Method for controlling cutting force mutation in curve turning machining

A technology for controlling curves and cutting forces, applied in program control, computer control, general control systems, etc., can solve problems such as lack of applicability, high energy consumption, and affecting the processing quality of parts, and achieve the effect of efficiently completing curve turning processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

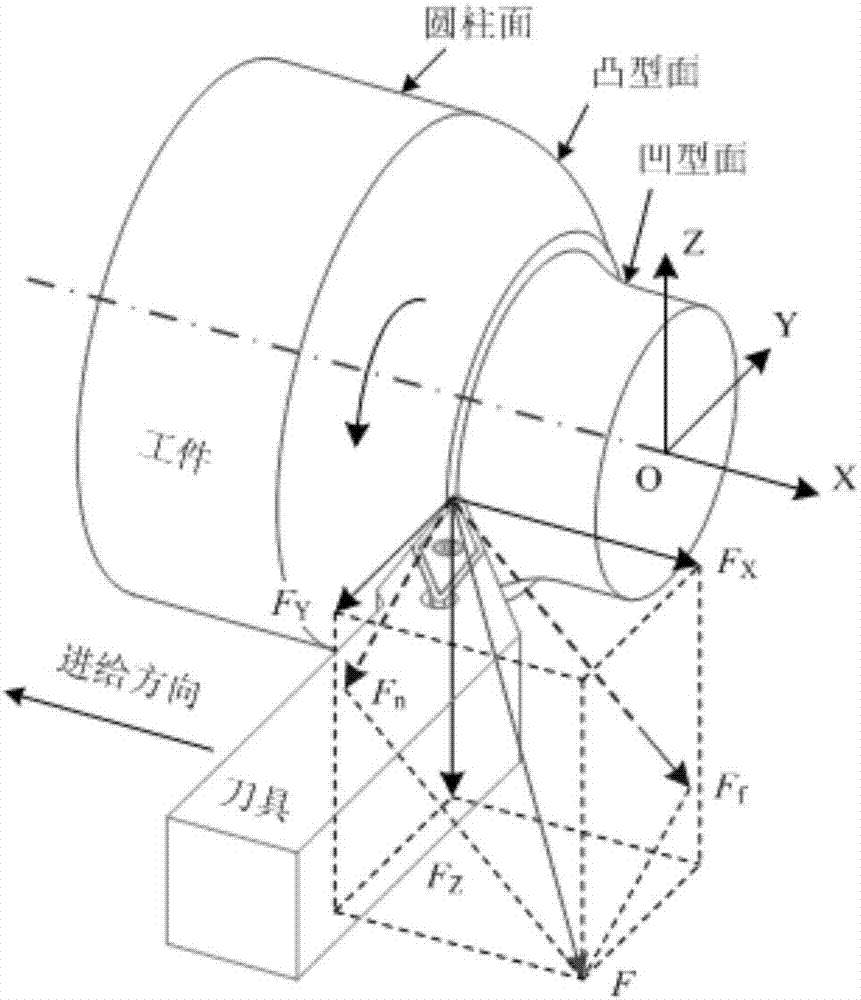

[0110] The test was carried out in the CNC precision turning center, and the cutting force F under the state of linear cutting was collected by the dynamometer on the world coordinate system OXYZ X1 , F Y1and F Z1 , the sampling frequency is 10KHz, the material of the test piece is 58SiMn high-strength steel, the rake angle of the tool is 0°, the rear angle is 5°, the main declination angle is 93°, the secondary declination angle is 52°, and the radius of the tool tip arc is 0.8mm.

[0111] 1. Conduct cutting force model coefficient calibration test

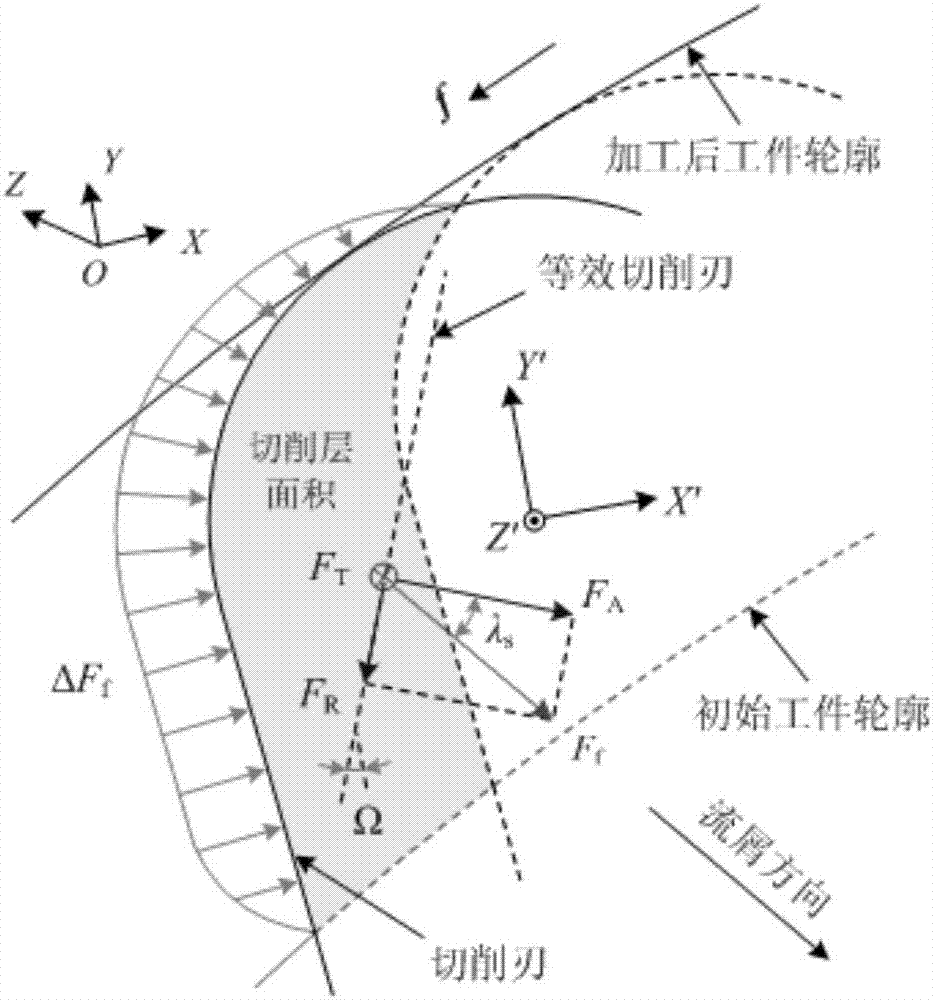

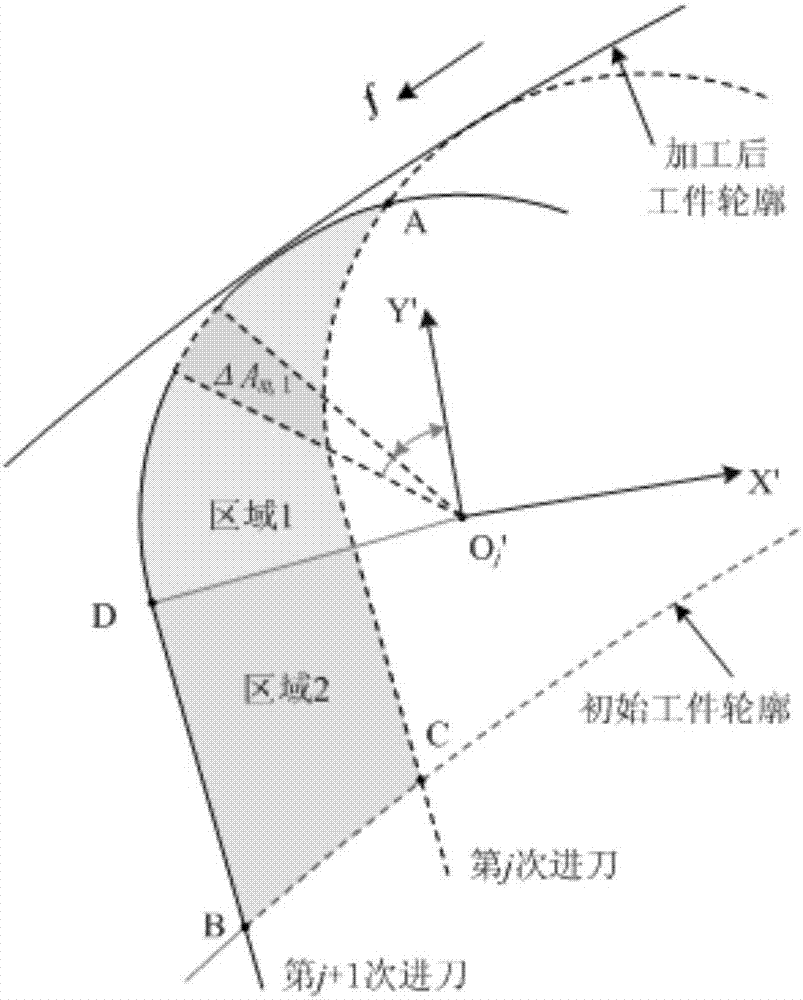

[0112] The factors and level design of the cutting force model coefficient calibration test are shown in Table 1, and the collected cutting force is expressed as a function of the cutting layer area, as shown in Figure 5 As shown, the cutting force model coefficients are calibrated according to the above calibration method, and the double exponential function

[0113]

[0114] Fit the coefficients of the cutting force mode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com