Simulated uniform-temperature electrically-driven standard heat source for isotope power supply system development

A technology of power supply system and standard heat source, applied in the direction of ohmic resistance heating components, heating elements, etc., can solve the problems of limited operating temperature range, high operating cost, low reliability, etc., and achieve stable performance, simple structure, and long working life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further elaborated below in conjunction with embodiment.

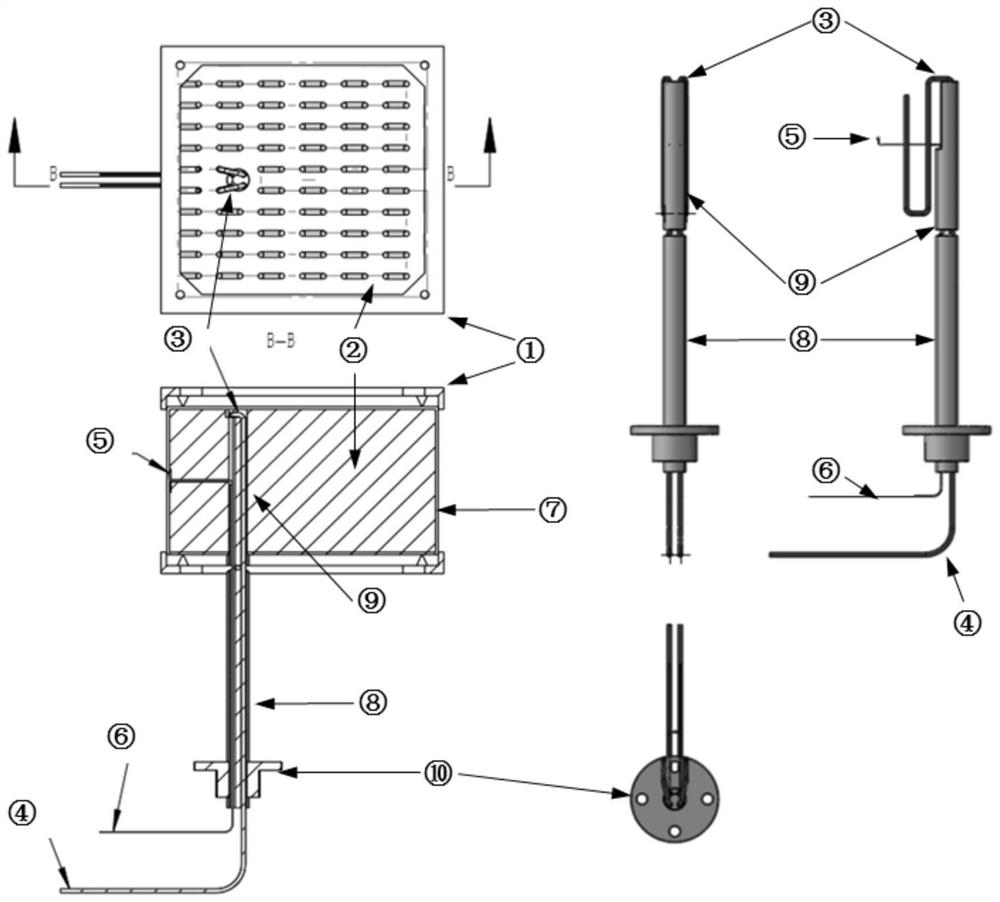

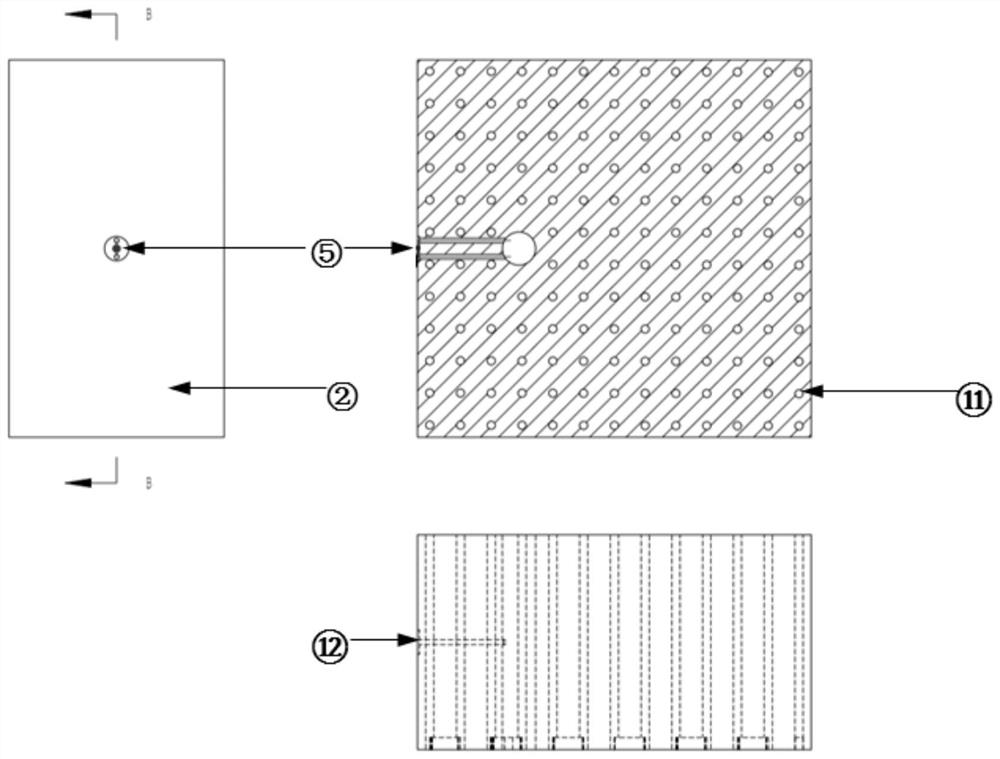

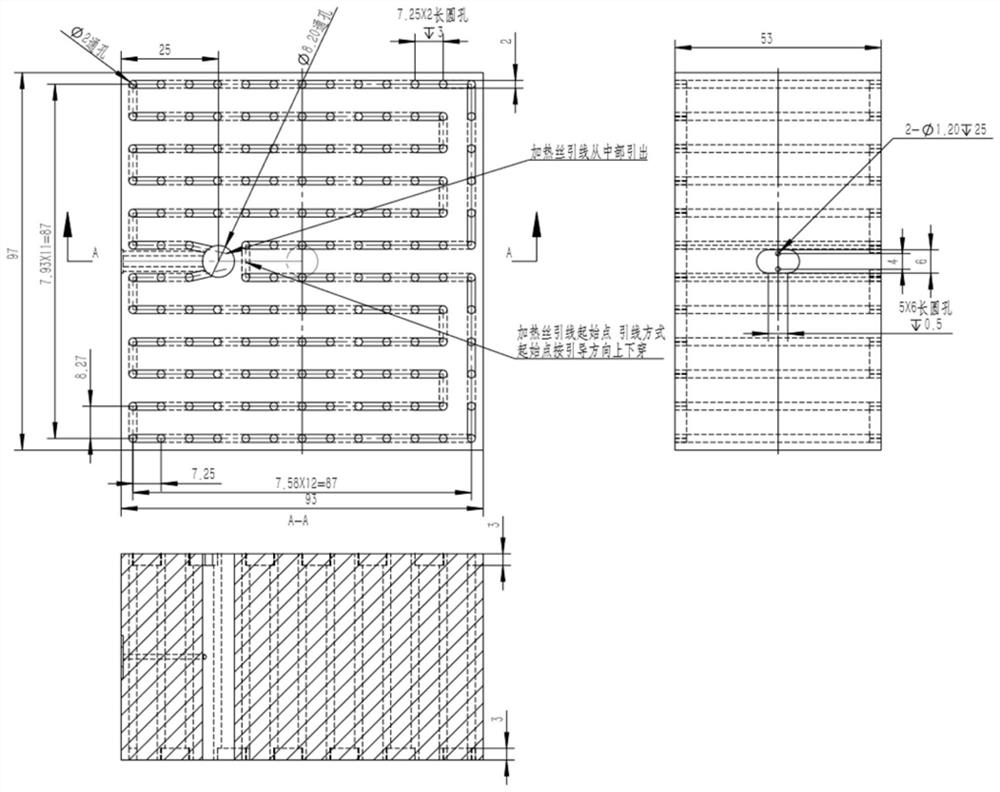

[0030] A simulated uniform temperature electrically driven standard heat source for isotope power system development, see figure 1 , including support frame 1, ceramic structure 2, heating wire 3, heating wire lead 4, high temperature thermocouple 5, thermocouple lead 6, heat source outer cladding 7, outer lead ceramic tube 8, inner lead ceramic tube 9, installation and fixing Flange10.

[0031] The heat source outer cladding 7 is wrapped on the outside of the ceramic structure 2, and the support frame 1 is assembled on the upper and lower ends of the heat source outer cladding 7. The above structures form a set of compact structural assemblies. The heating wire 3 high temperature thermocouple 5 is assembled in the perforation of the outer lead ceramic tube 8 and the inner lead ceramic tube 9; and the heating wire 3 is assembled in the longitudinal honeycomb hole of the ceramic str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com