Heat sink structure double-carrier LED drive circuit package and manufacturing method thereof

A technology of LED driving and circuit packaging, applied in circuits, electrical components, electric solid devices, etc., can solve the problems of dissipation, mutual penetration of insulating glue and conductive glue, and difficulty in heat of LED driving circuit, etc., to increase the thickness, The effect of enhancing the ability to withstand high pressure leak points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

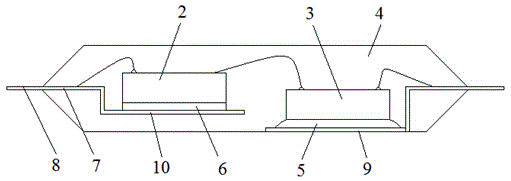

Embodiment 1

[0027]The insulating adhesive is coated on the back of the wafer by the wafer back coating process to form an insulating adhesive film with a thickness of 100 μm; then the wafer is cut into individual crystal grains to obtain IC control chips; then, the insulating adhesive is applied by dispensing process The slurry is drip-coated on the surface of the second base island. After the insulating slurry is cured, an insulating slurry layer with a thickness of 5 μm is formed, and then the IC control chip coated with an insulating adhesive layer on the back is pasted on the second base island. surface; paste the MOSFET power device on the upper surface of the first base island; use the existing production process of the LED drive circuit with built-in MOSFET devices for pressure welding, plastic packaging, curing and testing; during the plastic packaging process, the first base island is not pasted The bottom surface of the device is located outside the encapsulant, and a heat sink s...

Embodiment 2

[0029] The insulating adhesive is coated on the back of the wafer by the wafer back coating process to form an insulating adhesive film with a thickness of 20 μm; then the wafer is cut into individual crystal grains to obtain an IC control chip, and then the IC control chip is pasted on the second wafer. The upper surface of the second base island; paste the MOSFET power device on the upper surface of the first base island; adopt the existing production process of the LED drive circuit with built-in MOSFET device for pressure welding, plastic sealing, curing and testing; during the plastic sealing process, make the second base island The bottom surface of the base island without the pasted device is located outside the sealant, and a dual-carrier LED drive circuit package with a heat sink structure is prepared.

Embodiment 3

[0031] The insulating adhesive is coated on the back of the wafer by the wafer back coating process to form an insulating adhesive film with a thickness of 60 μm; then the wafer is cut into individual crystal grains to obtain IC control chips; then, the insulating adhesive is applied by dispensing process The slurry is drip-coated on the surface of the second base island. After the insulating slurry is cured, an insulating slurry layer with a thickness of 35 μm is formed, and then the IC control chip coated with an insulating adhesive layer on the back is pasted on the second base island. surface; paste the MOSFET power device on the upper surface of the first base island; use the existing production process of the LED drive circuit with built-in MOSFET devices for pressure welding, plastic packaging, curing and testing; during the plastic packaging process, the first base island is not pasted The bottom surface of the device is located outside the encapsulant, and a heat sink ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com