Thin-walled workpiece cutter back-off deformation error prediction model building method and application thereof

A technology of deformation error and prediction model, which is applied in the field of thin-walled part tool deformation error prediction model establishment, can solve the problems of low processing error accuracy, difficult data measurement and acquisition, etc., to reduce requirements, ensure reliability, and improve The effect of forecast accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

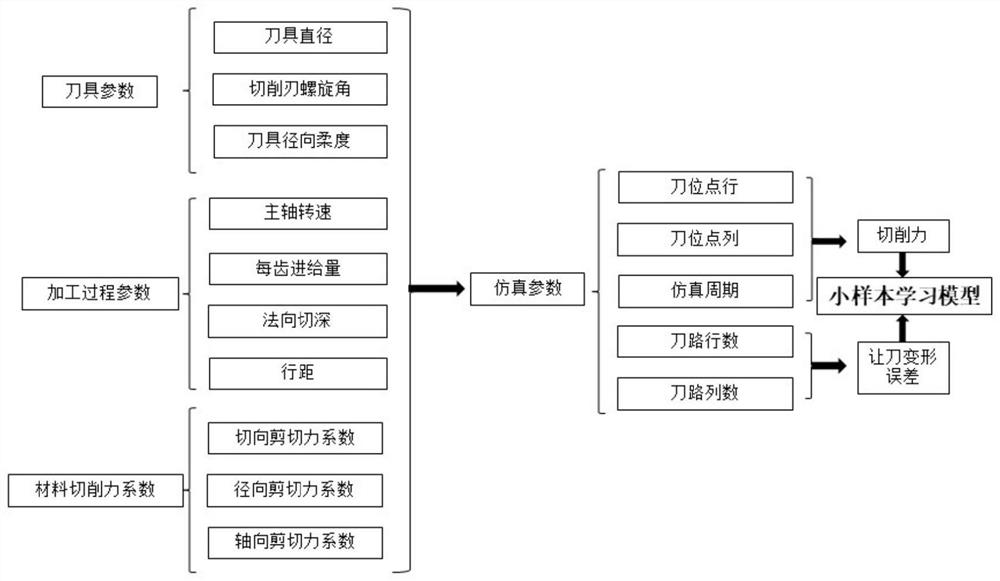

[0051] A method for establishing a thin-walled part tool deformation error prediction model, such as figure 1 shown, including:

[0052] The cutting force model is established by the finite element analysis method. The cutting force model is used to input the parameters in the processing process and output the corresponding cutting force and tool deformation error; the tool parameters of the actual production line of thin-walled parts under different processing conditions , The processing parameters and the material cutting force parameters are used as the input of the cutting force model, and the cutting force and the tool deformation error corresponding to each group of parameters are output by the cutting force model to obtain the training data set;

[0053] Obtain multiple sets of cutting force collected from the processing site of thin-walled parts and the corresponding deformation error of the tool, and obtain the test data set;

[0054] A small-sample learning model is...

Embodiment 2

[0093] A method for predicting the deformation error of a thin-walled part, including:

[0094] Input the real cutting force measured on the thin-walled part processing site into the thin-walled part tool deformation error prediction model established by the method for establishing the thin-walled tool deformation error prediction model provided by the above-mentioned embodiment 1, so that the thin-walled part allows The knife deformation error prediction model predicts the corresponding knife deformation error.

[0095] Because the thin-walled part allows the knife deformation error prediction model established by the method for establishing the thin-walled part to allow the knife deformation error prediction model provided by the above-mentioned embodiment 1 to have a higher prediction accuracy, the thin-walled part provided by the embodiment allows the knife to deform the error of the error The prediction method can accurately predict the tool-back deformation error during ...

Embodiment 3

[0097] A computer-readable storage medium, including a stored computer program; when the computer program is executed by a processor, the device where the computer-readable storage medium is located is controlled to execute the method for establishing a prediction model for the deformation error prediction of a thin-walled part provided in Embodiment 1, and / or the method for predicting the deformation error of the knife for the thin-walled part provided in the above-mentioned embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com