Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

268results about How to "Ensure sealing performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

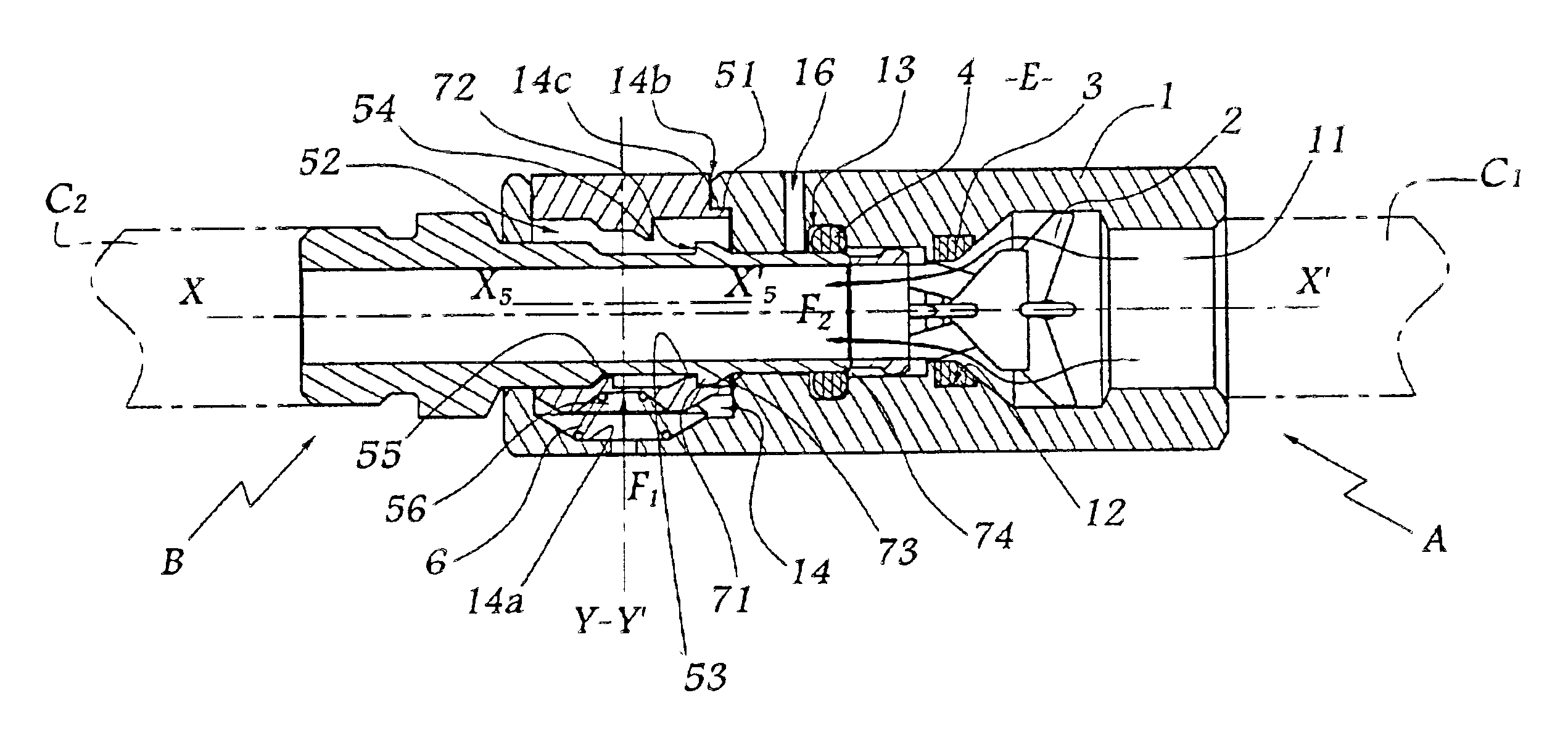

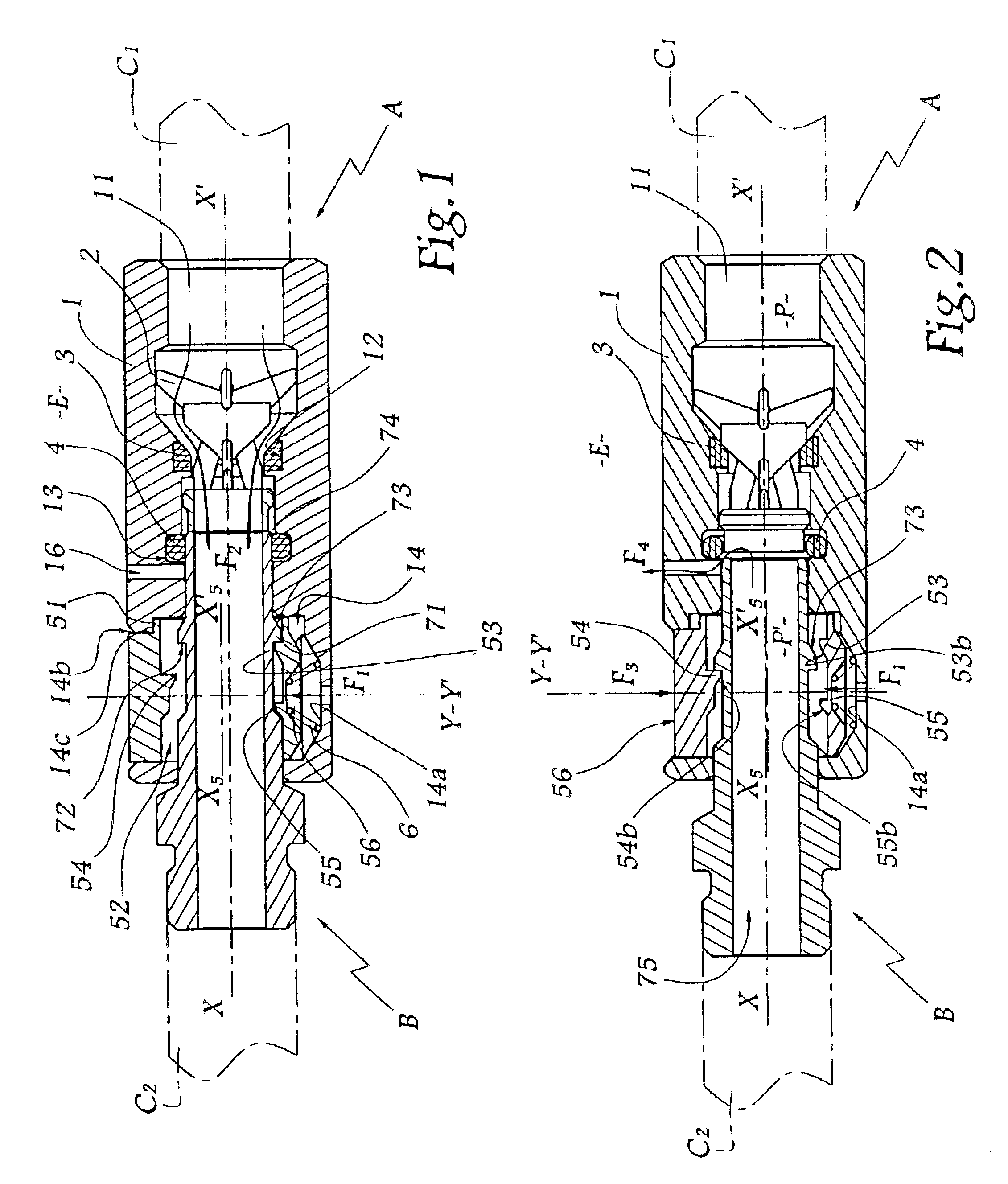

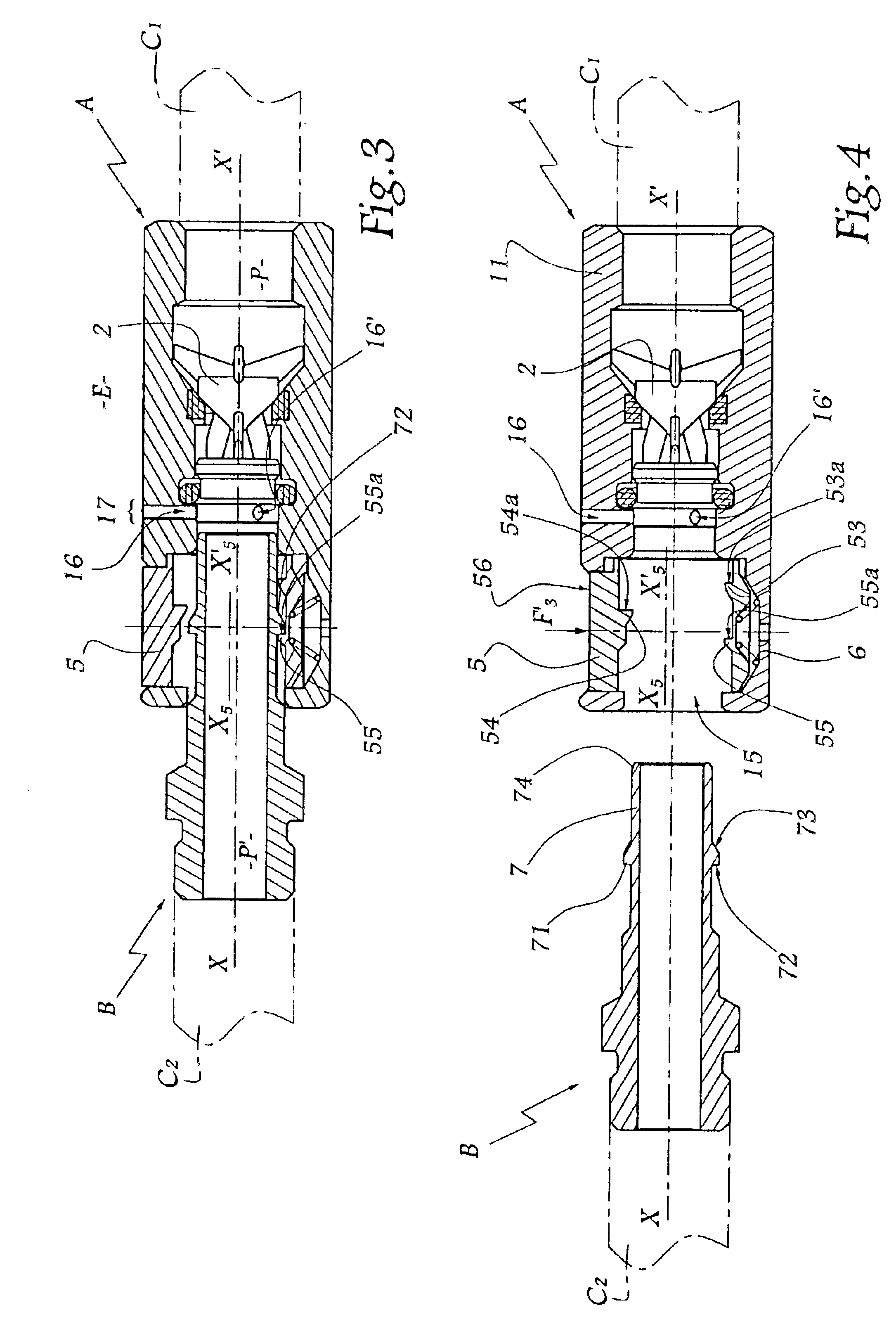

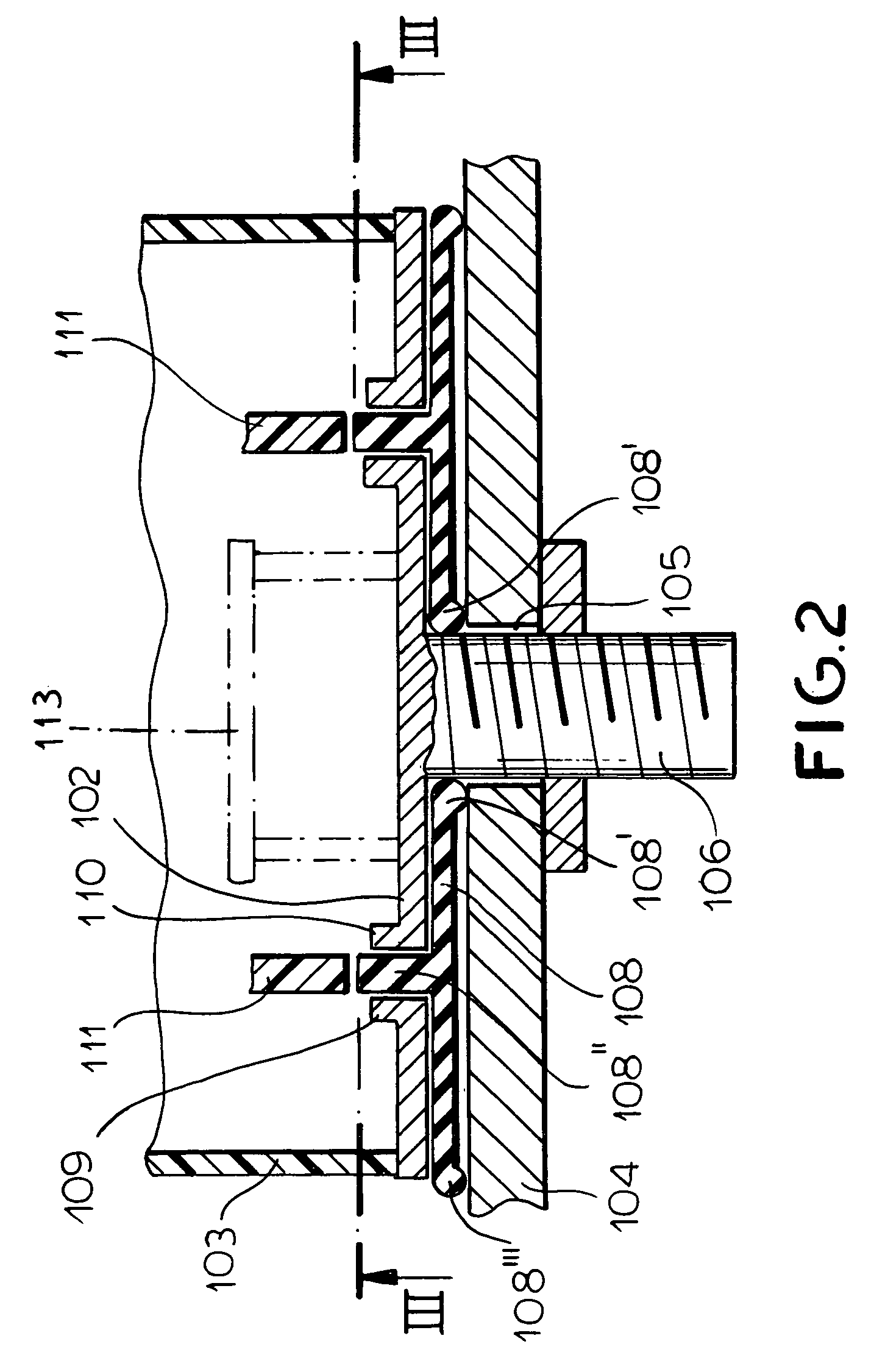

Quick connection for the removable join of pipes

InactiveUS6840548B2Easy to moveEnsure sealing performanceValve arrangementsPipe elementsMechanical engineeringEngineering

A quick connect coupling for joining two pipes which includes a male and a female element adapted to fit axially in each other. A body of the female element is equipped with a resiliently urged bolt mounted to slide in the body and provided with a central opening for receiving the male element. A wall of the opening is equipped with three teeth offset with respect to one another along a median axis of the opening. The male element is provided with a shoulder adapted to rest selectively against one of the teeth. When the male element rests against an intermediate tooth, a the downstream pipe is placed in communication with ambient atmosphere.

Owner:STAUBLI FAVERGES SA

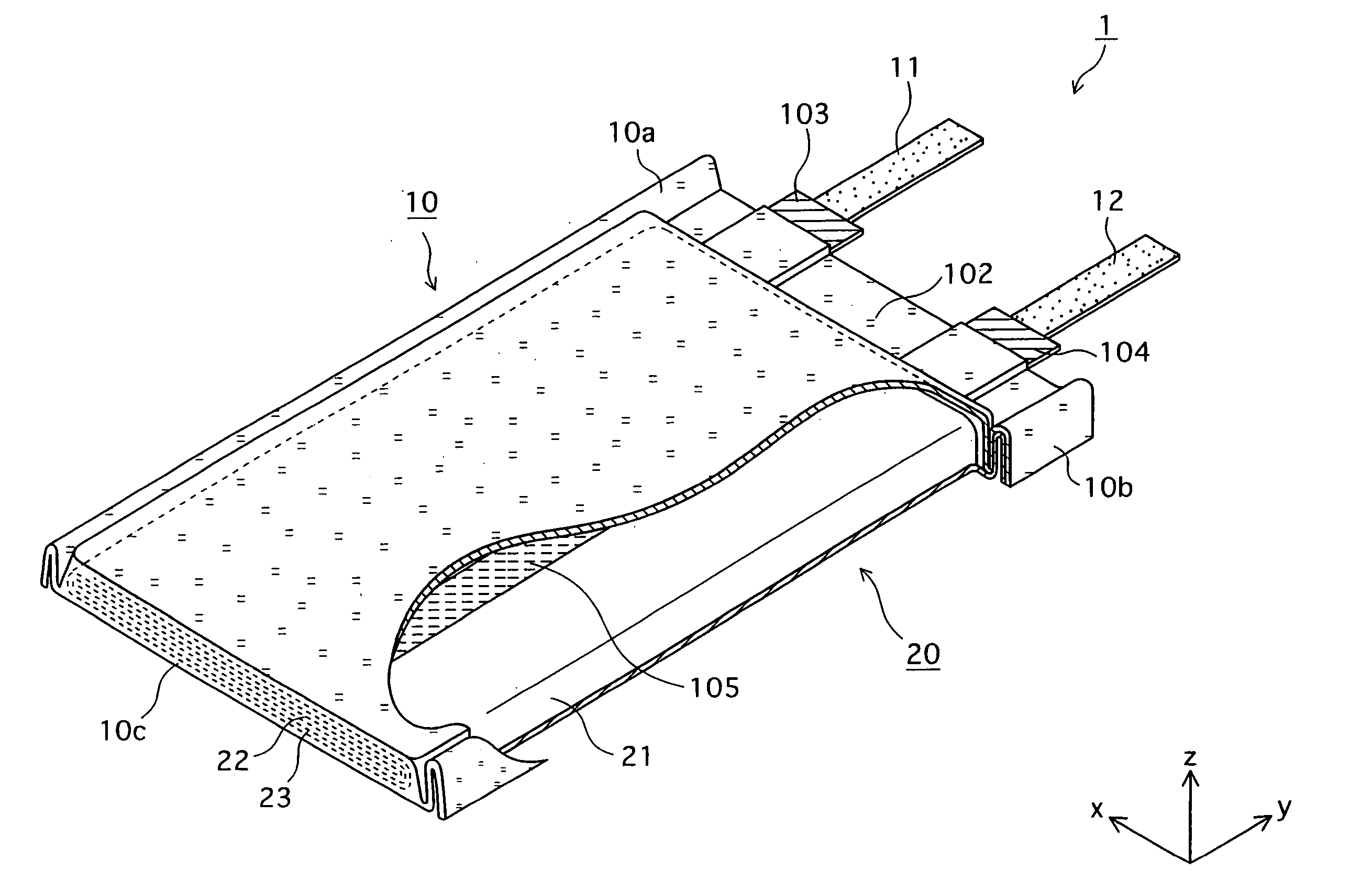

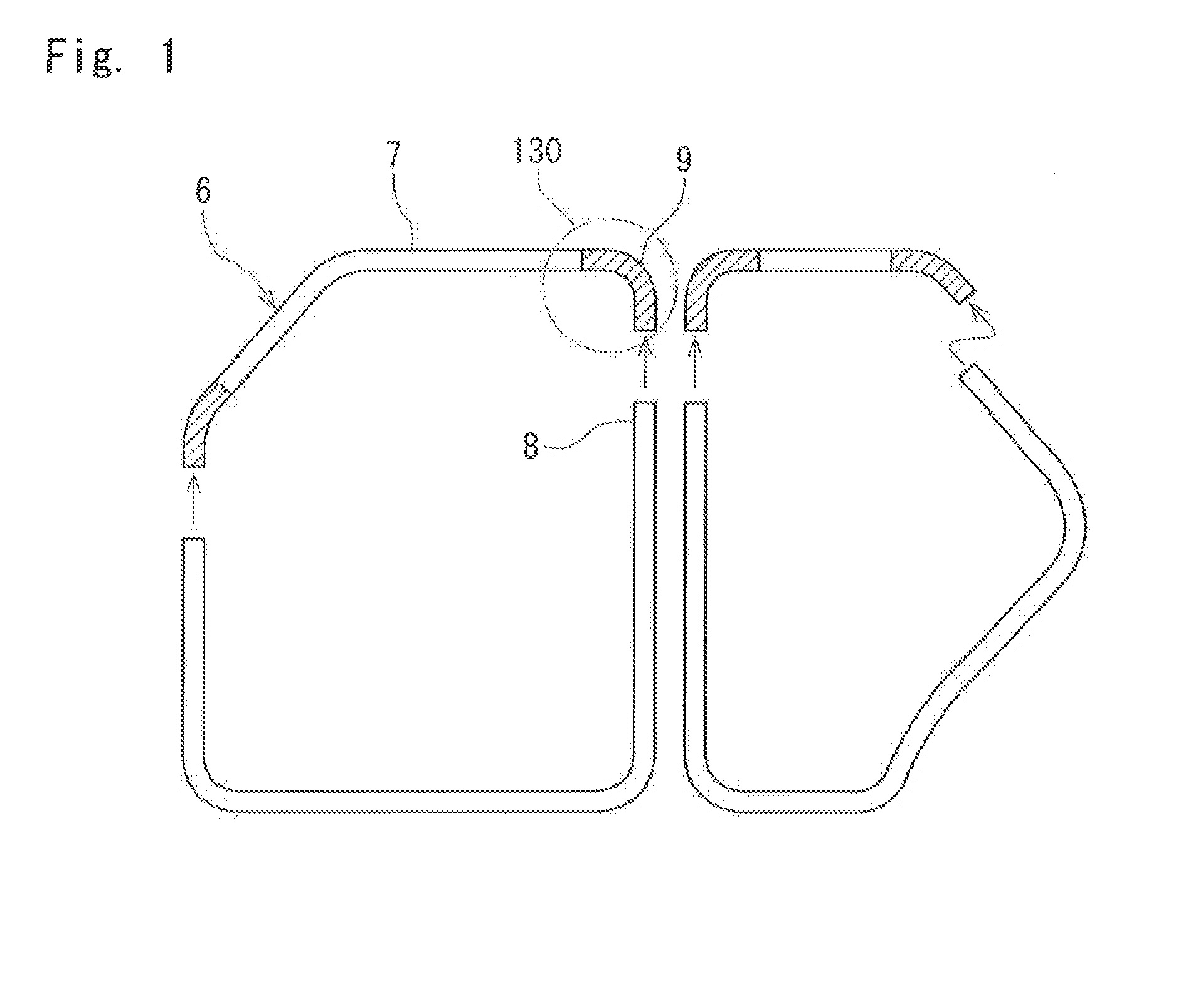

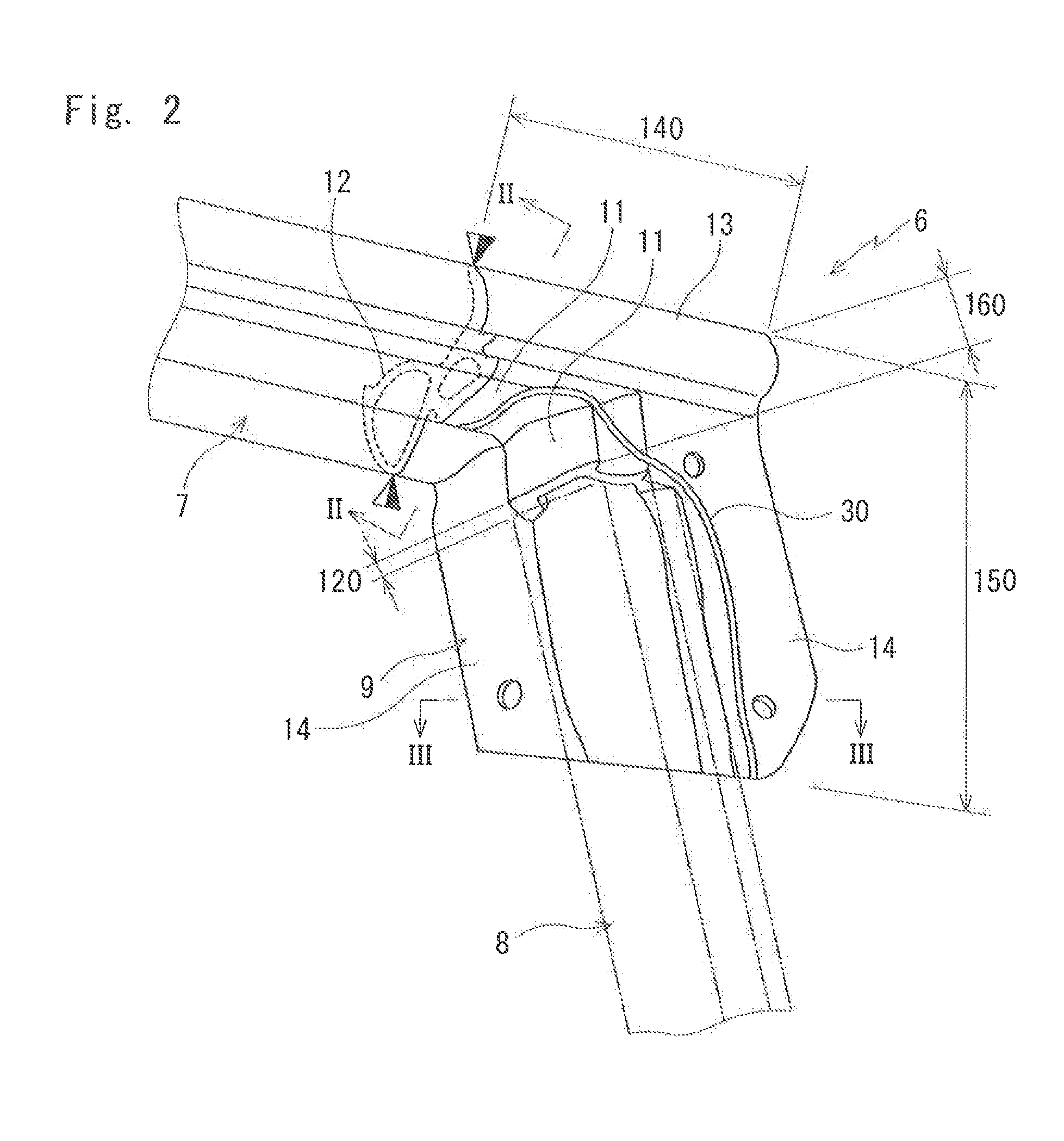

Battery

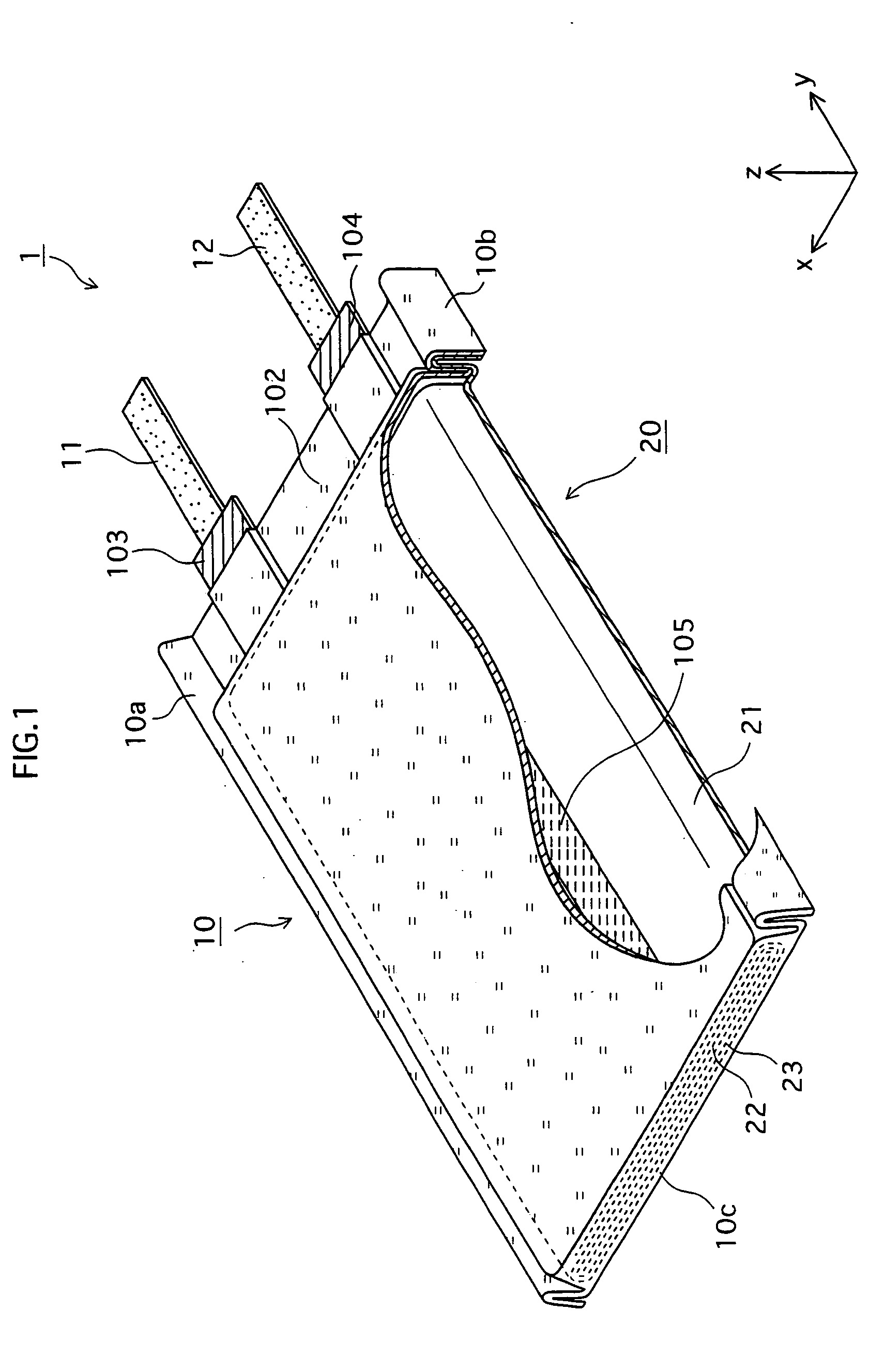

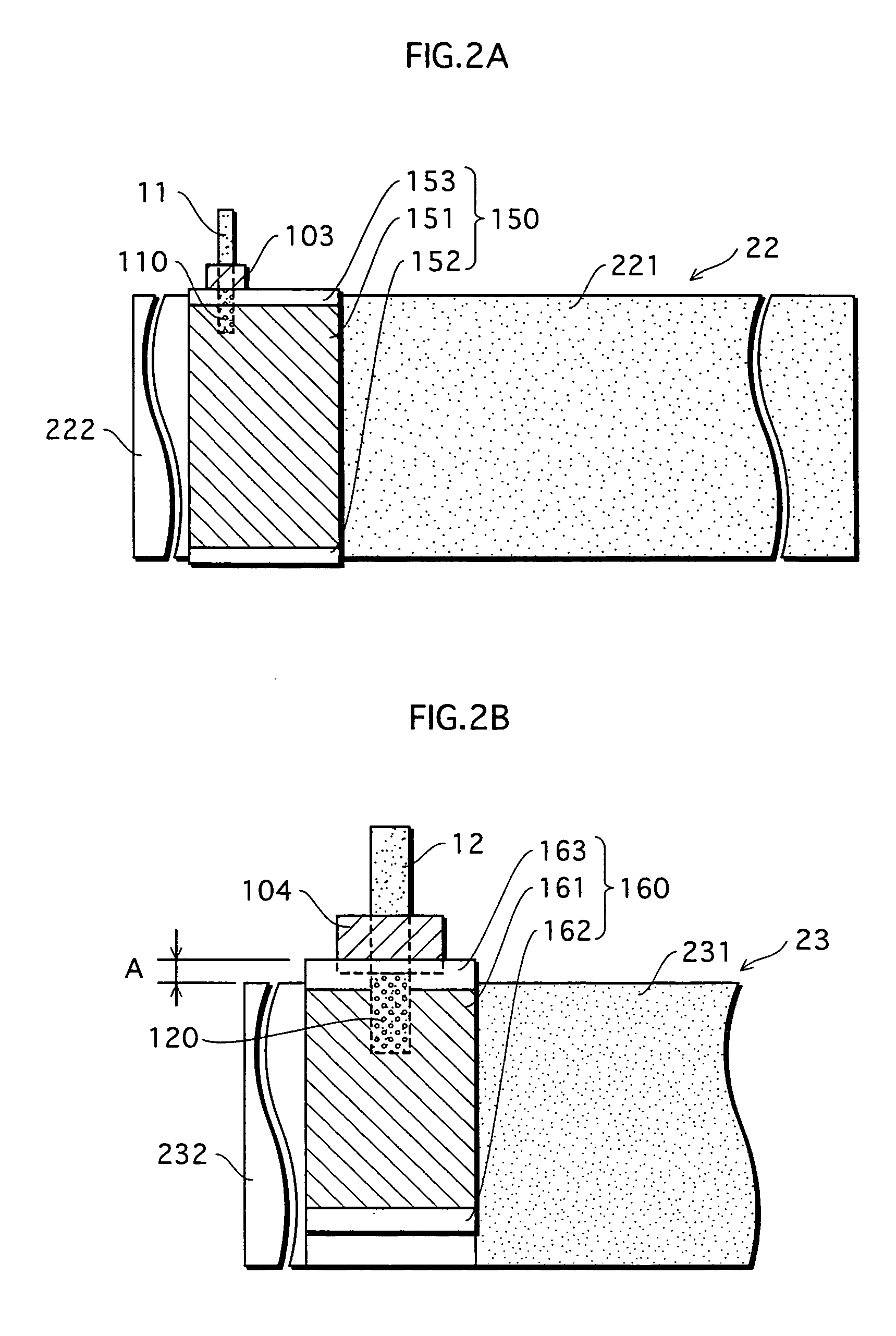

InactiveUS20060046137A1Improve heat resistancePrevent unnecessary shrinkCell seperators/membranes/diaphragms/spacersFinal product manufactureEngineeringElectrical and Electronics engineering

Provided is a battery such as a laminated battery, which has a favorable battery performance by being endowed with heat resistance. In the laminated battery 1, tab resins 103, 104, securing tape 105, protection tape 150, and protection tape 160 are made of cast polyolefin having heat resistance.

Owner:SANYO ELECTRIC CO LTD

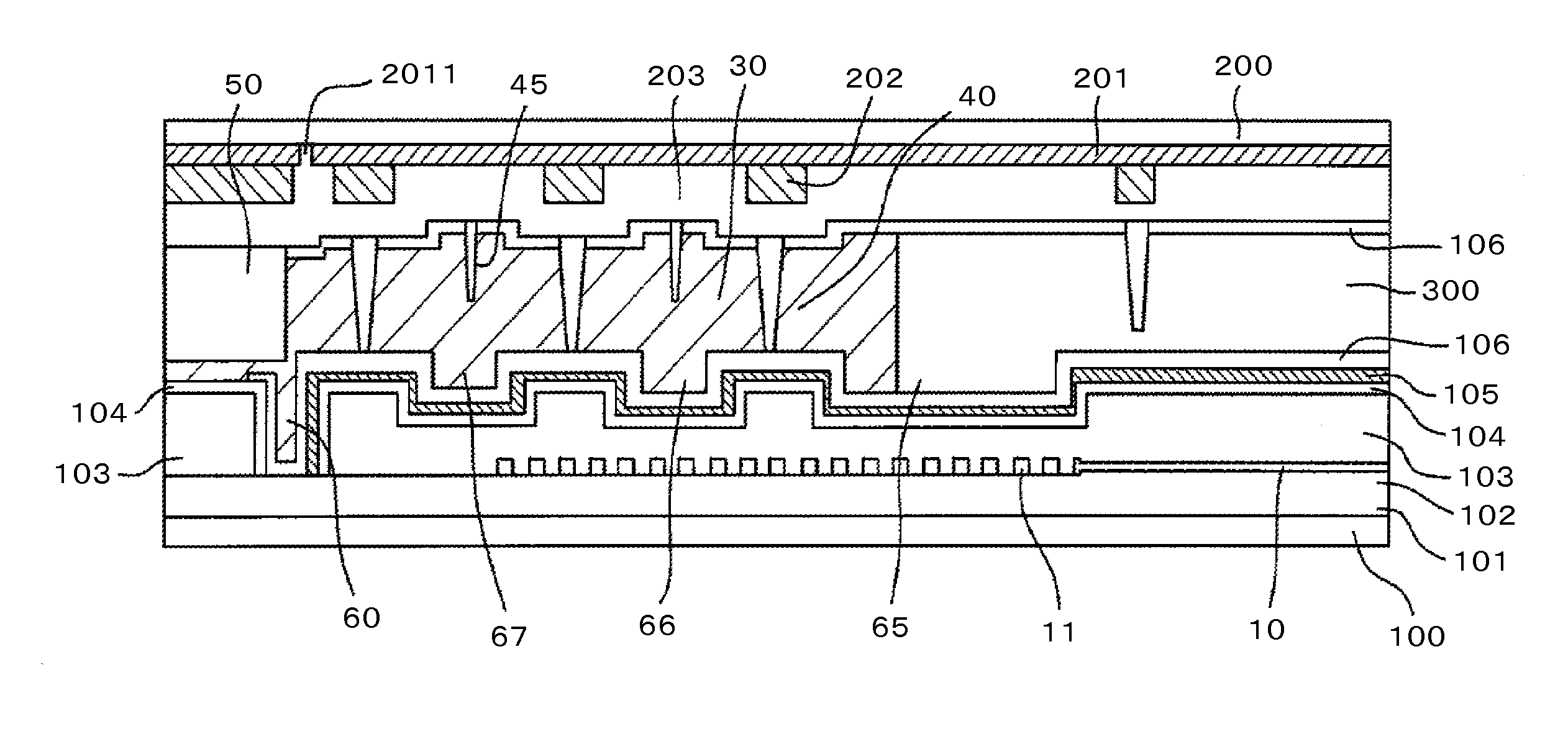

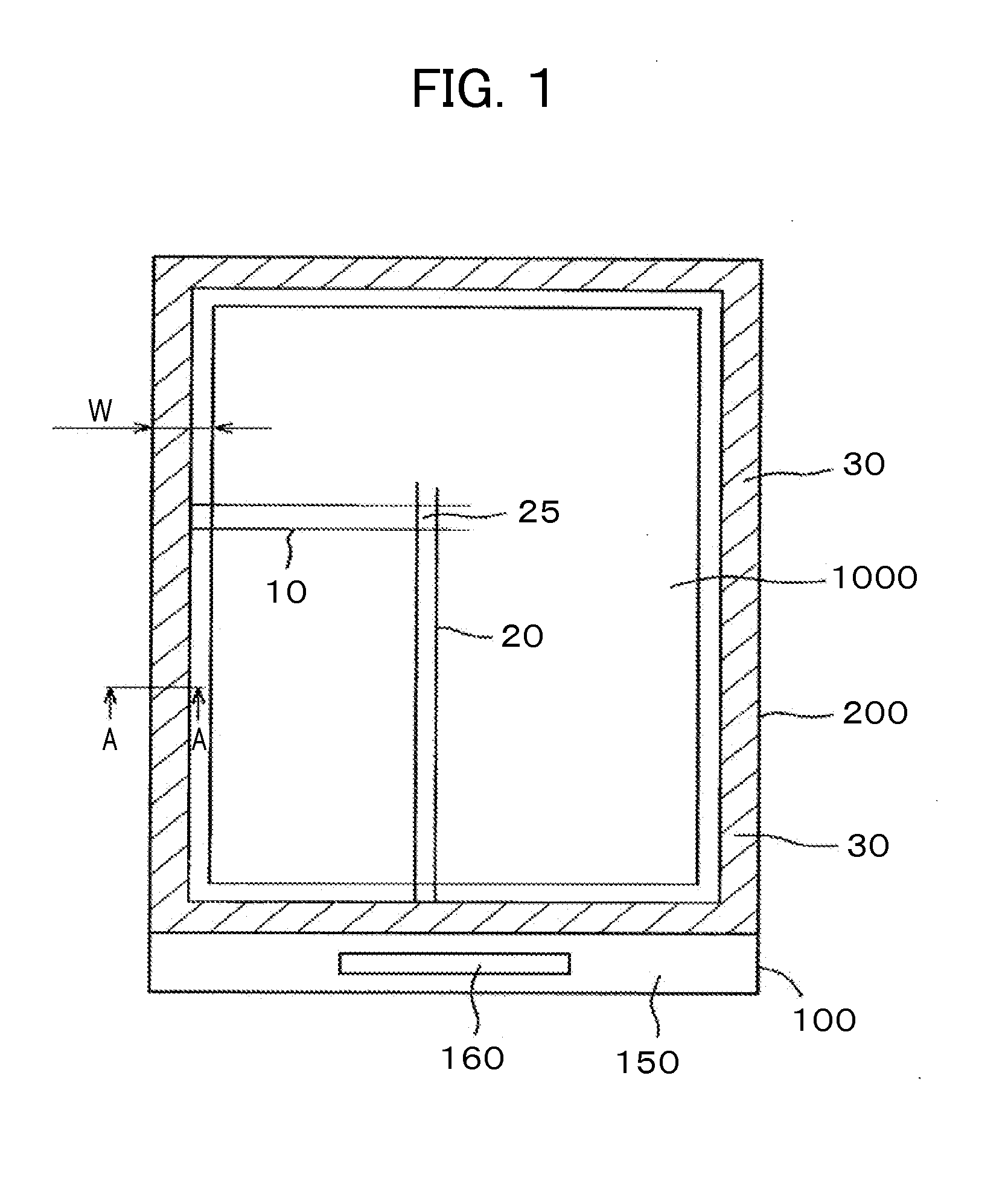

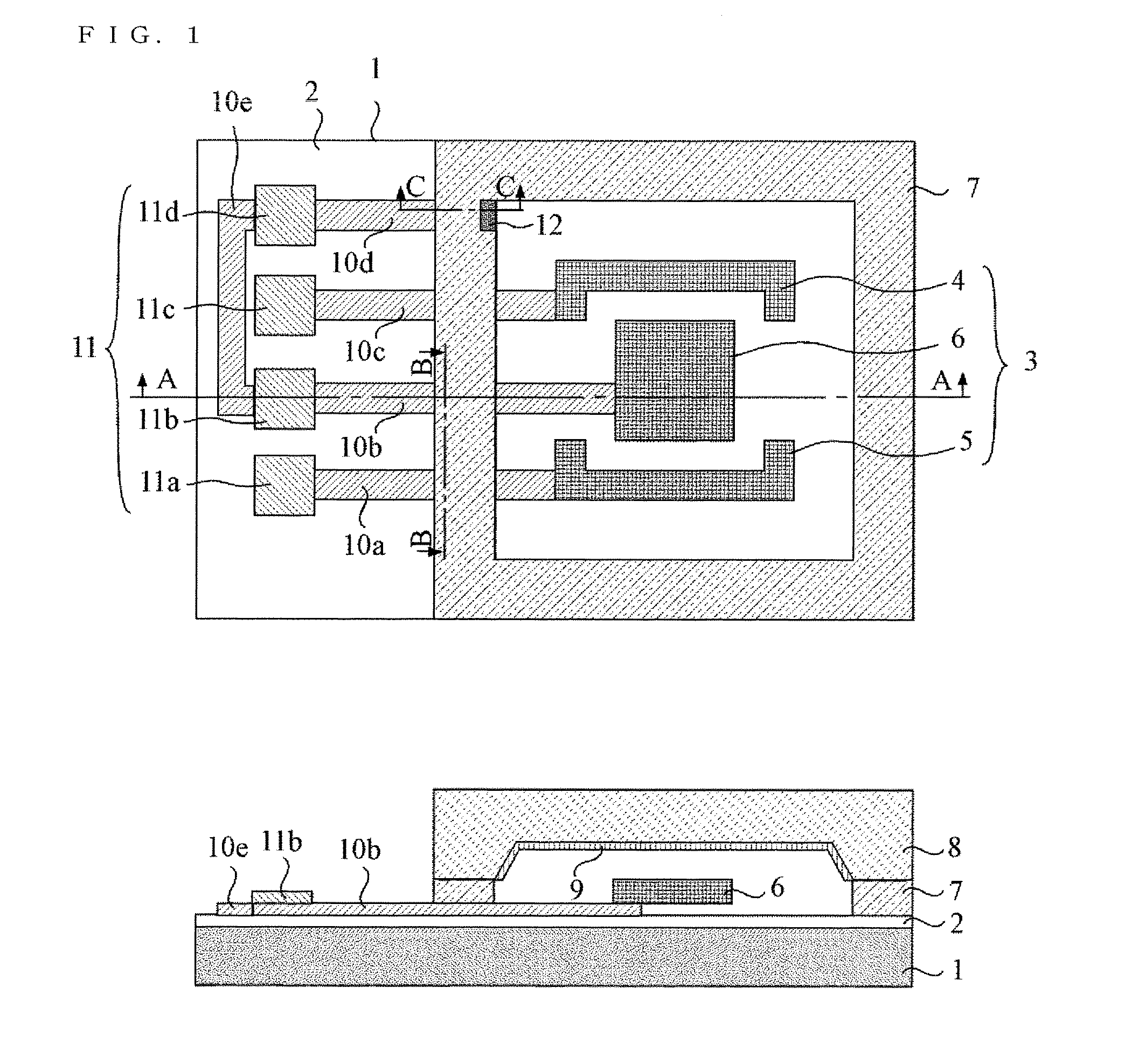

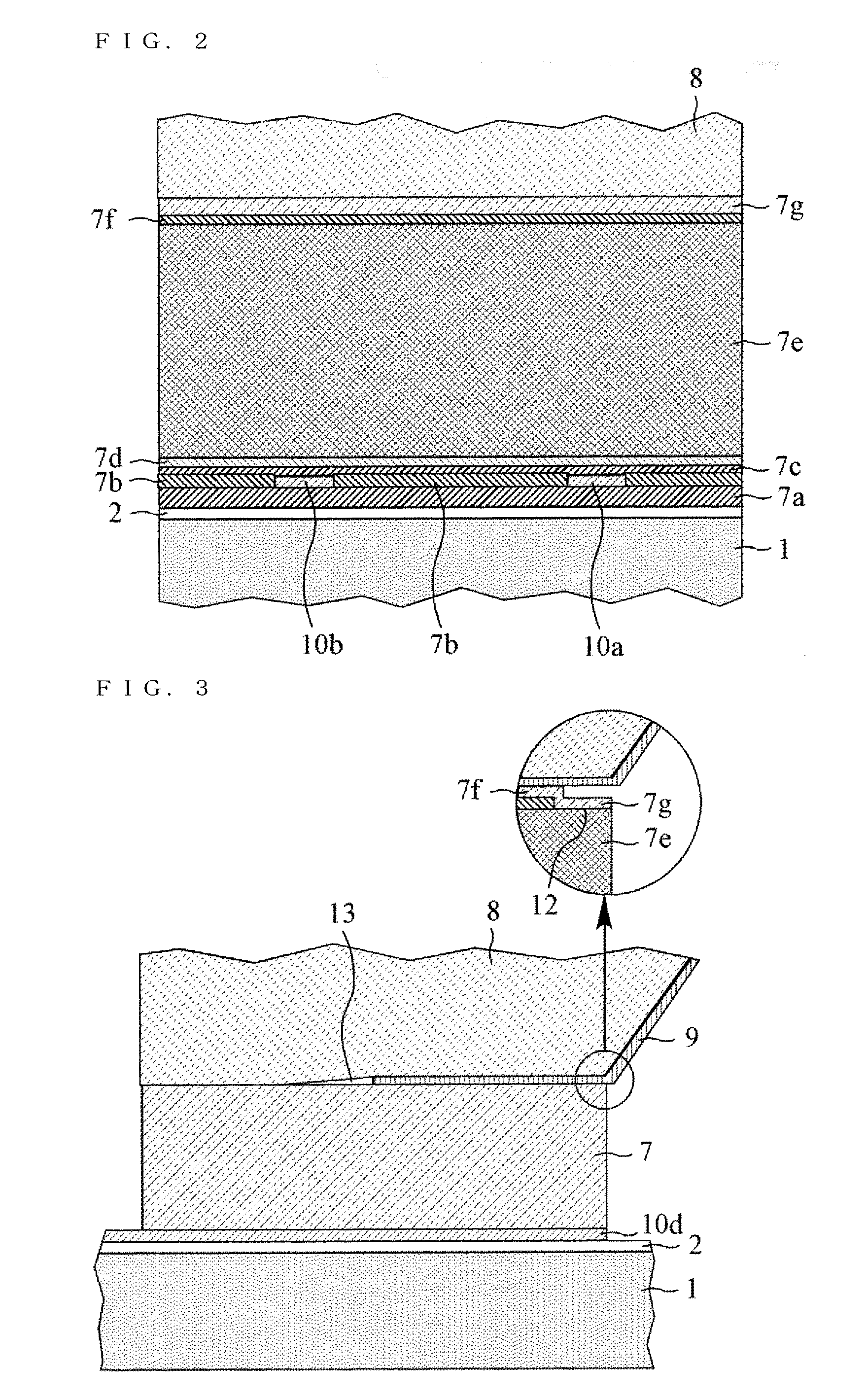

Liquid crystal display device

ActiveUS20150346556A1Ensure reliabilityHigh bonding strengthNon-linear opticsLiquid-crystal displayEngineering

A reliability of seal portion of a liquid crystal display device can be improved by the following structure. A liquid crystal display device includes: a TFT substrate which includes a display region and a terminal part, and has an inorganic insulating film formed on an organic passivation film and an alignment film formed over the inorganic insulating film; a counter substrate, the TFT substrate and the counter substrate bonded together by a sealing material formed at a seal part surrounding the display region; and a liquid crystal sealed inside. At the seal part, a transparent conductive oxide film is formed between the inorganic insulating film and the alignment film. The transparent conductive oxide film exists inside an edge of the TFT substrate and hence, the edge of the TFT substrate is free of the transparent conductive oxide film.

Owner:JAPAN DISPLAY INC

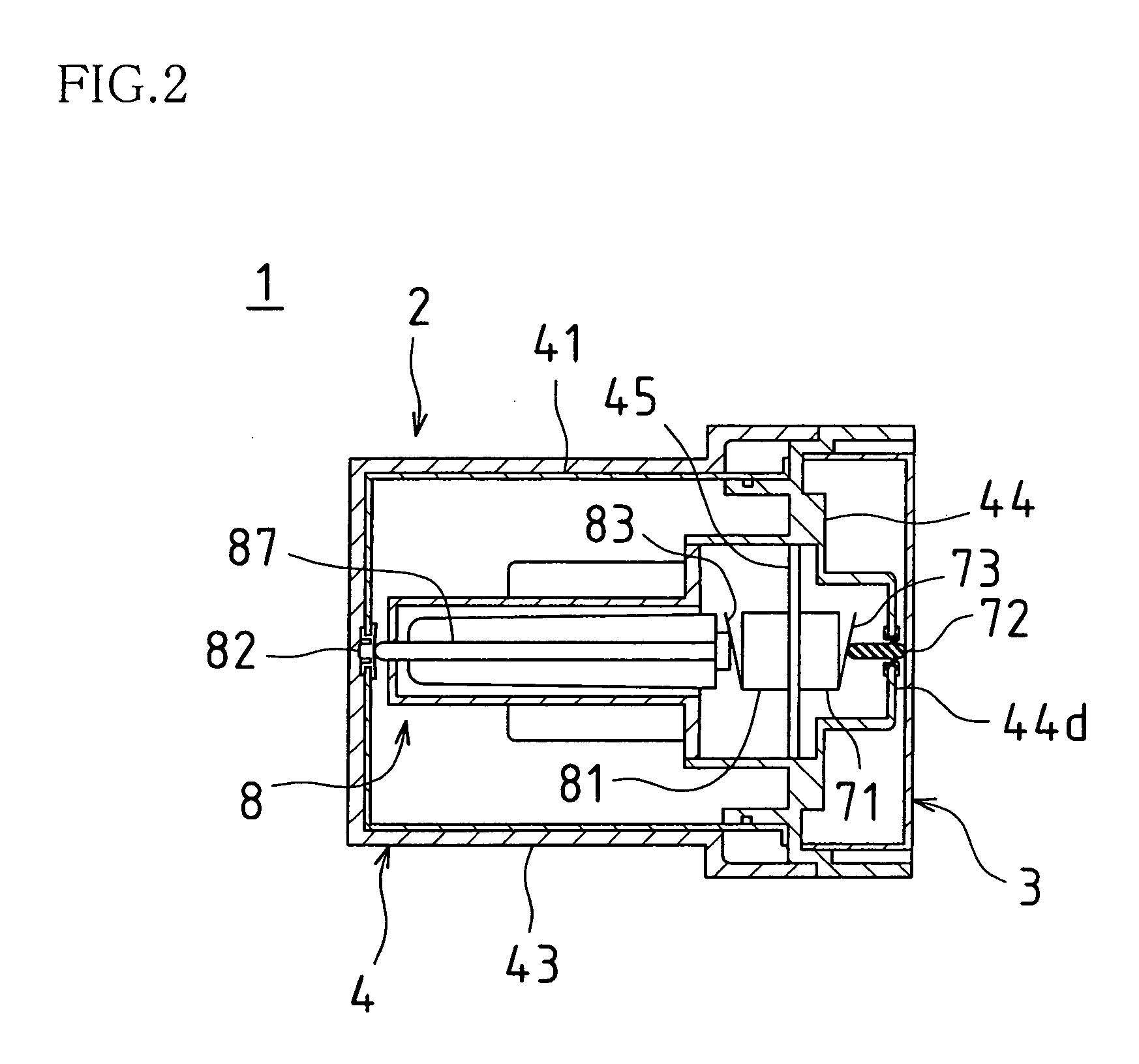

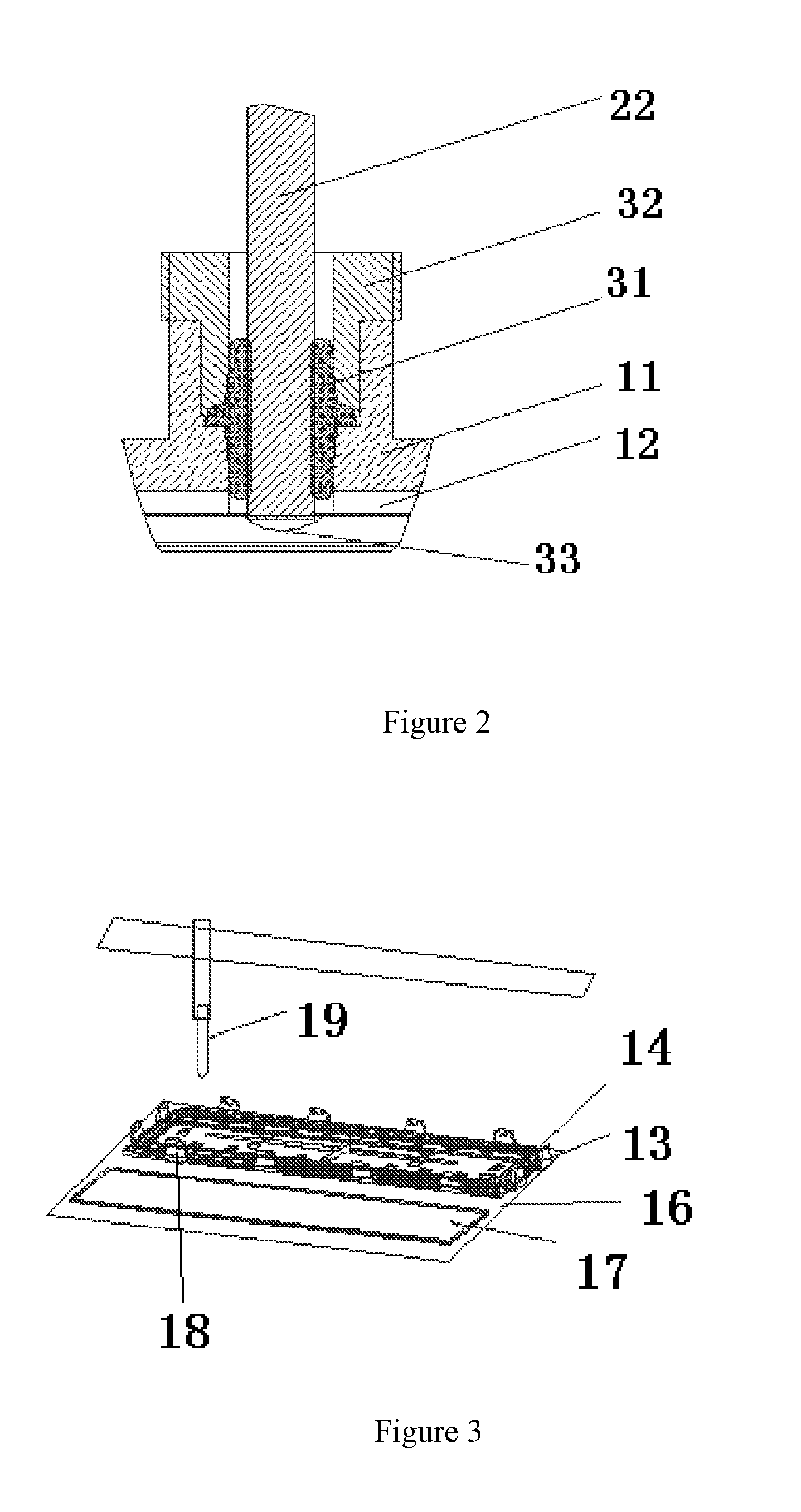

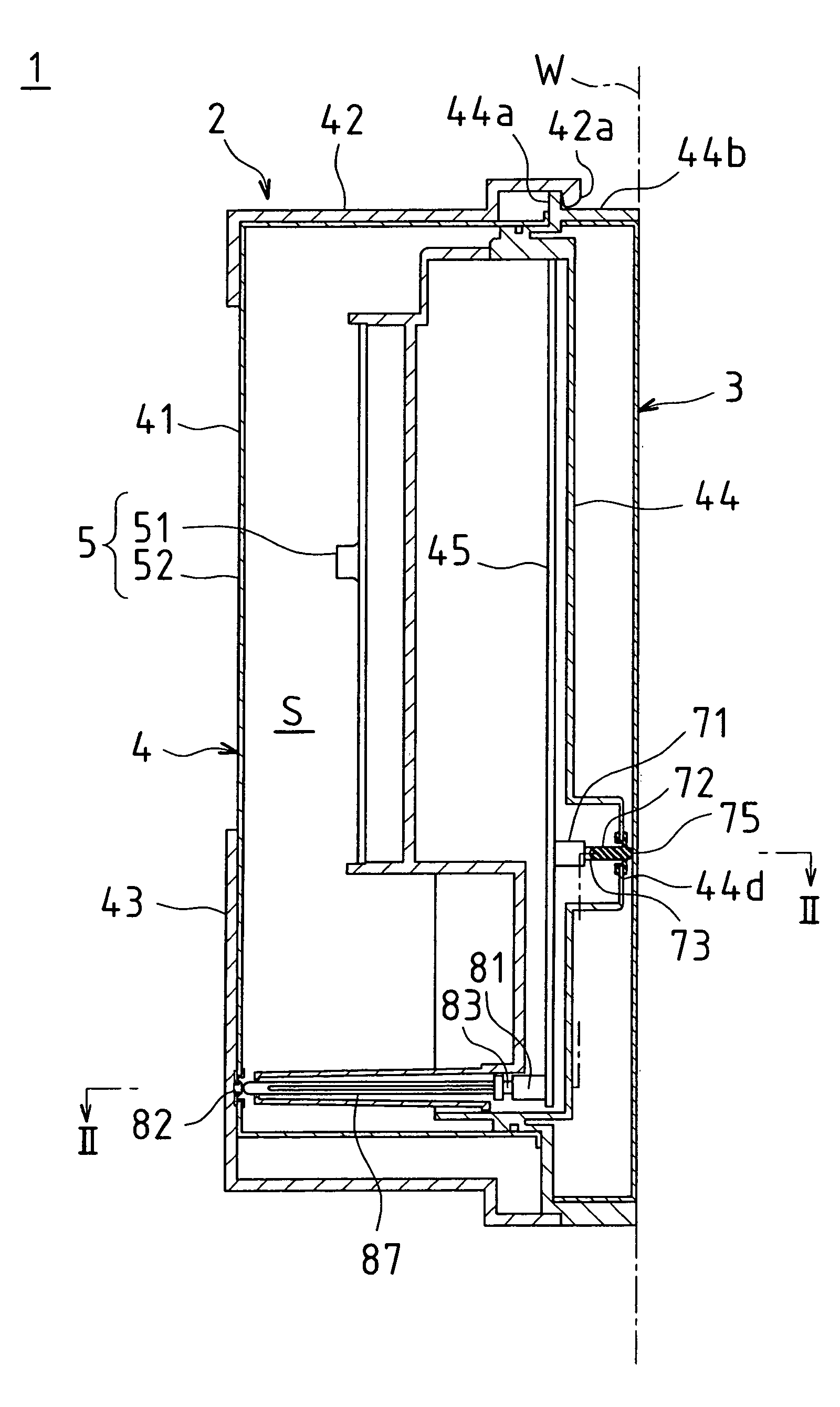

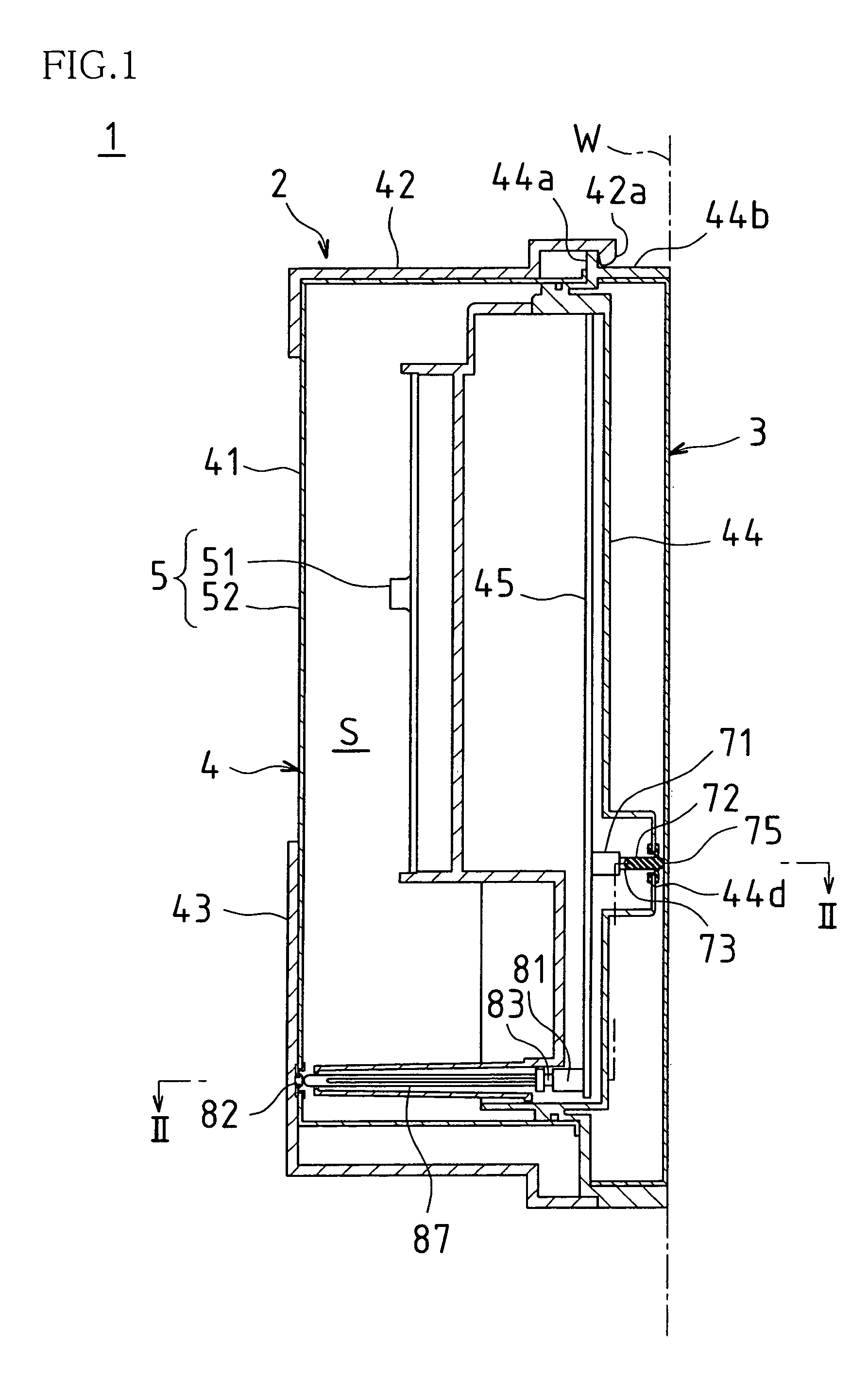

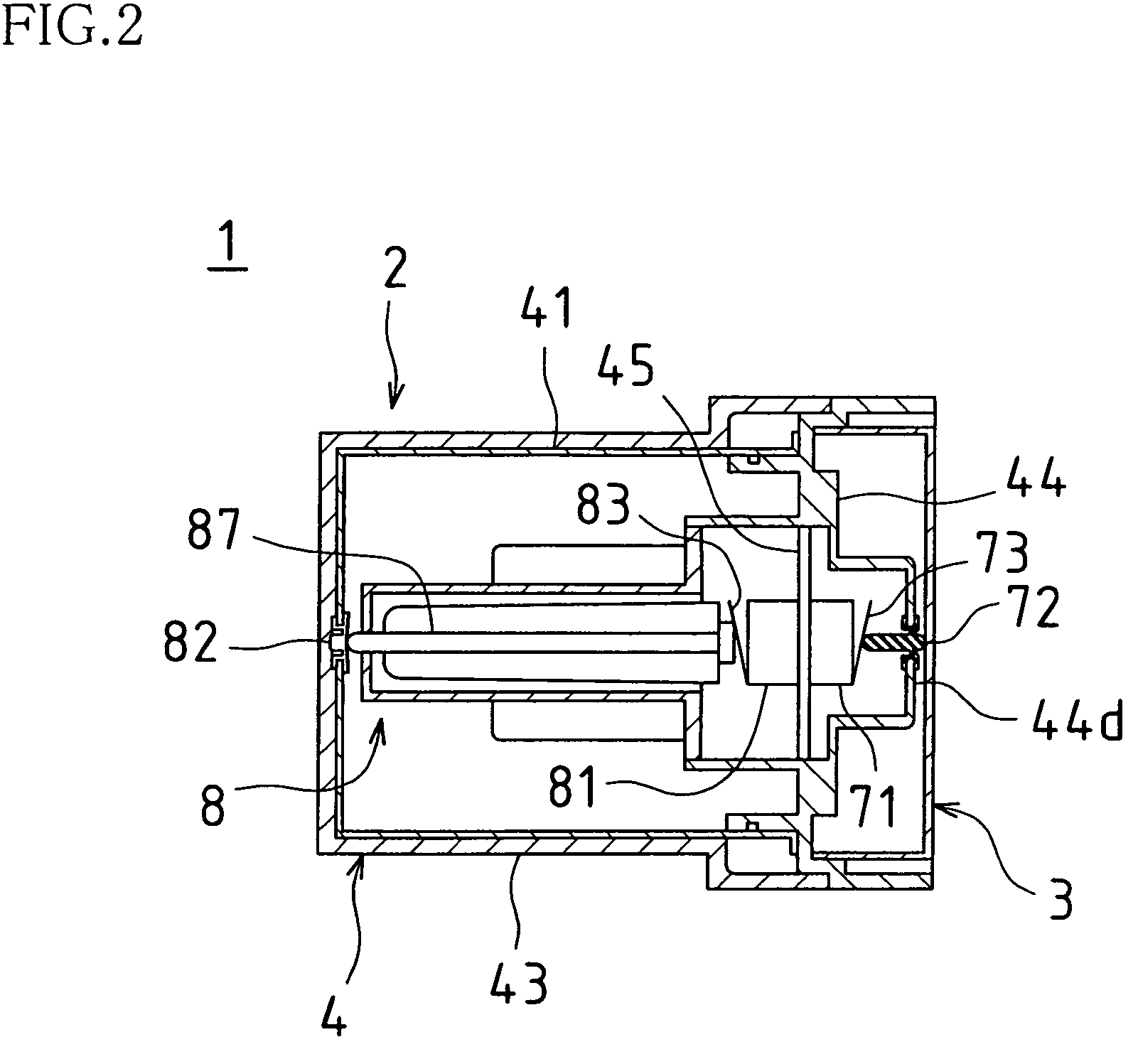

Seal structure for electronic control device

InactiveUS8942001B2Ensure sealing performanceEngine sealsHermetically-sealed casingsMechanical engineering

Owner:HITACHI AUTOMOTIVE SYST LTD

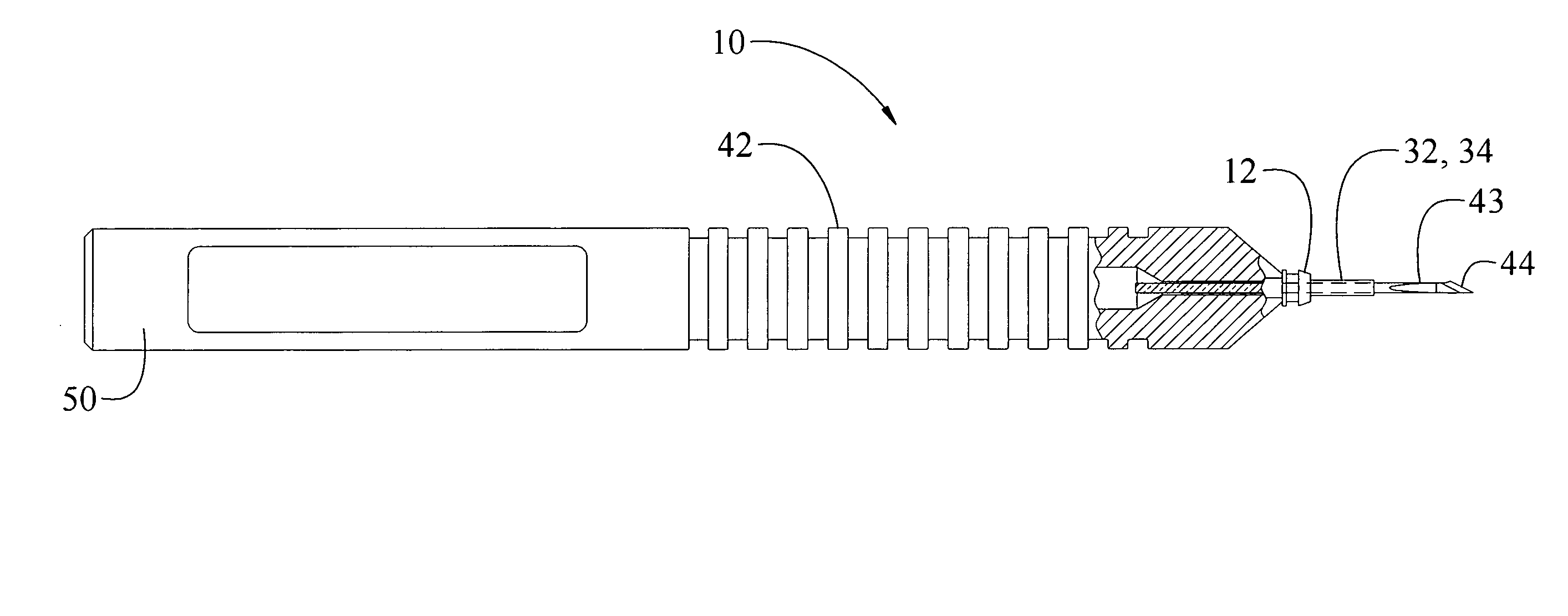

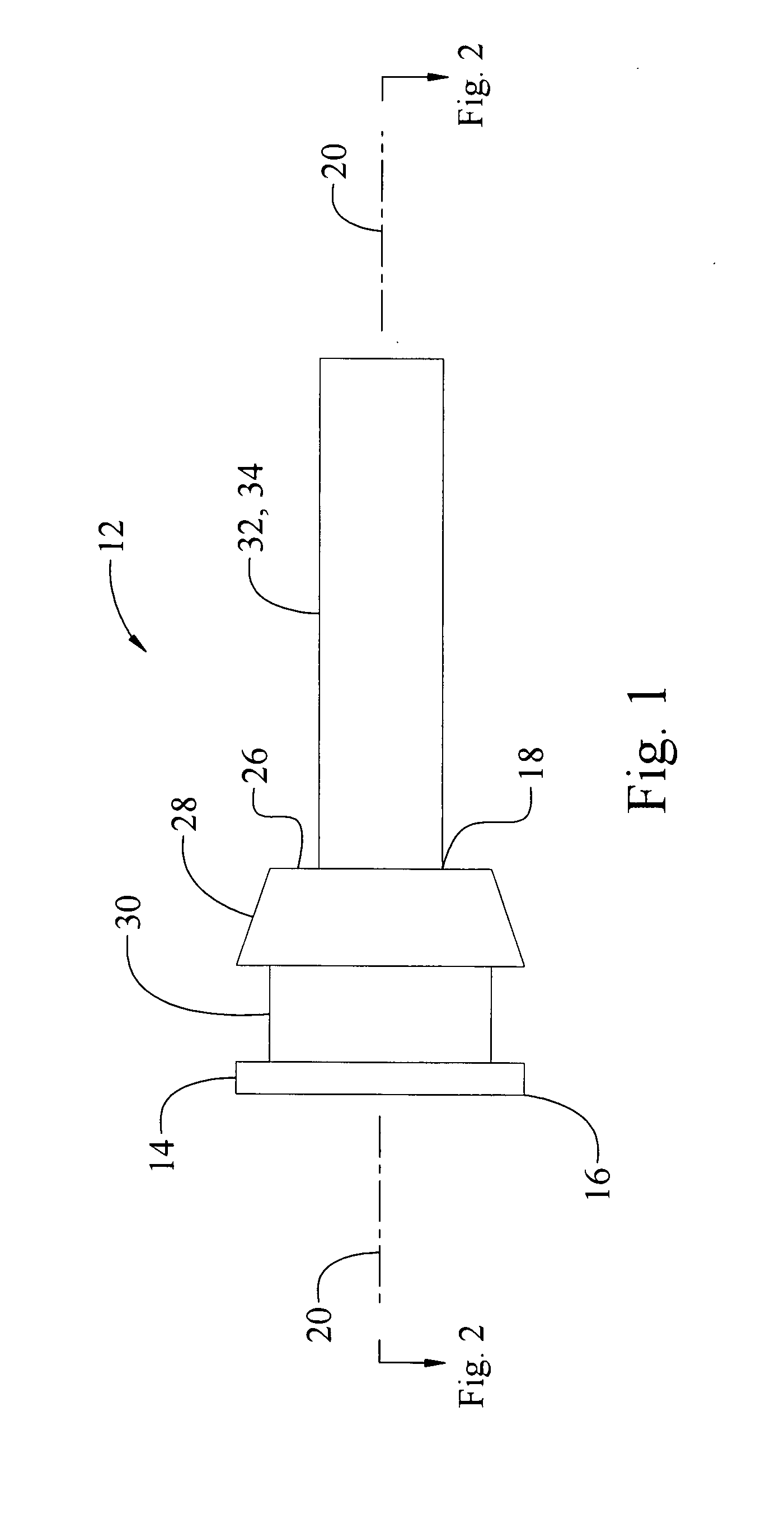

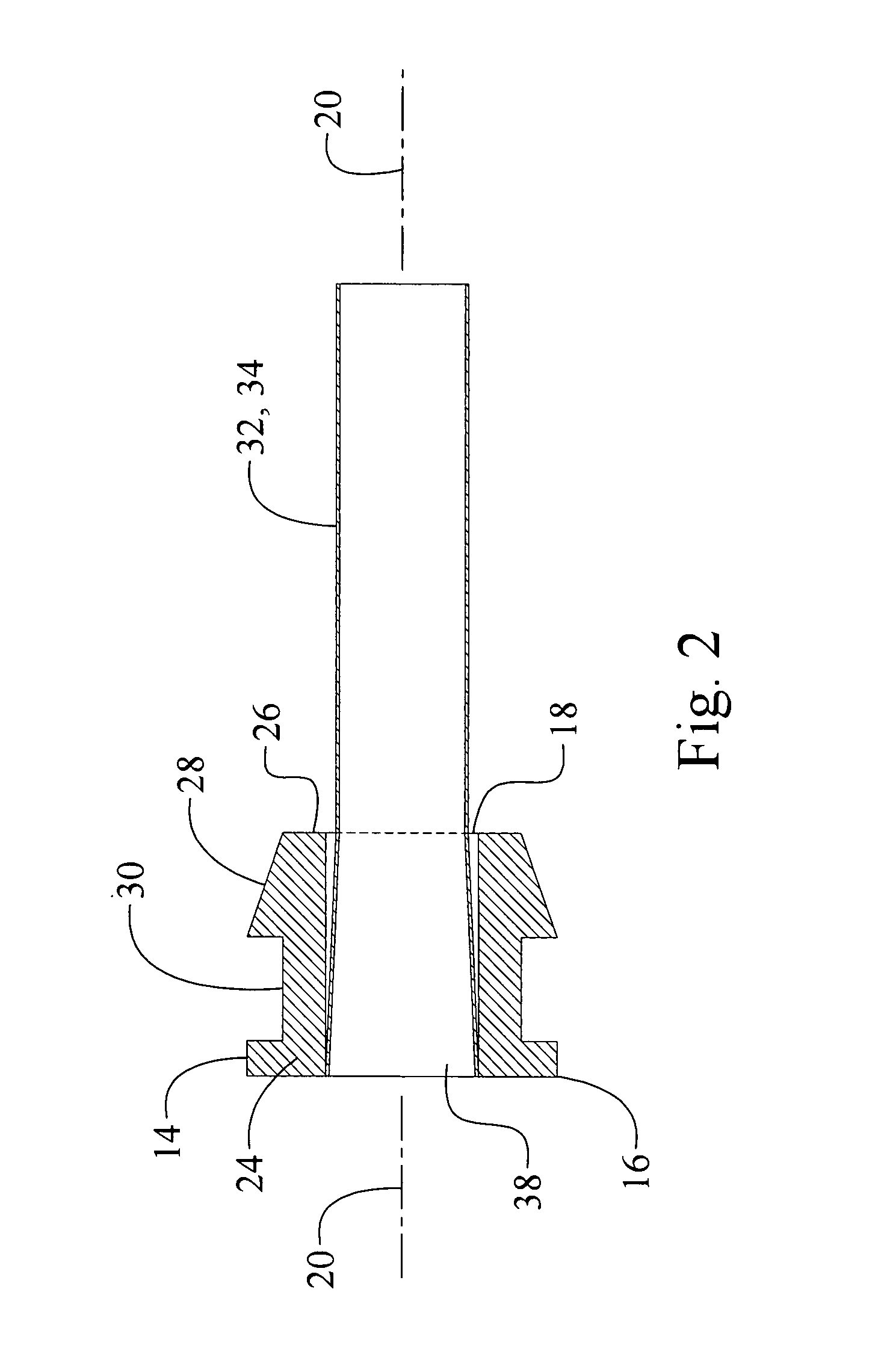

Flexible walled cannula

InactiveUS7846134B1Reduce liquid leakageHeal fastAdditive manufacturing apparatusEye surgerySurgical operationGrommet Insertion

A flexible walled cannula apparatus and method of use comprising a uniquely deformable cannula tube and head in combination with a uniquely shaped obturator which allows the use of heretofore unusable larger gauge surgical instruments while providing a self sealing incision. The apparatus and method of use provides a preassembled obturator and cannula assembly with which the surgeon forms an incision or channel, inserts the cannula tube, and through the cannula inserts surgical instruments to perform a surgical operation. The apparatus and method of use is especially suited for ophthalmic surgical operations. Alternative embodiments for use with even larger diameter instruments utilize a uniquely designed valve having leaflets which prevent bodily or other fluid leakage from the cannula when an instrument is not inserted.

Owner:SYNERGETICS

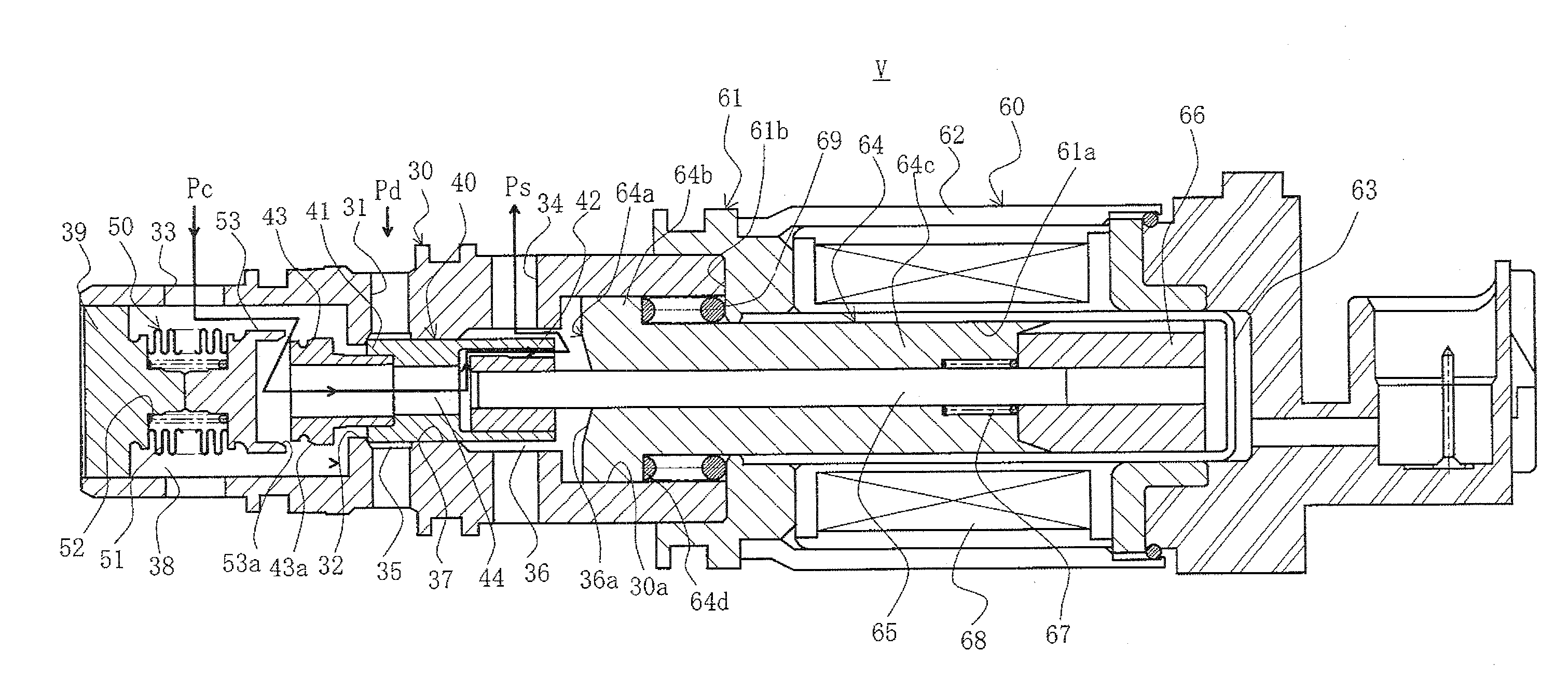

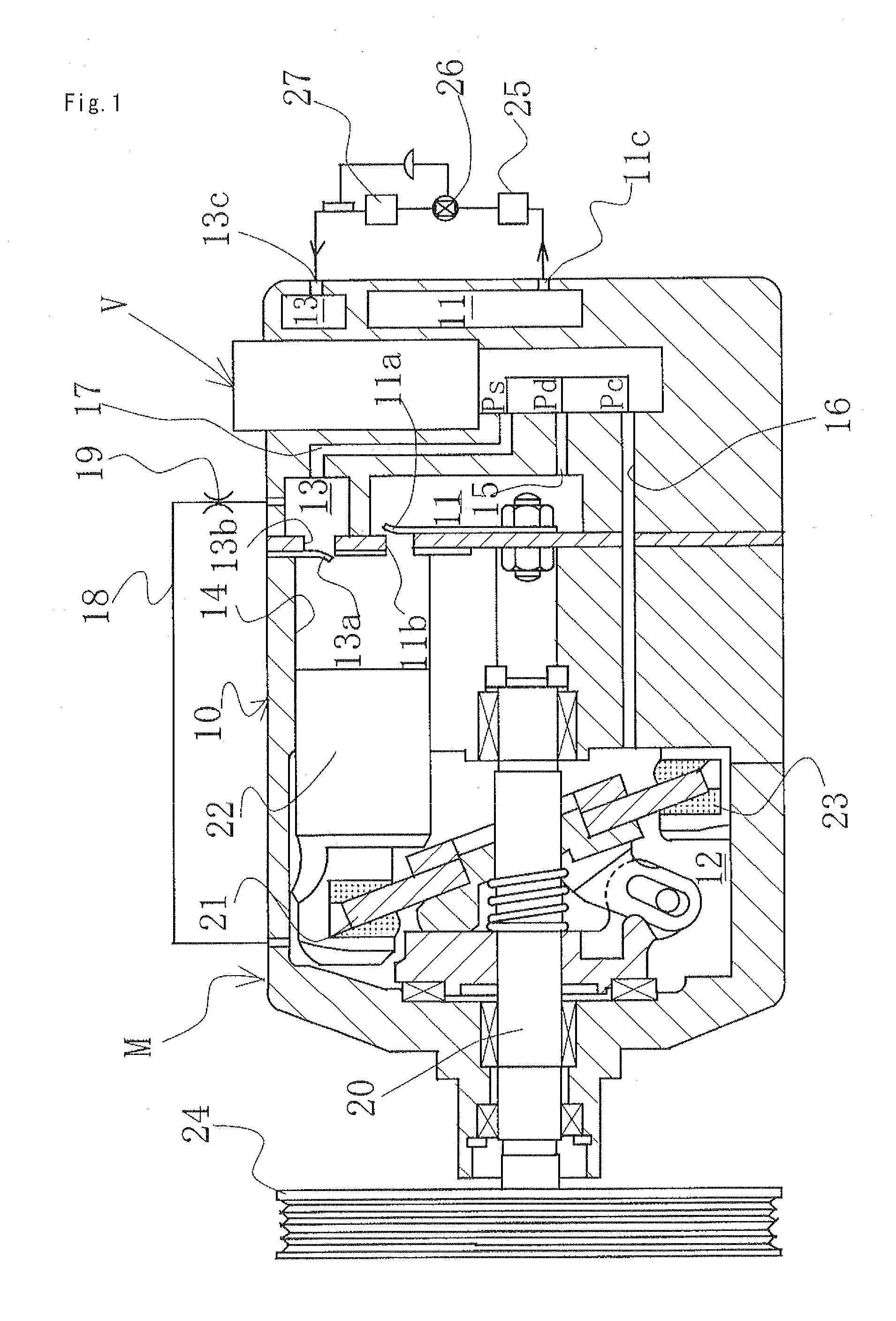

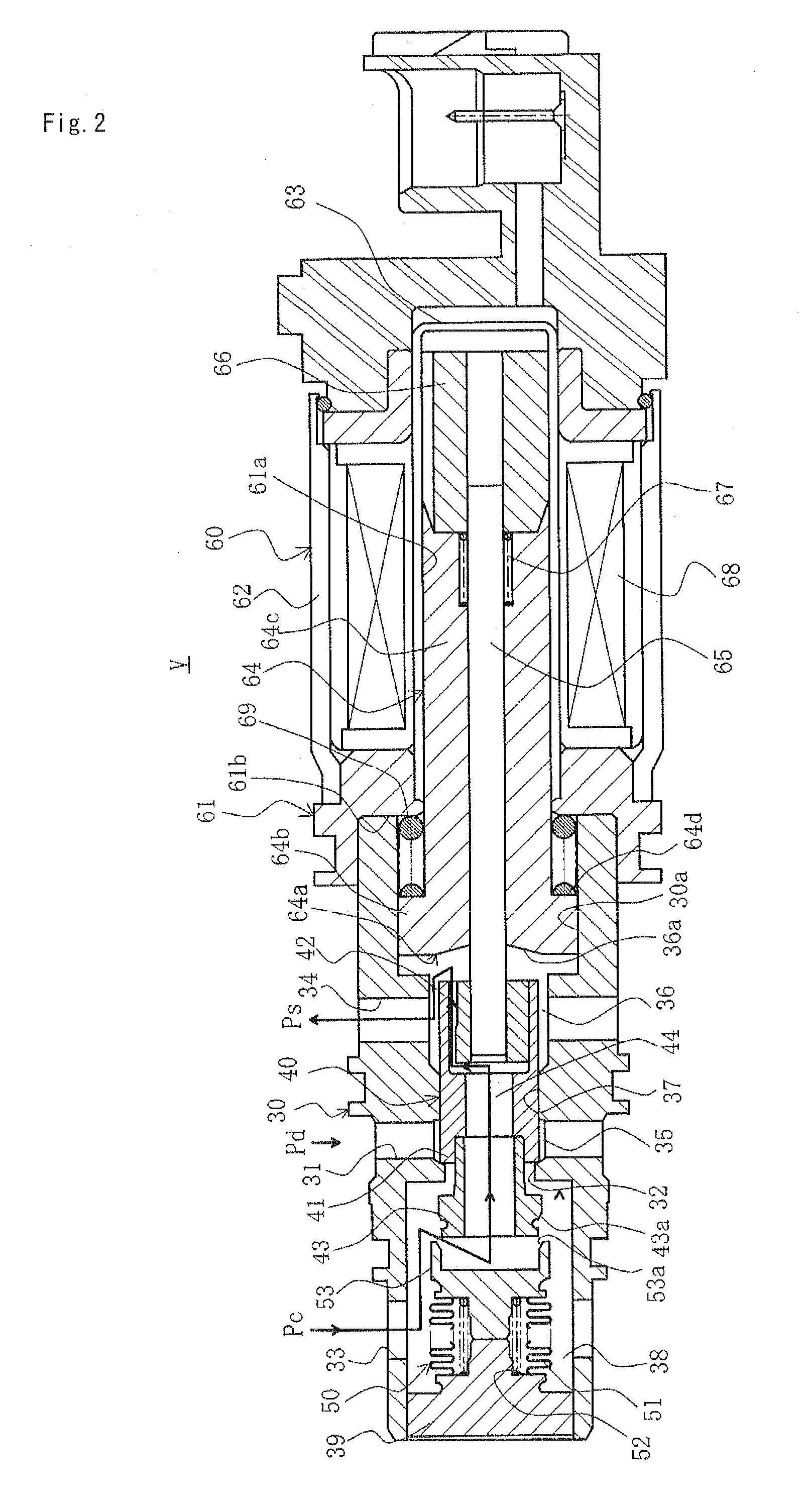

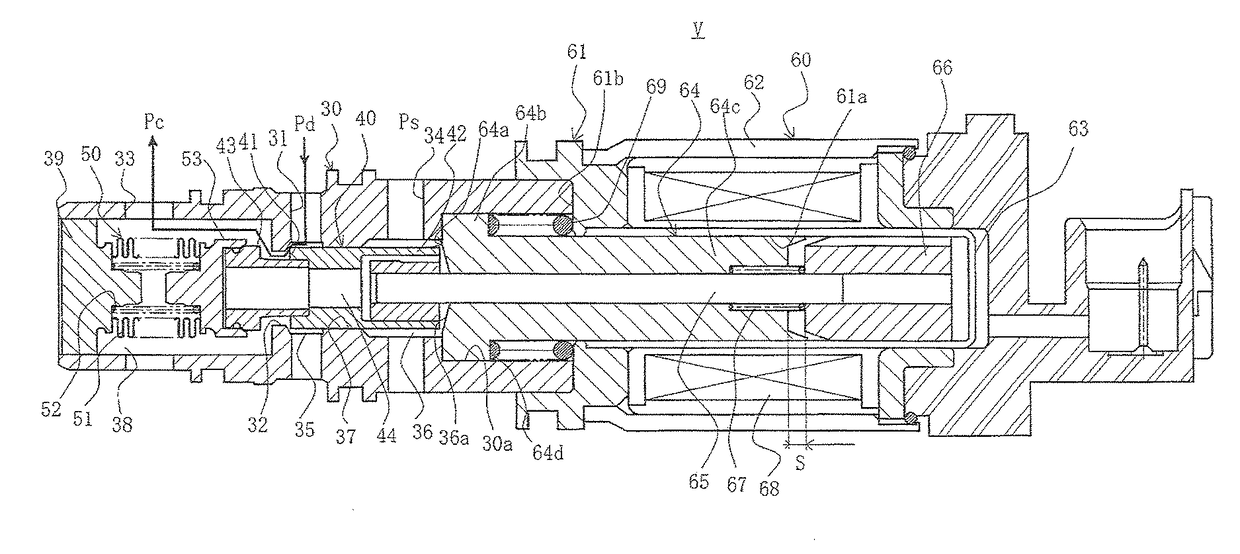

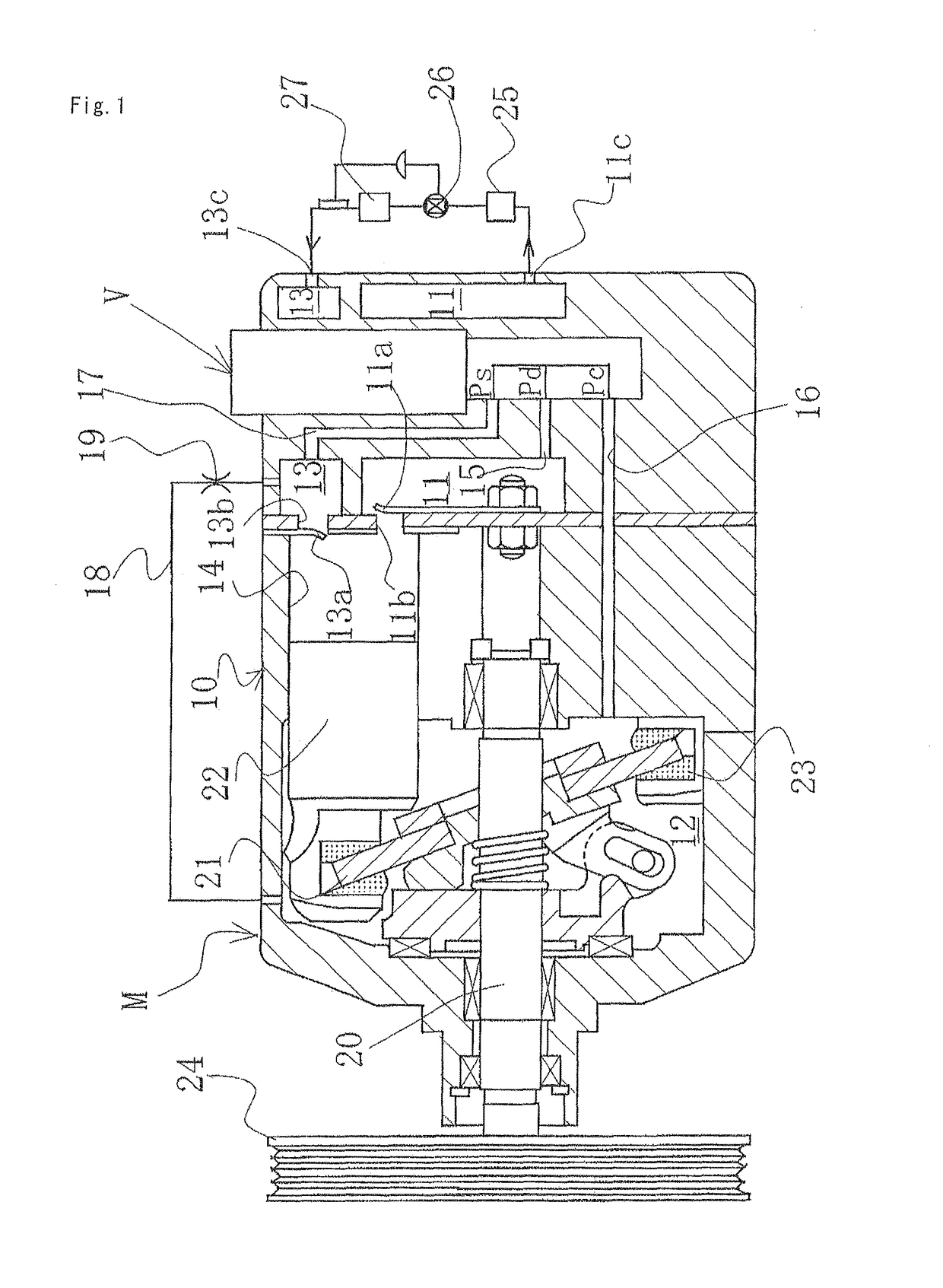

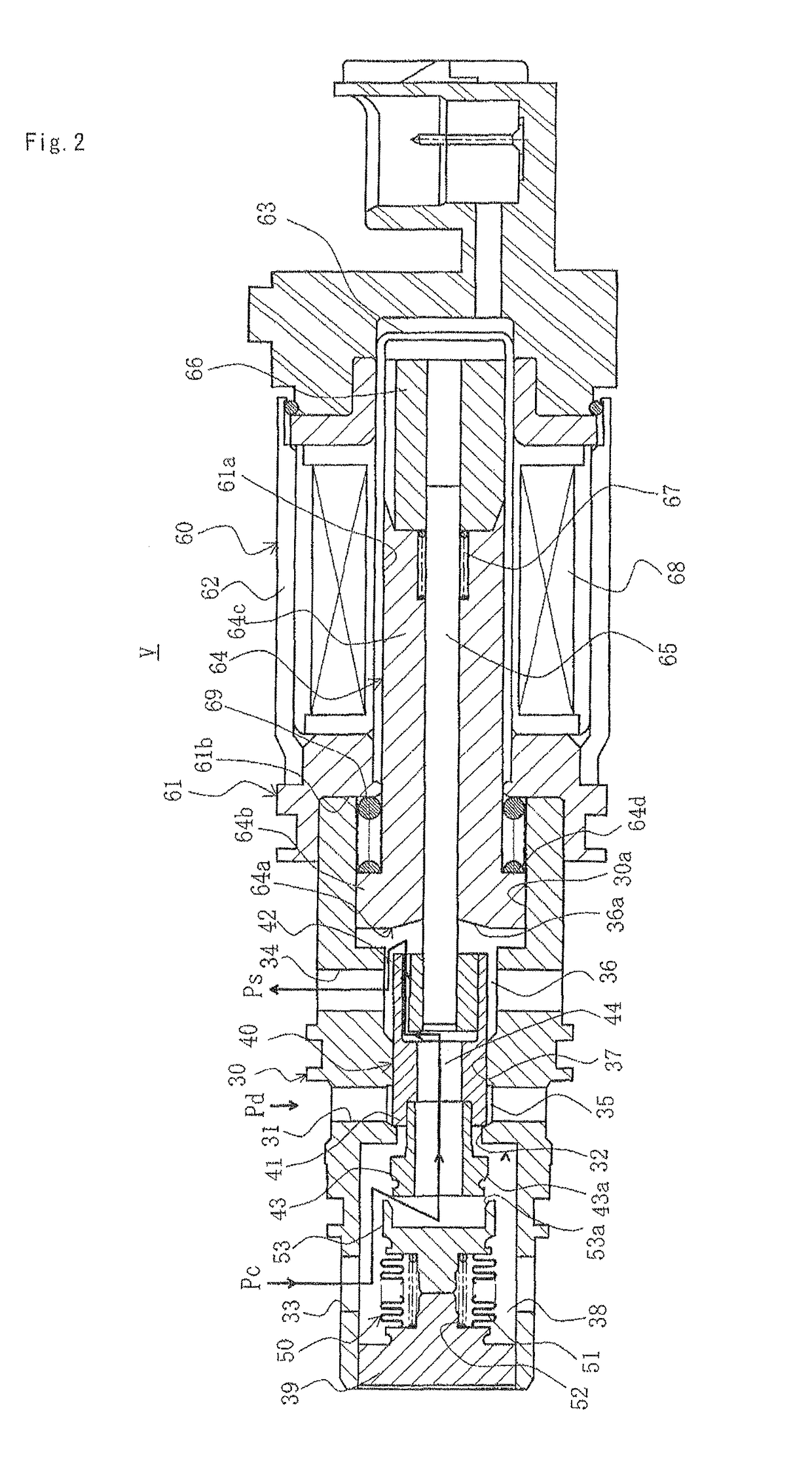

Capacity control valve

ActiveUS20150345655A1Superior effectIncrease in amountOperating means/releasing devices for valvesMultiple way valvesRefrigerantEngineering

A control valve for discharging a liquid refrigerant in a control chamber at the time of start-up of a variable capacity compressor has a movable a center post for increasing the area of a passage for discharging the liquid refrigerant when discharging the liquid refrigerant.

Owner:EAGLE INDS

Tamper switch structure and security sensor including the tamper switch structure

ActiveUS20050219046A1Prevent floodingGuaranteed uptimeContact operating partsElectric signalling detailsElectrical and Electronics engineeringEngineering

Owner:OPTEX CO LTD

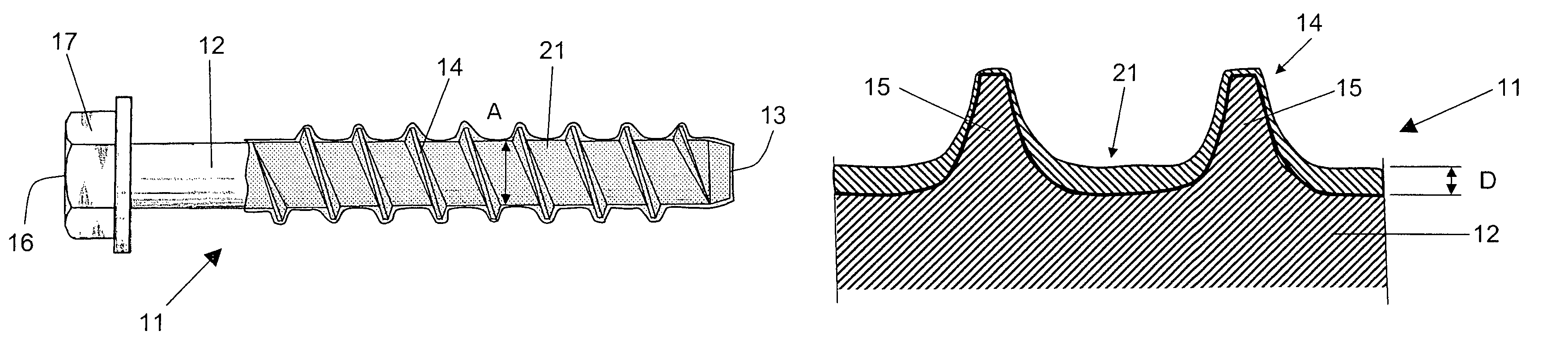

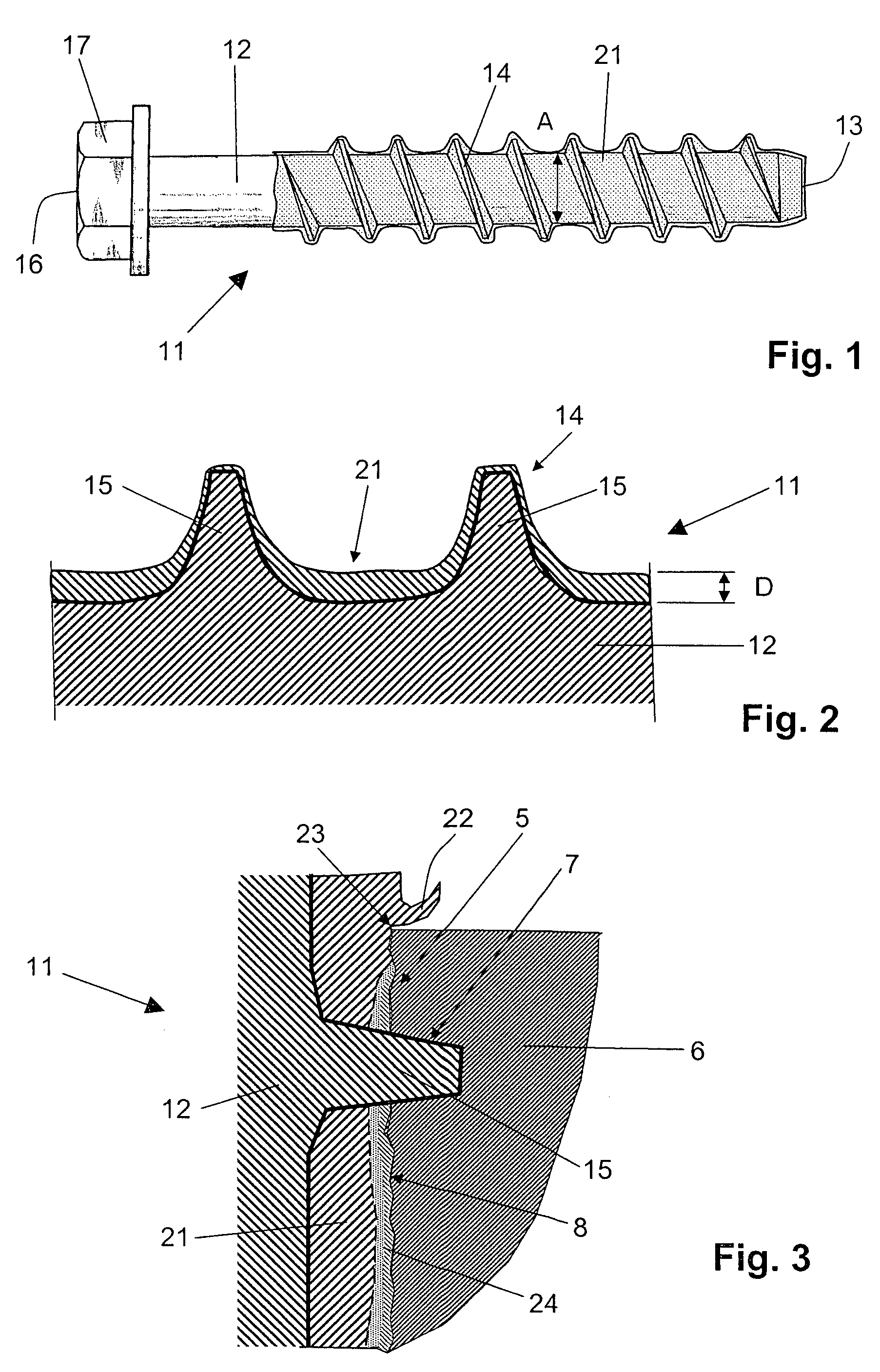

Fastening element

A fastening element for mineral constructional components has a shaft (12) provided with a tapping thread (14) extending, at least regionwise, along the shaft (12), and a coating (21) that covers the shaft (12) likewise at least regionwise and that is formed of a polar thermoplast.

Owner:RESTALYST PTE +1

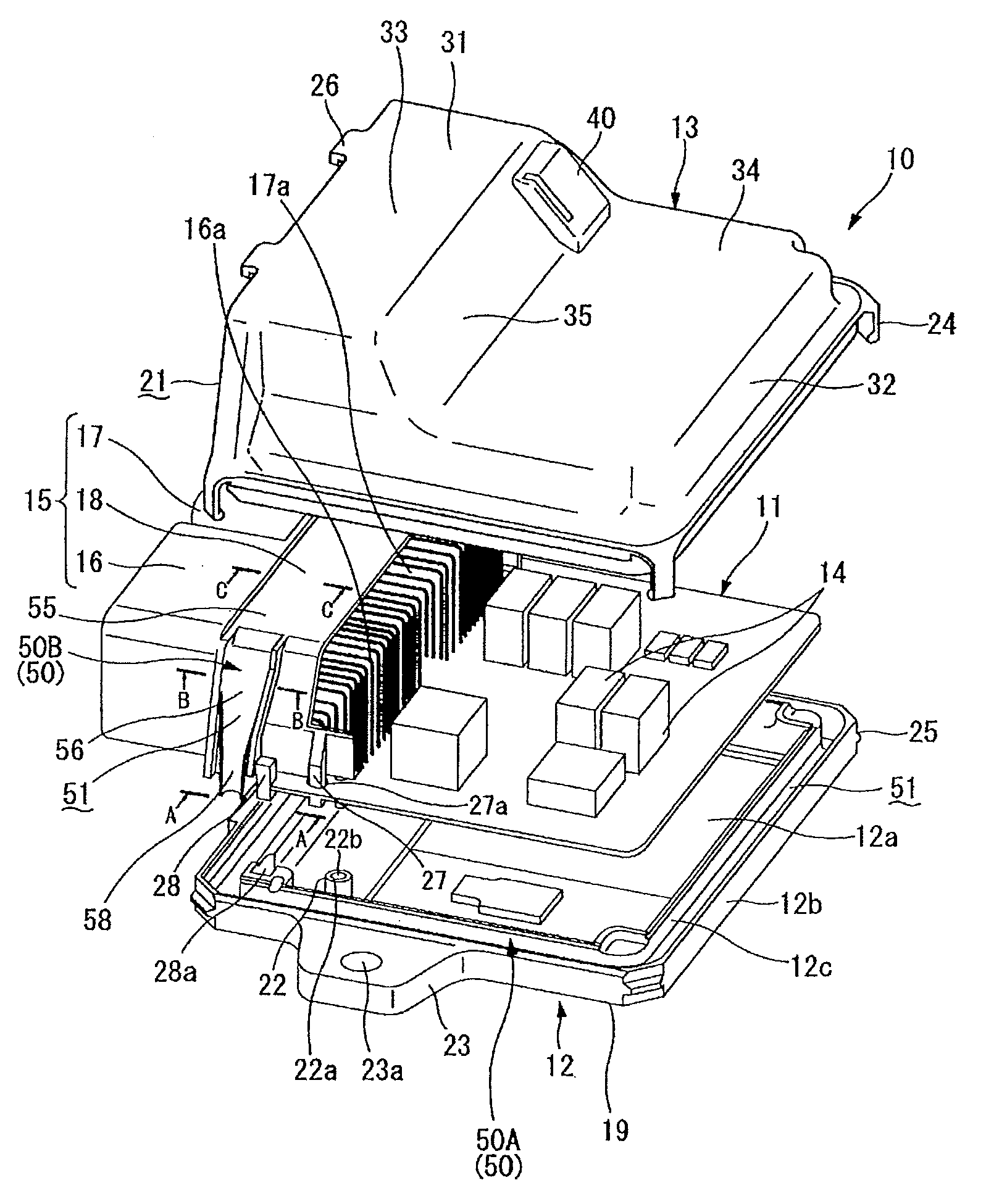

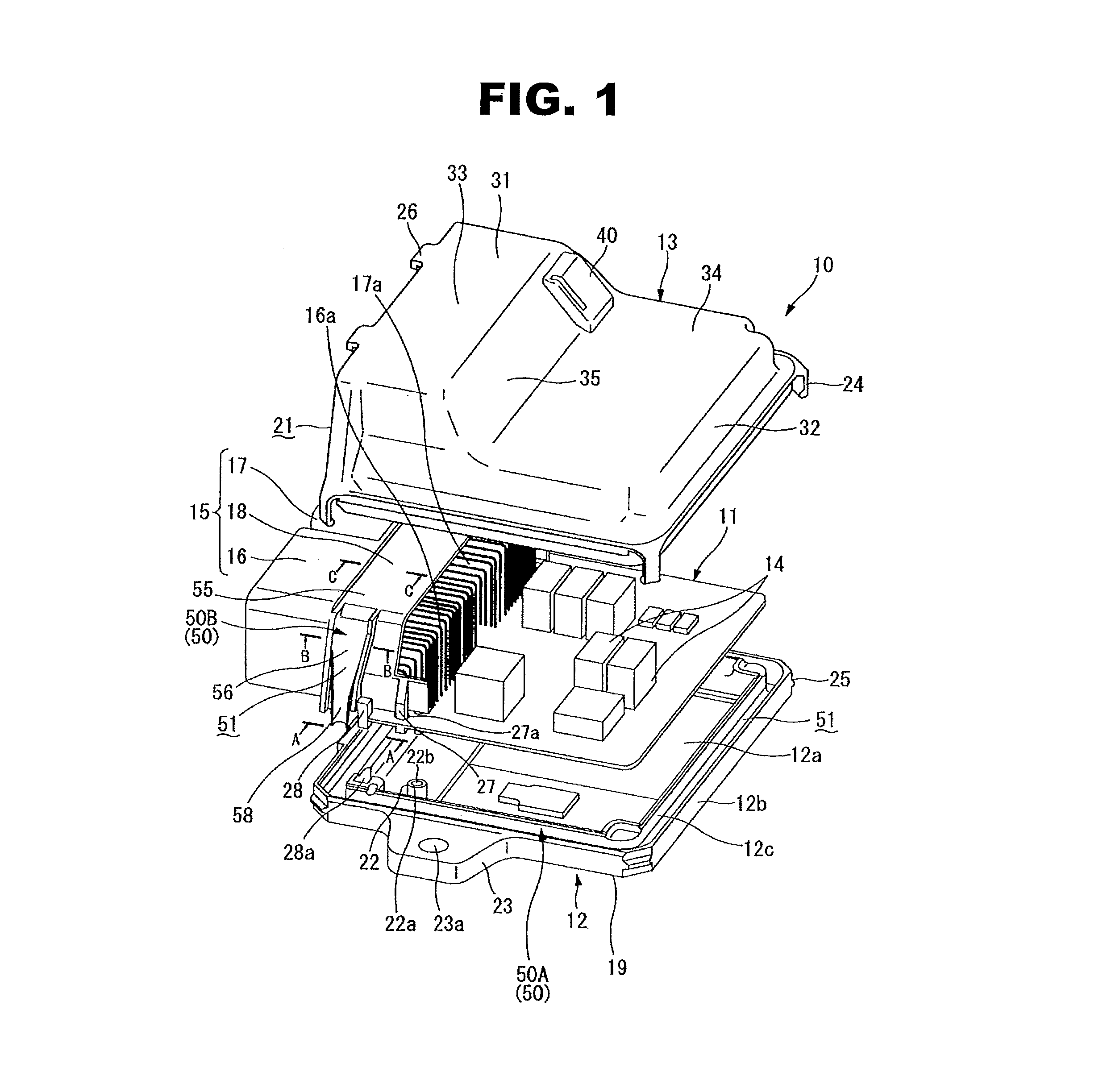

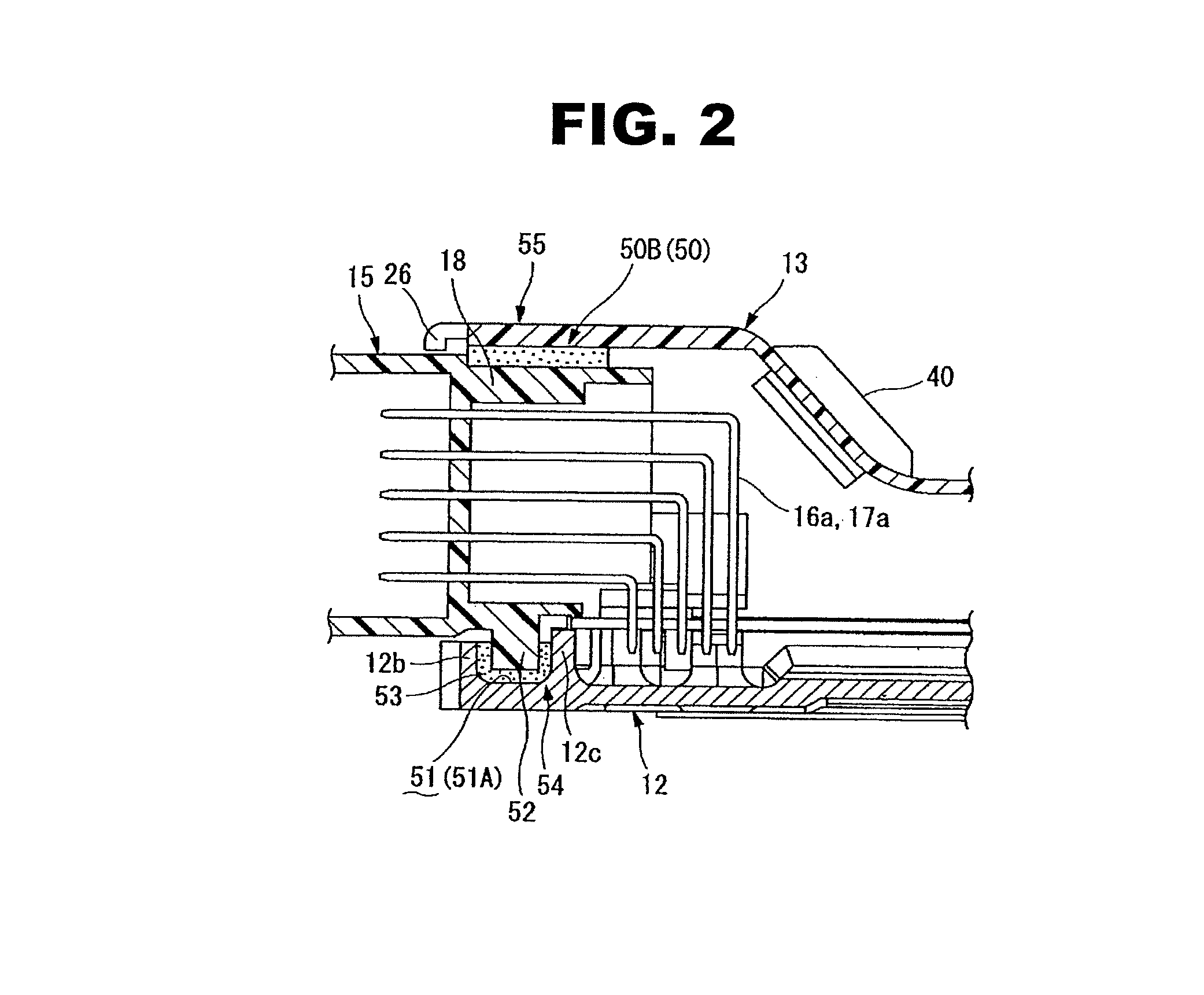

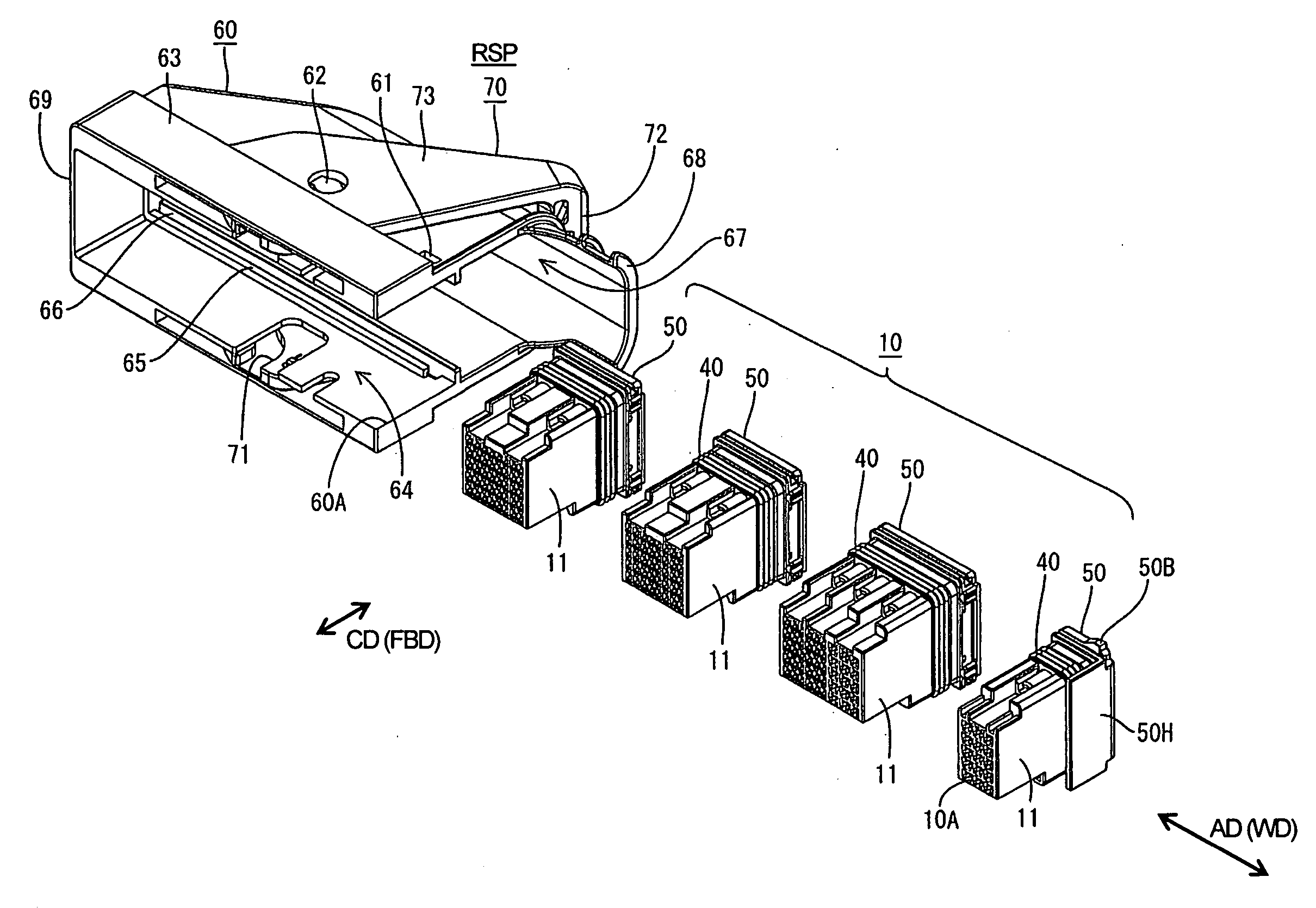

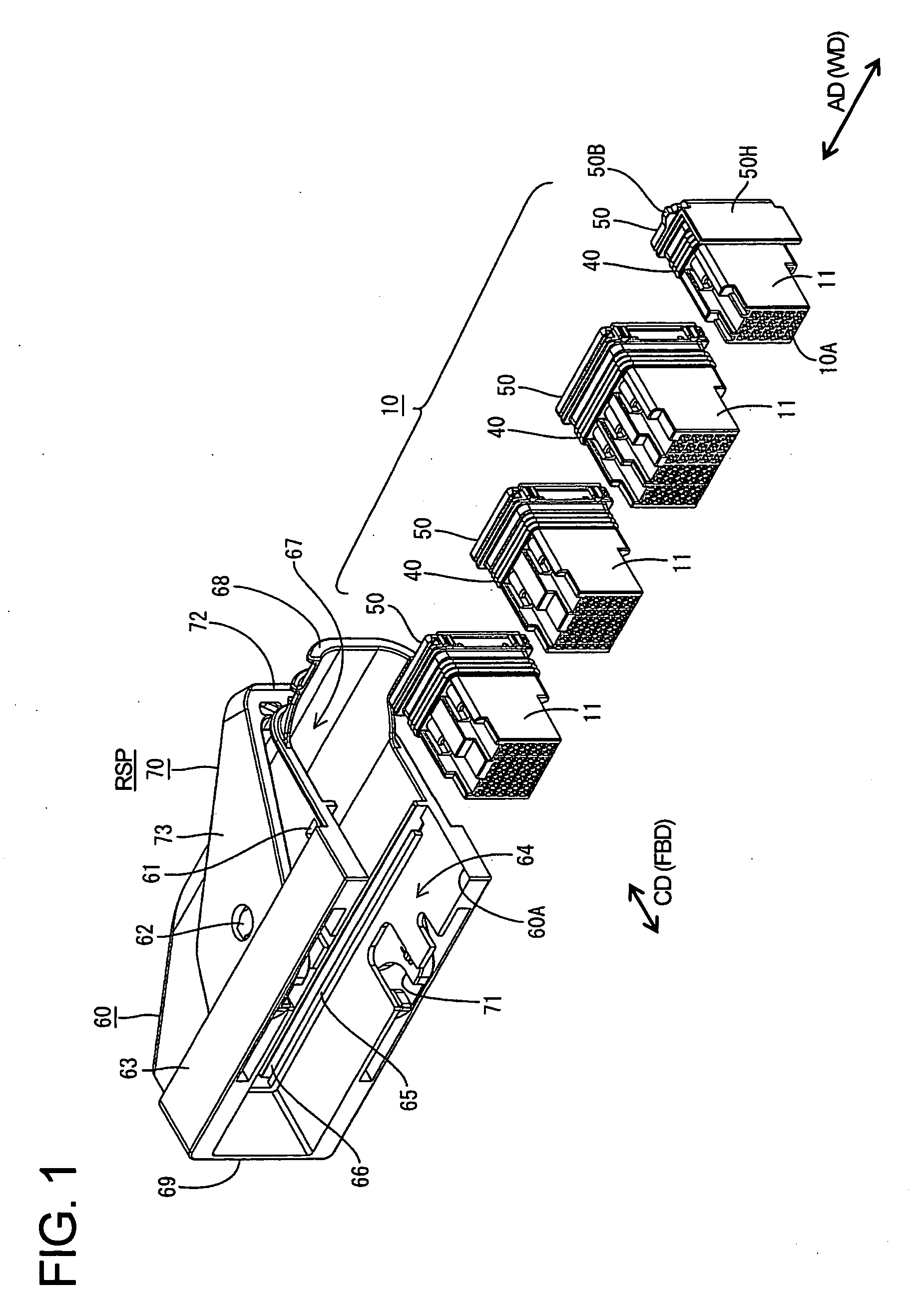

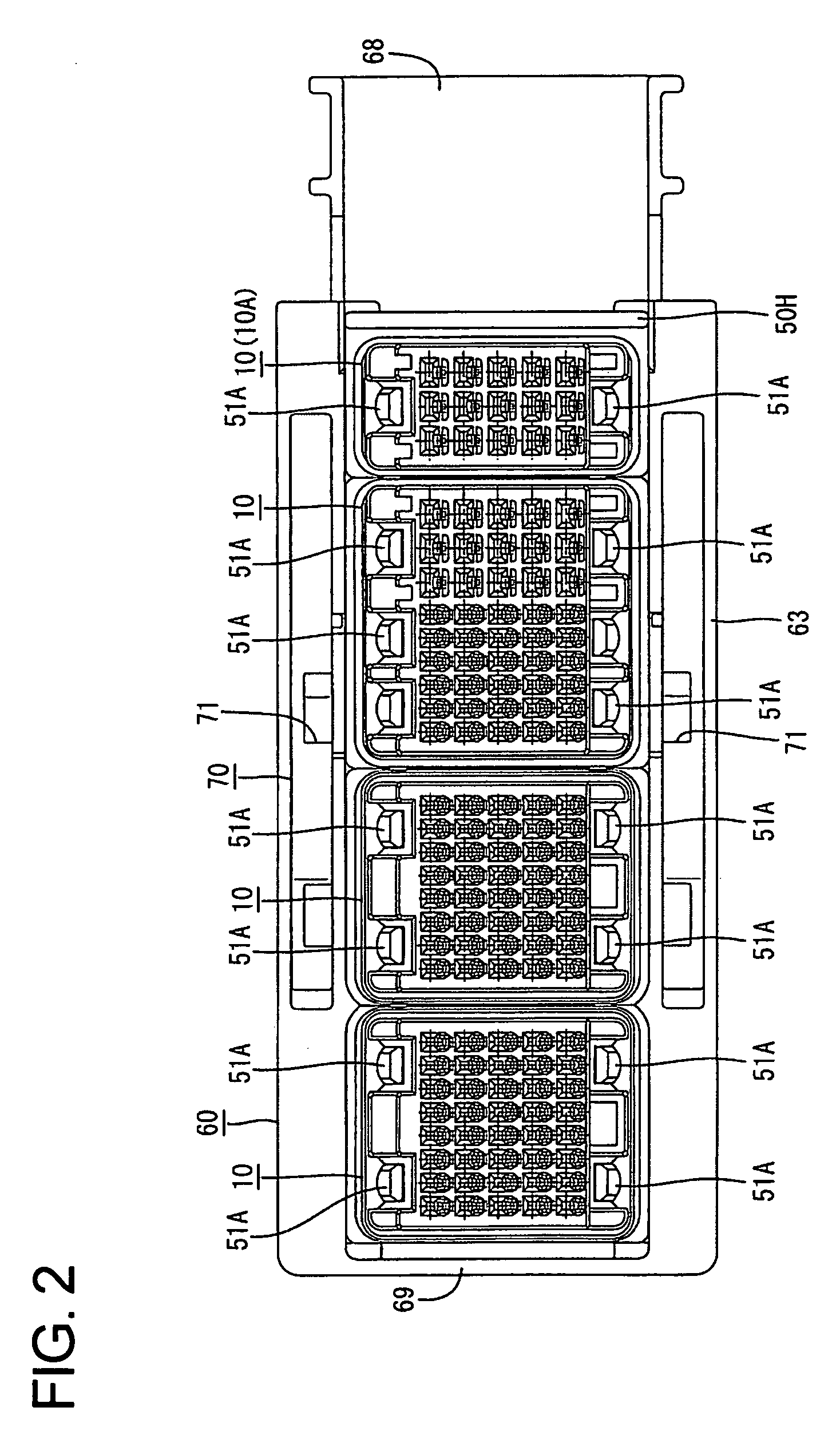

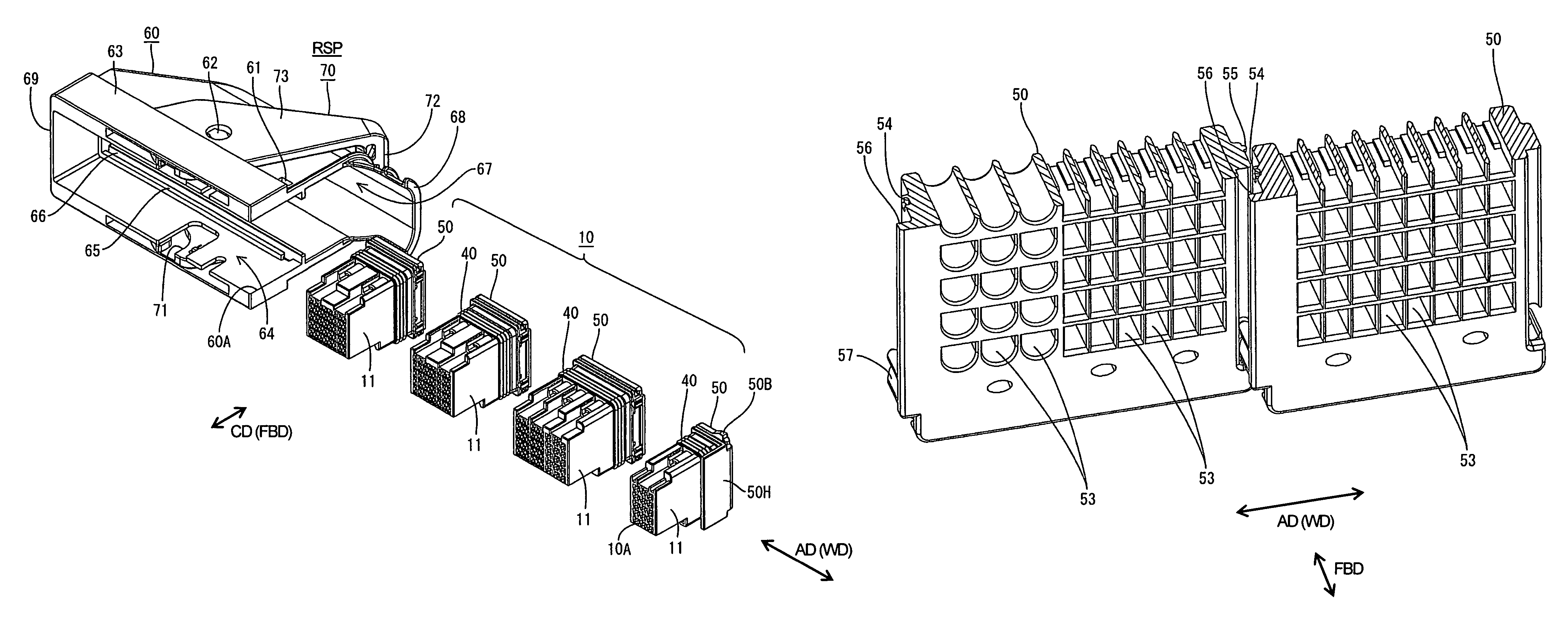

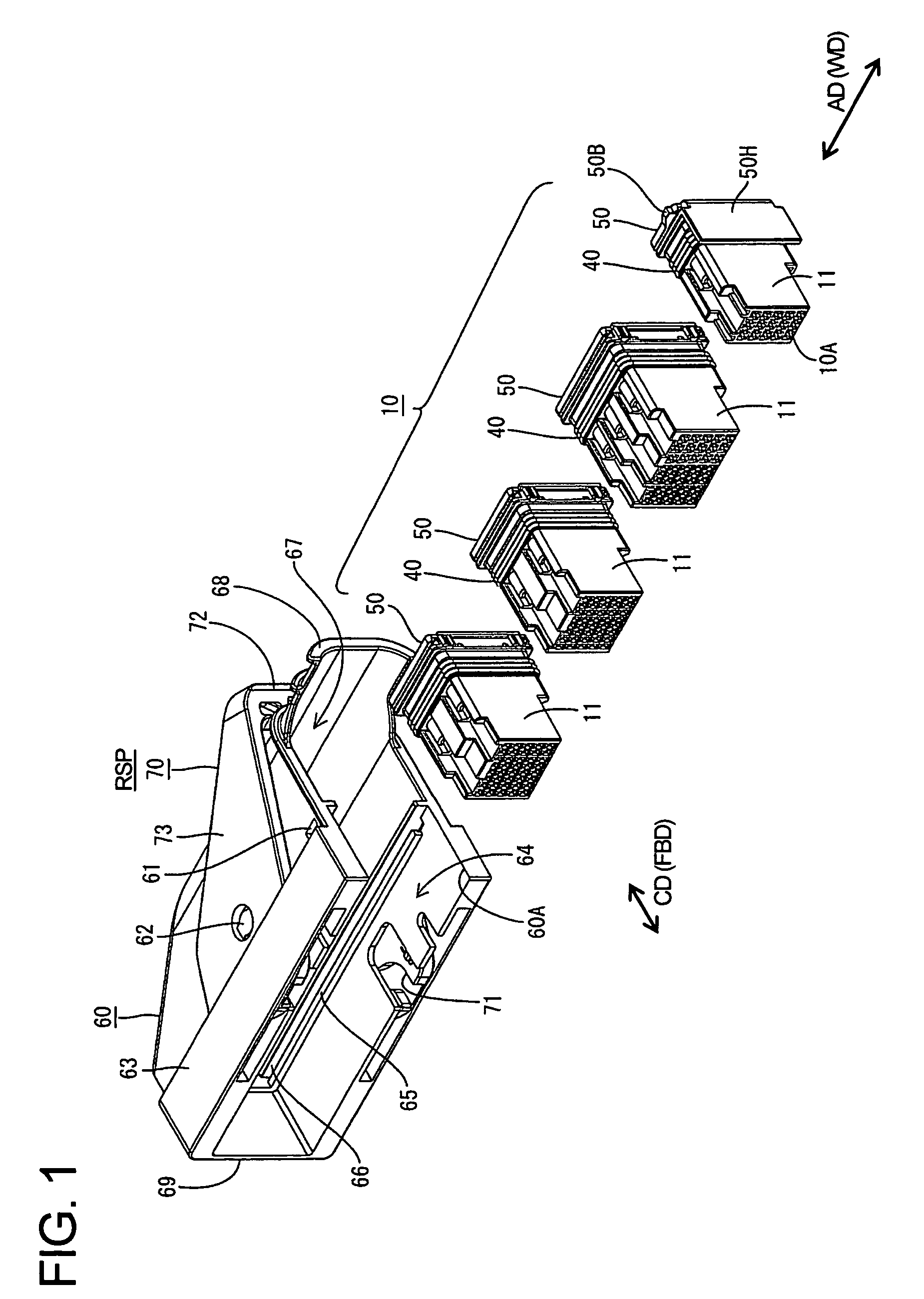

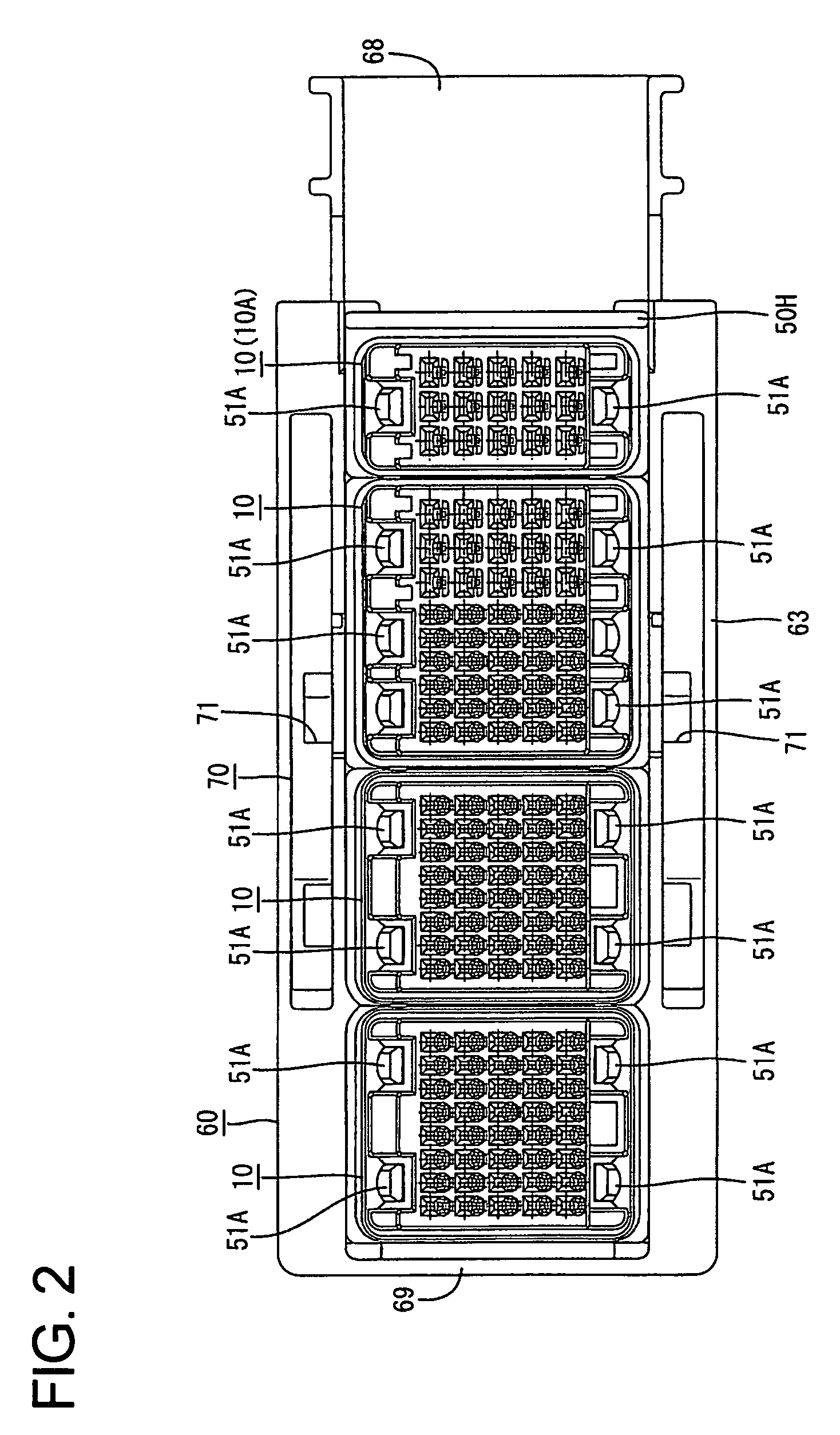

Connector and a connector assembly method

InactiveUS20070004274A1Avoid connectionMade smallElectrically conductive connectionsCoupling contact membersEngineeringTotal thickness

Each of a plurality of auxiliary connector (10) includes an auxiliary housing (11), a seal (40) attached to the rear of the auxiliary housing (11), and a rear holder (50) mounted on the rear of the seal (40) to retain the seal (40). Auxiliary connectors (10) that are adjacent in an arranging direction are united by the rear holders (50). The united auxiliary connectors (10) are inserted into a frame (60) in the arranging direction through an insertion opening (60A) of the frame (60), and are retained in the frame (60) by engaging a lock (50B) on the last auxiliary connector (10A) and an interlocking portion (61) of the frame (60). The frame (60) has no partition walls between the auxiliary connectors (10). Thus, the connector is narrowed by a total thickness of the partition walls.

Owner:SUMITOMO WIRING SYST LTD

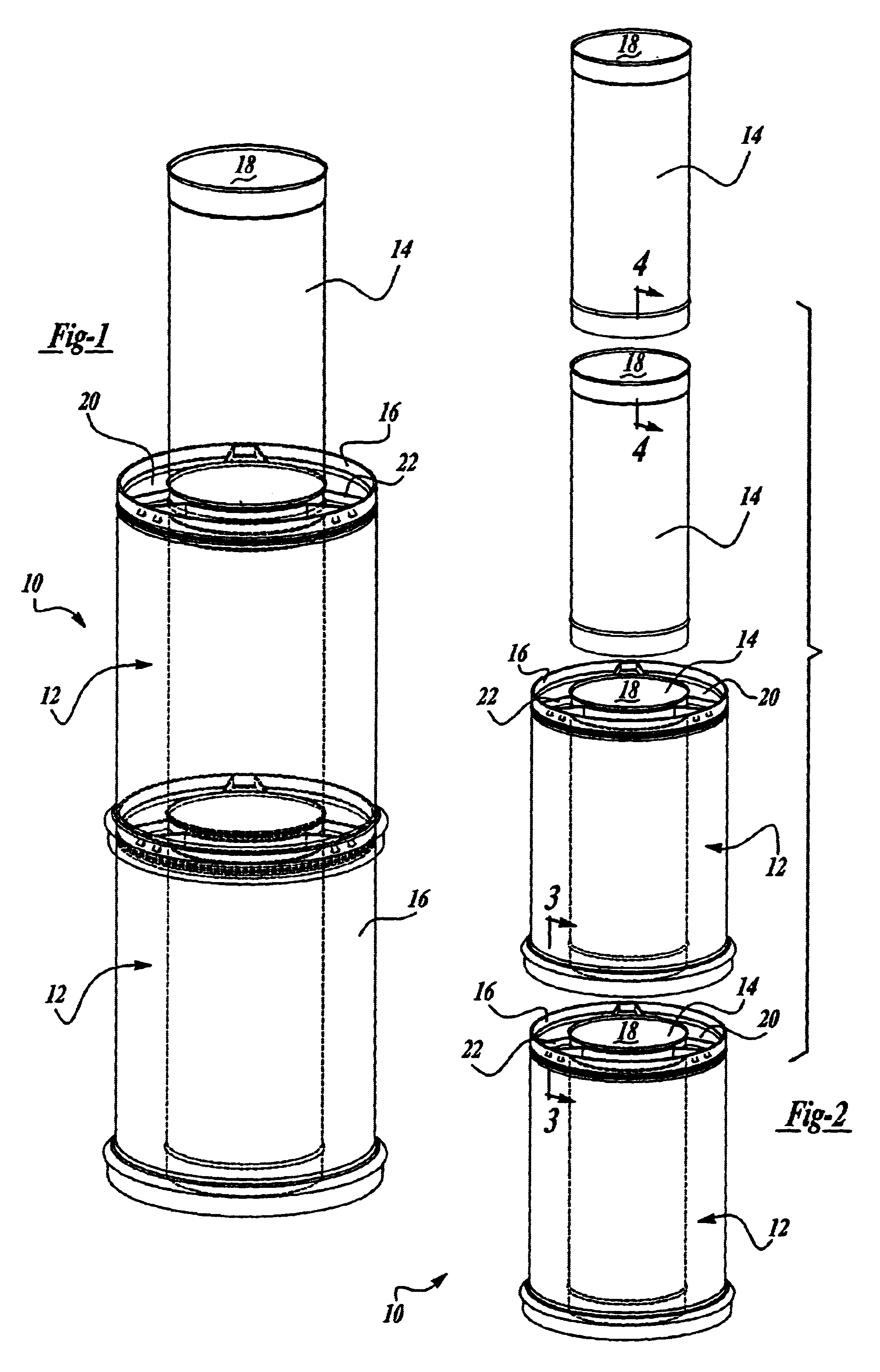

Direct venting vent pipe

InactiveUS6634352B2Facilitate run of unrestricted lengthEfficient combustionPipe supportsDomestic stoves or rangesDirect combustionDouble wall

A venting system for a direct vent fireplace or other direct vent appliance to direct combustion gases to an exterior area. The direct venting vent pipe facilitates unrestricted lengths of pipe installations. The vent pipe has a double wall construction forming an interior axial passageway and a coaxial outer passageway. The double walls are spaced apart by an insert to maintain coaxial spacing. Sections of the vent pipe are lockingly connected to prevent separation and ensure sealing connection between the pipe sections. Elastic seal members are utilized between the matingly connected sections and a mechanical lock assembly prevents separation.

Owner:CARDINAL IP HLDG LLC

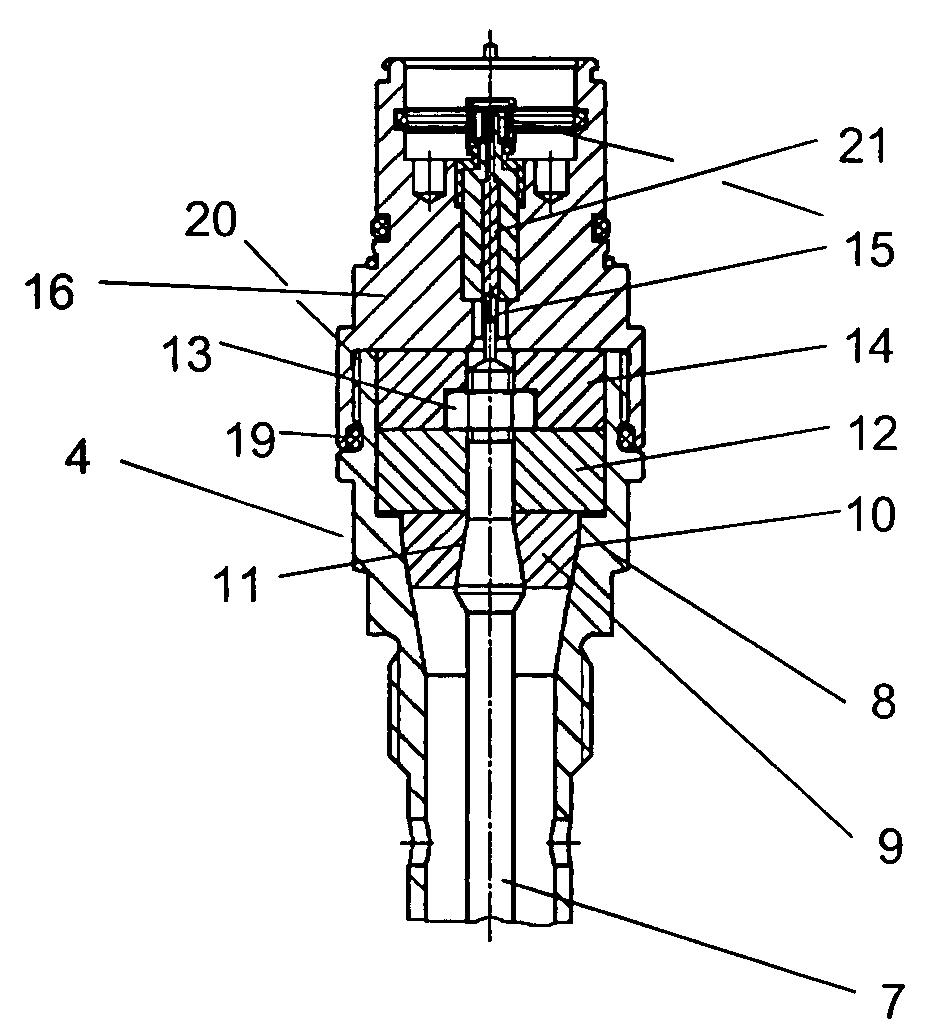

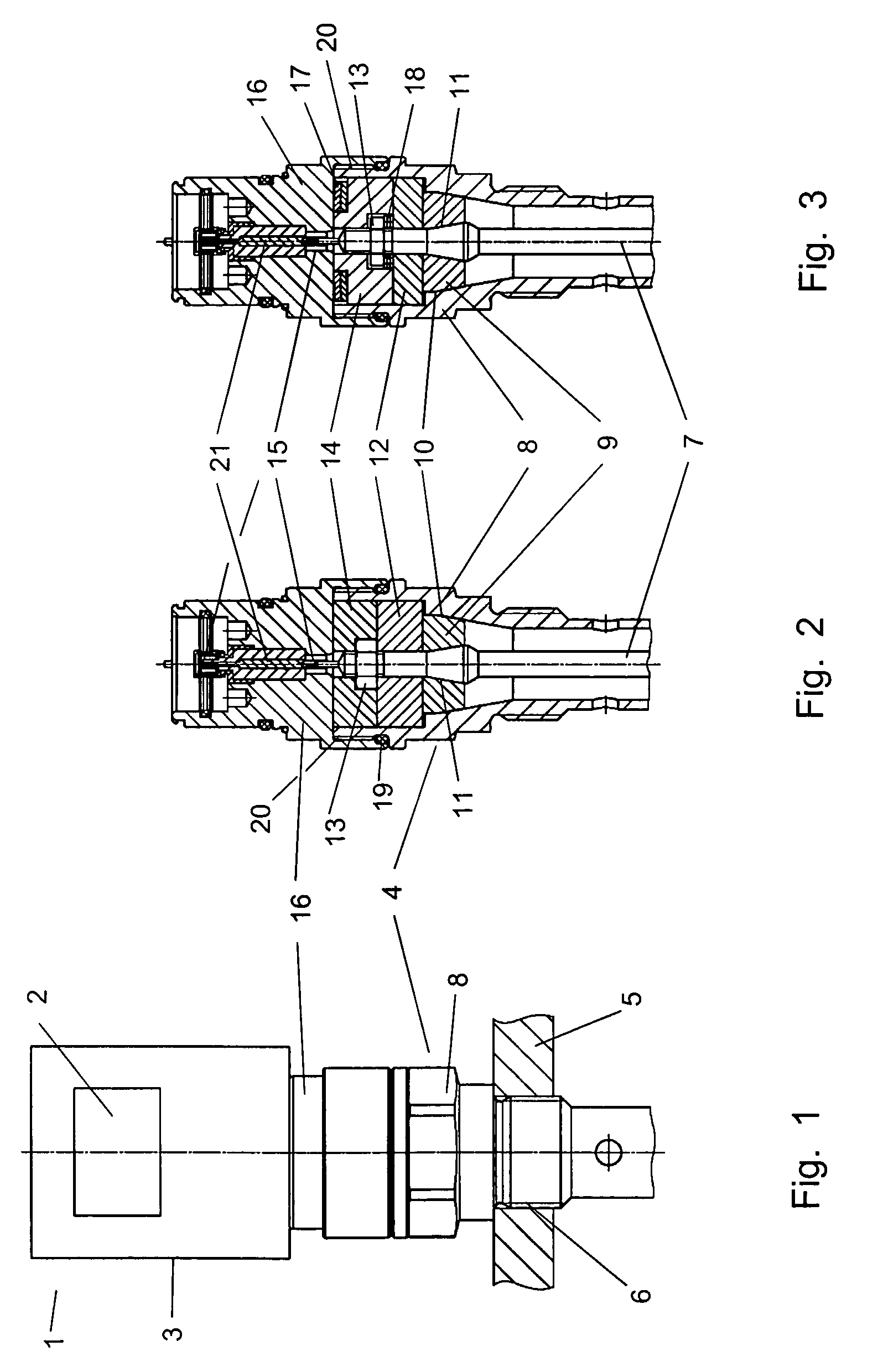

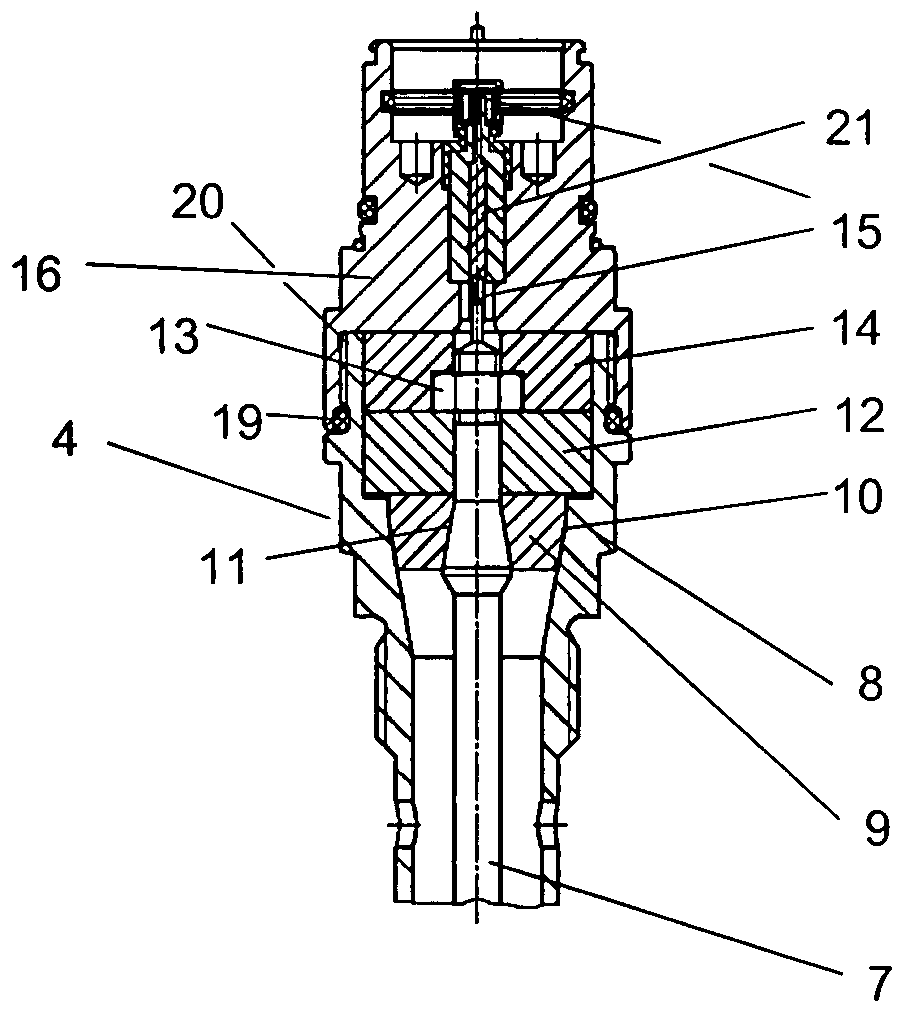

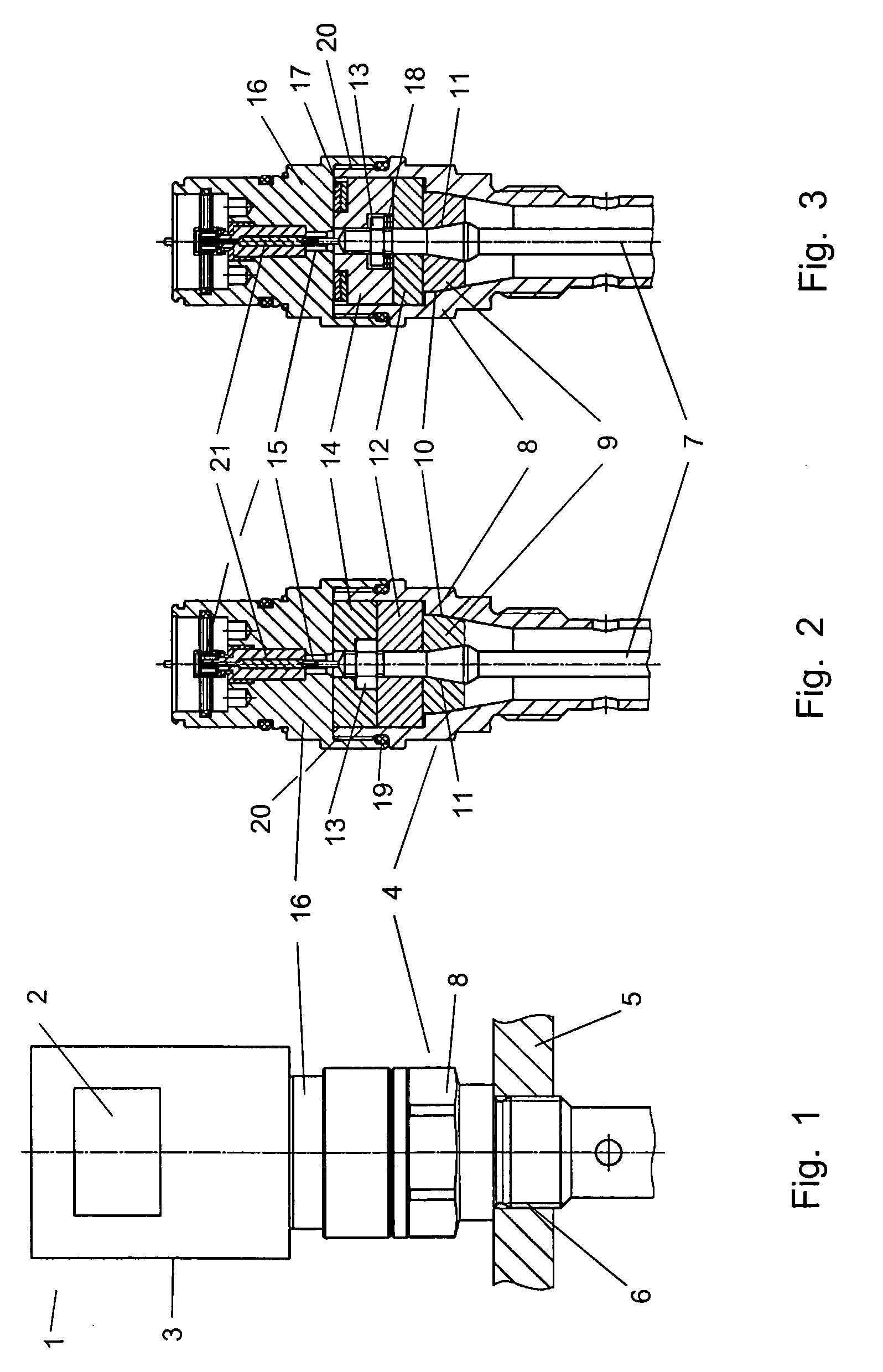

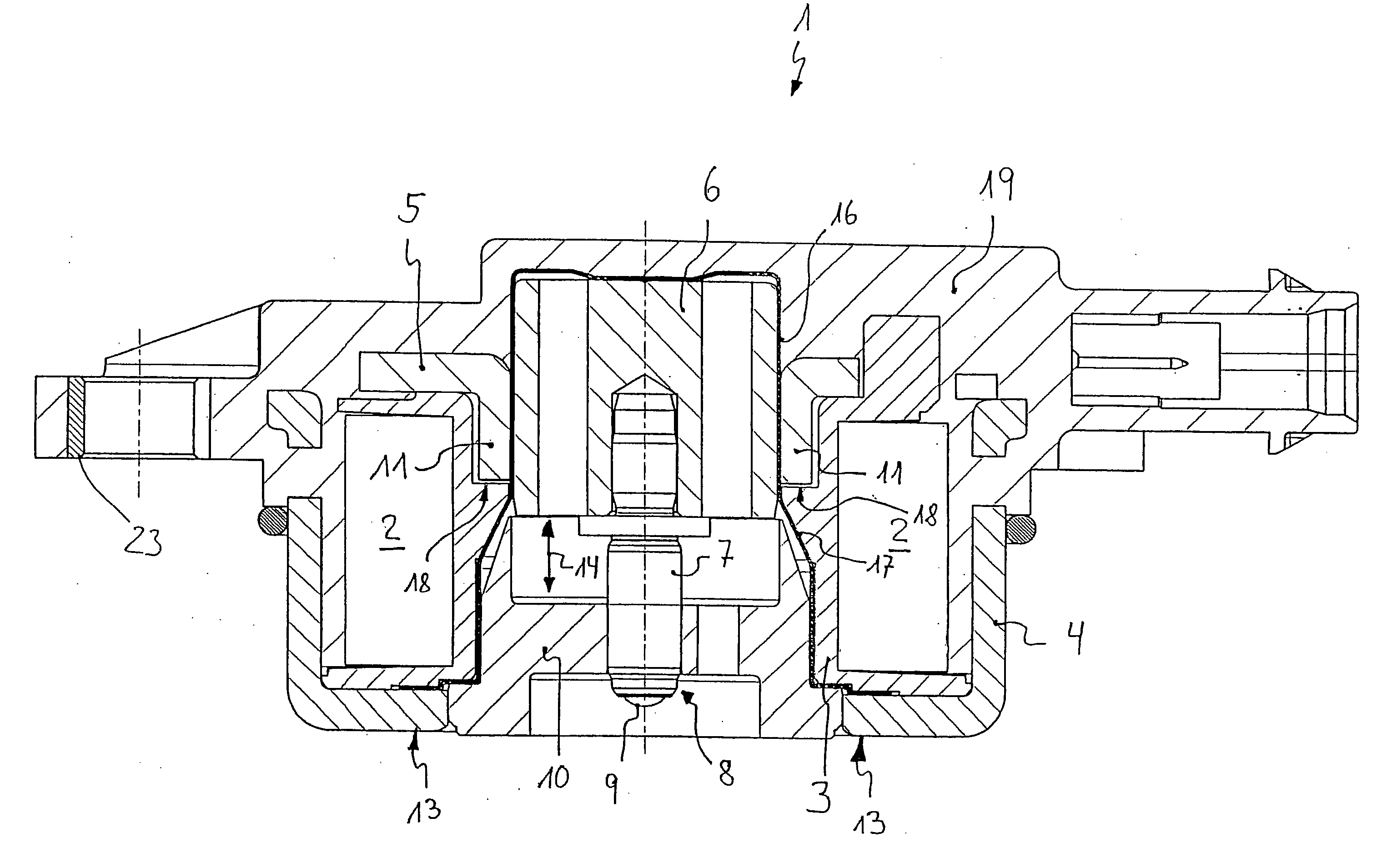

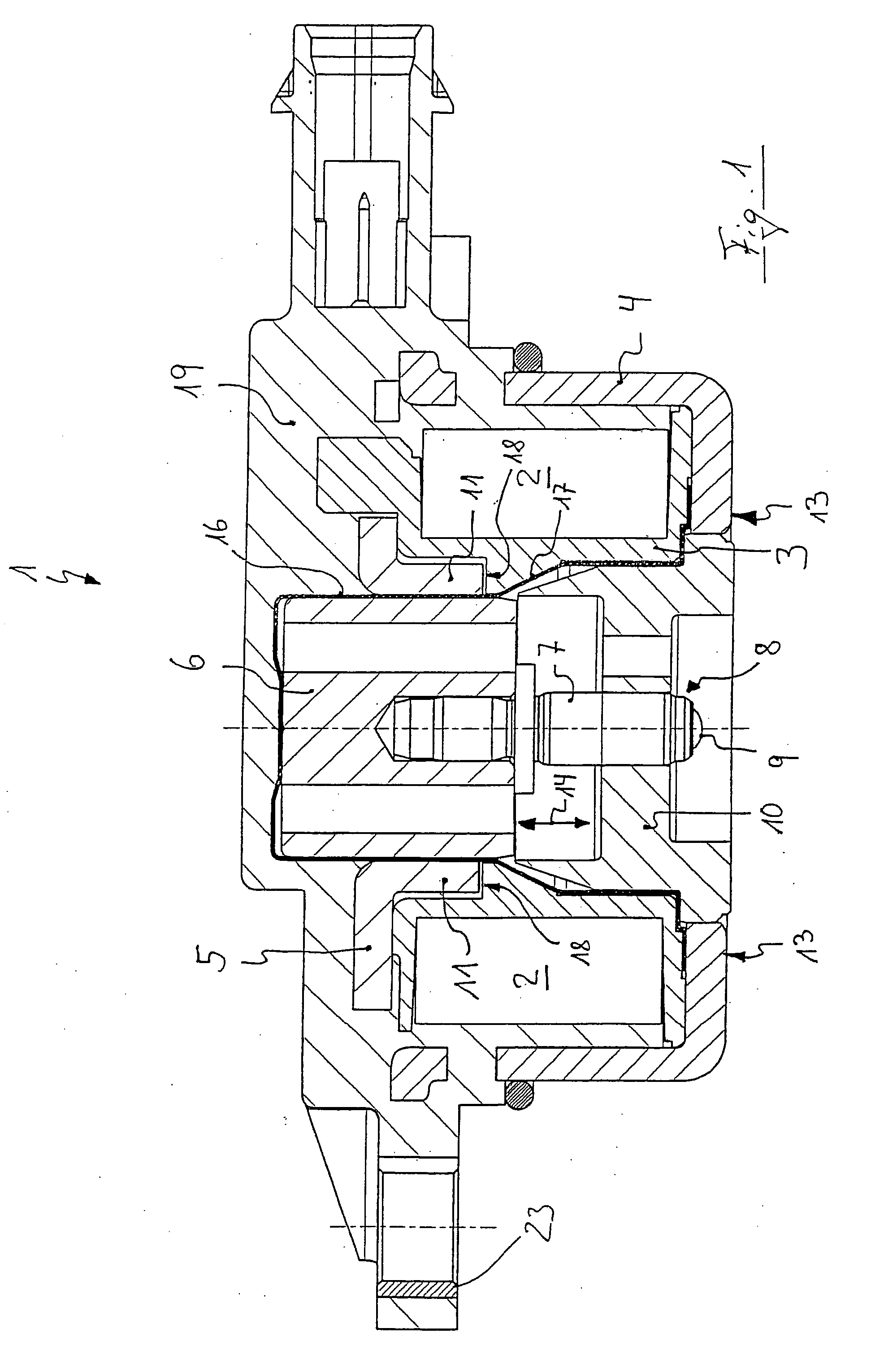

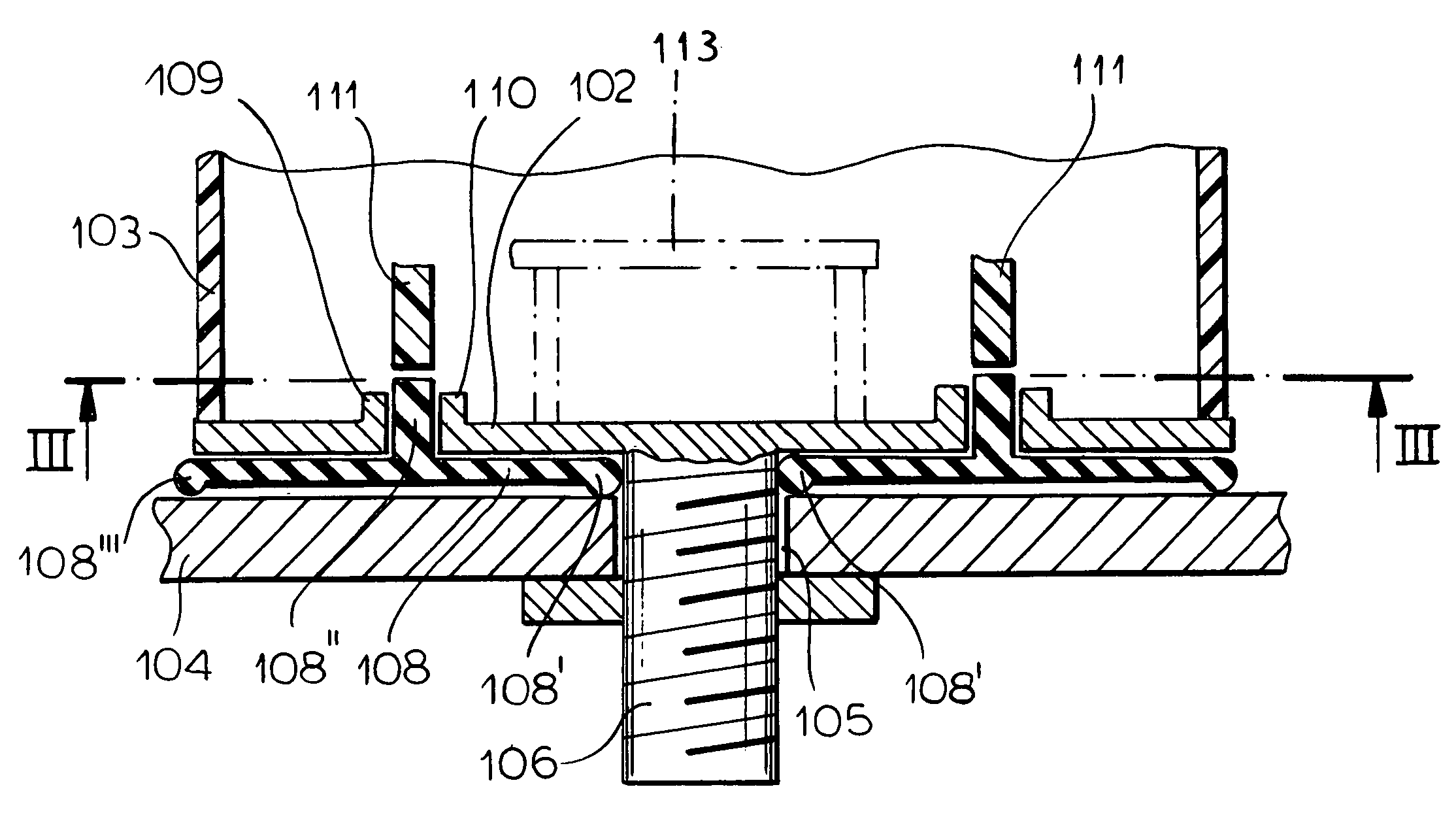

Coaxial gapless guide-through assembly for a filing level sensor

InactiveUS7401511B2Simpler and cheap constructionEnsure sealing performanceLiquid fillingLiquid flow controllersElectrical conductorLevel sensor

The present invention relates to a guide-through assembly (4) for a filling level sensor working according to the principle of delay measurement of guided electromagnetic waves or for a capacitive filling level sensor, which for sealing the interior of the vessel against the interior of the sensor has no elastomeric sealing materials and in particular no elastomeric o-rings seals. This can be ensured by precisely machining the components which are essentially concentrically arranged in the guide-through assembly (4) on their circumferential surfaces (10, 11), so that in an assembled state the components arranged in the guide-through assembly (4), such as the interior conductor (7) and the dielectric materials (9, 12, 14) surrounding the interior conductor (7), contact each other at their mutually adjacent circumferential surfaces (11) in a sealing and positive engagement, so that additional sealing elements are not needed.

Owner:VEGA GRIESHABER GMBH & CO

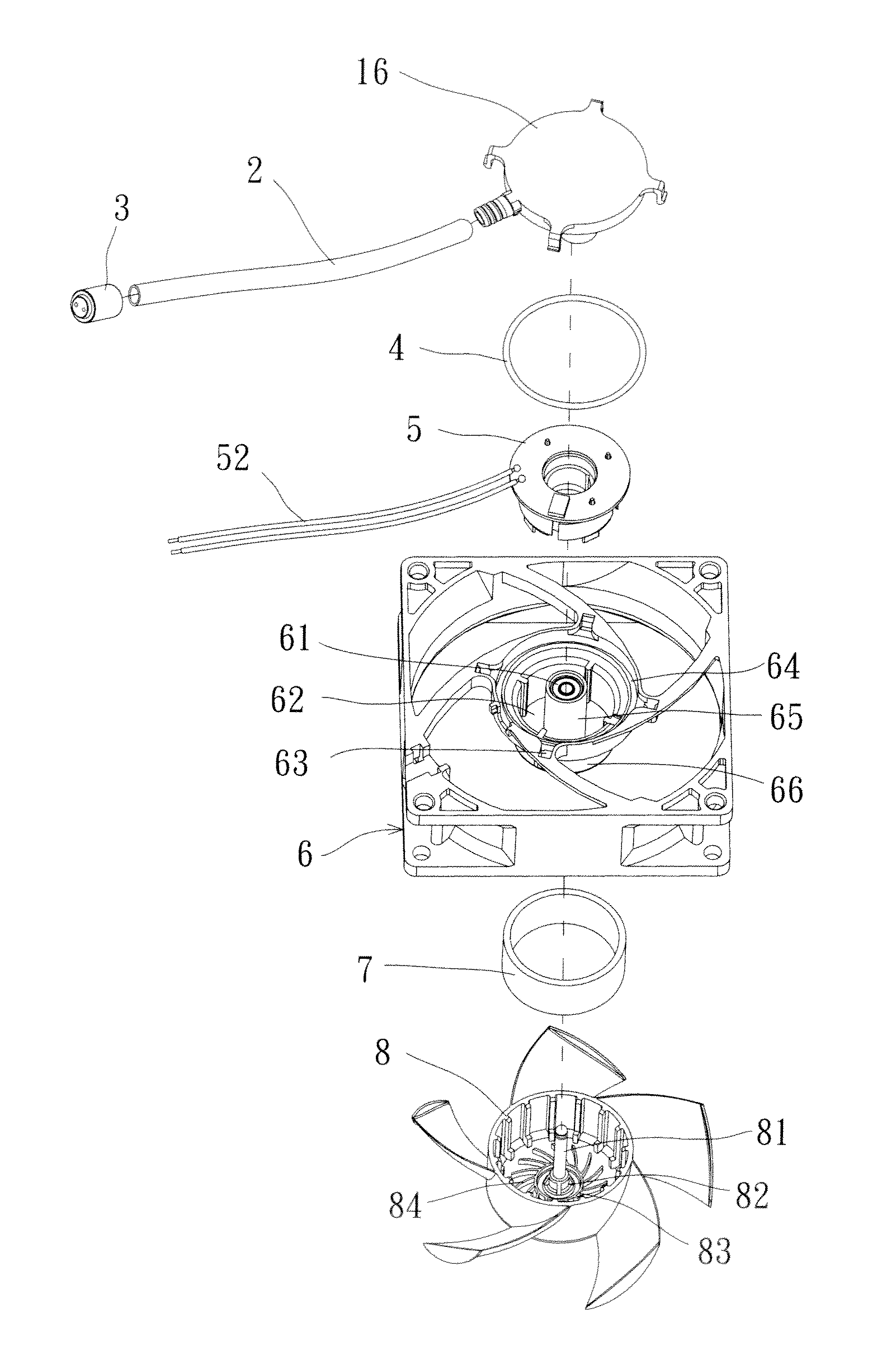

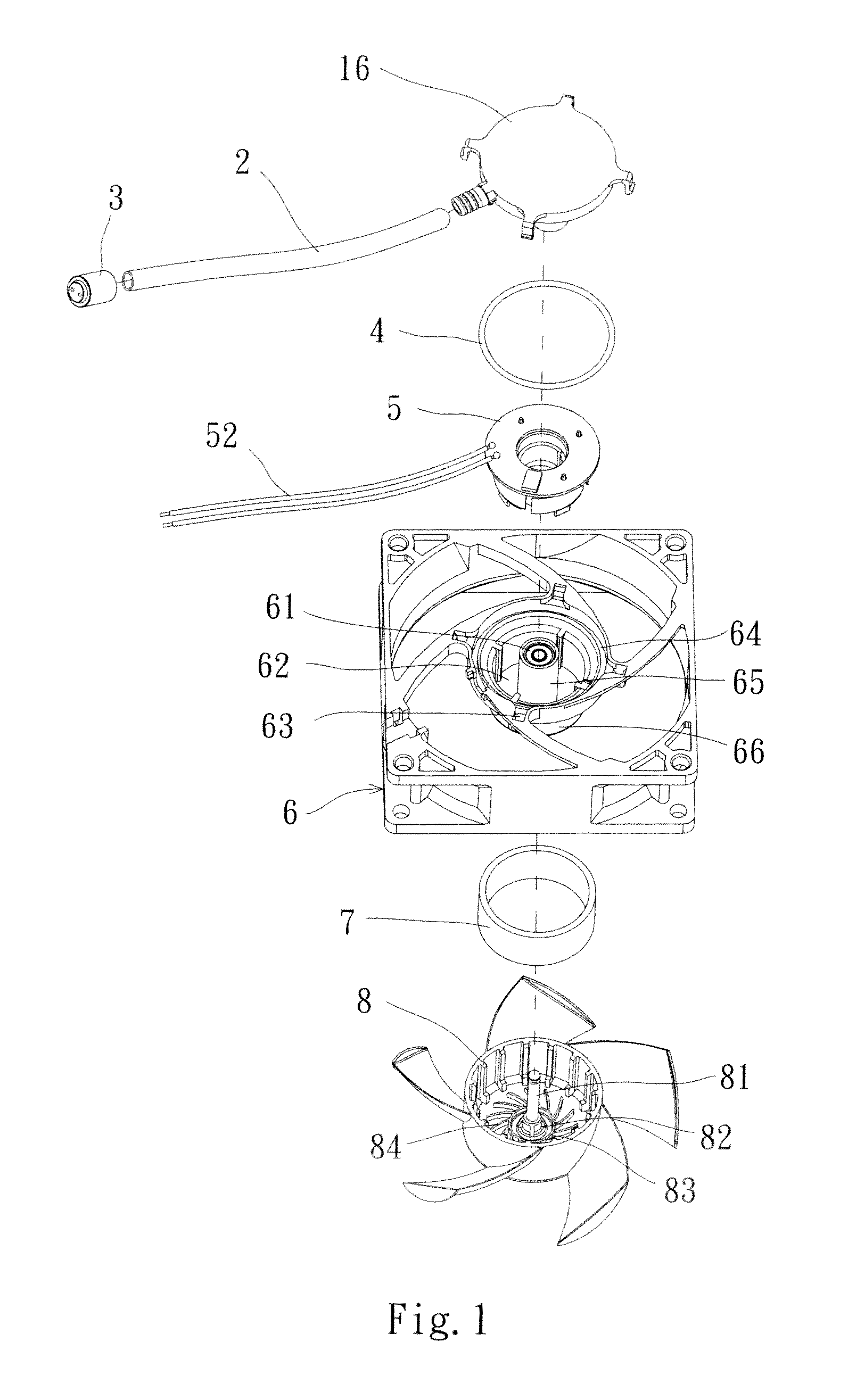

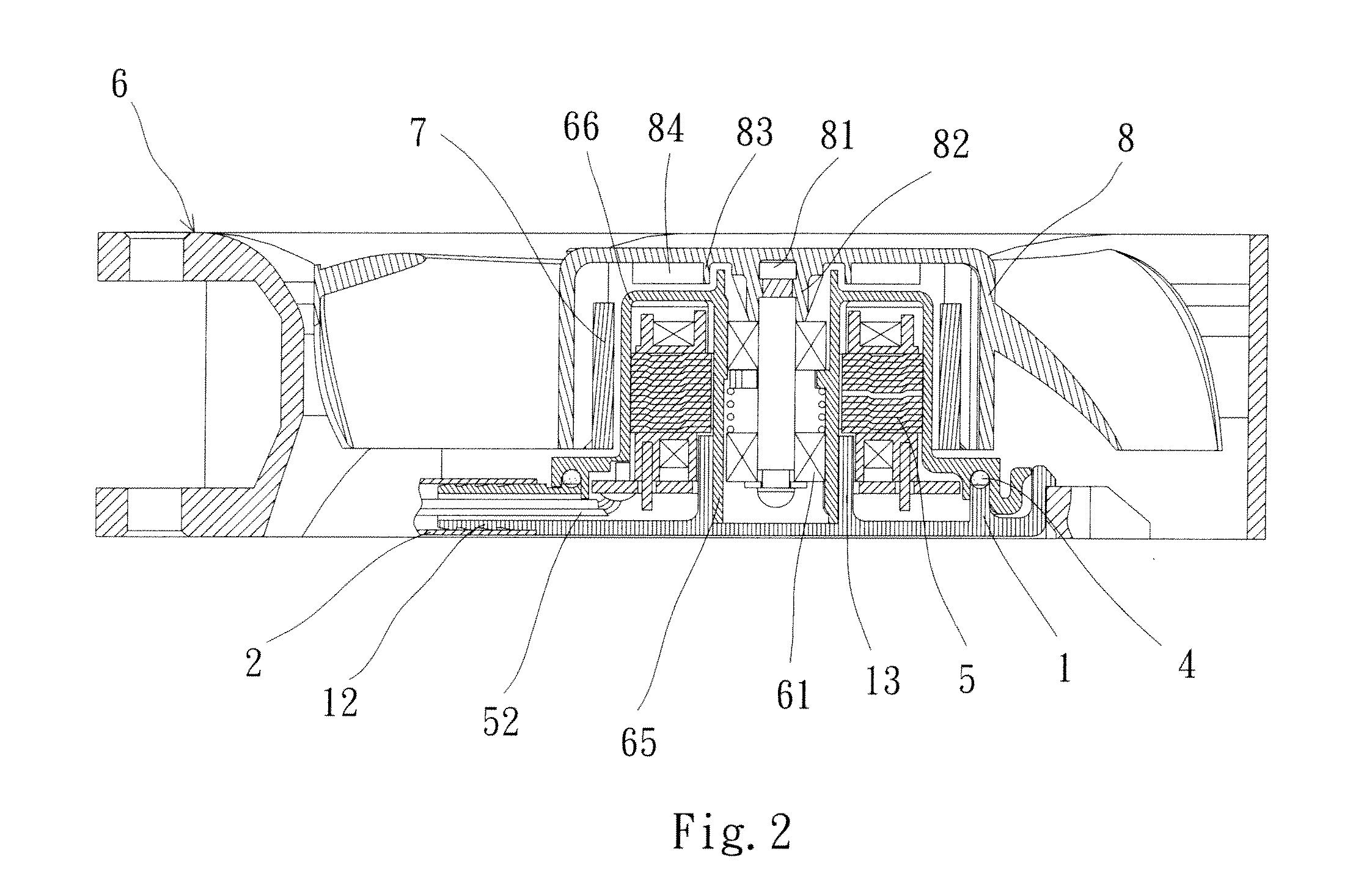

Water-proof dust-proof and salty-mist-proof cooling fan

InactiveUS20120032542A1Easily instalEnsure qualityPump componentsMechanical energy handlingEngineeringFan blade

A water-proof dust-proof and salty-mist proof cooling fan, comprising: a fan frame, which is provided with a fixing round stage inside, and a fixing sleeve is disposed in a center of said fixing round stage; a ring-shaped U slot is provided in a bottom end surface of said round stage, such that a sealing circle is provided in said ring-shaped U slot; a water-proof cover body, fixedly connected to said fan frame through said sealing circle; and a fan-blade hub, where an inverse cone-shaped fixing table is provided protruding from a cavity center of said fan-blade hub, and said fixing table is connected to a main axis. Said round stage is a blind hole, with its open end provided at a bottom portion of said fan frame, such that said round stage, said sealing circle, and said cover body together form a tight-sealing enclosure.

Owner:ROTECHNIC

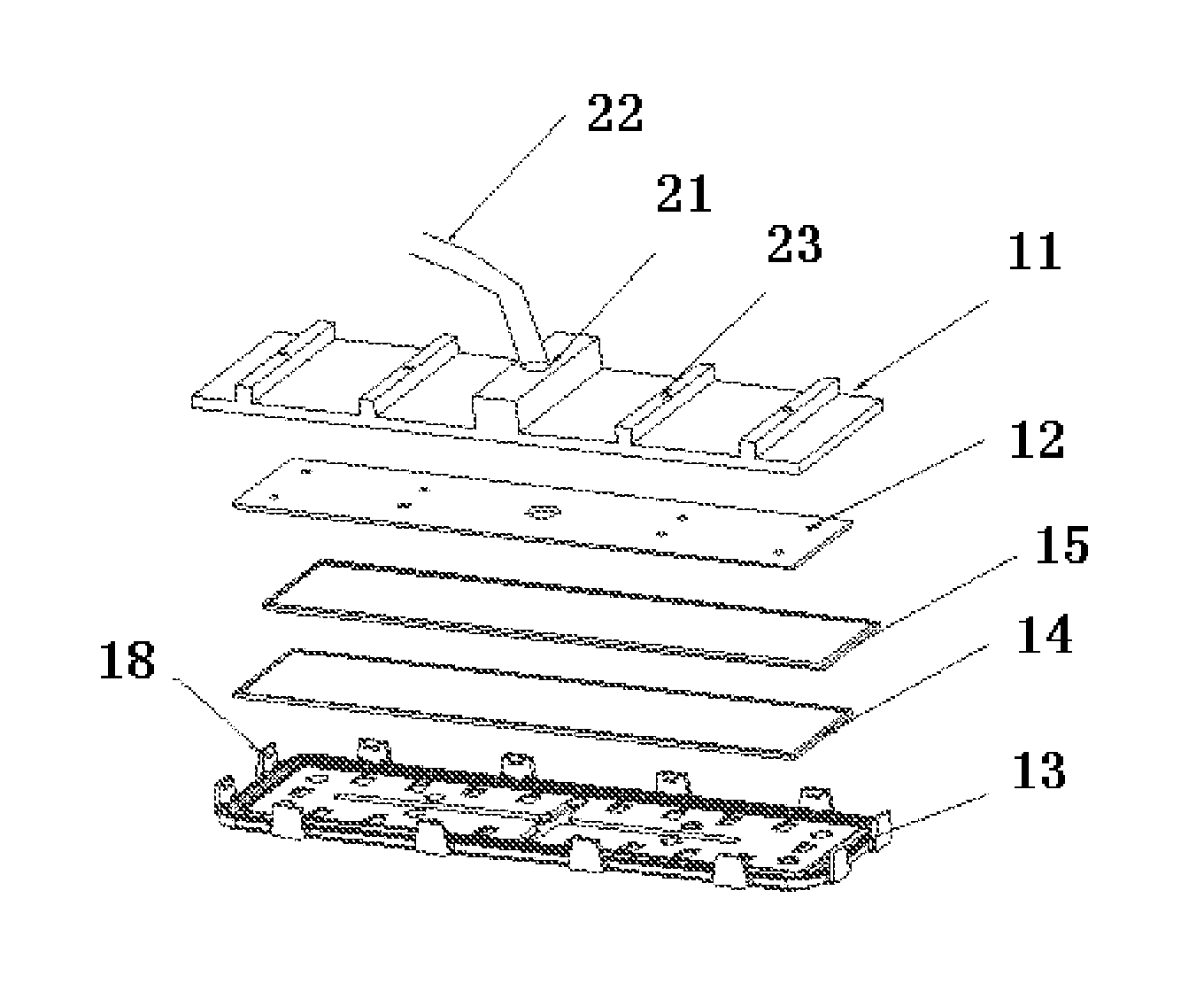

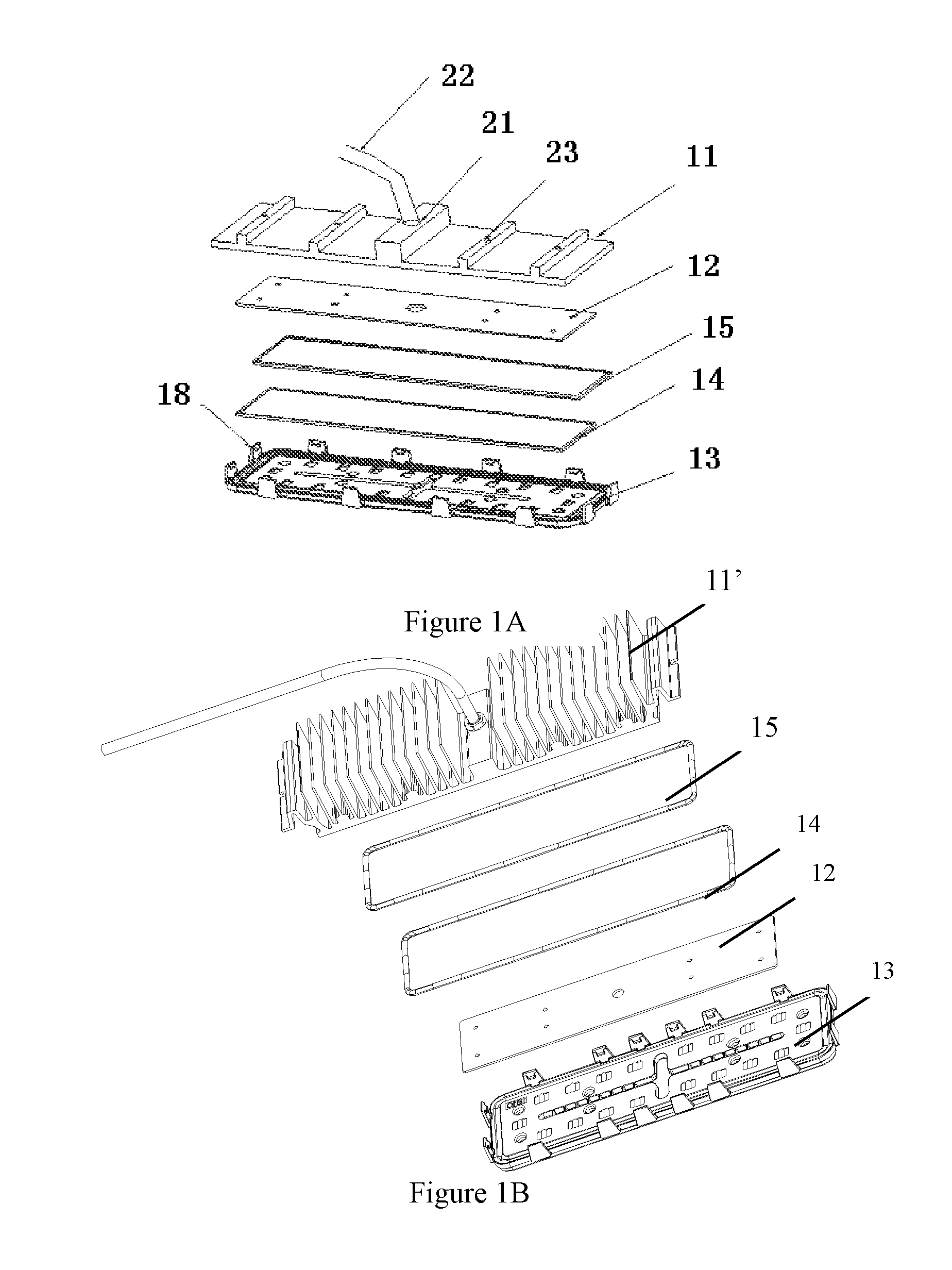

LED Module Sealing Technology

ActiveUS20150128409A1Easy to useReduce the amount requiredPlanar light sourcesPipesWater vaporEngineering

A sealing process of LED modules includes a waterproof wire put through a wire-through hole of a heat sink to be connected with a positive-negative solder joints on a PCB board, which are subjected to glue sealing treatment. A waterproof sealing process is operated between the waterproof wire and wire-through hole. The PCB board is fixed on the heat sink. One sealing ring is placed into a groove. A ring of liquid silica gel is evenly applied along the other groove. The heat sink installed with the PCB board and the waterproof wire are inversely buckled on the lens set which is fixed with the solid silica gel ring and liquid silica gel. At least two waterproof sealing rings are used to isolate an LED chip from the outside so as to prevent all water vapor or other harmful gases from corroding the chip and the PCB

Owner:HANGZHOU HPWINNER OPTO CORP

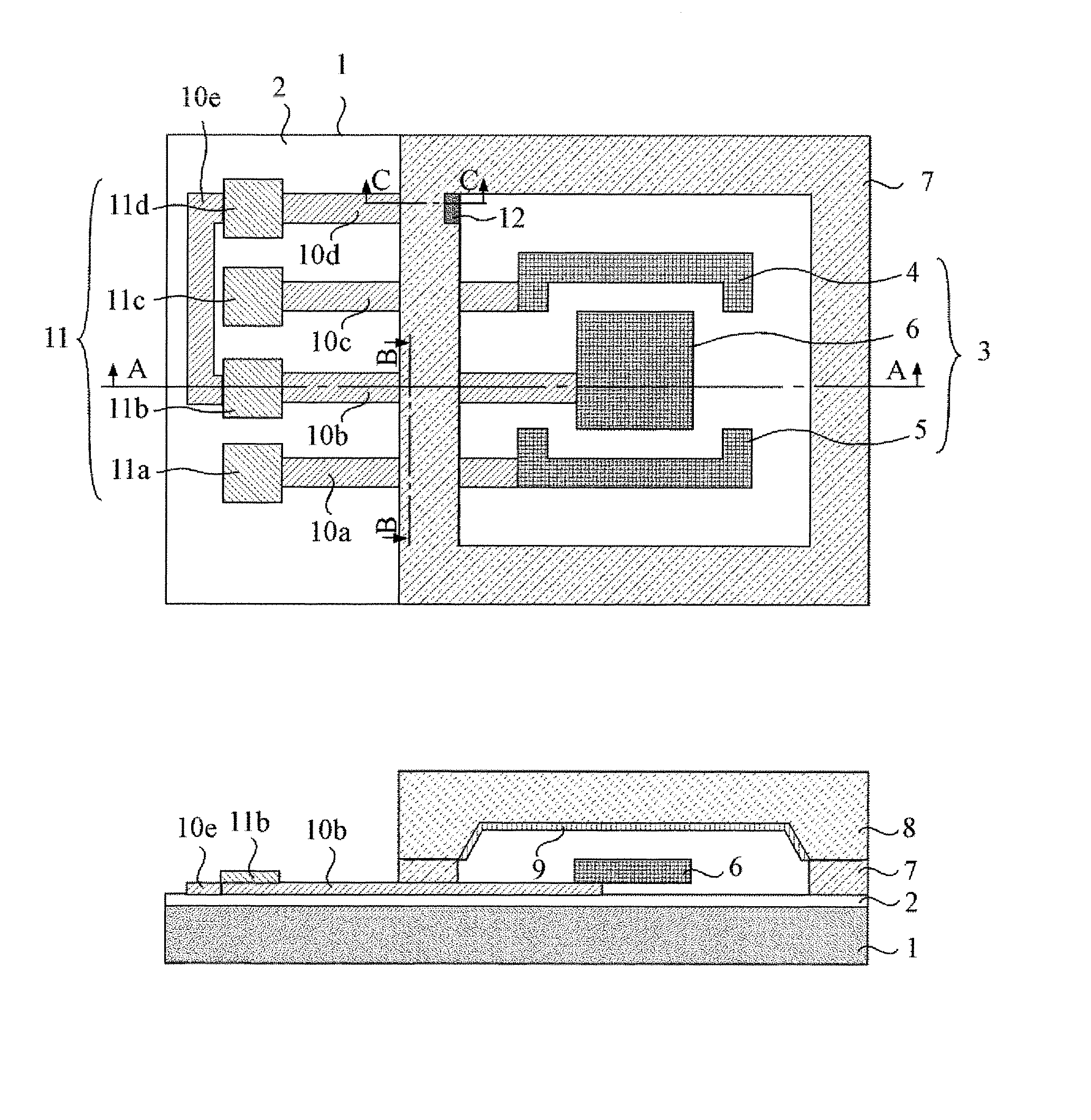

Electrostatic-capacitance-type acceleration sensor

ActiveUS20070062285A1Avoiding characteristicImprove sealingLinear/angular speed measurementAcceleration measurementCapacitanceAnodic bonding

In an electrostatic-capacitance-type acceleration sensor, water, etc. penetrating into a sealed space incorporating an acceleration detector having a movable electrode 6, and sticking of the movable electrode 6 to a cap 8 due to static charge accumulated on the cap 8 during the anodic bonding being performed are prevented. A conductive shielding film 9 that can be extendedly transformed on the entire inner face of the cap 8 constituting the sealed space is provided, which is not only extendedly arranged so as to be sandwiched between a bonding frame 7 and the cap 8, but also electrically connected to the movable electrode 6; thereby, even if unevenness exists on the surface of the bonding frame 7, not only sufficient anodic bonding between the bonding frame 7 and the cap 8 becomes possible, but also the electric field due to the static charge accumulated in the cap 8 can be shielded.

Owner:MITSUBISHI ELECTRIC CORP

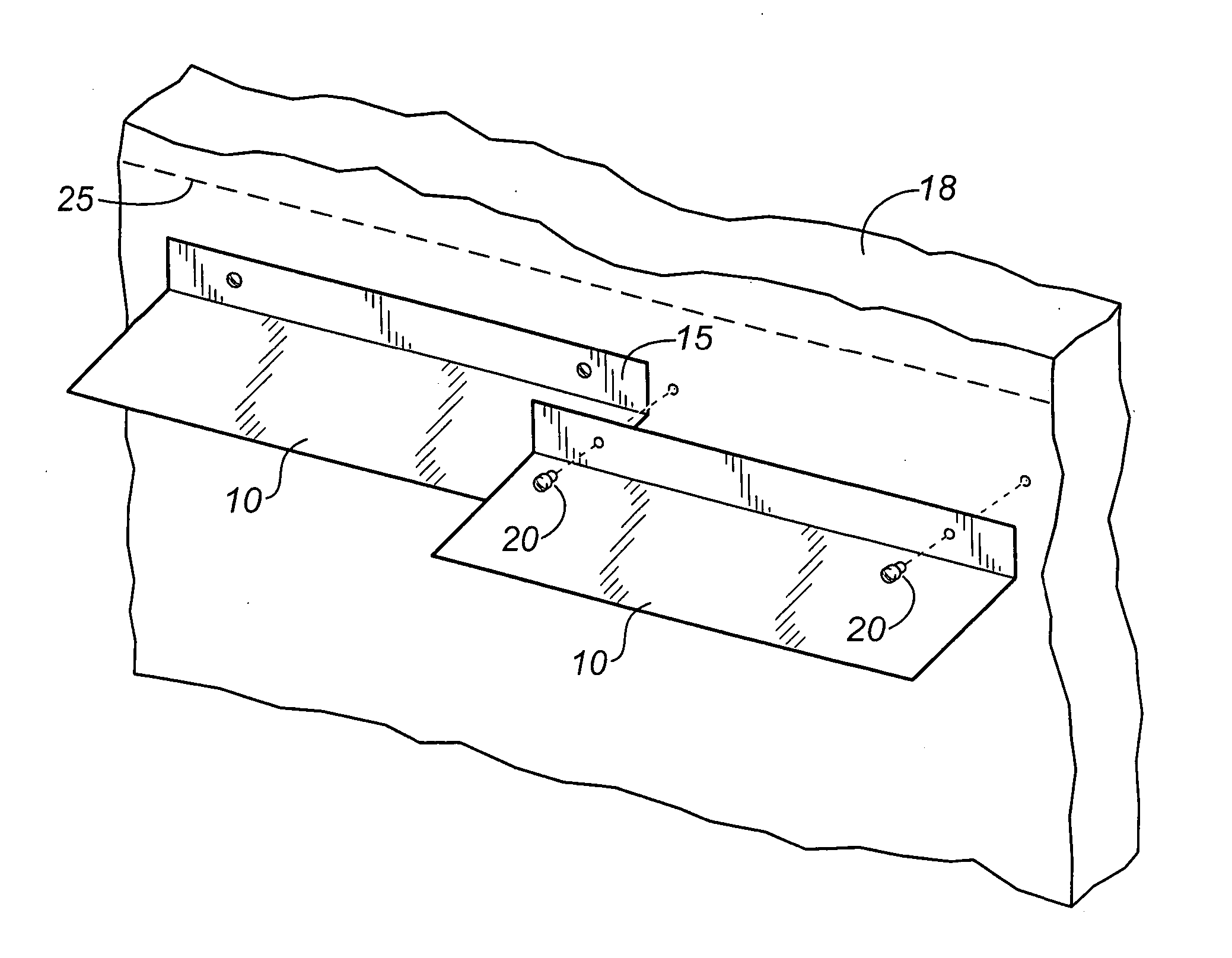

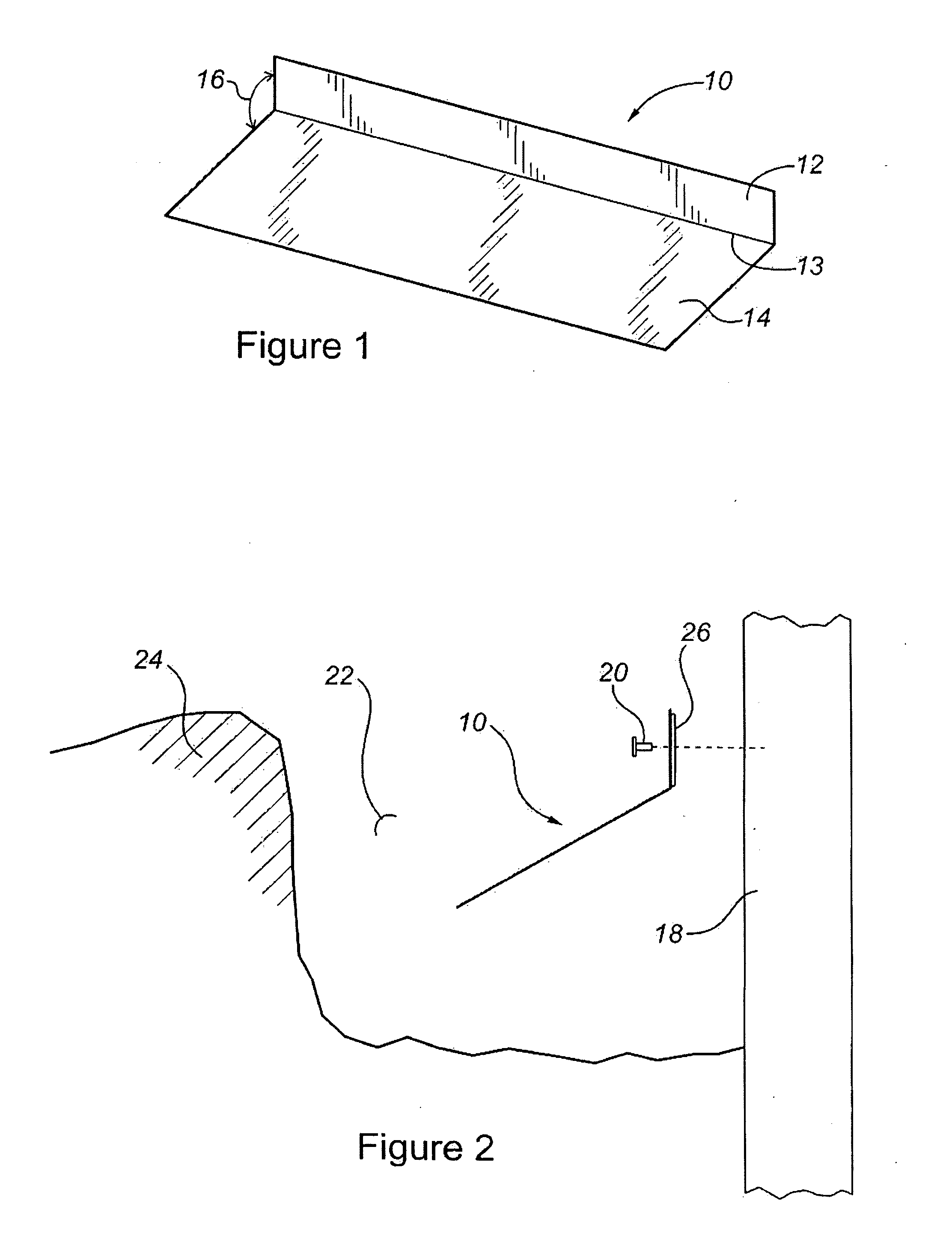

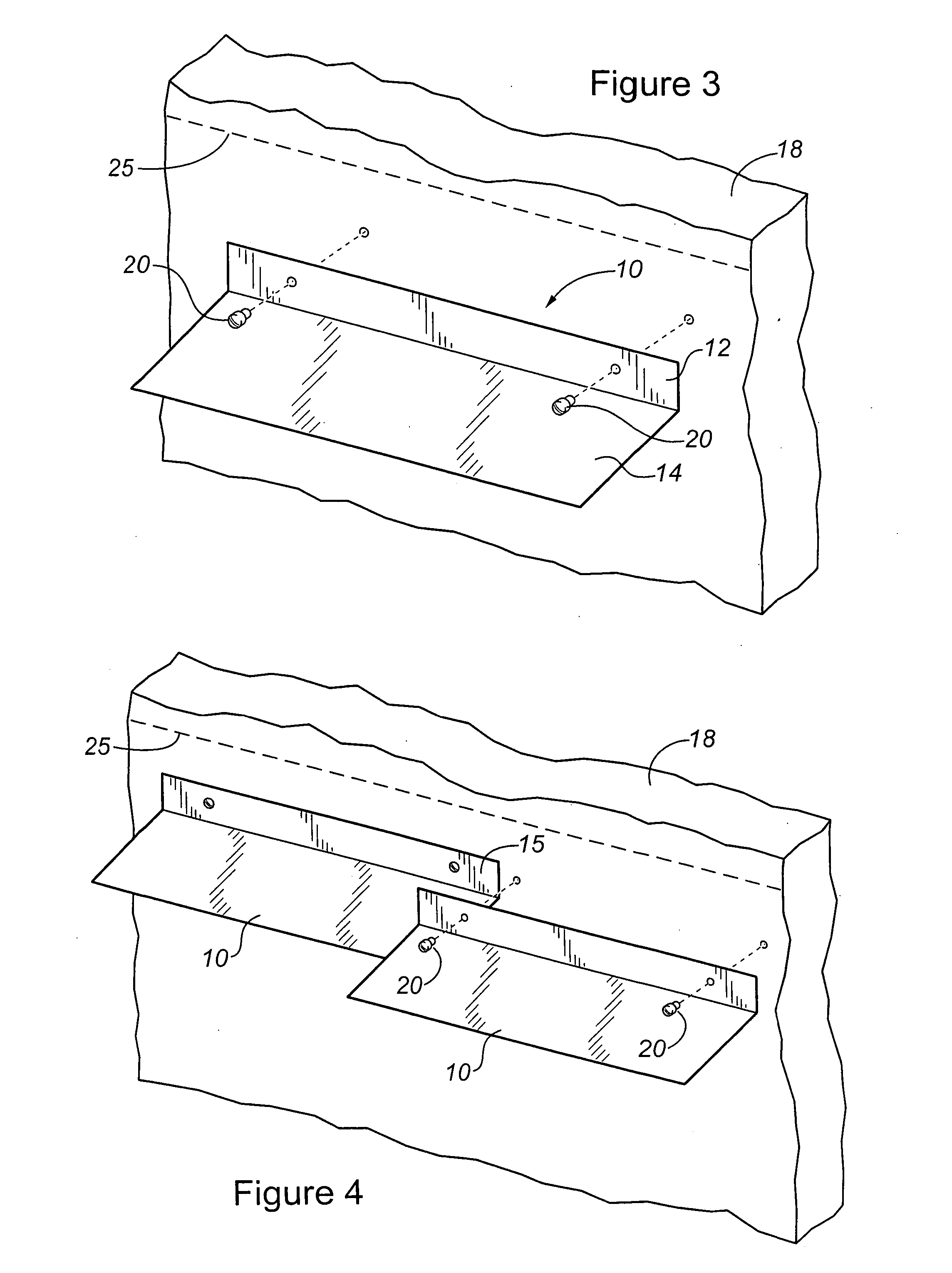

Method and apparatus for deflecting liquid from a foundation wall

InactiveUS20060032158A1Easy to moveAddressing Insufficient CoverageProtective foundationBuilding constructionsEngineeringStormwater

Rain water is deflected from the foundation wall of a building structure by a flashing of non-ferrous metal that is fastened to the foundation below the grade level of the soil. Soil is trenched and exposed about the foundation, and the flashing is installed in the trench around the perimeter of the foundation wall. After installation, the trench is backfilled with soil thereby covering the flashing and restoring grade. During heavy rains or floods, water seeping into the soil is deflected away from the foundation by the flashing. This prevents water from pooling at the bottom of the foundation and seeping up into the structure through the joint where the foundation meets the basement floor.

Owner:ALL TERM FINANCING

Connector and a connector assembly method

InactiveUS7347744B2Avoid connectionMade smallElectrically conductive connectionsCoupling contact membersTotal thicknessMechanical engineering

Each of a plurality of auxiliary connector (10) includes an auxiliary housing (11), a seal (40) attached to the rear of the auxiliary housing (11), and a rear holder (50) mounted on the rear of the seal (40) to retain the seal (40). Auxiliary connectors (10) that are adjacent in an arranging direction are united by the rear holders (50). The united auxiliary connectors (10) are inserted into a frame (60) in the arranging direction through an insertion opening (60A) of the frame (60), and are retained in the frame (60) by engaging a lock (50B) on the last auxiliary connector (10A) and an interlocking portion (61) of the frame (60). The frame (60) has no partition walls between the auxiliary connectors (10). Thus, the connector is narrowed by a total thickness of the partition walls.

Owner:SUMITOMO WIRING SYST LTD

Coaxial gapless guide-through assembly for a filling level sensor

InactiveUS20050150568A1Well formedImprove stabilityLiquid fillingLiquid flow controllersElectrical conductorLevel sensor

The present invention relates to a guide-through assembly (4) for a filling level sensor working according to the principle of delay measurement of guided electromagnetic waves or for a capacitive filling level sensor, which for sealing the interior of the vessel against the interior of the sensor has no elastomeric sealing materials and in particular no elastomeric o-rings seals. This can be ensured by precisely machining the components which are essentially concentrically arranged in the guide-through assembly (4) on their circumferential surfaces (10, 11), so that in an assembled state the components arranged in the guide-through assembly (4), such as the interior conductor (7) and the dielectric materials (9, 12, 14) surrounding the interior conductor (7), contact each other at their mutually adjacent circumferential surfaces (11) in a sealing and positive engagement, so that additional sealing elements are not needed.

Owner:VEGA GRIESHABER GMBH & CO

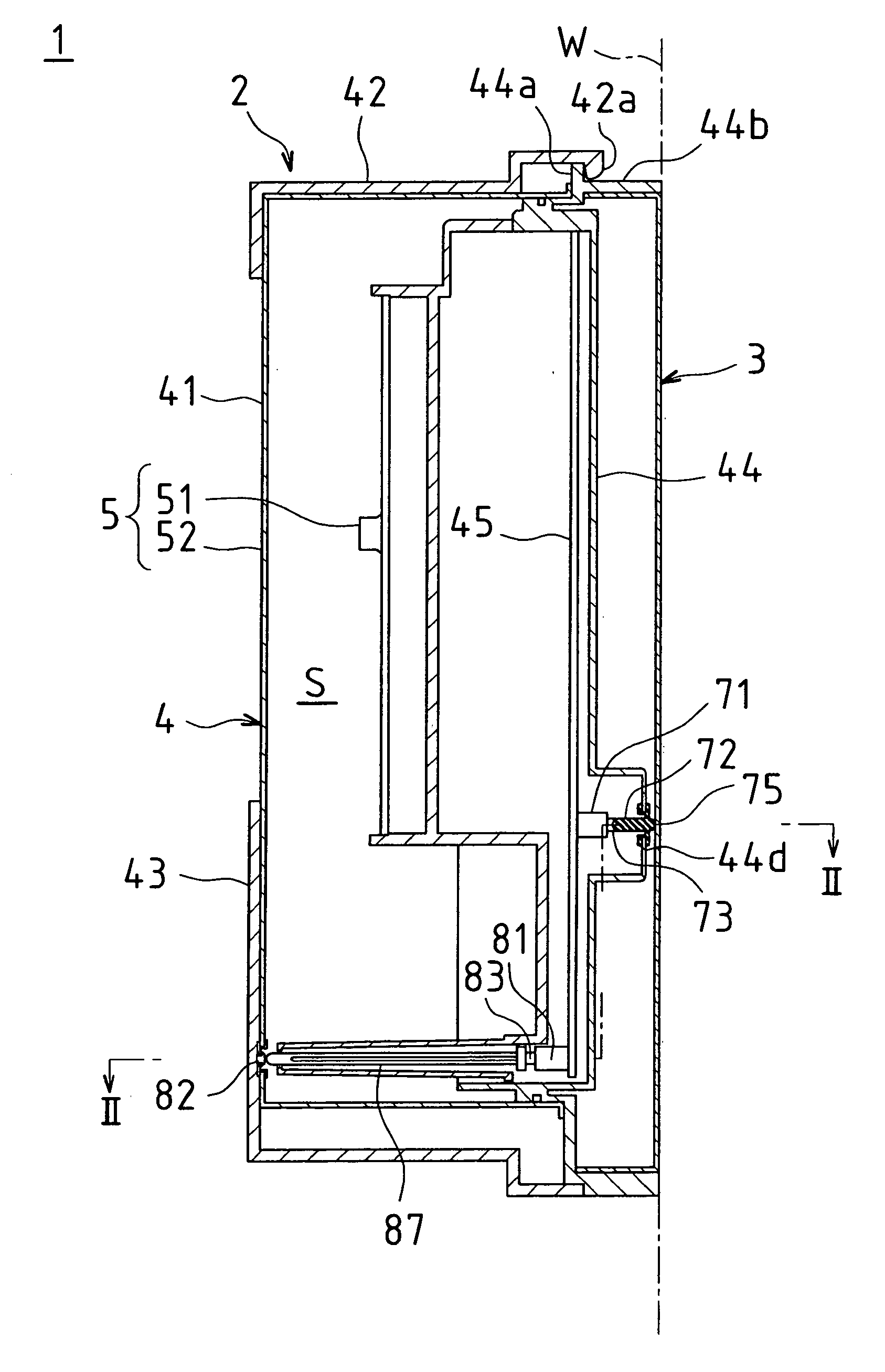

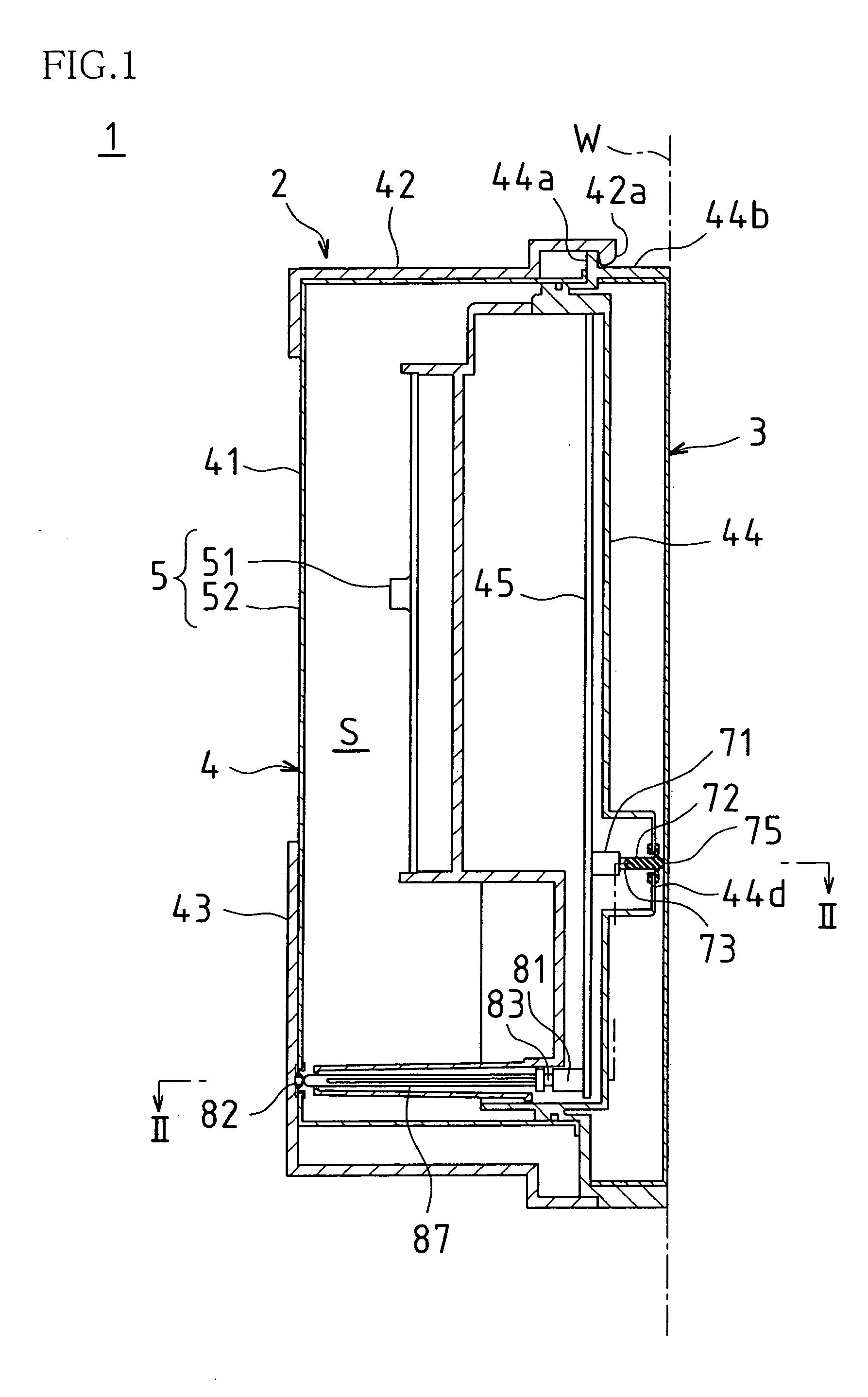

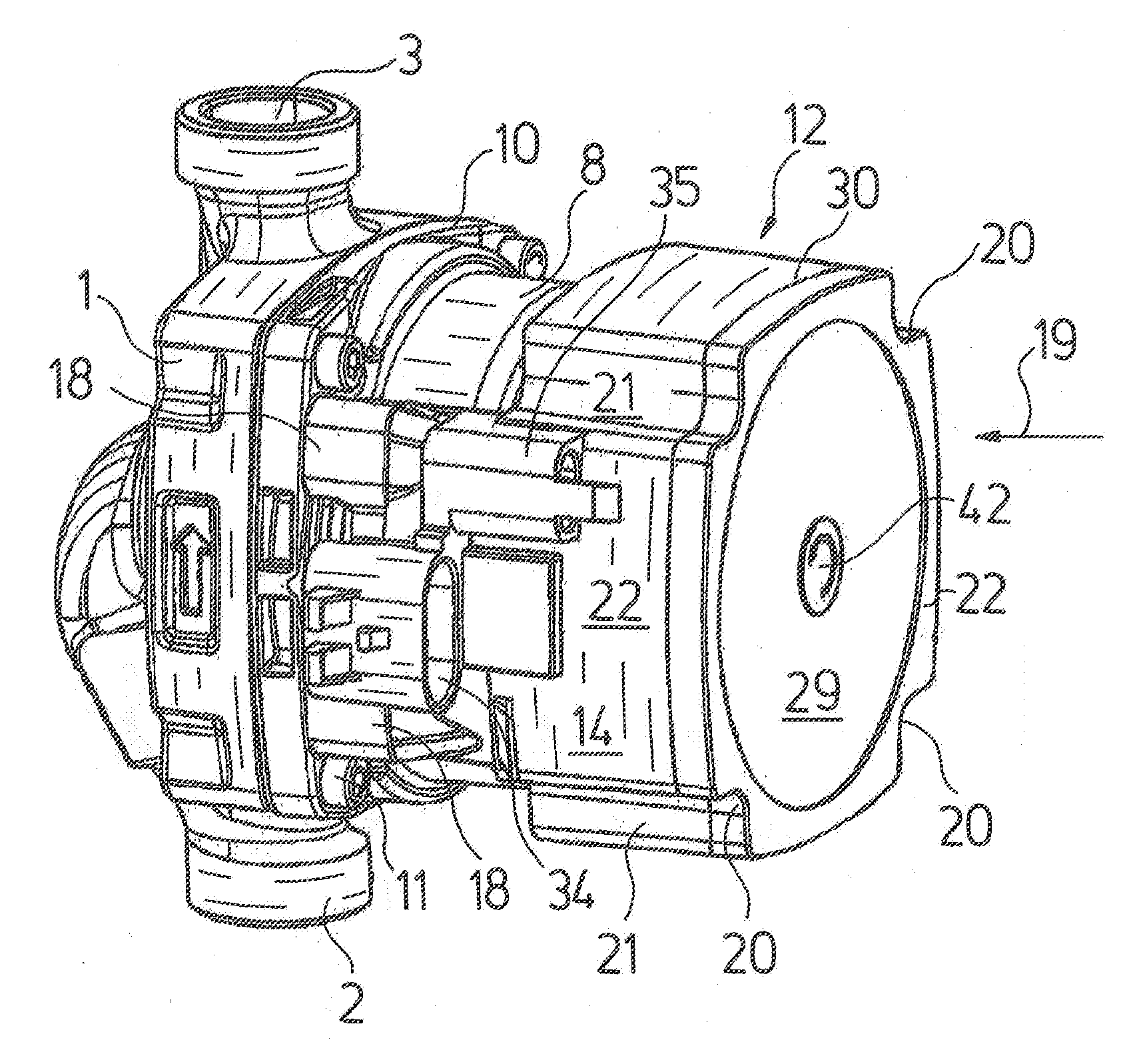

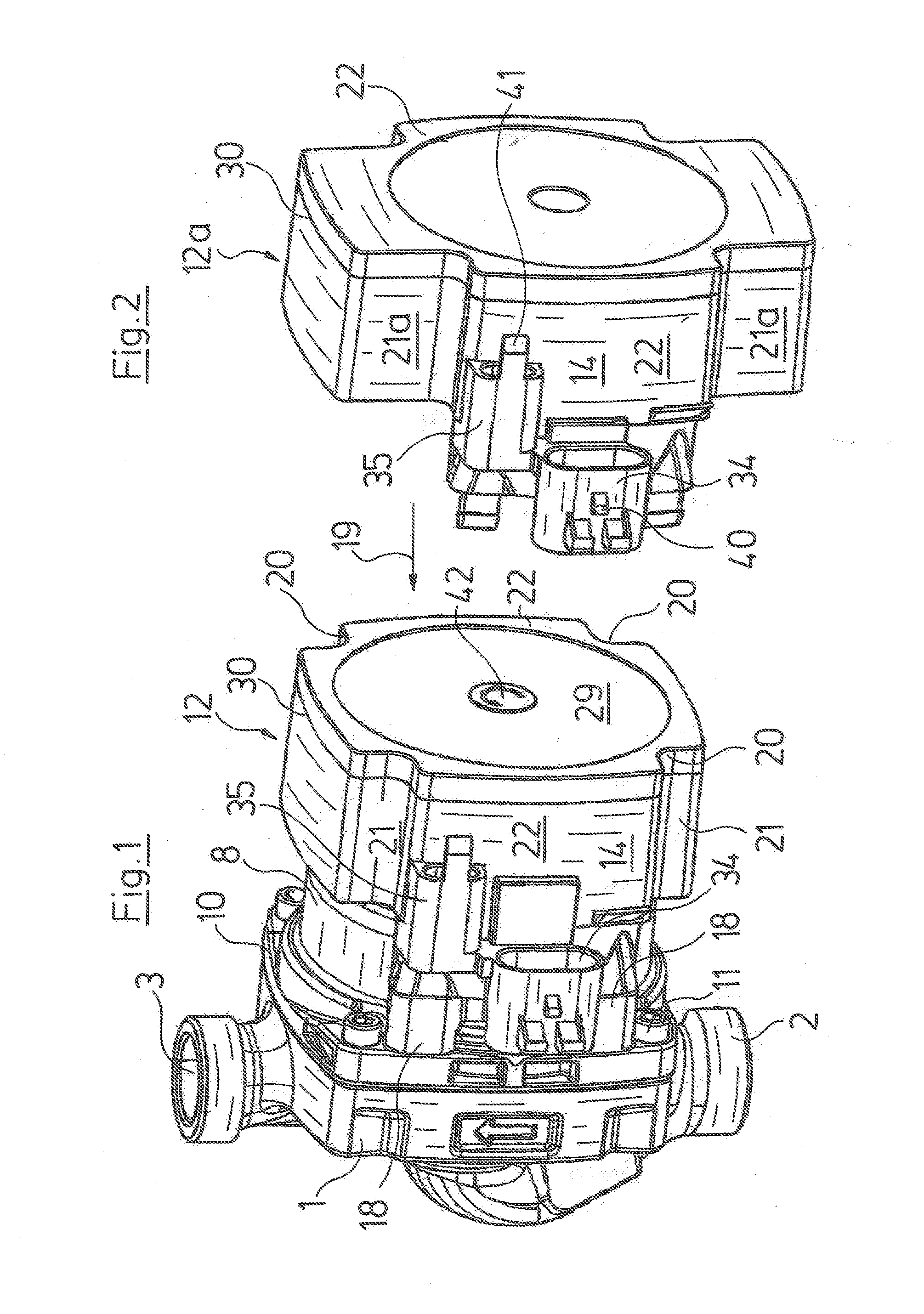

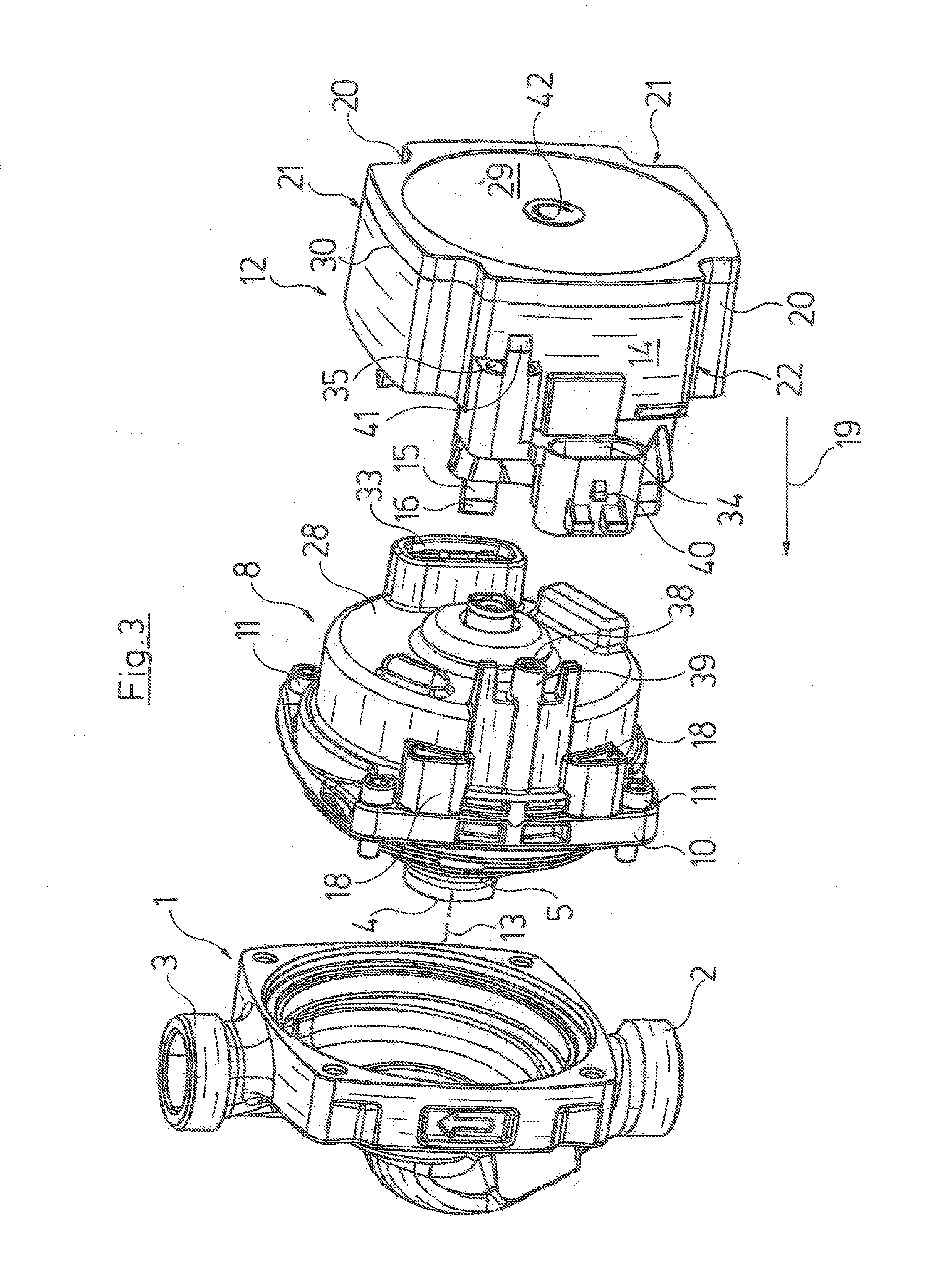

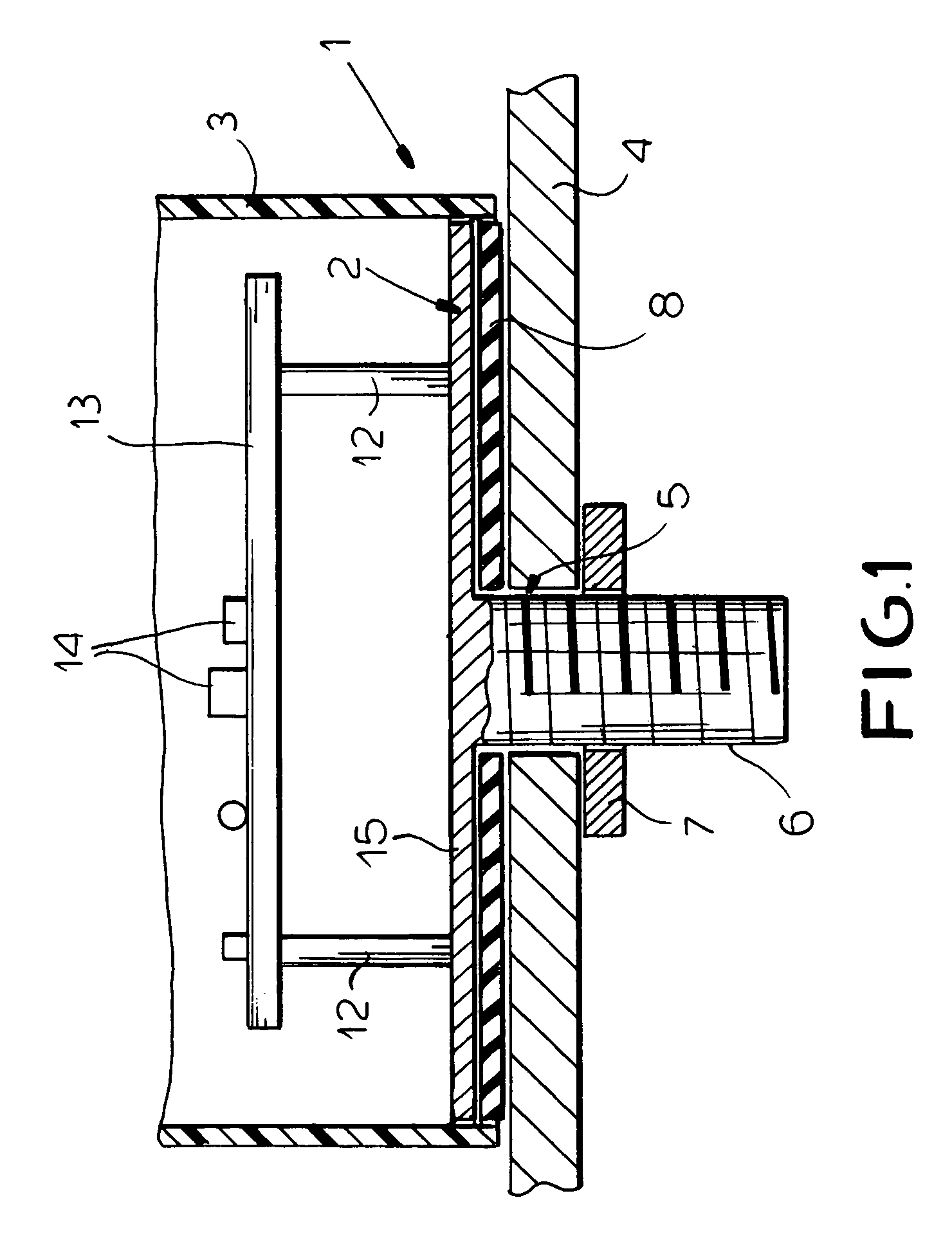

Heat circulation pump

ActiveUS20130343935A1Lower manufacturing requirementsLower assembly costsAssociation with control/drive circuitsPump componentsElectricityImpeller

A heat circulation pump includes a pump housing (1) with a pump impeller arranged therein which is driven by an electric motor arranged in a motor housing (8) which axially connects to the pump housing (1). The heat circulation pump also includes a terminal box (12) which is axially connected to the motor housing (8) in order to receive electric and / or electronic components of the engine control. A plug or socket (34) of an electric plug connection is arranged on the outside of the terminal box (12) for the electric connection. The plug or socket (34) is / are axially offset with respect to the terminal box (12) and is / are arranged adjacent to the motor housing (8).

Owner:GRUNDFOS MANAGEMENT AS

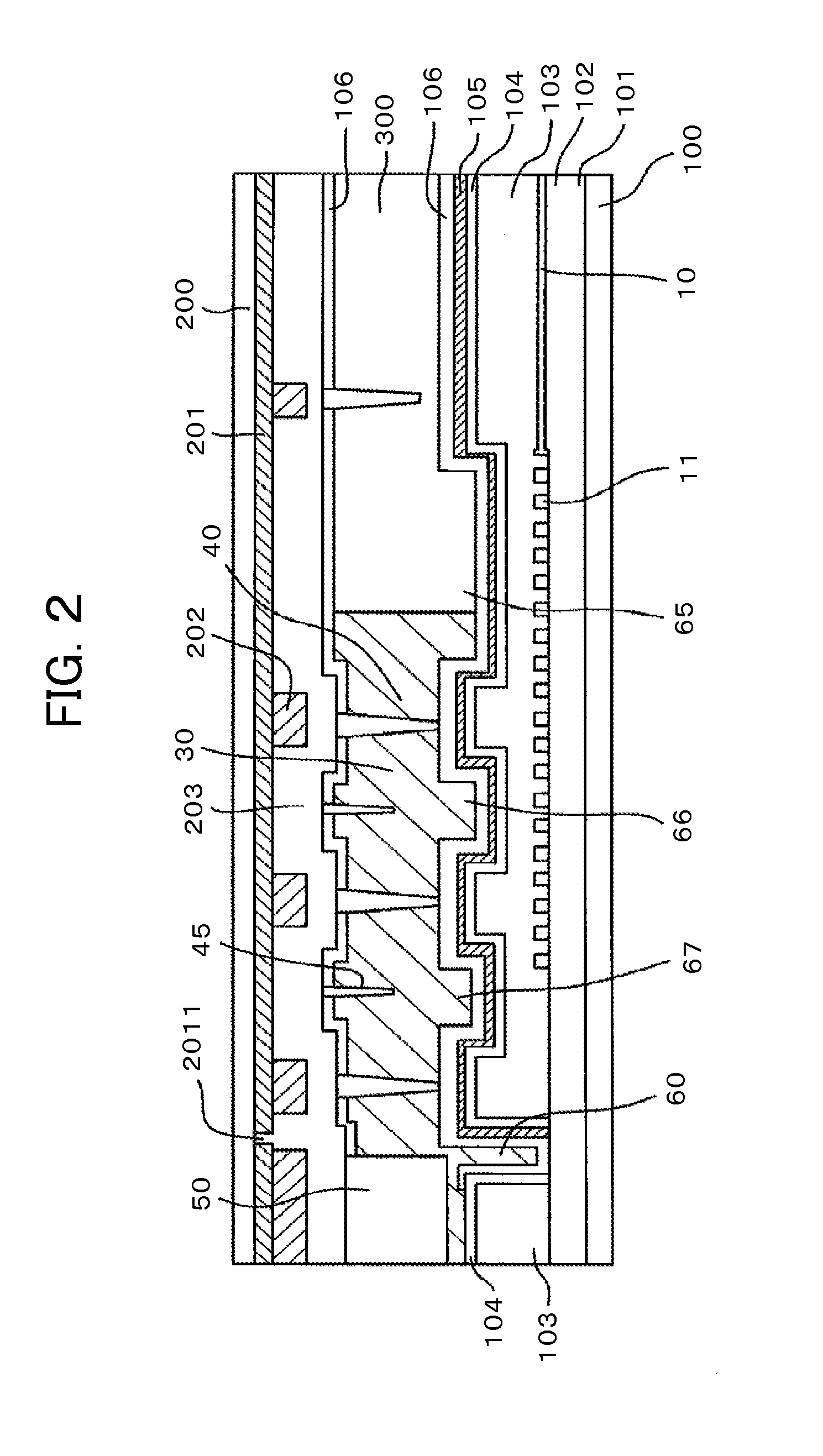

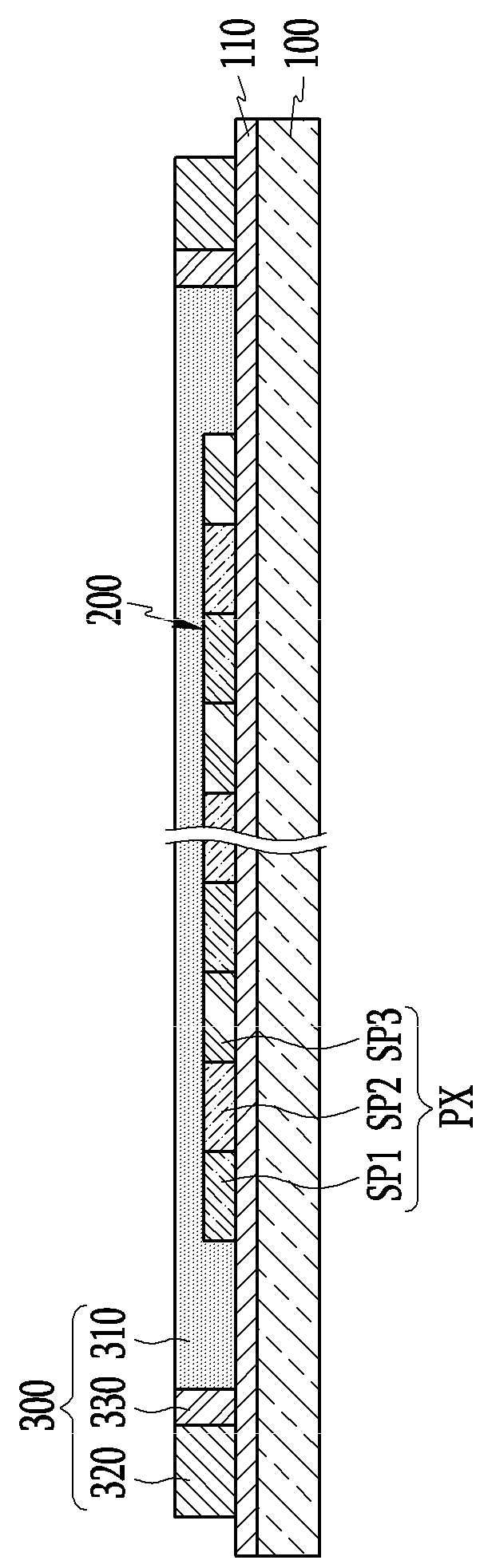

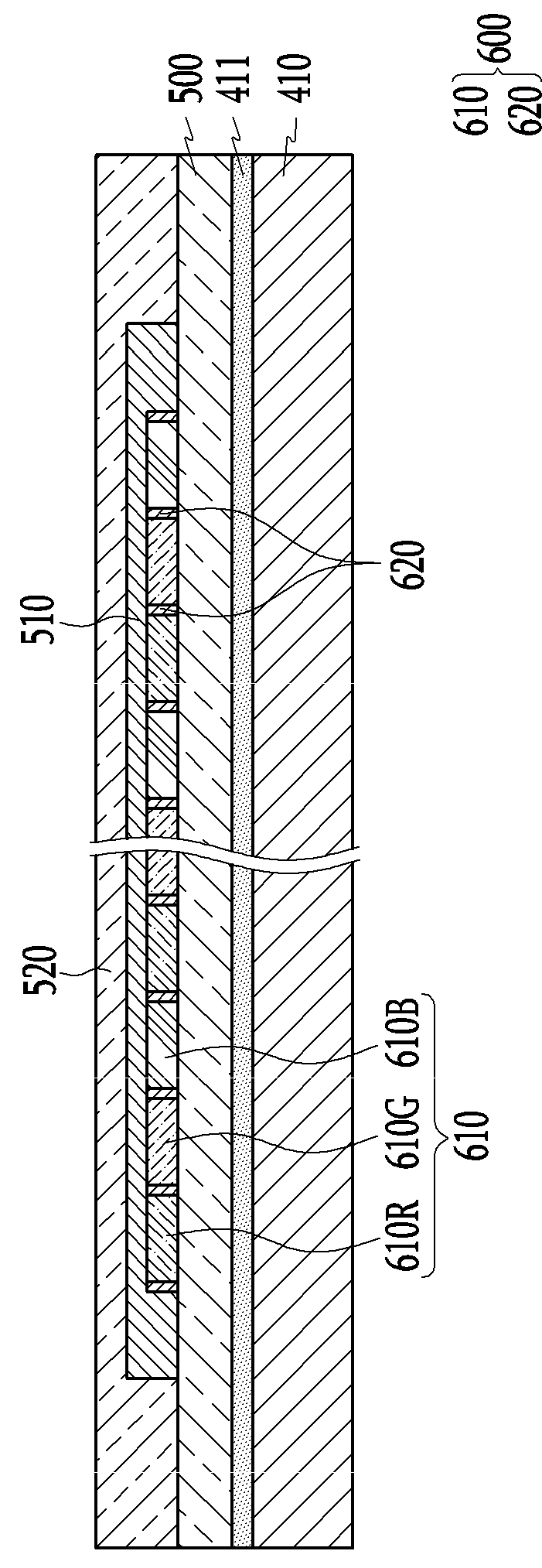

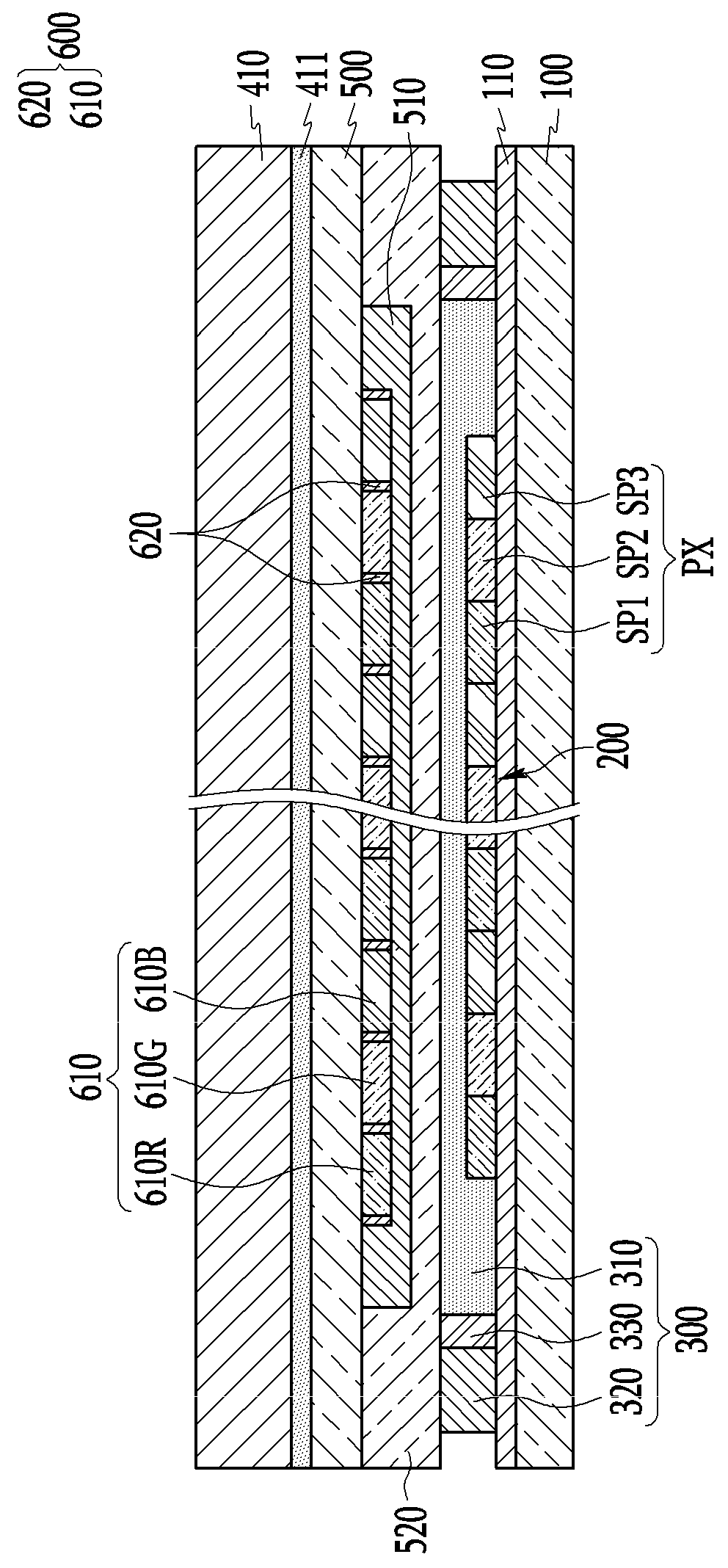

Flexible display device and manufacturing method thereof

ActiveUS20180182984A1Improve the display effectSmall sizeFinal product manufactureOptical filtersEngineeringSealant

A flexible display device includes: a first flexible substrate and a second flexible substrate facing each other; a display part positioned on a surface of the first flexible substrate facing the second flexible substrate and including a plurality of thin film transistors and a plurality of light emitting elements; a color filter positioned on a surface of the second flexible substrate facing the first flexible substrate; an overcoat layer positioned between the display part and the color filter and covering the color filter; a gas barrier layer positioned between the display part and the overcoat layer and covering the overcoat layer; and an encapsulation part including a filler positioned between the display part and the gas barrier layer, and a sealant positioned at an outside of the filler, and an area of the gas barrier layer is larger than an area of the encapsulation part.

Owner:SAMSUNG DISPLAY CO LTD

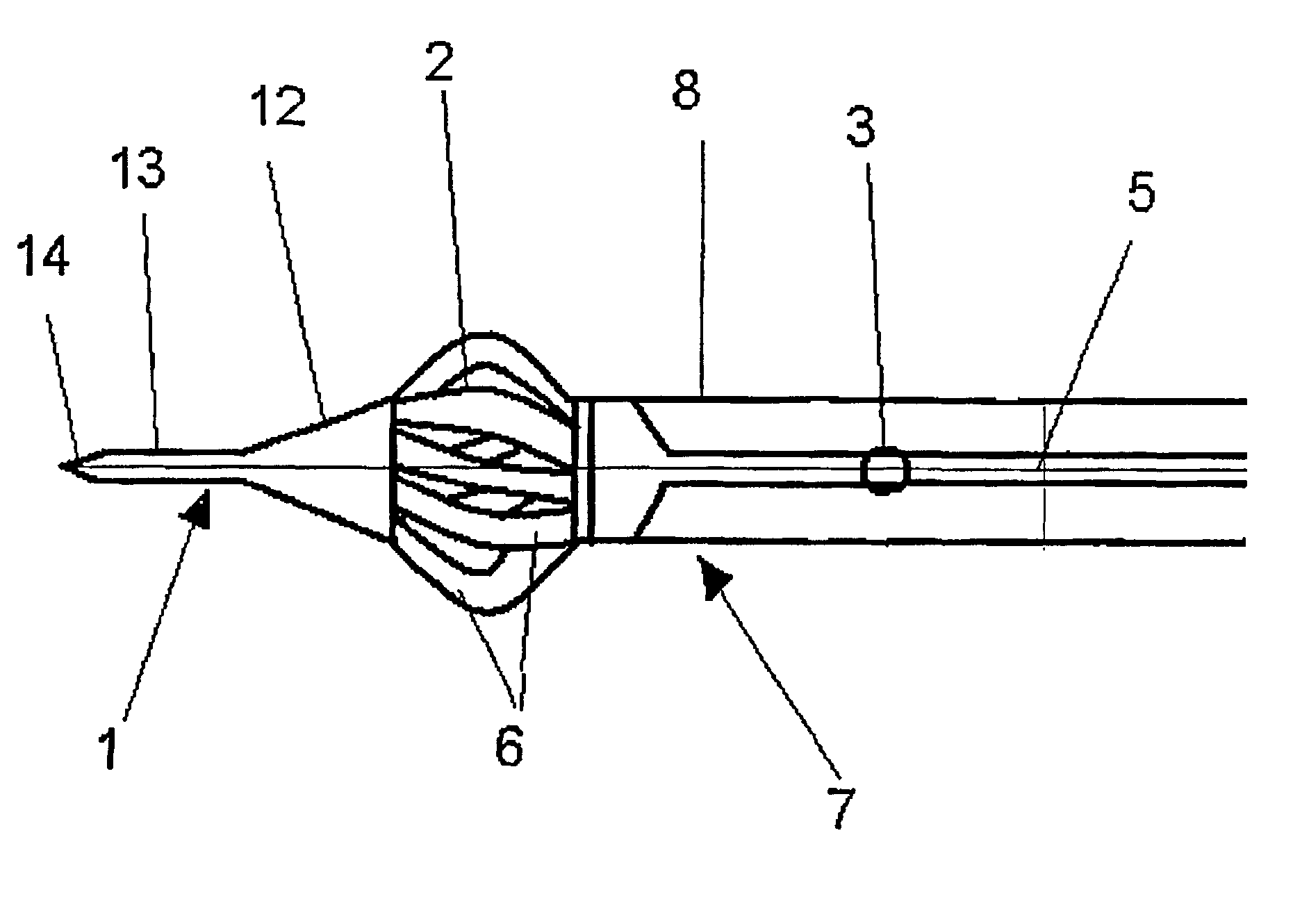

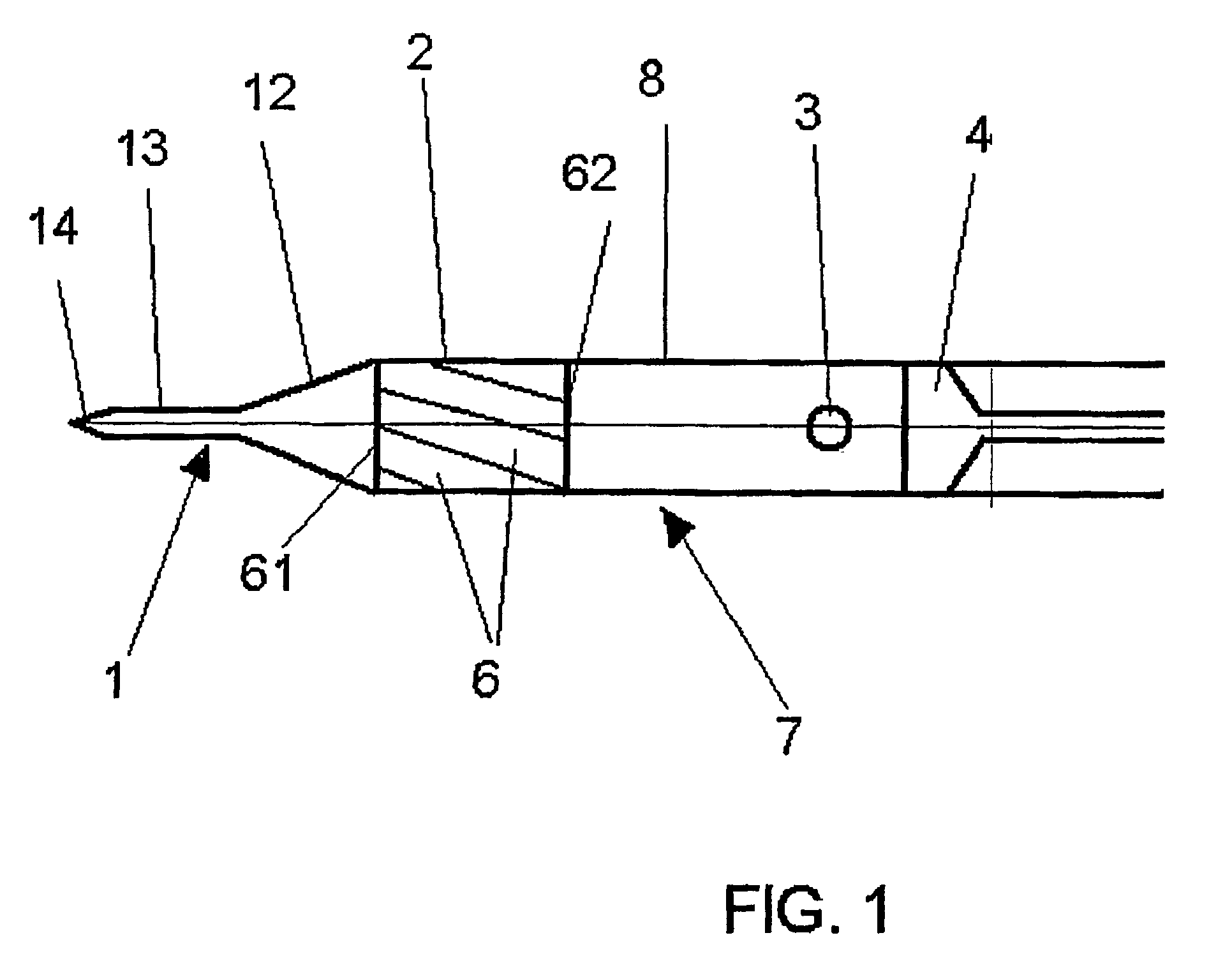

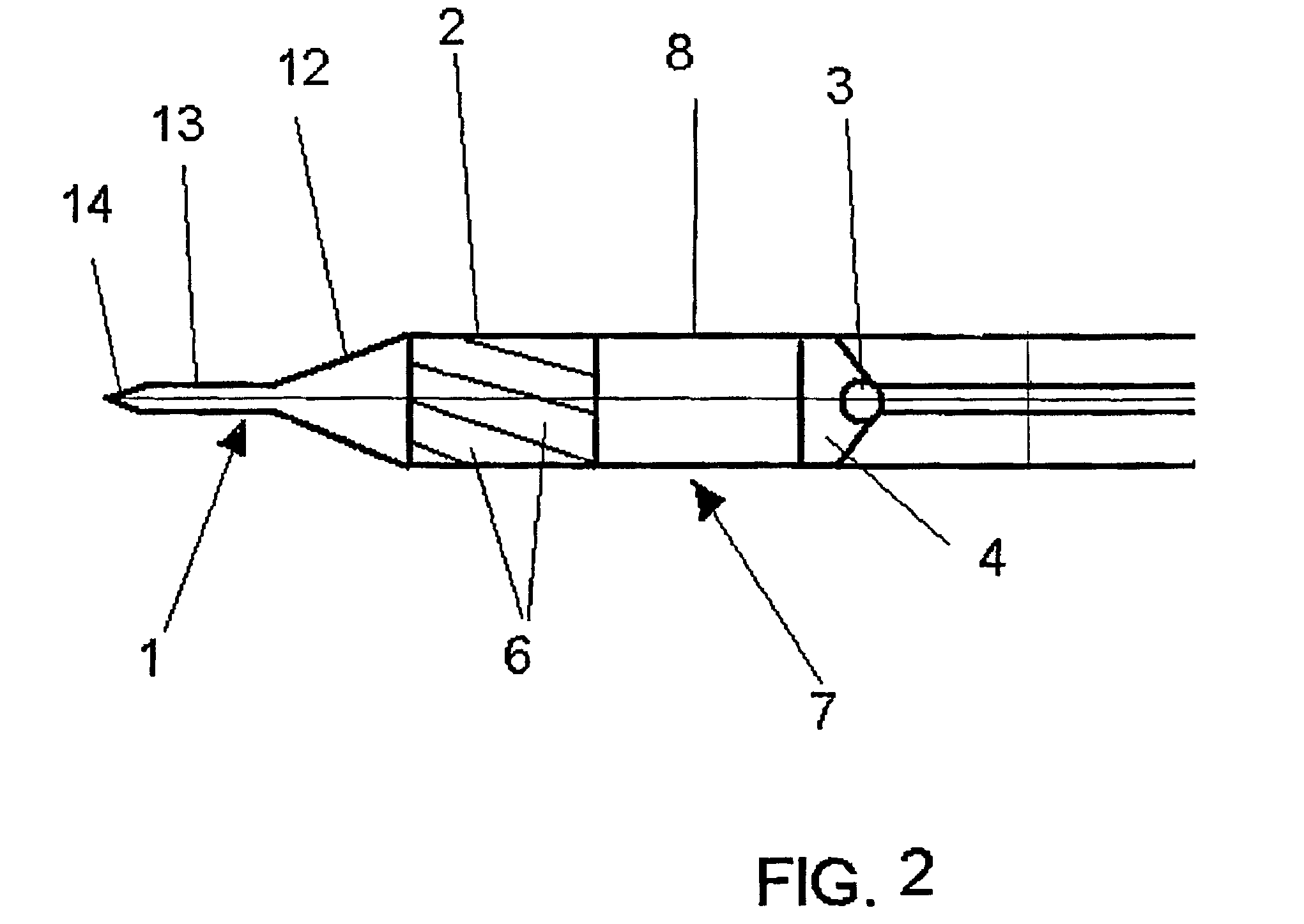

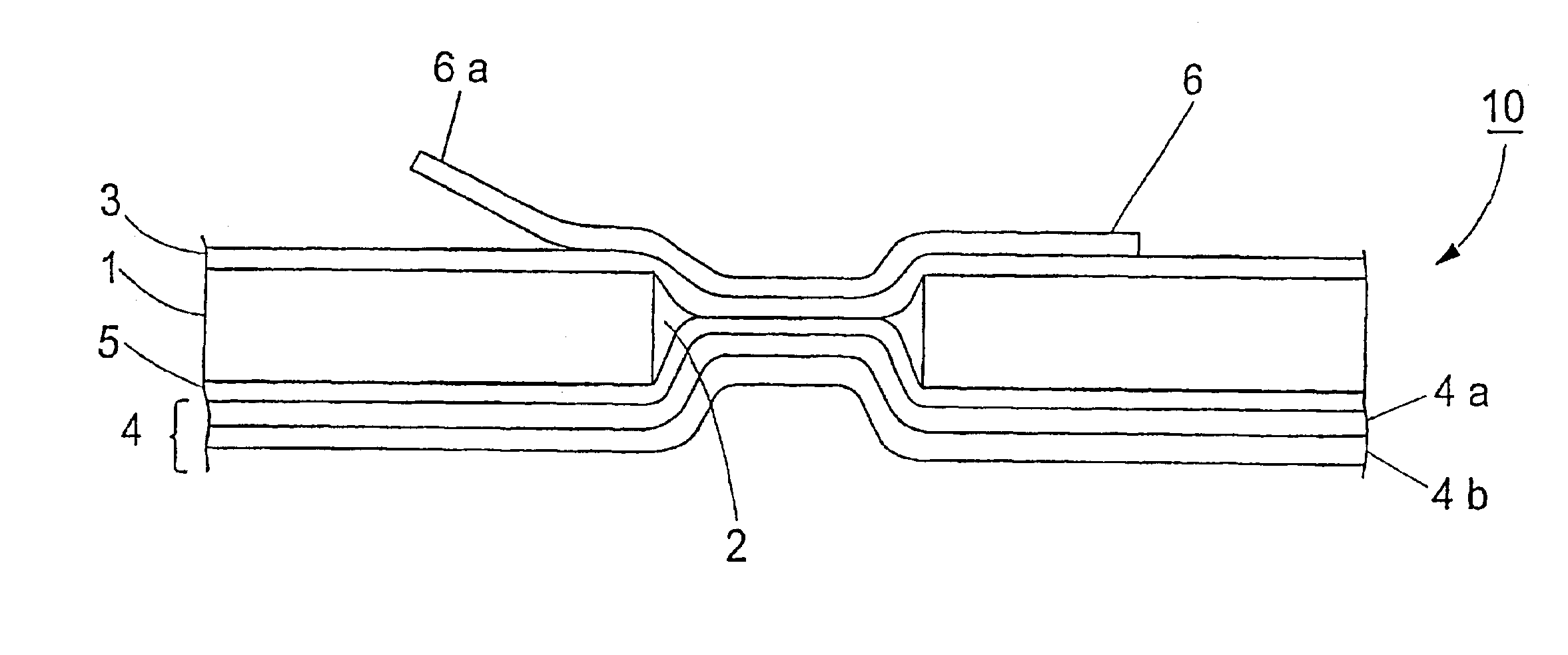

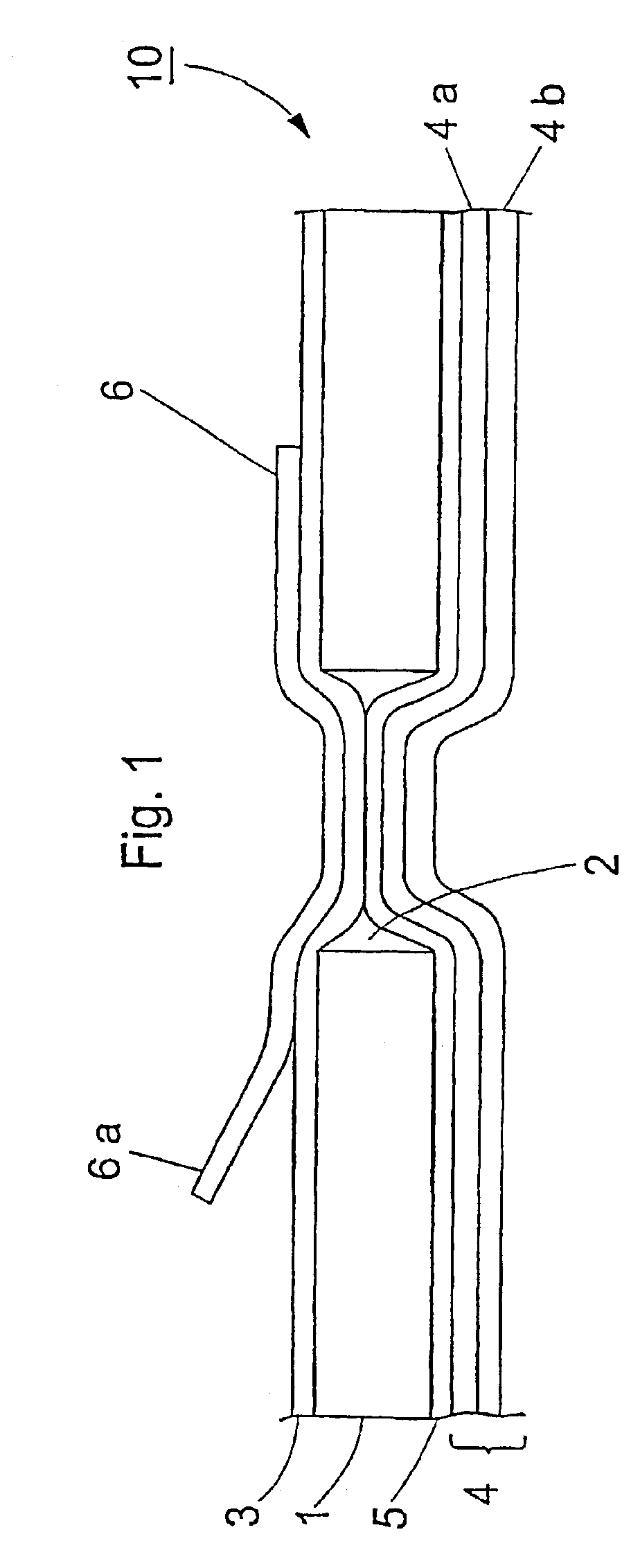

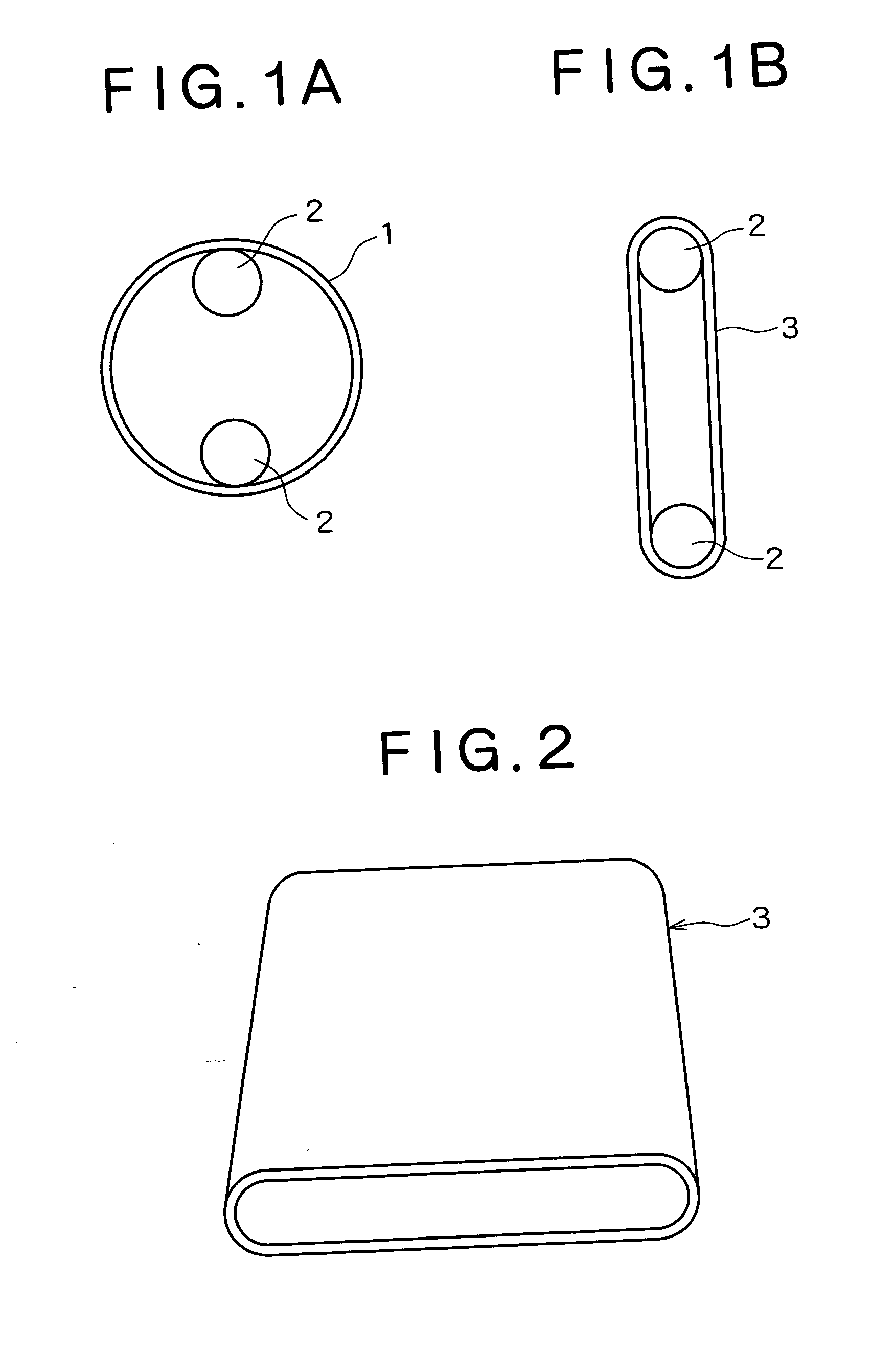

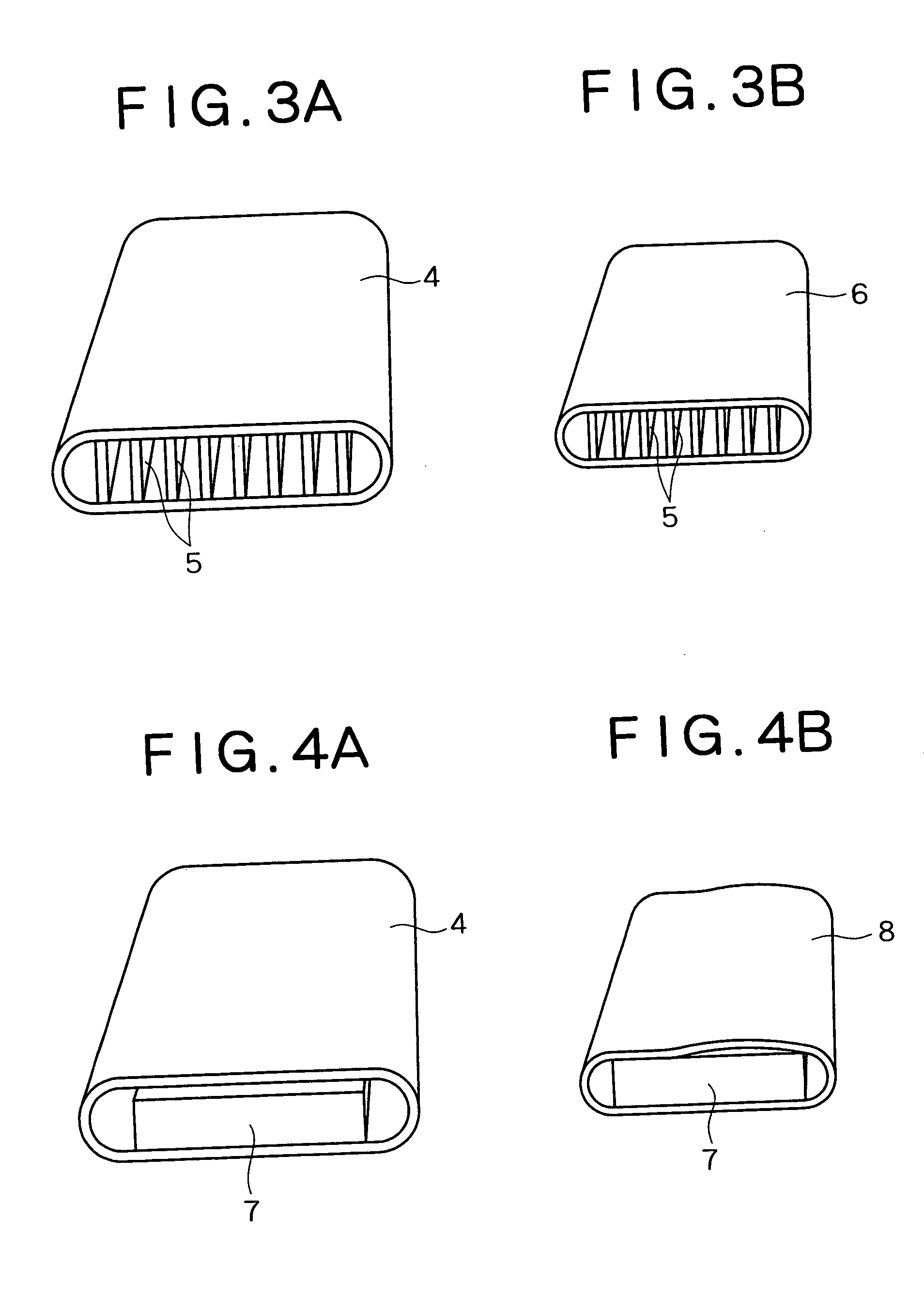

Apparatus for inserting particles into tissue, in particular muscle tissue

InactiveUS6979321B2Easy to insertAvoid it happening againAutomatic syringesSurgical needlesMuscle tissueBiomedical engineering

An apparatus for inserting particles (P) into a tissue (G), in particular a muscle tissue, wherein the apparatus (10) essentially represents a tubular body (7) with one closed end and comprises at least one sleeve (8), at least one positioning element (1), at least one outlet area (2), which extends over the entire circumference of the tubular body (7), at least one thrust means (4) for the particles (P), as well as an actuating device for the outlet area (2), and wherein the outlet area (2) is formed by a plurality of flexible elements (6), which are at least attached to the sleeve (8), which butts against the outlet area (2) in the axial direction, or the positioning element (1) in such a way, that in a tense condition the diameter of the outlet area (2) is larger than the diameter of the sleeve (8), and openings are present between the elements (6).

Owner:ABBOTT CARDIOVASCULAR

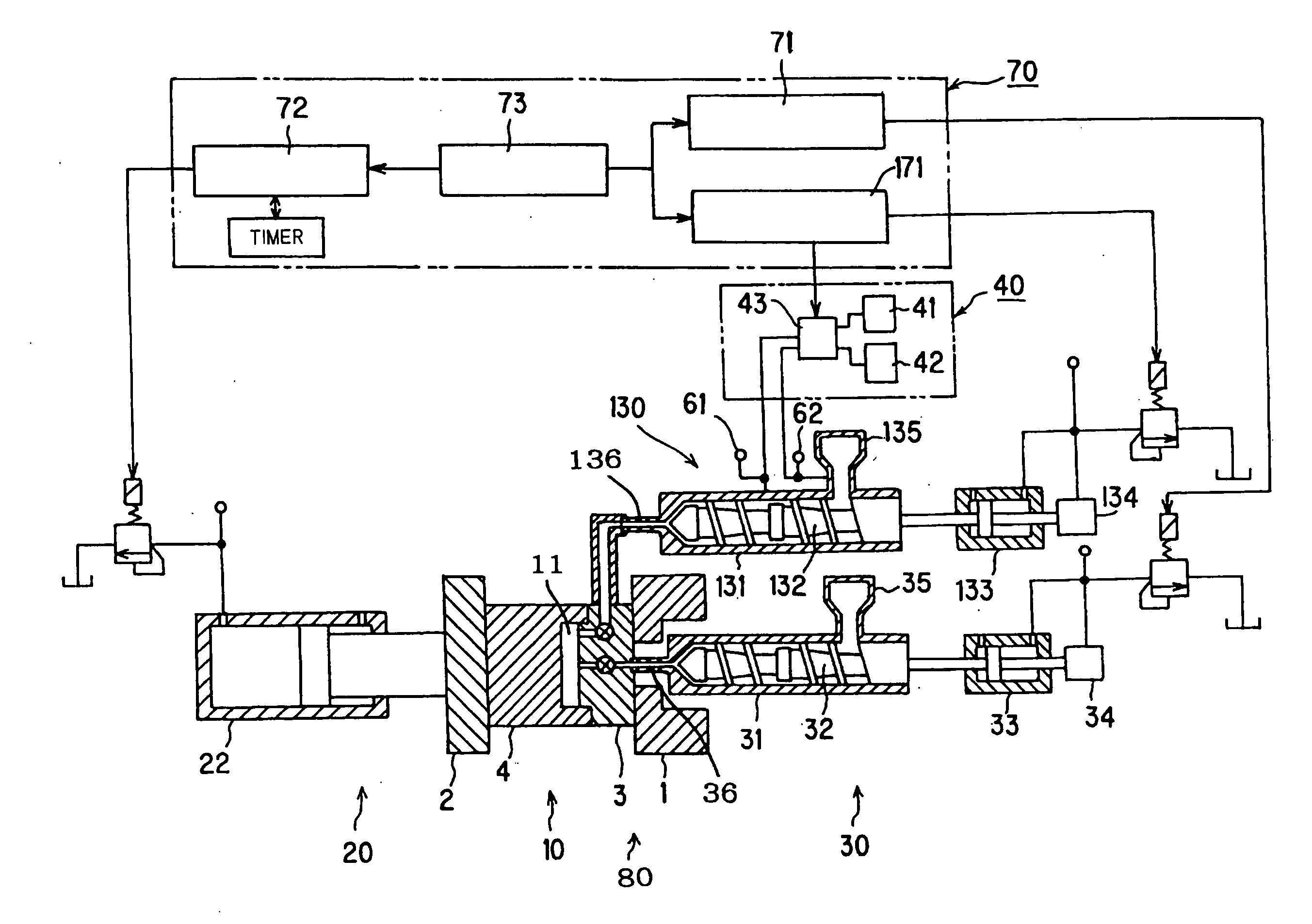

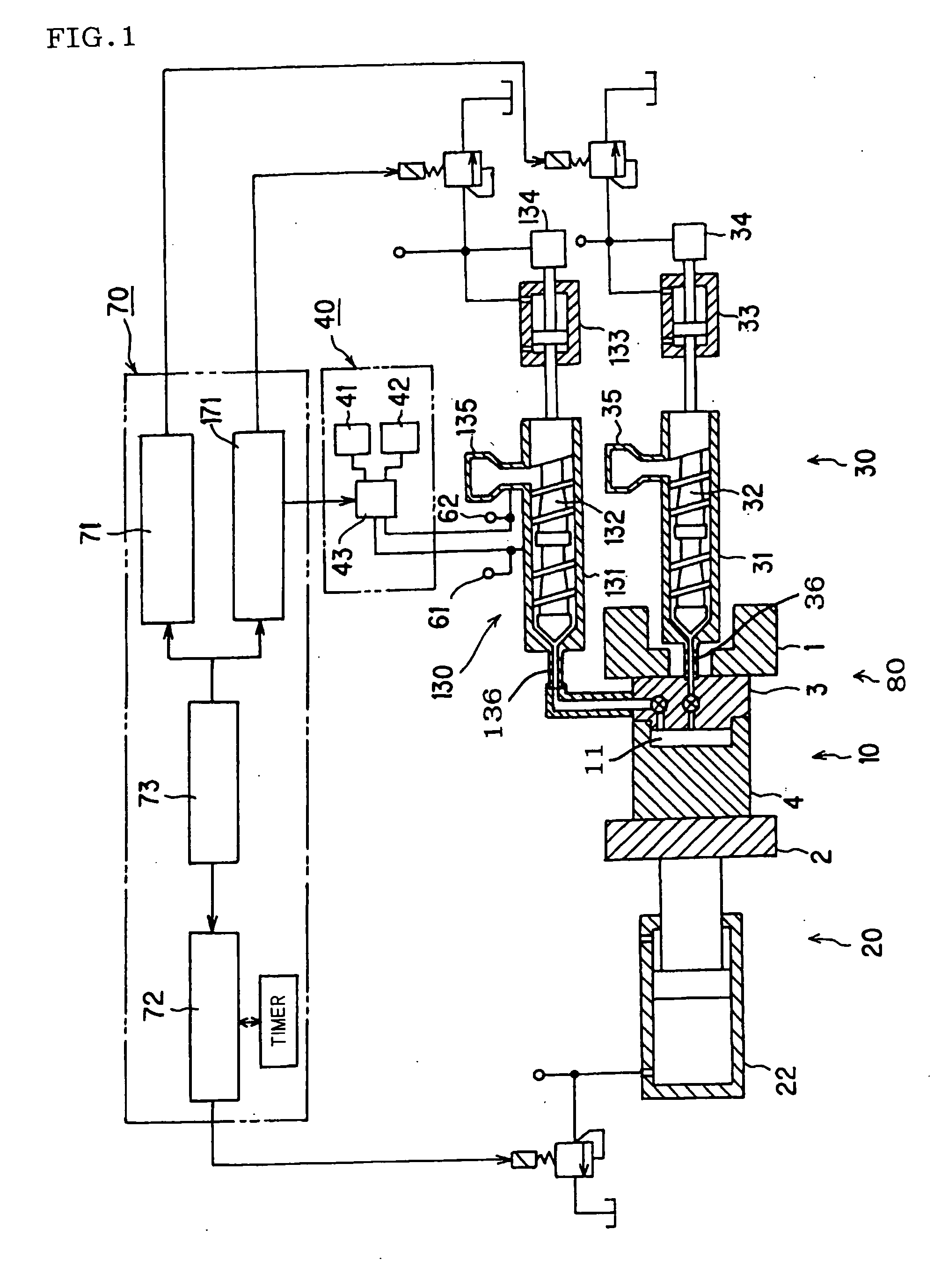

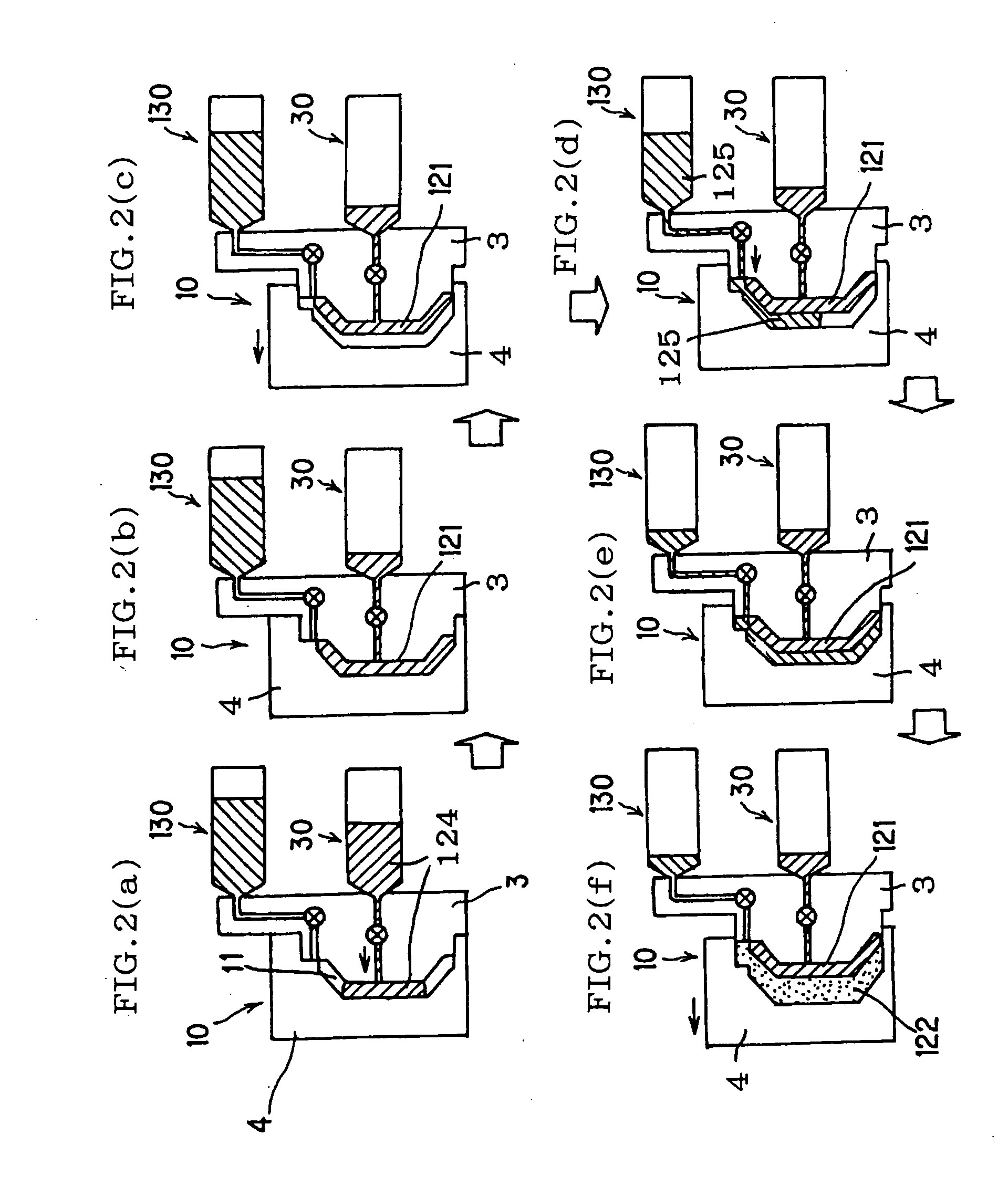

Method for multilayer molding of thermoplastic resins and multilayer molding apparatus

InactiveUS20090121375A1Hazardous to useReduction in plasticizing capacityShell moldingInjection molding machine

A multilayer-molding method includes the steps of mixing at least one thermoplastic resin selected from a plurality of types of thermoplastic resins with a bubble-nucleating agent and a foaming gas, injecting the plurality of types of thermoplastic resins into a mold cavity such that the thermoplastic resins are layered in the mold cavity, and then, after increasing the volume of the mold cavity, foaming the at least one thermoplastic resin mixed with the bubble-nucleating agent and the foaming gas. The multilayer-molding method is characterized in that the foaming gas is supplied at a pressure of 0.1 MPa or more but less than 1.0 MPa to at least one injection-molding machine selected from a plurality of injection-molding machines, and that the thermoplastic resin plasticized in the injection-molding machine is mixed with the foaming gas.

Owner:UBE MASCH CORP LTD

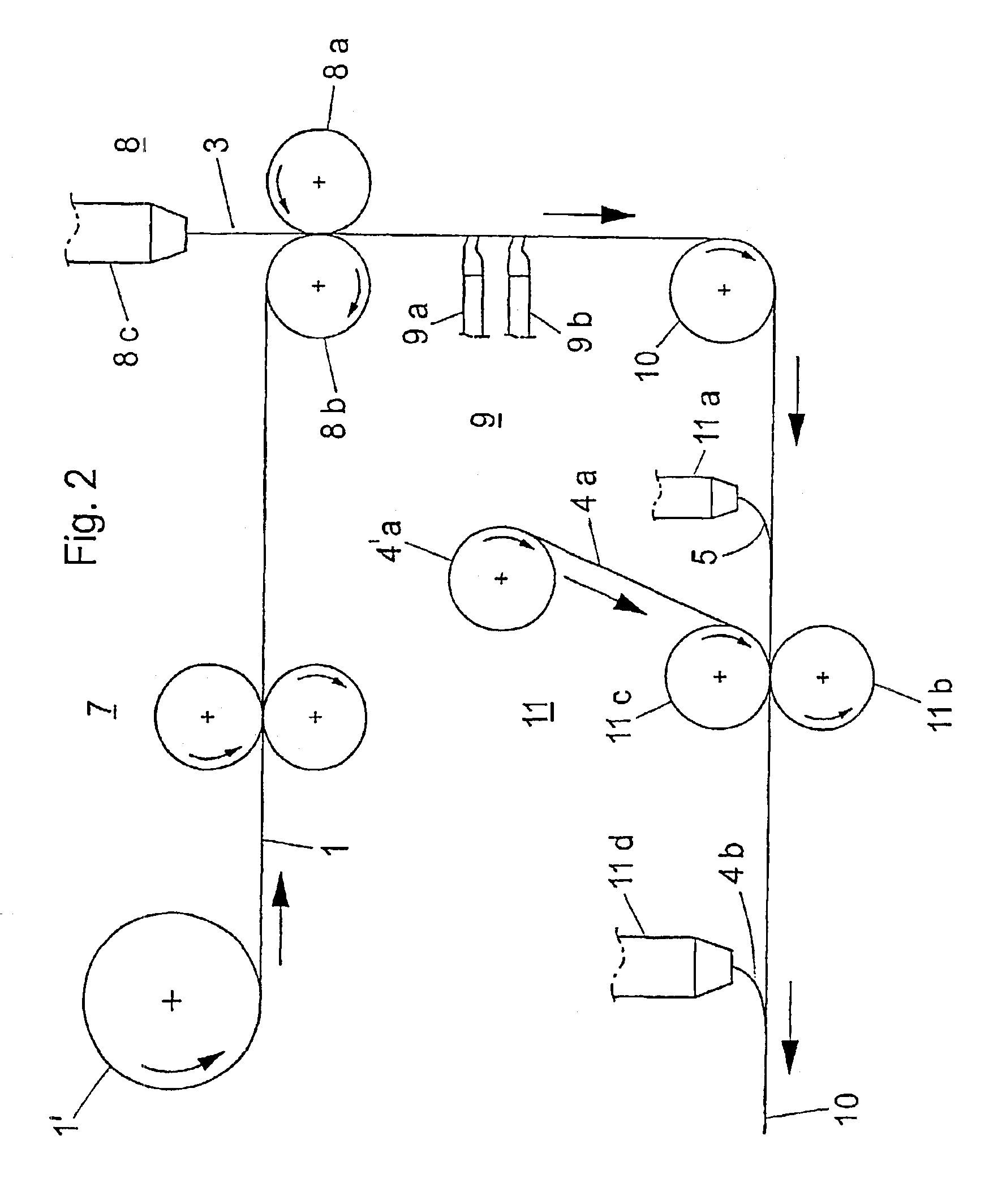

Method of producing a packaging material

InactiveUS6884206B2Efficient and expedient opening functionEnsure sealing performanceEnvelopes/bags making machineryFlexible coversEngineering

Owner:TETRA LAVAL HLDG & FINANCE SA

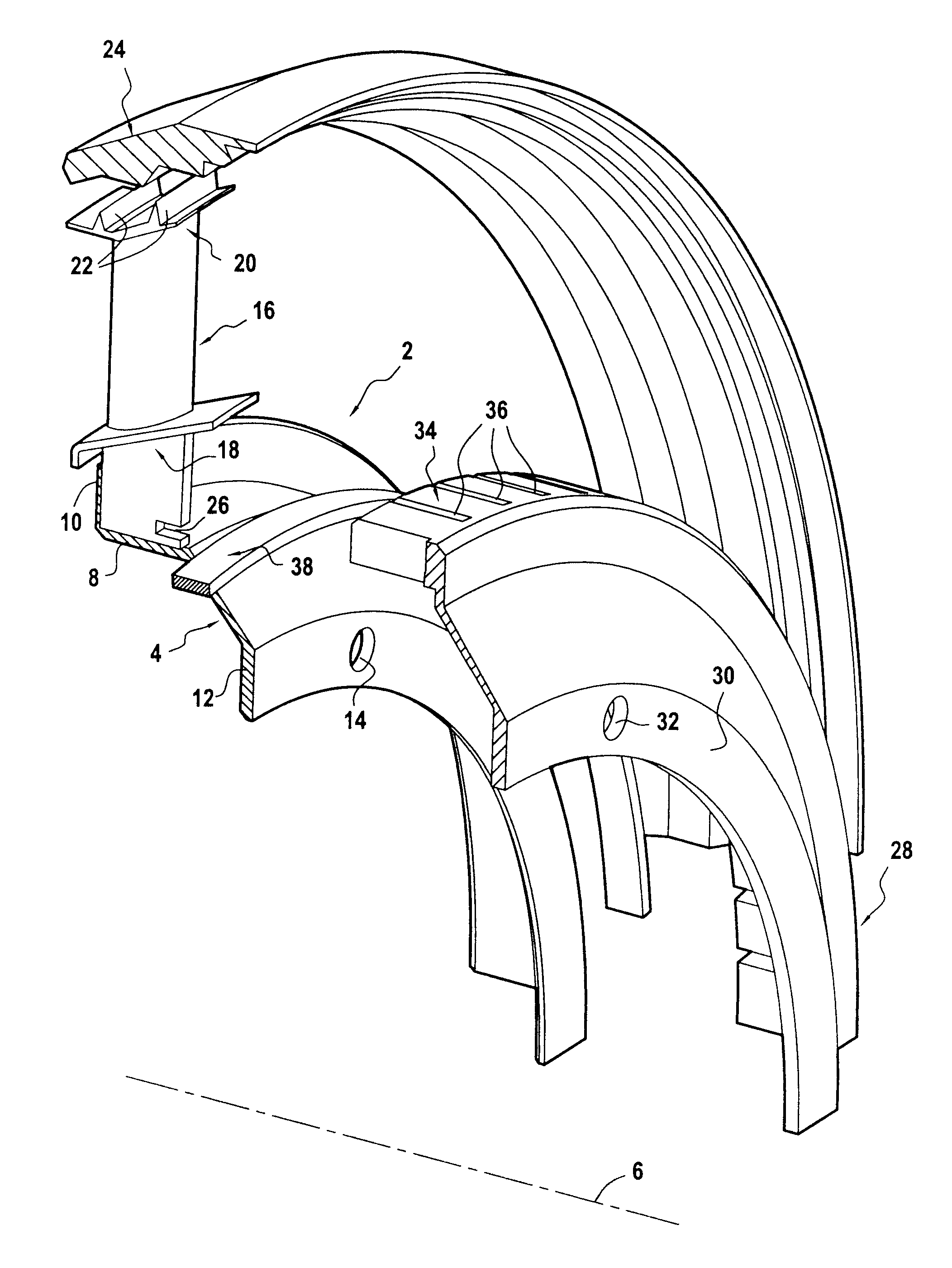

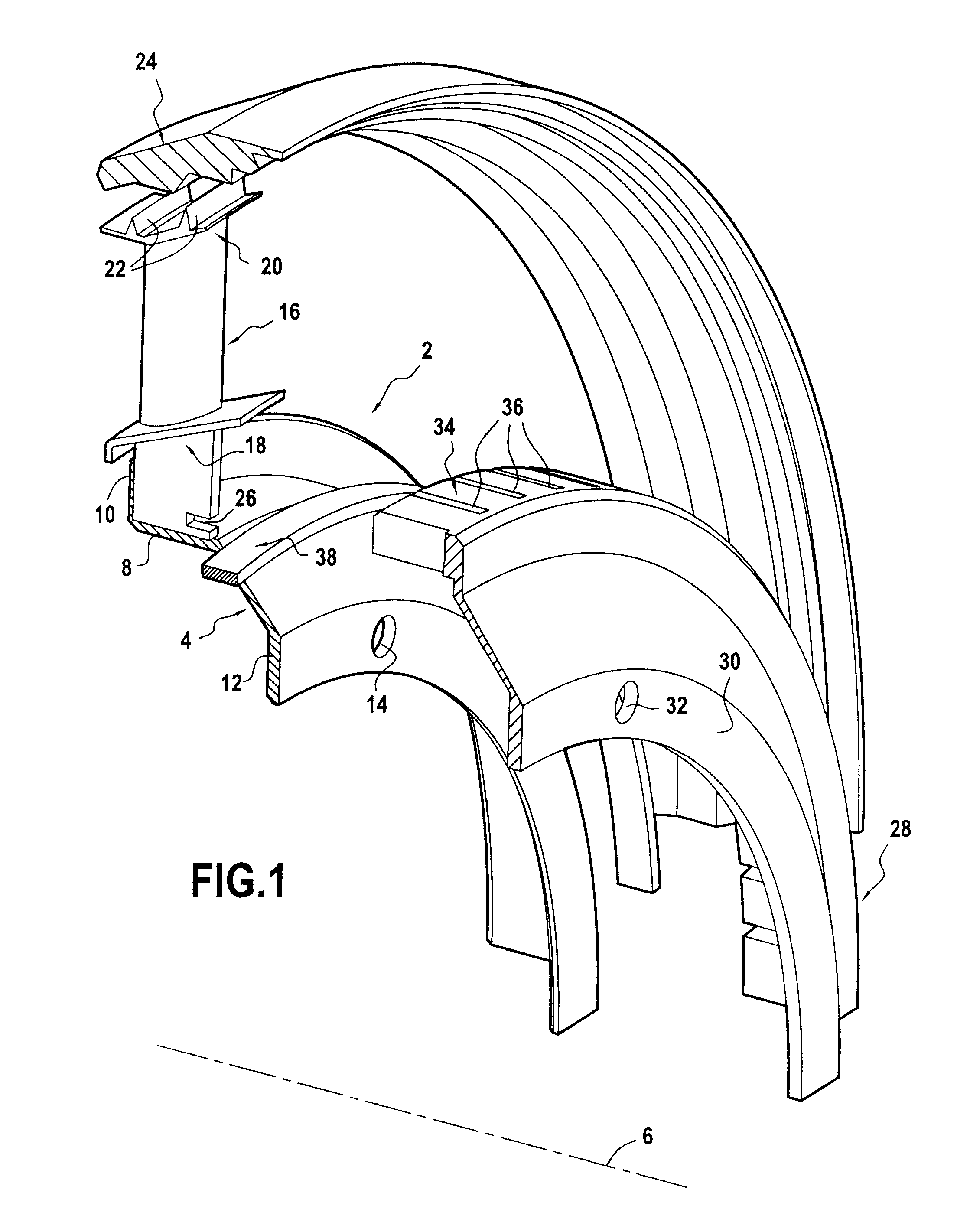

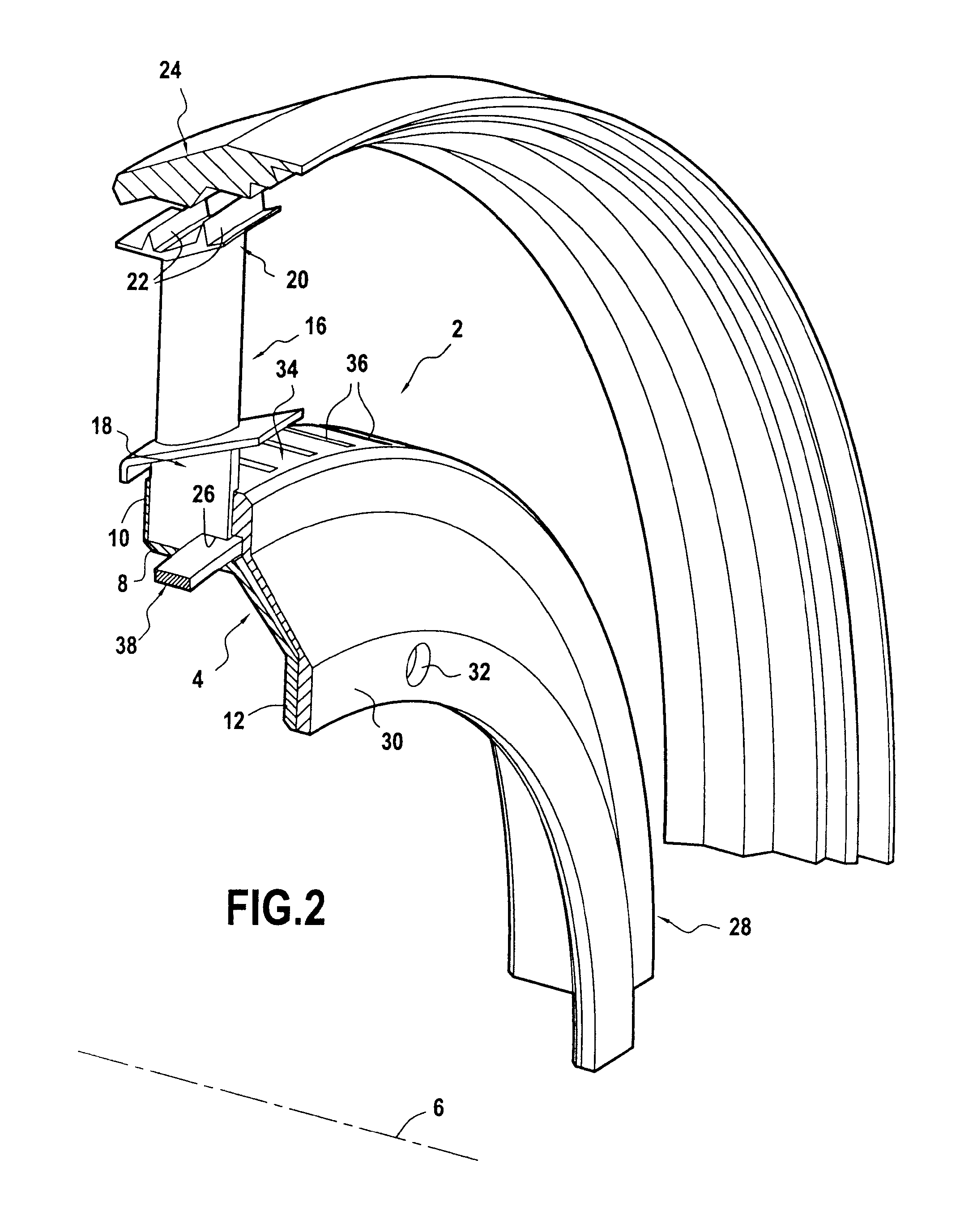

Turbine engine rotor wheel with blades made of a composite material provided with a spring ring

ActiveUS20110268561A1Mitigate such drawbackEnsure sealing performancePump componentsBlade accessoriesAbutmentEngineering

A turbomachine rotor wheel including blades made of composite material; an annular mounting plate; a plurality of composite material blades mounted on the mounting plate, each blade also including a top platform at its tip carrying radial labyrinth teeth; an orientation disk fastened coaxially around the mounting plate and including at its outer periphery a plurality of axial slots that are open at one end, each slot presenting a cross-section that matches the cross-section of a blade root so as to hold it angularly in position by co-operation of shapes; and a variable-diameter spring ring housed in part in an axial notch formed in each blade root and projecting axially relative thereto, the spring ring to come into radial abutment against an inside surface of the orientation disk during radial outward movement of the blades relative to the mounting plate.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Capacity control valve

ActiveUS9777863B2DistanceIncrease volumeOperating means/releasing devices for valvesMulti-stage pumpsEngineeringControl room

A control valve for discharging a liquid refrigerant in a control chamber at the time of start-up of a variable capacity compressor has a movable a center post for increasing the area of a passage for discharging the liquid refrigerant when discharging the liquid refrigerant.

Owner:EAGLE INDS

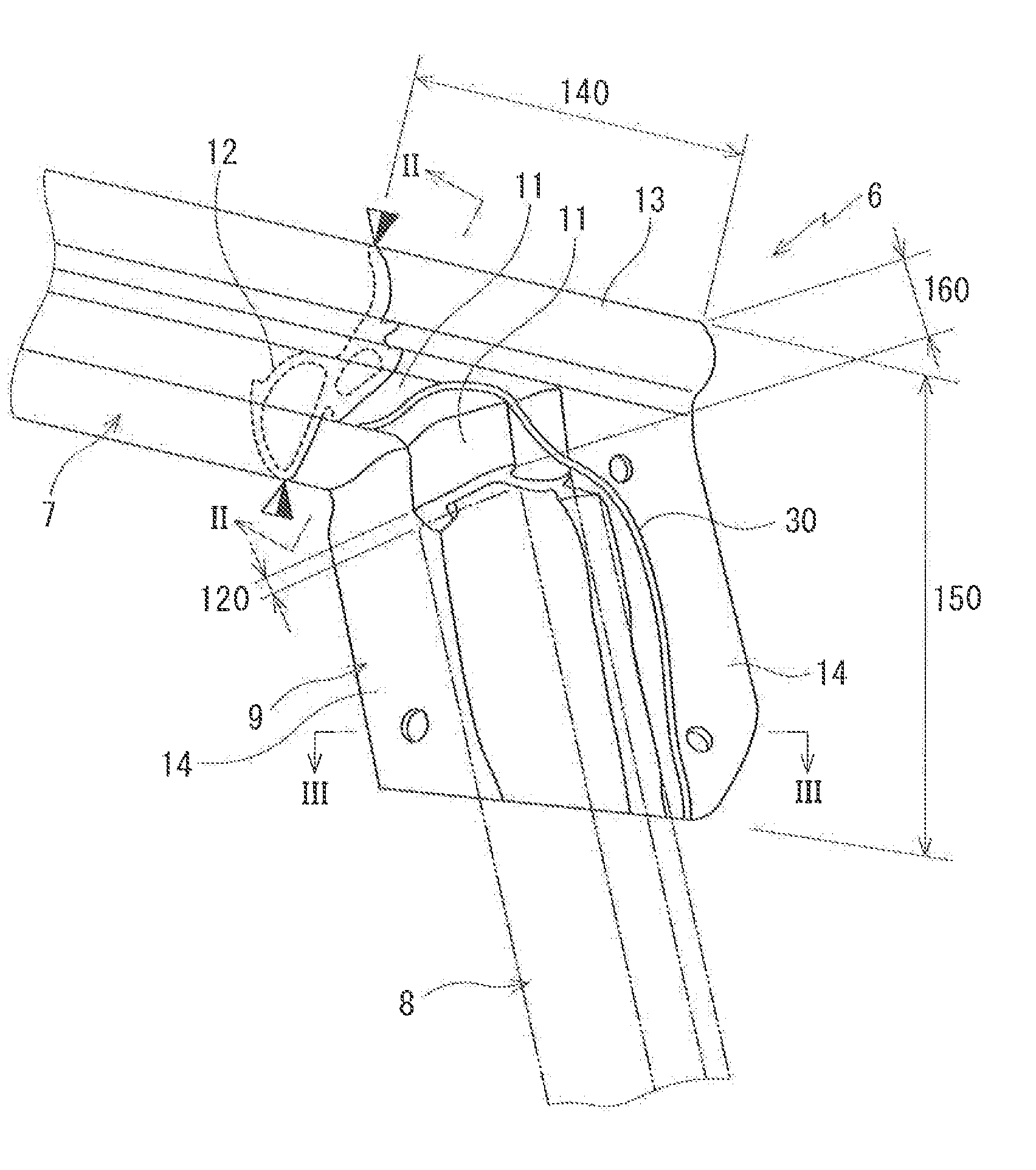

Door weather strip

ActiveUS20140059940A1Increase the number of lapsHold steadyEngine sealsSealing arrangementsEngineeringMechanical engineering

A door weather strip includes an upper extrusion molded part installed on a door sash on a roof side; a molded part without a slit thereon, connected to the upper extrusion molded part on a door corner part; and a lower extrusion molded part installed on a vertical part of the door sash and detachably inserted into the molded part; the upper and lower extrusion molded parts and the molded part having a base bottom part and a hollow seal member formed thereon, in which: a seal bead is formed on the molded part, the seal bead extending from an inner-cabin side toward an outer-cabin side relative to the base bottom part of the molded part on the roof side and descending along an outer-cabin side of a part of the molded part on the vertical part side of the door sash.

Owner:NISHIKAWA RUBBER

Solenoid arrangement

InactiveUS20060071560A1Reduce weightHigh mechanical reliabilityValve arrangementsMachines/enginesSolenoid valvePlastic materials

Owner:ERMERT MICHAEL +1

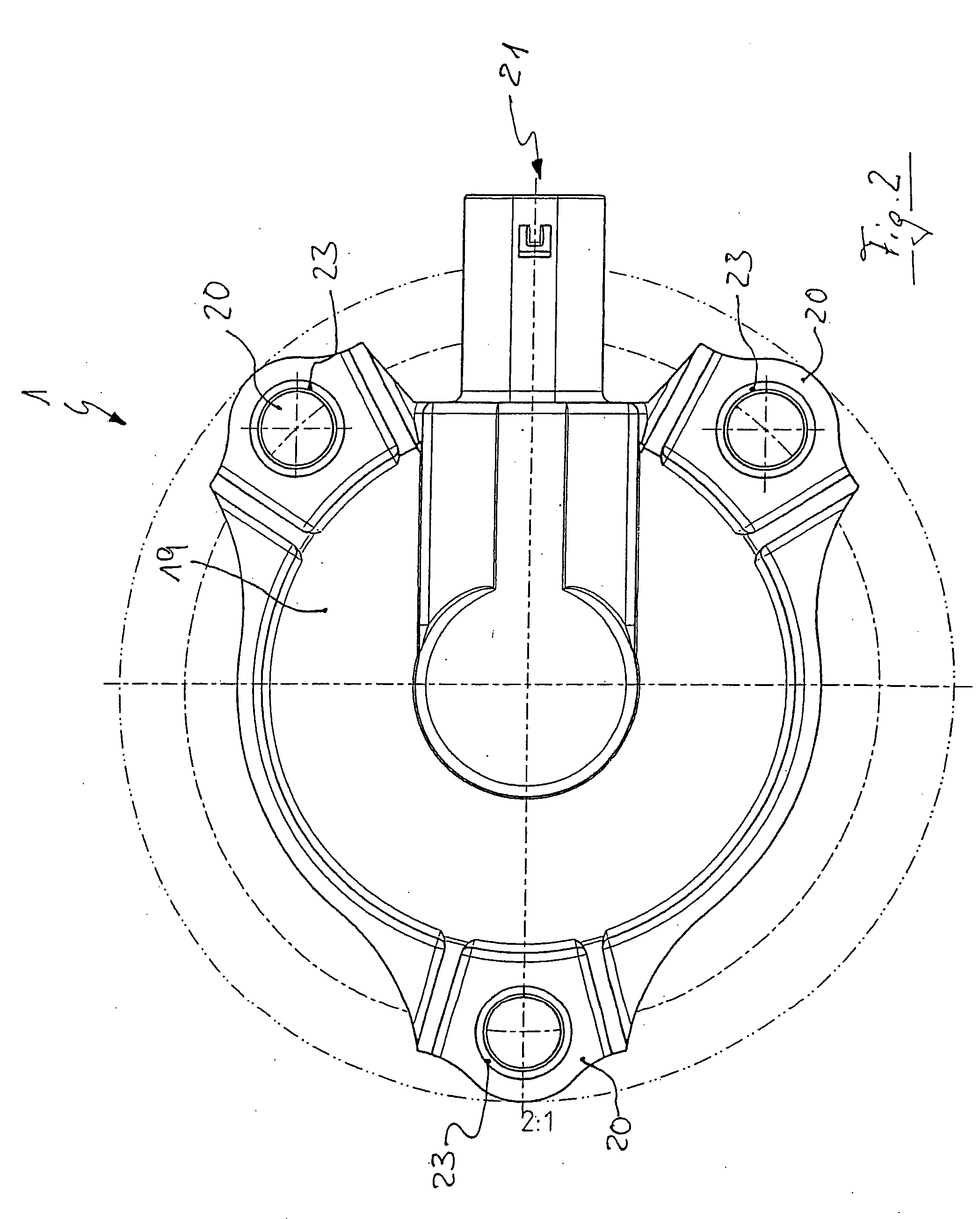

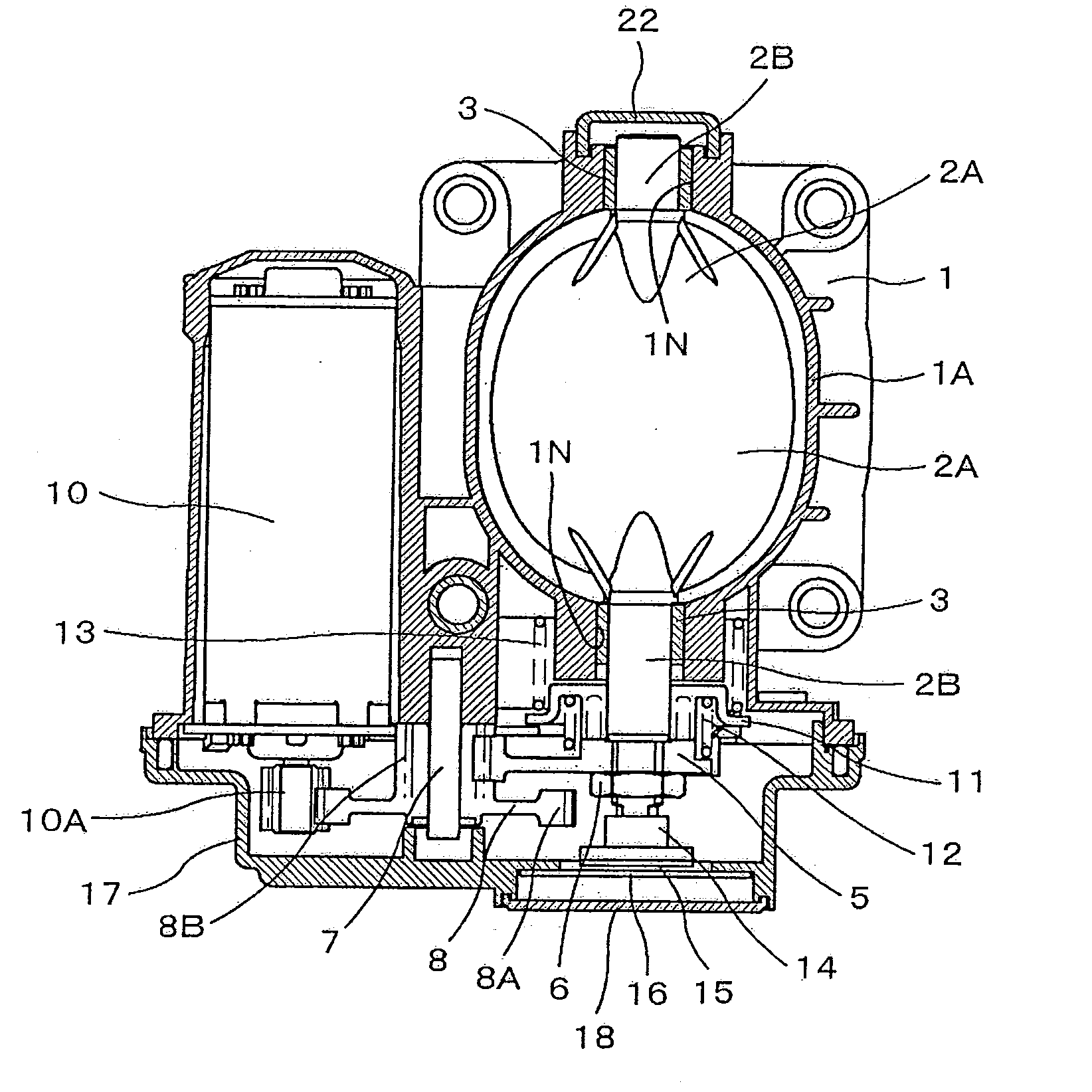

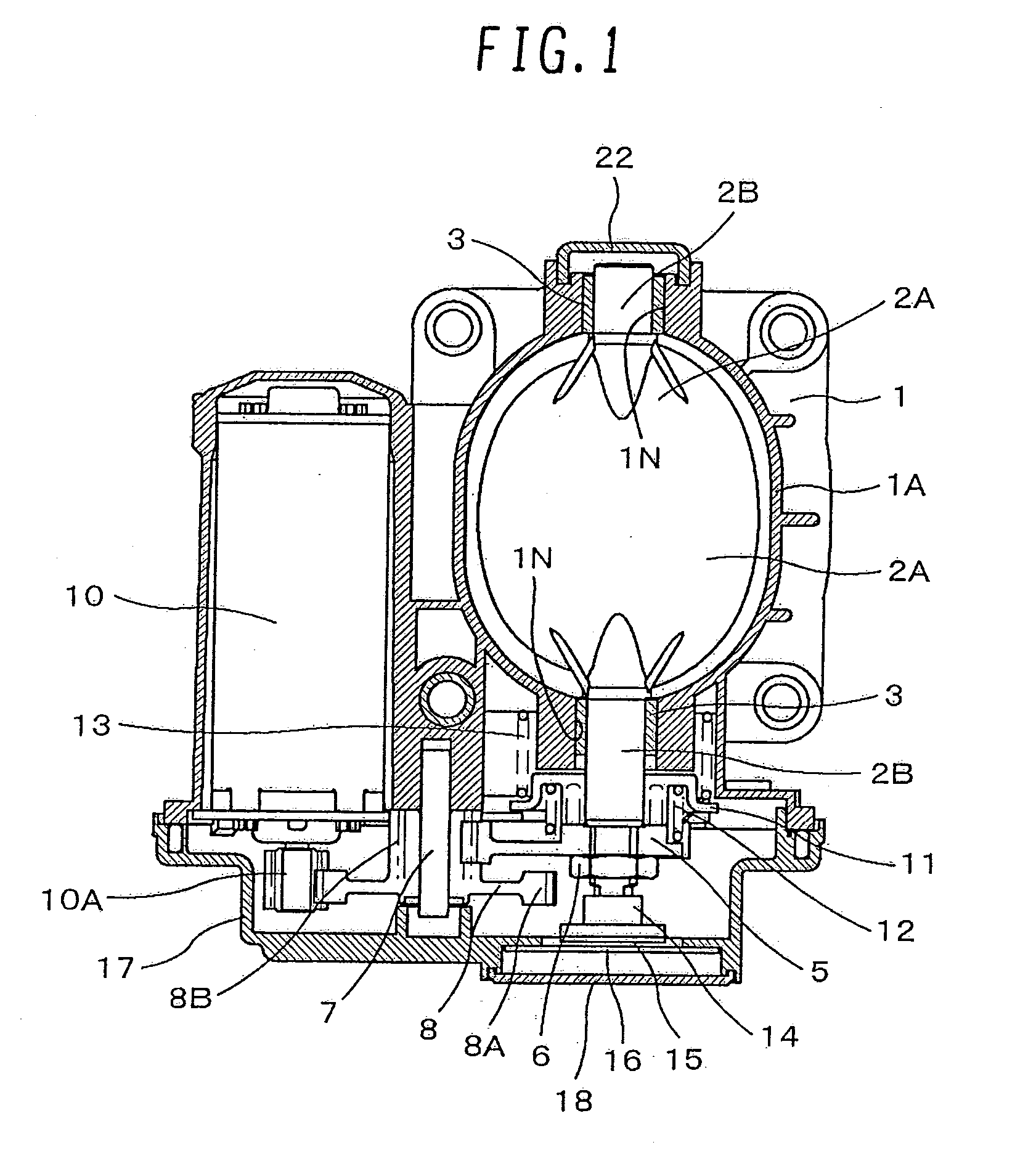

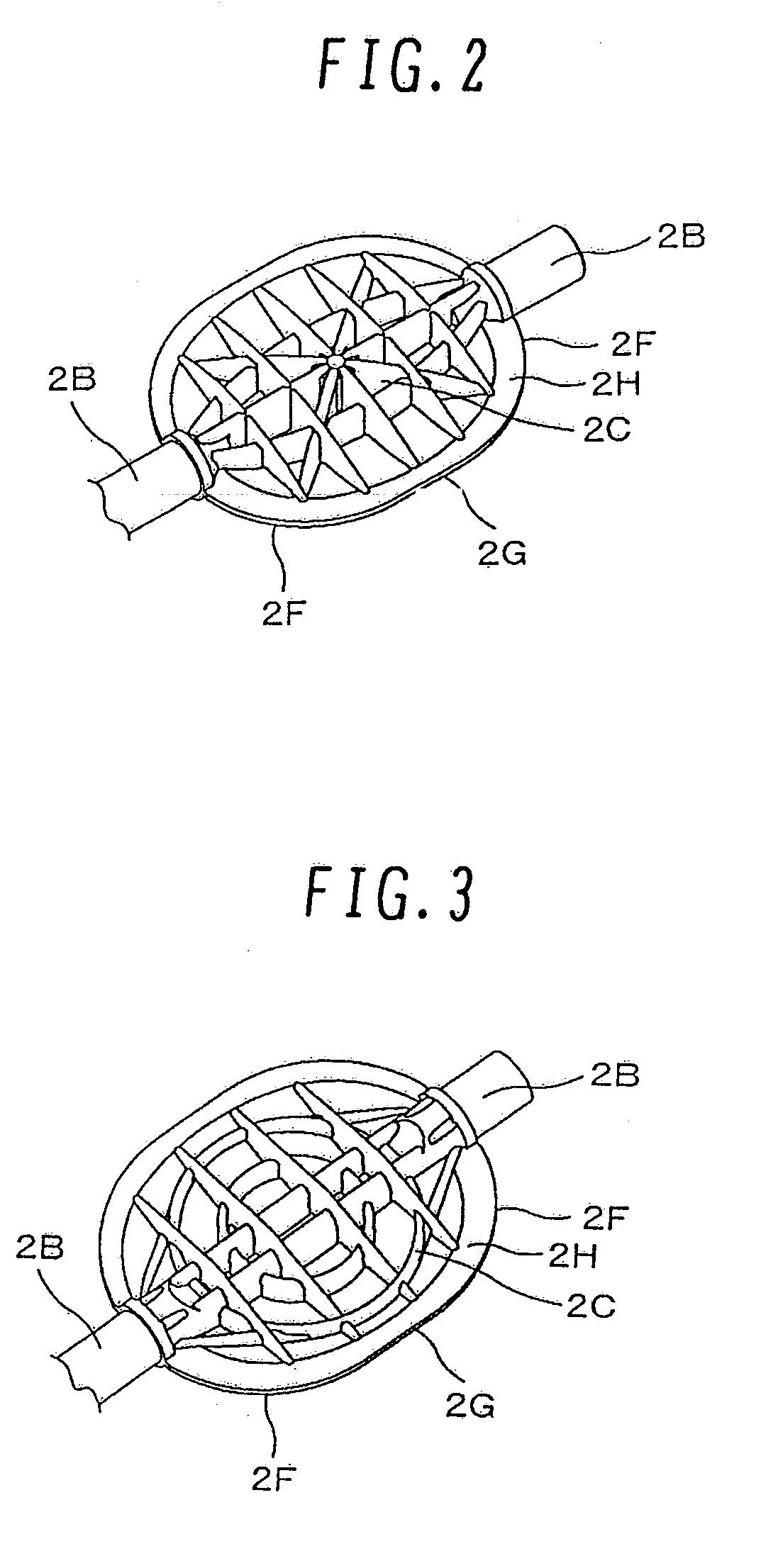

Butterfly Valve Device

InactiveUS20080168965A1Easily susceptible secular changeEnsure sealing performanceEngine controllersMachines/enginesAirflowEngineering

An object of the present invention is to provide a butterfly valve device made of resin, the butterfly valve device being little susceptible the secular change in gas flow (in particular, the minimum flow) or random changes.According to the present invention, when a butterfly valve is located at a full-closed position facing a peripheral lower surface of a semicircular portion with respect to a rotating shaft of the butterfly valve made of a resin material, a partial annular projection is adapted to radially inwardly extend towards an inner wall surface of a fluid path, the partial annular projection including a plane that contacts the peripheral lower surface of the valve to form a fluid seal. Preferably, while the valve opens only by the thickness thereof from a mechanically full-closed position, from which the valve cannot mechanically rotate any more in a close direction, a surface on the periphery of the valve is formed in a curved surface shape having the specific curvature so that the specified minimum airflow is achieved at the mechanically full-closed position. In addition, cylindrical elastic sealing members are mounted around the shaft in a bearing hole, and an edge on the fluid path side of the sealing members elastically contacts an annular surface formed at a position facing the bearing hole about the rotating shaft of the valve.

Owner:HITACHI LTD

Glass-like carbon deformed molded article, process for producing the same, and joint structure for jointing a connecting member to a glass-like carbon hollow molded article

InactiveUS20050230859A1High dimensional accuracyImprove sealingLayered productsPreformed elementsPlastic propertyMaterials science

Provided is a process for producing a glass-like carbon deformed molded article having a deformed section (typically, an elliptical section or a section composed of partial circles and linear portions), such as a glass-like carbon member in a deformed pipe form or a bent pipe, with relative ease and a good dimensional accuracy. The process comprises the step of molding a thermosetting resin to yield a thermosetting resin molded article, the step of deforming the thermosetting resin molded article plastically in the state that the article is heated, so as to yield a thermosetting resin deformed article, and the step of carbonizing the resultant thermosetting resin deformed article.

Owner:KOBE STEEL LTD

Antenna assembly with injection-molded seal

InactiveUS6999033B2Prevent rusting of the margins of the holePrevent rustAntenna supports/mountingsAntenna adaptation in movable bodiesInjection molding processEngineering

Owner:HIRSCHMANN ELECTRONICS GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com