Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Excellent structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quick-frozen and fresh-keeping thousand-layer Tofu and preparation method thereof

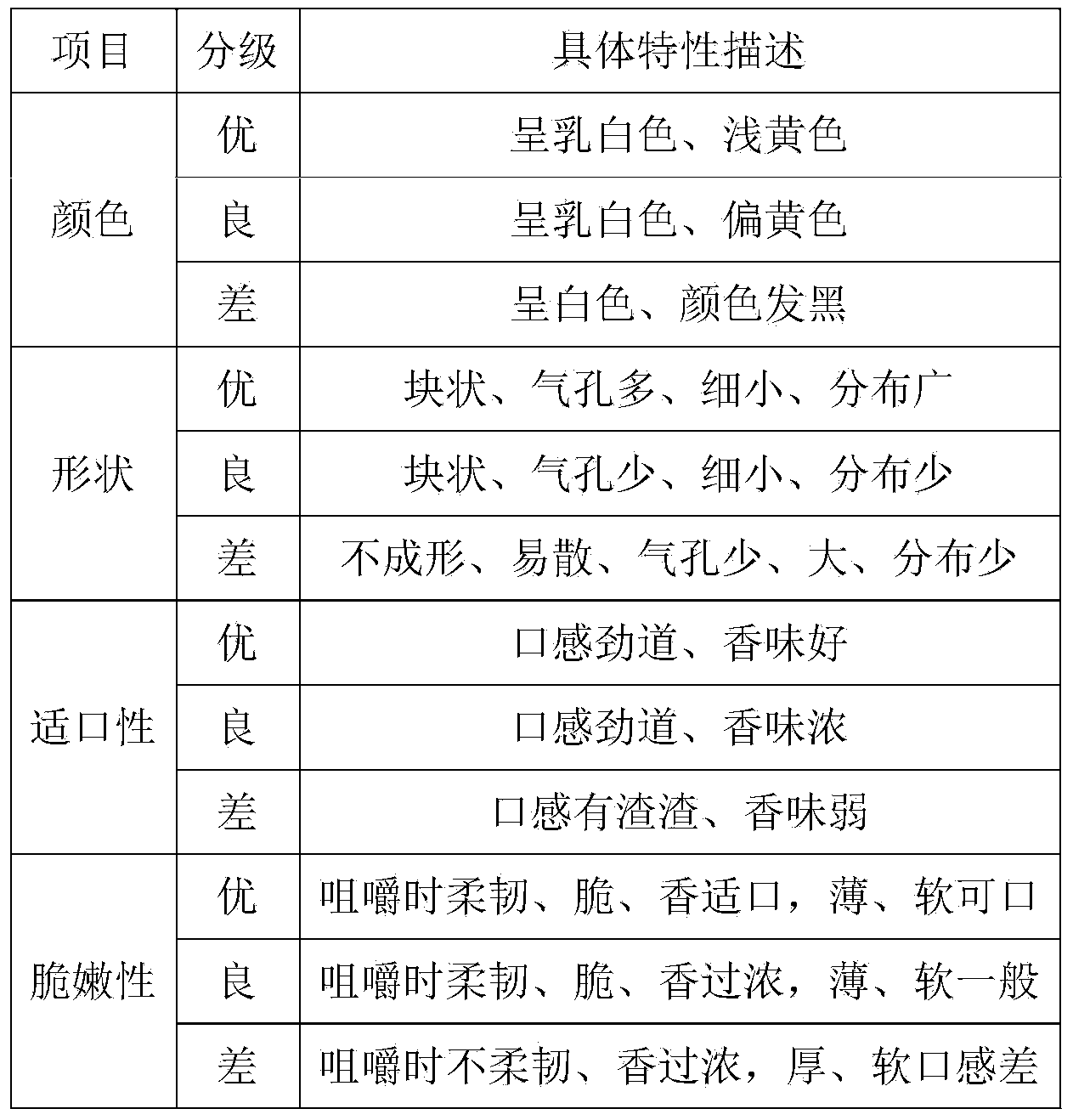

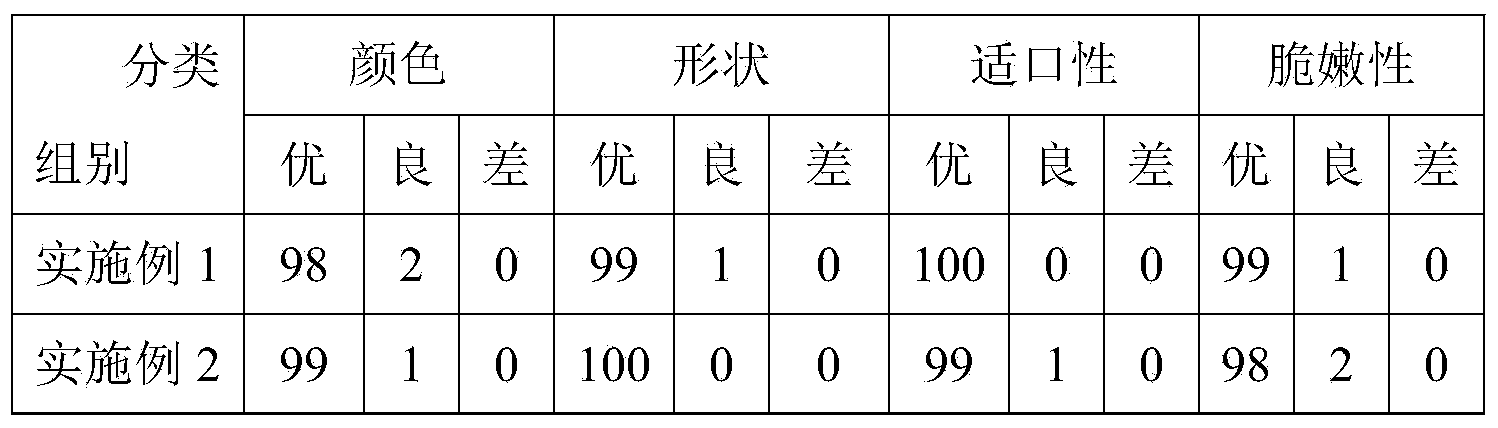

The invention discloses quick-frozen and fresh-keeping thousand-layer Tofu and a preparation method of the quick-frozen and fresh-keeping thousand-layer Tofu. The quick-frozen and fresh-keeping thousand-layer Tofu comprises the following components in parts by weight: 13-15 parts of soy isolate protein, 0.1-0.25 part of glutamine transaminase, 2-3 parts of cassava acetate modified starch, 5-8 parts of soybean oil, 0.3-0.6 part of aginomoto, 0.3-0.6 part of white sugar, 0.4-0.7 part of complex adhesive, 2.5-3.5 parts of duck egg white and 68-75 parts by weight of water. The quick-frozen and fresh-keeping thousand-layer Tofu disclosed by adopting the preparation method is prepared from the raw materials of the soy isolate protein, the glutamine transaminase, the cassava acetate modified starch, the soybean oil, the aginomoto, the white sugar, the complex adhesive and the duck egg white, keeps the original tender and fresh taste of Tofu, has a special tender, crisp, tasty, delicious taste, and has better elasticity and toughness, and strong soup water absorbing capacity; and regardless of frying, stir-frying, oil-frying, stewing or blending other seasonings, the quick-frozen and fresh-keeping thousand-layer Tofu is special in flavor and delicious in taste when being eaten.

Owner:云鹤食品有限公司

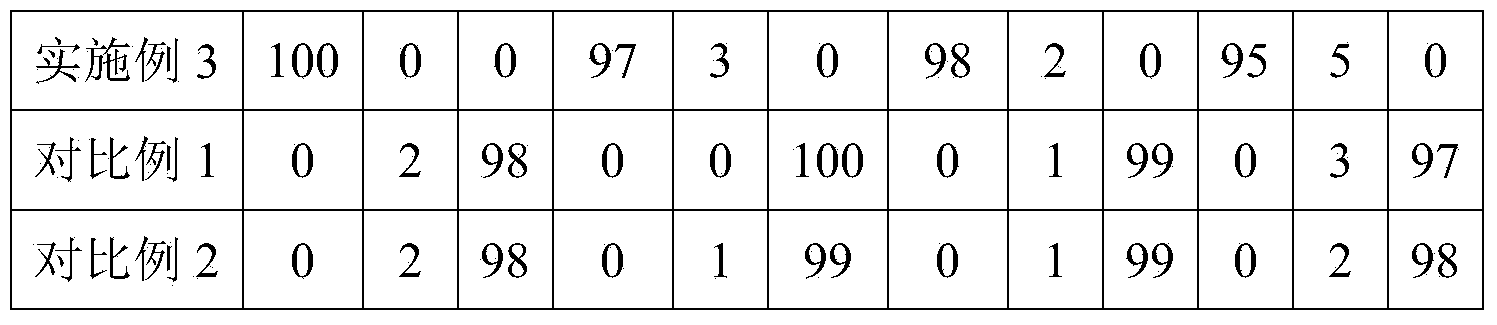

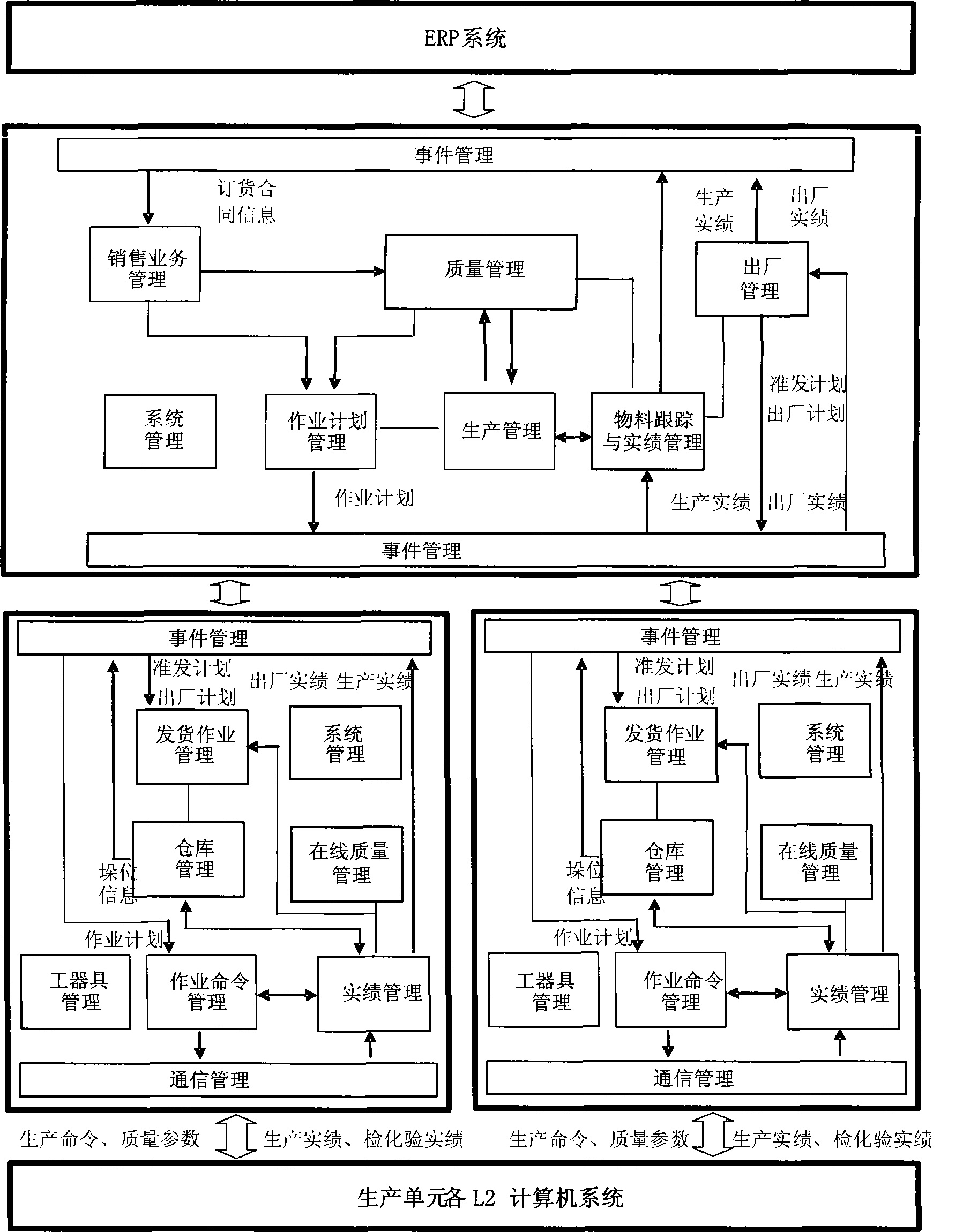

Layered MES software system architecture

InactiveCN101477655AExcellent structureImprove the efficiency of production organization managementSpecific program execution arrangementsSoftware system architectureSoftware

The invention relates to a layered MES software system architecture which comprises an upper-layer manufacturing management system and a lower-layer producing executive system, wherein, the manufacturing management system is connected with an upstream ERP system; the producing executive system is connected with a downstream PCS Process Control System; the manufacturing management system comprises a quality management module, a production management module and an operation plan management module; the producing executive system comprises an actual performance management module, a dispatch operation management module and a warehouse management module; and the connection between the manufacturing management system and the producing executive system is realized through a validity event process mode. The layered MES software system architecture has the advantages that the layered MES software system architecture is efficient, flexible and expandable; the efficiency of the producing organization management can be effectively improved; and various difficult problems in practical production management service caused by layer phenomenon are solved; and the layered MES software system architecture further has the advantages that the product quality can be effectively improved; the production cycle of the products is shortened; the output and the efficiency of the capital utilization are effectively increased; and the integrated production cost is reduced, thereby bringing great economic and social benefits to the enterprises.

Owner:SHAGANG GROUP

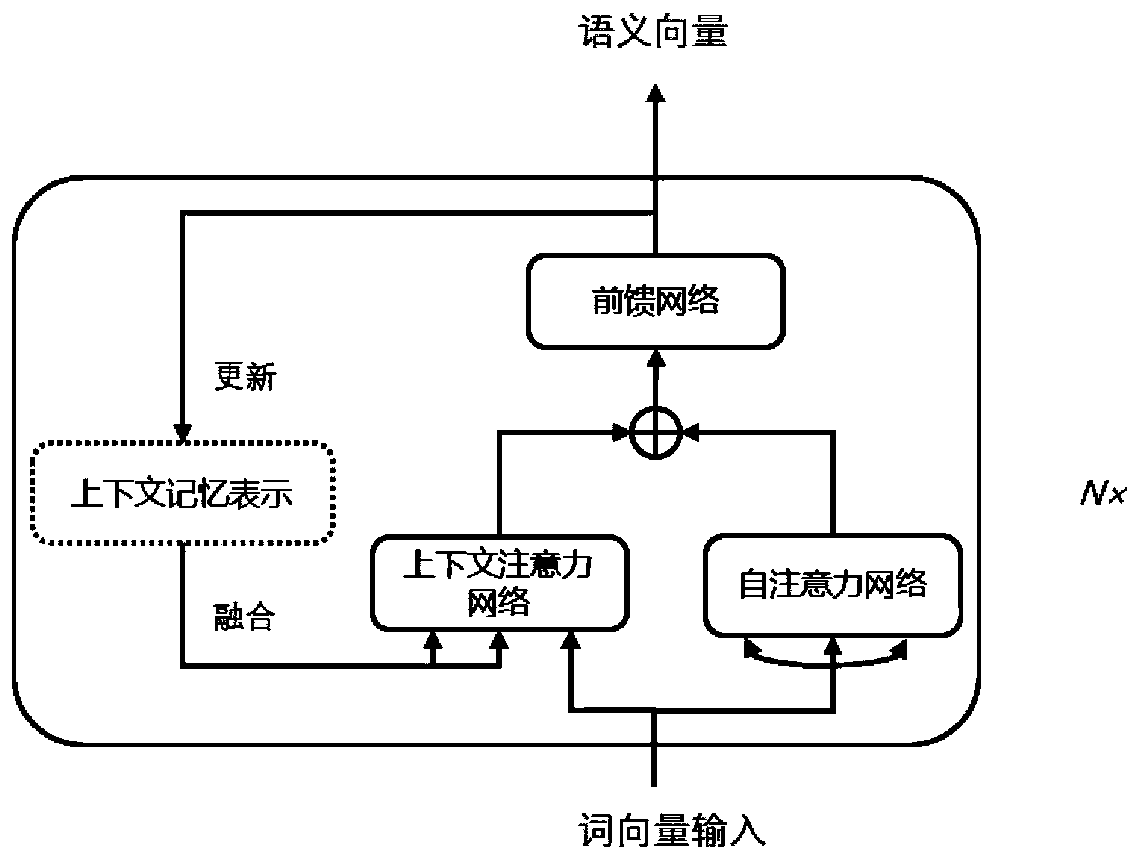

Text-level neural machine translation method based on context memory network

PendingCN111160050AExcellent structureContextually consistentNatural language translationText corpusMachine translation

The invention discloses a text-level neural machine translation method based on a context memory network. The method comprises the following steps: constructing a Transformer model of the context memory network; constructing a parallel corpus to obtain word embedding input of the model; at an encoder end, enabling source language input to be subjected to encoding representation in combination witha context memory module, and updating the current encoding representation into the context memory module; at a decoder end, processing the target language in combination with the source language coding representation to obtain vector representations with consistent lengths; performing softmax normalization operation on an output result of the decoder to obtain predicted distribution, and completing a training process of the model; and carrying out chapter-level machine translation by utilizing the trained model, sending the text into the model sentence by sentence for translation, and obtaining a translation result in an autoregression mode. The context memory module is added to dynamically maintain context memory information, related context information is introduced, and the problem that translation result contexts are inconsistent is solved.

Owner:沈阳雅译网络技术有限公司

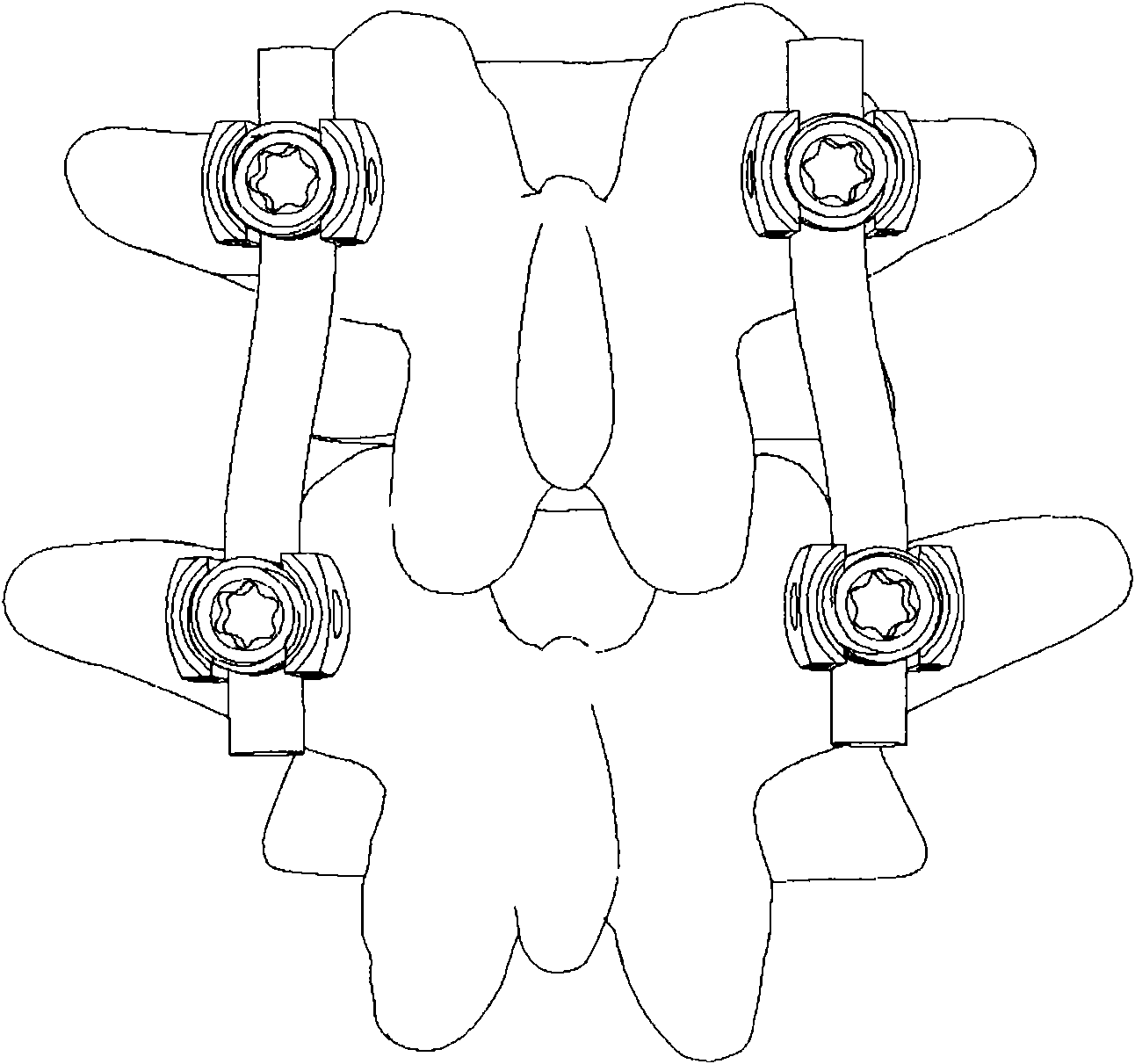

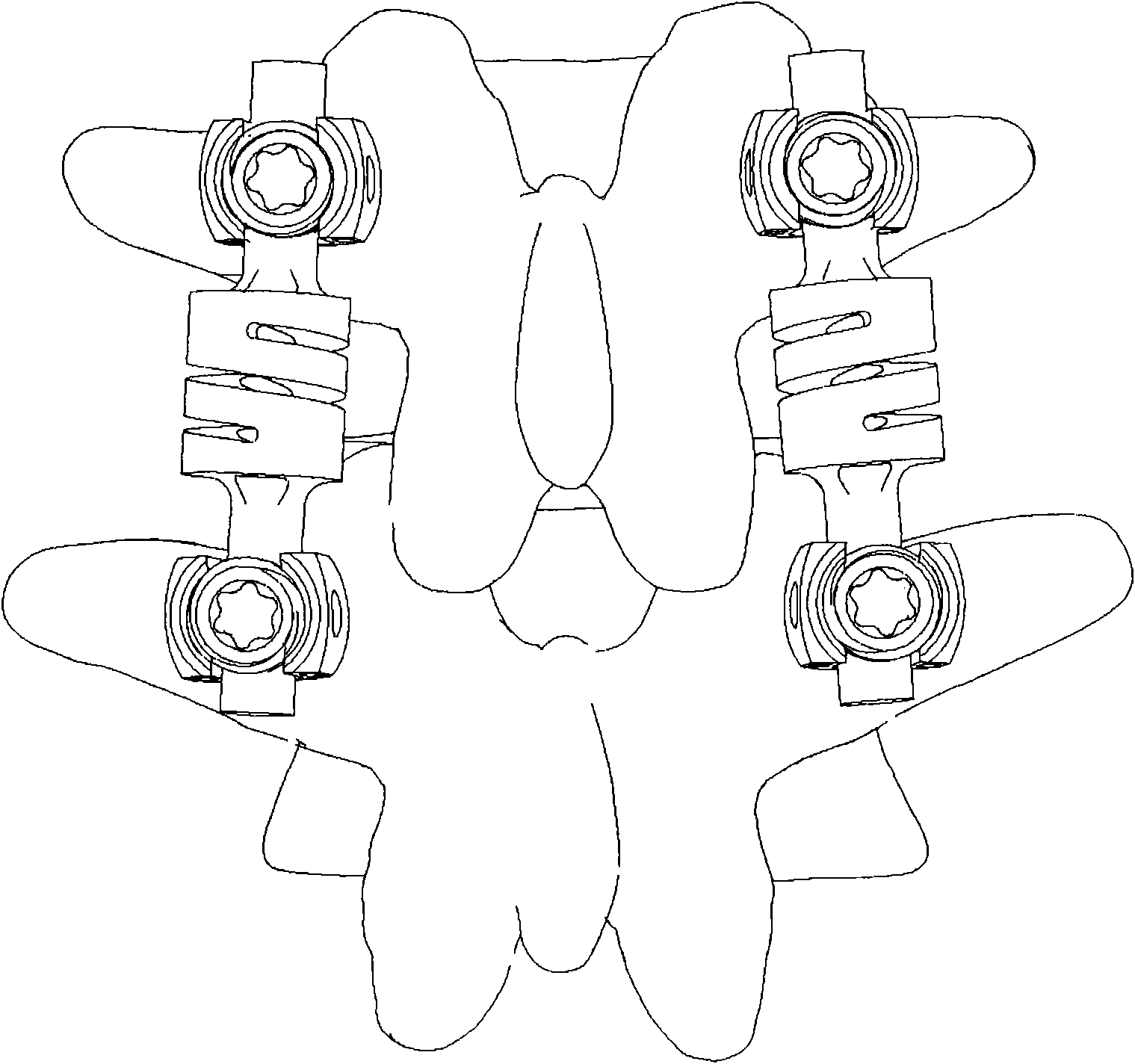

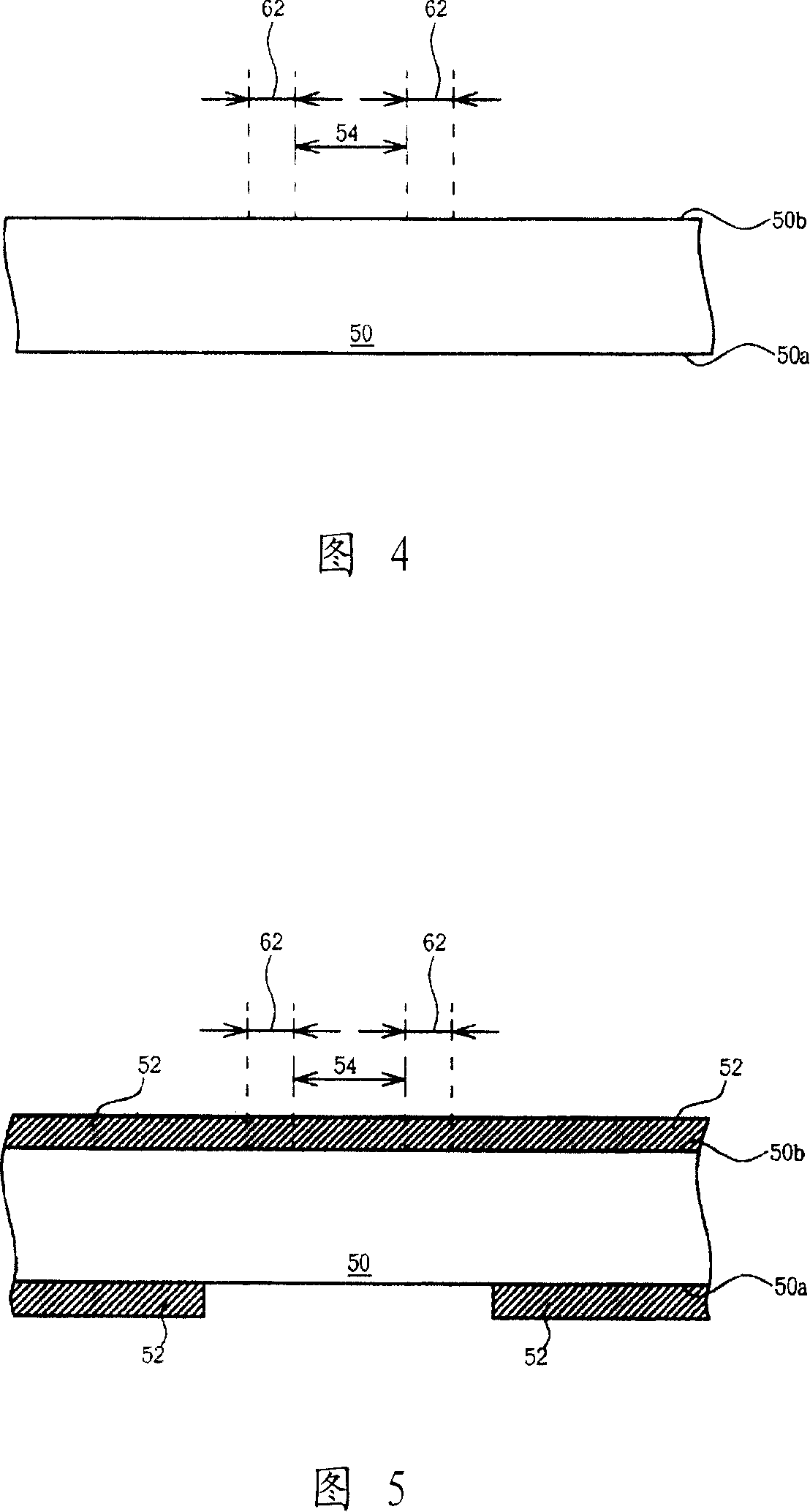

Spinal column dynamic connection rod

InactiveCN102106750AExcellent structureImprove performanceInternal osteosythesisSpinal columnPhysiological movement

The invention provides a spinal column dynamic connection rod, comprising an upper connection part, a lower connection part and an elastic piece, wherein the upper connection part and the lower connection part are connected with each other via the elastic piece. The spinal column dynamic connection rod is characterized in that: the upper connection part, the lower connection part and the elastic piece are integrally formed; the elastic piece is provided with an elastic hole; and an elastic groove is formed on an external periphery of the elastic piece. The spinal column dynamic connection rodprovided by the invention can realize stability of the spinal column and keep the normal physiological movement of the spinal column with a simple structure.

Owner:SHANGHAI MICROPORT ORTHOPEDICS

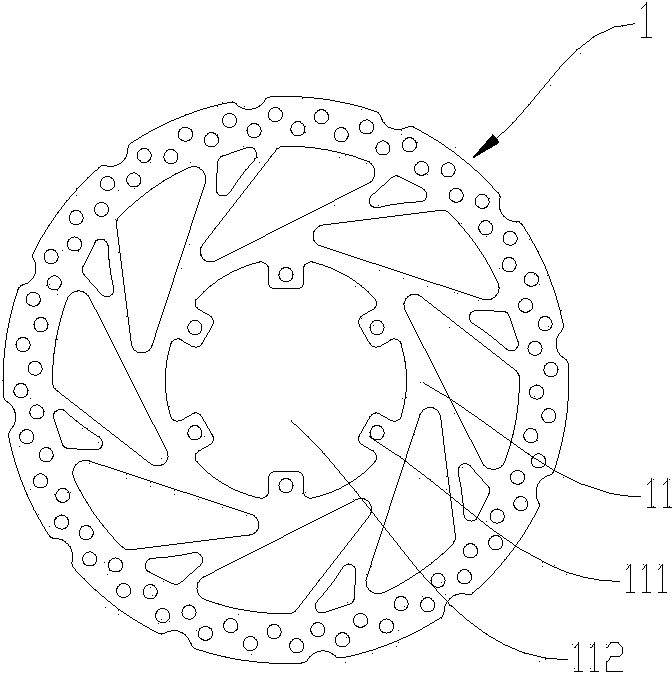

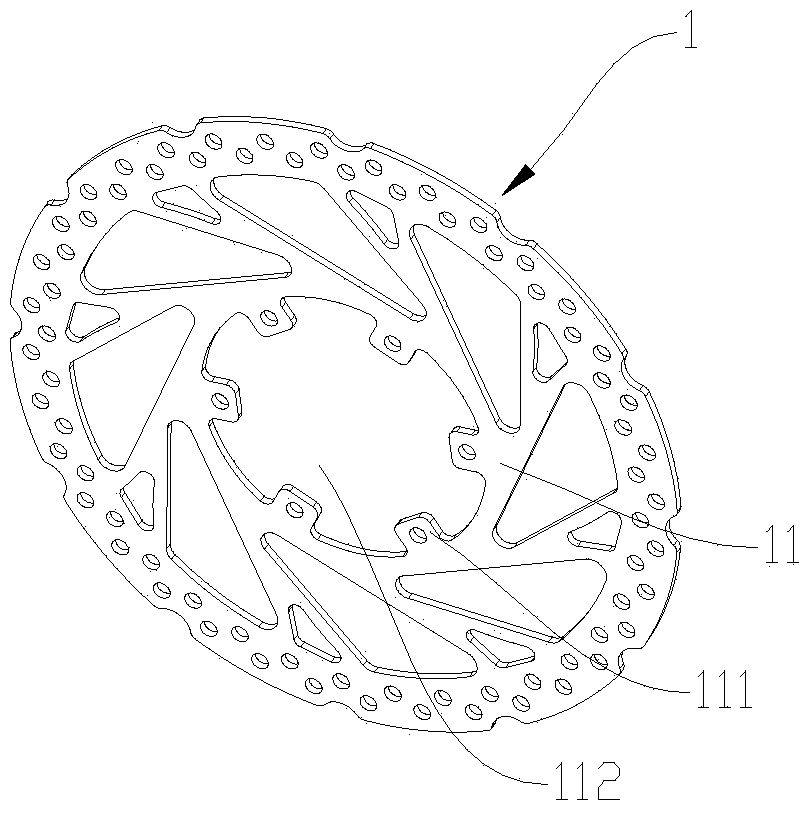

Disc brake for bicycle

ActiveCN103953670AExcellent structureImprove performanceBraking discsCycle brakesEngineeringDisc brake

The invention provides a disc brake for a bicycle. The disc brake comprises a brake disc, a hub shaft, a hub shell, a brake disc connecting piece, a mounting shaft sleeve and a locking piece, wherein the brake disc connecting piece is provided with a pipe-shaped main body provided with internal threads, and a ring-shaped lug boss; the mounting shaft sleeve is provided with a shaft sleeve main body and a disc connecting part; the locking piece is provided with a pipe-shaped part that is provided with external threads, and a flange; the external surface section of the pipe-shaped main body takes the structure of a polygon; bulges are arranged on the surface of the ring-shaped lug boss; the inner surface of a central hole of the shaft sleeve main body can be matched with the external surface of the pipe-shaped main body; concave pits that can be matched with the bulges are formed in the end surface, facing the brake disc connecting piece, of the shaft sleeve main body; when the external threads are matched with the internal threads, the inner surface of the mounting shaft sleeve is matched with the external surface of the pipe-shaped main body, and the bulges are matched with the concave pits, so that the mounting shaft sleeve is held by the locking piece and the brake disc connecting piece.

Owner:HONG ZHAN H P P SU ZHOUCO LTD

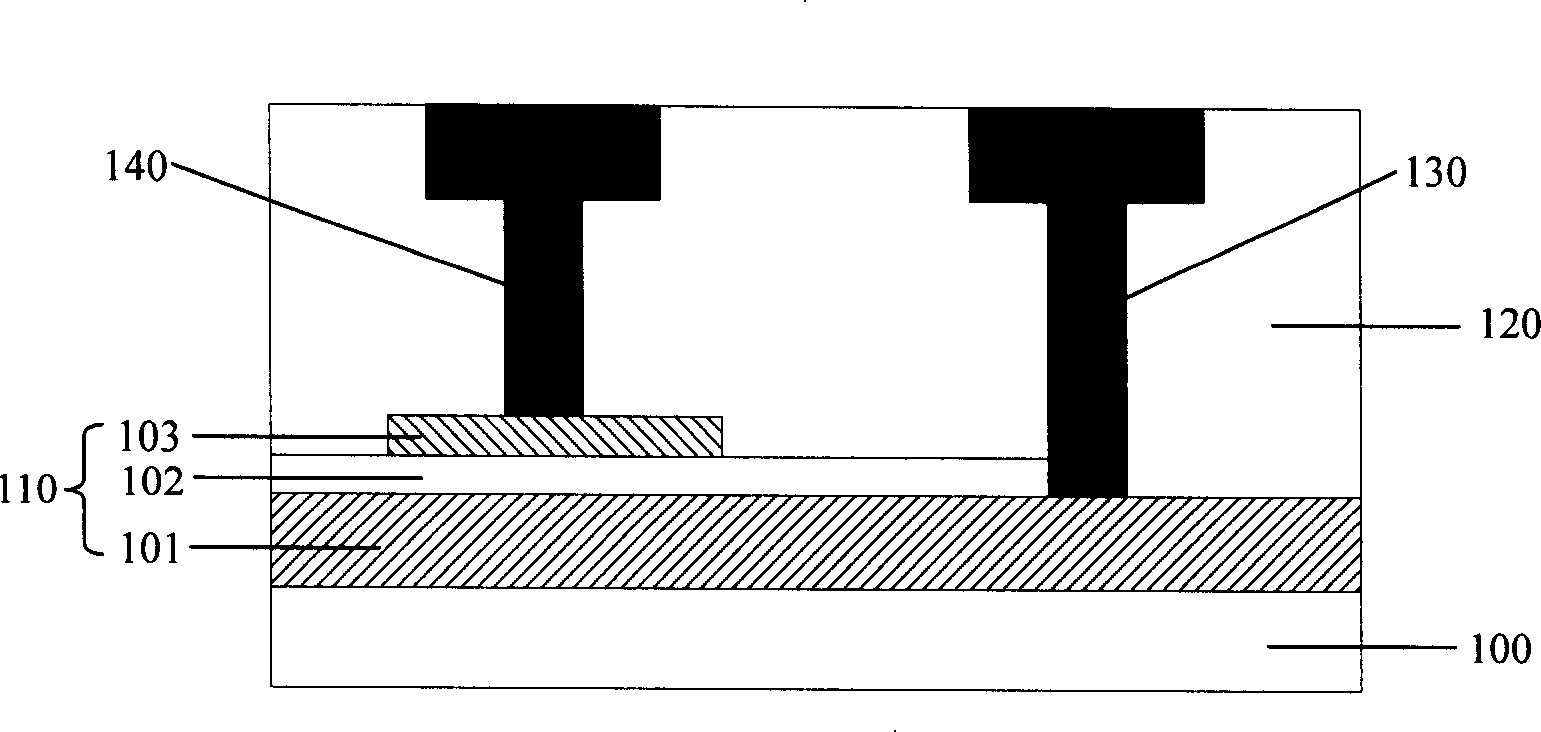

Metal-insulator-metal capacitor and its manufacture process

InactiveCN101192513AResolve Reaction Generated ResiduesExcellent structureSolid-state devicesSemiconductor/solid-state device manufacturingEtchingMetal

The invention discloses a method for manufacturing a metal-insulator-metallic capacitor. The method includes the following steps: a first metallic layer is generated on an insulating layer; a first dielectric layer is generated on the first metallic layer; a second dielectric layer is generated on the first dielectric layer; a groove is generated in the second dielectric layer; a second metallic layer is generated in the groove; the second metallic layer and the second dielectric layer are processes by planarization till the surface of the second dielectric layer is exposed. The invention also accordingly discloses a metal-insulator-metallic capacitor, which includes a lower electrode plate generated on the insulating layer, the dielectric layer generated on the lower electrode plate, an upper electrode plate generated on the dielectric layer and the dielectric layer between metals generated before the upper electrode plate and on two sides of the upper electrode plate. The metal-insulator-metallic capacitor and the manufacturing method of the invention can avoid an appearance of defect with coronal etching.

Owner:SEMICON MFG INT (SHANGHAI) CORP

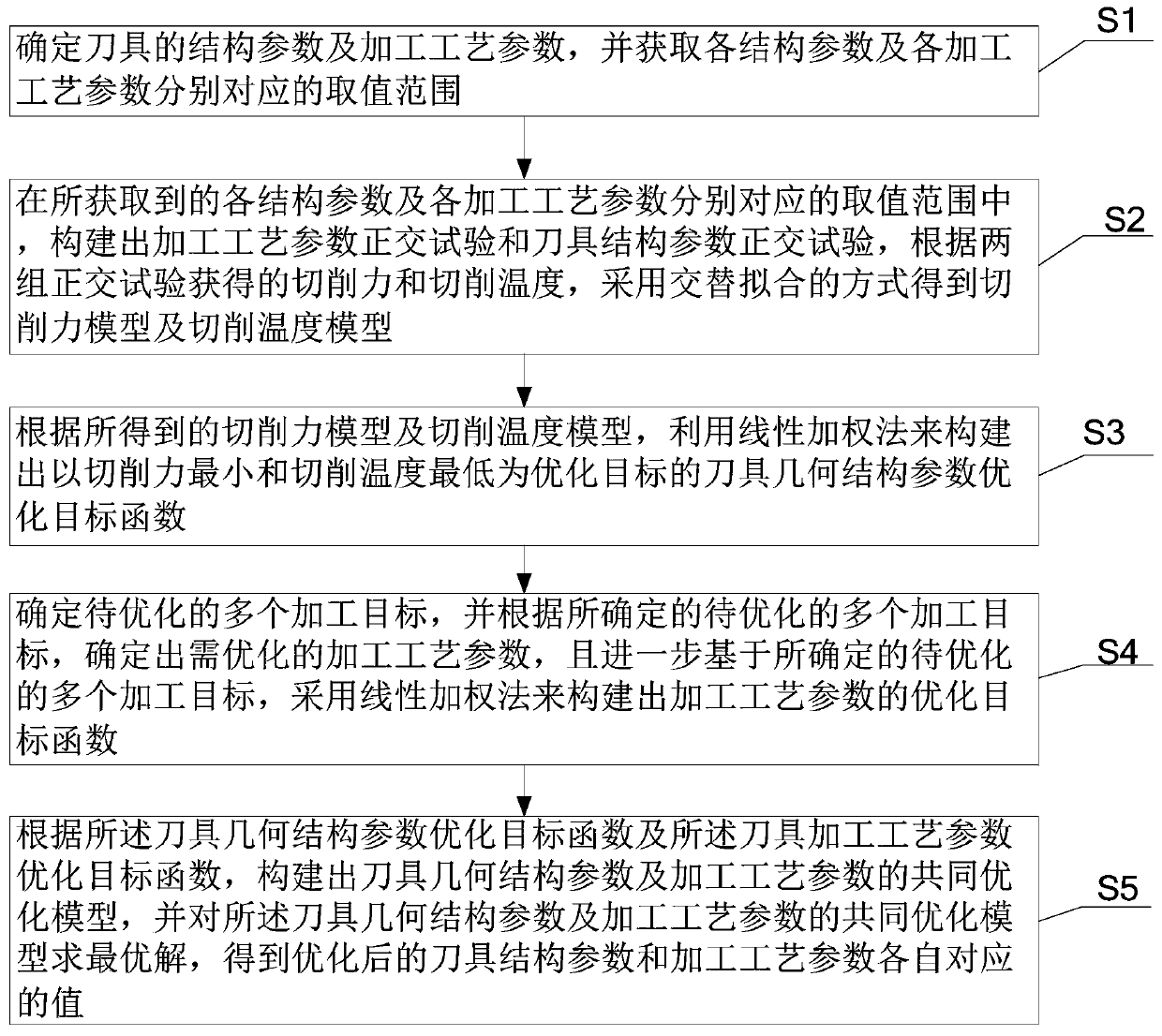

Method for jointly optimizing tool geometry parameters and machining process parameters

ActiveCN109839895AExcellent structureExcellent processabilityNumerical controlCutting force modelProcess engineering

The invention provides a method for jointly optimizing tool geometry parameters and machining process parameters. The method comprises the steps that structural parameters of a tool, machining processparameters and respective ranges of values are determined; the orthogonal test of the machining process parameters and the orthogonal test of the structural parameters of the tool are constructed inrespective ranges of values; a cutting force model and a cutting temperature model are acquired according to the cutting force data and cutting temperature data acquired by two orthogonal tests; according to the cutting force model and the cutting temperature model, the optimization objective function of the geometry structural parameters of the tool is constructed; according to a machining targetto be optimized, the machining process parameters to be optimized are determined, and the optimization objective function of the machining process parameter is constructed; and according to the abovetwo optimization objective functions, a common optimization model is constructed, and the optimal solution is acquired to acquire corresponding values of the optimized tool structural parameters andmachining process parameters. According to the invention, each machining target in the actual machining process is comprehensively considered, and the optimal tool structural parameters and machiningprocess parameters are acquired.

Owner:WENZHOU UNIVERSITY

Acute angle steel and triangular space steel structure including the same

The invention provides an acute angle steel and a triangular space steel structure including the same. The acute angle steel comprises an acute angle steel main body, the cross-section of the acute angle steel main body is in a < shape, the < shape is composed of a first side edge, a second side edge and an included angle between the first side edge and the second side edge, the length of the first side edge is A, the length of the second side edge is B, the included angle of the first side edge and the second side edge is alpha, A:B=0.4-1.0, and alpha is 40-80 degrees. The invention further provides the triangular space steel structure including the acute angle steel. According to the acute angle steel and the triangular space steel structure including the same, part of right angle steel is replaced by the acute angle steel, and conventional rectangular space steel truss and rectangular four-limb column composed of the right angle steel are replaced by triangular space steel truss and three-limb column. The acute angle steel and the triangular space steel structure including the same have the advantages of stable structure, simplified processing, convenient installation, wide adaptability, low cost and the like.

Owner:湖南科鑫电力设计有限公司 +1

Zeolite diatom ooze coating

The invention relates to a zeolite diatom ooze coating. According to the technical scheme, the zeolite diatom ooze coating mainly comprises the following components in percentage by mass: 15-35% of zeolite powder, 10-30% of diatomite, 10-20% of sea-foam stone powder, 10-25% of titanium dioxide, 5-20% of dolomite dust, 3-10% of white carbon black, 3-10% of kaolin, 3-8% of ash calcium powder, 0.3-1% of cellulose ether, and 0-10% of dispersible latex powder. The zeolite diatom ooze coating is prepared by combining zeolite and sepiolite with diatomite and adding a plurality of auxiliaries through a scientific formula, wherein zeolite with most molecular sieve representativeness and ion exchange, adsorption and dispersion, catalysis, chemical reaction and reversible dehydration properties is used as a main raw material, sepiolite with maximum specific surface area as a non-metallic mineral, unique content porous structure and the known strongest adsorption capability is used as an auxiliary raw material, and the technical effects of greatly improving the adsorption performance and ion exchange performance, increasing the removal of harmful substances such as formaldehyde, benzene, ammonia and the like, purifying air and eliminating peculiar smell are achieved.

Owner:李长松 +1

Adjustable polishing equipment for plastic mould production

InactiveCN109759940AEliminate polishing dead angleExcellent structureEdge grinding machinesPolishing machinesTooth missingAbrasive

The invention relates to adjustable polishing equipment for plastic mould production. The adjustable polishing equipment for the plastic mould production comprises a box body, a polishing cylinder, anelectric motor, a stirring shaft, stirring blades, a transmission shaft, a screw rod, a first sliding block, a ball nut pair, a transmission gear, a chain, a driving machine, a driving shaft, a tooth-missing gear, a material blocking plate, a transmission rod, a transmission piece, a cam, a second sliding block, a guide sleeve and a second pin shaft, wherein the polishing cylinder is arranged onthe bottom end surface of the interior of the box body, the stirring shaft is rotationally connected into the box body through a bearing sleeve, and the stirring blades are arranged on the stirring shaft; the first sliding block is slidably connected into the box body, the transmission shaft and the driving shaft are rotationally connected into the box body separately, and the material blocking plate is rotationally connected into the box body; and the second pin shaft is arranged at the right end of the material blocking plate, and the cam is arranged on the transmission shaft. The adjustablepolishing equipment for the plastic mould production is excellent in structure, reasonable in design, operation is simple and convenient, contact area between materials and abrasives is increased, the polishing effect is improved, the polishing efficiency is improved, and wide application prospect and high creativity are achieved.

Owner:安徽皖精模具科技有限公司

Load uncertainty-based material structure multi-scale topological optimization design method

ActiveCN112417692AExcellent structureReduce complexityDesign optimisation/simulationSpecial data processing applicationsMicro structureAlgorithm

The invention provides a load uncertainty-based material structure multi-scale topological optimization design method, which comprises the following steps of defining a design domain, initializing design parameters, sequentially performing finite element analysis on a microstructure and a macrostructure of a material, calculating an expected value and a variance of the flexibility of the structureby adopting a perturbation method, constructing a material structure multi-scale topological optimization model based on load uncertainty, performing sensitivity analysis, correcting an objective function and constraint sensitivity by using a mapping filtering method, updating a design variable by using an OC algorithm, judging whether a convergence criterion is met or not, and finally outputtinga macroscopic topological structure and a material microstructure topological structure. According to the method, the first-order perturbation method is adopted to quantize the uncertain load, the complexity of statistical index calculation is effectively reduced, the calculation efficiency is improved, the multi-scale robustness topological optimization design of a macrostructure and a materialmicrostructure is achieved, and the obtained periodic multi-space composite material structure has better robustness.

Owner:EAST CHINA JIAOTONG UNIVERSITY

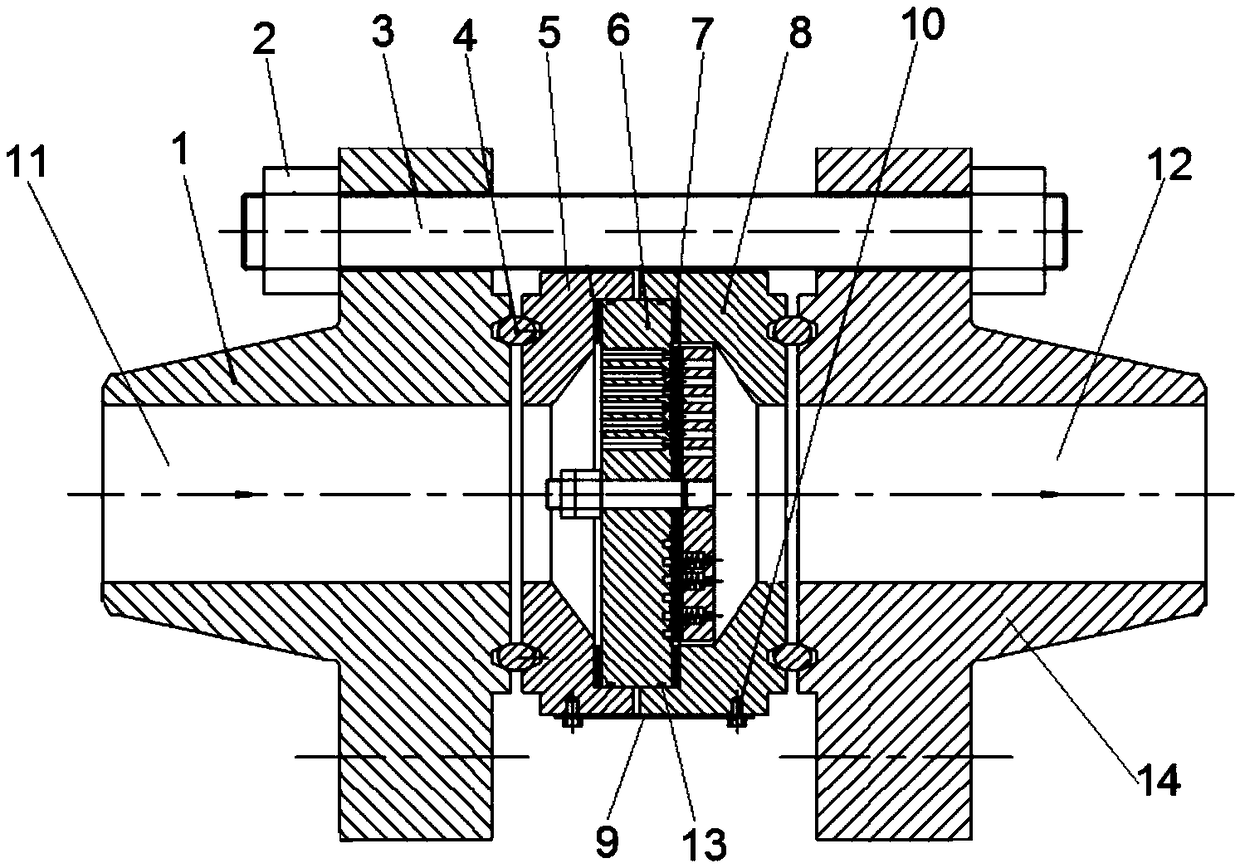

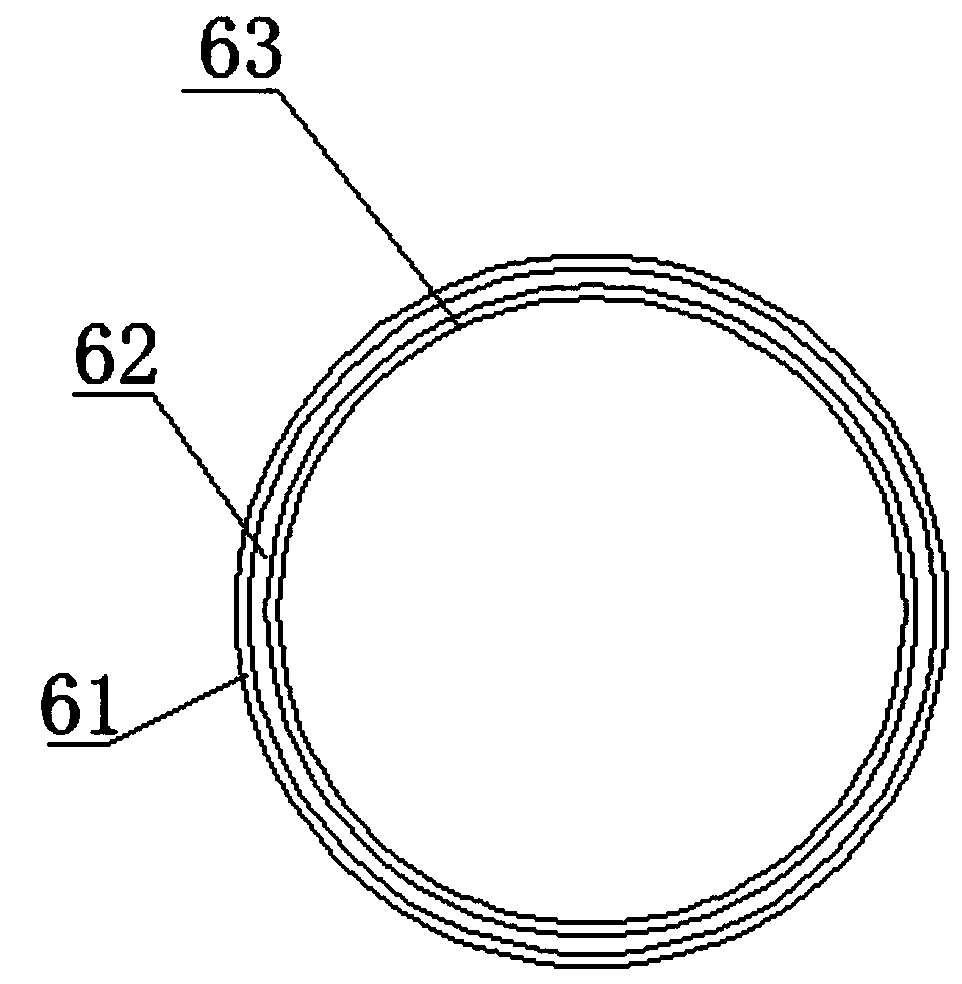

Novel air valve type check valve

InactiveCN109099193AExcellent structureExtended service lifeCheck valvesValve housingsEngineeringCheck valve

The invention discloses a novel air valve type check valve. The novel air valve type check valve comprises a left flange, a right flange and an air valve assembly, and a valve body assembly is arranged inside the left flange and the right flange. Two annular grooves are correspondingly formed in the joints of the outer side of the valve body assembly with the left flange and the right flange, thetwo annular grooves are correspondingly formed in the upper and lower portions of the joints of the valve body assembly with the left flange and the right flange, and the two annular grooves are symmetrically formed in an up and down mode. The novel air valve type check valve improves a sealing gasket, an original annular sealing gasket is changed into a graphite-coated type tooth-shaped sealing gasket, and a fit clearance between a valve body and the air valve assembly is reduced; and a fluorine rubber O-ring is added for secondary sealing, and a trace of leakage is completely blocked in thevalve body. The novel air valve type check valve adopts an open type air valve structure of which sealing of the valve body and the air valve assembly is all completed on a valve seat, so that a leakage point between the valve cover and the valve seat on an air valve is avoided, and the structure is more excellent, reasonable and safe.

Owner:ZHEJIANG CHANGLONG PETROCHEM EQUIP CO LTD

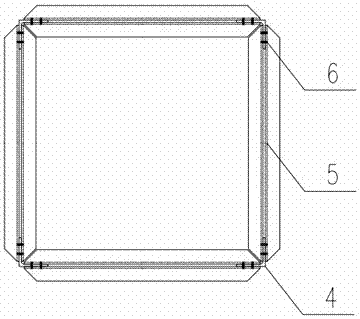

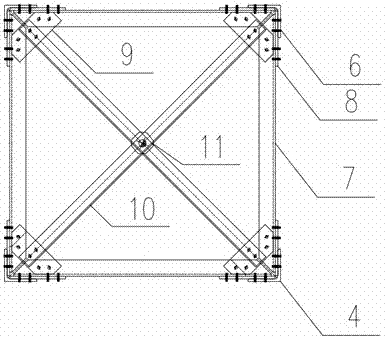

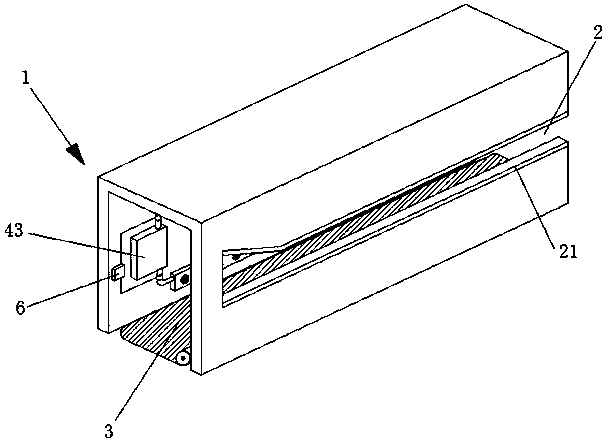

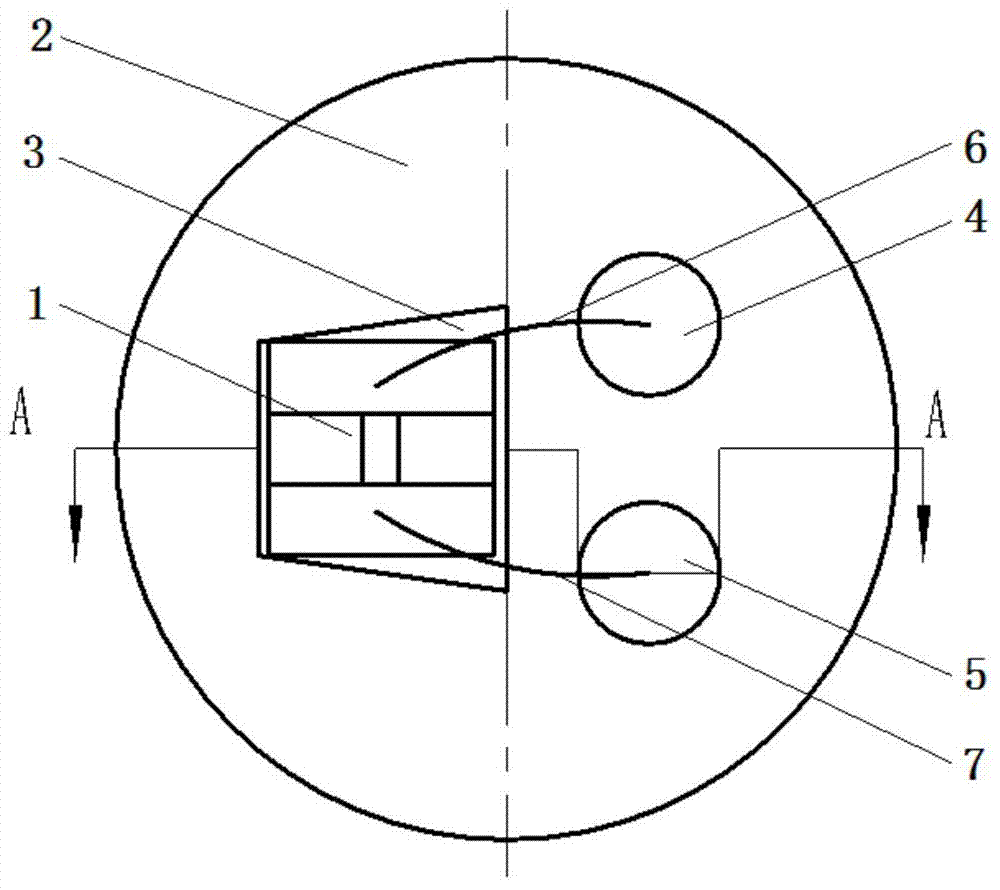

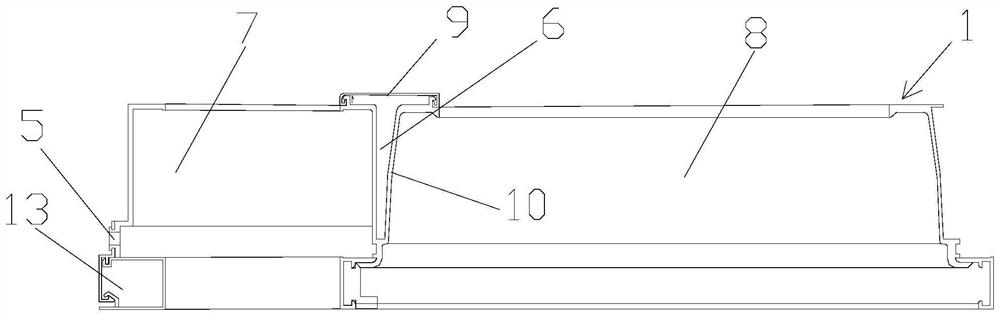

Prestressed self-locking anchor bolt reinforced variable-diameter single-pile fan foundation under offshore rock foundation condition and construction method thereof

ActiveCN106320360AExcellent structureSmall amount of workFoundation engineeringSelf lockingRock bolt

The invention discloses a prestressed self-locking anchor bolt reinforced variable-diameter single-pile fan foundation under an offshore rock foundation condition and a construction method of the prestressed self-locking anchor bolt reinforced variable-diameter single-pile fan foundation under the offshore rock foundation condition. The foundation comprises a variable-diameter single-pile foundation body (1) and prestressed casing self-locking head anchor bolts (2); the variable-diameter single-pile foundation body (1) comprises an underwater variable-diameter section steel cylinder (3) and a buried section straight cylinder (4), the top of the underwater variable-diameter section steel cylinder (3) is connected with an upper tower cylinder (5), and an inner boot beam (6) and an outer boot beam (7) are welded to the inner wall and the outer wall of the buried section straight cylinder (4); steel casings (8) penetrate the outer boot beam (7) and are welded to the outer wall of the buried section straight cylinder (4); and the prestressed casing self-locking head anchor bolts (2) penetrate the steel casings (8), the lower ends of the prestressed casing self-locking head anchor bolts (2) are anchored into rock, and the upper ends of the prestressed casing self-locking head anchor bolts (2) are fixed to the top faces of the steel casings (8) through press joints (9). According to the prestressed self-locking anchor bolt reinforced variable-diameter single-pile fan foundation under the offshore rock foundation condition, the designed variable-diameter single-pile foundation body can be matched with the stress of the different heights of the variable-diameter single-pile foundation body, the structure is more efficient and economical, and the fatigue resistance and the durability are high.

Owner:JIANGSU JINHAI NEW ENERGY TECH +1

Anti-corrosion heat tracing sampling composite pipe

PendingCN109404648AExcellent structureExtended service lifeThermal insulationPipe heating/coolingMetalMaterials science

The invention relates to an anti-corrosion heat tracing sampling composite pipe. The anti-corrosion heat tracing sampling composite pipe comprises sampling pipes, compensation cables, a self-temperature-limiting heat tracing belt, instrument power cables, a waterproof layer, a tough layer, iron wires, an anti-abrasion layer, a heat insulating layer, an anti-corrosion layer, a flame-retardant layer, a protective film layer, a protective sleeve layer and a metal shielding layer. The four compensation cables are arranged in a square, the self-temperature-limiting heat tracing belt is located among the four sampling pipes, the compensation cables and the instrument power cables are located on the two sides of the self-temperature-limiting heat tracing belt, the outer surface of the anti-abrasion layer is wrapped by the tough layer, the outer surface of the tough layer is wrapped by the waterproof layer, the iron wires are arranged in the tough layer, the outer surface of the flame-retardant layer is wrapped by the anti-corrosion layer, the outer surface of the anti-corrosion layer is wrapped by the heat insulating layer, the outer surface of the metal shielding layer is wrapped by theprotective sleeve layer, and the outer surface of the protective sleeve layer is wrapped by the protective film layer. The anti-corrosion heat tracing sampling composite pipe is excellent in structure, long in service life, good in protective performance and high in practicality, and has broad application prospects.

Owner:ANBANG ELECTRICAL GRP

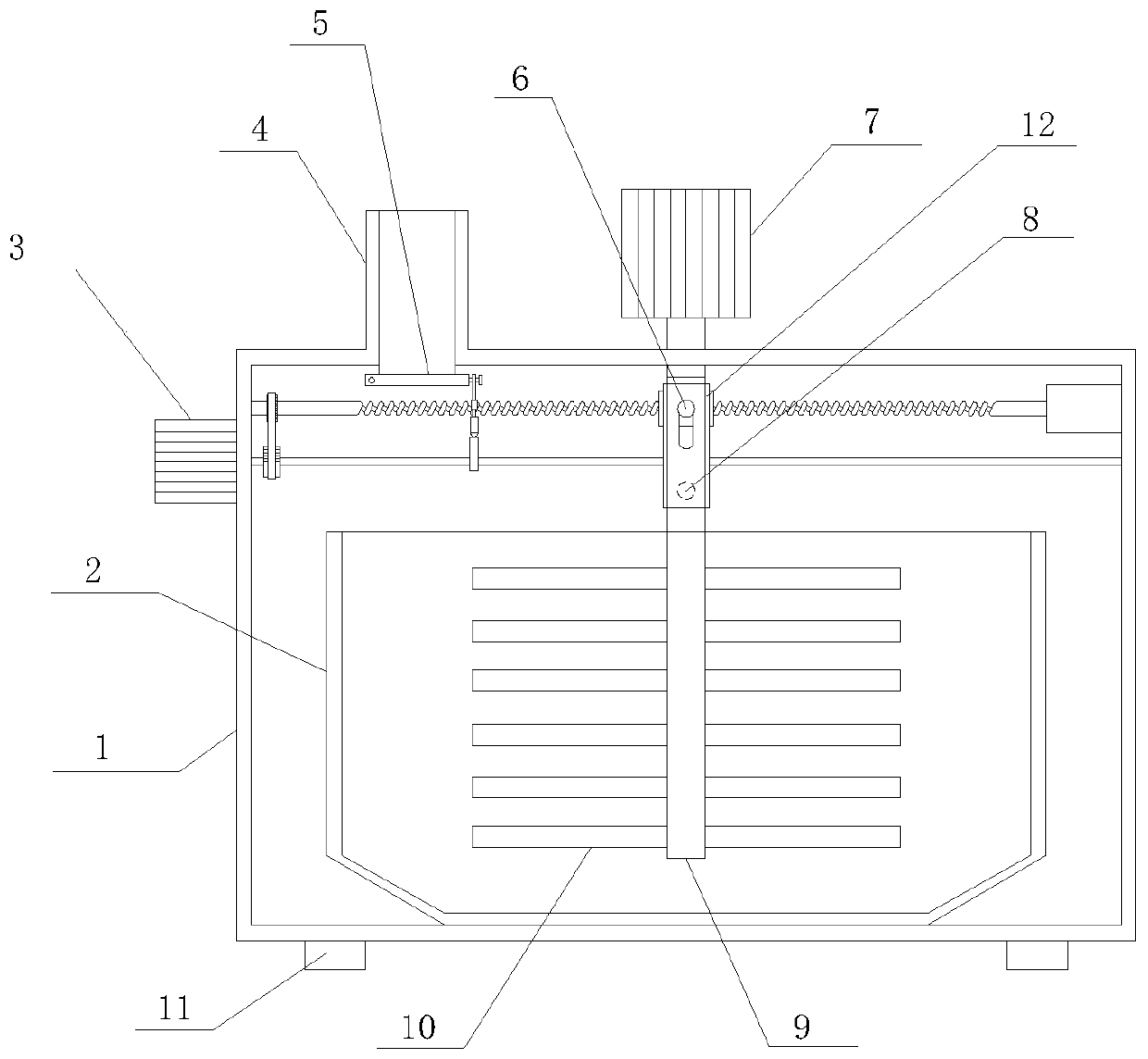

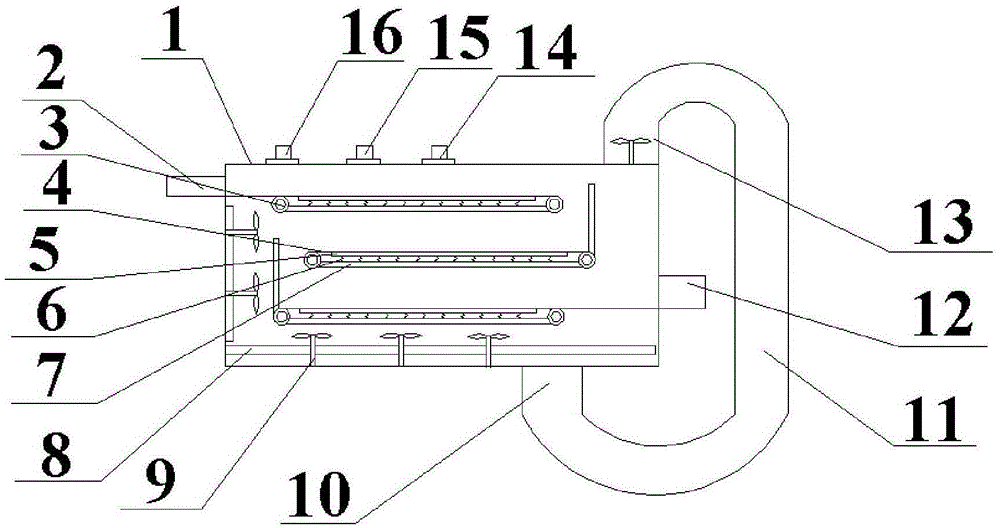

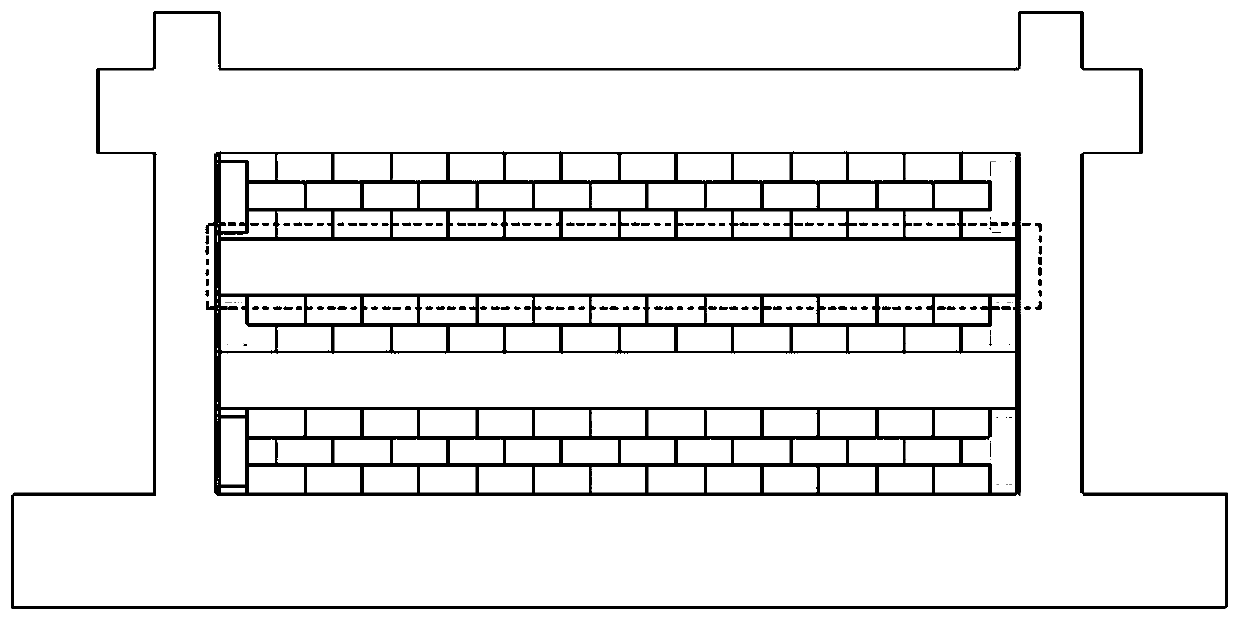

Drying oven of soybean products

InactiveCN106679385AExcellent structureGood uniformityDrying gas arrangementsDrying chambers/containersEngineeringEnergy consumption

The invention discloses a drying oven of soybean products. The drying oven comprises a heating device, a transmission device and an air supply device which are arranged in a box body, and a material inlet, a material outlet, an air inlet, an air outlet, a heating adjustment switch, a vibration adjustment switch, a conveying adjustment switch and an air duct which are arranged outside the box body, wherein the heating device comprises electrothermal pipes arranged on the inner wall of one perpendicular side of the box body and on the wall surface of the horizontal bottom; the transmission device comprises a conveying belt, a reel and a connection shaft; a vibration plate is arranged on the lower surface of the conveying belt; the vibration plate is connected with the connection shaft through a spring; the air supply device comprises fans respectively arranged on the perpendicular electrothermal pipe, the horizontal electrothermal pipe and the air outlet; and the external air outlet of the box body is connected with the air inlet in the lower surface of the box body. The drying oven has the beneficial effects of being good and simple in structure, being capable of adjusting drying conditions in a targeted manner, being high in product drying uniformity, being capable of recycling hot air, and reducing energy consumption.

Owner:曹宇

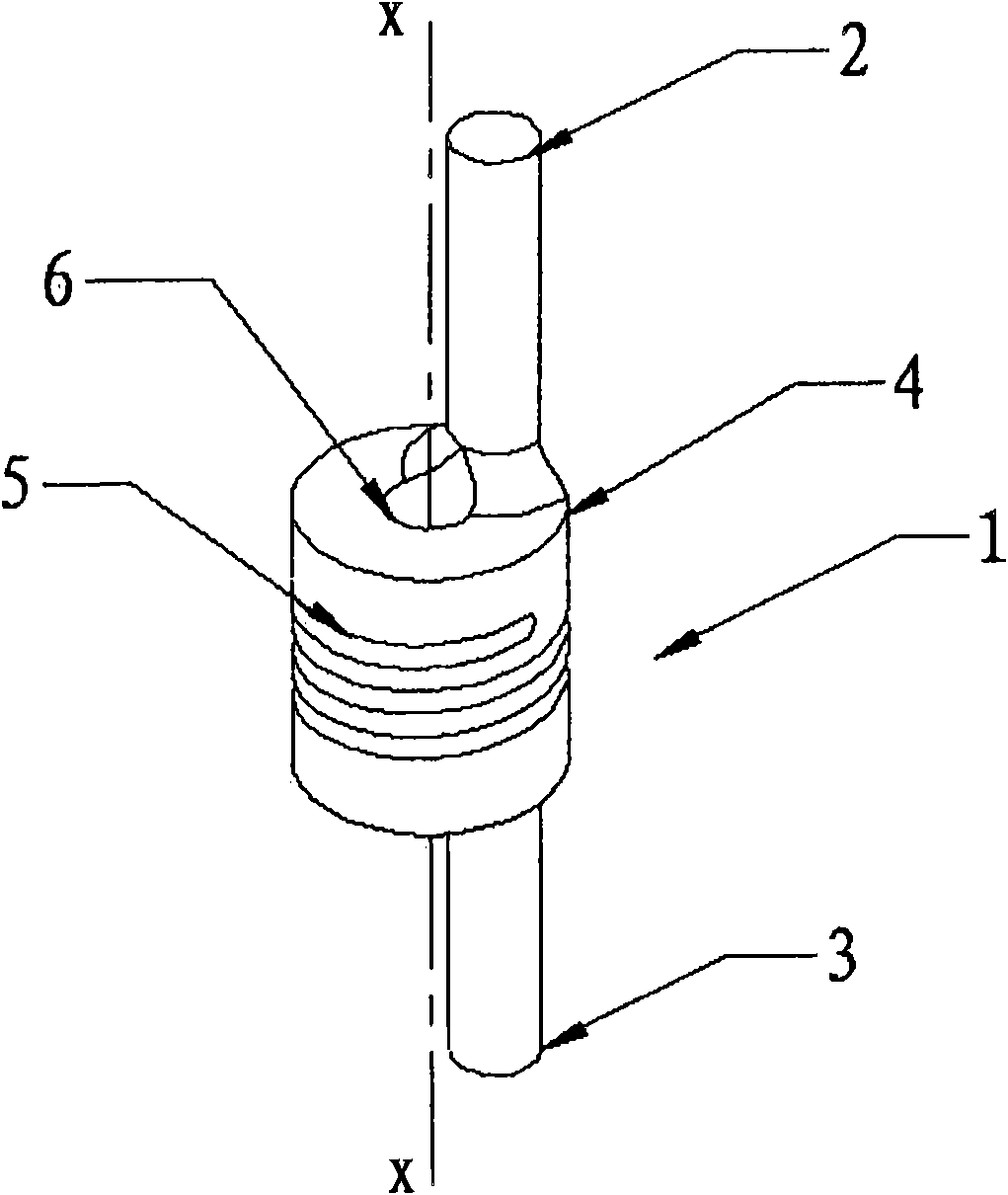

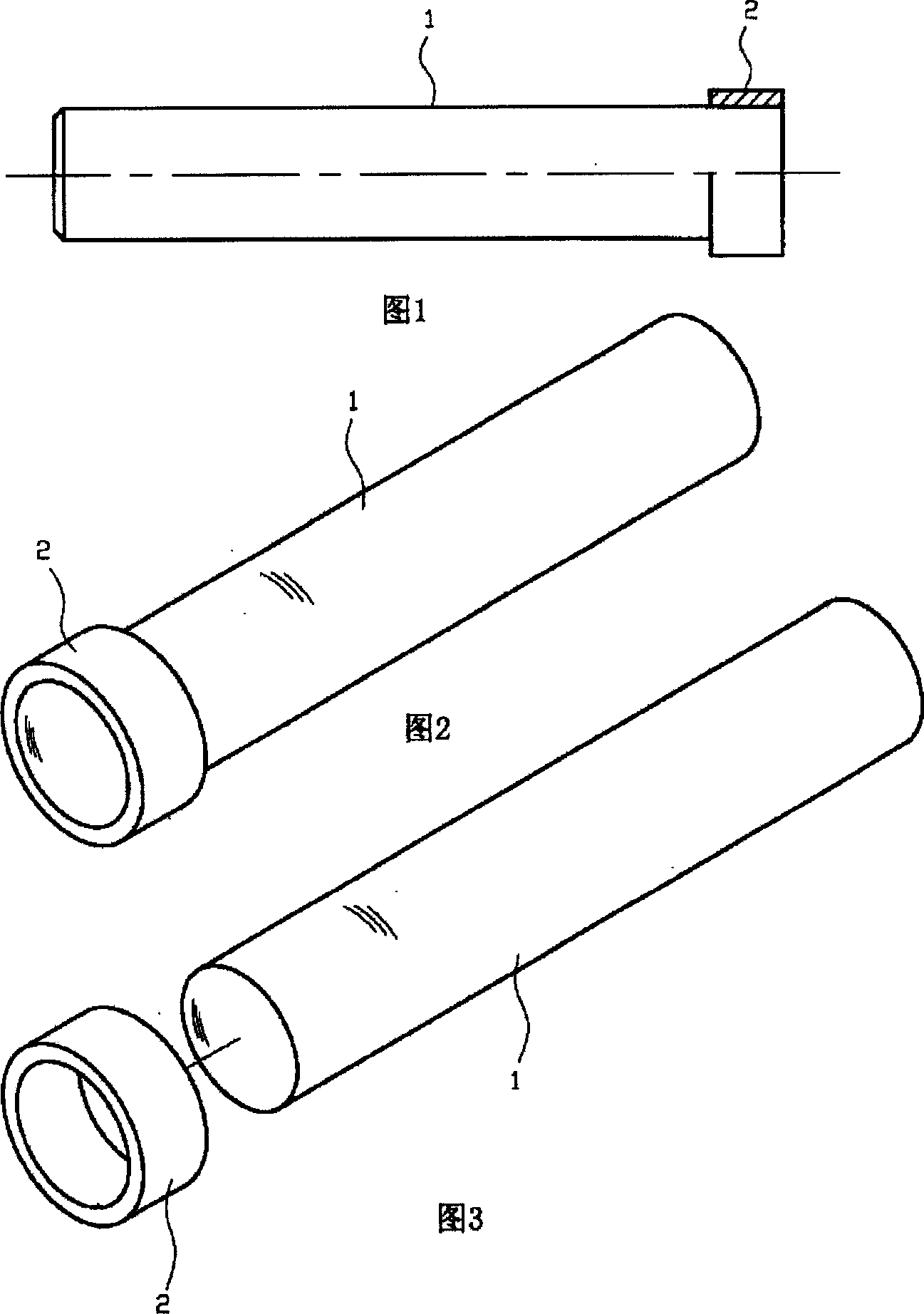

Assembling forming step pin axle

The present invention relates to various machine pin shafts, in particular it relates to a combination-formed stepped pin shaft. It is characterized by that the step greater than diameter of shaft body adopts shrink fit, it is made up by adopting circular ring step and shaft body through a certain assembling process. Said invention also provides its production method and concrete production steps.

Owner:万俊

Magnetron sputtering coating device

ActiveCN110144558AExcellent structureImprove utilization efficiencyVacuum evaporation coatingSputtering coatingSlide plateCoating

The invention discloses a magnetron sputtering coating device. The magnetron sputtering coating device comprises a vacuum chamber, a substrate table is arranged at the lower end of the interior of thevacuum chamber, a target seat is arranged at the upper end of the substrate table, a fixing device is arranged at the upper end of the target seat, a rotating device is arranged at the upper end of the interior of the vacuum chamber, a connecting piece is arranged at the lower end of the rotating device, a magnetic control target is arranged at one end of the connecting piece, the rotating devicecomprises a fixing frame, the upper end of the fixing frame is connected with the upper end of the interior of the vacuum chamber, two sets of fixing rods are arranged between the upper ends of the fixing frame, sliding plates are arranged on the fixing rods in a sleeved mode, two groups of movable rods are arranged on the two sides of the top of the sliding plates in a penetrating mode, one endsof the two groups of movable rods are fixedly connected with one side of the connecting piece, a movable block is arranged at one end, far away from the connecting piece, of the two groups of movablerods, a sliding block is arranged at the lower end of the movable block, the sliding block is located on the inner side of a sliding chute, the sliding block is matched with the sliding chute, the sliding chute is positioned at the upper end of a movable disc, on one side of the lower end of the movable disc and is connected with the fixed frame; a screw rod matched with the slide block is arranged in the slide block in a penetrating manner.

Owner:河南东微电子材料有限公司

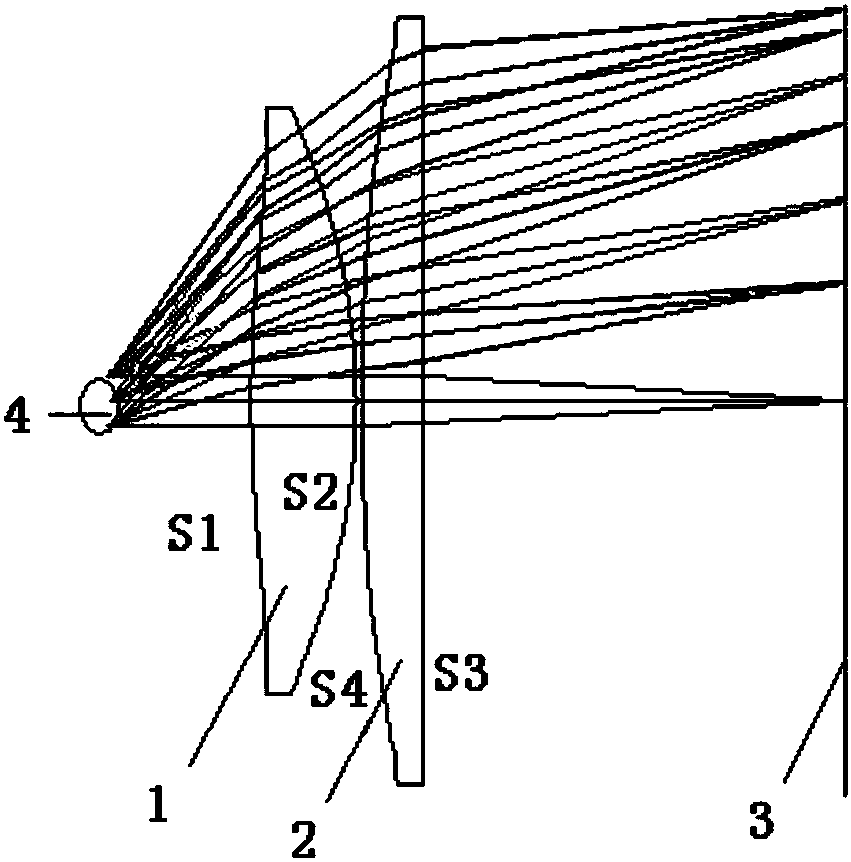

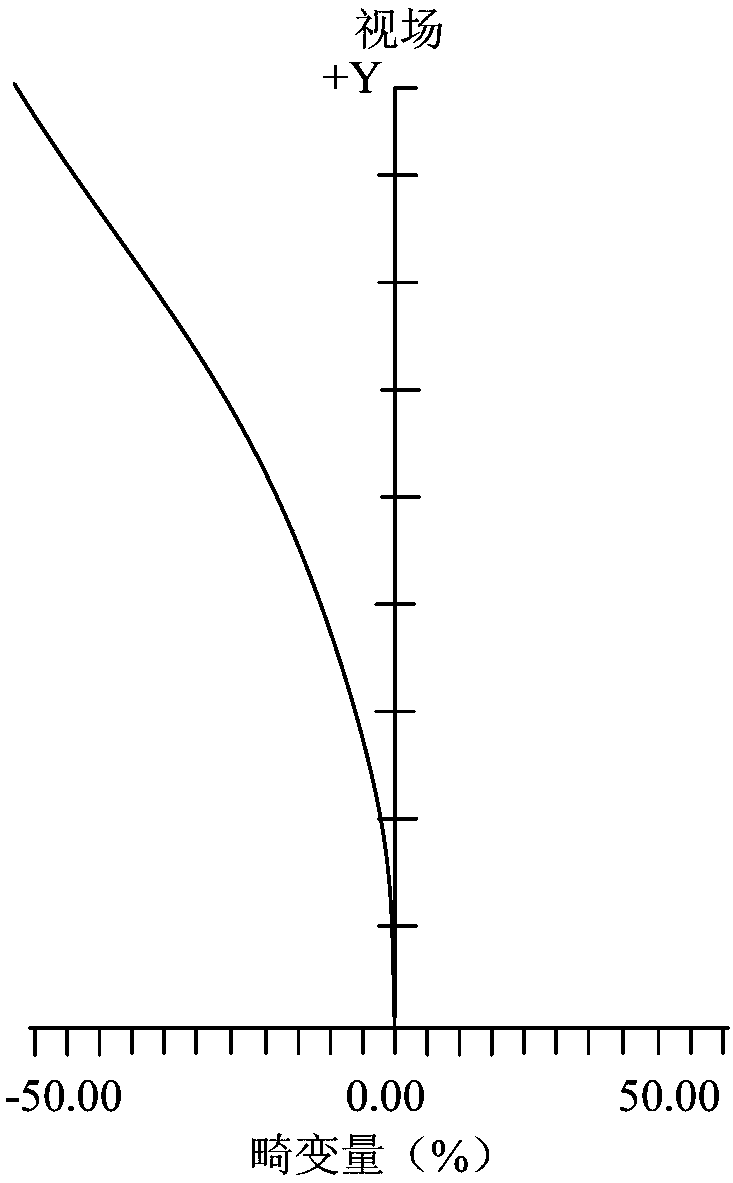

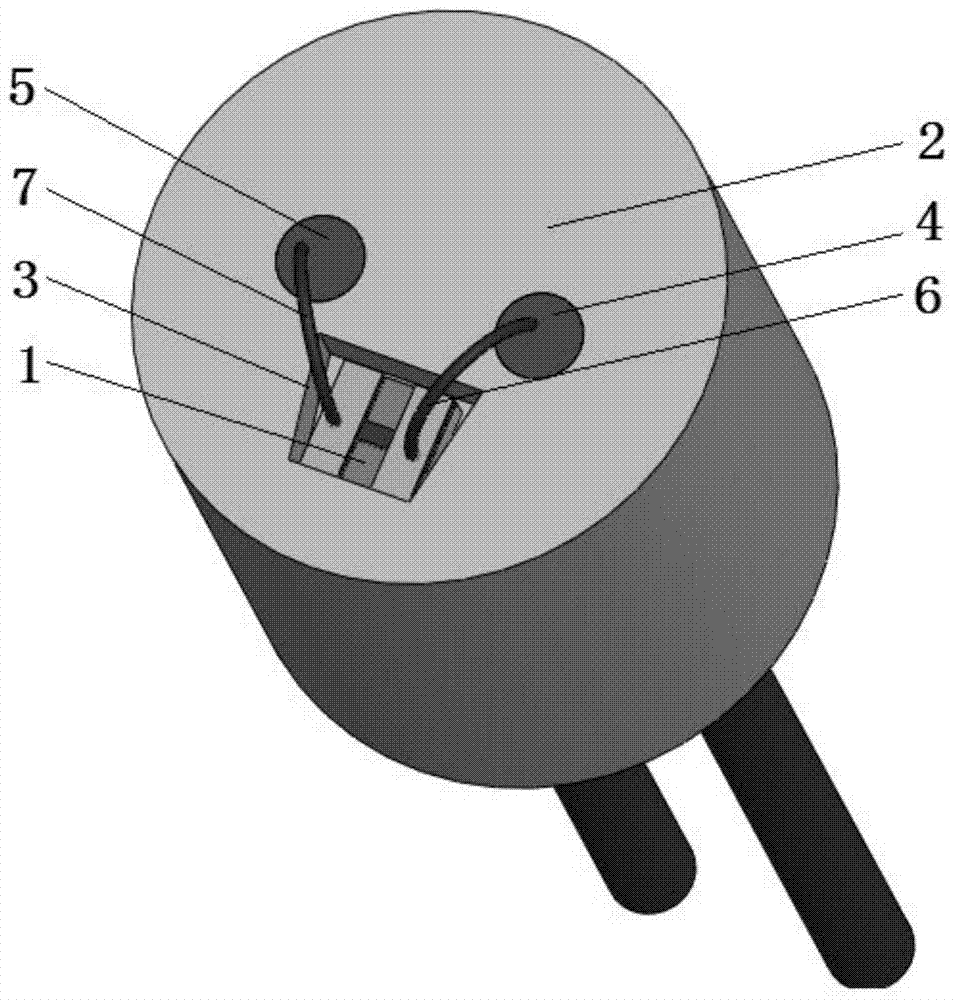

Virtual reality (VR) lens structure and display system

The invention provides a virtual reality (VR) lens structure and a display system, and belongs to the field of display technology. The VR lens structure comprises a first lens and a second lens whichare arranged oppositely, wherein the first lens has a first side face and a second side face which are arranged oppositely; at least one of the first side face and the second side face is a non-spherical face; the second lens is a Fresnel lens; the shiny side of the second lens is arranged opposite to the second side face; and relative to the shiny side, a Fresnel side is arranged far away from the second side face. The VR lens structure provided by the invention consists of two lenses, so that the VR lens structure has four optical effective surfaces when being applied to the display system.Accordingly, during design of the VR lens structure, the four optical effective surfaces can be analyzed and matched, so that the formed VR lens structure has a relatively large view angle, a better structure and better user experience when being applied to the display system.

Owner:BOE TECH GRP CO LTD +1

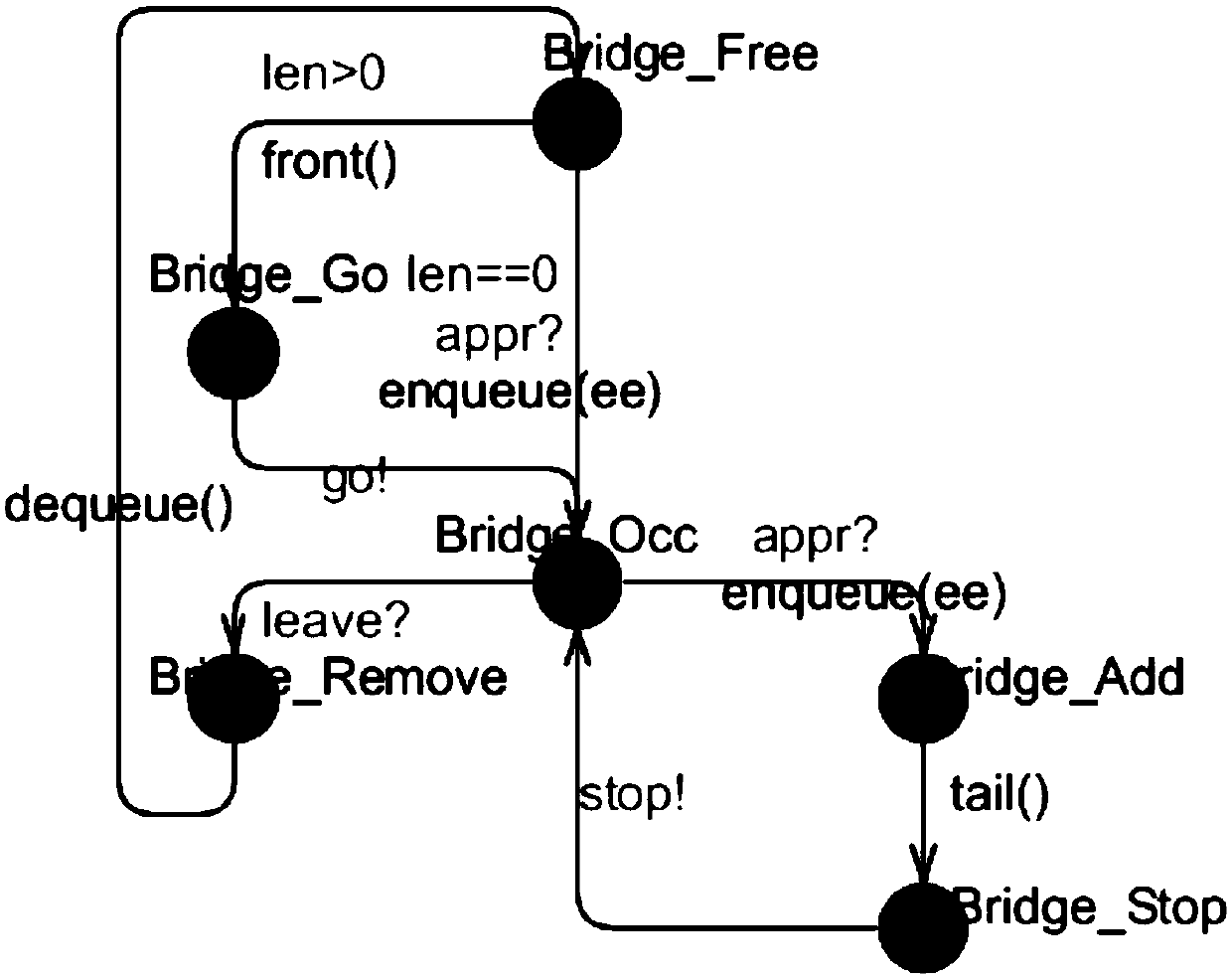

PLC program design method based on timed automata

ActiveCN108681445AExcellent structureThe logical relationship of program instructions is intuitiveSoftware designVisual/graphical programmingProgramming processComputer programming

The invention discloses a PLC program design method based on a timed automata. The method comprises the following steps: according to the application requirements of an industrial control system, dividing the industrial control system into a plurality of subsystems, and constructing a timed automata model for each subsystem; instantiating each constructed timed automata model to generate the corresponding process, and then simulating and verifying the generated process; converting each timed automata into its corresponding SFC language function block to obtain a plurality of SFC function blocks and a PLC project comprising the plurality of SFC function blocks; according to the designed conversion rules, converting the variable declarations, state and transition edges, synchronization and system declarations in the time automata into PLC programs correspondingly to obtain the complete PLC programs satisfying the IEC 61131-3 standard. The invention can solve the problems that the programming workload is tedious and the application program logic error is difficult to check due to the huge number of states in the PLC programming process of the complex industrial control system.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for manufacturing micro-torsion shaft

InactiveCN101121498AExcellent structureImprove reliability and withstand stressDecorative surface effectsChemical vapor deposition coatingEngineeringLevel measurement

The invention provides a method for manufacturing a micro-torsion shaft. Firstly, a wafer is provided, and at least one torsion axis area and at least two penetration areas are defined on the wafer. Afterwards, part of the wafer located in the torsion axis area is removed from the lower surface of the wafer, and the wafer located in the second penetration area is removed from the upper surface of the wafer until the wafer is penetrated to form a micro torsion axis. Next, a wafer-level measurement of the micro-torsion axis of the wafer is performed, followed by an etching process to adjust the geometry of the micro-torsion axis. According to the method of the invention, the thickness of the micro-torsion axis is no longer limited by the thickness of the wafer, and the micro-torsion axis can be measured at the wafer level.

Owner:TOUCH MICRO SYST TECH

High-rigidity PPS plate and forming process thereof

The invention relates to a high-rigidity PPS plate and a forming process of the high-rigidity PPS plate. The forming process comprises the following steps that (1) PPS particles are dried and mixed with glass fibers to obtain a raw material blend; (2) the raw material blend obtained in the step (1) is made to pass through a machine barrel, and extruded to a high-temperature charging barrel through a screw rod to form a bubble-free primary blank; (3) the bubble-free primary blank obtained in the step (2) is placed into a die, and pressed and formed by a die press to obtain a primary plate; and (4) the primary plate obtained in the step (3) is annealed to obtain the high-rigidity PPS plate. According to the forming process, the problem of difficulty in forming simultaneously extruded glass fibers and PPS particles is effectively solved, the internal stress of the plate is eliminated, and the density, the rigidity and the surface hardness of the plate are improved; and in addition, the problem of air holes in the product is completely eliminated, and the structure and density of the product are better than those of a common PPS plate.

Owner:深圳市顺进科技有限公司

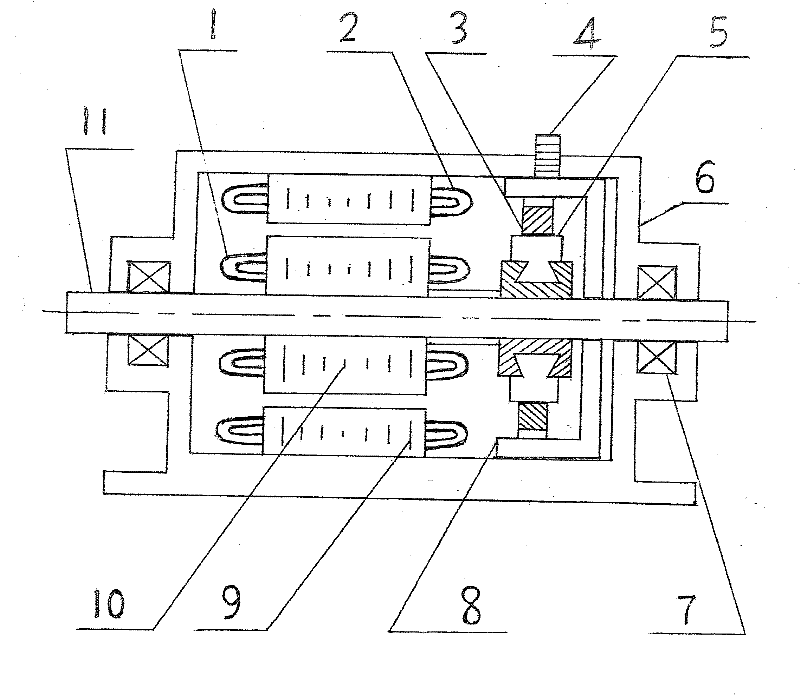

Composite electric motor

The invention relates to a composite electric motor which is invented on the basis of an AC (alternating current) induction motor. The composite electric motor comprises stators, rotors and a mechanical and electrical converter. When AC is switched on for stator windings, a stator AC magnetic field is generated. In the stator AC magnetic field, rotor windings induct to generate induced electromotive forces and induced currents. The mechanical and electrical converter is used, so the induced electromotive forces and the induced currents are output among the groups of the rotor windings ranked in order. When the induced electromotive forces and the induced currents are output, the stators and the rotors are inducted to generate electromagnetic torque, thus the rotors run. The composite electric motor can change the position of an electric brush or a sensor module and the direction of rotor rotation. The rotating speed of the electric motor can be regulated by increasing or decreasing the mechanical loads or input power of the electric motor. The higher the induced currents are, the stronger the mechanical energy output by the electric motor is.

Owner:解勤

Damping infilled wall of RC frame structure and manufacturing method of damping infilled wall

InactiveCN110593455AAvoid brittle failureExcellent limit displacementWallsProtective buildings/sheltersEngineeringRebar

The invention provides a damping infilled wall of an RC frame structure and a manufacturing method of the damping infilled wall. The structure comprises a masonry structure which is defined by frame columns and frame beams and arranged in space in a masonry manner. Column inner side steel plates are mounted on the inner sides of the frame columns of the masonry structure. Multiple transverse steelbars are welded between the two column inner side steel plates. A bottom-layer wall body, a first-layer H-shaped sliding rail, a middle-layer wall body, a second-layer H-shaped sliding rail and a top-layer wall body are sequentially arranged on the frame beam at the bottom in a masonry manner. Plane outer protection steel plates are mounted on the front portions and the rear portions of the contact positions of the bottom-layer wall body, the middle-layer wall body and the top-layer wall body with the column inner side steel plates. The problems that an existing masonry infilled wall suffersfrom brittle failures under the reciprocation loading function and collapses, stress redistribution is caused, and brittle failures happen to the frame structure are solved; and the novel damping infilled wall of the RC frame structure is provided, and the ductile failure form of the infilled wall and an RC frame is achieved so as to avoid collapsing of the infilled wall and brittle failures, caused by damage of the infilled wall, of an RC frame body.

Owner:HARBIN INST OF TECH

Flexible heat conduction shielding material and preparation method thereof

The invention relates to a flexible heat conduction shielding material and a preparation method thereof. The flexible heat conduction shielding material comprises 30-40 parts of a magnetic material, 30-40 parts of polyurethane, 15-25 parts of a heat conduction filler and 5-10 parts of an auxiliary agent. The magnetic material is a Cu / Ni nano alloy; and the heat conduction filler is a mixture of aluminum nitride and titanium diboride. During preparation, all the components are prepared according to the proportion through a eutectic method. The flexible heat conduction shielding material has thecharacteristics of high electromagnetic shielding efficiency, high heat conductivity, strong heat dissipation performance, light weight and good flexibility.

Owner:江西伟普科技有限公司

Method for preparing super-thick Ti-Al-C ternary coating using two-step method PVD technology

ActiveCN109957757APoor bindingAvoid introducingVacuum evaporation coatingSputtering coatingSputteringGraphite

The invention discloses a method for preparing super-thick Ti-Al-C ternary coating using a two-step method PVD technology. The surface of a zircon encased matrix sample is cleaned, the sample is clamped on a three-dimensional rotary frame in a vacuum chamber after being blown to dry by cold air, and the matrix sample is heated; Ar gas is inflated, high bias pressure is applied, and the matrix sample is subjected to glow sputtering cleaning or electron gun heating cleaning etching; a Ti<x>Al arc target is opened by using an arc striking needle, a Ti<x>Al target material is subjected to high bias pressure sputtering cleaning, and meanwhile a base layer is generated on the surface of the matrix; a Ti<x>Al coating is deposited in low bias pressure, and a transition coating is generated; appropriate arc current and bias pressure are adjusted, a mid-frequency magnetically controlled graphite target is opened, and the super-thick Ti-Al-C coating is deposited; and high temperature annealing isconducted. Material prepared from the method for preparing super-thick Ti-Al-C ternary coating using the two-step method PVD technology can be more suitable for the field of nuclear, using is safer,and the obtained materials have better performance.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Goat sterilizing room

InactiveCN109464210ADisinfect thoroughlyExcellent structureVeterinary instrumentsEngineeringElectromagnetic valve

The invention relates to a goat sterilizing room, which comprises a Pi-shaped passage with openings at both ends. An opening used for clamping the head of goat is arranged on a wall at one side of thepassage along the direction of passage length; a separator is vertically arranged at the upper end of the middle part in the passage, and the separator divides the inner passage into a disinfecting room and a drying room; a conveyor belt is horizontally arranged at the bottom part of the passage, and the conveying direction of the conveyor belt is from the disinfecting room to the drying room, and the conveyor belt is driven by a motor to convey; a plurality of first atomizing spray heads with downward nozzles are arranged at the top part of the disinfecting room, the first atomizing spray heads are communicated with a fluid storage tank pipeline, and a first electromagnetic valve is arranged on the communicated pipeline; a plurality of second atomizing spray heads are arranged at the side wall of the disinfecting room, the second atomizing spray heads are communicated with the fluid storage tank pipeline, and a second electromagnetic valve is arranged on the communicated pipeline; anultraviolet lamp and a drying outlet are arranged in the drying room, and the drying outlet is connected with a drying fan outside the passage.

Owner:闽清县金沙大龙湾生态养殖场有限公司

Multi-blade saw cutting equipment and control method thereof

The invention relates to multi-blade saw cutting equipment. The multi-blade saw cutting equipment comprises a hydraulic system, a transmission mechanism and an actuating mechanism, wherein the hydraulic system is used for supplying machinery to the actuating mechanism through the transmission mechanism; the hydraulic system comprises a main motor, a two-way constant delivery pump, an oil supply tank, a two-way hydraulic motor, a first overflow valve, a second overflow valve and a plurality of check valves; the two-way constant delivery pump is driven to pump oil by the main motor, both ends ofthe two-way constant delivery pump are connected with both ends of the two-way hydraulic motor respectively through a first oil way and a second oil way, and the hydraulic motor is driven to rotate;an oil inlet of the first overflow valve is connected to the first oil way, and an oil outlet of the first overflow valve is connected to the second oil way; an oil inlet of the second overflow valveis connected to the second oil way, and an oil outlet of the second overflow valve is connected to the first oil way; and the oil supply tank is connected with the first oil way and the second oil wayrespectively through the first check valve and the second check valve, and oil inlets of the first check valve and the second check valve face towards the oil supply tank.

Owner:林灵

Transversely-folded faucet

The invention discloses a transversely-folded faucet comprising a rotating shaft, a faucet body with a rotating shaft sleeve and a faucet base. The faucet base comprises a first plane and a second plane. The first plane is higher than the second plane. The perpendicular drop height between the first plane and the second plane forms an arc side wall. The rotating shaft is arranged on the second plane of the faucet base. The rotation shaft is hollow and used as a water outlet of the faucet base. The center of the circle of the arc side wall coincides with the center of the rotation circle of therotating shaft. The faucet body is connected with the faucet base in the manner that the faucet body is fixed to the rotating shaft through the rotating shaft sleeve. A closed connection position isformed through combination of the faucet body and the faucet base, external collision is effectively avoided, and the structure is good. Meanwhile, the design of arc and plane combination is differentfrom the ordinary round pipe design on the market, and the transversely-folded faucet can make an impression on consumers.

Owner:恩平市牧恩卫浴有限公司

Low-ignition-voltage and high-power-output miniature detonator

InactiveCN103499252AExcellent structureExcellent performance parametersAmmunition fuzesManganinExplosive train

The invention discloses a low-ignition-voltage and high-power-output miniature detonator. The low-ignition-voltage and high-power-output miniature detonator mainly comprises a foot line, a ceramic electrode plug, a detonator shell, a semiconductor bridge chip, an ignition explosive, a primary explosive and a high explosive. The Cl-20 high explosive and the carboxymethyl cellulose lead azide primary explosive are sequentially pressed into the detonator shell to increase the axial output power of the miniature detonator, and a semiconductor bridge ignition component is fixed at a mouth part of the detonator shell by performing a detonator shell necking-in process and coating a sealant at the mouth part. The technical indicators of the miniature detonator disclosed by the invention are characterized in that the minimum full-ignition voltage is as low as 3.83V (10 micro F), the minimum full-ignition energy is 0.074mJ, the safe current is not less than 200mA, the size of the detonator is not more than phi 2.5*4 mm, and when the output detonation pressure of the detonator is tested by a manganin pressure gauge, the maximum output power of the miniature detonator achieves 13-15 GPa. Compared with the technical indicators of an existing bridge wire type electric detonator, the comprehensive performance of the detonator is greatly improved. The low-ignition-voltage and high-power-output miniature detonator disclosed by the invention is suitable for design of explosive trains of micro-electromechanical systems requiring low ignition voltage and high power output.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

High-efficiency, low-cost and energy-saving building door and window structure

ActiveCN113236087AExcellent structureImprove work efficiencyFrame fasteningWindow/door framesHeat conservationSash window

The invention provides a high-efficiency, low-cost and energy-saving building door and window structure. The high-efficiency, low-cost and energy-saving building door and window structure comprises a window frame and a window sash, wherein the window frame is provided with a fixed window fixedly mounted on one side of a middle column and a window sash mounting frame formed on the other side of the middle column, the window sash is hinged to the interior of the window sash mounting frame of the window frame, and four edges of the window frame are embedded into the inner side of a concrete wall body at a window frame mounting opening of the concrete wall body from the indoor side. According to the high-efficiency, low-cost and energy-saving building door and window structure, a heat insulation principle different from that of traditional broken bridge aluminum is achieved, a broken-bridge-free and extremely-simple structure and a high-efficiency production mode are adopted, and a final product reaches energy-saving technical indicators including a heat preservation coefficient of 1.1, wind pressure resistance strength of level 9, air tightness of level 8, water tightness of level 6, and sound insulation of 30-40 decibels, and meets or exceeds the energy-saving standard of an existing product in China. The high-efficiency, low-cost and energy-saving building door and window structure also meets the requirements of energy conservation and environmental protection, and belongs to recyclable environment-friendly products.

Owner:卓筑(天津)建筑设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com