Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

234 results about "Tubeless tire" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tubeless tires or tyres (in some Commonwealth Nations) are pneumatic tires that do not require a separate inner tube. Unlike pneumatic tires which use a separate inner tube, tubeless tires have continuous ribs molded integrally into the bead of the tire so that they are forced by the pressure of the air inside the tire to seal with the flanges of the metal rim of the wheel.

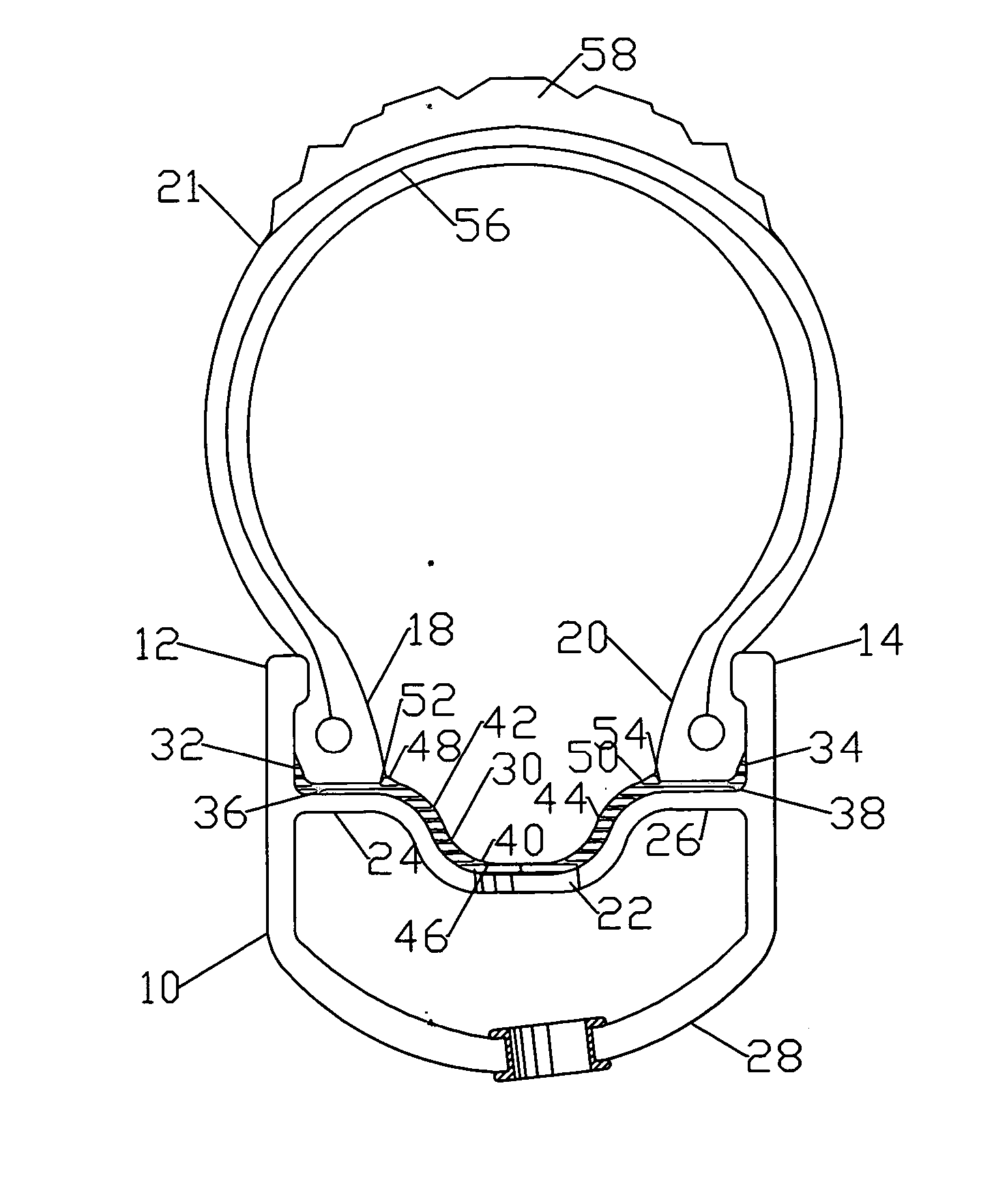

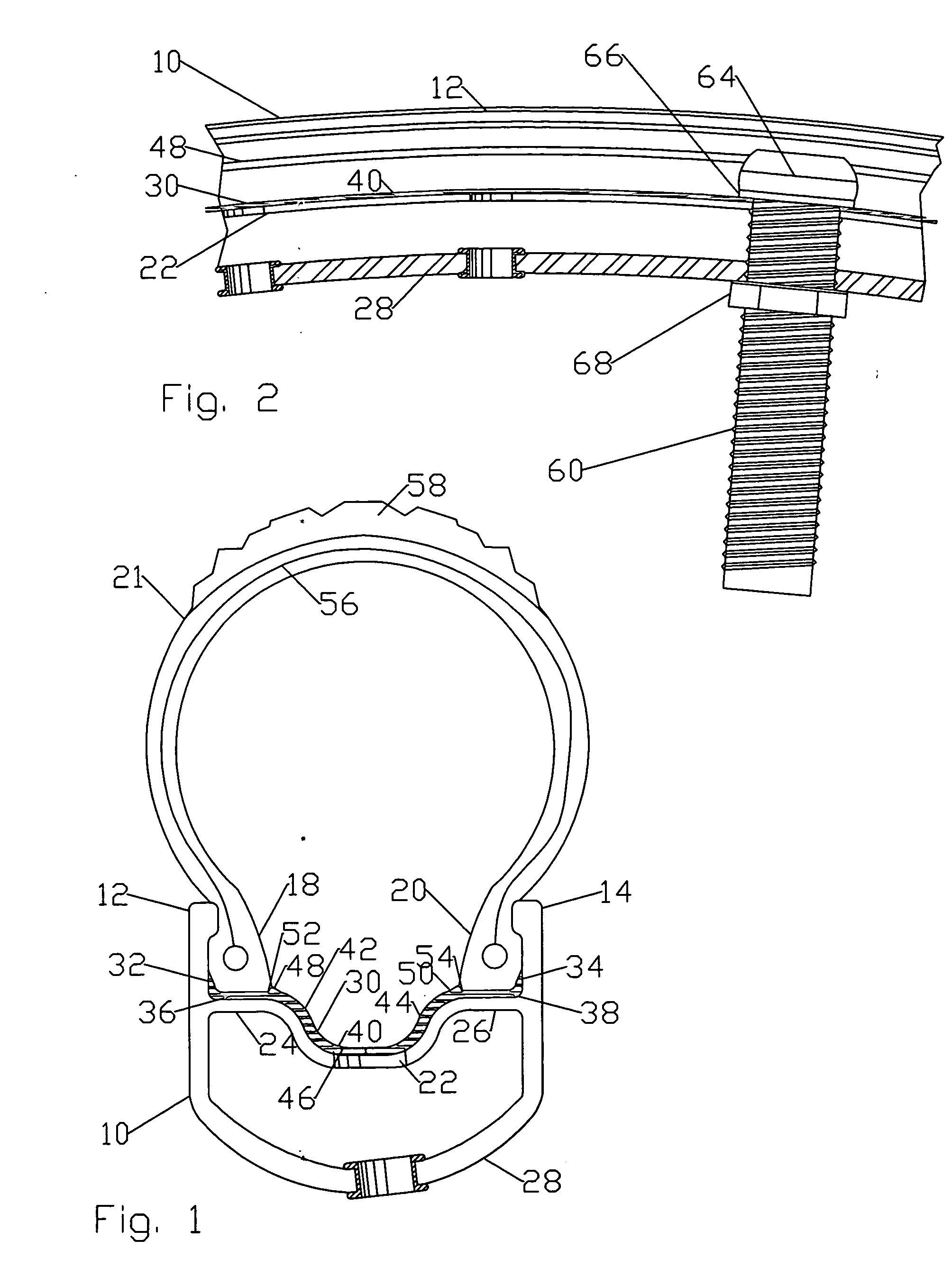

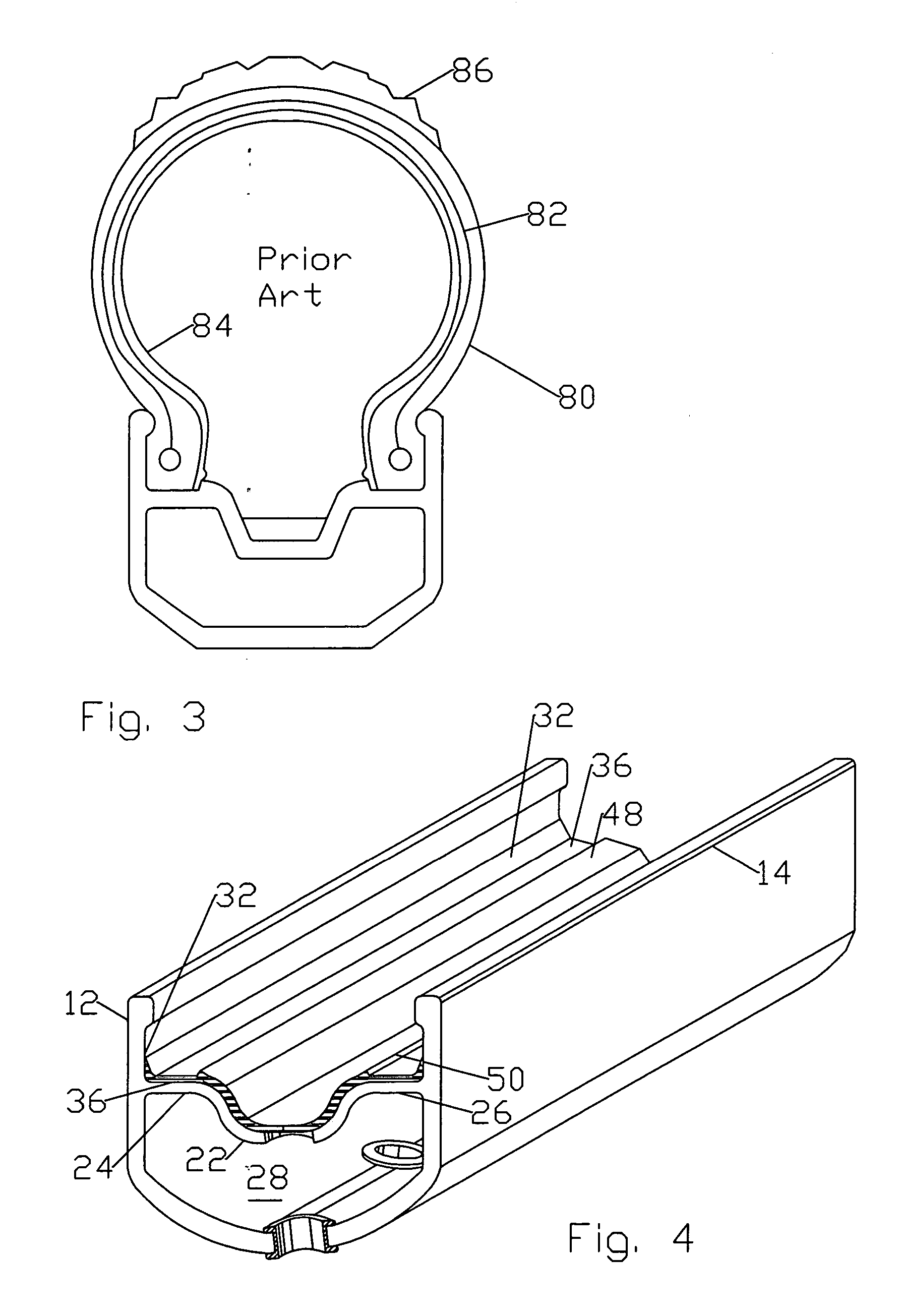

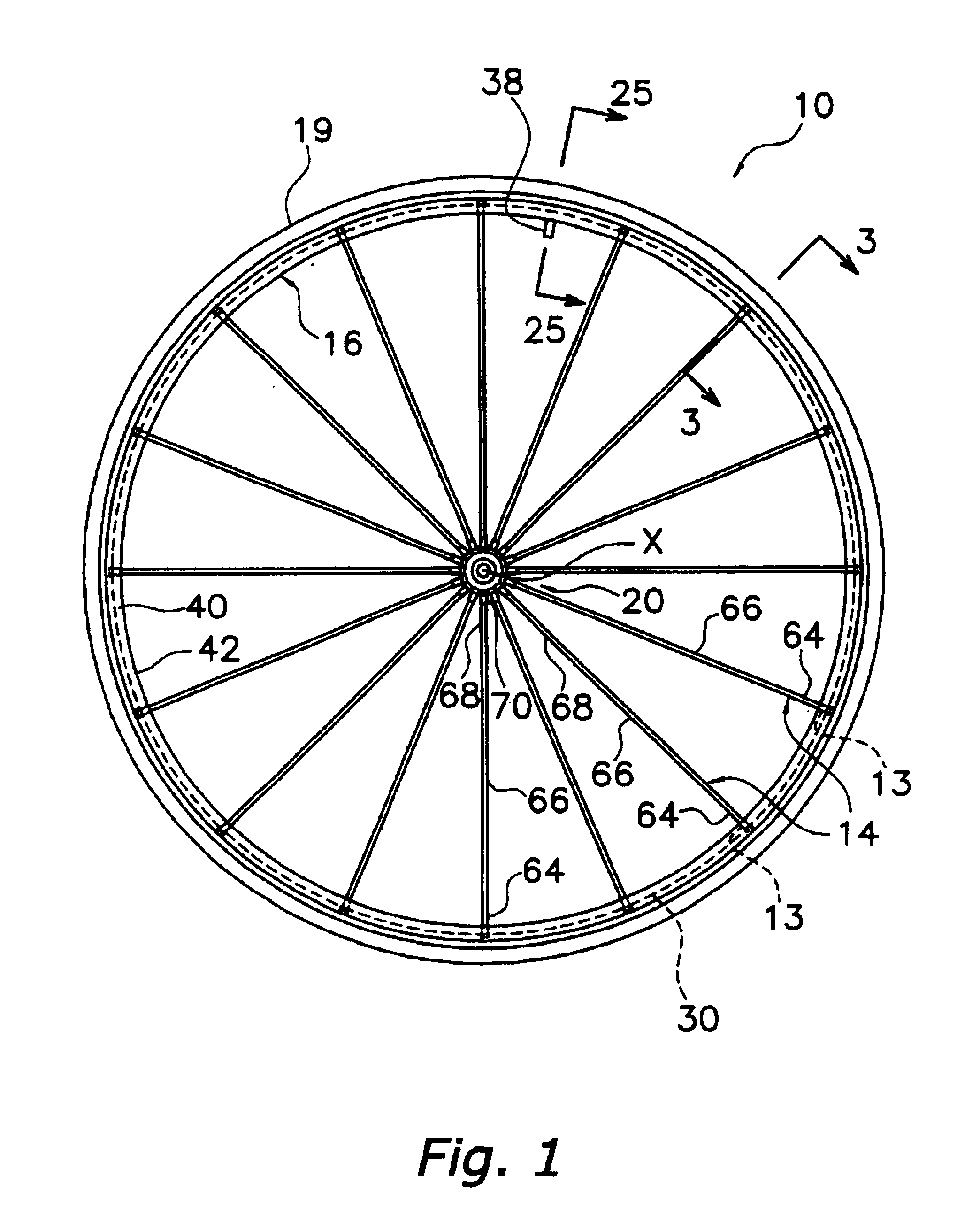

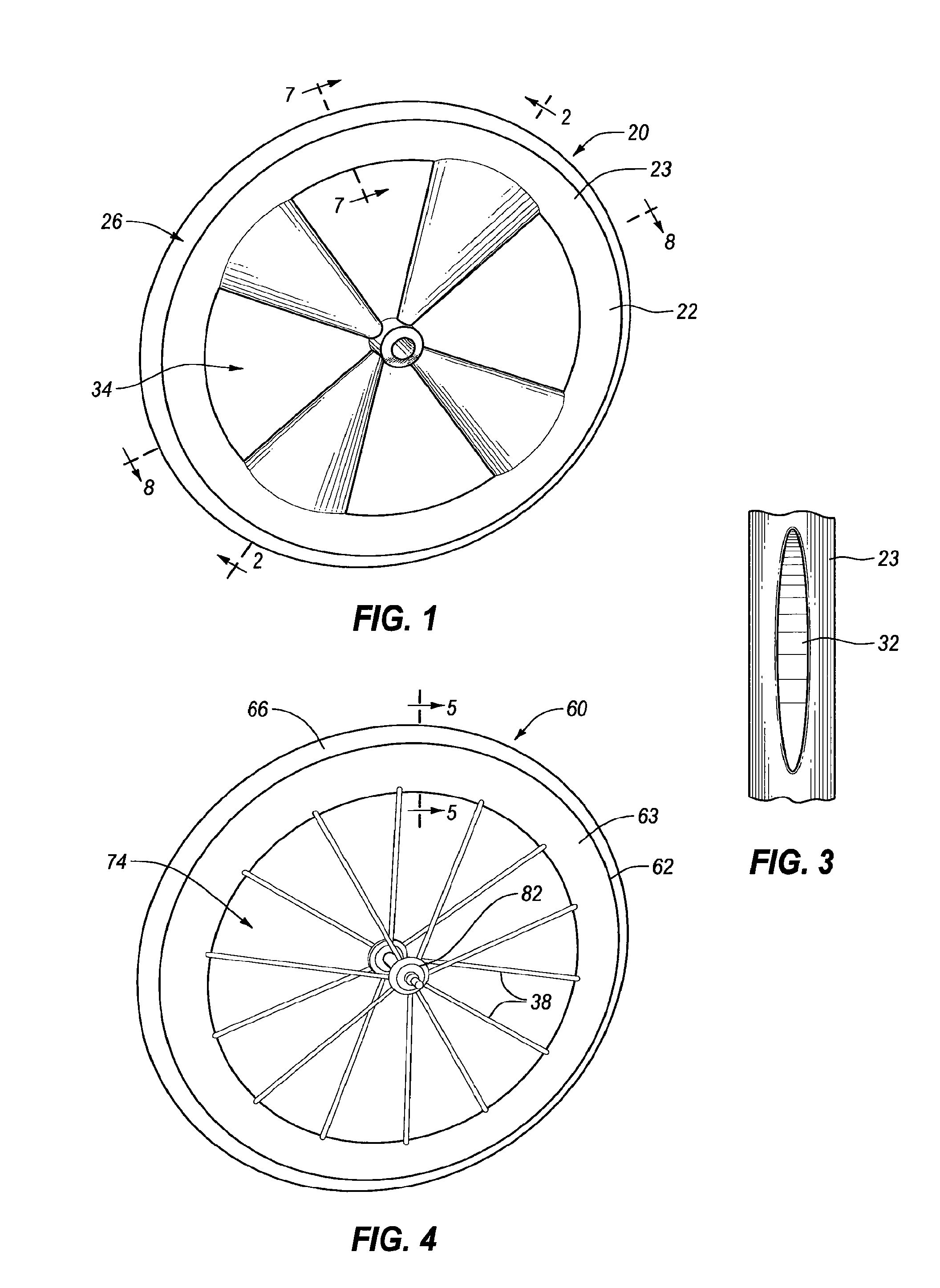

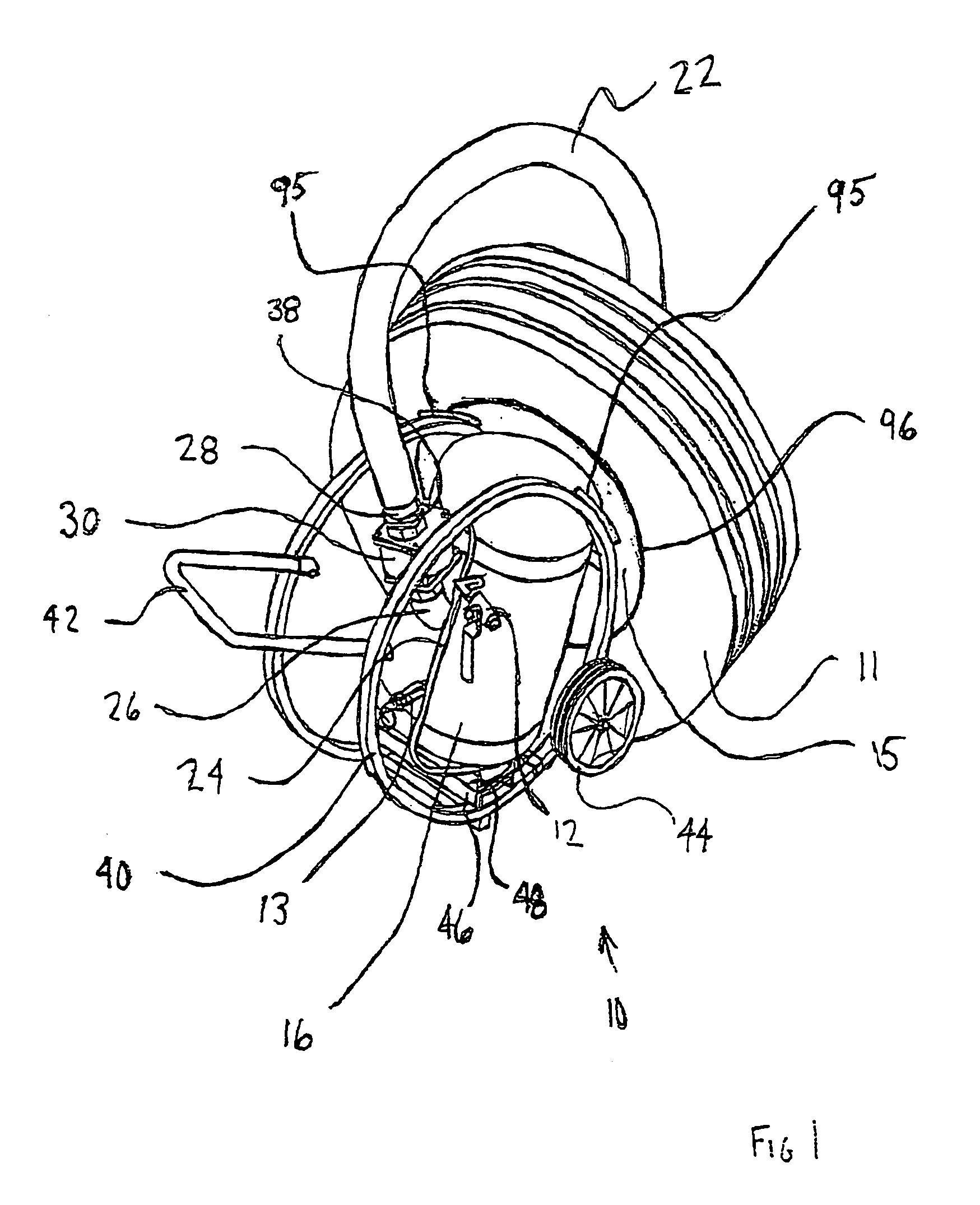

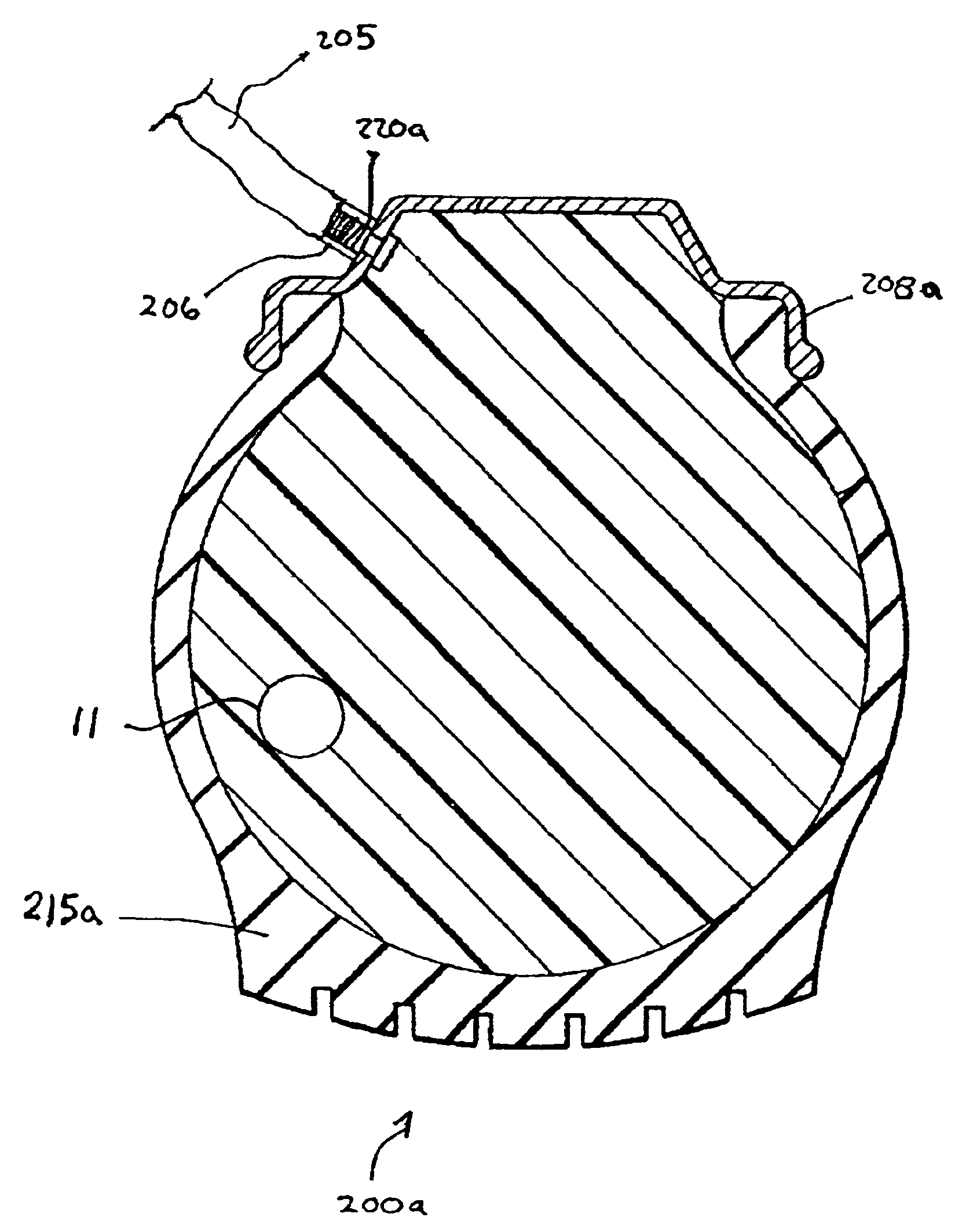

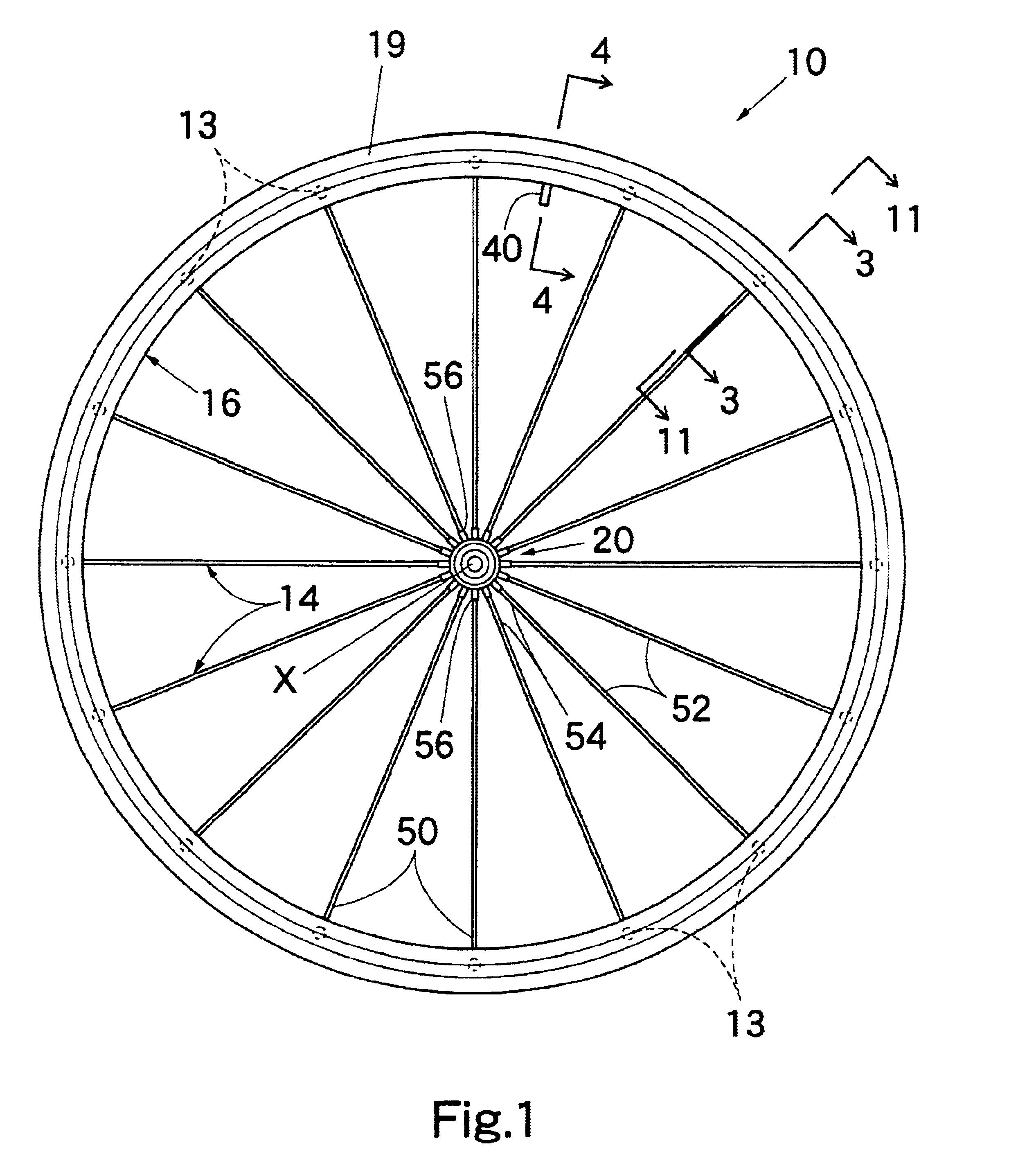

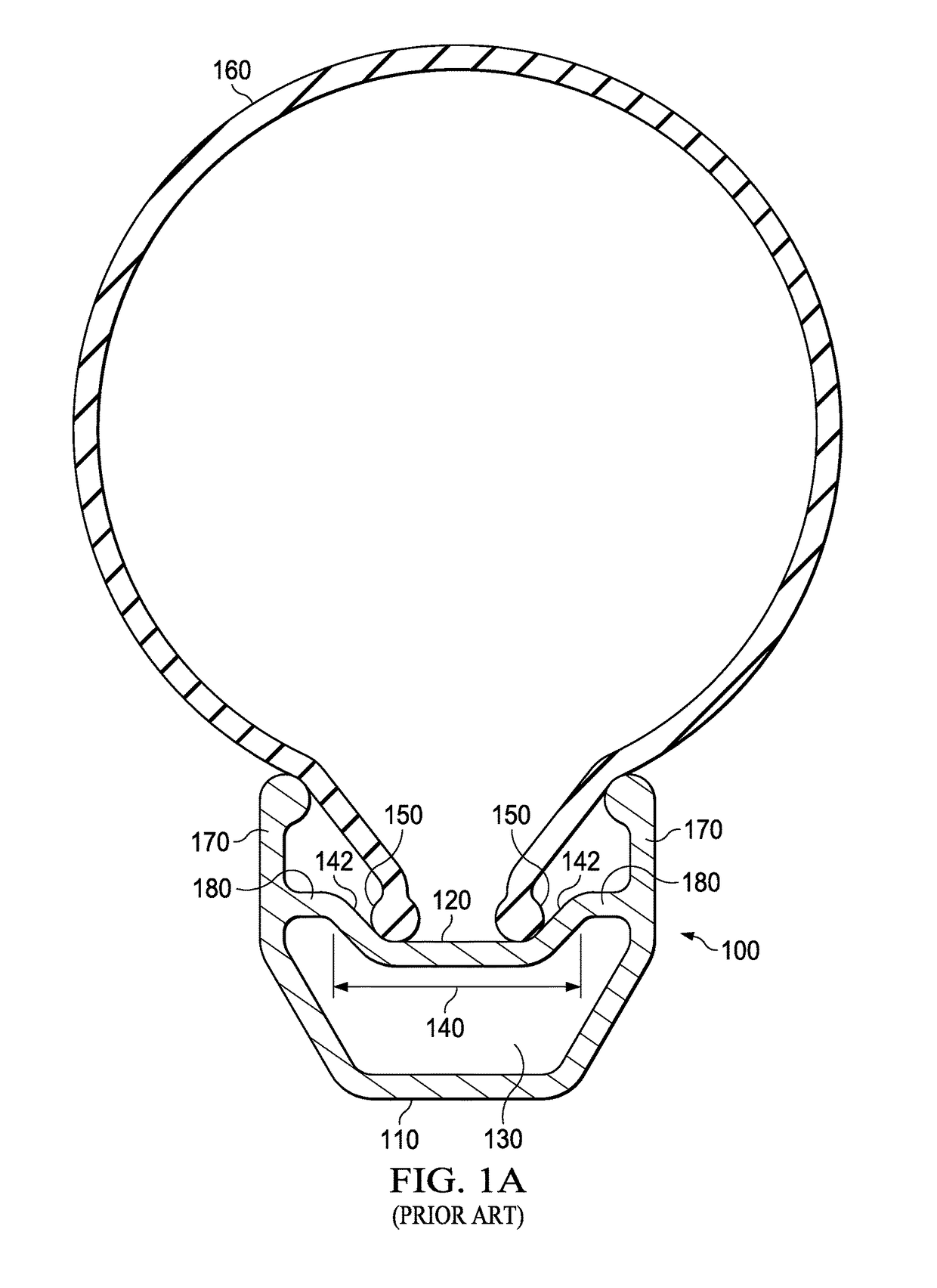

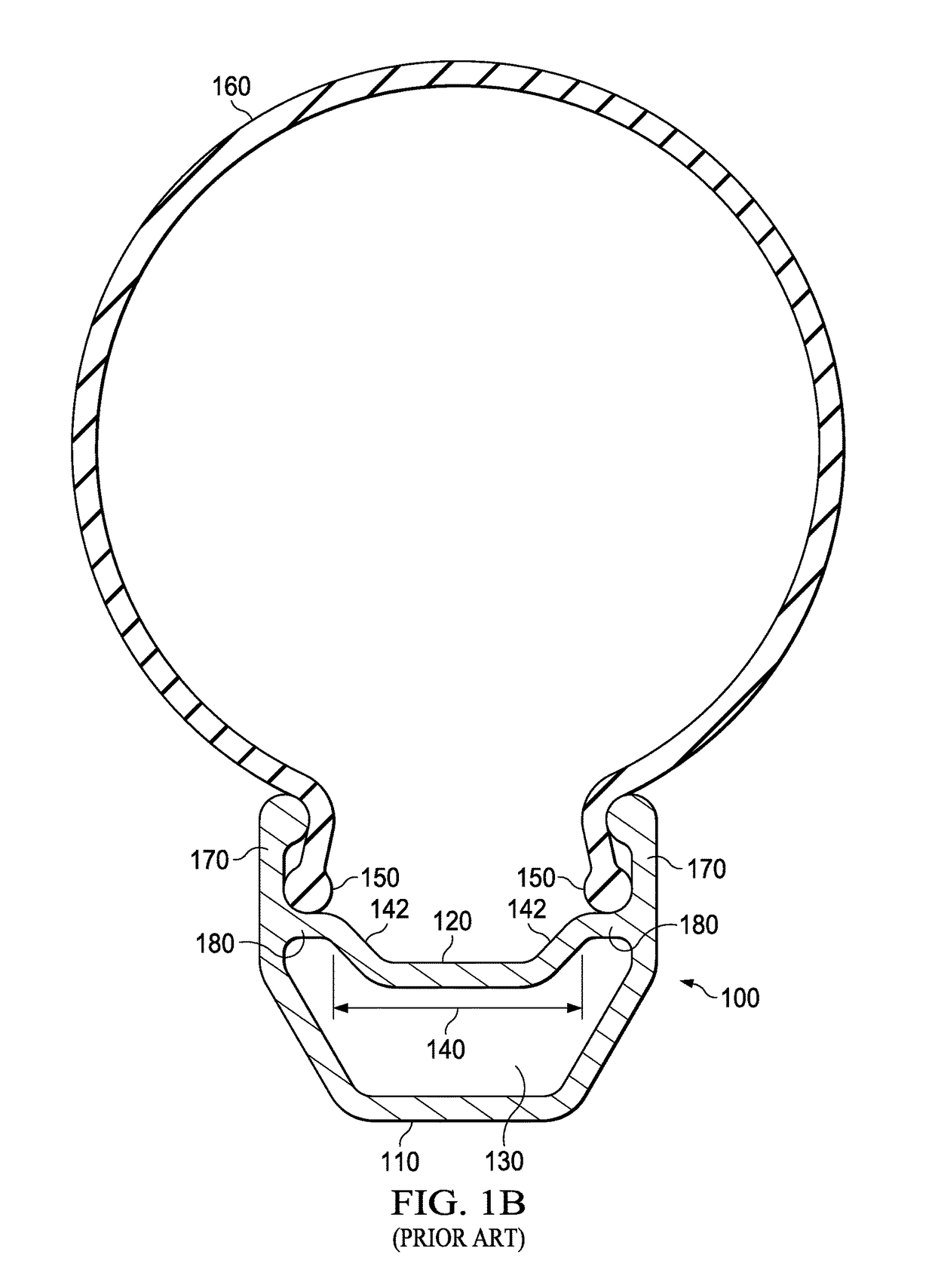

Sealed tubeless tire bicycle wheel

InactiveUS20050210675A1Good handling characteristicsImprove featuresWithout separate inflatable insertsWith separate inflatable insertsTubeless tireAutomotive engineering

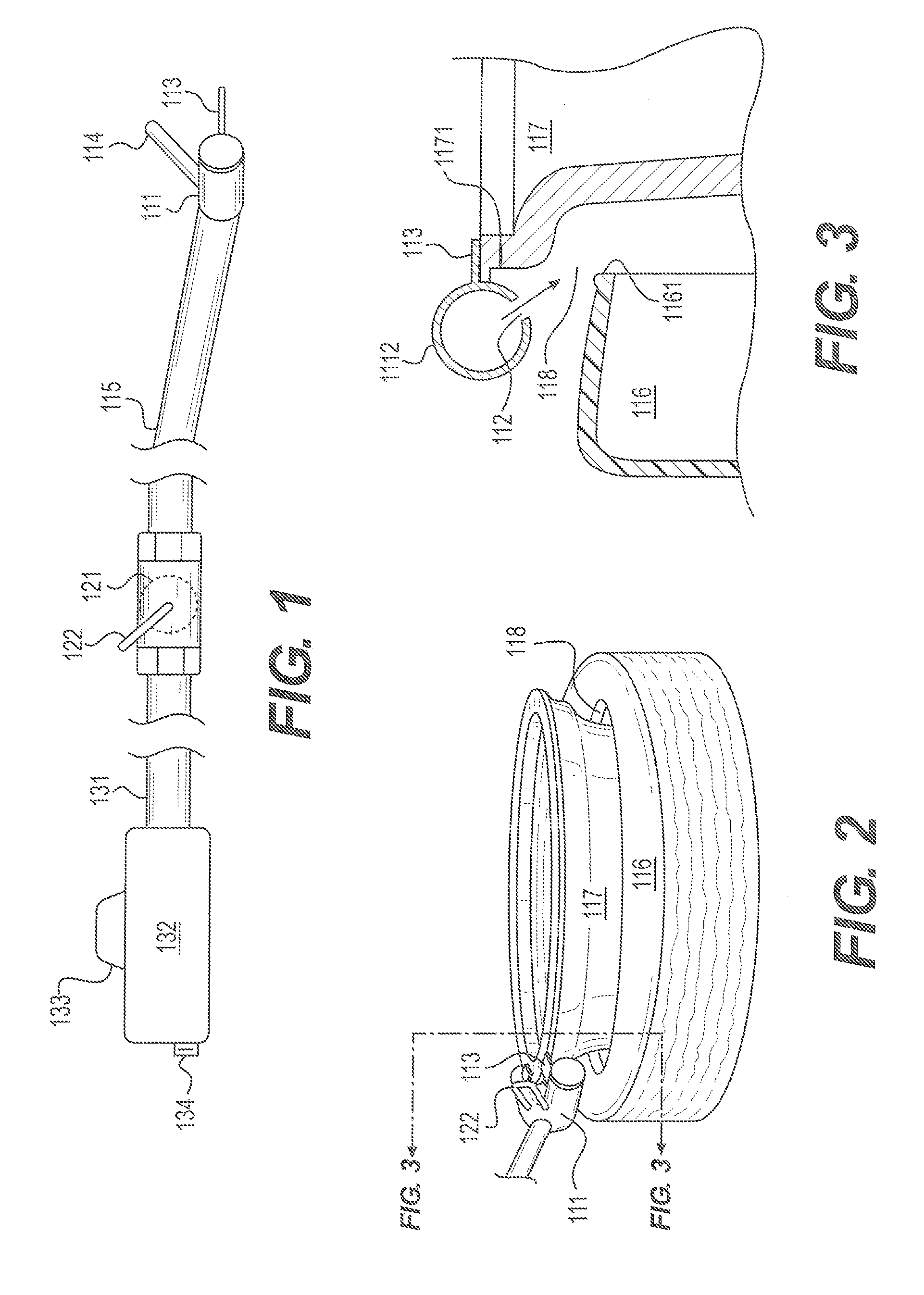

Pneumatic tires adapted to use on bicycles have a number of criteria that need to be evaluated. For high performance bicycle riding, such as in mountain bike races, it is advantageous to optimize performance. Standard tires with tubes have ease of repair in the replacement of a punctured tube, have the ability to maintain pressure for long periods, and do not require special adaptation of the rim for sealing.

Owner:PRICE CHAD NATHANIEL +1

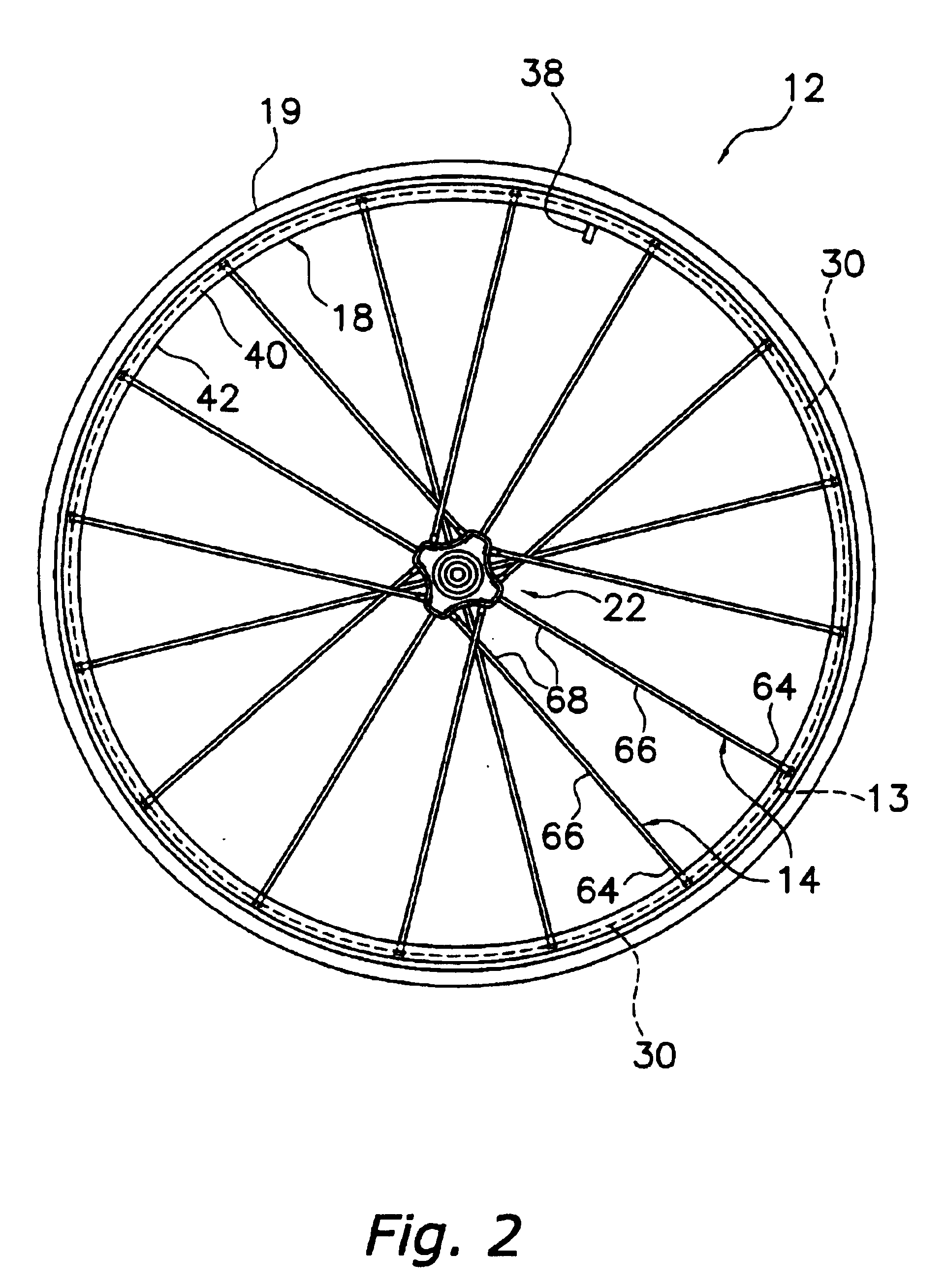

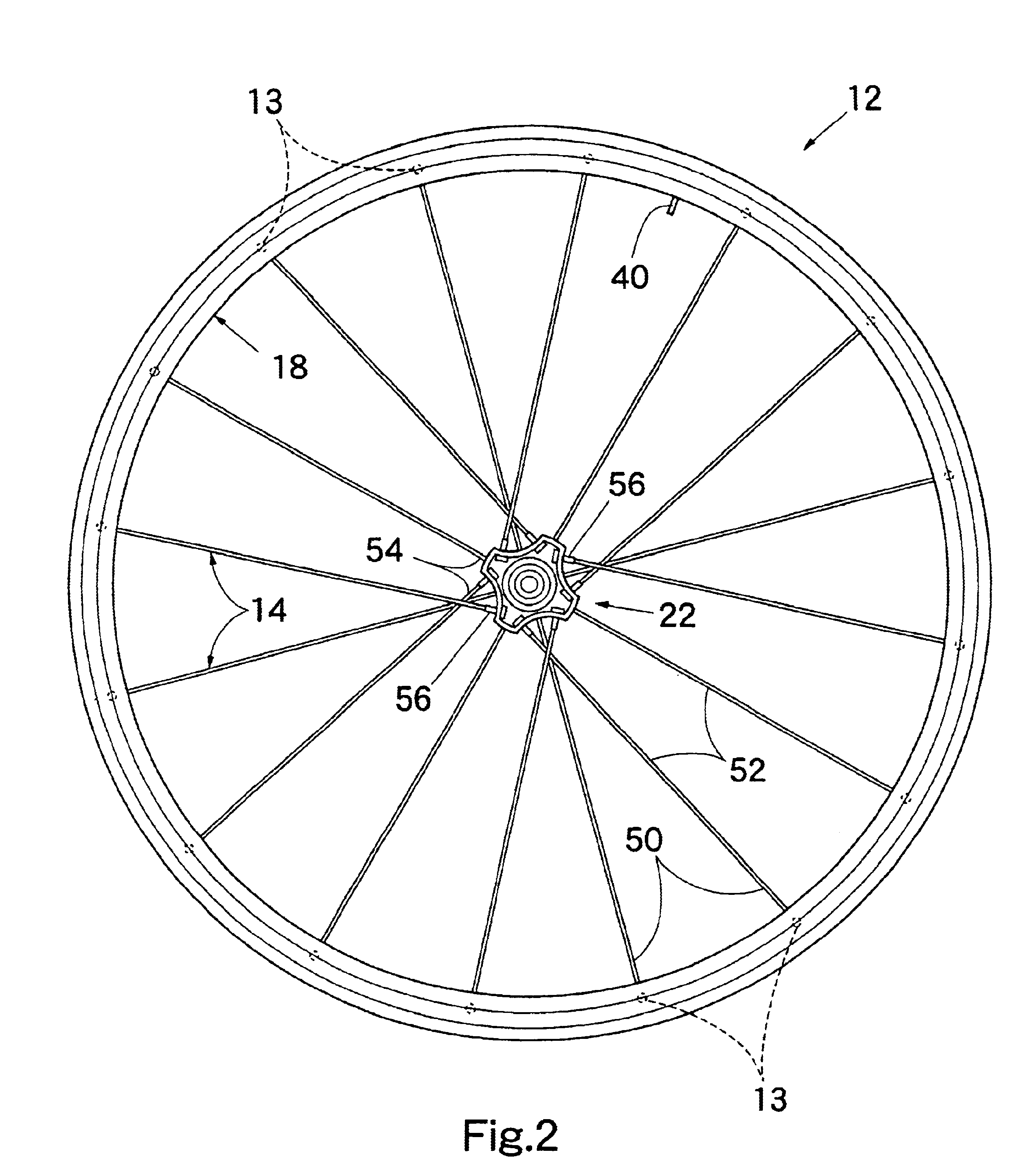

Bicycle rim

InactiveUS6736462B1Simple and inexpensive to manufactureSimple and inexpensive to and assembleHubsRimsTubeless tireEngineering

A hollow bicycle rim a plurality of tubular reinforcement members coupled to the inner and outer openings. Each of the reinforcement members has an internal abutment surface within an internal passageway designed to engage an enlarged head of a spoke to couple spokes to the rim. The inner and outer ends of the reinforcement members are secured to the inner and outer openings to prevent inner and outward movement of the reinforcement members, respectively. Each reinforcement member preferably has a pre-formed retaining surface and one or more deformed retaining surface to prevent inner and outer movement. Optionally, each reinforcement member can include a threaded connection instead of one or more the deformed retaining surfaces. Seal members are optionally mounted in the reinforcement members so that a tubeless tire can be used.

Owner:SHIMANO INC

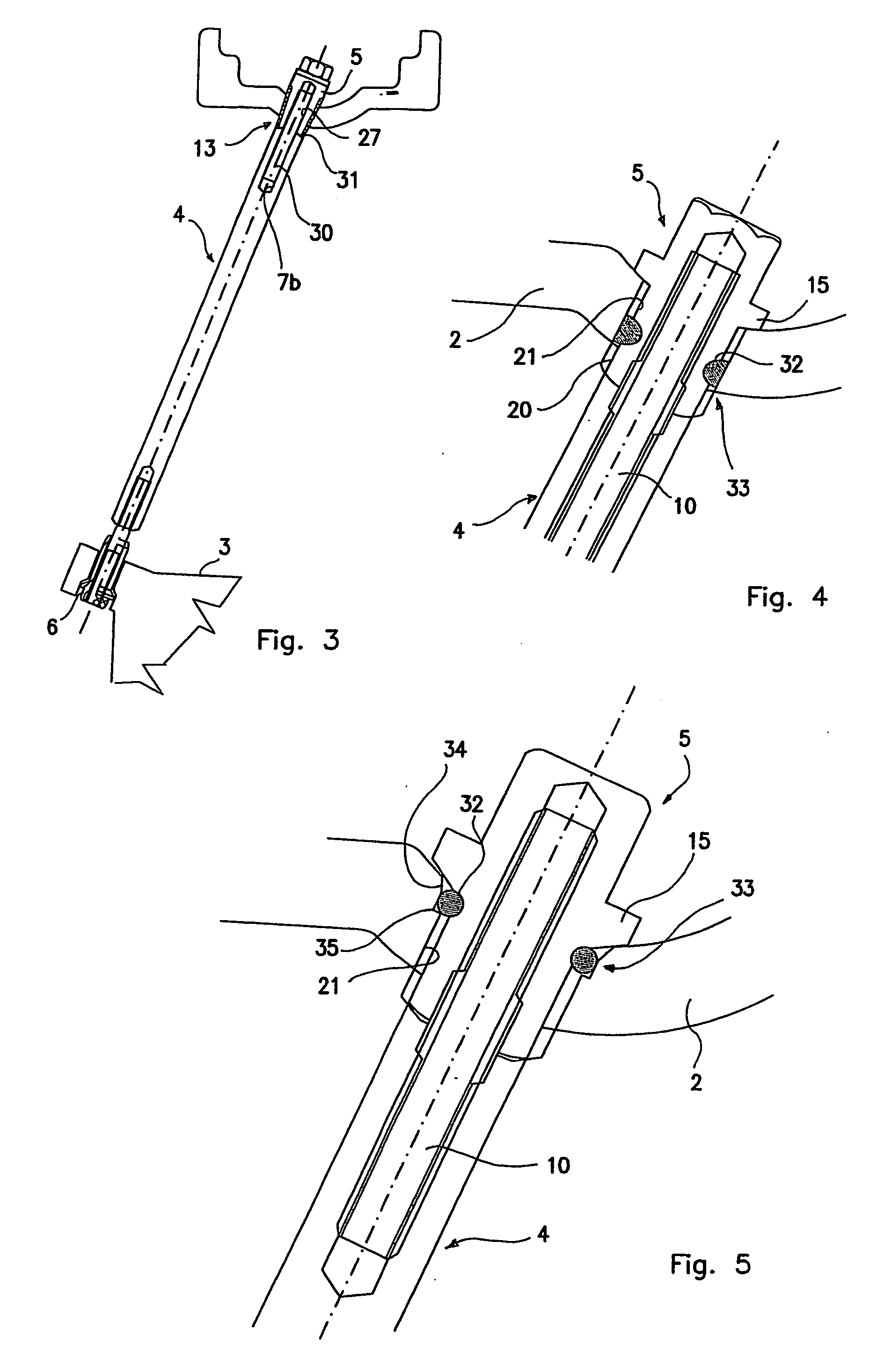

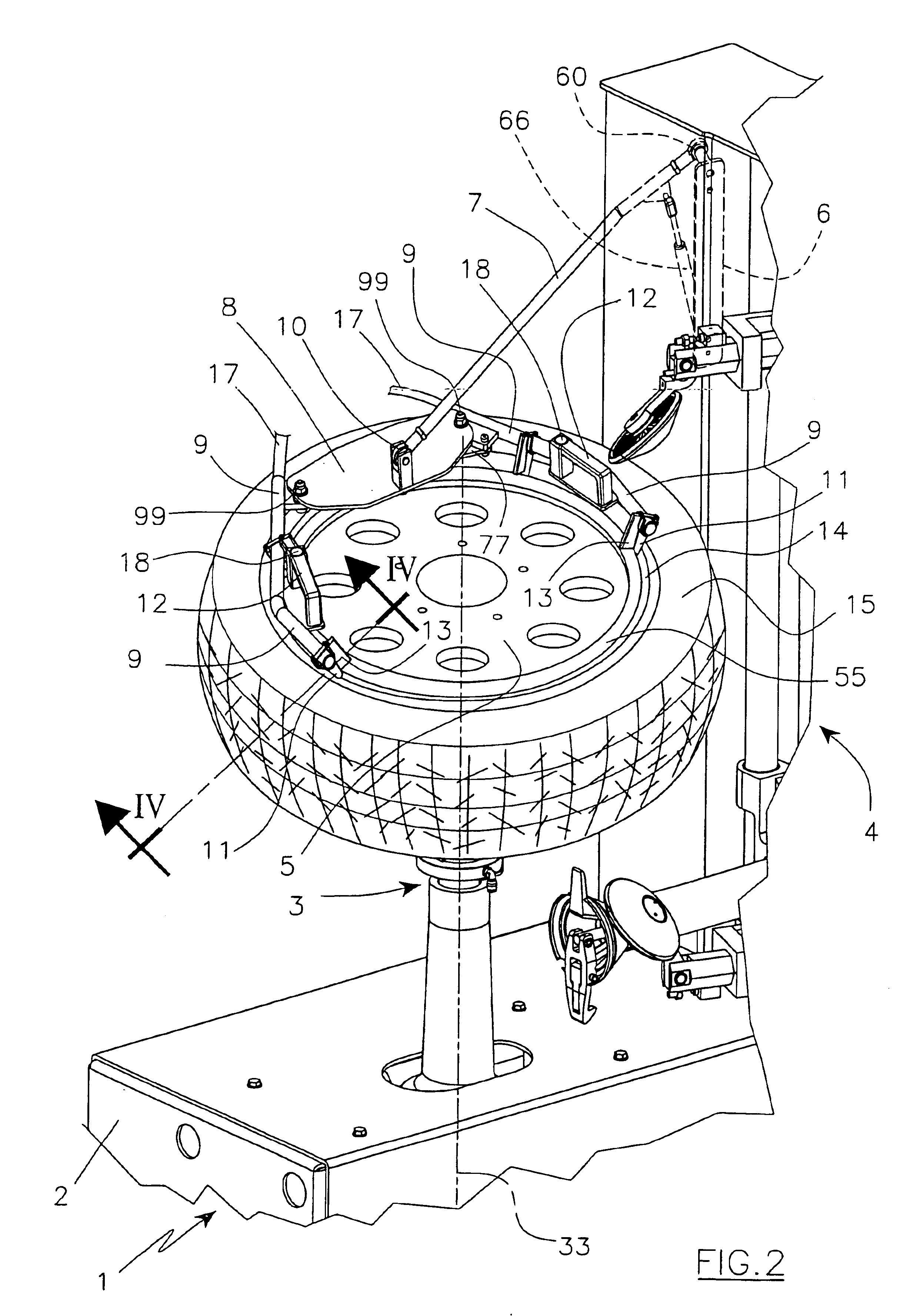

Spoked wheel for tires (amended)

Owner:ALPINA RAGGI

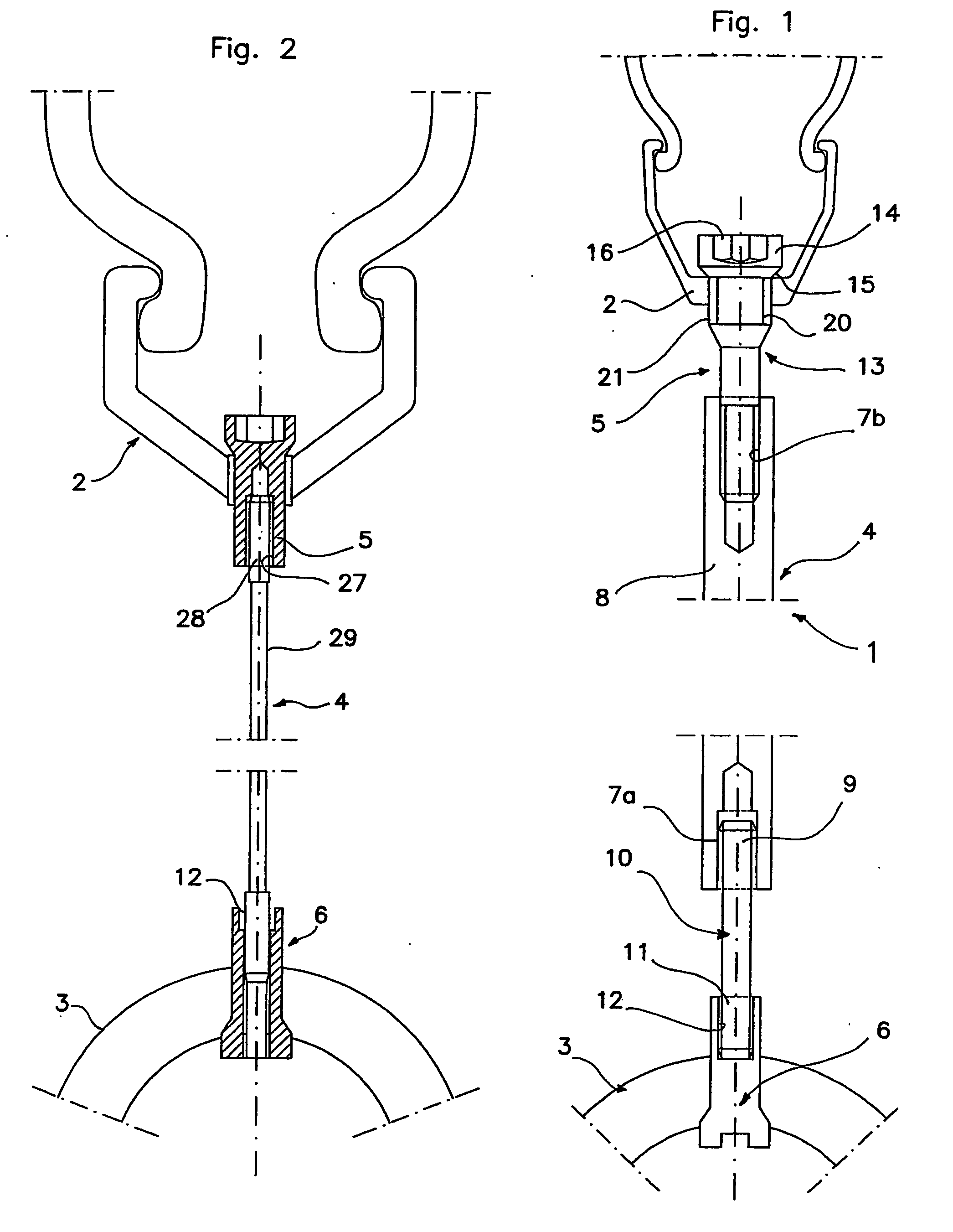

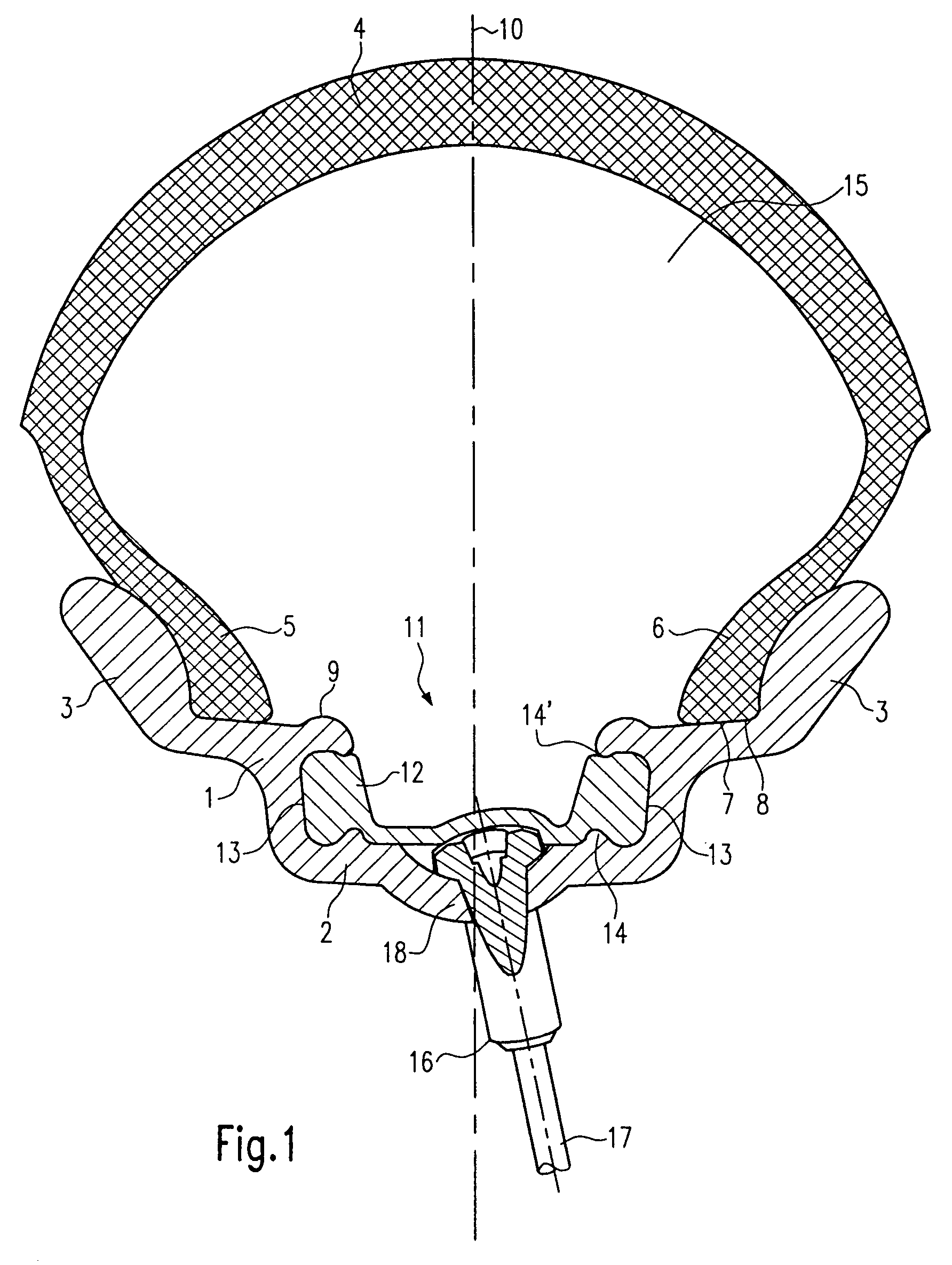

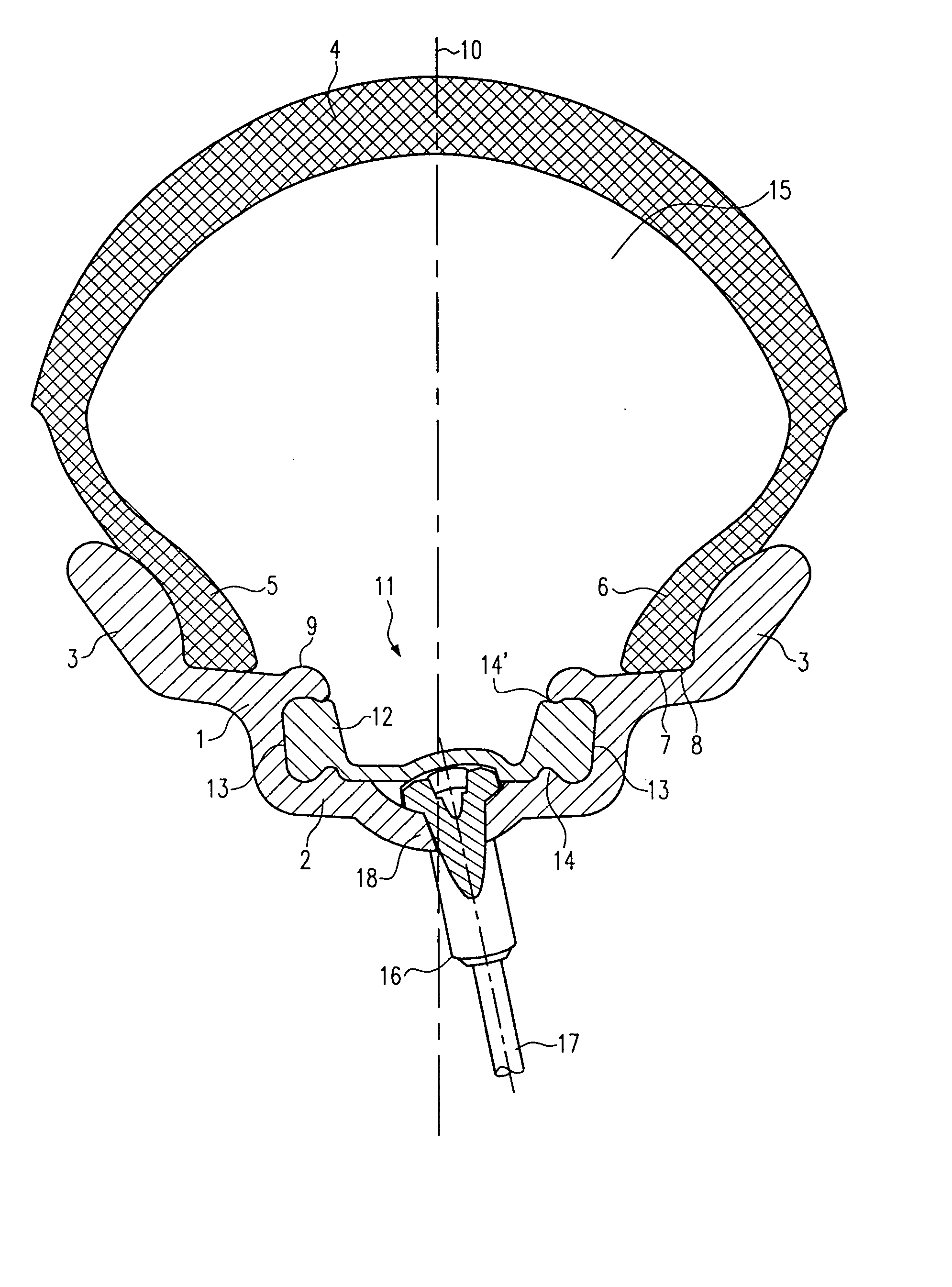

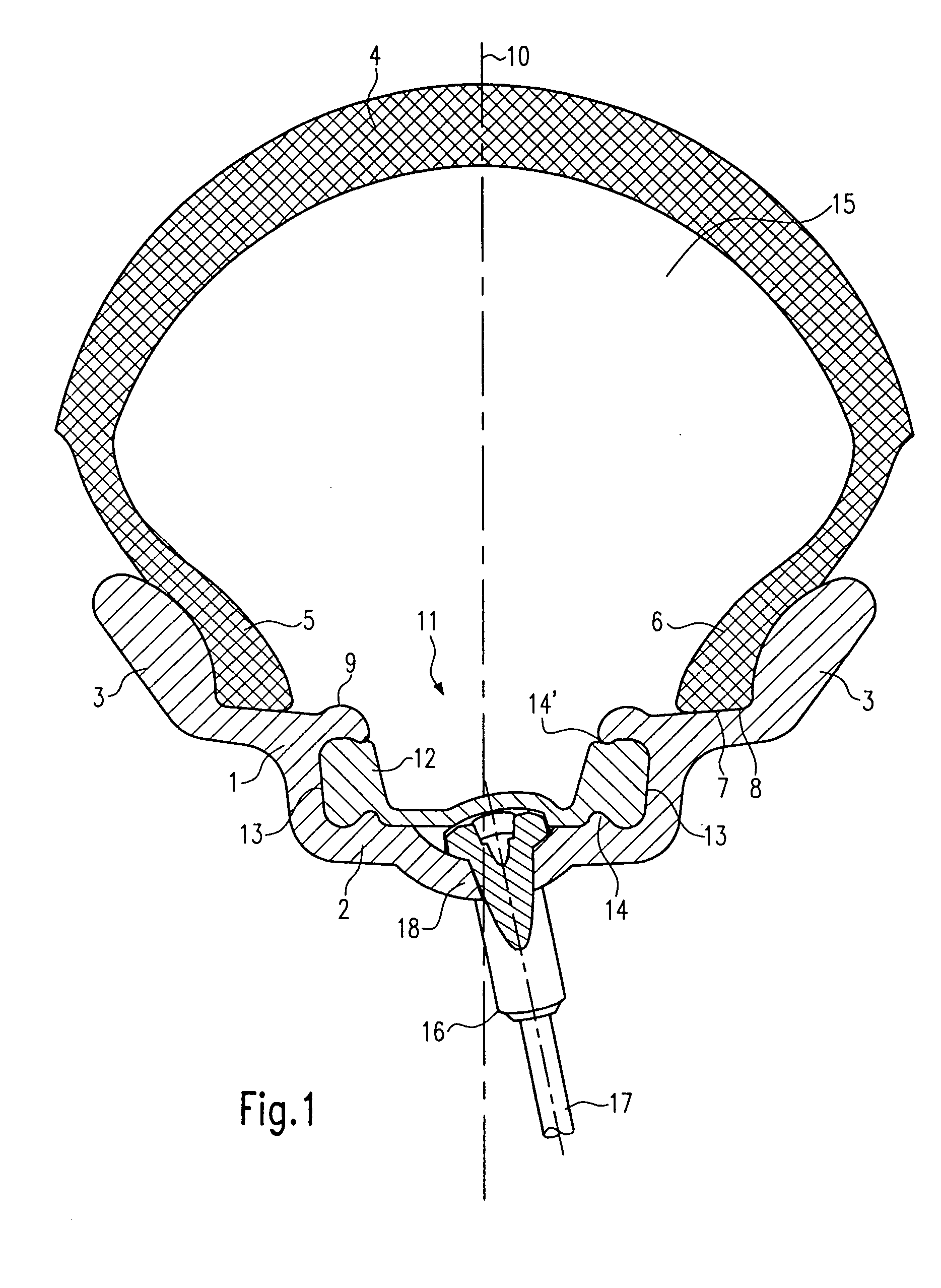

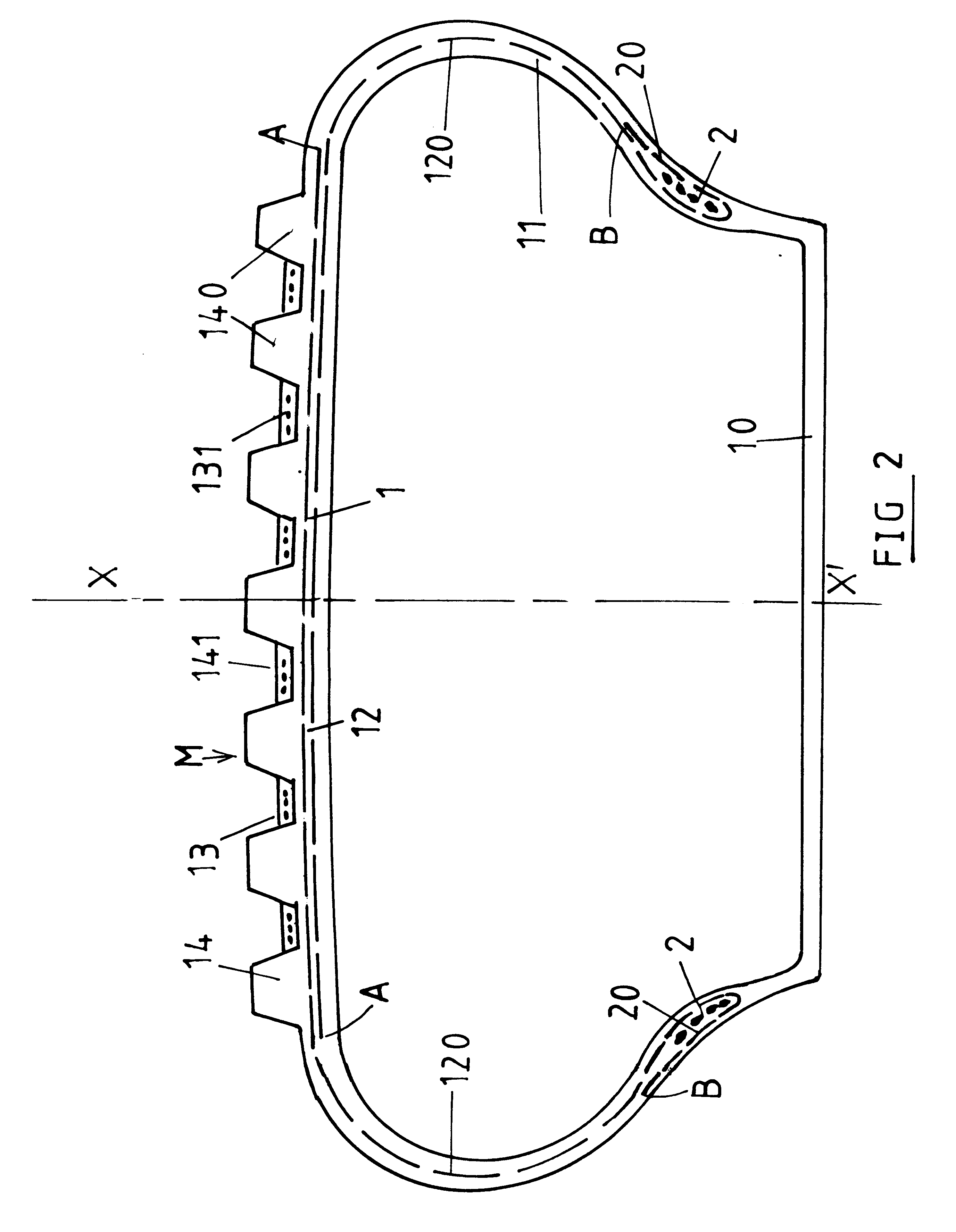

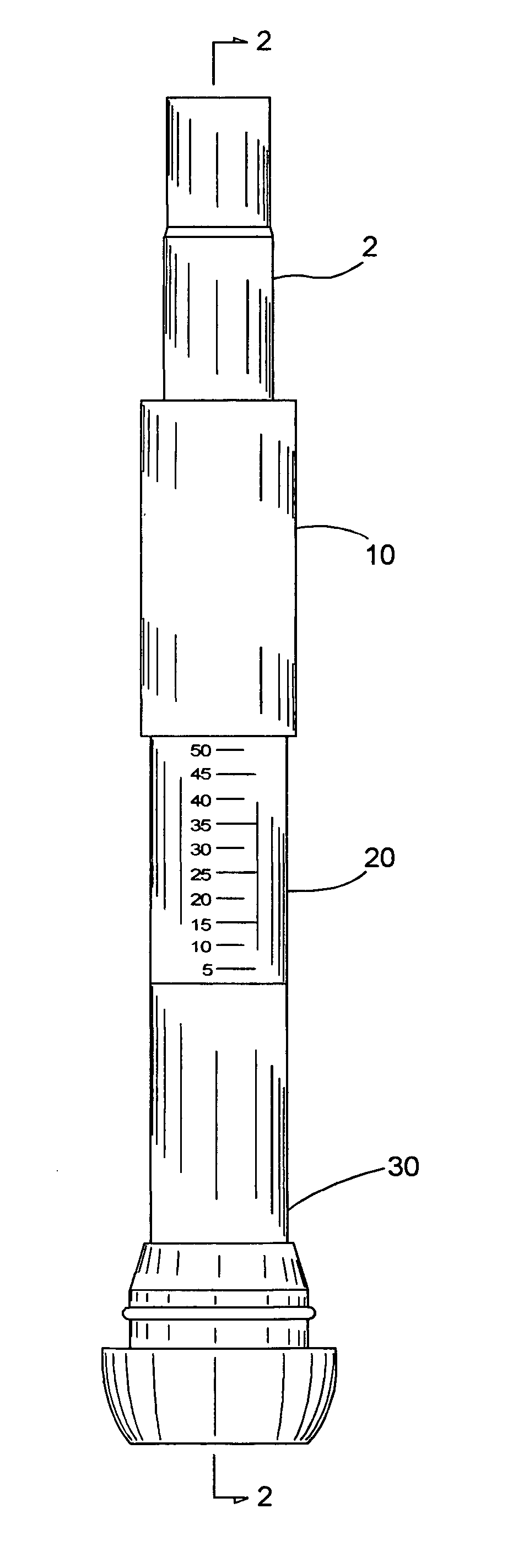

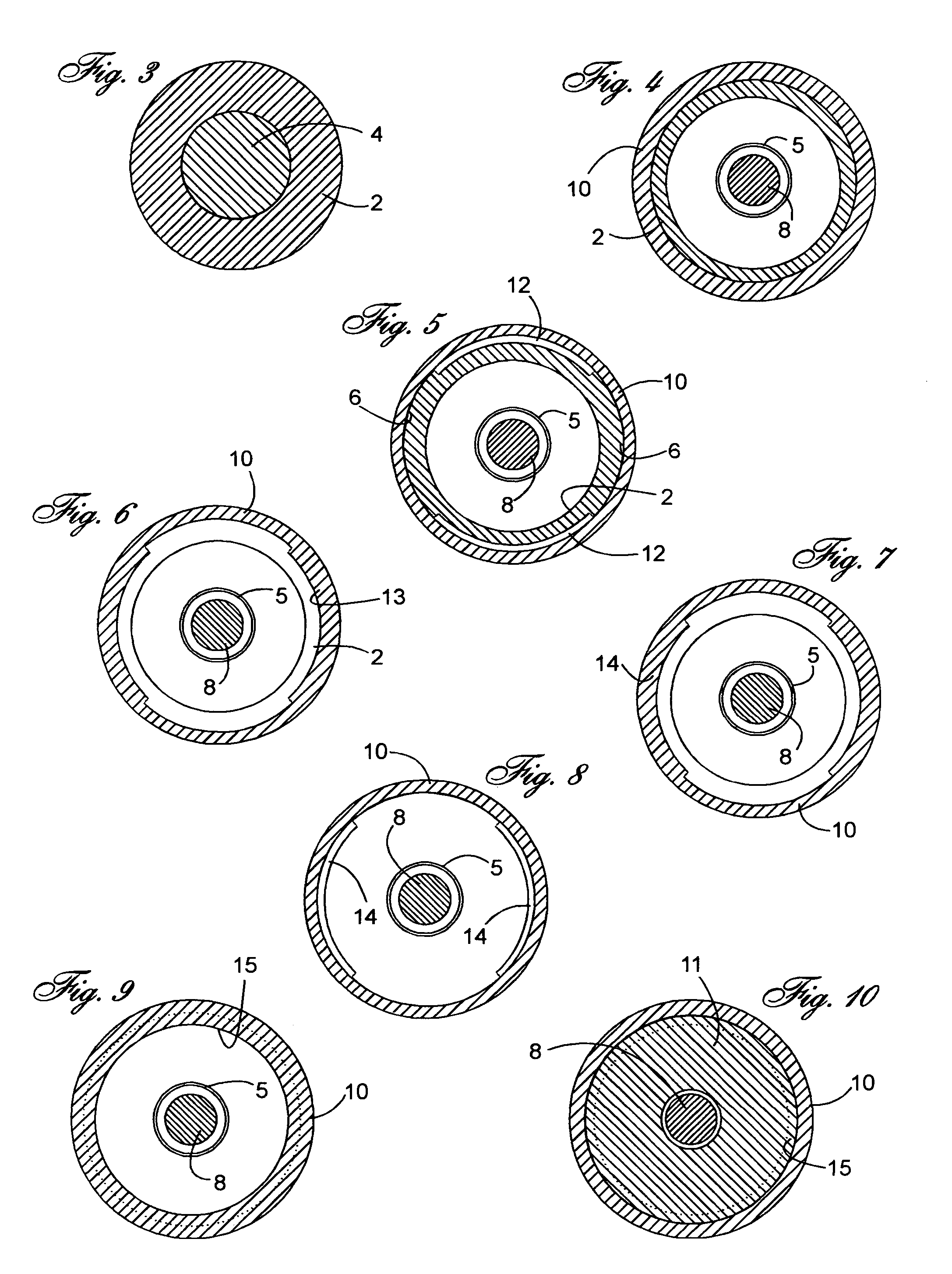

Spoke wheel rim for tubeless tires

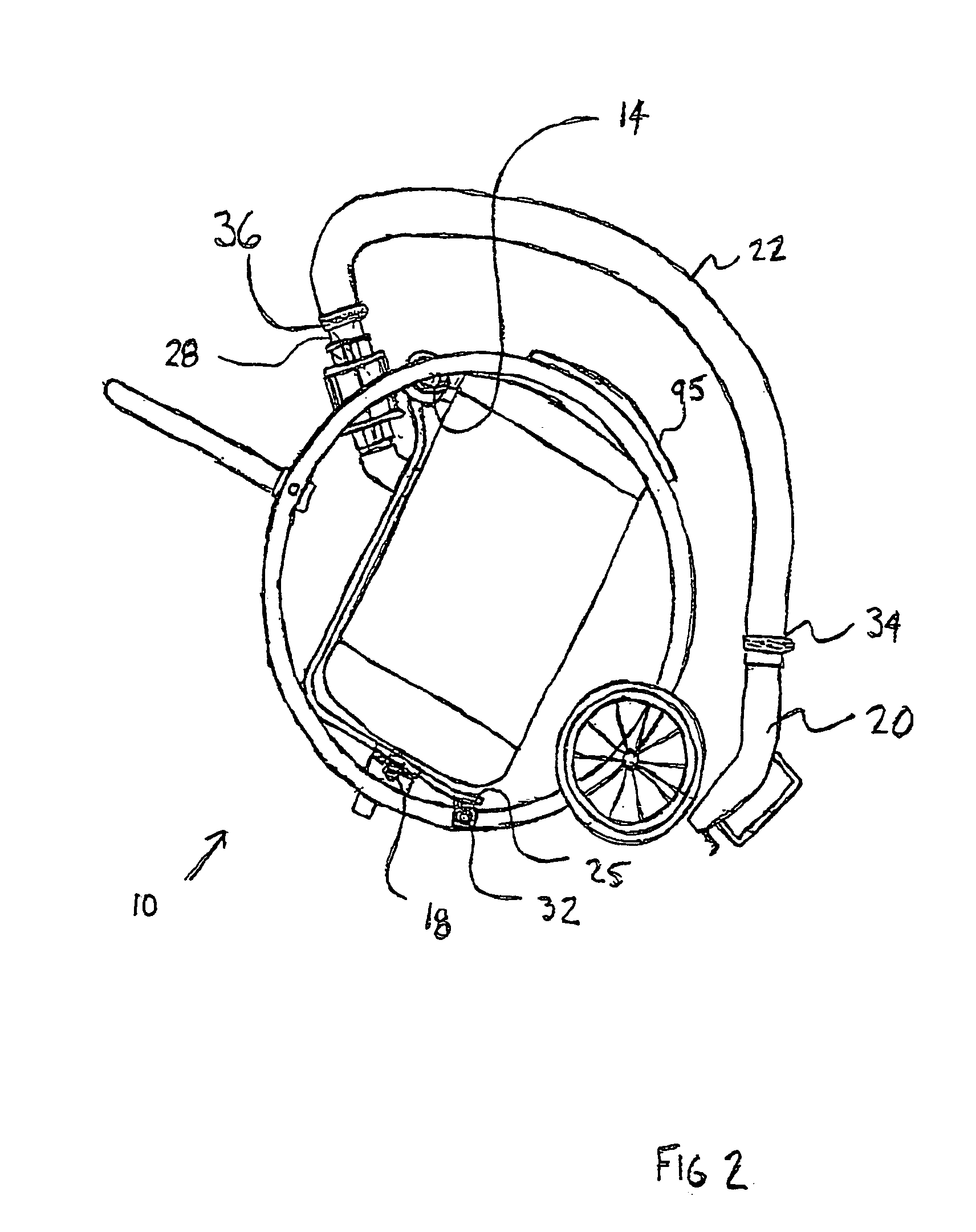

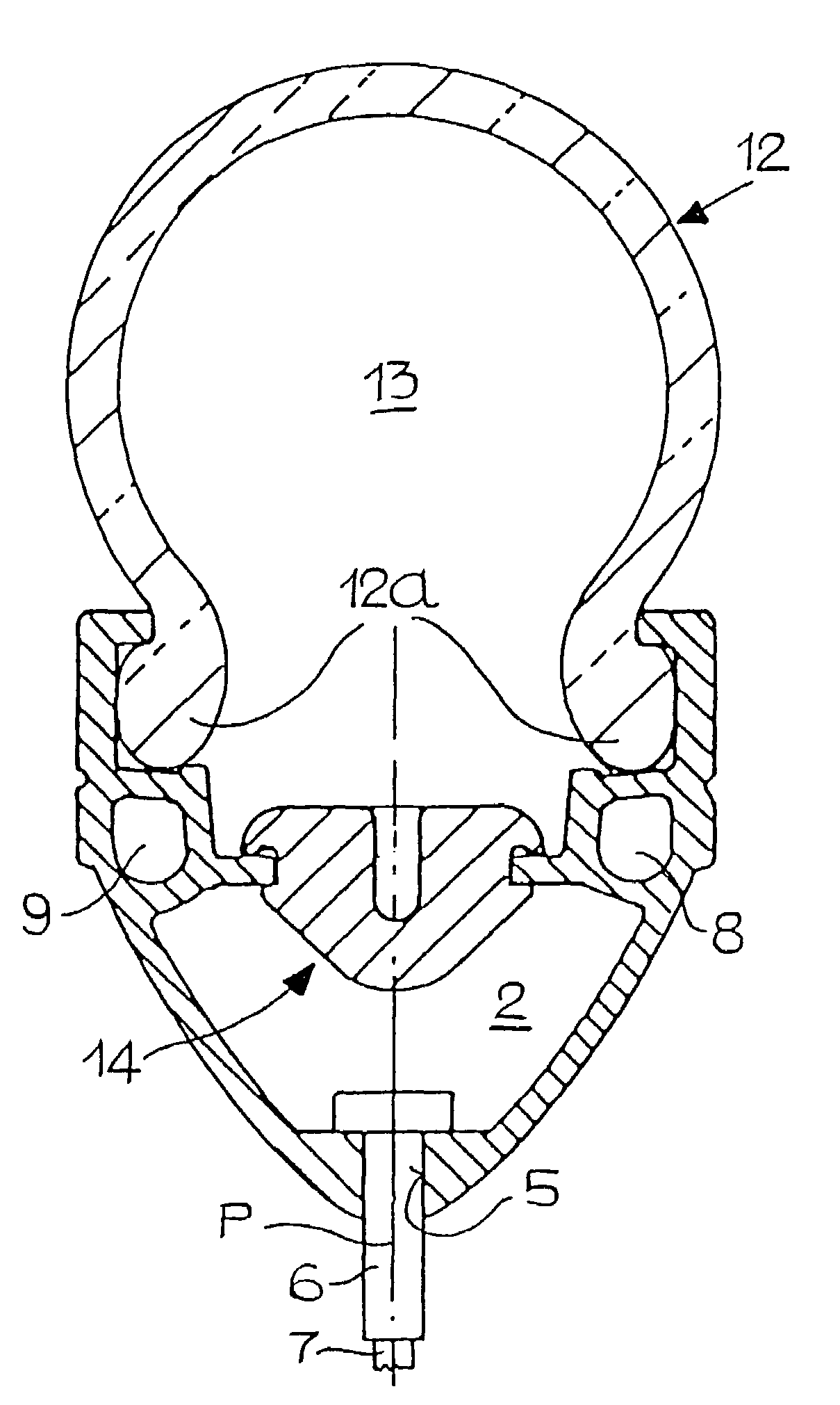

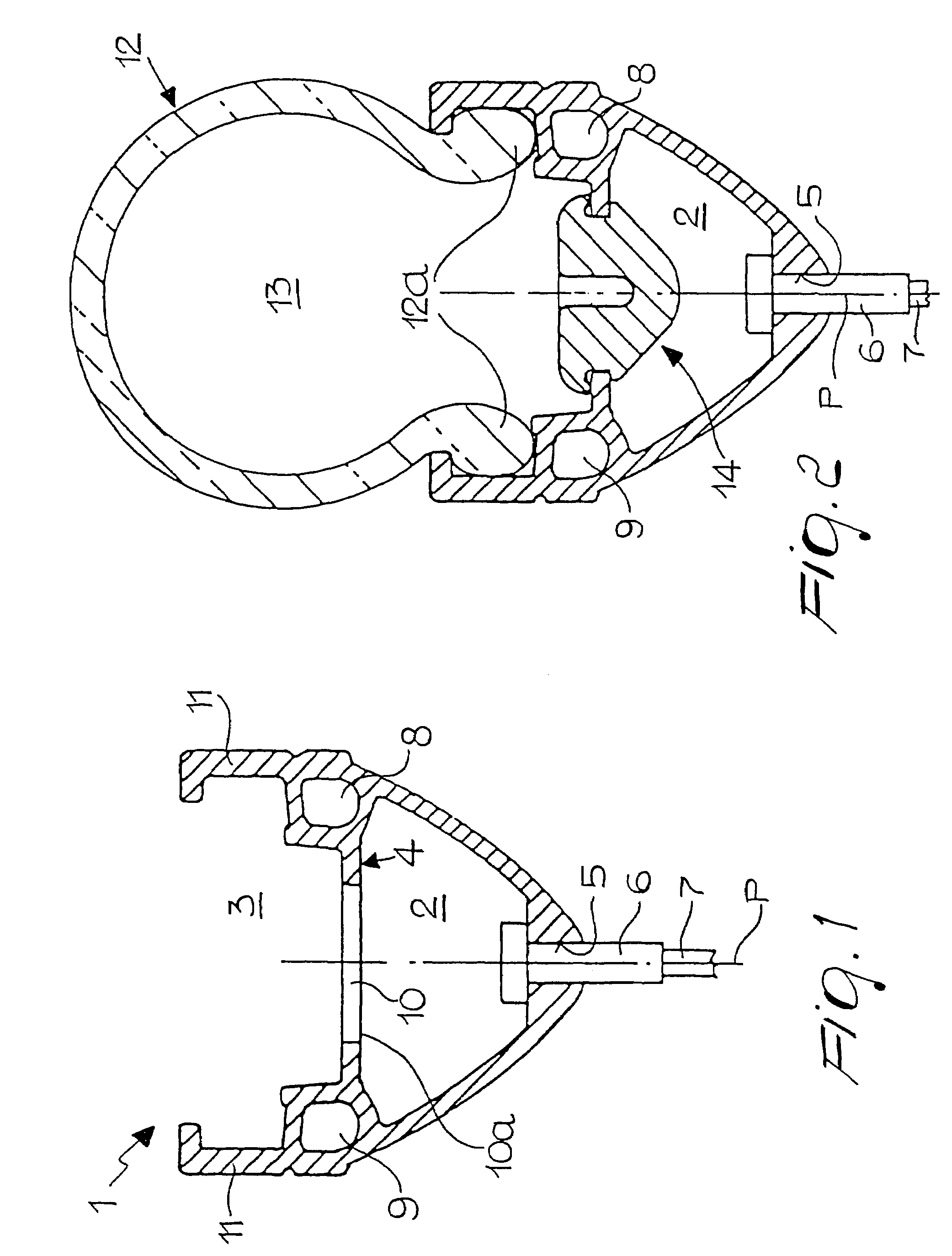

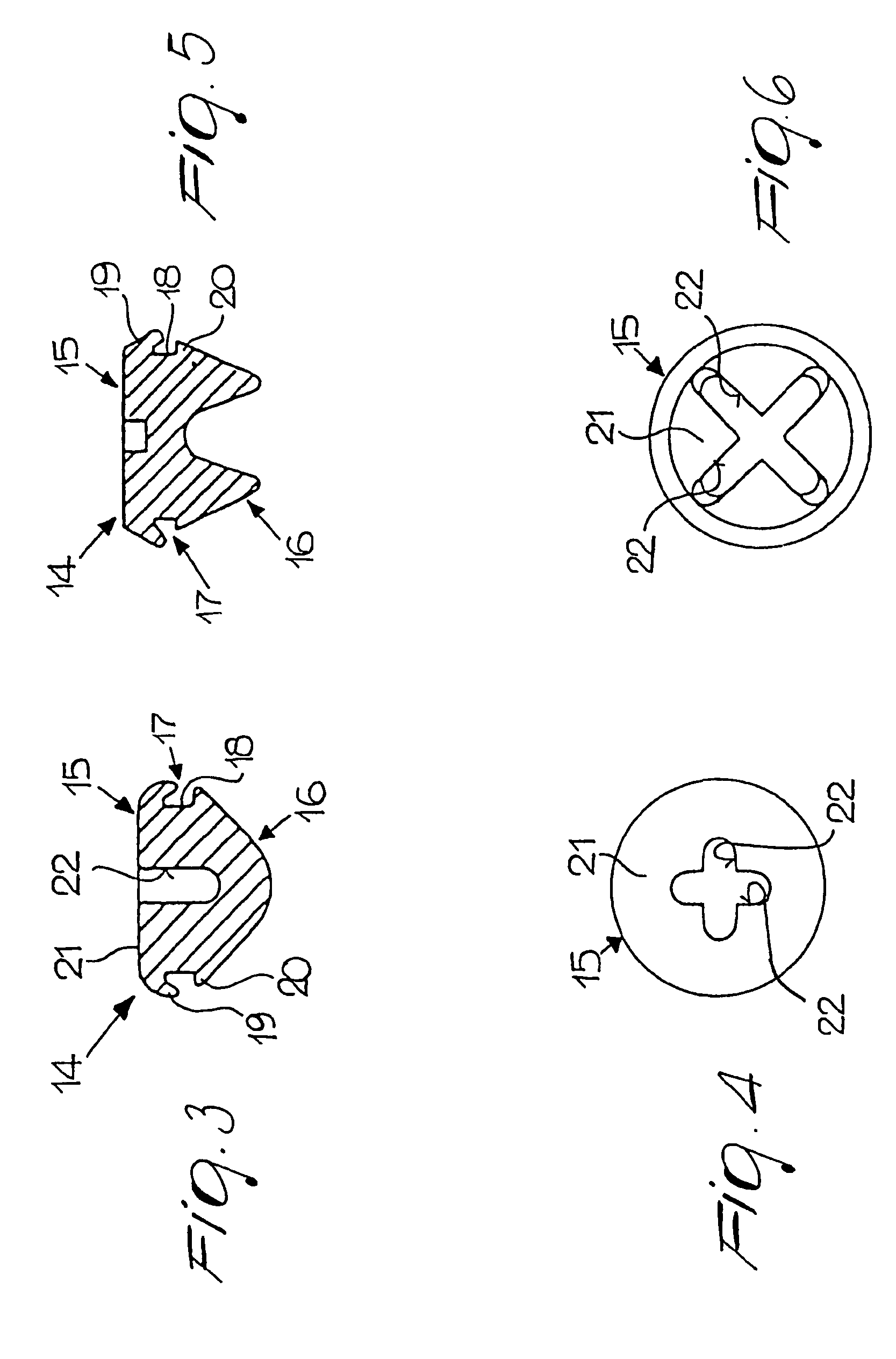

A rim of a spoke wheel for tubeless tires including a sealing device (12, 25, 27, 36, 44, 46, 48) arranged in the region of a rim bed (2) in a well (11) of the rim (1) and the rim (1) comprising on both sides of a rim center plane (10) a relief (13) with sealing areas, the relief (13) being provided with two constrictions forming the sealing areas (14, 14′) and the sealing device (12, 25, 27, 36, 44, 46, 48) being configured substantially complementary in shape and size to the relief (13) and is arranged therein.

Owner:KTM AG

Spoke wheel rim for tubeless tires

A rim of a spoke wheel for tubeless tires including a sealing device (12, 25, 27, 36, 44, 46, 48) arranged in the region of a rim bed (2) in a well (11) of the rim (1) and the rim (1) comprising on both sides of a rim center plane (10) a relief (13) with sealing areas, the relief (13) being provided with two constrictions forming the sealing areas (14, 14′) and the sealing device (12, 25, 27, 36, 44, 46, 48) being configured substantially complementary in shape and size to the relief (13) and is arranged therein.

Owner:KTM AG

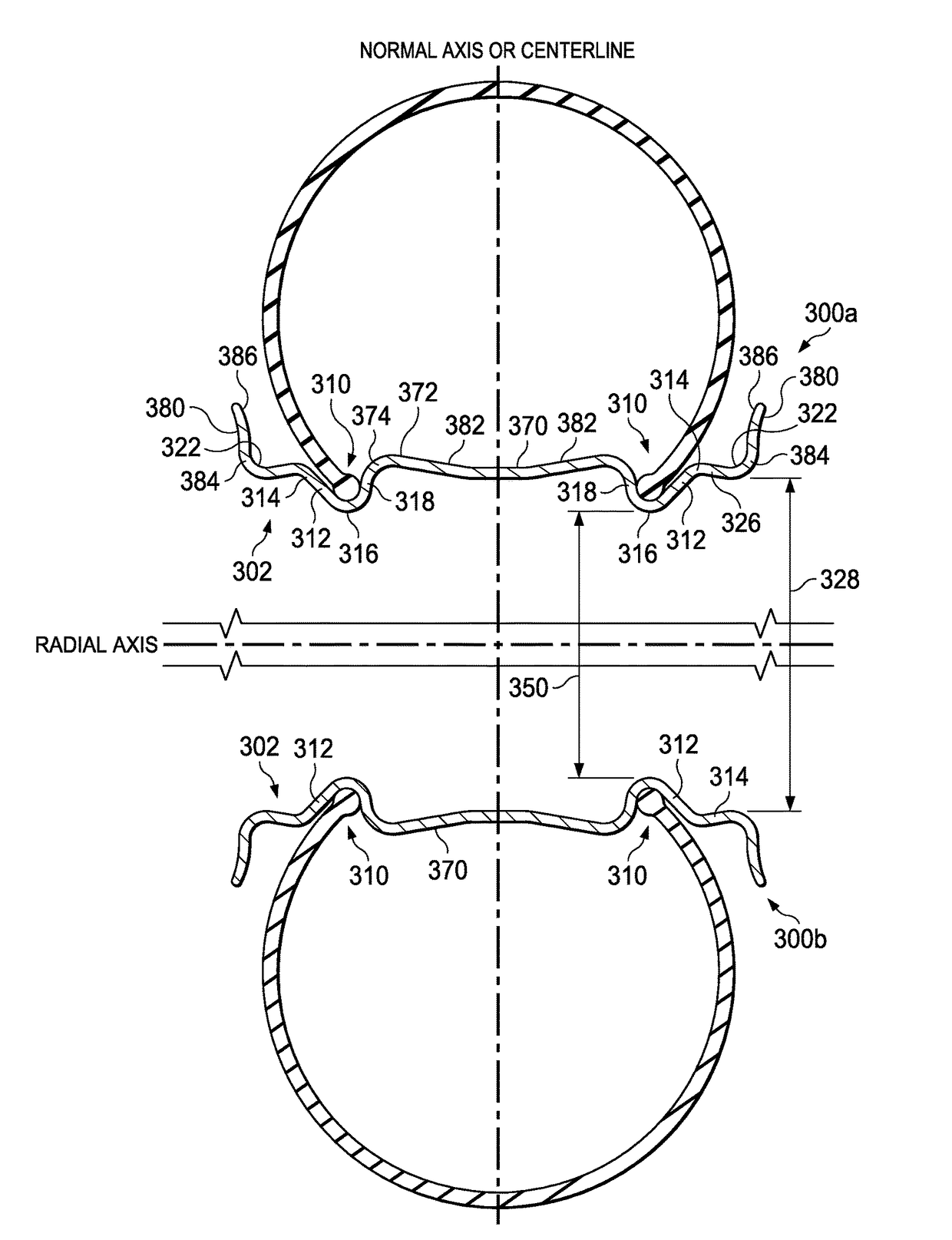

Multi-surface rim for enhanced efficiency

ActiveUS20130049441A1High trafficReduces inherent crosswind disadvantageRimsSpoked wheelsTubeless tireEngineering

Embodiments described herein provide for one or more of: (1) airflow enhancement around a rim using cusps that create virtual surfaces of air with the bike in motion, which also encourage favorable air attachment around the rim; (2) wake reduction by streamlining the airfoil around the rim using trip edges at various points of rim surface transition, which cause a laminar flow to go turbulent for enhancing the streamline effect; (3) a double rim surface, which provides an air slot between the two rim surfaces at a distance that enhances flow attachment and adds energy of air flow around the rim by moving air between areas of high and low pressure; and (4) a tubeless tire rim kit capable of converting conventional rims into tubeless ones and also promoting the sealing of the tire to the rim with minimal air pressure necessary to create the seal.

Owner:ENVE COMPOSITES

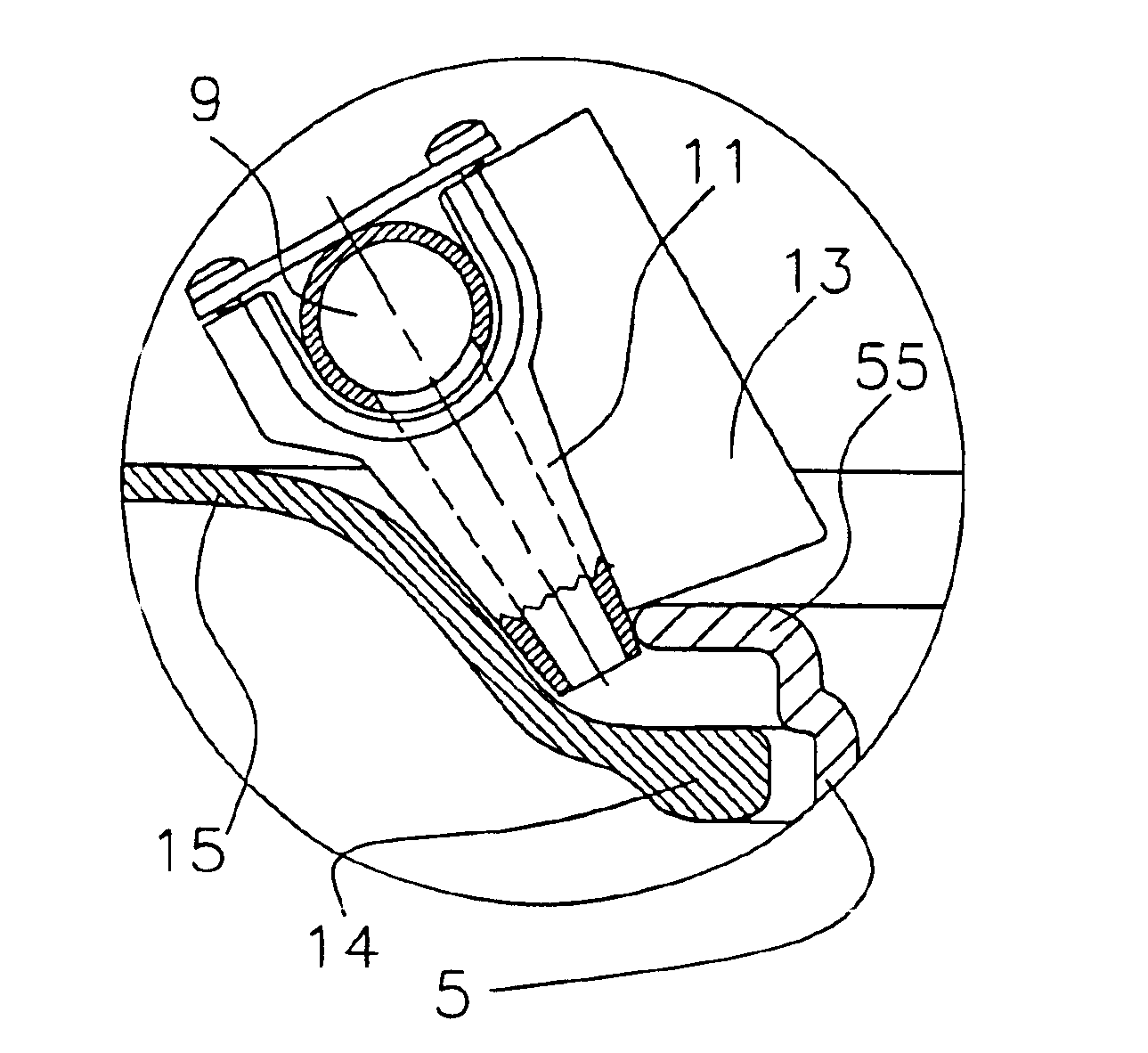

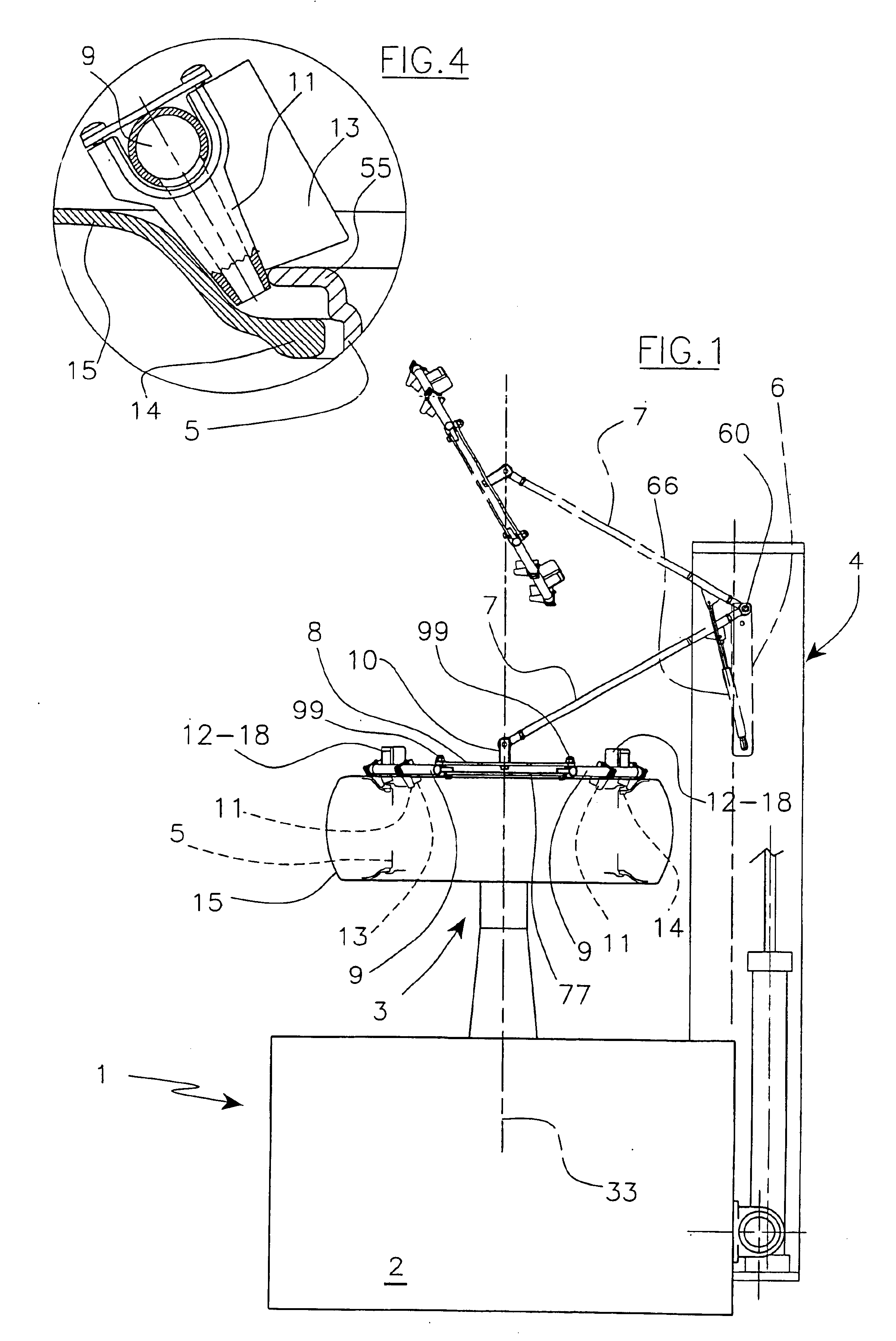

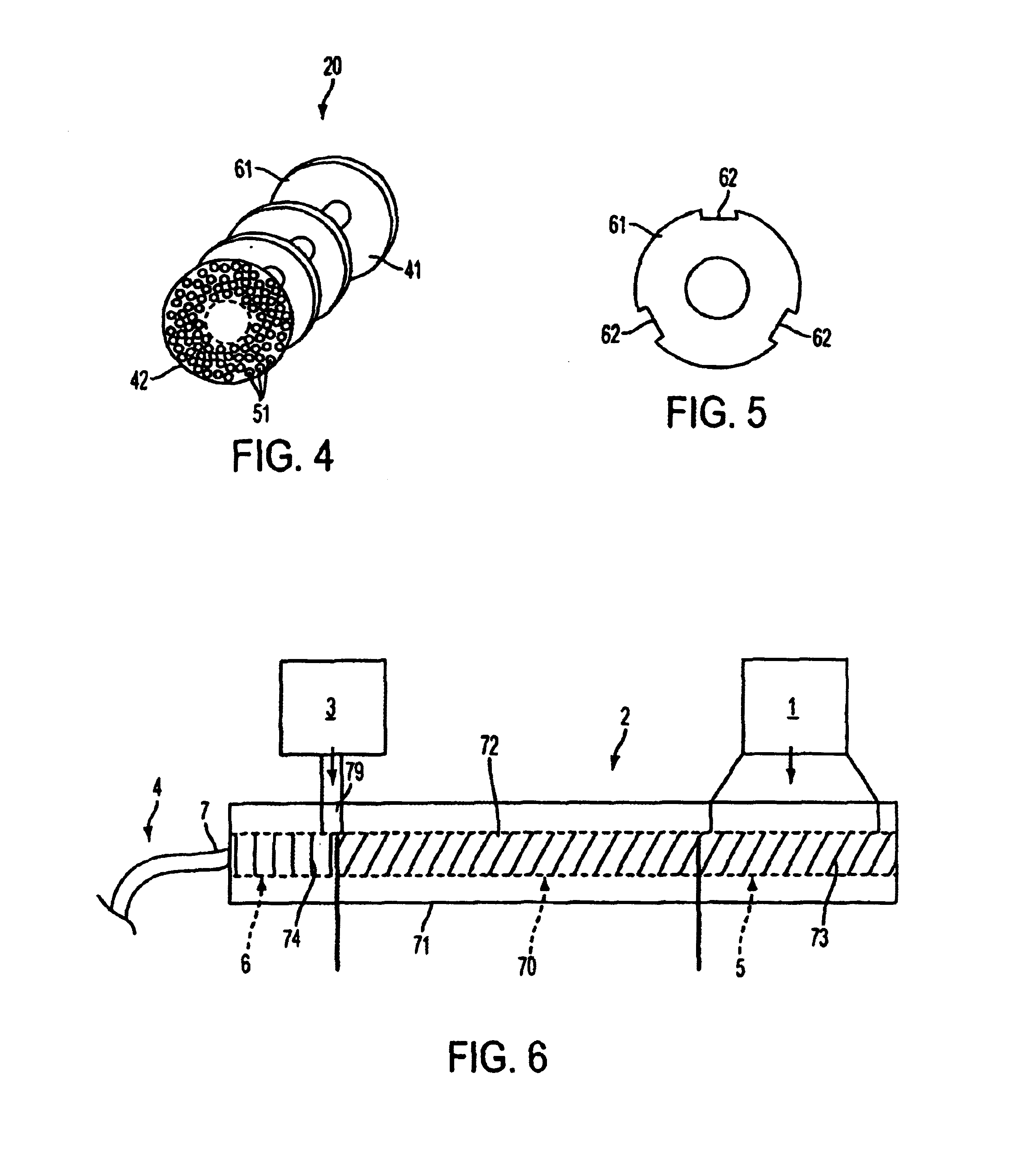

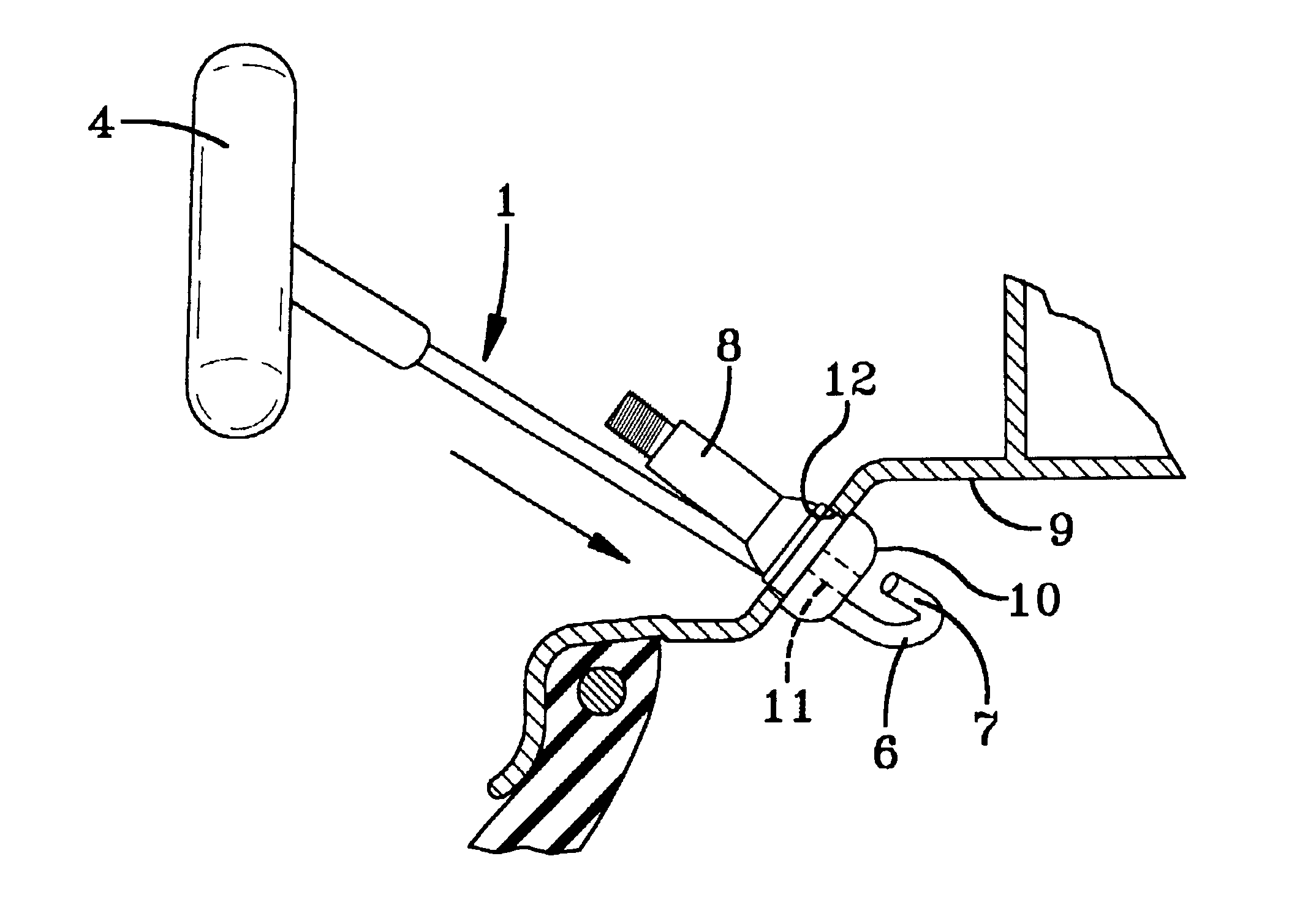

Device for tubeless tire bead engagement and inflation

InactiveUS6761061B2Readily and easily manipulatedReadily and easily and positionedRoads maintainenceVehicle tyre testingRest positionTubeless tire

Device for tubeless tire bead engagement and inflation, generally for tire removal machines (1) having a unit for supporting and locking a wheel (wheel rim+tire) (5-15) in a bedded position, comprises a movable implement to be associated with the structure of the tire removal machine, and generally shaped as a handlebar the handles (9) of which are lowerly provided with at least one compressed air delivery nozzle (11), said handlebar being able to move between a rest position in which it is spaced from said bedded wheel, and a working position in which said nozzles, retained thereat by the operator, extend beyond the upper bead retention flange (55) of the wheel rim (5) to blow air below it at the command of said operator.

Owner:CORGHI

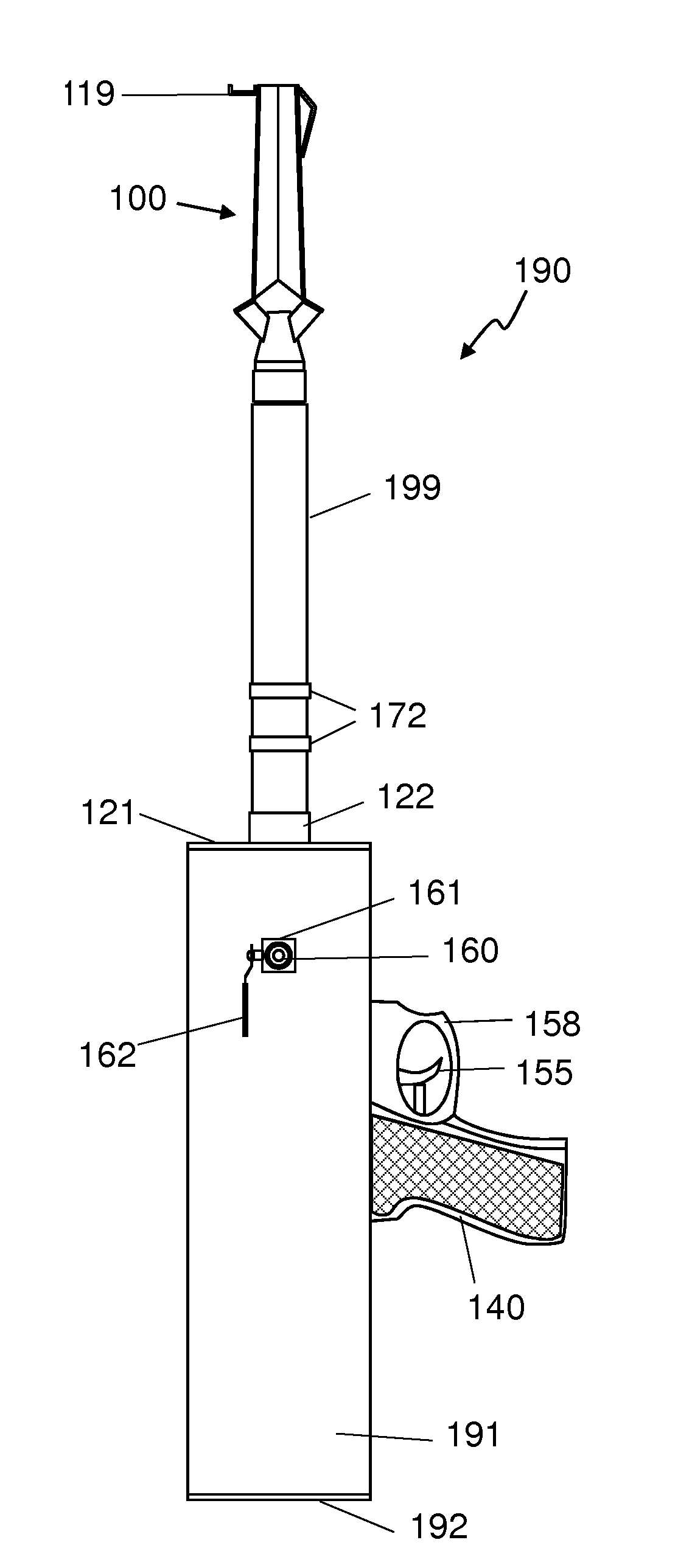

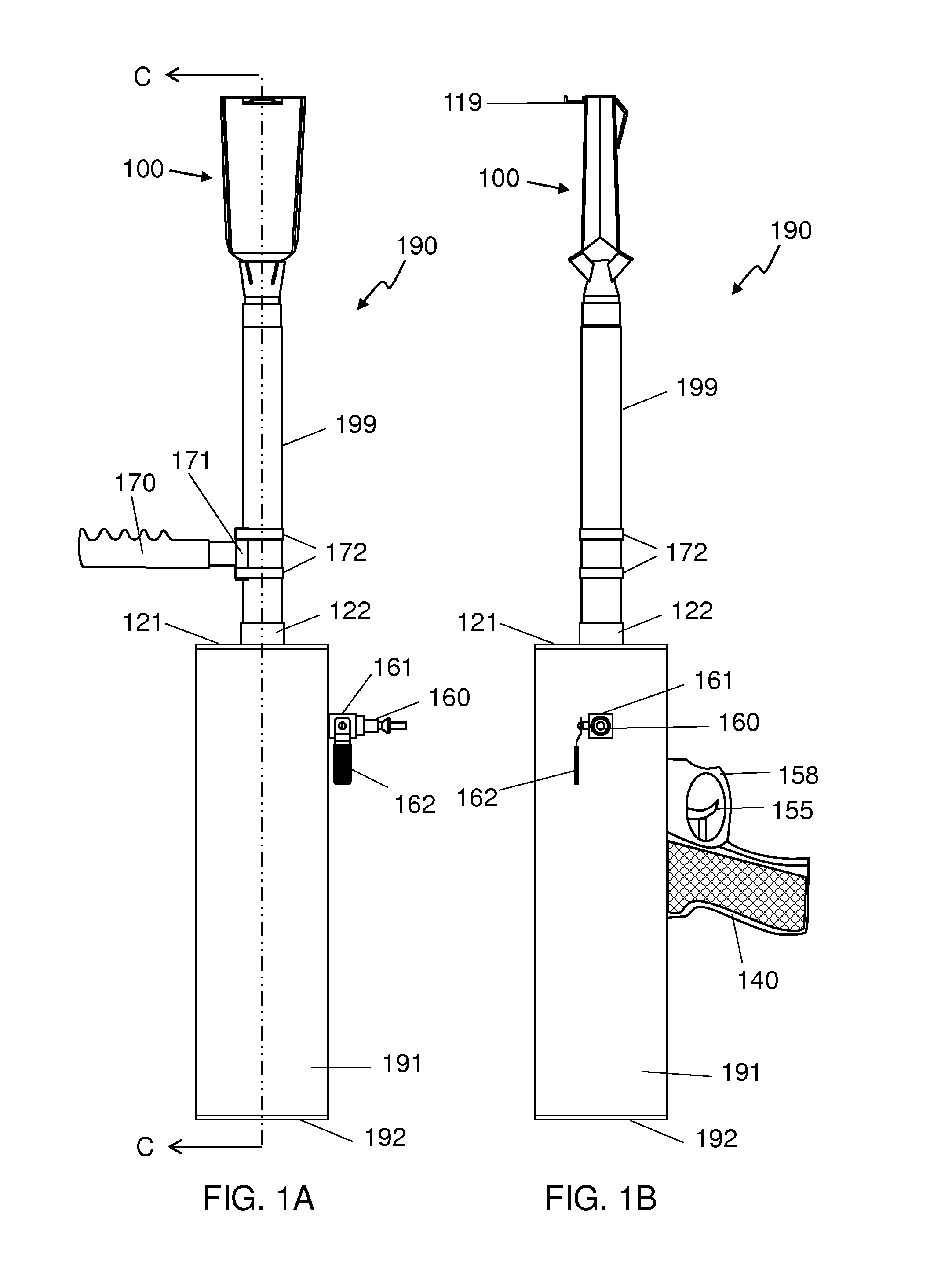

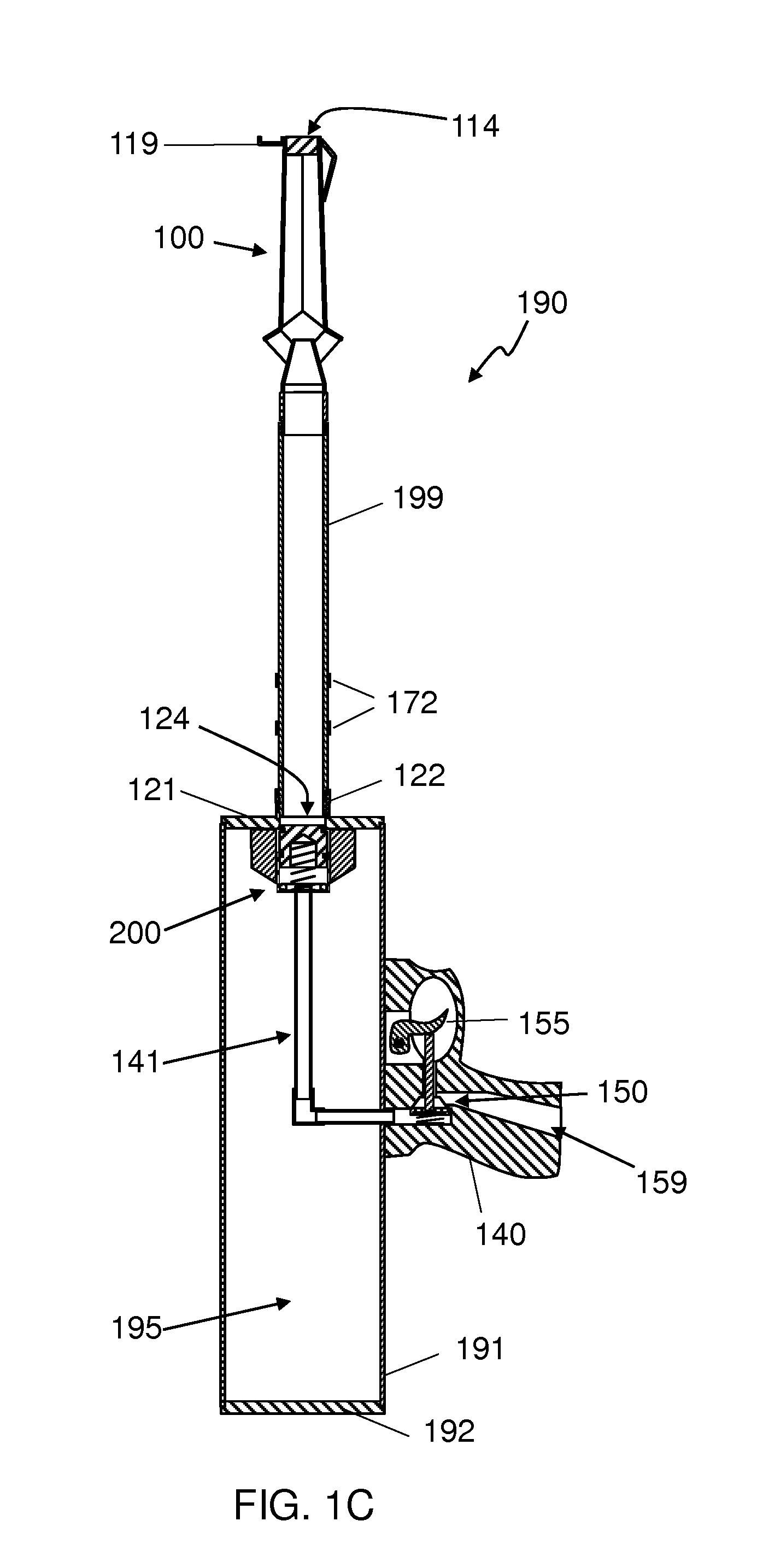

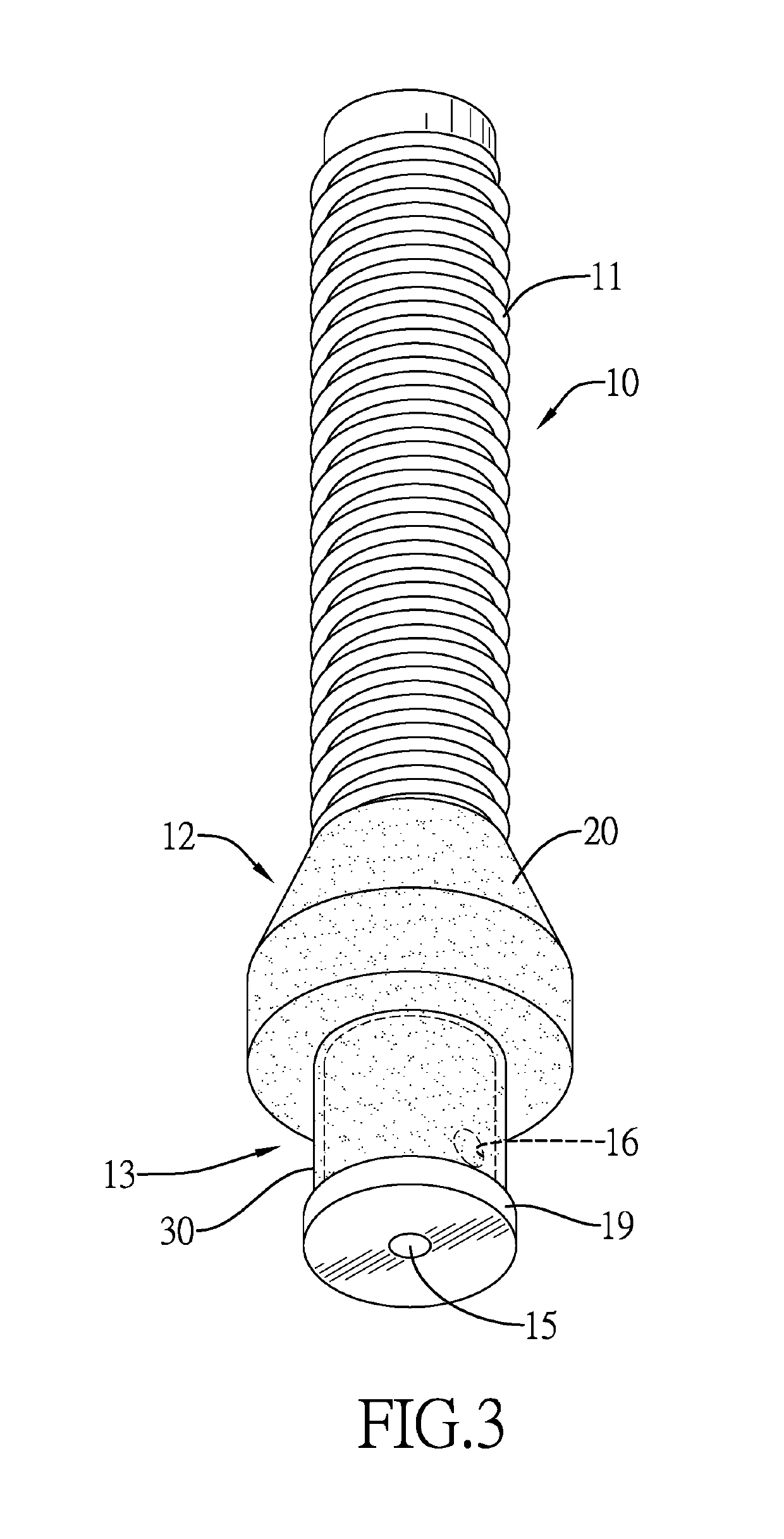

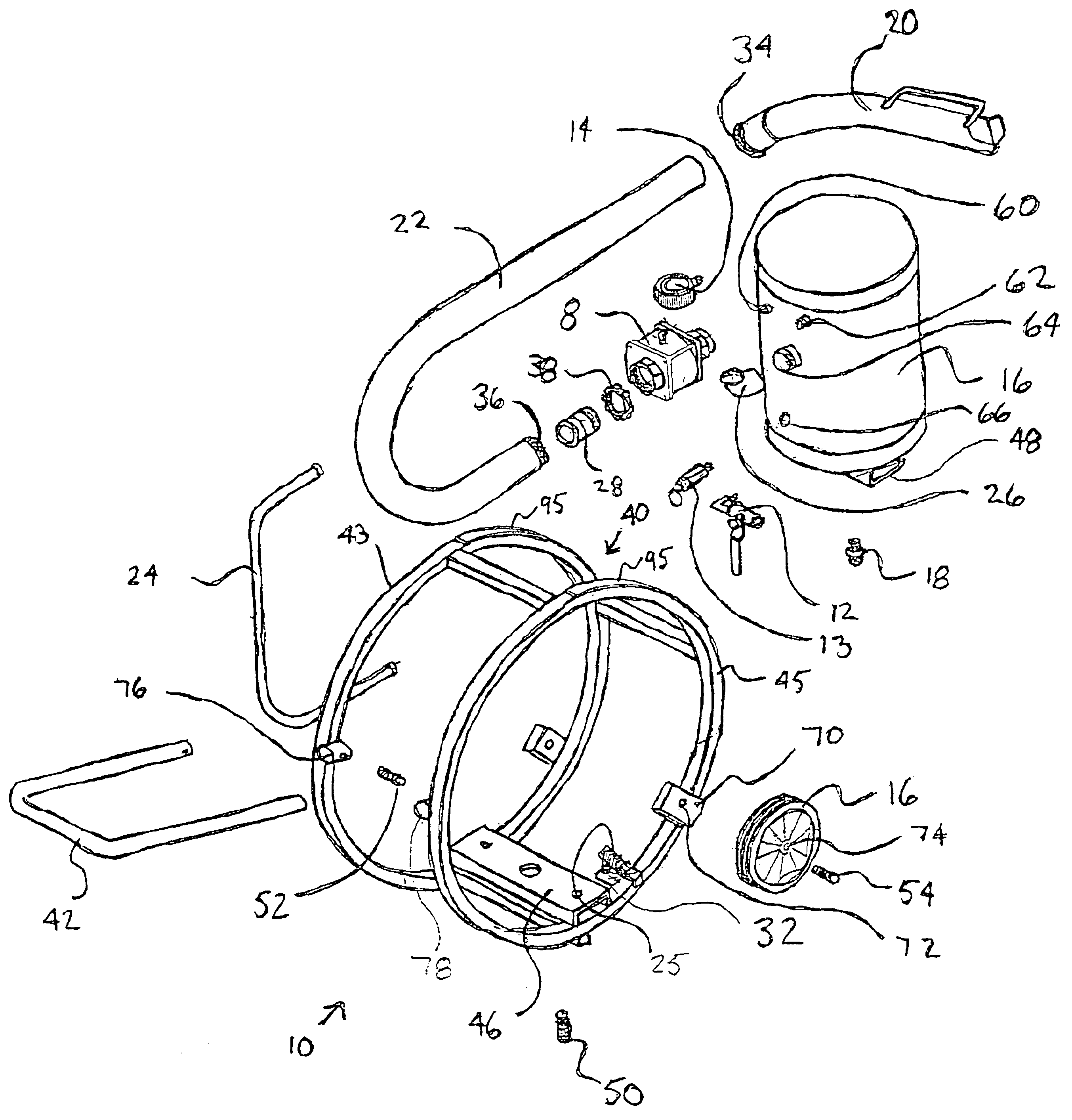

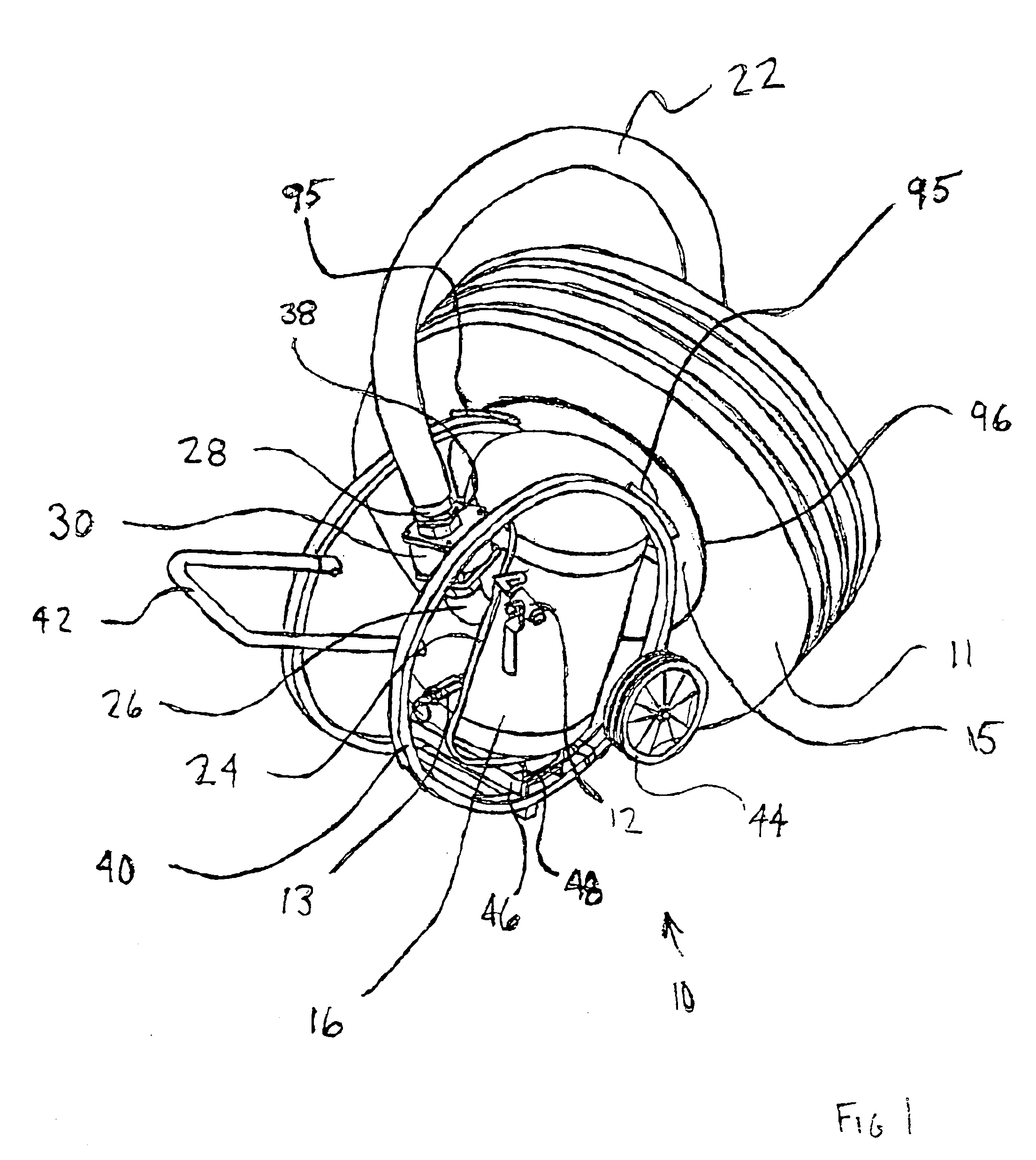

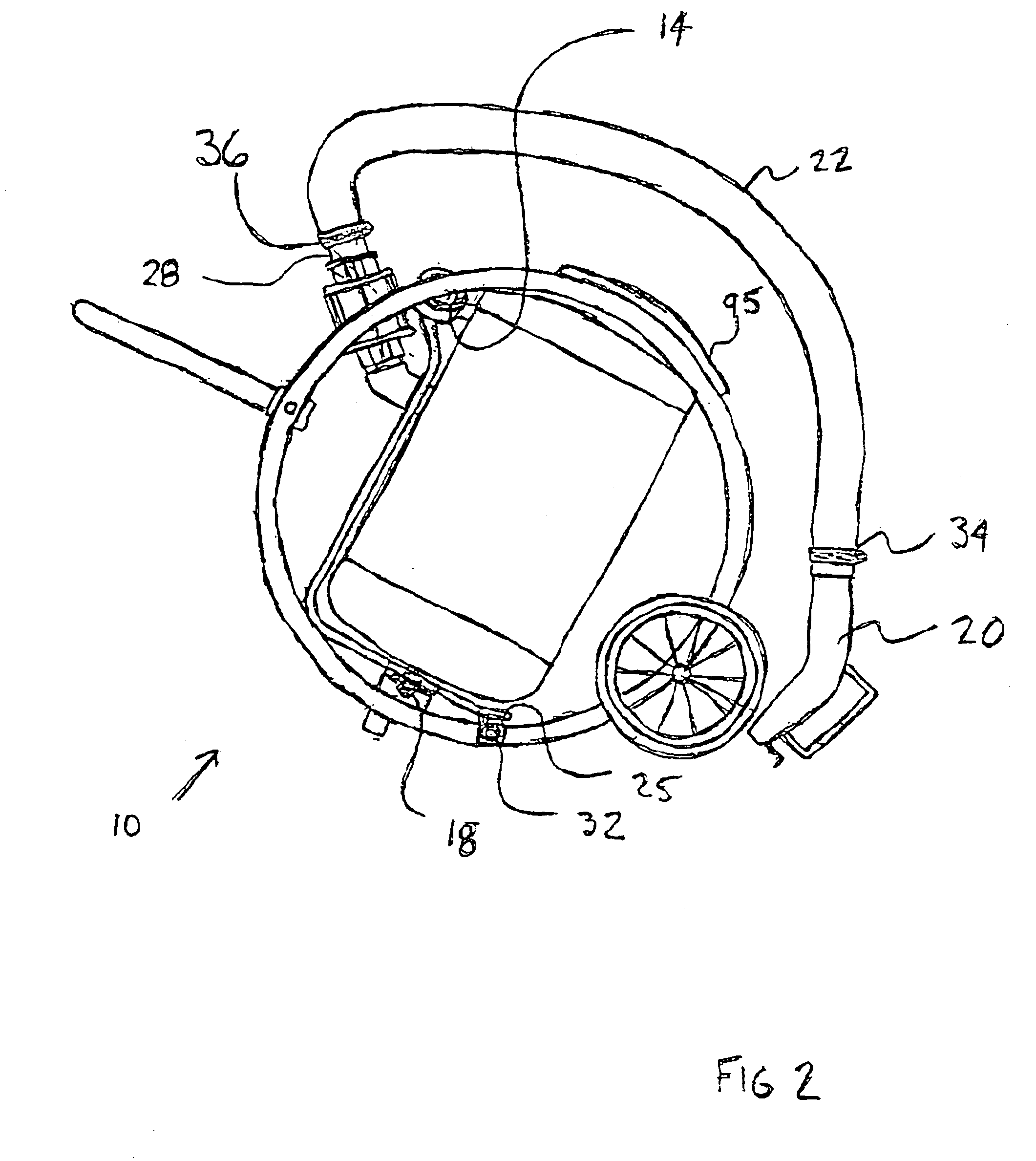

Tubeless Tire Seating Device

A tool for seating a tubeless tire on a rim using pressurized gas includes a cylindrical pressure vessel with a pistol grip extending radially from the tank. The tool includes a rapid opening gas valve positioned between the cylindrical pressure vessel and a nozzle. In some embodiments the nozzle includes a jet configured to receive pressurized gas from the cylindrical pressure vessel into a chamber of the nozzle so that as the stream of gas enters the chamber, the Venturi effect causes air to enter the chamber through air intake ports and the stream of gas and air from the air intake ports is blown out of the outlet of the nozzle. The tire is seated on the rim by positioning the system so that the air from the nozzle rapidly blows into the tire between the bead of the tire and the rim upon the valve being opened.

Owner:GAITHER TOOL COMPANY

Puncture resistant leak-less material for tyre without inner tuber and its prepn process

InactiveCN1931910AImprove air tightnessImprove adhesionSpecial tyresBuilding insulationsTubeless tireSulfur

The present invention relates to one kind of puncture resistant leak-less material for tyre without inner tuber and its preparation process. The material consists of two components mixed together, the component A consists of SEBS1 and white oil; and the component B consists of natural rubber, sulfur, promoter DM, stearic acid, zinc oxide and calcium carbonate. The preparation process includes the following steps: mixing SEBS1 and white oil and foaming the mixture; heating the mixture in a reactor, cooling and crushing; heating the materials of the component B, cooling, adding the crushed component A material, heating and cooling. The material for tyre has high heat resistance, high cool resistance, high oil resistance and high water resistance, and the tyre of the said material has no leakage and self repairing function.

Owner:刘俭 +1

Rubber composite applicable to inside liner of tubeless tire

The invention discloses a rubber composite applicable to an inside liner of a tubeless tire. The composite comprises the following components in parts by weight: 70 to 100 parts of halogenated butyl rubber, 0 to 30 parts of natural rubber, 30 to 65 parts of carbon black, 20 to 45 parts of inorganic filler, 1 to 4 parts of vulcanizing agent, 1 to 2 parts of accelerant, 1 to 2 parts of active agent, 5 to 15 parts of softening agent and 6 to 10 parts of processing aid, wherein halogenated butyl rubber and natural rubber are blended to form a substrate material. The rubber composite is low in themogenesis, high in self-adhesion performance, outstanding in air impermeability and fatigue resistance, excellent in tensile property and ageing resistance, and applicable to the inside liner of the tubeless tire.

Owner:BEIJING RES & DESIGN INST OF RUBBER IND

Inflating device for tires

InactiveUS7017642B2Facilitates selective positioningMitigate kickbackTyre repairingTubeless tireWaste management

A portable device for seating the beads of a tubeless tire and rim assembly, the device including an air tank containing pressurized air, the air tank being mounted substantially within a bracket, the bracket having a surface for supportably receiving the tire and rim assembly, a means for directing the pressurized air between a bead of the tire and the rim, and a positioning member which selectively stores the means for directing the pressurized air between a bead of the tire and the rim during seating.

Owner:BRAHLER II RICHARD W

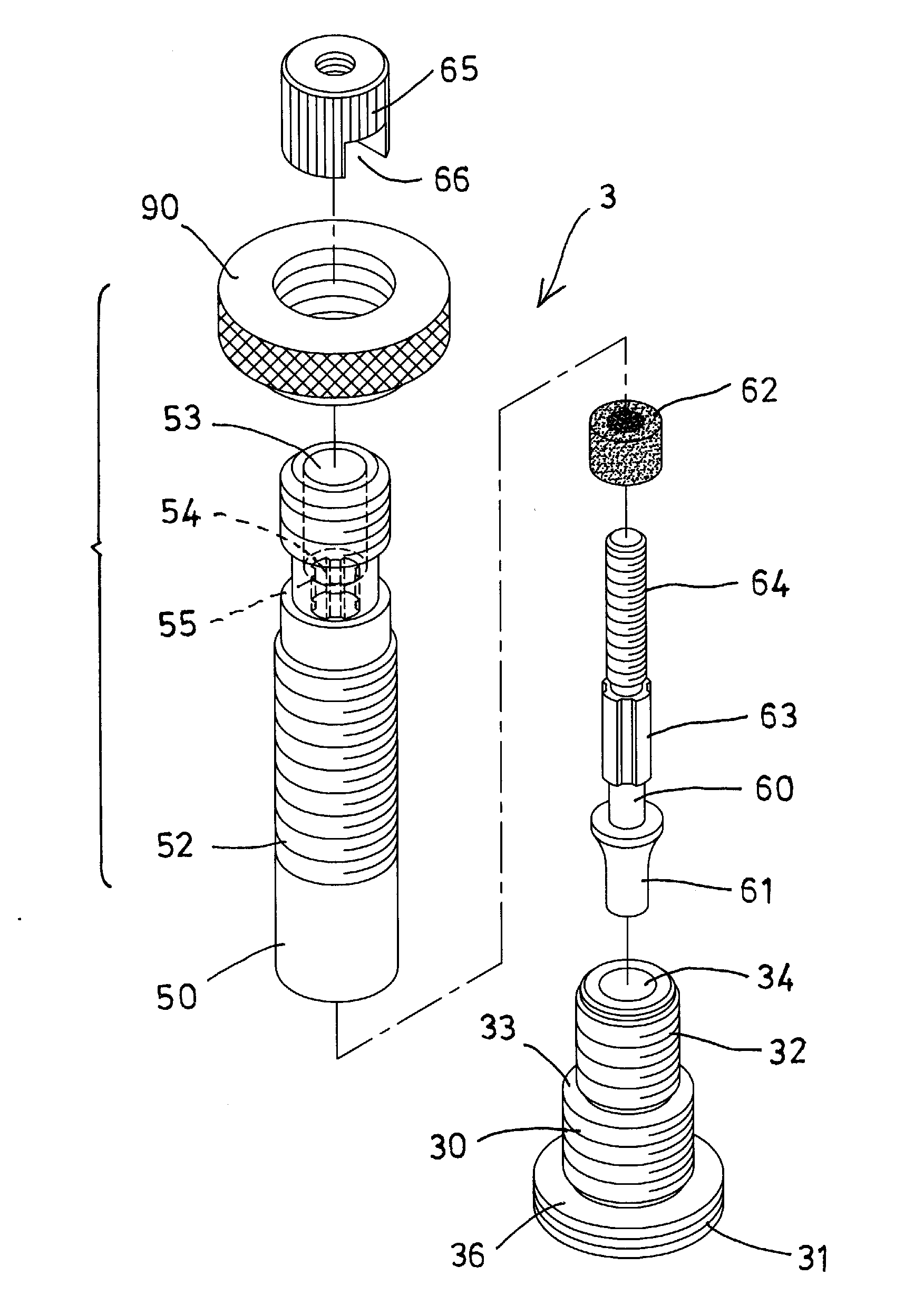

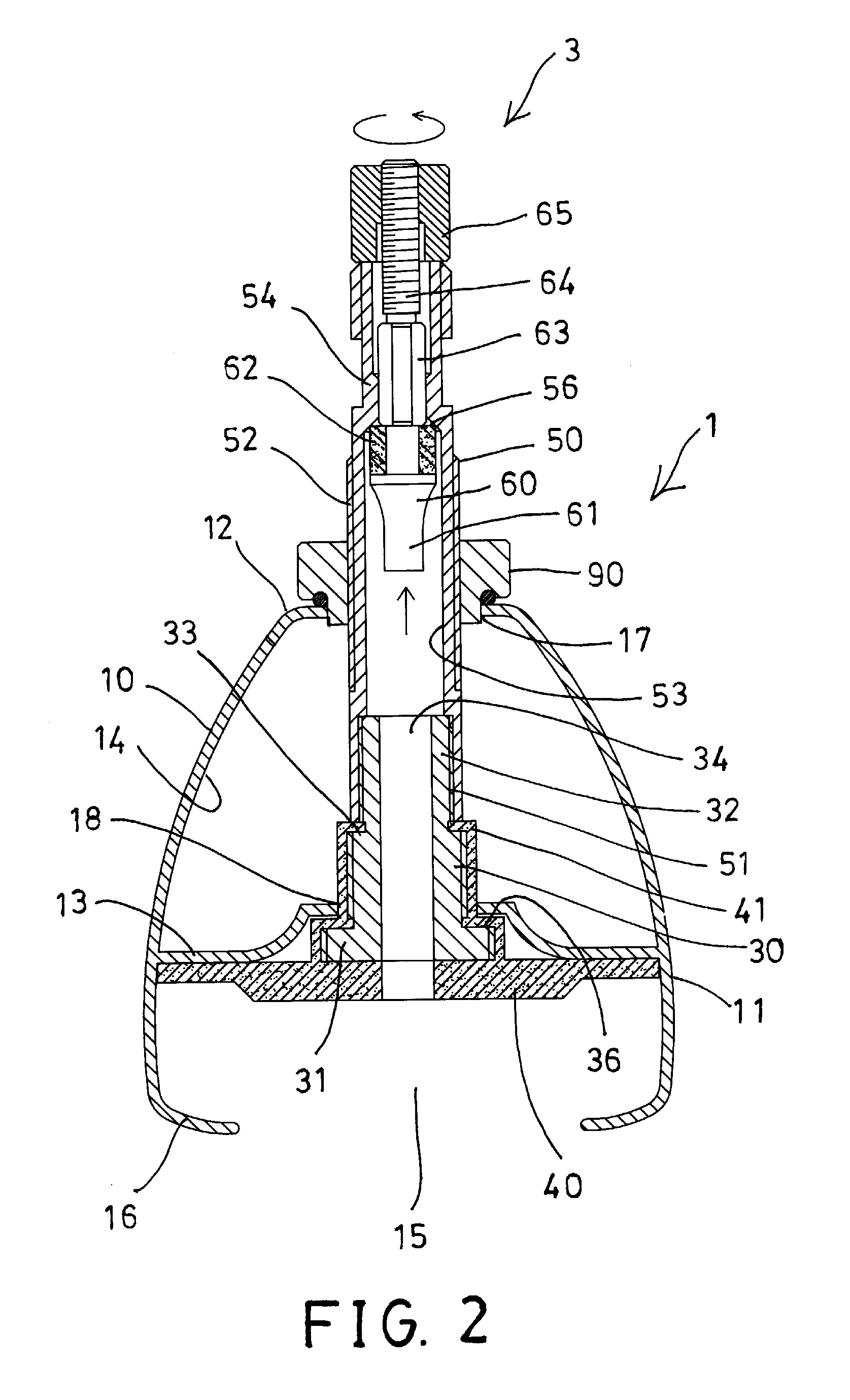

Valve device for tubeless tire

A wheel rim device includes a rim member having a bridge extending between two side walls, and a valve device having a valve stem engaged with the bridge and having a sealing member attached to the valve stem for engaging with the bridge and for anchoring the valve stem to the bridge of the rim member and for making an air tight seal between the valve stem and the rim member, and the sealing member includes a casing engaged onto the valve stem and engaged between the valve stem and the bridge for further making a solid and stable air tight seal between the valve stem and the rim member. The casing is engaged onto a flanged head of the valve stem for engaging with the bridge.

Owner:BAO LEY

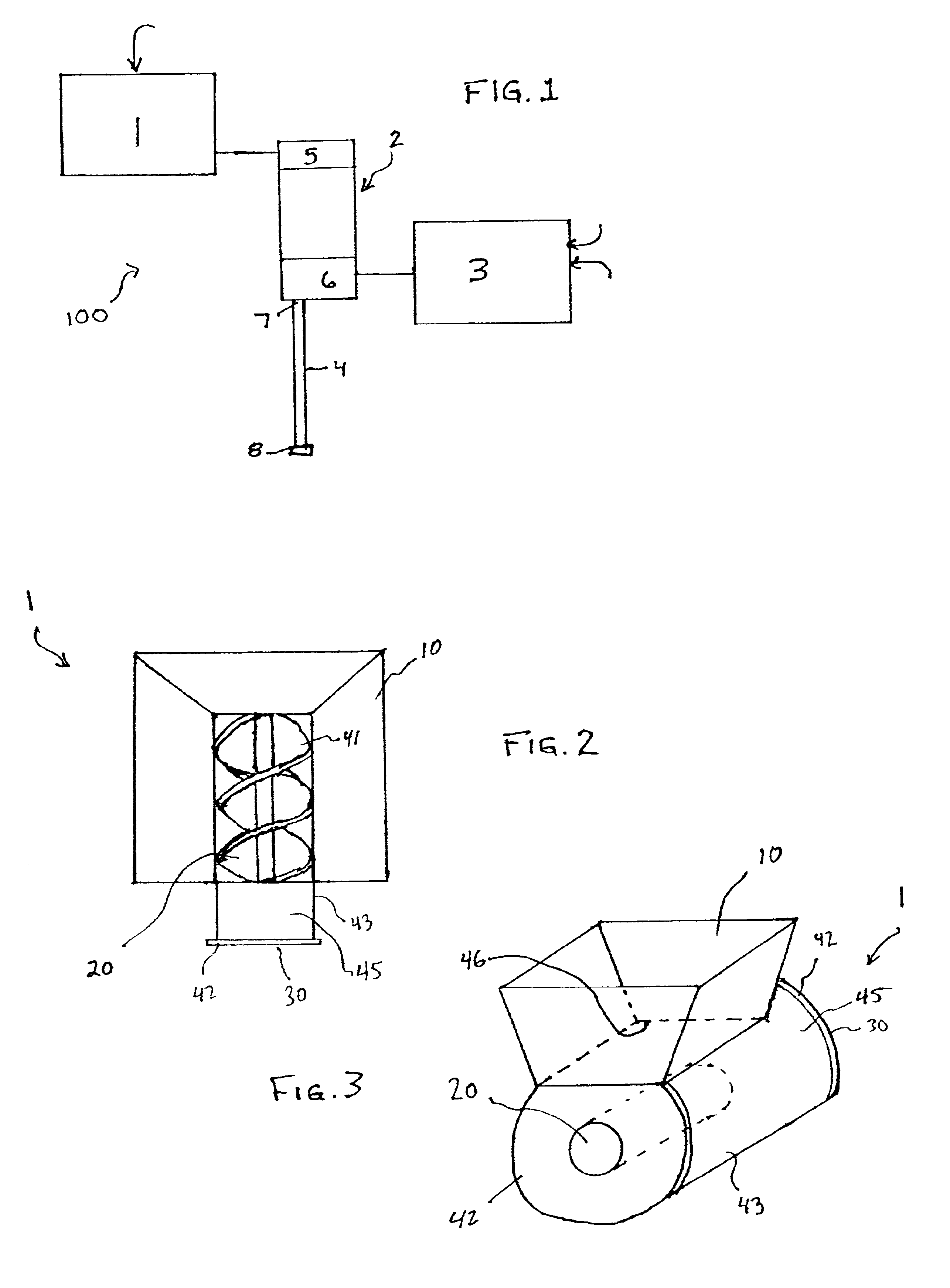

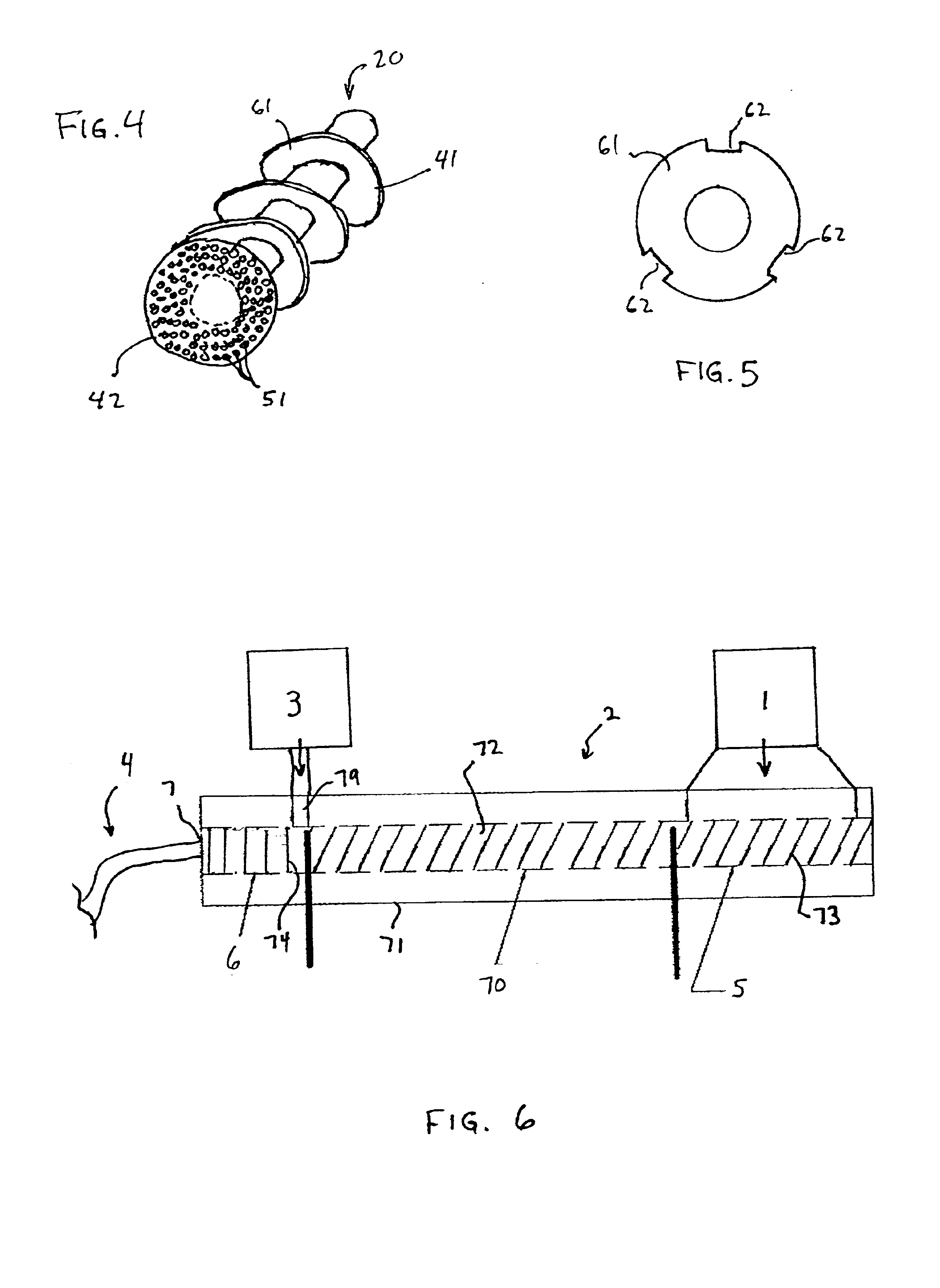

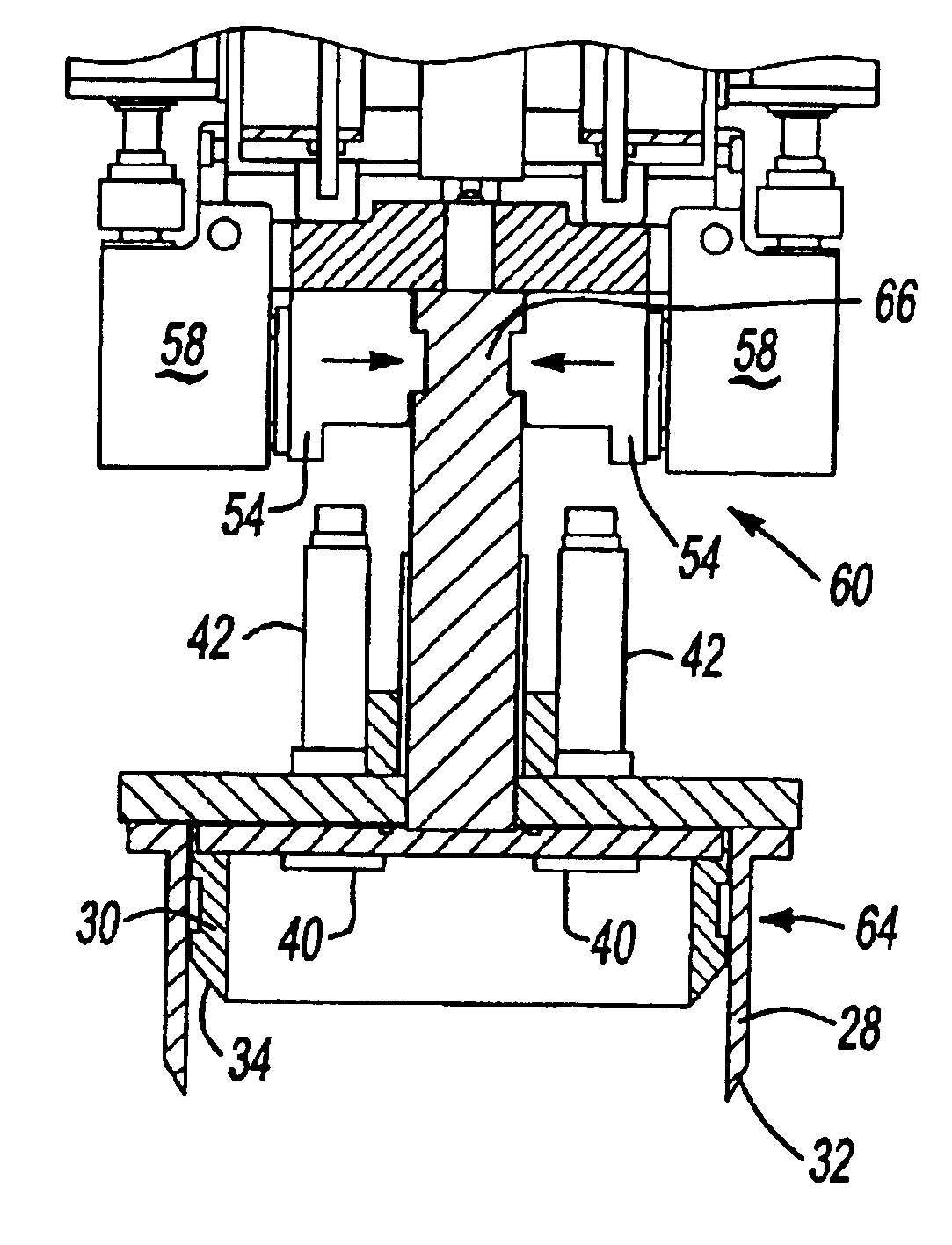

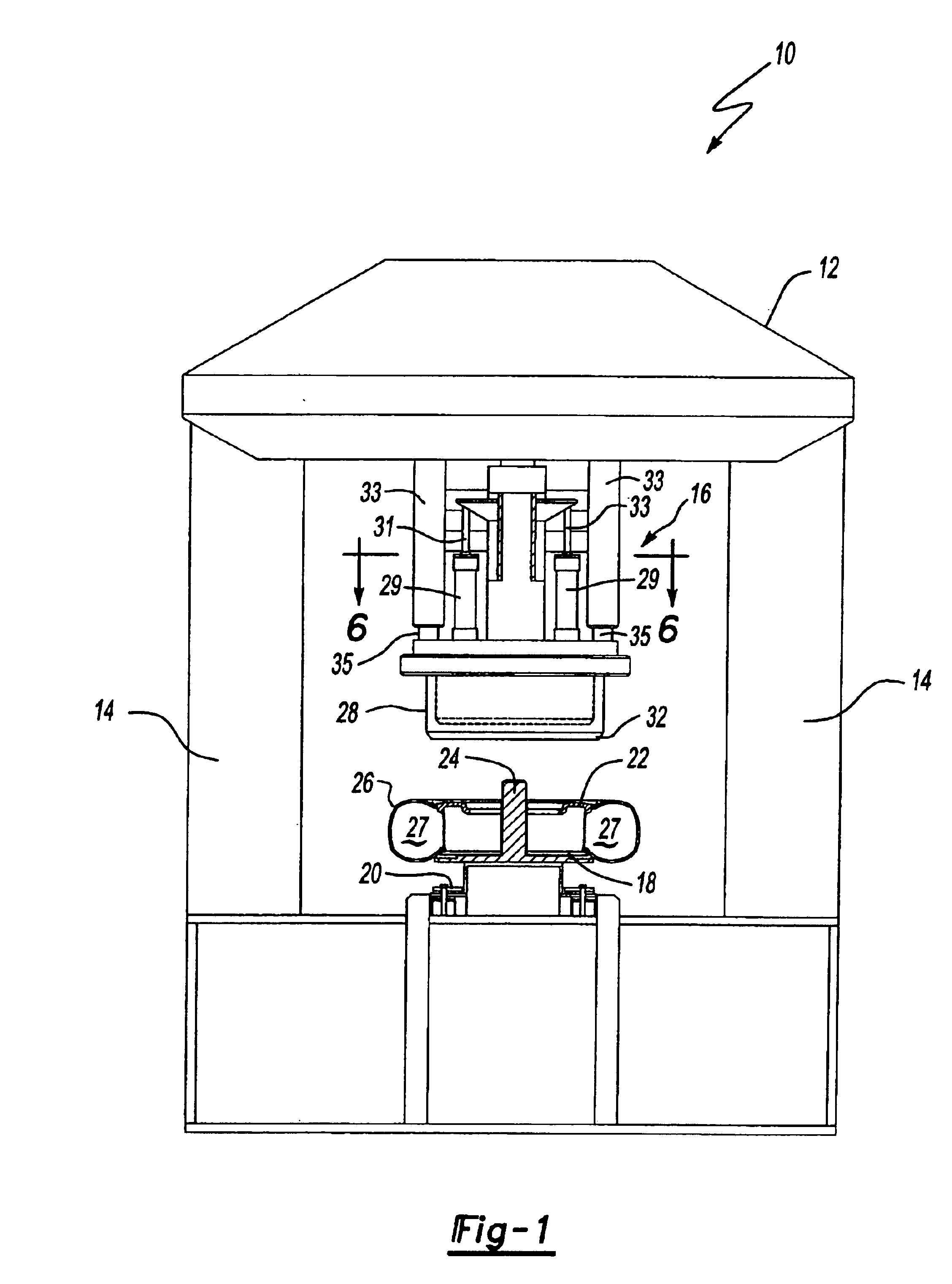

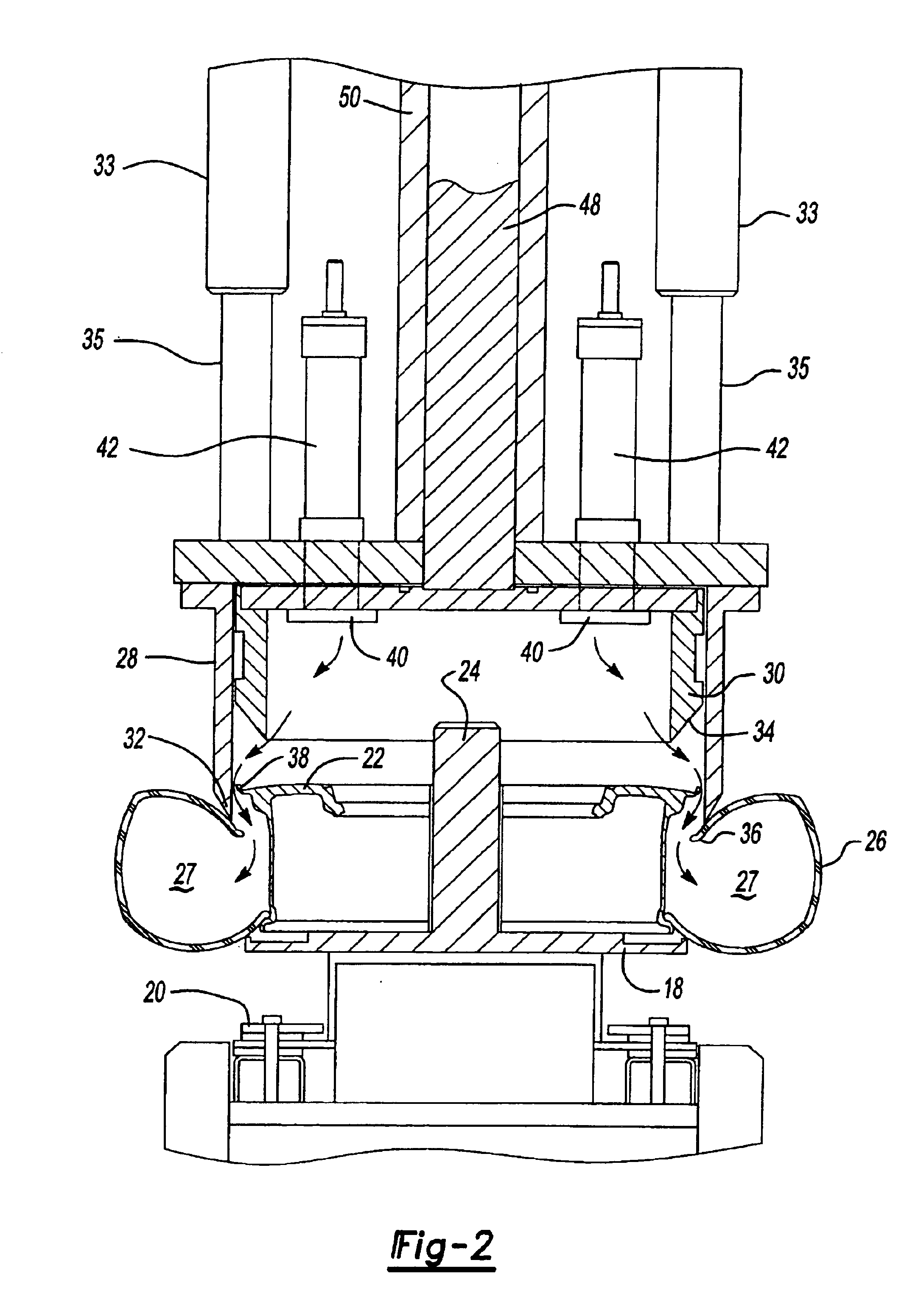

Method for making tires filled with flatproofing material

InactiveUS6918979B2More to premature failureShort set-up timeNon-inflatable tyresTyresTubeless tireEngineering

A tire, and an apparatus and method for forming a tire. The tire may either be a tubed or tubeless tire, and is filled with a mixture of virgin rubber and small rubber pieces. Preferably, a machine grinds the core of used flatproofed tires, or pieces thereof, into a finely communicated pulverulent. The pulverent is mixed with liquid virgin flatproofing material, such as a polyurethane. An injector introduces this mixture, into the core of a tire, typically through a valve. The core of the tire is preferably substantially filled with this mixture. The injector may take the form of one or more elongated screws and the mixing may occur as the ground rubber is being conveyed by the screw.

Owner:ACCELLA POLYURETHANE SYST LLC

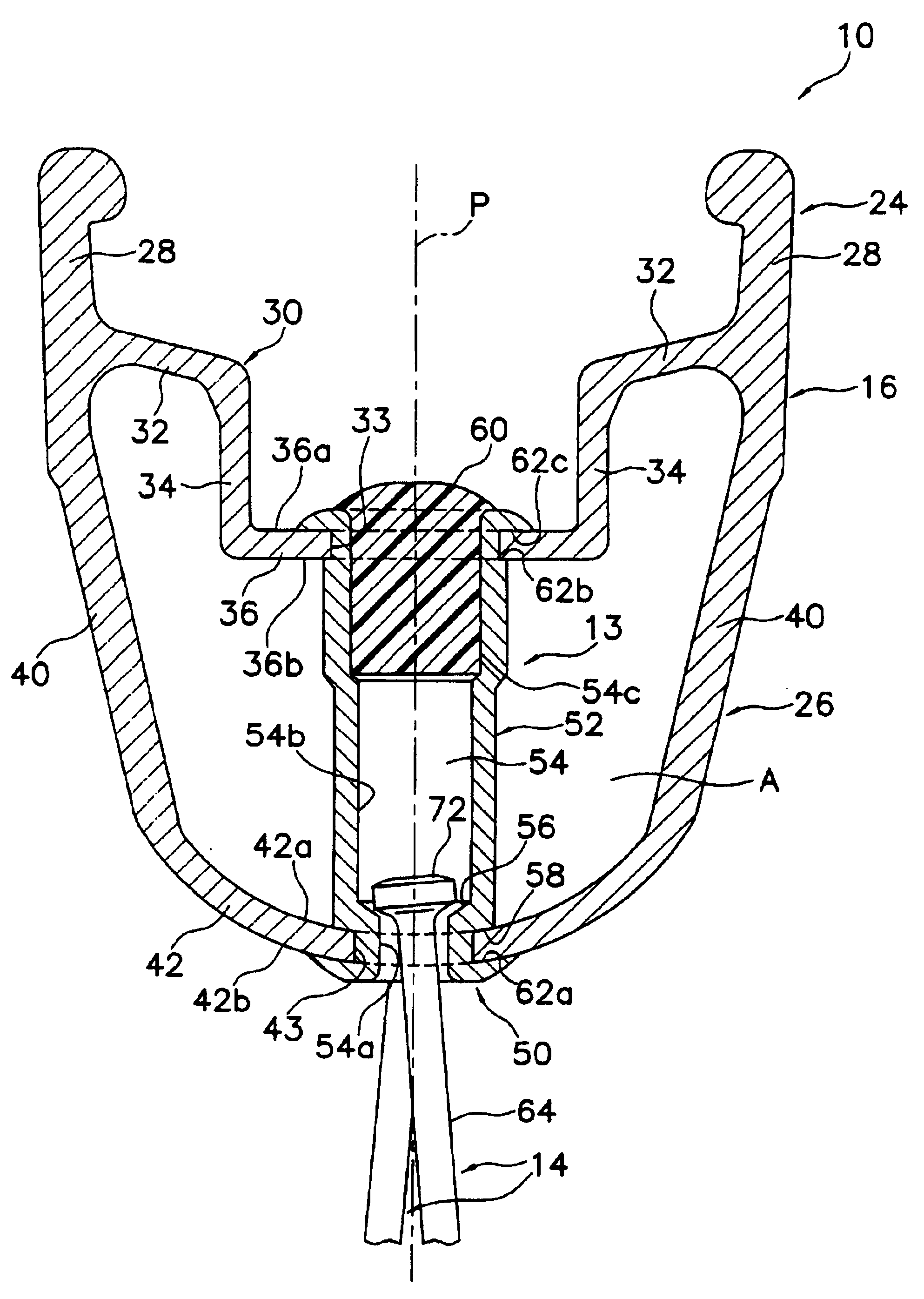

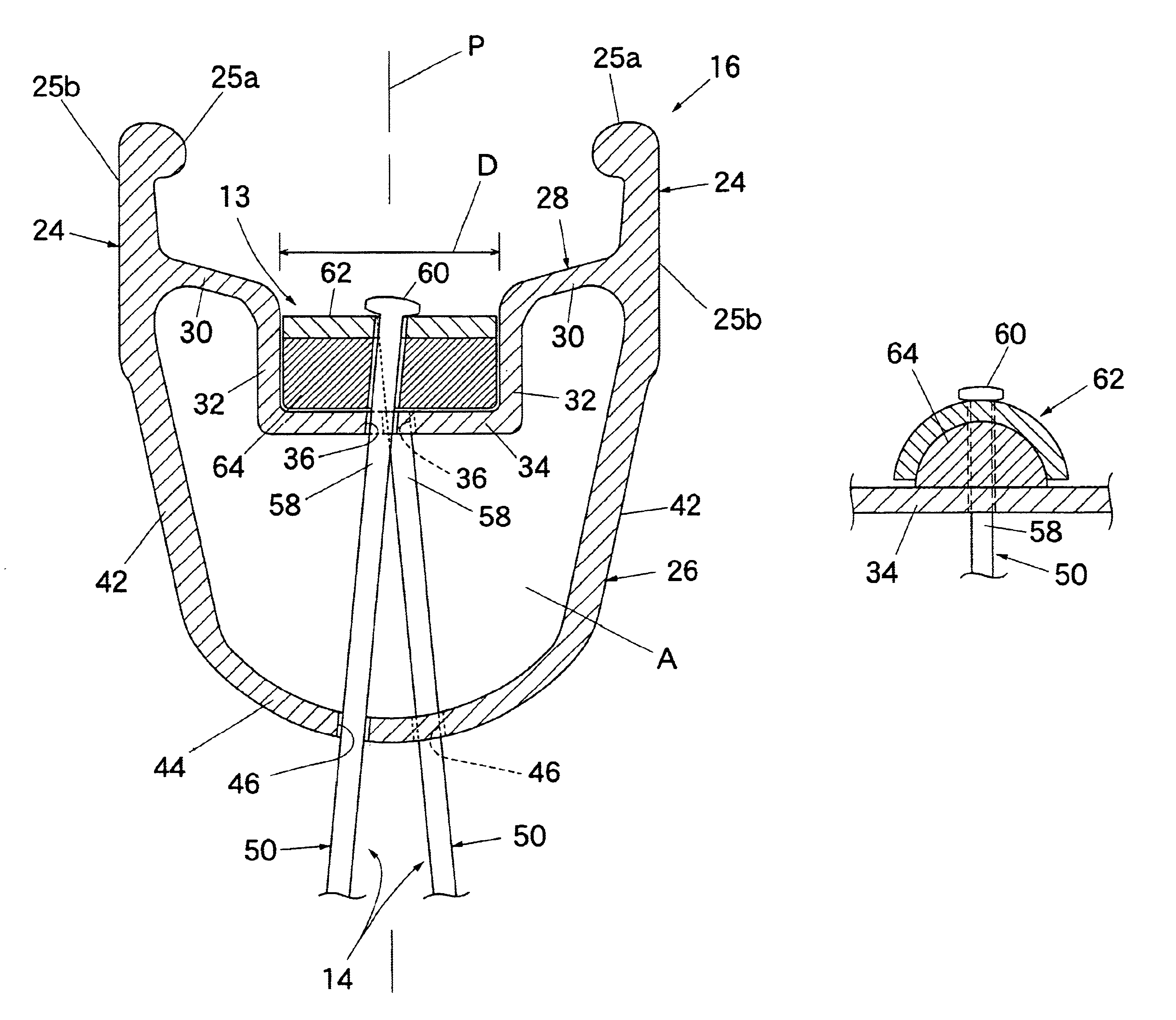

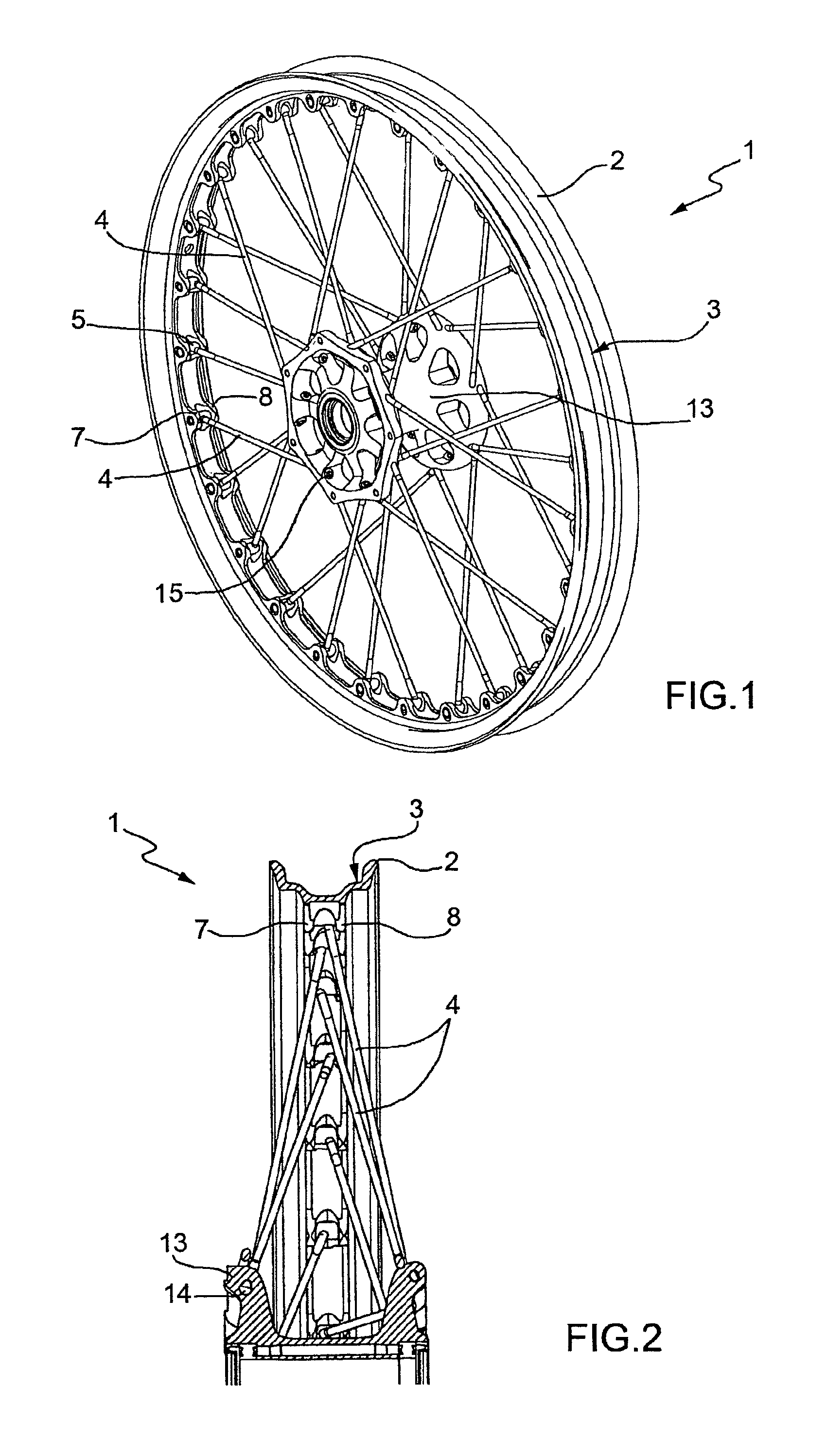

Bicycle wheel

A spoked rim assembly includes an annular rim and a plurality of spokes. Each of the spokes is provided with a seal structure so that a tubeless tire can be used with the rim. The rim preferably has an annular recess with a plurality of spoke attachment openings. Each of the spokes has an outer end portion coupled to one of the spoke attachment openings. Each of the outer end portions of the spokes includes a support member and a resilient seal member that form the seal structure for the spoke. The support members and the seal members are arranged and configured such that the support members selectively contact the spoke attachment portion to prevent full compression of the seal members when a radial force is applied to the support members. The support members can be separate or integrally formed with the spokes.

Owner:SHIMANO INC

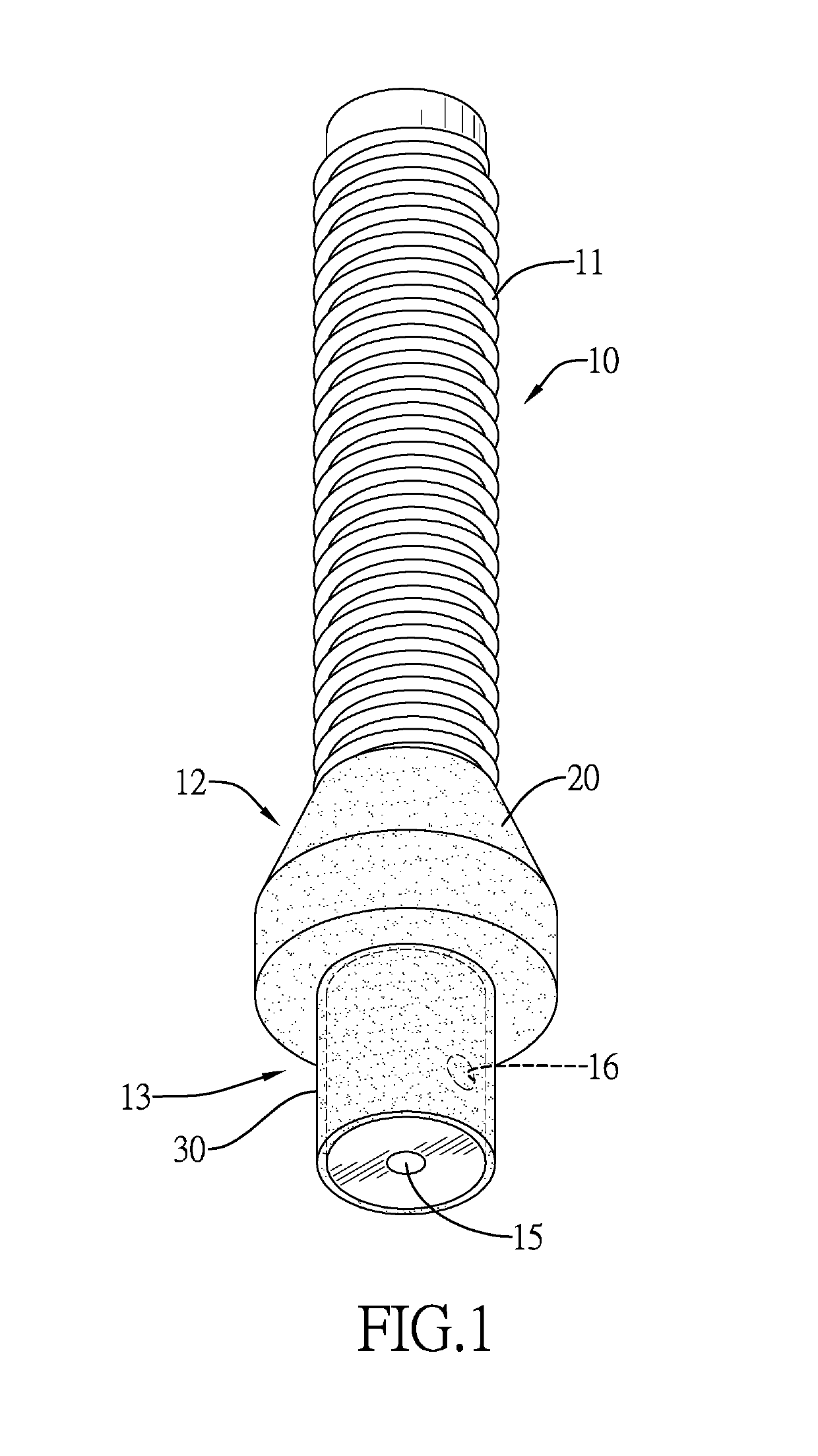

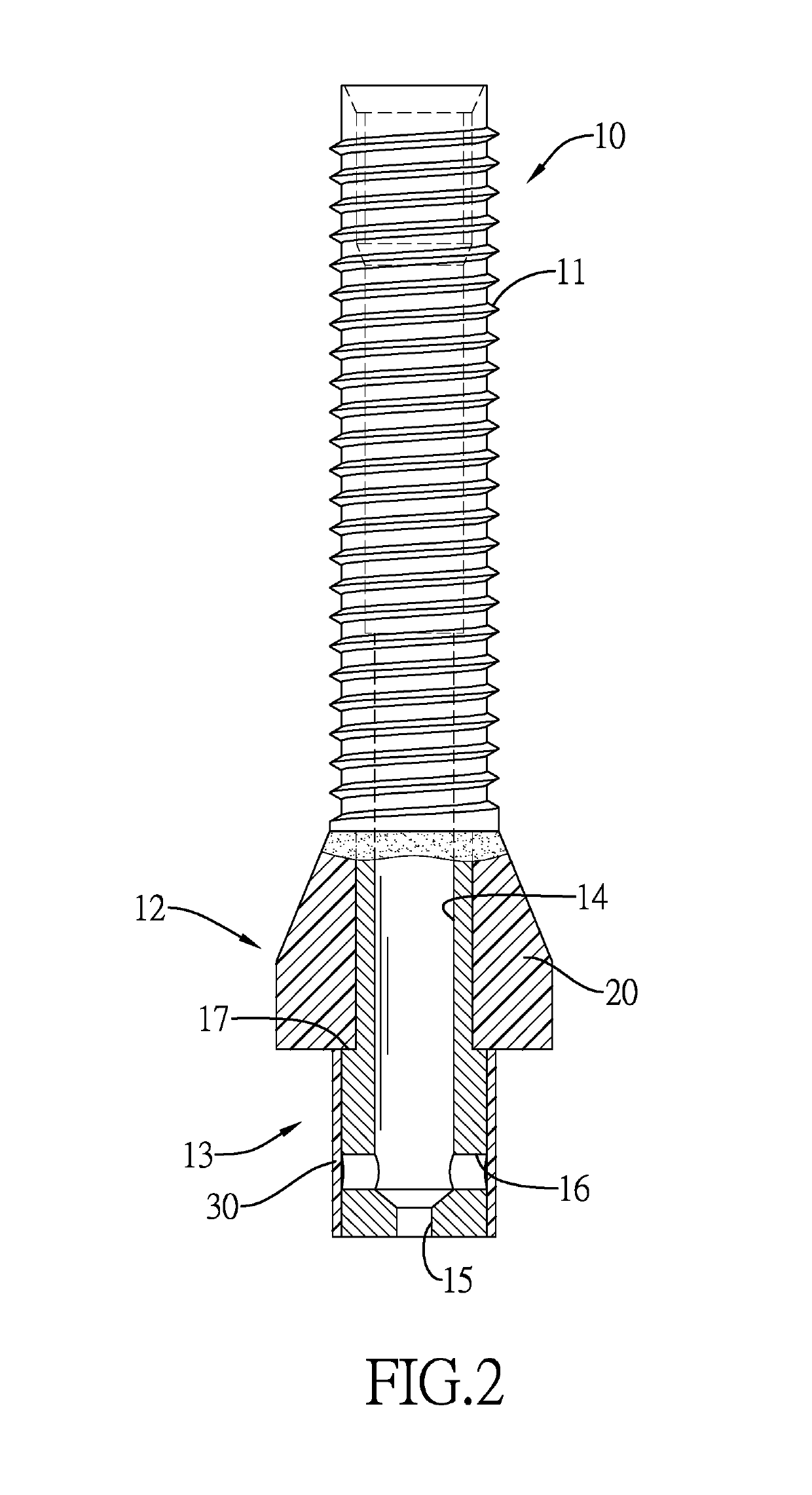

Tubeless air valve stem

ActiveUS20190263201A1Reduce gas volumeThin material handlingTyre-inflating valvesTubeless tireValve stem

A tubeless air valve stem has a body, an airtight element, and a sleeve. The body has a passage, a through hole, and at least one side hole. The passage is formed on a top end of the body. The through hole is formed through a bottom end of the body and is in communication with the passage. The at least one side hole is formed through an outer surface of the body and is in communication with the passage. The airtight element is disposed around the body. The sleeve is disposed around the body for closing the at least one side hole. Gas or liquid can be injected into a tubeless tire via the at least one side hole. The intake efficiency of the tubeless air valve stem can be maintained and is not influenced by the remaining reinforcing agent.

Owner:RIM MASTER INDAL

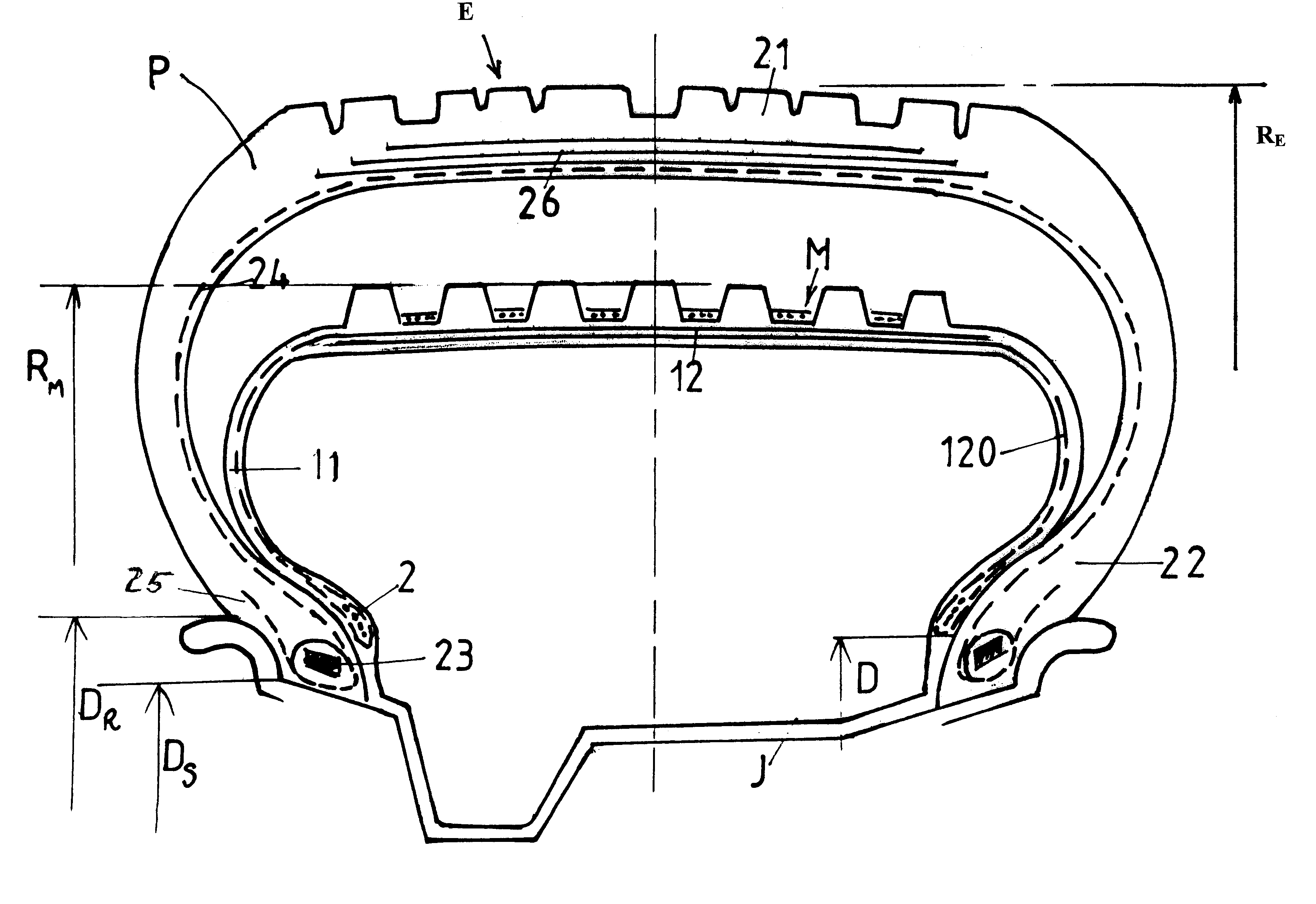

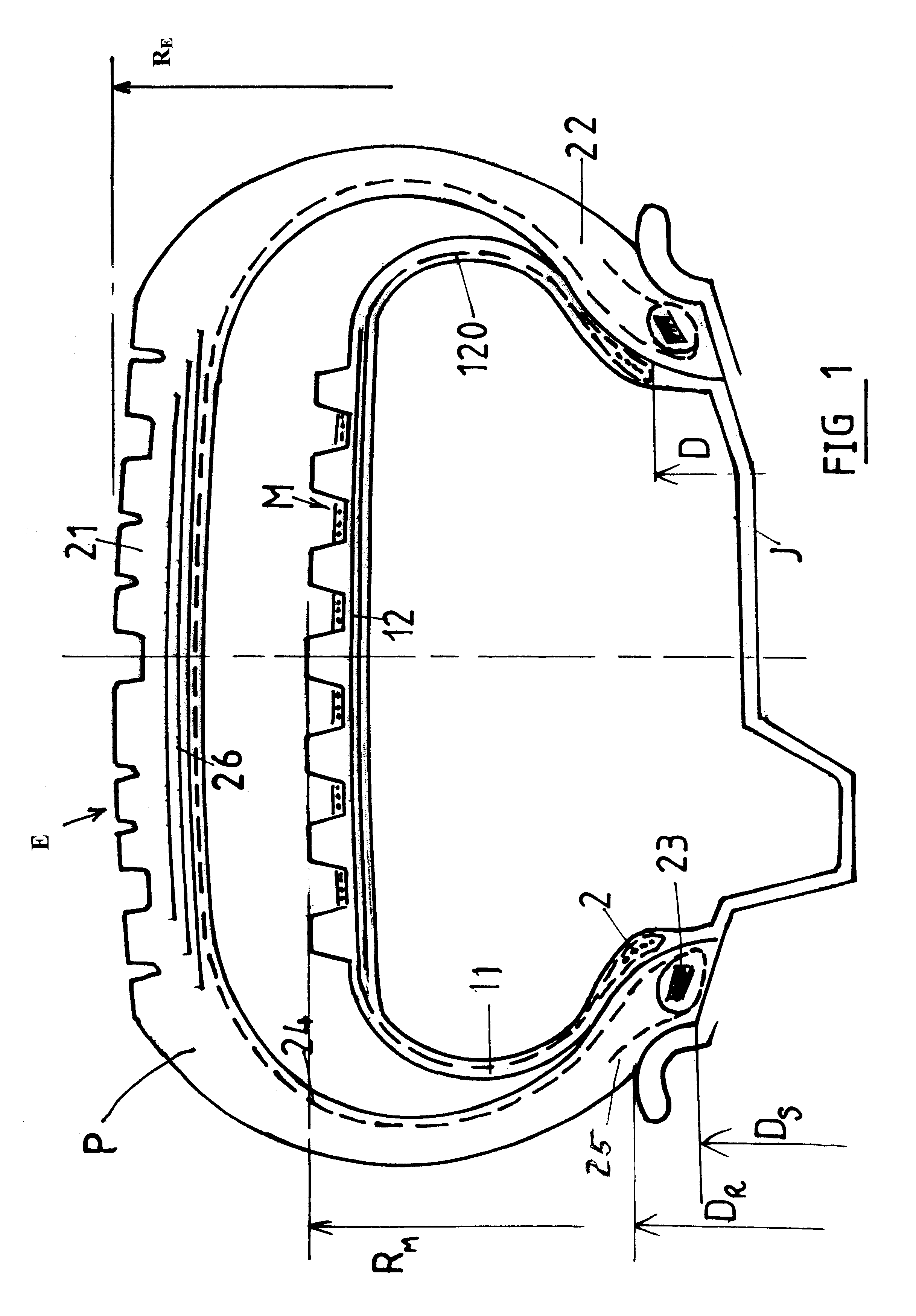

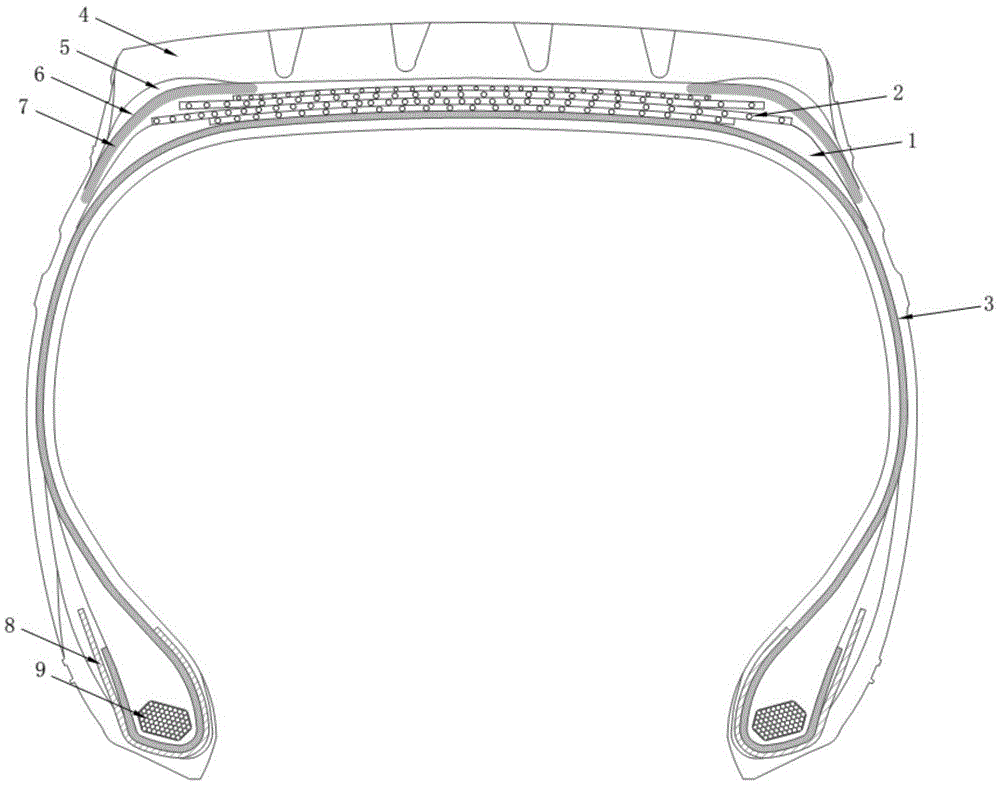

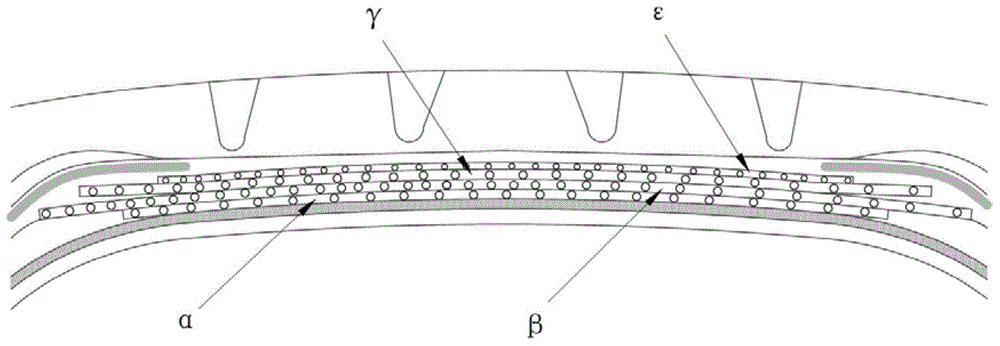

Supporting membrane for a tread

InactiveUS6467518B1Faster and more complete expansionWith separate inflatable insertsWith multiple inflatable chambersHoopingTubeless tire

A toric membrane of reinforced rubber, used as a support for the tread of a tubeless tire and forming with the tire P and its mounting rim a rolling assembly, characterized in that, when inflated to a pressure p0 greater than the pressure p1 of the cavity of the tire, it has in the inflated state a crown radius RM less than the loaded radius RE of the tire when used at its recommended pressure, the membrane being reinforced in its crown by a crown reinforcement and a hooping reinforcement composed of circumferentially oriented cords or cables, and in its sidewalls by at least one reinforcement ply, wound around an annular reinforcement element having a breaking load slightly greater than that of the hooping reinforcement.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

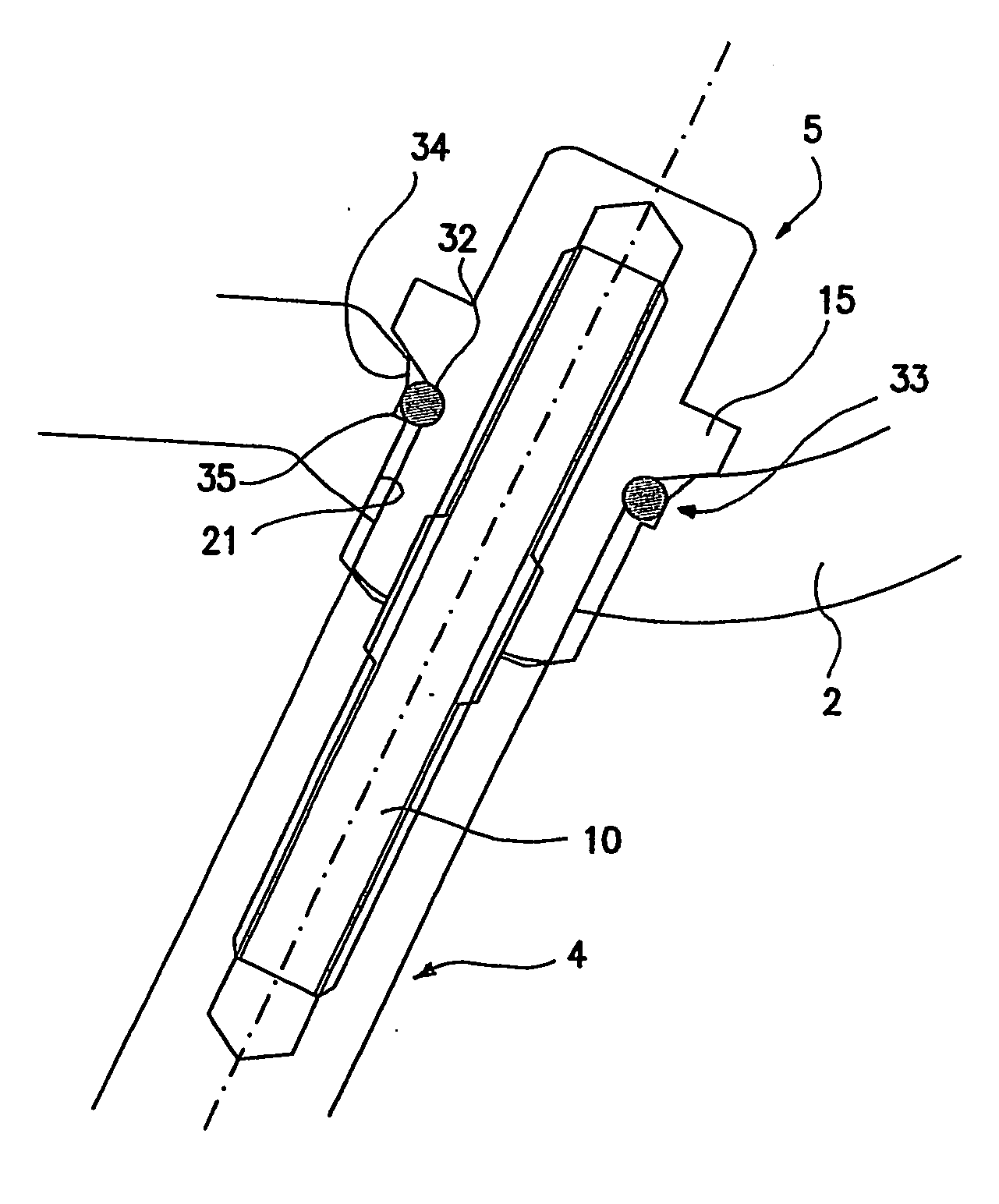

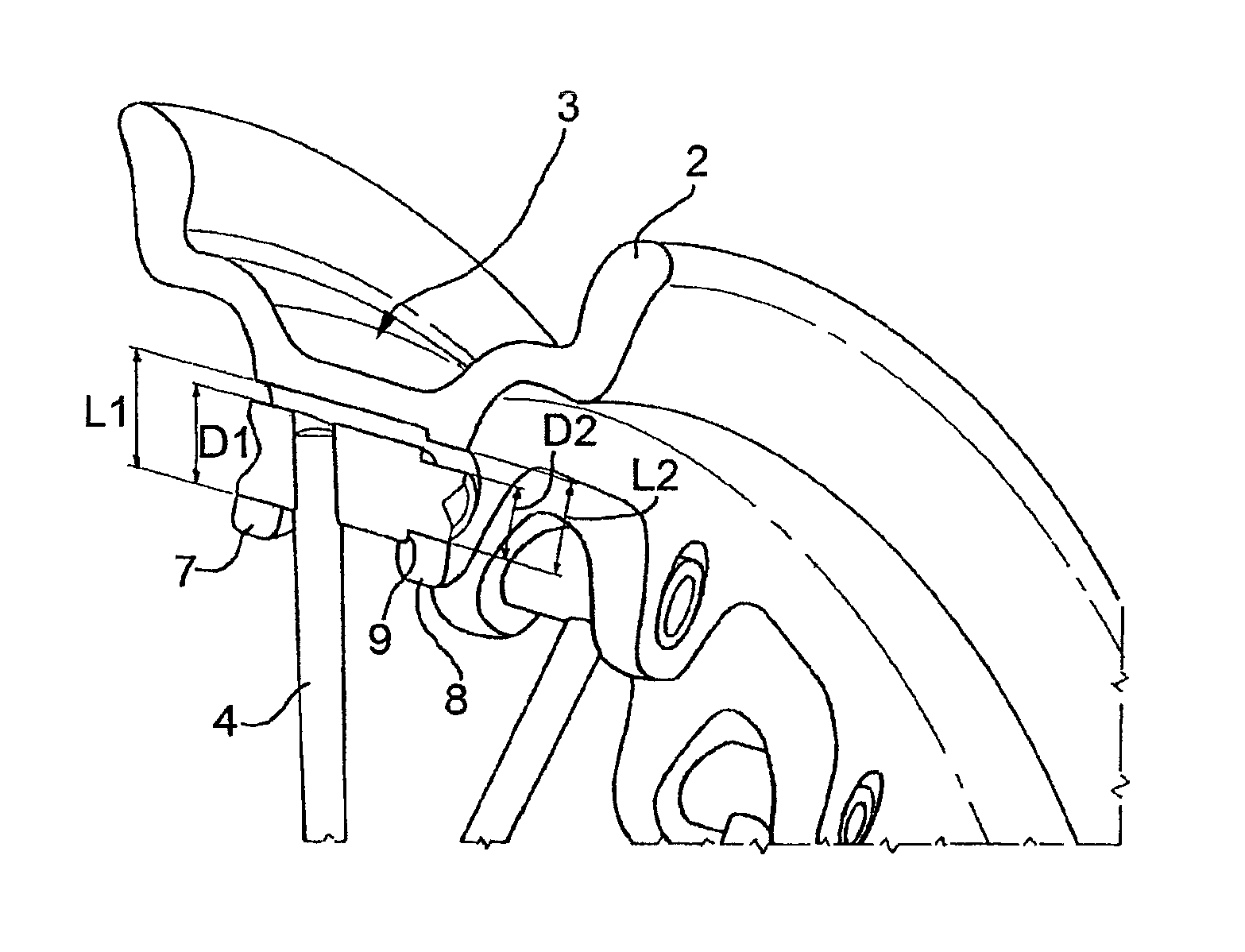

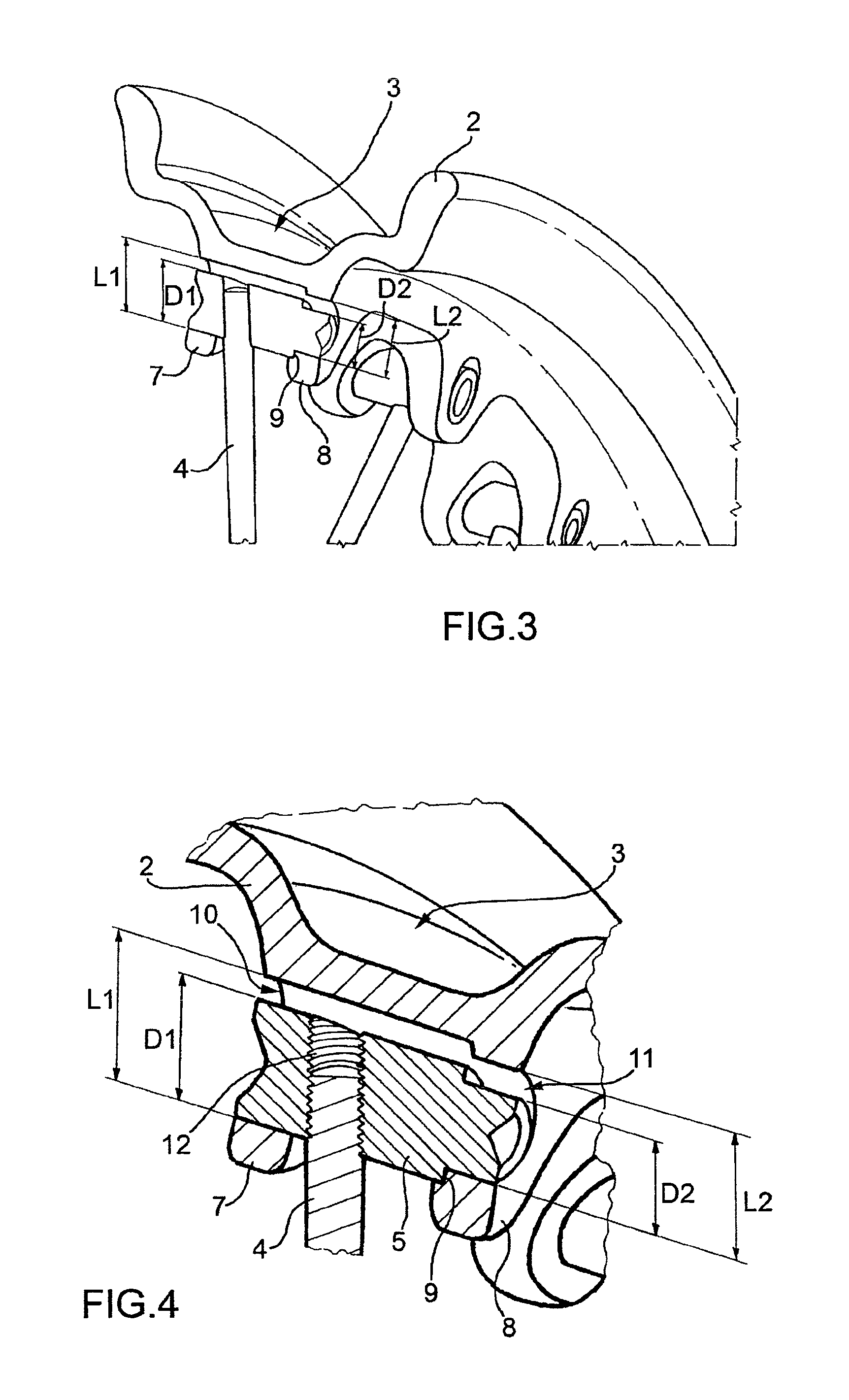

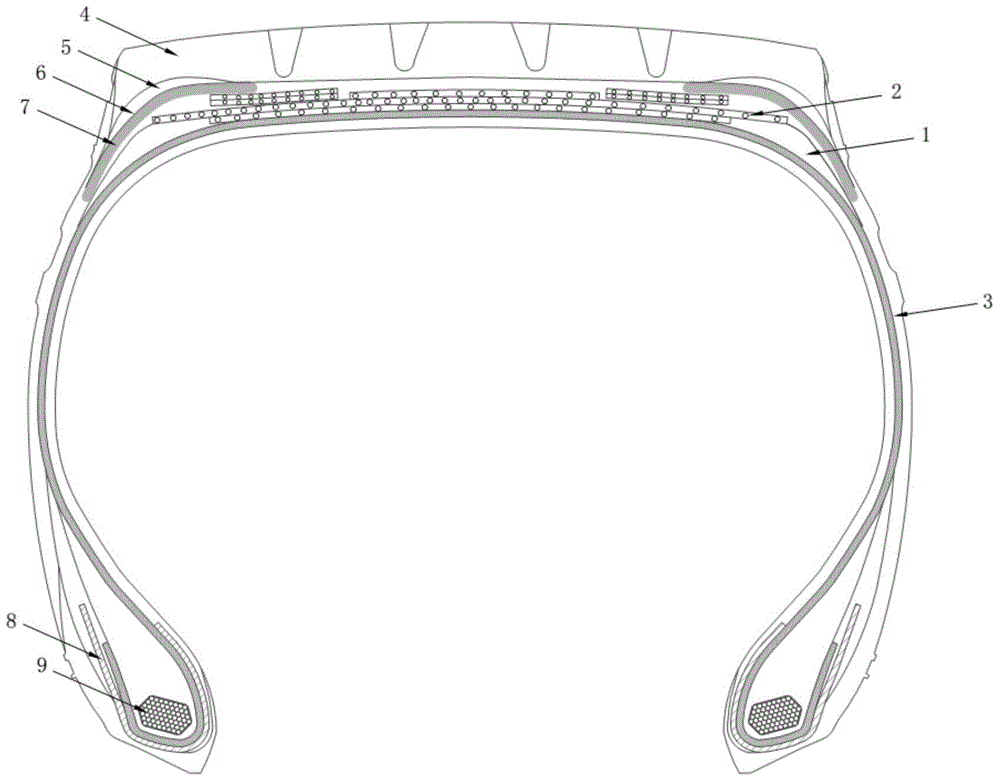

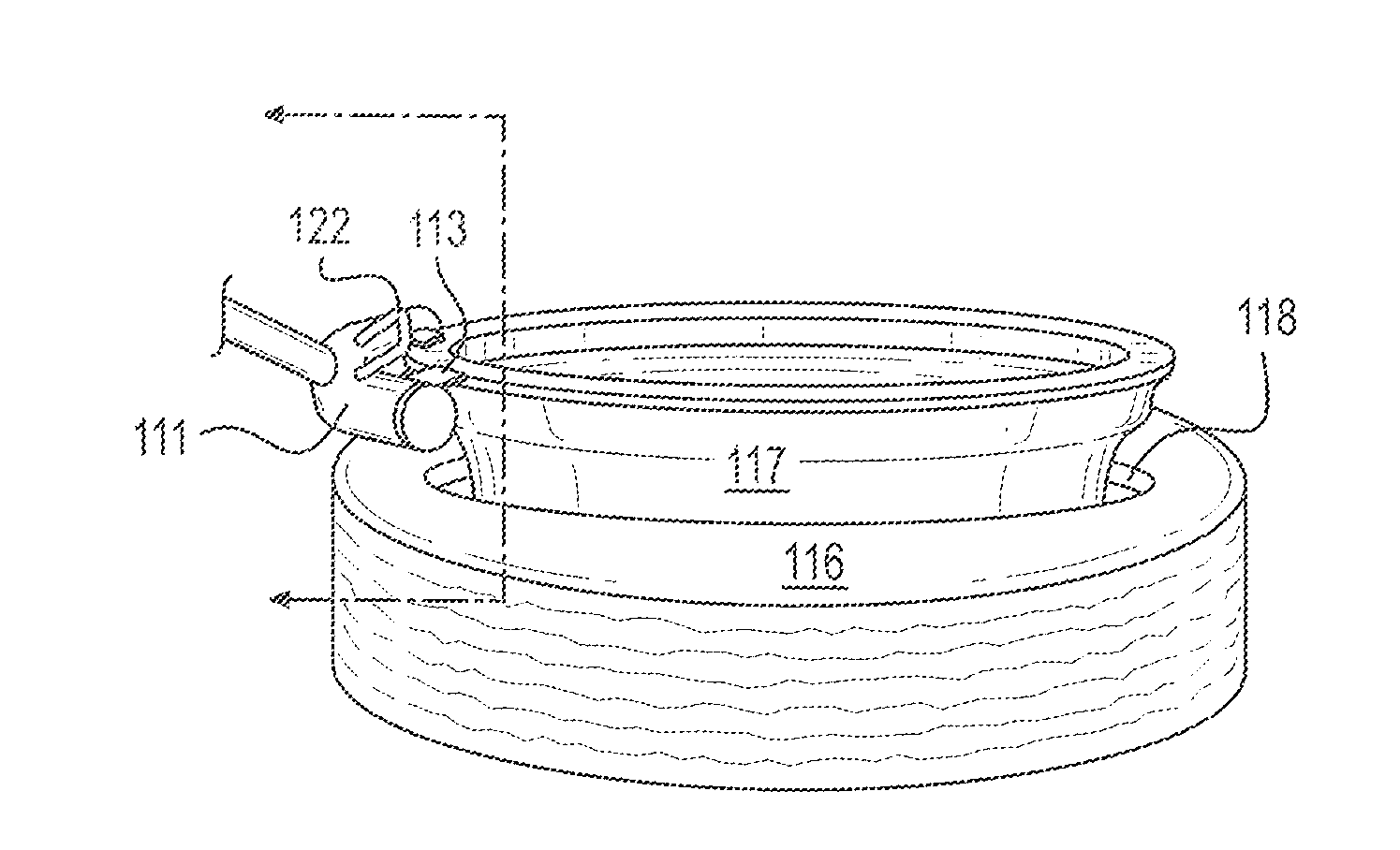

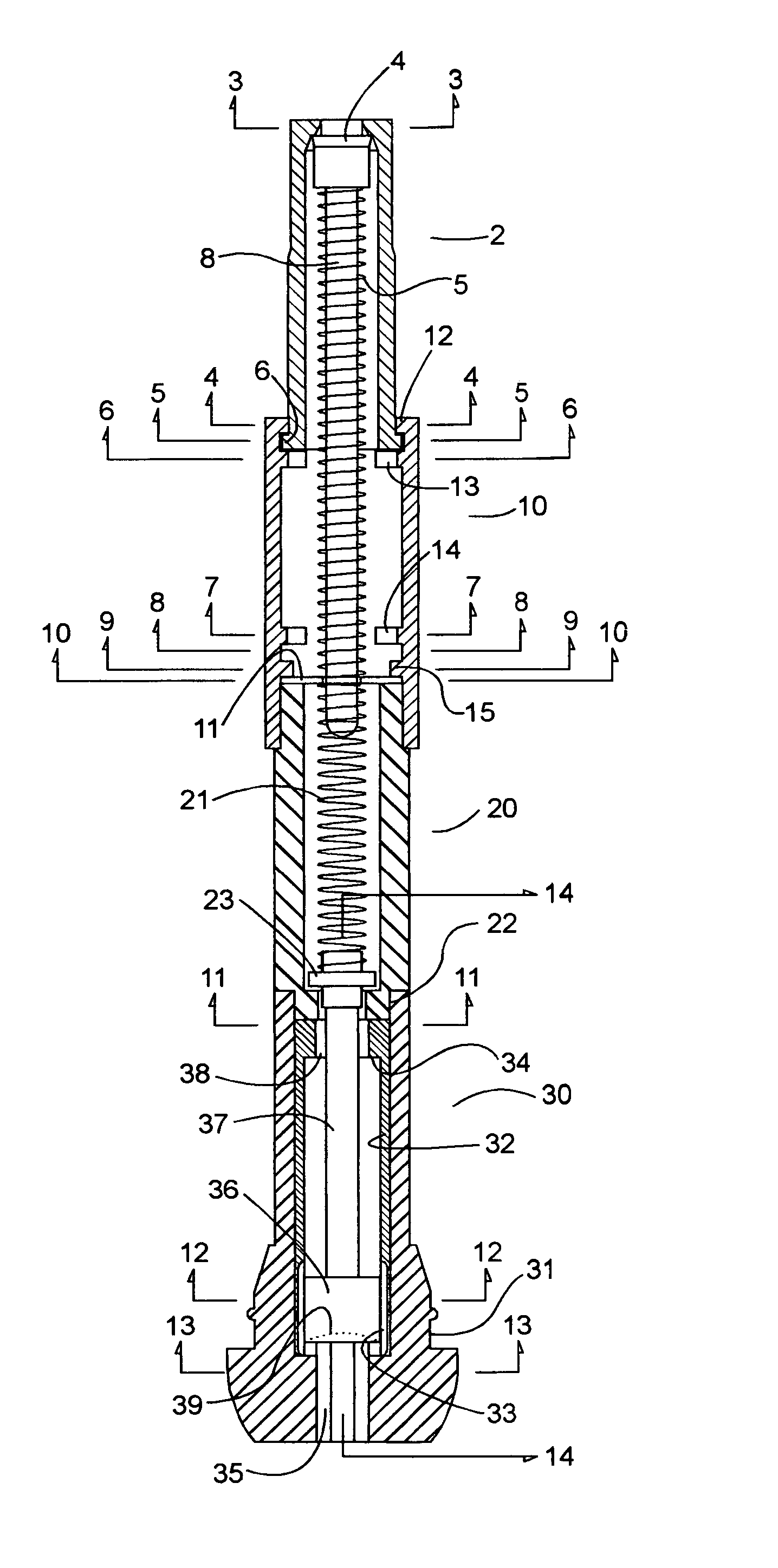

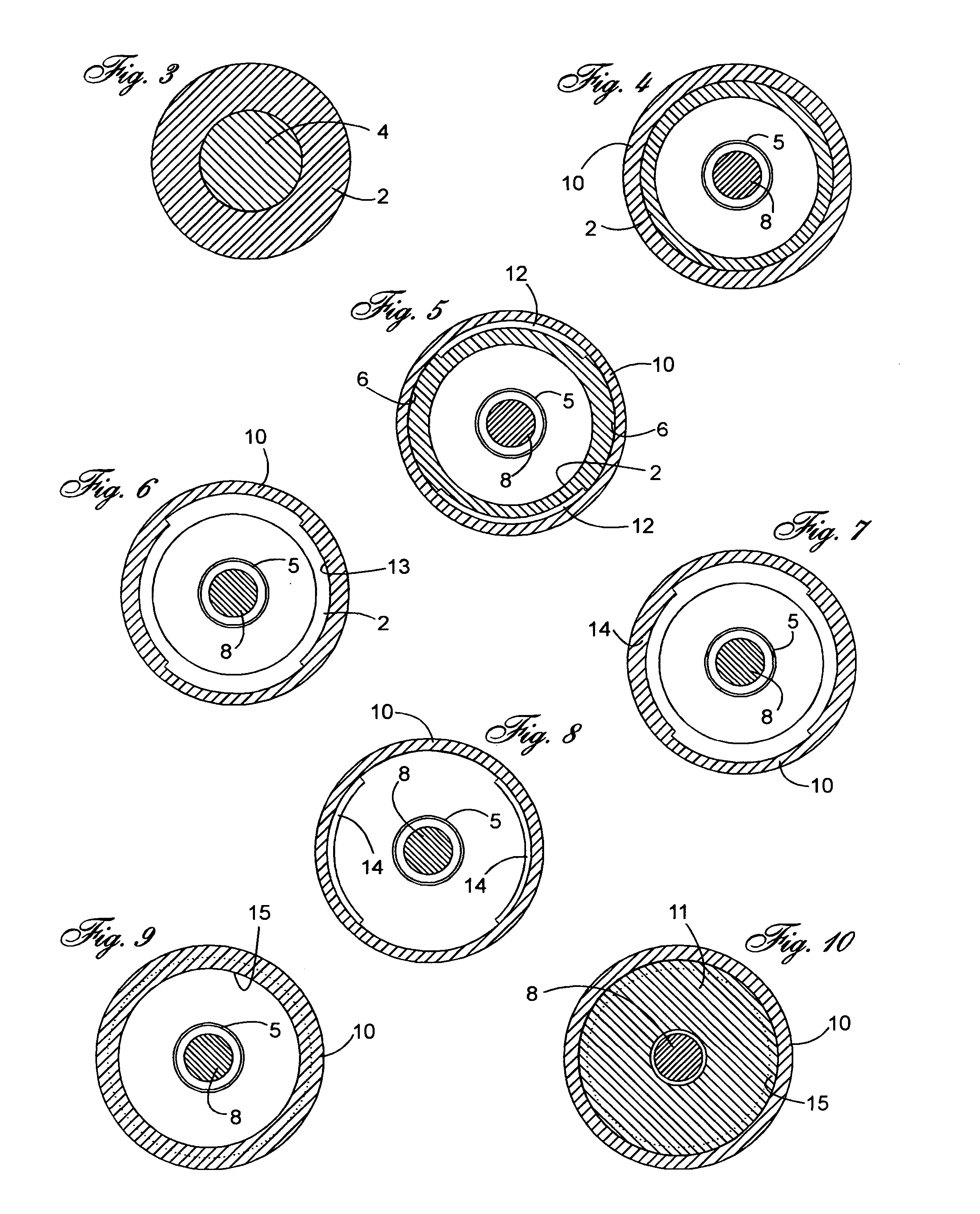

Spoked wheel for tubeless tires

ActiveUS9522570B2Strong and lightweightEasy to useRimsNon-metallic wheel bodyTubeless tireMechanical engineering

A spoked wheel for tubeless tires, particularly for motorcycles, cars and similar vehicles includes a rim, a hub, and spokes suitable for fixing the rim to the hub. Each spoke is connected to the rim by a fastening device inserted in two opposite ears located in an inner surface of the rim.

Owner:IN MOTION SRL

All-steel radial tubeless tire and preparation method thereof

ActiveCN104442211AImprove rigidityReduced circumferential deformationPneumatic tyre reinforcementsEngineeringTubeless tire

The invention relates to an all-steel radial tubeless tire. An outer side end point of a rubber sheet below a crown is positioned between the inner side of the crown side and tire shoulder pad rubber; the inner side end point is positioned between a tire crown buffer rubber sheet and a No.4 (or zero degree) belt ply, and seals the end points of a No.2 belt ply, a No.3 belt ply and a No.4 belt ply (or zero degree). By the improvement of the tire crown structure, the rigidity of the tire crown is increased, so that the peripheral deformation in the driving process of a tire is relatively small, the rolling resistance is low, and oil is saved; meanwhile, the bonding force between the tire crown and the pad rubber is also intensified; the shearing stress among the belt plies is reduced, and the splitting among the belt plies as well as among the belt plies and the tire crown, which is caused by stress concentration and ultra high thermogenesis, is prevented, so that the durable safety of the tire shoulder part is improved greatly; the safety hazard of a tire in the aspects of over loading, high-speed long-distance transportation and the like is reduced; the service life of the tire is prolonged; the scheme is feasible, economic and reliable.

Owner:HANGZHOU CHAOYANG RUBBER

Apparatus for making tires filled with flatproofing material

InactiveUS6988524B2More to premature failureShort set-up timeArtificial filament recoveryOther chemical processesTubeless tireEngineering

A tire, and an apparatus and method for forming a tire. The tire may either be a tubed or tubeless tire, and is filled with a mixture of virgin rubber and small rubber pieces. Preferably, a machine grinds the core of used flatproofed tires, or pieces thereof, into a finely communicated pulverulent. The pulverent is mixed with liquid virgin flatproofing material, such as a polyurethane. An injector introduces this mixture, into the core of a tire, typically through a valve. The core of the tire is preferably substantially filled with this mixture. The injector may take the form of one or more elongated screws and the mixing may occur as the ground rubber is being conveyed by the screw.

Owner:ACCELLA POLYURETHANE SYST LLC

Bicycle rim for tubeless tire

Owner:HED CYCLING PRODS

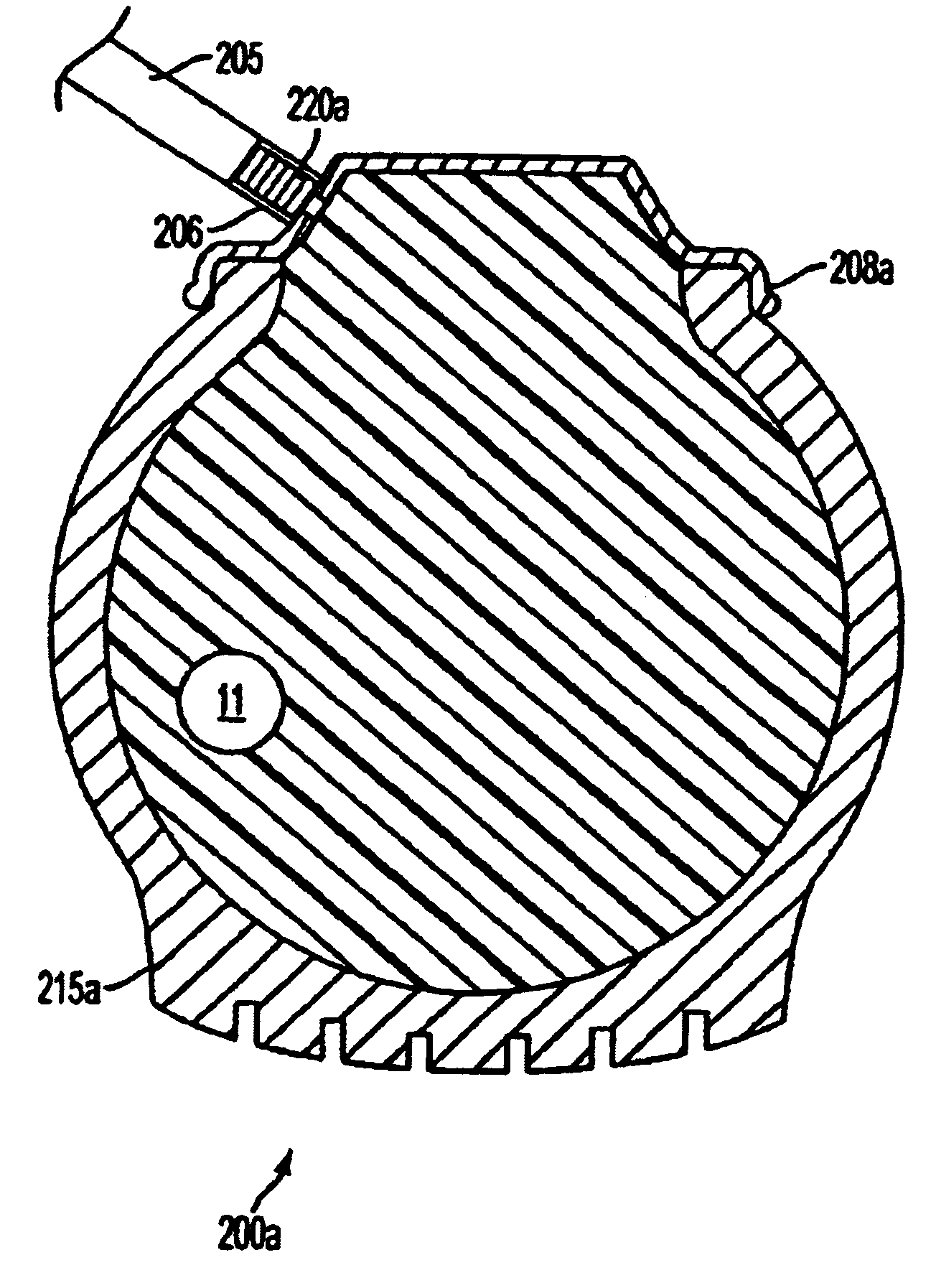

Concentric bell assembly

ActiveUS6918423B2Overcome deficienciesWheelsWood-rimmed wheels manufacturingTubeless tireEngineering

A bell assembly for inflating a tubeless tire on a wheel includes a first bell and a second bell slidably disposed within the first bell. The second bell includes a smaller diameter than the first bell. A shaft extends upwardly from the second bell in one of a relative to the first bell. A locking member is engagable with the shaft and is movable between a first locking position and a second locking position. The locking member secures the second bell in the first bell position when the locking member is disposed in the first locking position. The locking member secures the second bell in the second bell position when the locking member is disposed in the second locking position.

Owner:DURR SYST INC

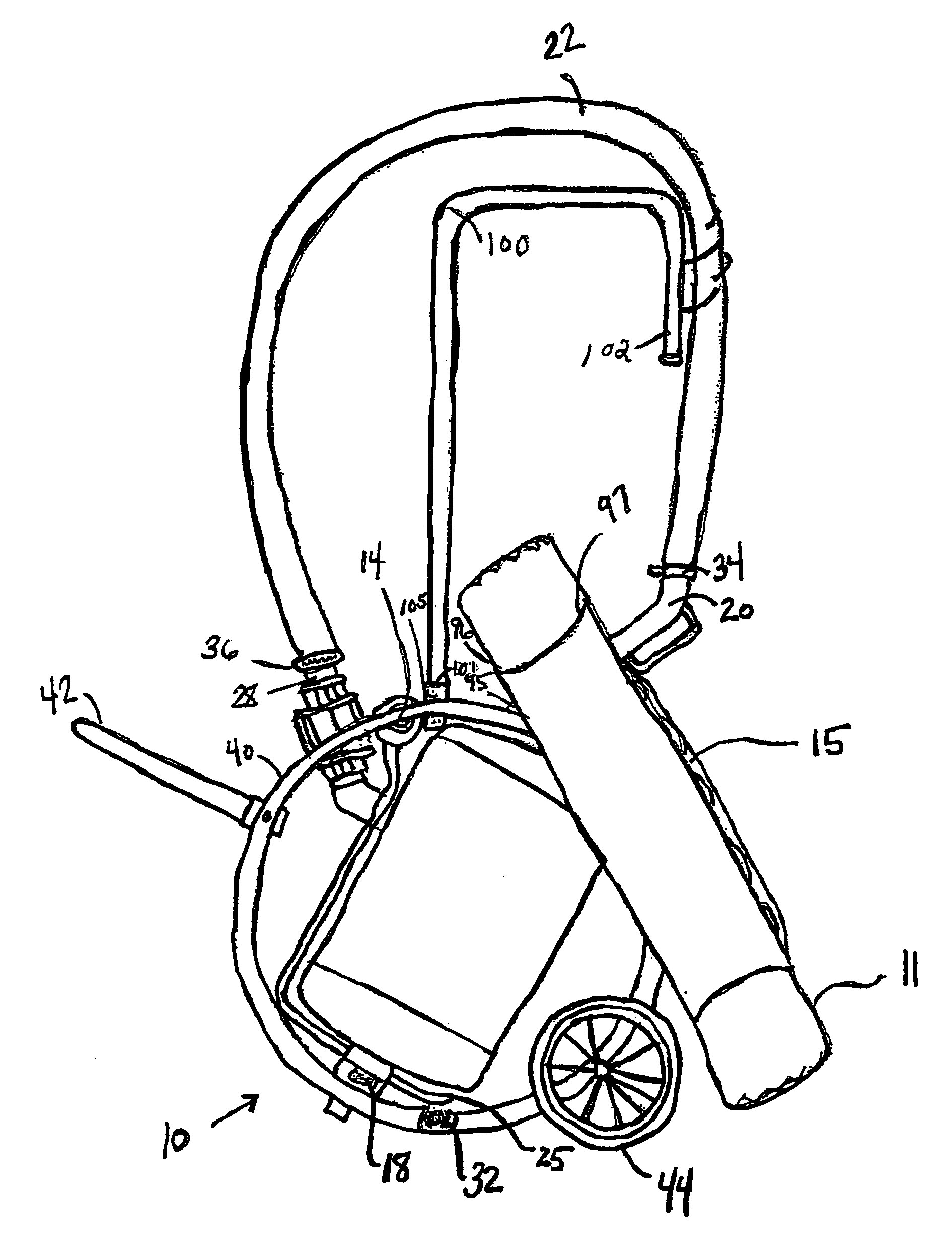

Apparatus and method for sealing tubeless tires

An apparatus and method to seat a tire on a rim are described. Protrusions and a handle on the apparatus allow a user to brace the protrusions against the rim to prevent blow back when air is vented into the gap between the tire and the rim to seat the tire bead. The air is vented through a plurality of holes in the apparatus and the flow of the air into the apparatus is controlled by positioning a bridge handle of a flow control valve situated between the apparatus and a tank of air.

Owner:BOSCH AUTOMOTIVE SERVICE SOLUTIONS

Prick-resistant leakage-proof material for inner tube-free tyre and its preparation method and spray-coating method

InactiveCN1995262AImprove air tightnessImprove adhesionOther chemical processesTubeless tireSpray coating

The invention discloses a tubeless tyre leak-proof material and making and spraying method, which comprises the following parts: 1% SEBS, 1. 5-2% industrial white oil, 0.01-0.03% carbon 9 and 0.01-0.05% TPE. The making method comprises the following steps: blending SEBS and industrial white oil; stirring; foaming to form composite material; putting foamed composite material in the autoclave; adding carbon 5 or carbon 9 and TPE; heating to 250-280 deg. c; cooling to 170-190 deg. c. The spraying method comprises the following steps: spraying fused leak-proof material into tyre at 190-170 deg. c; distributing the lead-proof material on the inner wall of tyre evenly.

Owner:SHANGHAI HONGWEI ENTERPRISE MANAGEMENT

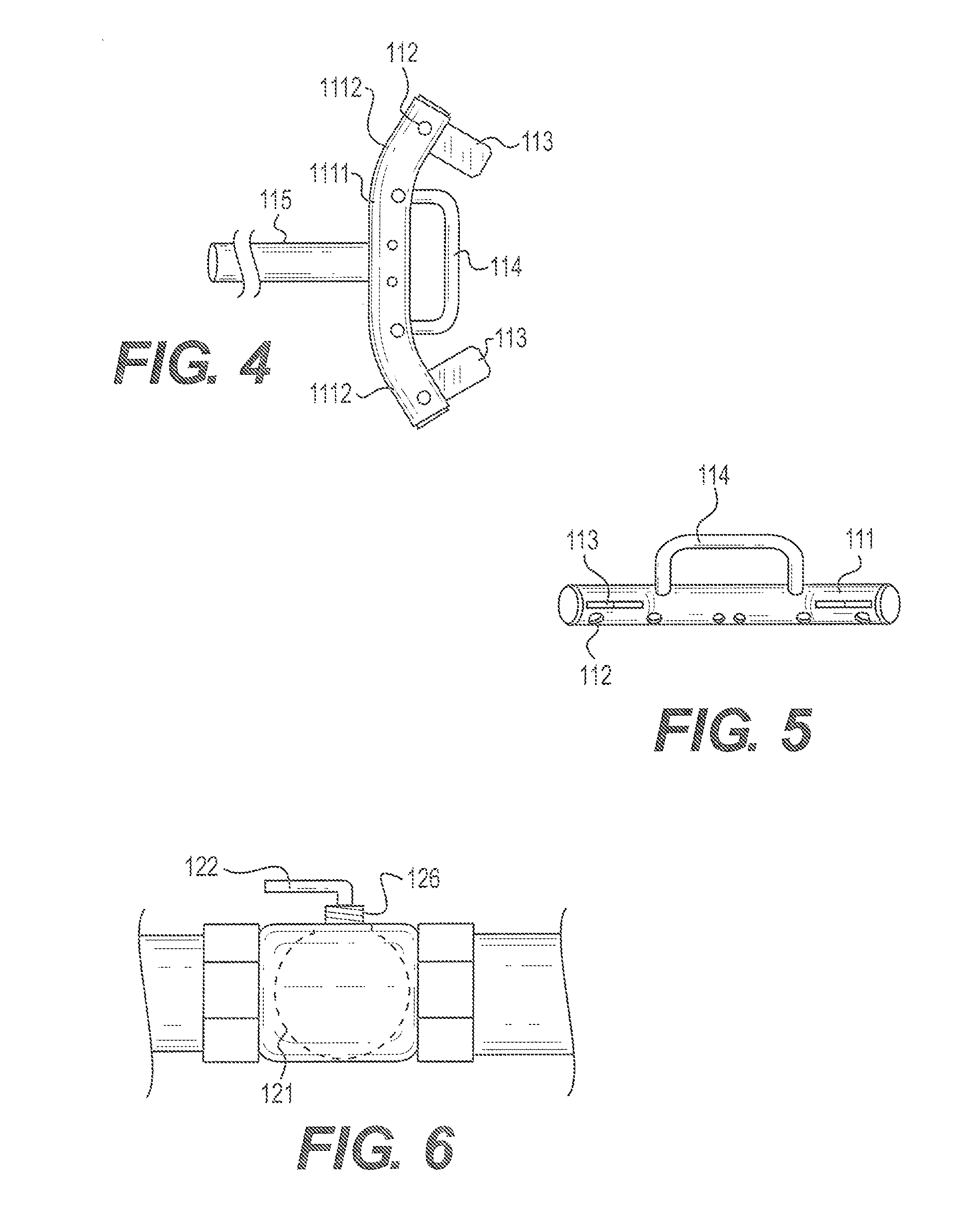

Tire valve-gauge combination

InactiveUS6978670B2AccuracyIncreased durabilityCheck valvesLiquid transferring devicesTubeless tirePositive pressure

A tire valve-gauge combination utilized to inflate and deflate conventional tubed or tubeless tires while giving the user an indication of the amount of air pressure within the tire's chamber. The accessory device of the present invention comprises; a flexible rim-attaching base having a larger lower body portion than the rim perforation of a conventional tire and a central neck portion having an outside diameter equal or lesser than said rim perforation, a rigid gauge portion having a transparent molded tube-like form imprinted with markings identifying the location of a moveable luminescent indicator adapted to travel longitudinally within said gauge portion, a cap base portion adapted to securedly attach to the upper portion of the gauge portion and slidably communicating with a cap portion. Therefore, when a tire is under pressure, the inner air pressure exerts positive pressure against the under side of the piston, which in turn, displaces the location of said indicator, indicating the tire's air pressure.

Owner:COUSINEAU WILLIAM

Tire valve-gauge combination

InactiveUS20050217363A1AccuracyIncreased durabilityCheck valvesLiquid transferring devicesTubeless tirePositive pressure

A tire valve-gauge combination utilized to inflate and deflate conventional tubed or tubeless tires while giving the user an indication of the amount of air pressure within the tire's chamber. The accessory device of the present invention comprises; a flexible rim-attaching base having a larger lower body portion than the rim perforation of a conventional tire and a central neck portion having an outside diameter equal or lesser than said rim perforation, a rigid gauge portion having a transparent molded tube-like form imprinted with markings identifying the location of a moveable luminescent indicator adapted to travel longitudinally within said gauge portion, a cap base portion adapted to securedly attach to the upper portion of the gauge portion and slidably communicating with a cap portion. Therefore, when a tire is under pressure, the inner air pressure exerts positive pressure against the under side of the piston, which in turn, displaces the location of said indicator, indicating the tire's air pressure.

Owner:COUSINEAU WILLIAM

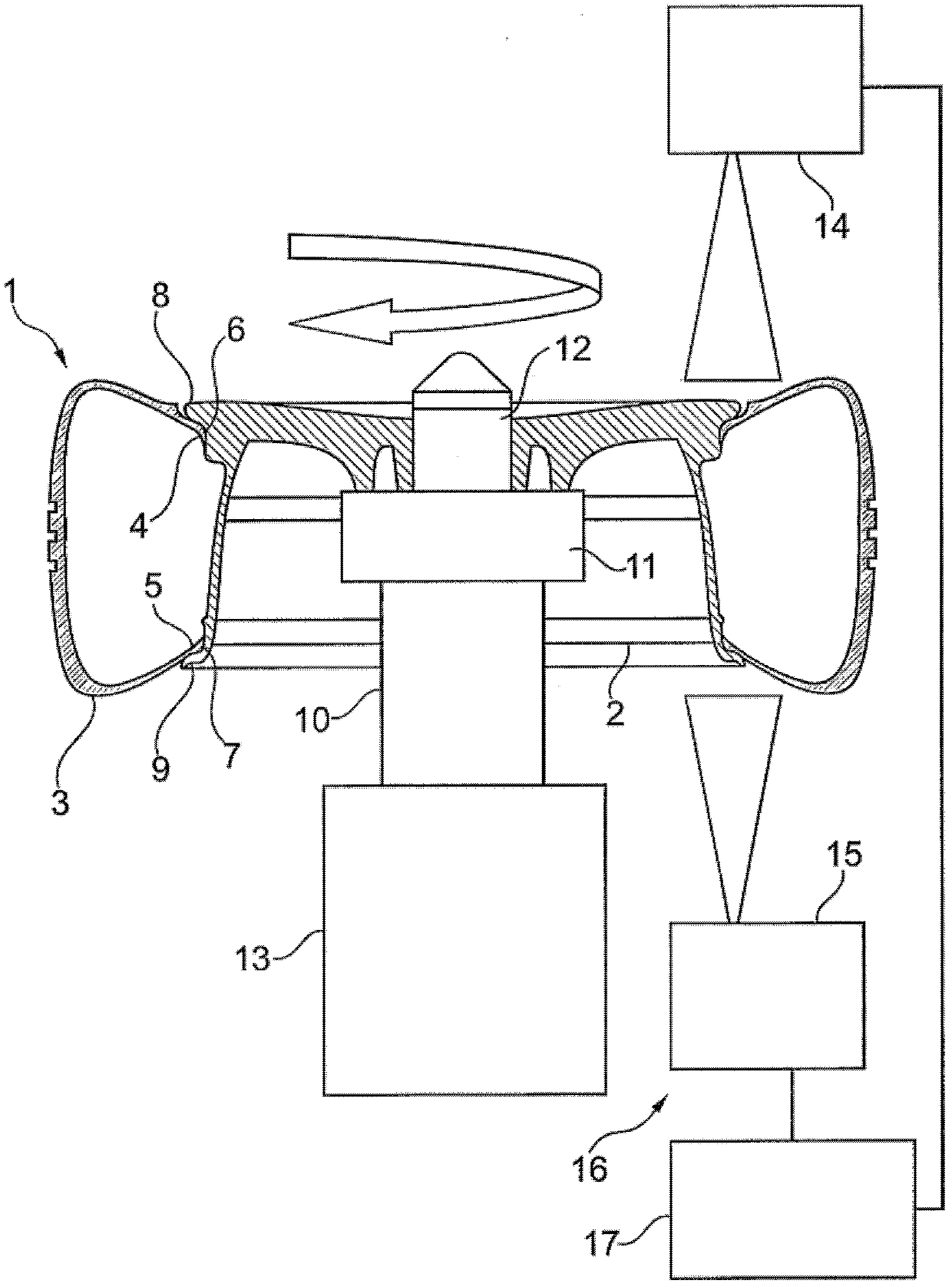

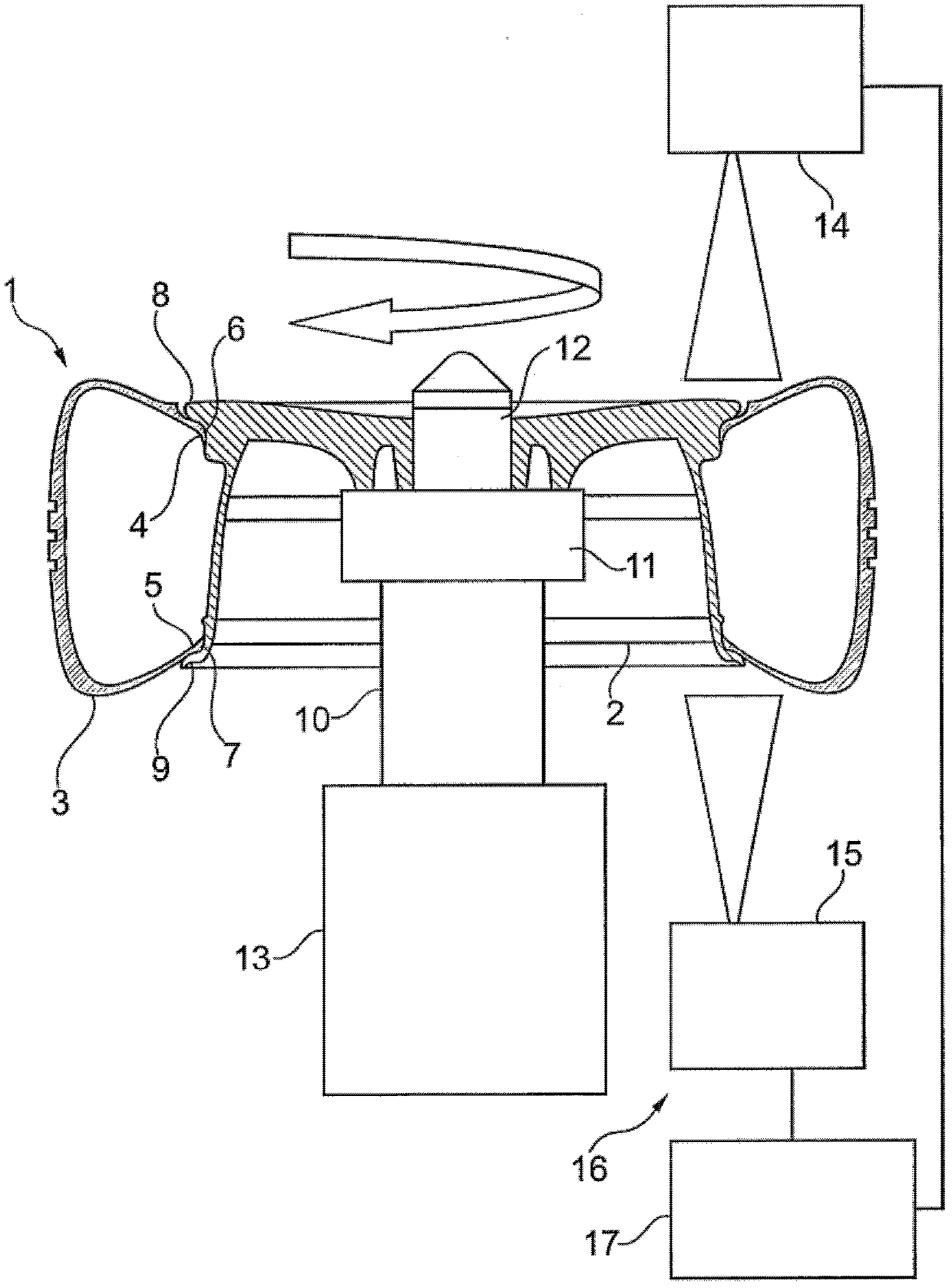

Method and device for checking the tyre seat on vehicle wheels

InactiveCN102384724AEliminate assembly errorsAccurate measurementVehicle testingStatic/dynamic balance measurementTubeless tireAxial distance

The invention relates to a method and a device for checking the seat of a tubeless tire (3) fitted to a rim (2) of a vehicle wheel (1), the vehicle wheel (1) is fastened with its rim (2) centrically on a rotary mount and is rotated about its axis of rotation through at least one revolution. During rotation of the wheel, the outer contours of the radially outer edge areas of the rim (2) and the adjoining areas of the tire (3) are scanned by means of a distance measuring device, and the axial distance differences between the rim (2) and the tire (3) are detected and evaluated.

Owner:SCHENCK ROTEC GMBH

Inflating device for tires

A portable device for seating the beads of a tubeless tire and rim assembly, the device including an air tank containing pressurized air, the air tank being mounted substantially within a bracket, the bracket having a surface for supportably receiving the tire and rim assembly, and a means for directing the pressurized air between a bead of the tire and the rim.

Owner:BRAHLER II RICHARD W

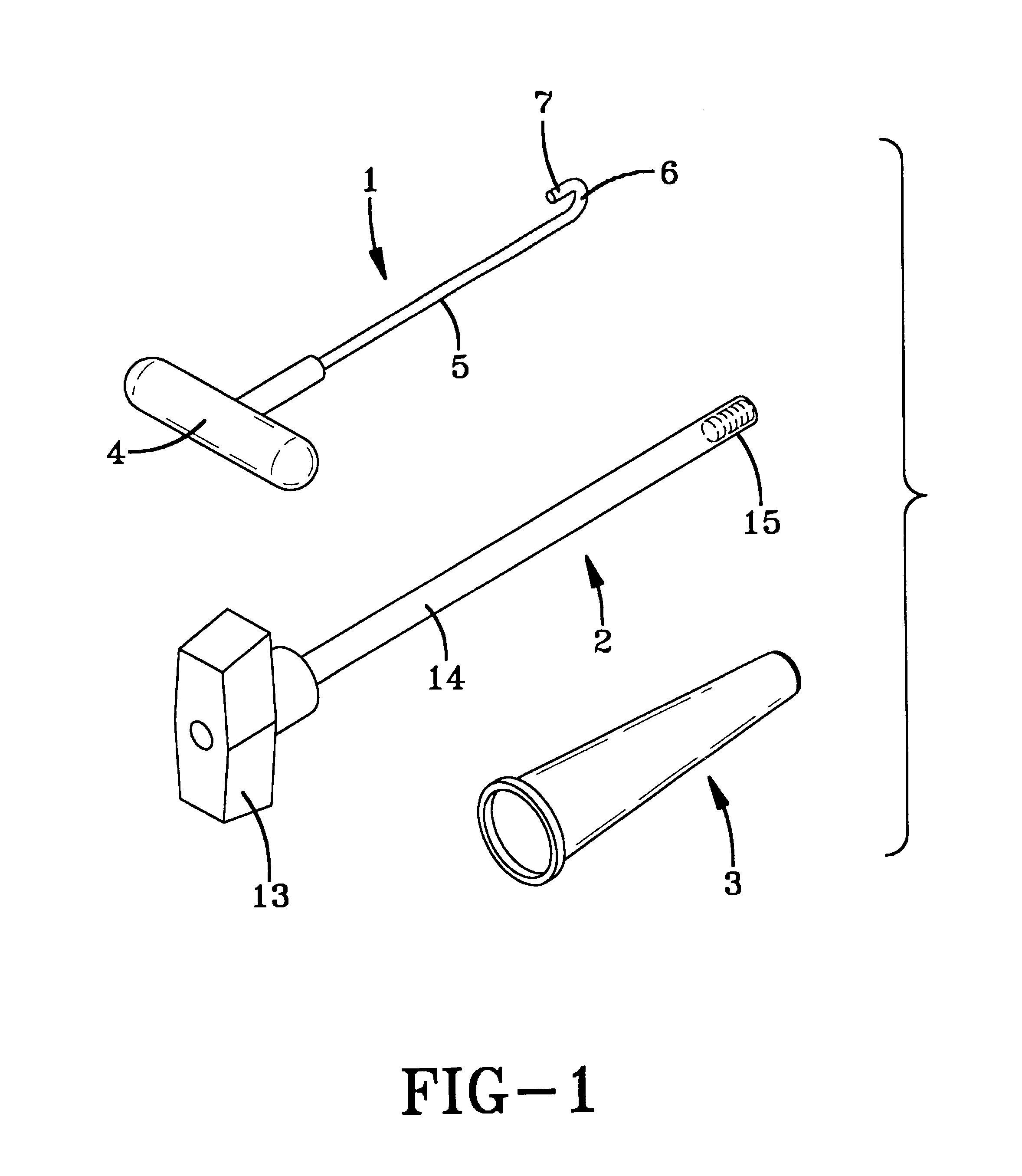

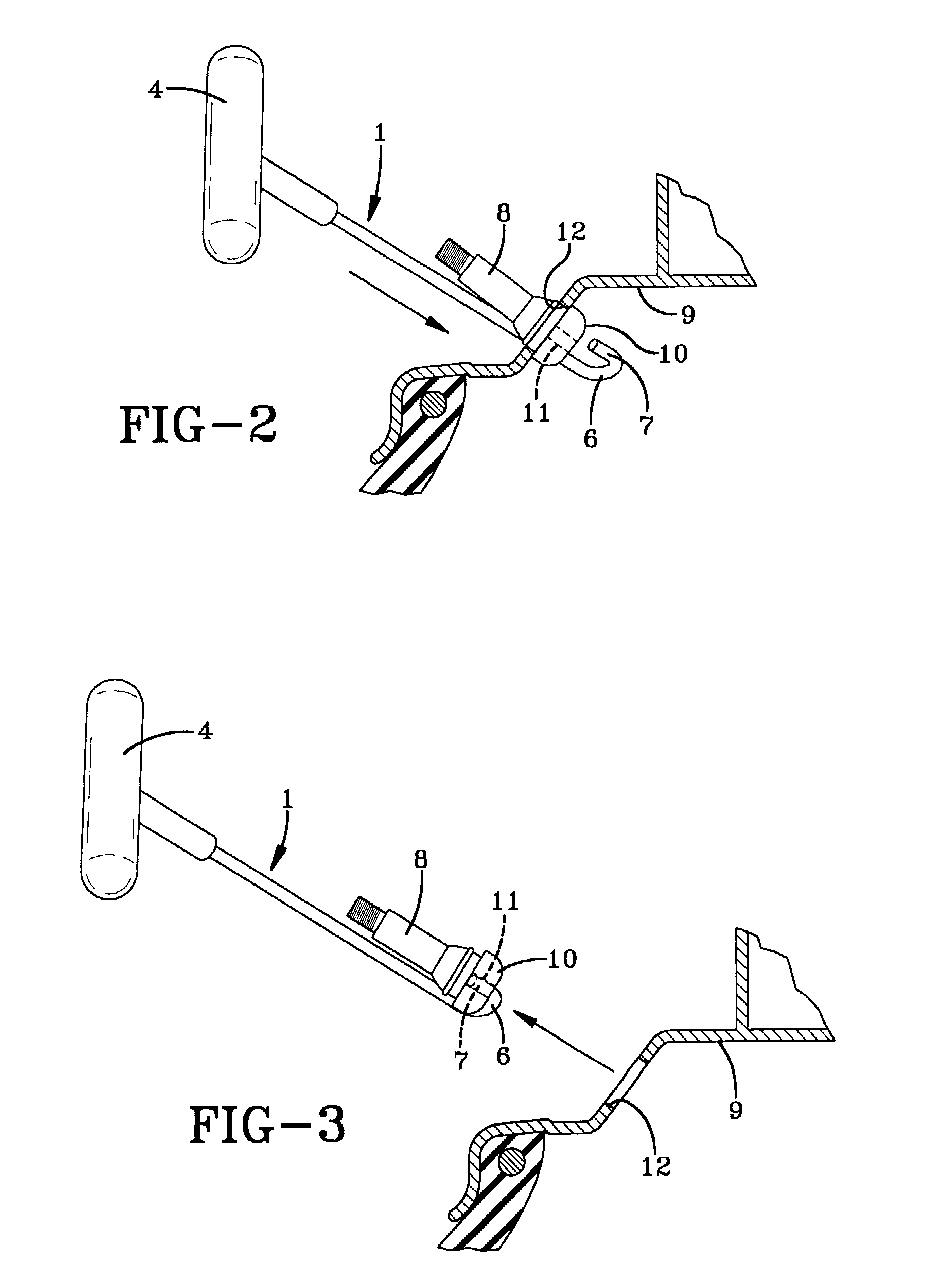

Valve stem remover and installer tool kit

InactiveUS7017247B2Easy to buyMetal working apparatusMetal-working hand toolsTubeless tireValve stem

The present invention is a simple kit for removal and insertion of valve stems for tubeless tires while the tire remains mounted on the rim.

Owner:DETZEL DAVE

Rim for mounting tubeless tires, particularly for bicycles, motorcycles and mopeds

InactiveUS7374250B2Usefulness and economical industrial applicationEasy to provideRimsSpoked wheelsTubeless tireEngineering

Owner:ALPINA RAGGI

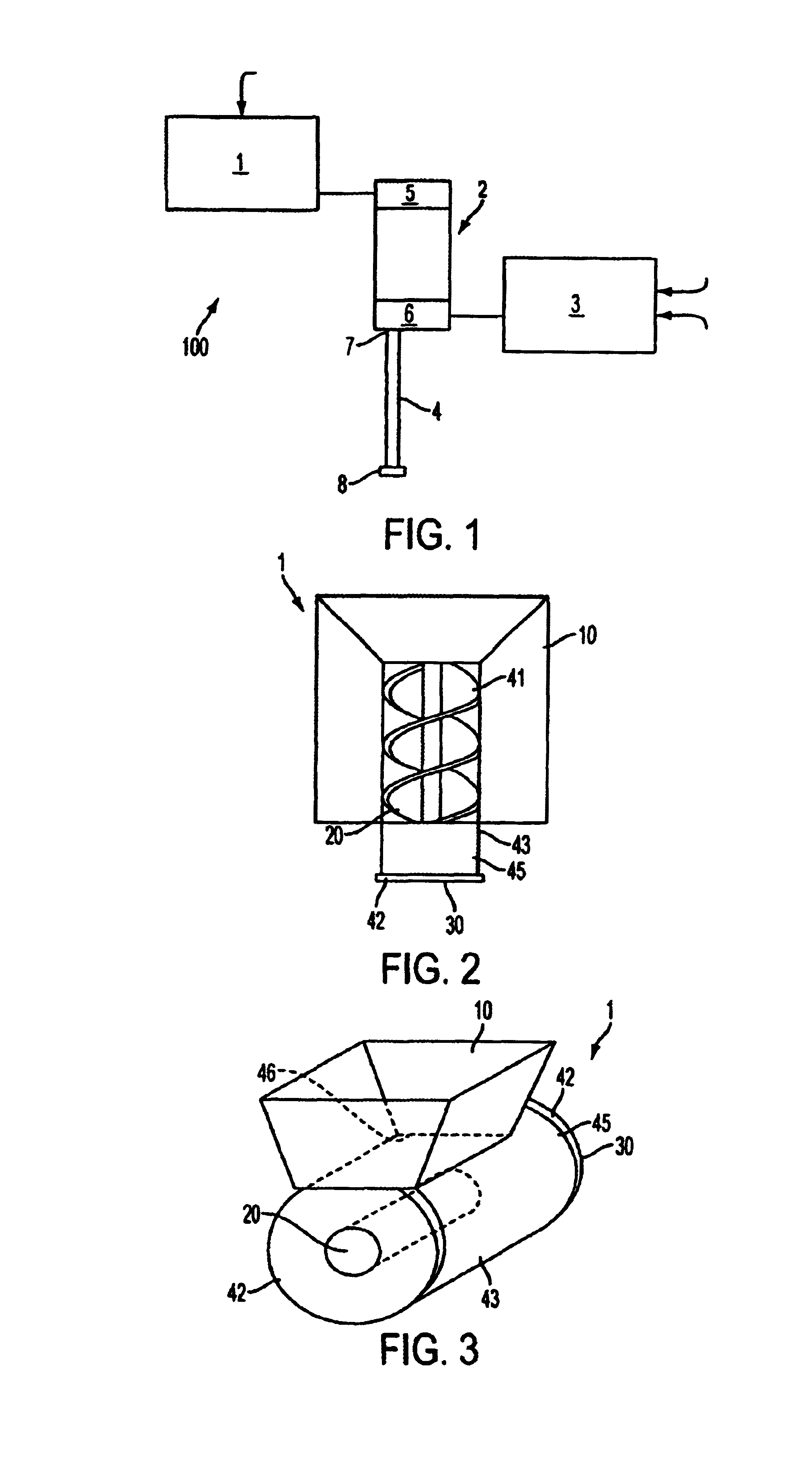

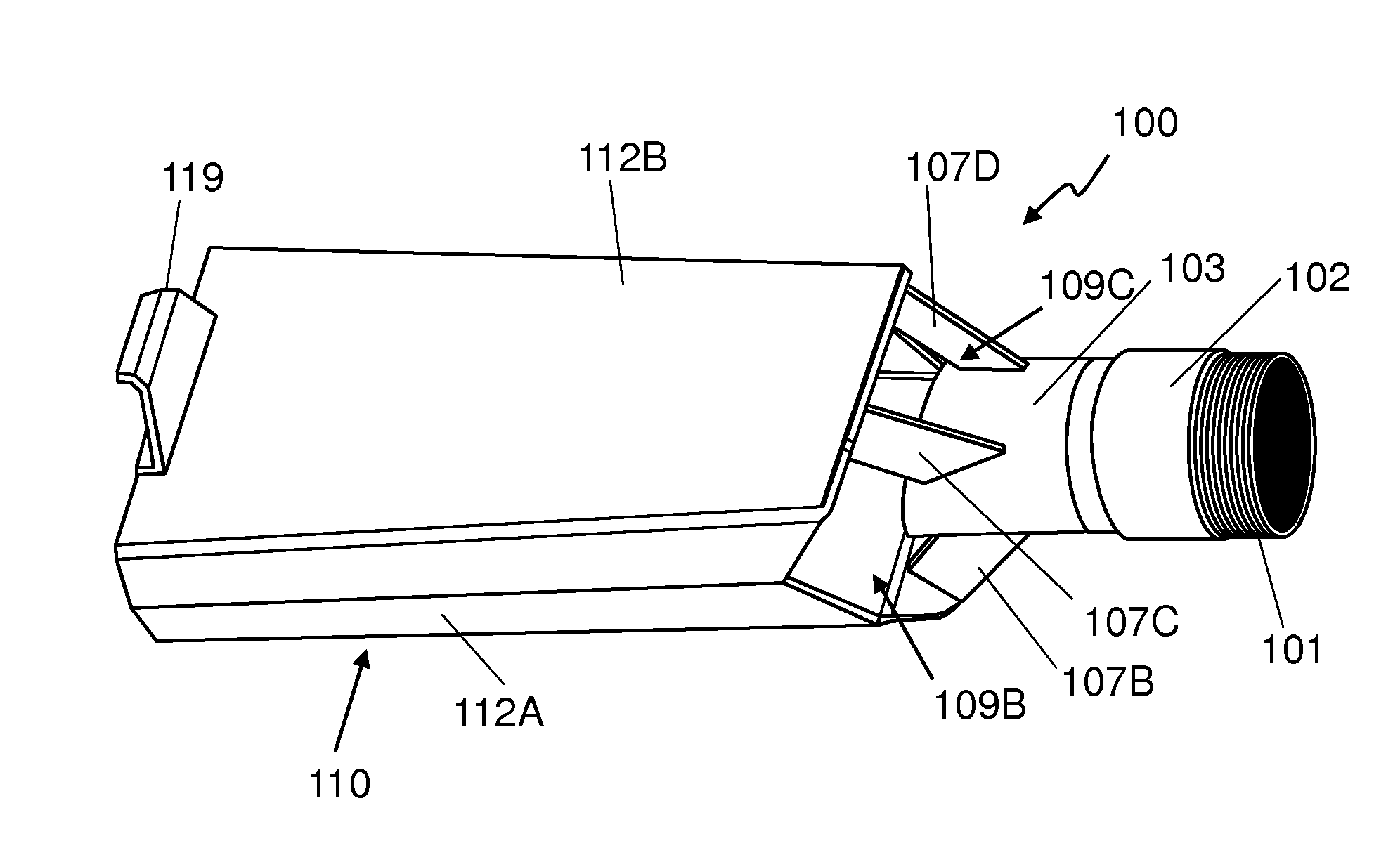

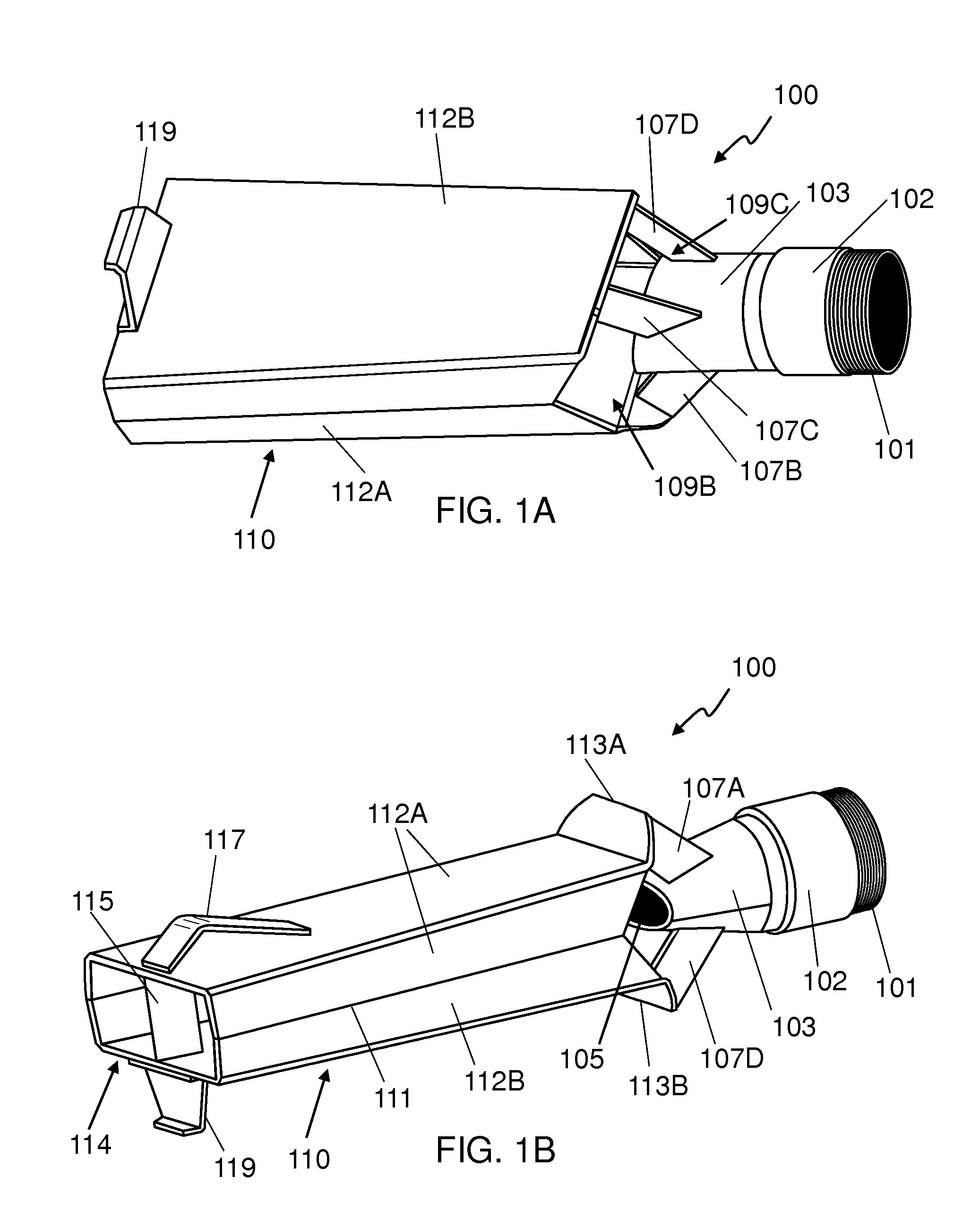

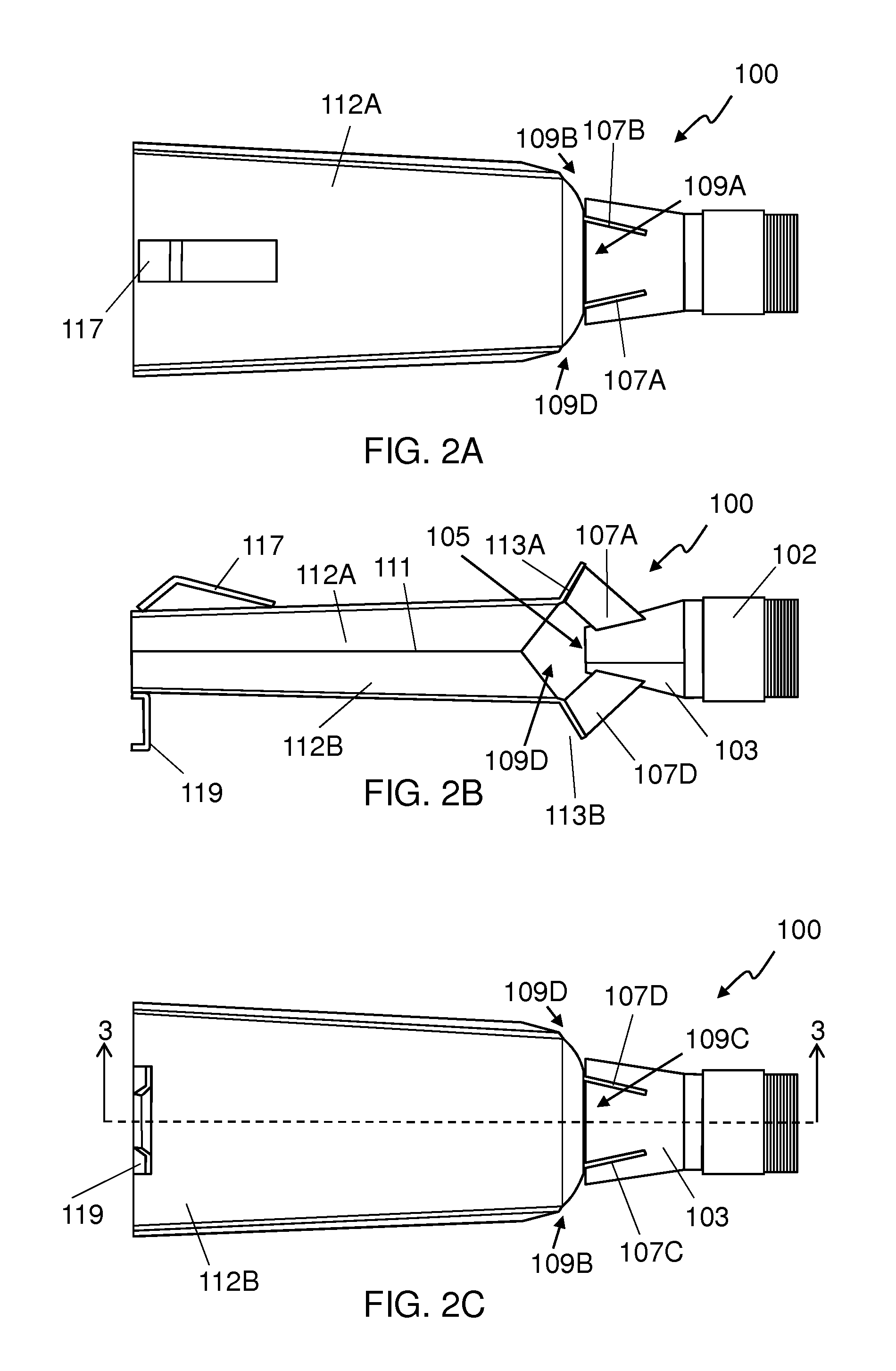

Jet assisted tubeless tire seating device

A nozzle for seating a tubeless tire on a rim using pressurized gas includes an outlet, a jet configured to accept pressurized gas and emit a stream of gas through an orifice into a chamber. As the stream of gas enters the chamber, the Venturi effect causes air to enter the chamber through air intake ports and the stream of gas and air from the air intake ports is blown out of the outlet of the nozzle. A system for seating a tubeless tire on a rim includes the nozzle, a tank and a valve configured to control the flow of pressurized gas from the tank to the nozzle. The tire may be seated on the rim by positioning the system so that the air from the nozzle blows into the tire between the bead of the tire and the rim if the valve is opened.

Owner:GAITHER TOOL COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com