Anchor rod drill truck

A technology for rock bolters and anchor drills, which is applied in the installation of rock bolts, earthwork drilling, mining equipment, etc. It can solve the problems of high physical energy consumption, dusty environment of operators, and easy roof fall in the empty roof area, so as to reduce the workload , reduce construction risk, improve the effect of safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings. It is only intended to describe the specific implementation of the present invention in detail, and does not impose any limitation on the present invention, and the scope of protection of the present invention shall be determined by the claims.

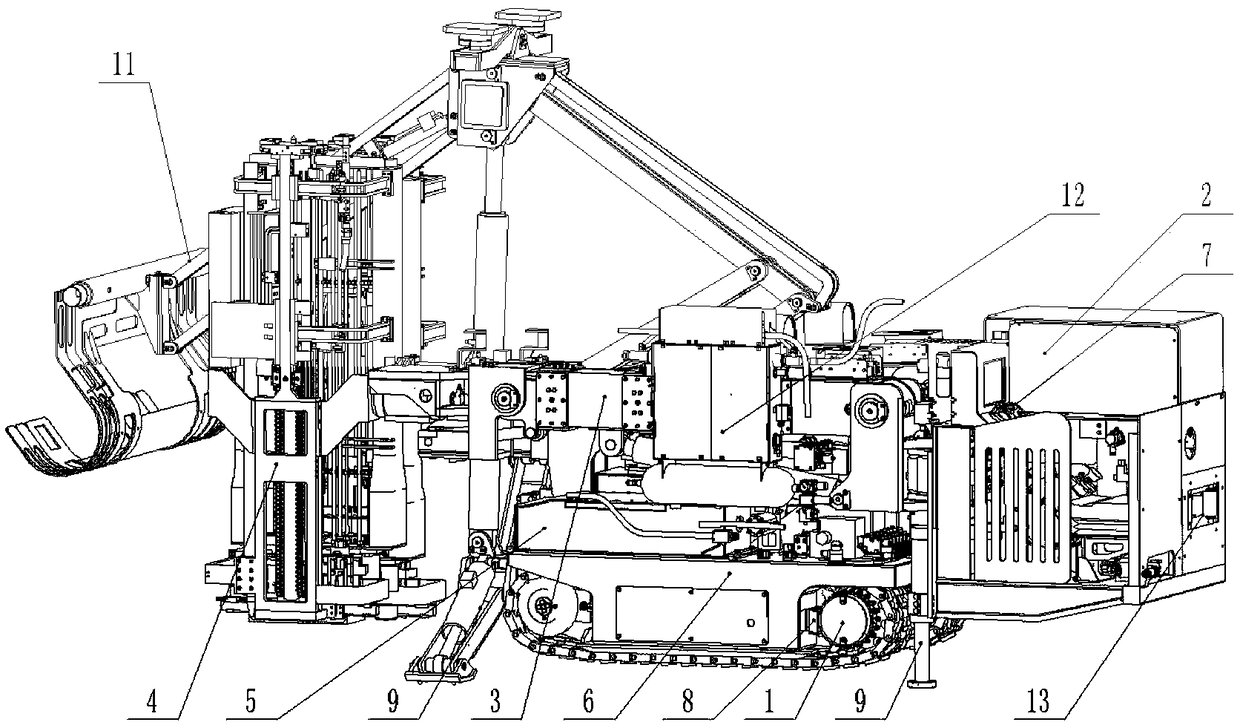

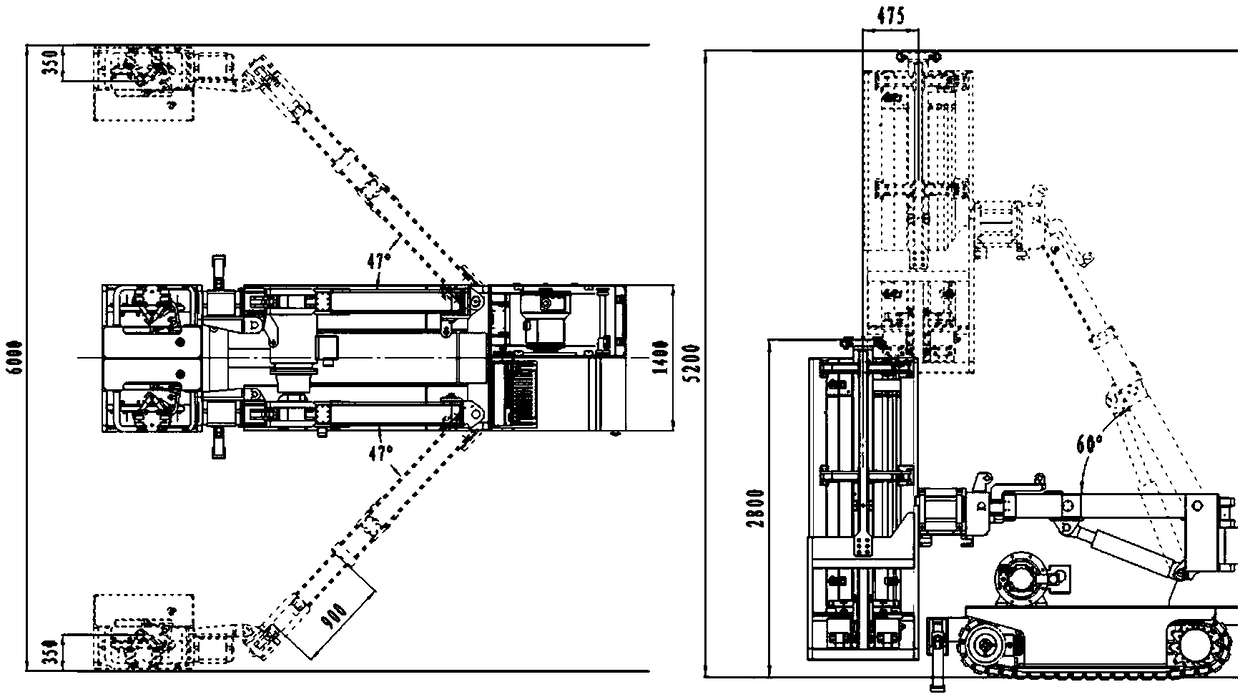

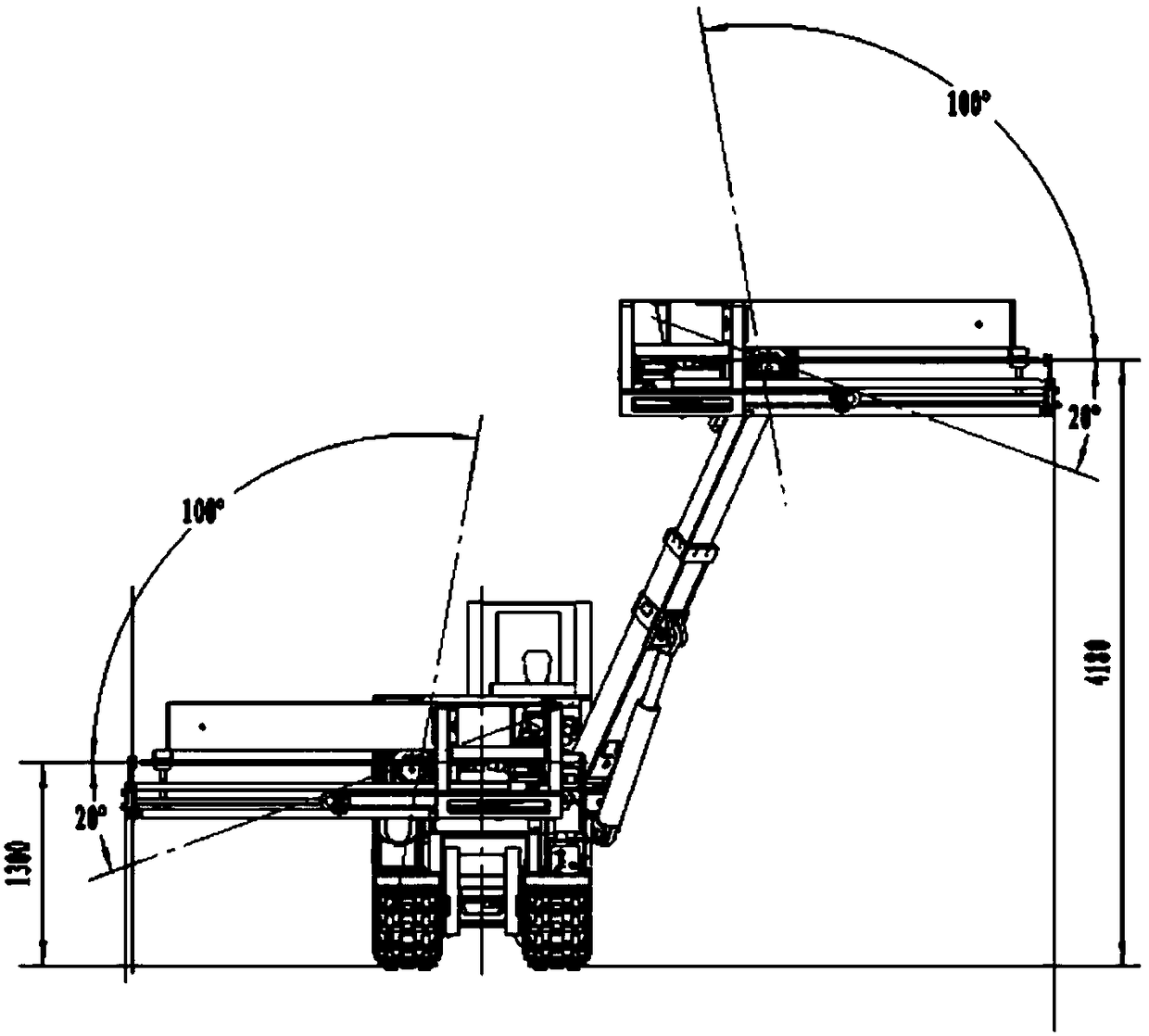

[0038] refer to figure 1 , the present invention proposes a rock bolter, comprising:

[0039] Frame body 6, frequency conversion speed regulation walking mechanism 1, electrical control system 2, hydraulic system 5, directional cruise control and step distance measurement system 8, front and rear stabilizing devices 9 and anchor drilling system, the anchor drilling system includes: telescopic working arm 3, Drill frame 4, net laying and temporary support mechanism 11 and automatic spraying powder roll system 12;

[0040] The variable frequency speed regulation walking mechanism 1 is installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com