Large radial-axial ring rolling machine

A ring rolling machine, axial technology, applied in the direction of metal rolling, etc., can solve the problems of increasing the depth of the equipment installation pit, poor lubrication conditions of the rotating parts, and increasing the cost of the equipment foundation, so as to improve the difficulty of assembly, simple structure, The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

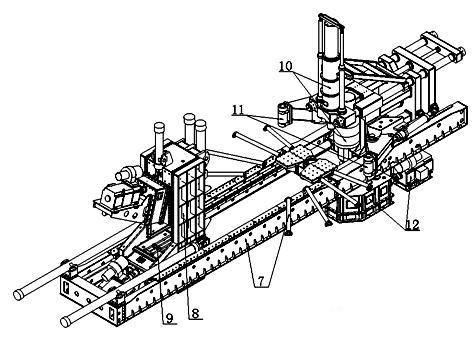

[0020] Such as figure 2As shown, a large-scale radial-axial ring rolling machine includes a complete machine base 7 and a radial rolling part 10 and an axial rolling part 8 arranged on the complete machine base 7, which are arranged on the axial rolling The length measuring device 9 on the lower tapered roller seat 42 of the section 8, as well as the holding roller section 11 and the main transmission section 12. The radial rolling section 10 adopts an upward-drawing core roller shaft mechanism and a four-column type up-and-down double-action mechanism, and the lower tapered roller drive motor 44 of the axial rolling section 8 adopts positive installation. Due to the large size and complex structure of the present invention, the radial rolling section 10 and the axial rolling section 8 are described separately below to illustrate the technical features of the present invention.

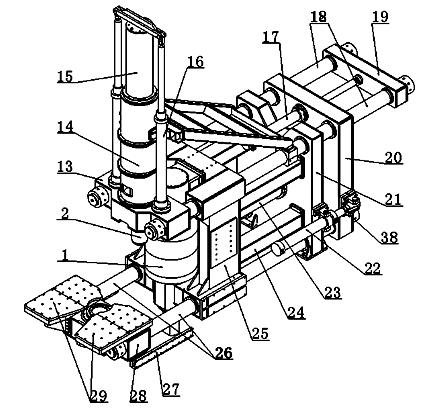

[0021] Such as image 3 and 4 As shown, the four-column up and down double-action mechanism of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com