Method for jointly optimizing tool geometry parameters and machining process parameters

A technology of processing technology and structural parameters, applied in the field of mechanical processing, can solve the problem of not optimizing the structural parameters and processing parameters of the tool at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

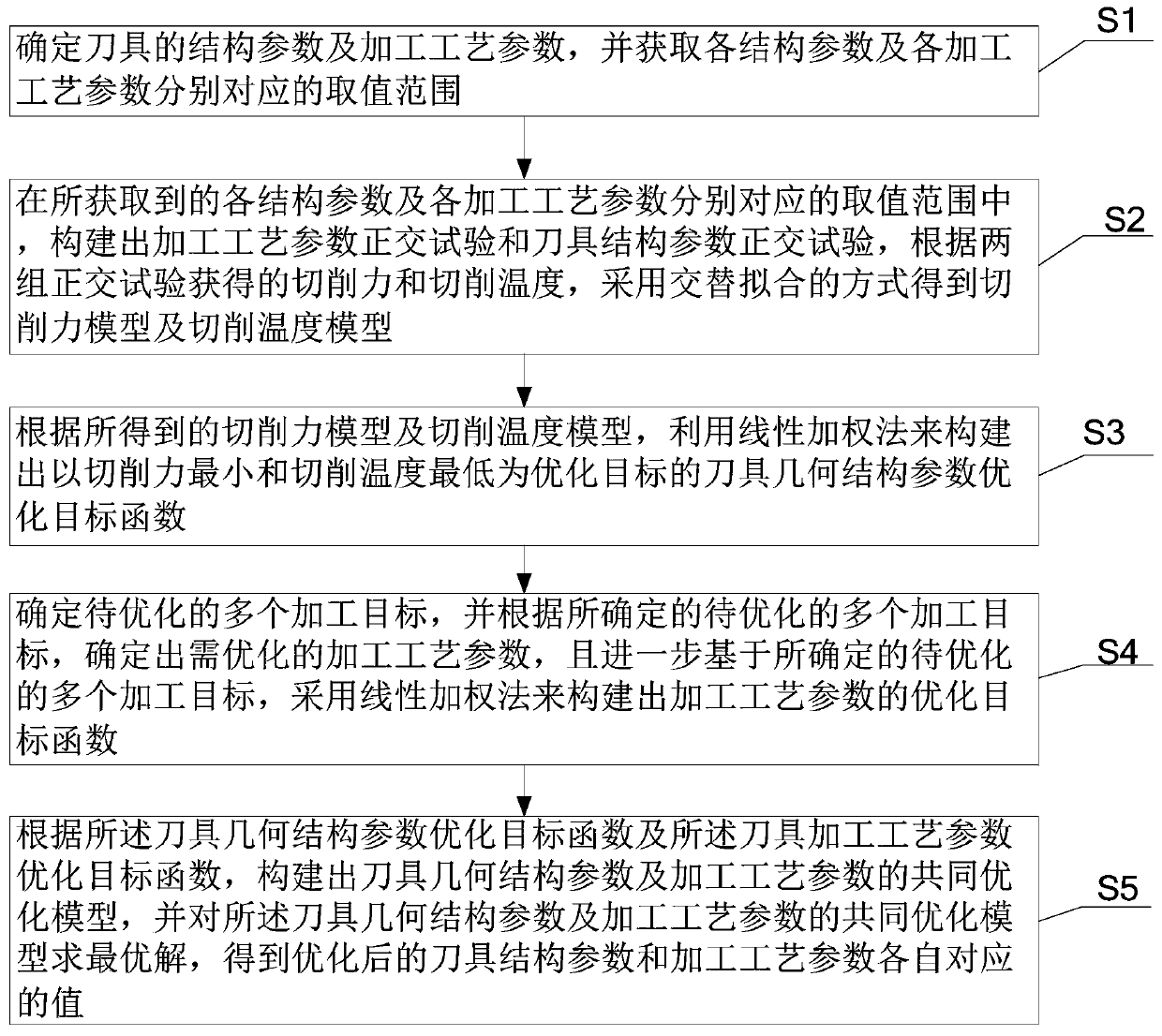

[0023] Such as figure 1 As shown, in the embodiment of the present invention, a method for co-optimizing the geometric structure parameters of the tool and the processing technology parameters is proposed, which includes the following steps:

[0024] Step S1, determining the structural parameters and processing technology parameters of the tool, and obtaining the value ranges corresponding to each structural parameter and each processing technology parameter;

[0025] Step S2. In the value ranges corresponding to the obtained structural parameters and processing technology parameters, construct the processing technology parameter orthogonal test and the tool structure parameter orthogonal test, and the cutting force obtained according to the two sets of orthogonal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com