A simulation design method for the spacing between boreholes based on the representative temperature of the borehole wall

A technology of simulation design and spacing, which is used in calculations, special data processing applications, instruments, etc., and can solve problems such as slow calculation speed and inability to directly analyze the influence of the heat transfer process of borehole spacing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

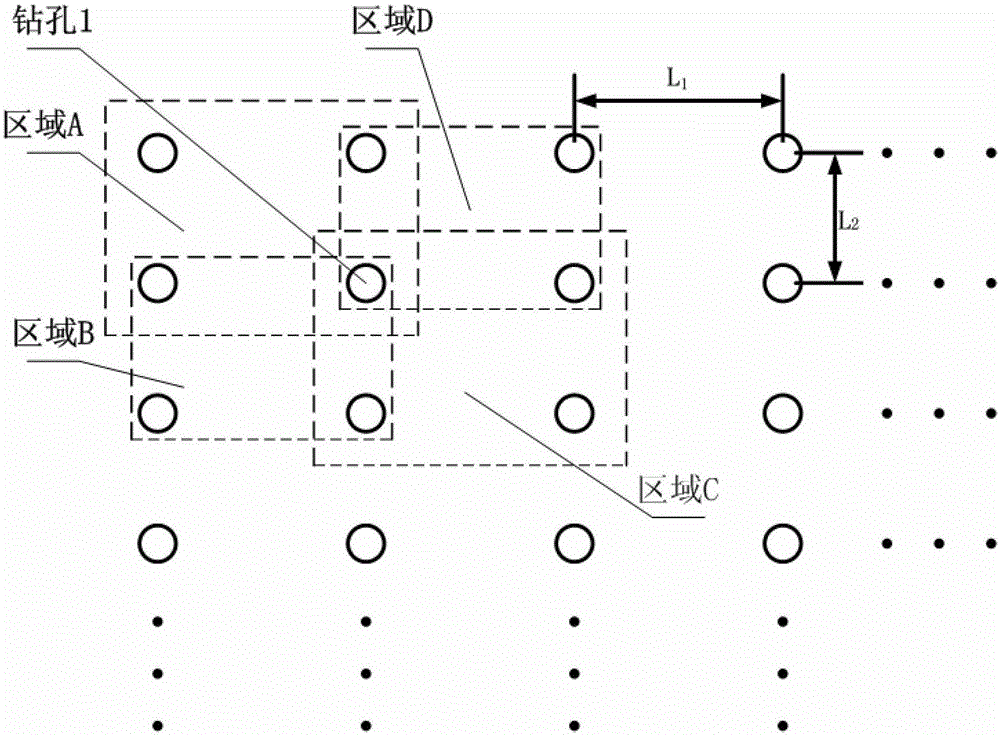

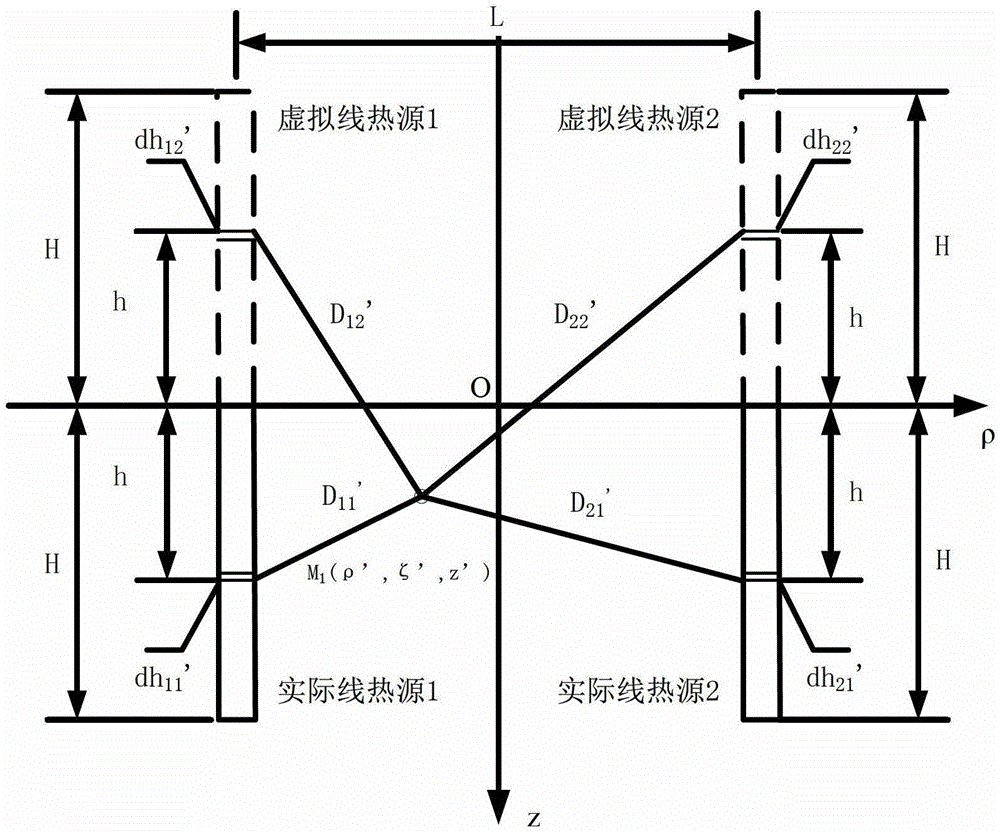

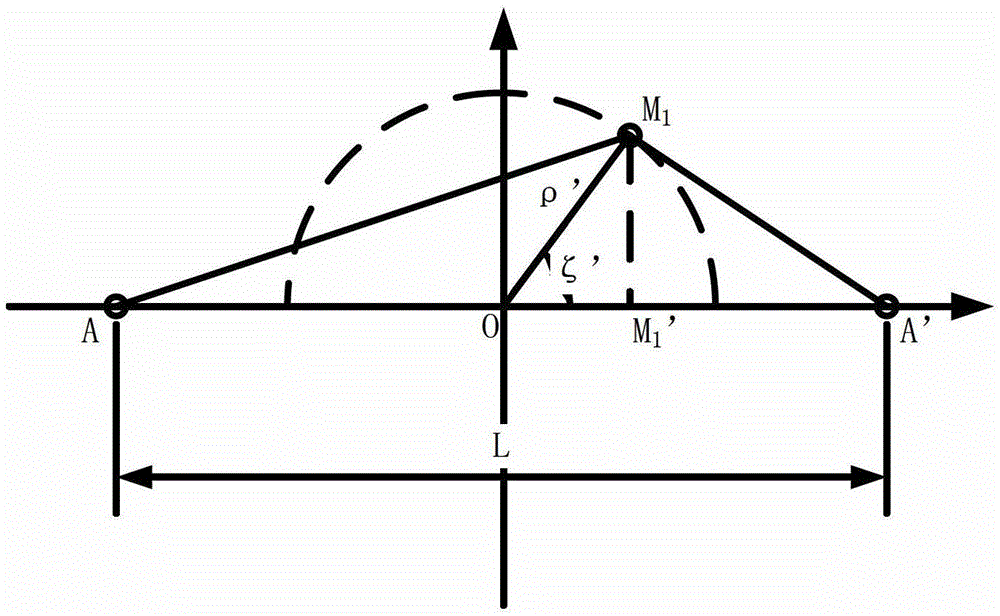

[0094] Based on the principle of finite long-line heat source, the invention establishes the heat transfer model outside the hole with double boreholes and four boreholes in the cylindrical coordinate system, and analyzes the influence of the change of borehole spacing on the representative temperature of the hole wall. The representative temperature of the hole wall is a key parameter in engineering calculations. Substituting it into the heat transfer model in the borehole can solve the outlet temperature. In order to simplify the calculation process, the one-dimensional heat transfer model in the borehole is commonly used to estimate the temperature response of the borehole wall. The physical equations are as follows:

[0095] T f =T b +QR b (1)

[0096] T outlet = 2T f -T inlet (2)

[0097] where T f1 is the average temperature of the fluid, T b is the representative temperature of the hole wall, Q is the exothermic intensity of the U-shaped tube, R b is the tota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com