Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Sealing performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

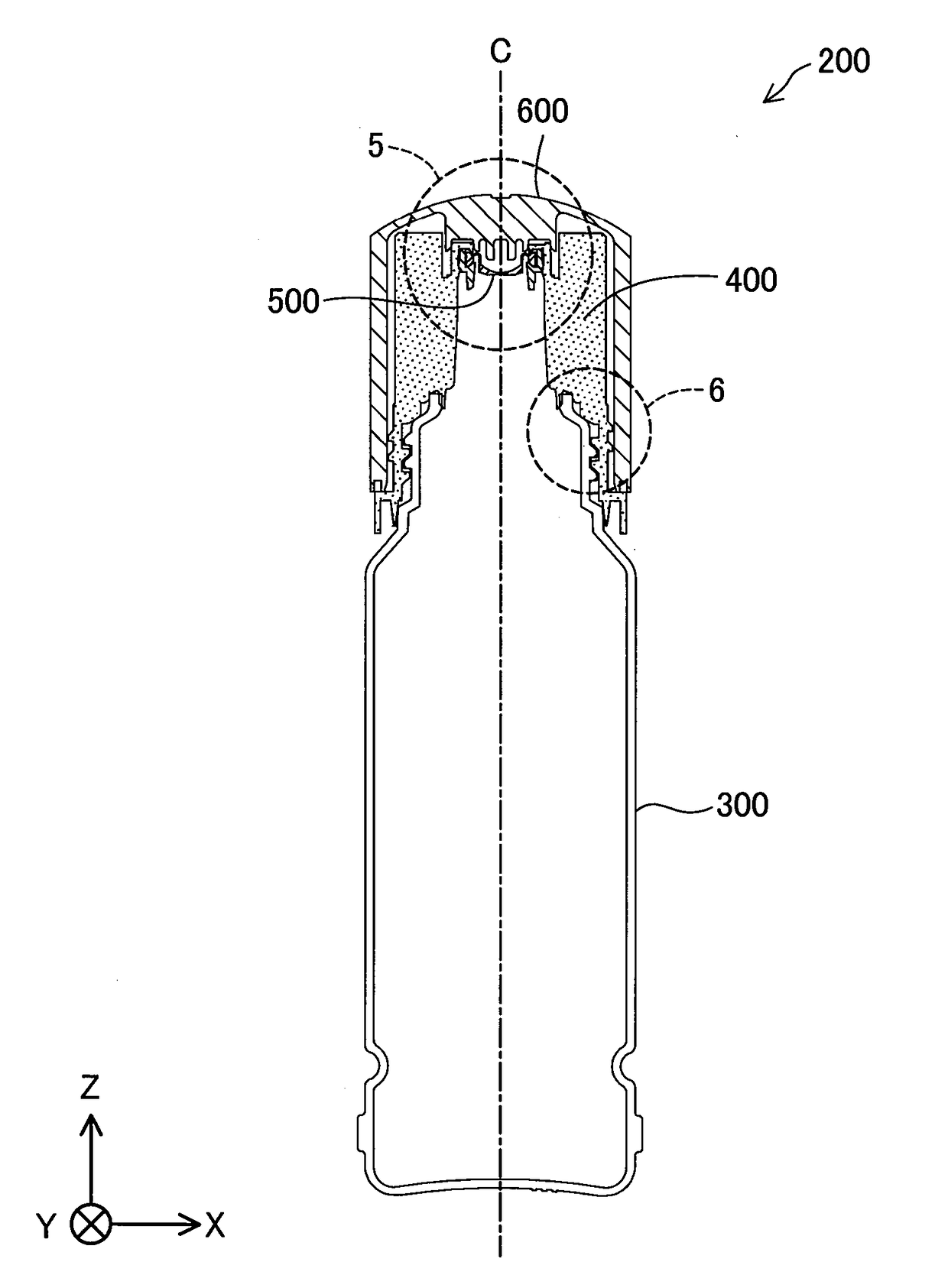

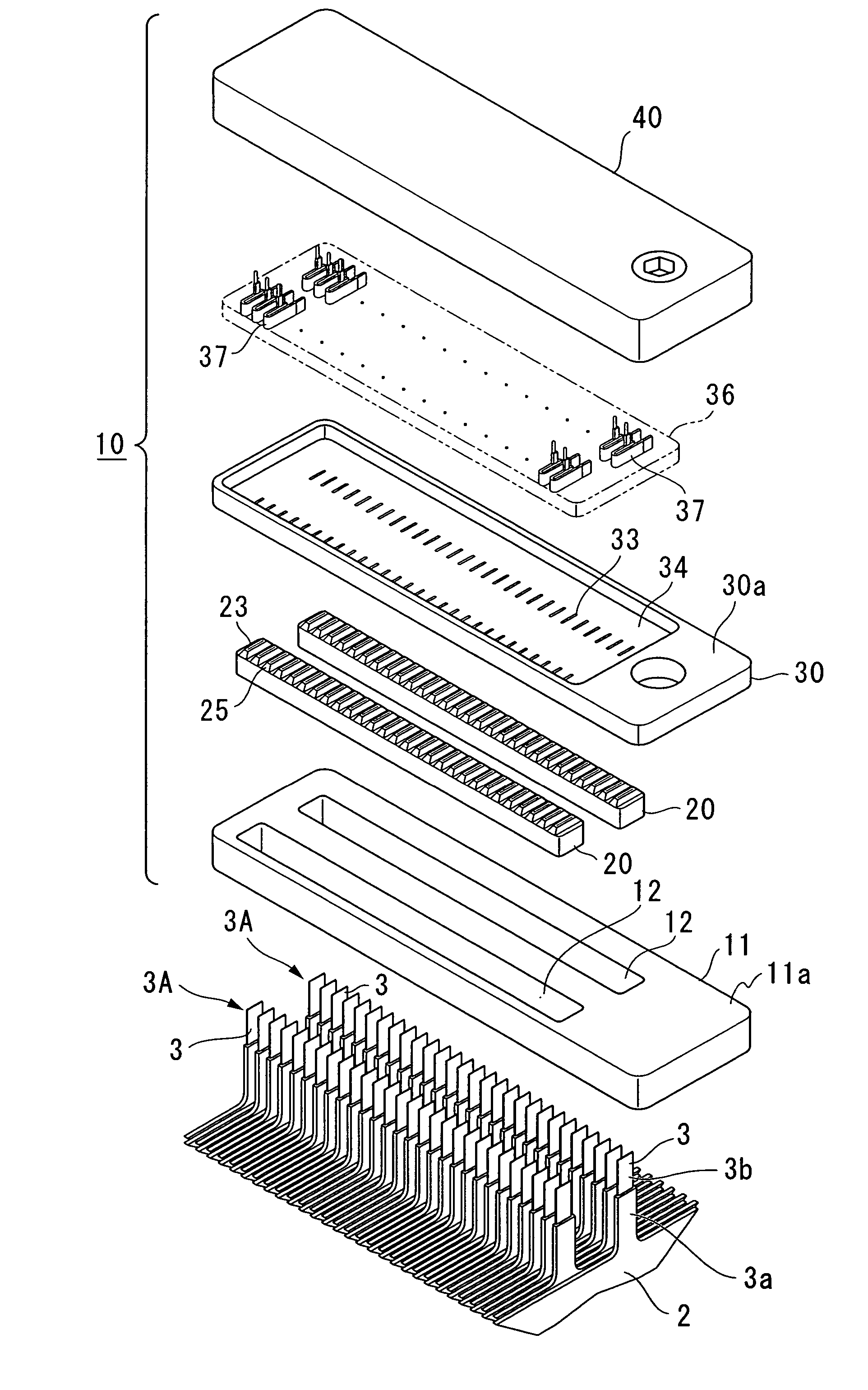

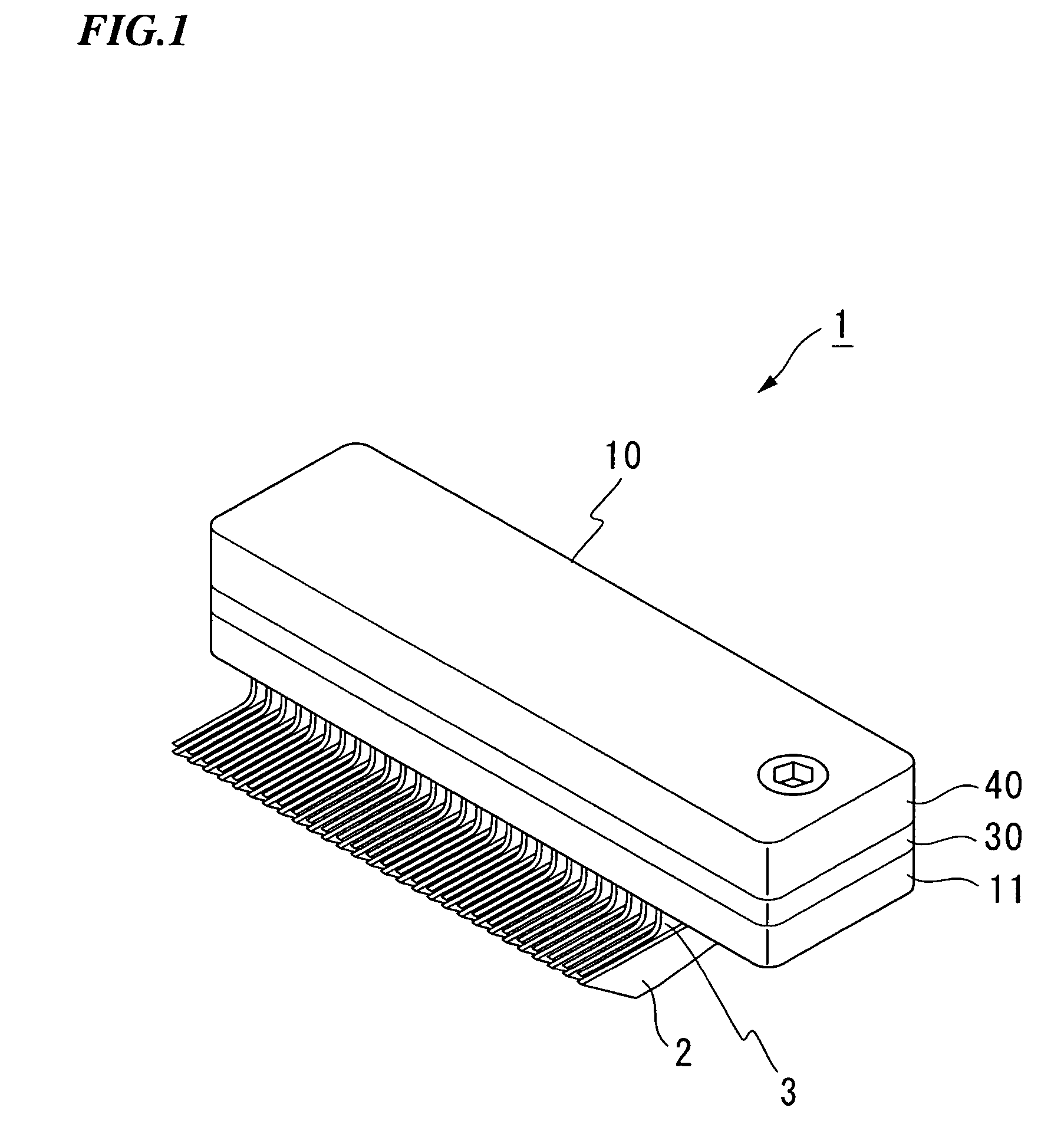

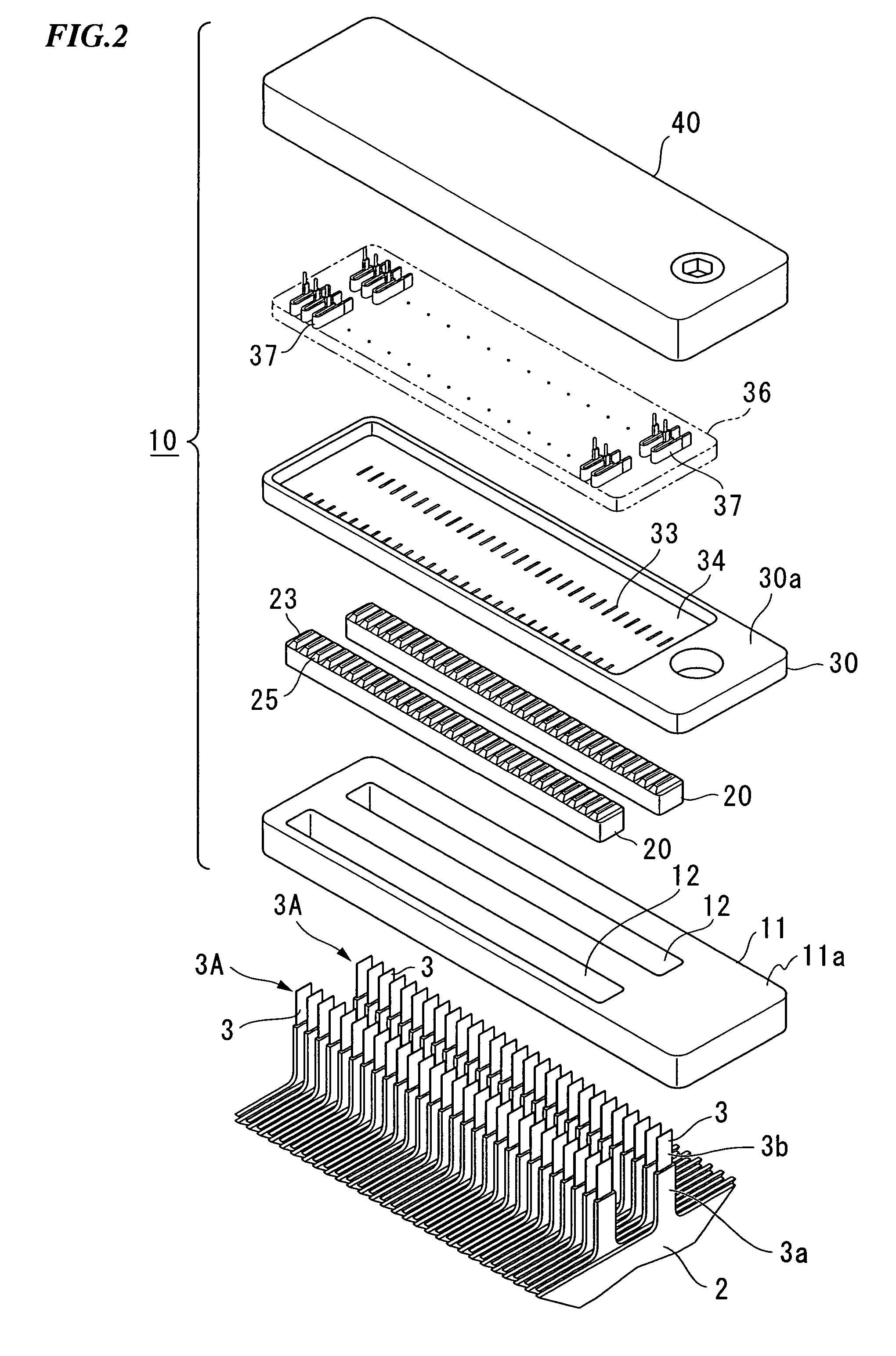

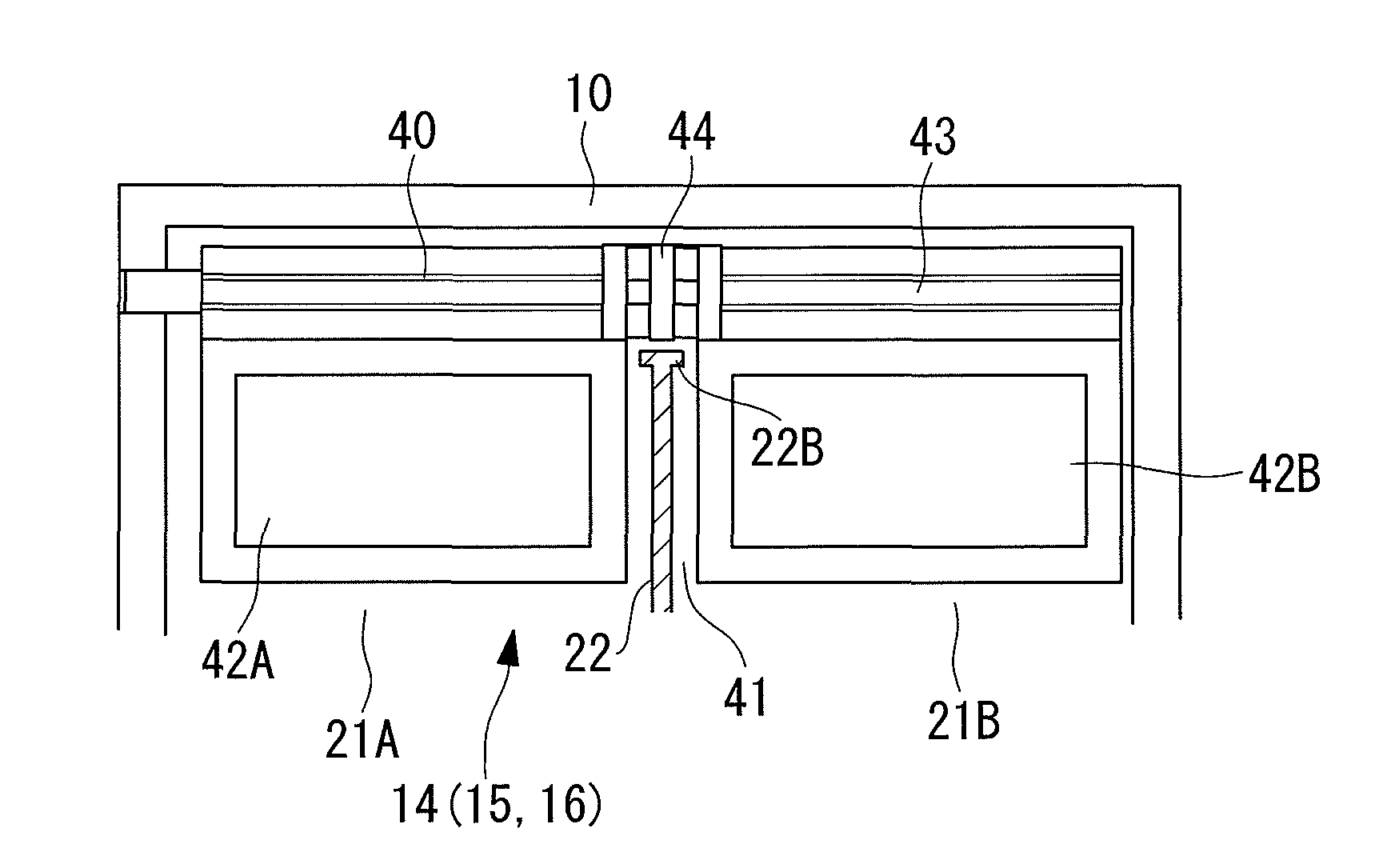

Rechargeable battery

InactiveUS20090186269A1Sealing performanceIncrease contact areaSmall-sized cells cases/jacketsCell lids/coversRechargeable cellEngineering

The present invention relates to a rechargeable battery. The rechargeable battery includes an electrode assembly, a case, electrode terminals, and a cap plate. The electrode assembly includes a separator and an anode and a cathode disposed at both sides of the separator. The case houses the electrode assembly. The electrode terminals are electrically connected to the electrode assembly and protrude outwardly from the case. The cap plate closes and seals the case. The cap plate includes a terminal hole for receiving the electrode terminals and a sealing reinforcing member formed along a circumference of the terminal hole and having a greater thicker than a periphery thereof.

Owner:SAMSUNG SDI CO LTD

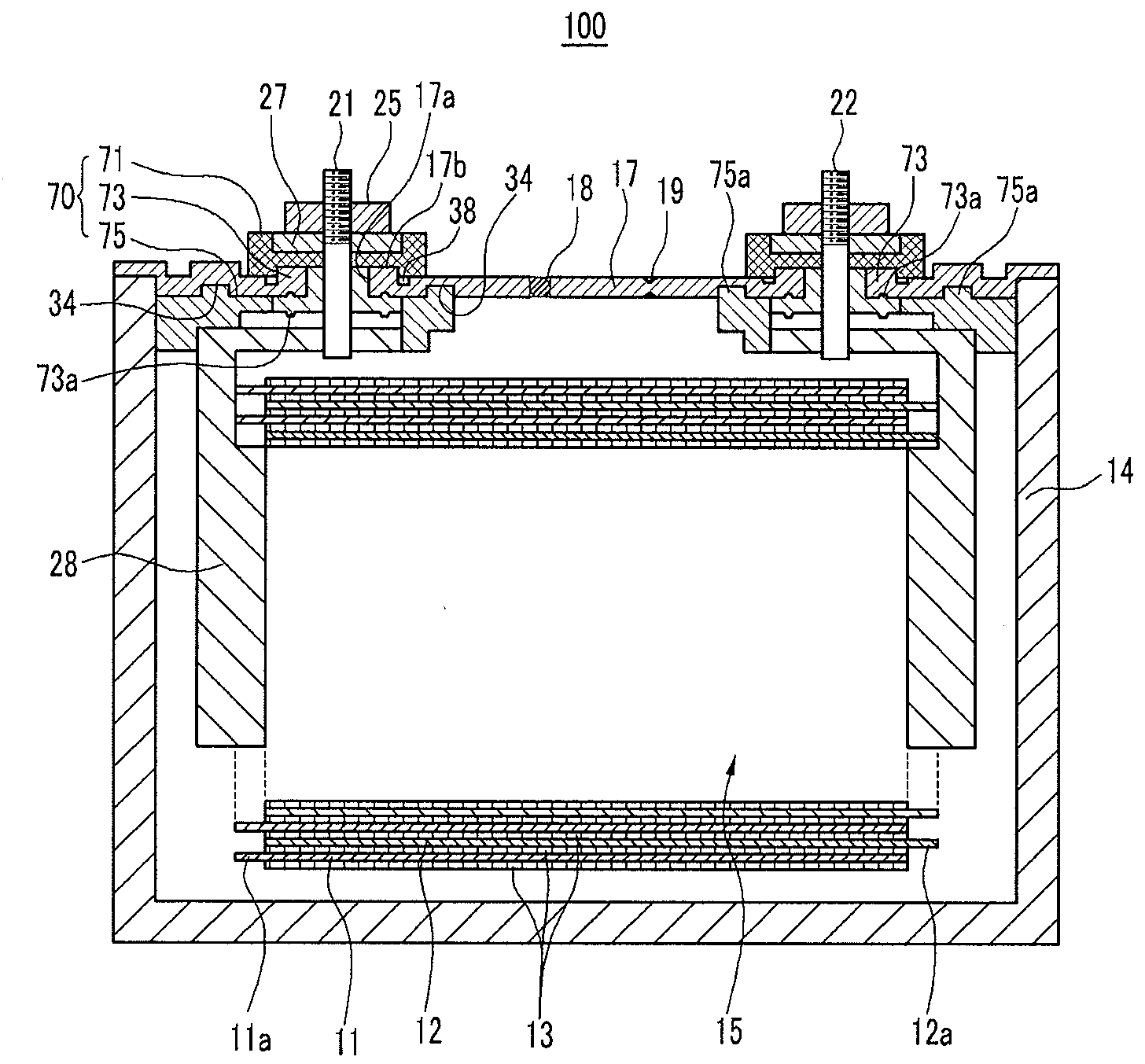

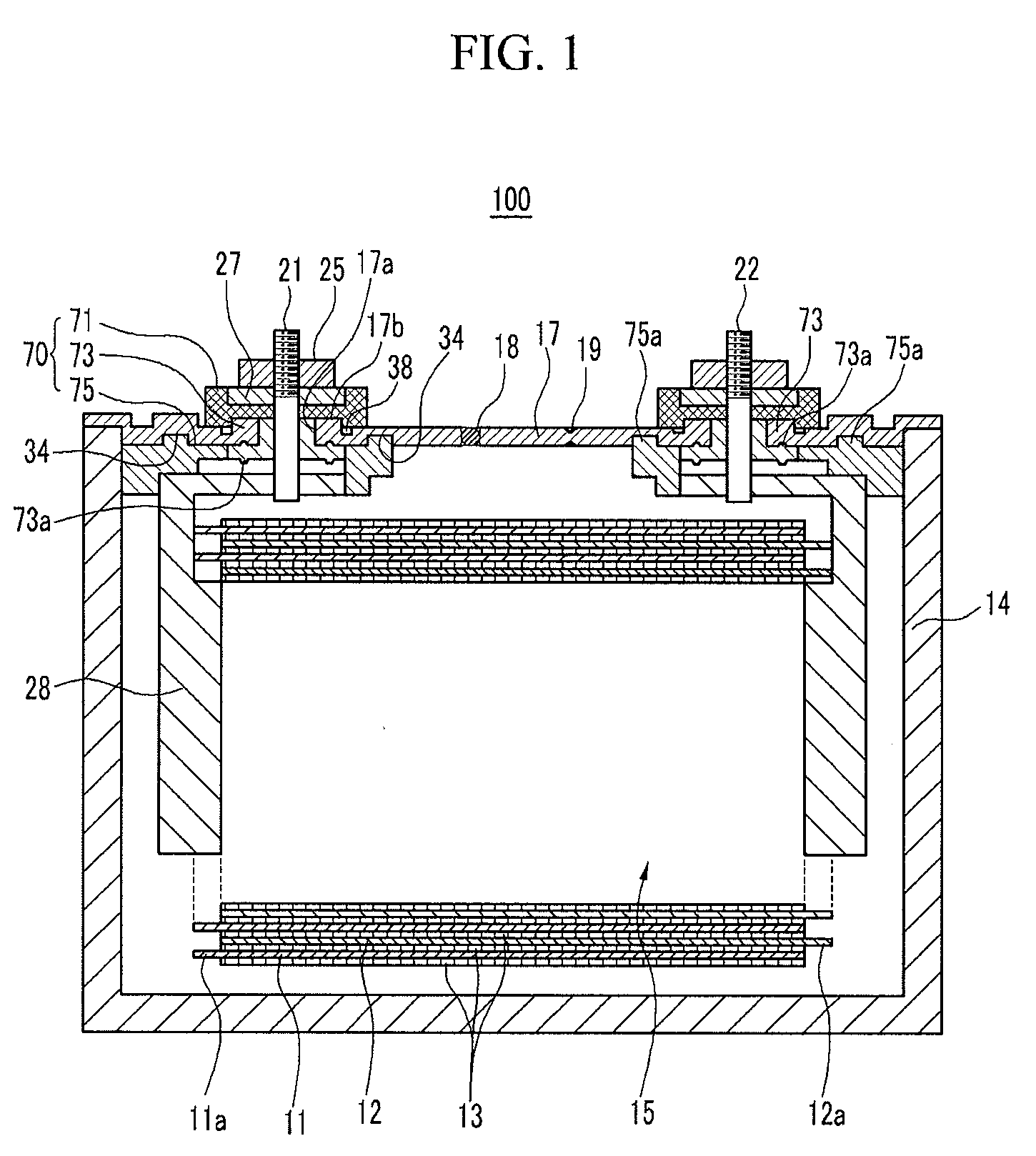

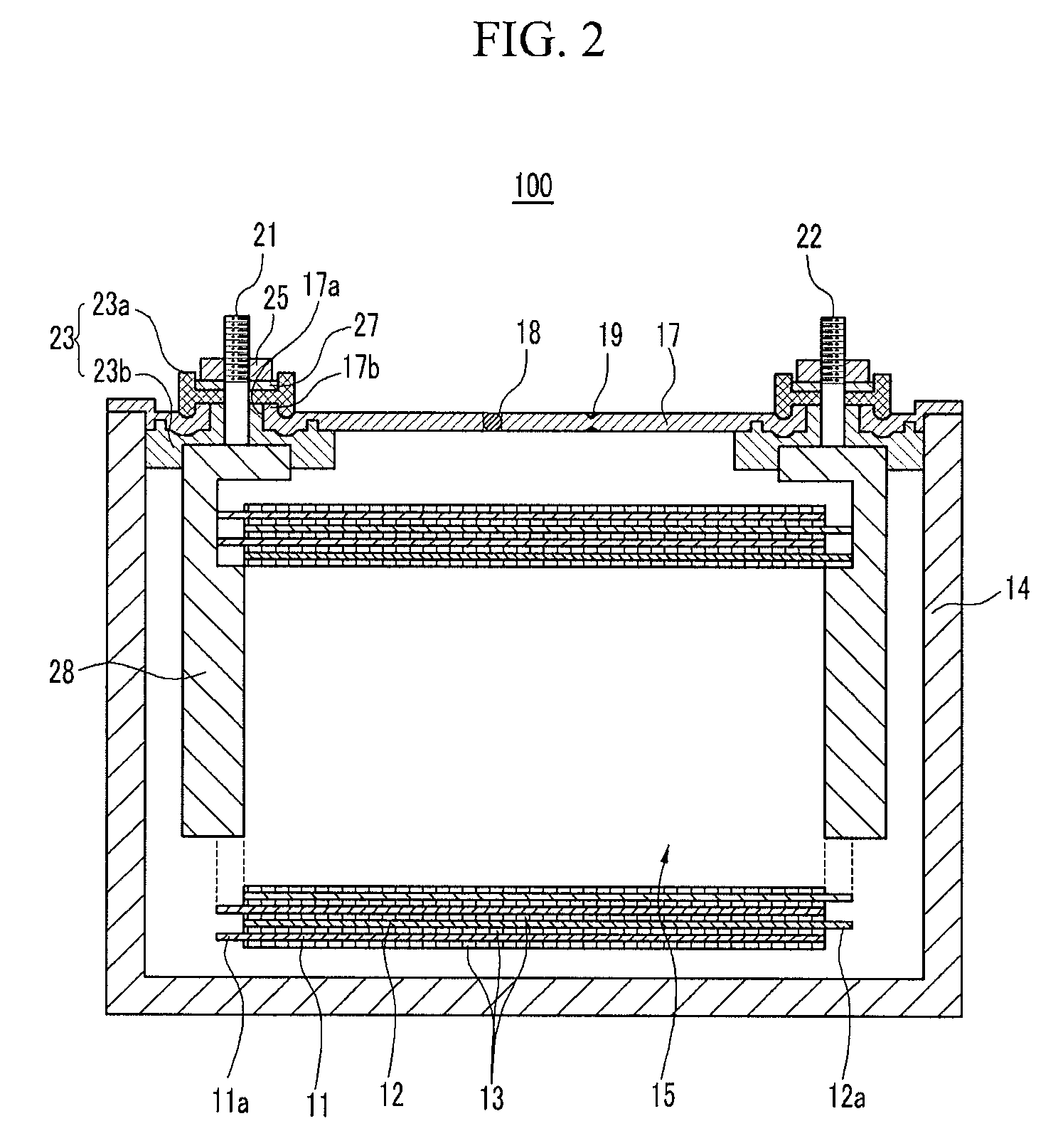

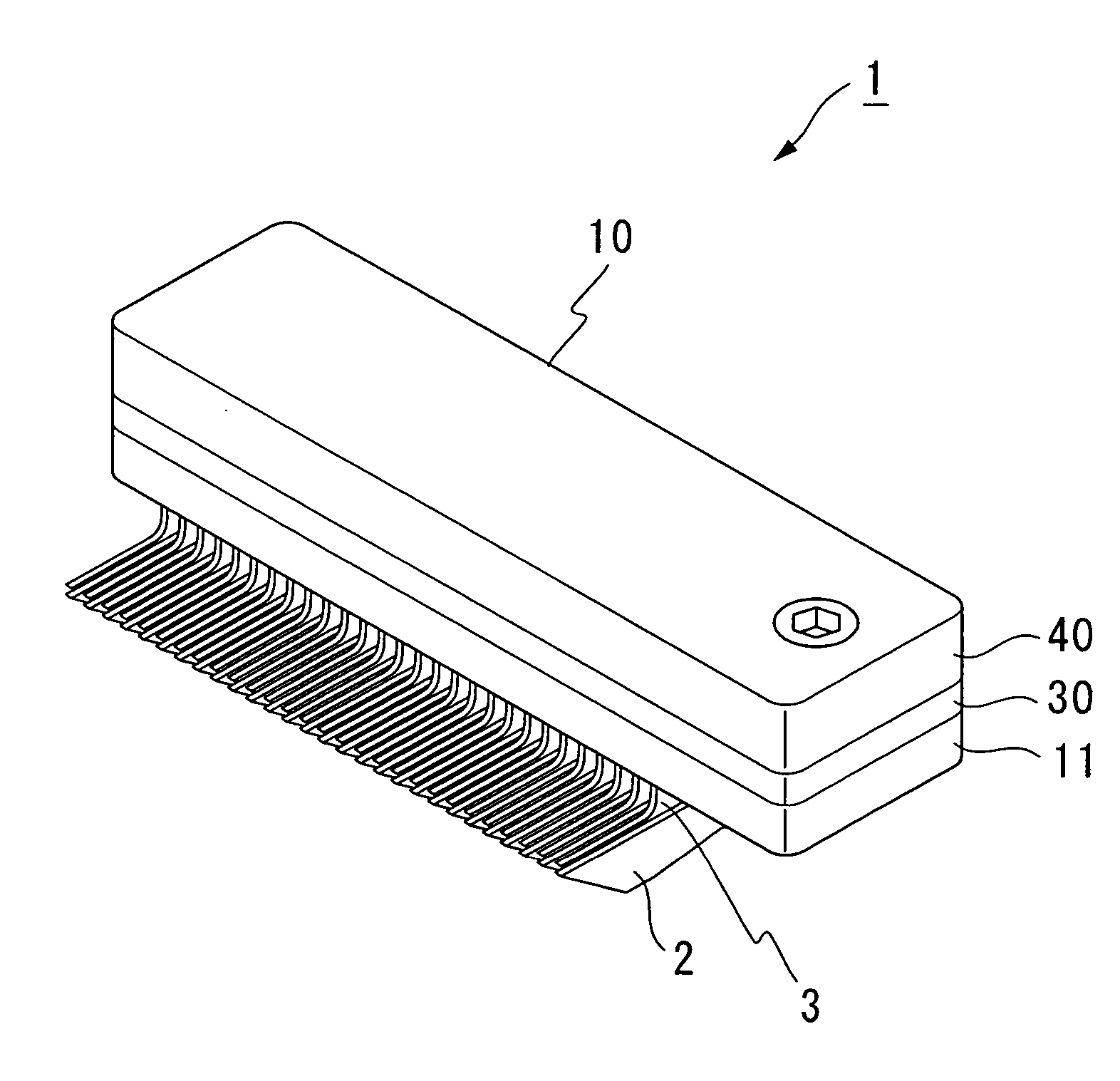

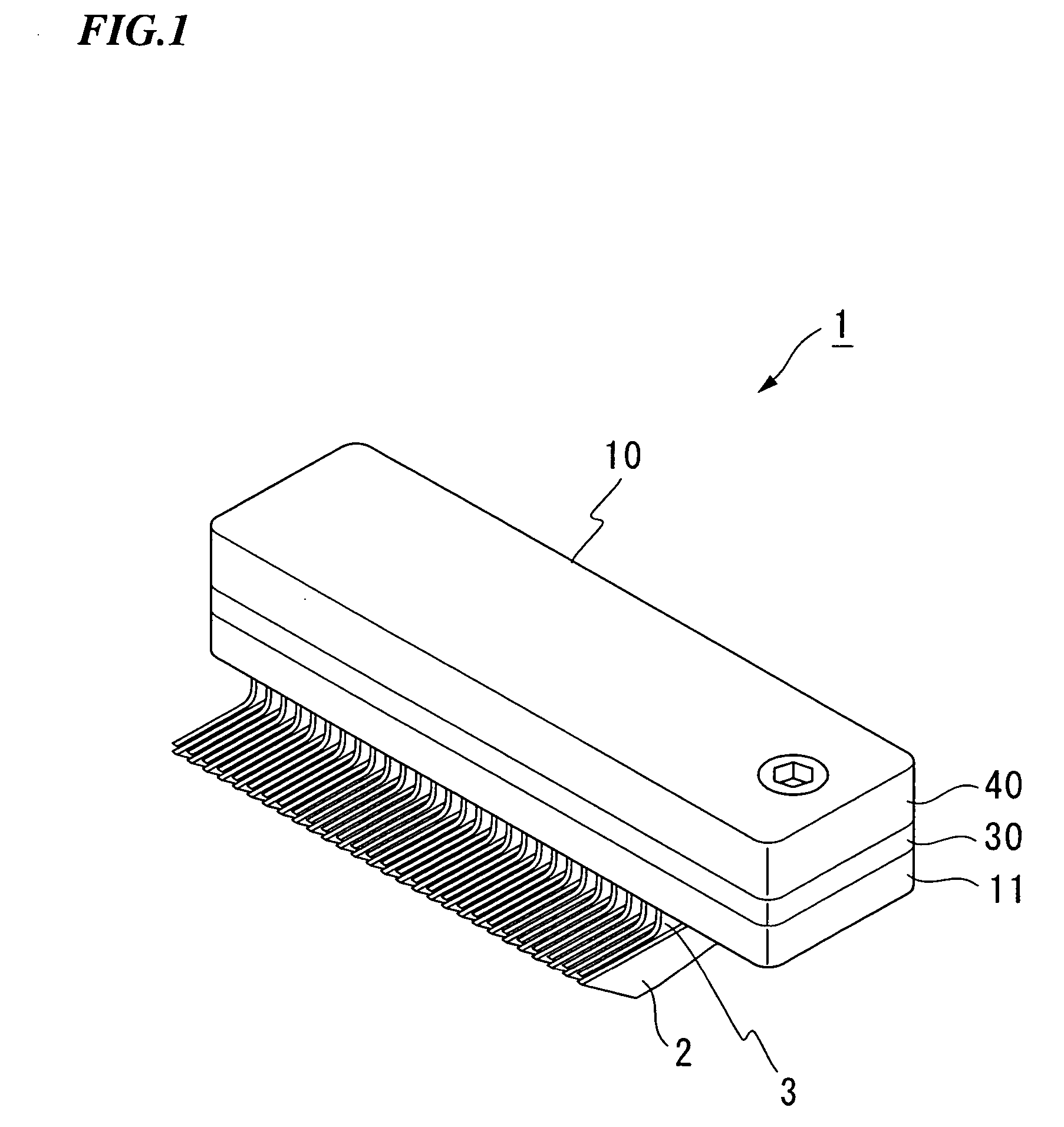

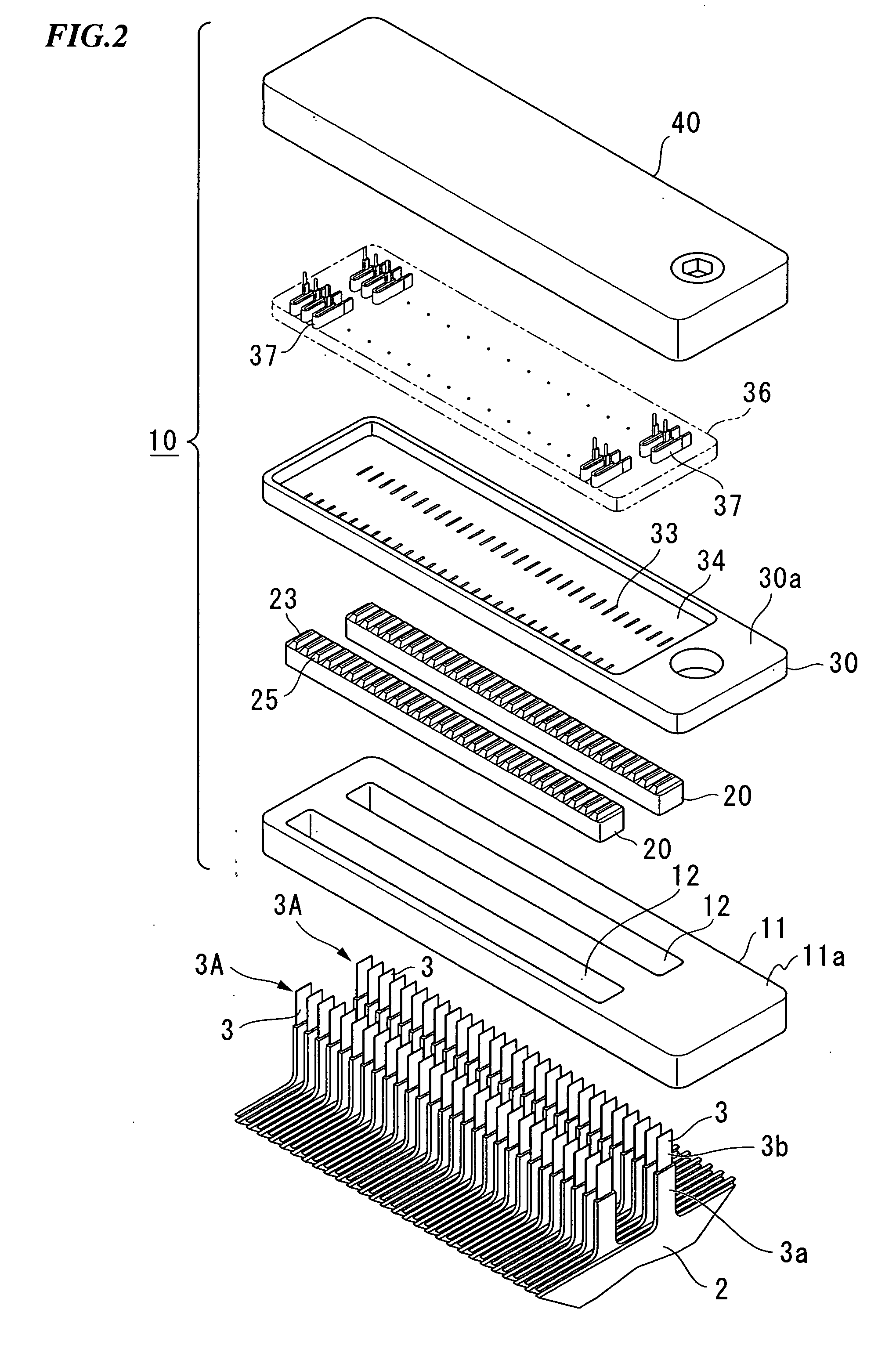

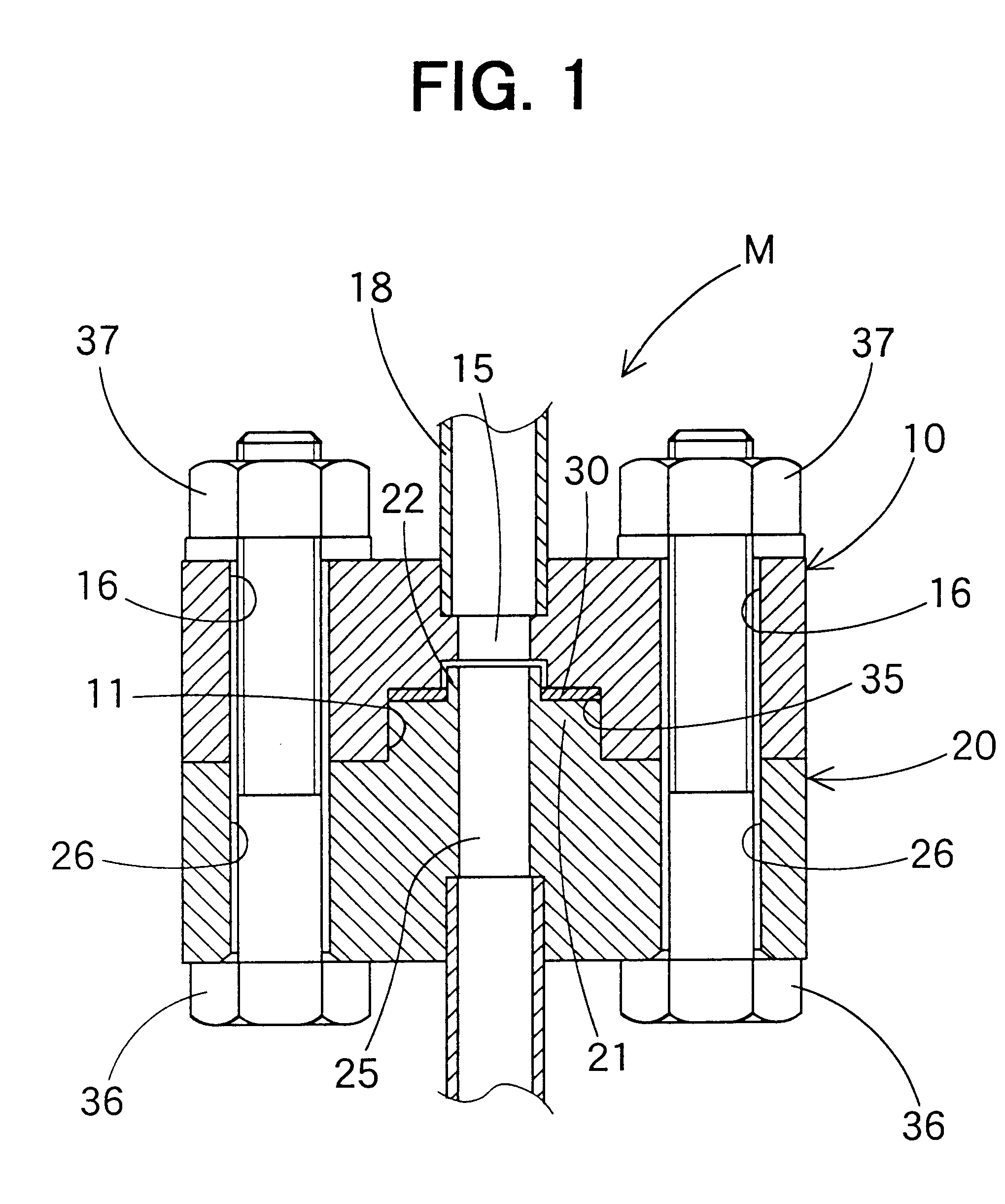

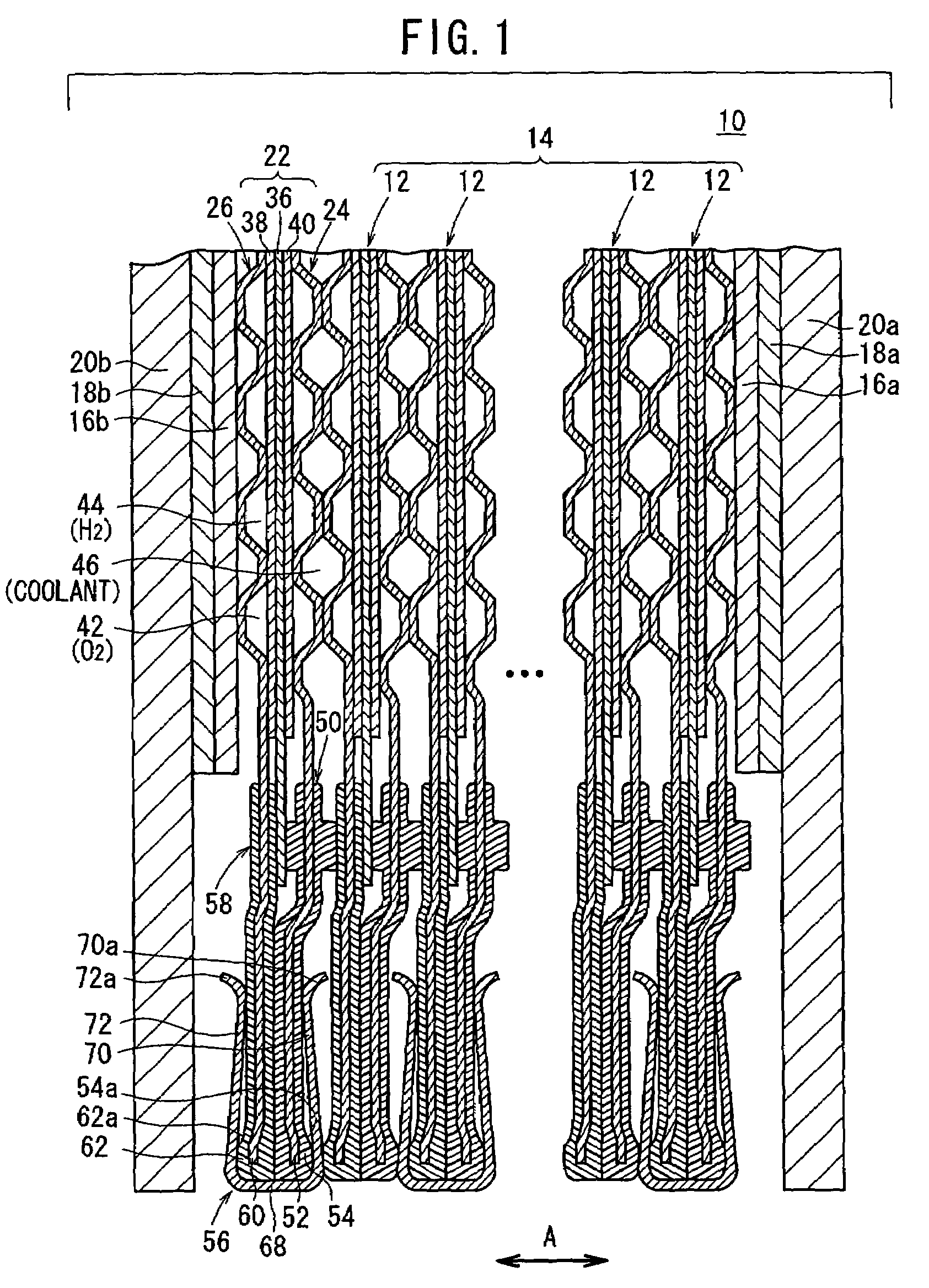

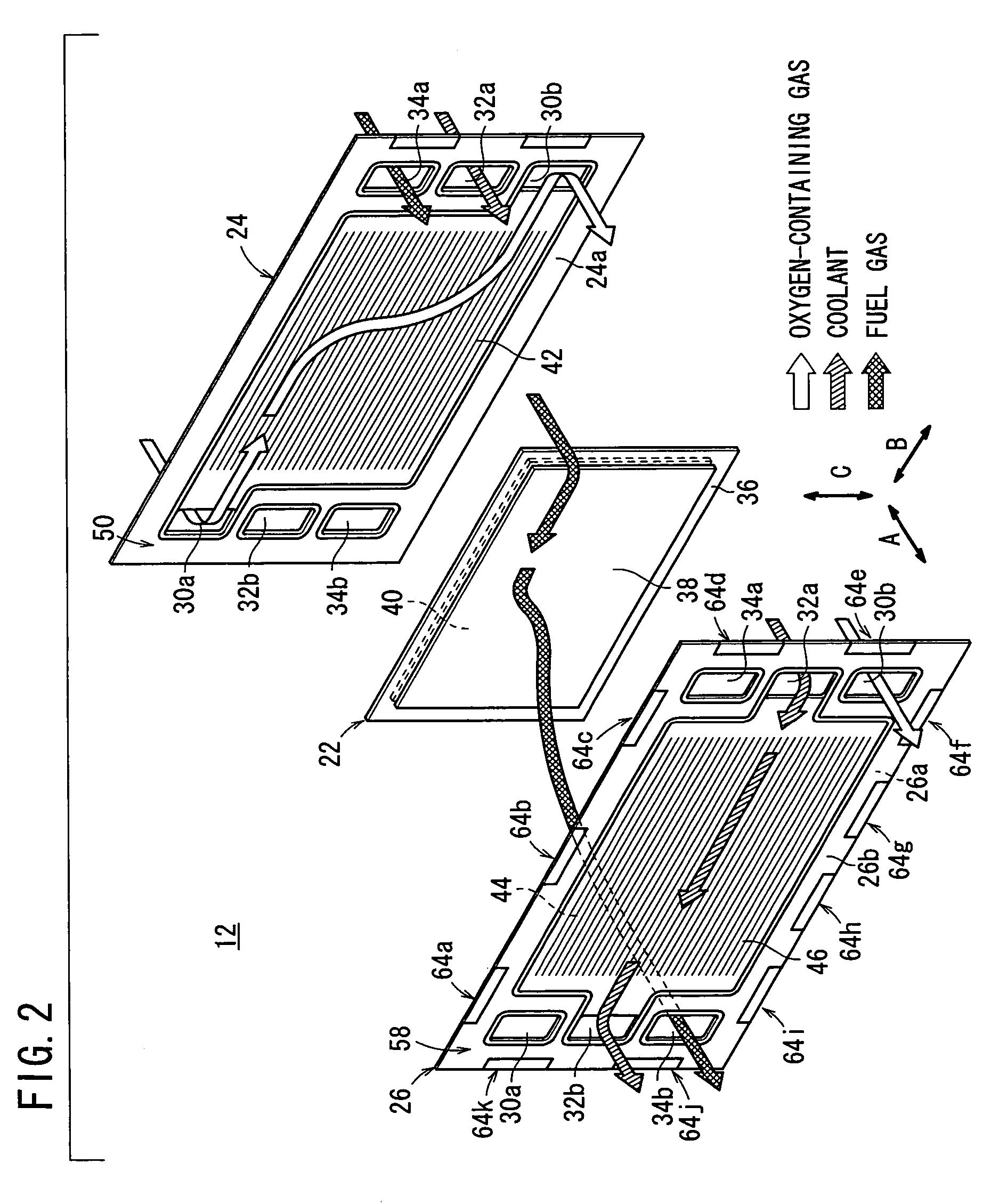

Fuel cell stack

ActiveUS20050213409A1Improve sealingSealing performancePrimary cell to battery groupingFuel cells groupingFuel cellsElectrical battery

A fuel cell stack is provided with a plurality of stacked separators. This fuel cell stack includes: terminals that extend from the separators; packing in which are formed a plurality of through holes through which the terminals are inserted; a packing casing that has a packing housing concave portion that envelops side surfaces of the packing and supports a bottom surface of the packing, and has through holes through which the terminals are inserted; and a connector housing that has a pressing surface that presses a top surface of the packing. Mountain-shaped protruding portions whose apex portions are formed by circumferential edges of apertures of the respective through holes are provided on the top surface of the packing, and the pressing surfaces of the connector housing are formed in a configuration that conforms to the side surfaces of the protruding portions. Internal surfaces of the through holes in the packing are in contact without a gap in between with external surfaces of the terminals. The sealing performance in extraction portions of terminals that are used for cell voltage detection is improved.

Owner:HONDA MOTOR CO LTD

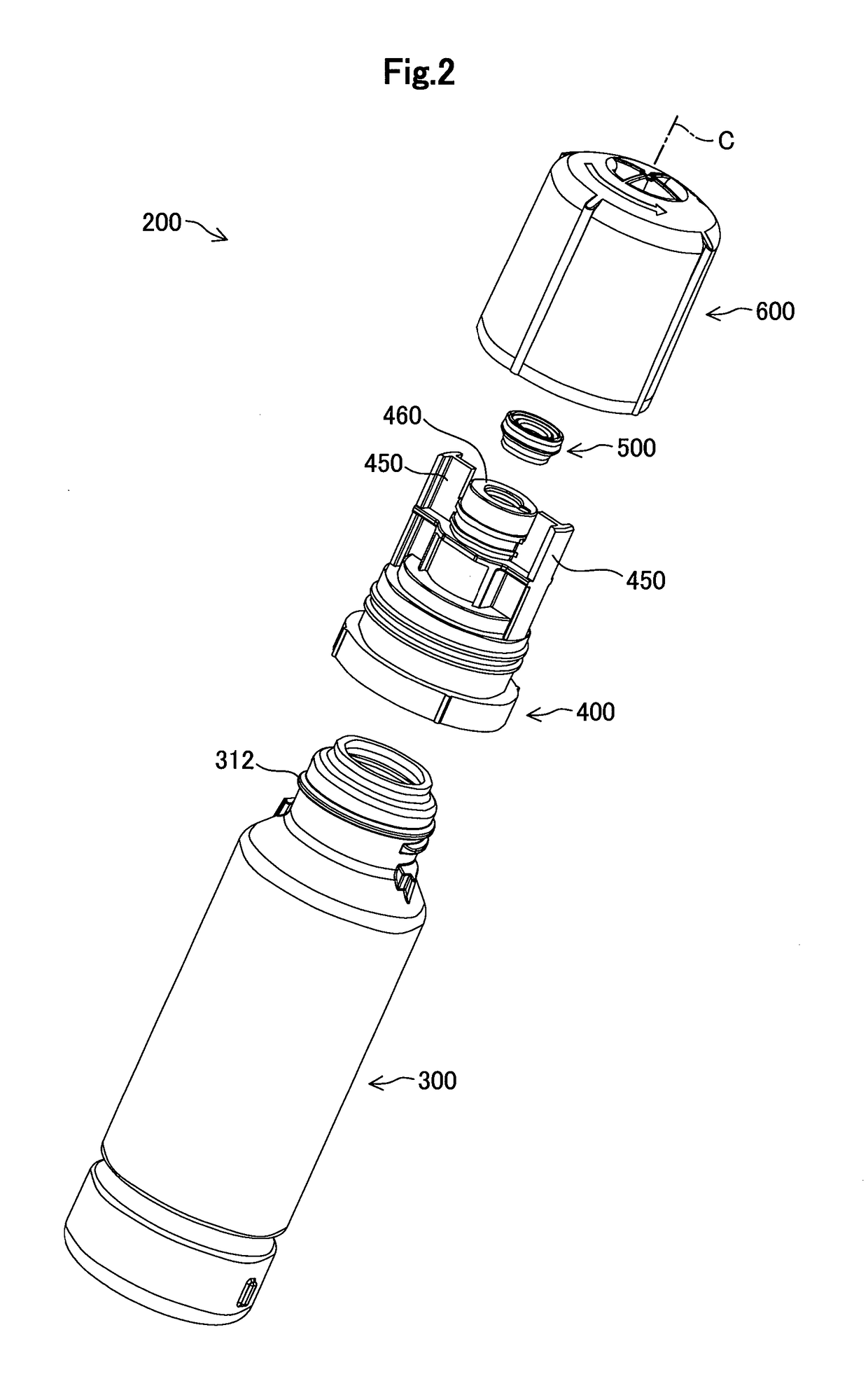

Ink replenish container

ActiveUS20170355195A1Avoid Sealing ProblemsReduce the possibilityPrintingEngineeringMechanical engineering

Owner:SEIKO EPSON CORP

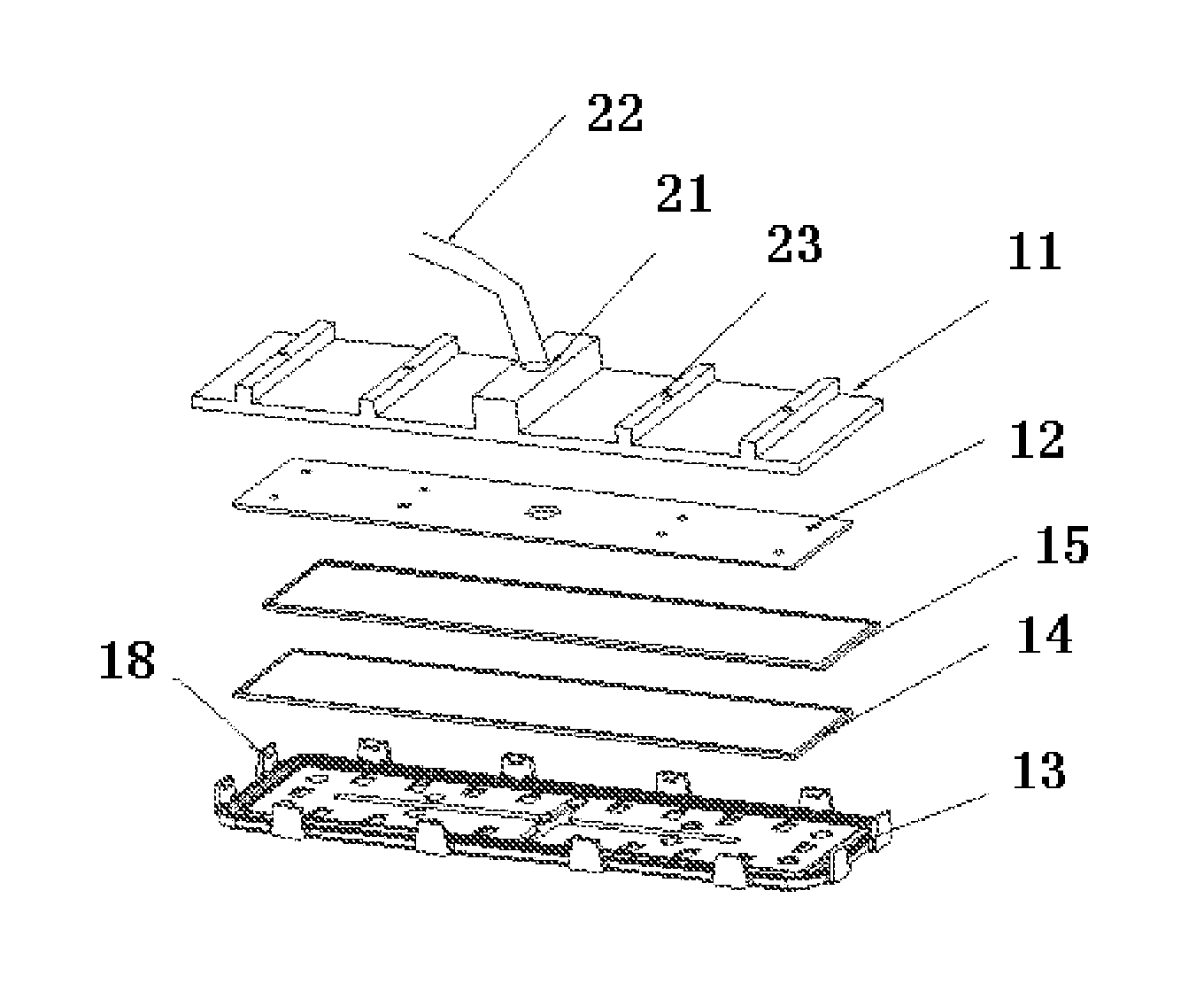

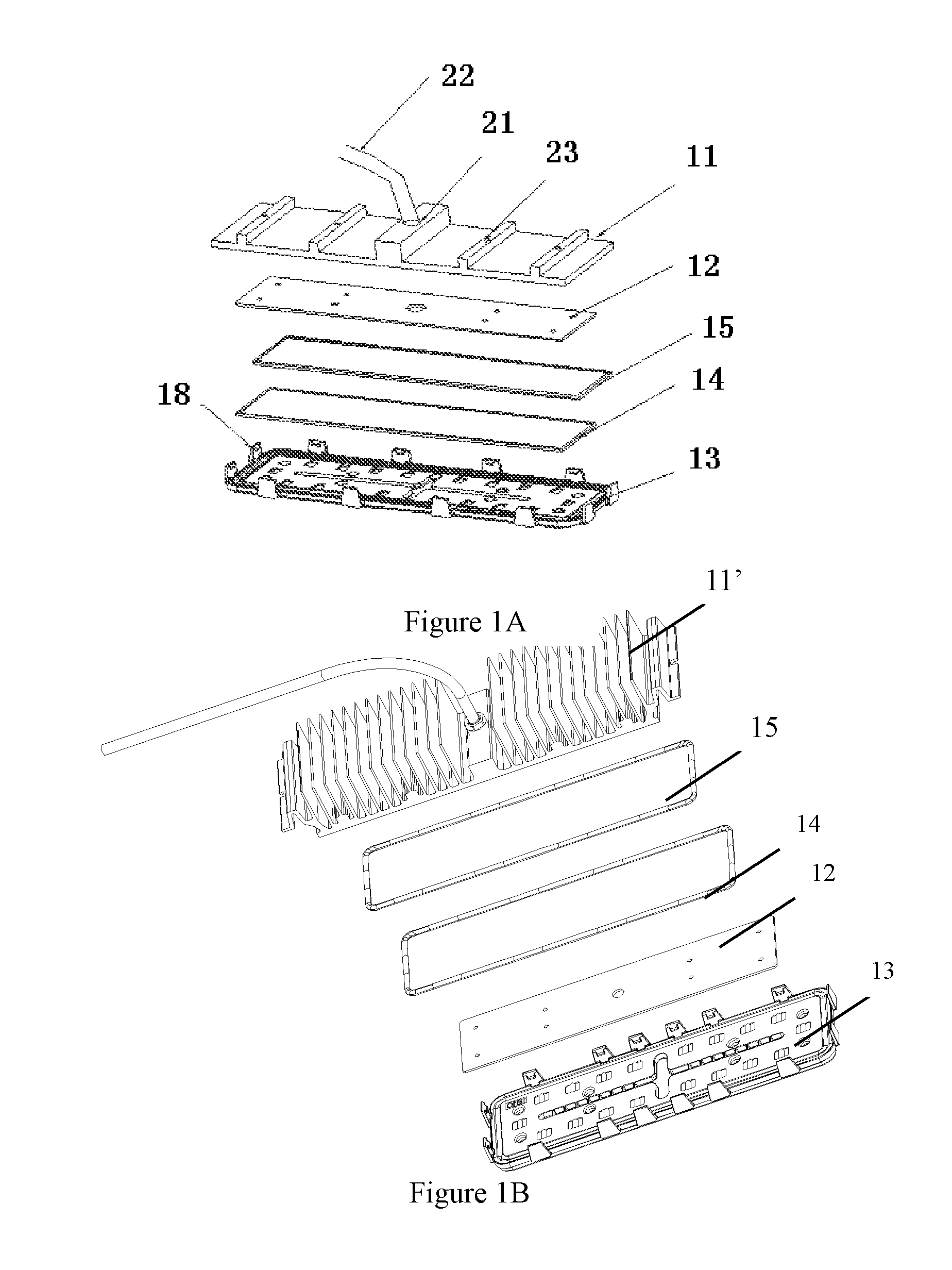

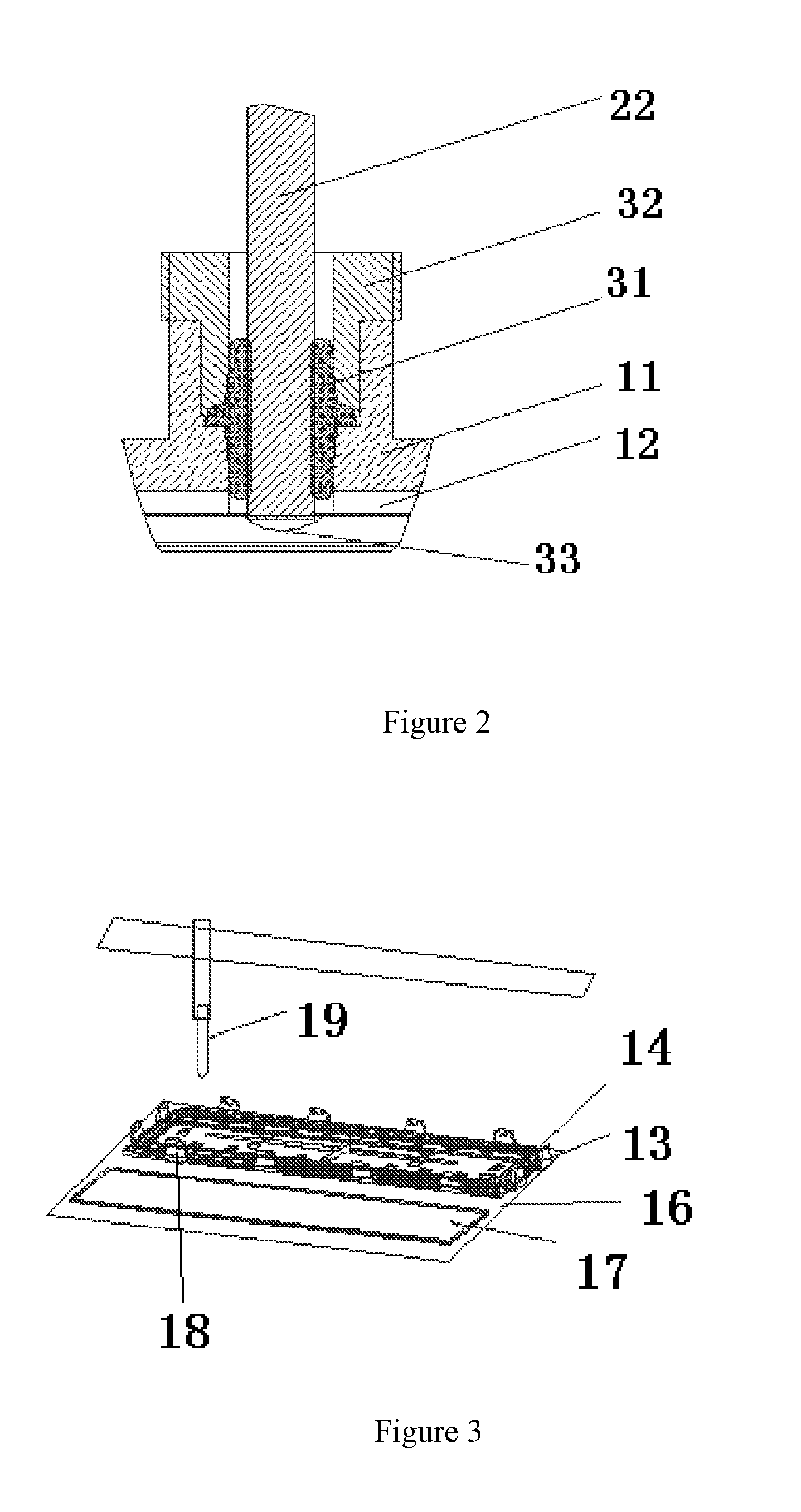

LED Module Sealing Technology

ActiveUS20150128409A1Easy to useReduce the amount requiredPlanar light sourcesPipesWater vaporEngineering

A sealing process of LED modules includes a waterproof wire put through a wire-through hole of a heat sink to be connected with a positive-negative solder joints on a PCB board, which are subjected to glue sealing treatment. A waterproof sealing process is operated between the waterproof wire and wire-through hole. The PCB board is fixed on the heat sink. One sealing ring is placed into a groove. A ring of liquid silica gel is evenly applied along the other groove. The heat sink installed with the PCB board and the waterproof wire are inversely buckled on the lens set which is fixed with the solid silica gel ring and liquid silica gel. At least two waterproof sealing rings are used to isolate an LED chip from the outside so as to prevent all water vapor or other harmful gases from corroding the chip and the PCB

Owner:HANGZHOU HPWINNER OPTO CORP

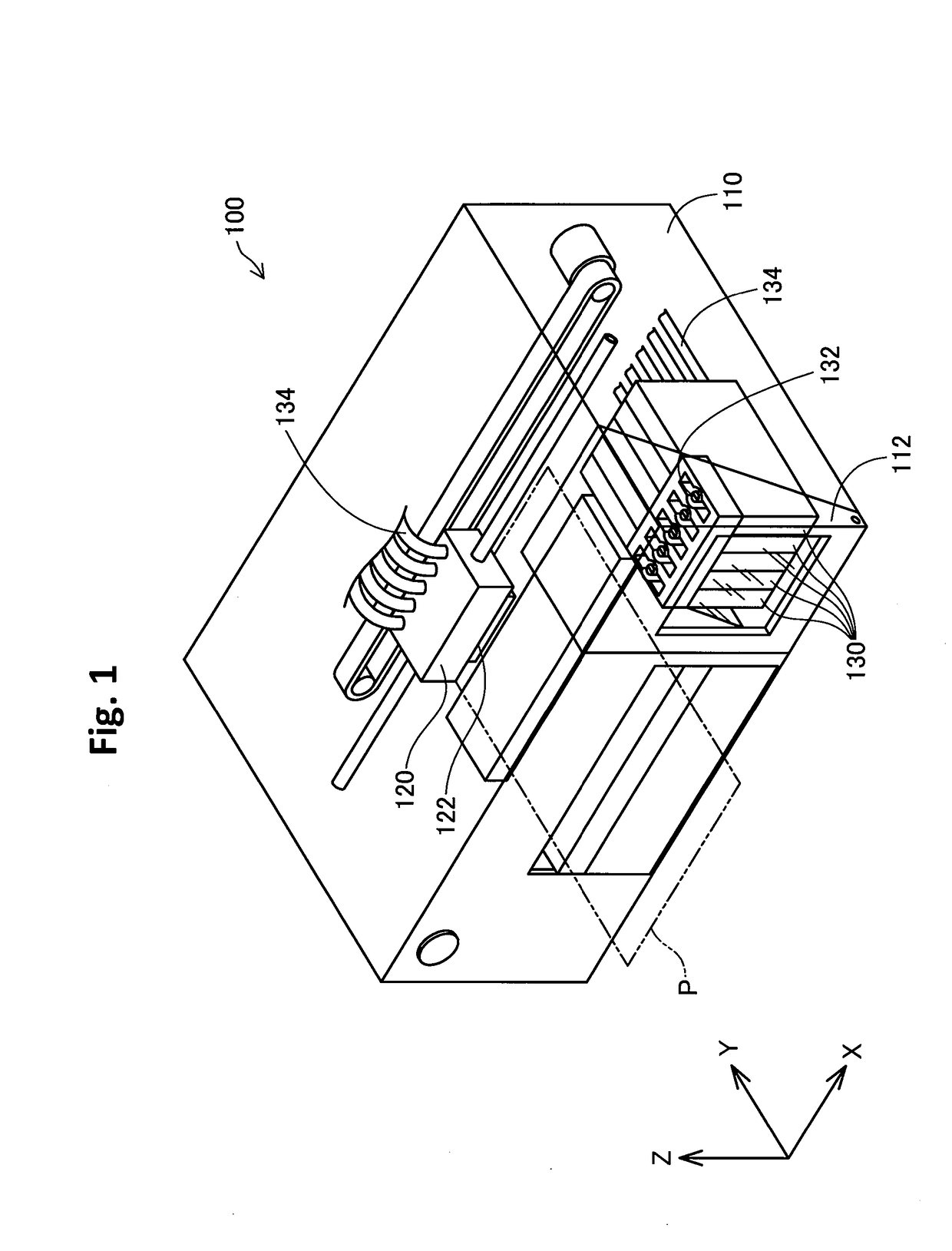

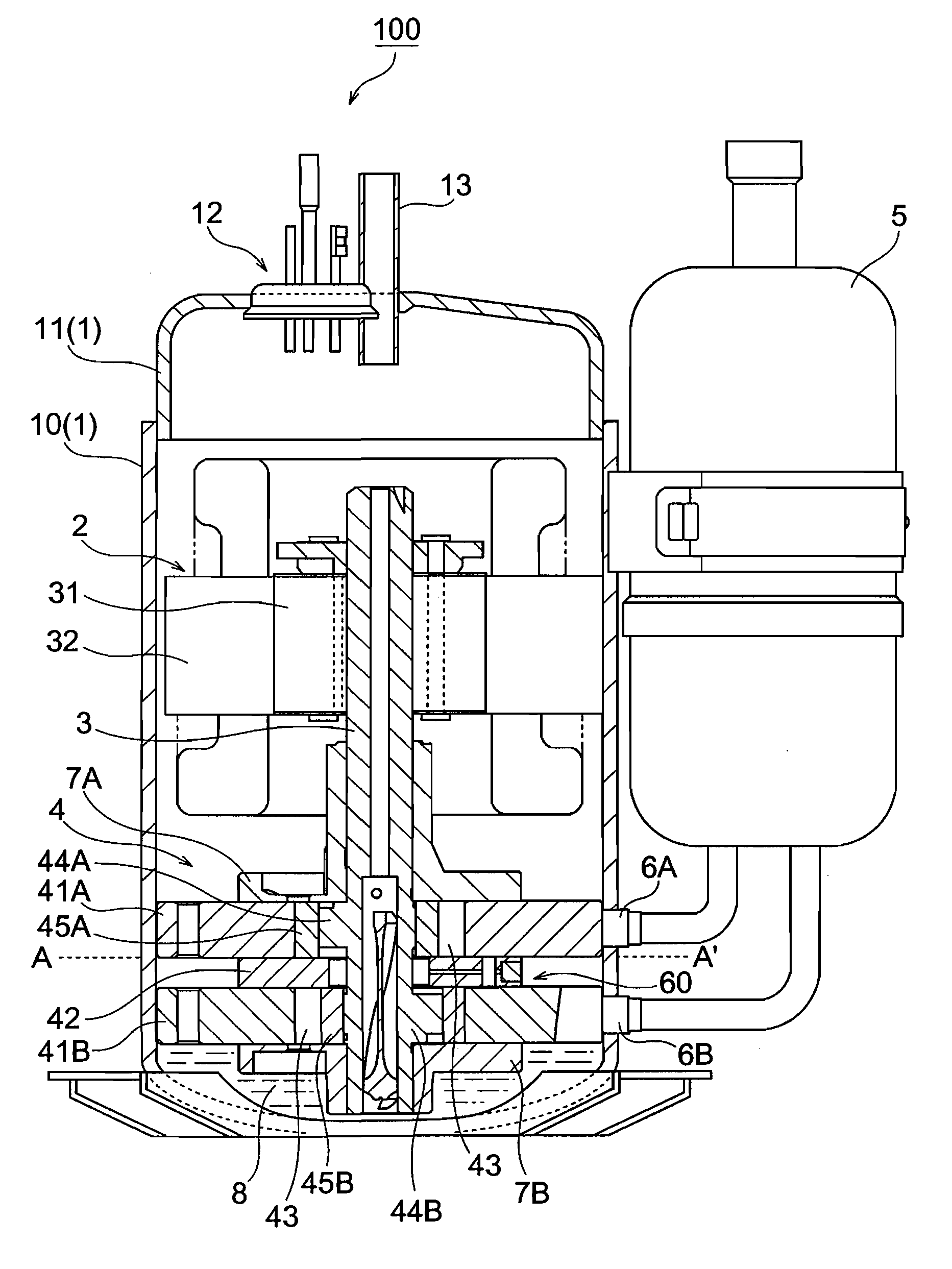

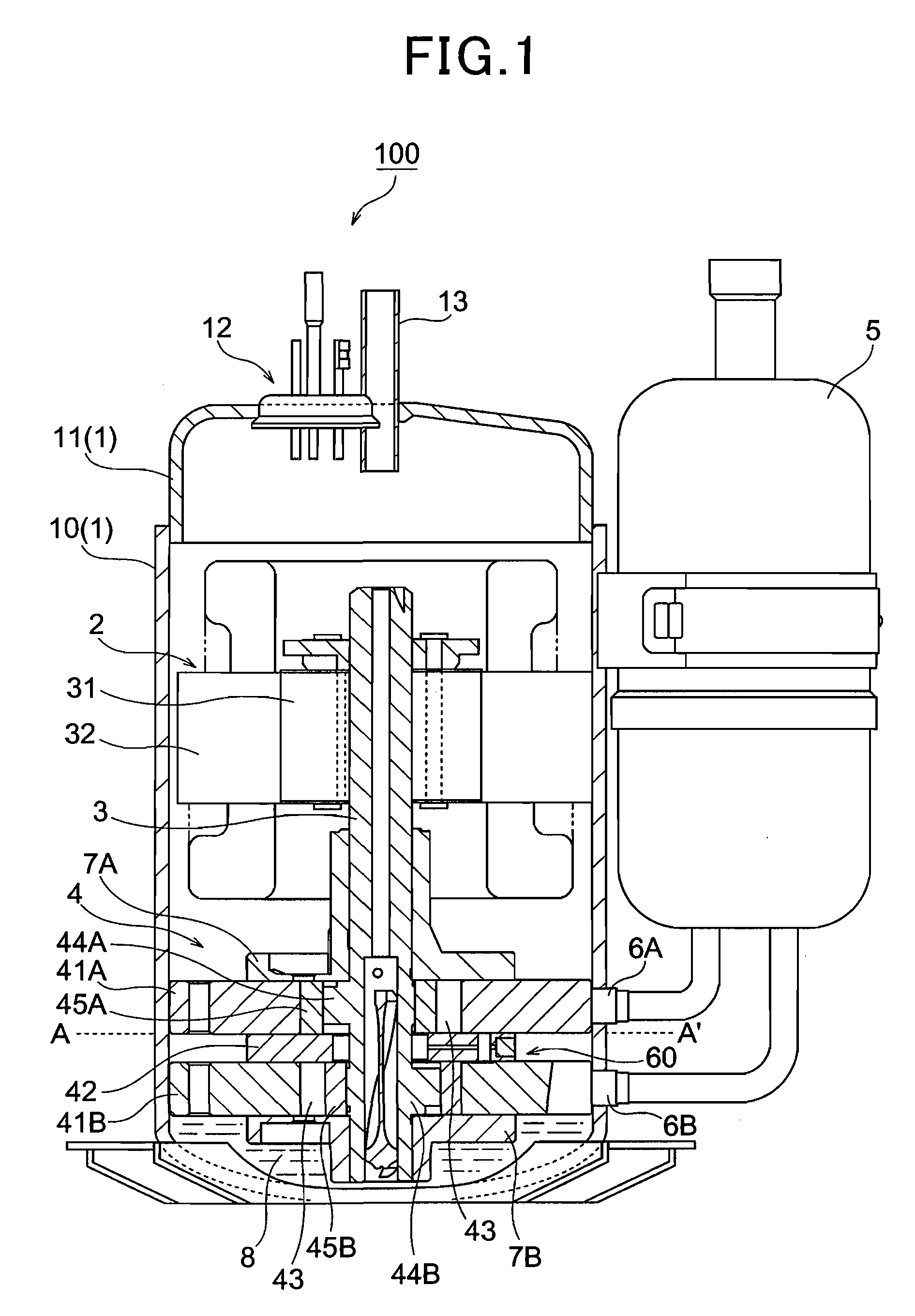

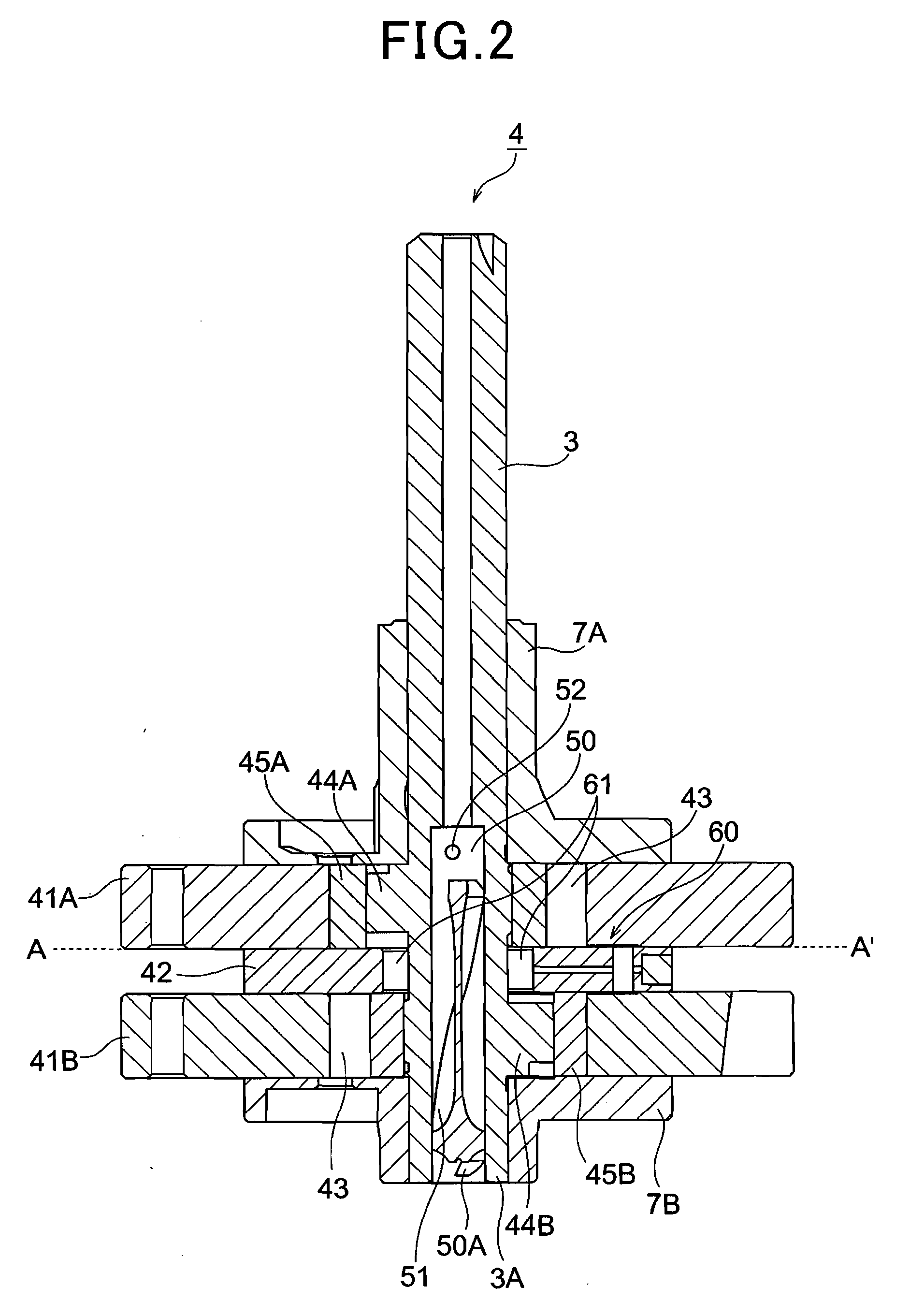

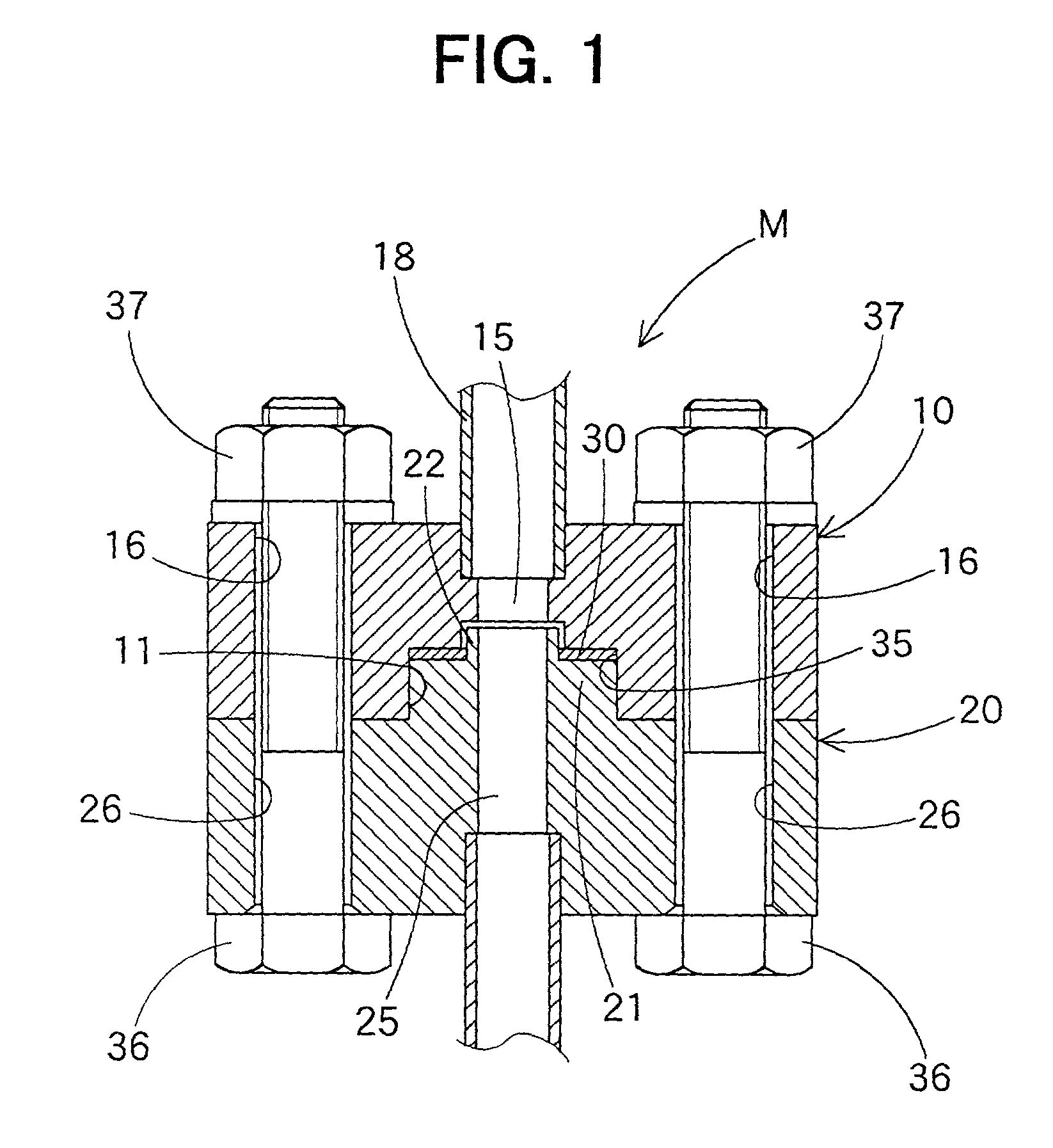

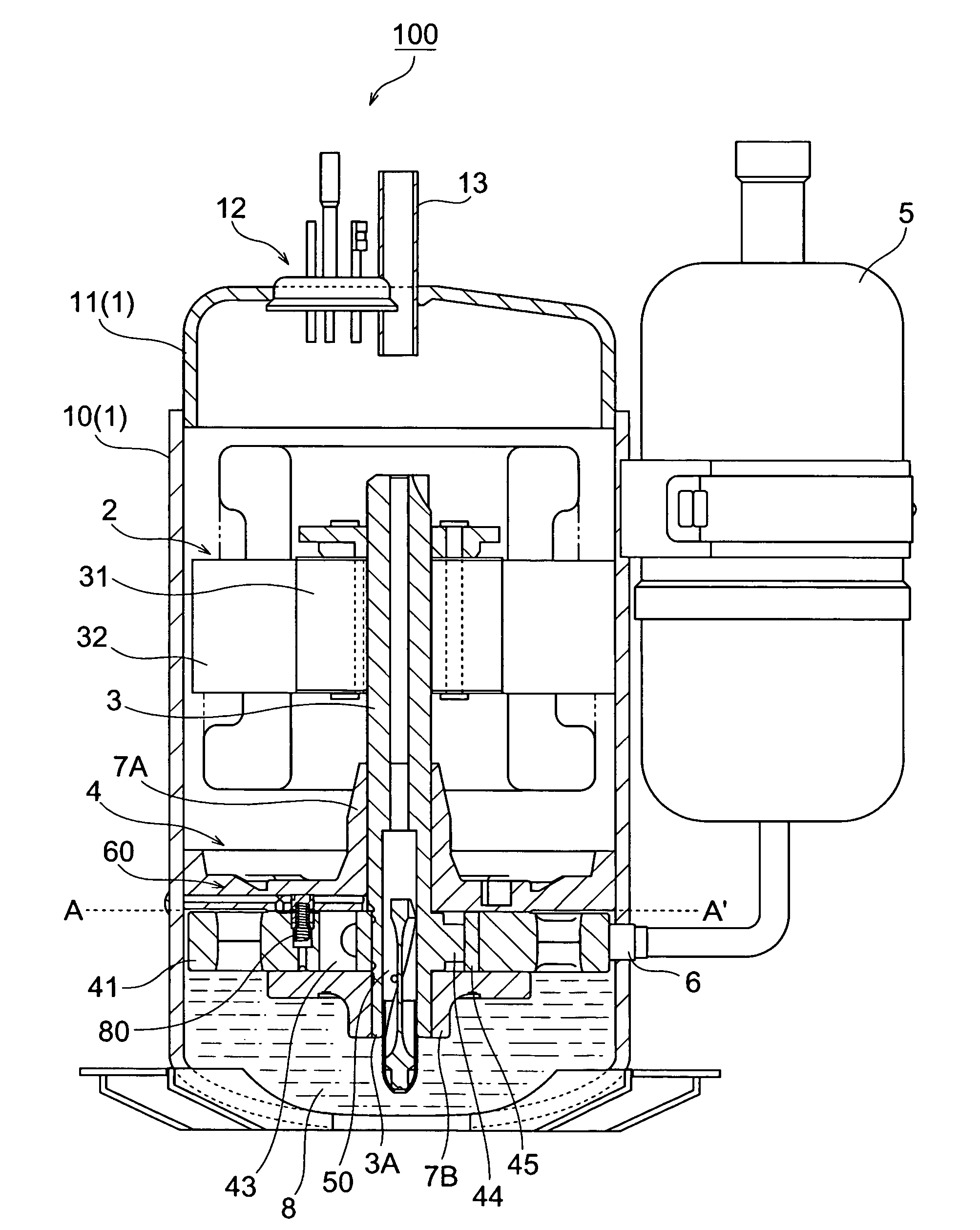

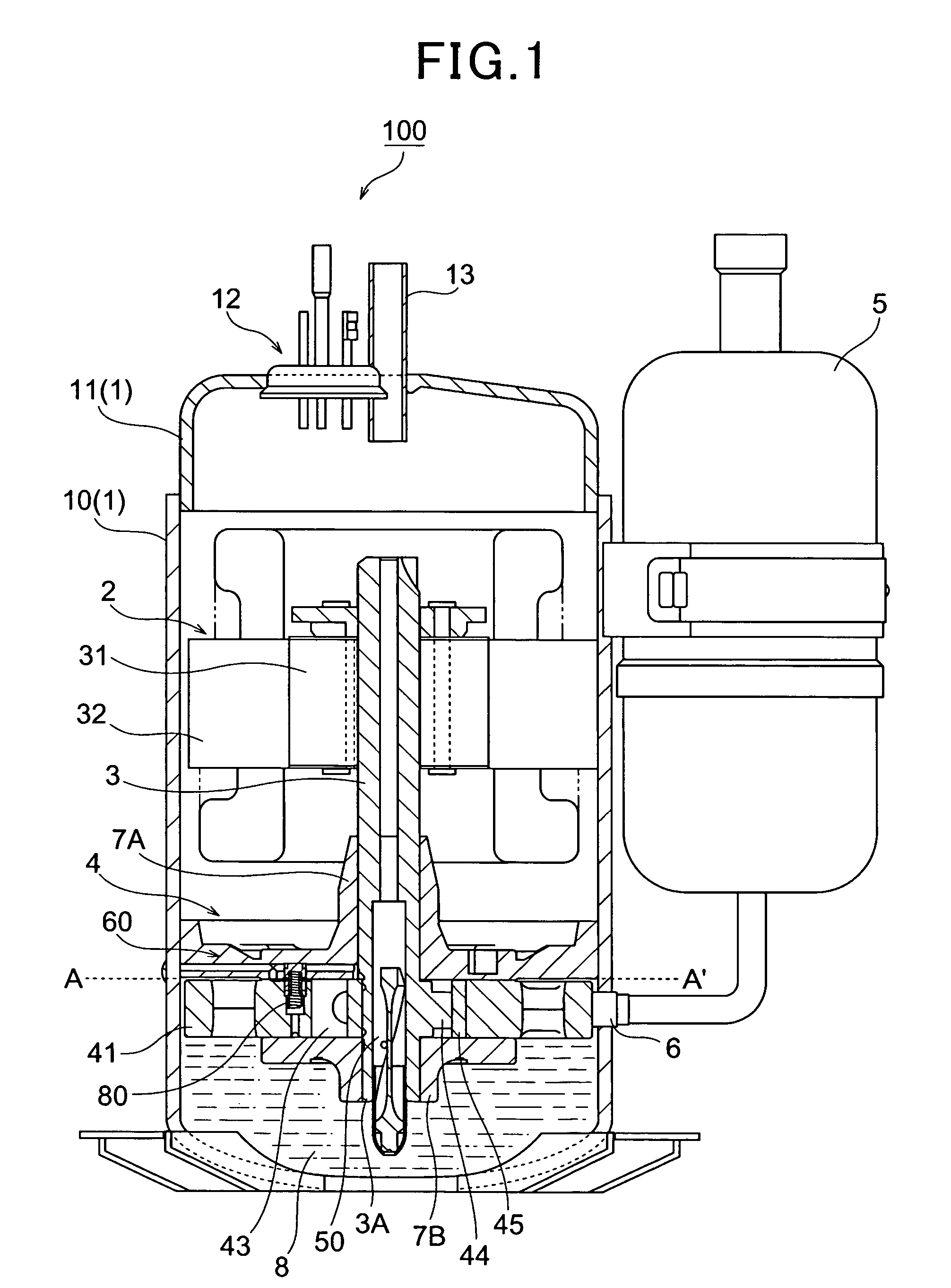

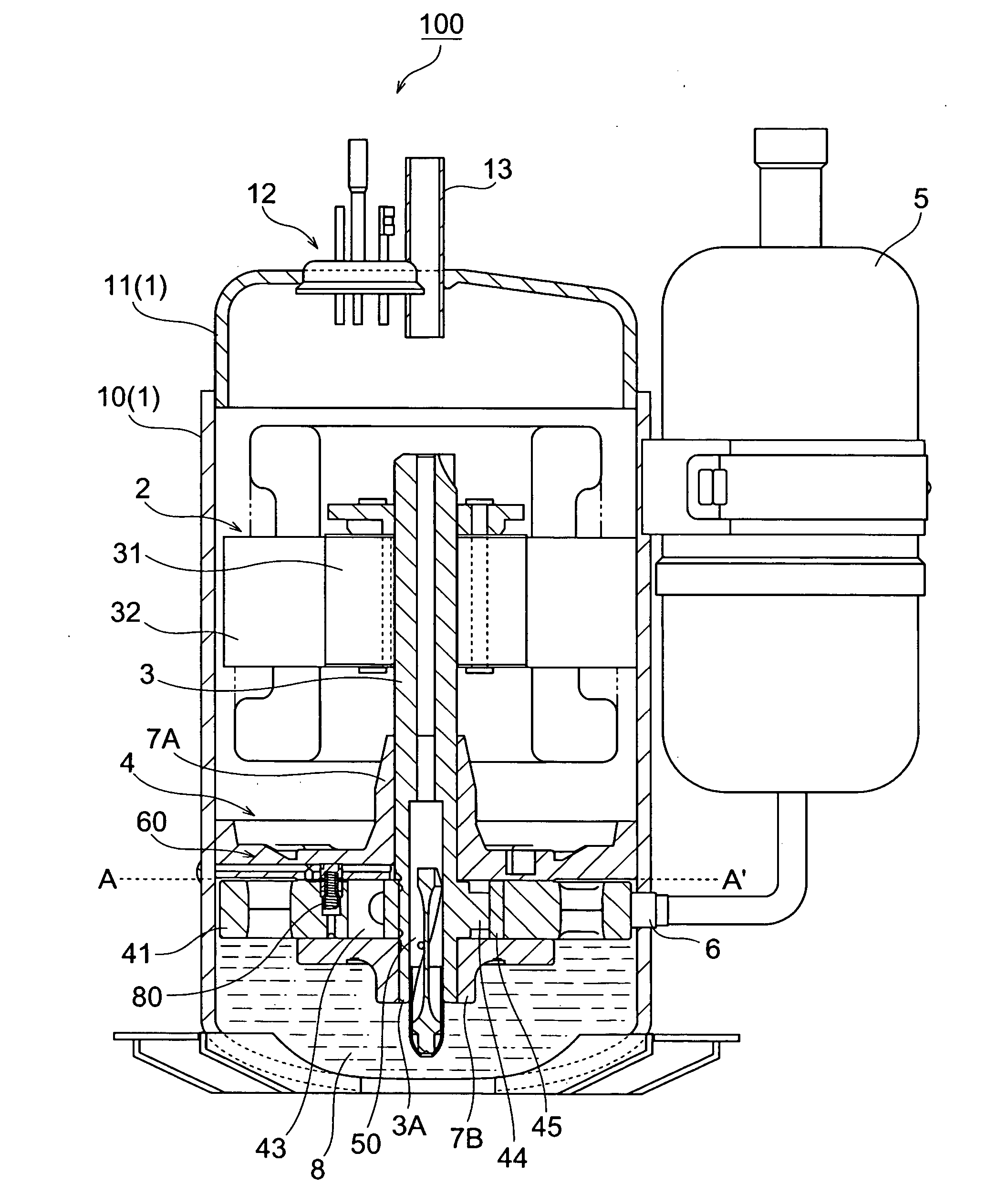

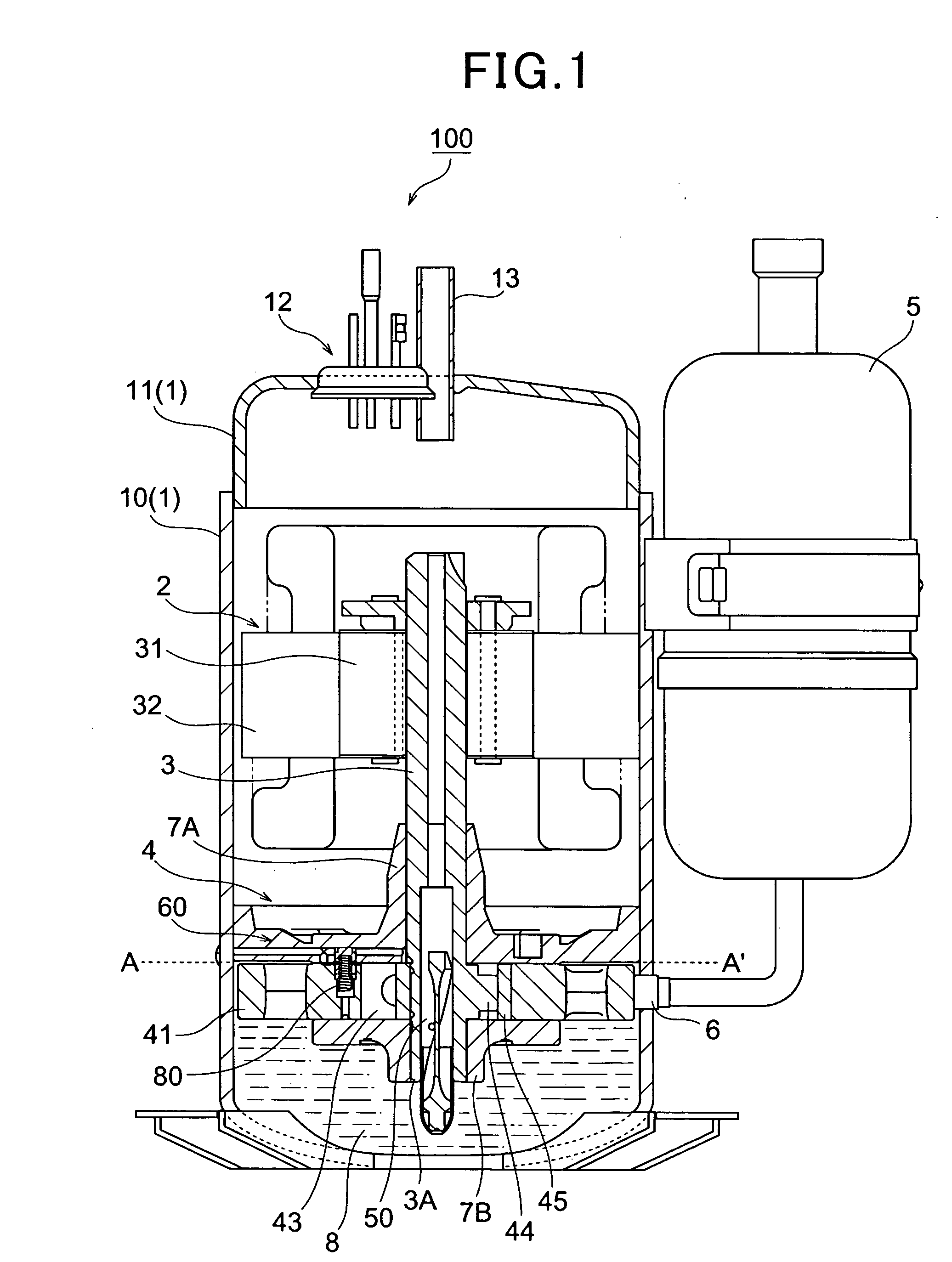

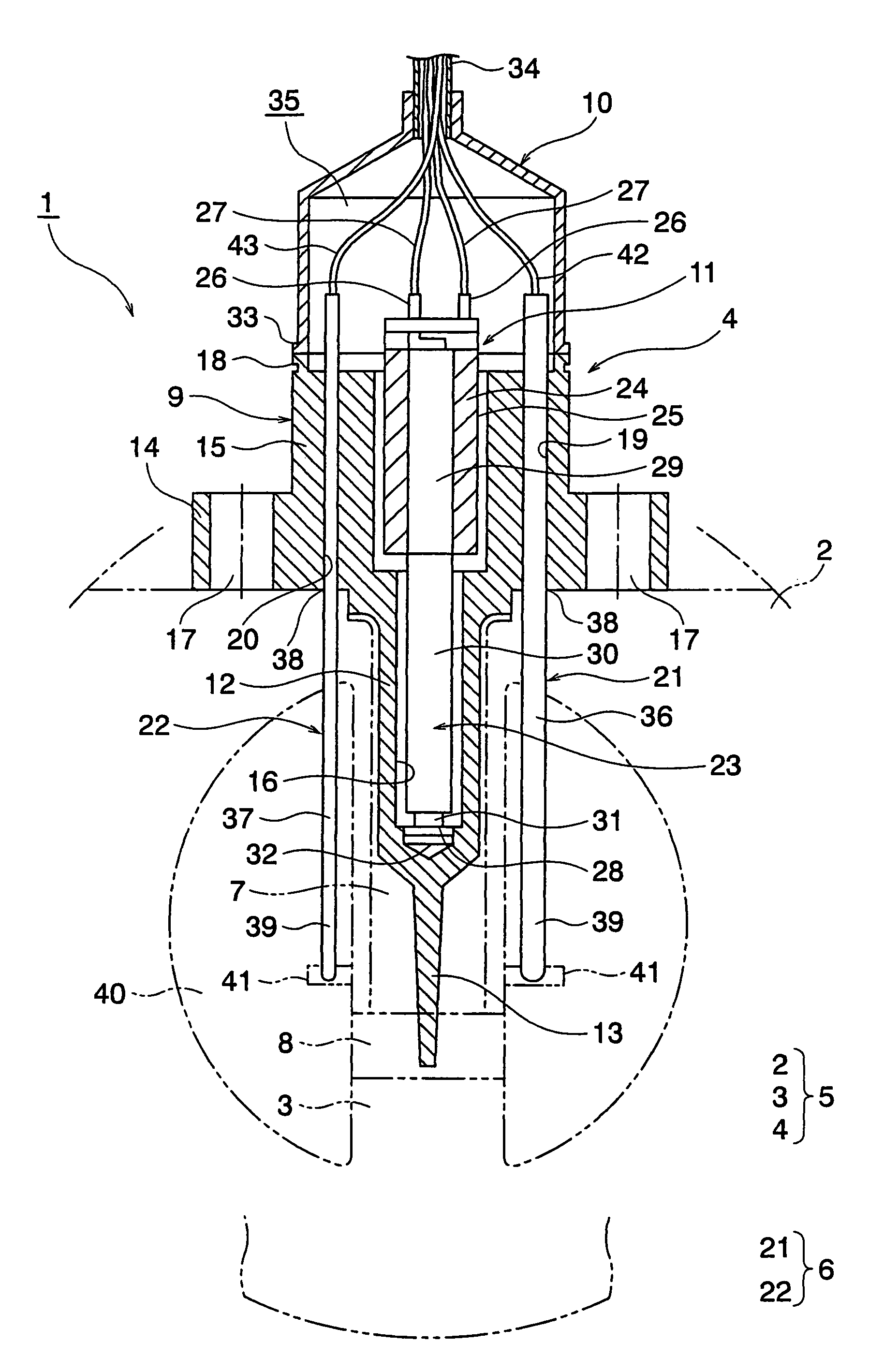

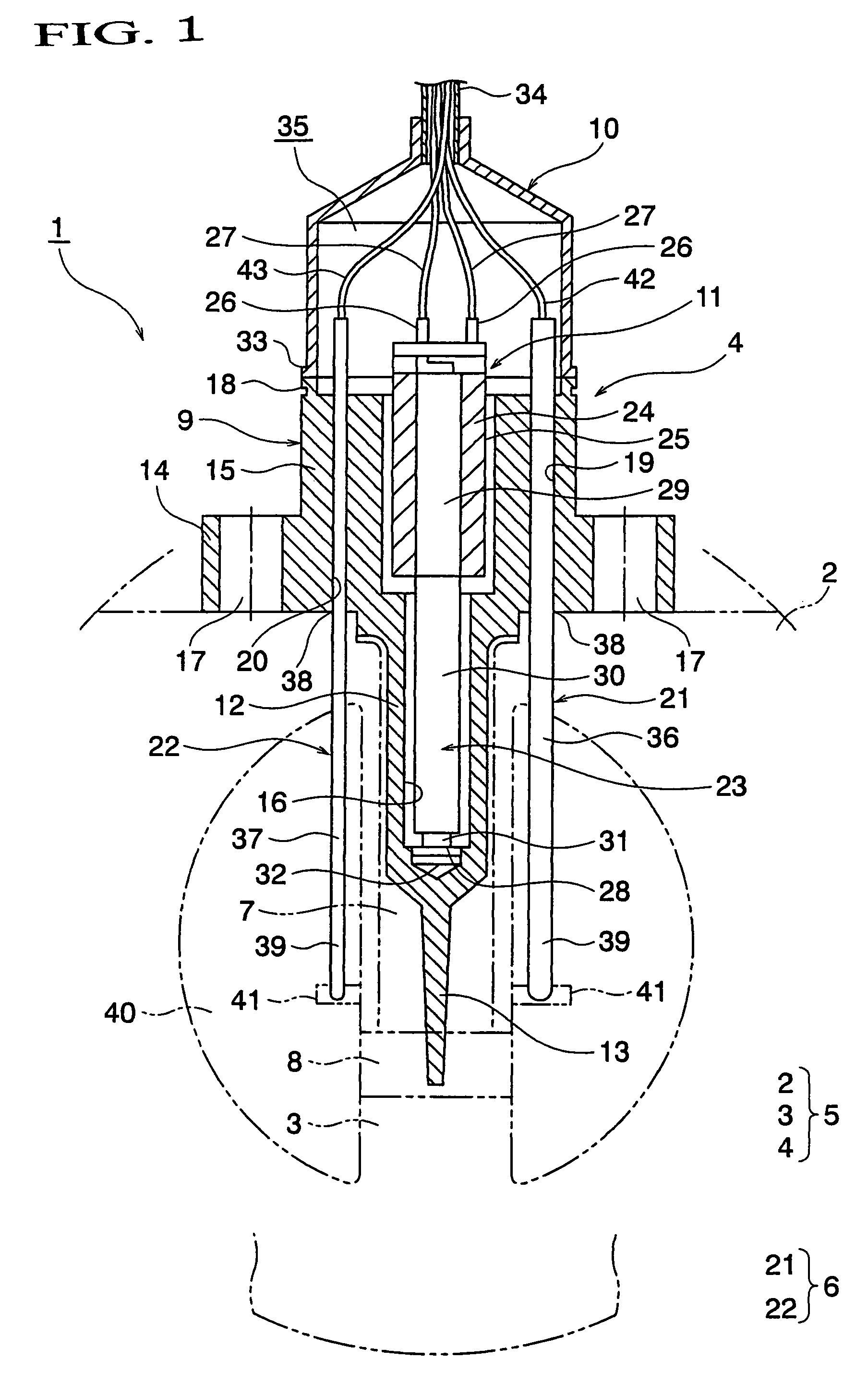

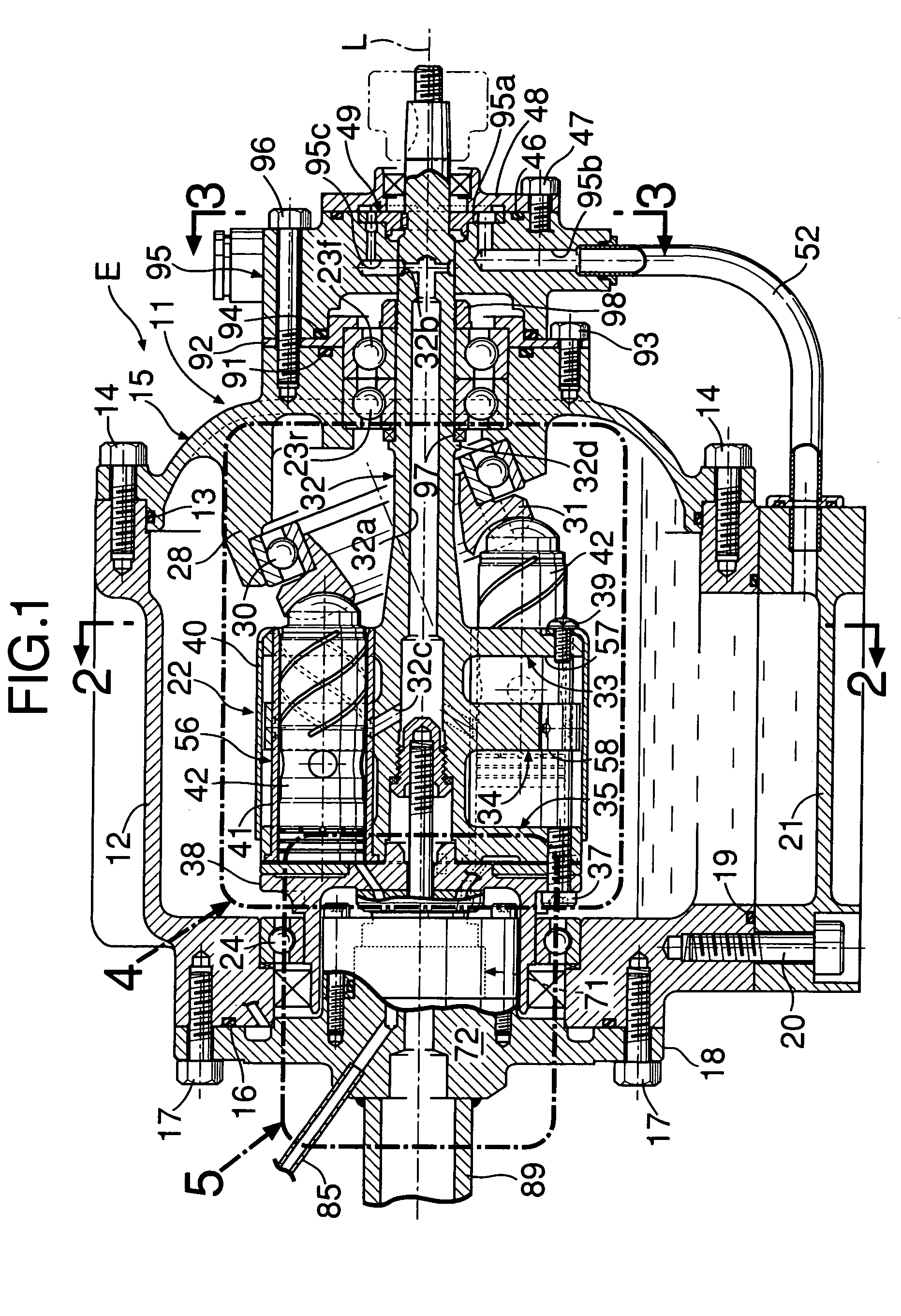

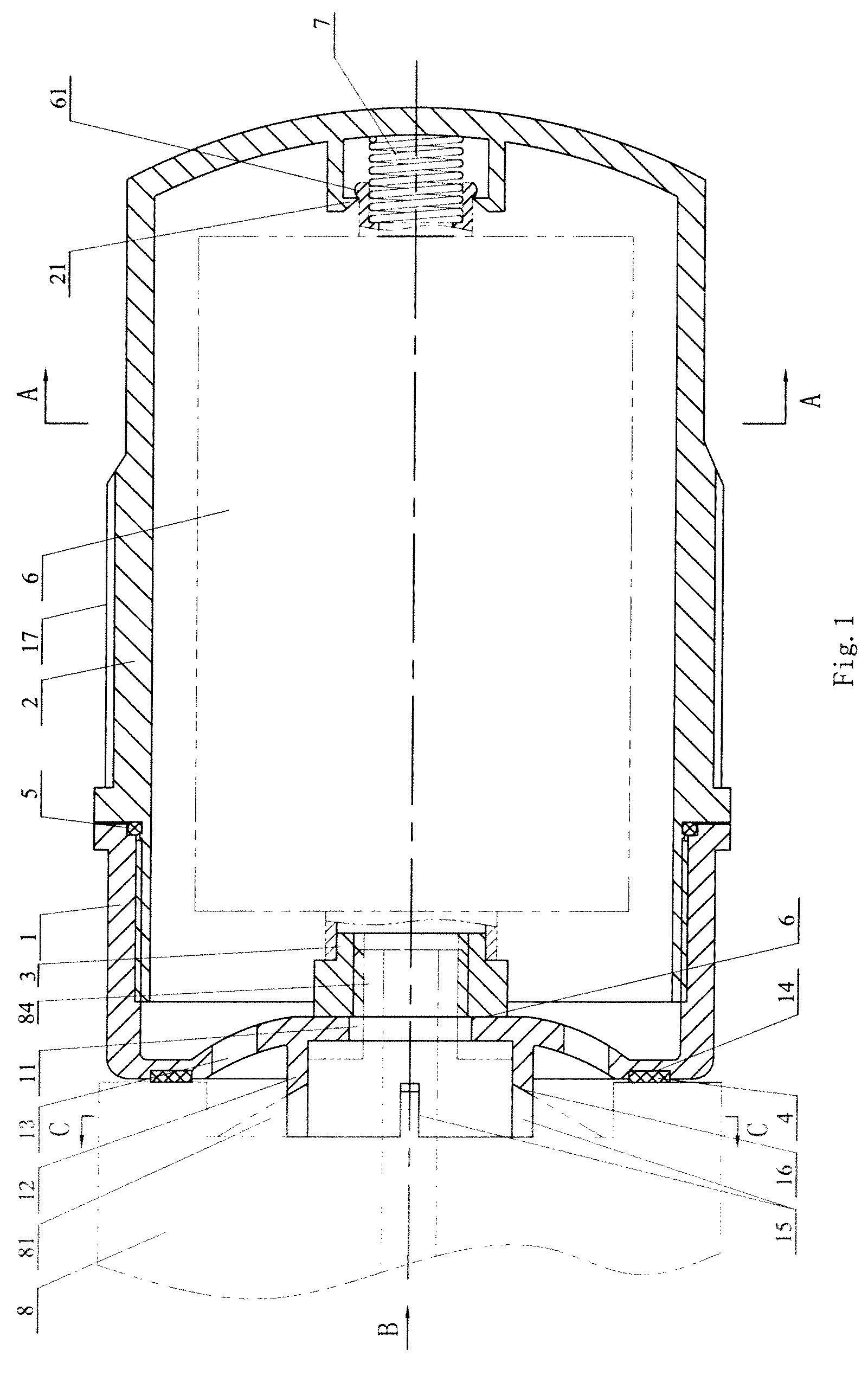

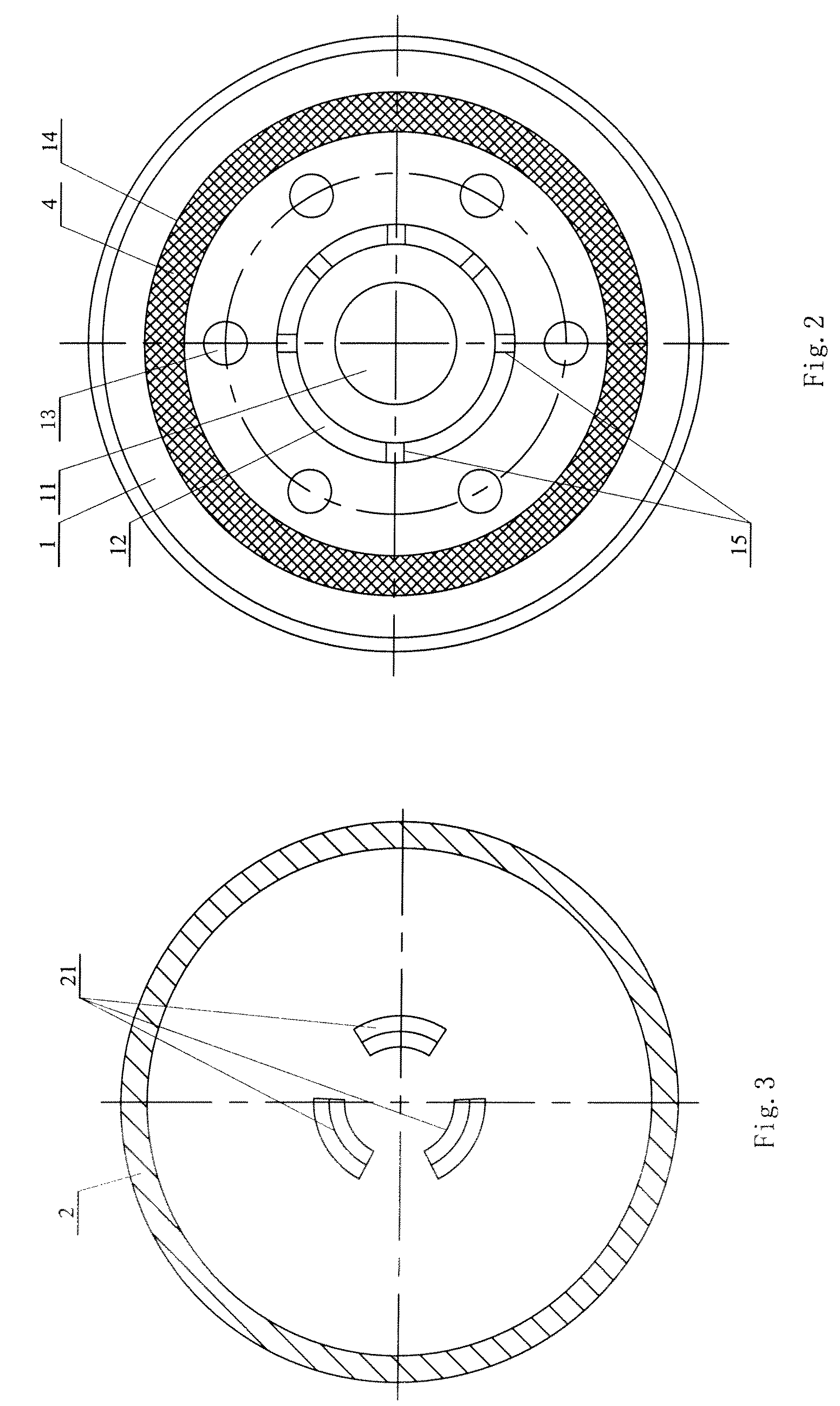

Hermetically sealed compressor and method of manufacturing the same

ActiveUS20080112831A1Sealing performanceImprove cooling efficiencyRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringRefrigerant

In a hermetically sealed compressor 100 including a rotary compressing element (4) having at least one cylinder (43A, 43B), and a roller (45) provided to the cylinder so as to be freely eccentrically rotatable, an electrically-driven element (2) for driving the roller (45) and a hermetically sealed container in which the rotary compressing element and the electrically-driven element are accommodated, oil (8) being stocked in the hermetically sealed container (1), the oil (8) in the hermetically sealed container (1) is injected into the compression chamber (43) when refrigerant is sucked into the compression chamber (43) of the cylinder.

Owner:SANYO ELECTRIC CO LTD

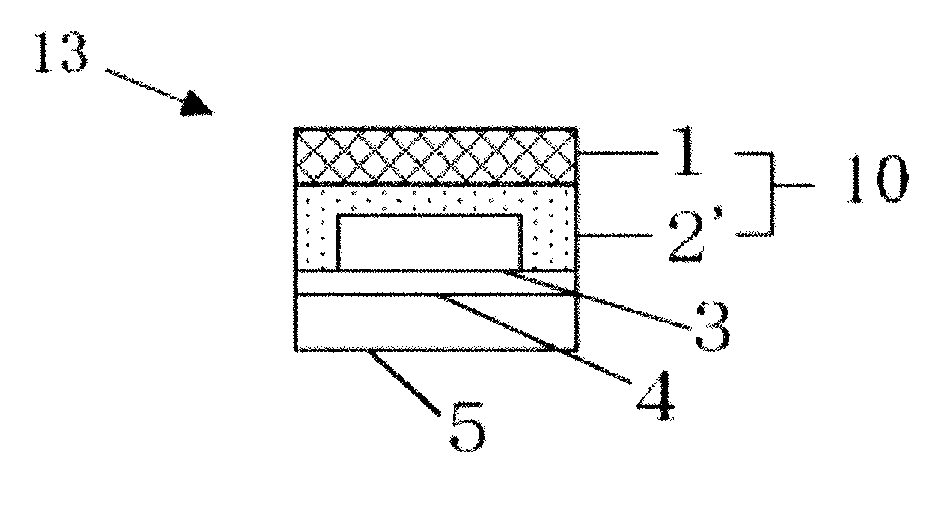

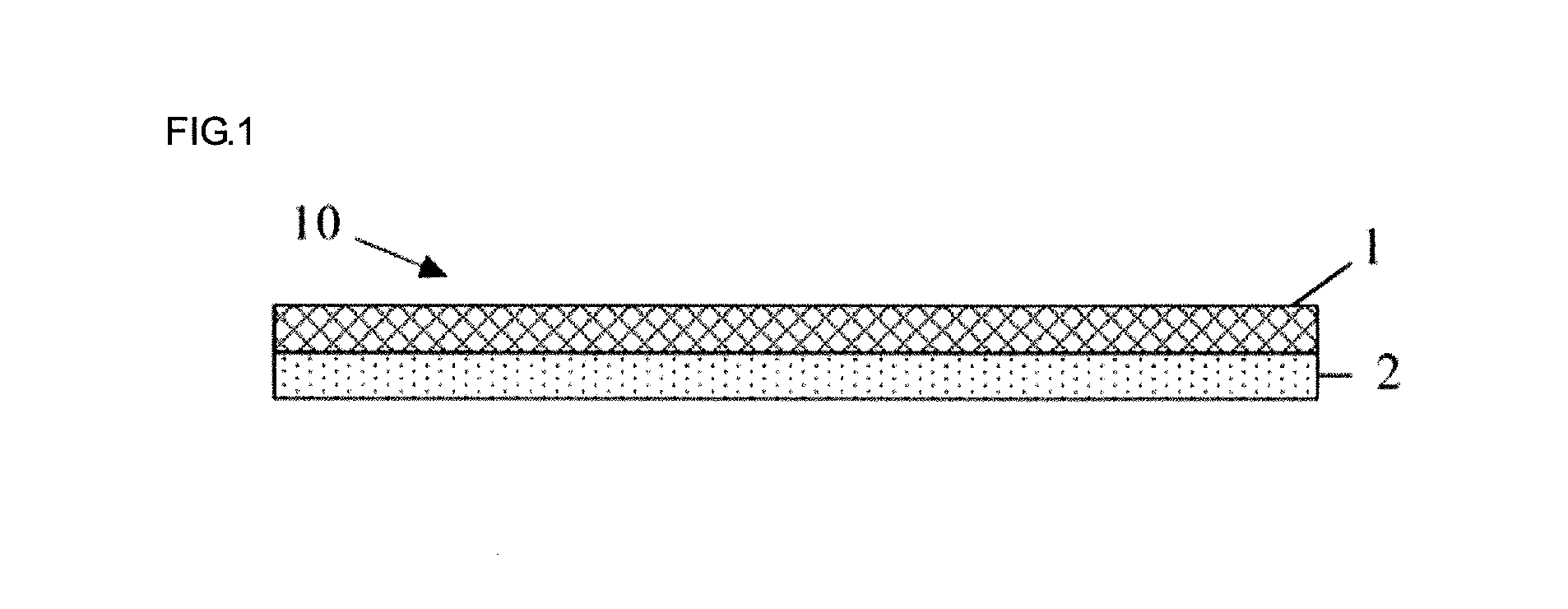

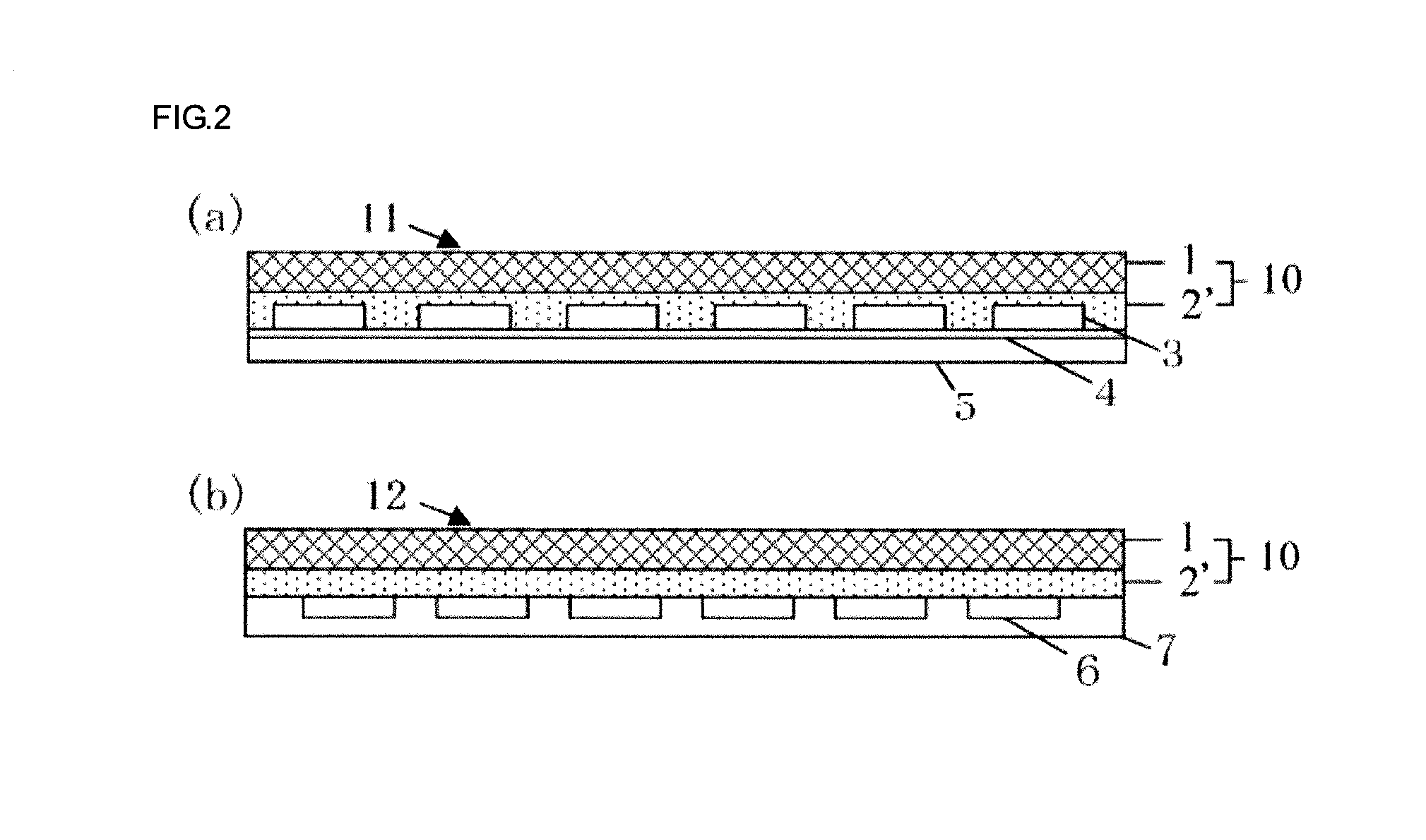

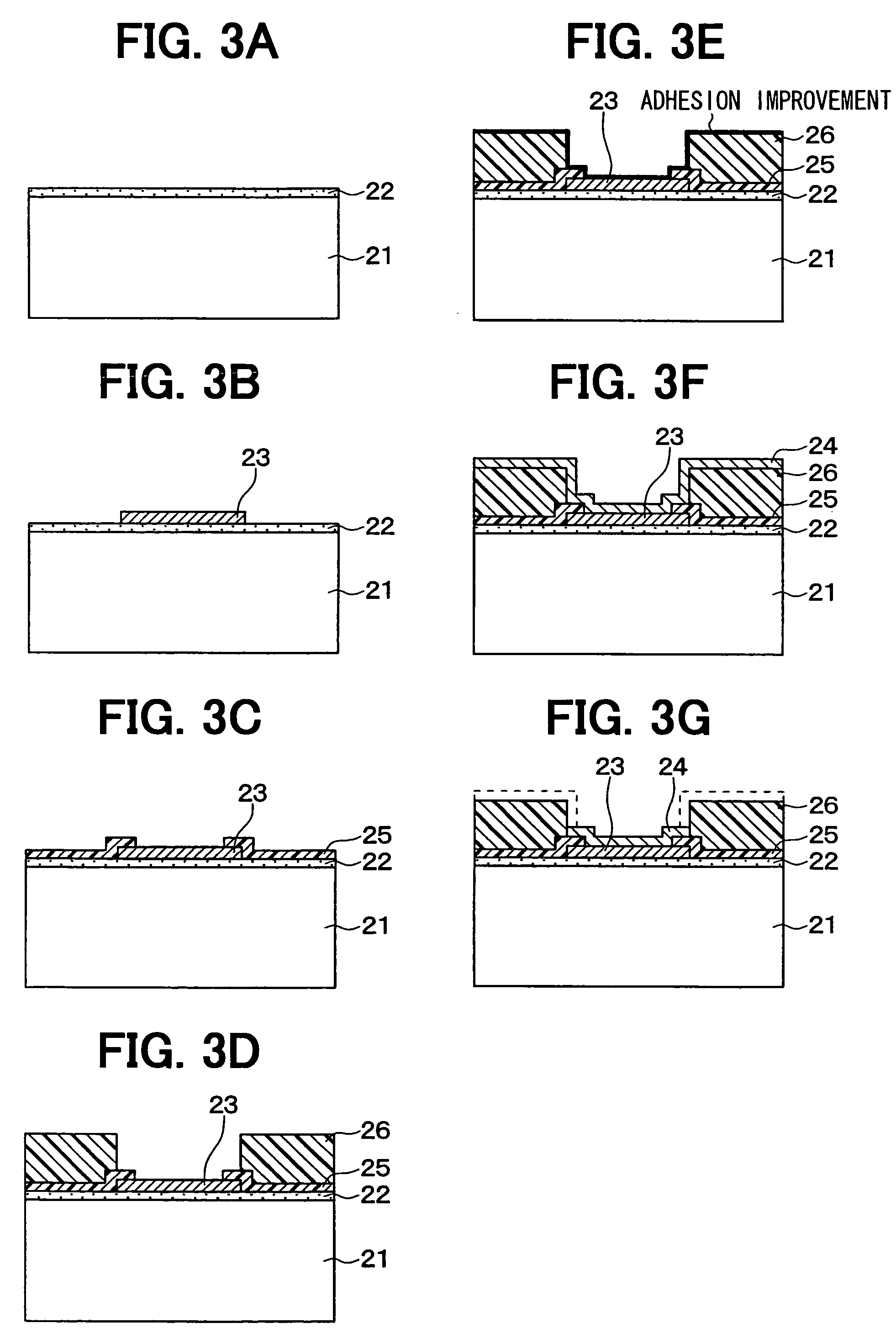

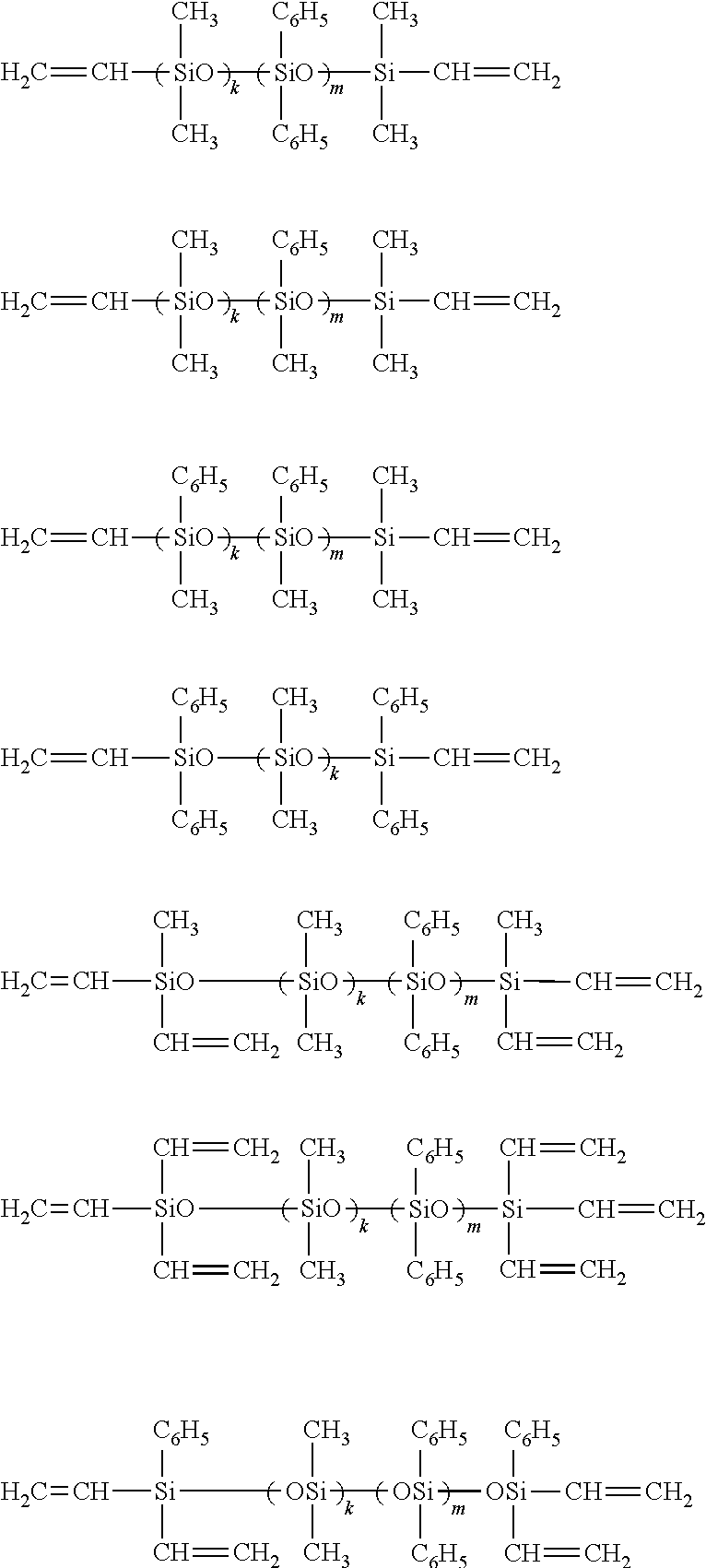

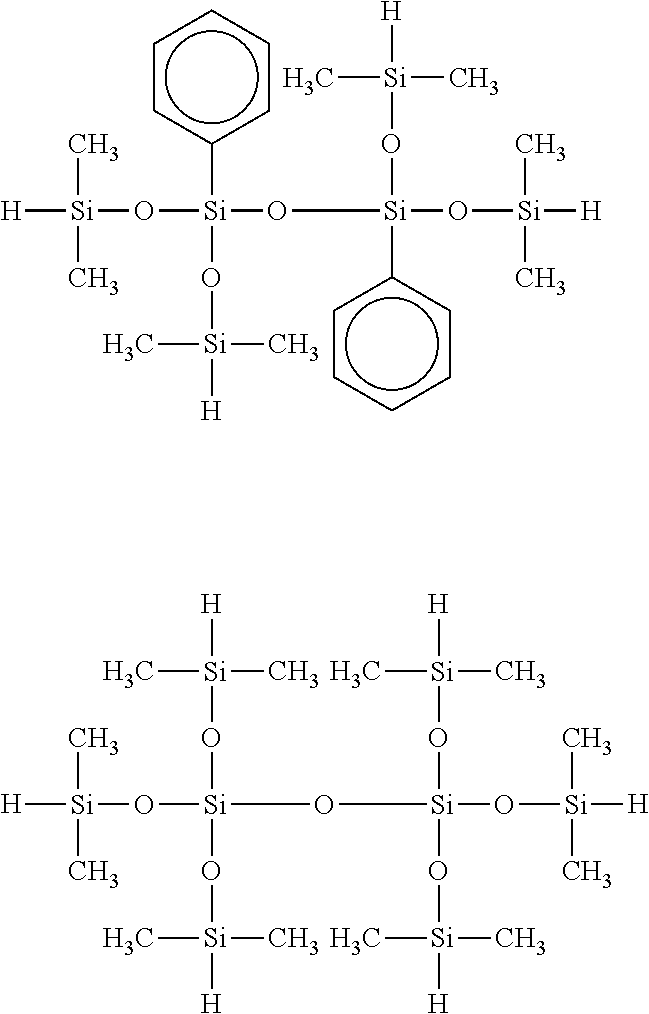

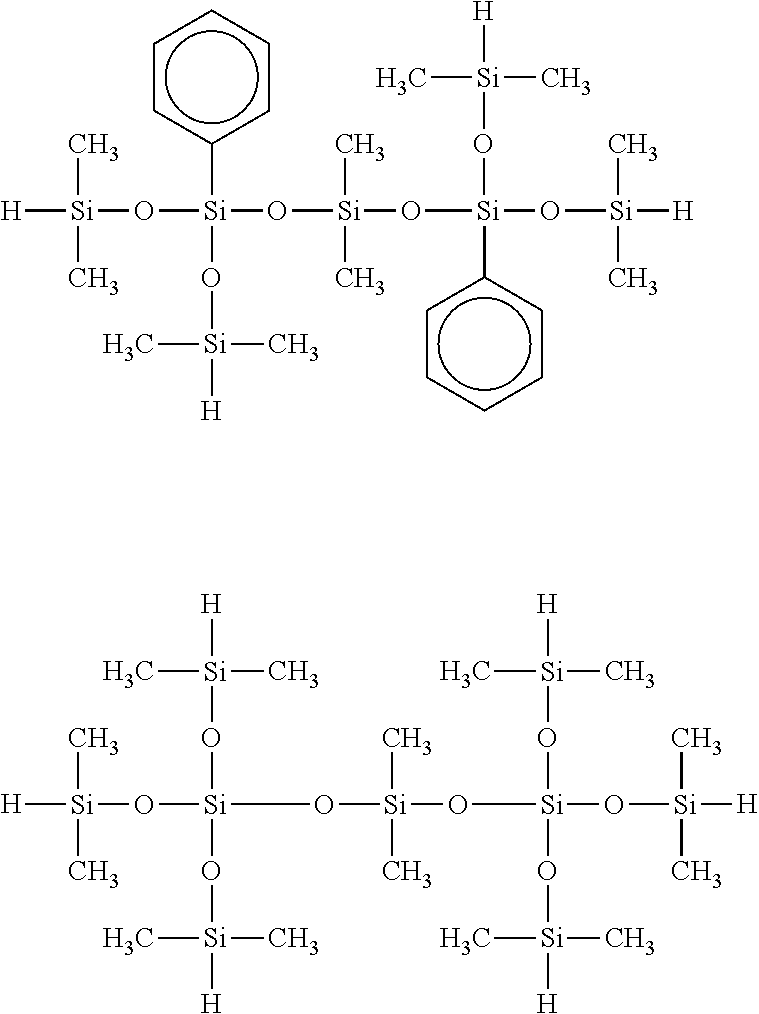

Sealant laminated composite, sealed semiconductor devices mounting substrate, sealed semiconductor devices forming wafer, semiconductor apparatus, and method for manufacturing semiconductor apparatus

ActiveUS20130200534A1Suppress contraction stressImprove sealing propertiesSemiconductor/solid-state device detailsSynthetic resin layered productsEngineeringSealant

Described herein is a sealant laminated composite for collectively sealing a semiconductor device's mounting surface of a substrate on which semiconductor devices are mounted or a semiconductor device's forming surface of a wafer on which semiconductor devices are formed. The composite can include a support wafer and an uncured resin layer constituted of an uncured thermosetting resin formed on one side of the support wafer. In certain aspects, the sealant laminated composite is very versatile, even when a large diameter or thin substrate or wafer is sealed. In certain aspects, this can prevent the substrate or wafer from warping and the semiconductor devices from peeling; can collectively seal a semiconductor device's mounting surface of a substrate on which semiconductor devices are mounted or a semiconductor device's forming surface of a wafer on which semiconductor devices are formed on a wafer level; and can provide a sealant laminated composite that is excellent in the heat resistance and humidity resistance after sealing.

Owner:SHIN ETSU CHEM IND CO LTD

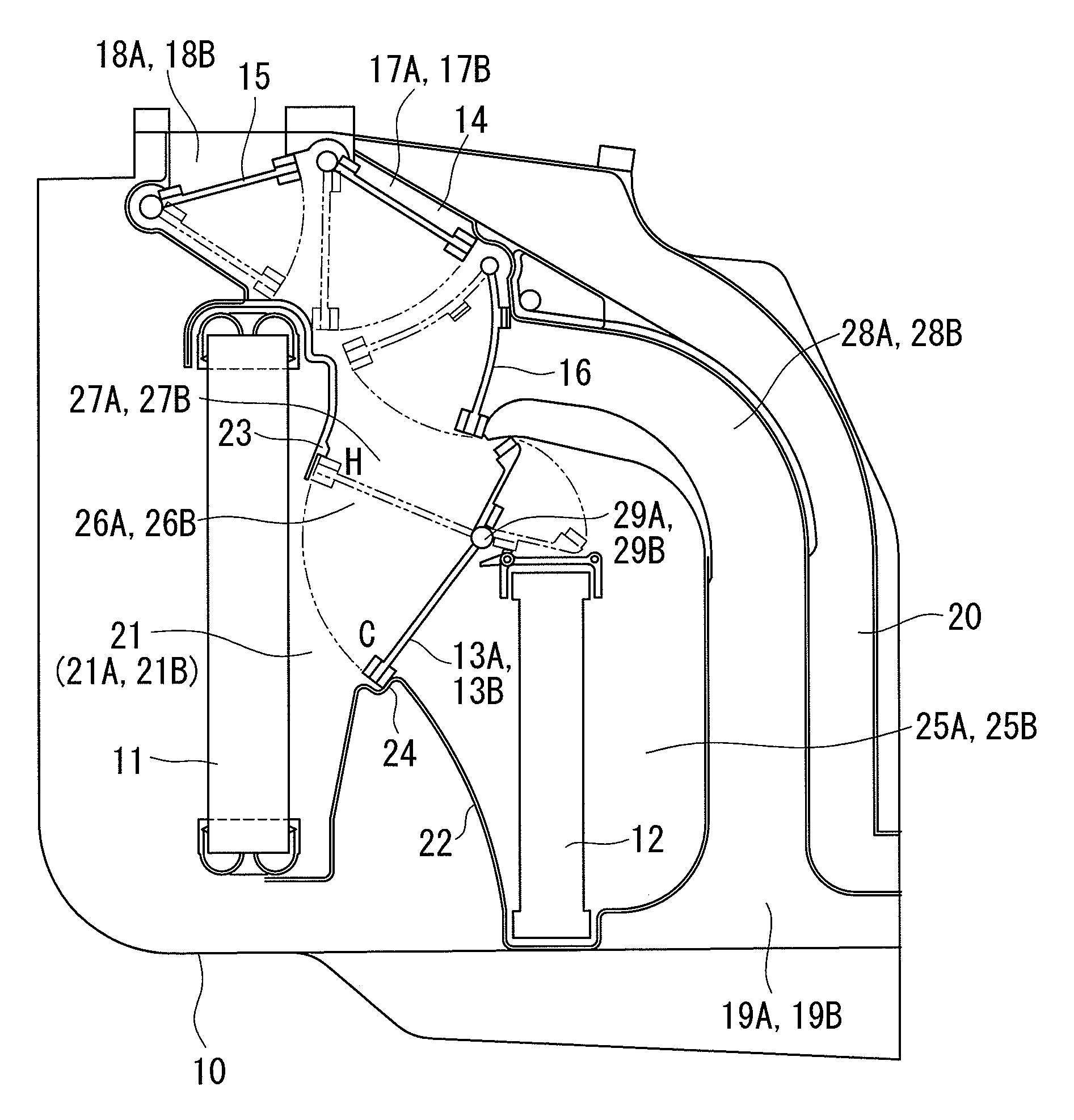

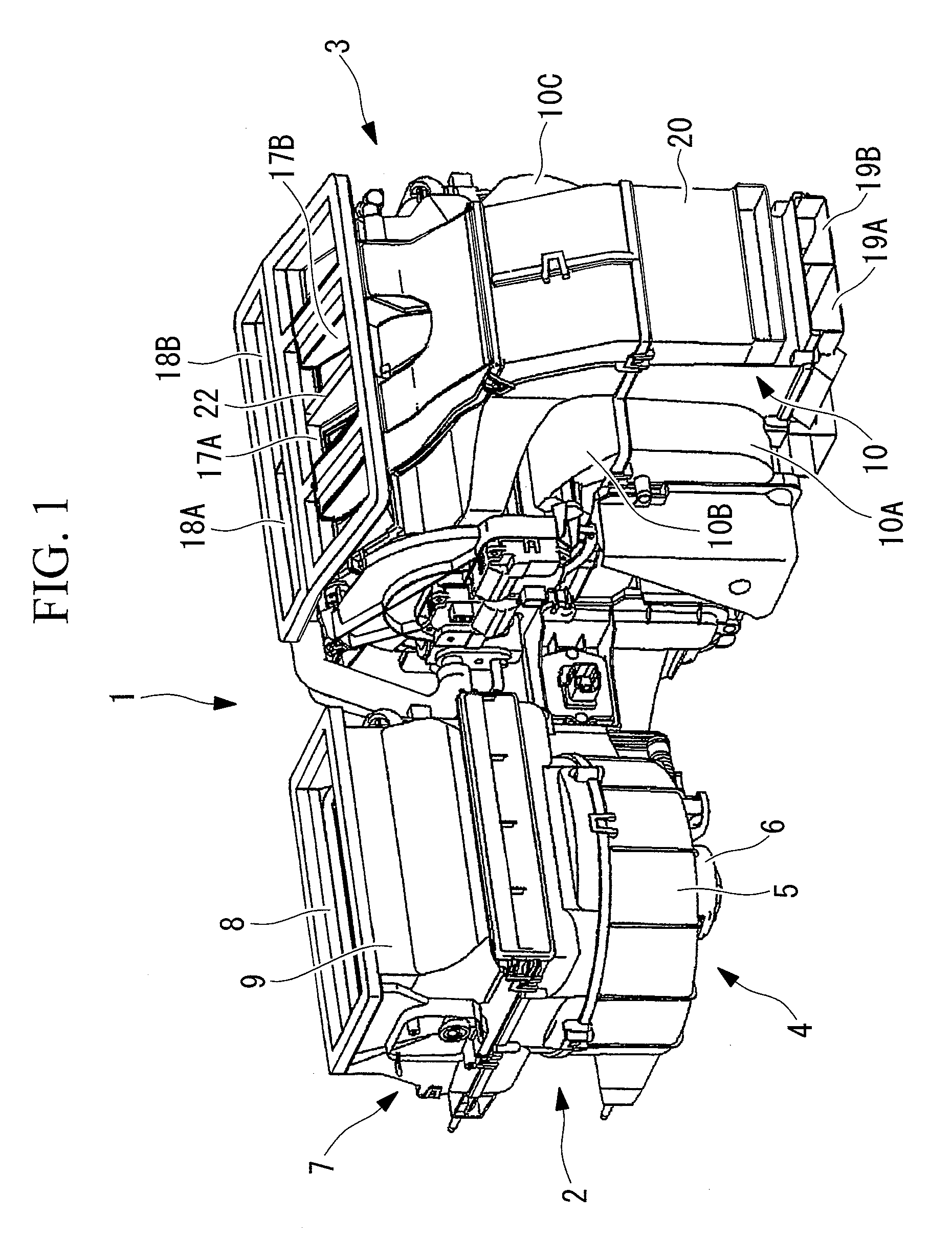

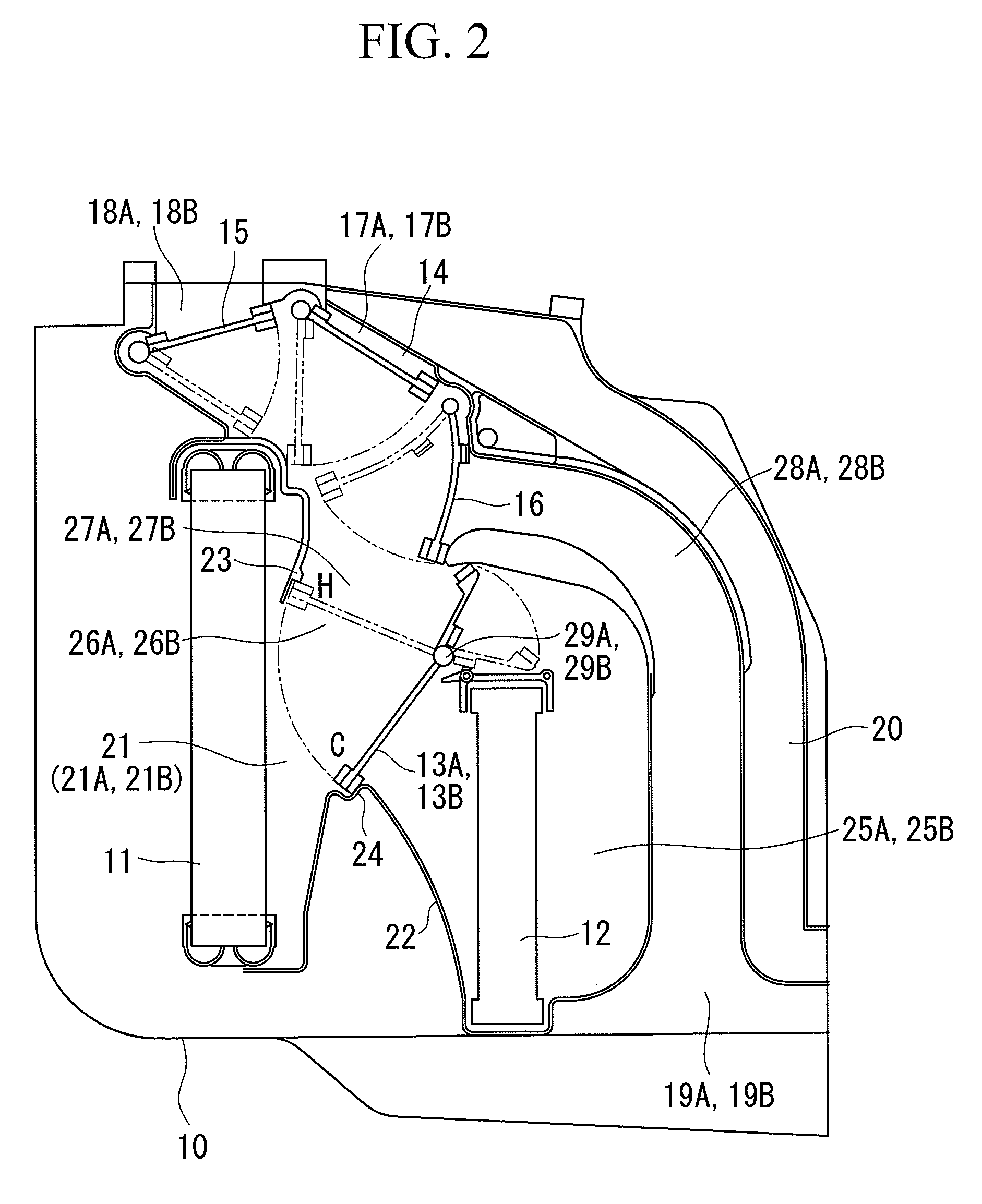

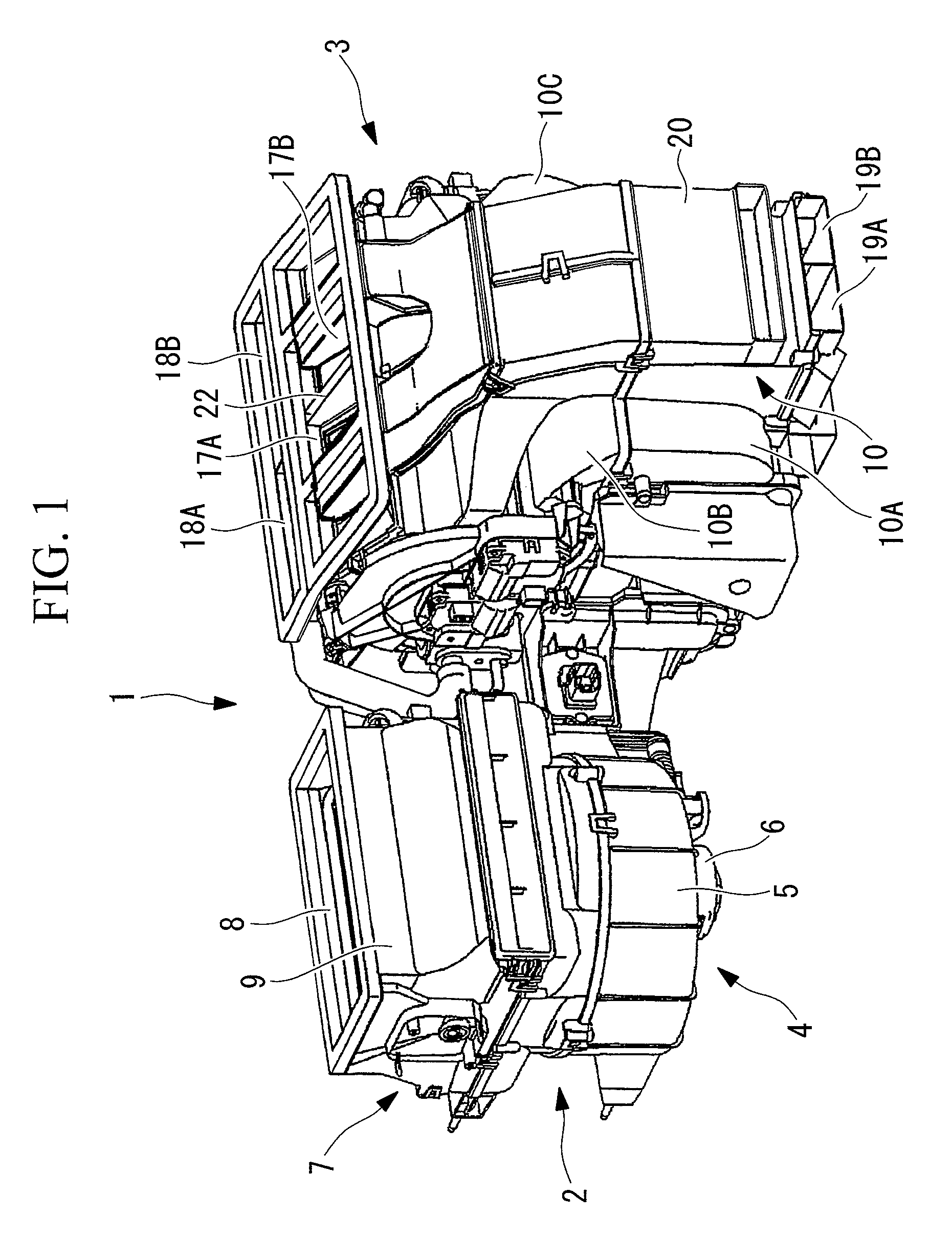

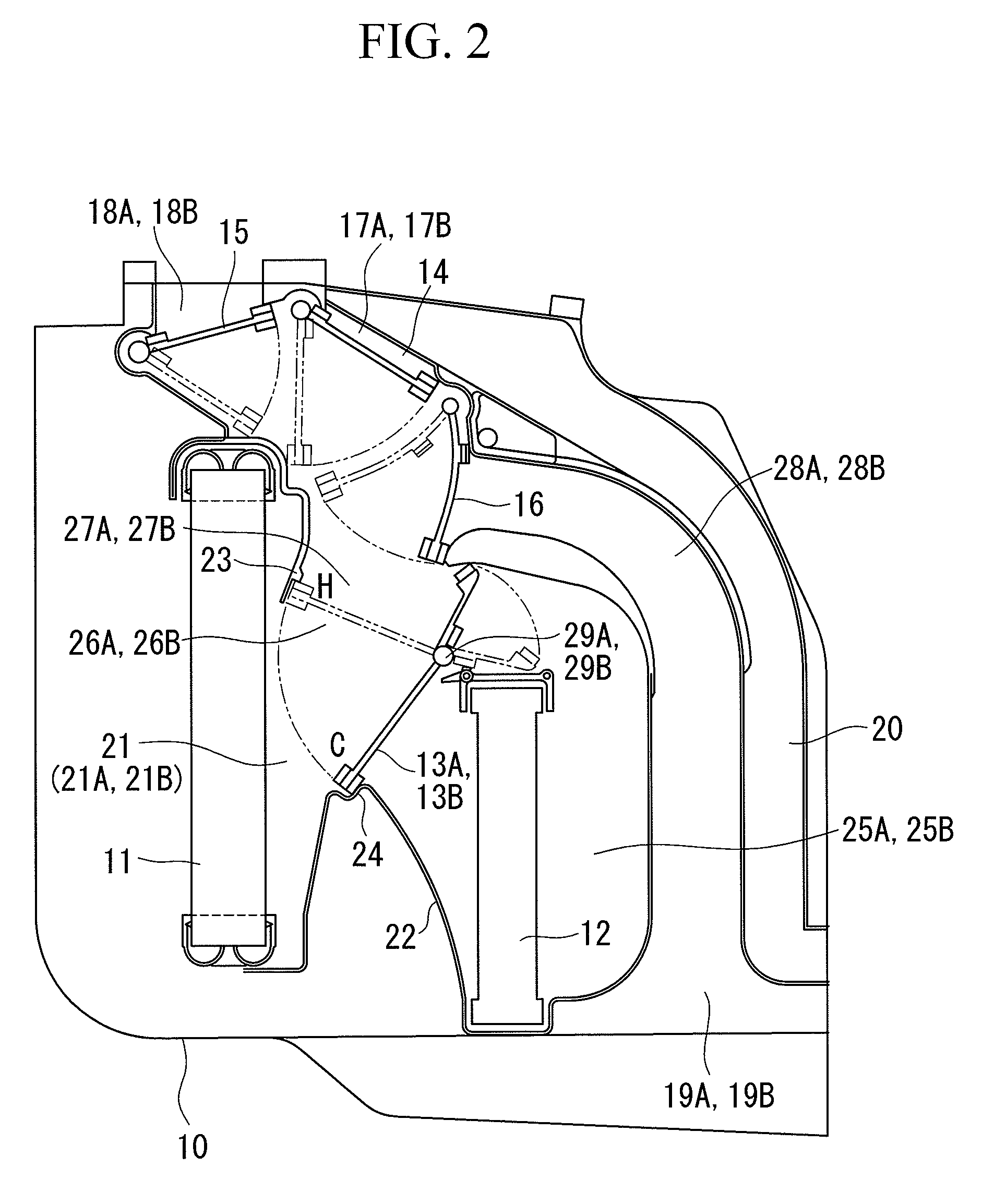

Blowing-mode door for vehicle air-conditioning apparatus and vehicle air-conditioning apparatus using the same

ActiveUS20100120348A1Reduce leakageEliminate needAir-treating devicesVehicle heating/cooling devicesRotational axisEngineering

There are provided a blowing-mode door for a vehicle air-conditioning apparatus in which leakage of temperature-adjusted air can be prevented to improve independent temperature-adjusting performance by minimizing the gap between the mode door and a partition plate and increasing the rigidity of the mode door, as well as a vehicle air-conditioning apparatus using the same. A blowing-mode door applied to a vehicle air-conditioning apparatus with an independent temperature-adjusting system is provided in which the blowing-mode door includes a rotating shaft having a predetermined length and a pair of left and right plate-like doors that are molded integrally with the rotating shaft, with a gap for preventing interference with a partition plate therebetween.

Owner:MITSUBISHI HEAVY IND LTD

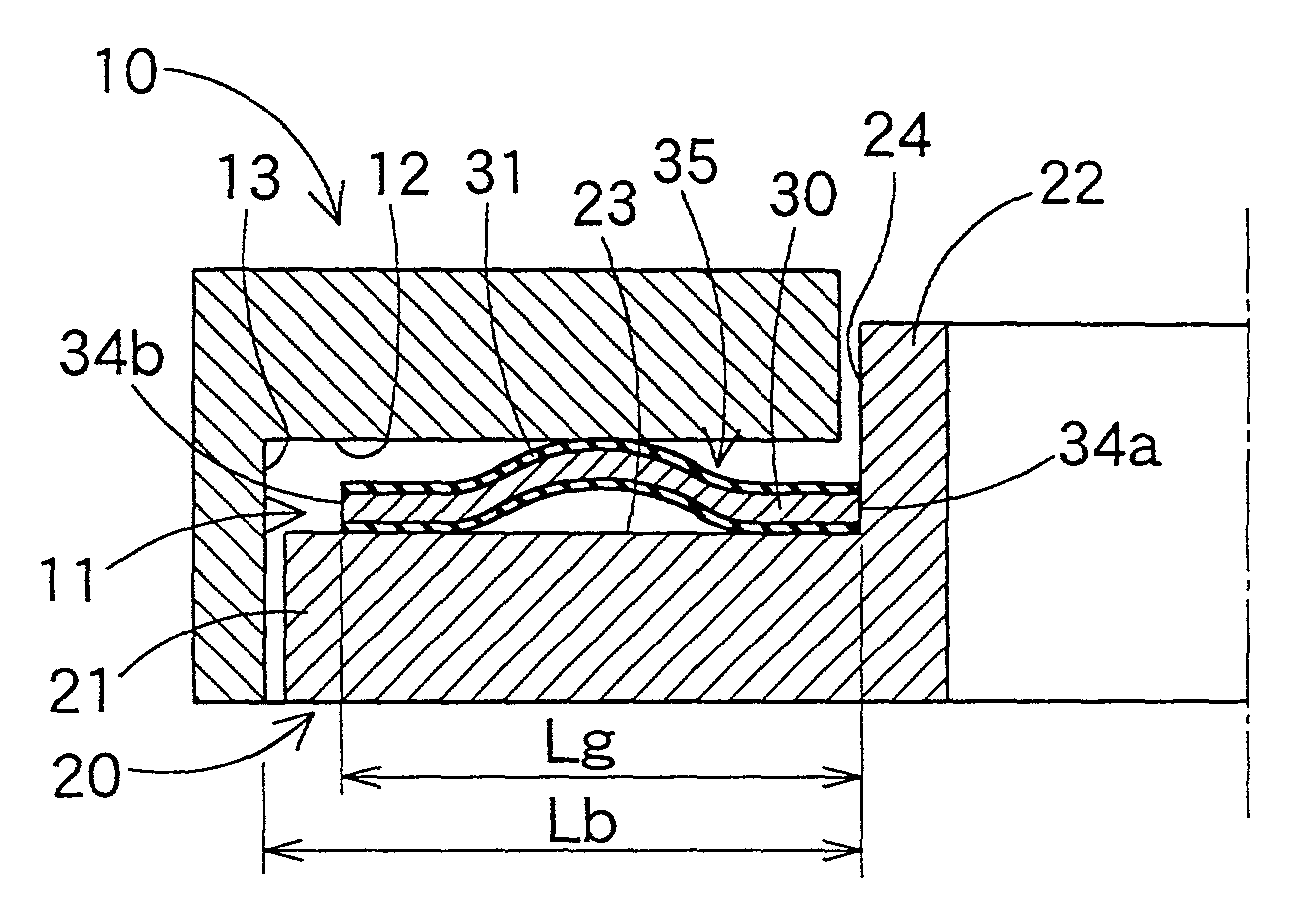

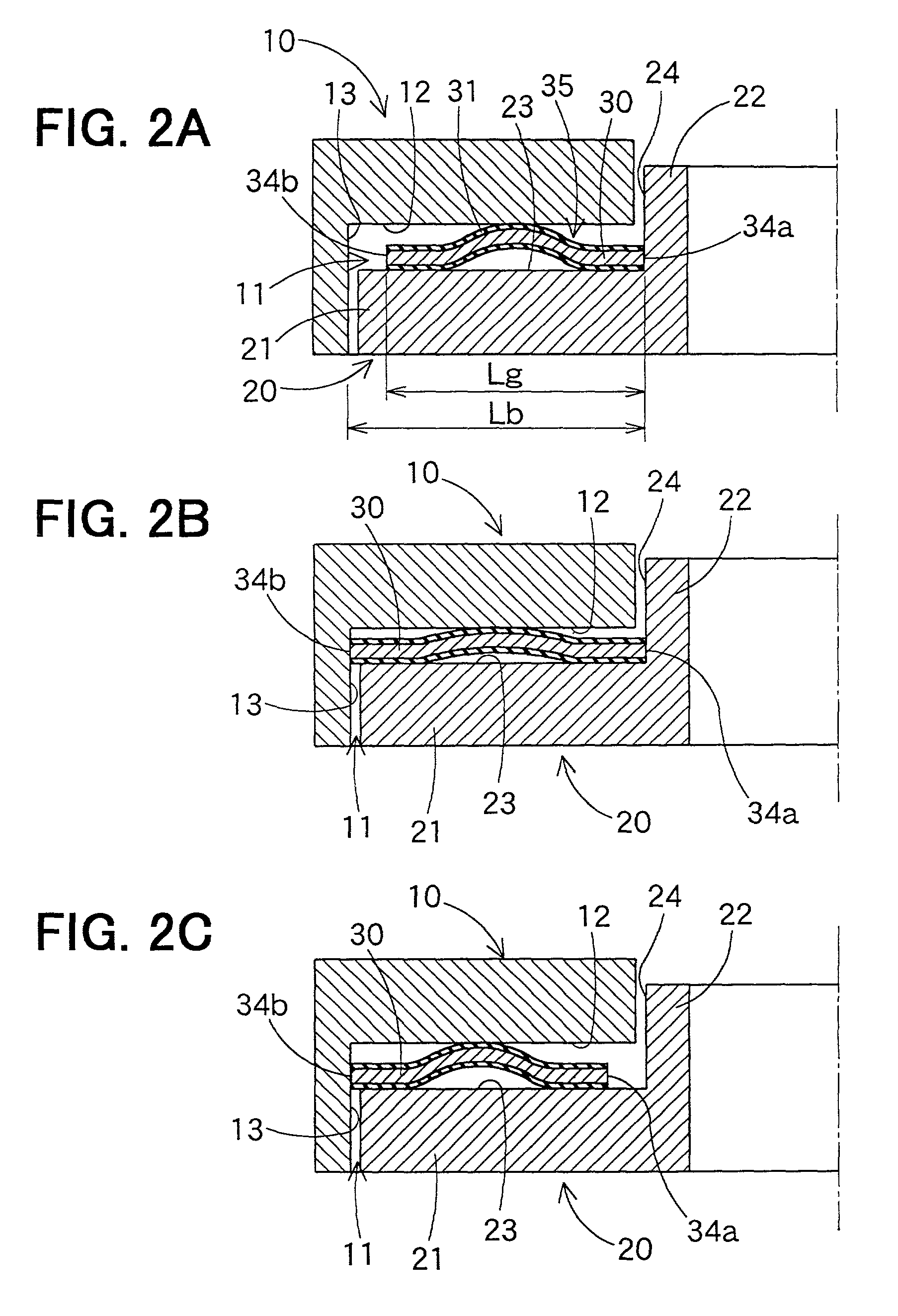

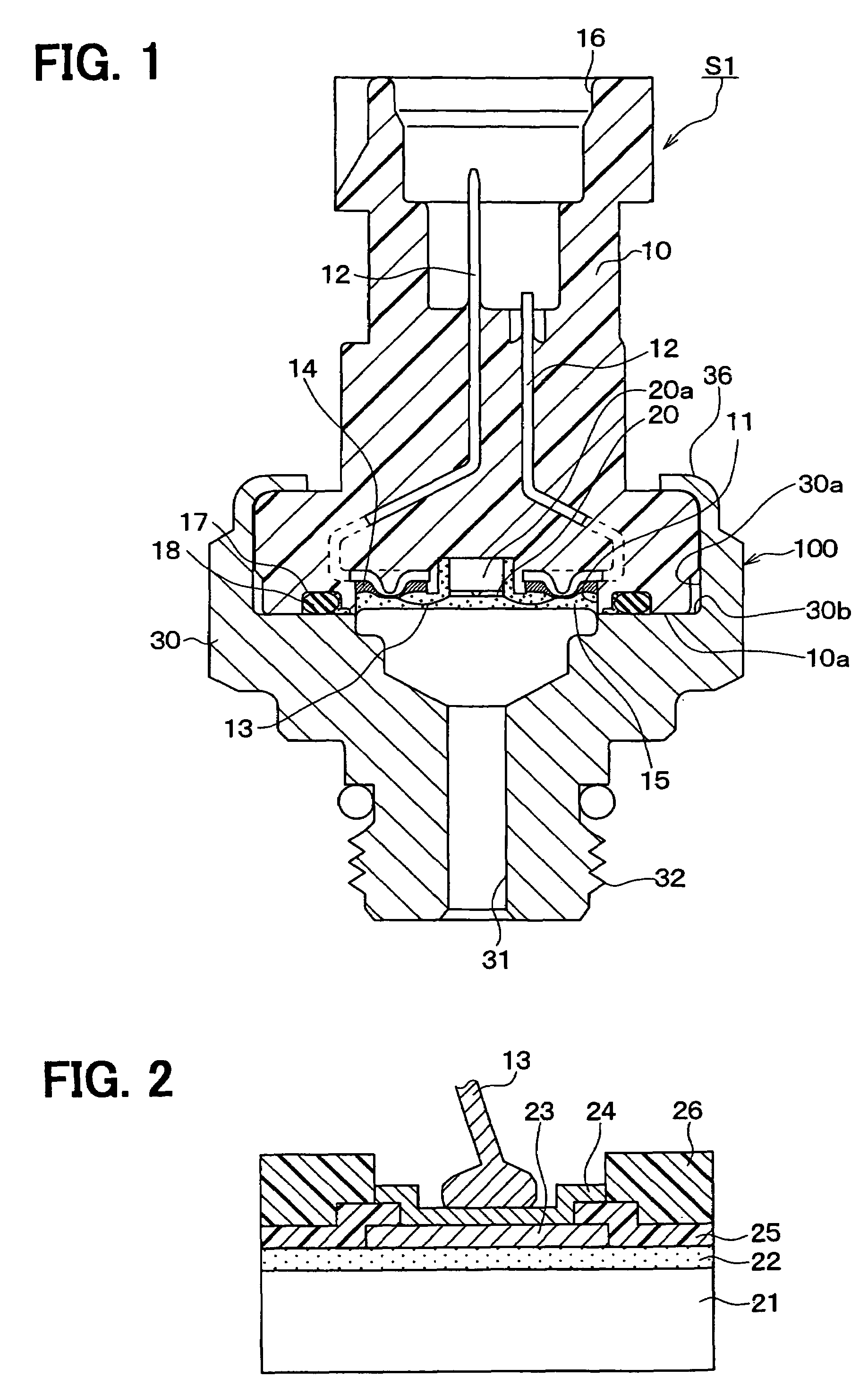

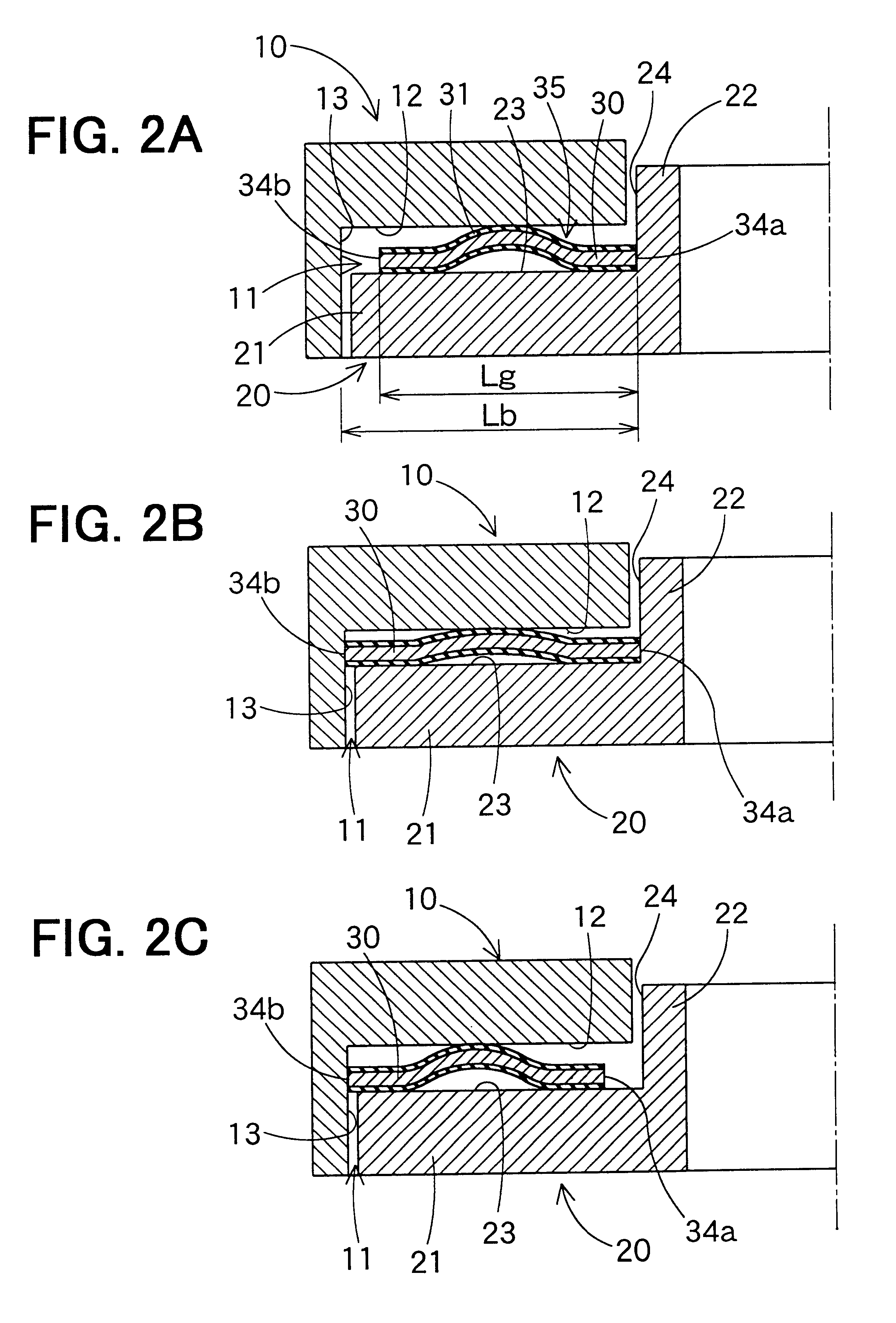

Gasket attachment structure for refrigerant-seal

InactiveUS20020000695A1Minimal leakageHigh sealing pressureEngine sealsFlanged jointsEngineeringRefrigerant

In an attachment structure of a gasket for a refrigerant-seal, both first and second connection members are disposed to define a seal space by first and second opposite surfaces and first and second wall surfaces, and the gasket having a beam portion is disposed in the seal space so that one end surface of the gasket is held on the first wall surface of the first connection member and the other end surface of the gasket is separated from the second wall surface of the second connection member by a predetermined clearance, before both the first and second connection members are fastened. After both the first and second connection members are fastened, the gasket extends, and the other end surface of the gasket press-contacts the second wall surface.

Owner:DENSO CORP

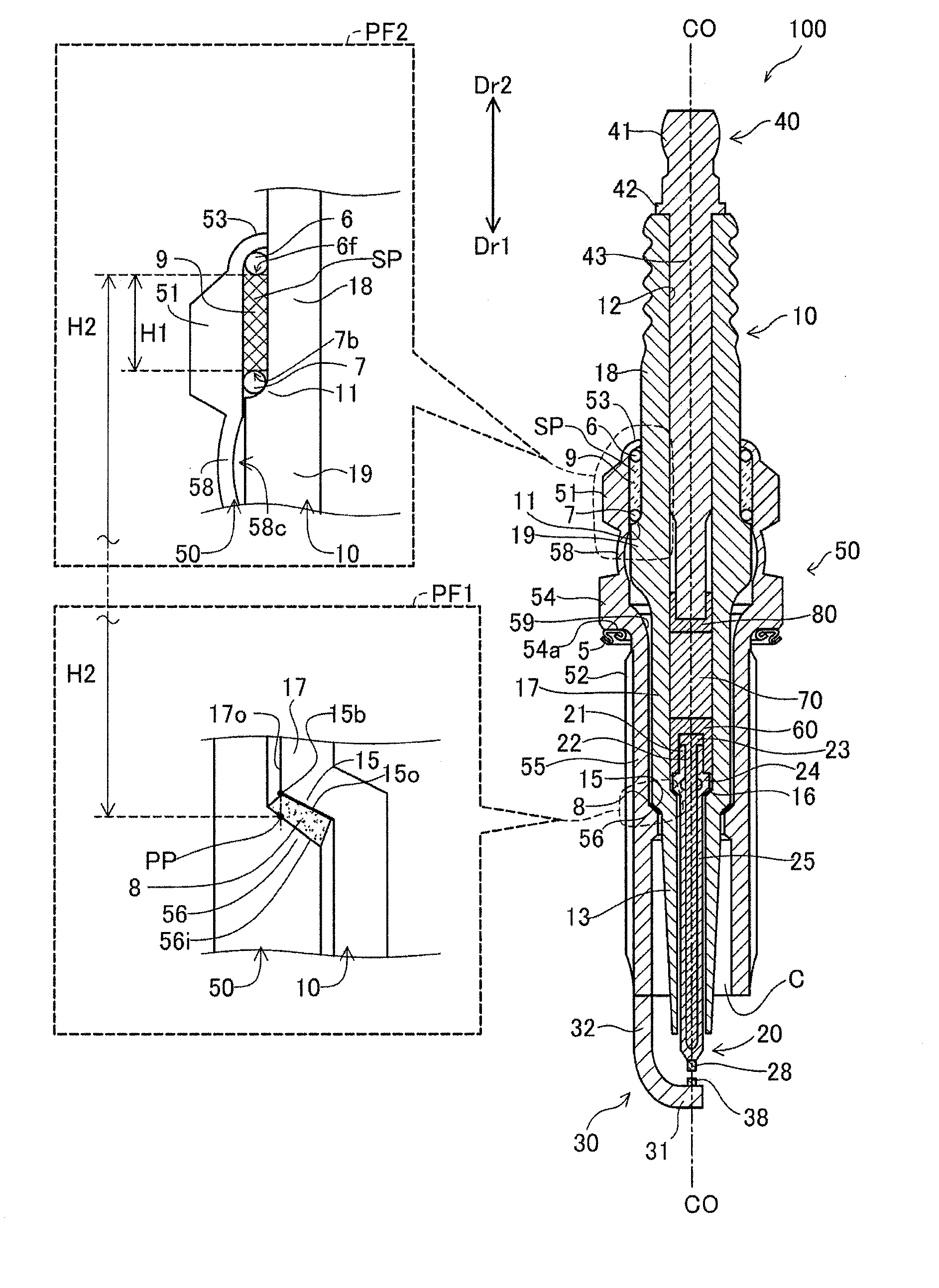

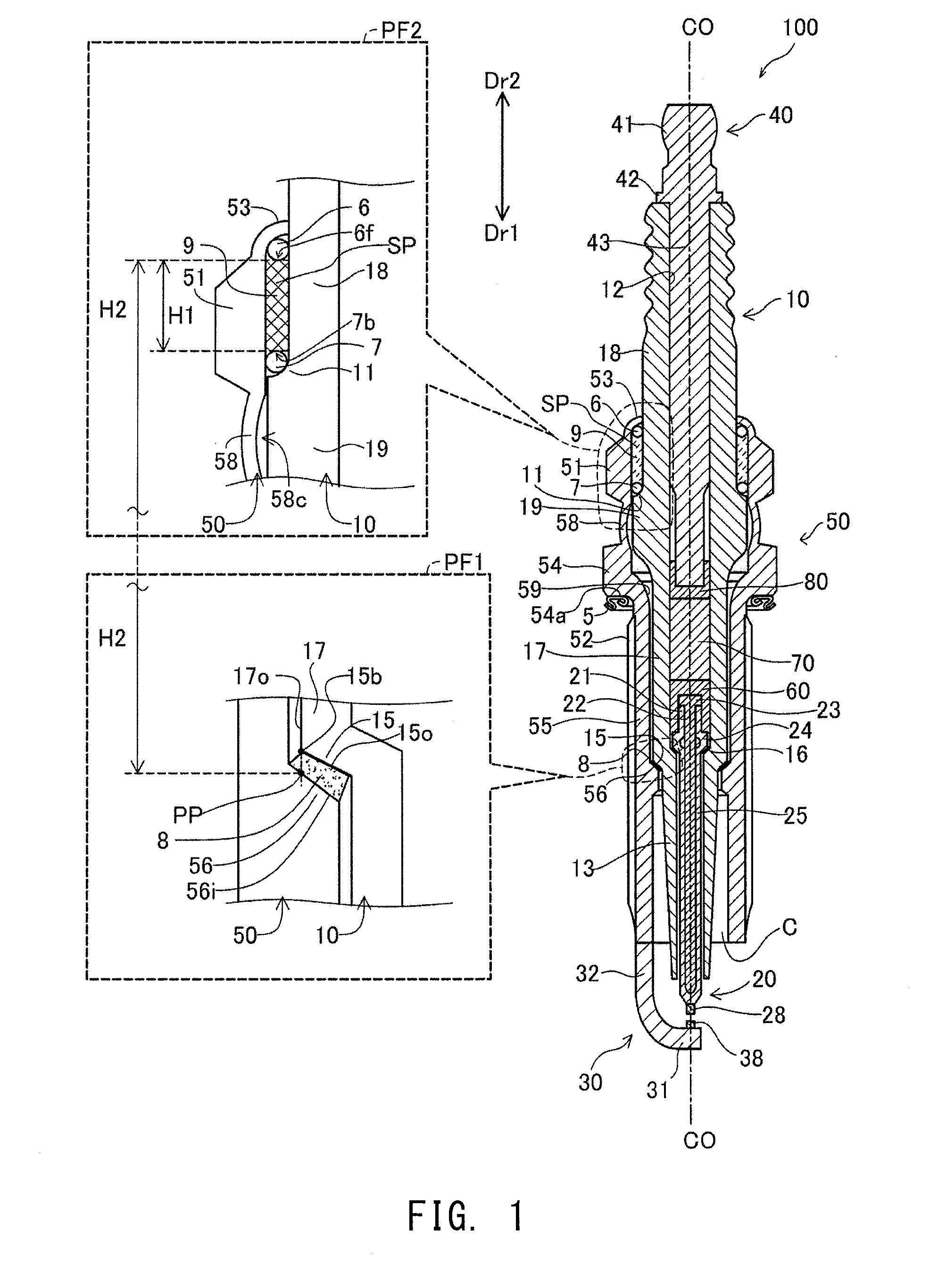

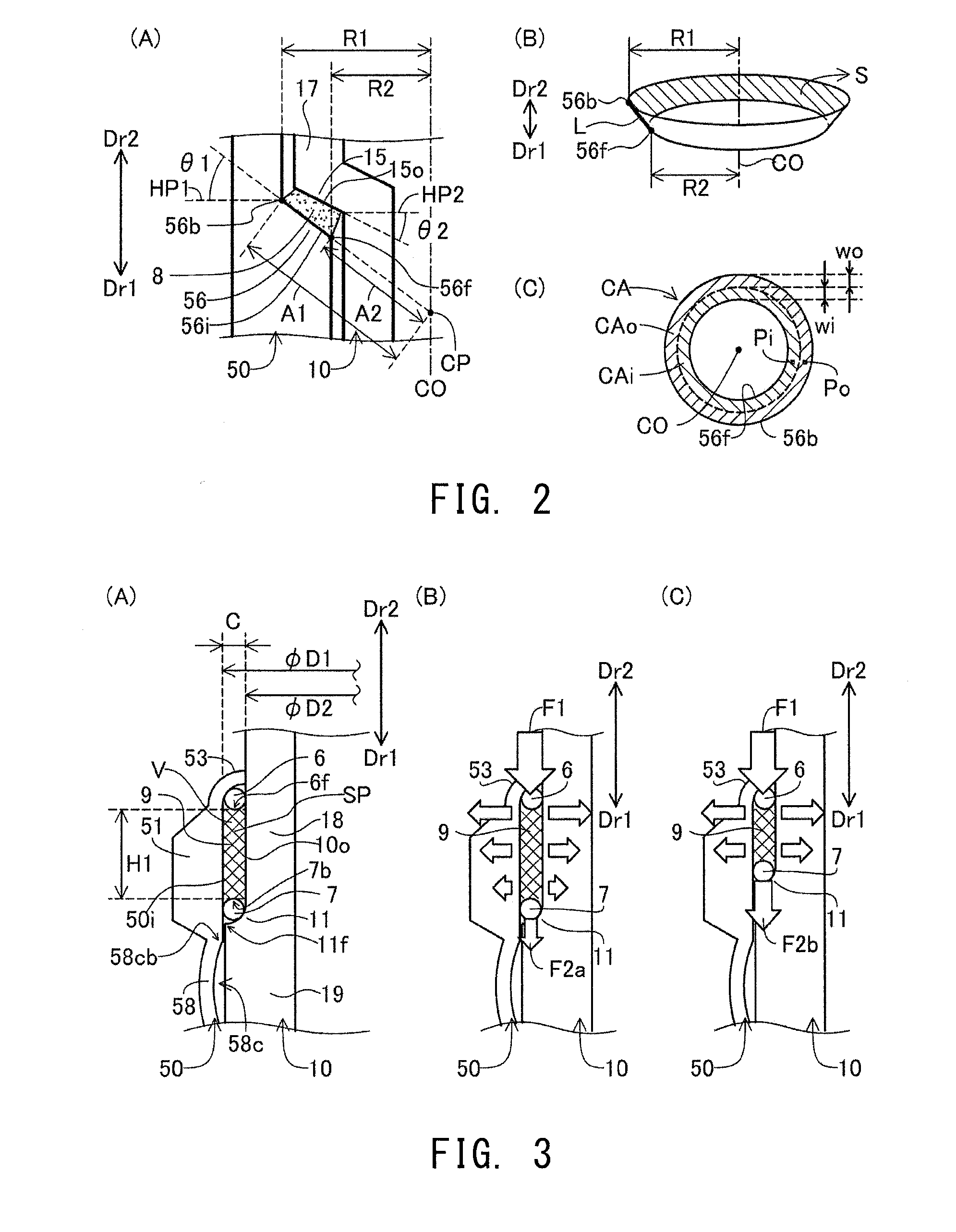

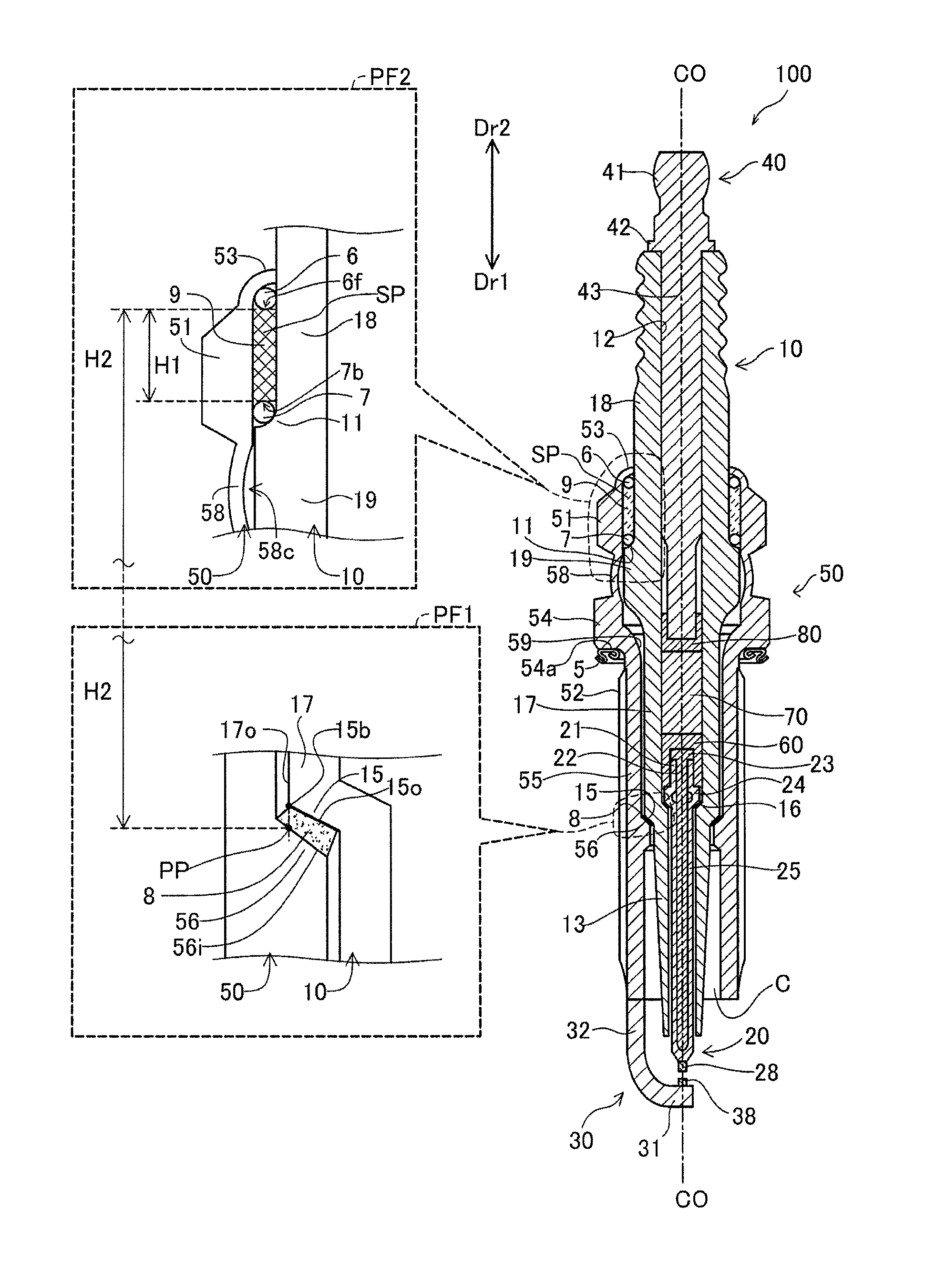

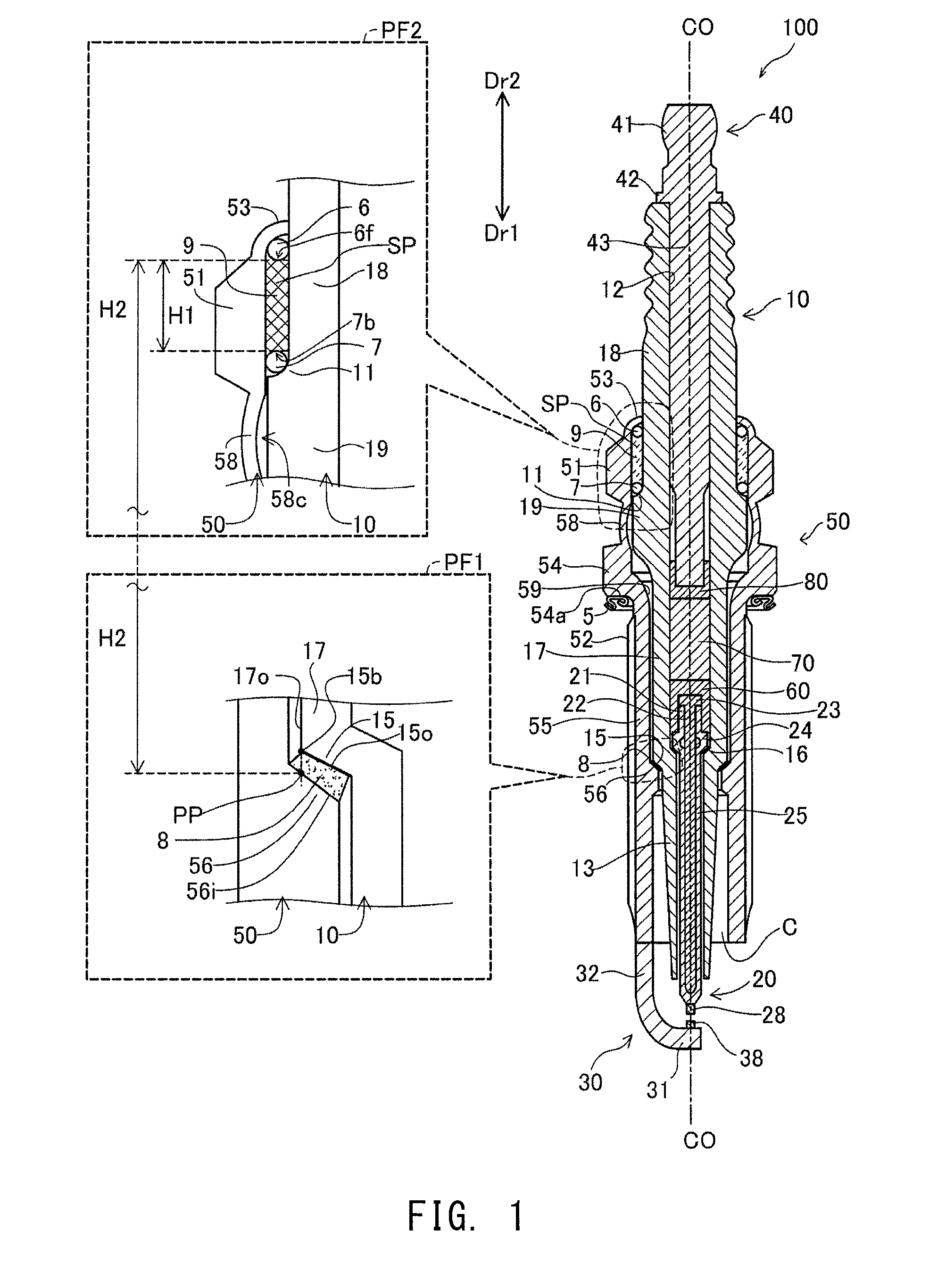

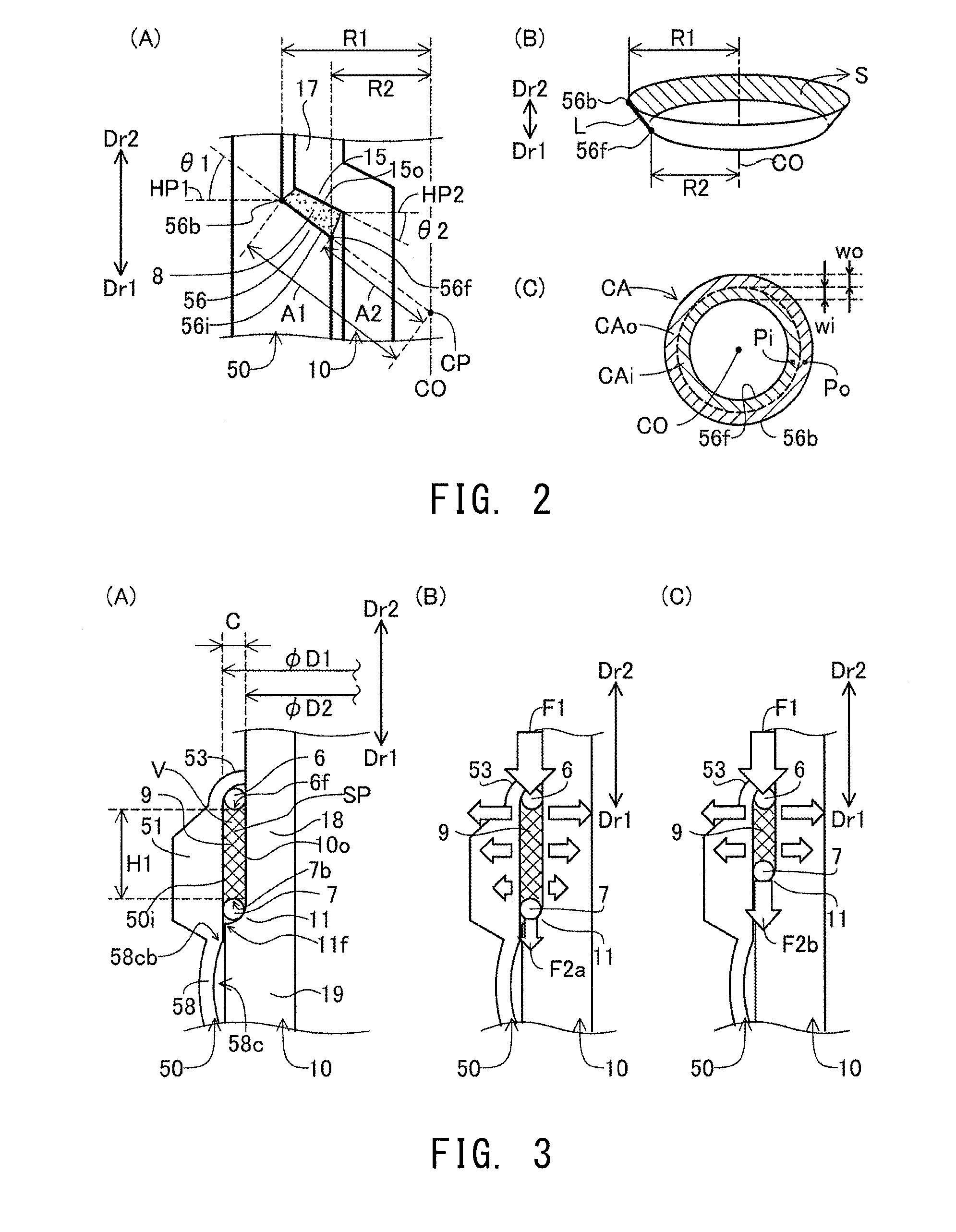

Spark plug

ActiveUS20150188293A1Avoid deformationSealing performanceSparking plugsCeramicsEngineeringSpark plug

A spark plug includes a center electrode, an insulator, a metallic shell, and a seal member for providing a seal between the insulator and the metallic shell. The insulator includes a first portion, a second portion located axially forward of the first portion and being smaller than the first portion, and an insulator first-diameter-reducing-portion whose outside diameter reduces forward and which connects the first portion and the second portion. The metallic shell includes a protrusion that includes a metallic shell diameter-reducing-portion whose inside diameter reduces forward. The seal member is disposed between the insulator first-diameter-reducing-portion and the metallic shell diameter-reducing-portion. A relationship θ21>θ22 is satisfied, where the angle θ21 is an angle between a straight line orthogonal to the axial line and the outline of the metallic shell diameter-reducing-portion, and the angle θ22 is an angle between the straight line and an outline of the insulator first-diameter-reducing-portion.

Owner:NGK SPARK PLUG CO LTD

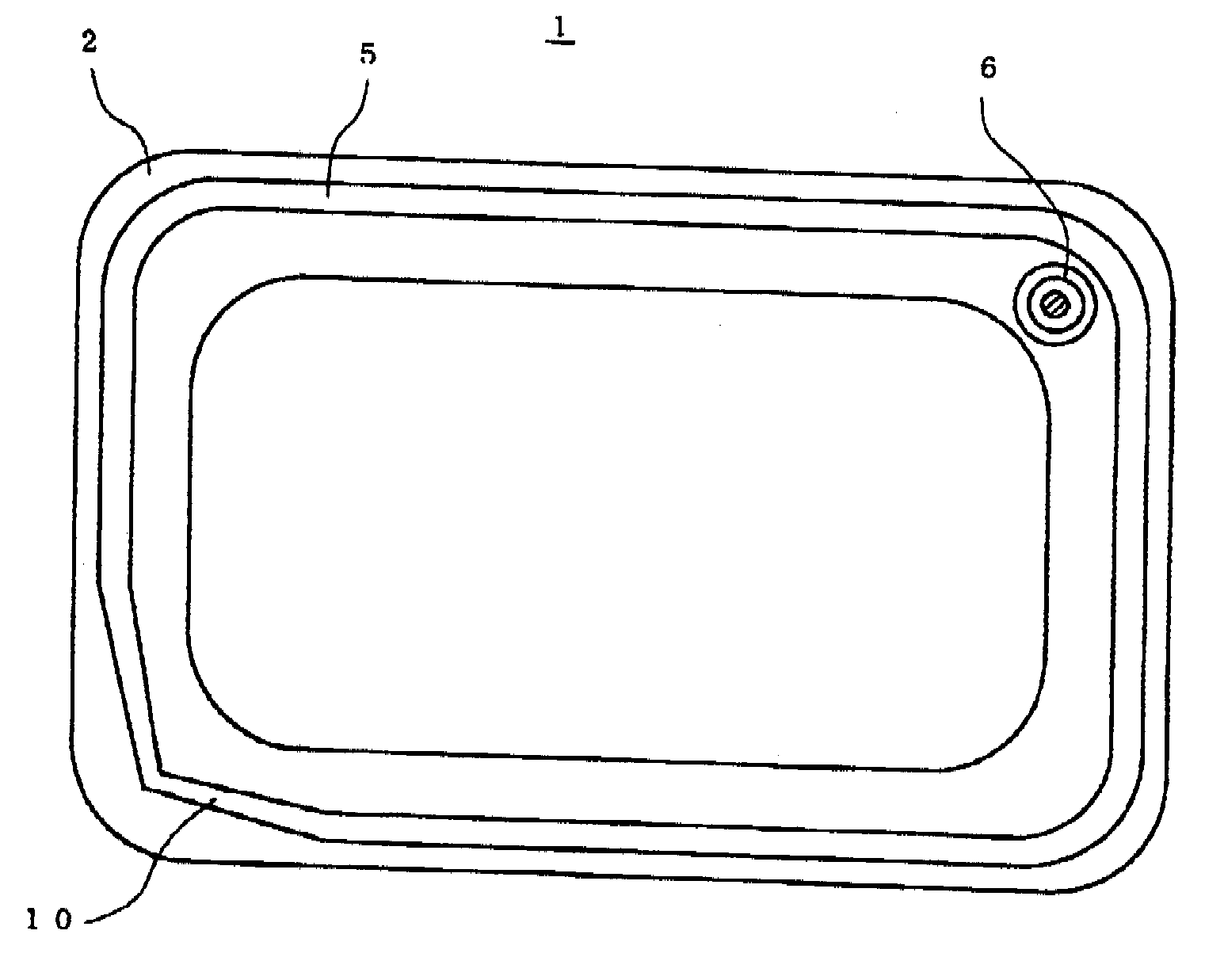

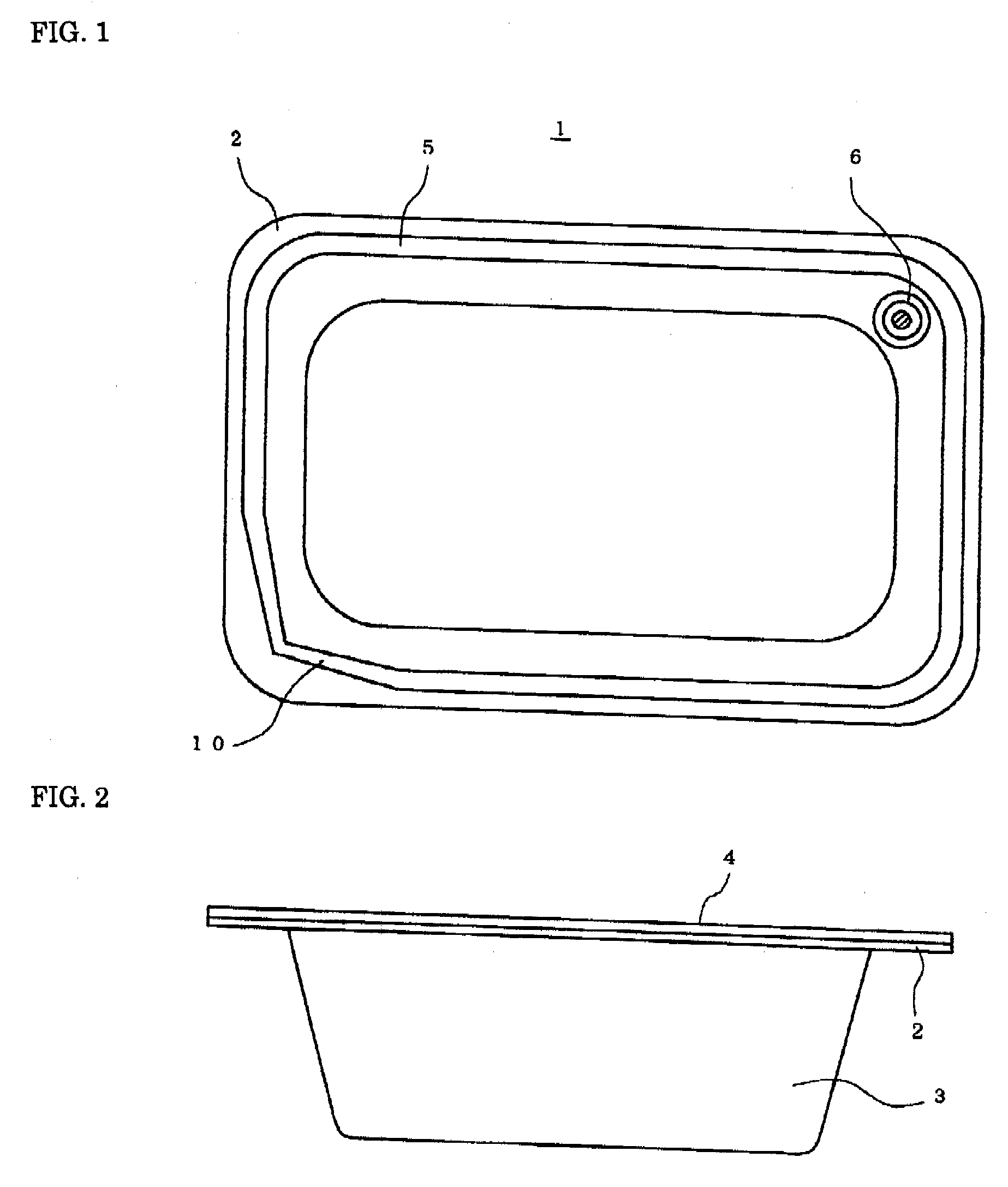

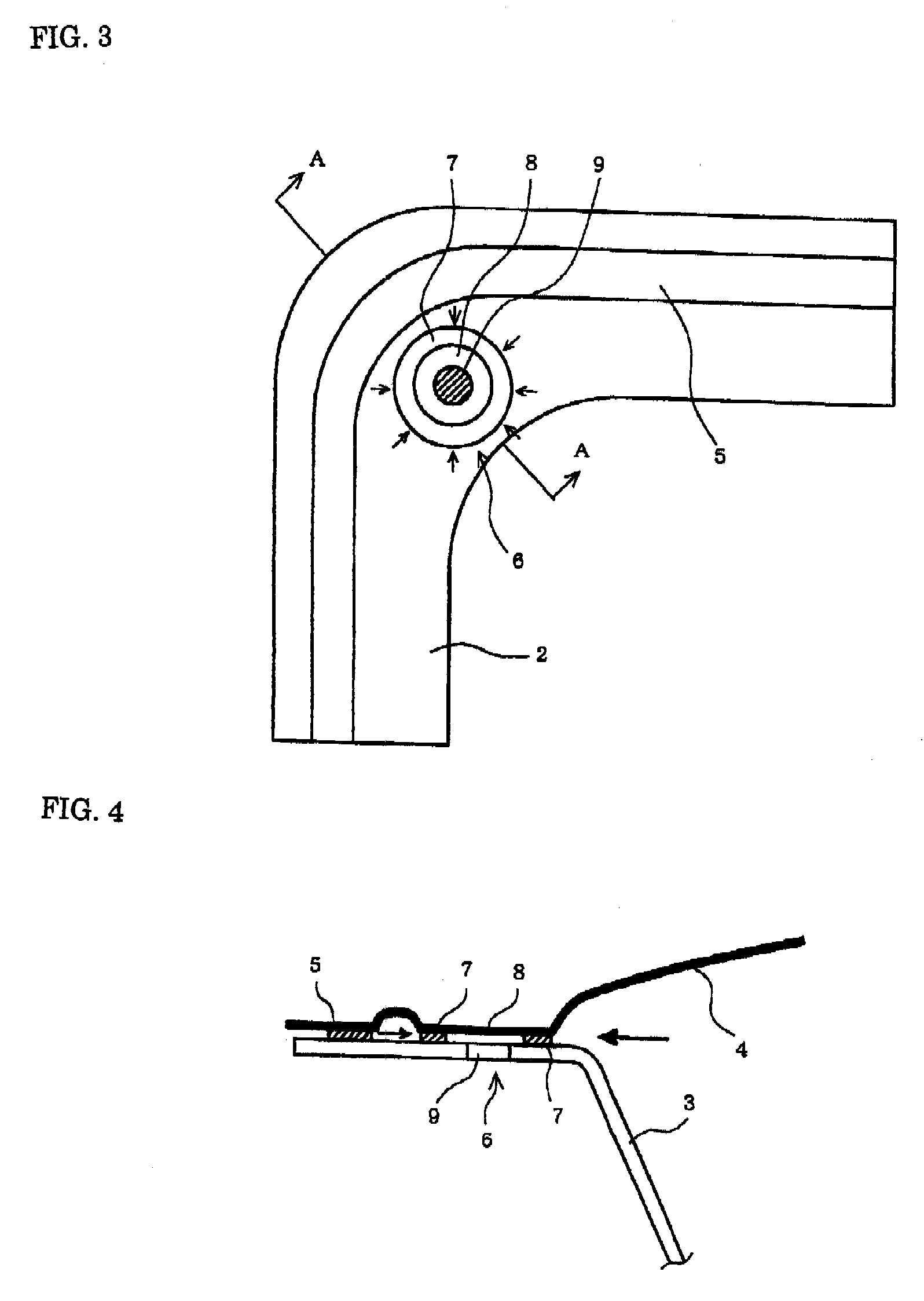

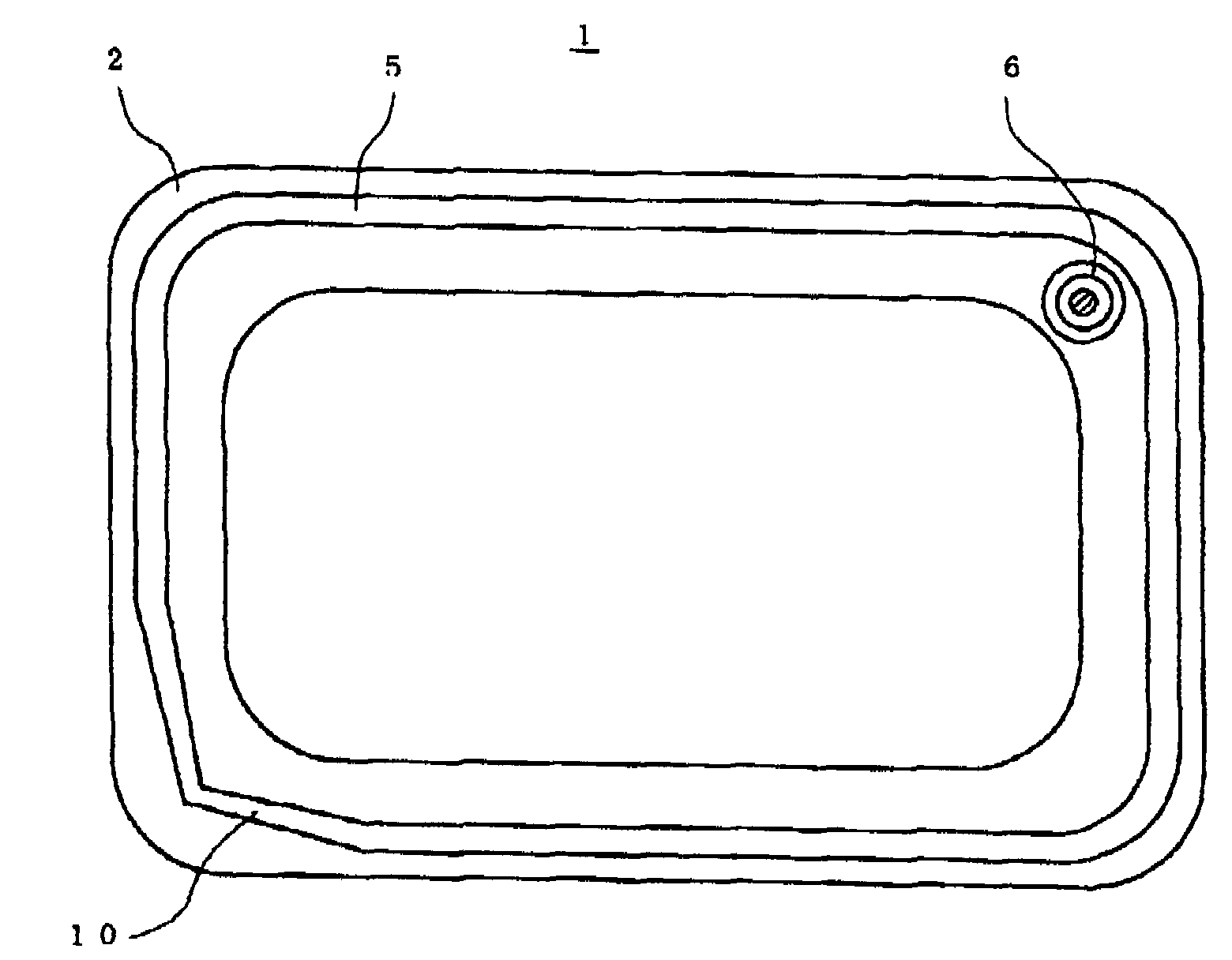

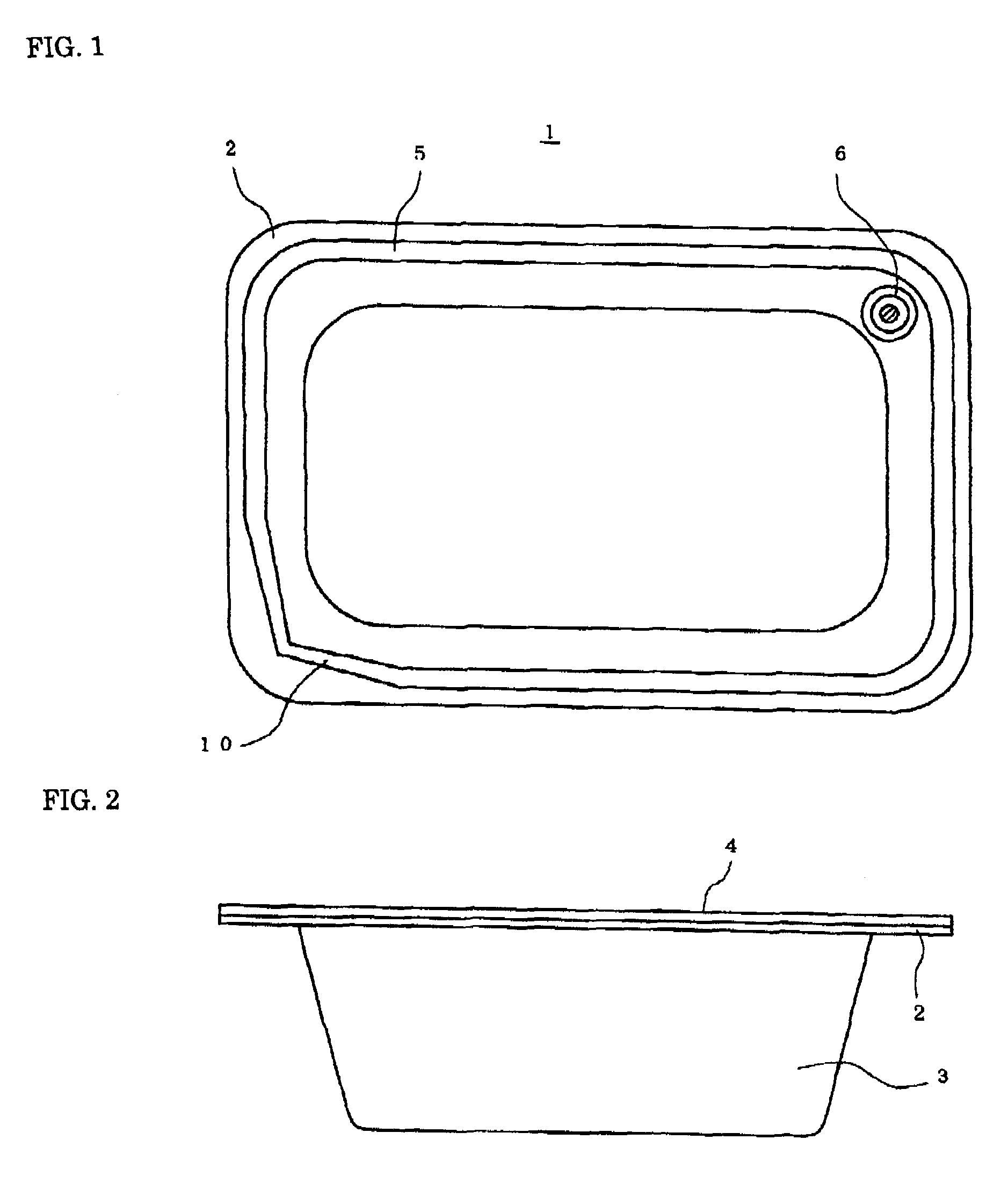

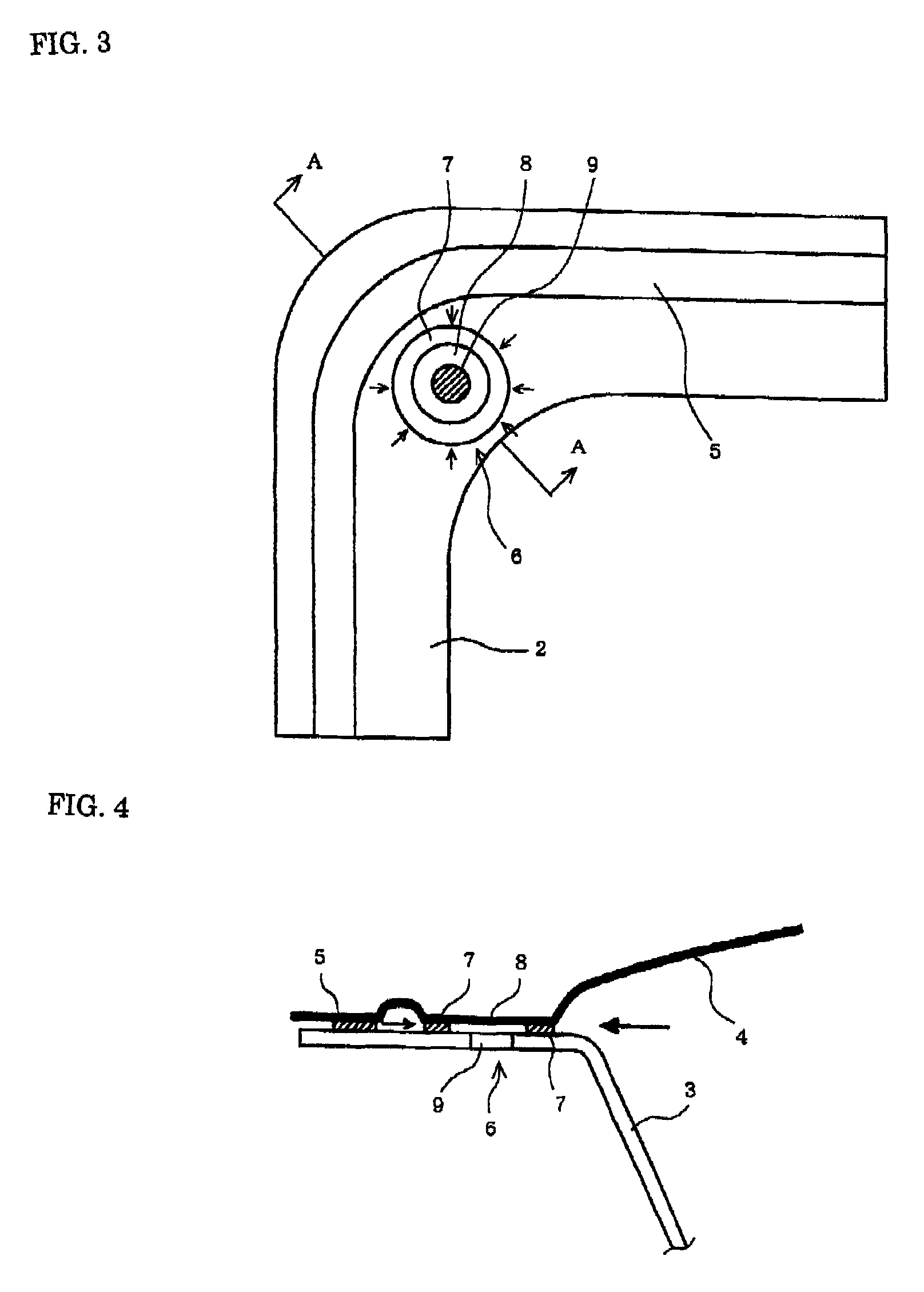

Packaging container for microwave oven and process for manufacturing the same

ActiveUS20090110784A1Sealing performanceSatisfactory seal performanceReady-for-oven doughsCapsMicrowave ovenEngineering

Provided are a packaging container for a microwave oven that excels in the sealing performance between a container body and lid, and that at heating / cooking by a microwave oven, maintains the internal pressure of the container for a given period of time to thereby enhance the taste of contents through steaming effect, and that thereafter, can spontaneously open with certainty from a steam releasing seal part; and an efficient process for manufacturing the packaging container. In the packaging container for microwave oven having a lid heat-sealed to the periphery of a flange part of container body made of a synthetic resin so as to attain hermetic sealing, at least one steam releasing seal part with a weakened part is disposed inside the peripheral seal part of the flange part at a position separate from the peripheral seal part.

Owner:TOYO SEIKAN KAISHA LTD

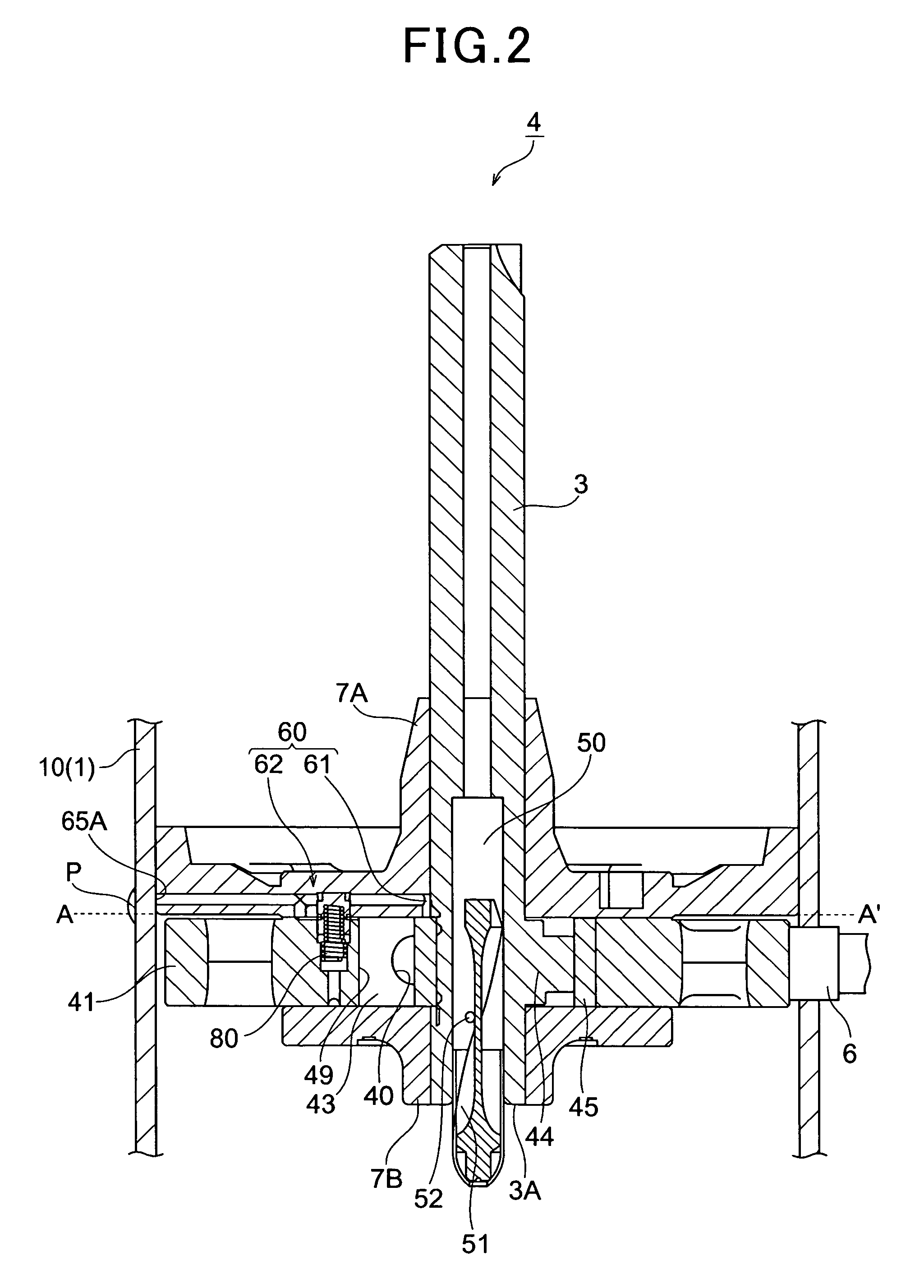

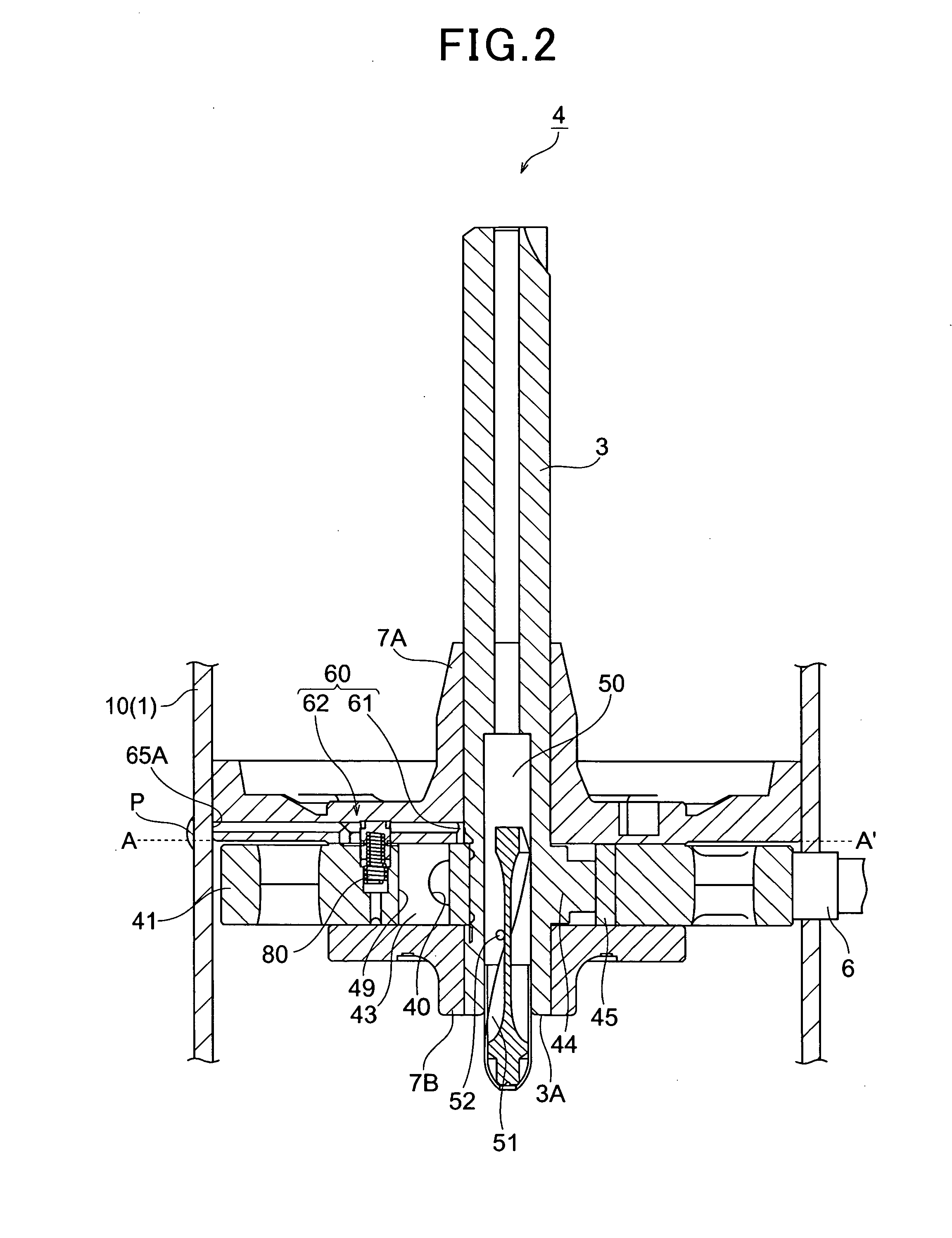

Hermetically sealed compressor having oil supply mechanism based on refrigerant pressure

ActiveUS7581936B2Sealing performanceImprove cooling efficiencyRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringRefrigerant

A hermetically sealed rotary compressor 100 including an electrically-driven element 2, a rotary compressing element 4 equipped with a cylinder 41 having a compression chamber 43 and a hermetically sealed container 1 in which oil 8 is stocked, is equipped with an oil path 62 for injecting the oil 8 into the compression chamber 43 when refrigerant is sucked into the compression chamber 43, and an opening / closing valve 80 for opening / closing the oil path 62 in accordance with the discharge pressure of the rotary compressing element 4 of the pressure of the compressed refrigerant compressed by the rotary compressing element 4.

Owner:SANYO ELECTRIC CO LTD

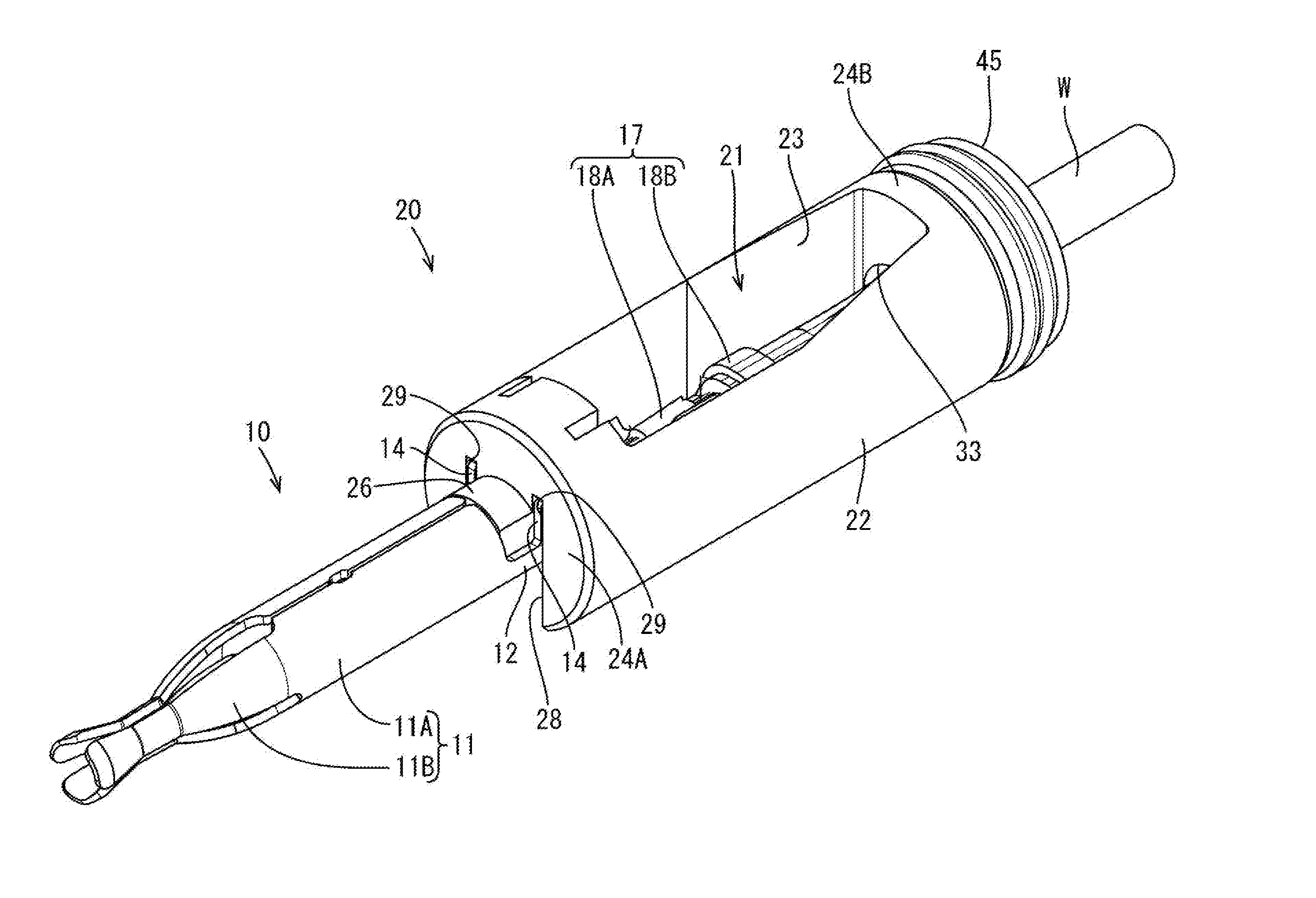

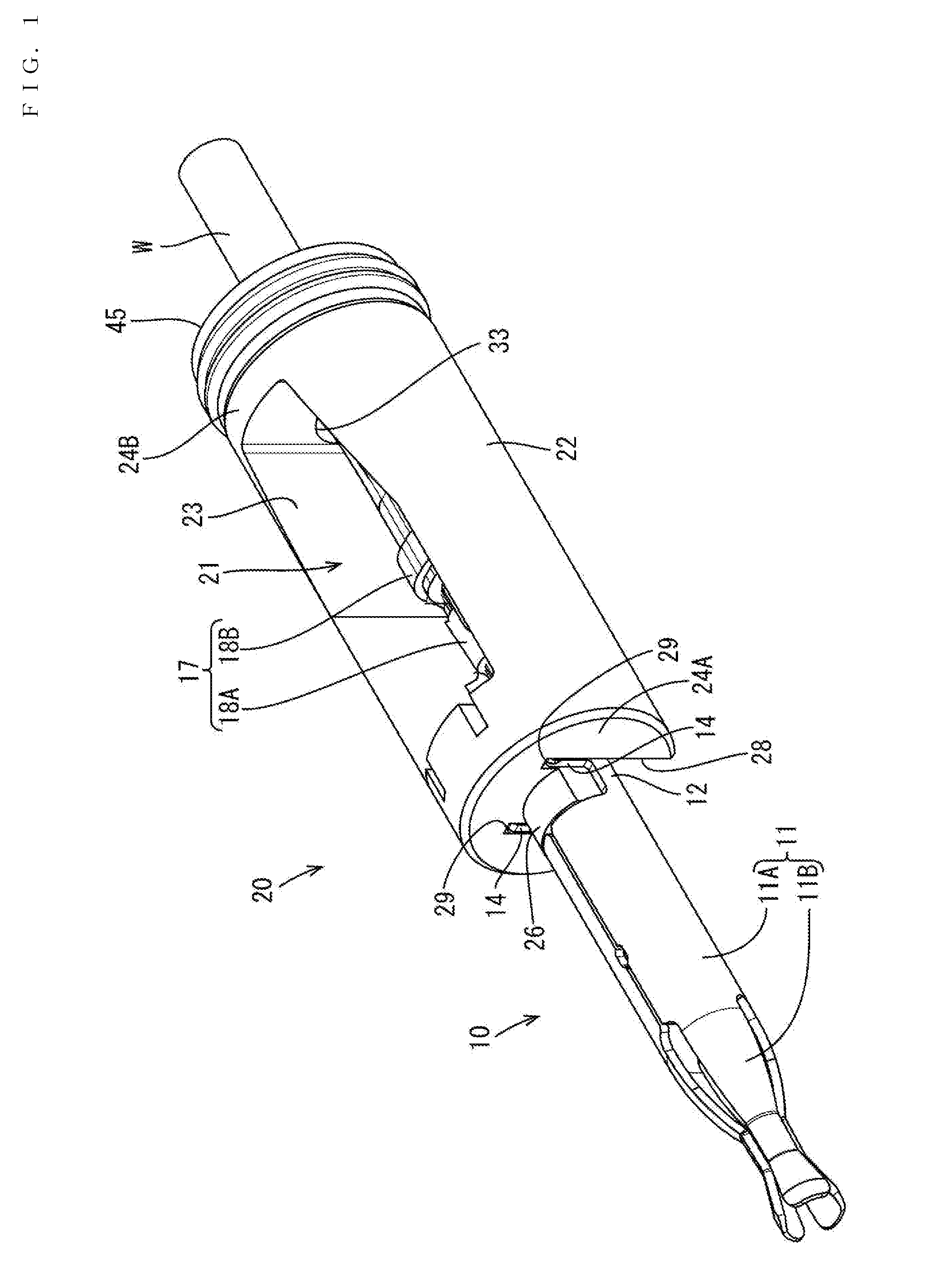

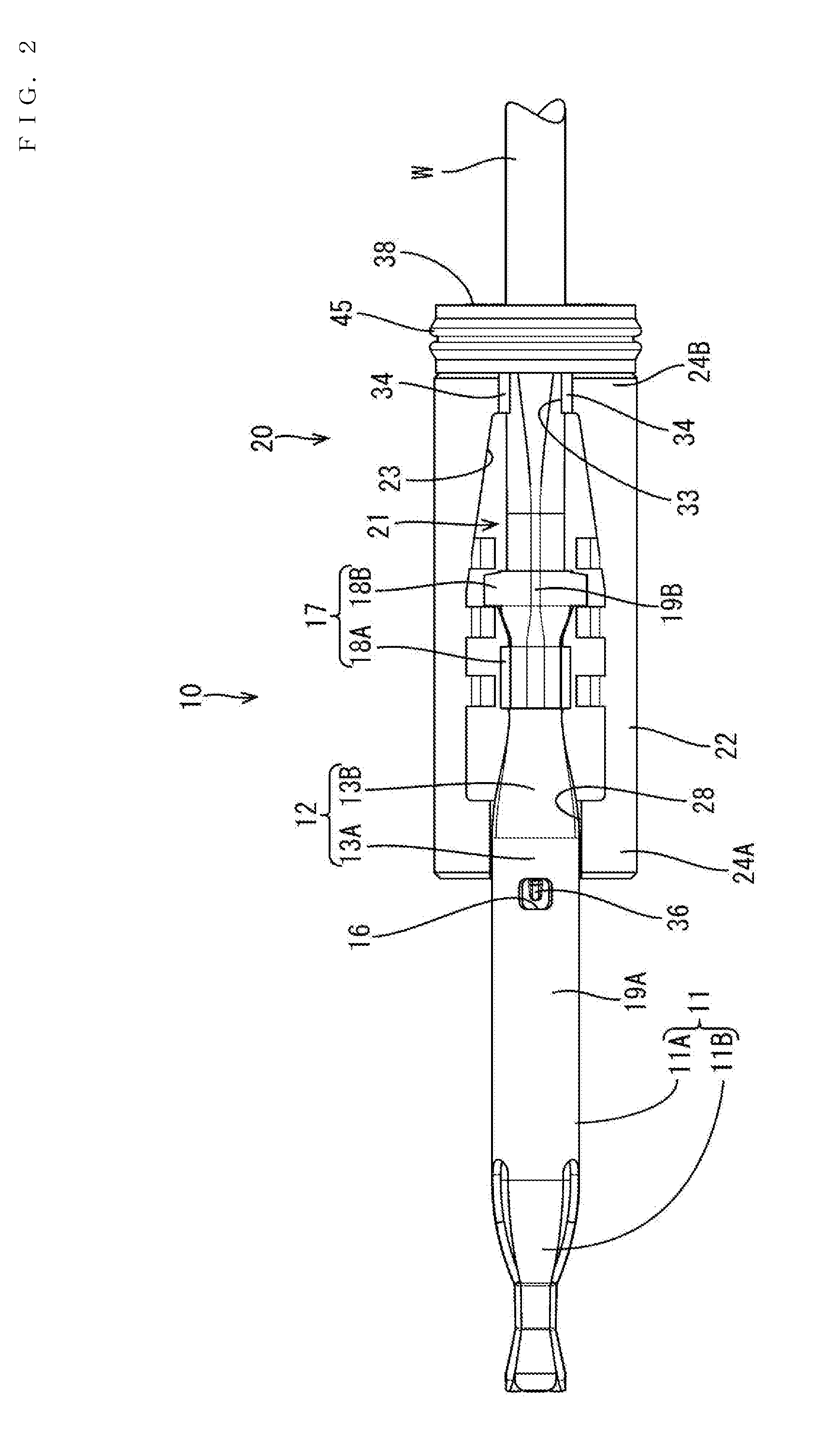

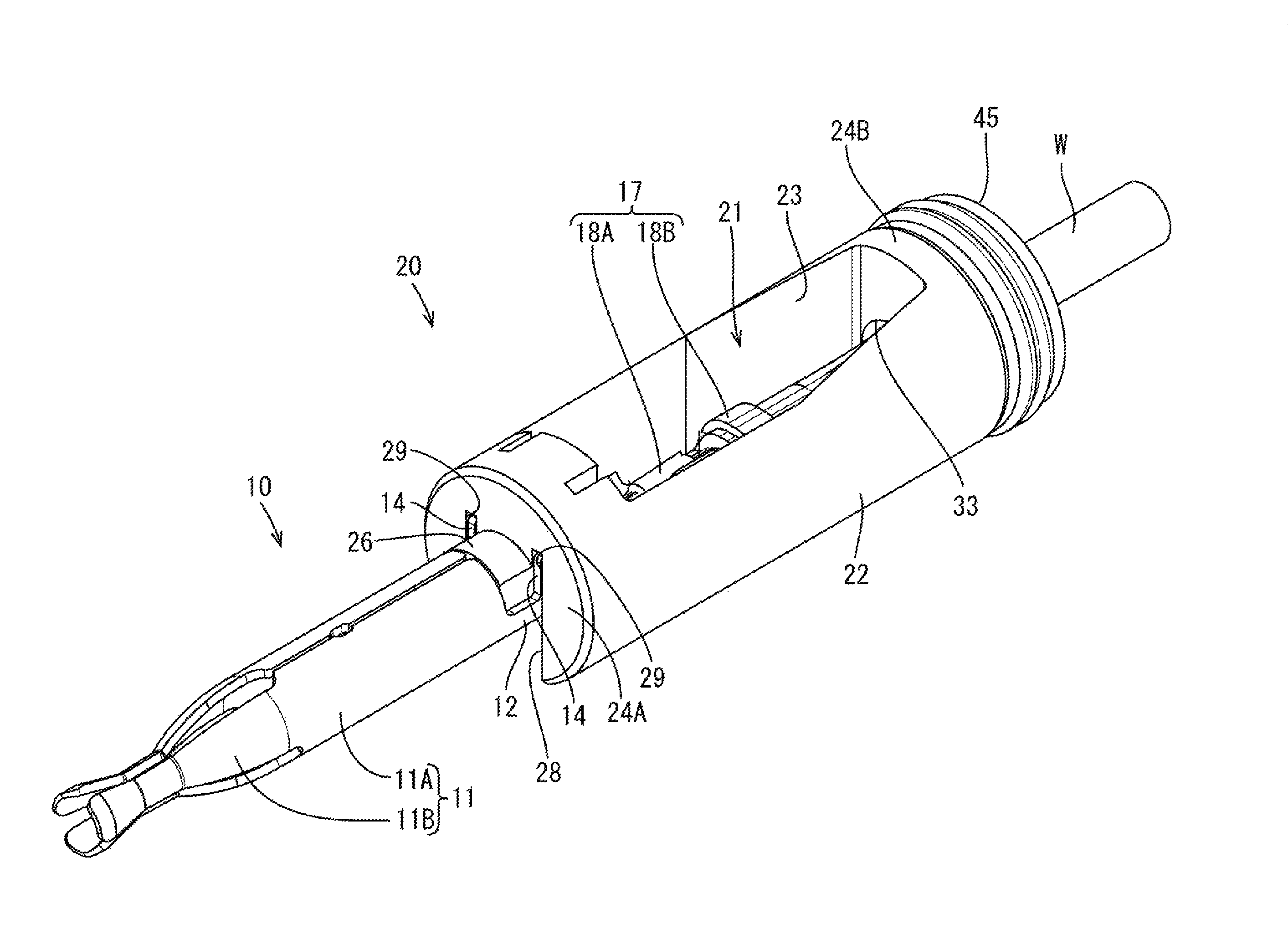

Connector

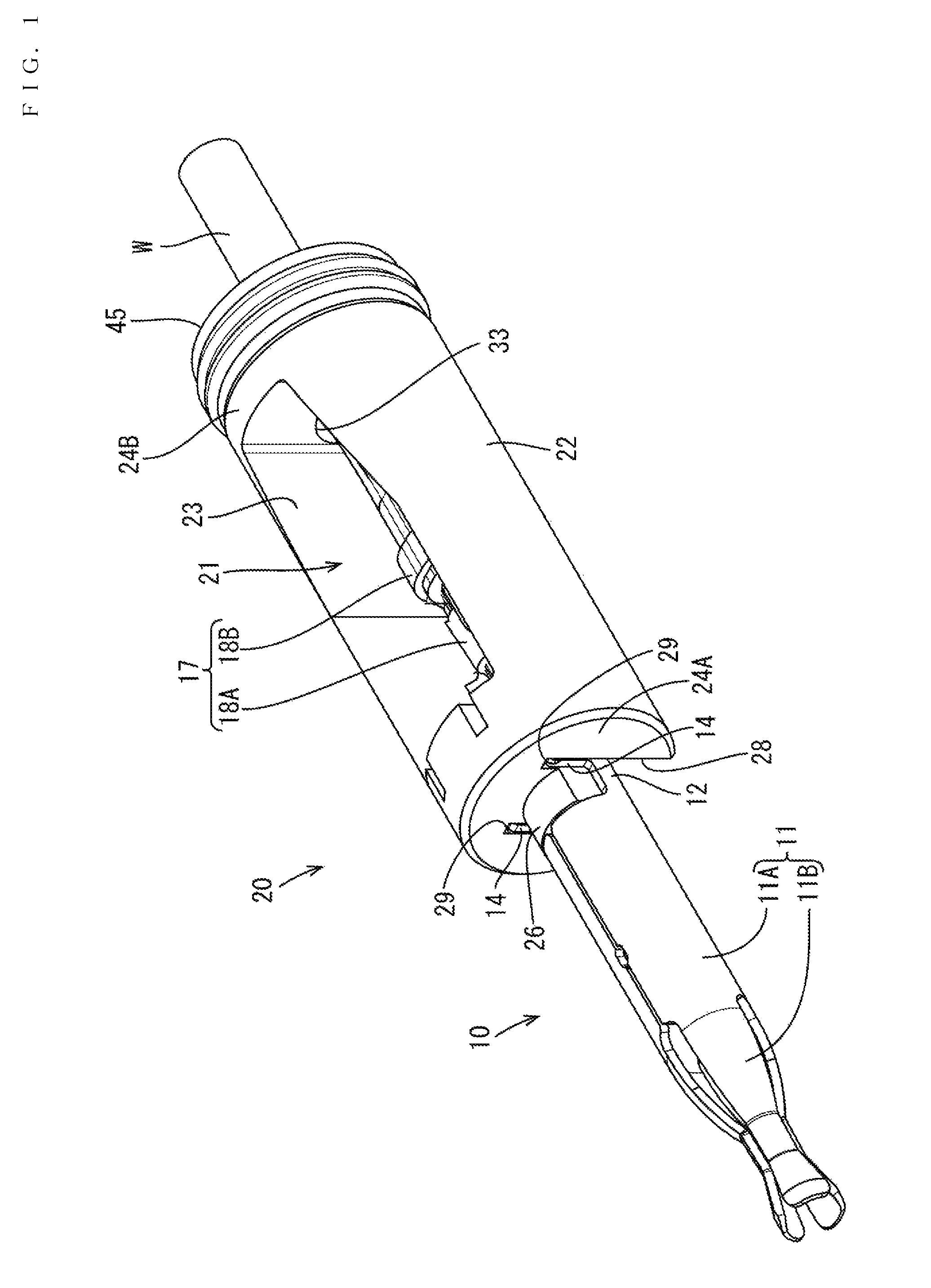

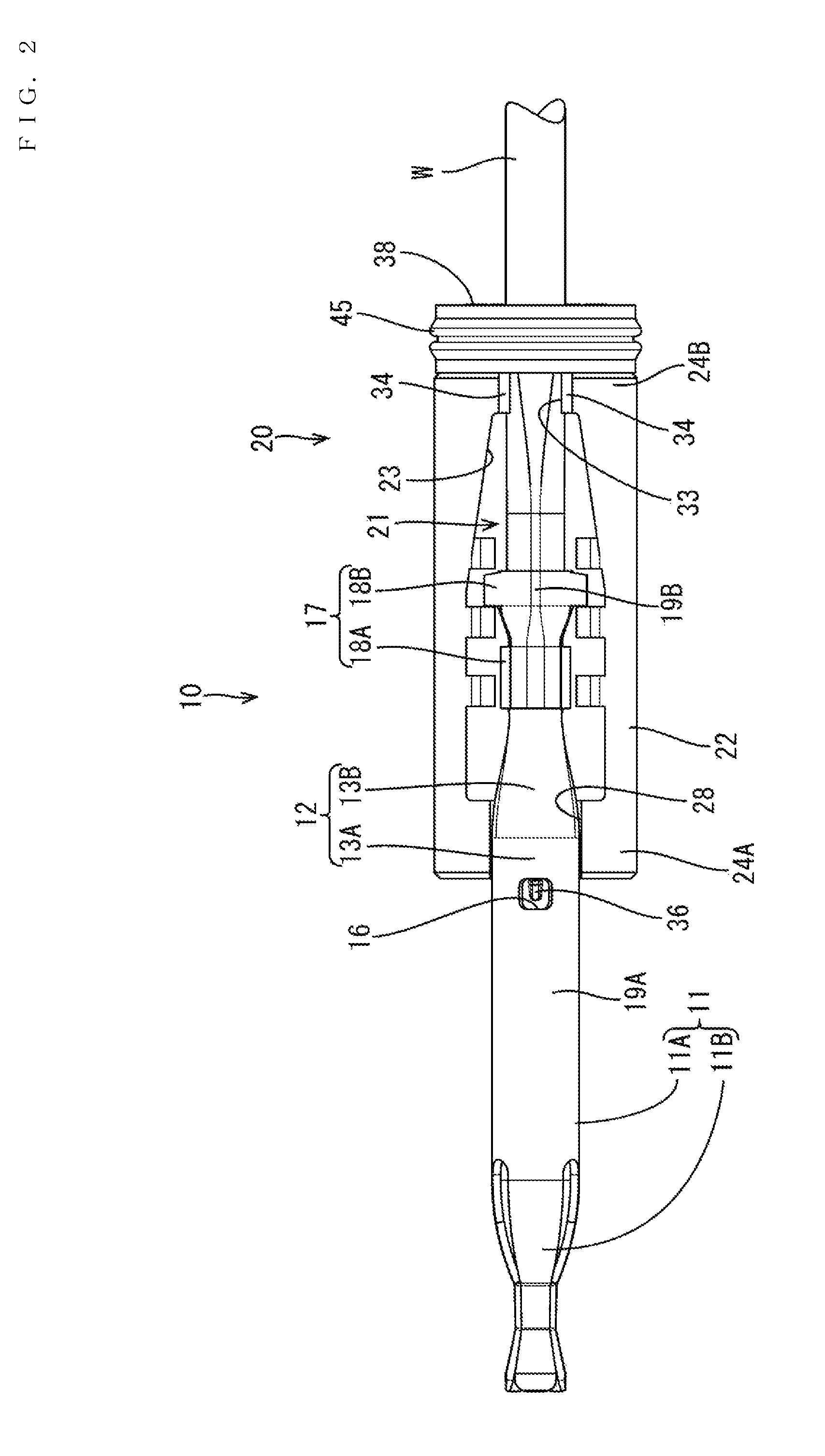

ActiveUS20160294097A1Increase the scope of applicationEnsure sealing performanceElectrically conductive connectionsCouplings bases/casesMechanical engineeringEngineering

A connector (C) has a terminal fitting (10) including a terminal connecting portion (11) to be connected to a mating terminal and barrels to be crimped to a wire (W). A housing (50) has a terminal accommodating chamber (57) that is configured to accommodate the terminal fitting (10). A sleeve (20) has an accommodation space (21) configured to accommodate the barrels crimped to the wire (W). A rubber plug (45) includes a center hole (46) and is configured so that the wire (W) extending back from a rear wall (24B) of the accommodation space (21) penetrates therethrough in a sealed state. A rear holder (60) obstructs rearward movement of the terminal fitting (10) via the sleeve (20). A center position (P2) of the center hole (46) is displaced toward a rear bottom plate (19B) from a center position (P1) of the terminal connecting portion (11).

Owner:SUMITOMO WIRING SYST LTD

Packaging container for microwave oven and process for manufacturing the same

ActiveUS8245869B2Sealing performanceSatisfactory performanceReady-for-oven doughsButtonsInternal pressureMicrowave oven

Provided are a packaging container for a microwave oven that excels in the sealing performance between a container body and lid, and that at heating / cooking by a microwave oven, maintains the internal pressure of the container for a given period of time to thereby enhance the taste of contents through steaming effect, and that thereafter, can spontaneously open with certainty from a steam releasing seal part; and an efficient process for manufacturing the packaging container. In the packaging container for microwave oven having a lid heat-sealed to the periphery of a flange part of container body made of a synthetic resin so as to attain hermetic sealing, at least one steam releasing seal part with a weakened part is disposed inside the peripheral seal part of the flange part at a position separate from the peripheral seal part.

Owner:TOYO SEIKAN KAISHA LTD

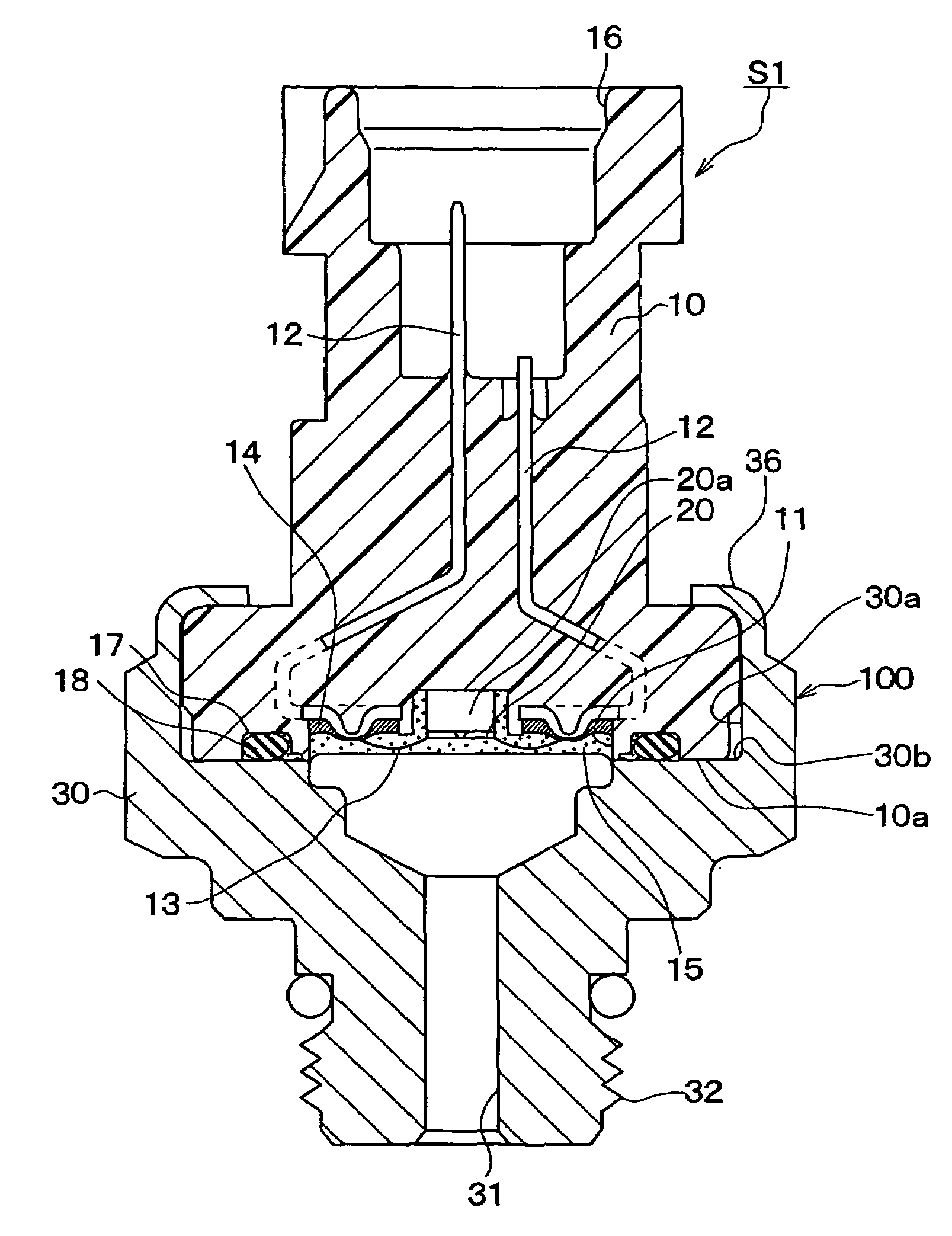

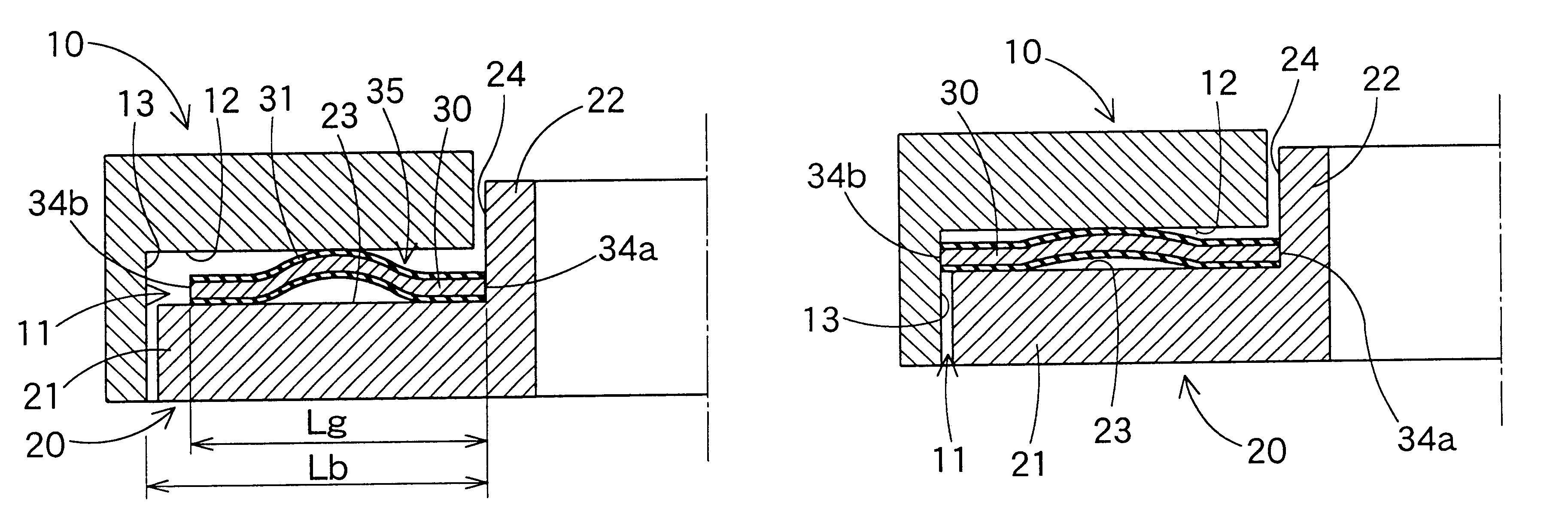

Method for manufacturing pressure sensor

InactiveUS7268008B2Improve sealingSealing performanceFluid pressure measurement by electric/magnetic elementsSolid-state devicesReduction treatmentEngineering

Owner:DENSO CORP

Gasket attachment structure for refrigerant-seal

InactiveUS6547253B2Minimal leakageHigh sealing pressureEngine sealsFlanged jointsEngineeringRefrigerant

Owner:DENSO CORP

Sealant laminated composite, sealed semiconductor devices mounting substrate, sealed semiconductor devices forming wafer, semiconductor apparatus, and method for manufacturing semiconductor apparatus

InactiveUS20140264956A1Low reliabilityInhibit flakingSemiconductor/solid-state device detailsSynthetic resin layered productsEngineeringSealant

Disclosed is a sealant laminated composite for collectively sealing a semiconductor devices mounting surface of a substrate on which semiconductor devices may be mounted or a semiconductor devices forming surface of a wafer on which semiconductor devices may be formed, including a support wafer that may be composed of silicon and an uncured resin layer that may be constituted of an uncured thermosetting resin formed on one side of the support wafer.

Owner:SHIN ETSU CHEM IND CO LTD

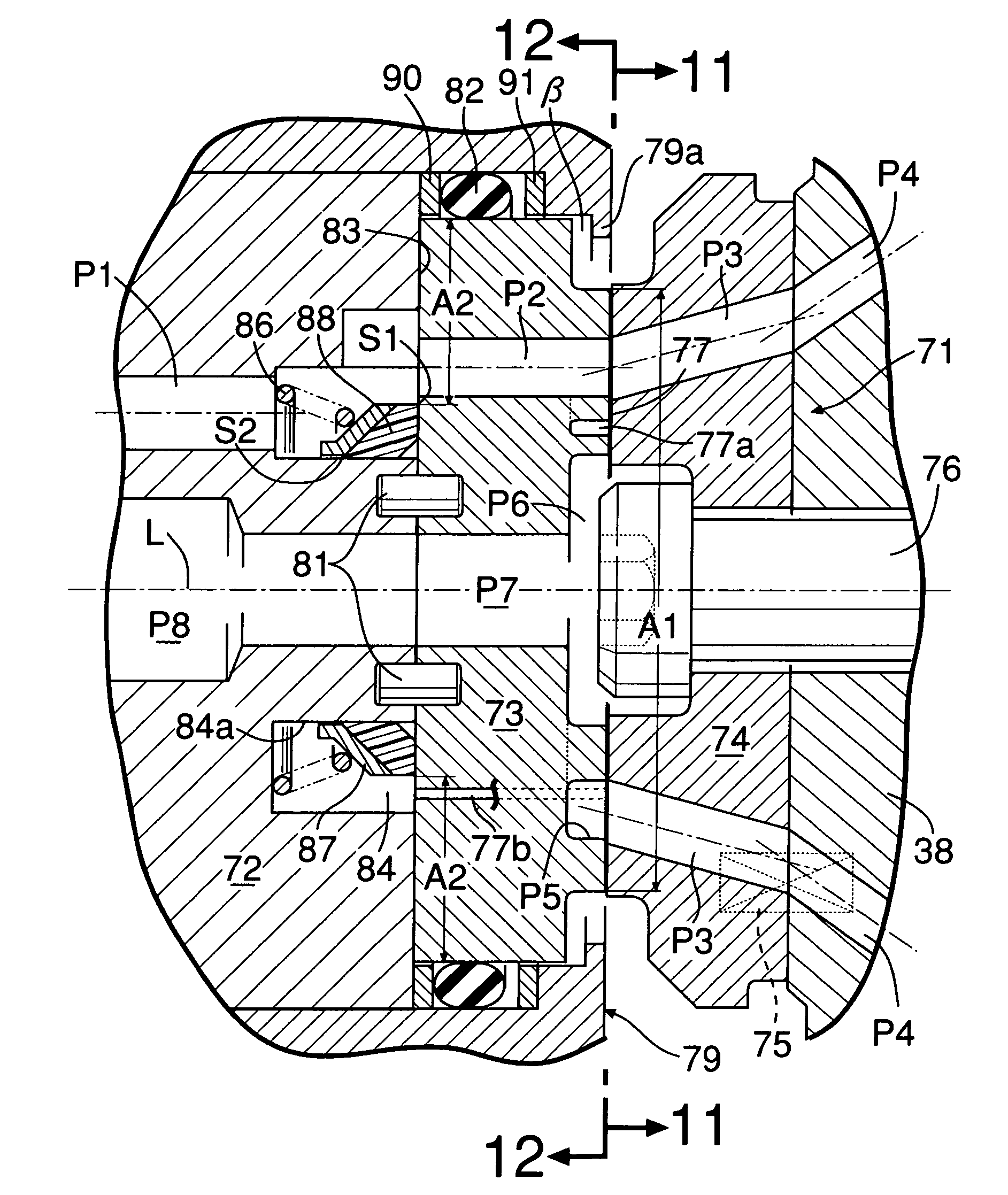

Hermetically sealed compressor

ActiveUS20060210408A1Reduce oil pressureReduce pressureRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeDischarge pressureRefrigerant

A hermetically sealed rotary compressor 100 including an electrically-driven element 2, a rotary compressing element 4 equipped with a cylinder 41 having a compression chamber 43 and a hermetically sealed container 1 in which oil 8 is stocked, is equipped with and oil path 62 for injecting the oil 8 into the compression chamber 43 when refrigerant is sucked into the compression chamber 43, and an opening / closing valve 80 for opening / closing the oil path 62 in accordance with the discharge pressure of the rotary compressing element 4 of the pressure of the compressed refrigerant compressed by the rotary compressing element 4.

Owner:SANYO ELECTRIC CO LTD

Fuel cell stack

ActiveUS7732079B2Sealing performanceImprove sealingPrimary cell to battery groupingFuel cells groupingFuel cellsEngineering

A fuel cell stack is provided with a plurality of stacked separators. This fuel cell stack includes: terminals that extend from the separators; packing in which are formed a plurality of through holes through which the terminals are inserted; a packing casing that has a packing housing concave portion that envelops side surfaces of the packing and supports a bottom surface of the packing, and has through holes through which the terminals are inserted; and a connector housing that has a pressing surface that presses a top surface of the packing. Mountain-shaped protruding portions whose apex portions are formed by circumferential edges of apertures of the respective through holes are provided on the top surface of the packing, and the pressing surfaces of the connector housing are formed in a configuration that conforms to the side surfaces of the protruding portions. Internal surfaces of the through holes in the packing are in contact without a gap in between with external surfaces of the terminals. The sealing performance in extraction portions of terminals that are used for cell voltage detection is improved.

Owner:HONDA MOTOR CO LTD

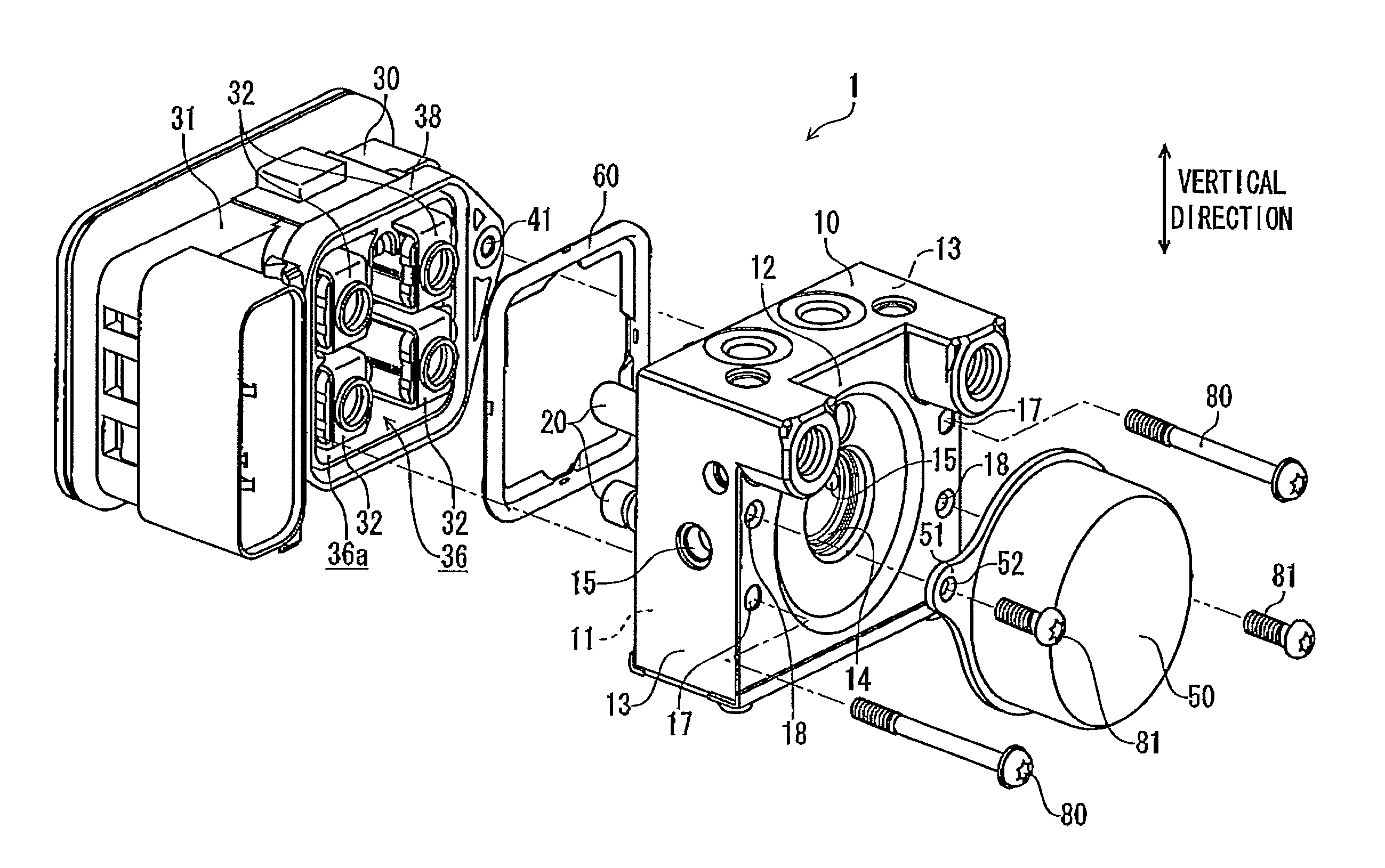

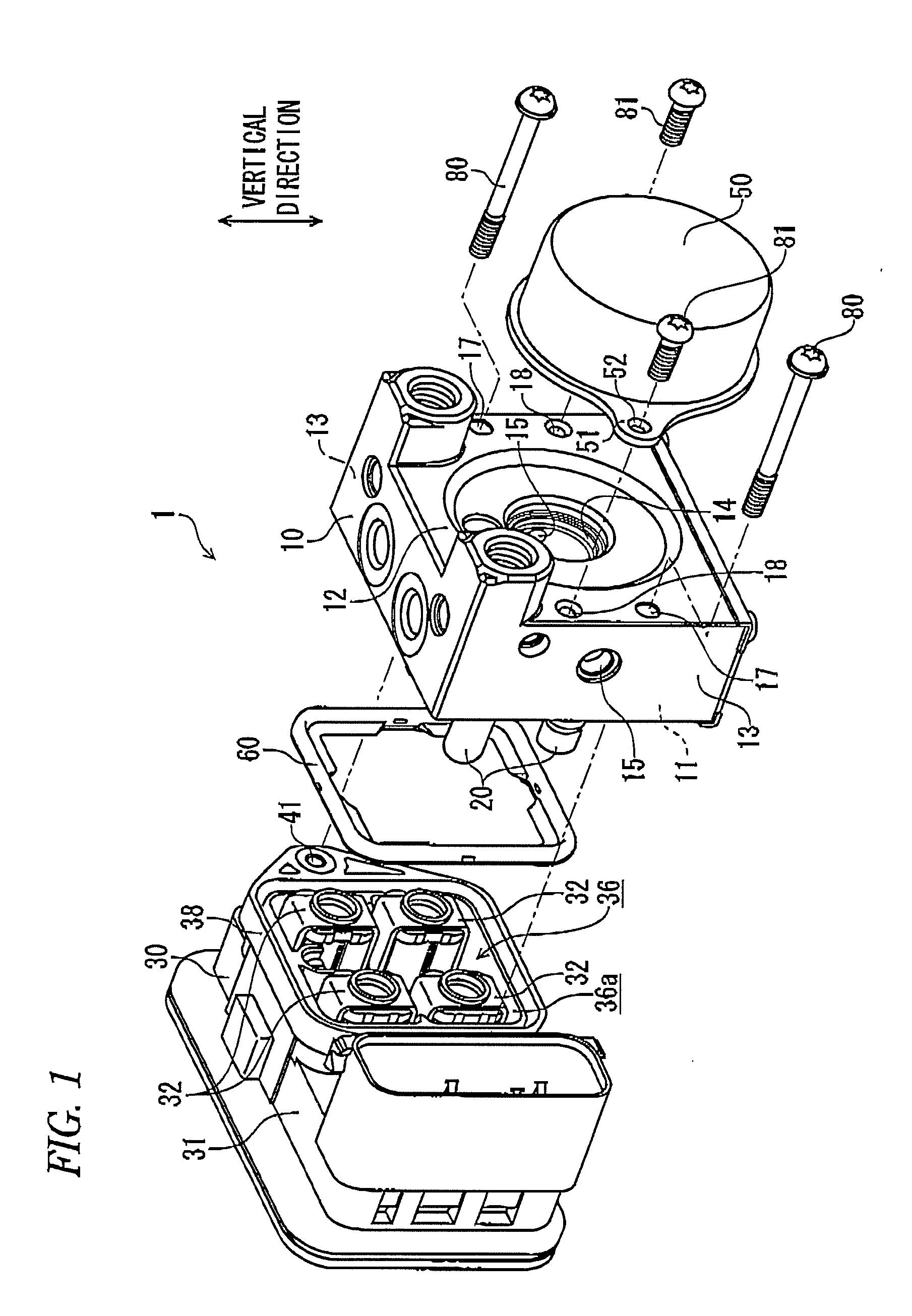

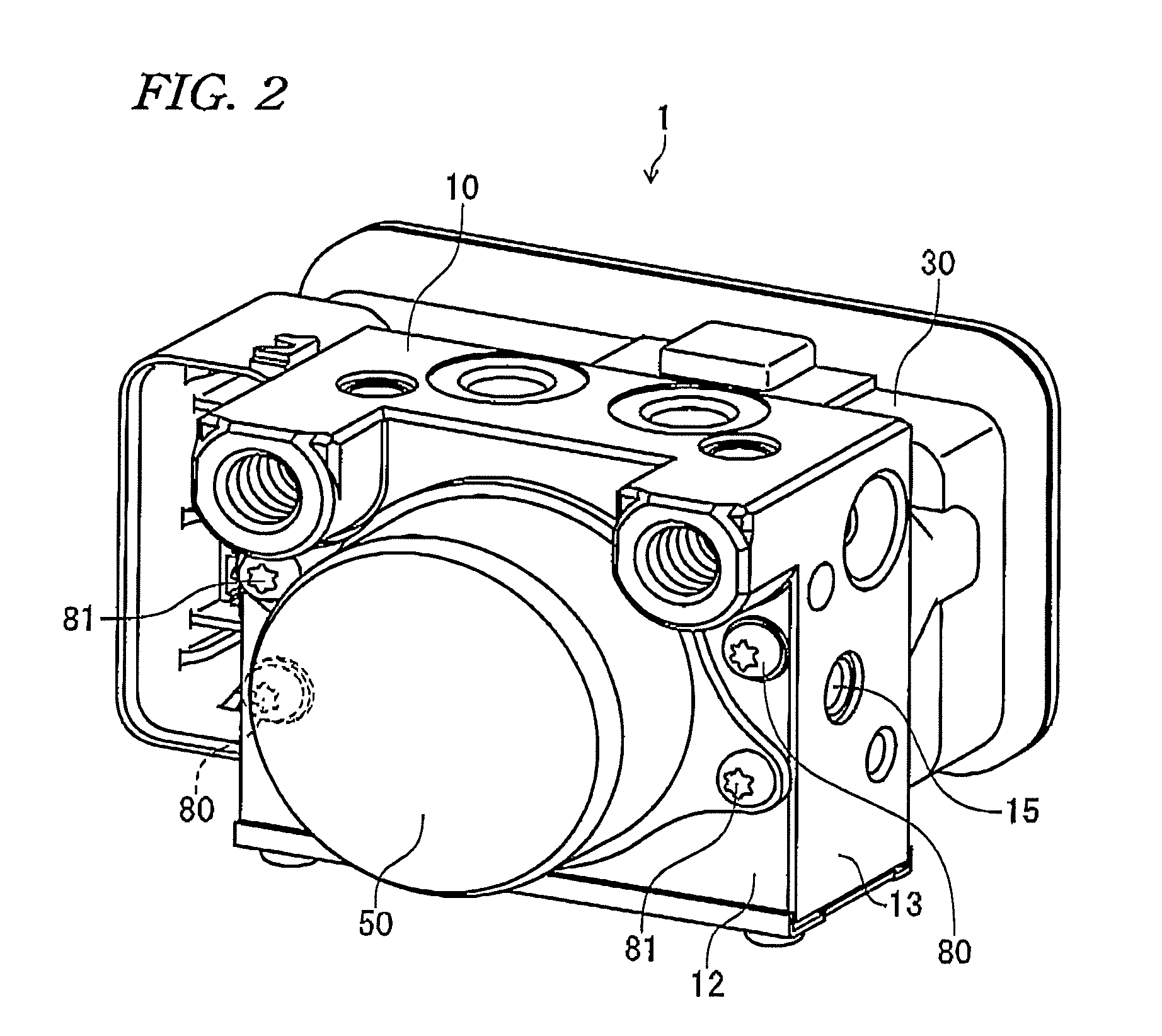

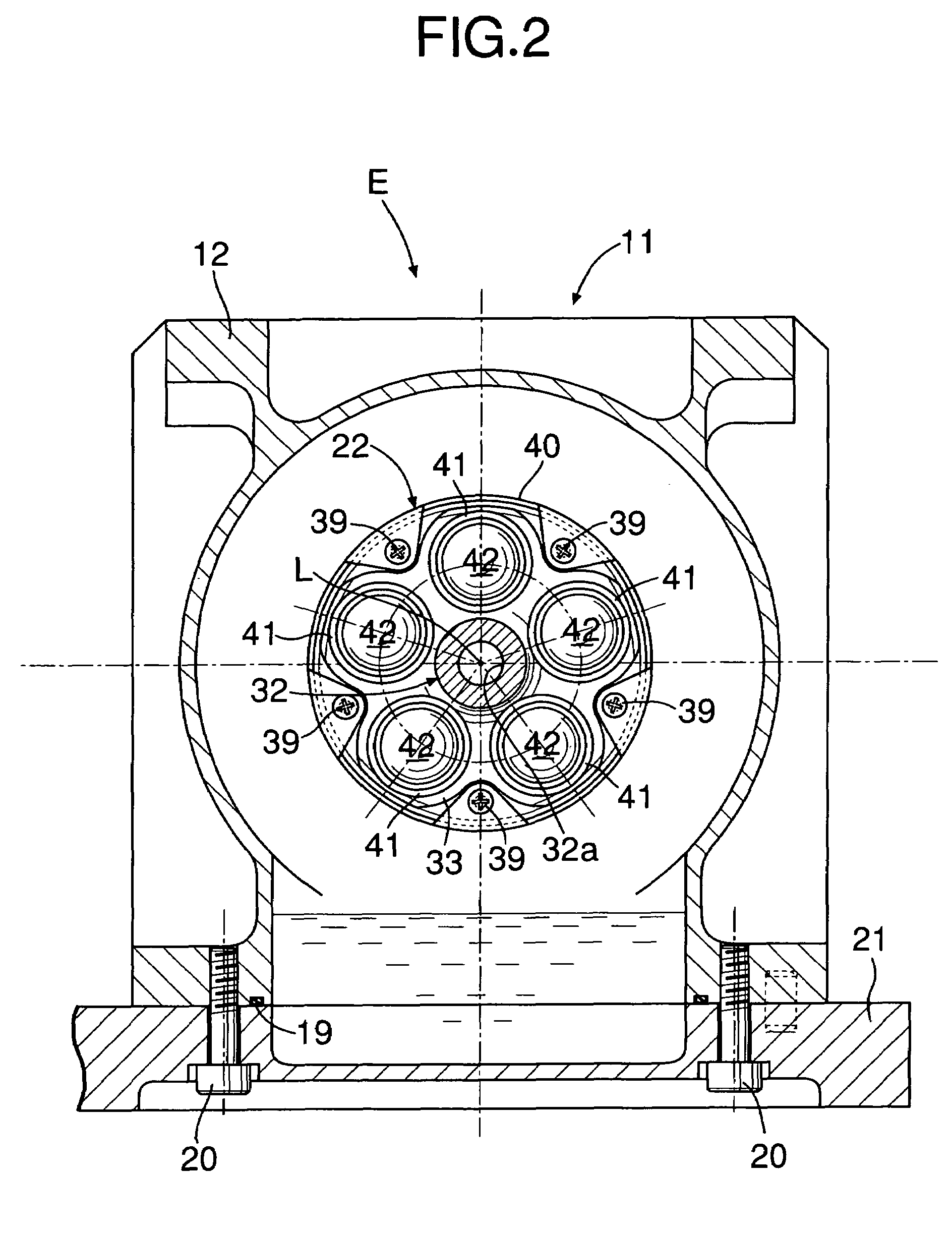

Brake hydraulic pressure control apparatus for vehicle

ActiveUS20110265901A1Reduce in quantitySmall sizeTank vehiclesWatering devicesDrive motorElectromagnetic valve

A brake hydraulic pressure control apparatus for a vehicle includes: a base member; a control housing including a storage space for storing an electromagnetic valve on one face of the base member and a coil assembly; and a pump driving motor on a back face of the base member. The base member are provided with: two housing mounting penetration holes through which housing mounting screws for fixing the control housing are to be inserted; two motor mounting holes into which motor mounting screws for fixing the motor are to be inserted; and a rotation shaft storage hole into which a rotation shaft of the motor is to be stored, wherein the housing mounting penetration holes and the motor mounting holes are respectively disposed point-symmetrically with respect to the center of the rotation shaft storage hole.

Owner:HITACHI ASTEMO LTD

Blowing-mode door for vehicle air-conditioning apparatus and vehicle air-conditioning apparatus using the same

ActiveUS8480462B2Reduce leakageDegrading independent temperature-adjusting performanceAir-treating devicesVehicle heating/cooling devicesAir conditioningElectrical and Electronics engineering

There are provided a blowing-mode door for a vehicle air-conditioning apparatus in which leakage of temperature-adjusted air can be prevented to improve independent temperature-adjusting performance by minimizing the gap between the mode door and a partition plate and increasing the rigidity of the mode door, as well as a vehicle air-conditioning apparatus using the same. A blowing-mode door applied to a vehicle air-conditioning apparatus with an independent temperature-adjusting system is provided in which the blowing-mode door includes a rotating shaft having a predetermined length and a pair of left and right plate-like doors that are molded integrally with the rotating shaft, with a gap for preventing interference with a partition plate therebetween.

Owner:MITSUBISHI HEAVY IND LTD

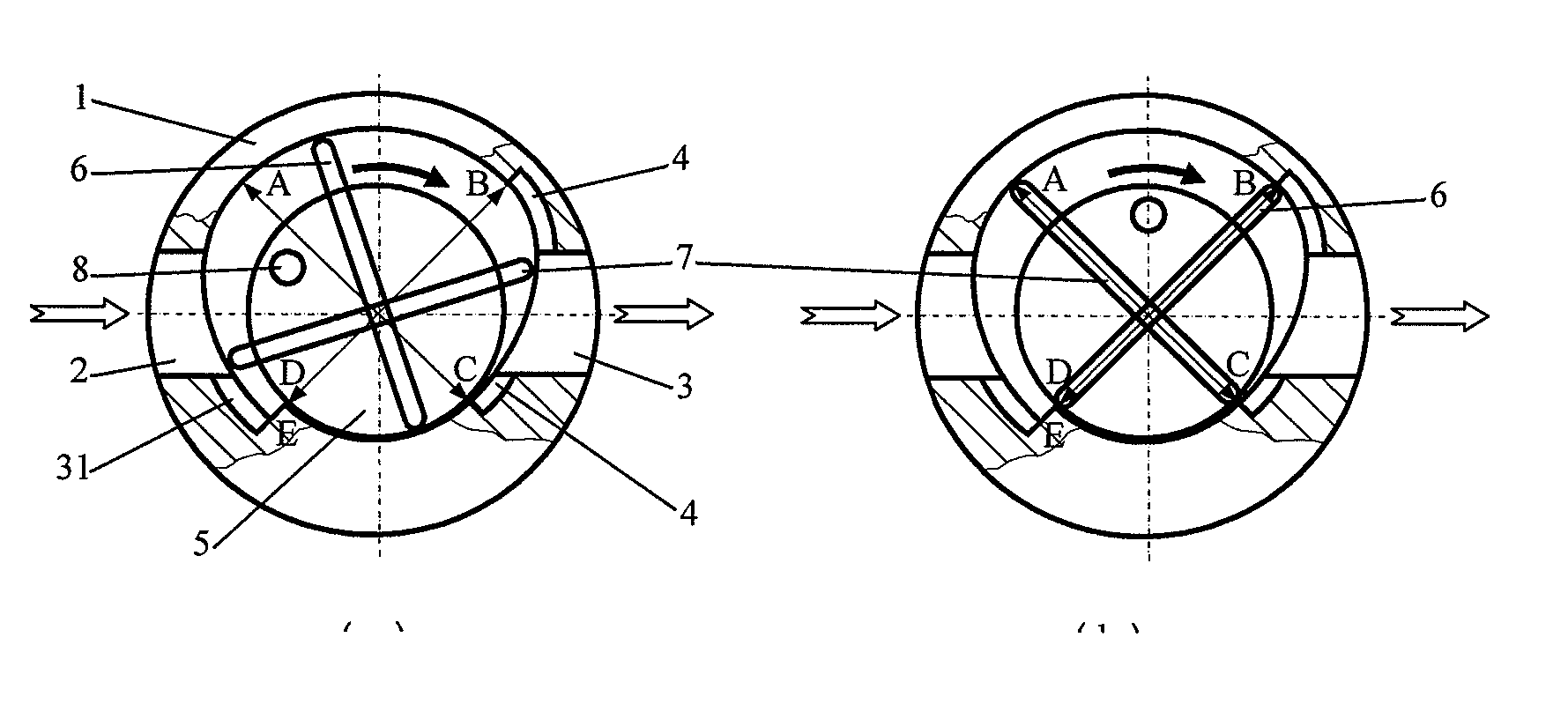

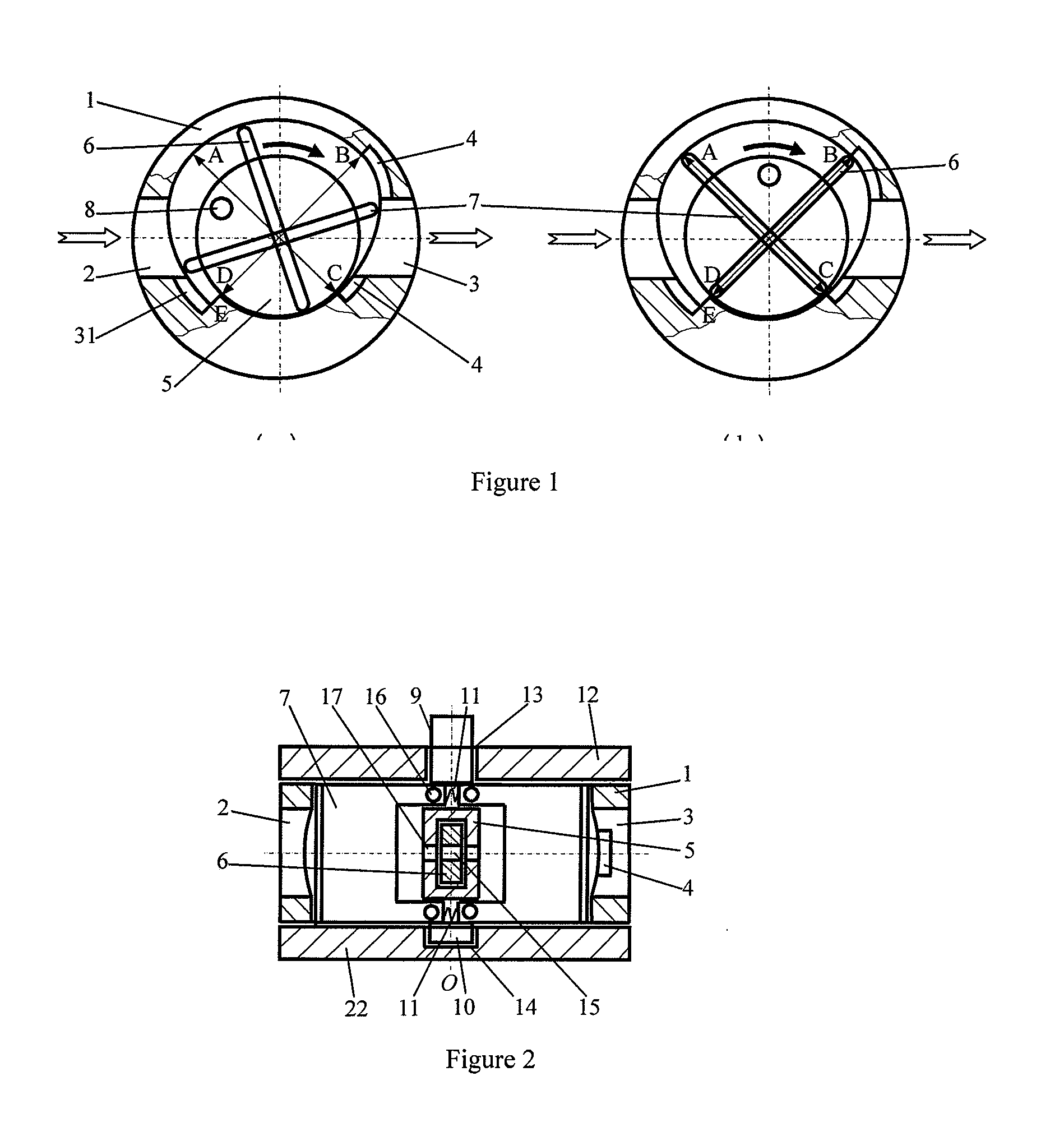

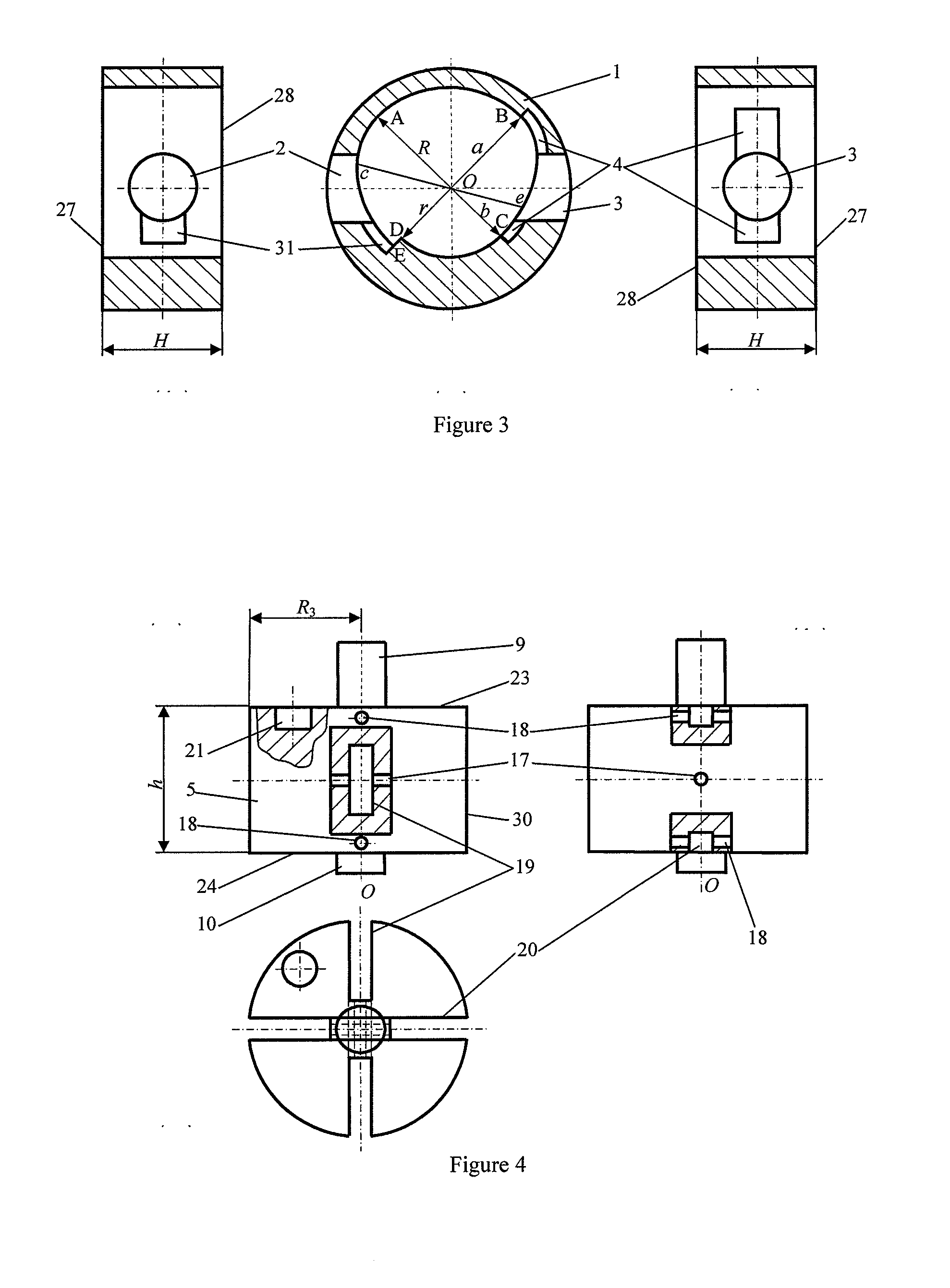

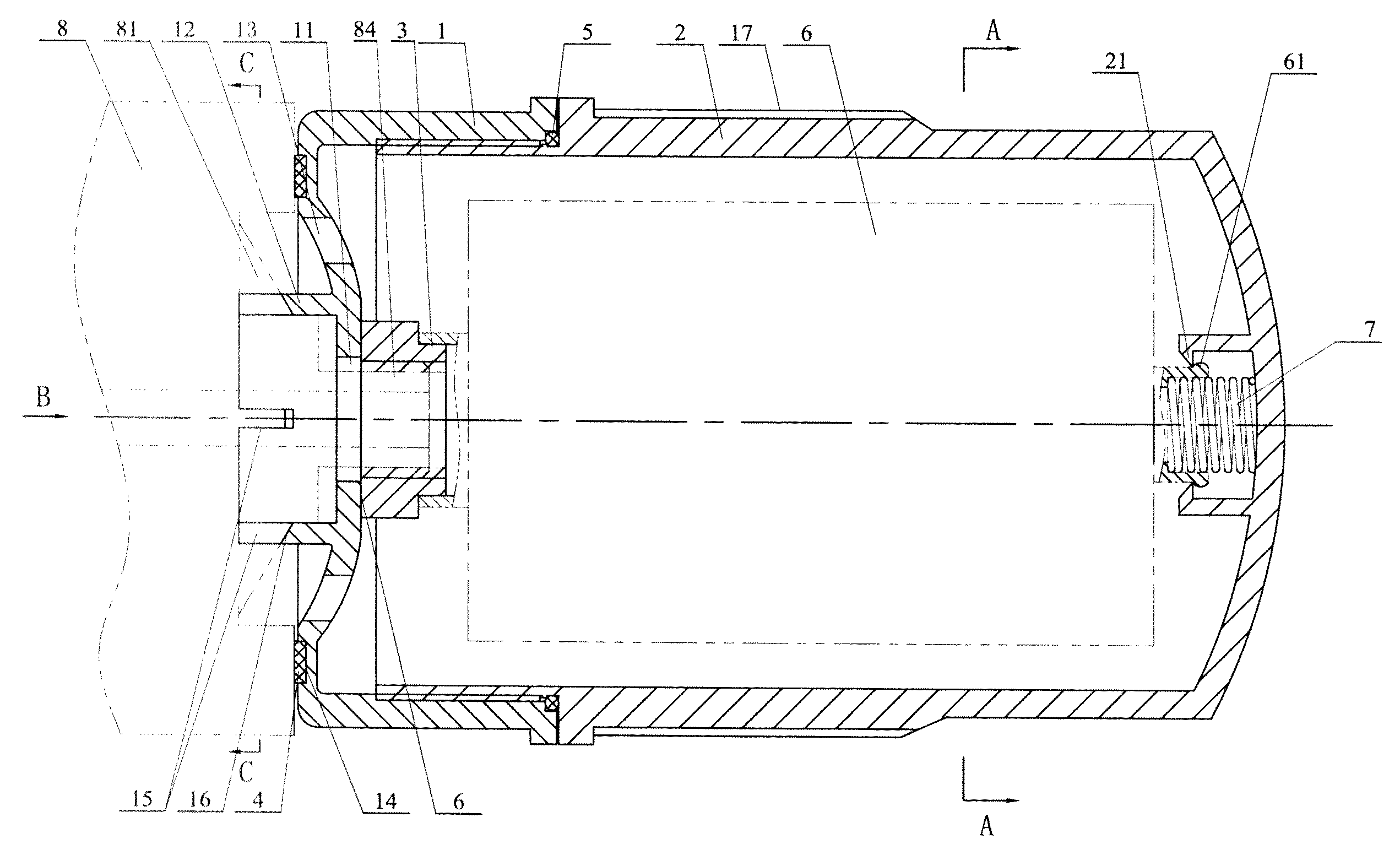

Metering pump with special-shaped cavity

InactiveUS20120164018A1Pressure increment is greatImprove pump efficiencyOscillating piston enginesRotary piston pumpsDrive shaftSlide plate

The invention discloses a metering pump with a special-shaped cavity, which comprises a housing, a rotor and two cover plates. The housing is a cylinder with a special-shaped surface inner cavity, an inlet and an outlet, and the special-shaped surface inner cavity is formed by combining a circular arc surface with a non-circular arc surface. The rotor comprises a rotor body and two pairs of combined sliding plates, wherein the rotor body is a column body processed with a transmission shaft, a centering shaft and crisscross guide grooves, and the combined sliding plates are mounted in the guide grooves. The cover plates are flat plates processed with bearing holes. The two end surfaces of the housing are matched with the cover plates for constituting a sealed cavity. In the sealed cavity, the rotor is matched with the bearing holes on the cover plates through the transmission shaft and the centering shaft. External driving force couple is acted on the transmission shaft so as to enable the rotor to rotate. When the rotor rotates, the non-circular arc surface of the special-shaped surface inner cavity can enable the two pairs of the combined sliding plates to slide in a cross manner so as to suck in fluid from the inlet and press out the fluid from the outlet. When the rotor rotates one cycle, four standard volumes are formed in a cavity body and the equal quantity of the fluid flows by the cavity body when the rotor rotates every one cycle. The flow rate of the fluid is metered by counting the number of rotation cycles of the rotor.

Owner:ZHEJIANG UNIV

Connector

ActiveUS9548556B2Reduced tightnessImprove performanceElectrically conductive connectionsCouplings bases/casesElectrical and Electronics engineering

A connector (C) has a terminal fitting (10) including a terminal connecting portion (11) to be connected to a mating terminal and barrels to be crimped to a wire (W). A housing (50) has a terminal accommodating chamber (57) that is configured to accommodate the terminal fitting (10). A sleeve (20) has an accommodation space (21) configured to accommodate the barrels crimped to the wire (W). A rubber plug (45) includes a center hole (46) and is configured so that the wire (W) extending back from a rear wall (24B) of the accommodation space (21) penetrates therethrough in a sealed state. A rear holder (60) obstructs rearward movement of the terminal fitting (10) via the sleeve (20). A center position (P2) of the center hole (46) is displaced toward a rear bottom plate (19B) from a center position (P1) of the terminal connecting portion (11).

Owner:SUMITOMO WIRING SYST LTD

Spark plug

A spark plug includes a center electrode, an insulator, a metallic shell, and a seal member for providing a seal between the insulator and the metallic shell. The insulator includes a first portion, a second portion located axially forward of the first portion and being smaller than the first portion, and an insulator first-diameter-reducing-portion whose outside diameter reduces forward and which connects the first portion and the second portion. The metallic shell includes a protrusion that includes a metallic shell diameter-reducing-portion whose inside diameter reduces forward. The seal member is disposed between the insulator first-diameter-reducing-portion and the metallic shell diameter-reducing-portion. A relationship θ21>θ22 is satisfied, where the angle θ21 is an angle between a straight line orthogonal to the axial line and the outline of the metallic shell diameter-reducing-portion, and the angle θ22 is an angle between the straight line and an outline of the insulator first-diameter-reducing-portion.

Owner:NGK SPARK PLUG CO LTD

Explosion-proof high temperature compatible, multi-vortex flow meter

InactiveUS7861602B2Easy to performSealing performanceVolume/mass flow by thermal effectsVolume/mass flow by dynamic fluid flow effectHeating temperatureTemperature sensitive

A temperature-sensitive sensor (21) and a heating temperature-sensitive sensor (22) are fixed in position in a liquid-tight fashion by welding, with the metal tubular bodies (36 and 37) being inserted into the tubular body insertion holes (19 and 20) of a vortex detector (4). Sealing performance is secured without using any O-ring. The temperature-sensitive sensor (21) and the heating temperature-sensitive sensor (22) respectively have lead wires (42 and 43) held together with the lead wires (27) of a vortex detection sensor (11) within the internal space (35), and the lead wires (27, 42, and 43) thus held together are led out toward the flow rate converter (not shown) via a metal pipe (34). Since the lead wires (27, 42, and 43) are held together within the internal space (35) and led out toward the flow rate converter via the metal pipe (34), there is involved only one joint portion between the sensors and the flow rate converter. With this structure, explosion-proof performance can be attained easily.

Owner:OVAL CORP

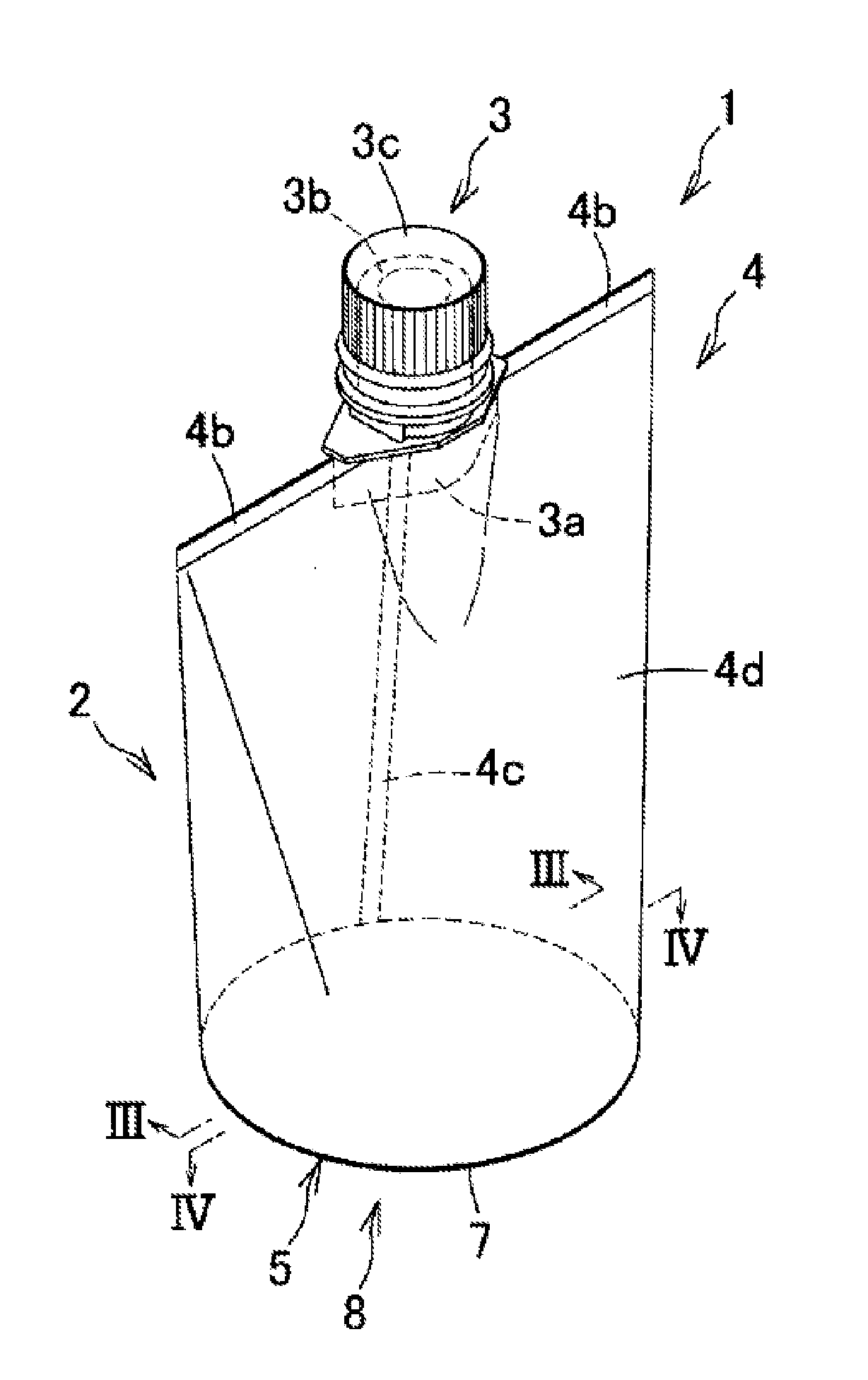

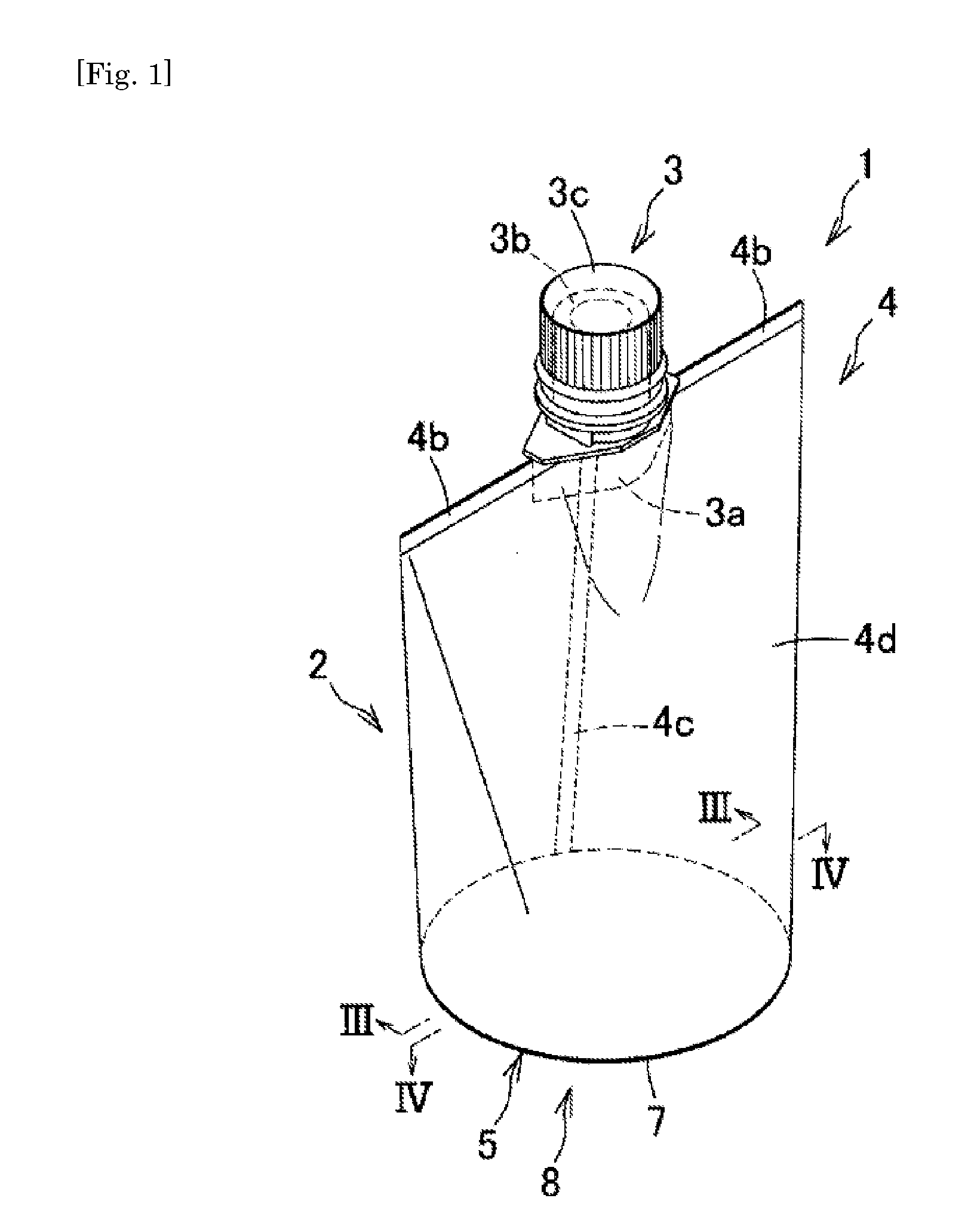

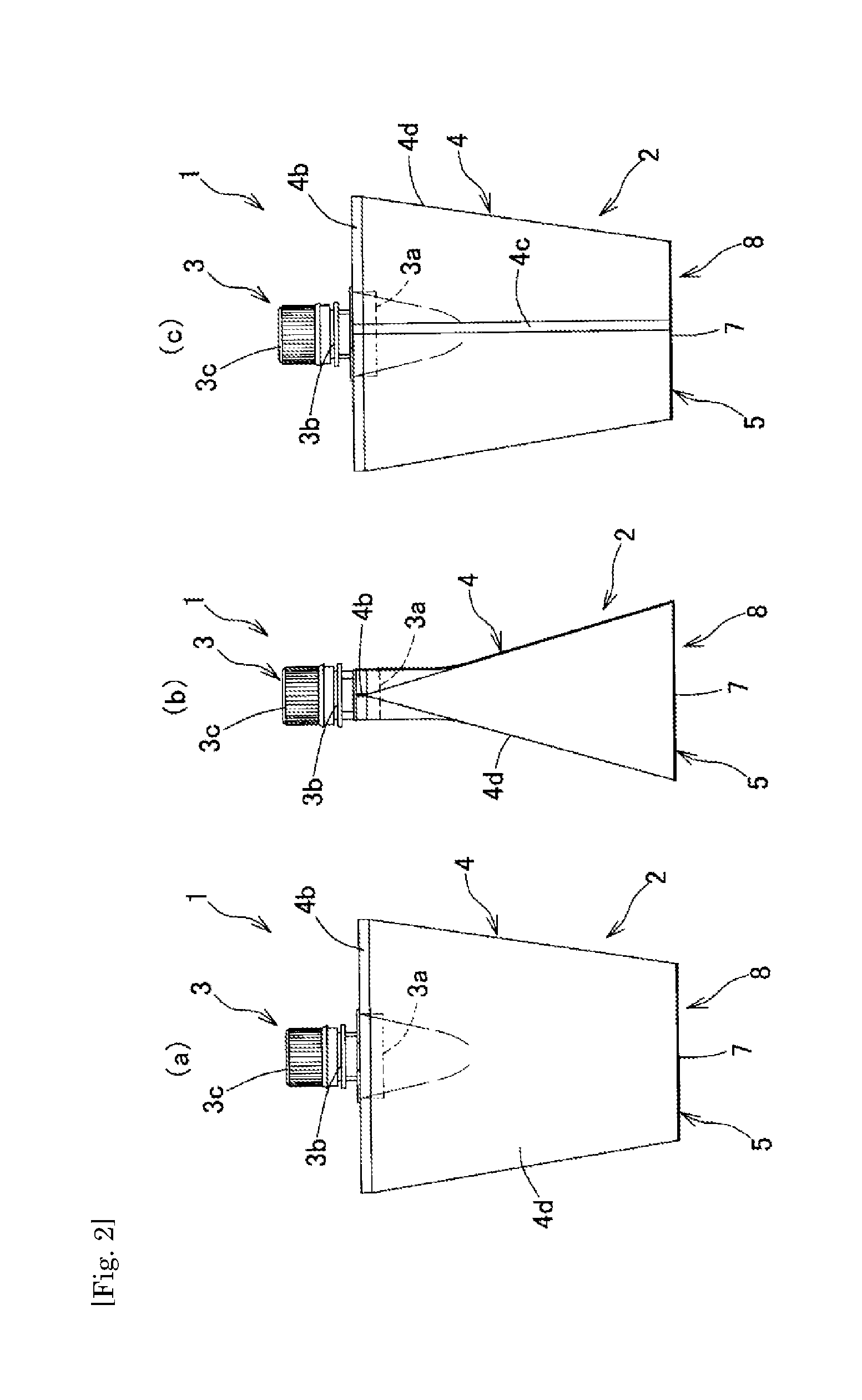

Pouch container

InactiveUS20150284145A1Improve self-standing stabilityImprove shape retention propertyEnvelopes/bags making machineryBag making operationsThin membraneMechanical engineering

The invention provides a pouch container which is excellent in a design property as well as being excellent in a self-standing stability and a shape retention property, can be volume-reduced, can prevent an adhesive agent from seeping into the content even in the case of using a multilayer film material employing the adhesive agent, and can sufficiently secure a sealing performance between the body side end part joint portion and a closing member. In a self-standing pouch container (1) provided with a body member (4) which is made of a film material, and a lower end closing member (5) which closes one end opening portion of the body member (4) in a liquid tight manner and is made of a film material, an annular body side end part joint portion (4a) is formed in one end portion of the body member (4) by being bent inside, and an inside member (6) and an outside member (7) are provided as the lower end closing member (5), the inside member (6) being fusion bonded to an inner surface side of the container in the body side end part joint portion (4a) and the outside member (7) being fusion bonded to an outer surface side of the container.

Owner:NIHON YAMAMURA GLASS CO LTD

Rotating fluid machine

InactiveUS7367783B2Prevent leakageGood followabilityFlexible member pumpsPiston pumpsRotary valveHigh pressure

A rotary valve for switching supply passages, and discharge passages of high-temperature and high-pressure steam for a rotor rotatably supported at a casing is constructed by making a fixed side valve plate and a movable side valve plate abut to each other on a slide surface. A pressure chamber into which the high-temperature and high-pressure steam is introduced from the supply passage is opened to a mating surface of a valve body portion with the fixed side valve plate. The fixed side valve plate supported to float is pressed against the movable side valve plate with a pressing load generating in the pressure chamber to bring it into close contact with the slide surface. Leakage of the high-temperature and high-pressure steam from the pressure chamber is prevented by placing a V-packing inside the pressure chamber.

Owner:HONDA MOTOR CO LTD

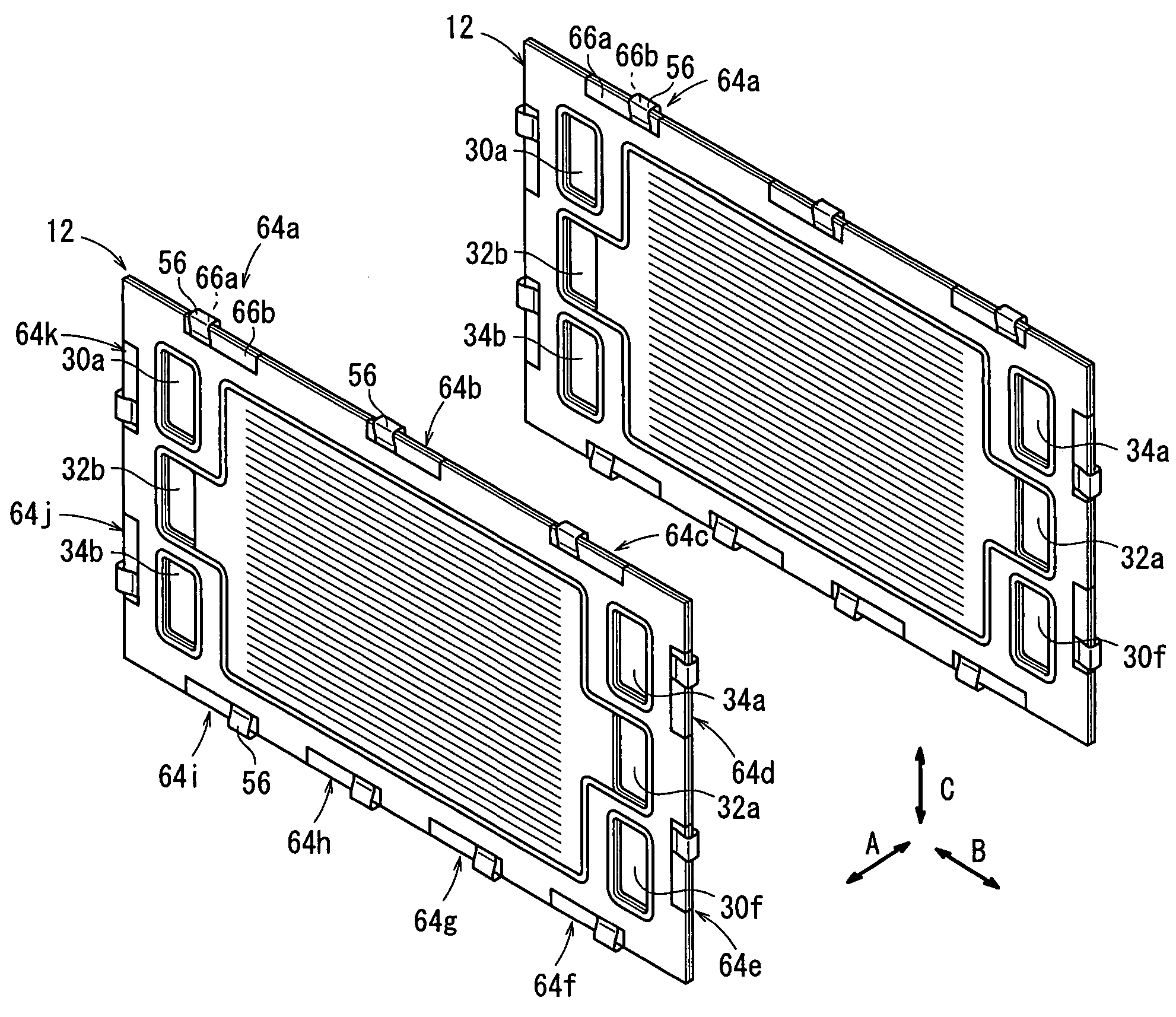

Fuel cell

InactiveUS7323269B2Easy to assembleSimple and compact structureFuel cells groupingCell component detailsFuel cellsEngineering

A fuel cell includes a plurality of metal clip members for holding outer regions of first and second metal separators at a plurality of positions. Each of the metal clip member includes a side plate and first and second holding portions. The side plate is curved at opposite ends, and the first and second holding portions are extending from the opposite ends of the side plate. The first and second holding portions generates a predetermined elastic force for holding the first and second metal separators. The outer ends of the first and second metal separators are covered by insulating sections, and the insulating sections are held between the first and second holding portions so that the entire unit cell is tightened by the predetermined elastic force.

Owner:HONDA MOTOR CO LTD

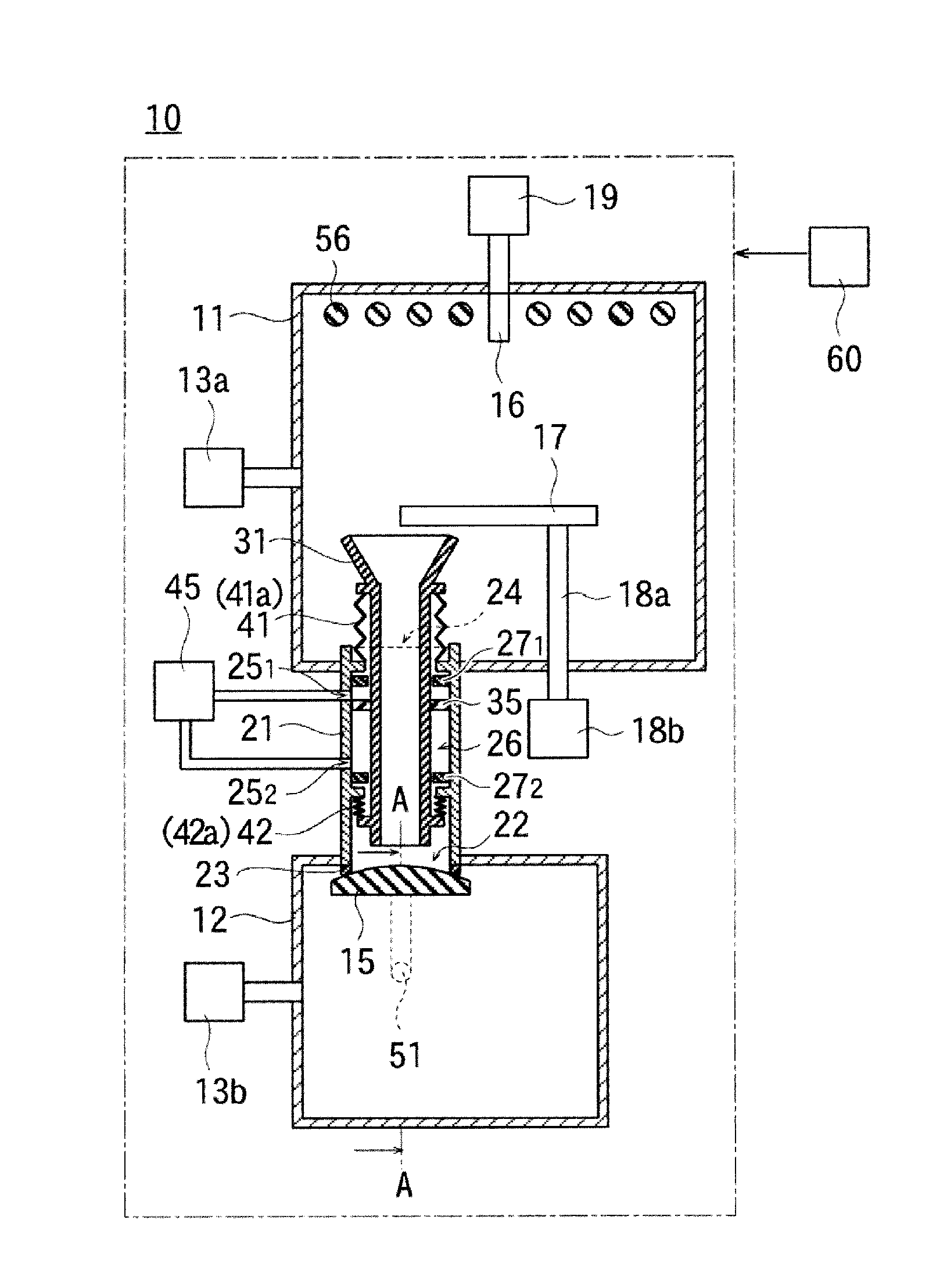

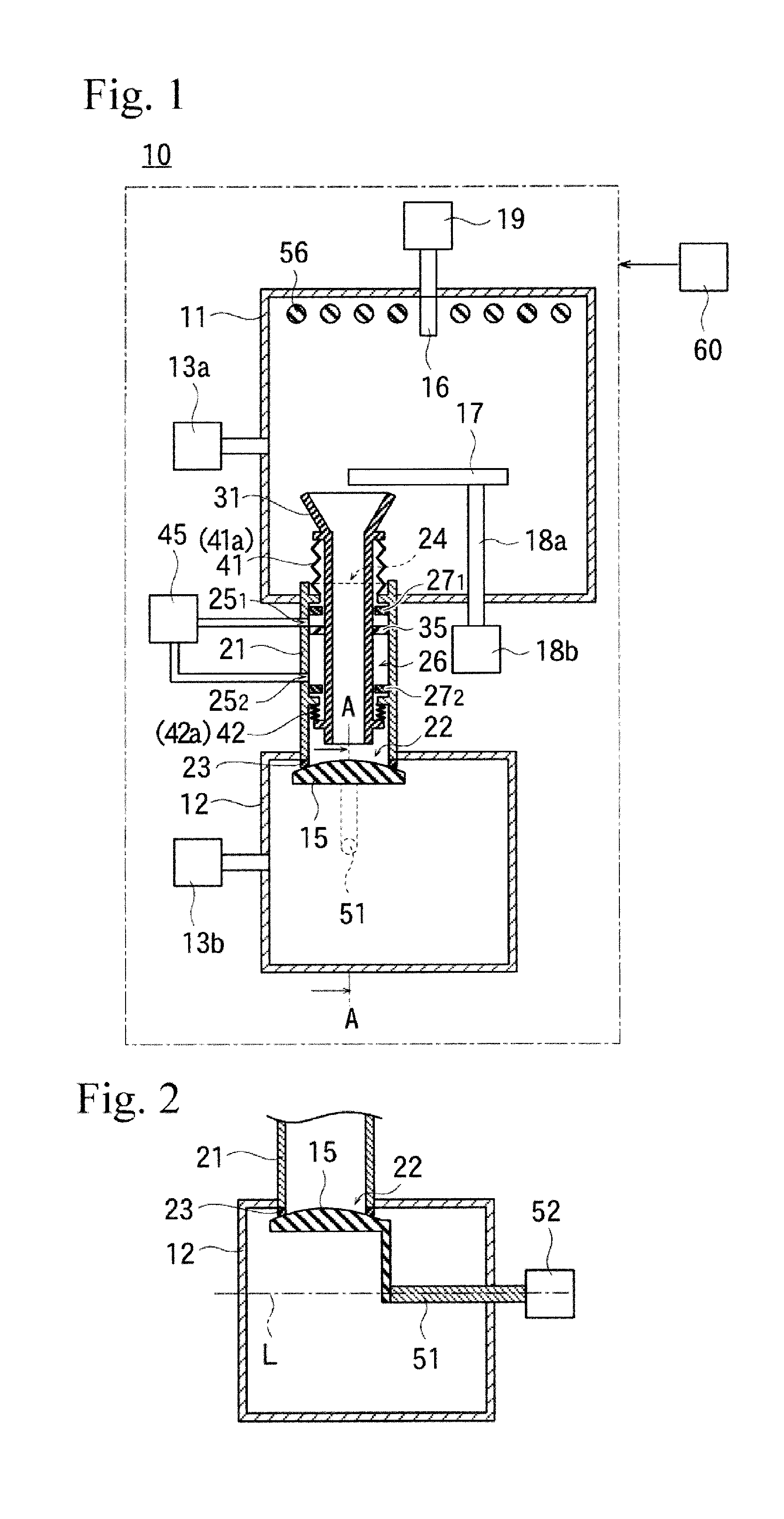

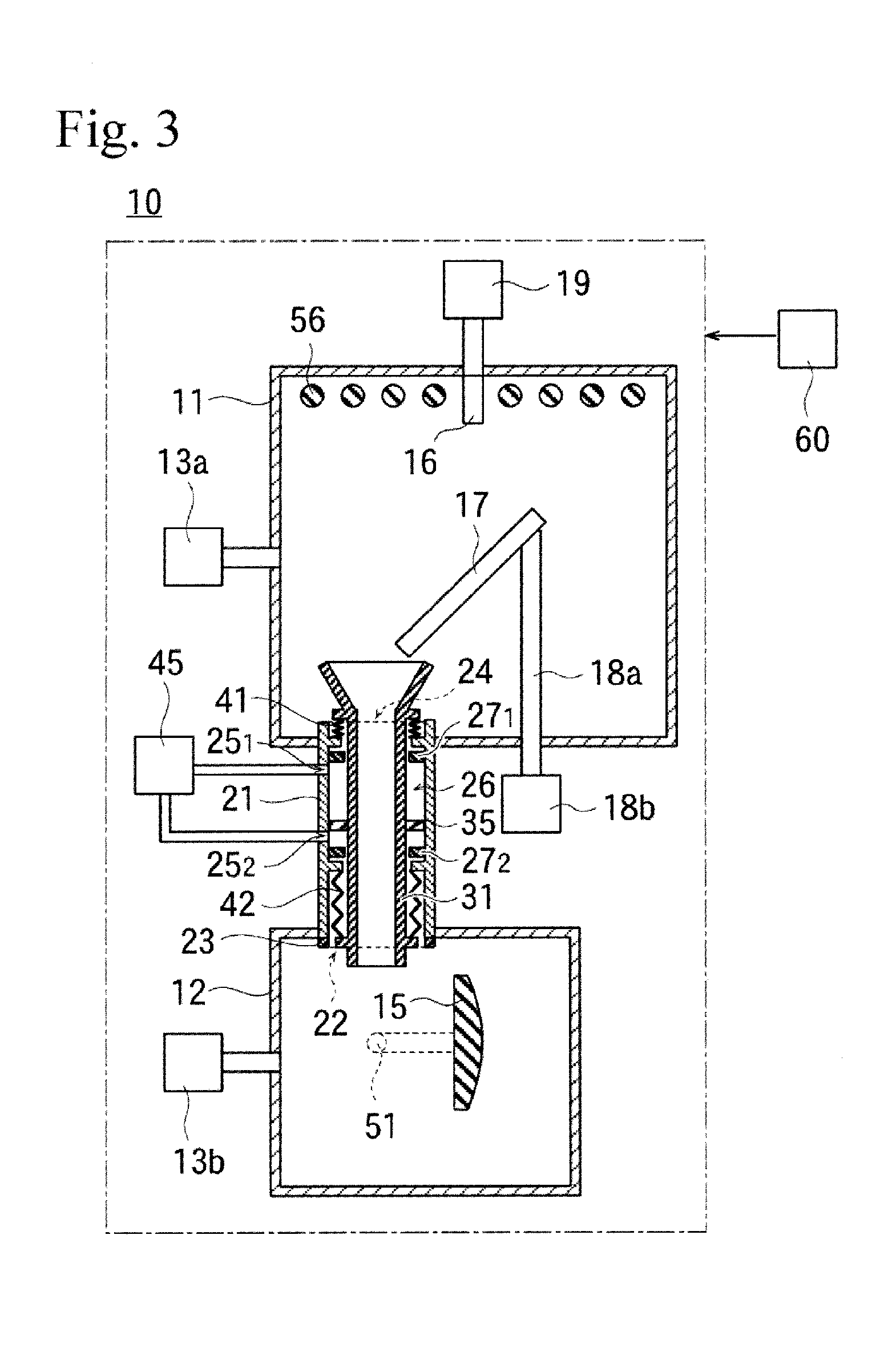

Vacuum freeze-drying apparatus and frozen particle manufacturing method

ActiveUS20130239430A1Sealing performanceEasy to collectDrying solid materials without heatFood preservationFreeze-dryingEngineering

A technology for protecting a valve seat inside a collection tank from the adherence of frozen particles in a vacuum freeze-drying apparatus and a frozen particle manufacturing method. The inside of a vacuum tank and a collection tank are vacuum evacuated; a raw material liquid is injected into the vacuum tank to produce frozen particles; and the frozen particles are piled up on a surface of a heating / cooling shelf. When the frozen particles on the heating / cooling shelf are transferred into the collection tank through the inside of an auxiliary pipe, the frozen particles do not adhere to a valve seat which surrounds an opening of a main pipe inside the collection tank.

Owner:ULVAC INC

Oil filter housing

ActiveUS7544295B2Easy to operateSealing performanceCartridge filtersLubricant mounting/connectionEngineeringMechanical engineering

The present invention discloses an oil filter housing, comprising an upper bowl adapted to be mounted onto a filter-mounting base of an engine, a top end of the upper bowl being formed with oil inlets and an oil outlet, and a protruding structure being provided on an outer top end surface of the upper bowl, the protruding structure adapted to be engaged with the filter-mounting base so as to position the upper bowl and limit rotation of the upper bowl relative to the filter-mounting base; and a lower bowl detachably coupled to the upper bowl and a bottom end of the lower bowl being closed. The oil filter housing according to an embodiment of the present invention is simple in structure, low in cost, easy to operation and safe.

Owner:BEIJING SZYN TECH

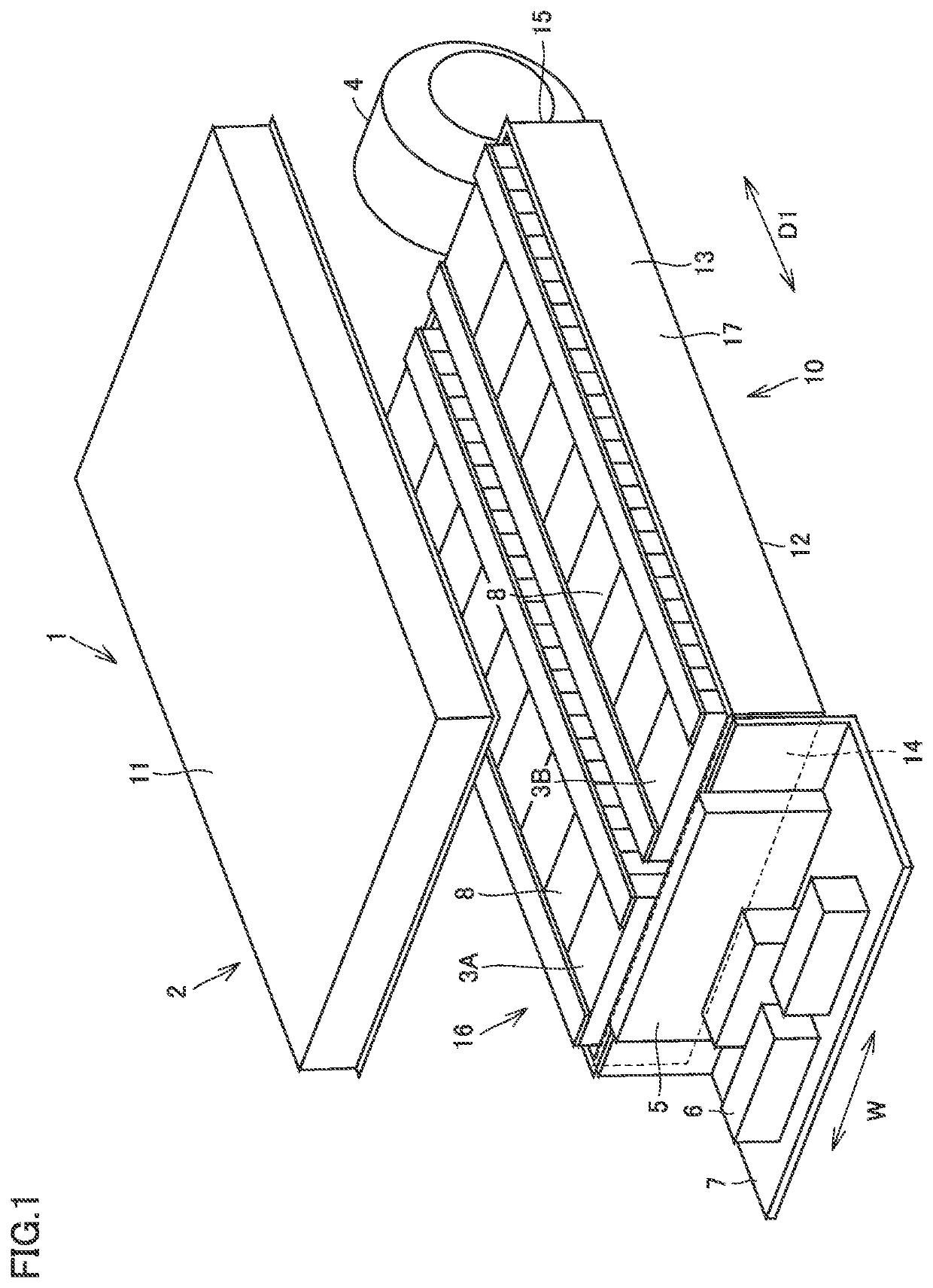

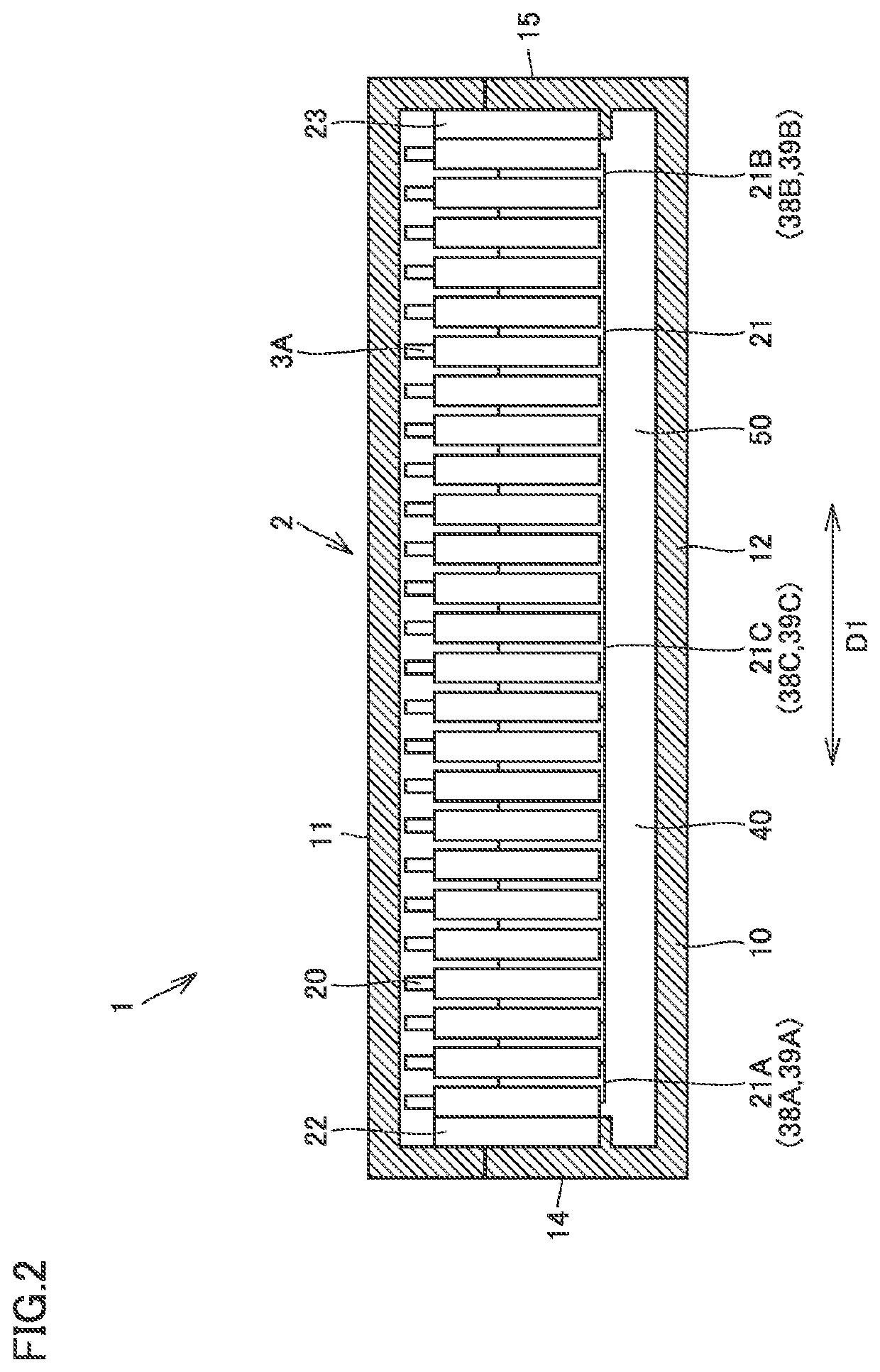

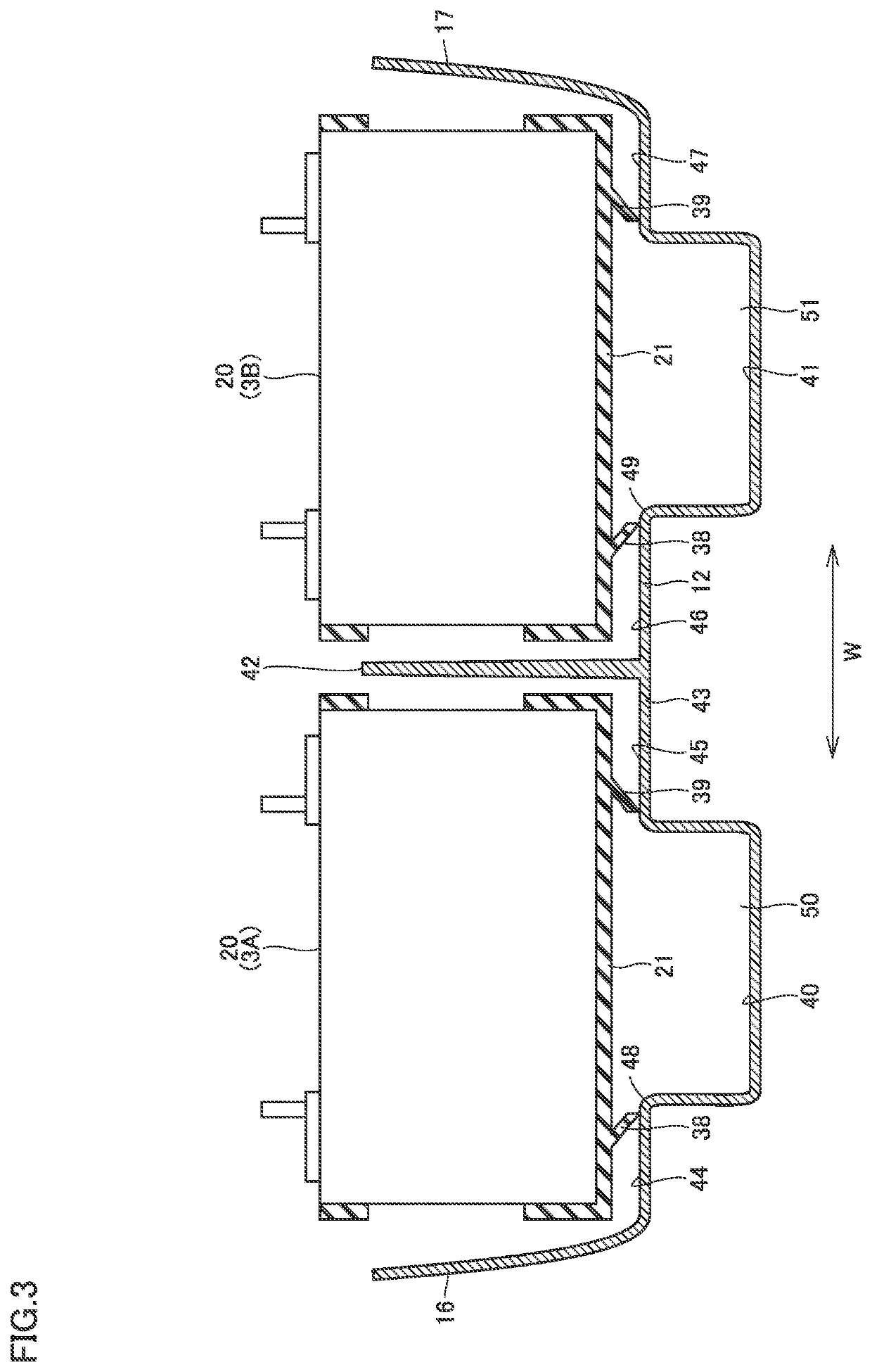

Power storage device

PendingUS20220006149A1Seal performance be improveSuppress gapBattery isolationSecondary cellsPower storageStructural engineering

A power storage device includes: a housing case; a power storage module including a plurality of power storage cells disposed inside the housing case; and a plurality of resin frames each disposed between the plurality of power storage cells. A contact piece is formed on each of the resin frames. The contact piece is in contact with an inner circumferential surface of the housing case and elastically deforms.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com