Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about "Wood-rimmed wheels manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

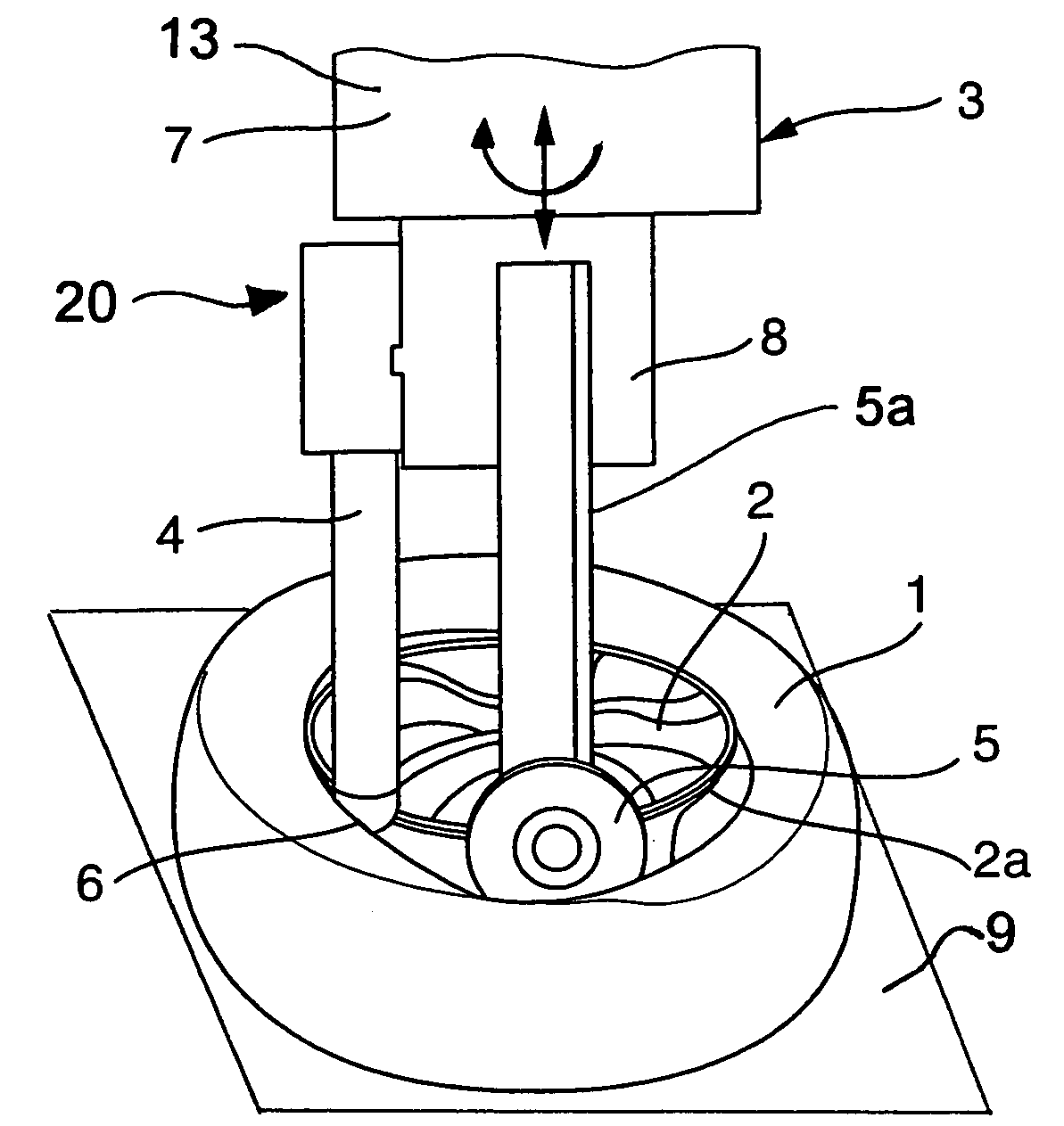

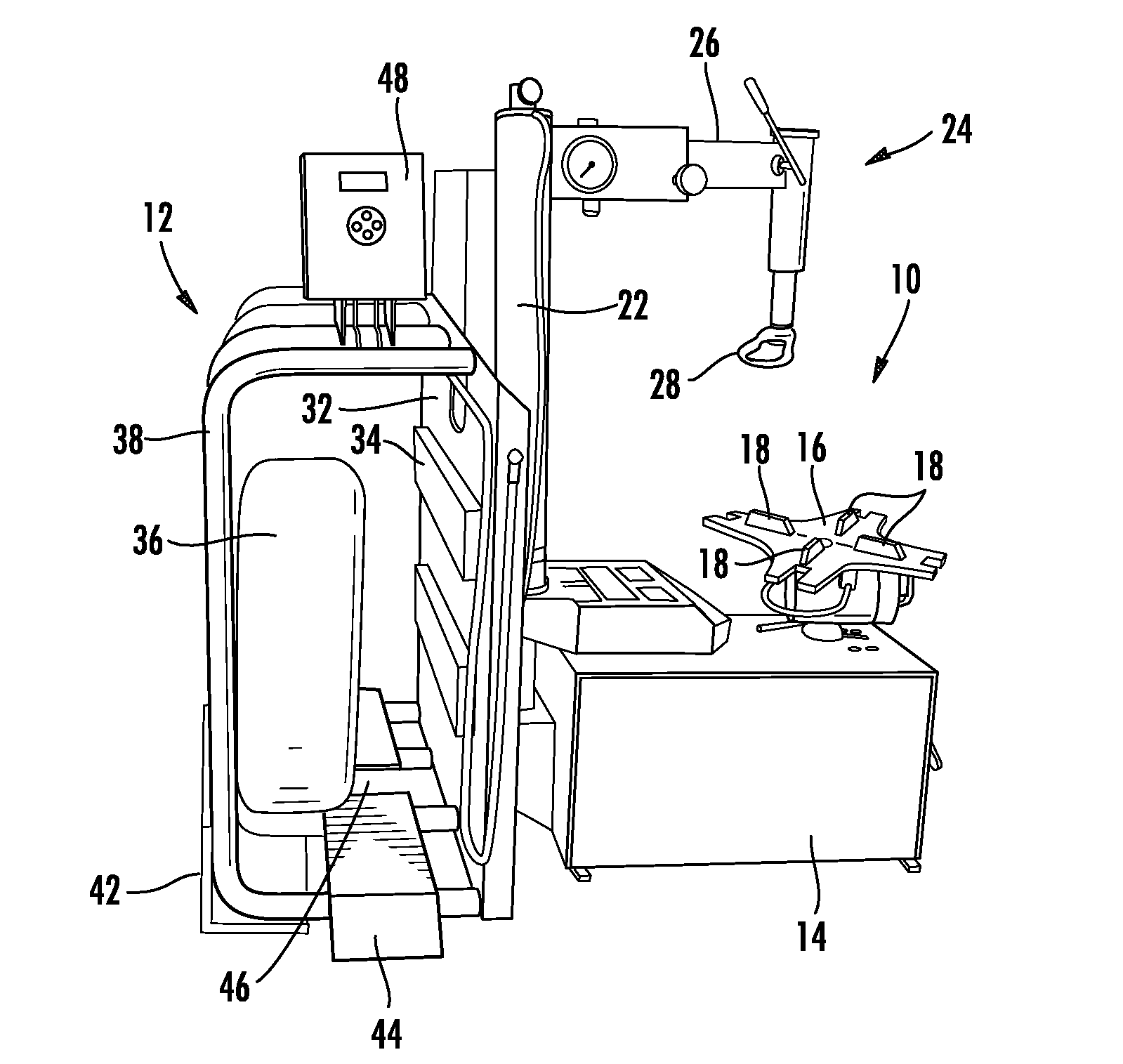

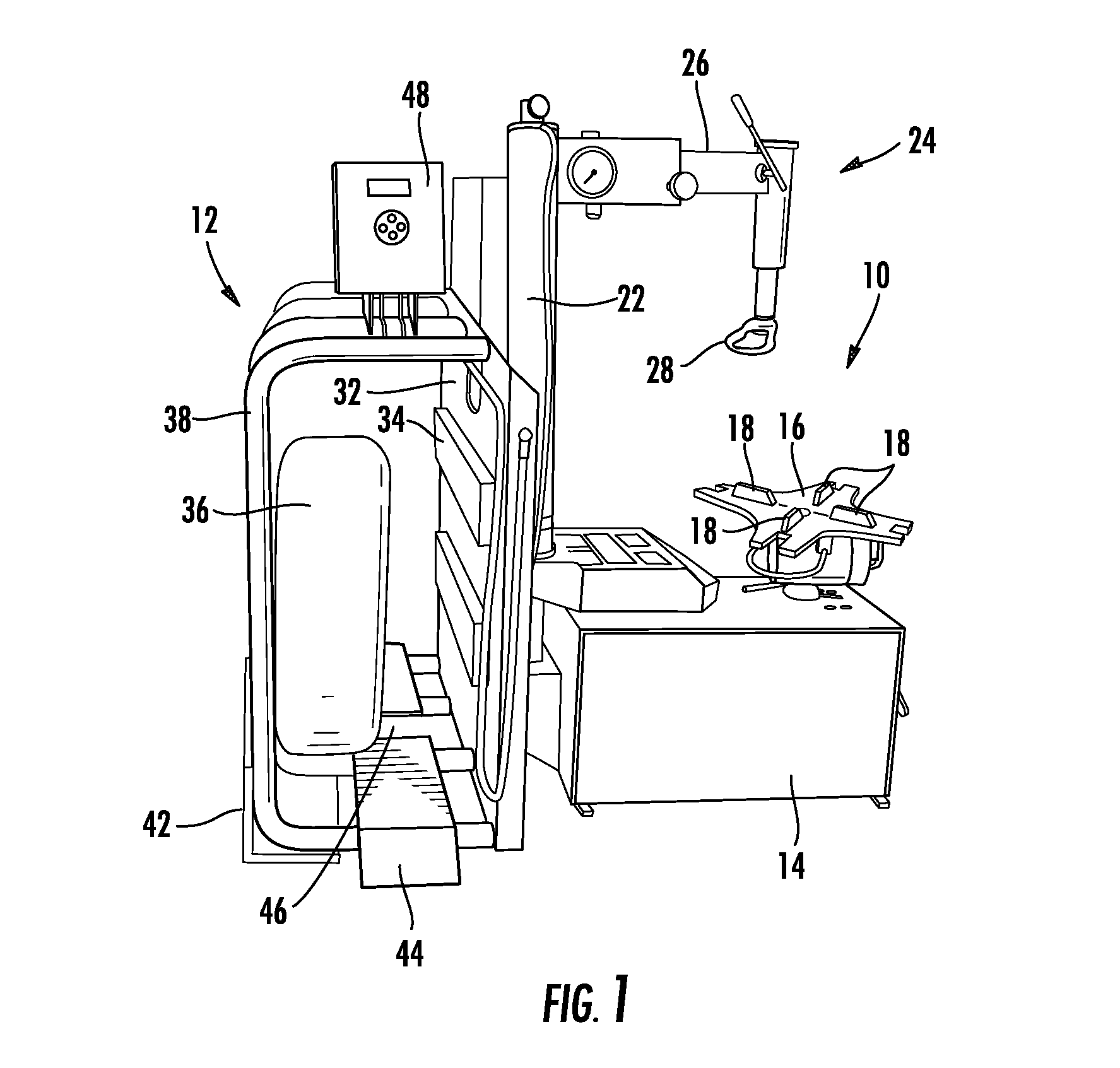

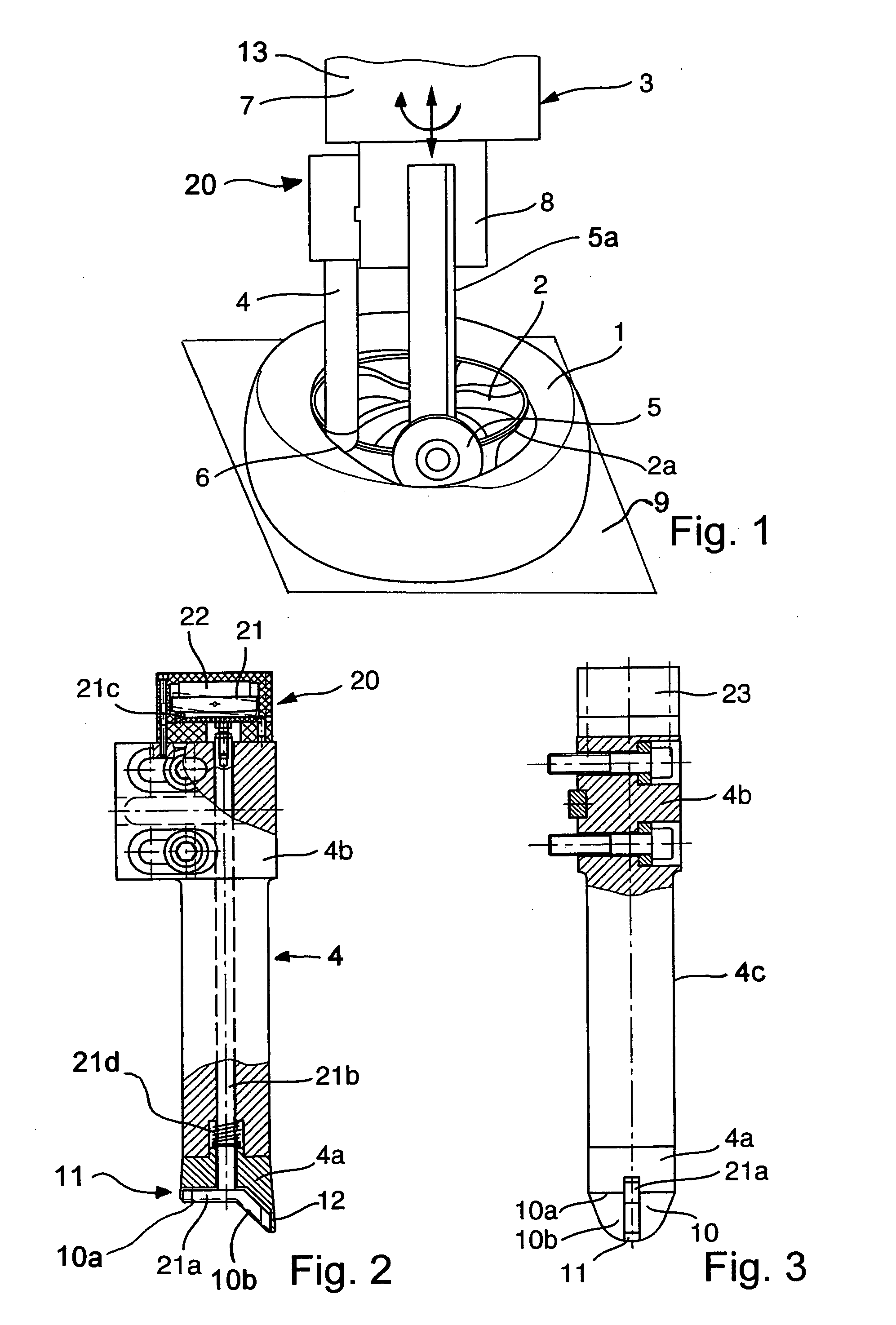

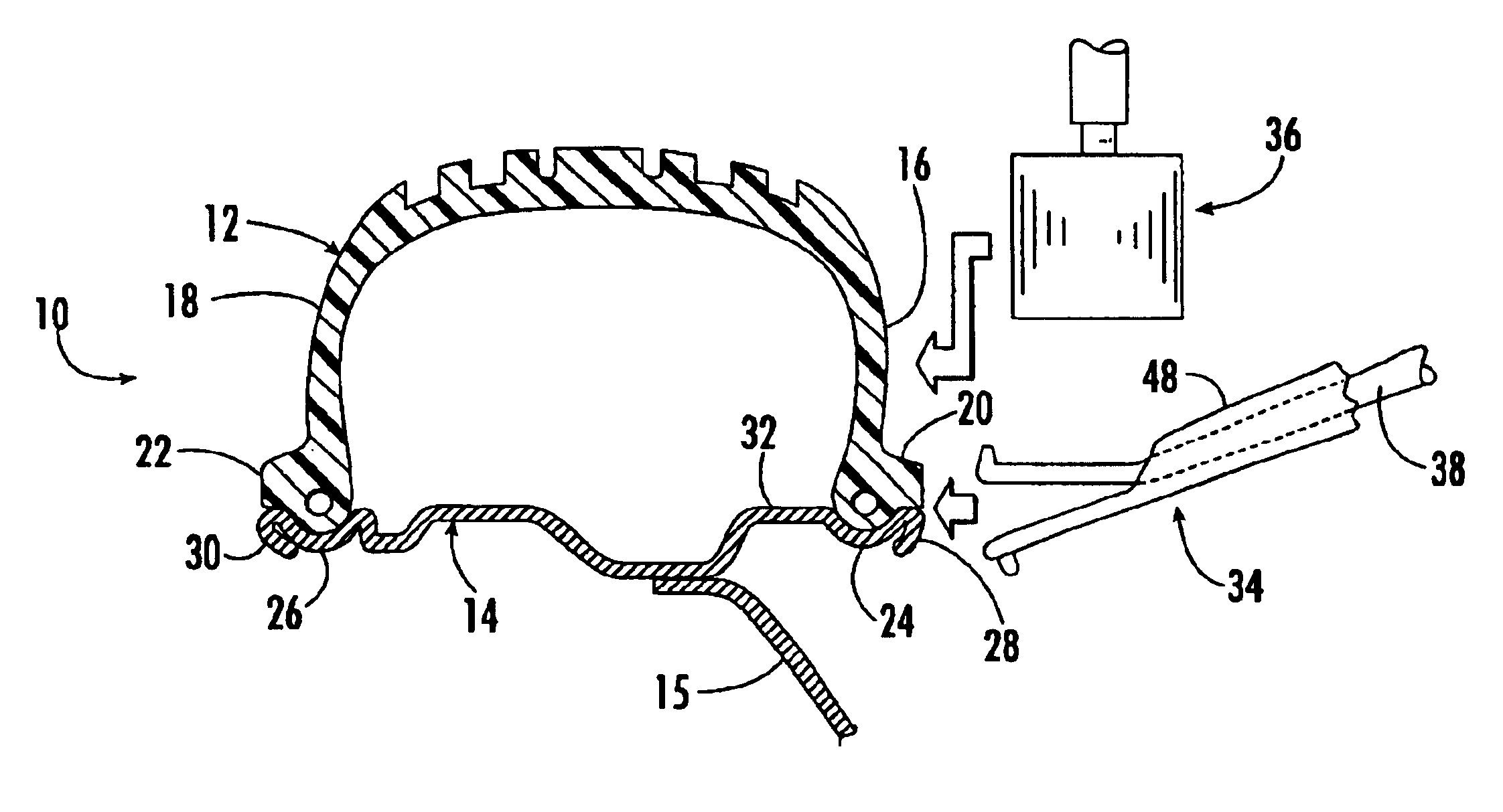

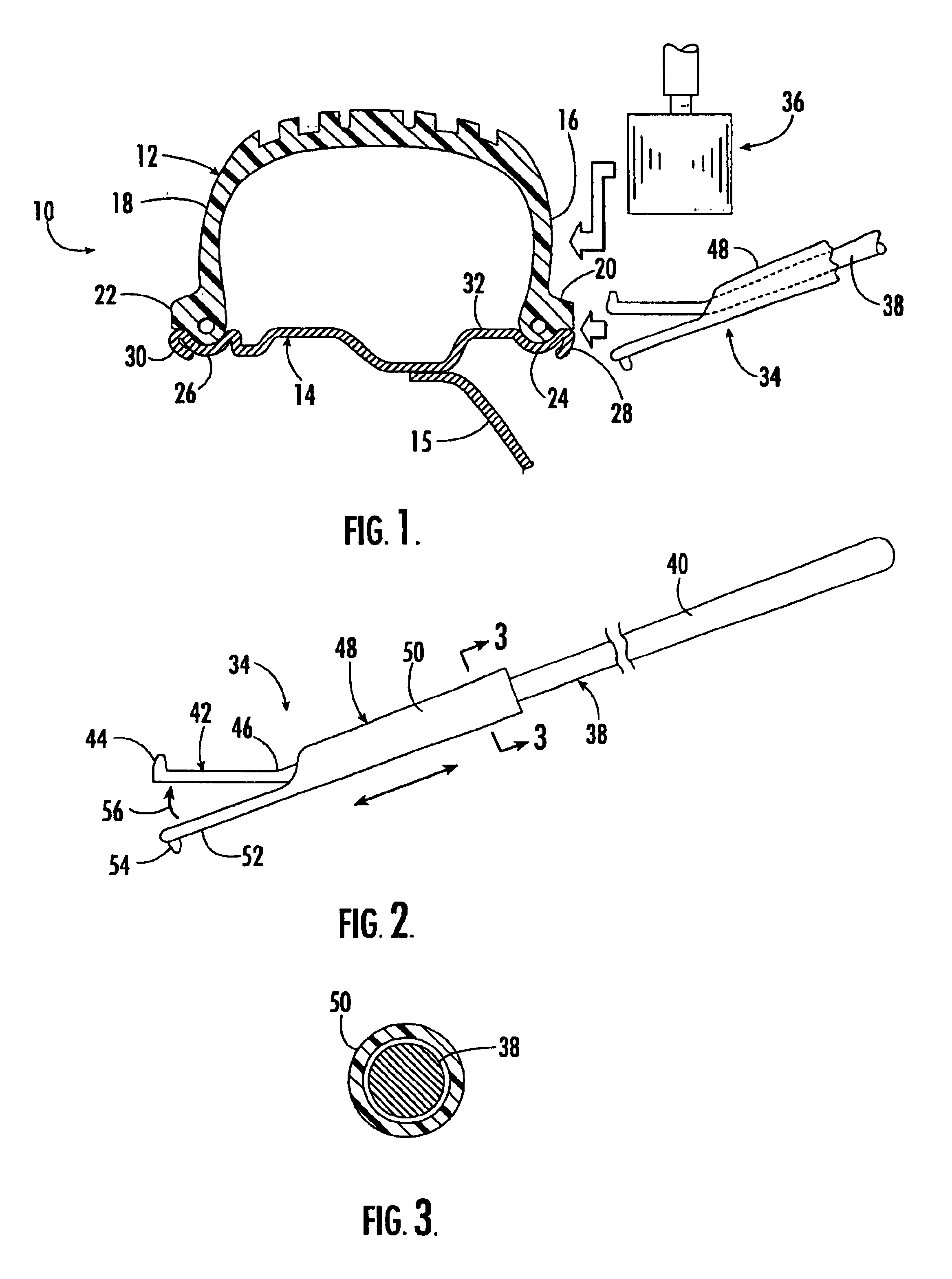

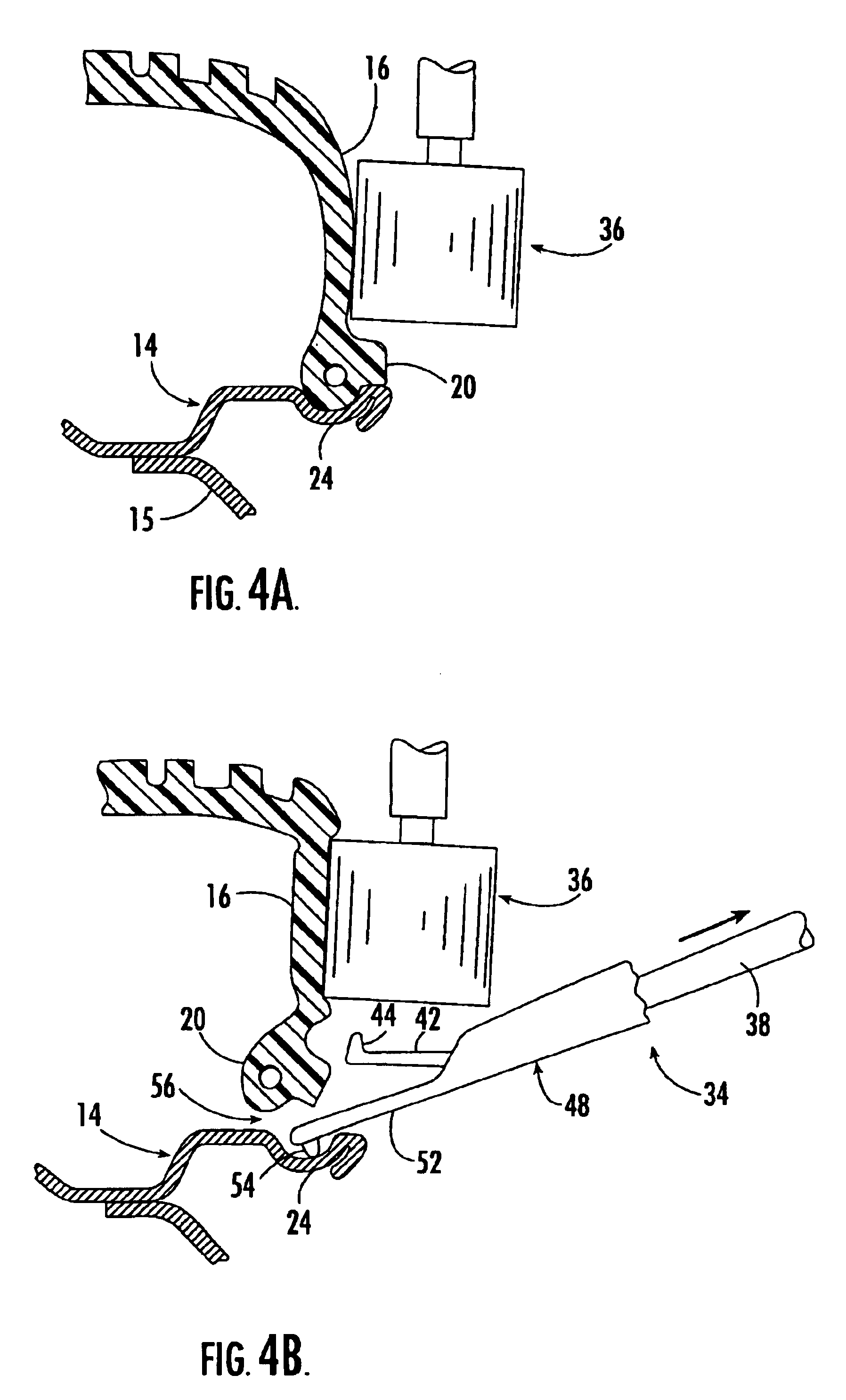

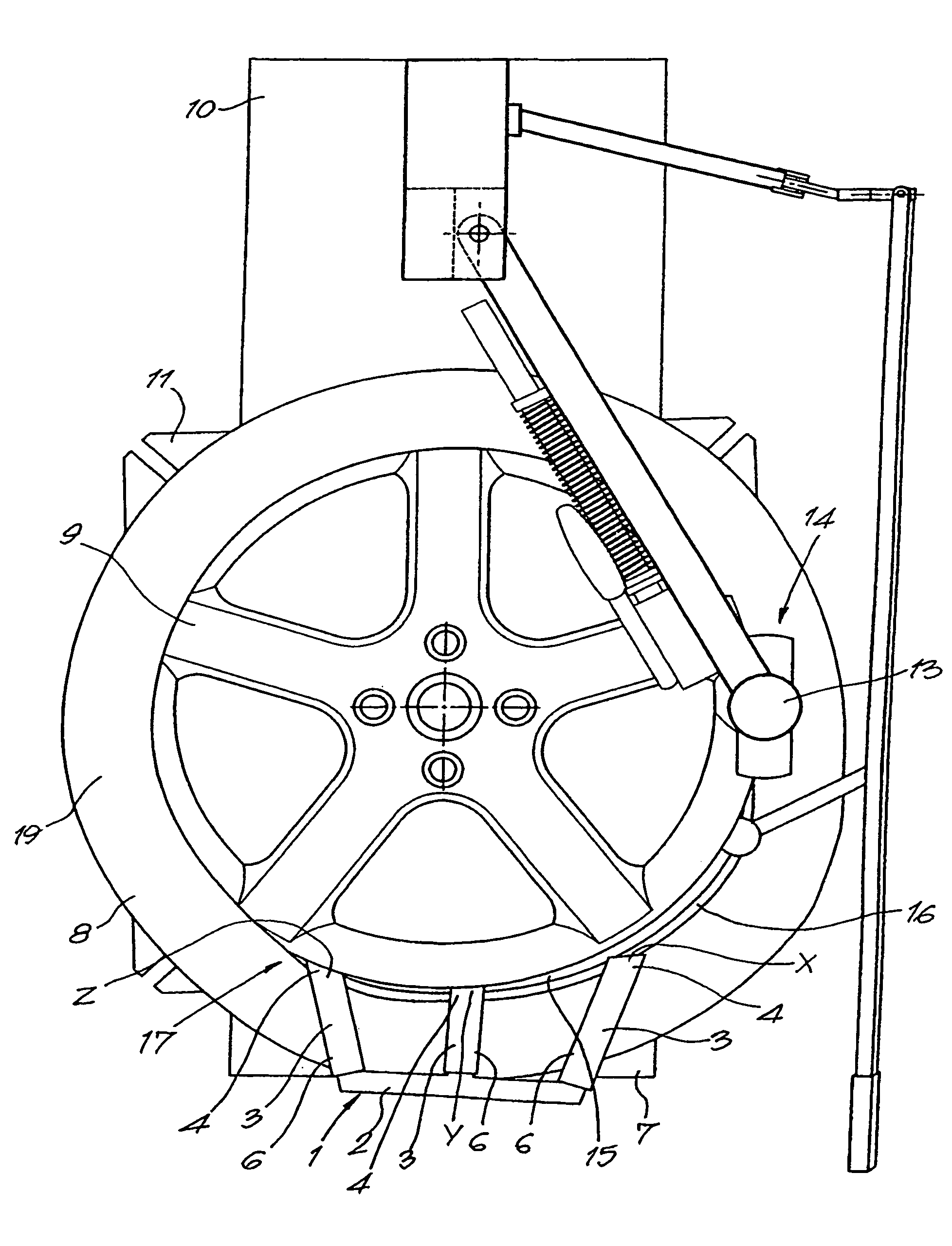

Tire buffing apparatus

InactiveUS7040371B2Consistent texture profileIncrease productionRevolution surface grinding machinesTyresRaspEngineering

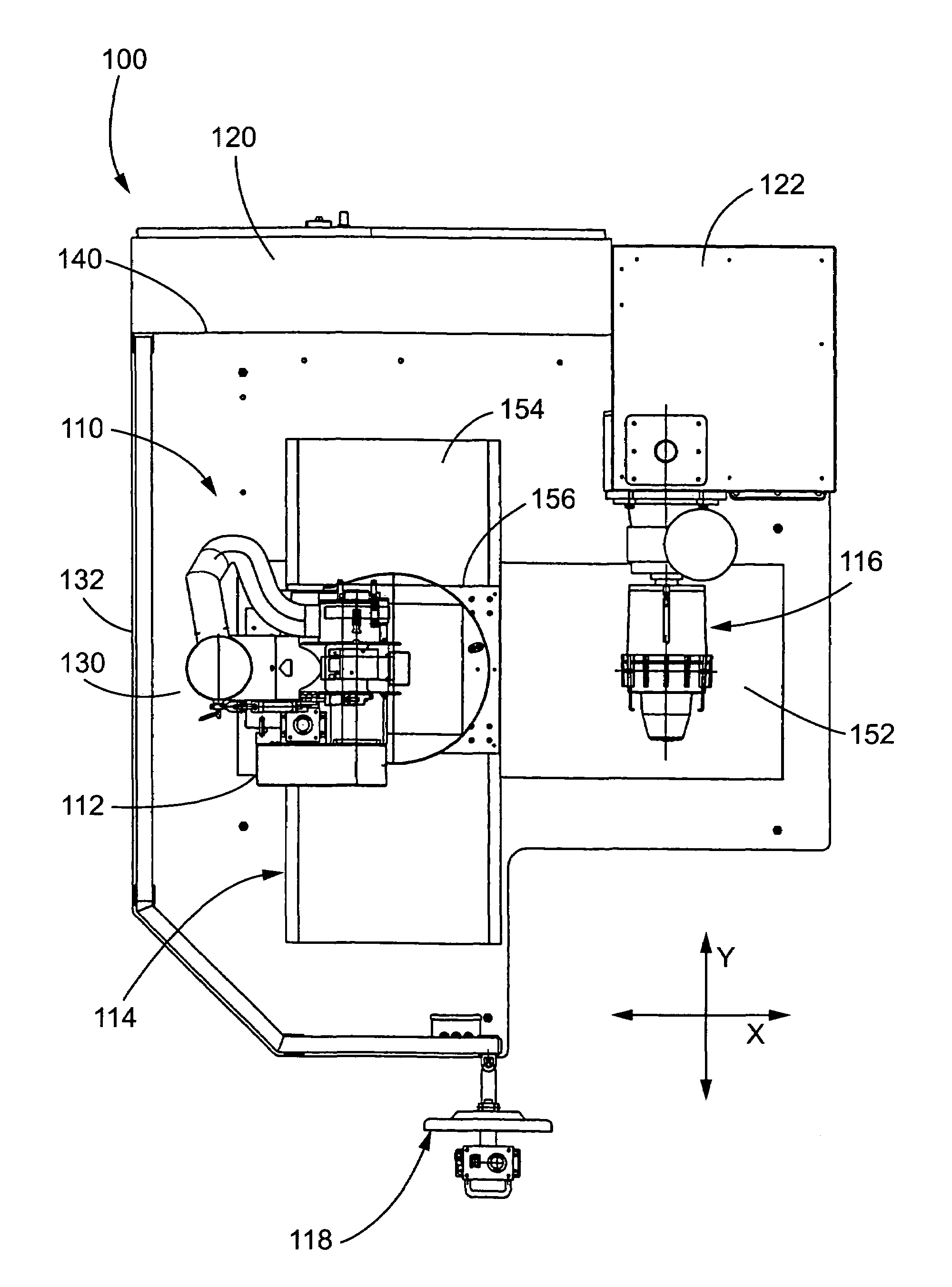

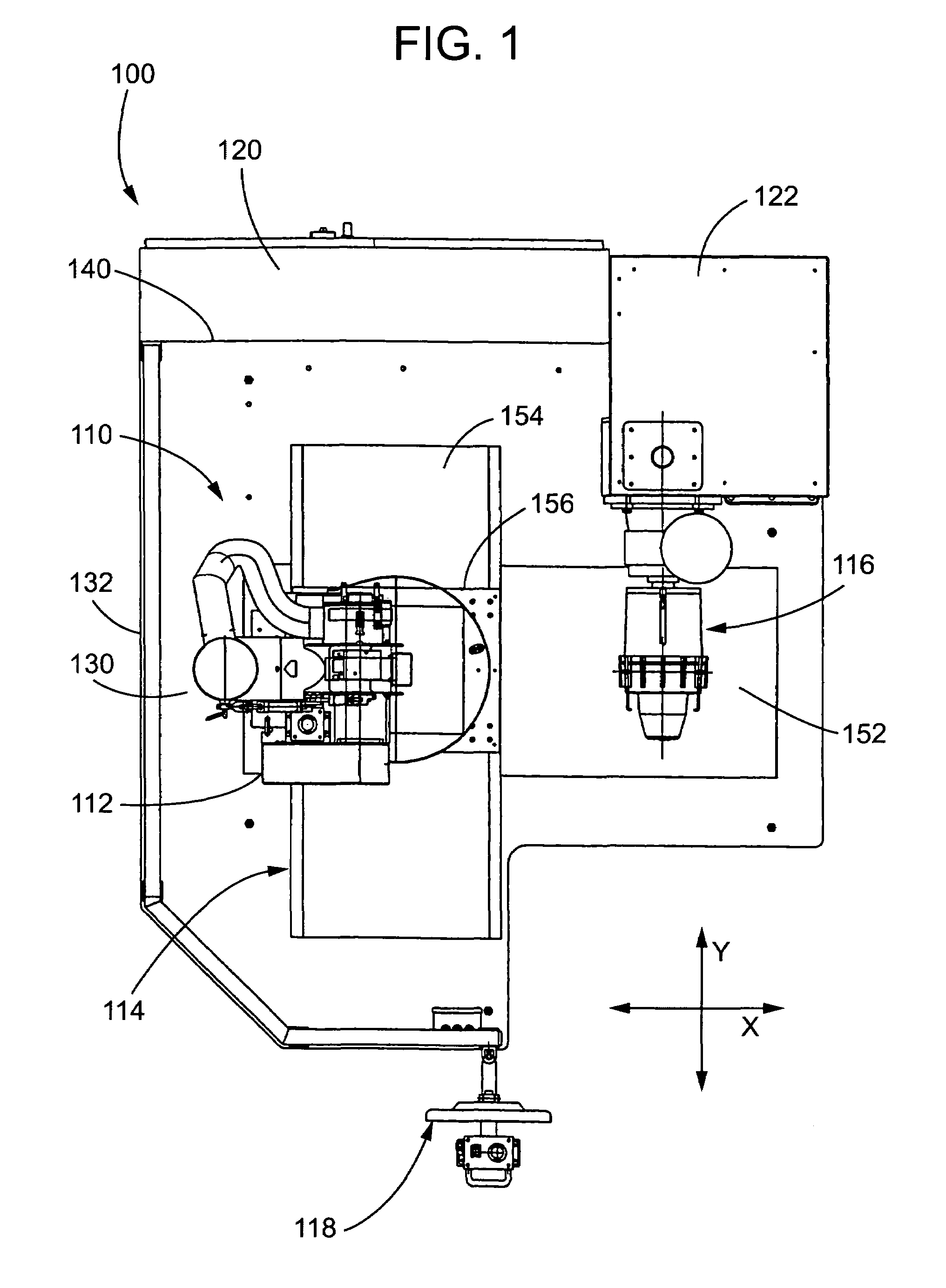

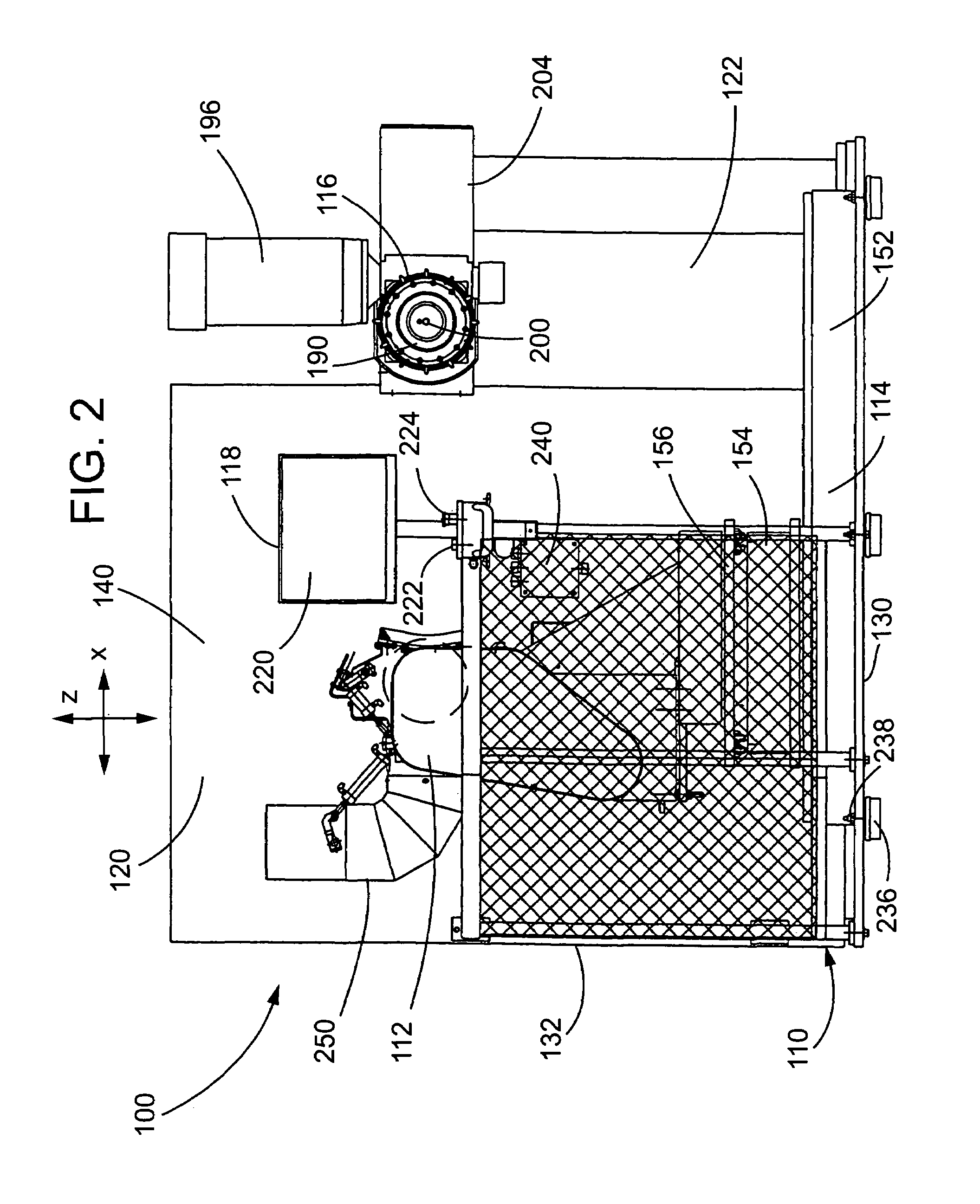

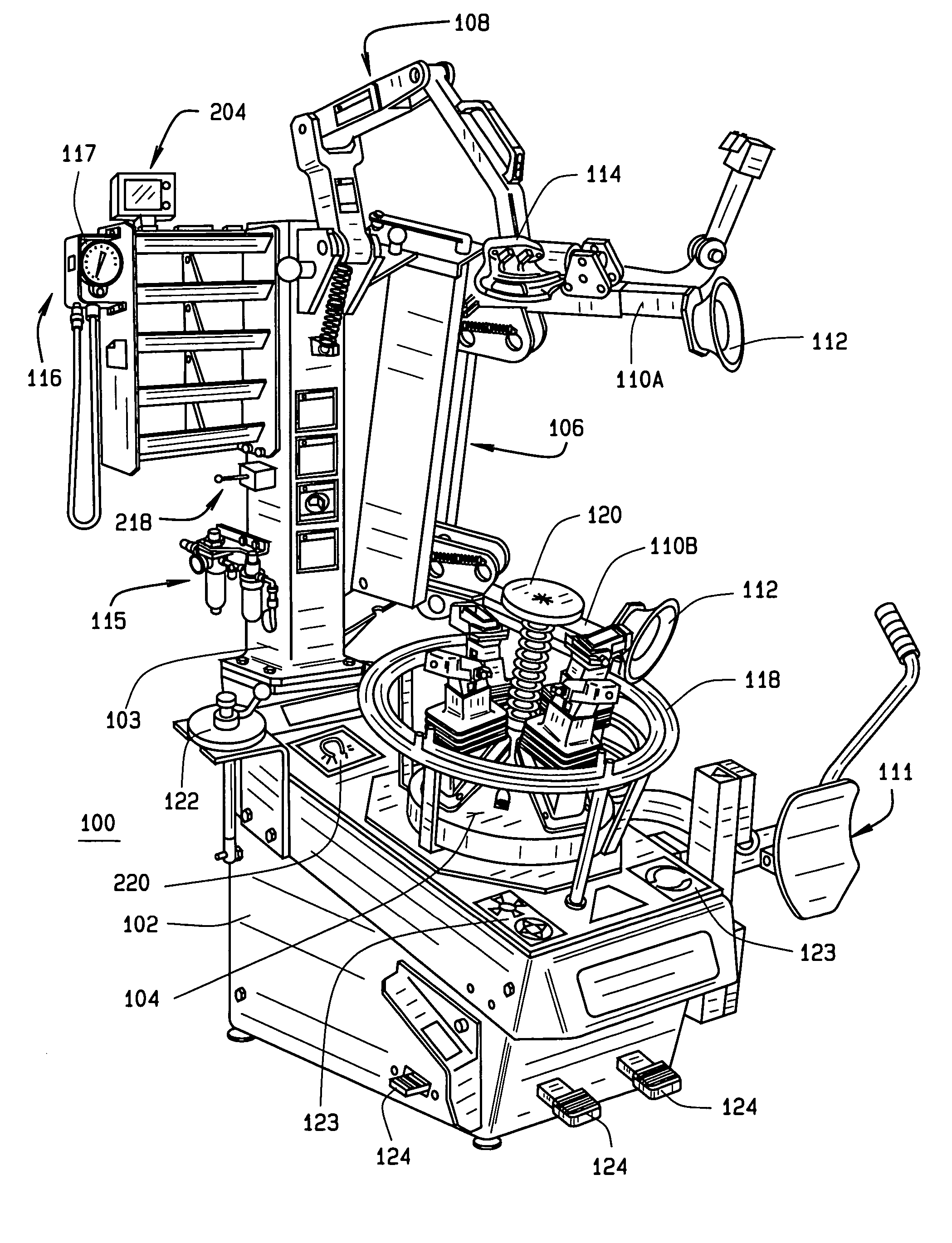

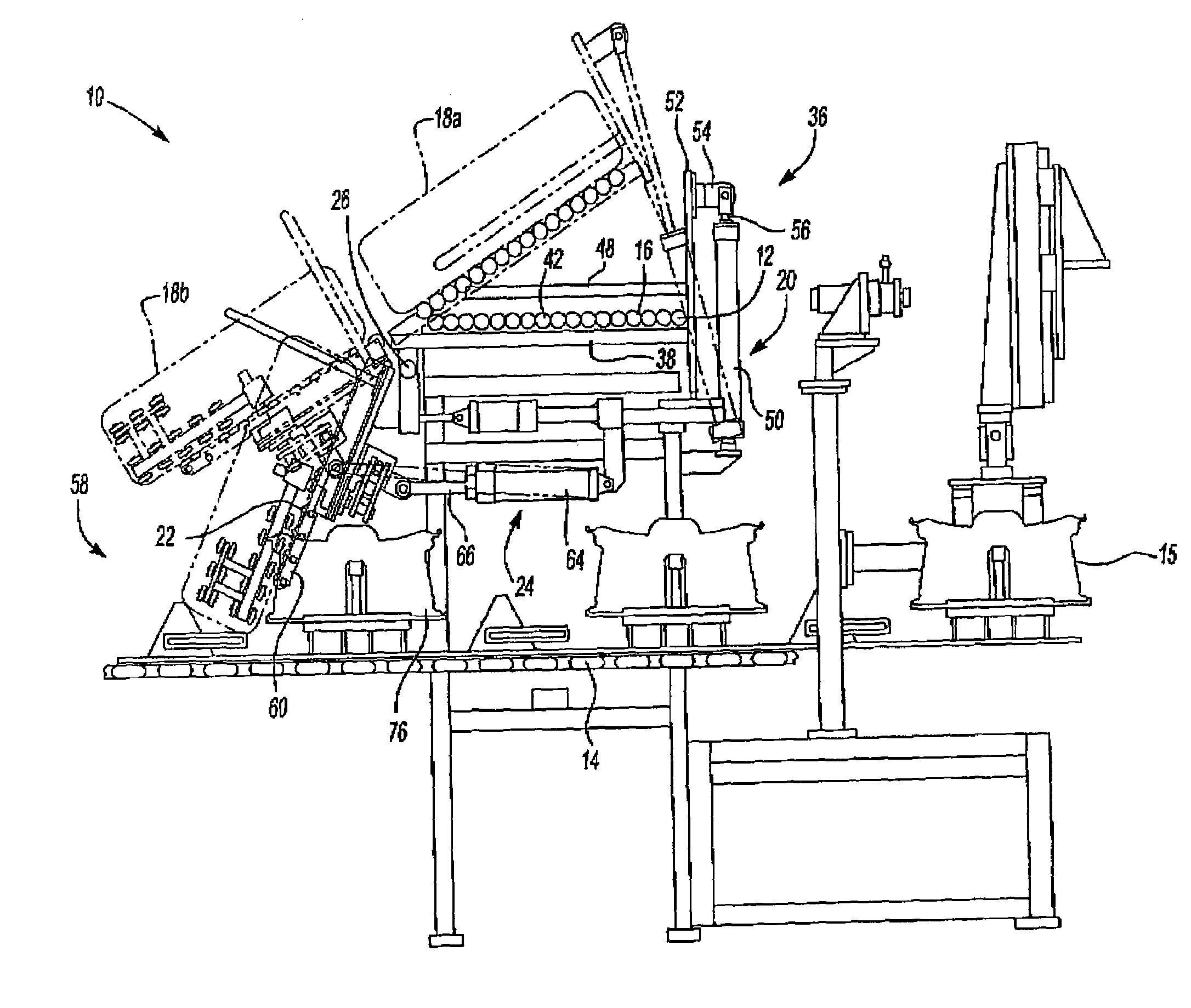

A tire buffer for buffing a tire casing as part of a retread operation can include a rasp pedestal having a rasp head and a texturing device. A moving assembly can be connected to the rasp pedestal for selectively moving the rasp pedestal along a pair of perpendicular axes. The rasp pedestal can rotate about a vertical axis. A tire hub assembly can be included for rotating the tire casing. The tire buffer can be operated at an operator station by interfacing with a control unit. The tire buffer can automatically buff a tire casing to achieve a predetermined tire casing profile and impart a texture thereto. The tire buffer includes a tire location mechanism and a tire measurement mechanism mounted to the rasp pedestal. The control unit can monitor an operating parameter of the rasp pedestal or the tire hub assembly during the buffing sequence, compare the actual value of the operating parameter to a predetermined target value of the parameter, and adjust an operating characteristic of the rasp pedestal, the tire hub assembly, or both such that the actual value of the operating parameter is urged toward the calculated target value of the operating parameter.

Owner:BANDAG INC

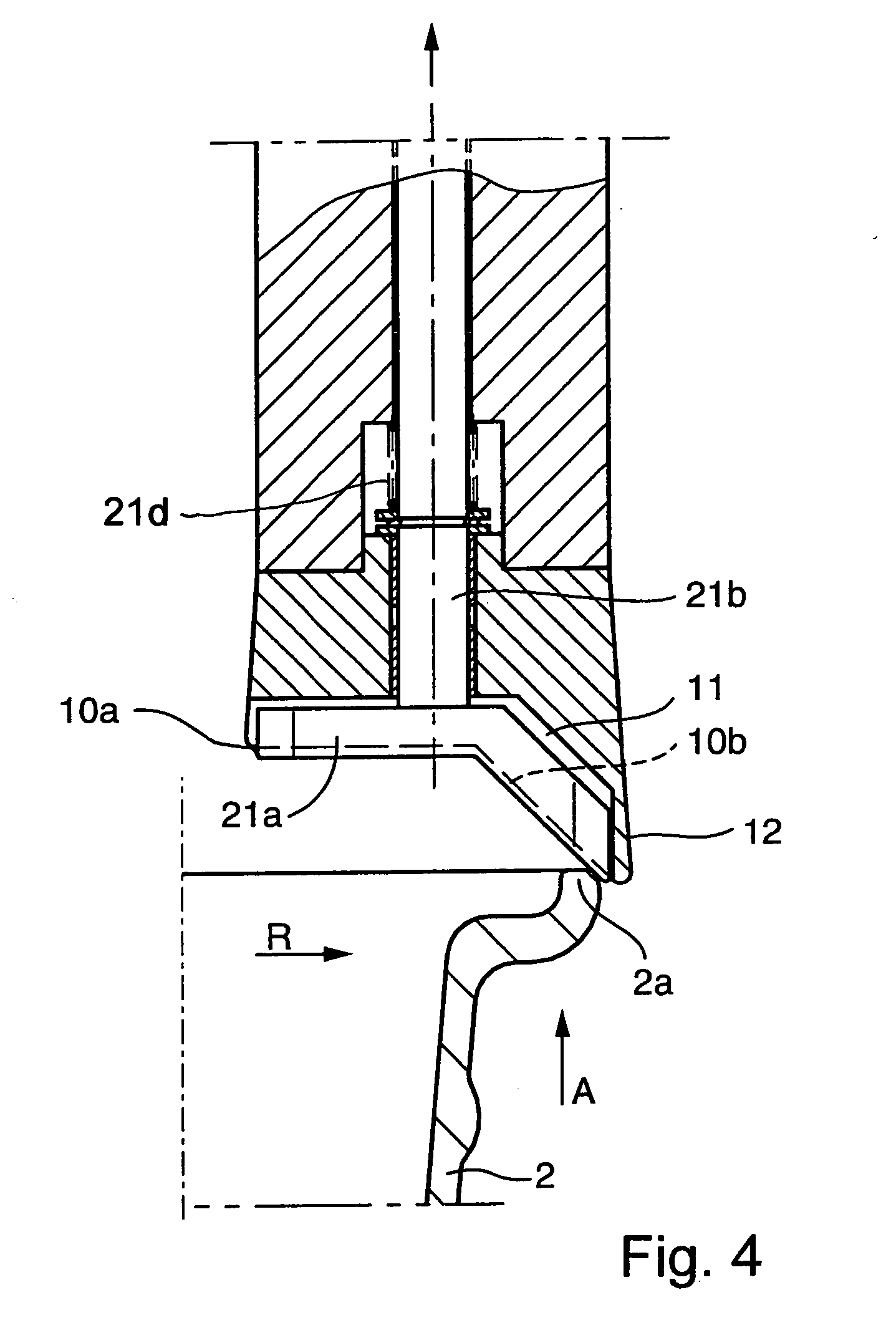

Tire filing method and apparatus adaptable to different sizes of tires

InactiveUS6467524B2Check valvesPackaging under special atmospheric conditionsEngineeringMechanical engineering

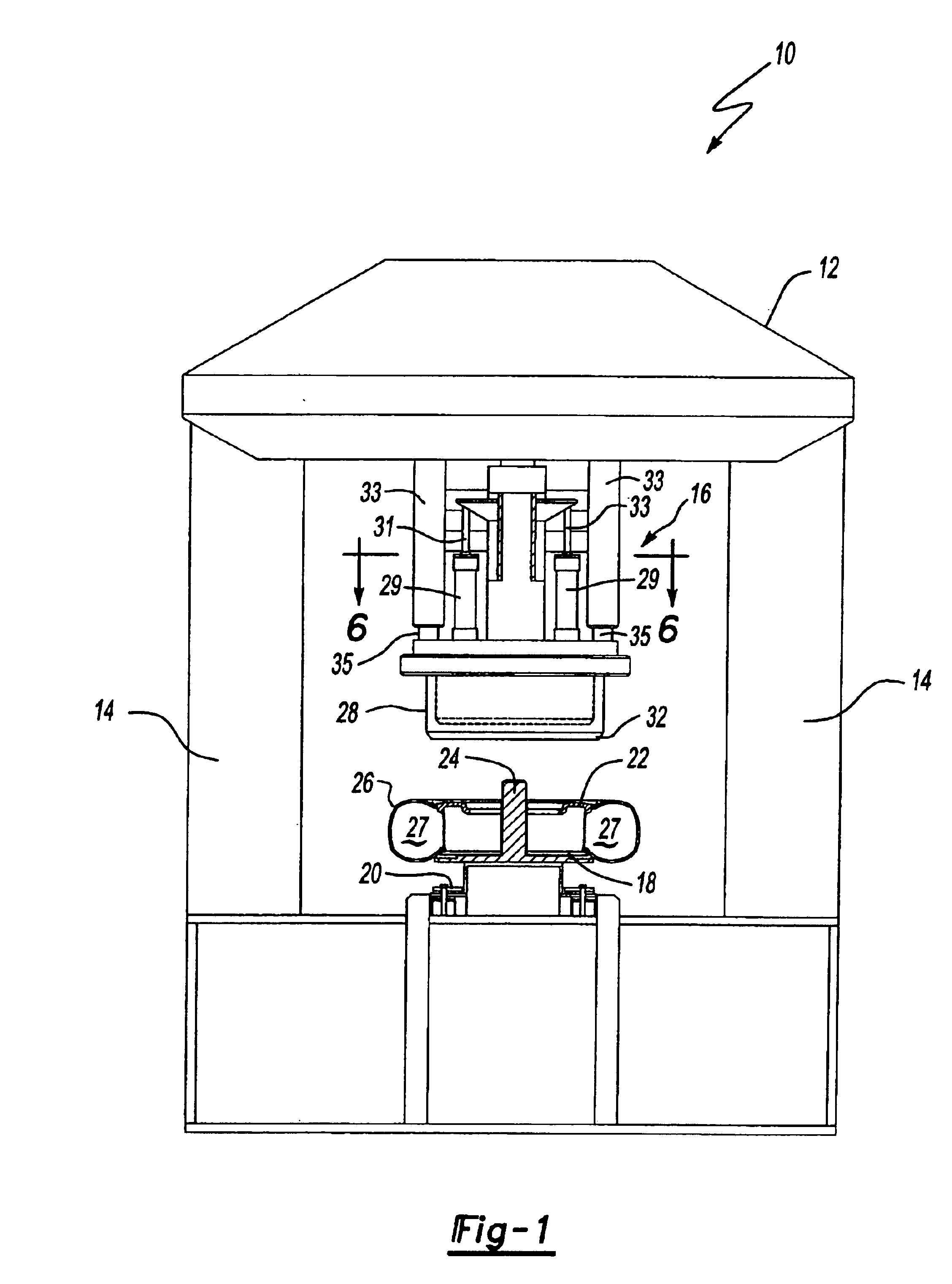

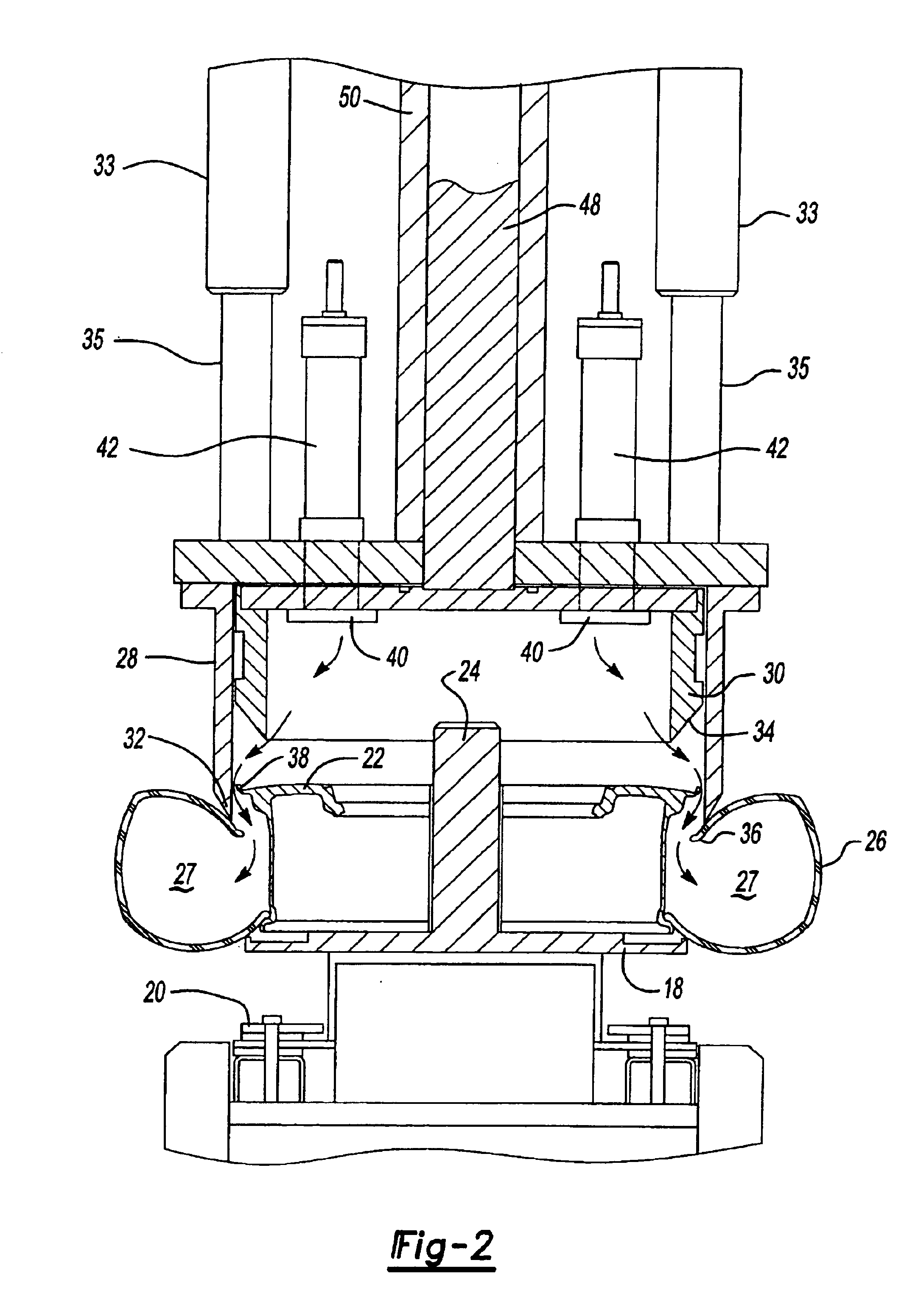

A pneumatic tire filling station includes a support and seal arrangement on which one side wall of the tire is supported and sealed, and a tire filling bell that presses and seals against the opposite side wall of the tire and then supplies pressurized air into the tire. The filling bell includes outer and inner rings that are concentrically slidable relative to each other. One of the rings is selected for the filling operation depending on the size of the tire. The support and seal arrangement includes plural plate members that are joined and sealed together to form a continuous support and seal surface, or moved laterally apart to allow a transport apparatus to carry and support the mounted tire from underneath. The tire filling station is adaptable to different models and sizes of mounted tires even in a mixed process flow, in an automated manner.

Owner:SCHENCK ROTEC GMBH

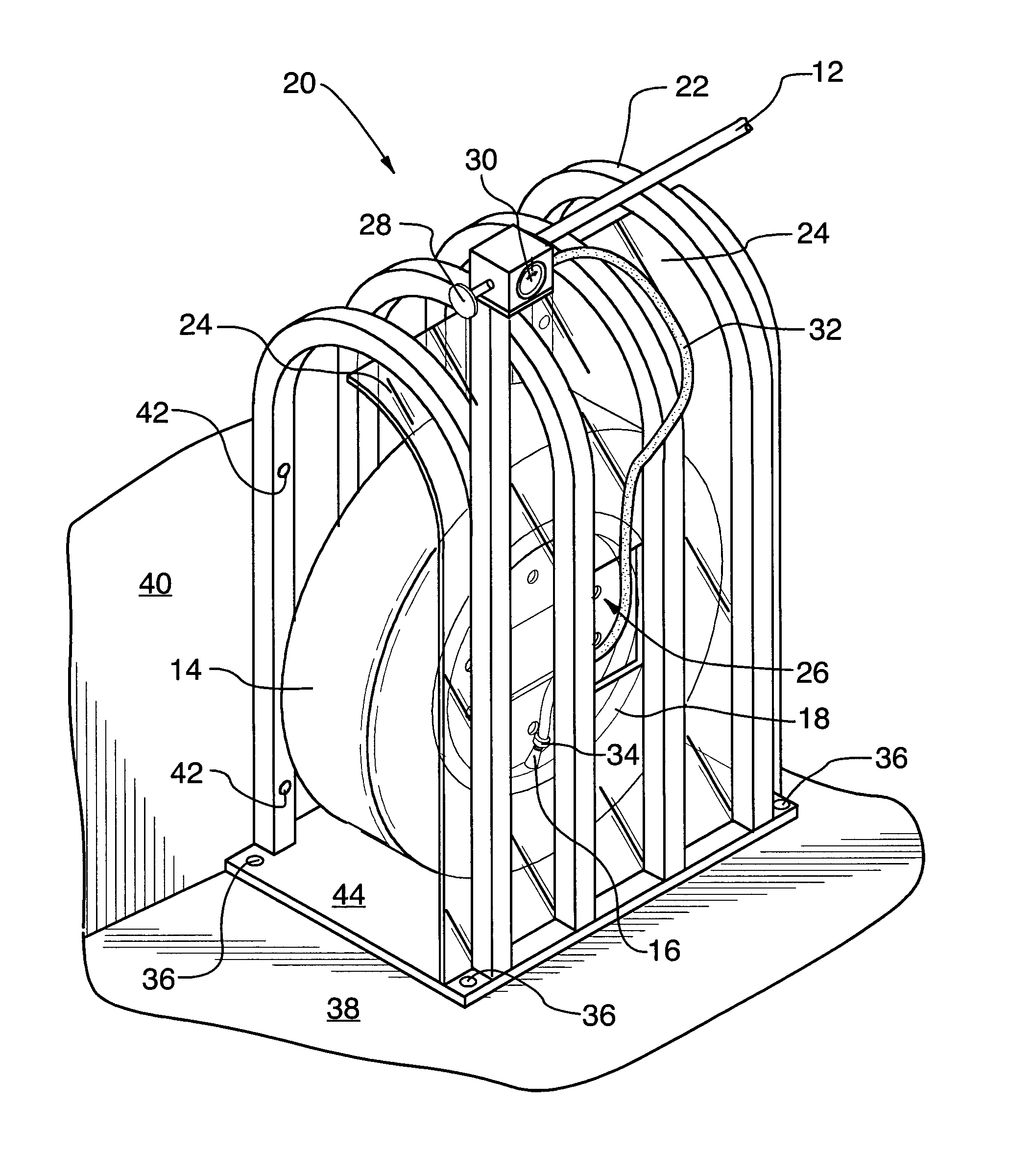

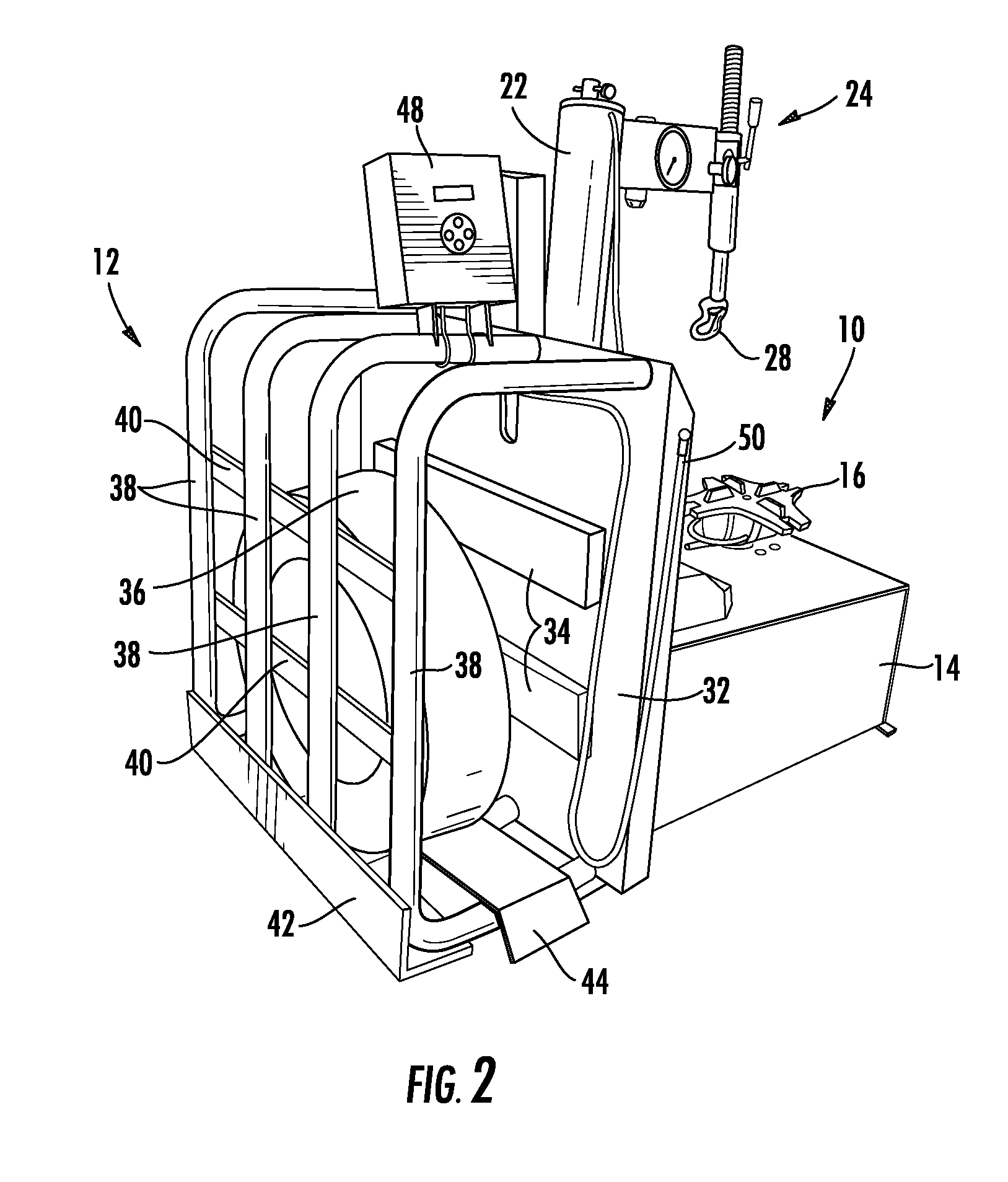

Protective tire shield

InactiveUS20050082013A1Improve securityAvoid injurySpecial tyresVehicle servicing/repairingVehicle frameEngineering

The apparatus which protects from an explosive air blast when inflating a wheel comprises: a frame having a front side, a back side, a top side and an end portion for entry of the wheel into the cage; a transparent shield positioned on an interior front side of the frame to allow for convenient inspection of the wheel after the wheel is inflated, and to prevent the explosive air blast from passing through the front side of the cage to the technician; and, a central opening through the shield to allow the technician to access the valve on the wheel. The apparatus can be adapted to be anchored to a supporting structure so that in the event of an explosion the cage will remain stationary. A method of inflating a tire on a comprises the steps of: a) providing a tire safety cage as above; b) rolling the wheel to be inflated into the cage; c) accessing the valve on the wheel with an air hose through the central opening in the shield and inflating the tire to required air pressure; d) observing the pressurized wheel in the cage through the shield for a period of time to ensure that the tire will safely hold air; and finally, e) rolling the wheel out of the cage.

Owner:WHITE JOEL M

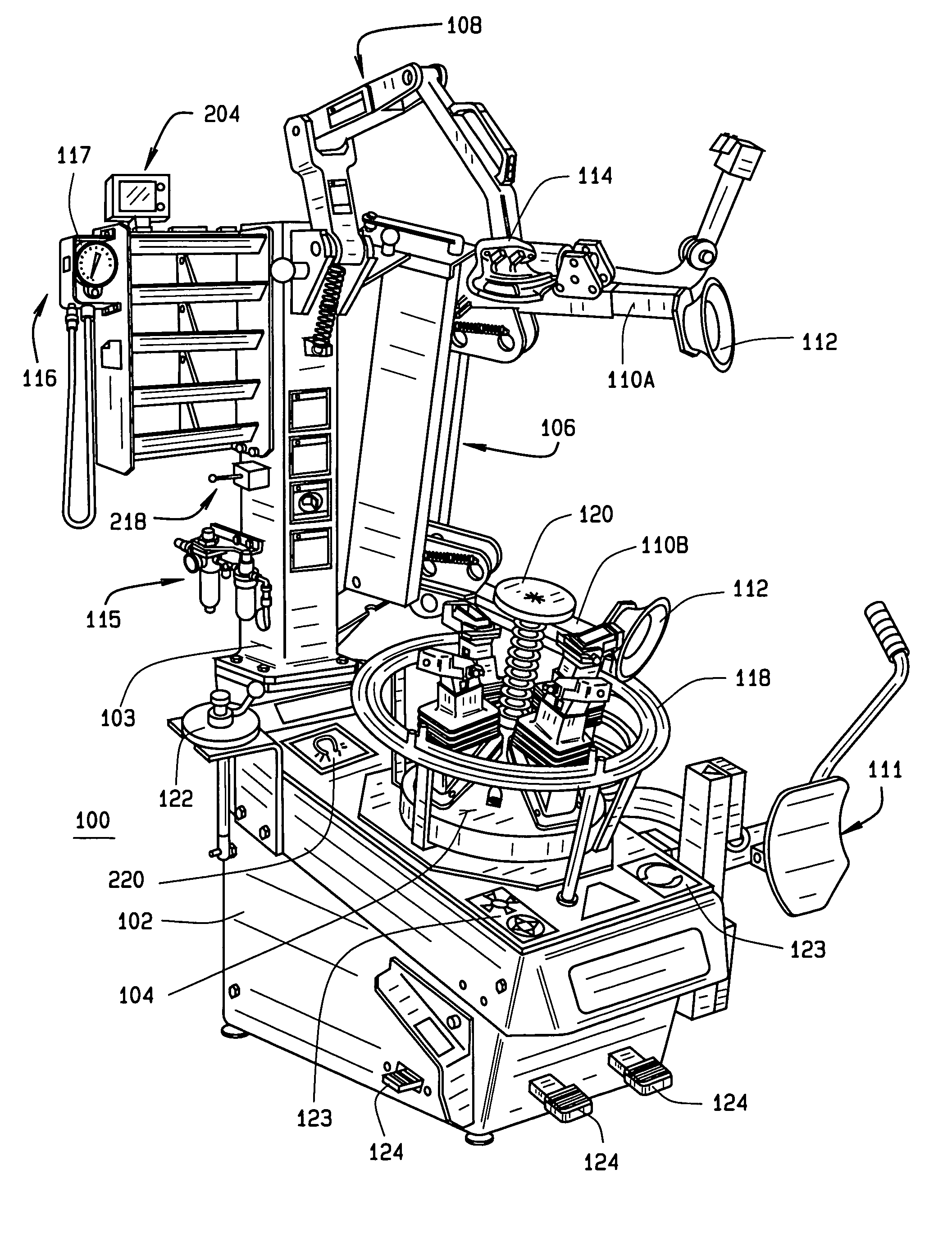

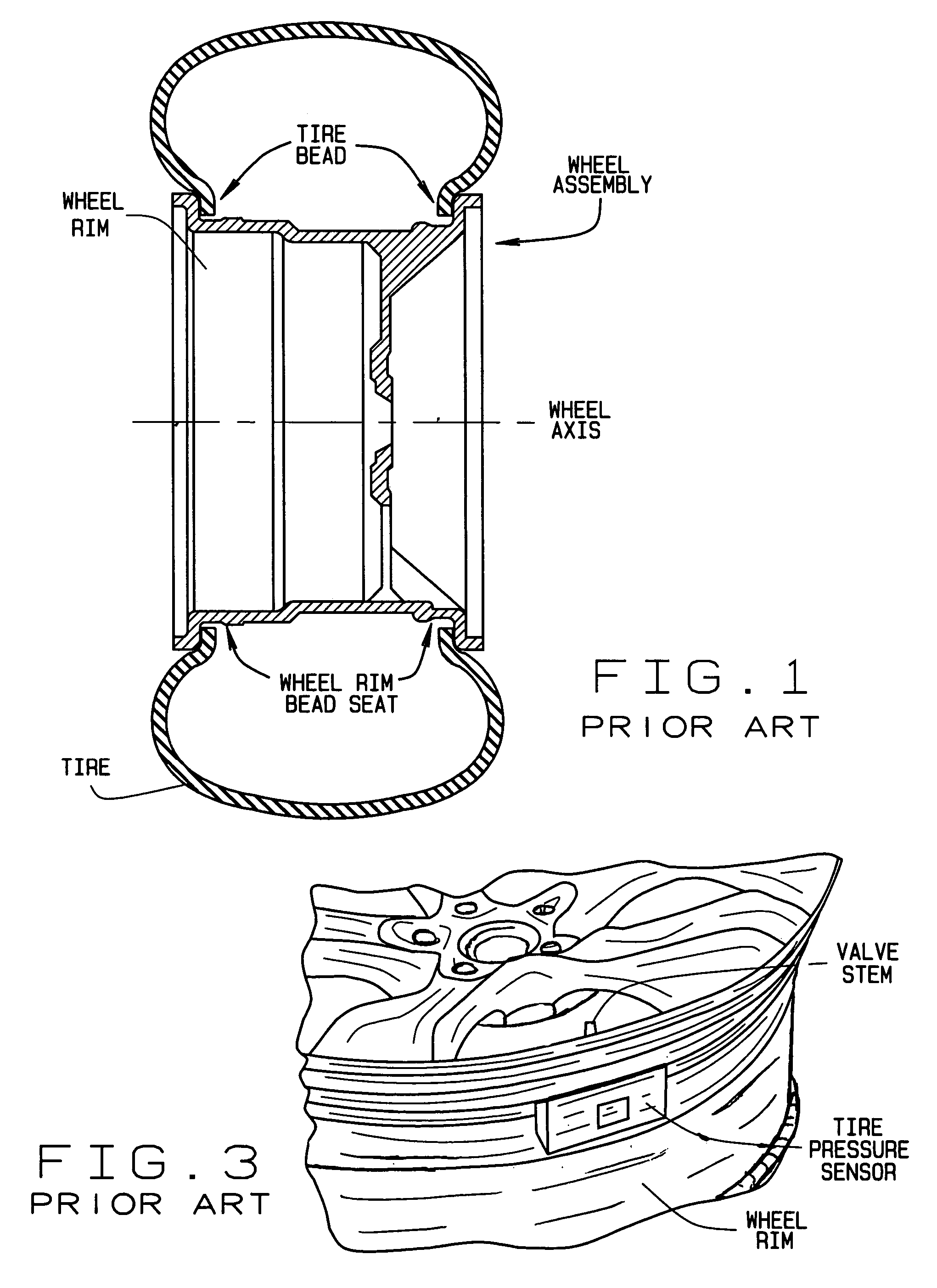

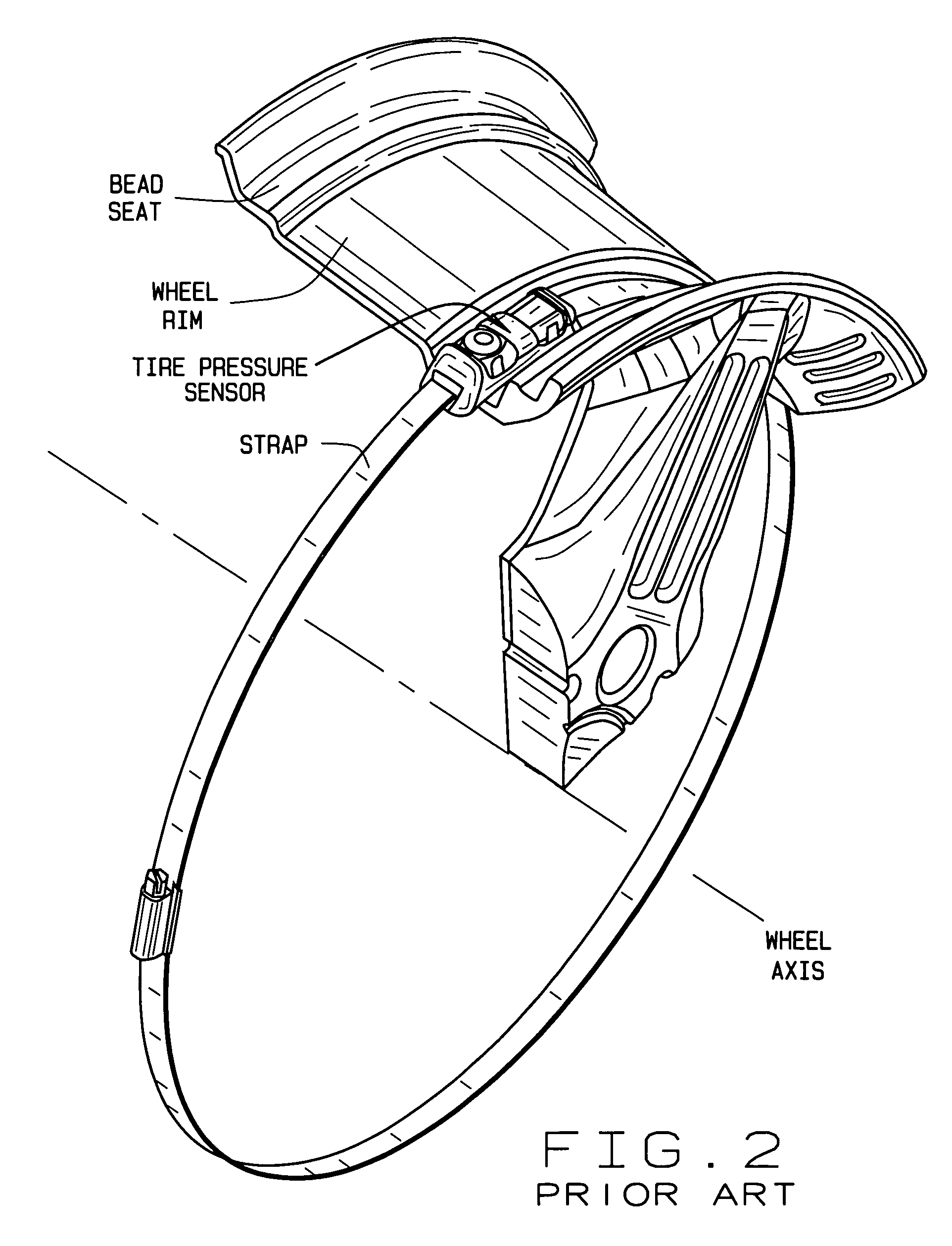

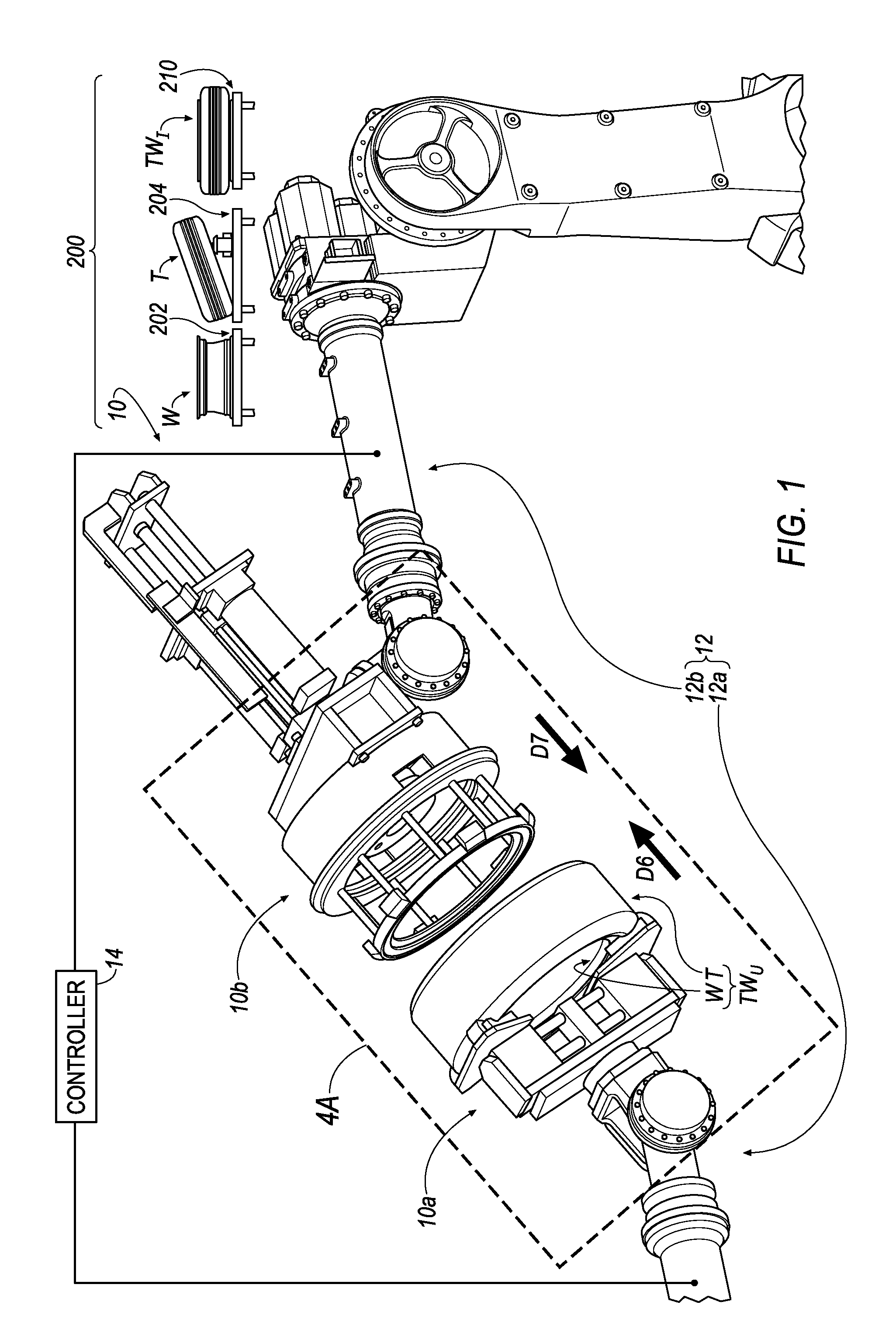

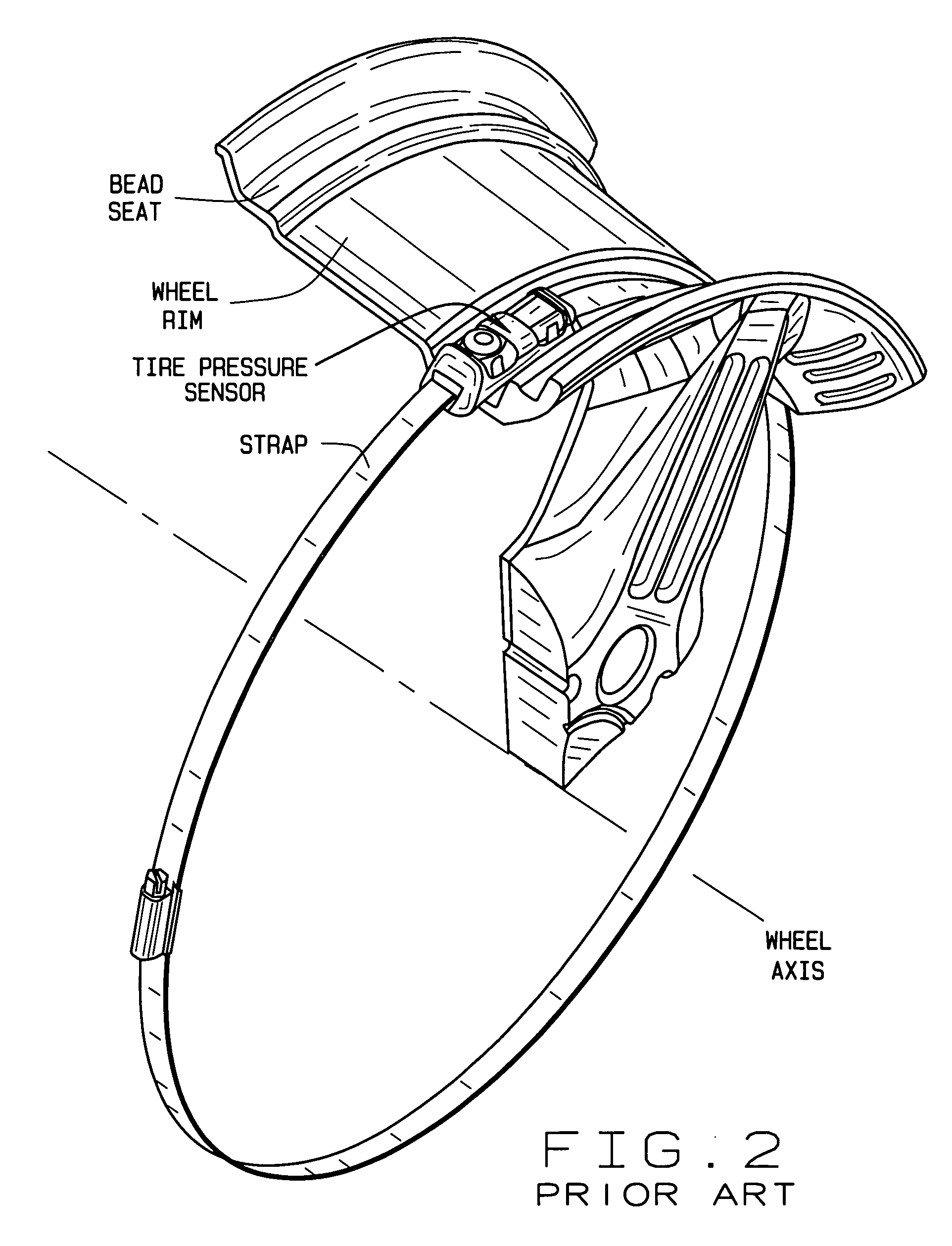

Vehicle tire changer with integrated detector for tire pressure sensors

An improved vehicle wheel tire changing system having a tire mount / dismount head coupled to an articulating tire mount / dismount arm assembly and a tire pressure sensor system which is configured to detect the presence of a tire pressure monitoring system sensor, mounted within a vehicle wheel assembly, prior to altering the mounting of a tire on an associated wheel rim.

Owner:HUNTER ENG

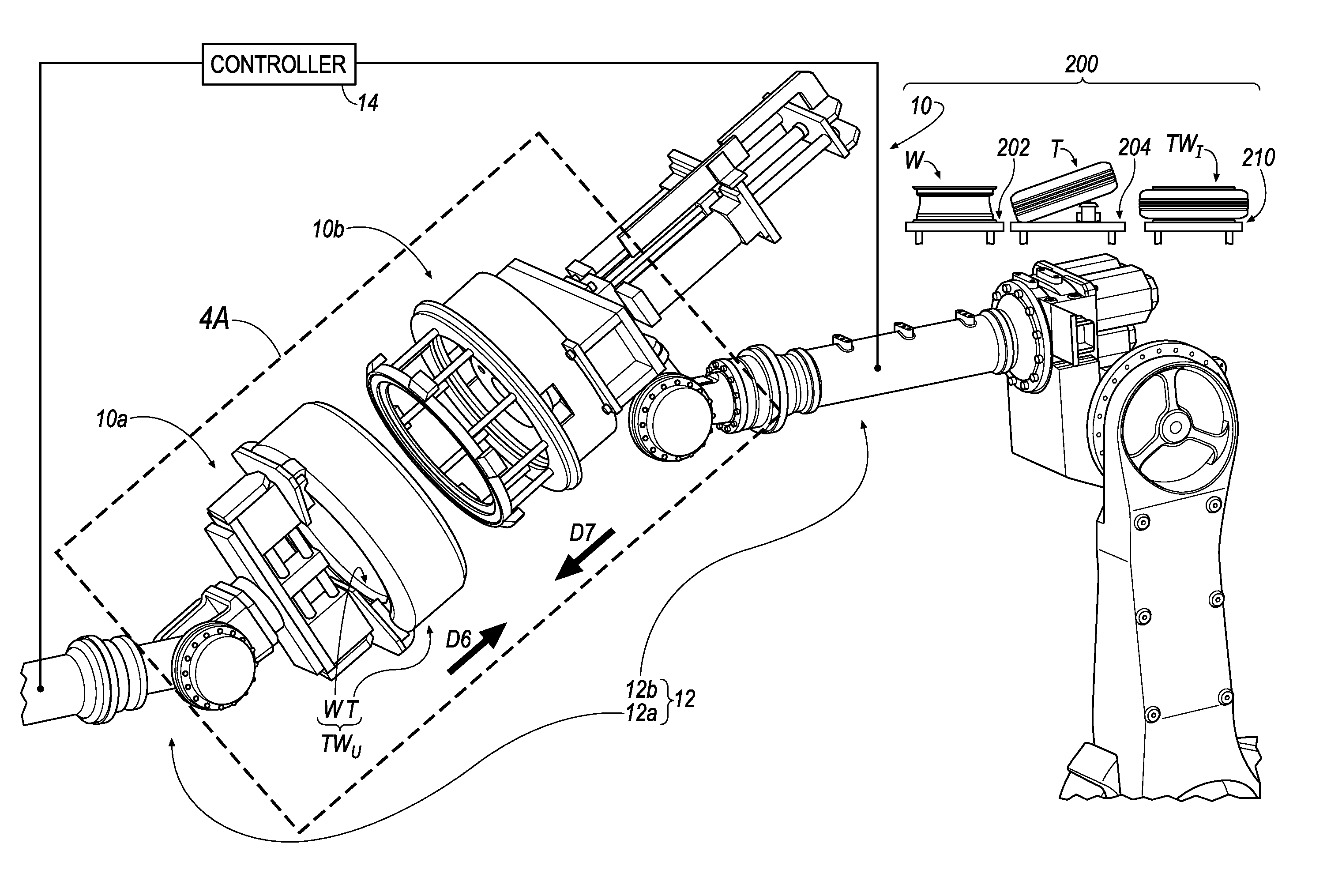

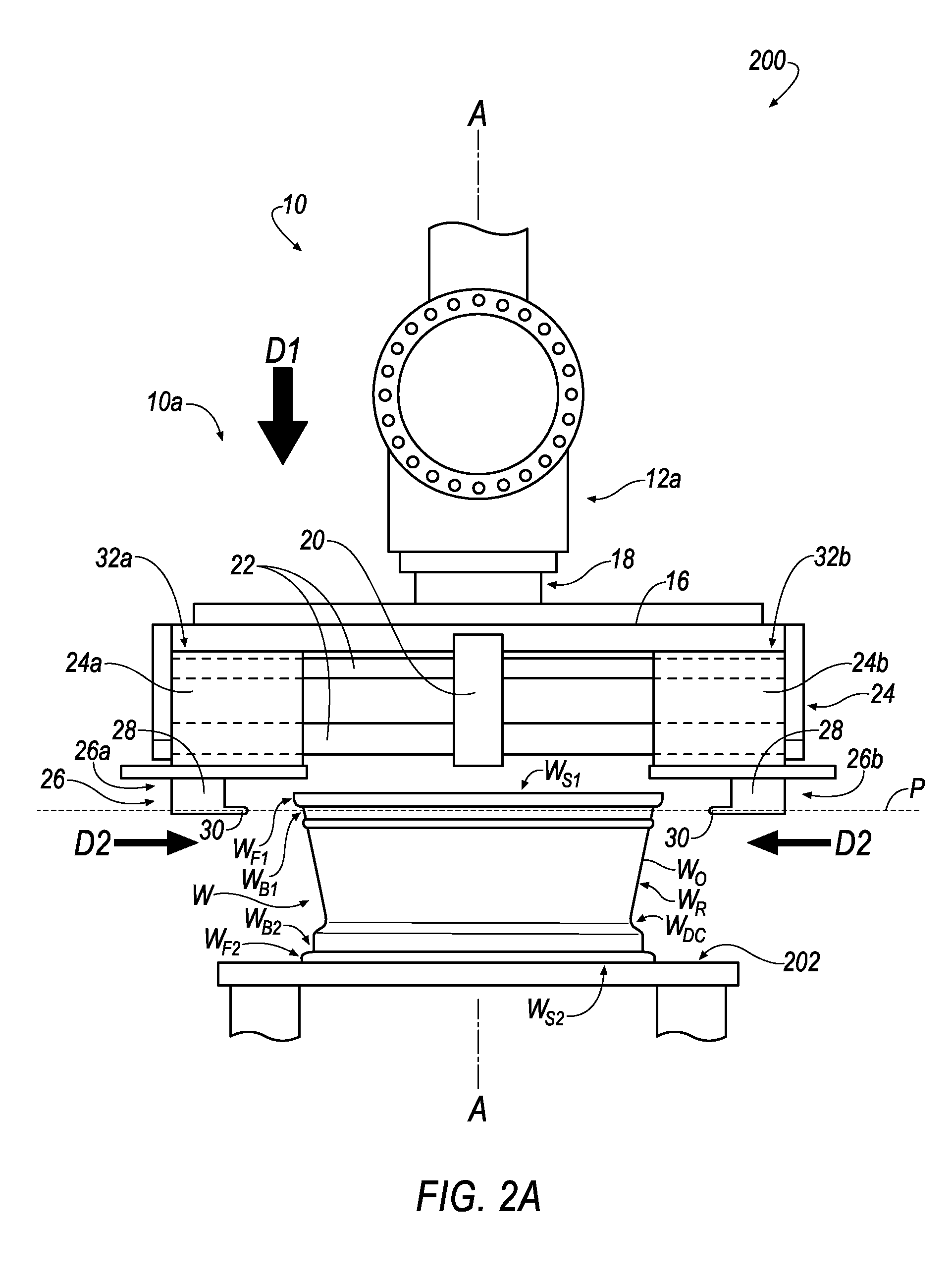

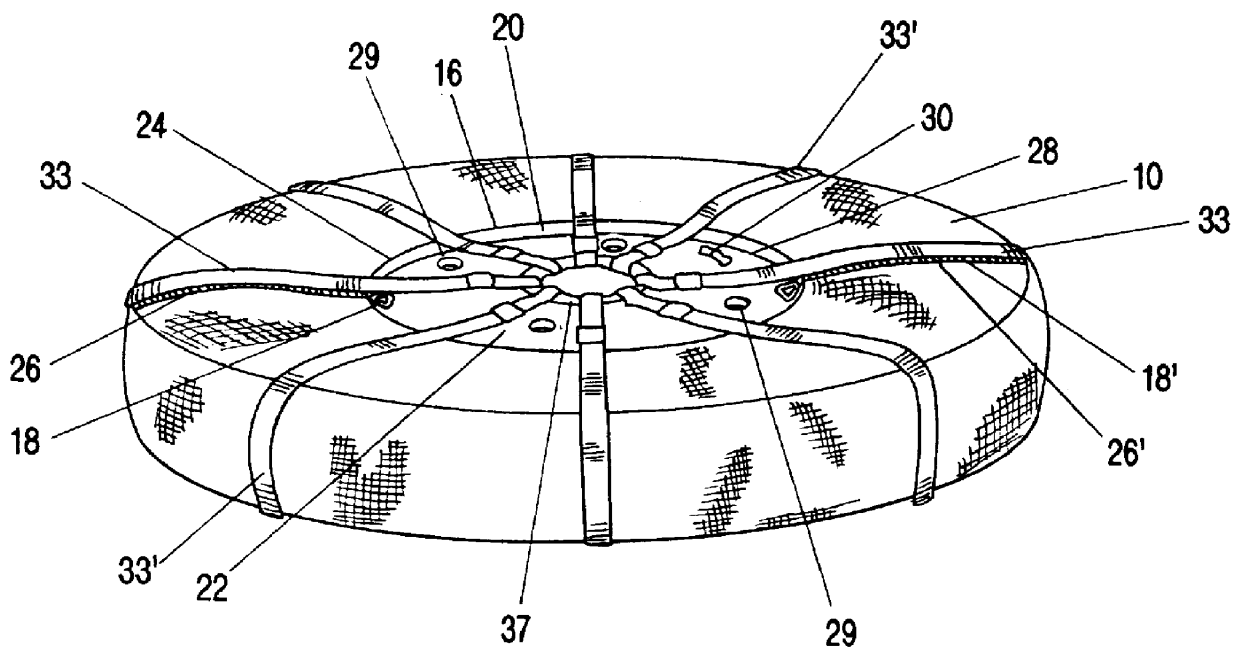

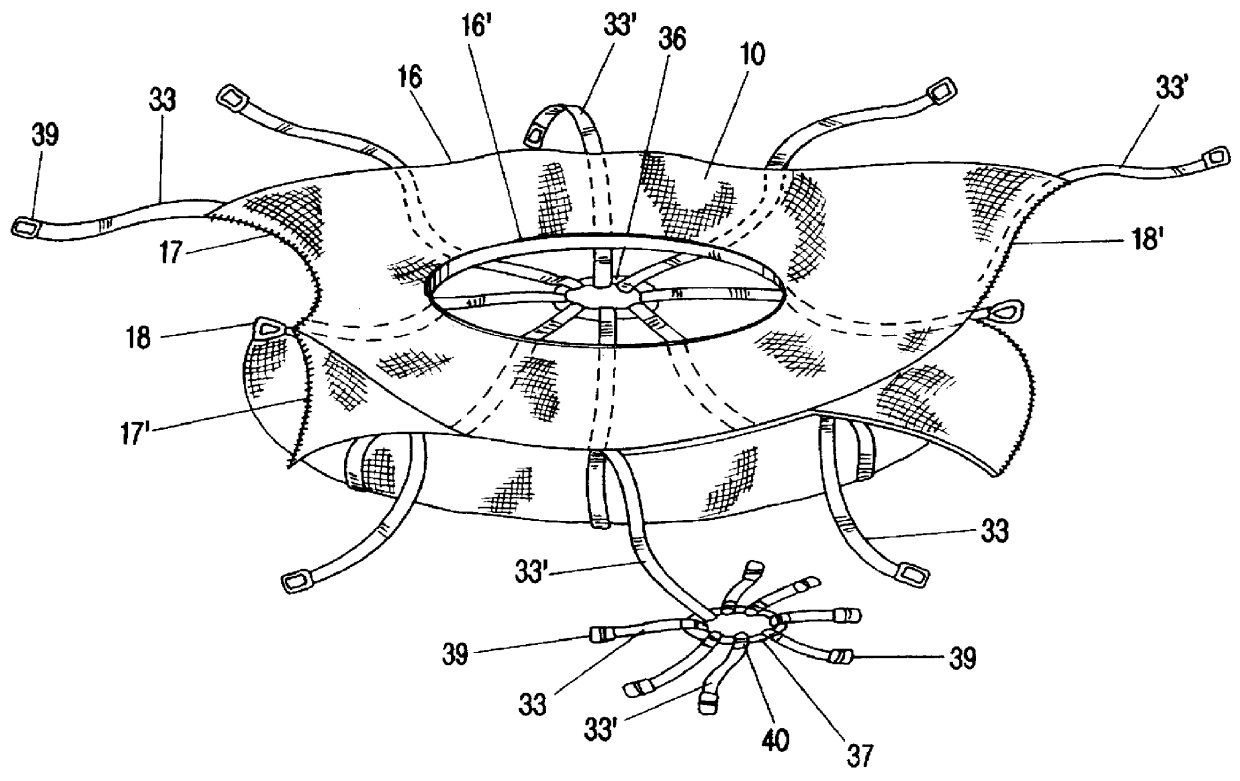

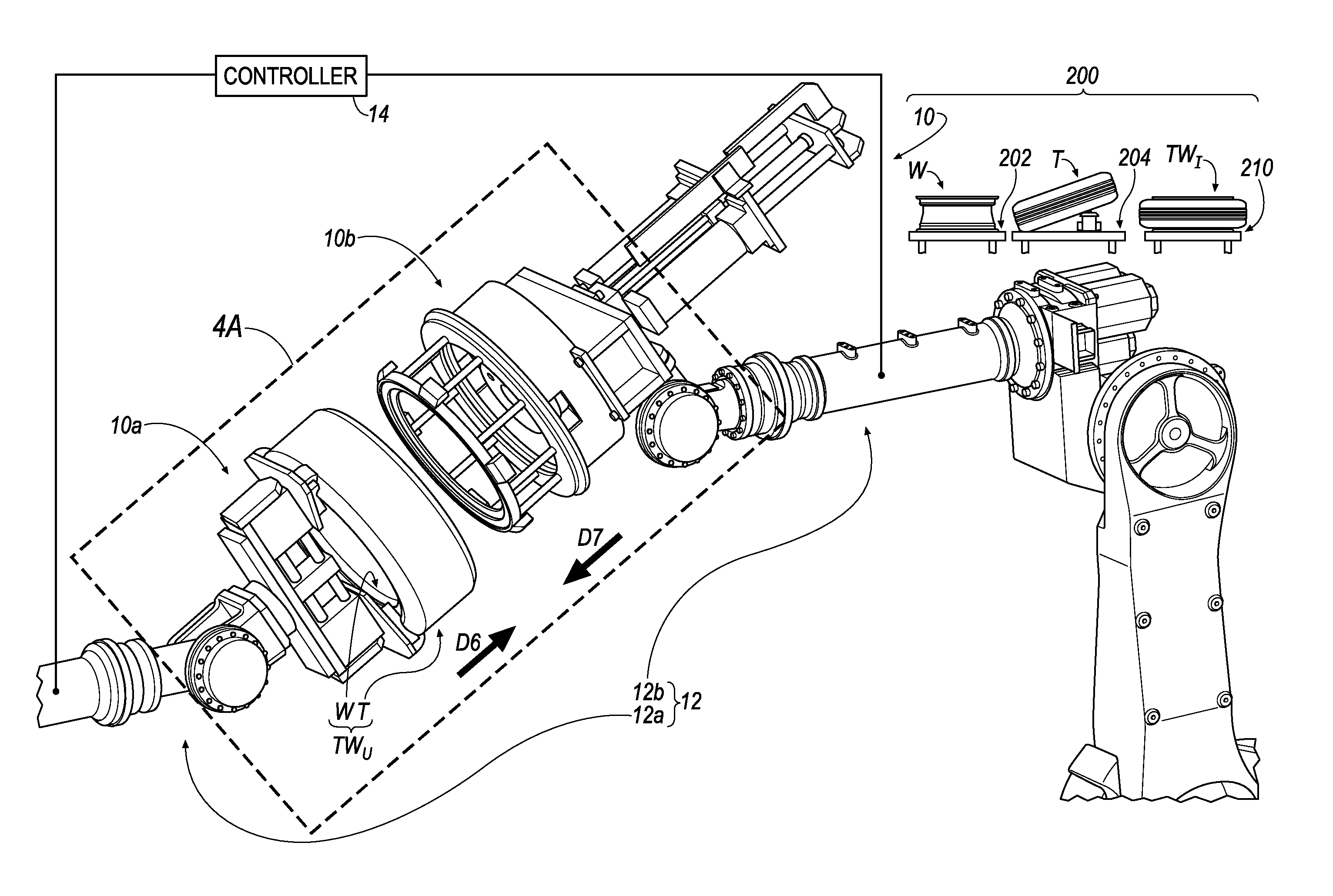

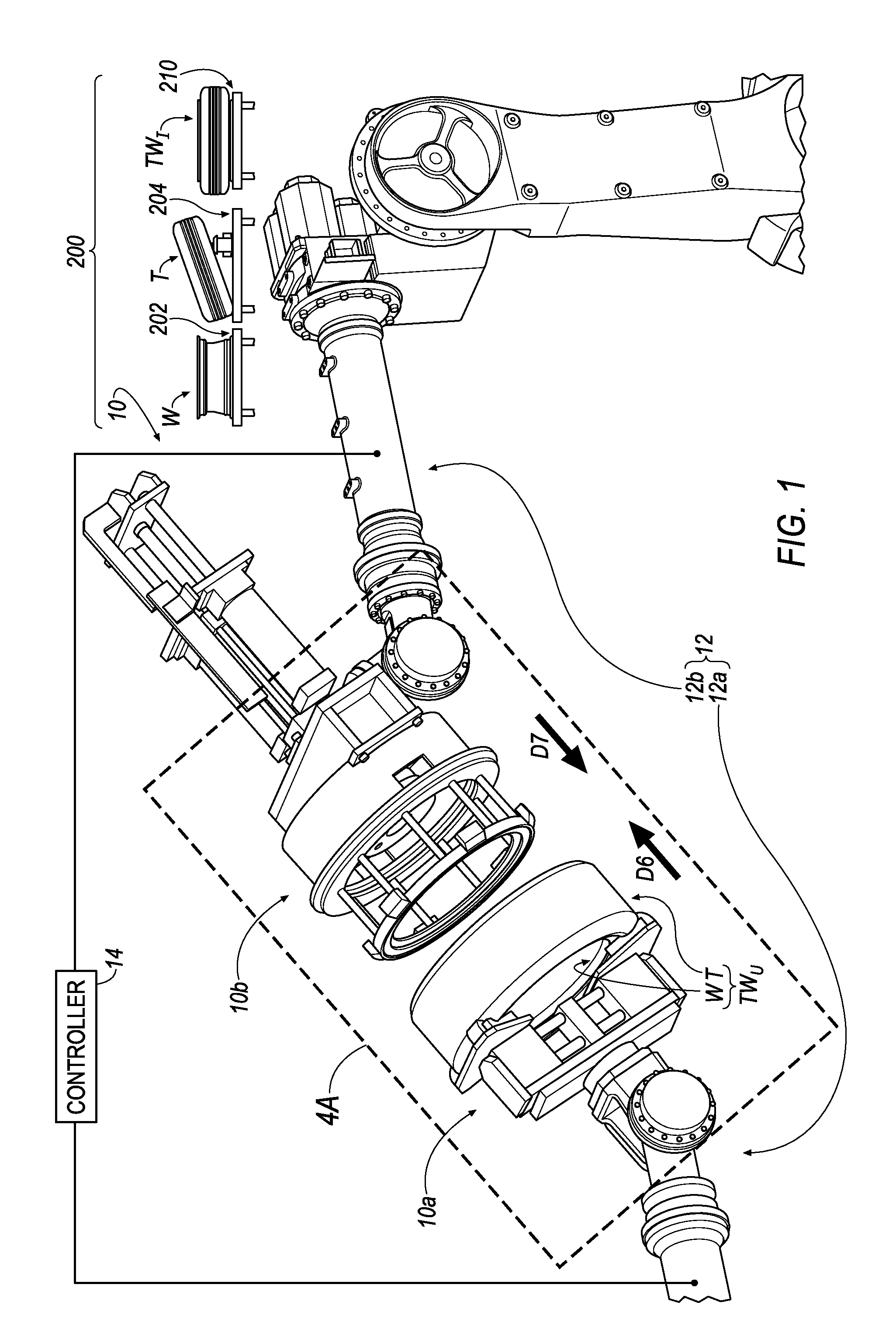

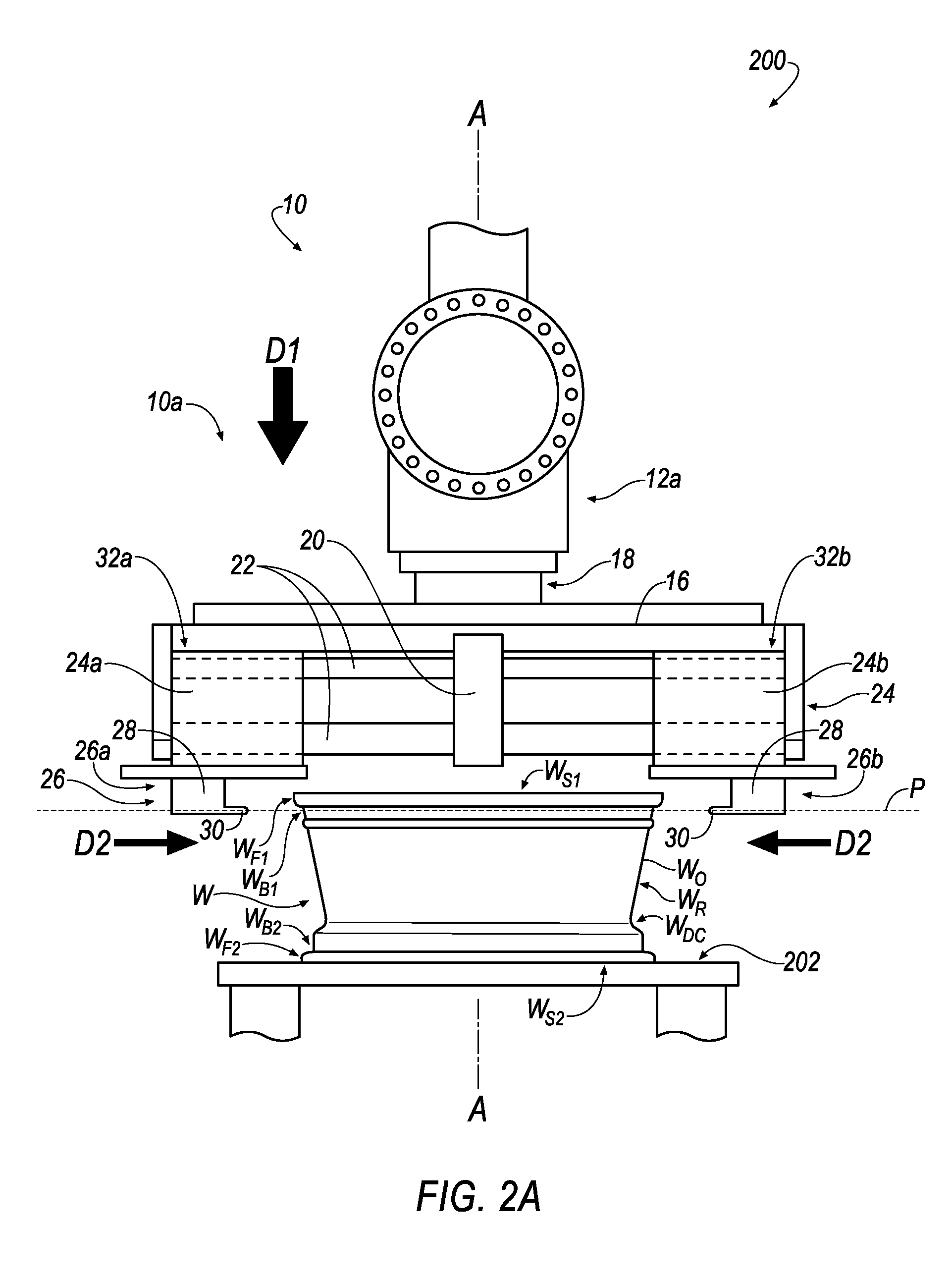

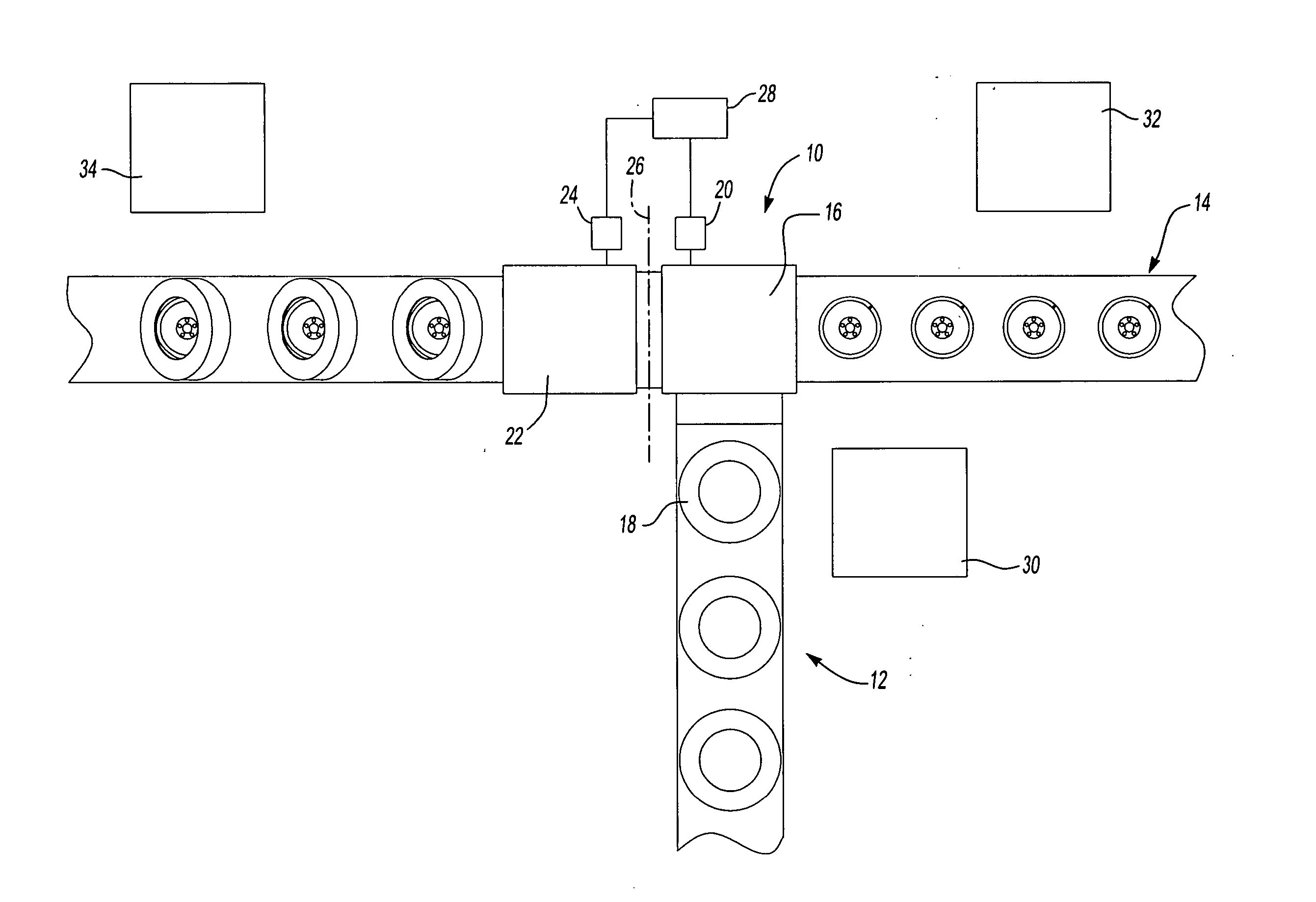

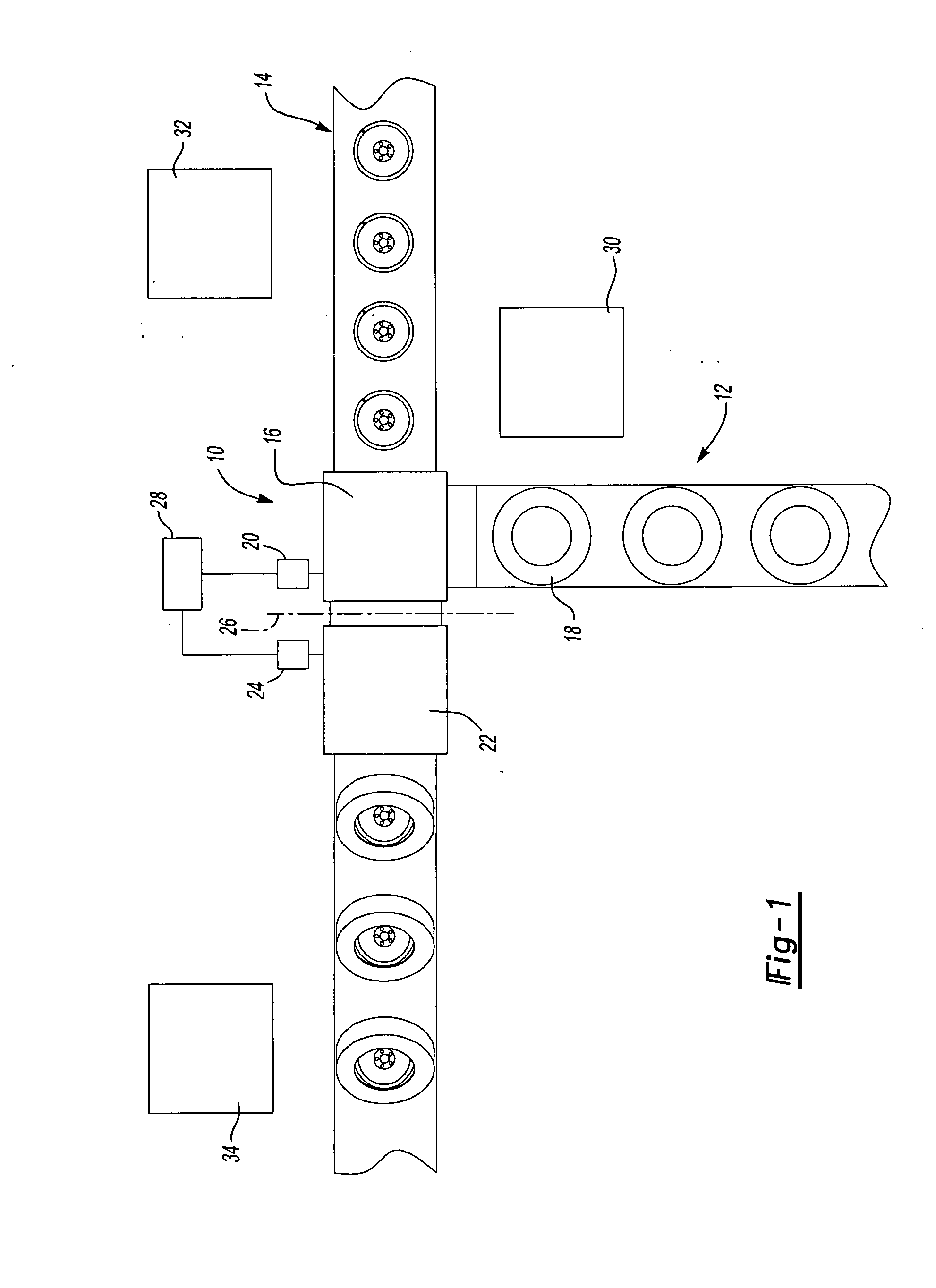

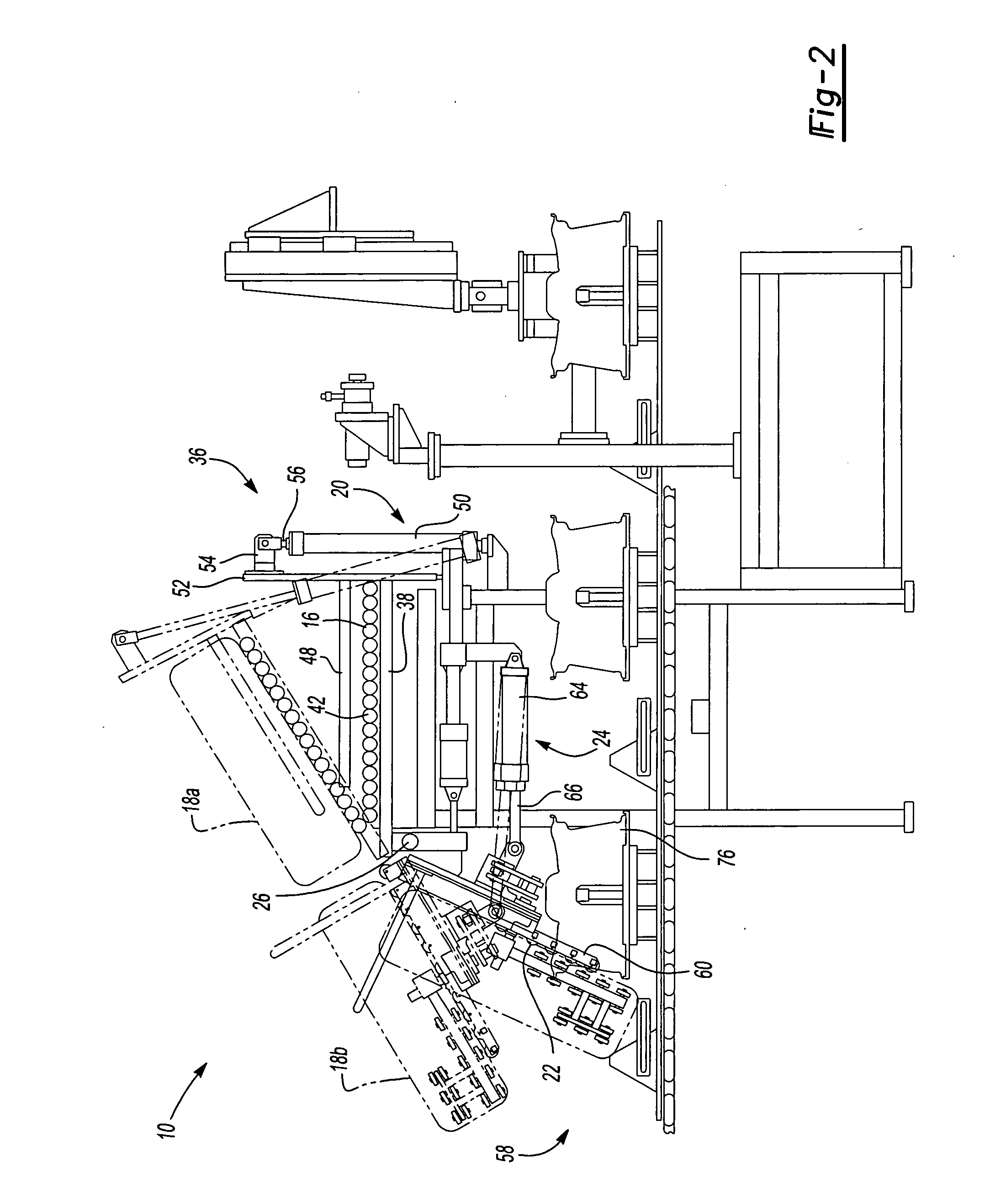

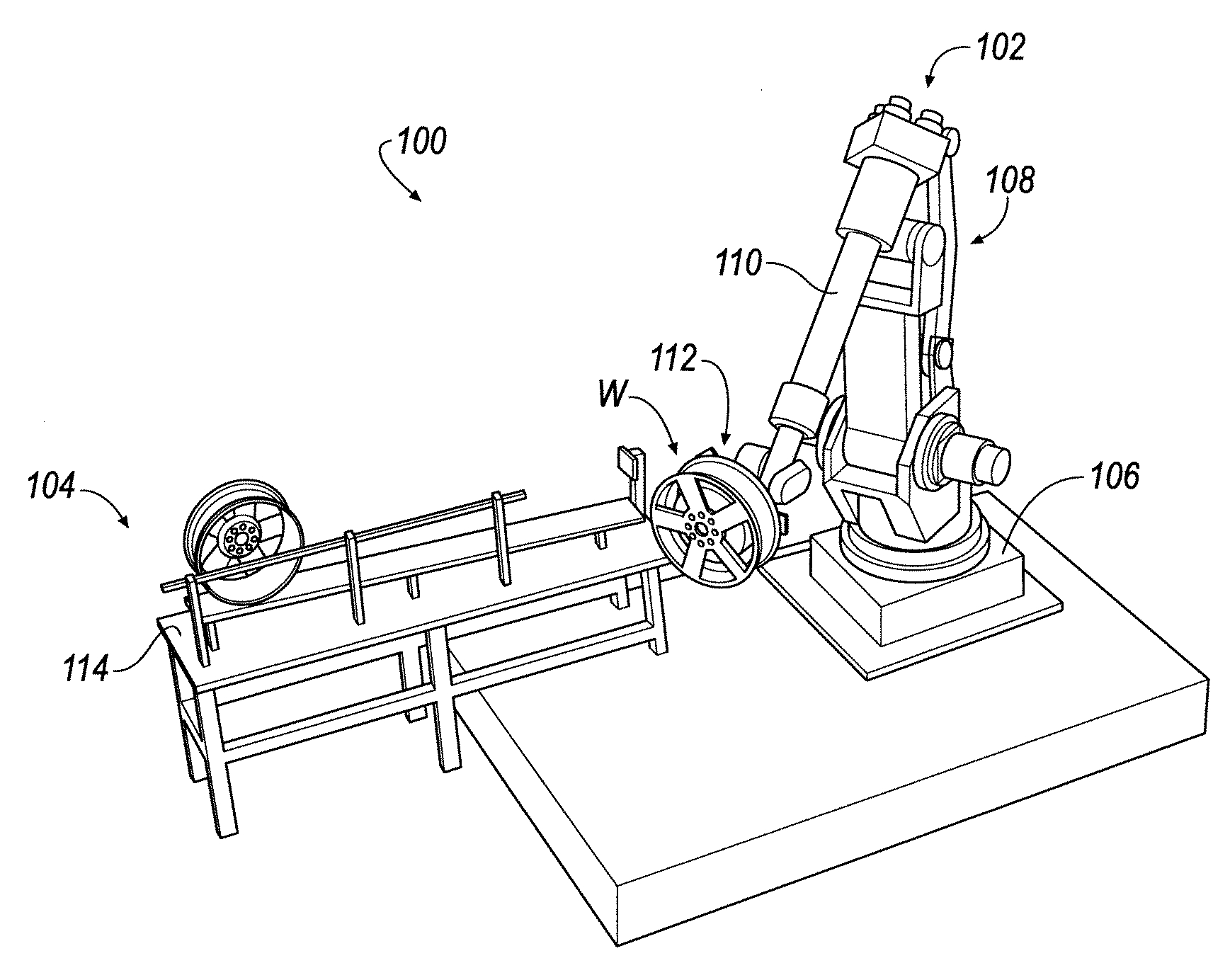

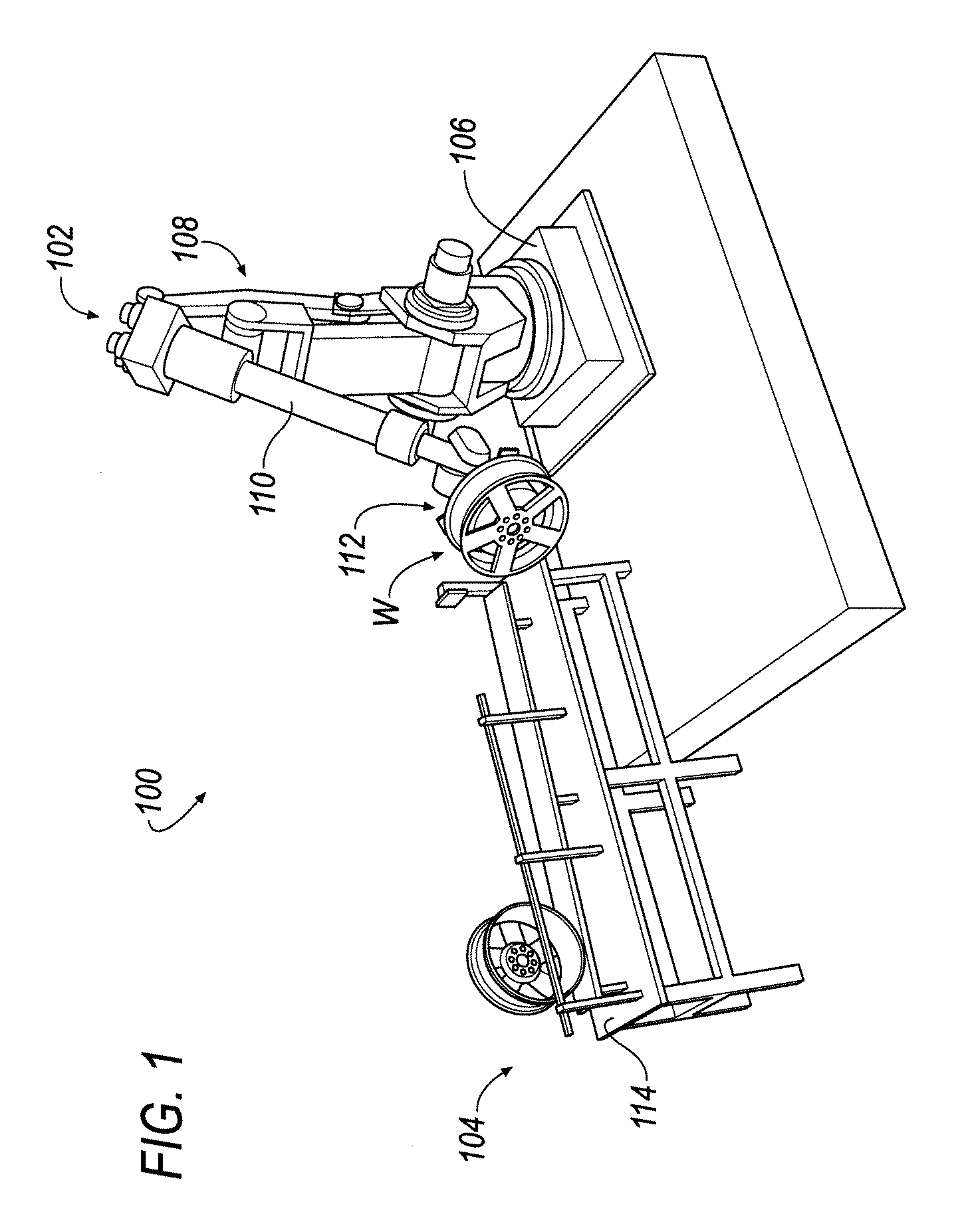

Apparatus, methods, components, and systems for assembling and/or inflating a tire-wheel assembly

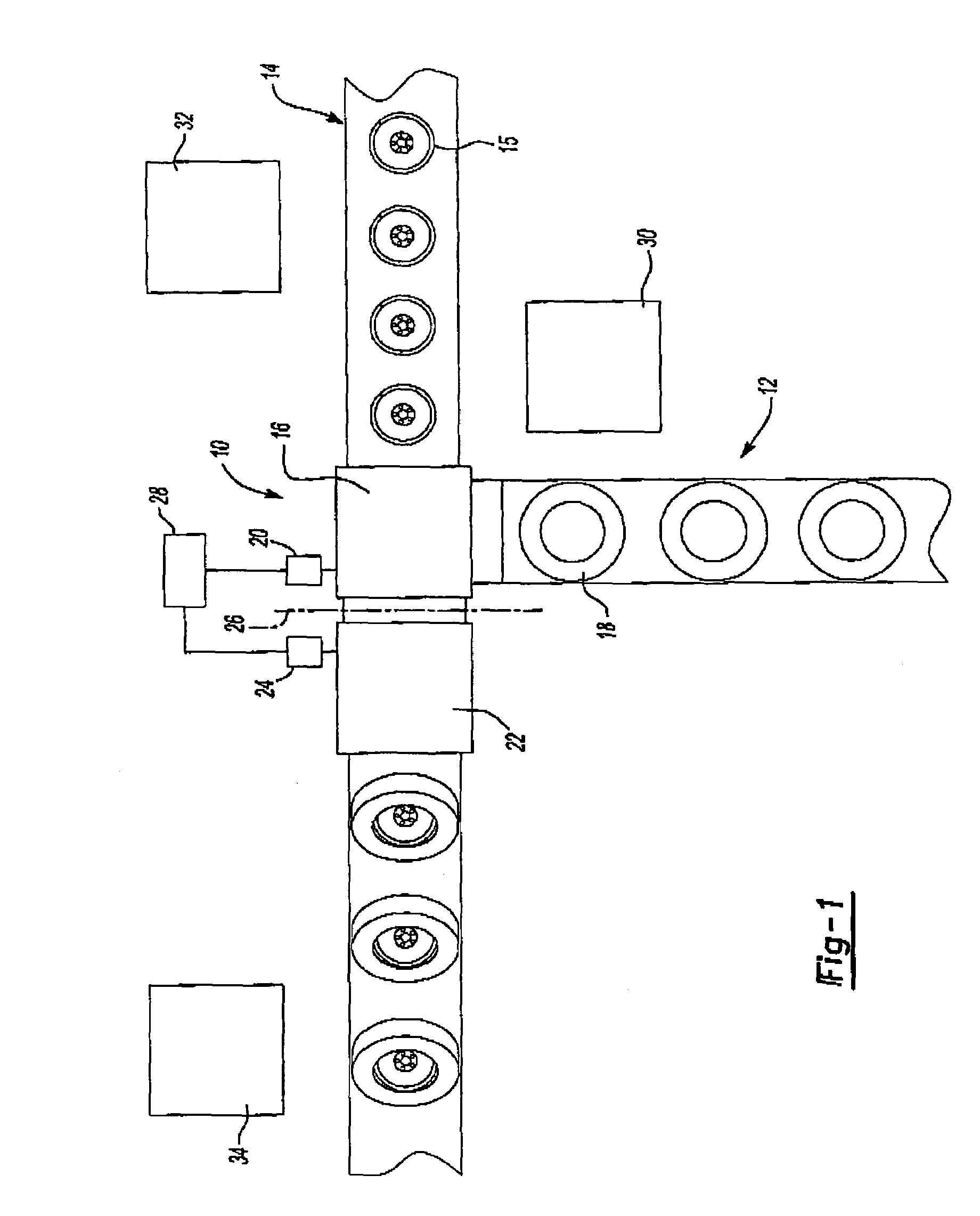

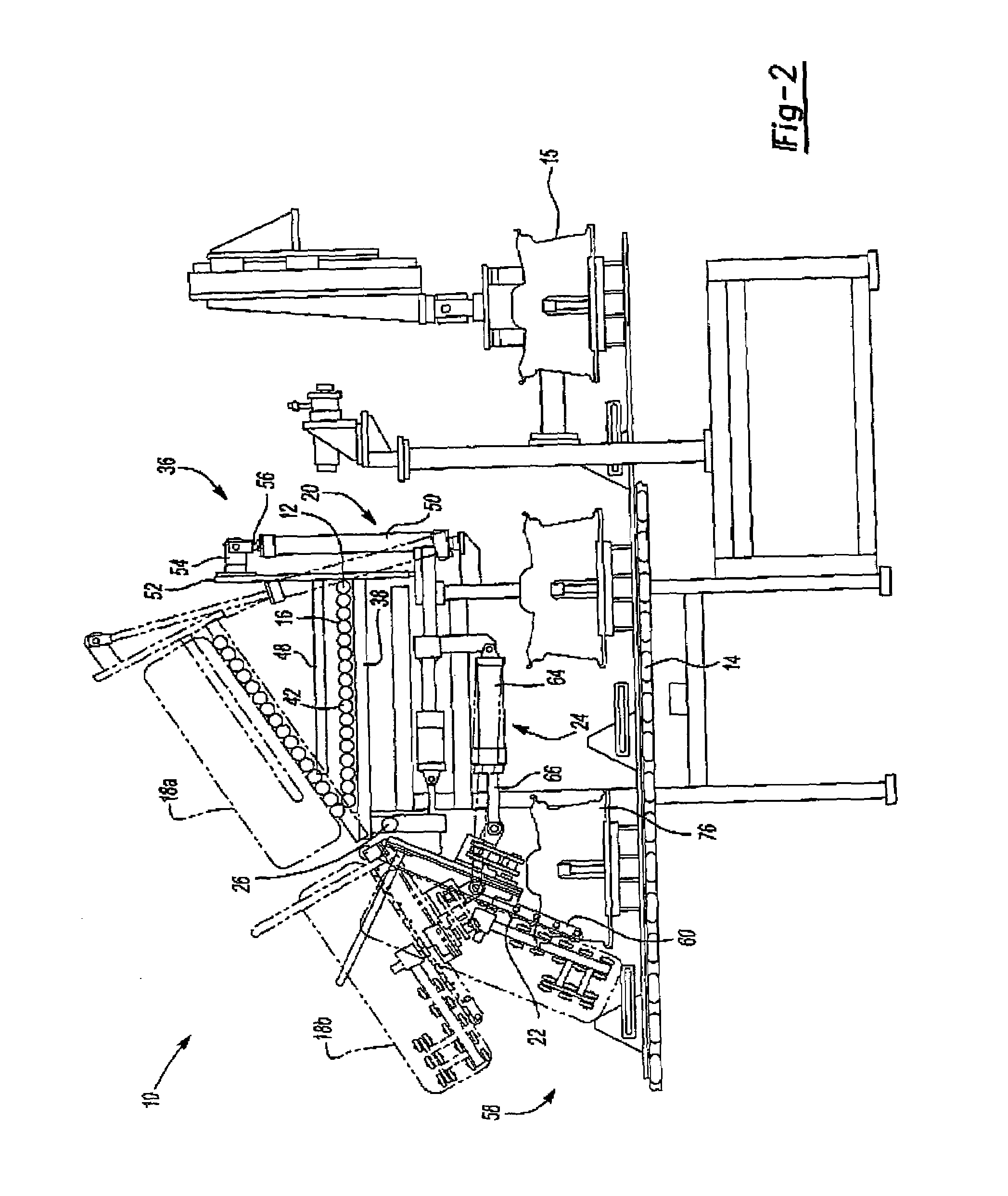

An apparatus for processing an un-inflated tire-wheel assembly for forming an inflated tire-wheel assembly is disclosed. The apparatus includes at least a first robotic arm and a second robotic arm forming a pair of robotic arms; an assembling end effecter attached to the first robotic arm; and an inflating end effecter attached to the second robotic arm, wherein the assembling end effecter is indirectly interfaceable with the inflating end effecter by way of the un-inflated tire-wheel assembly. One or more methods are also disclosed. One or more components are also disclosed. One or more systems are also disclosed.

Owner:ANDROID INDS OF MICHIGAN

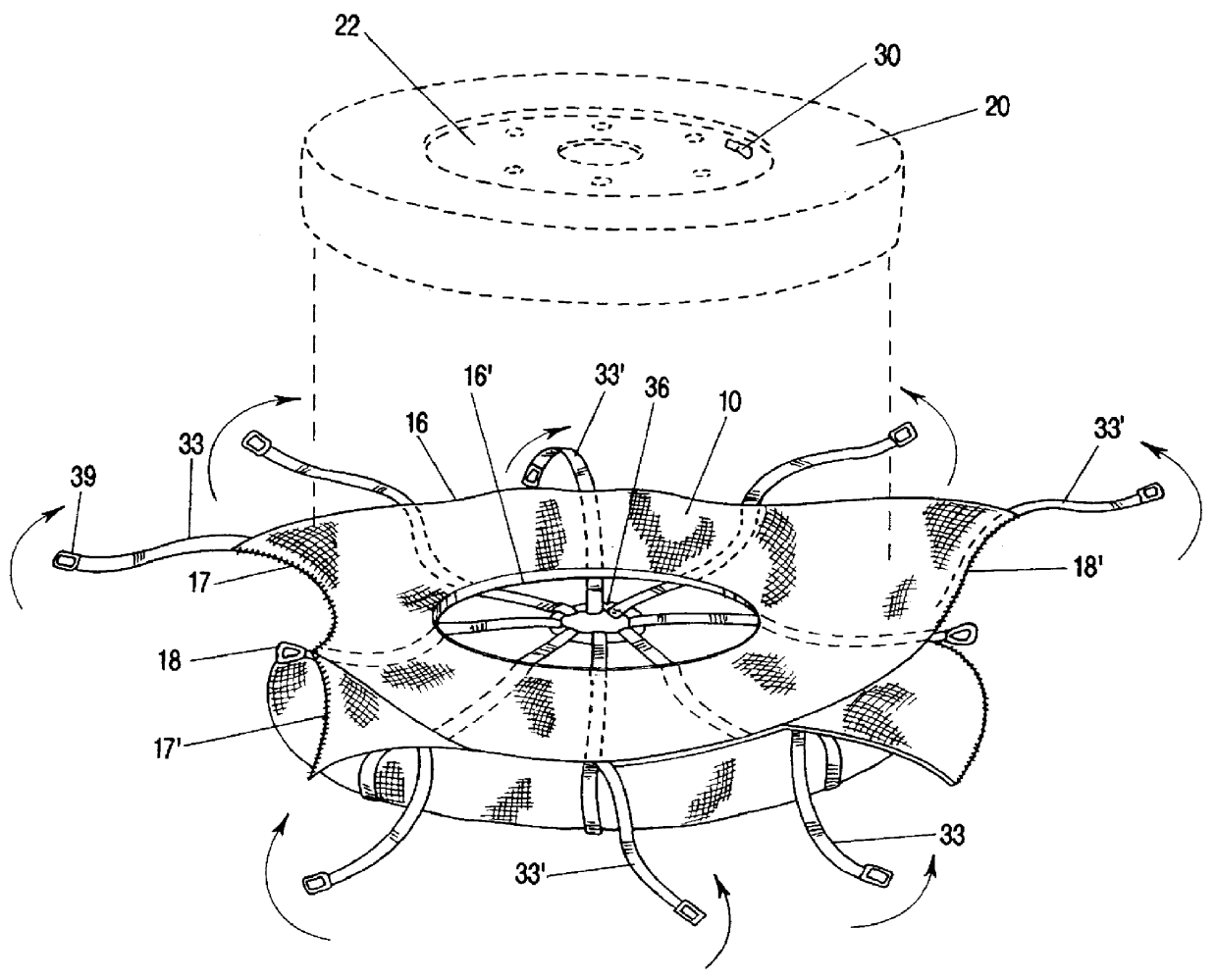

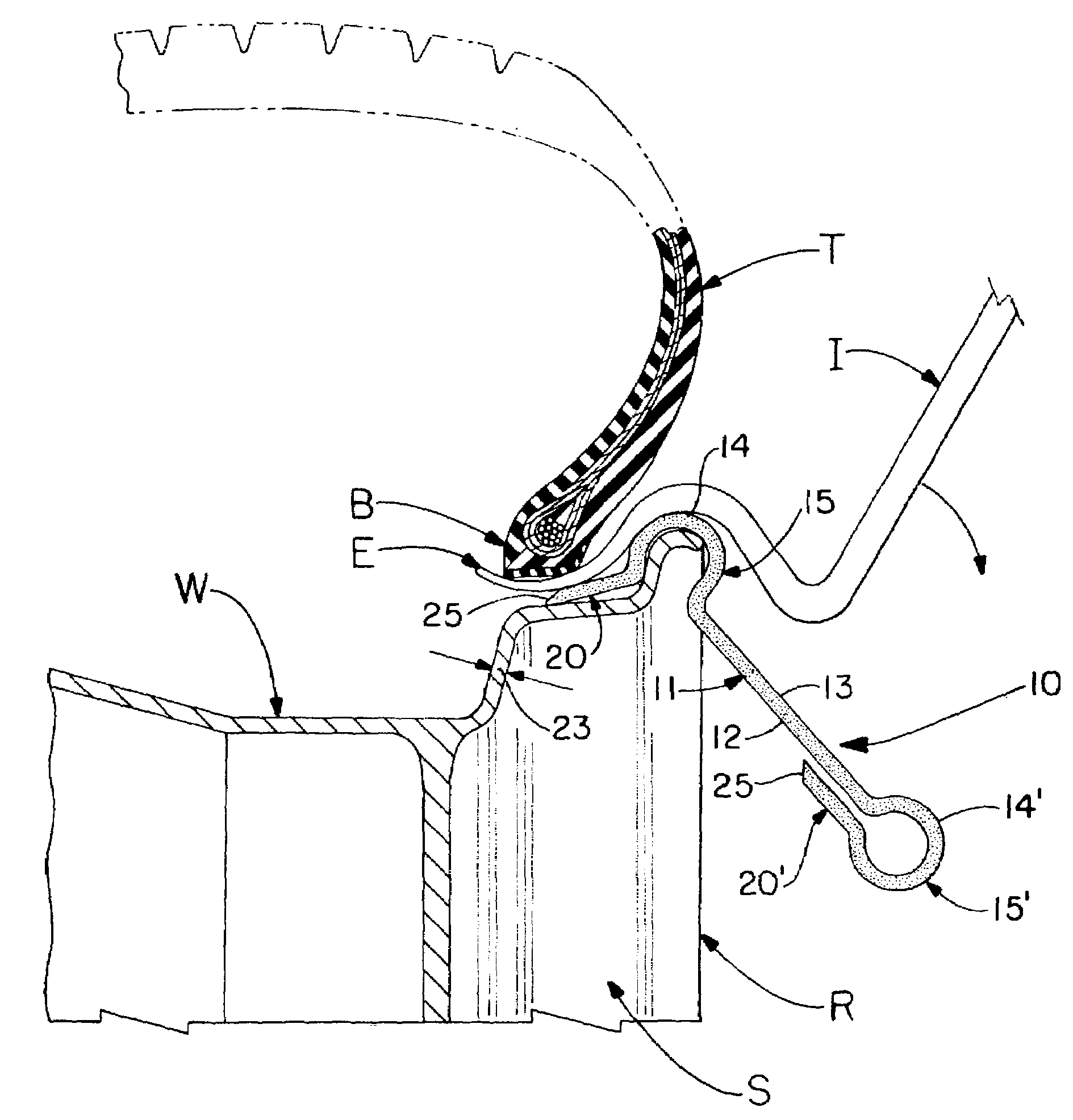

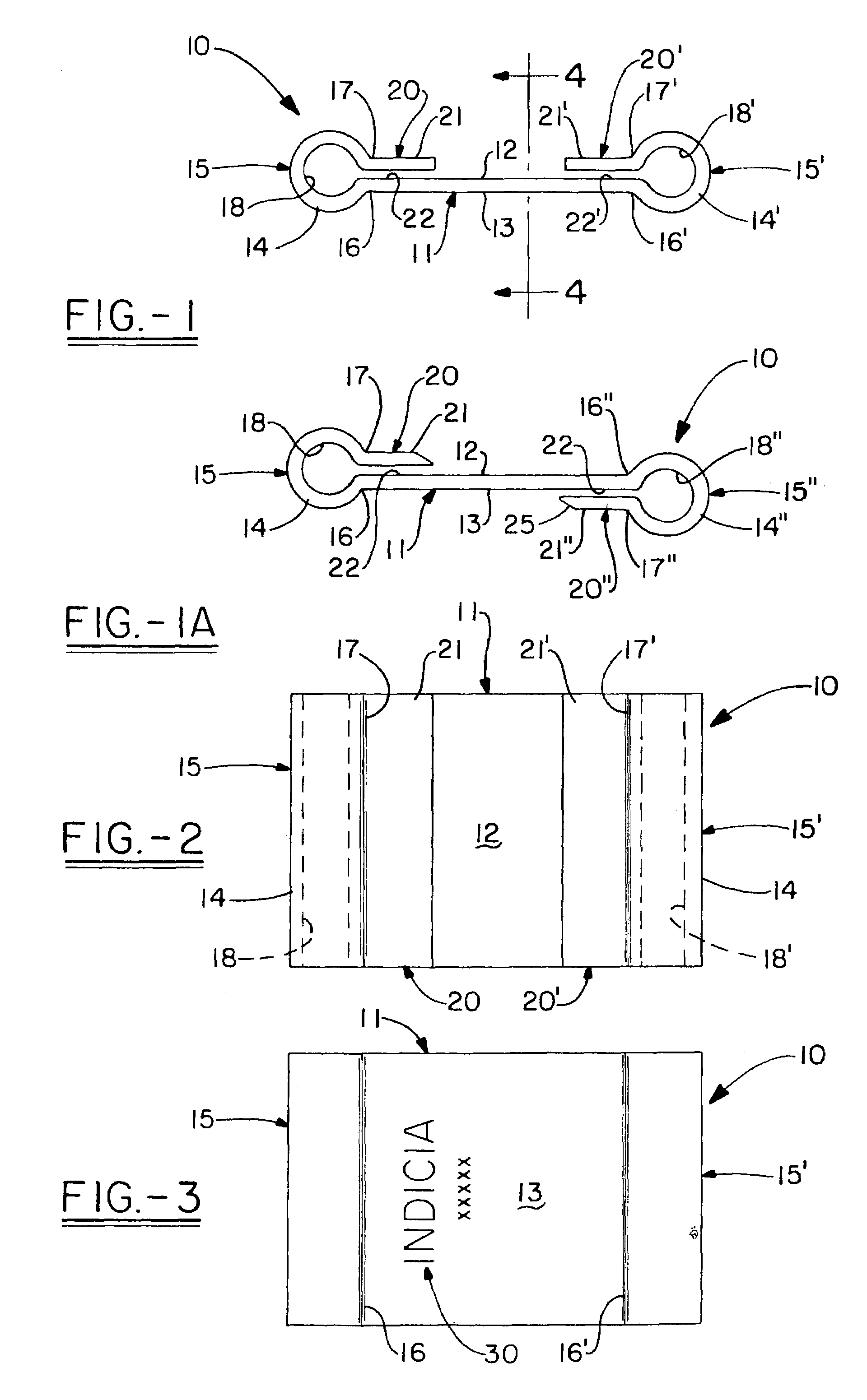

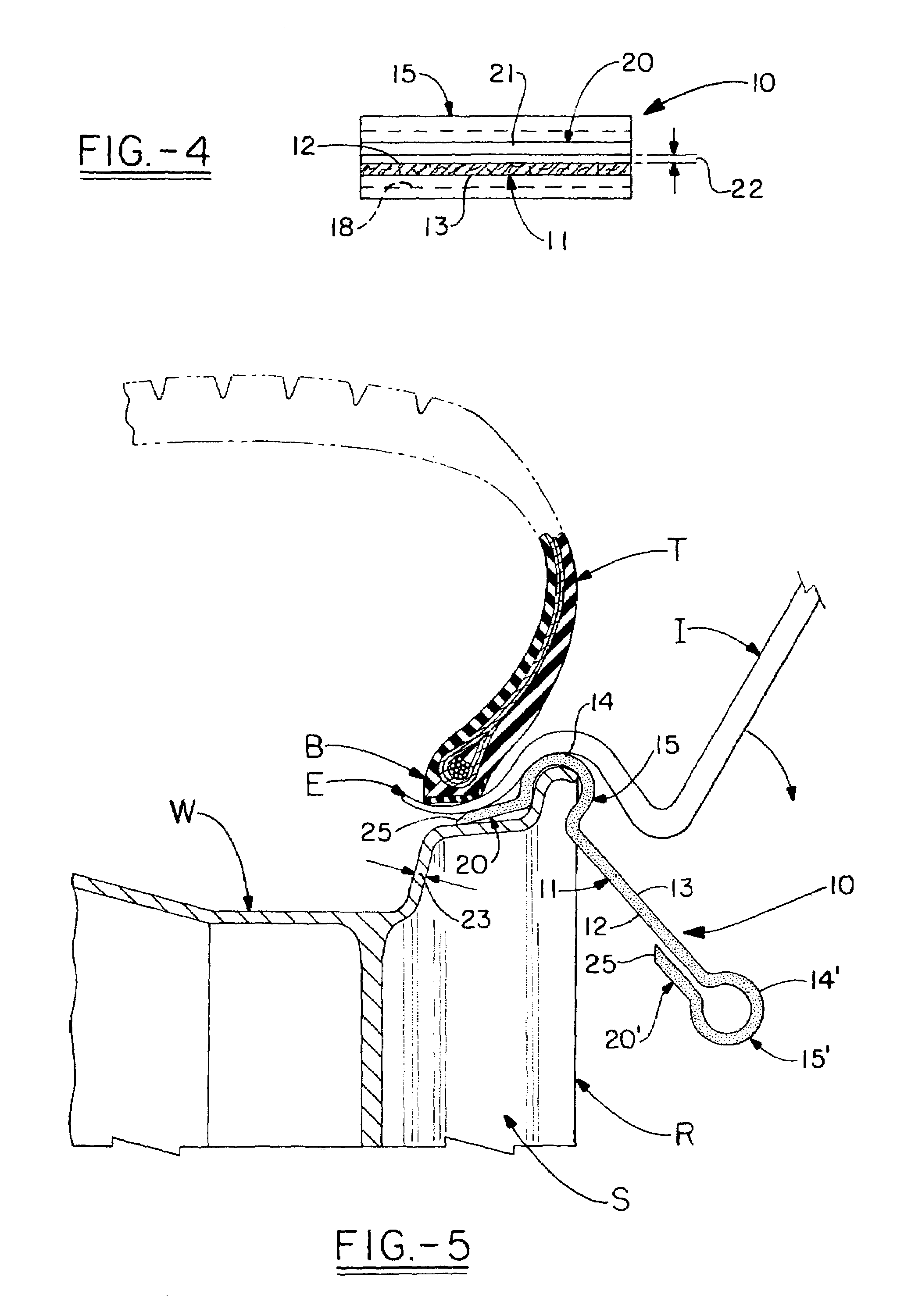

Tire changing bag

InactiveUS6155323ASafely mounting and inflatingSupplementary fittingsWheelsEngineeringMechanical engineering

Owner:GOUGELET ROBERT M

Apparatus, Methods, Components, and Systems for Assembling and/or Inflating a Tire-Wheel Assembly

An apparatus for processing an un-inflated tire-wheel assembly for forming an inflated tire-wheel assembly is disclosed. The apparatus includes at least a first robotic arm and a second robotic arm forming a pair of robotic arms; an assembling end effecter attached to the first robotic arm; and an inflating end effecter attached to the second robotic arm, wherein the assembling end effecter is indirectly interfaceable with the inflating end effecter by way of the un-inflated tire-wheel assembly. One or more methods are also disclosed. One or more components are also disclosed. One or more systems are also disclosed.

Owner:ANDROID INDS OF MICHIGAN

Improper working position detection for tire mounting apparatus and method

InactiveUS7264032B2Ensure trouble-freeAvoid damageWheelsTyre repairingTire beadMechanical engineering

An apparatus for mounting a tire on a wheel rim includes a mounting head with a tire bead deflector and a tire press-in roller, and a drive that moves the mounting head toward, and rotates the bead deflector and the press-in roller around, the wheel rim. To avoid a damage-causing contact between the bead deflector and the wheel rim, an arrangement for monitoring a minimum spacing distance between the wheel rim and the mounting head is arranged preferably on the bead deflector. If an improper working position closer than the minimum spacing distance is detected, the arrangement produces a signal that influences, e.g. stops, the motion of the mounting head. The arrangement preferably includes a contact member of a comparatively soft low-friction material at a working end of the bead deflector. If the contact member contacts the wheel rim, this actuates a piezoelectric element to generate the required electrical signal.

Owner:SCHENCK ROTEC GMBH

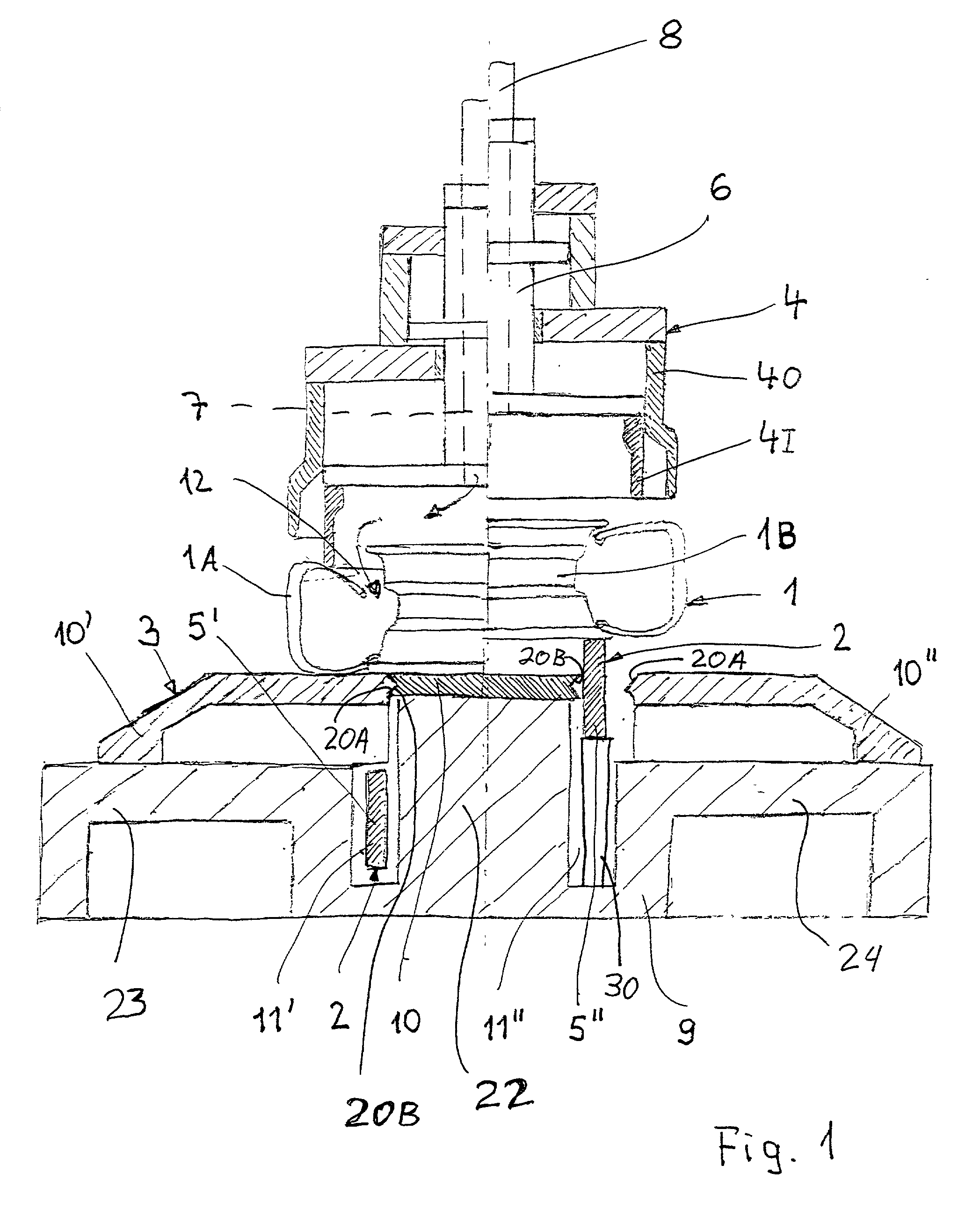

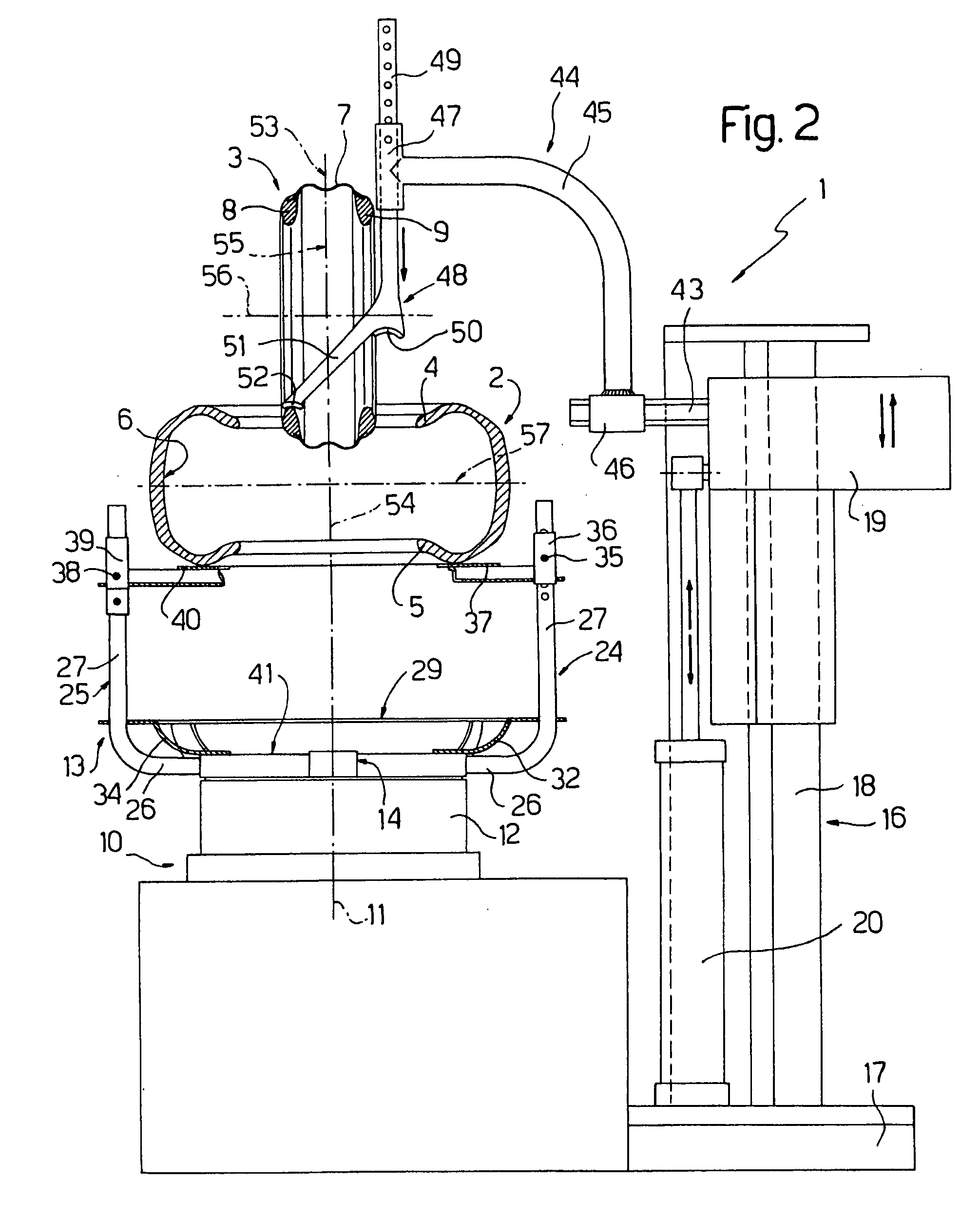

Tire filling method and apparatus adaptable to different sizes of tires

InactiveUS20010013396A1Check valvesPackaging under special atmospheric conditionsMechanical engineeringIndustrial engineering

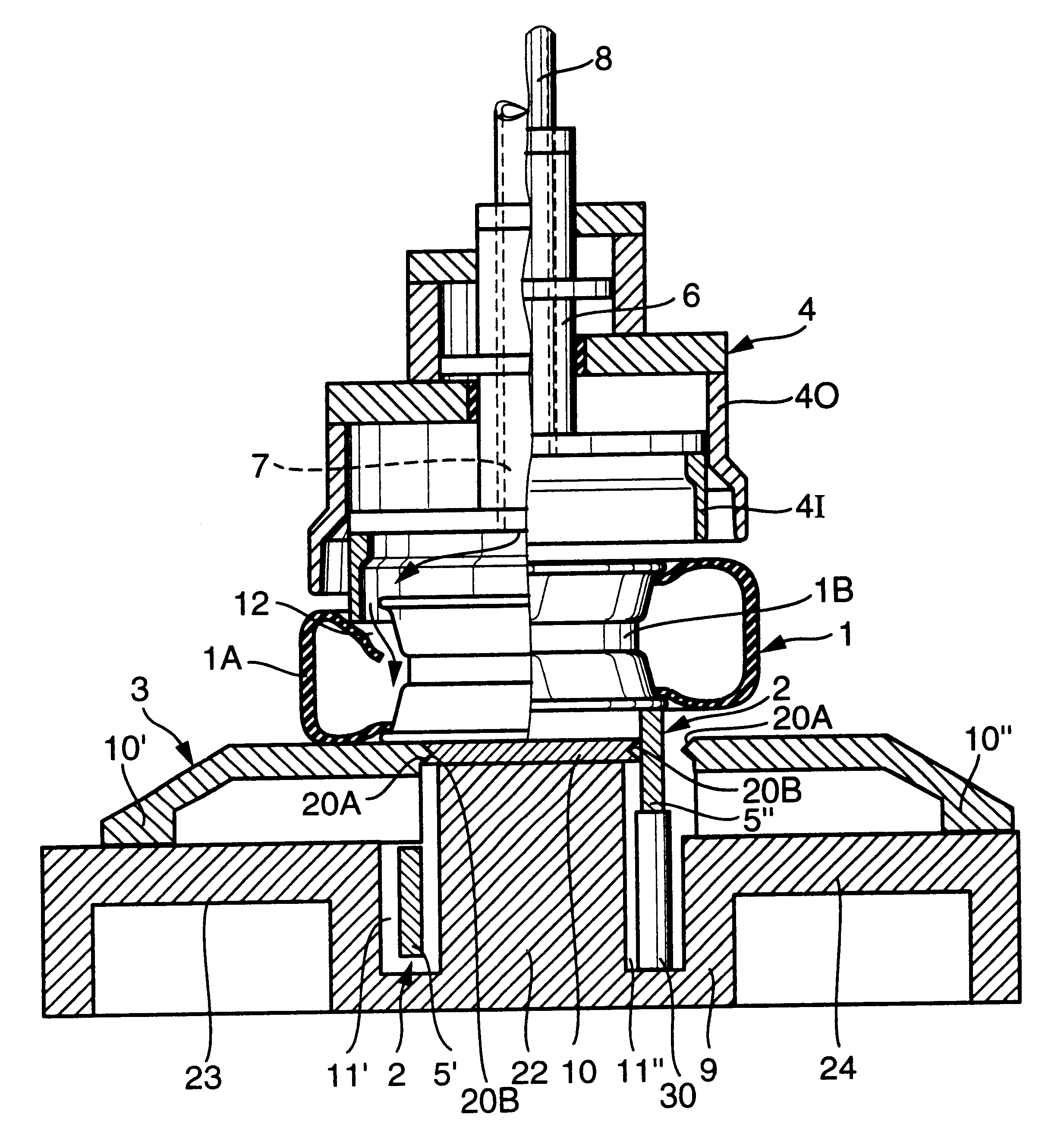

A pneumatic tire filling station includes a support and seal arrangement on which one side wall of the tire is supported and sealed, and a tire filling bell that presses and seals against the opposite side wall of the tire and then supplies pressurized air into the tire. The filling bell includes outer and inner rings that are concentrically slidable relative to each other. One of the rings is selected for the filling operation depending on the size of the tire. The support and seal arrangement includes plural plate members that are joined and sealed together to form a continuous support and seal surface, or moved laterally apart to allow a transport apparatus to carry and support the mounted tire from underneath. The tire filling station is adaptable to different models and sizes of mounted tires even in a mixed process flow, in an automated manner.

Owner:SCHENCK ROTEC GMBH

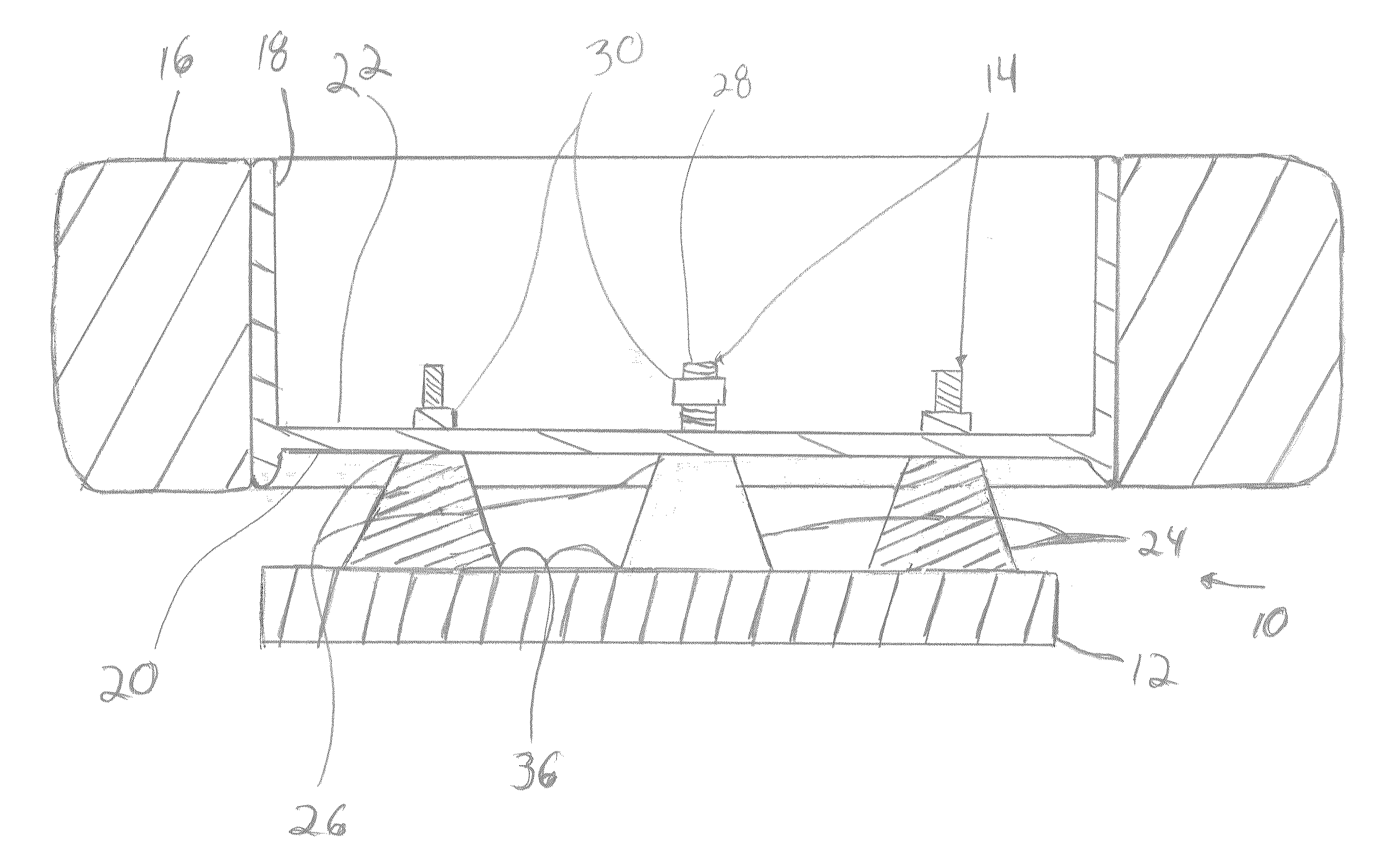

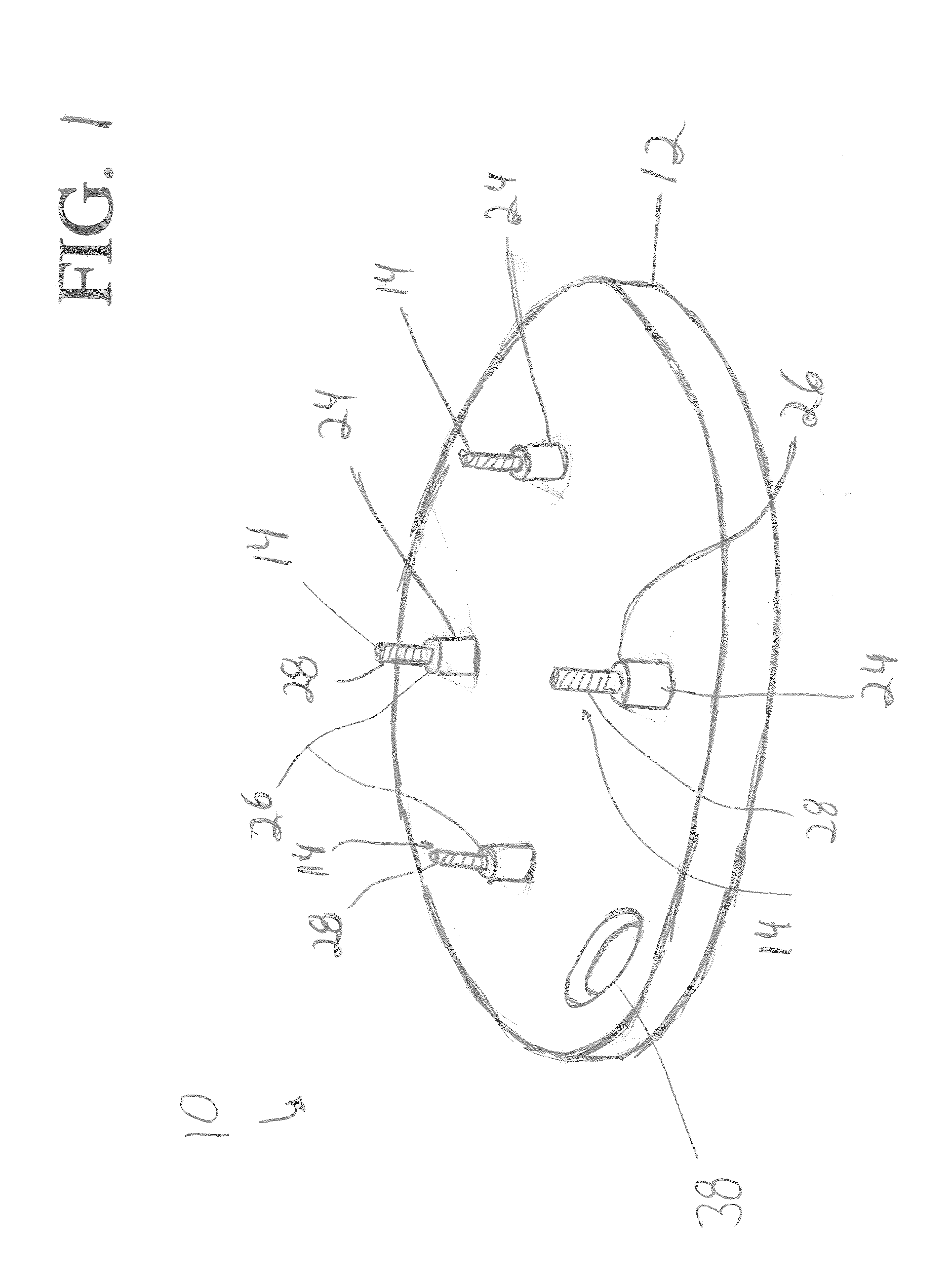

Tire Removal Aid For Large Tires To Minimize / Eliminate Scuffing Of The Wheel

ActiveUS20080185106A1Assist in removingHigh surfaceStatic/dynamic balance measurementTyresEngineeringShaft collar

An apparatus for protecting the exterior or polished surface of wheels as tires are removed and placed on the wheel. The apparatus includes a substantially flat base having a plurality of stanchions extending out from the base. Each stanchion has a collar positioned adjacent to the base that includes a diameter greater than the stanchion. The stanchions are sized to fit through the bolt holes of the wheel in order to generally align each stanchion with one of those holes. Each collar is sized to be preferably slightly larger than the average bolt, or lug, hole on the wheel. Additionally, each collar is sized to cover substantially the same area as the lug nut or nut that normally attaches the wheels to the vehicle upon which they are used.

Owner:MELZO INNOVATIONS

Safety device for pressurizing an envelope at risk of bursting

InactiveUS6923200B2Easy to operateCompetitive production costCheck valvesStatic/dynamic balance measurementEngineeringMechanical engineering

A safety device for inflating an envelope at risk of bursting comprising: a tubular body, a piston element slidably and sealably mounted within at least one inner portion of the tubular body; at least one piston rod integral with the piston element and extending so as to protrude from a first end of the tubular body; an annular bottom member, located in the tubular body or at the first end of the tubular body and suitable for slidably guiding the piston rod and for closing the tubular body whereby delimiting an annular space together with the tubular body and with the piston; removable anchoring device suitable for acting at a protruding end of piston rod and for constraining the piston rod to a support; at least one inlet opening and at least one outlet opening formed in the tubular body at the annular space, in operation said inlet opening being suitable for being connected to a pressurize fluid source and the outlet opening being designed to be connected to the envelope to be pressurized; and a yielding retainer for holding in position the said piston element, so that in case of bursting, the unit formed by the tubular body and the annular bottom member can be moved longitudinally following a bursting impact with respect to the piston element in contrast with the yielding retainer.

Owner:BUTLER ENG & MARKETING

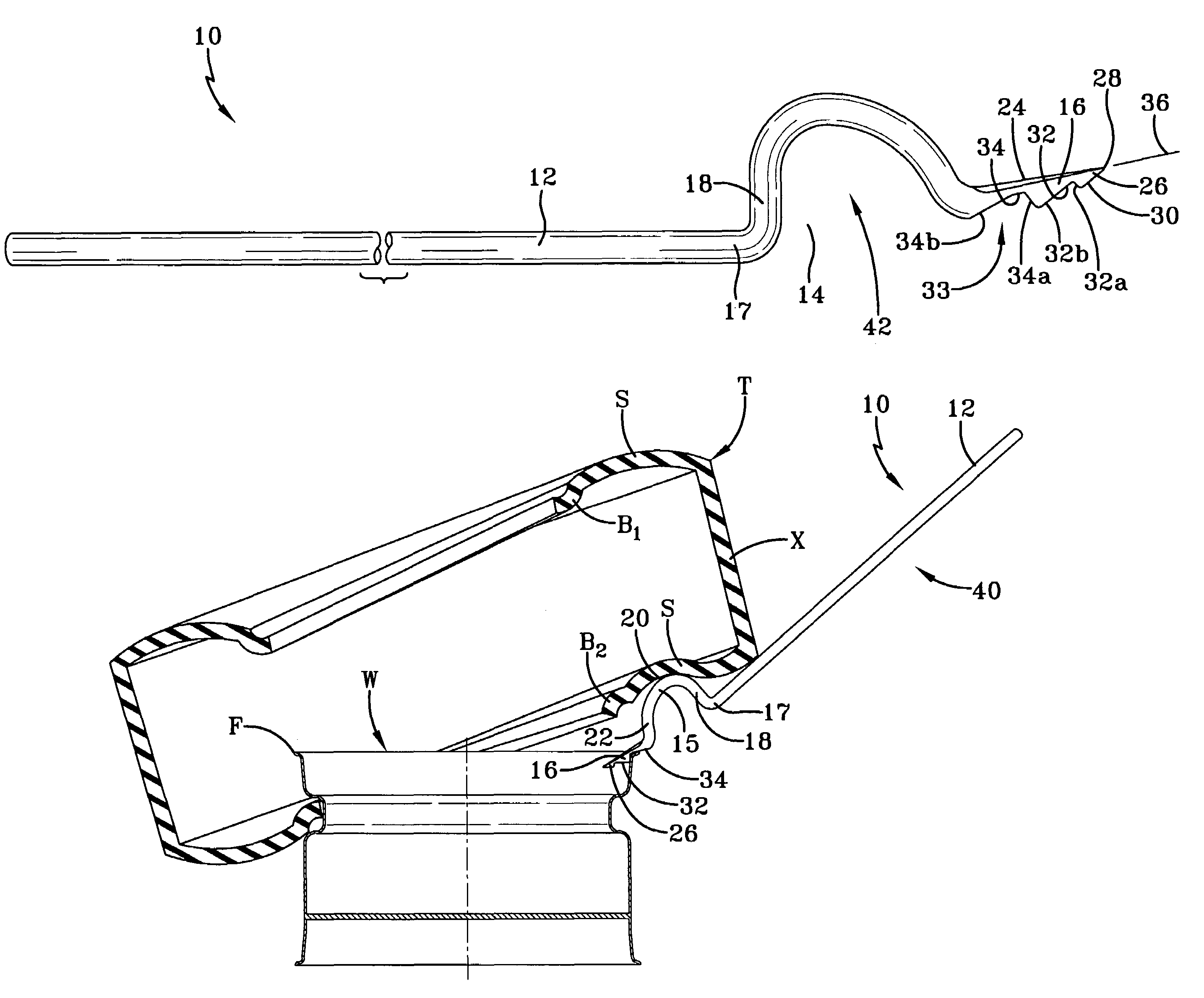

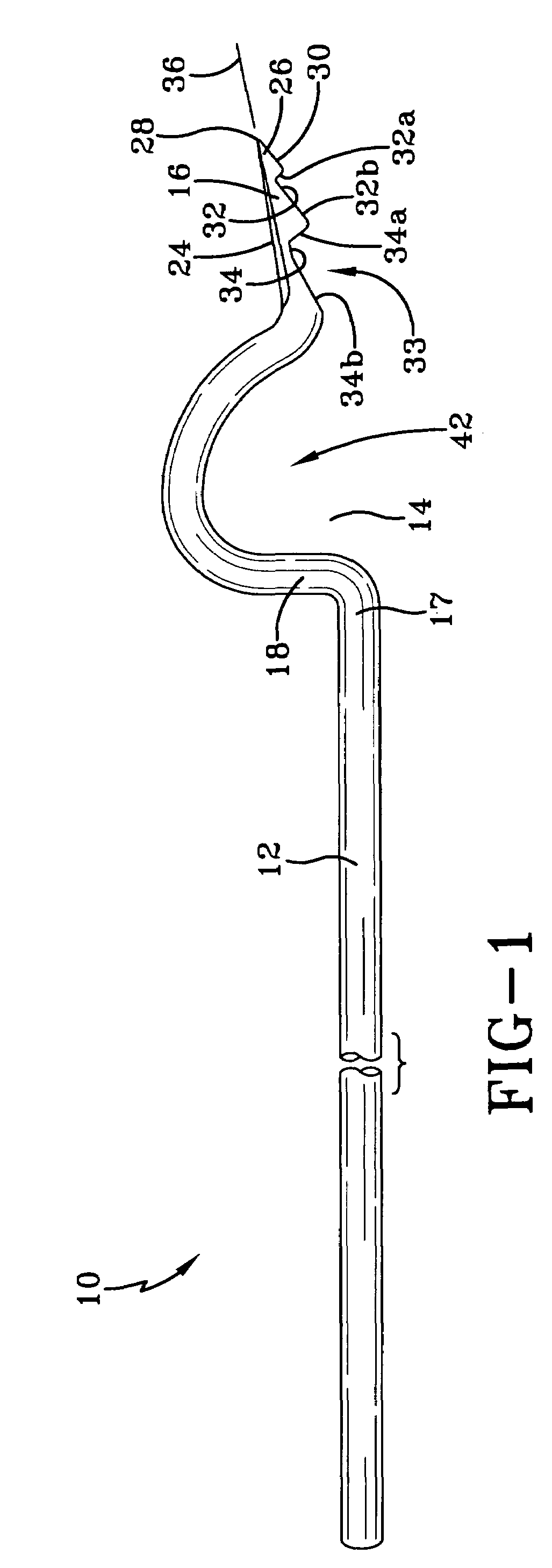

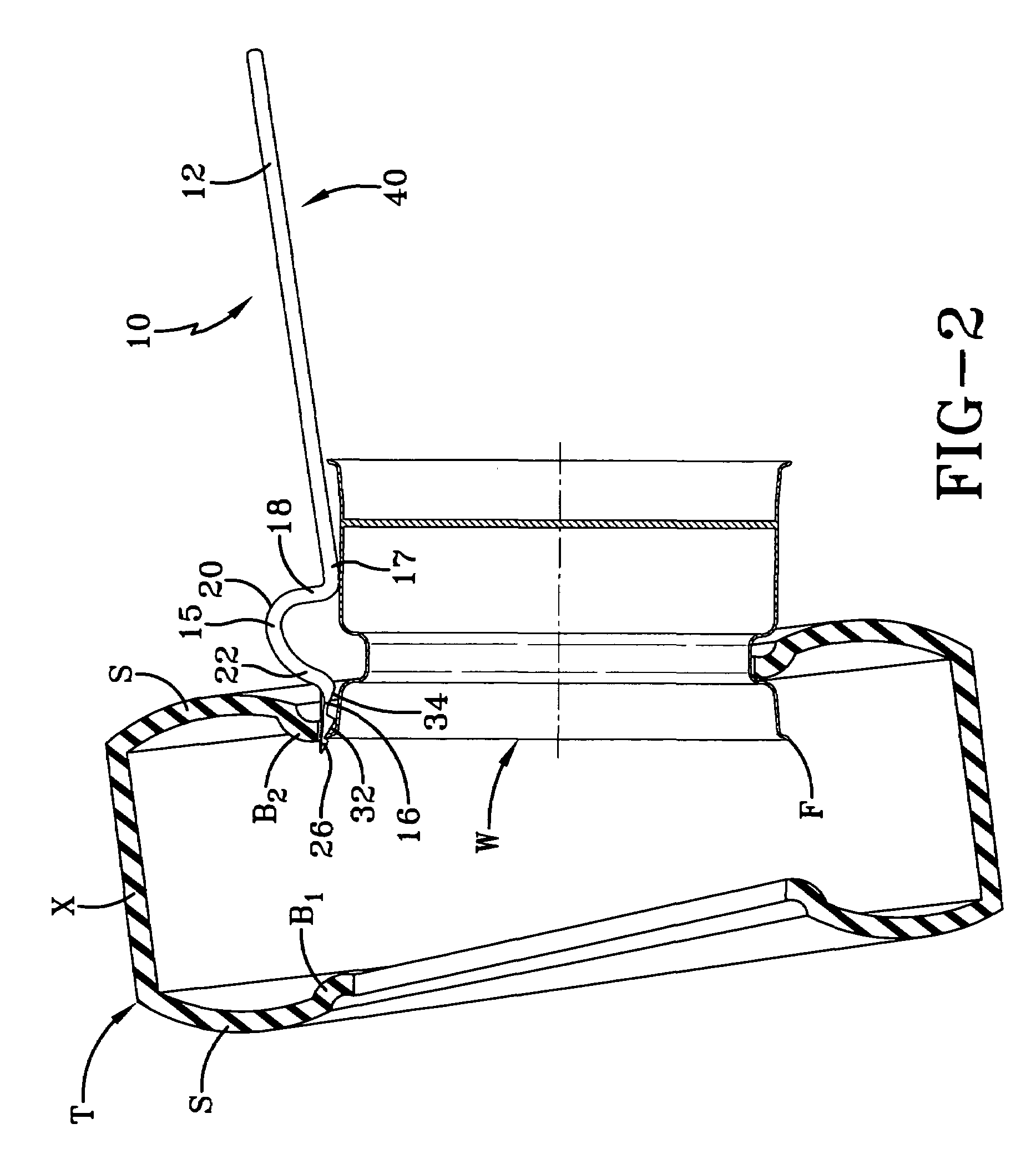

Tire demounting tool

A tire demounting tool for demounting a second bead of a tire from a rim having a flange, the tire demounting tool including a handle; a head extending radially outward as it extends axially outward from the handle; a bill extending axially outward from the head, wherein the bill includes a tip insertable between the second bead and the rim and wherein the head extends radially outward relative to the bill to capture the second bead when the bill is inserted between the rim and the second bead.

Owner:SUMMIT TOOL

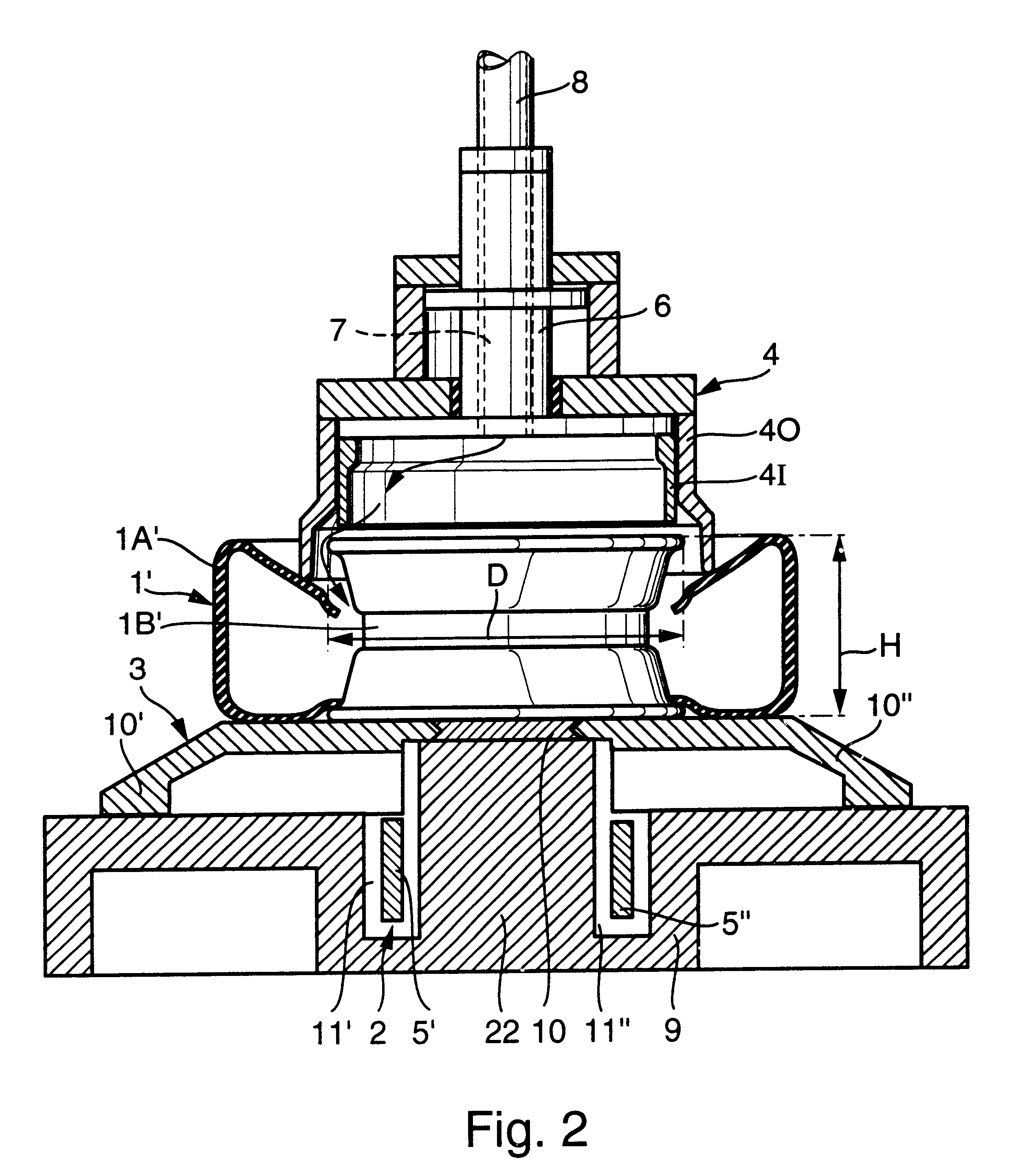

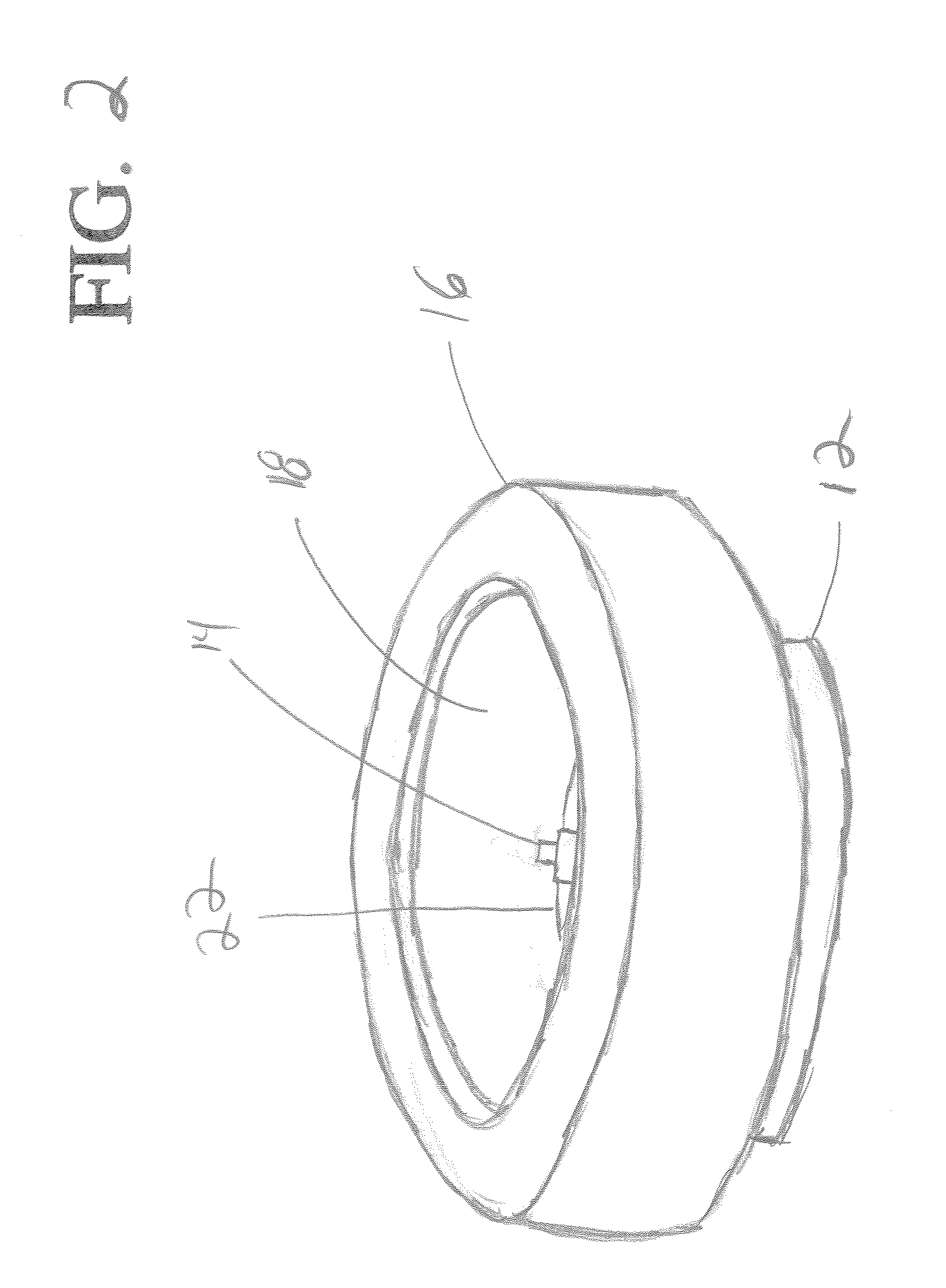

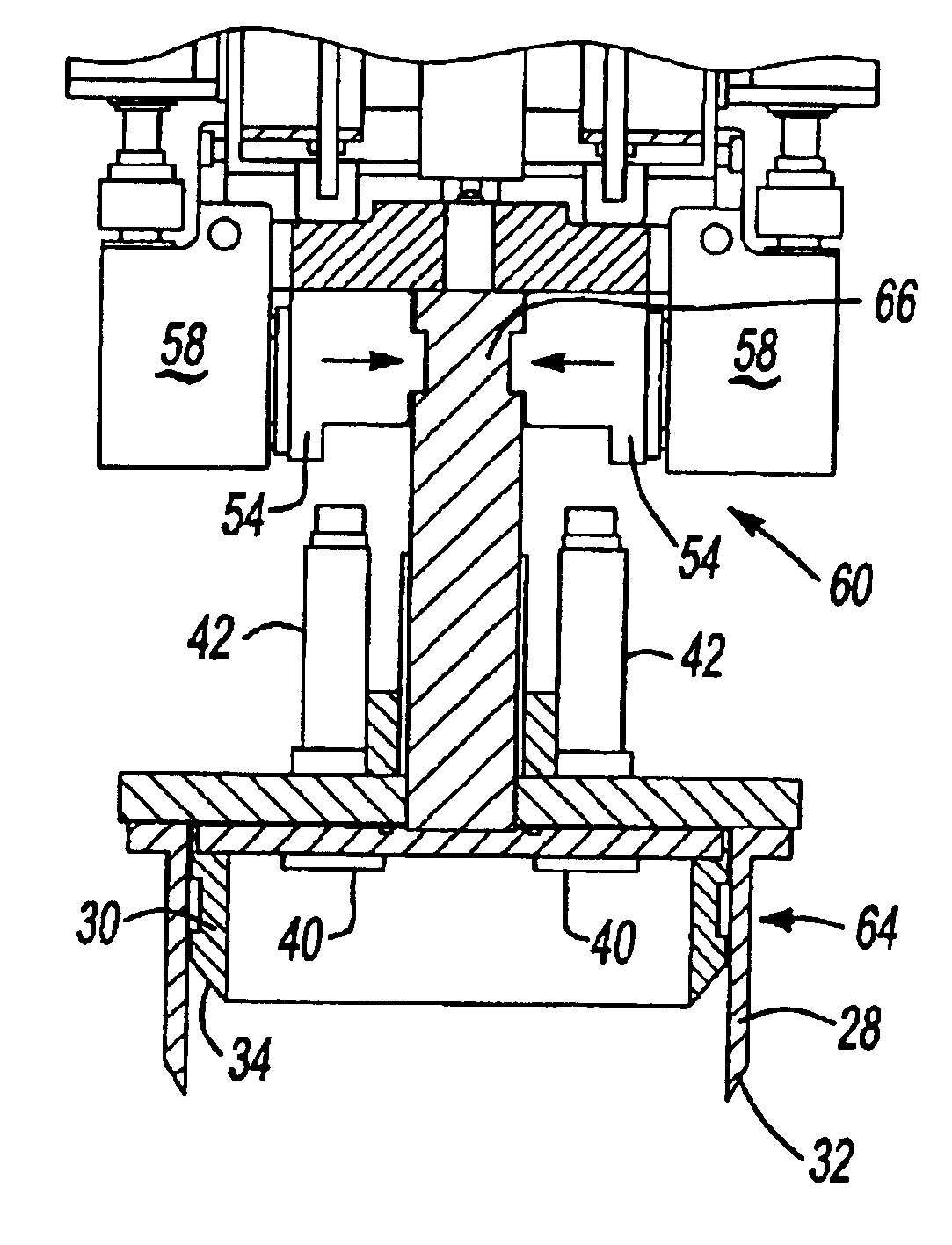

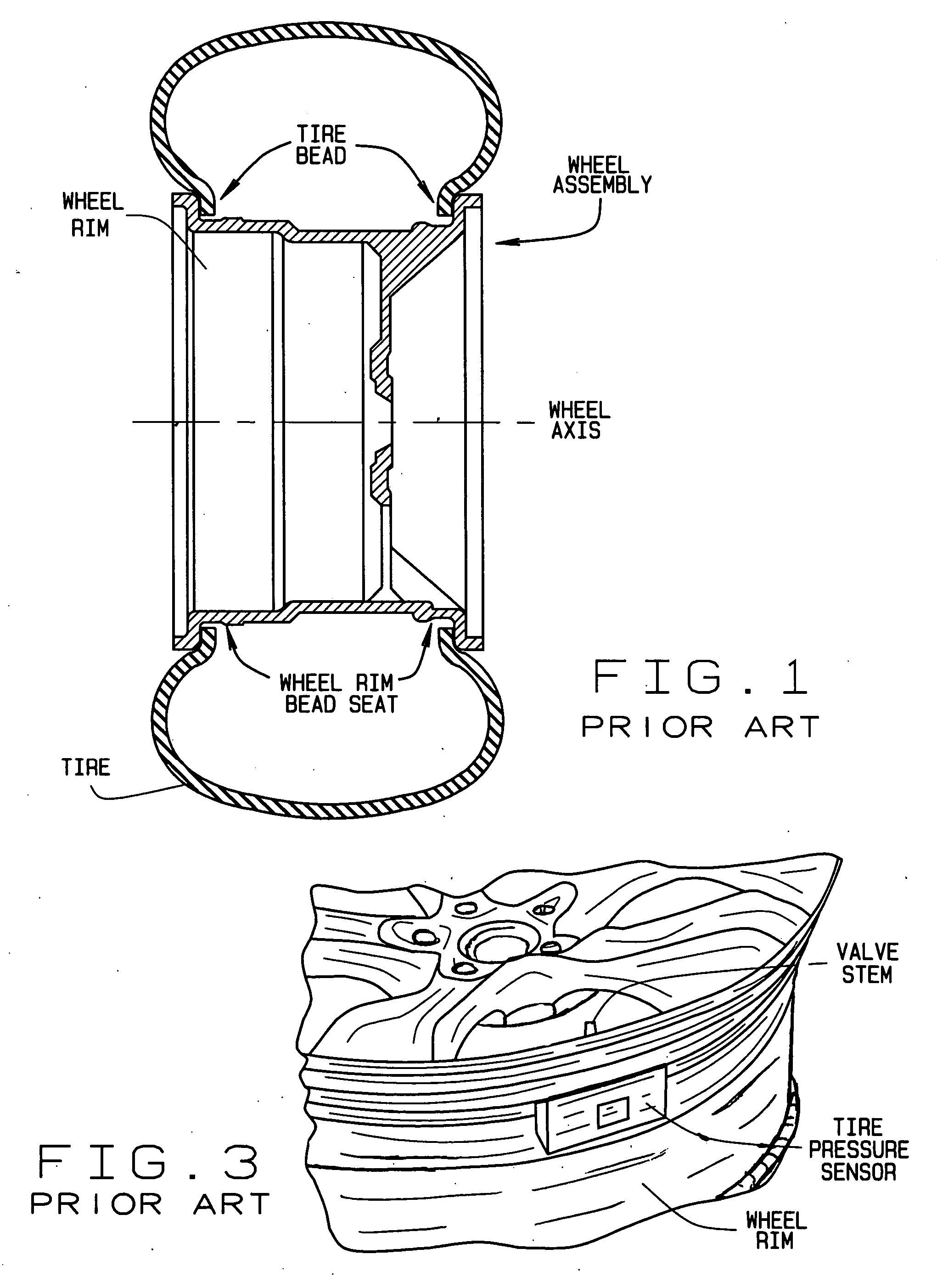

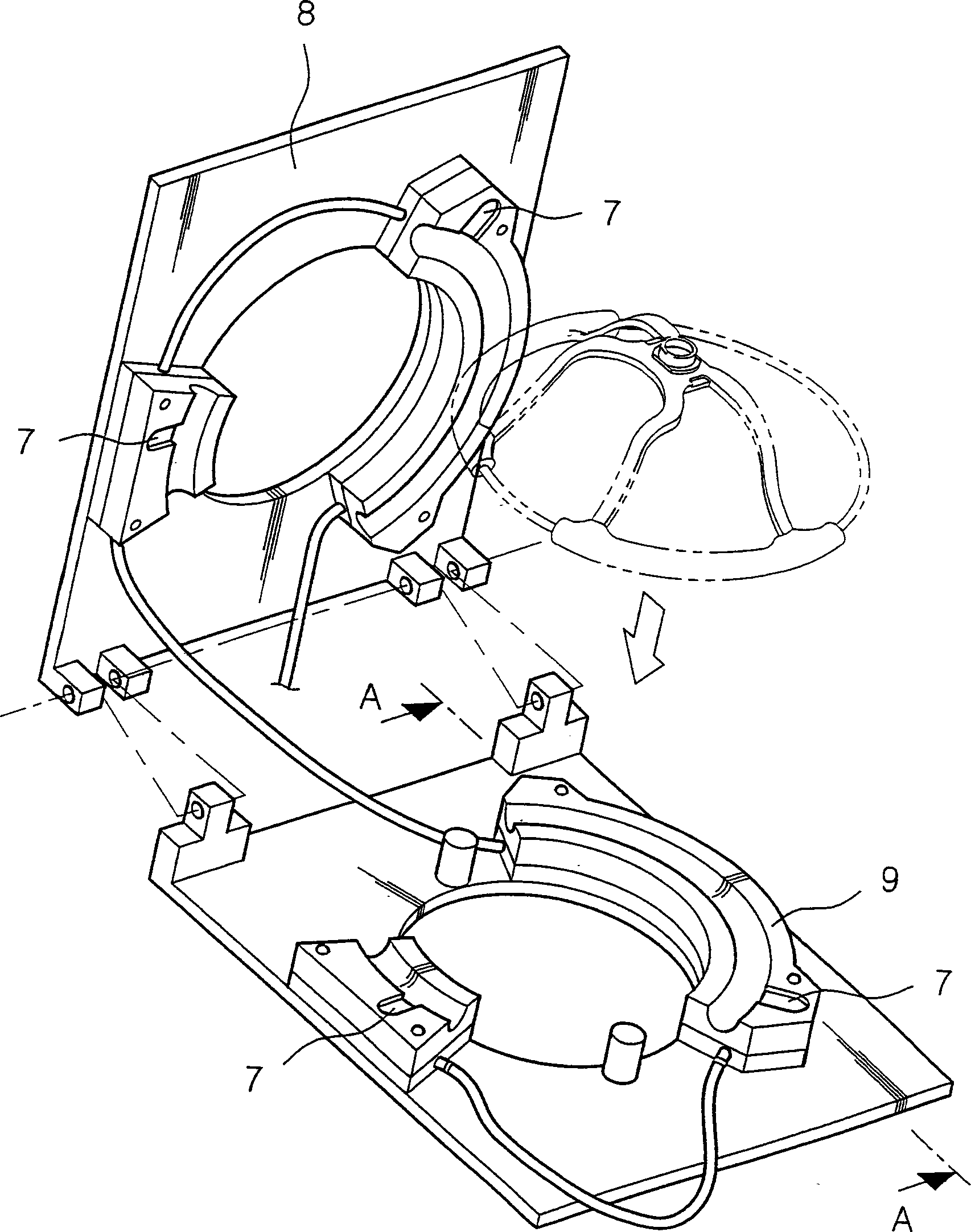

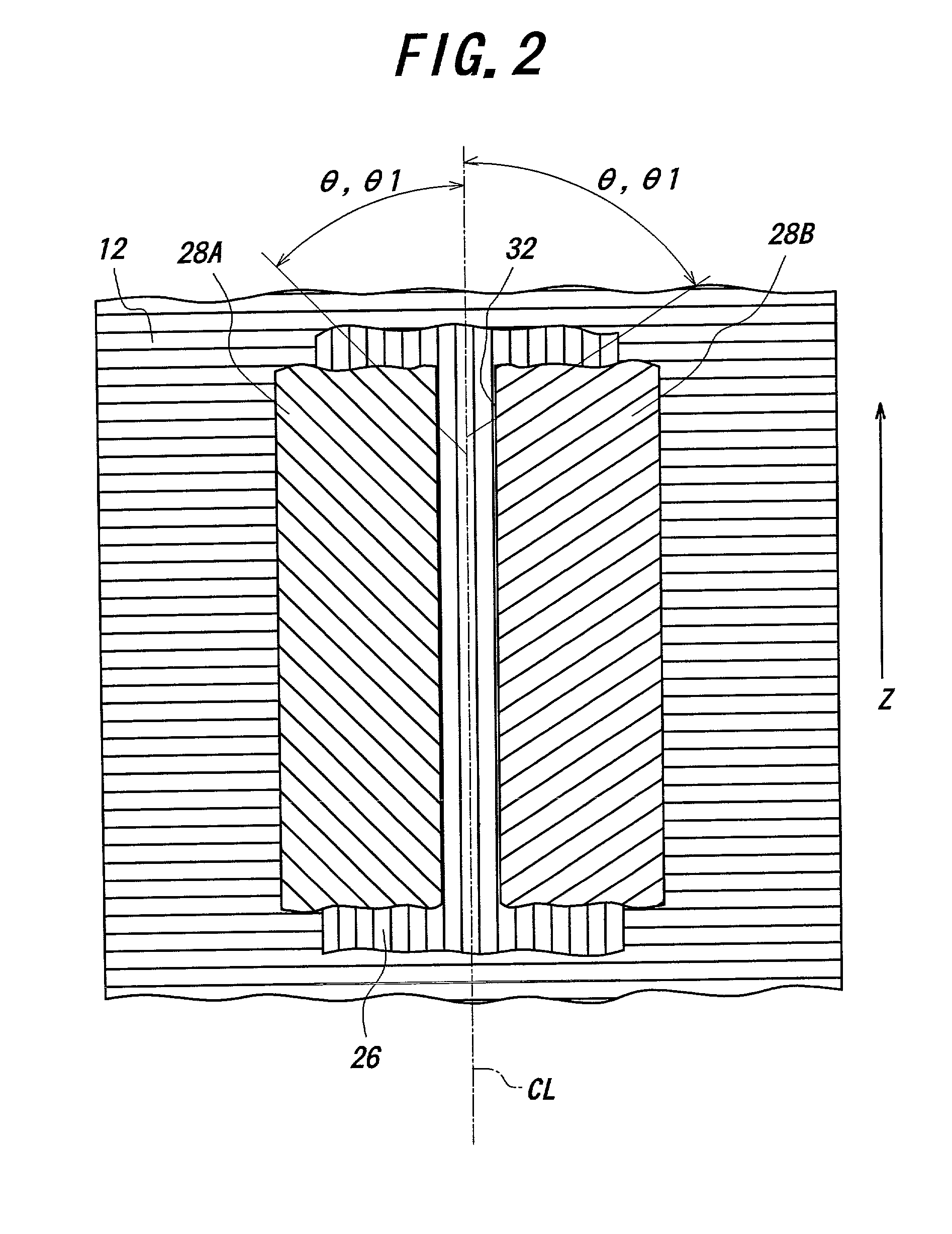

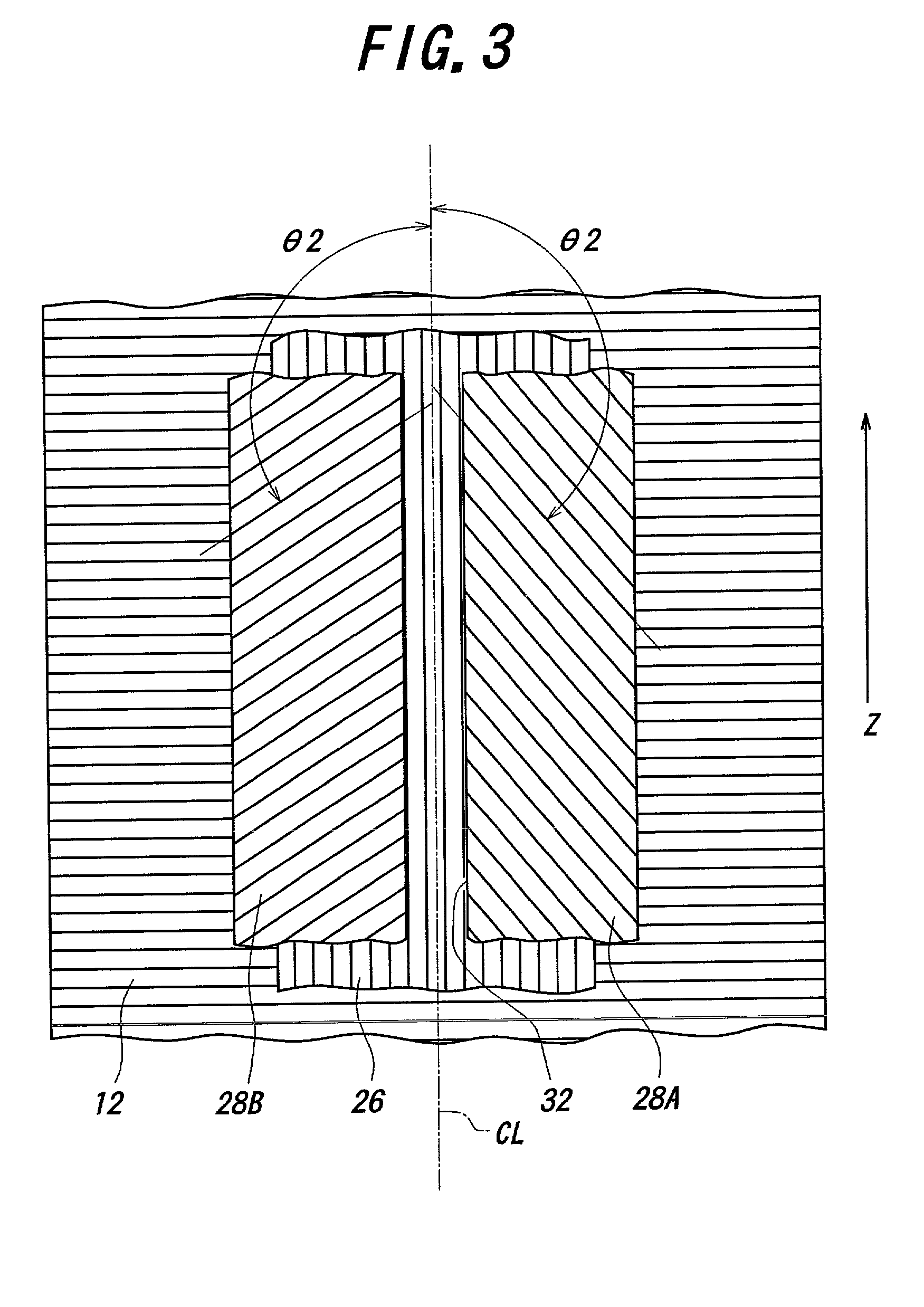

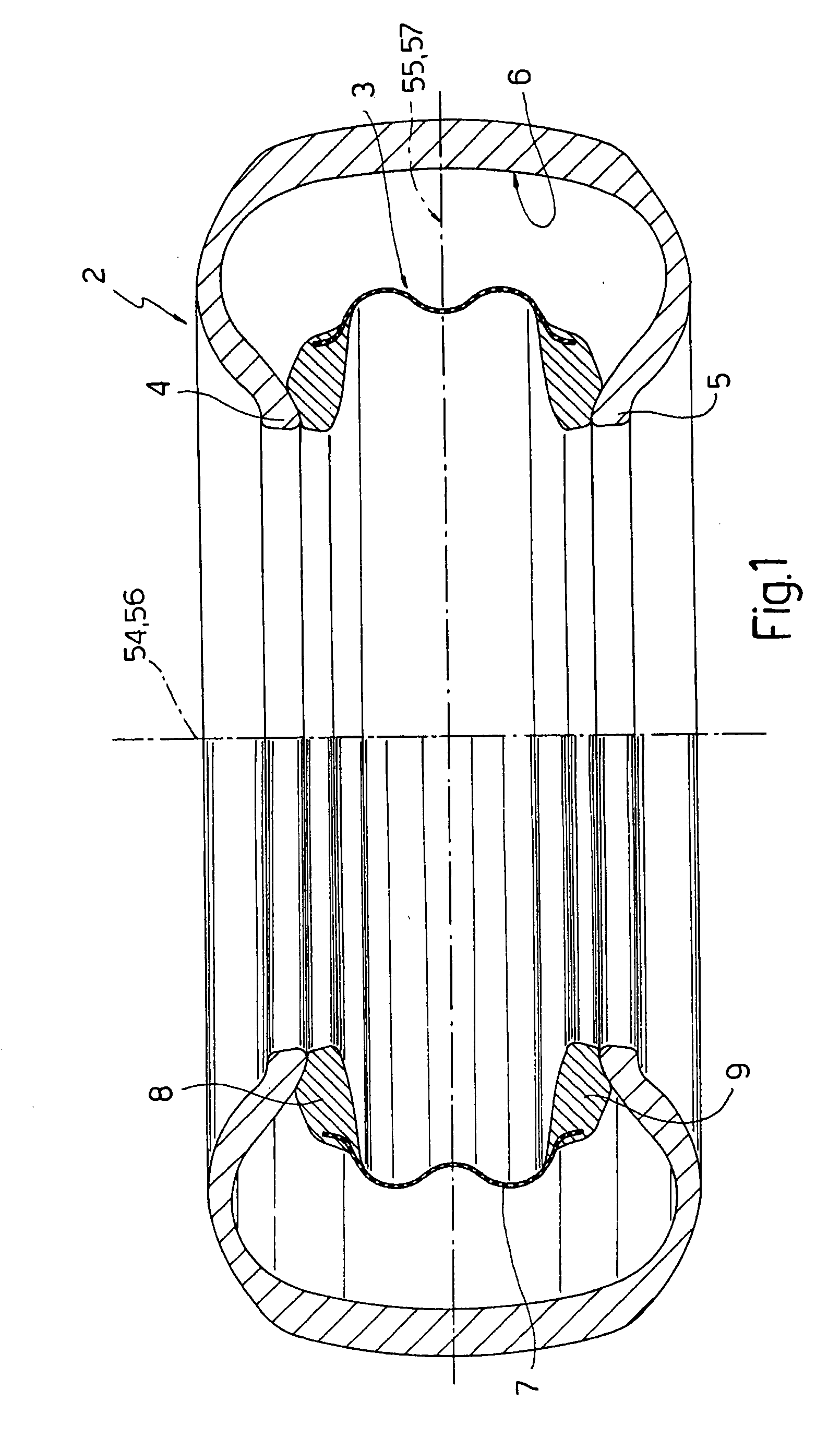

Concentric bell assembly

ActiveUS6918423B2Overcome deficienciesWheelsWood-rimmed wheels manufacturingTubeless tireEngineering

A bell assembly for inflating a tubeless tire on a wheel includes a first bell and a second bell slidably disposed within the first bell. The second bell includes a smaller diameter than the first bell. A shaft extends upwardly from the second bell in one of a relative to the first bell. A locking member is engagable with the shaft and is movable between a first locking position and a second locking position. The locking member secures the second bell in the first bell position when the locking member is disposed in the first locking position. The locking member secures the second bell in the second bell position when the locking member is disposed in the second locking position.

Owner:DURR SYST INC

Vehicle tire changer with integrated detector for tire pressure sensors

An improved vehicle wheel tire changing system configured to detect the presence of a tire pressure monitoring system sensor, mounted within a vehicle wheel assembly, prior to altering the mounting of a tire on an associated wheel rim.

Owner:HUNTER ENG

Vertical transfer device for tire assembly line

ActiveUS20050056526A1Effective movementPrecise positioningWheelsConveyor partsAssembly lineEngineering

Owner:DURR SYST INC

Vertical transfer device for tire assembly line

Owner:DURR SYST INC

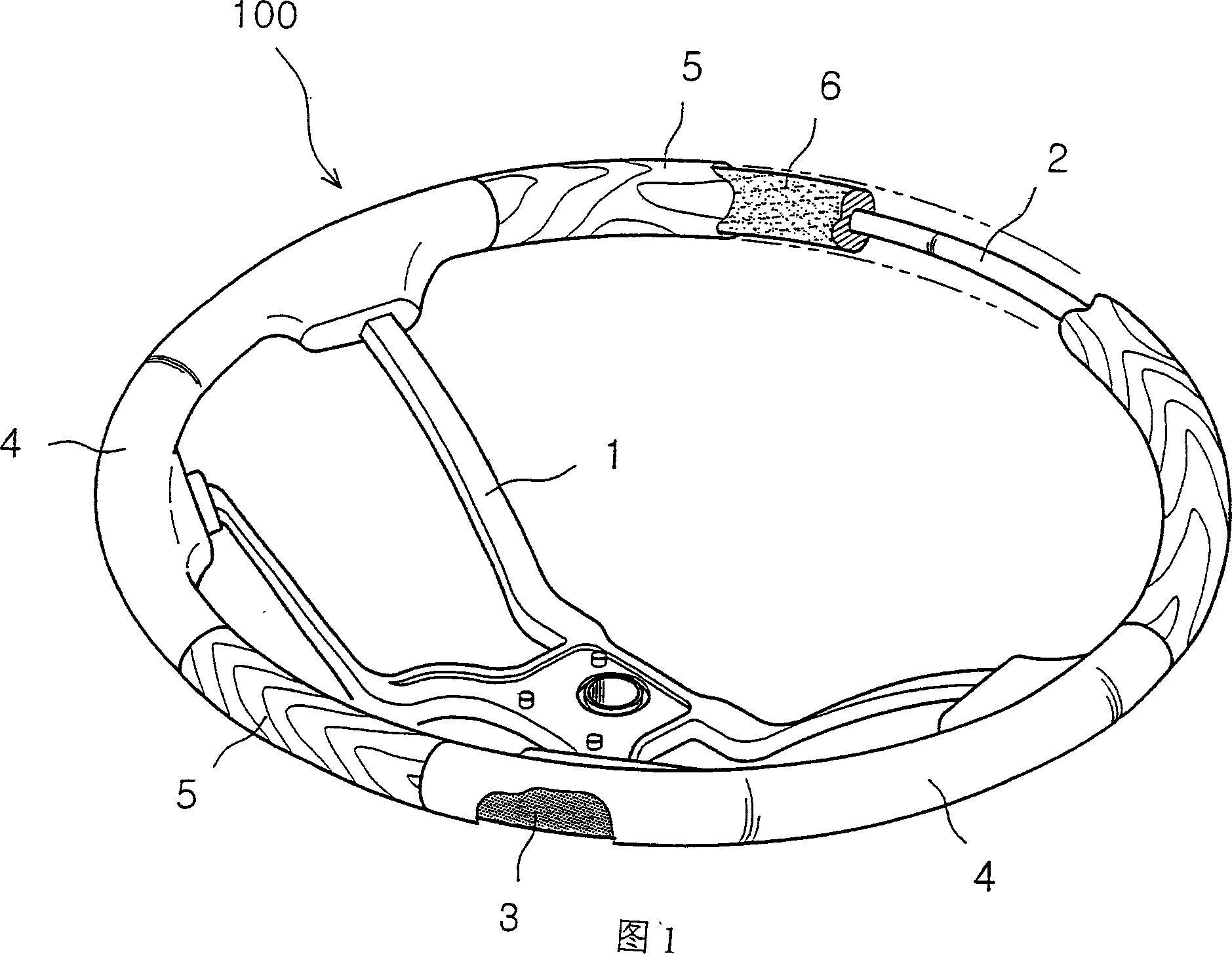

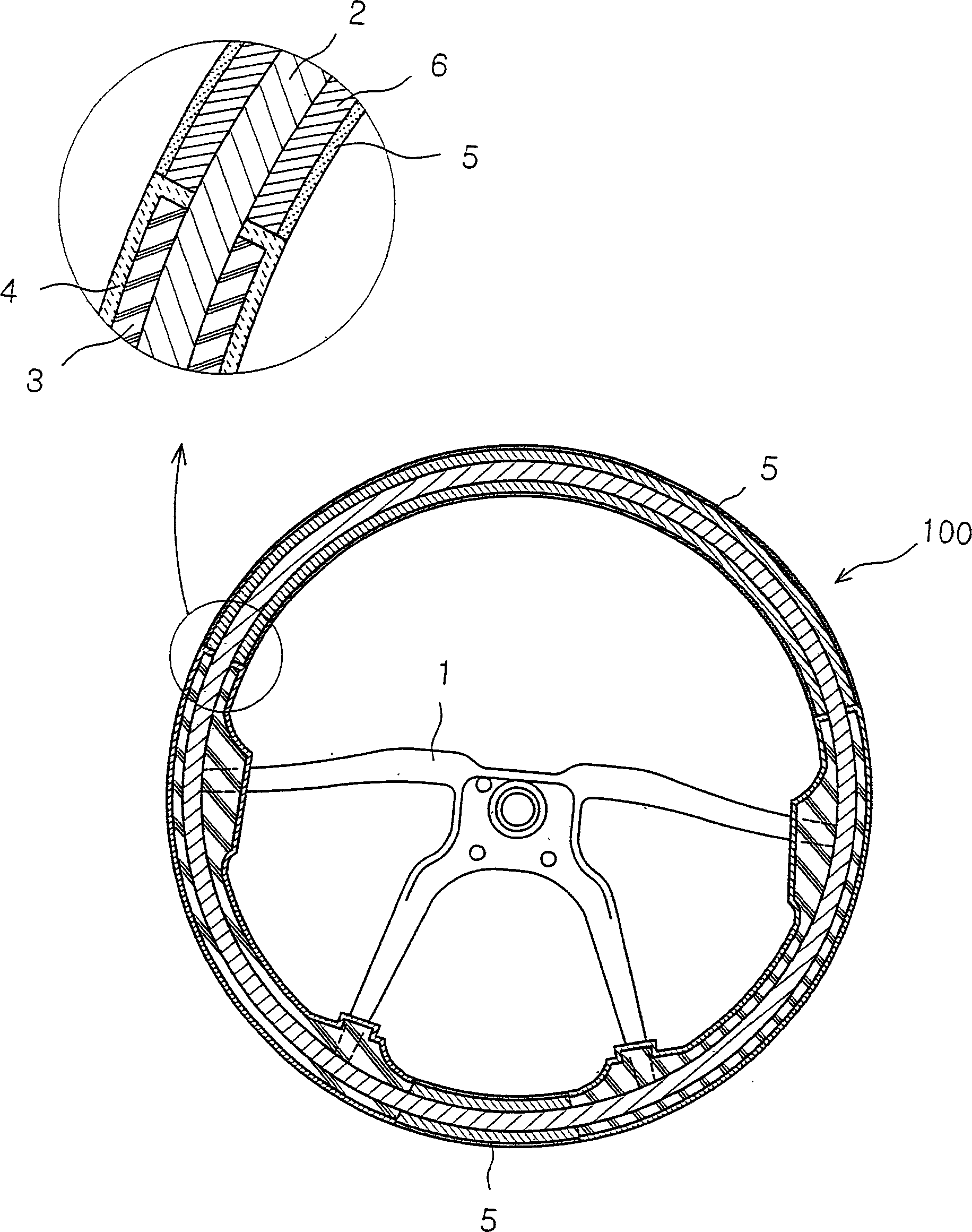

Wood grain steering wheel for car and its making method

The invention discloses a steering wheel for automobiles partially molded from a wood-grain film and a manufacturing method thereof. In particular, it relates to a steering wheel for automobiles which is partly integrally molded with non-foamed polyurethane resin and molded with a wood-grained film, thereby having a good woody feel, and a wood-grained film molded with non-foamed polyurethane resin. The resin part is molded to improve the adhesion of the film to the manufacturing method of the steering wheel of the car. The manufacturing method of the automobile steering wheel includes 1. mixing raw materials; 2. installing the steering wheel between the upper and lower metal molds and connecting the upper and lower metal molds to prepare for non-foaming molding; 3. injecting the mixed raw materials to make non-foaming polyurethane resin molding And take out the product; 4, remove the burr (burr) on the product and clean it; 5, dry and grind the surface to remove the pores; 6, fill the surface pores and re-dry and grind the surface to remove the pores and other six processes.

Owner:李基何 +1

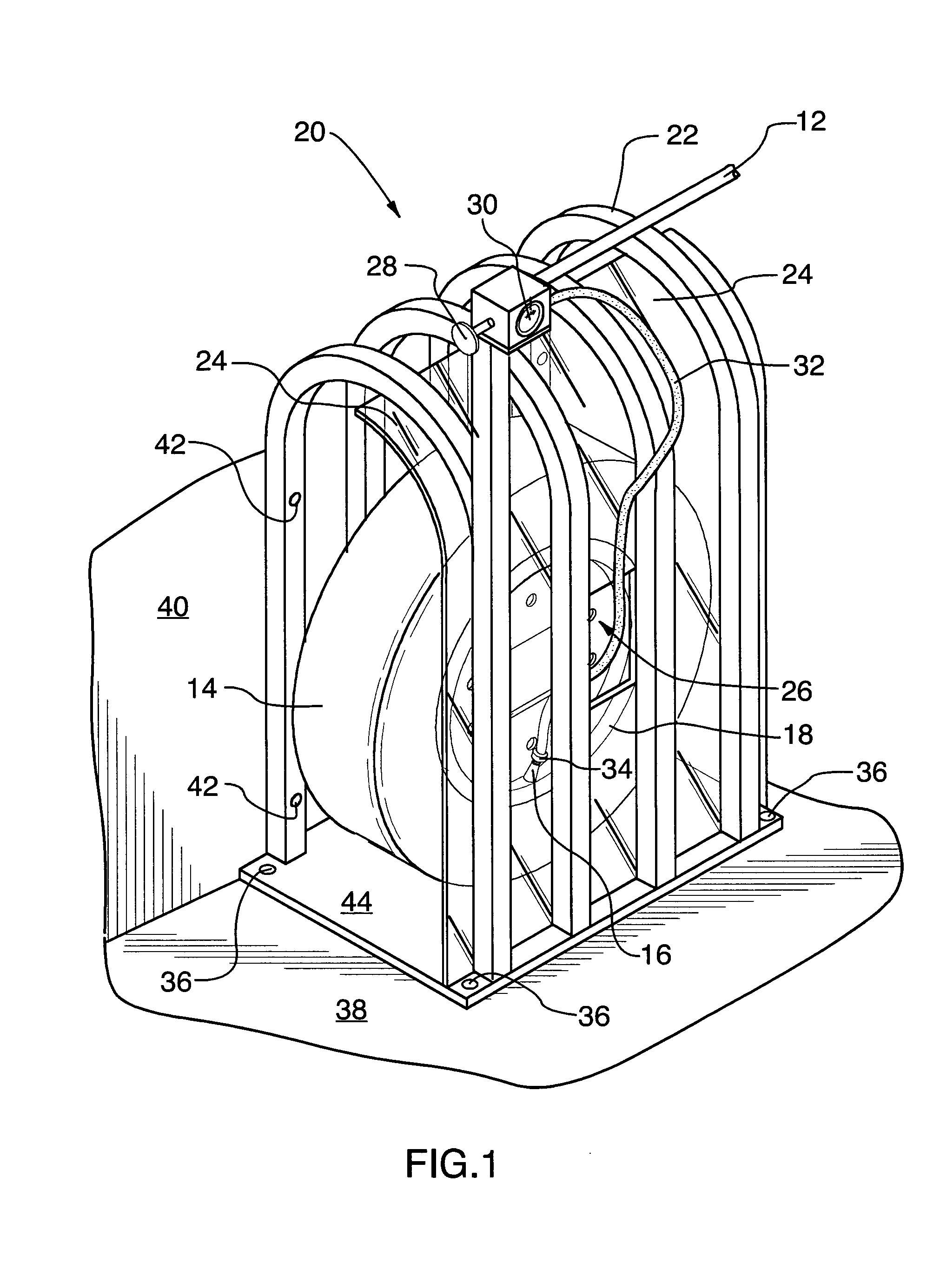

Tire changer with attached inflation cage

A tire changing machine comprises a chassis base and a rotatable wheel holder configured to retain a wheel rim. A tower, carrying a mount / demount head movable toward and away from the wheel rim, extends upward from the chassis base. An inflation cage is fixed with respect to the chassis base. The inflation cage defines an interior accessible through a first opening for ingress and egress of a vehicle wheel. Preferably, the inflation cage may be located at a back of the tire changer to rest on a common floor surface with the chassis base.

Owner:HENNESSY IND

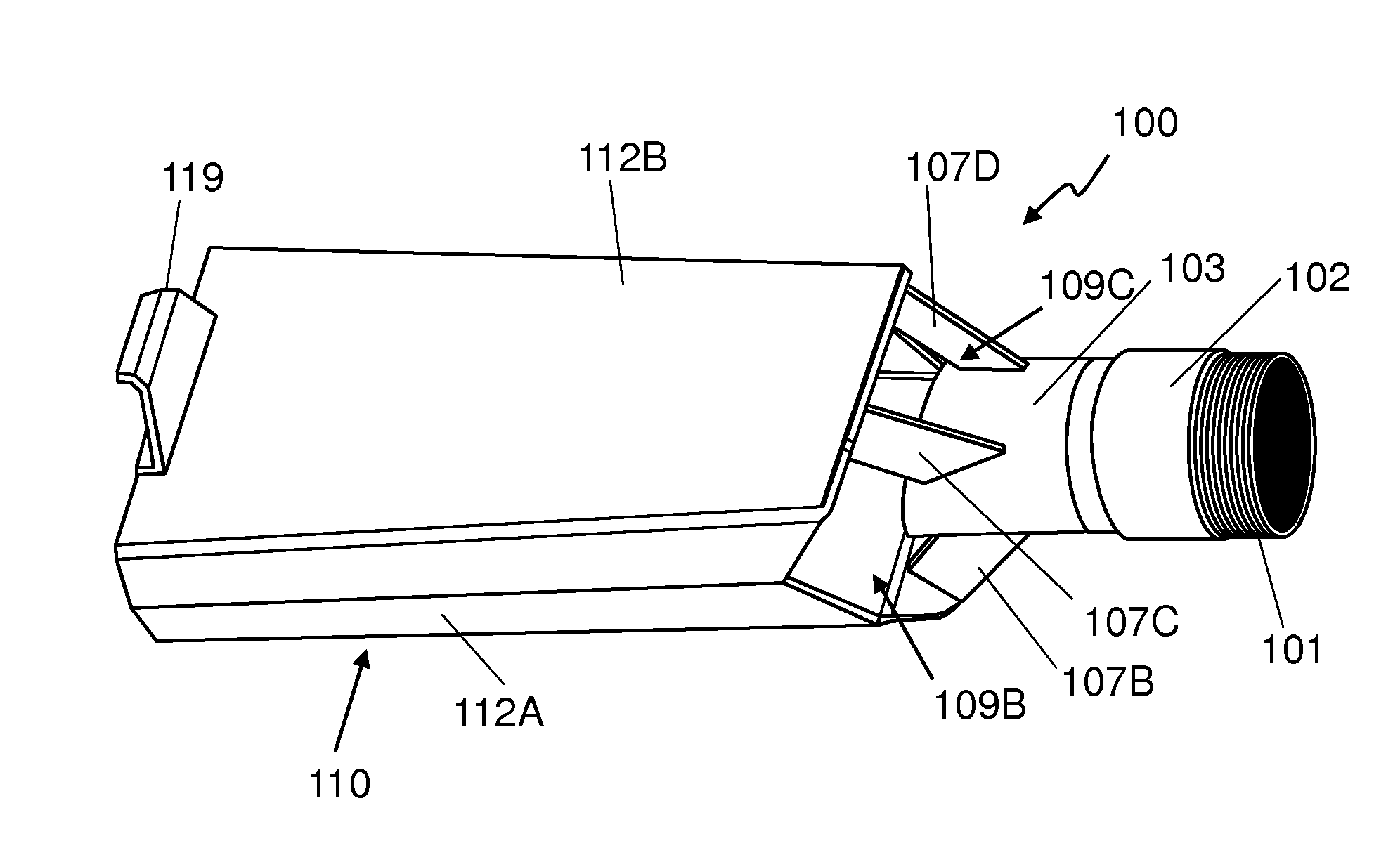

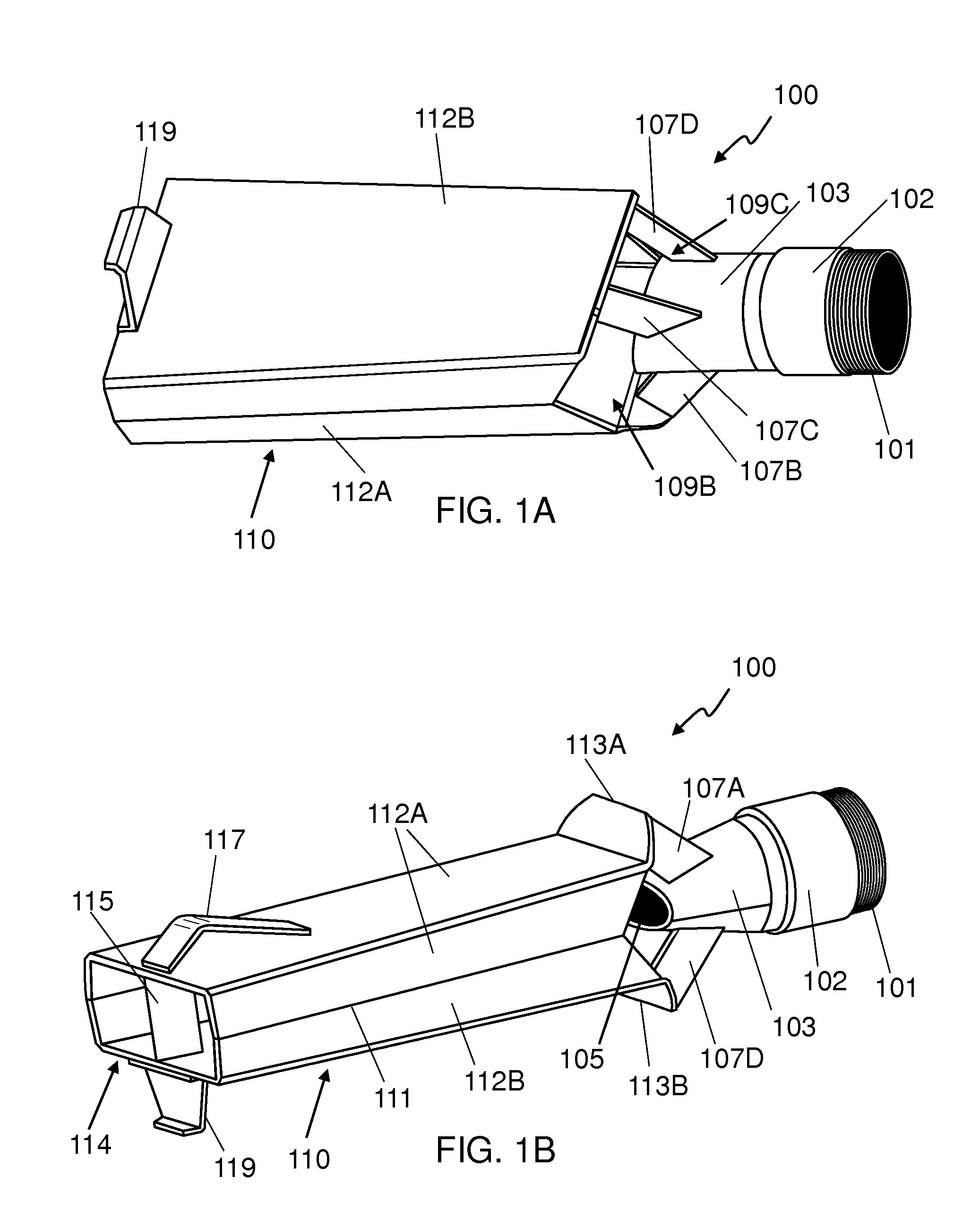

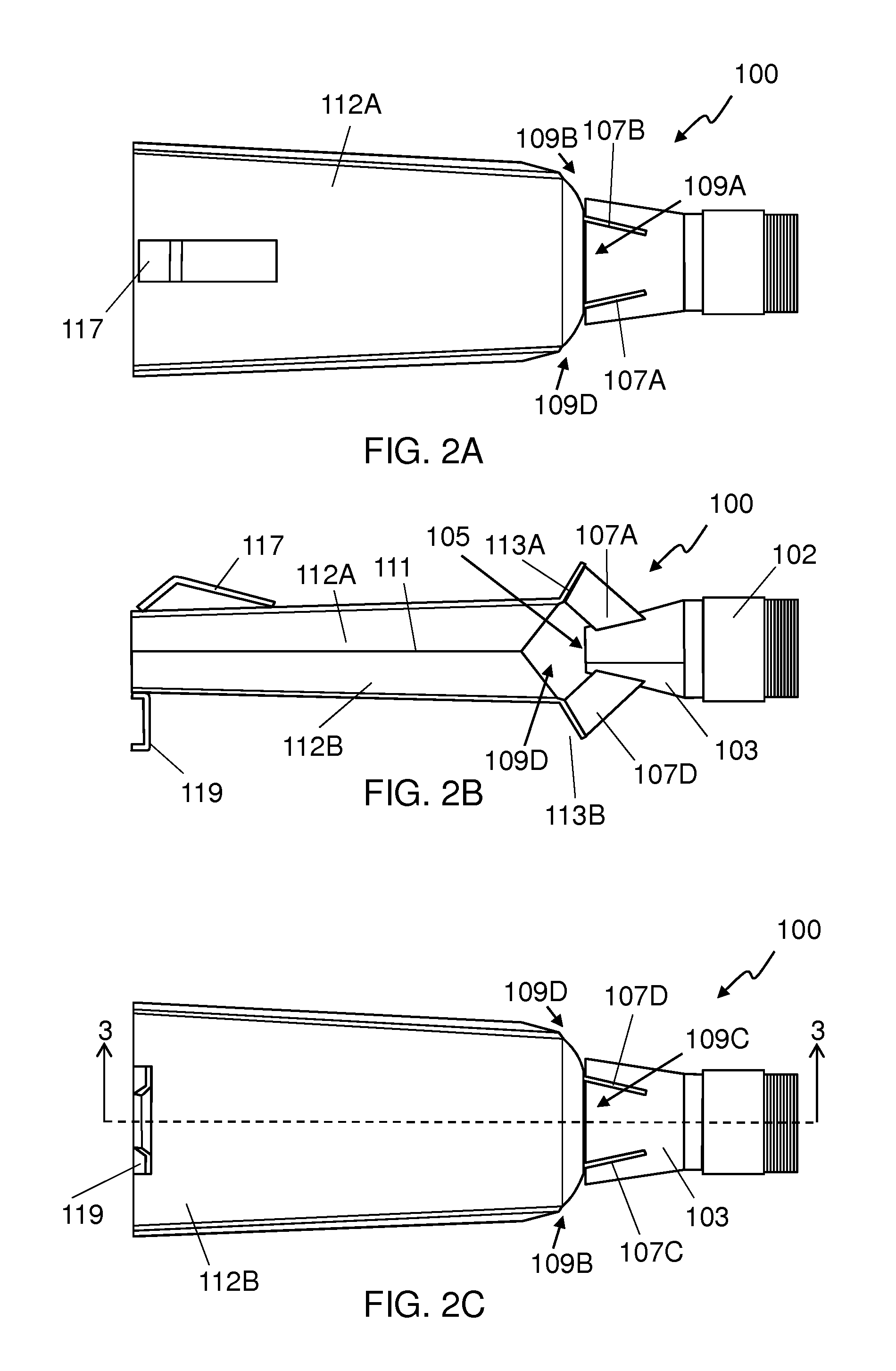

Jet assisted tubeless tire seating device

A nozzle for seating a tubeless tire on a rim using pressurized gas includes an outlet, a jet configured to accept pressurized gas and emit a stream of gas through an orifice into a chamber. As the stream of gas enters the chamber, the Venturi effect causes air to enter the chamber through air intake ports and the stream of gas and air from the air intake ports is blown out of the outlet of the nozzle. A system for seating a tubeless tire on a rim includes the nozzle, a tank and a valve configured to control the flow of pressurized gas from the tank to the nozzle. The tire may be seated on the rim by positioning the system so that the air from the nozzle blows into the tire between the bead of the tire and the rim if the valve is opened.

Owner:GAITHER TOOL COMPANY

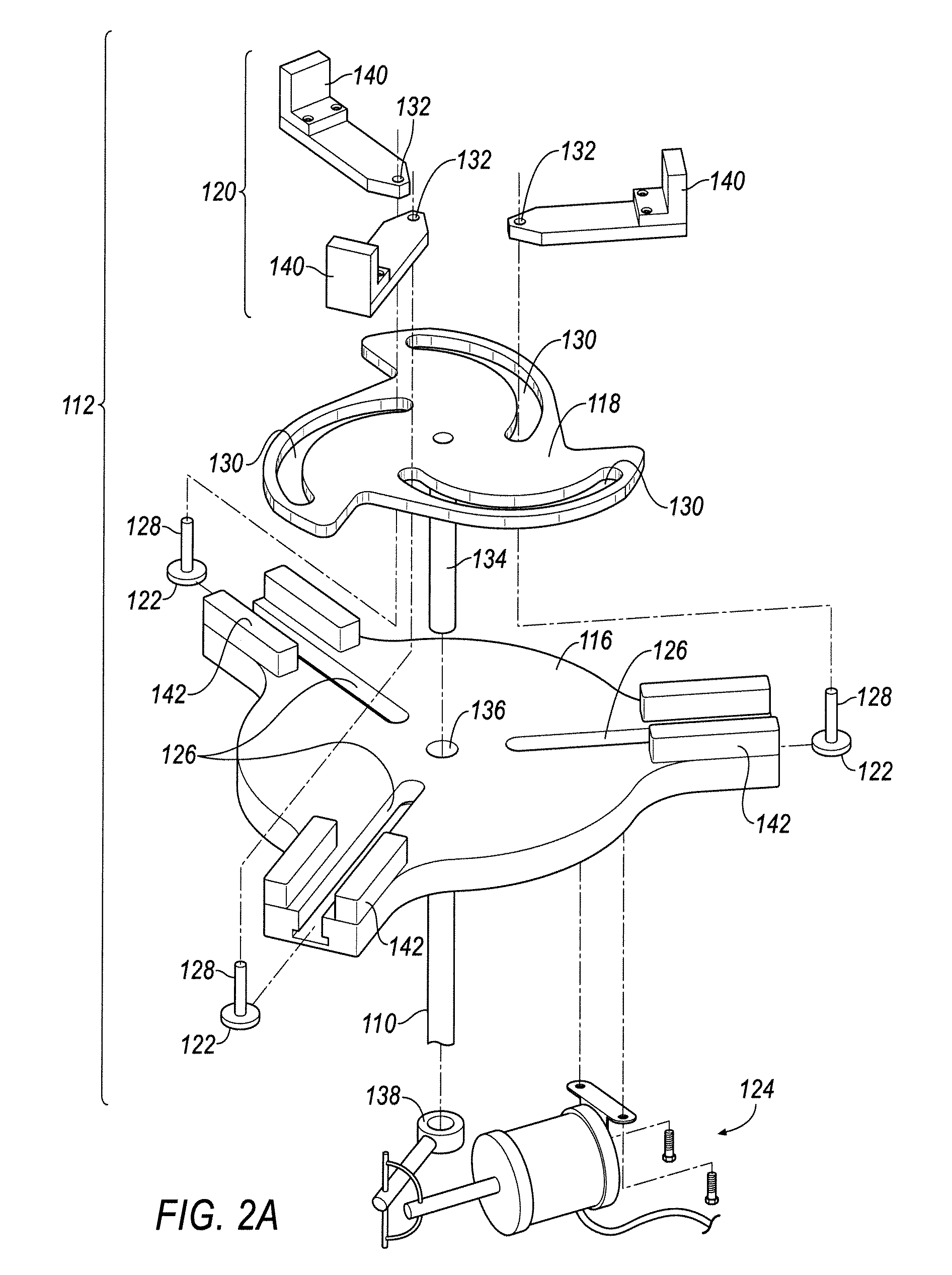

Method and Apparatus for Retaining a Wheel

A device for retaining a wheel having an inner diameter during an assembly operation of a tire-wheel assembly at a single-cell workstation includes a claw portion that releasably-attaches to the inner diameter of the wheel, including a fixed portion and a rotatable portion, wherein the rotatable portion is rotatably-disposed upon the fixed portion; wheel-engaging portions slidably-disposed upon the rotatable portion; sliding portions that are slidably-disposed within the fixed portion, wherein each sliding portion is coupled with one of each wheel-engaging portion, and an actuator portion coupled to the rotatable portion. A method is also disclosed.

Owner:ANDROID INDS OF MICHIGAN

Improper working position detection for tire mounting apparatus and method

An apparatus for mounting a tire on a wheel rim includes a mounting head with a tire bead deflector and a tire press-in roller, and a drive that moves the mounting head toward, and rotates the bead deflector and the press-in roller around, the wheel rim. To avoid a damage-causing contact between the bead deflector and the wheel rim, an arrangement for monitoring a minimum spacing distance between the wheel rim and the mounting head is arranged preferably on the bead deflector. If an improper working position closer than the minimum spacing distance is detected, the arrangement produces a signal that influences, e.g. stops, the motion of the mounting head. The arrangement preferably includes a contact member of a comparatively soft low-friction material at a working end of the bead deflector. If the contact member contacts the wheel rim, this actuates a piezoelectric element to generate the required electrical signal.

Owner:SCHENCK ROTEC GMBH

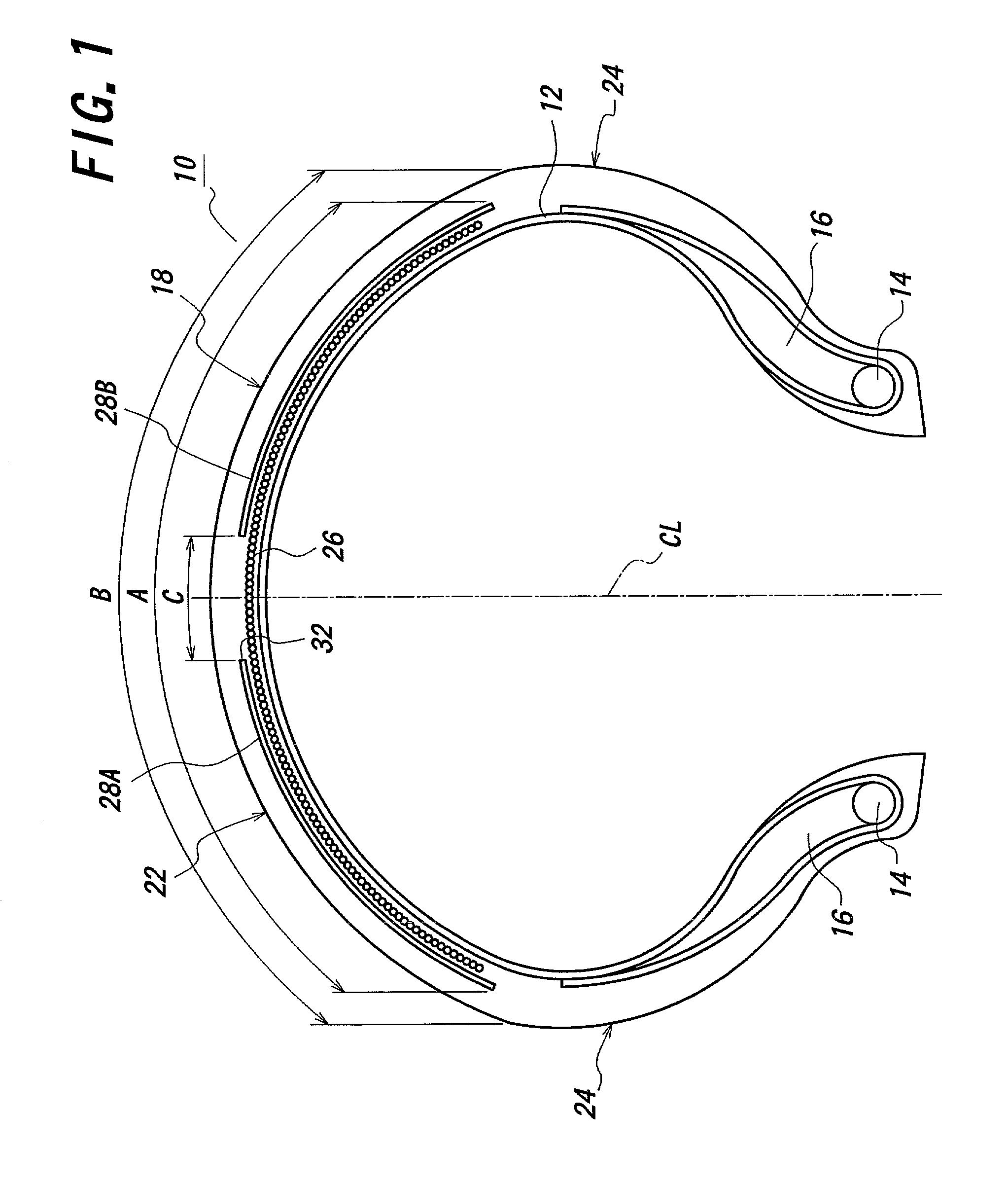

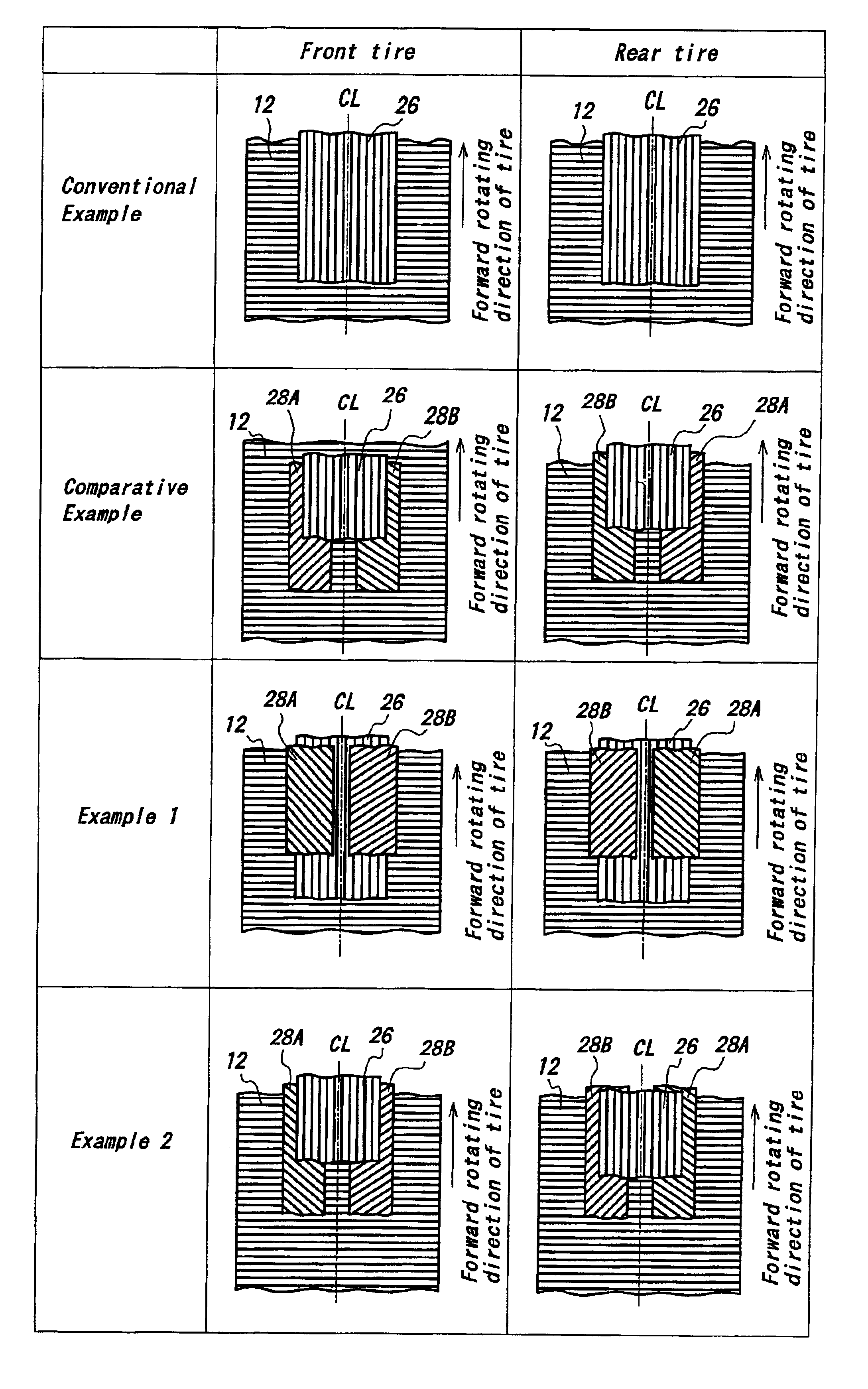

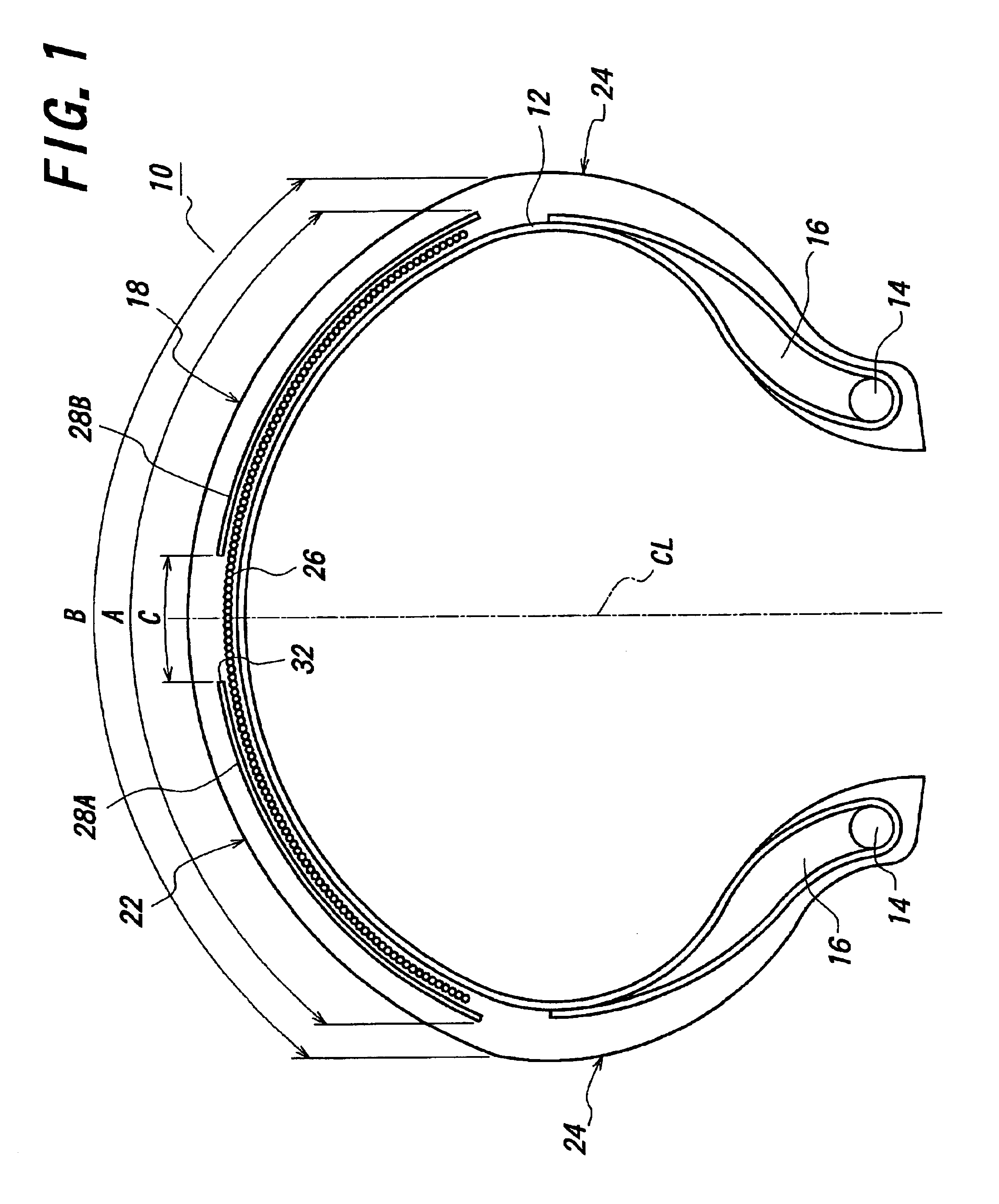

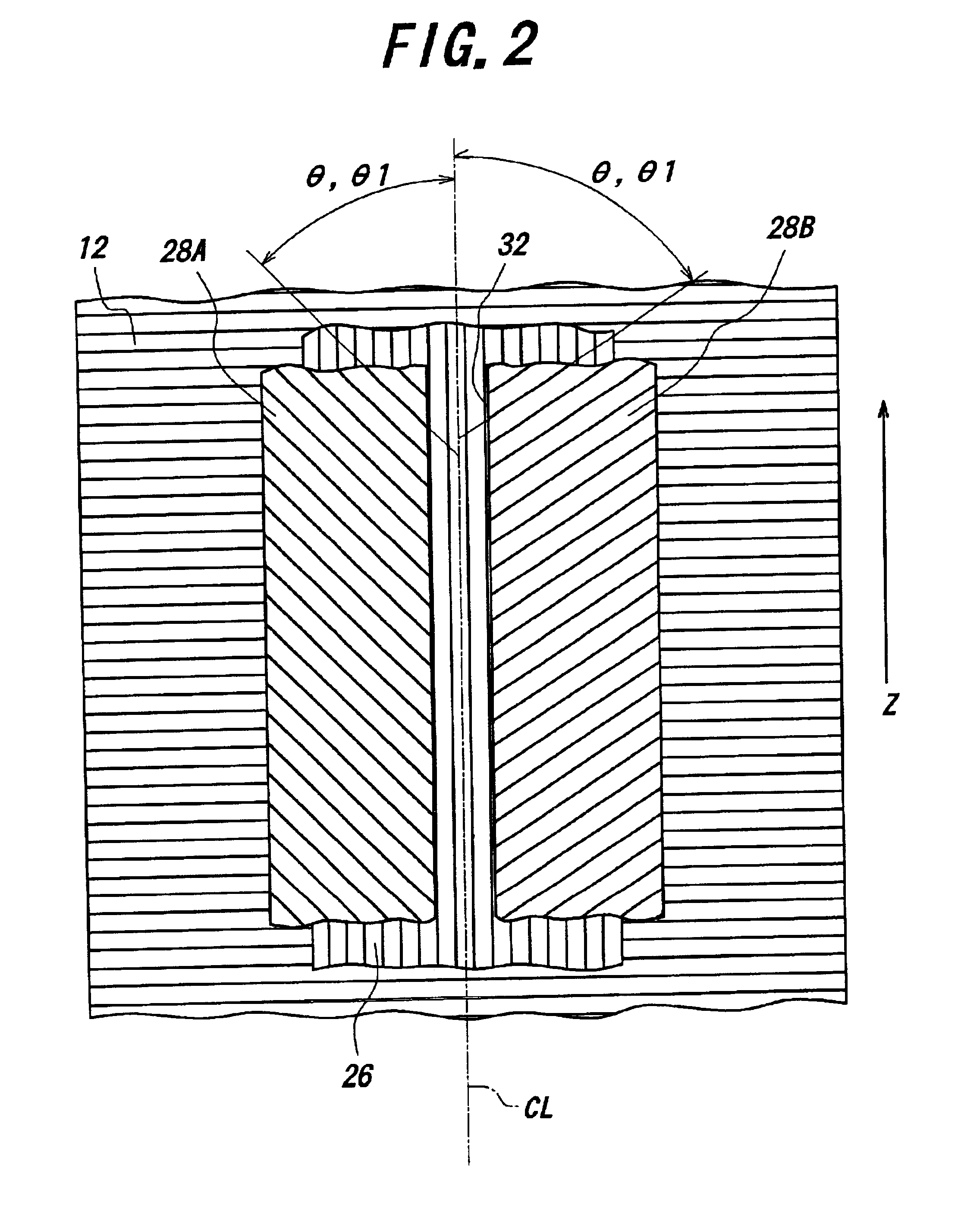

Method of mounting a pneumatic radial tire

InactiveUS20010045263A1Ensures rigiditySpecial tyresPneumatic tyre reinforcementsMechanical engineeringRadial tire

In the method of mounting a pneumatic radial tire comprising a spiral belt and a pair of cross belt members arranged in parallel to each other at both sides of an equatorial plane of the tire and at a given opening space onto a vehicle body, the tire is mounted as a front tire and / or a rear tire so as to contact a portion of the cord in the belt member facing the opening space with ground under a given condition in a forward rotating direction of the tire.

Owner:BRIDGESTONE CORP

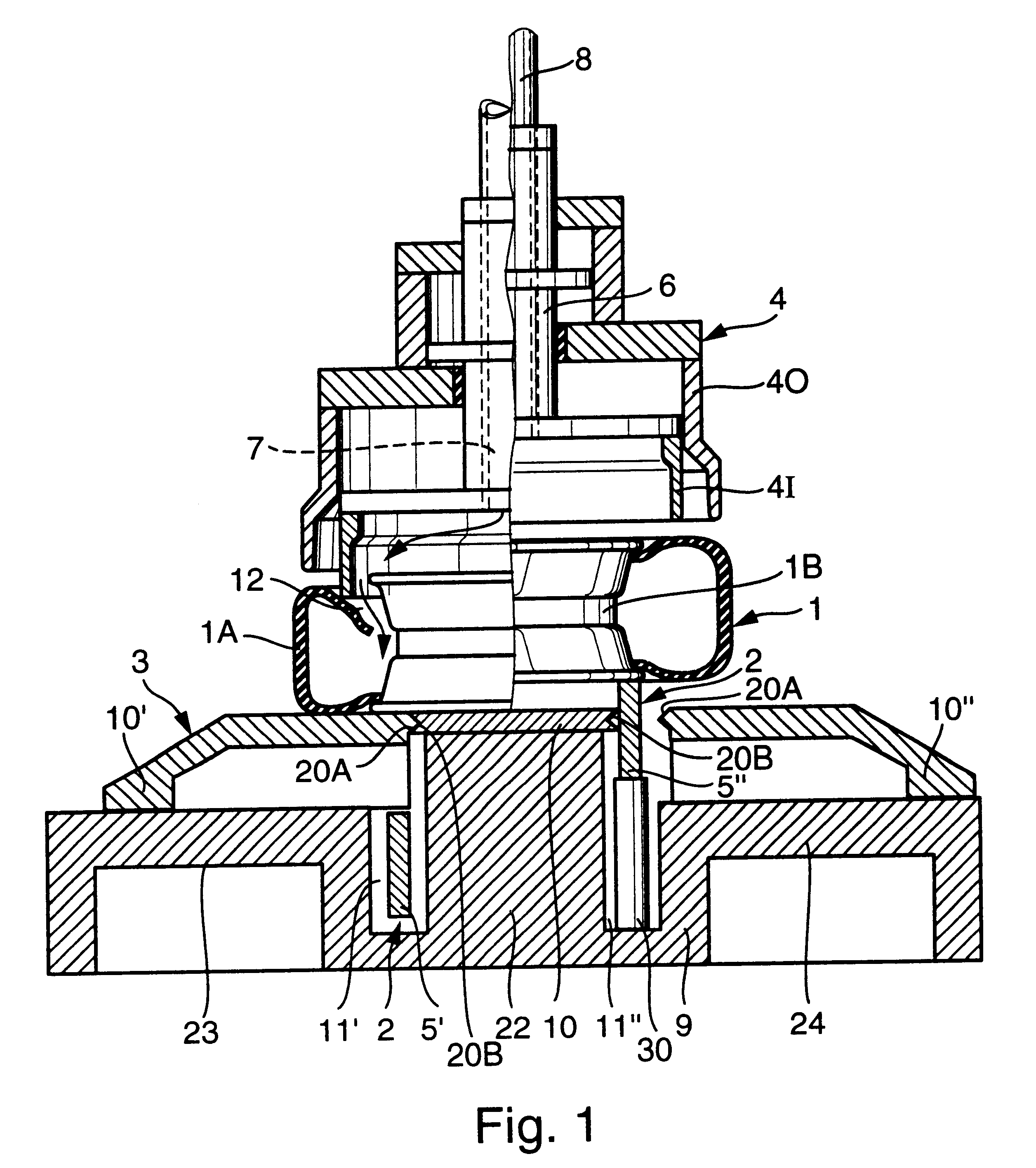

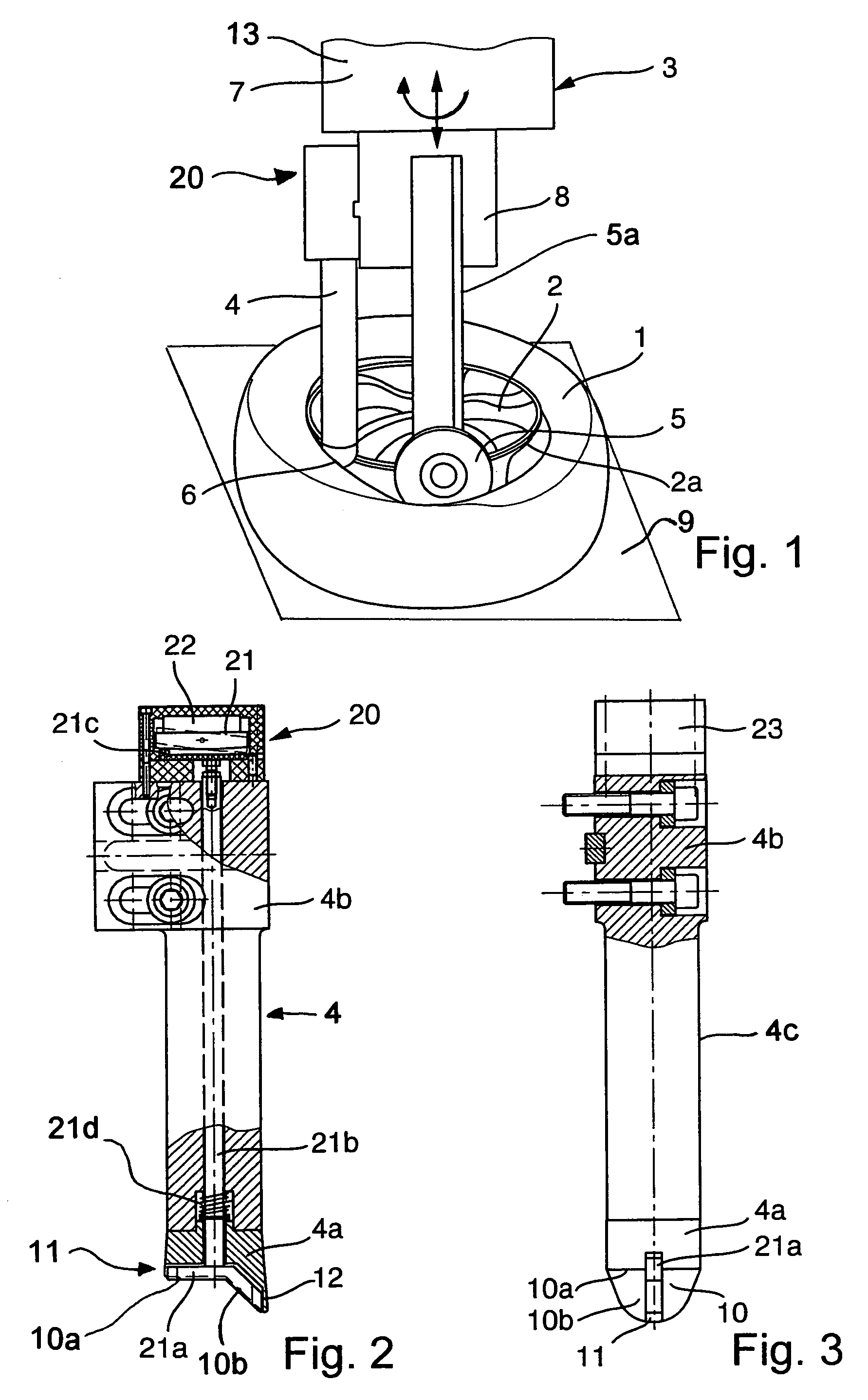

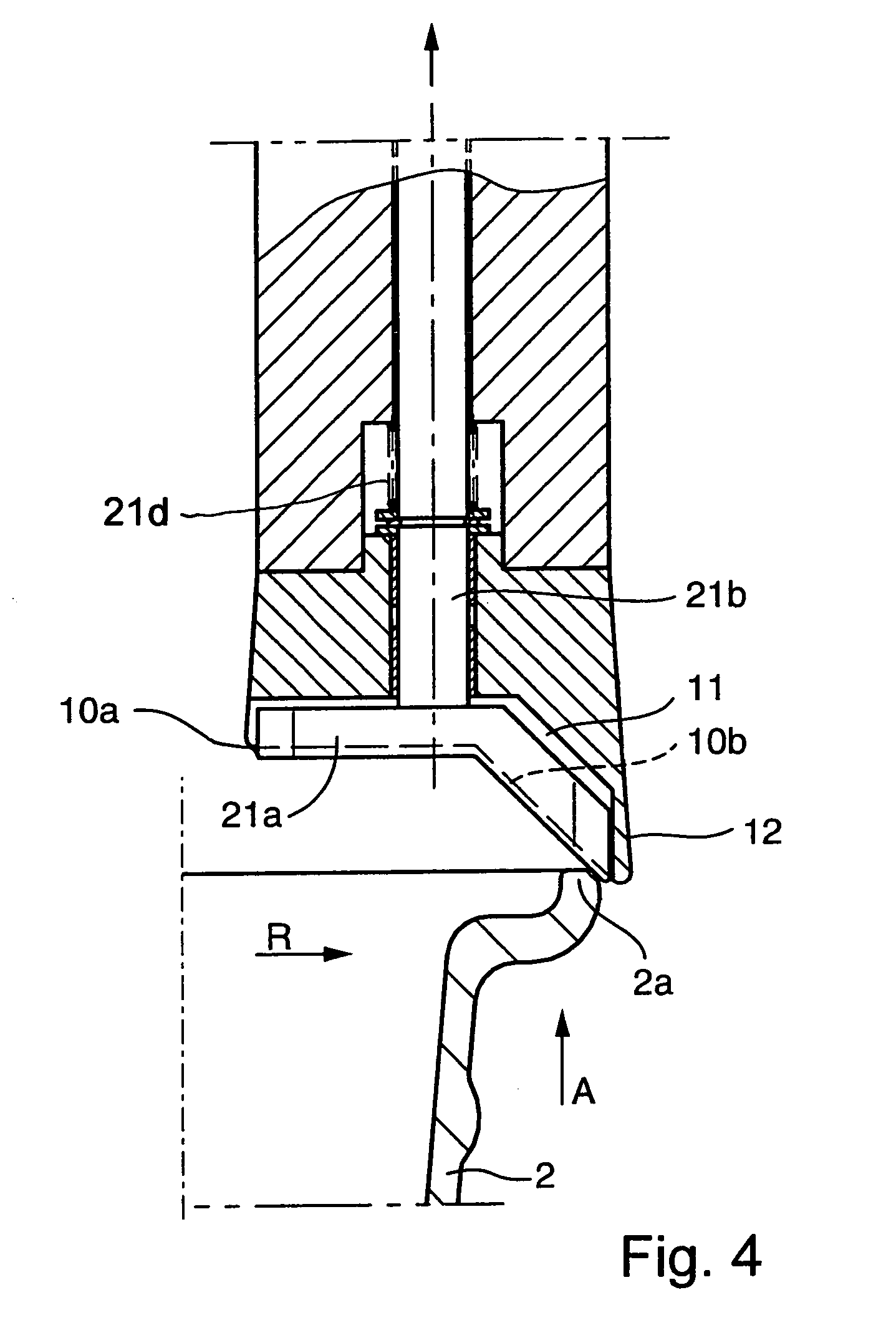

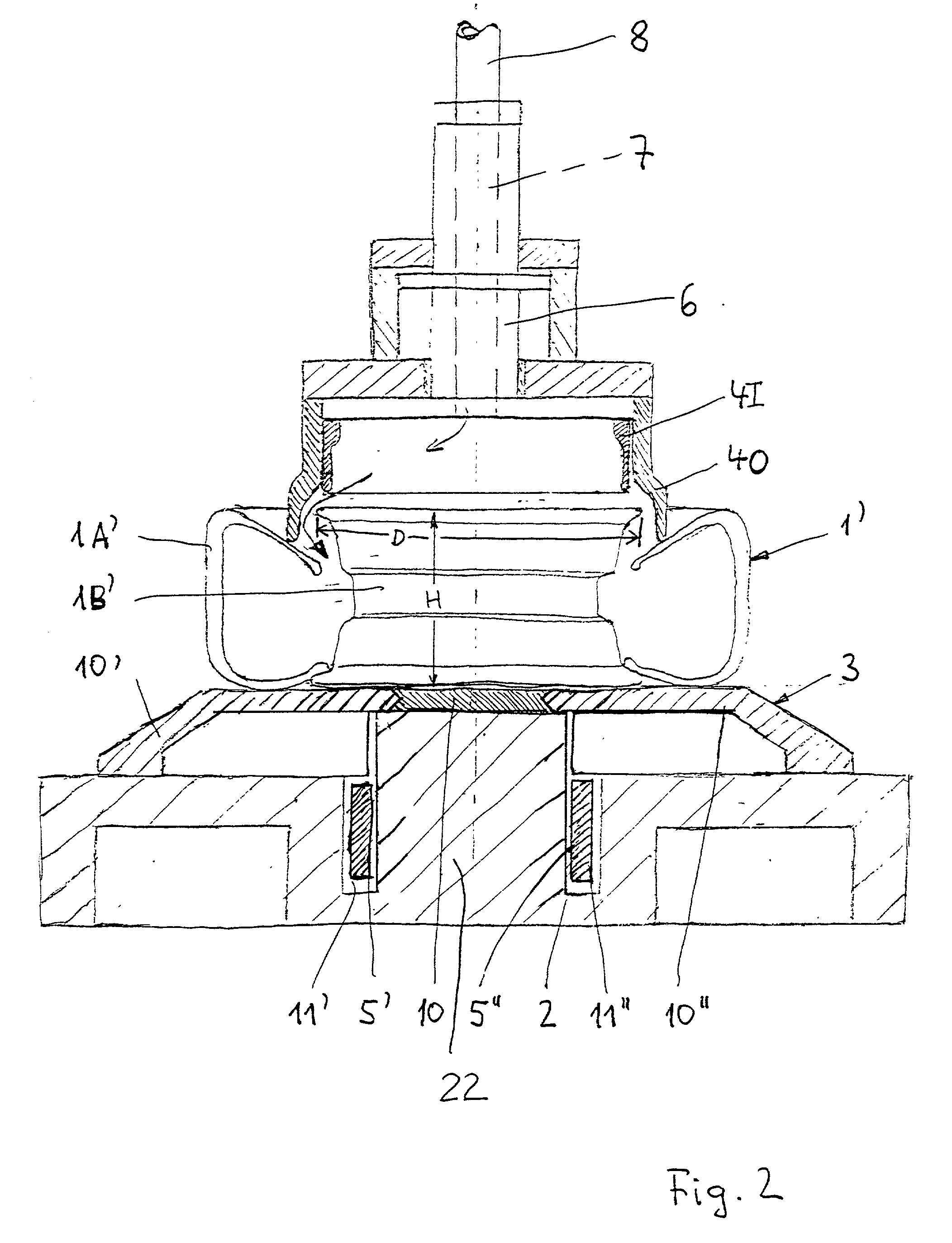

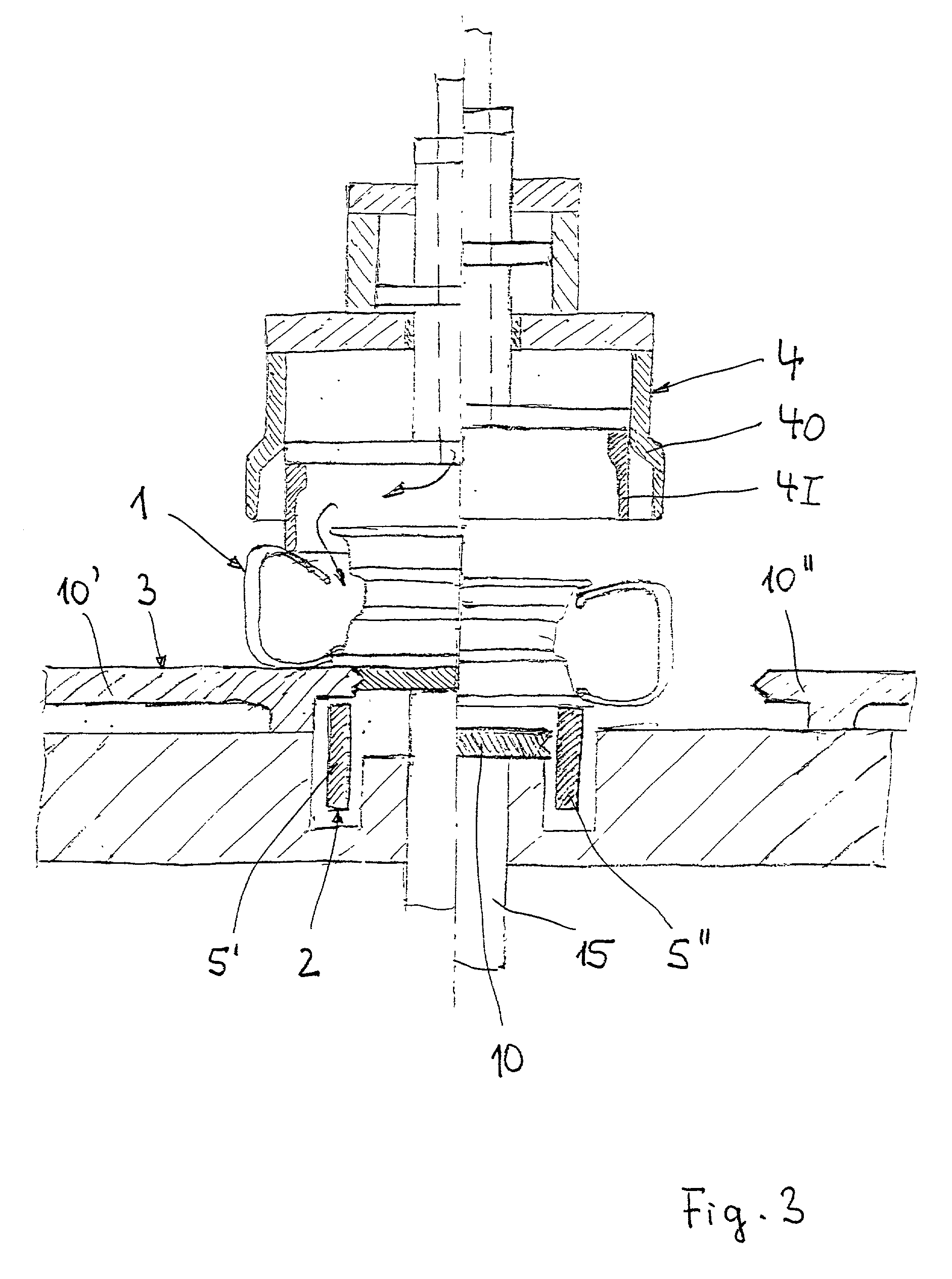

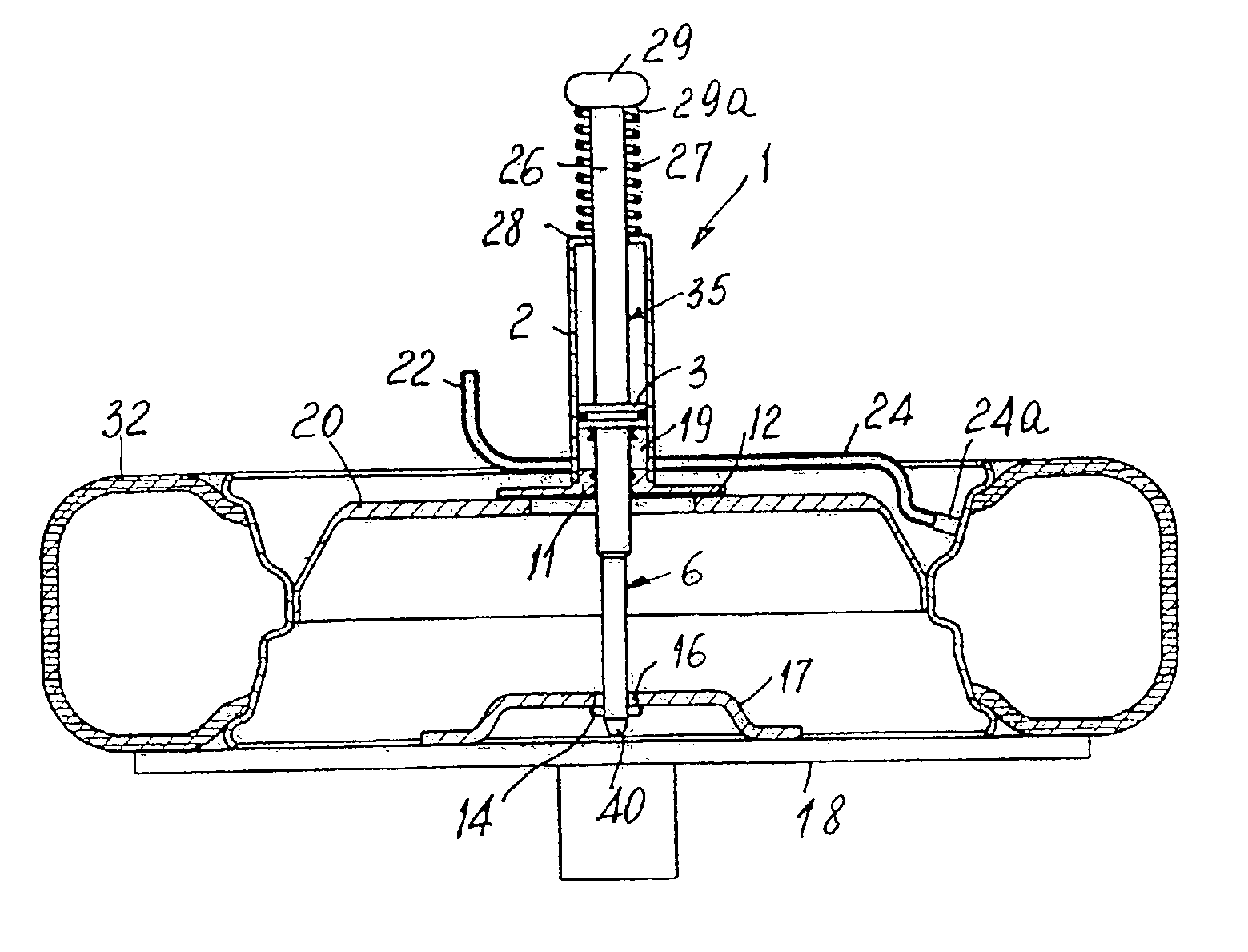

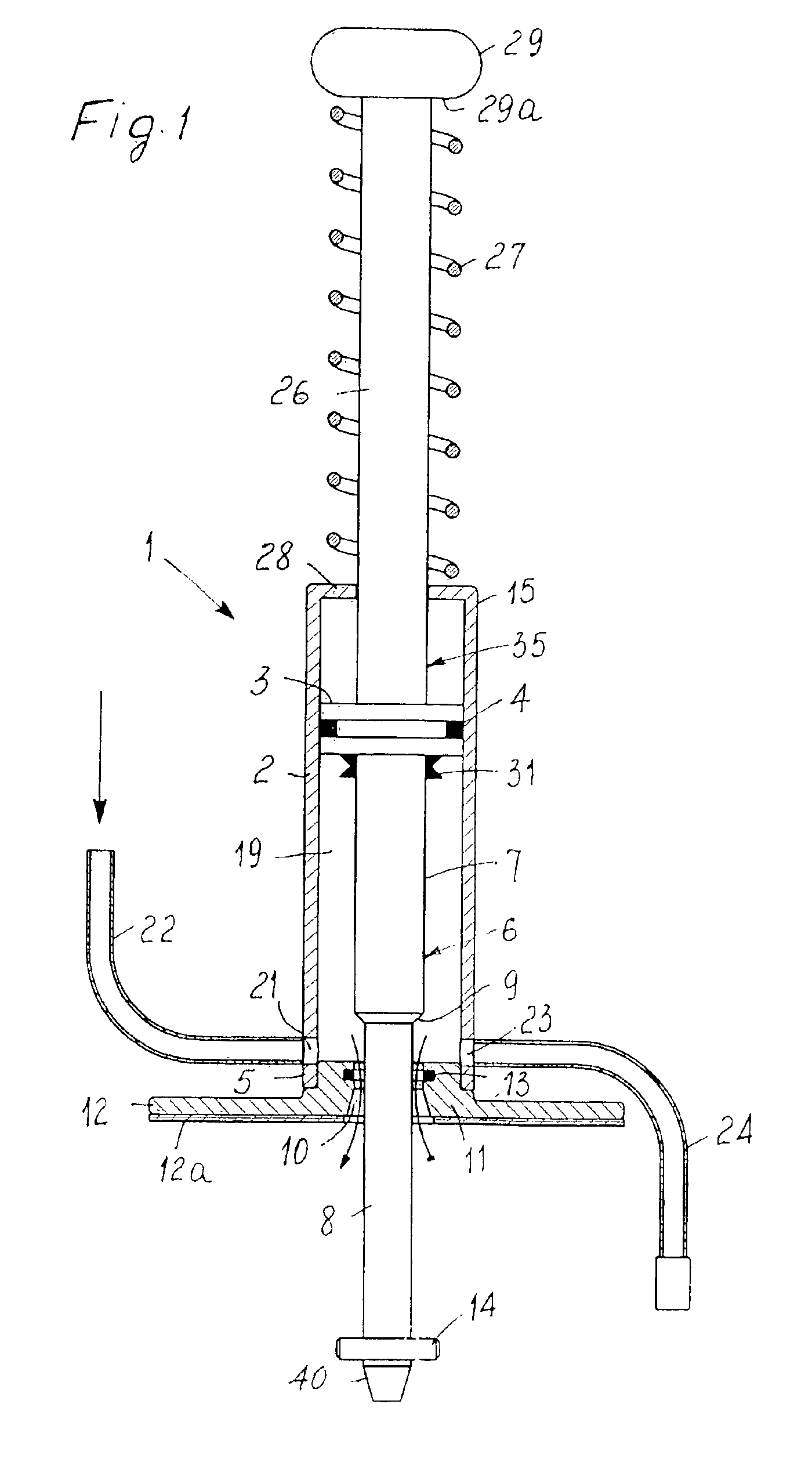

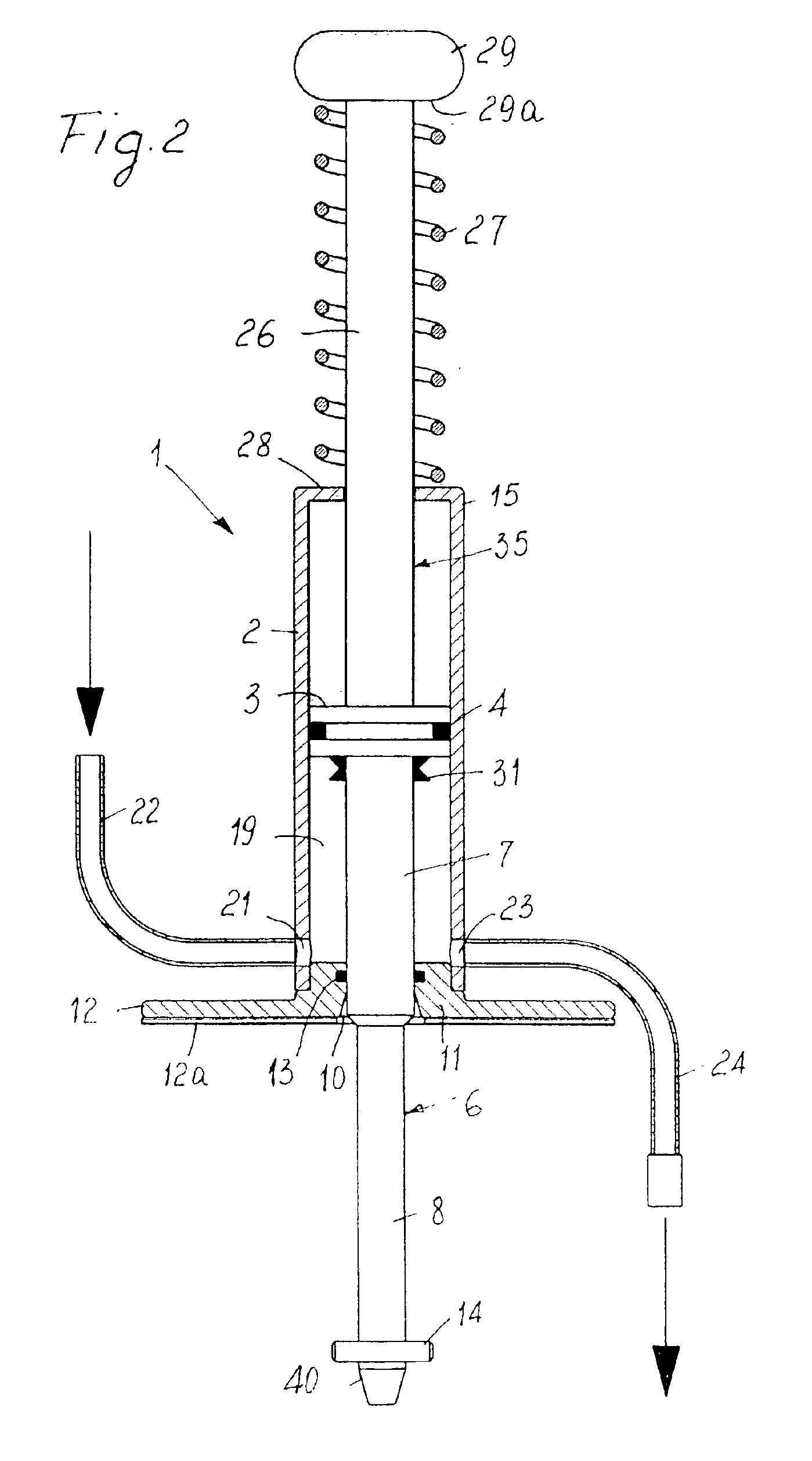

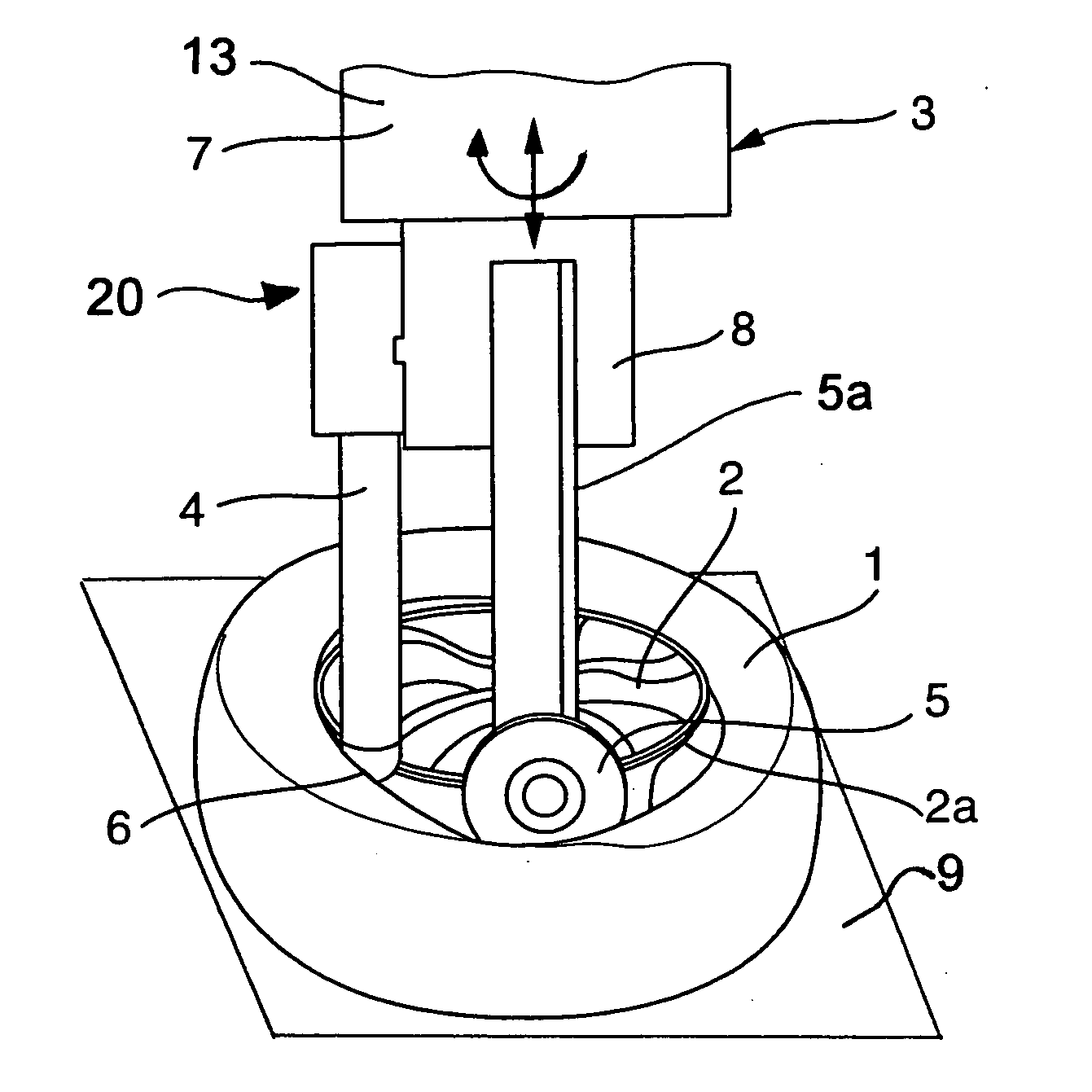

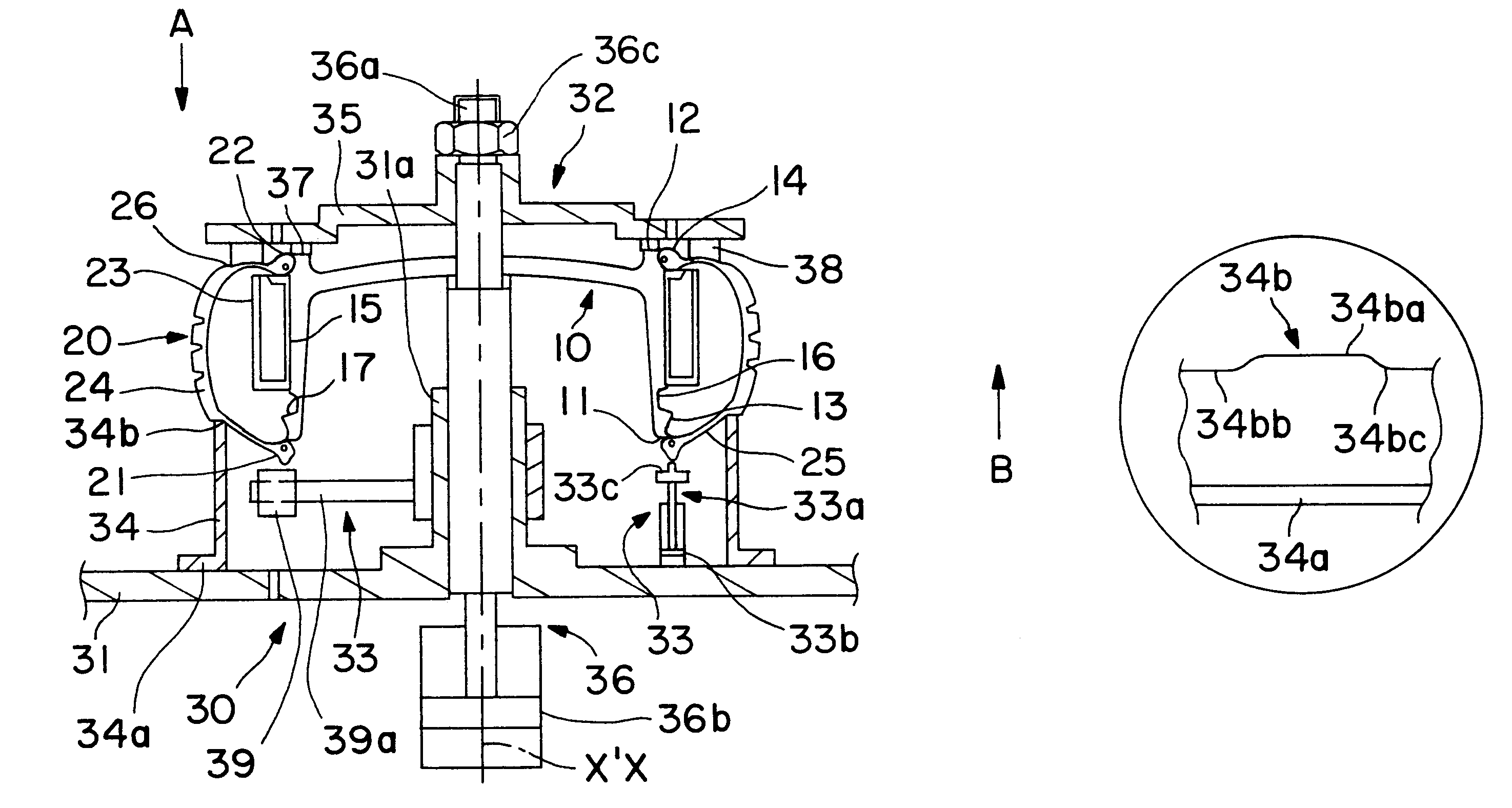

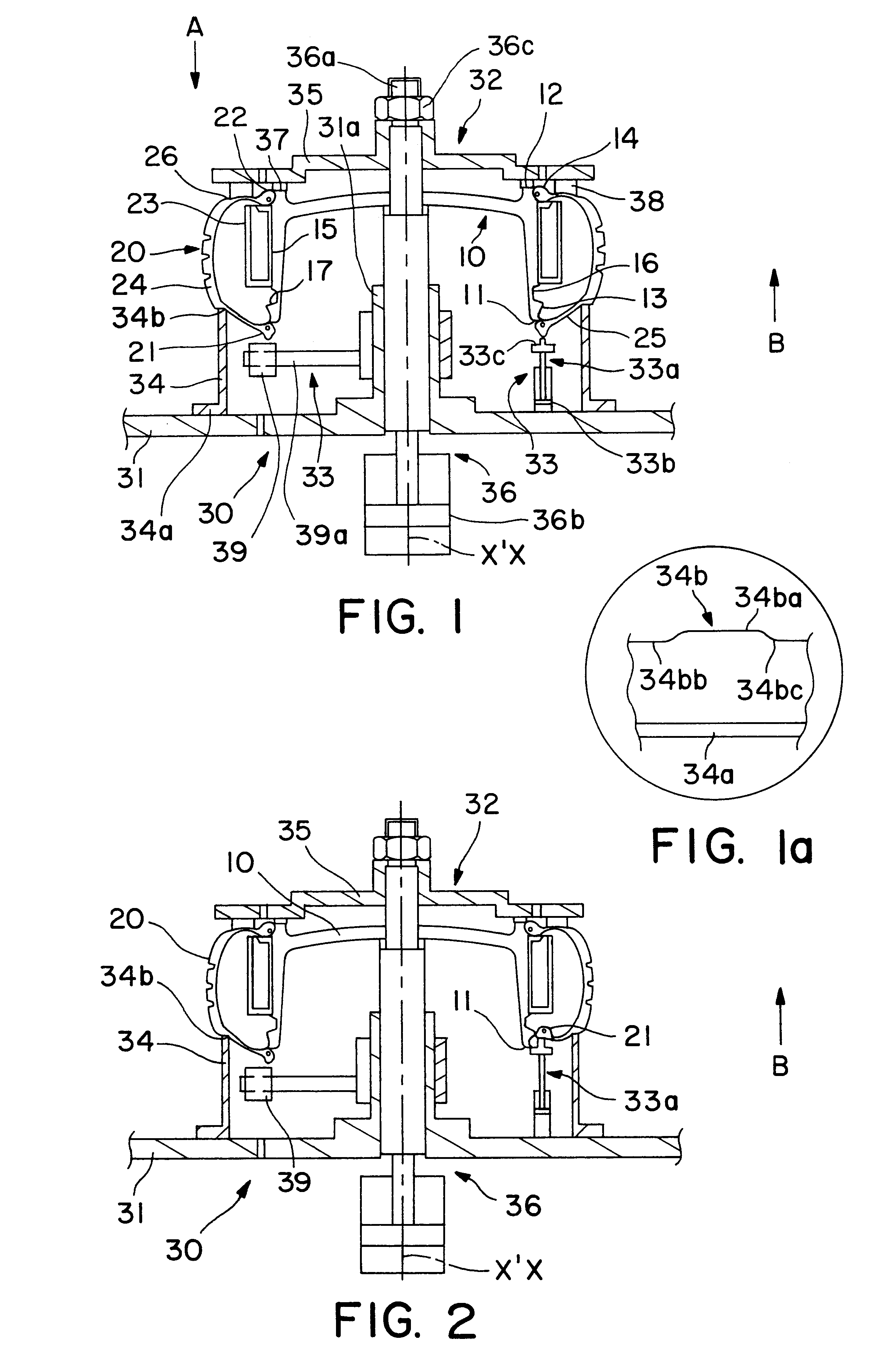

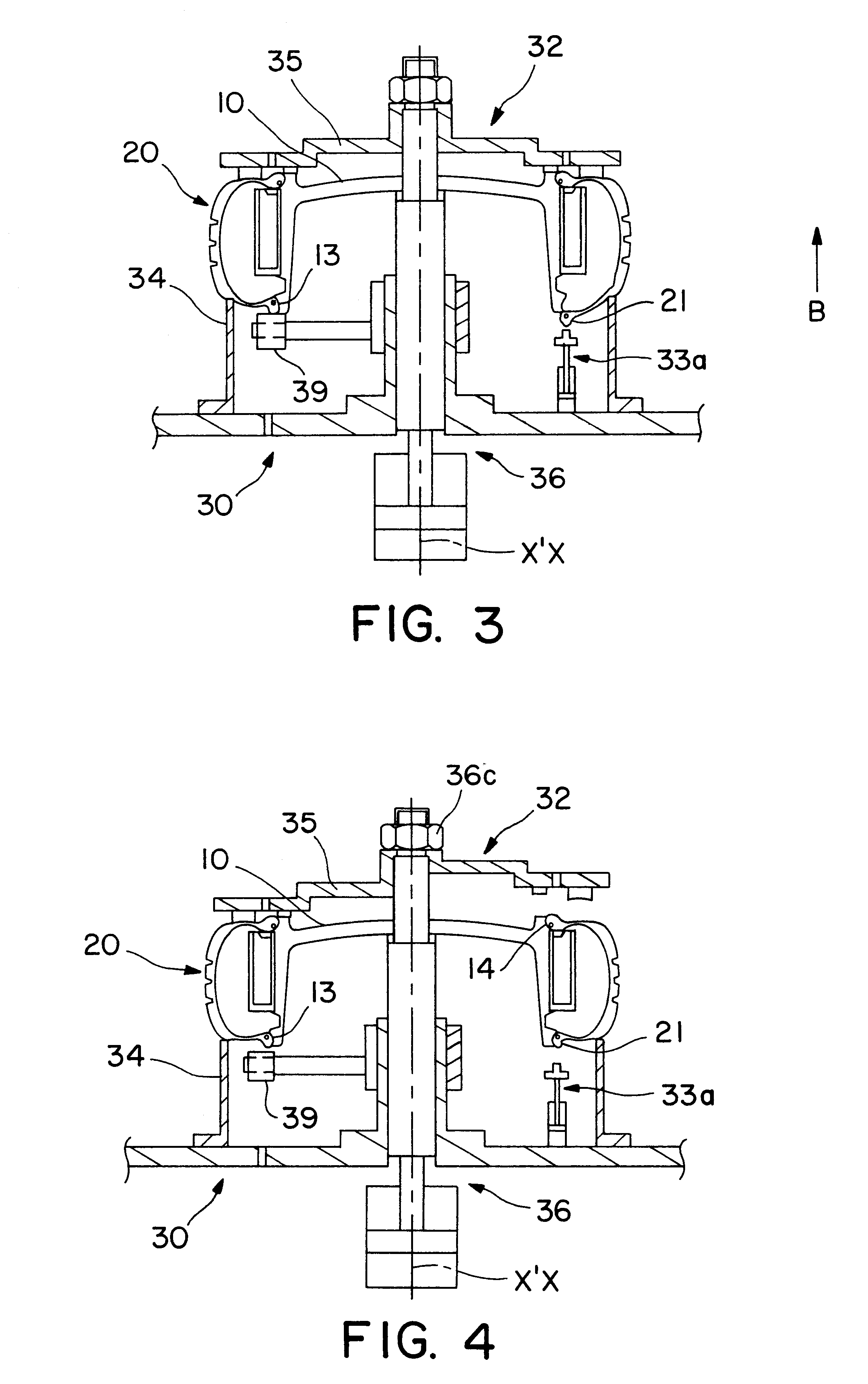

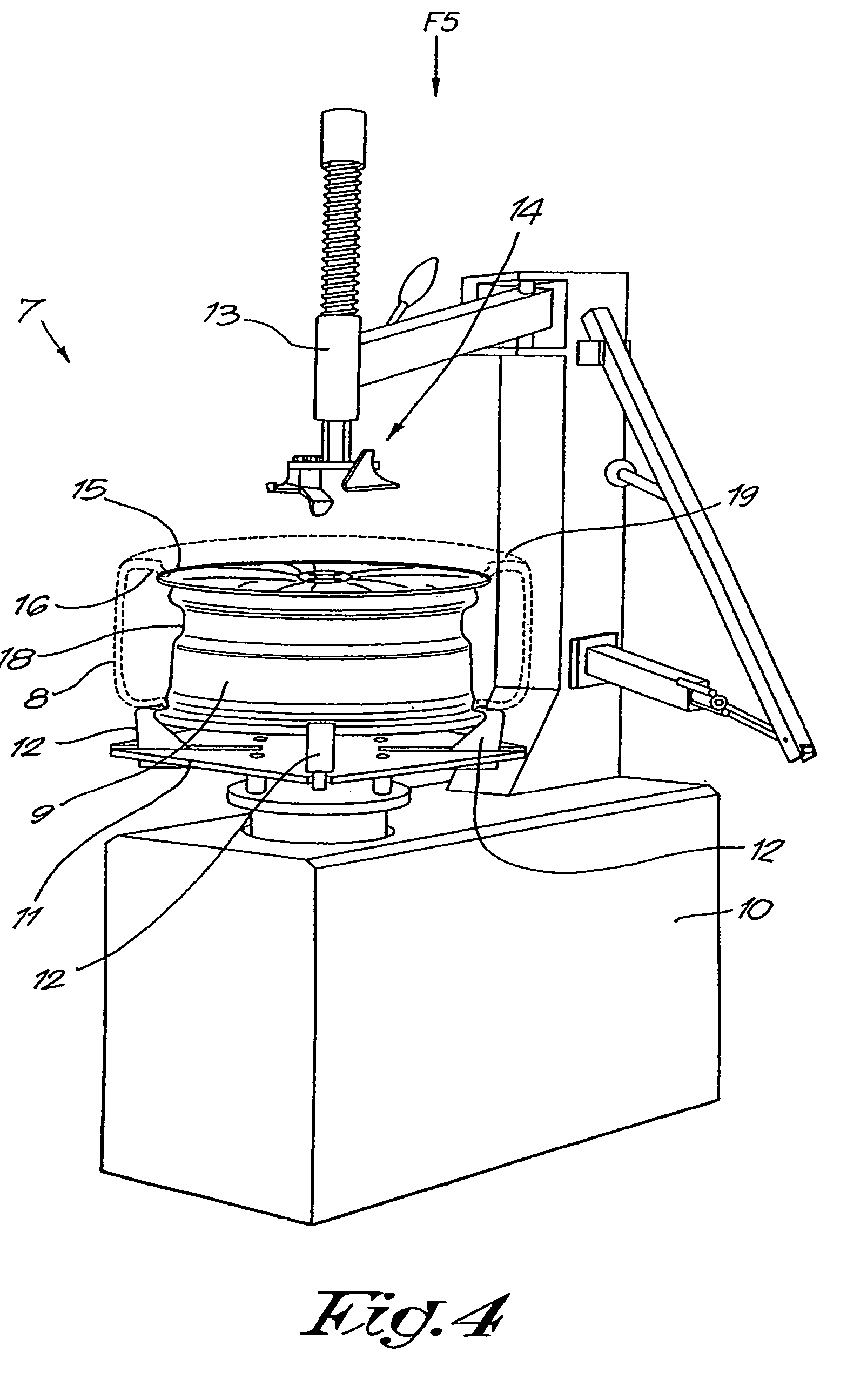

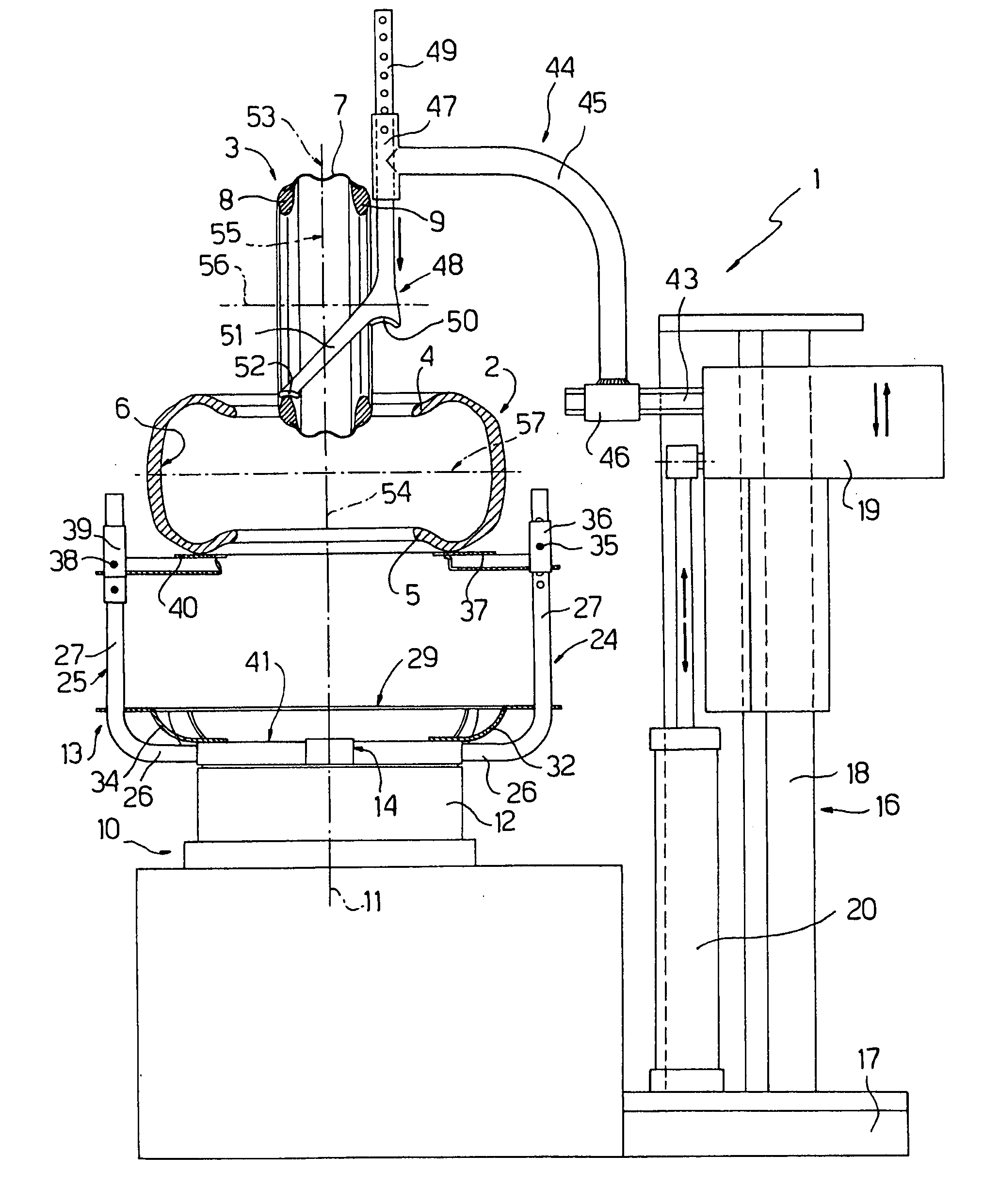

Process and device for inflating a tire

InactiveUS6286578B1Static/dynamic balance measurementTyresElectrical and Electronics engineeringCompressed air

A process and device for inflating a tire by forming, within an enclosure in which there are enclosed the rim and the beads of the tire, an inflation orifice between a first seat of the rim and a first bead, then introducing compressed air into said orifice and closing it such that the tire is inflated and mounted hermetically on the rim. Before forming this orifice, the first bead of the tire is located axially to the outside of the first seat and the second bead is mounted hermetically on the second seat, then, to form the orifice, points on the first bead are pressed. The device for implementing the process includes a bell formed of a fixed part and a mobile part intended to slide relative thereto to tightly surround the tire on the rim for its inflation, and including, within the bell, a finger for pressing at points on said bead.

Owner:MICHELIN RECH & TECH SA

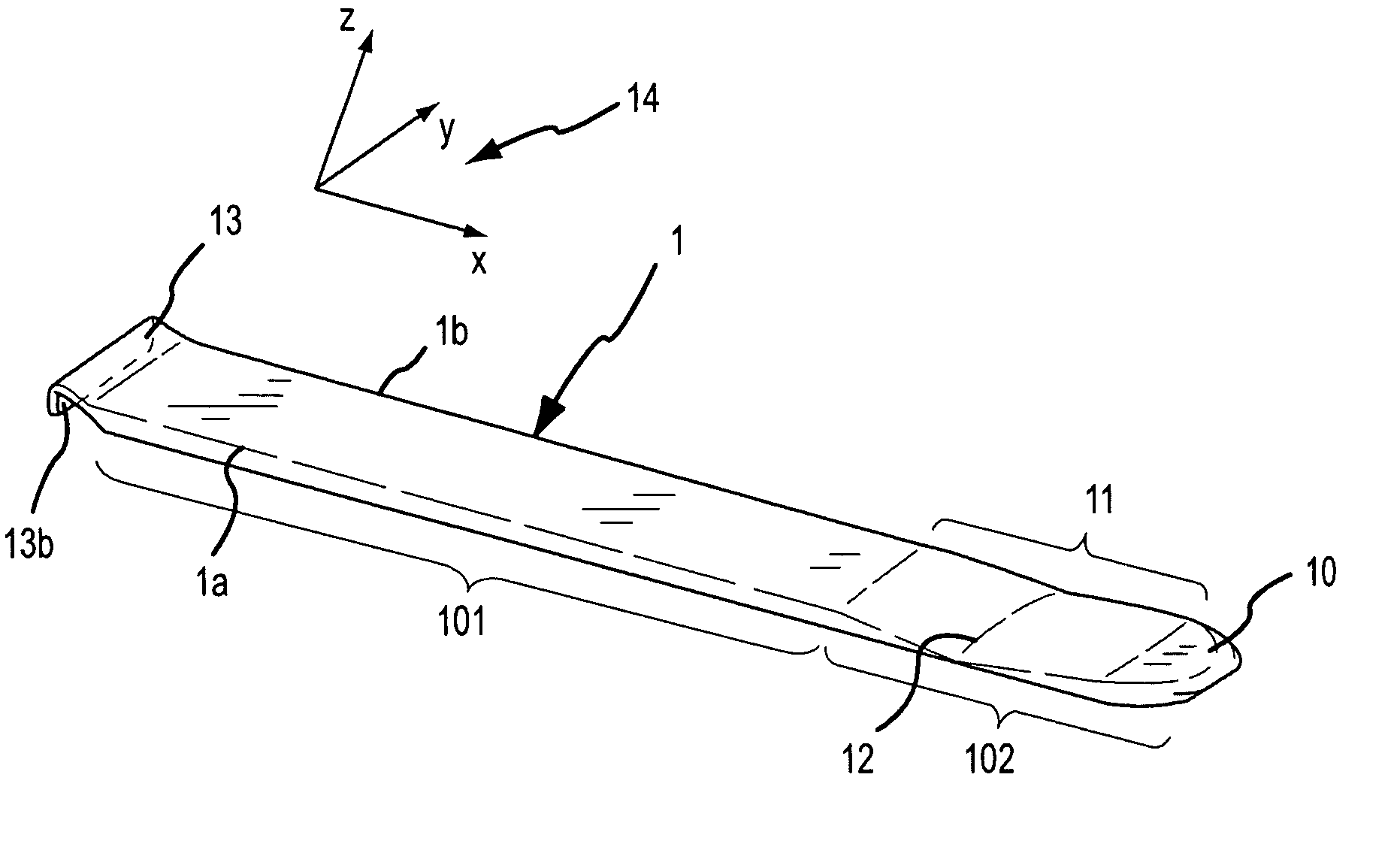

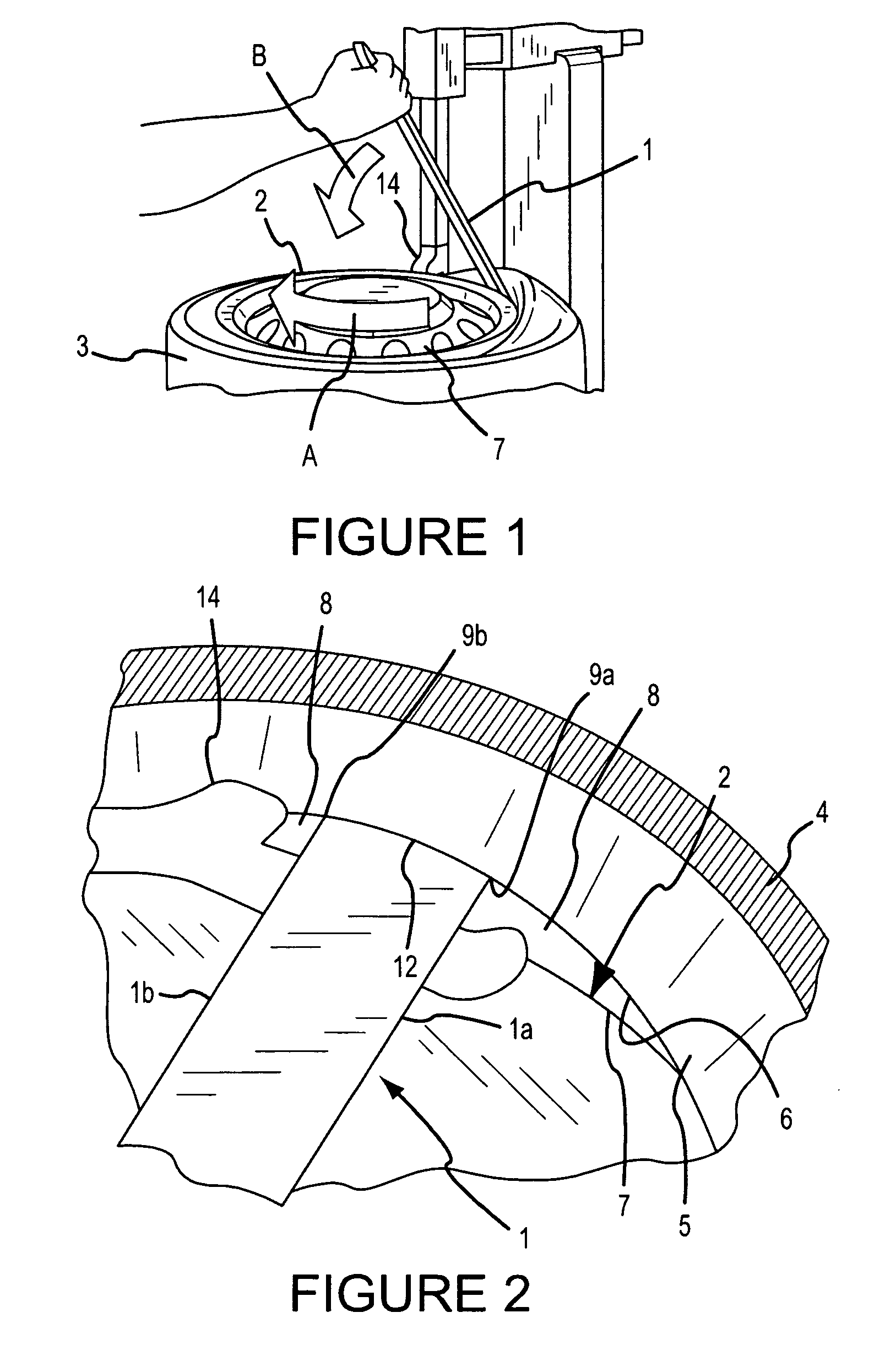

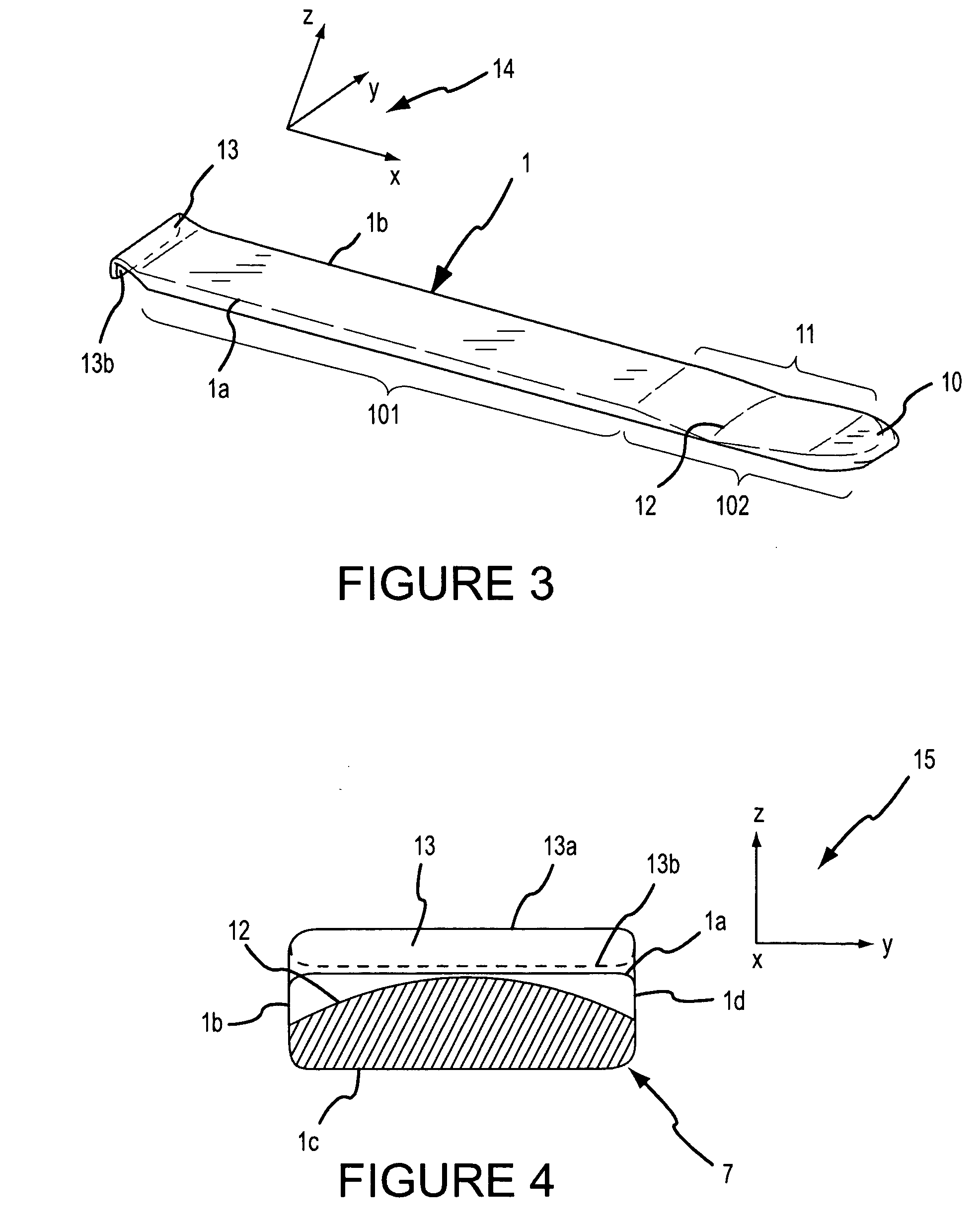

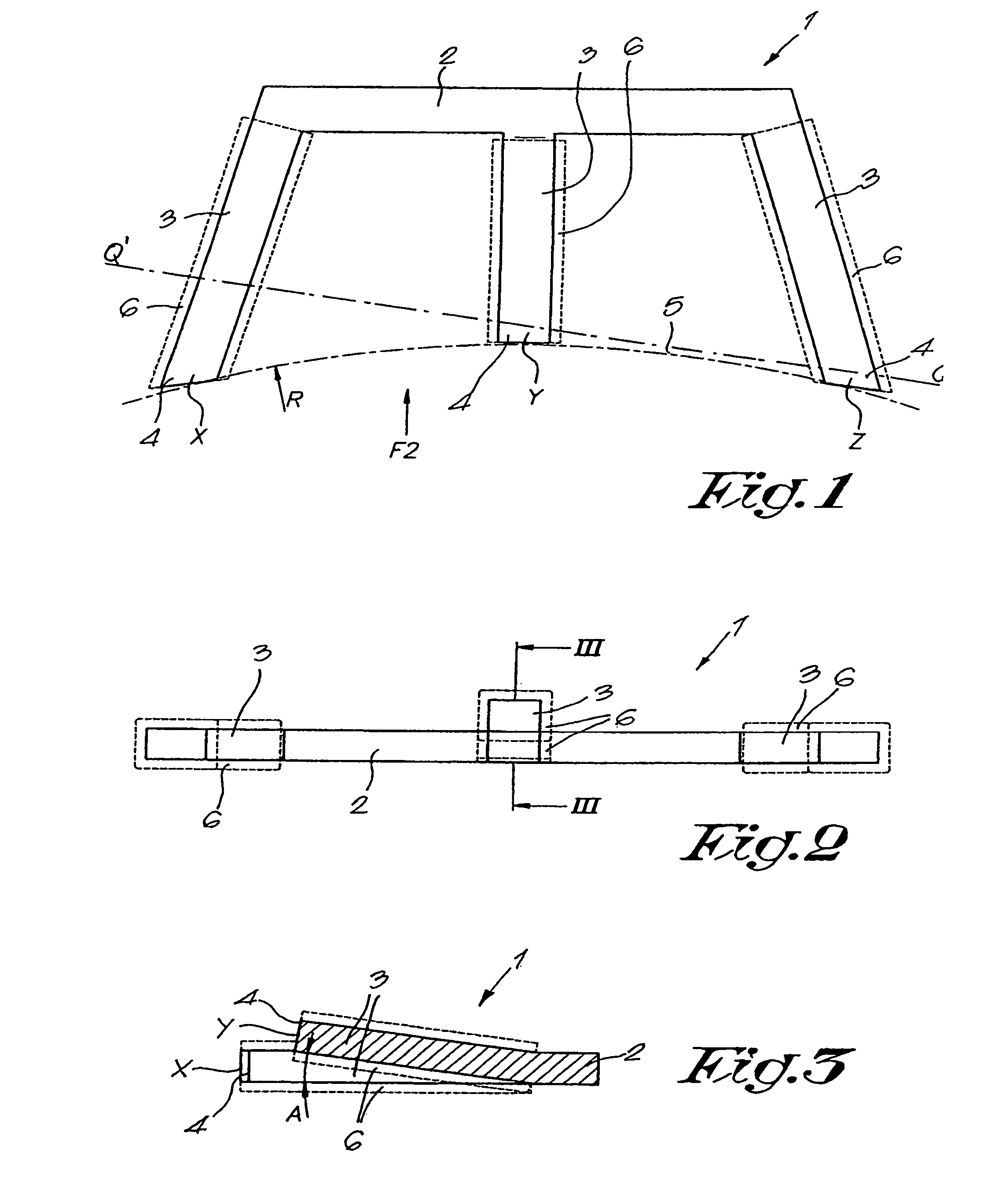

Tire mounting lever having a curved mounting surface

InactiveUS20070240830A1Reduce tensionAvoid damageWheelsTyre repairingEngineeringMechanical engineering

A mounting lever (1) according to one embodiment of the invention for dismantling a vehicle tire from a rim comprises a rod-formed handle portion (101) and a work portion (102) provided at its front end. The work portion (102) has a convex mounting surface (11).

Owner:BEISSBARTH

Method of mounting a pneumatic radial tire

In the method of mounting a pneumatic radial tire comprising a spiral belt and a pair cross belt members arranged in parallel to each other at both sides of an equational plane of the tire and at a given opening space onto a vehicle body, the tire is mounted as a front tire and / or a rear tire so as to contact a portion of the cord in the belt member facing the opening space with ground under a given condition in a forward rotating direction of the tire.

Owner:BRIDGESTONE CORP

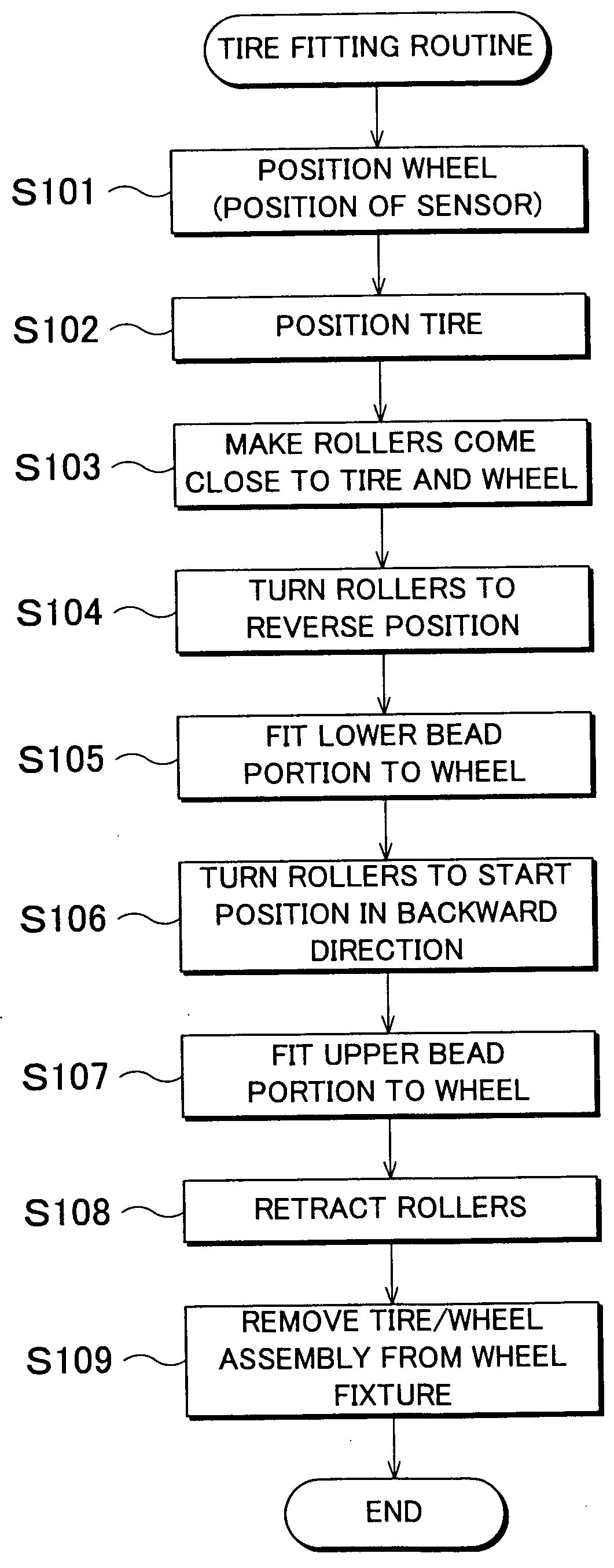

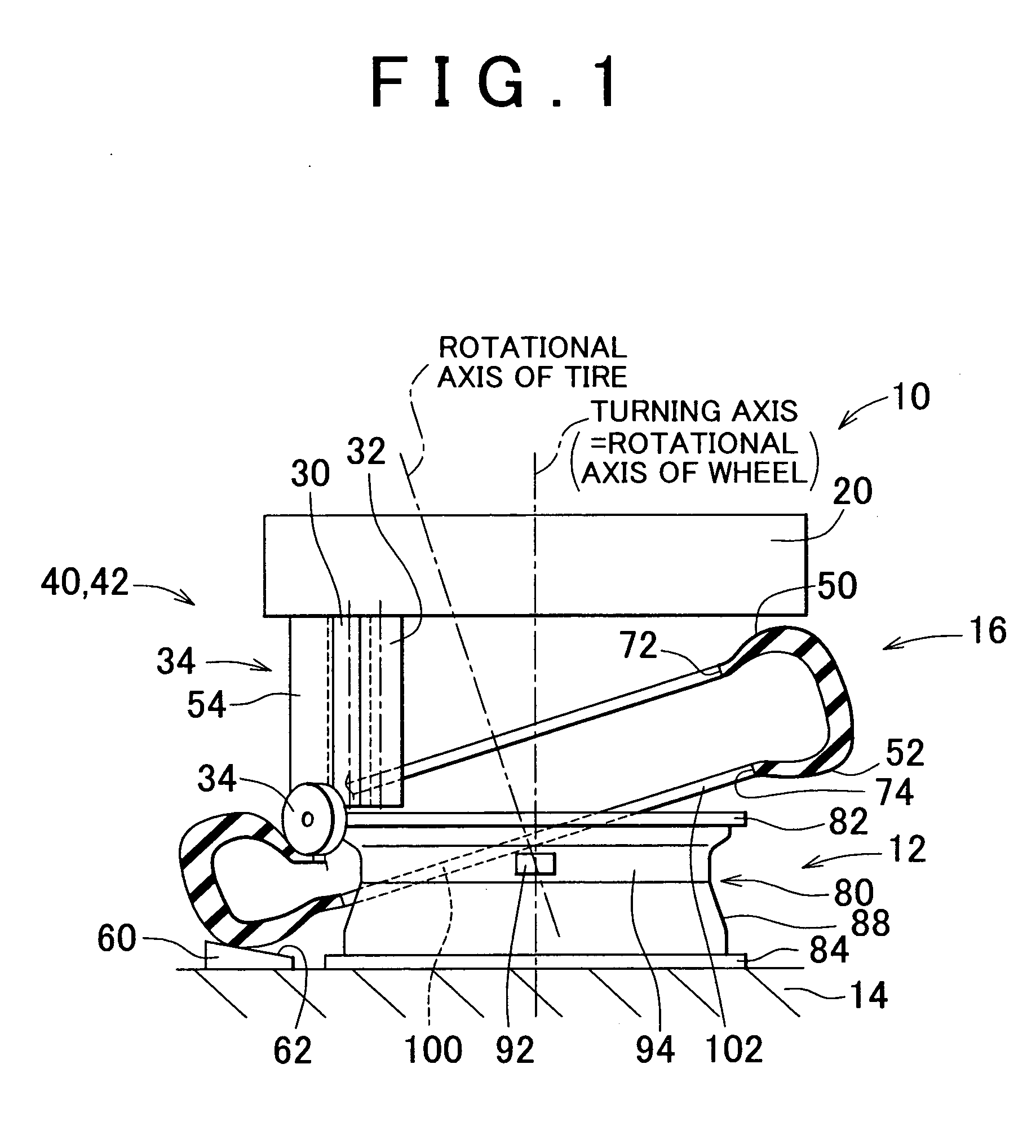

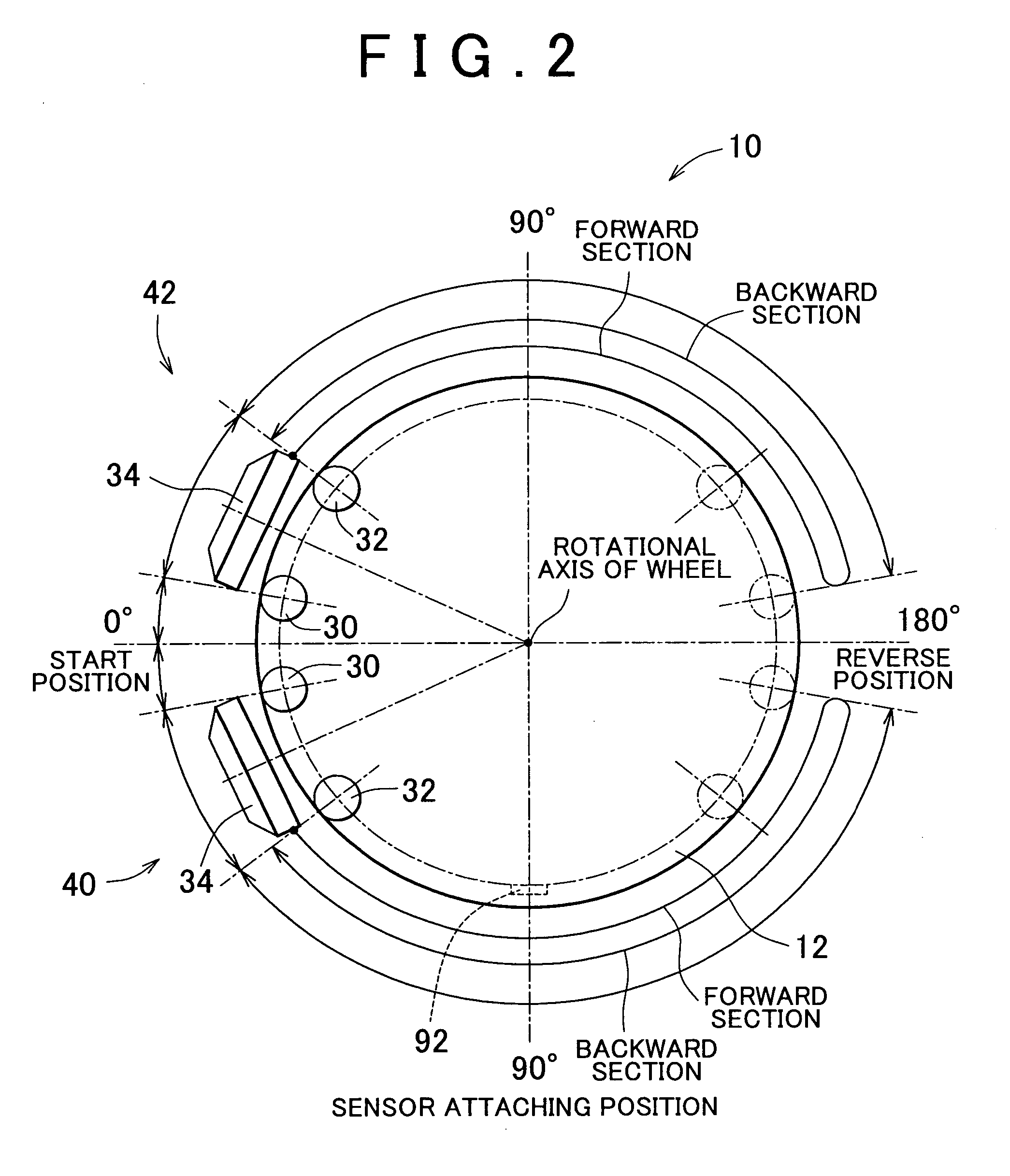

Tire fitting method and device

InactiveUS20050067114A1Avoid damageReduce loadSpecial tyresTyre measurementsRotational axisEngineering

A wheel is positioned at an initial position by partially fitting a tire, from above, to the wheel in a slanting direction. From state where the wheel is positioned at the initial position, an expander, which expand paired bead portions of the tire in a radial direction of the wheel, is turned around the rotational axis of the wheel. In the initial position, the tire is positioned with respect to the wheel while an accessory does not overlap a lower portion of a lower bead portion that is provided at a lower position from among the paired bead portions in the initial position, the lower portion being provided below an upper rim flange portion that is provided at an upper position from among the paired rim flange portions, and the lower portion already being fitted to the wheel.

Owner:TOYOTA JIDOSHA KK

Method and apparatus for removing vehicle wheel

Owner:SERVICE STATION PRODS

Protecting pad

Owner:SUMMIT TOOL

Auxiliary tool for putting a tire on a rim

ActiveUS7431066B2Simple designEasy to operateWheelsWood-rimmed wheels manufacturingMechanical engineering

Owner:DU QUESNE BERTRAND

Machine for assembling and disassembling a tyre fitted with a rigid inner run-flat ring

InactiveUS20070251649A1Eliminate needStatic/dynamic balance measurementTyresEngineeringMechanical engineering

A machine for assembling and disassembling a tyre fitted with a rigid inner run-flat ring, wherein the machine is a tyre removing machine having a turntable; a tool column located alongside the turntable and having a guide located alongside and parallel to the turntable; a slide mounted to run along the guide; and an actuating device for moving the slide along the guide; the tyre removing machine having tooling defined by a first tool fitted to the turntable to support the tyre and the rigid ring, and by a second tool fitted to the slide and movable with the slide along the tool column to engage the rigid ring and move the rigid ring with respect to the tyre.

Owner:BRIDGESTONE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com