Dodging special-shaped lens used for shaping semiconductor laser leams, dodging laser source and optical system

A technology of laser light source and special-shaped lens, which is applied in the field of laser optics, can solve the problems of long processing steps, high cost, and large loss of optical power, and achieve good light uniformity and aberration elimination performance, improved utilization rate, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

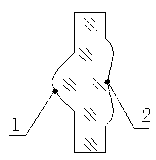

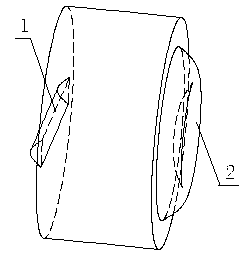

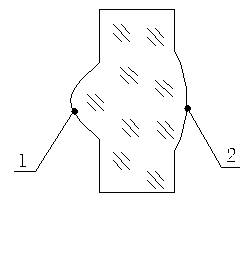

[0069] In order to overcome the phenomenon that the ratio of the vertical divergence angle θ⊥ to the horizontal divergence angle θ∥ of the laser emitted by the semiconductor laser is too large, the utilization rate of light energy is low and the energy distribution of the light field formed by Gaussian distribution is uneven, so as to improve the utilization rate of light power and provide a relatively uniform light field of the light source, this embodiment provides a Figure 1 to Figure 22 The shown homogenous special-shaped lens for shaping the laser spot output by a semiconductor laser includes an incident surface 1 for receiving the incident laser light and an exit surface 2 for the laser to exit, and the incident surface 1 is a semi-cylindrical The exit surface 2 is an aspheric surface, and the distance between the two ends of the generatrix of the aspheric surface is greater than the distance between the two ends of the generatrix of the semi-cylindrical curved surface, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com