Loading device for testing permeability of concrete chloride ions and test method

A technology of chloride ion penetration and loading device, which is applied in the field of loading device for concrete chloride ion permeability coulometric method, which can solve the problems of inability to realize the test piece, blank test method, applied load, etc., and achieve stable test results and simple structure , the effect of load stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

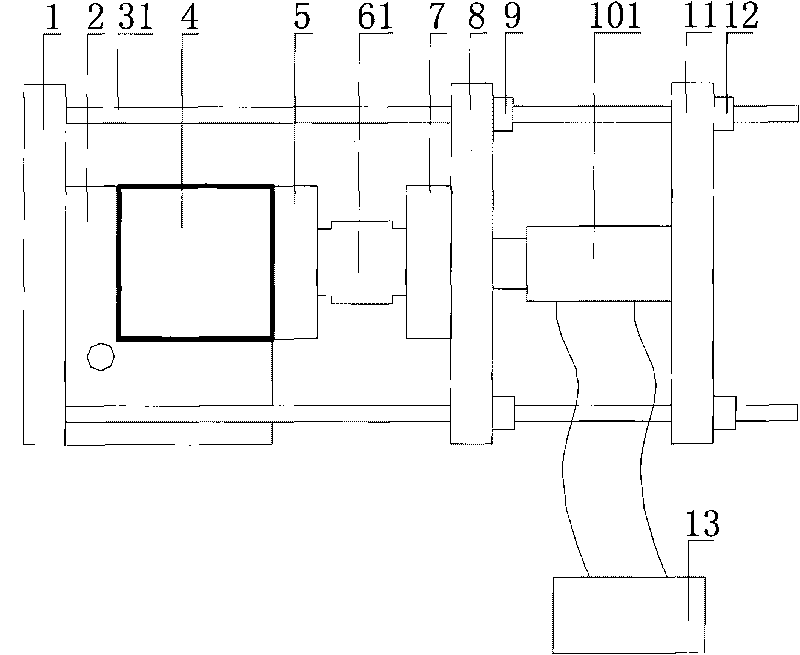

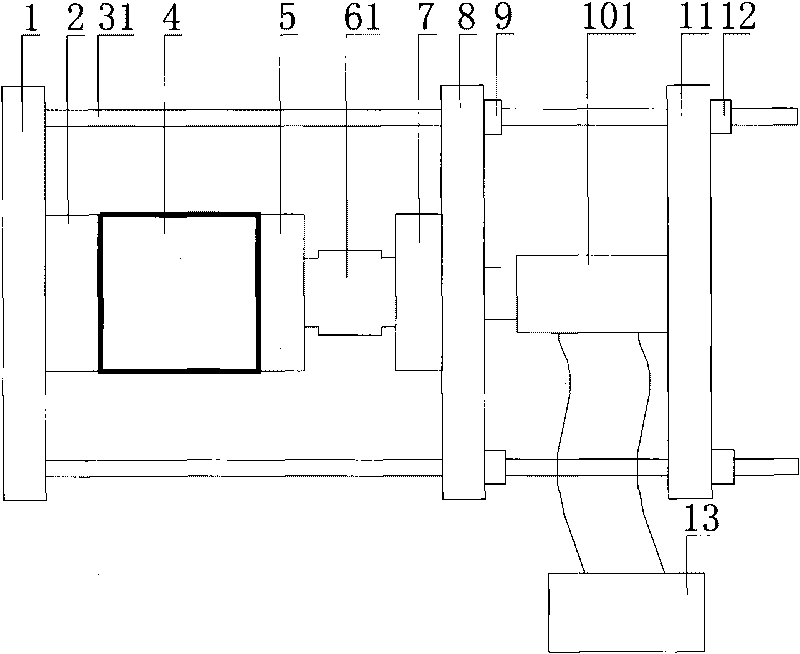

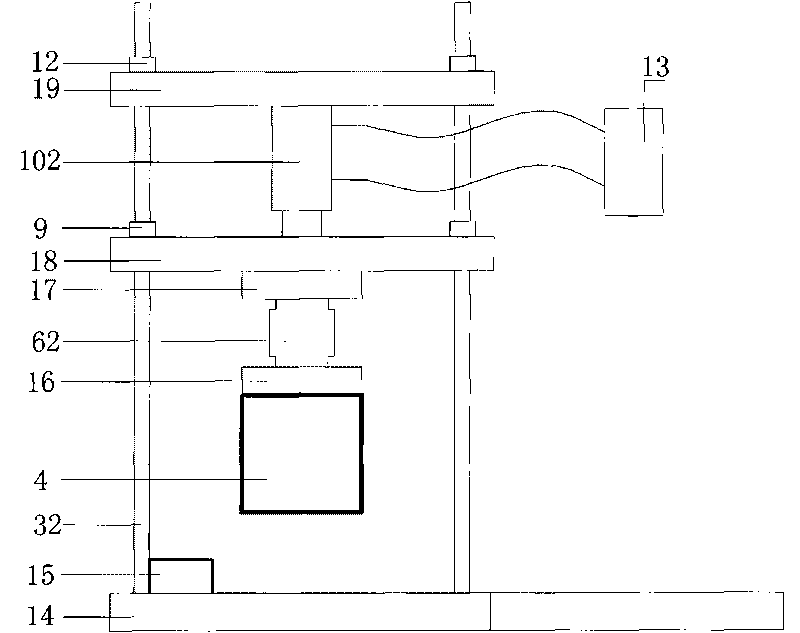

[0034] A loading device for testing the chloride ion permeability of concrete, which consists of two parts: a lateral loading system and a longitudinal loading system. The lateral load-bearing steel plate 1 in the lateral loading system is vertically arranged on the longitudinal load-bearing steel plate 14. "L" shaped positioning piece 15 is fixed;

[0035] The side end of the lateral loading system is a lateral load-bearing steel plate 1, four high-strength screw anchor holes are symmetrically arranged in the four corner regions of the lateral load-bearing steel plate 1, and four lateral high-strength force-transmitting screws 31 Anchored in four high-strength screw anchor holes; the bottom of the "L"-shaped test piece seat 2 is flush with the lower edge of the lateral load-bearing steel plate 1, and the vertical surface of the "L"-shaped test piece seat 2 is located on the side to the middle of the load-bearing steel plate 1; the four corner regions of the lateral load-bearing...

Embodiment 2

[0049] Fabrication and assembly steps of the loading device for testing the chloride ion permeability of concrete under complex compressive loading conditions:

[0050] The first step: Use steel plates with a length of 240mm, a width of 240mm, and a thickness of 20mm to make the lateral load-bearing steel plate 1, the lateral load steel plate 8 and the lateral fixed steel plate 11 in the lateral loading system; the four lateral load-bearing steel plates 1 One M25 bolt hole is processed in the corner area, one circular hole with a diameter of 26.5mm is processed at the corresponding positions of the lateral loading steel plate 8 and the lateral fixed steel plate 11, and the four lateral high-strength force transmission rods with a length of 600 mm and a diameter of 25 mm are processed. The screw rod 31 is reliably connected with the lateral bearing steel plate 1 .

[0051] Step 2: Make an "L"-shaped test piece seat 2, whose outer dimensions are 200mm high, 120mm long, and 100mm...

Embodiment 3

[0059] Test method for testing chloride ion permeability of concrete under complex compressive load conditions:

[0060] 1. Raw materials and test pieces

[0061] Use P·O 42.5 grade cement (see Table 1 for physical properties), river sand with a fineness modulus of 2.5, limestone artificial gravel with a maximum particle size of 20mm, and tap water to prepare concrete according to the mix ratio shown in Table 2, and form it into a 100mm ×100mm×100mm cubic concrete specimens, 24 specimens for each ratio. After the specimens were cured in the concrete standard curing room for 28 days, 3 specimens of each proportion were selected to measure the compressive strength as a reference for the loading size of the remaining specimens in the chloride ion permeability test. The compressive strength of each group of specimens is shown in Table 2.

[0062] Table 1 Basic physical properties of P·O 42.5 grade cement

[0063]

[0064] Table 2 Concrete mix ratio and compressive strength o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com