Tool holder with internal rigid retaining device

A technology for holding devices and clamps, applied in positioning devices, manufacturing tools, clamping, etc., can solve problems such as tool holder and tool vibration, difficulty in maintaining rigidity, tool holder or tool damage, etc., to achieve suppression Vibration phenomenon, improvement of rigidity, effect of optimizing workpiece surface finish and machining precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

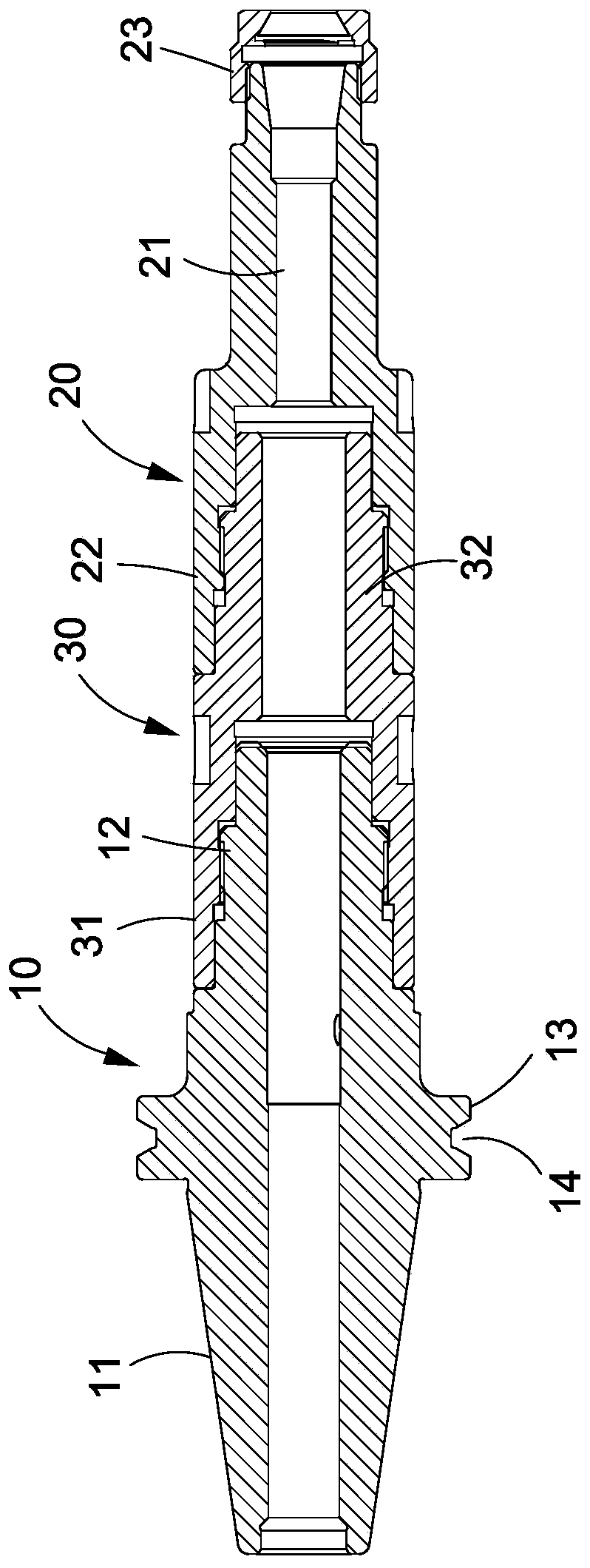

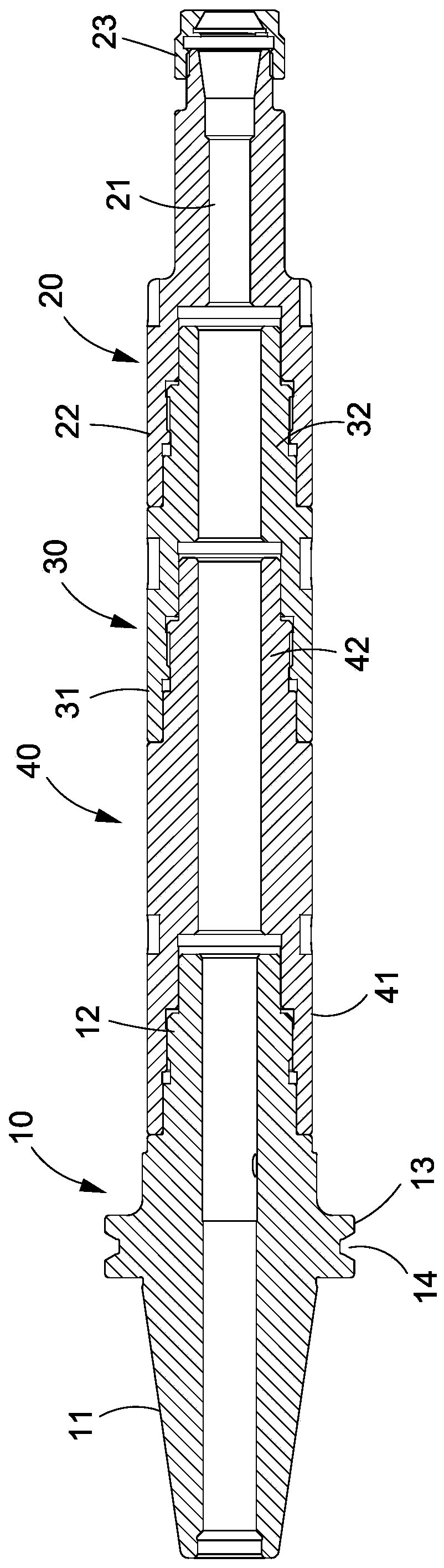

[0015] see figure 1 , the tool holder provided by the present invention with an internal rigid holding device is used in a processing machine with a mandrel (not shown), the tool holder includes: a handle 10, the The shank has a tapered outer surface 11 received in the mandrel and a shank pin end 12; a tool mount 20 optionally made of a high rigidity material such as tungsten carbide (TungstenCarbide), Including an axially extending tool mounting aperture 21 capable of receiving and securing a tool and a portion of a tool chuck 23, the tool mounting portion 20 also has a mating shank pin end portion 12 and at least one rigid retaining sleeve 30 made of a highly rigid material such as tungsten carbide, the rigid retaining sleeve 30 has a sleeve female that matches the handle male end 12 The joint end 31, and a sleeve male joint end 32 matching the erection part female joint end 22, and the handle 10, the rigid retaining sleeve 30 and the tool erection part 20 can be connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com