Method for constructing branch guide pits of tunnels

A construction method and technology for tunnels, which are applied to tunnels, tunnel linings, and earth-moving drilling and mining, etc., can solve the problems of large horizontal displacement, large construction safety risks and impacts, and achieve the effect of preventing arch collapse and ensuring no safety production accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in further detail below in conjunction with the accompanying drawings.

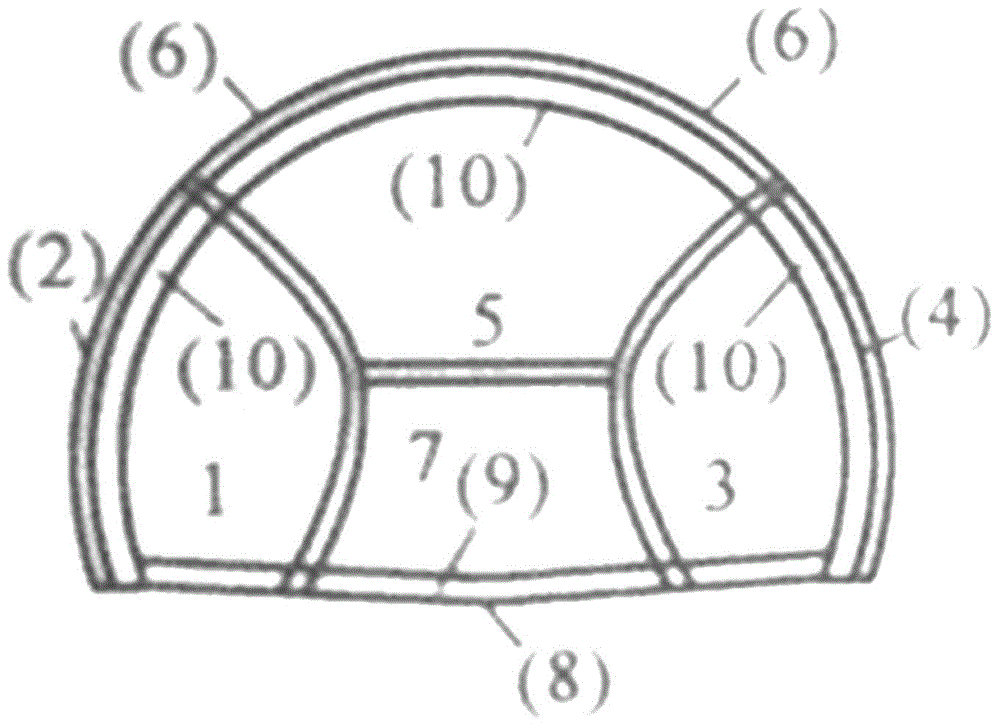

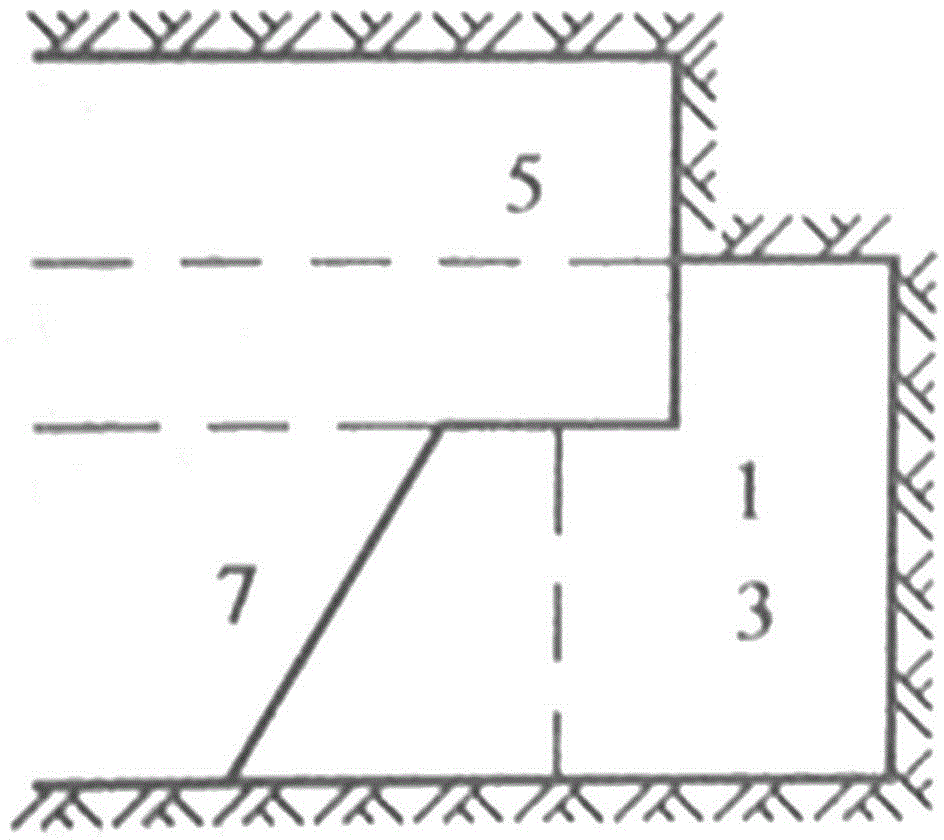

[0055] The technical principle of the sub-pilot method of the present invention: based on the theory of rock mass mechanics, the construction method of the sub-pilot method is summarized by adopting the principle of the new Austrian method, that is, the excavation section of the cavern is divided into an annular arch, left and right side pilot pits , the four parts of the central core soil. The principle of determining the size of the pilot pit can be flexibly arranged according to the actual situation on site. The size of the annular arch is suitable for the convenience of construction operations. The general height is about 2m. The width of the left and right pilot pits should not exceed 1 / 3 of the maximum span of the section, and the shape should be close to an ellipse The staggered distance between the left and right pilot pits should be determined accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com