Antifouling paint containing nano oxides

A technology of nano-oxide and antifouling coatings, applied in antifouling/underwater coatings, rubber derivative coatings, rosin coatings, etc., to achieve strong absorption and dissipation properties, good wear resistance, and good bonding properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

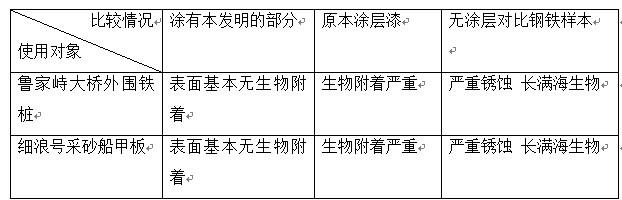

Examples

Embodiment 1

[0026] Determined to be made of the following raw materials by weight ratio: 5% nano titanium dioxide, 5% nano zinc oxide, 15.5% cuprous oxide, 20% chloroether resin, 40% xylene solvent, 4% rosin, 1.5% high It is composed of molecular dispersant EFKA-4010, 4% tricresol phosphate and 5% organic bentonite.

[0027] Configure 100g according to the following steps:

[0028] First, add 20g of chloroether resin powder to 20g of xylene solvent and stir at high speed (1500r / min) until a transparent colloidal solution is obtained;

[0029] Then add 1.5g polymer dispersant EFKA-4010 to 20g xylene, then add 5g nano titanium dioxide and 5g nano zinc oxide, disperse at 2000rpm for 15 minutes at high speed, and then grind with a sand mill for 2 hours to make nano titanium dioxide slurry .

[0030] Then add 31.5g of nano pulp, 15.5g of cuprous oxide, 4g of rosin, 4g of tricresol phosphate and 5g of organic bentonite in proportion to 40g of the above-mentioned chloroether resin solution under high-s...

Embodiment 2

[0033] It is determined to be made of the following raw materials in weight ratio: 7% of nano titanium dioxide, 14% of cuprous oxide, 23% of chlorinated rubber, 40% of xylene and n-butanol solvent with a weight ratio of 3:1, 5% of rosin, It is composed of 3% polymer dispersant Haichuan Chemical 5040, 4% tricresol phosphate and 4% silica.

[0034] Configure 100g according to the following steps:

[0035] First add 23g of chlorinated rubber powder to 23g of xylene and n-butanol solvent with a weight ratio of 3:1, and stir at high speed (1500 r / min) until a transparent colloidal solution is obtained;

[0036] Then add 3g of polymer dispersant Haichuan Chemical 5040 to 17g of xylene and n-butanol solvent with a weight ratio of 3:1, add 7g of nano titanium dioxide, disperse at 2000rpm for 15 minutes at high speed, and then grind with a sand mill for 2 hours. Nano titanium dioxide slurry.

[0037] Then add the prepared 27g nano pulp, 14g cuprous oxide, 5g rosin, 4g tricresol phosphate and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com