Mechanical underground excavation construction method for large underground parking lot

An underground parking lot and construction method technology, applied in the field of mechanical underground excavation construction of large underground parking lots, can solve problems such as damaging the environment, affecting work and living order, interfering with traffic, etc., achieve a high degree of mechanization, reduce environmental impact and construction risks, The effect of small environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

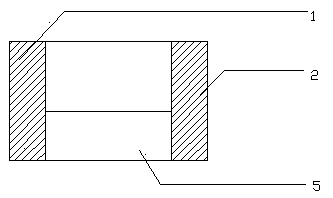

Image

Examples

Embodiment 1

[0044] The construction method of mechanical underground excavation in a large underground parking lot in this embodiment comprises the following steps:

[0045] First of all, according to the design of the parking lot, two parallel construction tunnels shall be built at both ends of the planned space of the parking lot. The side wall is the construction work surface of the parking lot;

[0046] Secondly, mark the rectangular section of the parking lot space on the side wall of the construction tunnel, and divide the entire rectangular section of the parking lot space into several small rectangular sections of equal size;

[0047] Then, the rectangular pipe jacking machine is used to sequentially carry out the partial jacking construction of each small rectangular section, that is, the straight-line distance between the two construction tunnels, and simultaneously install the rectangular pipe jacking inside. The rectangular pipe jacking is made of prefabricated concrete and se...

Embodiment 2

[0051] The construction method of mechanical underground excavation in a large underground parking lot in this embodiment comprises the following steps:

[0052] First of all, according to the design of the parking lot, at least four vertical shafts shall be constructed in the proposed space of the parking lot, and each two vertical shafts shall form a group. The linear distance between the two shafts shall be excavated and supported. Two parallel construction tunnels, the section height of the construction tunnel is greater than the height of the parking lot space, and the width should meet the construction requirements; one side wall of the construction tunnel is the construction work surface of the parking lot;

[0053] Secondly, mark the rectangular section of the parking lot space on the side wall of the construction tunnel, and divide the rectangular section of the parking lot space, that is, the side wall of the construction tunnel, into several small rectangular section...

Embodiment 3

[0059] The mechanical underground excavation construction method of the large underground parking lot of this embodiment is characterized in that it comprises the following steps:

[0060] First of all, build a shaft at the four corners of the overall space E of the parking lot. The two shafts form a group and are divided into two groups. Each group of shafts is used as the originating shaft and the receiving shaft. The straight-line distance jacking from the delivery shaft to the receiving shaft is carried out for excavation and support work, and two construction tunnels are constructed. The section height of the construction tunnels is greater than the height of the parking lot space, and the width should meet the construction requirements; The construction work surface of the parking lot;

[0061] Then, mark the rectangular section of the parking lot space on the side wall of the construction tunnel, and divide the overall space section of the parking lot into several small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com