Heat-superconducting plate and manufacturing technology thereof

A technology of superconducting heat and heat conducting plates, applied in the field of heat exchange, can solve the problems of low production efficiency, difficulty in high-efficiency mass production, cumbersome manufacturing methods, etc., and achieve the effect of simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

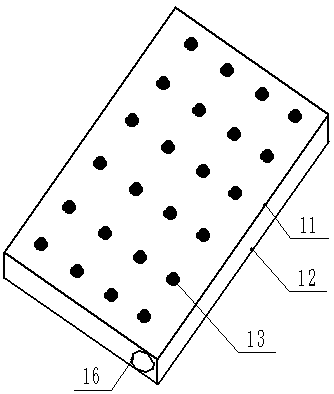

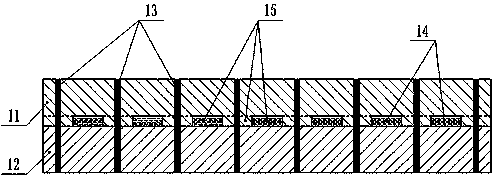

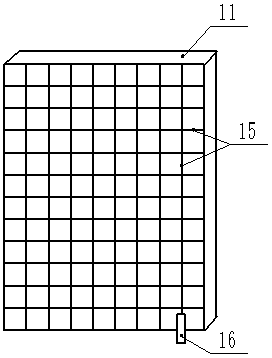

[0017] Such as figure 1 , 2 It is a schematic diagram of the heat conduction plate (1), and its manufacturing process includes the following steps:

[0018] 1. First make two rectangular metal plates by stamping or casting.

[0019] 2. Place the upper metal plate in the etching solution to etch the inner surface to form a well-shaped communication channel (15) that can smoothly circulate the working medium.

[0020] 3. Coat the well-shaped communication channel (15) in the upper metal plate and the inner surface of the lower metal plate with a liquid-absorbing film that can ensure that the working medium can flow smoothly between the upper and lower metal plates.

[0021] 4. Seal the two metal plates around and place a liquid filling tube (16) with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com