Assembling forming step pin axle

A combined molding and step pin technology, applied in bolts and other directions, can solve the problems of wasting materials, labor-intensive consumables, increasing the workload of lathes, etc., and achieve the effect of saving man-hours, improving service life, and saving production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

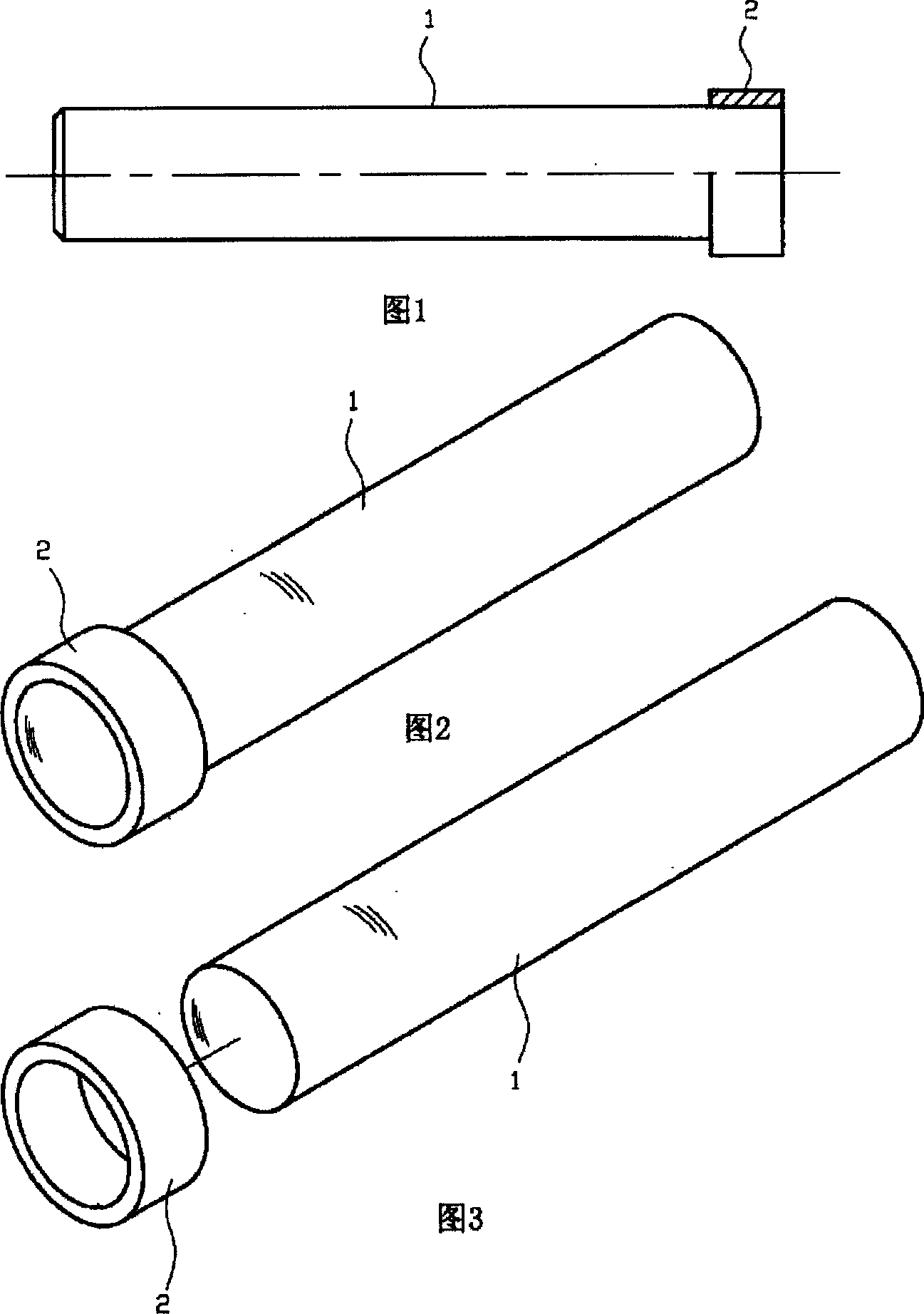

[0009] As can be seen from Figures 1 to 3, the feature of the present invention is that the step 2 larger than the diameter of the shaft body 1 is formed by assembling the annular step 2 with the shaft body 1 through interference fit.

[0010] The shaft body 1 of the present invention may be a cylinder made by cold drawing or turning. The step 2 can be installed at any position of the shaft body 1 . The step 2 may also be composed of multiple steps.

[0011] The process steps of the present invention are as follows: first, a round steel with a length of 6-8 meters and the outer diameter equal to the small end of the pin shaft is drawn by cold drawing, cut according to the designed length of the pin shaft, and then according to the design requirements of the pin shaft step, use a A steel pipe whose outer diameter is slightly larger than the outer diameter of the pin shaft step and whose inner diameter is slightly smaller than the outer diameter of the small end of the pin shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com