An in-situ characterization device for extremely low thermal conductivity at the nanoscale

A nanoscale, in-situ technology, applied in the direction of measuring devices, instruments, scanning probe microscopy, etc., can solve the problems of difficult to meet the urgent needs of microscopic thermal conductivity measurement, and the research of thermoelectric properties is not in-depth, so as to achieve easy promotion and Application, simple structure, direct effect of test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

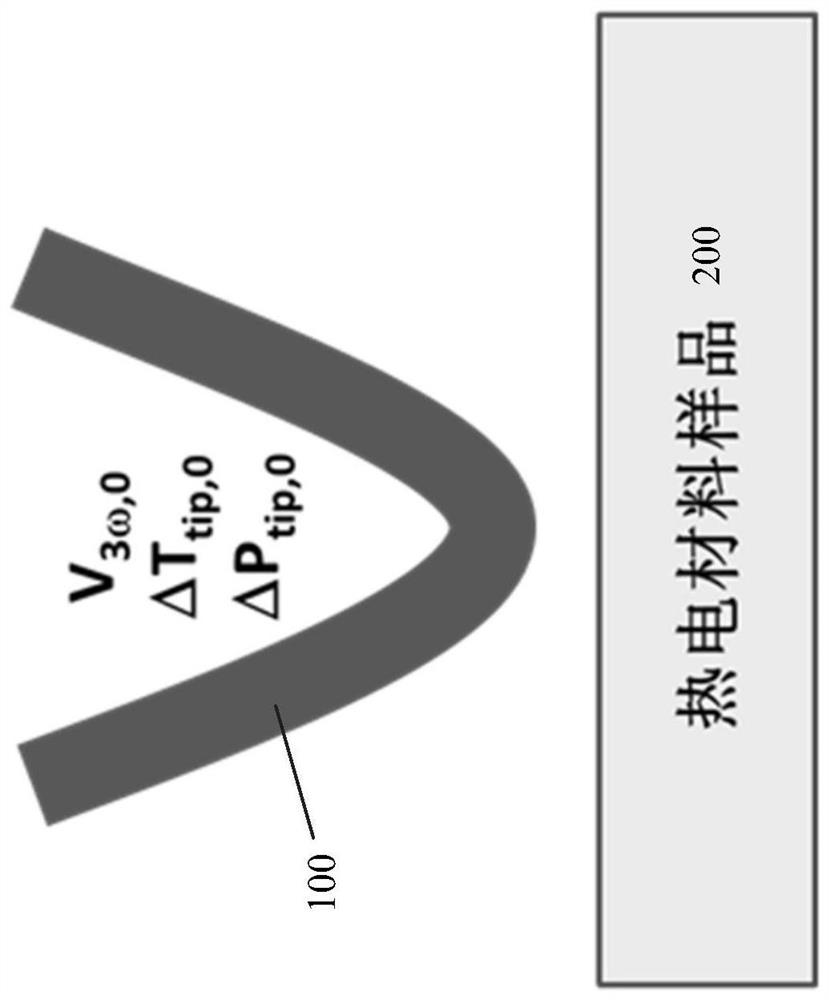

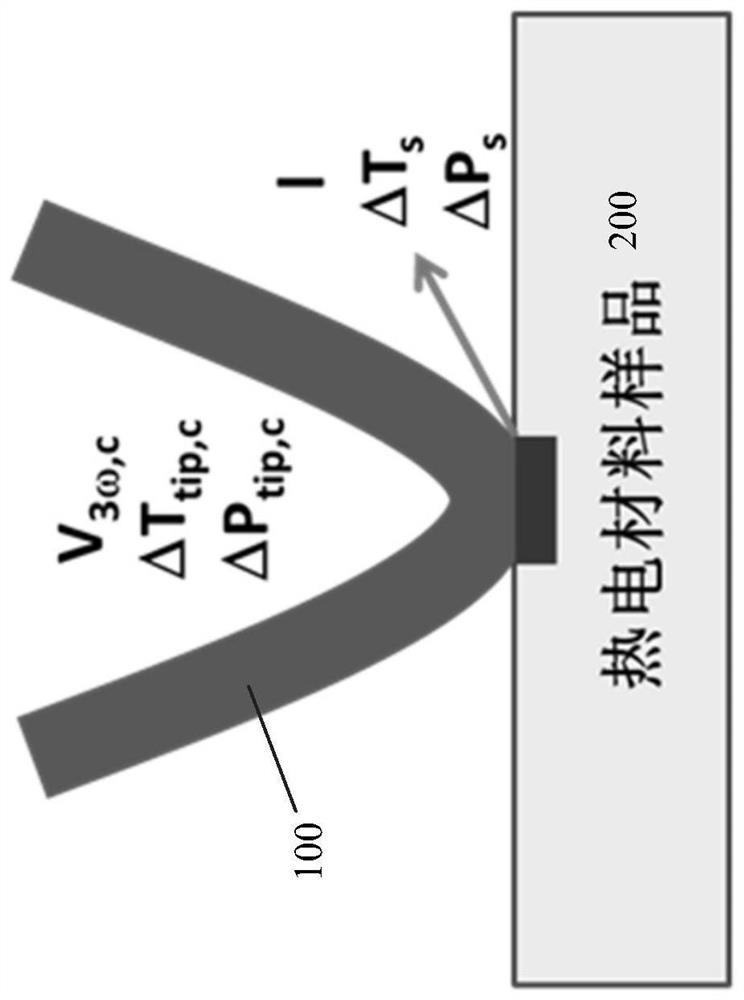

Method used

Image

Examples

Embodiment 1

[0106] The micro-region thermal conductivity of the organic thermoelectric material P3HT was tested by using the atomic force microscope-based in-situ characterization device for extremely low thermal conductivity at the nanometer scale. The polymer of 3-hexylthiophene (P3HT) is an organic thermoelectric material that has attracted extensive attention due to its suitable band gap, excellent doping reversibility and wide doping range. Pure P3HT has poor electrical transport properties due to the random aggregation of polymer chains induced by the flexible side hexyl chains, and the treatment of 1,3,5-trichlorobenzene (TCB) can make P3HT into a fibrous directional arrangement , thereby greatly improving the thermoelectric conversion performance of the fiber axis. The P3HT materials involved in the experiment include: TCB-treated oriented P3HT fiber axial (TCB-P3HT-axial), TCB-treated oriented P3HT fiber radial (TCB-treated P3HT-radial), and non-TCB-treated The surface of the am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com