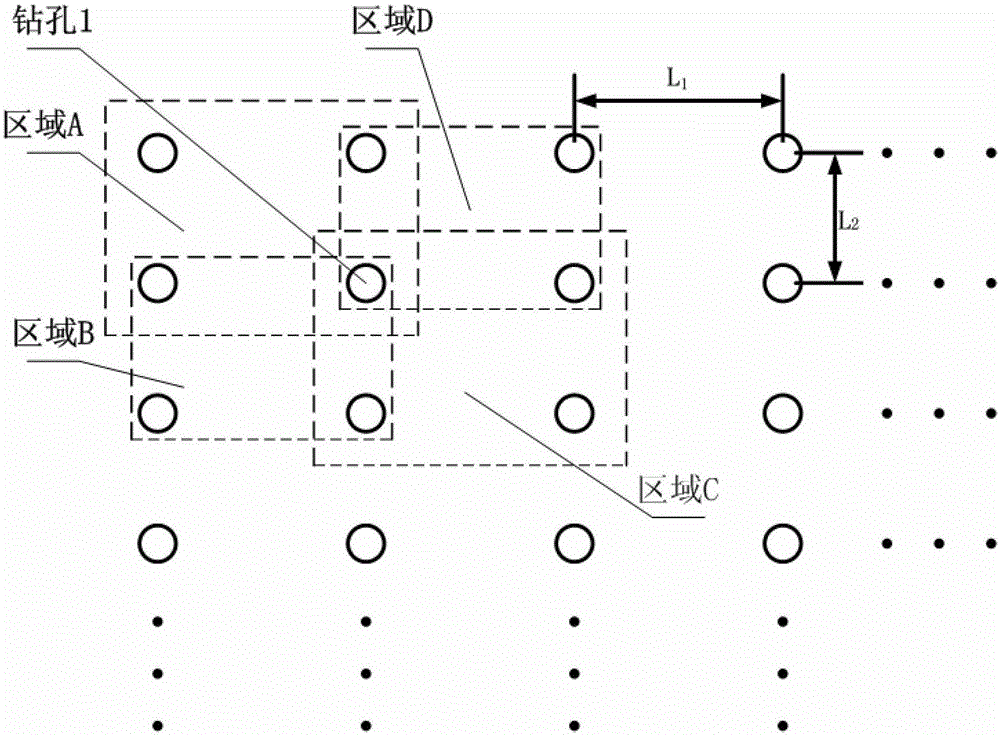

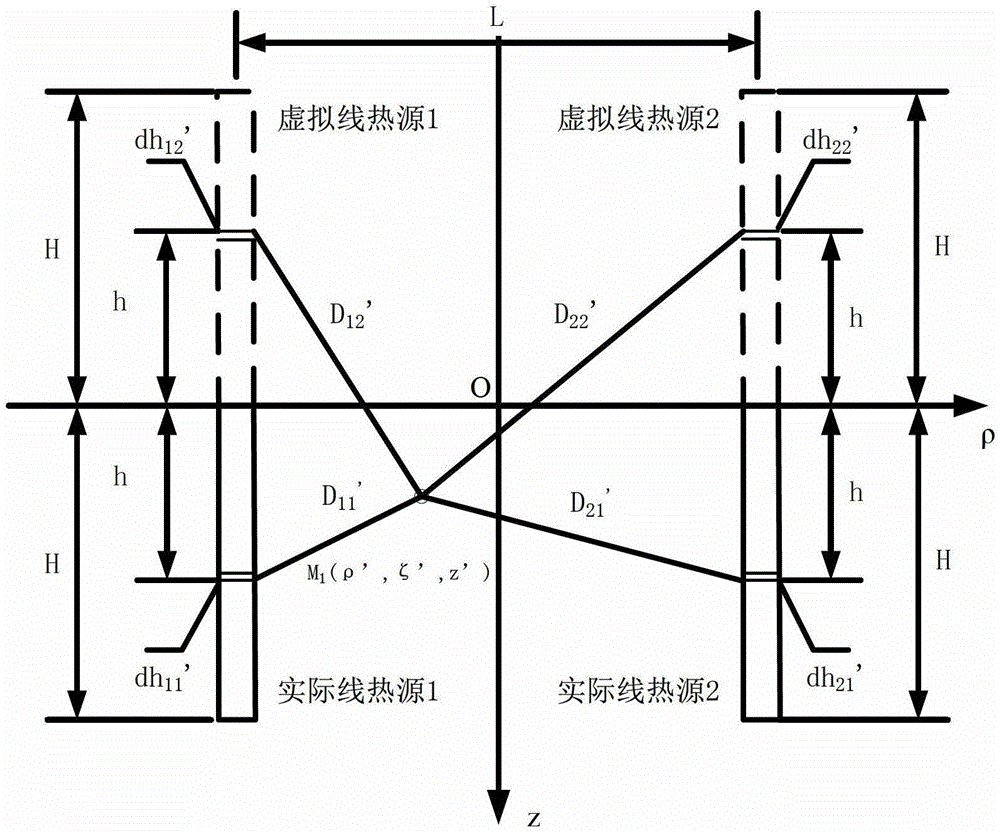

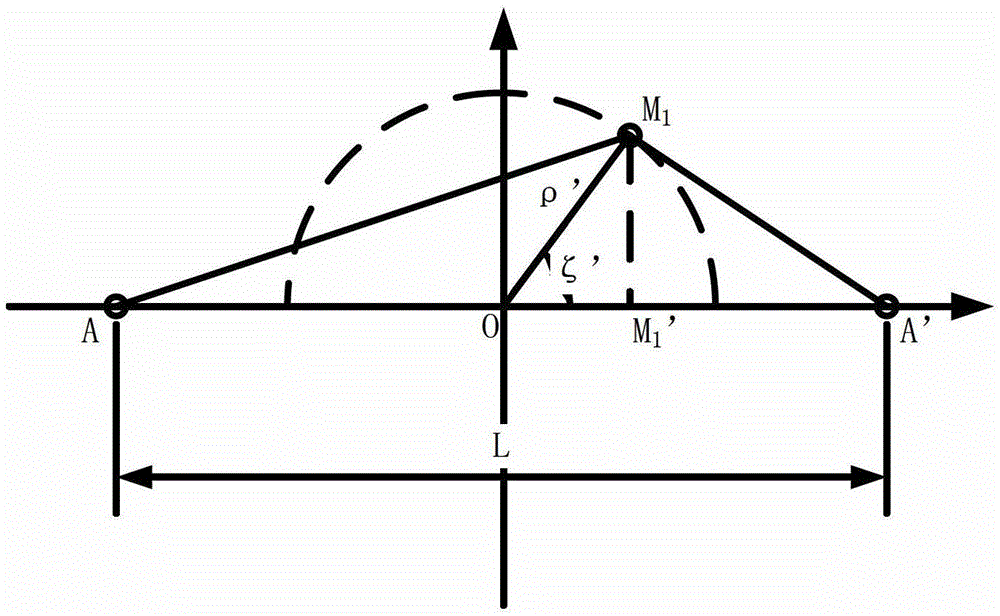

Hole wall representation temperature based simulation design method for drill hole space

InactiveCN103235860AWeaken the effect of "thermal interference"Improve heat transfer efficiencySpecial data processing applicationsEngineeringLine heat source

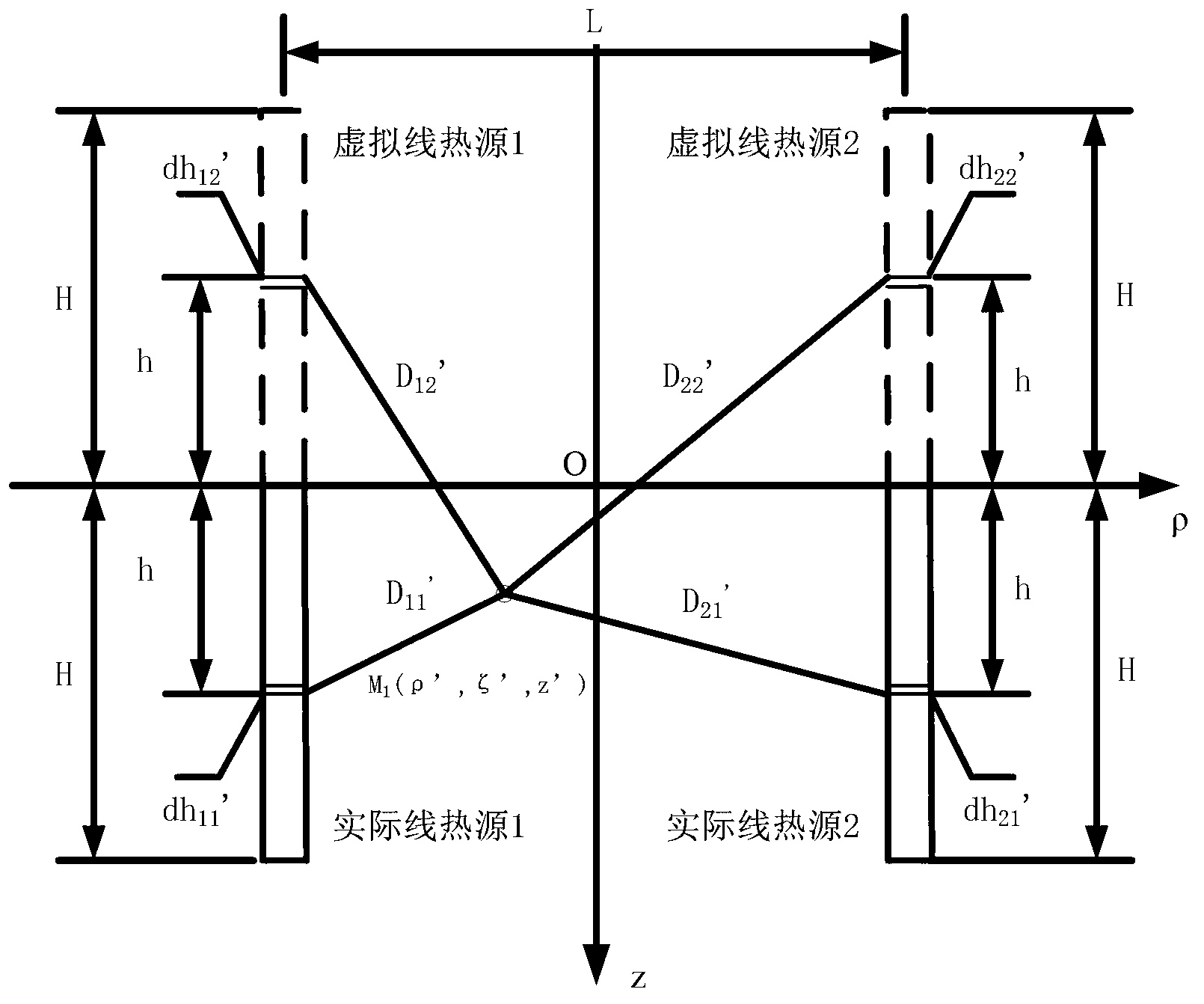

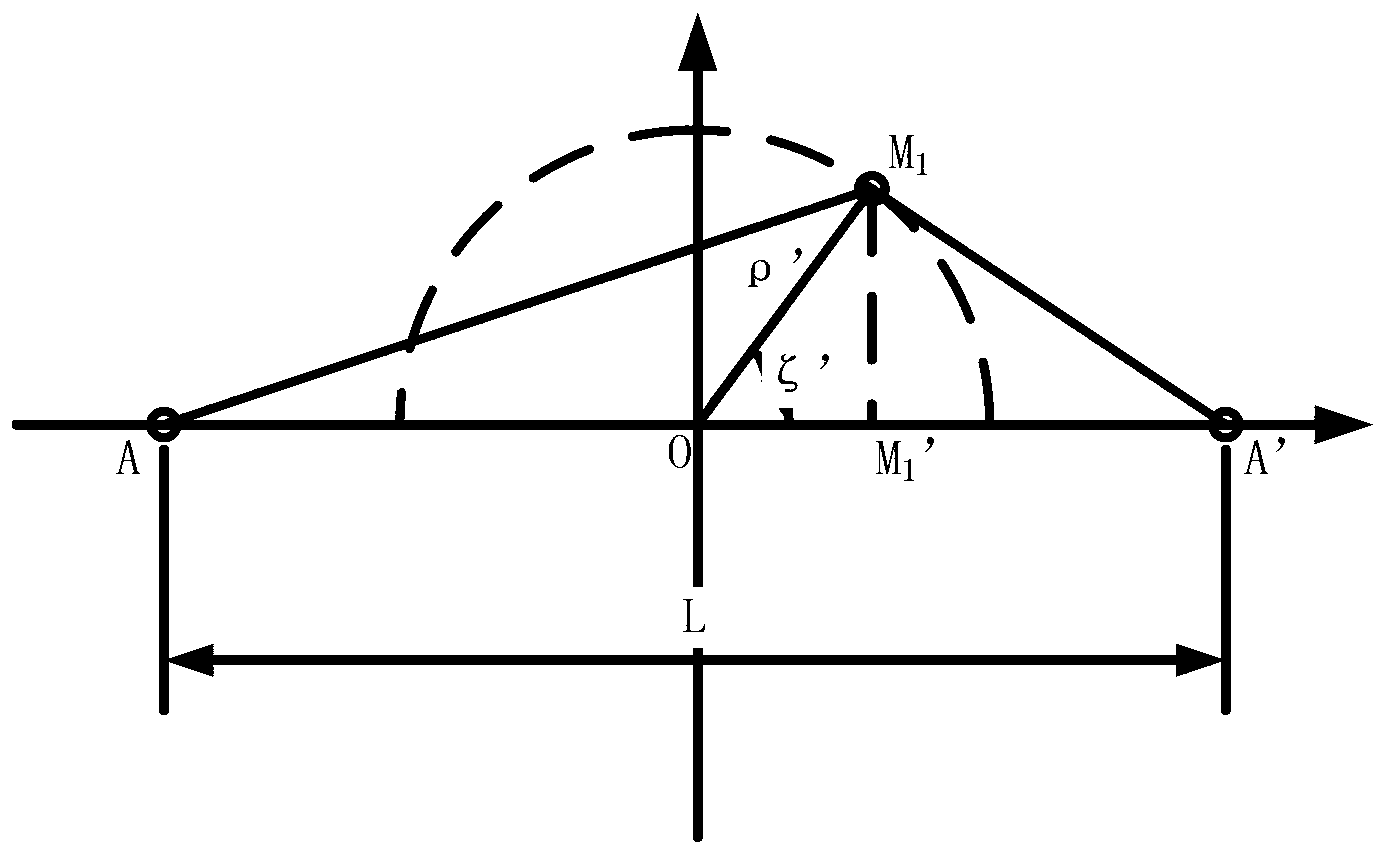

The invention discloses a hole wall representation temperature based simulation design method for drill hole space and belongs to the field of drill hole space design in the geothermal technology. The simulation design method is characterized in that the method comprises arbitrarily selecting four adjacent drill holes with perpendicular U-shaped buried pipes arranged inside from a drill hole group to form a four-drill-hole region, which is also called a unit drill hole group region; dividing the region into two double-drill-hole sub-regions from a horizontal direction, calculating a general formula for a transient temperature of a point M1 under a cylindrical coordinate system of the double-drill-hole sub-regions; mapping the point M1 transversely onto a vertically contacted virtual line heat source or actual line heat source to obtain the hole wall representation temperature Tb1 under the double drill holes; calculating the hole wall representation temperature Tb2 by transverse mapping of middle point M2 in the four-drill-hole region onto the virtual line heat source or the actual line heat source in the same way; setting thresholds of hole wall representation temperature change rates P1 and P2 of the double-drill-hole sub-regions and the four-drill-hole region as P1MAX and P2MAX successively; and calculating L1OPT and L2OPT in a threshold range successively through multiple times of iteration to obtain an optimal value of the drill hole space. According to the simulation design method, contradictions between the drill hole space and the heat exchanging efficiency are solved, the problem of slow calculation speed is solved under the condition that the accuracy is guaranteed, and the drill hole space and the hole wall representation temperature are balanced.

Owner:BEIJING UNIV OF TECH

Line heat source

ActiveCN101868070AHigh mechanical strengthHigh mechanical toughnessIndividual molecule manipulationHeating element shapesElectricityLine heat source

The invention relates to a line heat source comprising a line-shaped supporting structure, a heating element arranged at the surface of the line-shaped supporting structure and two electrodes, wherein the two electrodes are arranged at intervals and are electrically connected with the heating element, the heating element comprises at least one carbon nano pipe composite structure, and the carbon nano pipe composite structure comprises a basal body and a carbon nano pipe structure compounded in the basal body. The line heat source can be used for manufacturing heating clothes, heating gloves or heating shoes with spontaneous heating, an electric heater, an infrared therapeutic apparatus, an electric room heater and the like and has extensive application range.

Owner:TSINGHUA UNIV +1

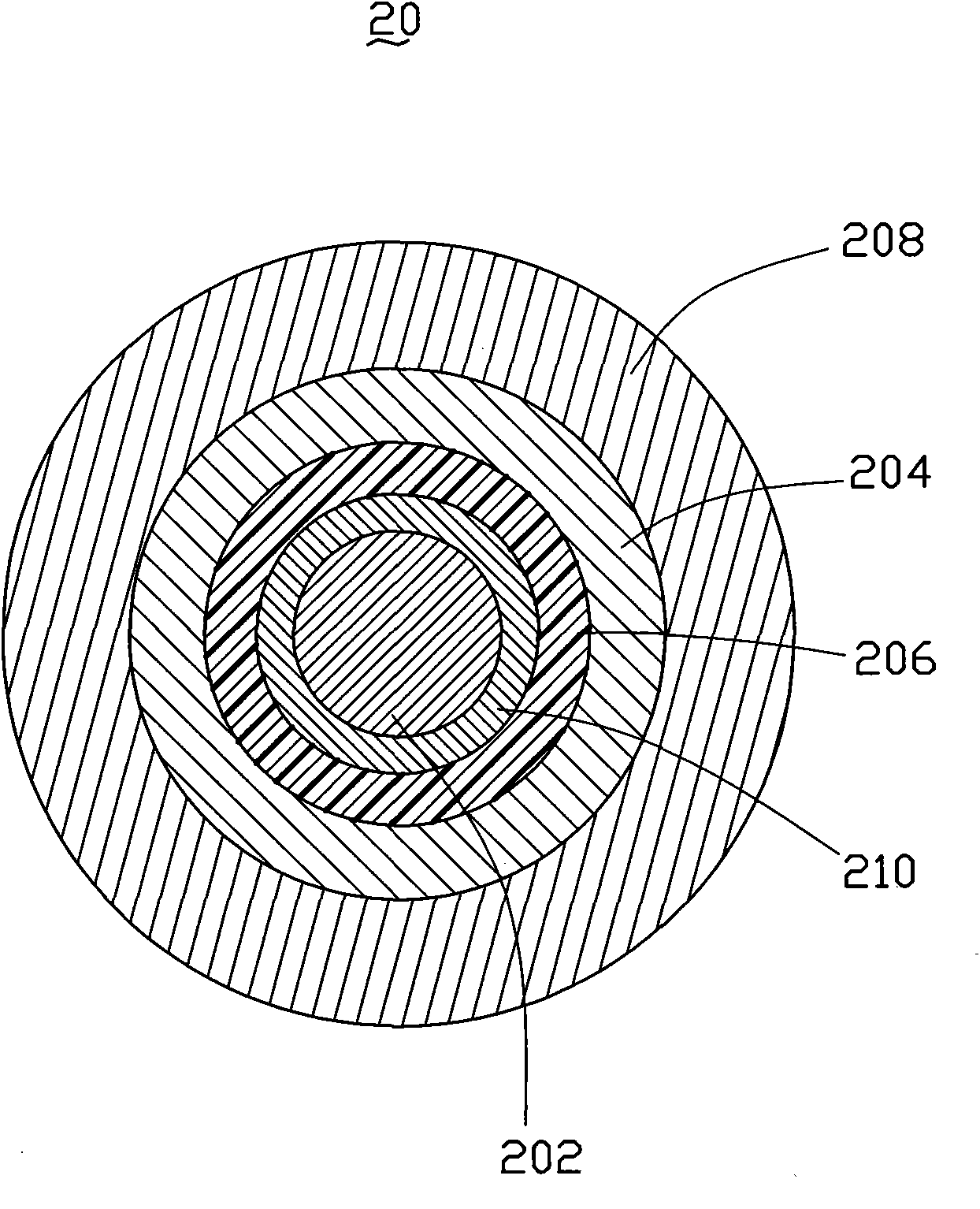

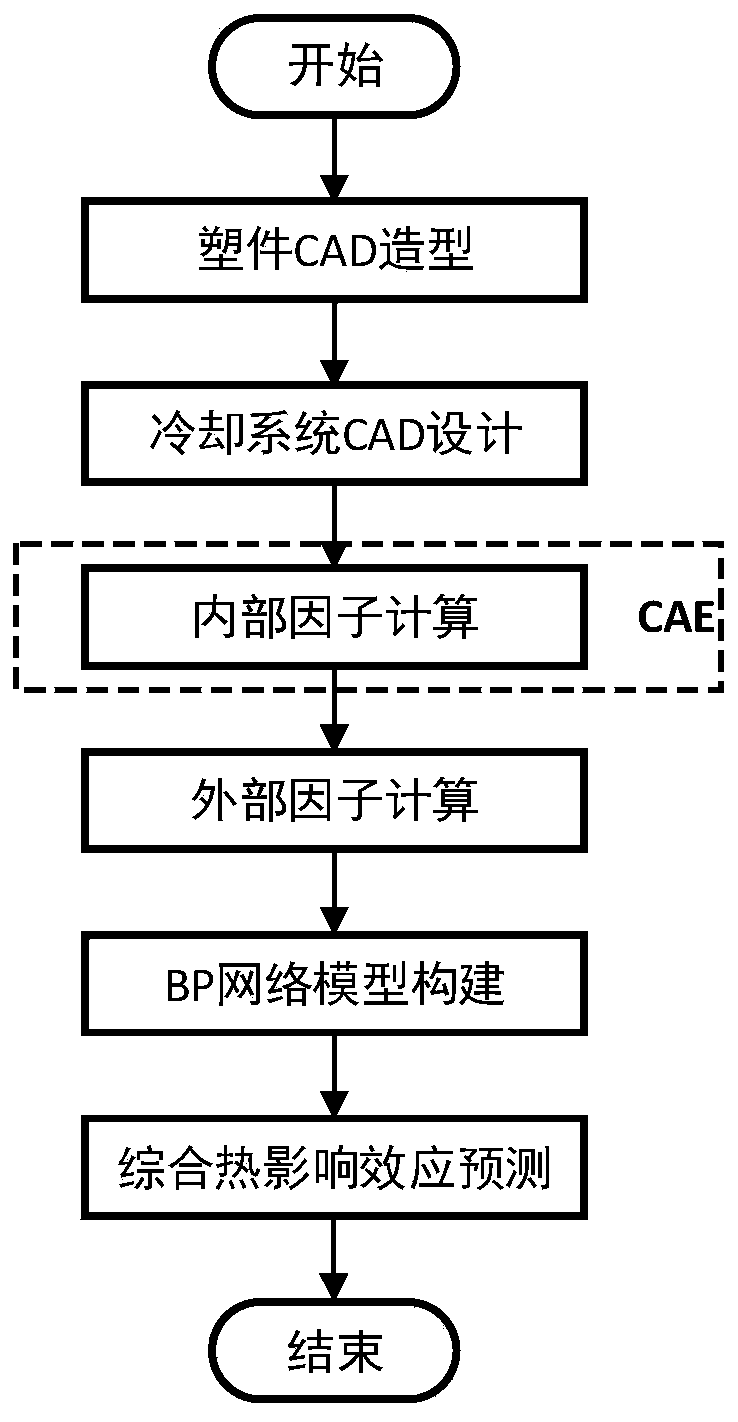

Online analysis method and equipment for injection mold cooling system

ActiveCN111444619ARealize computingThe number of iteration calculations is reducedDesign optimisation/simulationNeural learning methodsThermodynamicsCooling effect

The invention belongs to the field of mold design and evaluation, and discloses an online analysis method and equipment for an injection mold cooling system. The method comprises the following steps:carrying out model cooling analysis on a mold and a plastic part under the condition of not considering a cooling system to obtain internal factors representing the influence of the internal factors on the cooling effect of the plastic part; introducing a finite-length continuous line heat source model of a constant-temperature boundary, and calculating an external factor representing the influence of the external factor on the cooling effect of the plastic part; simulating the whole system model to obtain the cooling time of the plastic part, namely the comprehensive heat influence effect; establishing and training a neural network model of the internal factors, the external factors and the comprehensive heat influence effect; and during online analysis, recalculating the external factoraccording to the modified size and position data of the cooling pipeline, not recalculating the internal factor, and predicting the comprehensive heat influence effect by adopting the trained neural network model. The method is simple and easy to implement, and online analysis of the cooling system can be achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

Line heat source

ActiveCN101616516AReduce weightEasy to useIndividual molecule manipulationHeating element shapesElectricityCarbon nanotube

The invention relates to a line heat source. The line heat source comprises a linear support structure, a heating element which is arranged on the surface of the linear support structure, and two electrodes which are arranged at interval and respectively connected with the heating element, wherein, the heating element comprises a carbon nanotube structure.

Owner:TSINGHUA UNIV +1

Preparation method of line heat source

ActiveCN101868072AAvoid breakingIndividual molecule manipulationHeating element shapesLine heat sourceNanotube

The invention relates to a preparation method of a line heat source, which concretely comprises the following steps of: providing a carbon nano pipe structure; providing a line-shaped supporting structure; arranging the carbon nano pipe structure at the surface of the line-shaped supporting structure; forming two electrodes at intervals and forming the electric connection of the two electrodes and the carbon nano pipe structure respectively; and providing a prefabricated body of a base material and compounding the prefabricated body of the base material and the carbon nano pipe structure to form a carbon nano pipe composite structure.

Owner:TSINGHUA UNIV +1

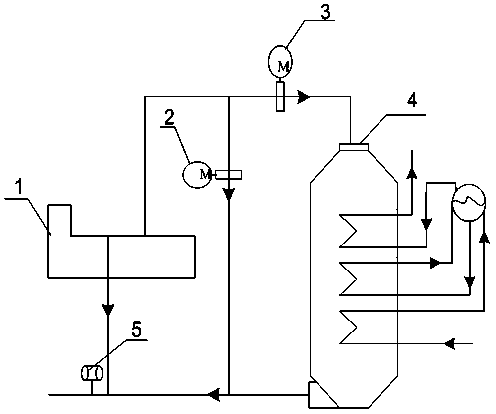

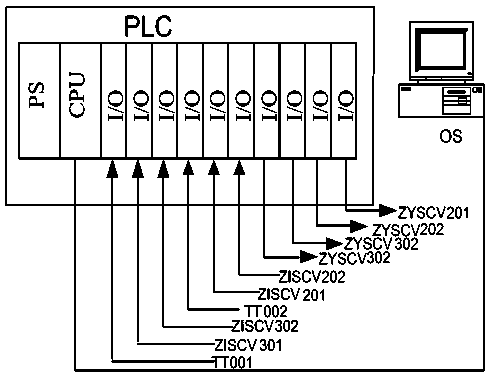

Method and device for controlling material drying temperature of cement production line with waste heat power generation

InactiveCN103759523AAvoid competing heat situationsGuaranteed uptimeDrying gas arrangementsIncreasing energy efficiencyComputer control systemProduction line

The invention discloses a method and a device for controlling the material drying temperature of a cement production line with a waste heat power generation. The method is characterized in that the opening of a kiln head and kiln tail bypass waste gas valve is controlled by temperature measured by a temperature sensor mounted at an inlet of a kiln head and kiln tail drying system. The device mainly comprises the temperature sensor, electric louver valves and a computer control system. The temperature sensor is mounted at a drying system inlet waste gas pipeline, one electric louver valve is mounted on a kiln tail waste gas bypass, the other electric louver valve is mounted at a boiler waste gas inlet, temperature signals and valve opening given and feedback signals are accessed to the computer control system, and the computer control system controls the opening of the waste gas bypass valve according to temperature signal change. Compared with past manual adjustment, the control device has the advantages that a clinker line and the waste heat power generation are prevented from fighting over heat sources, stability of a clinker line heat source is ensured, and operation difficulty of operators is reduced.

Owner:娄卡奔新能源科技发展(上海)有限公司

Line heat source

ActiveCN101868074AHigh mechanical strengthHigh mechanical toughnessIndividual molecule manipulationHeating element shapesElectricityCarbon nanotube

The invention relates to a line heat source comprising a heating element and two electrodes, wherein the two electrodes are arranged at intervals and are electrically connected with the heating element; and the heating element comprises at least one line-shaped carbon nano pipe composite structure, wherein the line-shaped carbon nano pipe composite structure comprises a basal body and at least one carbon nano pipe line-shaped structure compounded in the basal body. The line heat source can be used for manufacturing heating clothes, heating gloves or heating shoes with spontaneous heating, an electric heater, an infrared therapeutic apparatus, an electric room heater and the like and has extensive application range.

Owner:TSINGHUA UNIV +1

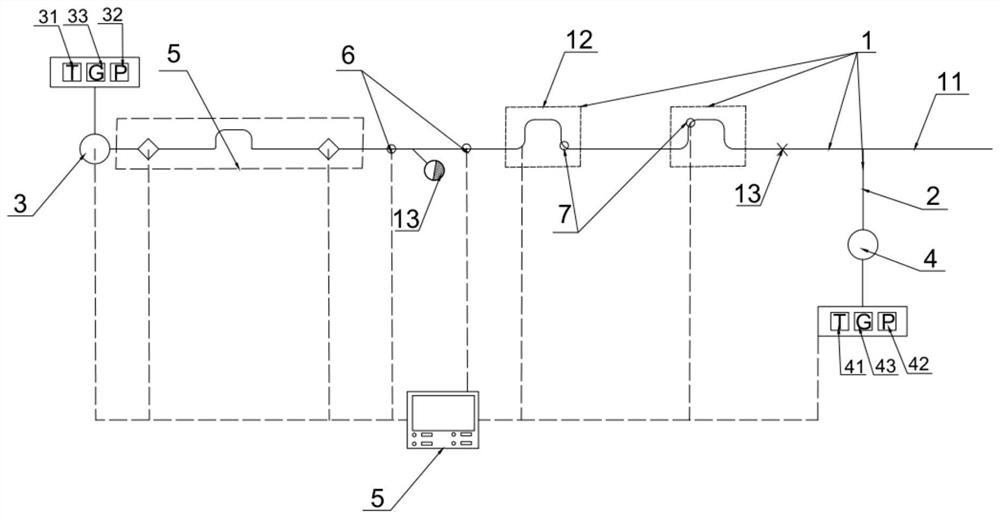

Comprehensive detection and evaluation system and method for heat dissipation loss characteristics of overhead steam heat supply network

PendingCN114216713AClarify the ratio of heat lossImprove accuracyMaterial thermal conductivityMaterial heat developmentHeat flowPipe fitting

The invention relates to a comprehensive detection and evaluation system for heat dissipation loss characteristics of an overhead steam heat supply network. The comprehensive detection and evaluation system comprises a steam heat supply network main pipeline, a plurality of heat consumer branch lines, a heat source node, a plurality of heat consumer nodes, an enthalpy drop test section, a plurality of straight pipe surface heat dissipation test points, a plurality of bent pipe surface heat dissipation test points and a data processing terminal. The method has the beneficial effects that quantitative analysis of heat leakage in heat dissipation of different mechanisms in heat dissipation of the heat supply network is realized, the heat dissipation loss proportion of the heat supply network of different mechanisms is sorted out, and the accuracy and reliability of heat dissipation analysis of the heat supply network pipeline are improved; an internal and external heat flow meter method is adopted to accurately test heat leakage characteristics in heat preservation and heat dissipation, heat conduction and heat dissipation and heat leakage loss of a unit section of a pipeline are obtained, meanwhile, an enthalpy drop method is combined, pipe fitting heat dissipation loss on a test section is calculated, and finally the proportion of heat conduction and heat dissipation, heat leakage and pipe fitting heat dissipation is obtained. Quantitative characterization of the heat leakage proportion in heat preservation and heat dissipation is achieved, and a reliable basis is provided for accurate evaluation of heat preservation and heat dissipation performance.

Owner:ZHEJIANG ZHENENG TECHN RES INST

line heat source

ActiveCN101616512BReduce weightEasy to useHeating element shapesHeating element materialsCarbon nanotubeLine heat source

The invention discloses a linear heat source, which comprises a linear substrate, a heating layer arranged on the surface of the linear substrate, and two electrodes arranged on the surface of the heating layer at intervals, wherein the two electrodes and the heating layer are electrically connected; the heating layer comprises a carbon nanotube layer; and the carbon nanotube layer comprises a plurality of isotropic carbon nanotubes preferentially arranged along a fixed direction or different directions.

Owner:TSINGHUA UNIV +1

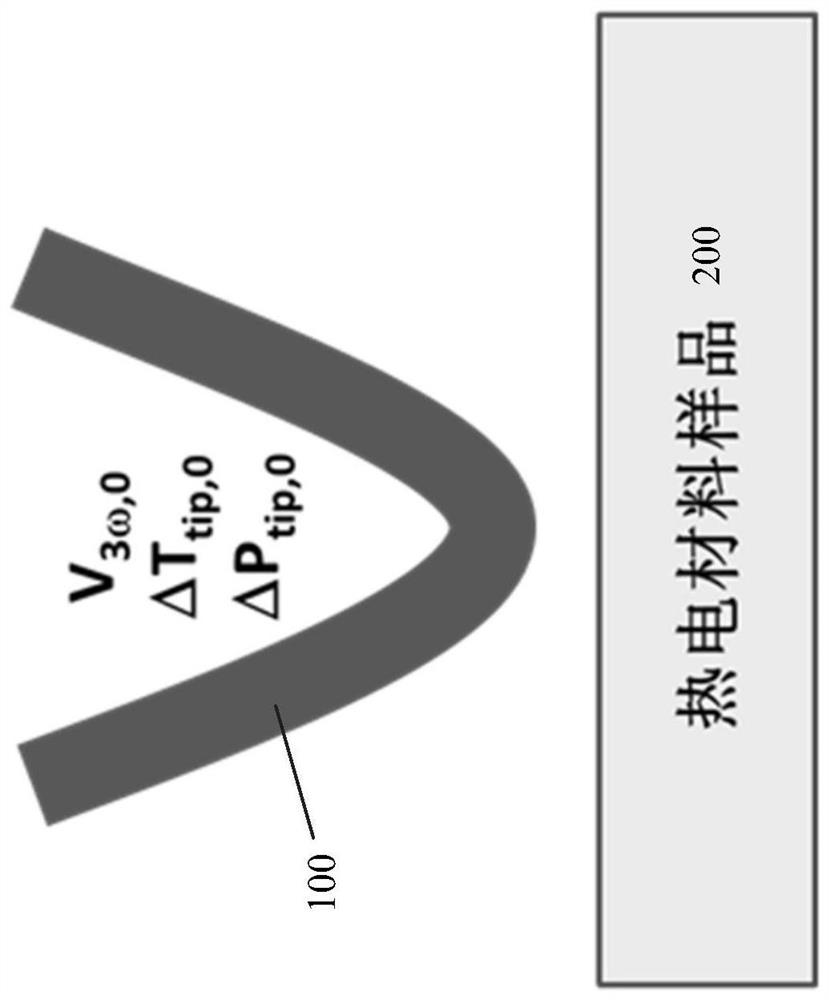

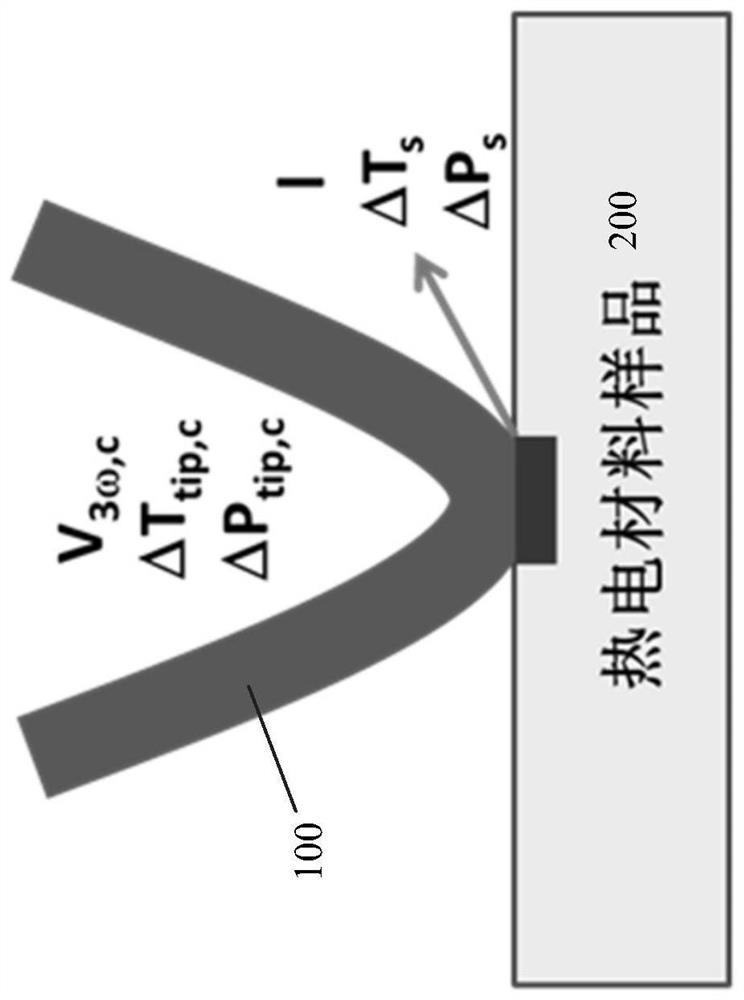

An in-situ characterization device for extremely low thermal conductivity at the nanoscale

ActiveCN110579628BHigh resolutionHigh sensitivityScanning probe microscopyThermoelectric materialsAfm atomic force microscopy

This application discloses an in-situ characterization device for extremely low thermal conductivity at the nanometer scale, which is used to detect the micro-region thermal conductivity of a sample of a thermoelectric material to be tested, including: a nanoscale thermal signal in-situ excitation module for in-situ excitation Double-frequency and triple-frequency thermal signals related to the micro-region thermal conductance before and after the contact of the tested material; a nanoscale thermal signal in-situ detection module, used to realize the double-frequency and triple-frequency thermal signals In-situ real-time detection and processing, and display the in-situ characterization results of micro-area thermal conductivity; the heating frequency of the thermoelectric probe is in the range of 90Hz to 760Hz, ΔV 3ω It has a linear relationship with lnω, and according to the slope of its linear part, the thermal conductivity λ of the micro-area can be quantitatively characterized s . This application combines the nano-detection function of the atomic force microscope, the Joule heating effect of the probe, the three-fold frequency excitation of the thermal detection and the line heat source model, and establishes an in-situ characterization device based on the atomic force microscope with extremely low thermal conductivity at the nanometer scale.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Line heat source

ActiveCN101868073BAvoid breakingIndividual molecule manipulationHeating element shapesElectricityLine heat source

The invention relates to a line heat source comprising a line-shaped supporting structure, a heating element arranged at the surface of the line-shaped supporting structure and two electrodes, wherein the two electrodes are arranged at intervals and are electrically connected with the heating element, the heating element comprises at least one carbon nano pipe composite structure, the carbon nanopipe composite structure comprises a basal body and a carbon nano pipe membrane structure compounded in the basal body, and the carbon nano pipe membrane structure comprises a plurality of carbon nano pipes which are mutually wound. The line heat source can be used for manufacturing heating clothes, heating gloves or heating shoes with spontaneous heating, an electric heater, an infrared therapeutic apparatus, an electric room heater and the like and has extensive application range.

Owner:TSINGHUA UNIV +1

Line heat source

ActiveCN101616516BReduce weightEasy to useIndividual molecule manipulationHeating element shapesCarbon nanotubeEngineering

The invention relates to a line heat source. The line heat source comprises a linear support structure, a heating element which is arranged on the surface of the linear support structure, and two electrodes which are arranged at interval and respectively connected with the heating element, wherein, the heating element comprises a carbon nanotube structure.

Owner:TSINGHUA UNIV +1

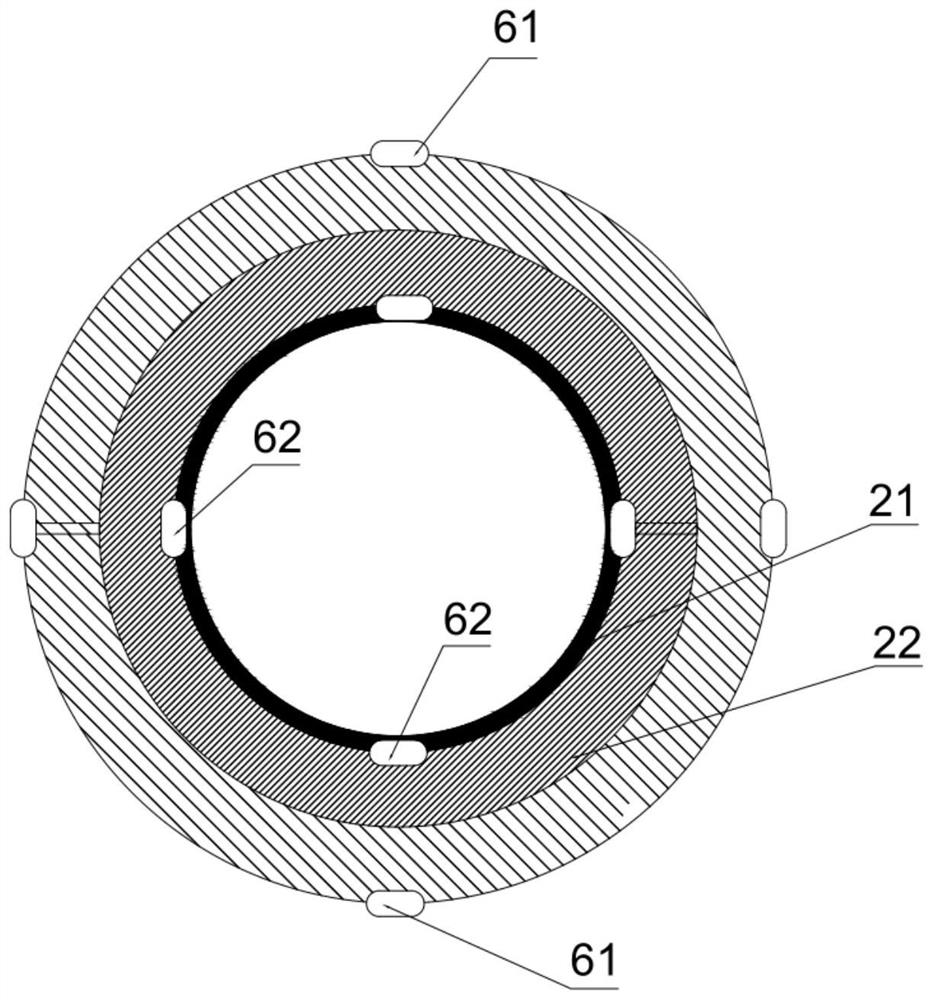

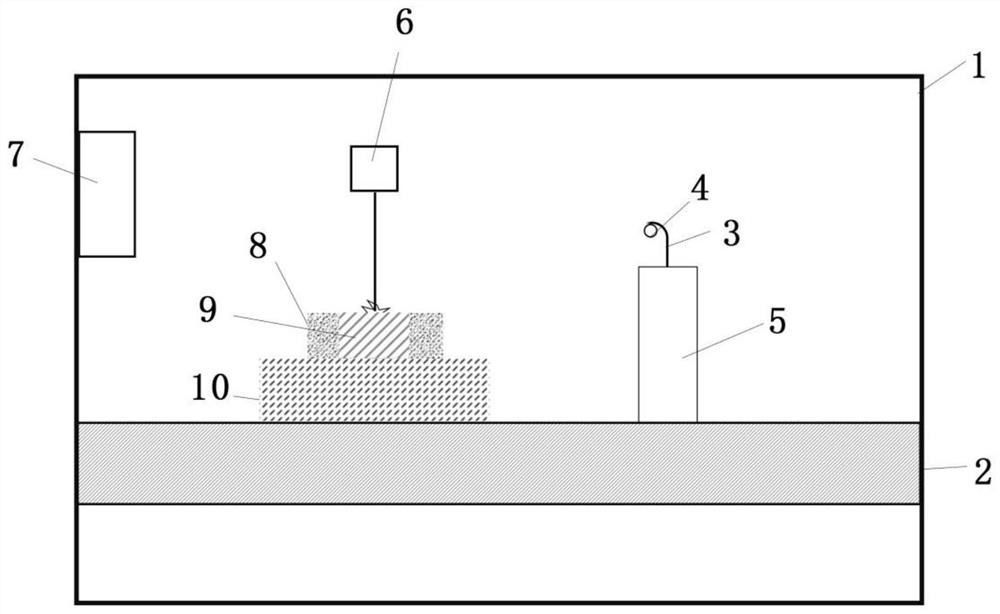

System and method for measuring composite thermal parameters of phase change concrete member

ActiveCN114487008AAccurate measurementGuaranteed accuracyMaterial heat developmentThermal dilatationEngineering

The invention discloses a system and a method for measuring composite thermal parameters of a phase change concrete member, which are applied to the technical field of structural model test, and the measuring system comprises a model unit, an air treatment unit, a monitoring unit and a loading unit, the model unit comprises a metal container, a metal sheet, a to-be-tested phase-change concrete member placed in the container, and insulating and heat-insulating materials inside and outside the metal container; the loading unit comprises a constant-temperature line heat source heater, a constant-temperature cold plate, an electric control multi-gradient constant-temperature heating plate, a constant-temperature heating device, a constant-temperature water inlet, a water outlet, a water circulation temperature control device and a water tank; the air treatment unit comprises an air outlet and a vacuum pump; the monitoring unit comprises a temperature sensor, a heat flux sensor and a strain gauge, and the system can measure thermal parameters of a non-standard component, specifically a composite heat conductivity coefficient, a specific heat capacity and a thermal expansion coefficient.

Owner:SHENZHEN UNIV

High precision soil thermophysical nature measurer for ground source heat pump

InactiveCN101393149BCompact structureWide range of test powerMaterial thermal conductivityMaterial heat developmentTest powerEngineering

Owner:SHANGHAI JIAOTONG UNIV +3

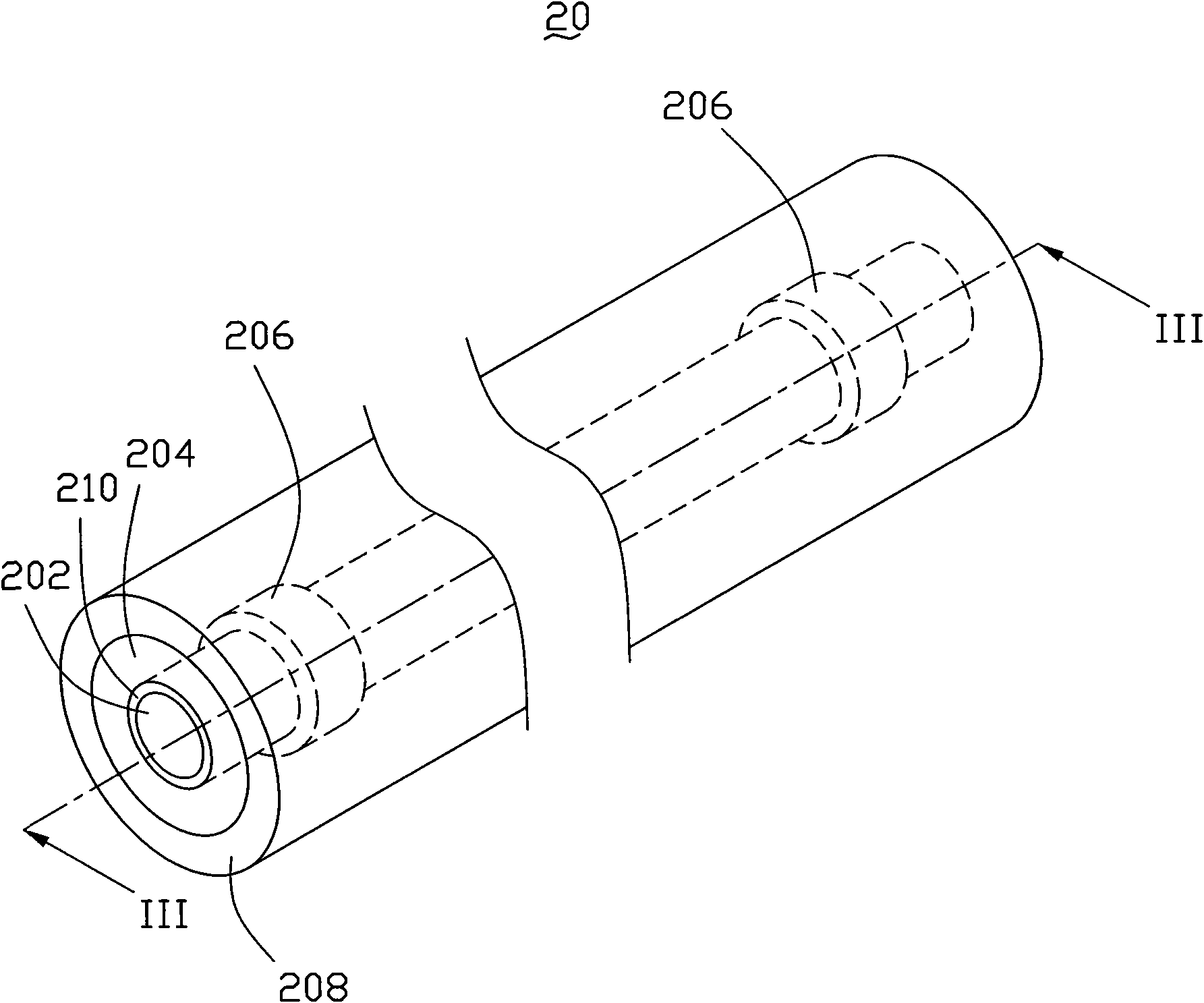

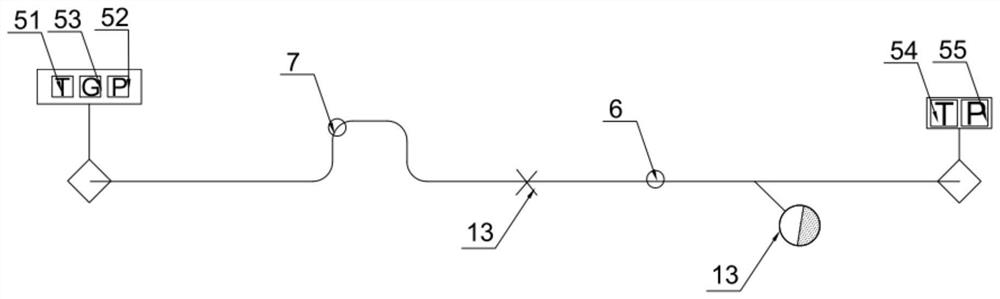

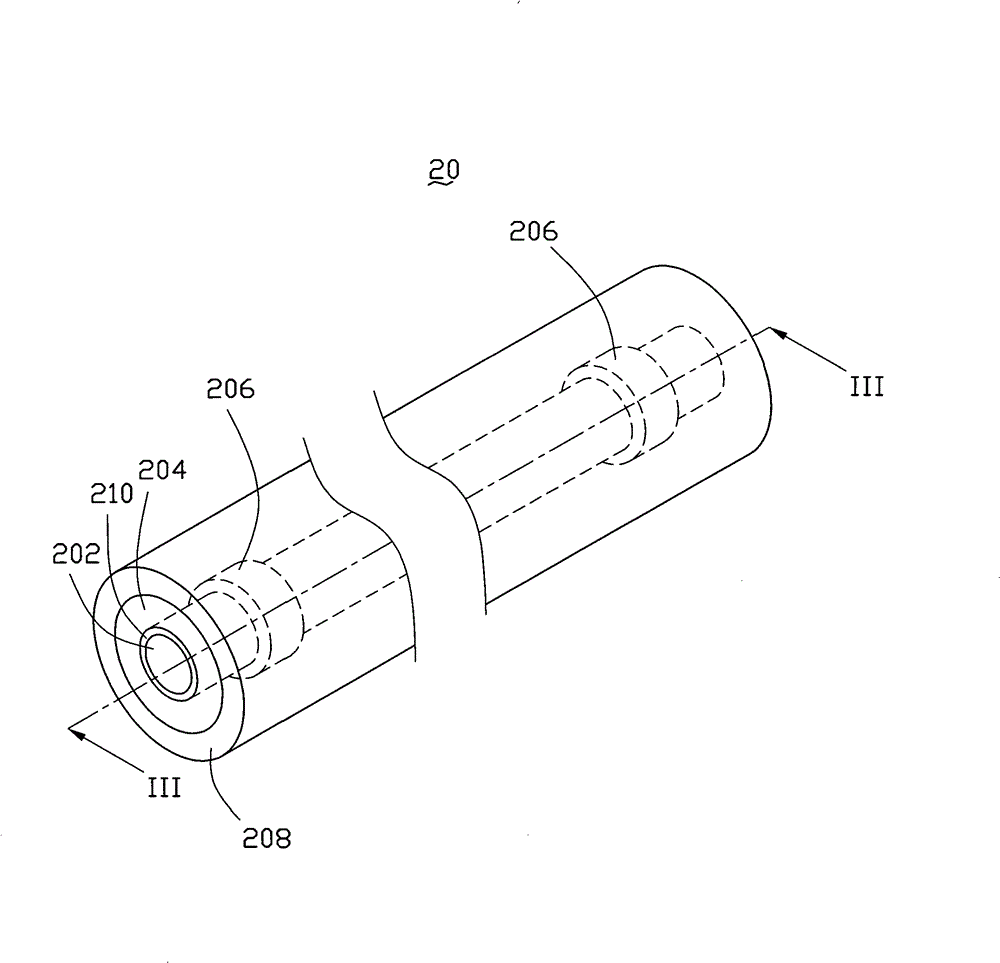

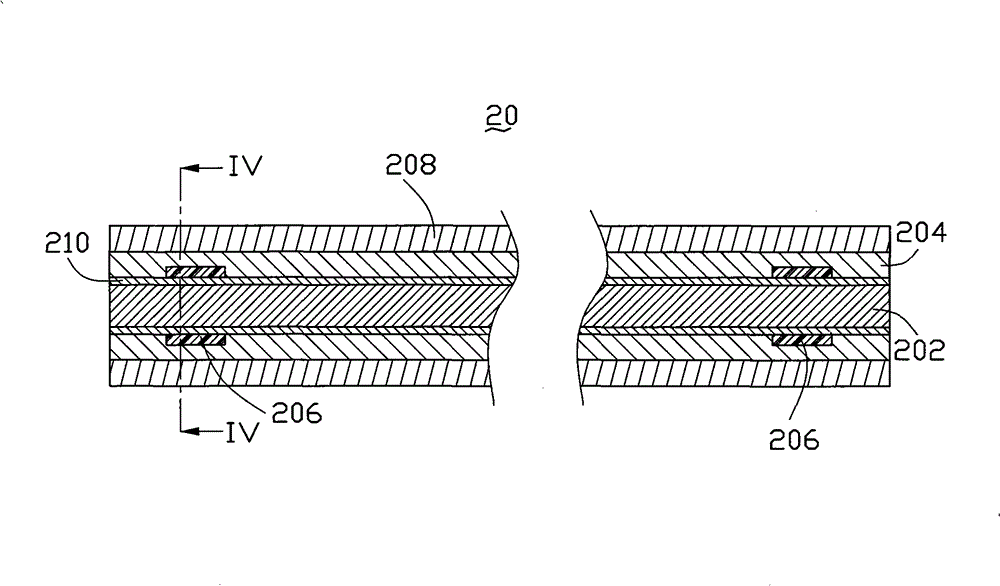

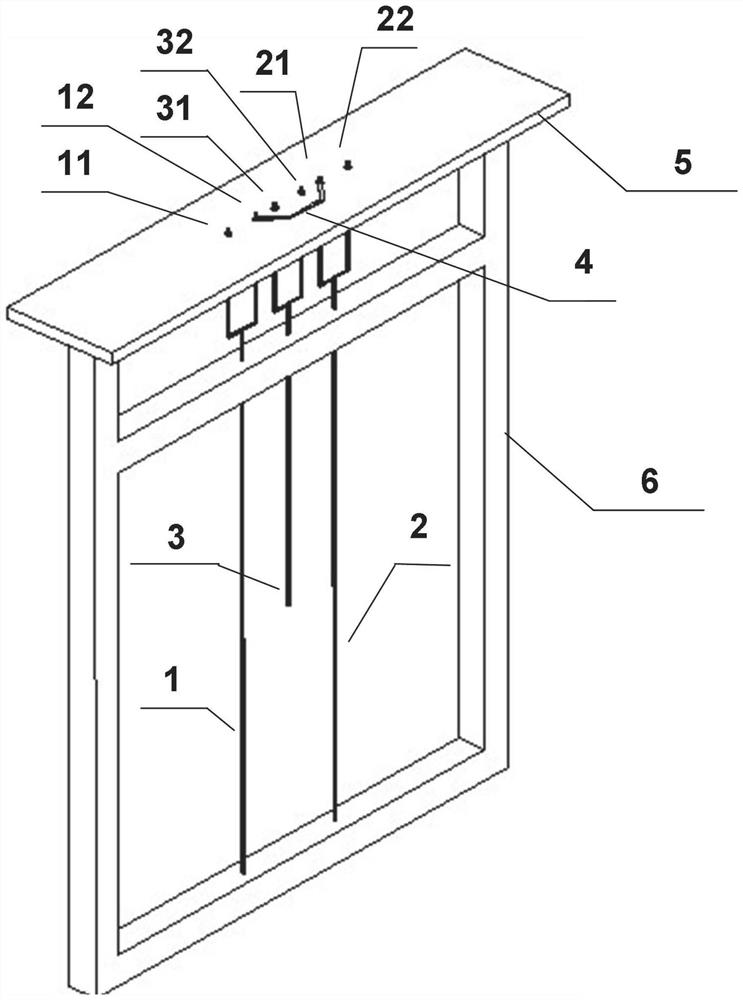

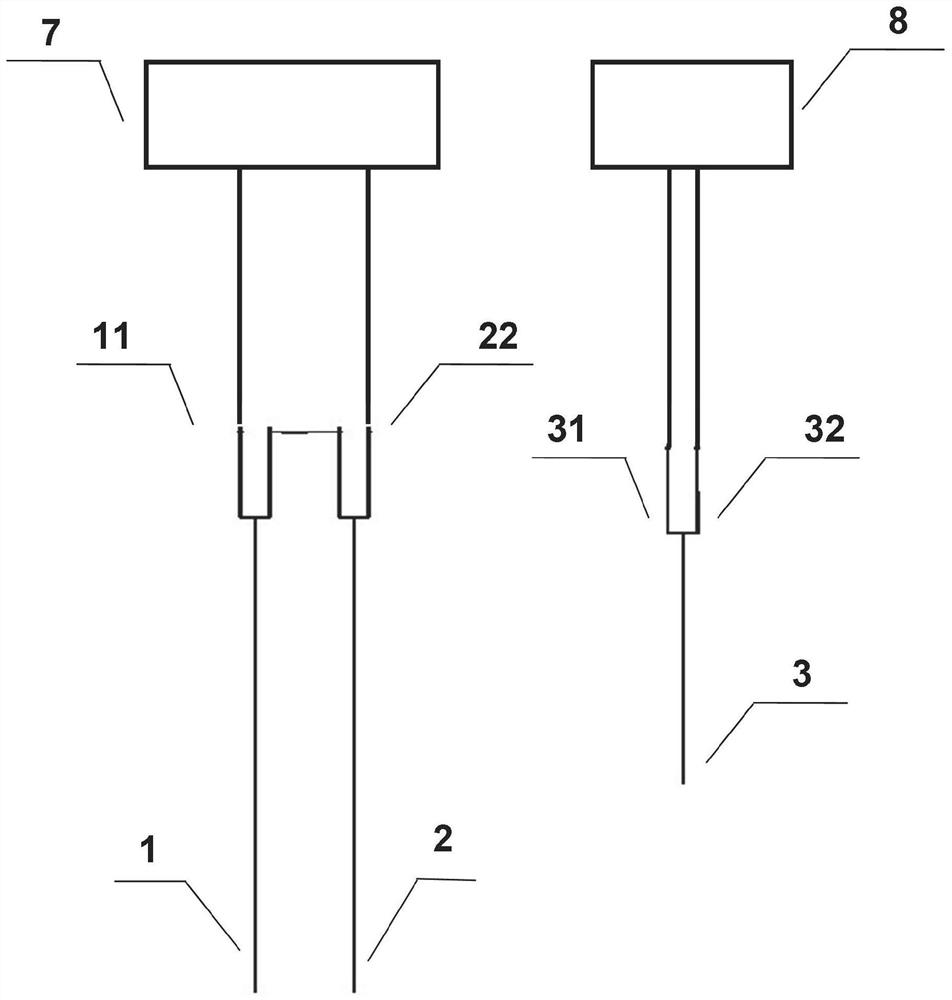

Liquid thermophysical property device for measuring temperature at symmetrical points of parallel double-line heat source and measuring method

PendingCN114740043ASimple structureQuick measurementNuclear energy generationMaterial heat developmentThermal diffusion coefficientElectrical conductor

A liquid thermophysical property device for measuring temperature at symmetrical points of parallel double-line heat sources comprises a first slender electric heater, a second slender electric heater and a temperature sensor, wherein the first slender electric heater and the second slender electric heater are arranged in parallel and are equal in size and heating power, and the temperature sensor is arranged at the plane-shaped center of the first electric heater and the second electric heater. The two electric heaters are respectively provided with two extraction electrodes, wherein the extraction electrode of the first electric heater is connected with the extraction electrode of the second electric heater through a conductor. According to the method for measuring the thermophysical property of the liquid by using the thermophysical property sensor, a theoretical solution of a transient heat conduction equation under the action of a parallel double-line heat source and an extreme point of a symmetrical point temperature rise rate are utilized, temperature rise and the temperature rise rate are measured, and the thermophysical property of the liquid is measured according to time and temperature rise corresponding to the extreme point of the temperature rise rate. And the thermal diffusion coefficient and the thermal conductivity are directly calculated.

Owner:南京常春藤科技有限公司

Line heat source

ActiveCN101868074BAvoid breakingIndividual molecule manipulationHeating element shapesElectricityCarbon nanotube

The invention relates to a line heat source comprising a heating element and two electrodes, wherein the two electrodes are arranged at intervals and are electrically connected with the heating element; and the heating element comprises at least one line-shaped carbon nano pipe composite structure, wherein the line-shaped carbon nano pipe composite structure comprises a basal body and at least one carbon nano pipe line-shaped structure compounded in the basal body. The line heat source can be used for manufacturing heating clothes, heating gloves or heating shoes with spontaneous heating, an electric heater, an infrared therapeutic apparatus, an electric room heater and the like and has extensive application range.

Owner:TSINGHUA UNIV +1

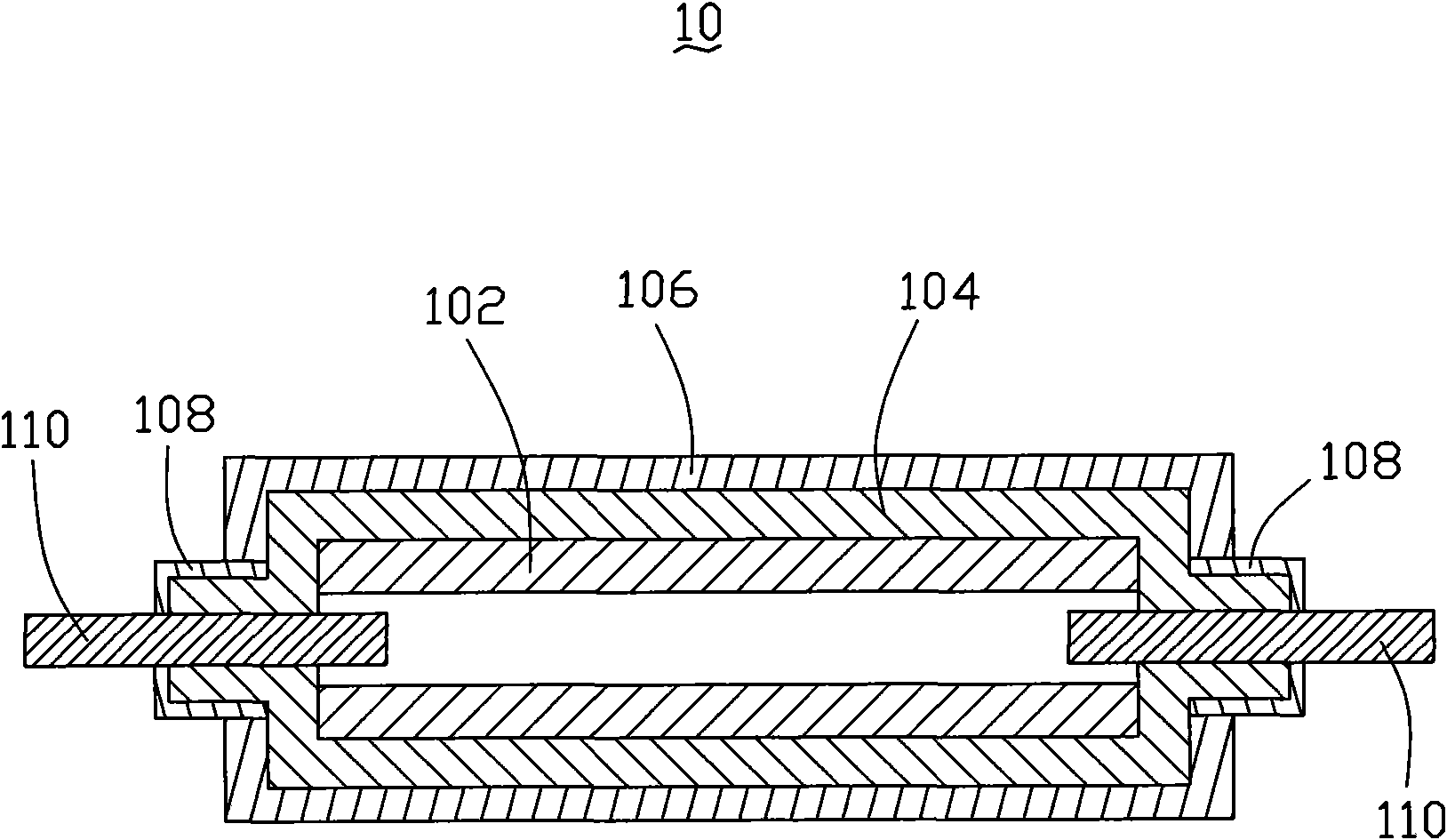

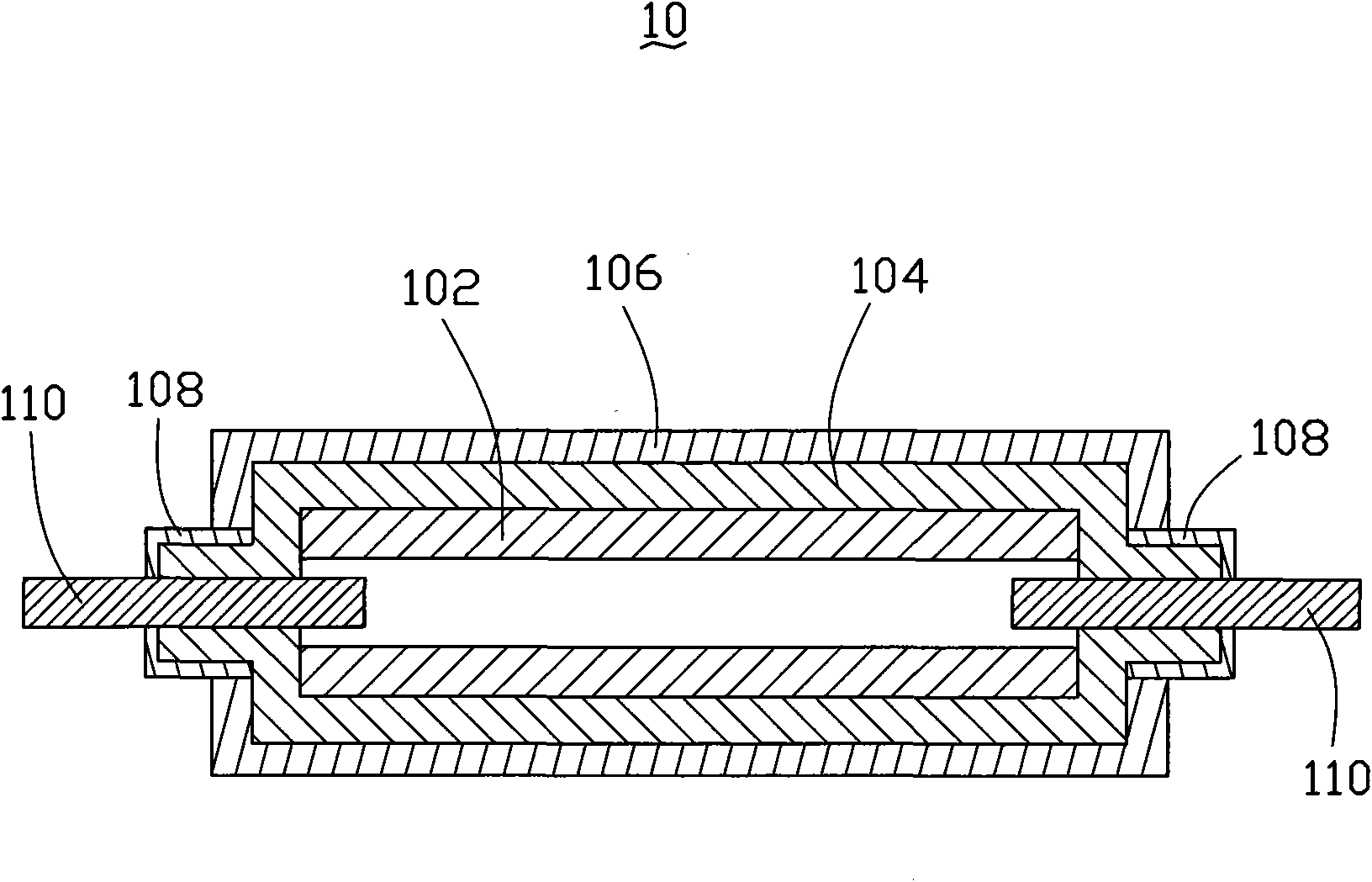

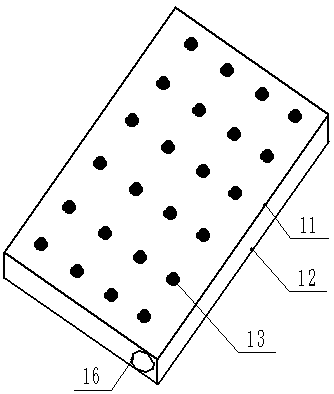

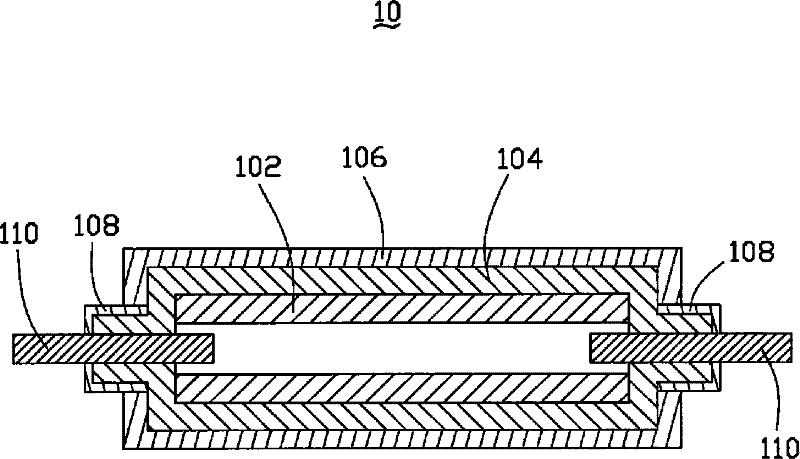

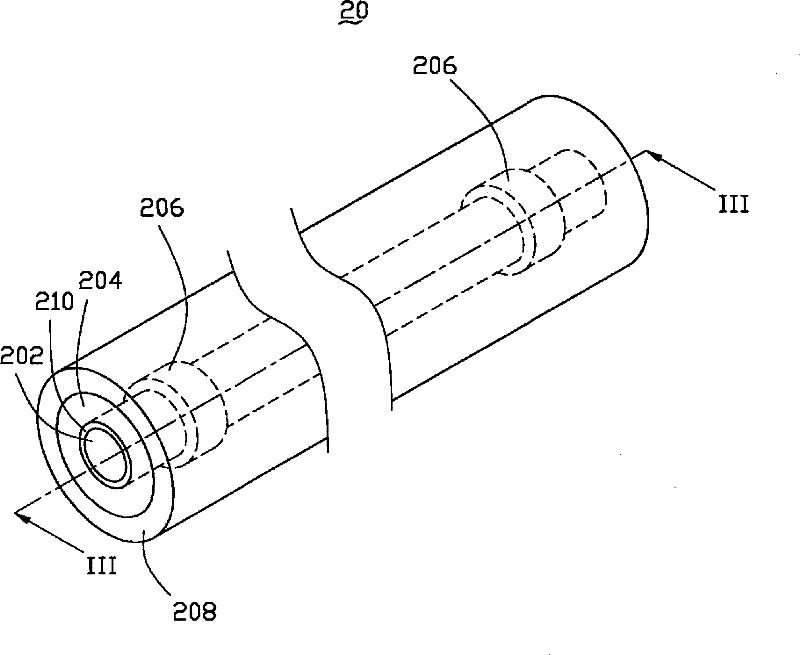

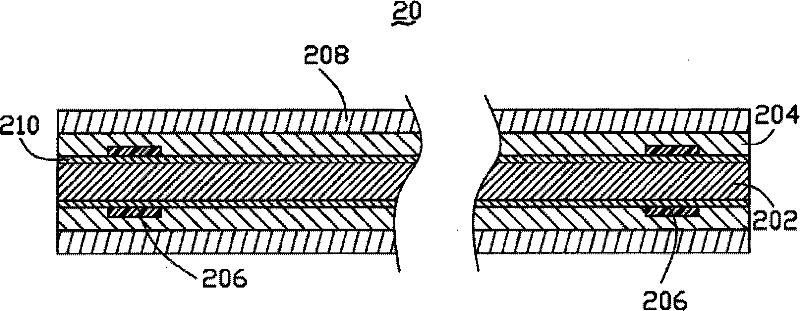

Heat-superconducting plate and manufacturing technology thereof

PendingCN107906989ASimple preparation processIndirect heat exchangersHeat exchange apparatusManufacturing technologyHigh volume manufacturing

The invention discloses a heat conducting plate mainly composed of an upper metal plate, a lower metal plate, a working medium and a liquid filling pipe. The upper metal plate and the lower metal plate are rectangular flat plates identical in size. After the upper metal plate and the lower metal plate are arranged in a vertically aligned manner, the peripheral edges of the upper metal plate and the lower metal plate are sealed through welding, then a metal shell is formed, and reinforcing points are welded at the middle position so that the strength of the shell is improved. A communicating channel shaped like a Chinese character 'jing' is etched on the inner surface of the upper metal plate and enables the work medium to flow, and the whole metal plate shell can be filled with the work medium in a one-off manner. The liquid filling pipe penetrates through the side face of the metal shell to communicate with the communicating channel shaped like the Chinese character 'jing', and therefore vacuumizing and work medium filling are convenient. The heat conducting plate has the advantages that the heat conducting plate has isotropy in the heat transfer directions, and the heat conducting plate can be used for heat dissipation of a point heat source, a line heat source and a face heat source; a manufacturing technology is simple, and mass production can be conducted; and the heat conducting plate can be produced into different shapes so as to adapt to cooling components. The heat conducting plate can be widely applied to heat dissipation of electronic products or constant-temperature heating of food or chemical equipment and can also be used as a heat exchanger.

Owner:BEIJING FULLLINK OREITH TECH CO LTD

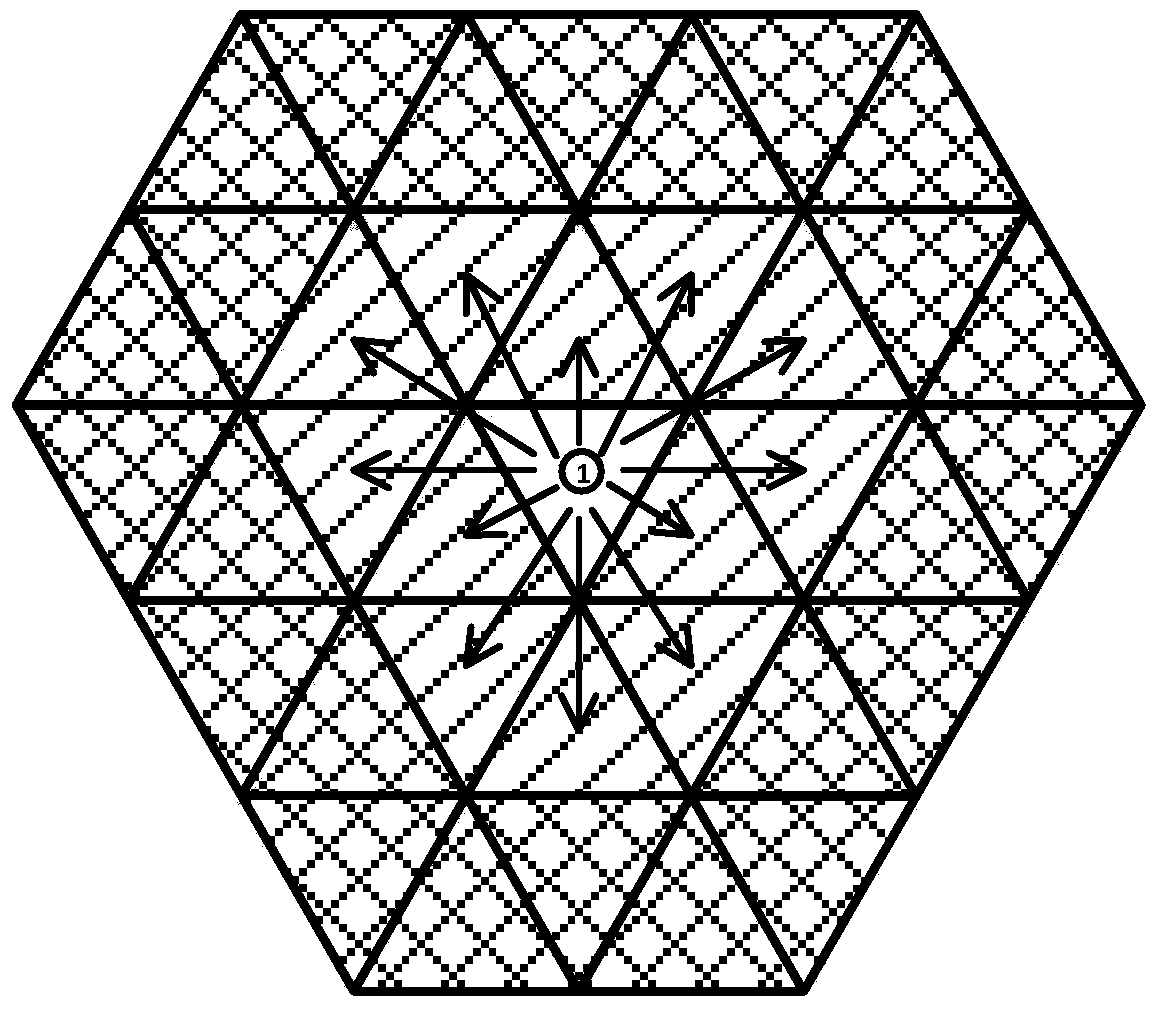

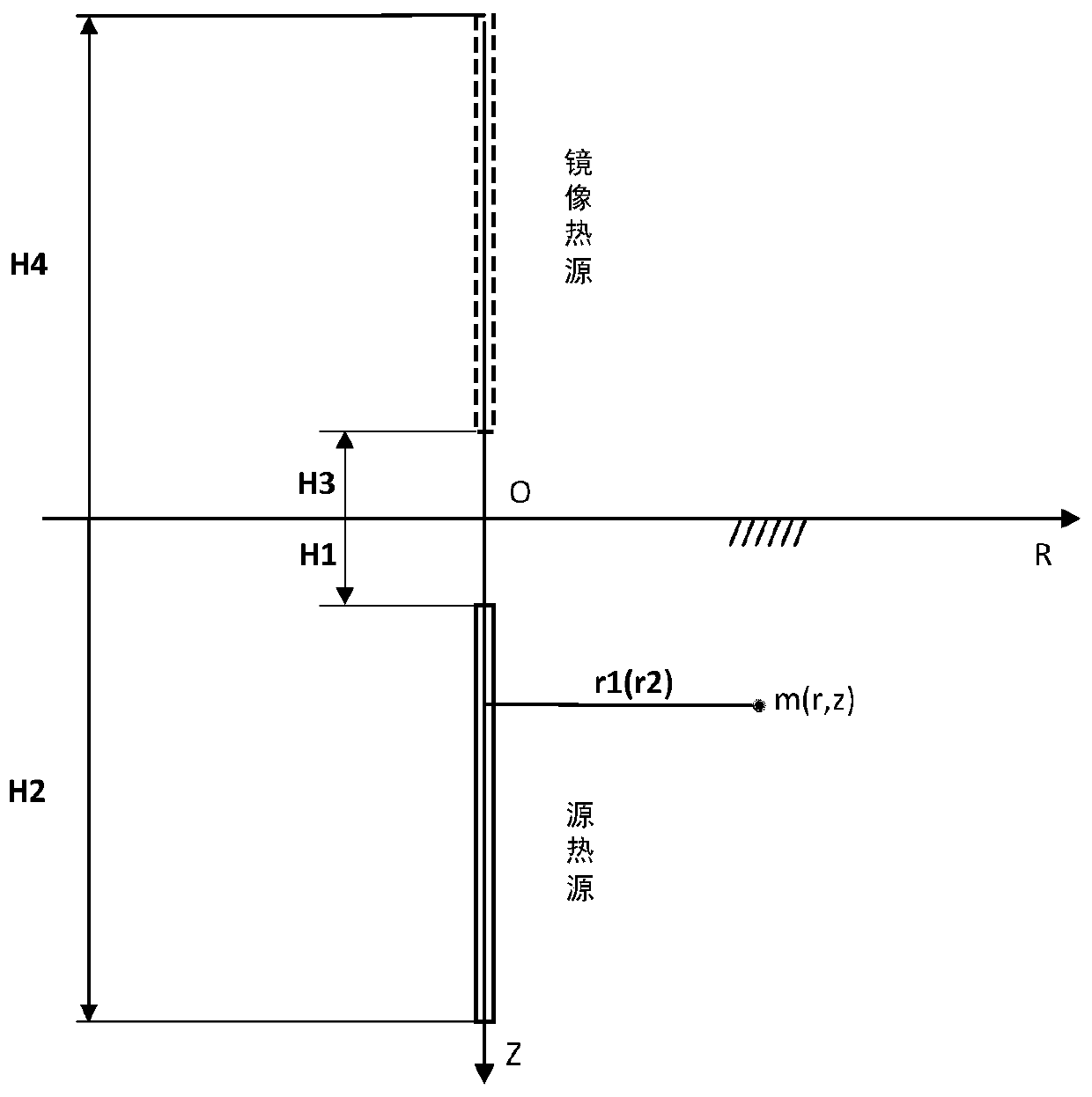

A simulation design method for the spacing between boreholes based on the representative temperature of the borehole wall

InactiveCN103235860BWeaken the effect of "thermal interference"Improve heat transfer efficiencySpecial data processing applicationsEngineeringLine heat source

The invention discloses a hole wall representation temperature based simulation design method for drill hole space and belongs to the field of drill hole space design in the geothermal technology. The simulation design method is characterized in that the method comprises arbitrarily selecting four adjacent drill holes with perpendicular U-shaped buried pipes arranged inside from a drill hole group to form a four-drill-hole region, which is also called a unit drill hole group region; dividing the region into two double-drill-hole sub-regions from a horizontal direction, calculating a general formula for a transient temperature of a point M1 under a cylindrical coordinate system of the double-drill-hole sub-regions; mapping the point M1 transversely onto a vertically contacted virtual line heat source or actual line heat source to obtain the hole wall representation temperature Tb1 under the double drill holes; calculating the hole wall representation temperature Tb2 by transverse mapping of middle point M2 in the four-drill-hole region onto the virtual line heat source or the actual line heat source in the same way; setting thresholds of hole wall representation temperature change rates P1 and P2 of the double-drill-hole sub-regions and the four-drill-hole region as P1MAX and P2MAX successively; and calculating L1OPT and L2OPT in a threshold range successively through multiple times of iteration to obtain an optimal value of the drill hole space. According to the simulation design method, contradictions between the drill hole space and the heat exchanging efficiency are solved, the problem of slow calculation speed is solved under the condition that the accuracy is guaranteed, and the drill hole space and the hole wall representation temperature are balanced.

Owner:BEIJING UNIV OF TECH

Line heat source

ActiveCN101610613BReduce weightEasy to useIndividual molecule manipulationHeating element shapesCarbon nanotubeNanometre

The invention relates to a line heat source, which comprises a linear support structure, a heating element arranged on the surface of the linear support structure and at least two electrodes arranged at intervals, the at least two electrodes are electrically connected with the heating element, wherein the heating element comprises at least one carbon nanotube film, and carbon nanotubes in the same carbon nanotube film are arranged by preferred orientation along the same direction.

Owner:TSINGHUA UNIV +1

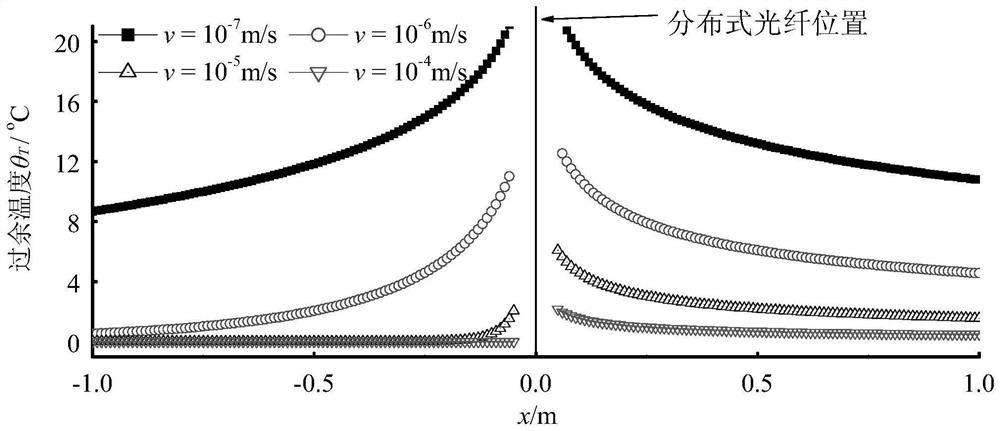

Analytical model for measuring flow velocity of groundwater by heating distributed optical fibers through pulses

PendingCN112179814AEasy to calculateEasy to operateHydrodynamic testingMaterial heat developmentFiberPorous medium

The invention discloses an analytical model for measuring the flow velocity of underground water by heating distributed optical fibers through pulses, which is characterized in that the distributed optical fibers are buried in a water-containing medium, the magnitude and the direction of the seepage flow velocity are quantitatively determined through the difference of the optical fiber cooling process, and a convective heat transfer analysis model of the seepage field is deduced under the action of a continuous linear heat source, wherein the model is more suitable for the heat transfer problem of the optical fibers buried in the porous medium. Model calculation results show that if the optical fibers are continuously heated, long heating time is needed when the temperature of the opticalfibers reaches the maximum temperature rise, so that more energy is consumed, a theoretical model for quantitatively calculating the flow velocity of underground water by adopting a thermal pulse-timedomain reflection technology is constructed, and a double-optical-fiber thermal pulse method and a four-optical-fiber thermal pulse method are provided. That is to say, after thermal pulses are injected into a heating element, the flow velocity of underground water can be conveniently calculated and the flow direction of the underground water can be determined by utilizing difference values or ratios of optical fiber temperature measurement data at different positions.

Owner:ZHEJIANG ELECTRIC POWER DESIGN INST

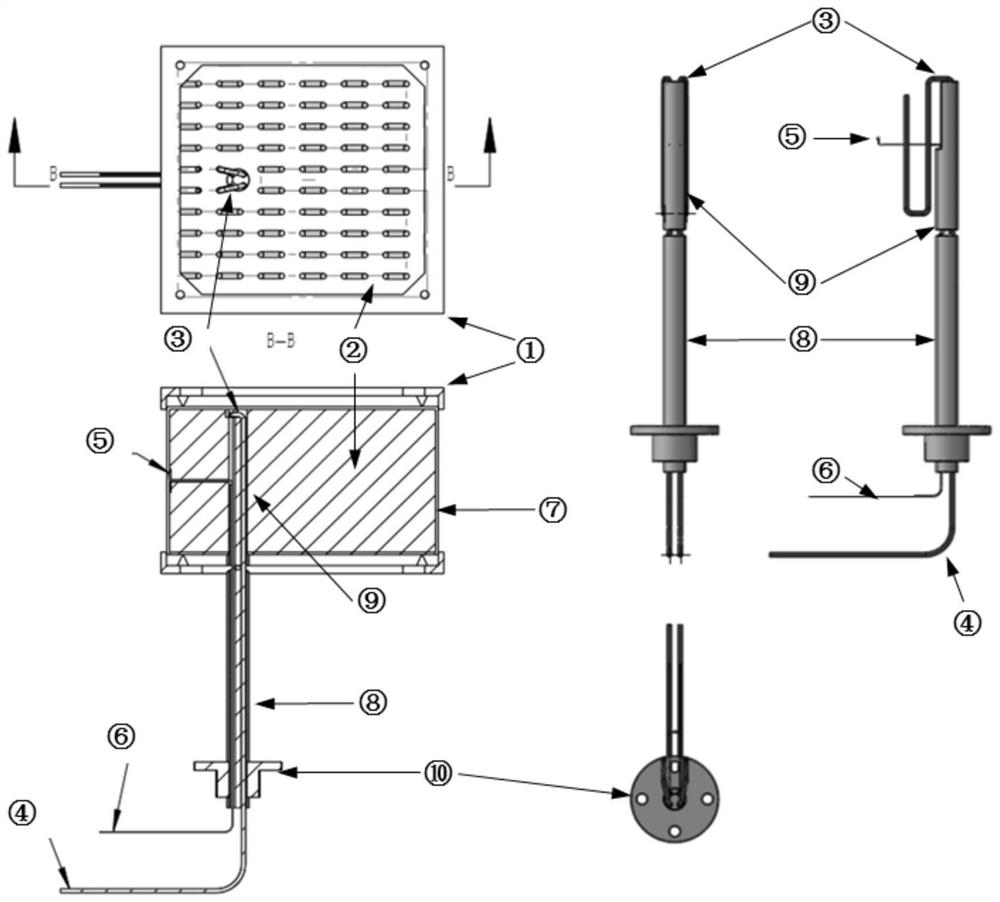

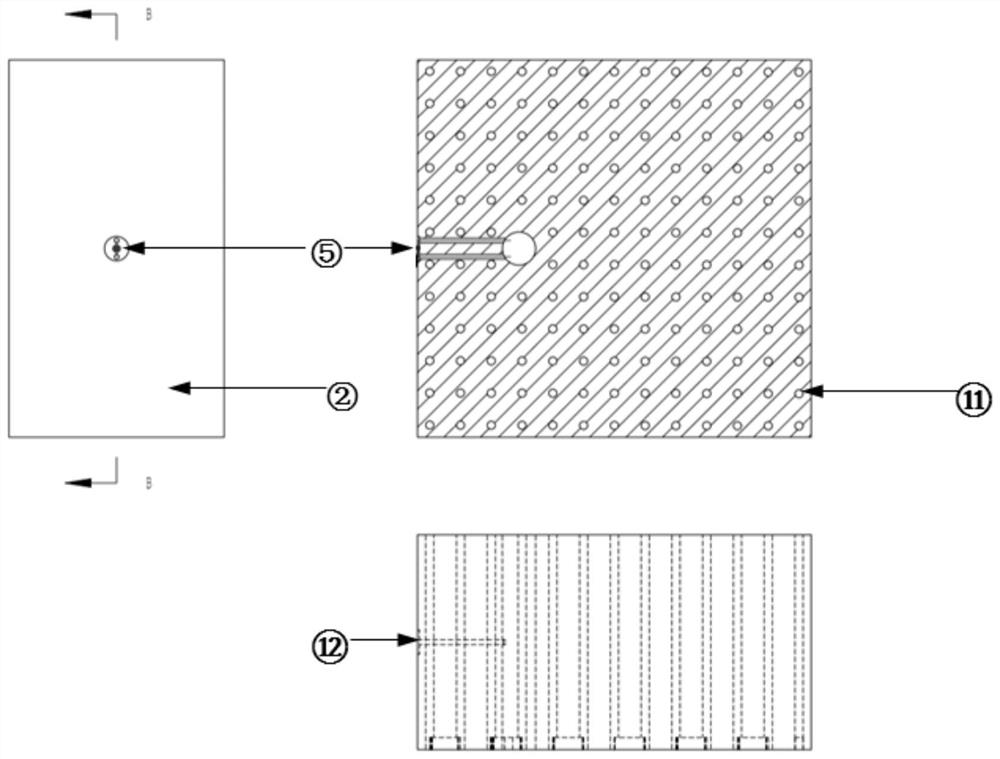

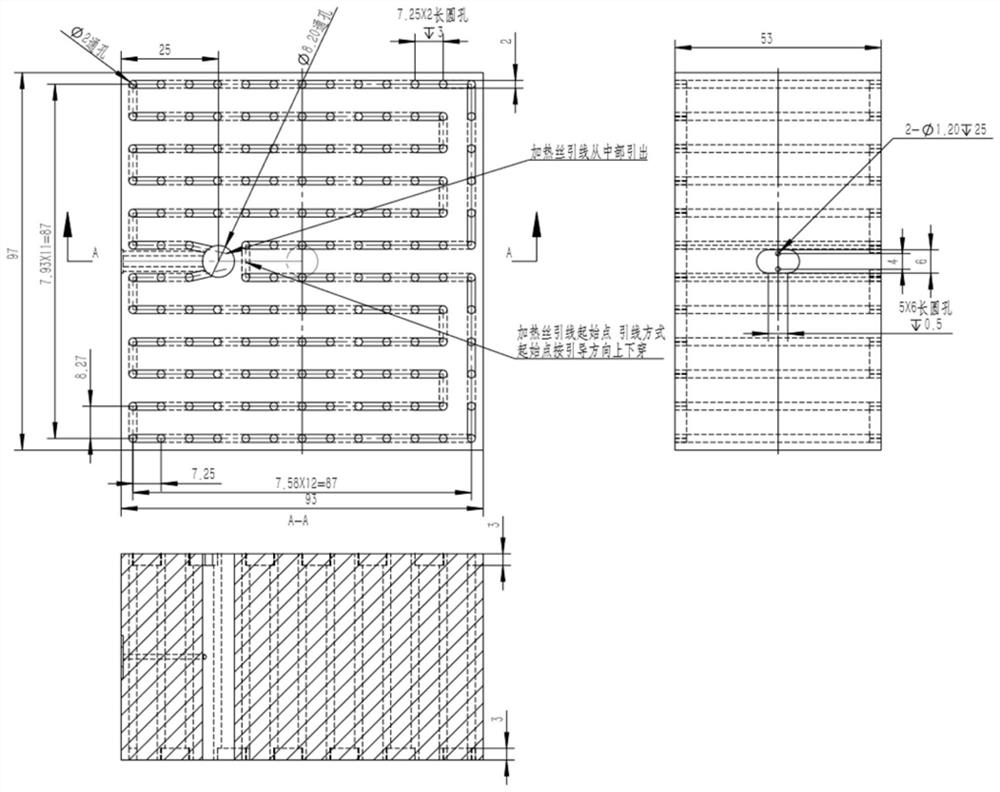

Simulated uniform-temperature electrically-driven standard heat source for isotope power supply system development

The invention relates to a simulated uniform-temperature electrically-driven standard heat source for isotope power supply system development. The heat source comprises a supporting frame, a ceramic structure body, a heating wire, a heating wire lead, a thermocouple, a thermocouple lead, a heat source outer cladding, an external lead ceramic tube, an internal lead ceramic tube and a mounting and fixing flange, and the mounting and fixing flange is used for fixing the heating wire lead and the thermocouple lead to realize fixation of a lead leading-out experimental environment; the heat source outer cladding wraps the ceramic structure body, and the supporting frame is assembled at the upper end and the lower end of the heat source outer cladding to form a set of structure assembly body; the heating wire lead is led out from the heating wire and is connected to an external power supply end; and the thermocouple lead is led out from one end of the thermocouple and is connected to an external instrument. According to the invention, the problem of lack of long-life, high-reliability, easy-to-maintain and low-cost simulated heat source requirements in the space isotope power supply technology development process is effectively solved.

Owner:BEIJING INST OF SPACECRAFT SYST ENG +1

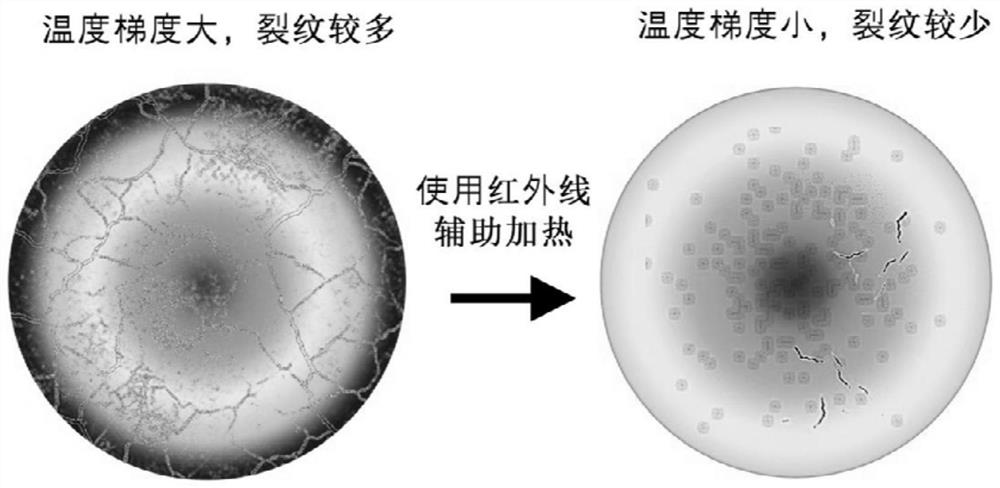

Preparation method of laser additive manufacturing hot crack sensitive material based on infrared auxiliary preheating

PendingCN114871450AGood formabilityEasy to installAdditive manufacturing apparatusIncreasing energy efficiencyStress concentrationAlloy

The invention discloses a preparation method of a laser additive manufacturing hot crack sensitive material based on infrared auxiliary preheating. According to the method, in the process of laser additive manufacturing of hot crack sensitive materials such as aluminum-based alloy, tungsten-based alloy and nickel-based alloy, an infrared heat source is adopted for conducting preheating treatment on alloy powder. The infrared heat source can improve the preheating temperature of the laser to-be-scanned alloy powder, heat a specific area, reduce the temperature gradient of a molten pool and prolong the solidification time, so that the thermal stress concentration of a formed thermal crack sensitive material is reduced, the thermal cracking tendency of materials such as an aluminum-based alloy, a tungsten-based alloy and a nickel-based alloy in the laser forming process is reduced, and the laser forming quality is improved. And the laser additive manufacturing formability of the hot crack sensitive material and the quality of a formed part are improved. According to the method, the forming efficiency and the forming quality are synchronously improved, and laser additive manufacturing of hot crack sensitive materials such as high-quality formed aluminum-based, tungsten-based and nickel-based alloys becomes possible.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Preparation method of line heat source

ActiveCN101868072BAvoid breakingIndividual molecule manipulationHeating element shapesLine heat sourceNanotube

The invention relates to a preparation method of a line heat source, which concretely comprises the following steps of: providing a carbon nano pipe structure; providing a line-shaped supporting structure; arranging the carbon nano pipe structure at the surface of the line-shaped supporting structure; forming two electrodes at intervals and forming the electric connection of the two electrodes and the carbon nano pipe structure respectively; and providing a prefabricated body of a base material and compounding the prefabricated body of the base material and the carbon nano pipe structure to form a carbon nano pipe composite structure.

Owner:TSINGHUA UNIV +1

Line heat source

ActiveCN101868070BAvoid breakingIndividual molecule manipulationHeating element shapesElectricityCarbon nanotube

The invention relates to a line heat source comprising a line-shaped supporting structure, a heating element arranged at the surface of the line-shaped supporting structure and two electrodes, wherein the two electrodes are arranged at intervals and are electrically connected with the heating element, the heating element comprises at least one carbon nano pipe composite structure, and the carbon nano pipe composite structure comprises a basal body and a carbon nano pipe structure compounded in the basal body. The line heat source can be used for manufacturing heating clothes, heating gloves or heating shoes with spontaneous heating, an electric heater, an infrared therapeutic apparatus, an electric room heater and the like and has extensive application range.

Owner:TSINGHUA UNIV +1

Preparation method of line heat source

ActiveCN101626640BReduce weightEasy to useHeating element shapesHeating element materialsReflective layerProtection layer

Owner:TSINGHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com