Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1248 results about "Tire-pressure monitoring system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

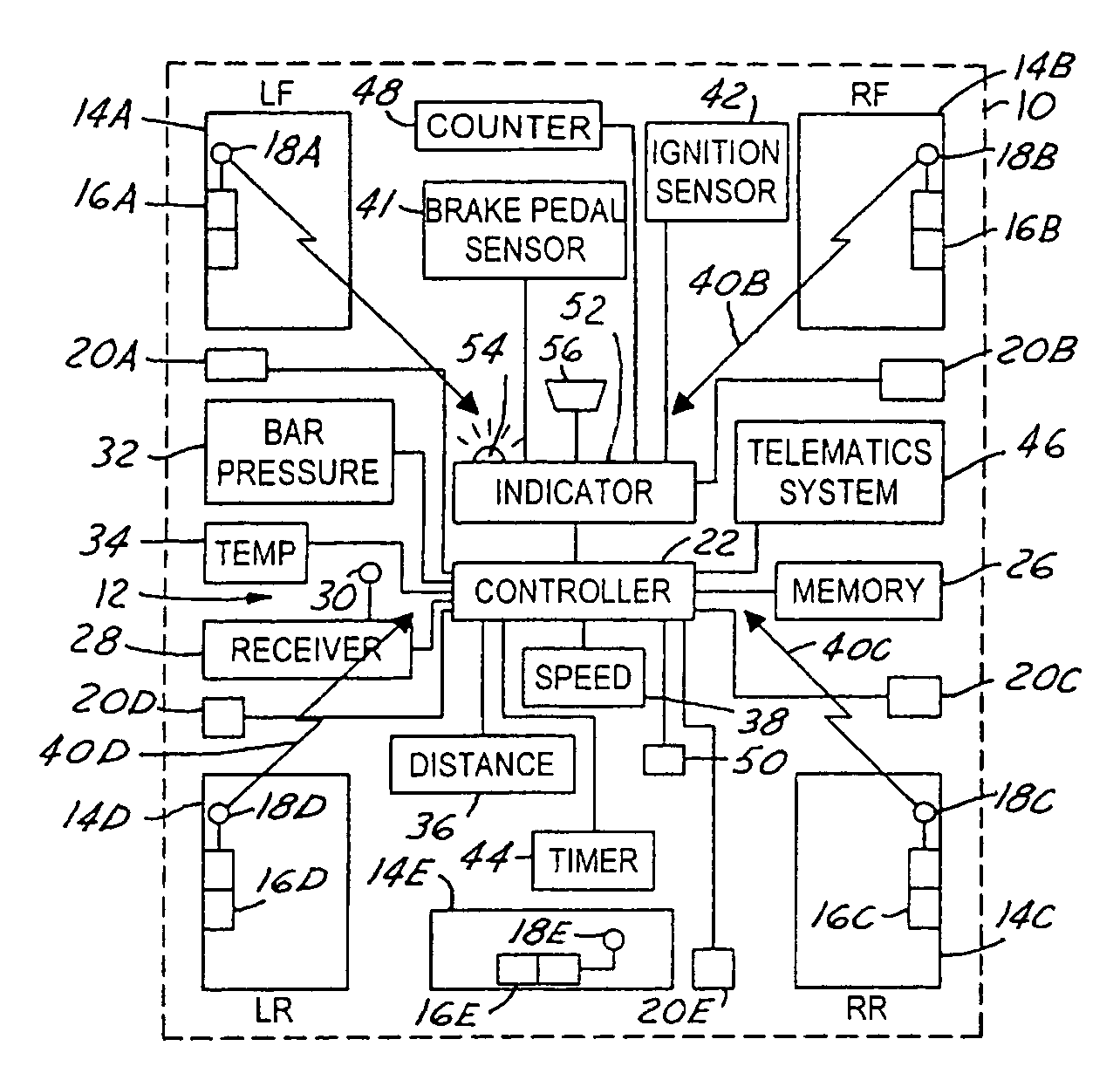

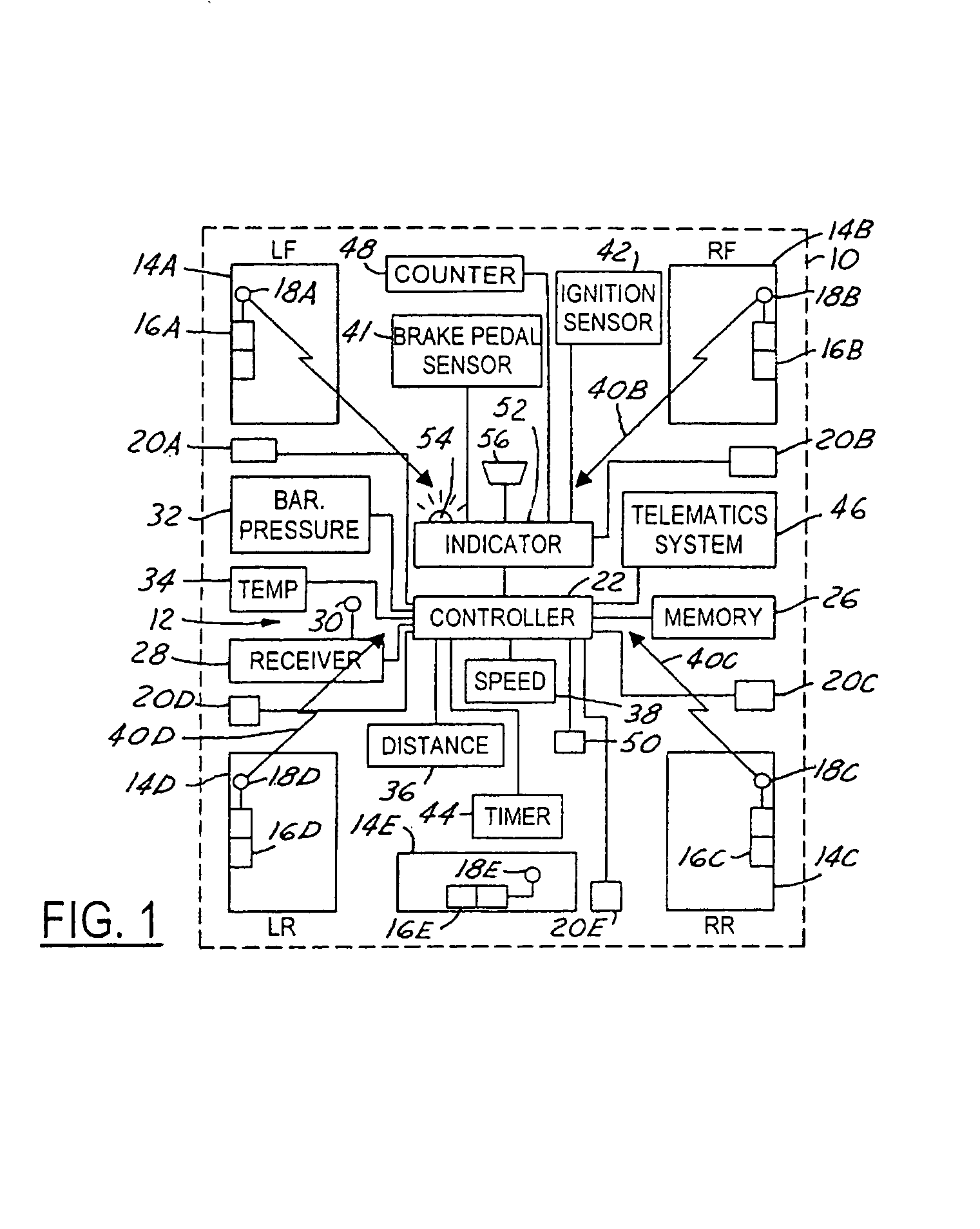

A tire-pressure monitoring system (TPMS) is an electronic system designed to monitor the air pressure inside the pneumatic tires on various types of vehicles. TPMS report real-time tire-pressure information to the driver of the vehicle, either via a gauge, a pictogram display, or a simple low-pressure warning light. TPMS can be divided into two different types – direct (dTPMS) and indirect (iTPMS). TPMS are provided both at an OEM (factory) level as well as an aftermarket solution. The target of a TPMS is avoiding traffic accidents, poor fuel economy, and increased tire wear due to under-inflated tires through early recognition of a hazardous state of the tires. This functionality first appeared in luxury vehicles in Europe in the 1980s, while mass-market adoption followed the USA passing the 2000 TREAD Act after the Firestone and Ford tire controversy. Mandates for TPMS technology in new cars have continued to proliferate in the 21st century in Russia, the EU, Japan, South Korea and many other Asian countries.

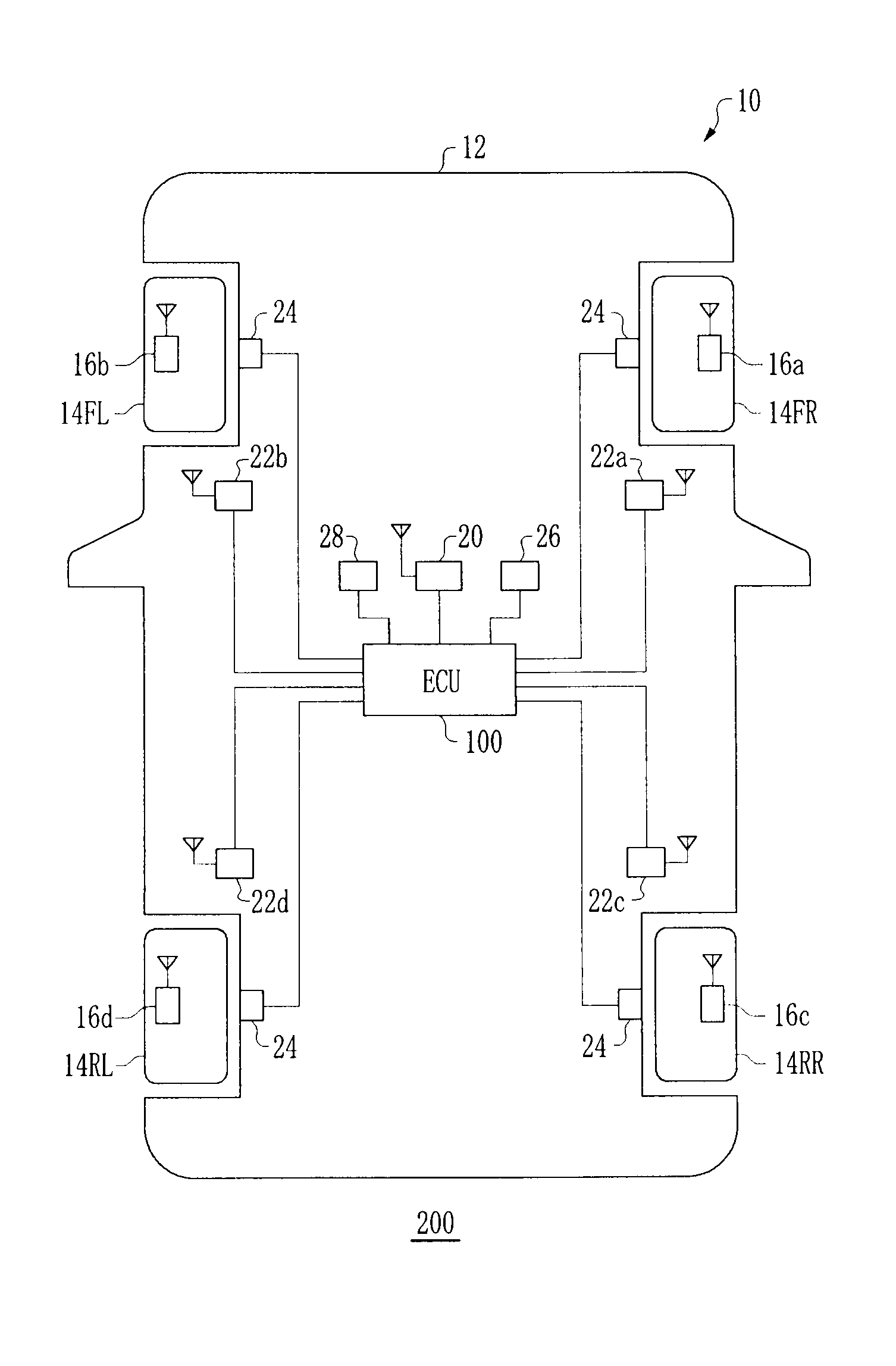

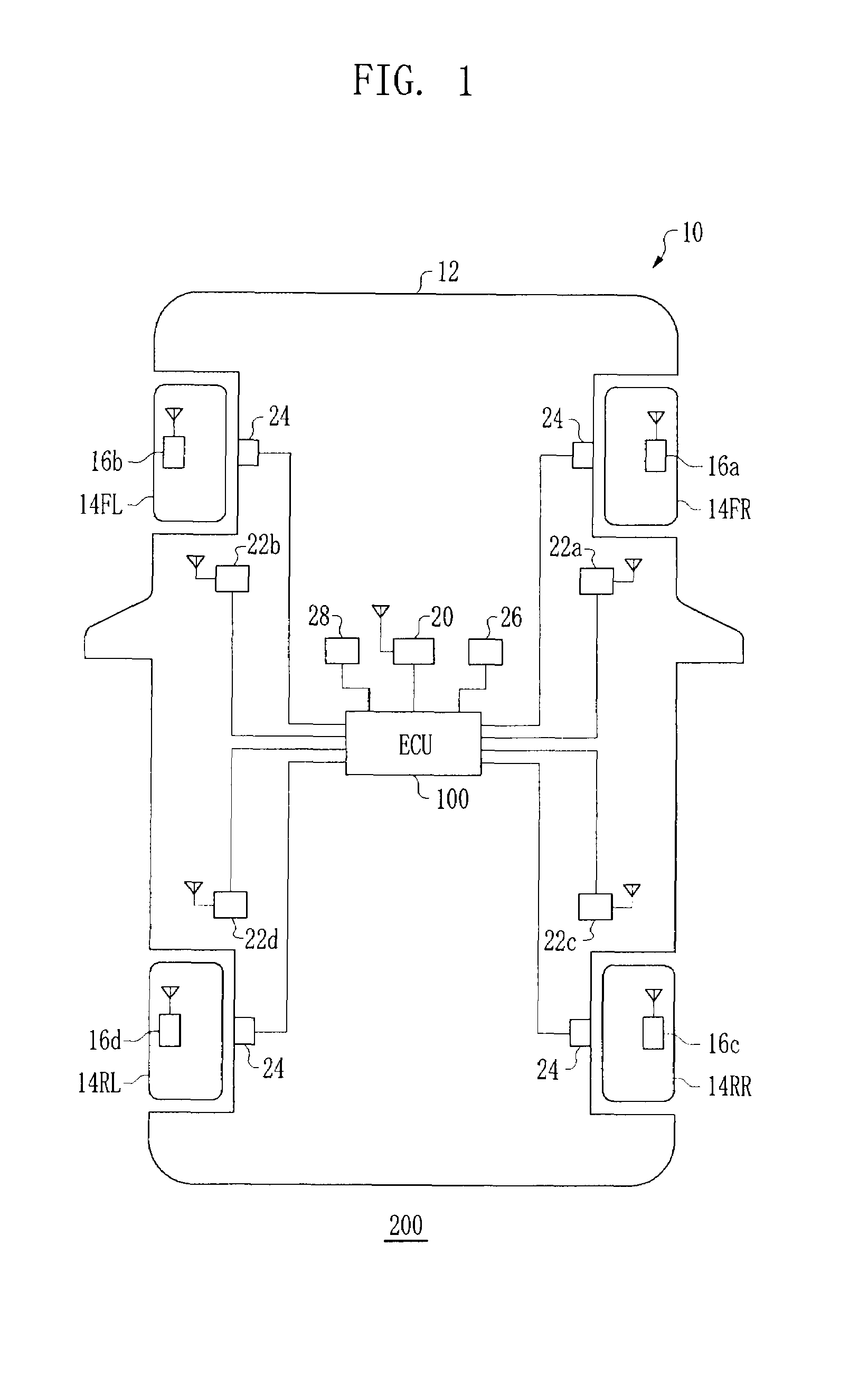

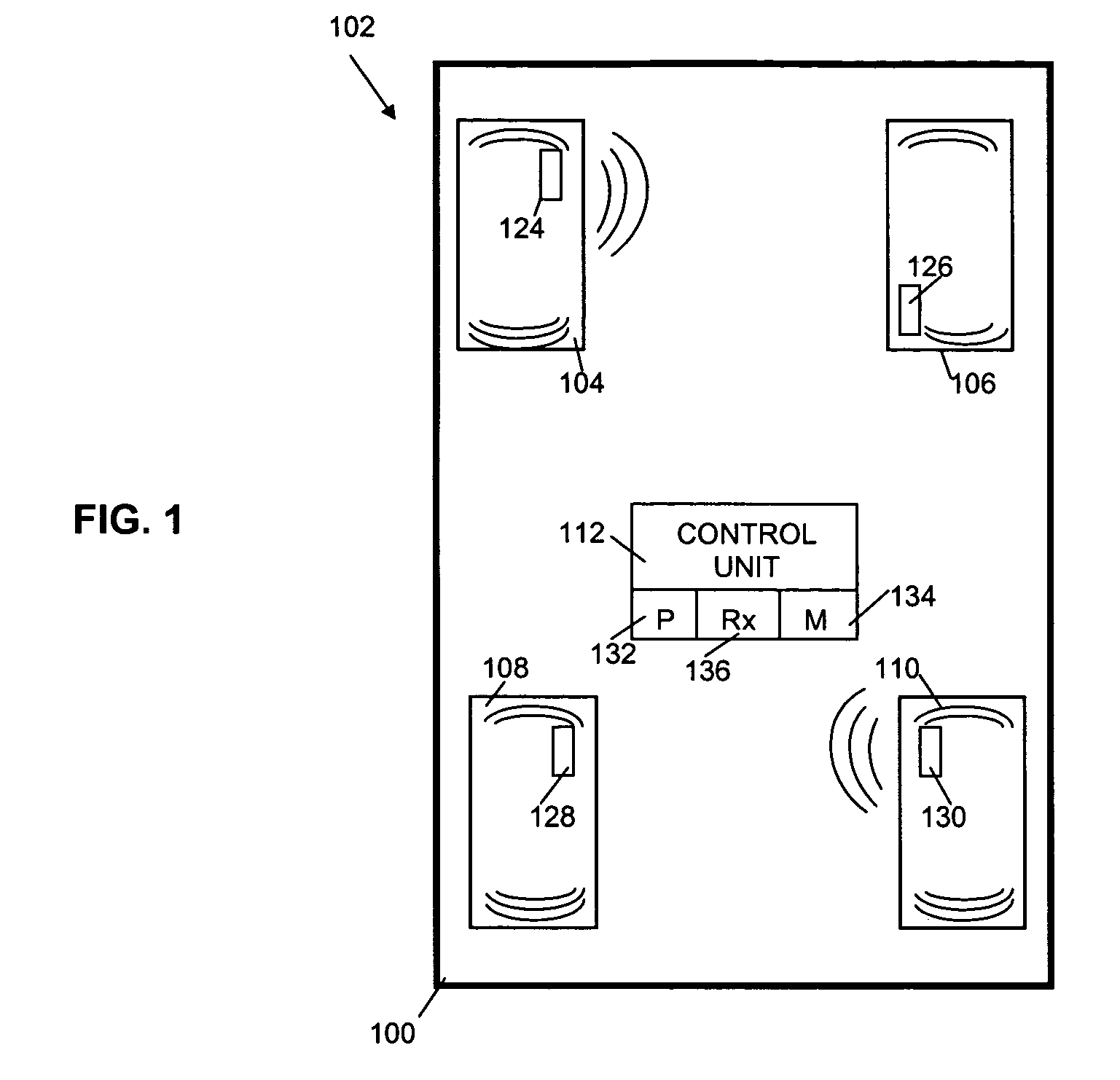

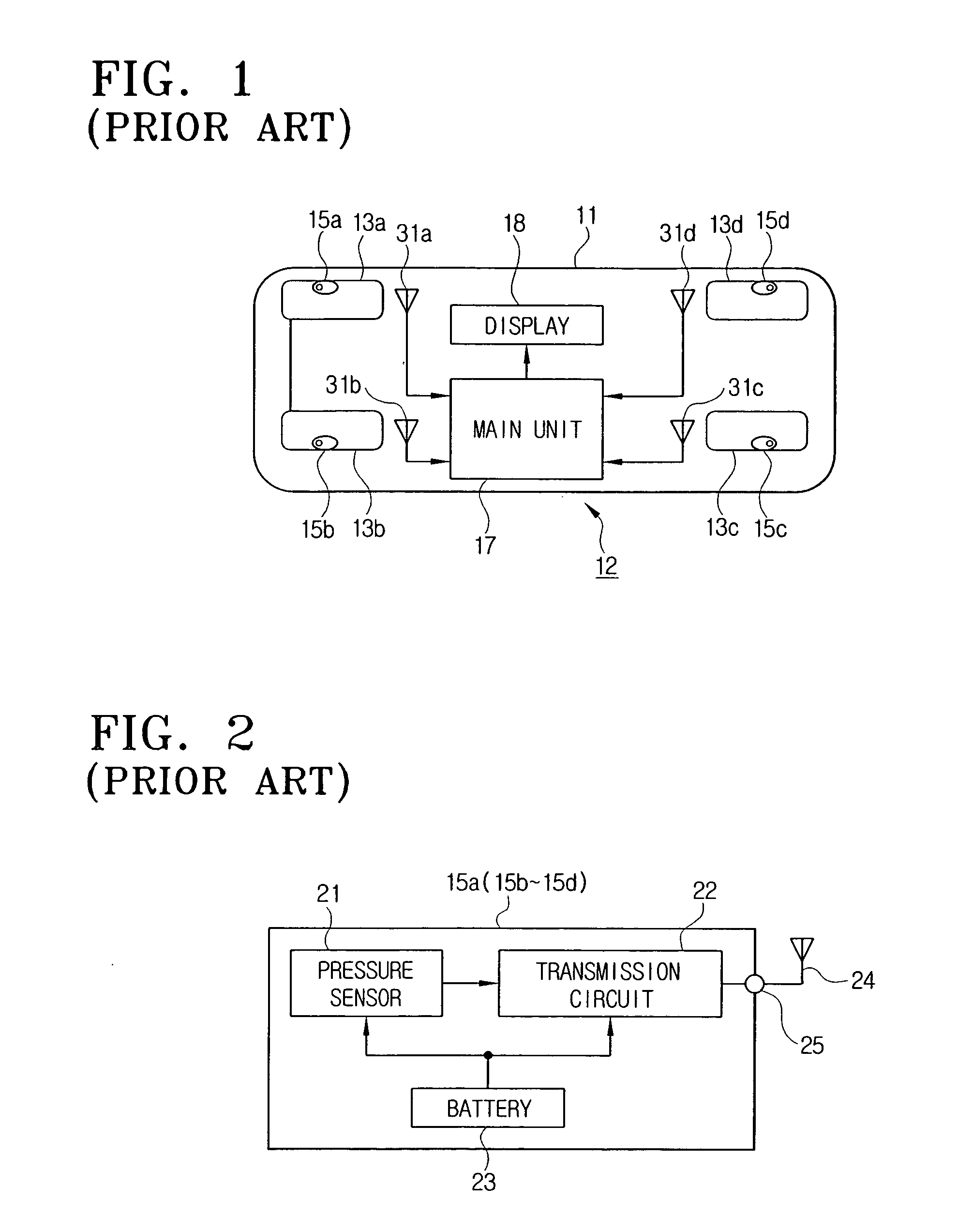

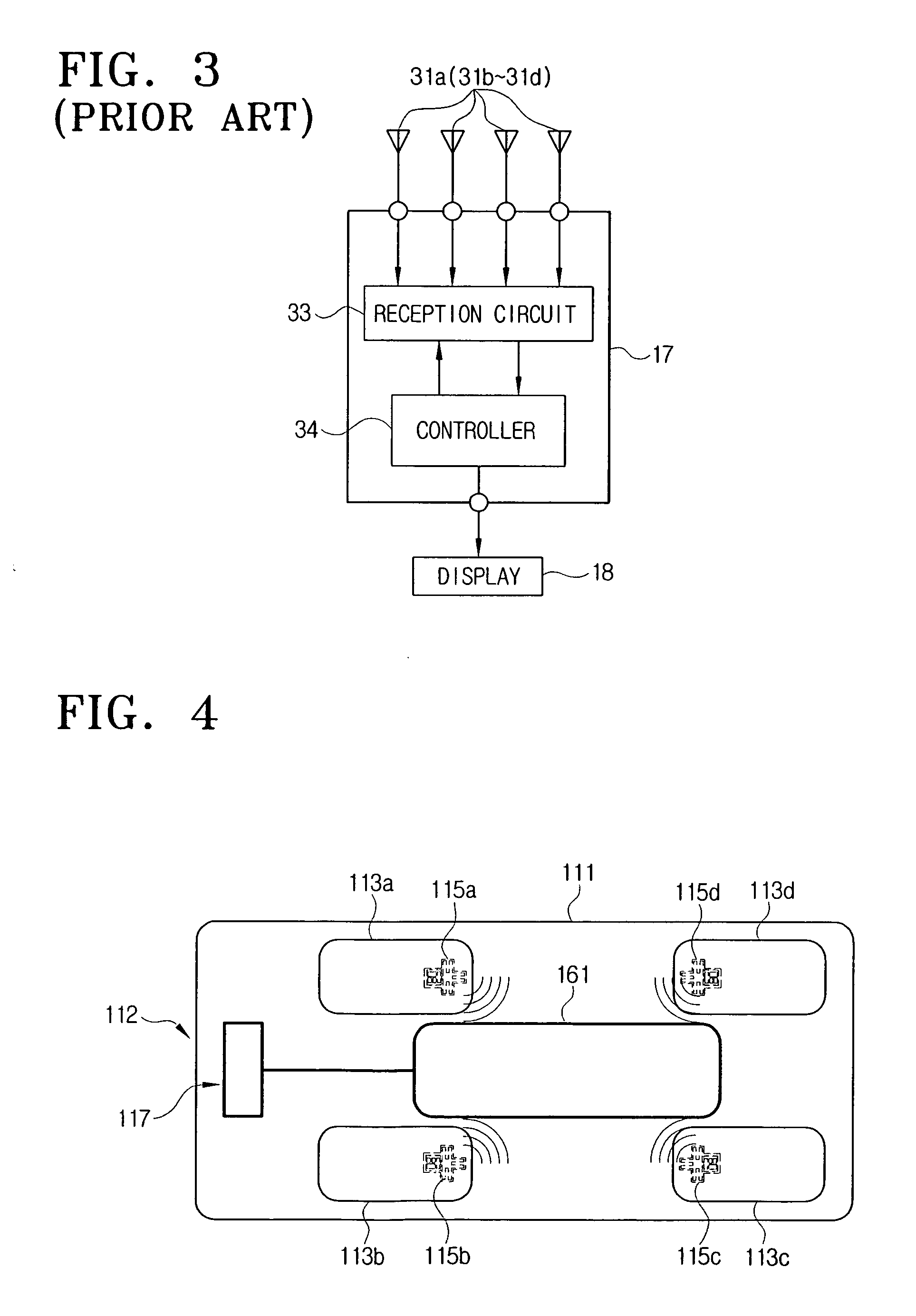

Wheel state monitoring system and wheel state detecting apparatus

InactiveUS7661299B2Tyre measurementsRoads maintainenceMonitoring systemTire-pressure monitoring system

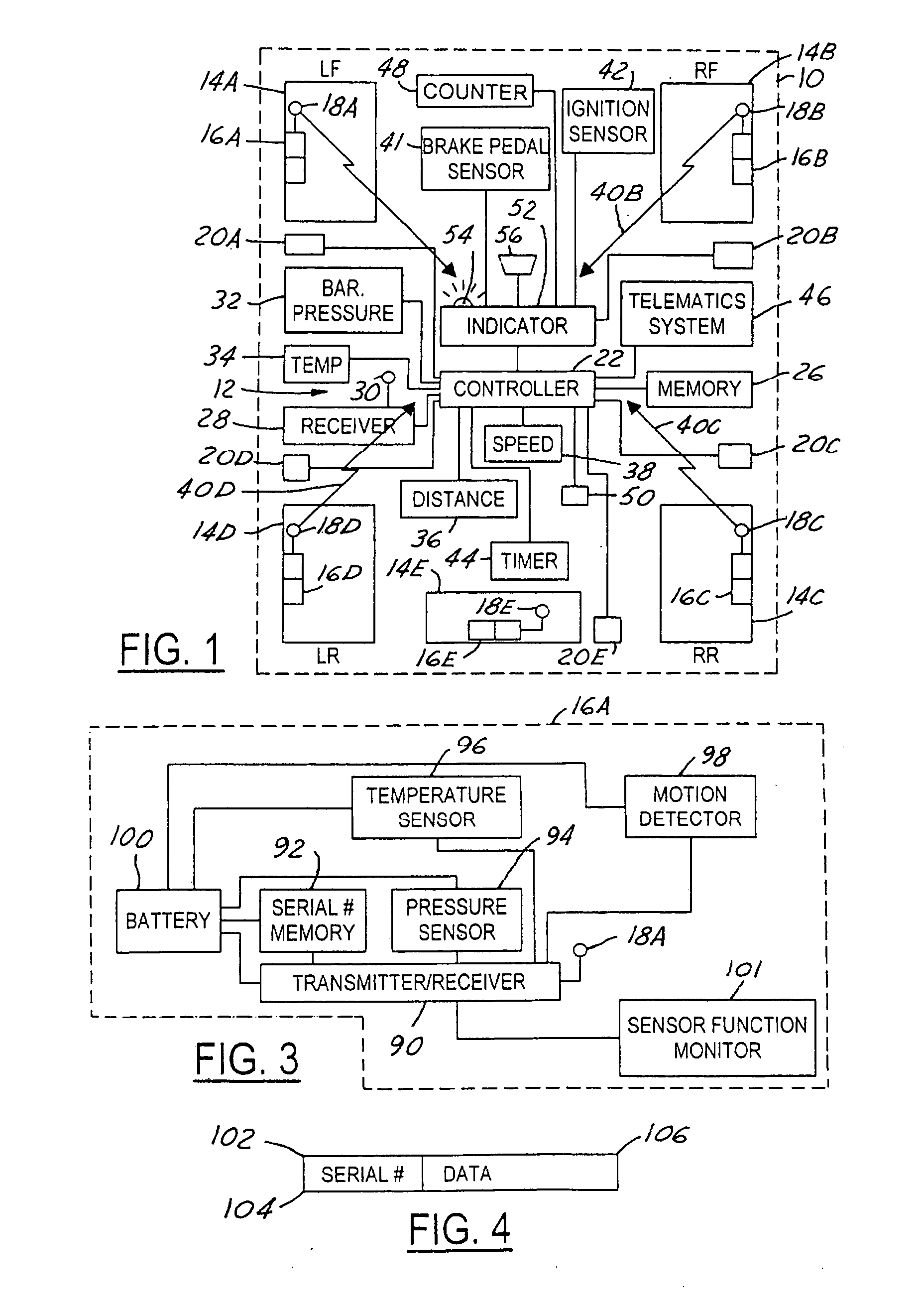

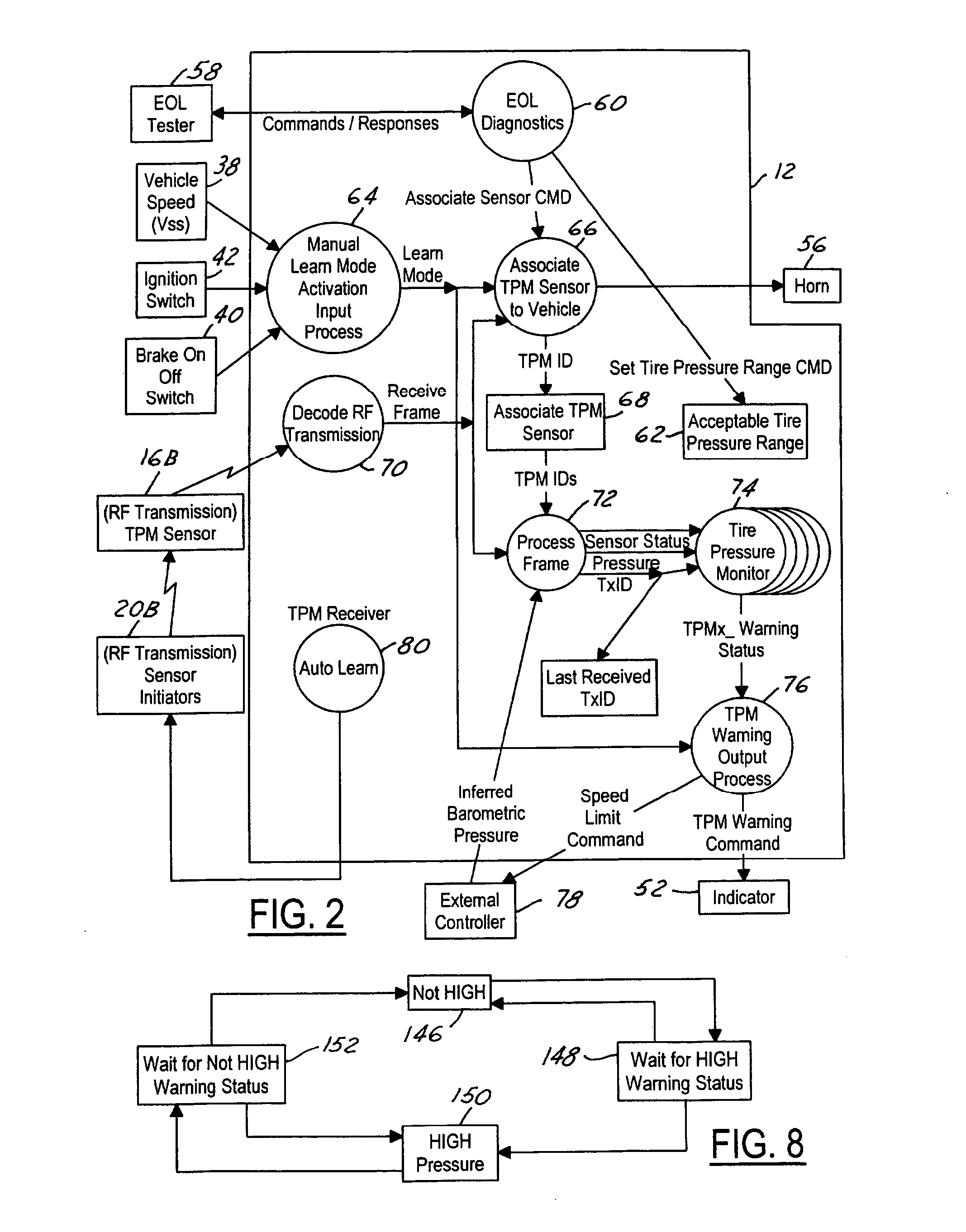

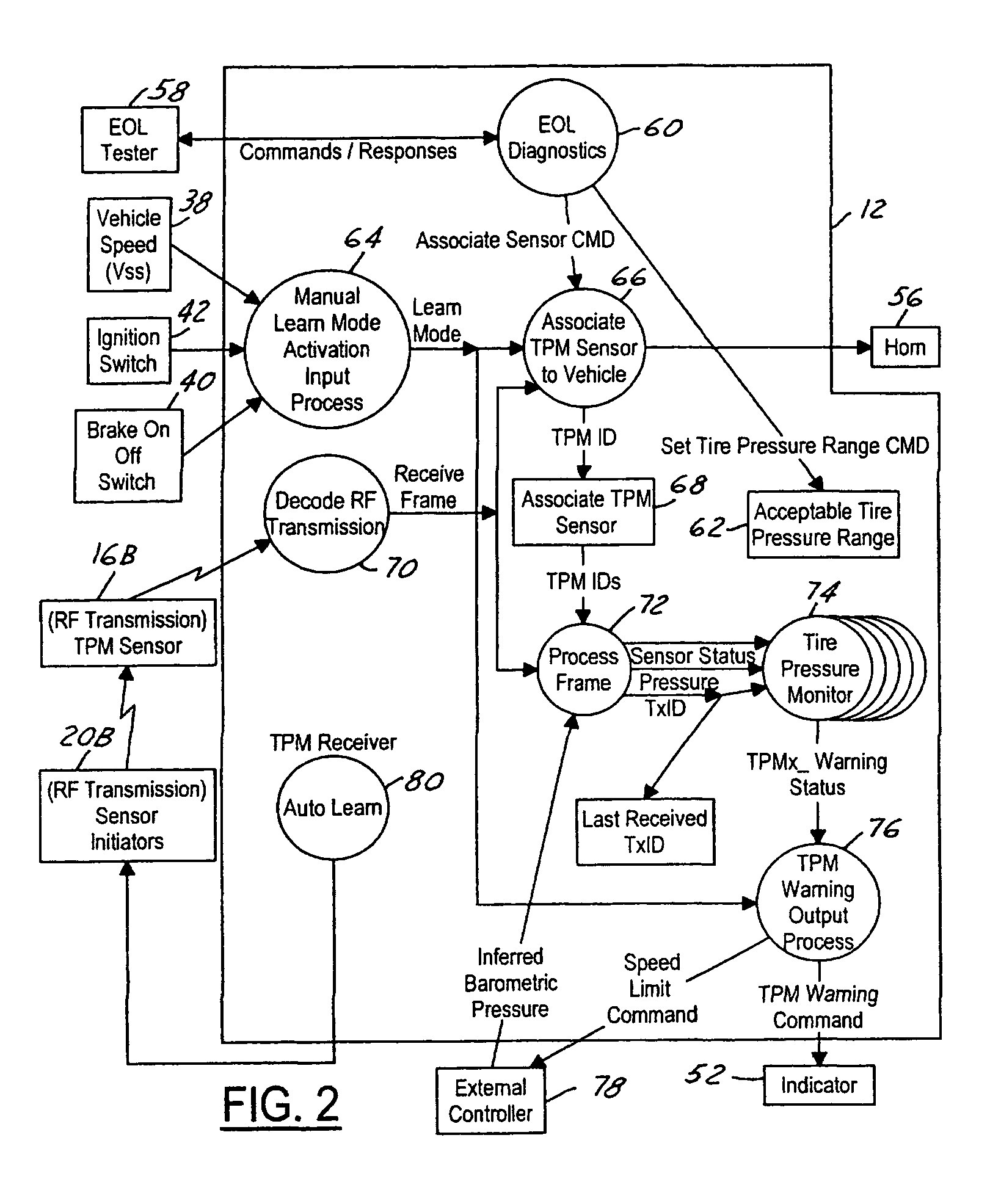

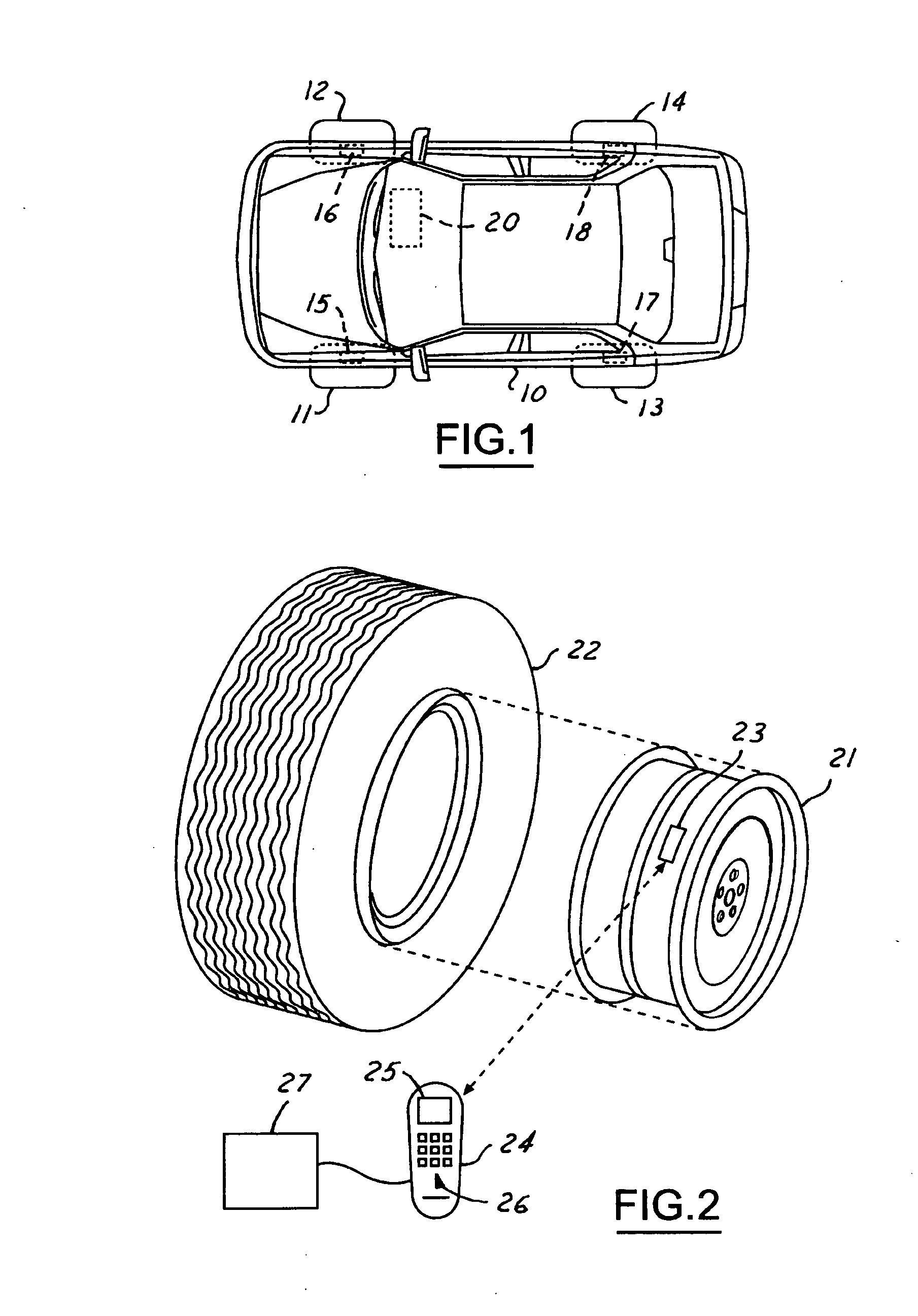

A tire pressure monitoring system, that includes a plurality of the wheel state detection unit, provided at wheel of a vehicle, and that transmits detected wheel state information. A request signal transmitter transmits a request signal to request transmission of the detected wheel state information. When each wheel state detection unit receives the request signal, it transmits the detected wheel state together with the indication information indicating that the wheel state is detected in response to the transmission request signal. The ECU sets a determination threshold value for triggering an alert regarding tire pressure based on the detected wheel state information transmitted from the plurality of wheel state detection units.

Owner:TOYOTA JIDOSHA KK

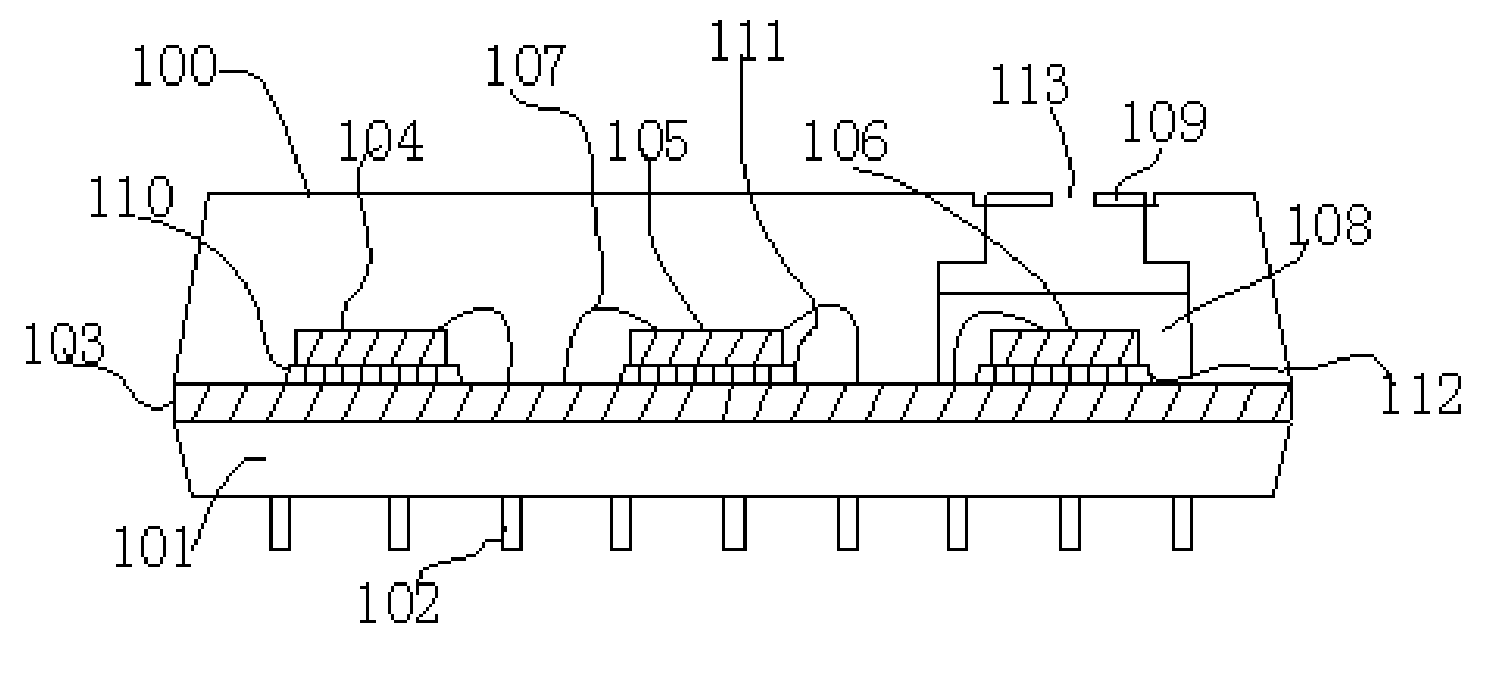

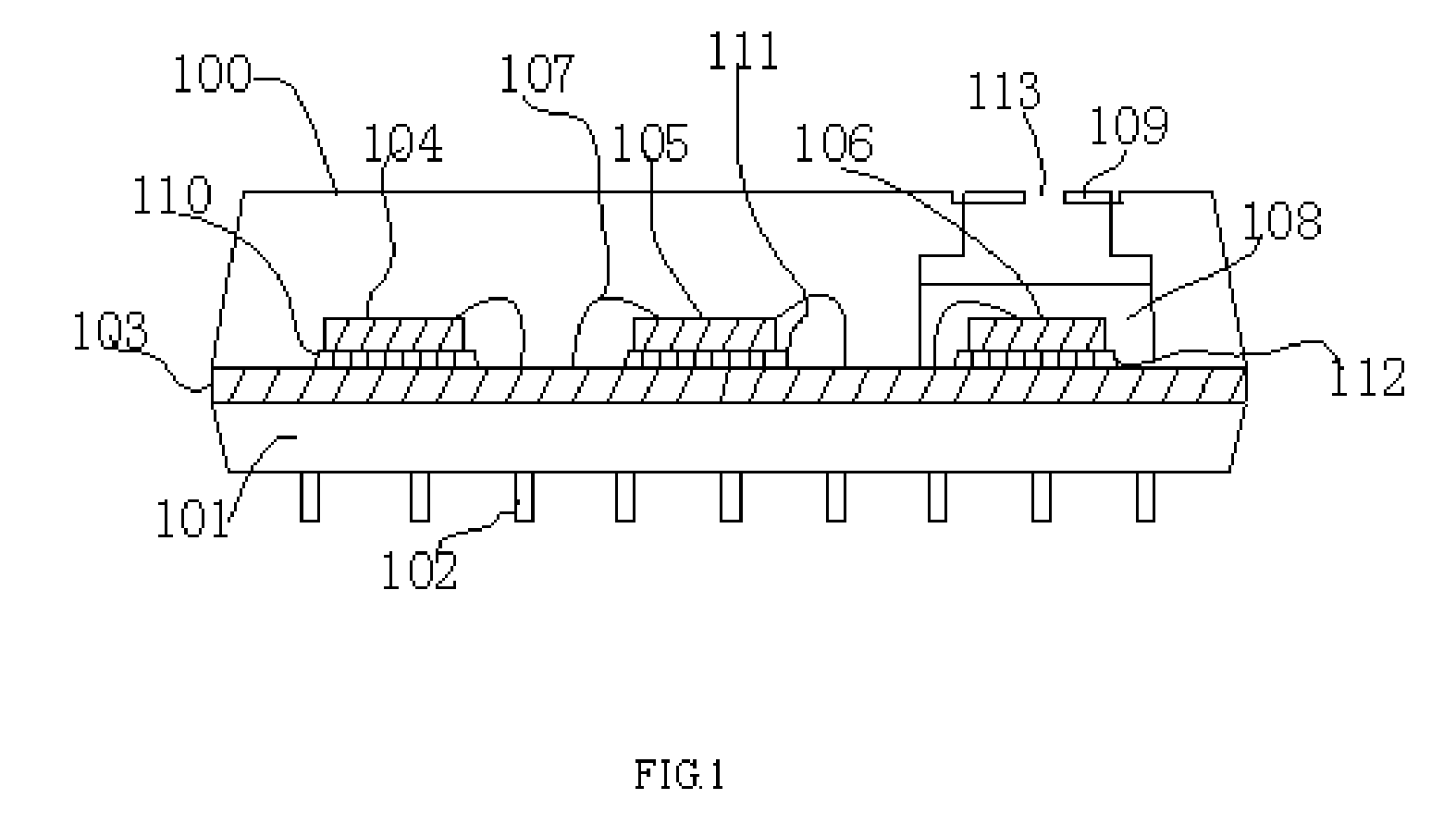

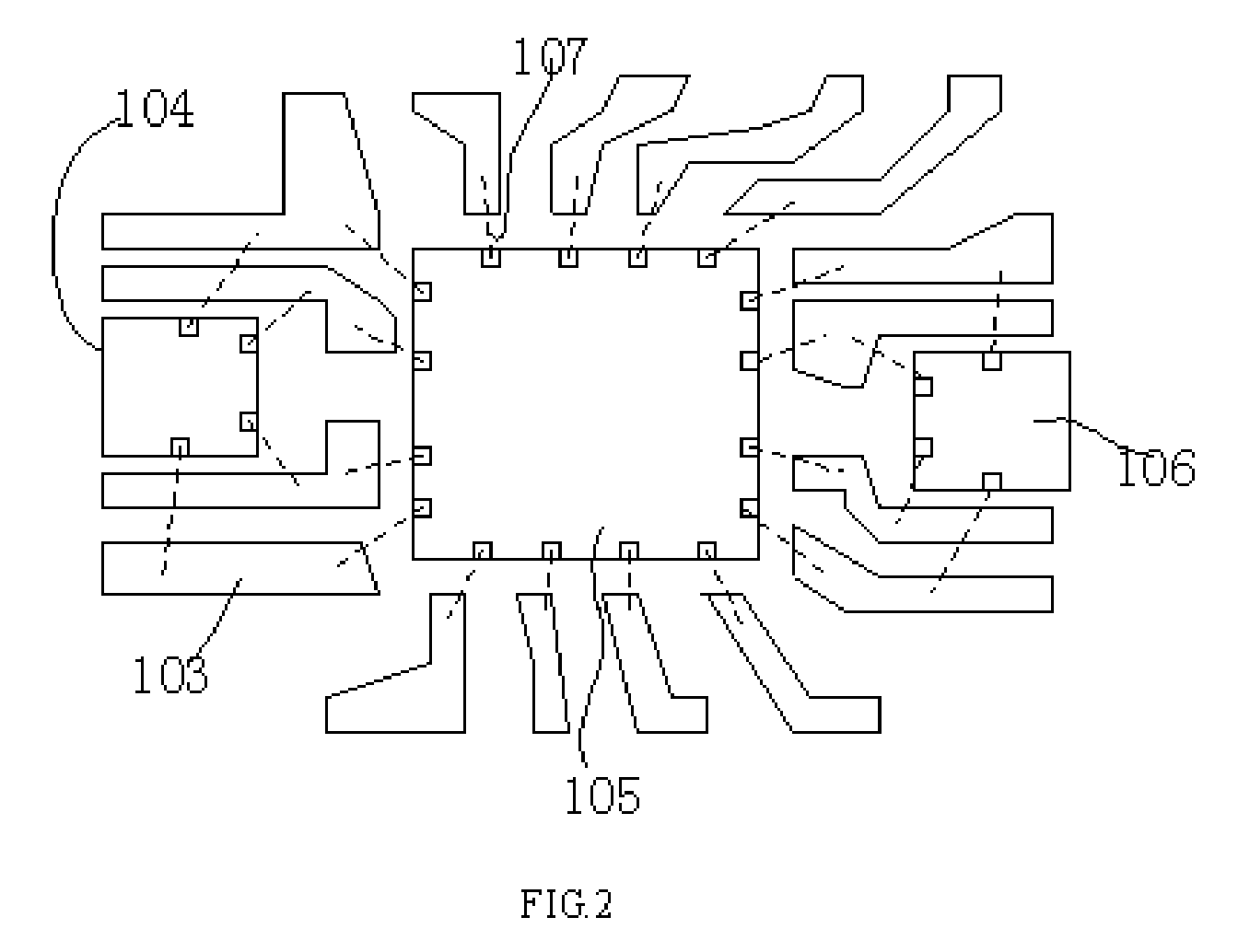

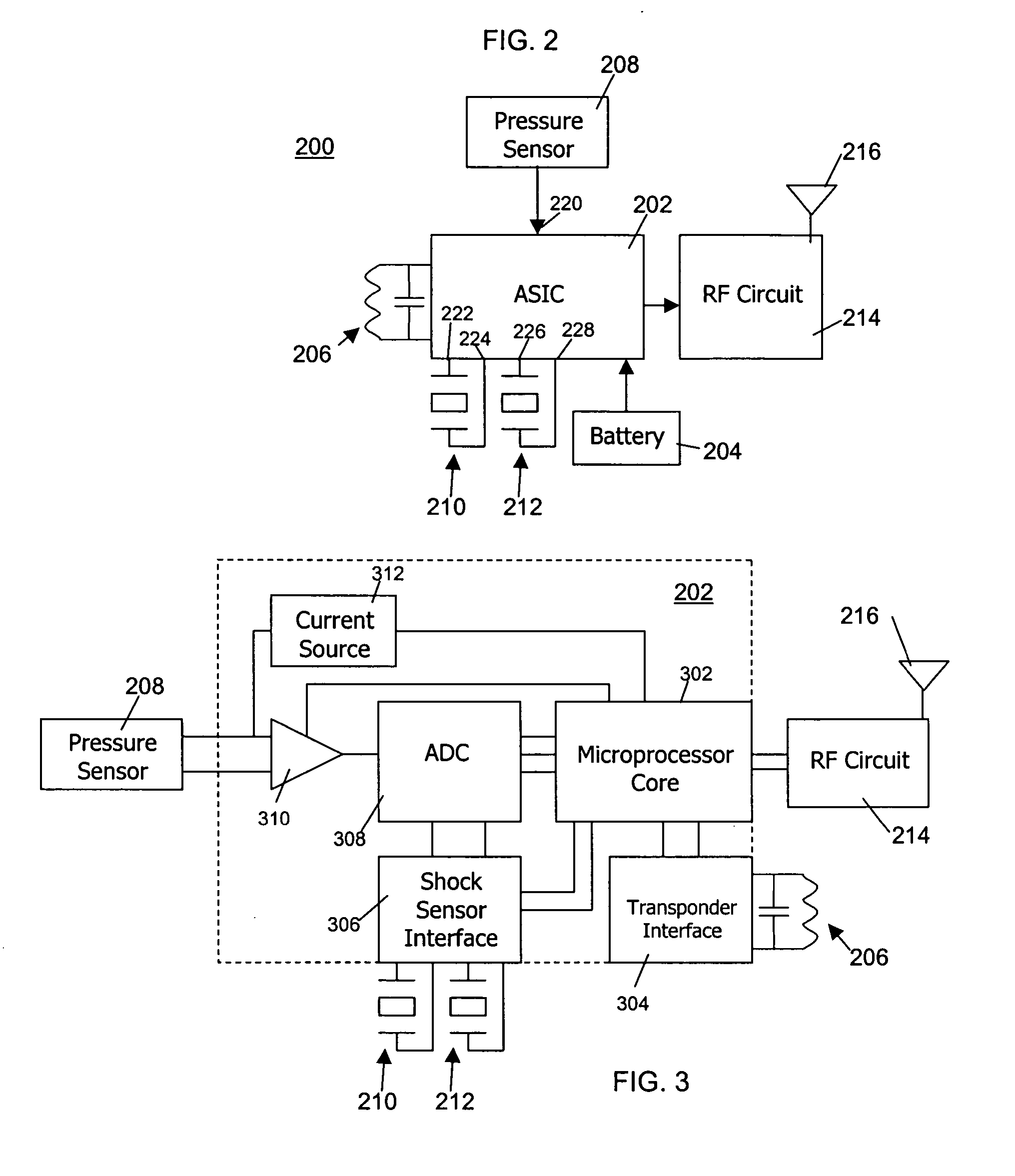

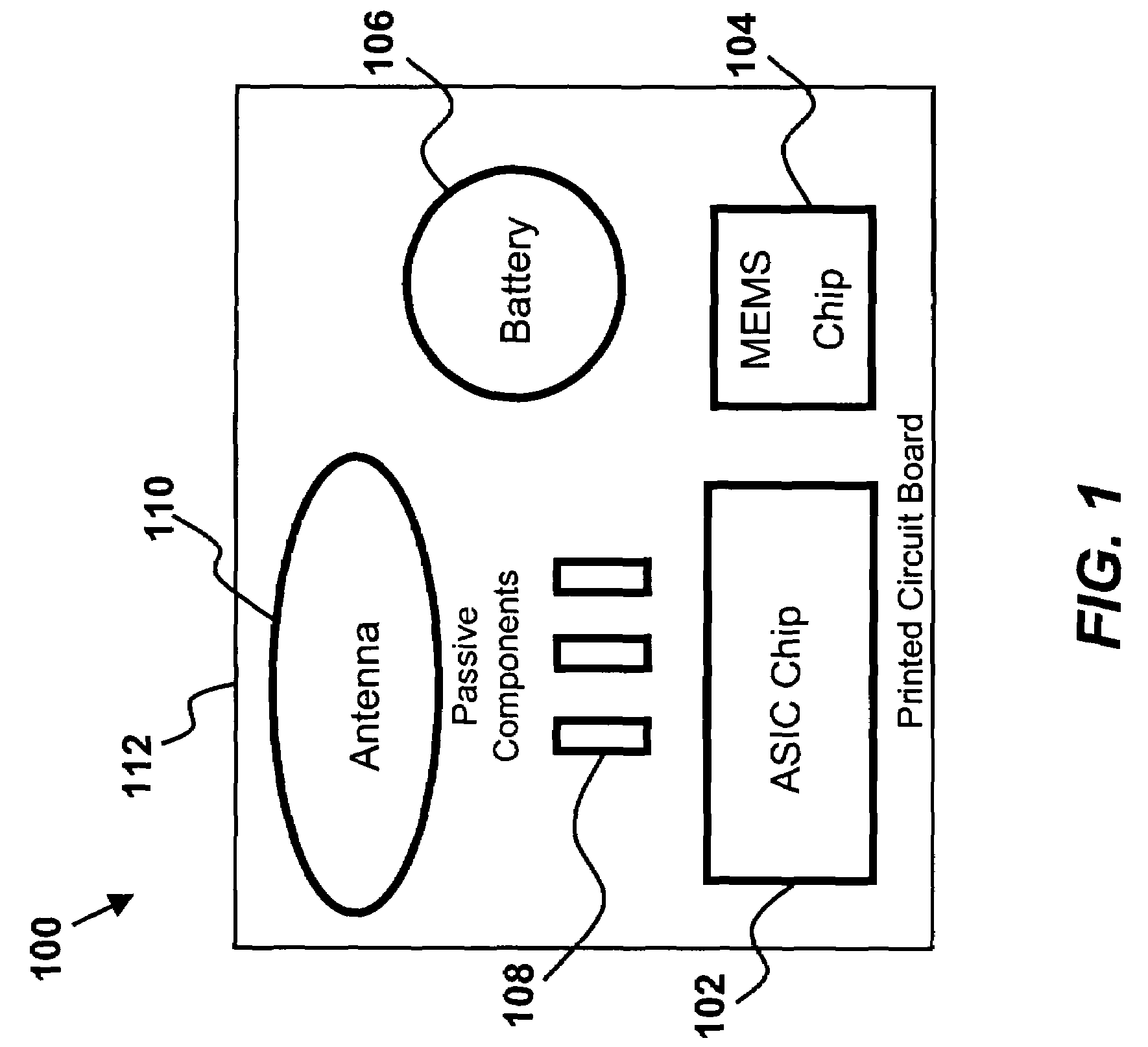

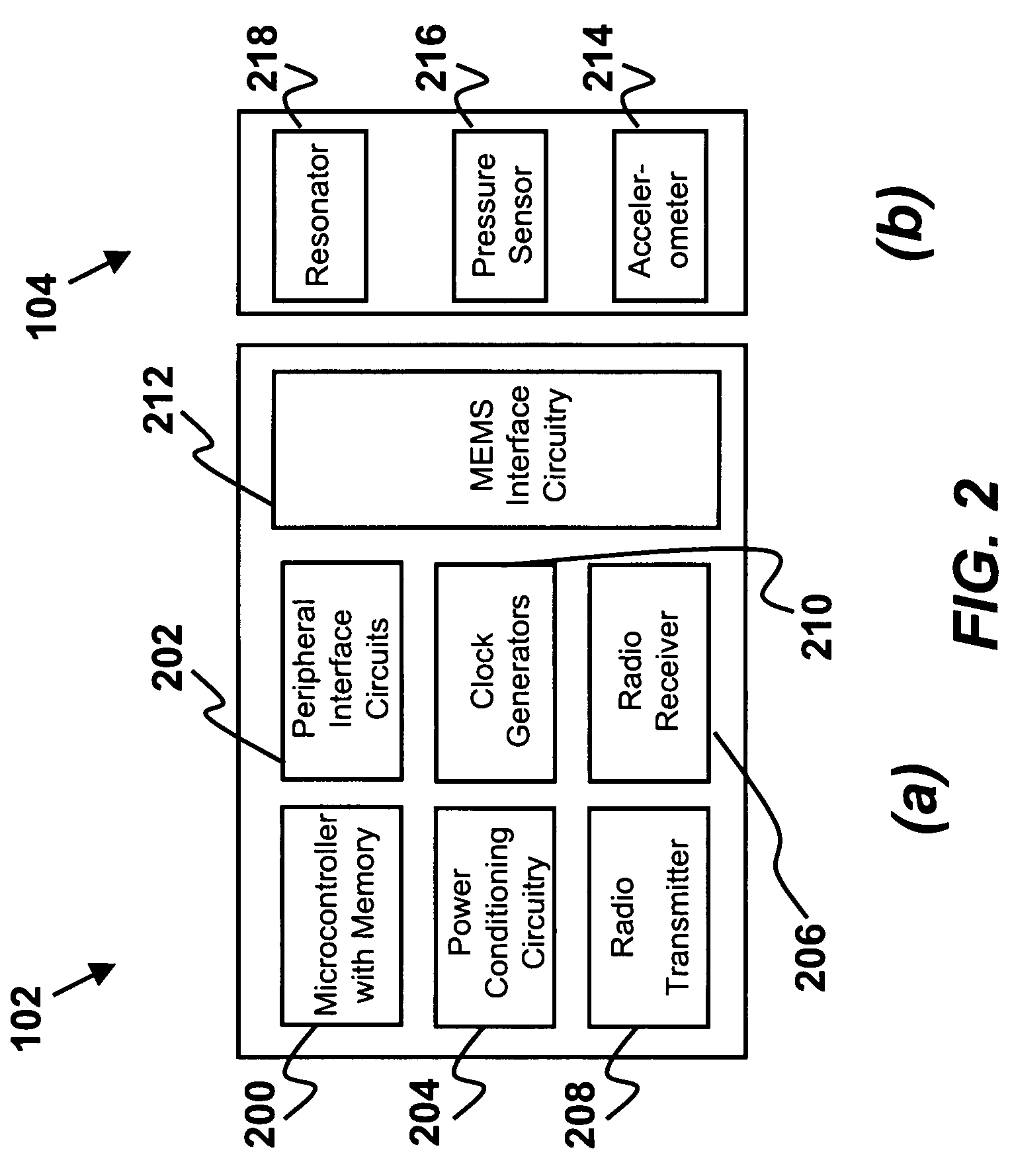

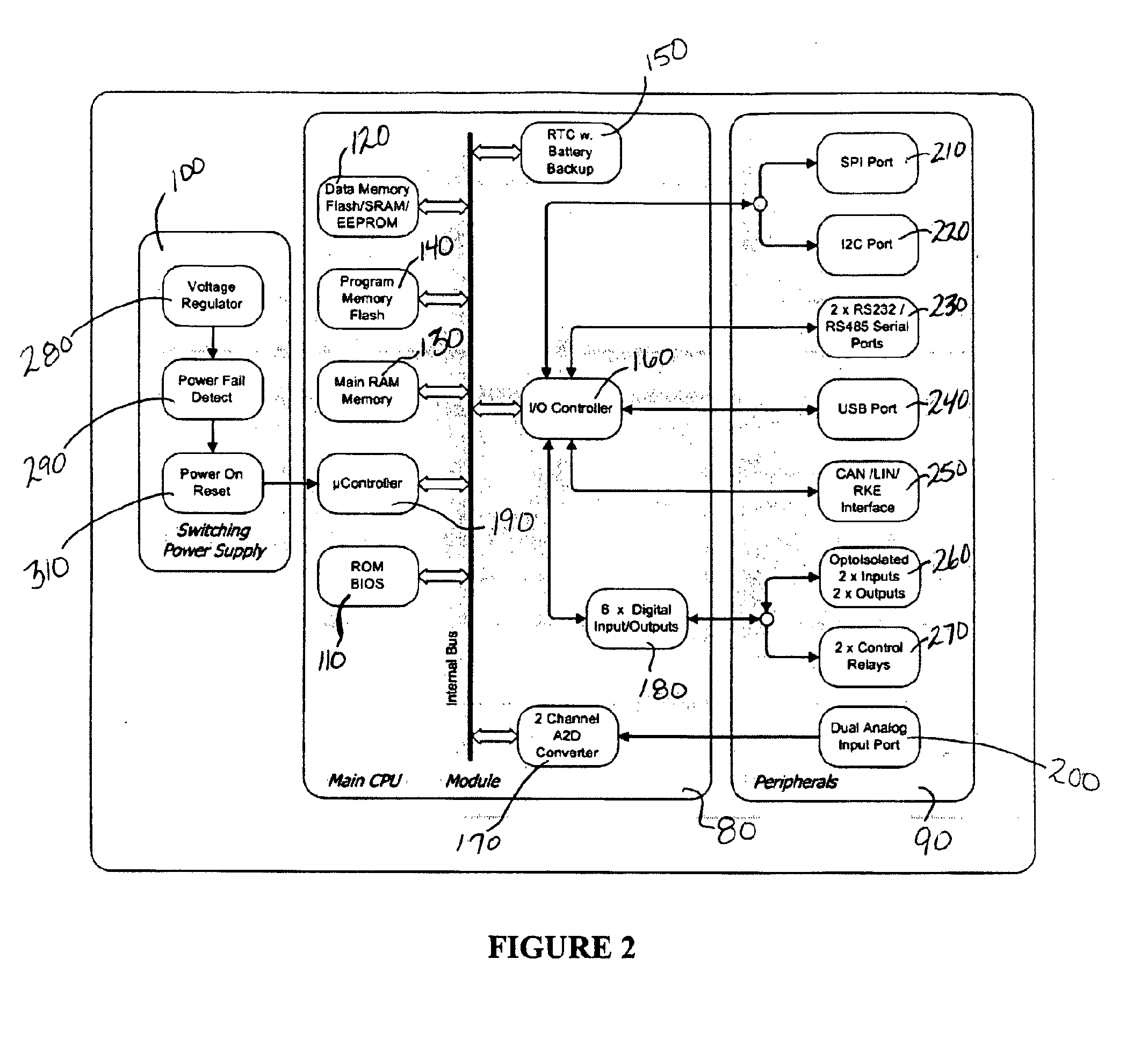

An Intelligent Integrated Sensor Of Tire Pressure Monitoring System (TPMS)

InactiveUS20060185429A1Precise size controlAccurate identificationSolid-state devicesTyre measurementsAccelerometerEngineering

A single integrated sensing chip with multi-functions for tire pressure monitor system (TPMS) comprises: a pressure sensor, an accelerometer, a temperature sensor, and an ASIC (Applied Specific Integrated Circuit) that implements signal conditioning and digitalizes pressure output. The accelerometer incorporated for vehicle motion is used to determine centrifugal acceleration or three-axial acceleration of the rotating wheel, and used for the TPMS sensor wake-up from “power down” mode, or when the velocity of the vehicle is higher than certain speed threshold, which is more robust and lower in cost than the mechanical vibration switch and is naturally integrated with the electronic control unit. The accelerometer can be used for regular motion sensing to monitor the dynamic stability. The integrated sensor system can be packaged into one plastic package first, and then surface mounted to the printed circuit board, or the multi-function single chip can be wafer bonded on the wafer level first and diced into many individual chips, with each chip being directly attached on to the printed circuit board by wire bonding or flip-chip assembly.

Owner:WUHAN FINEMEMS

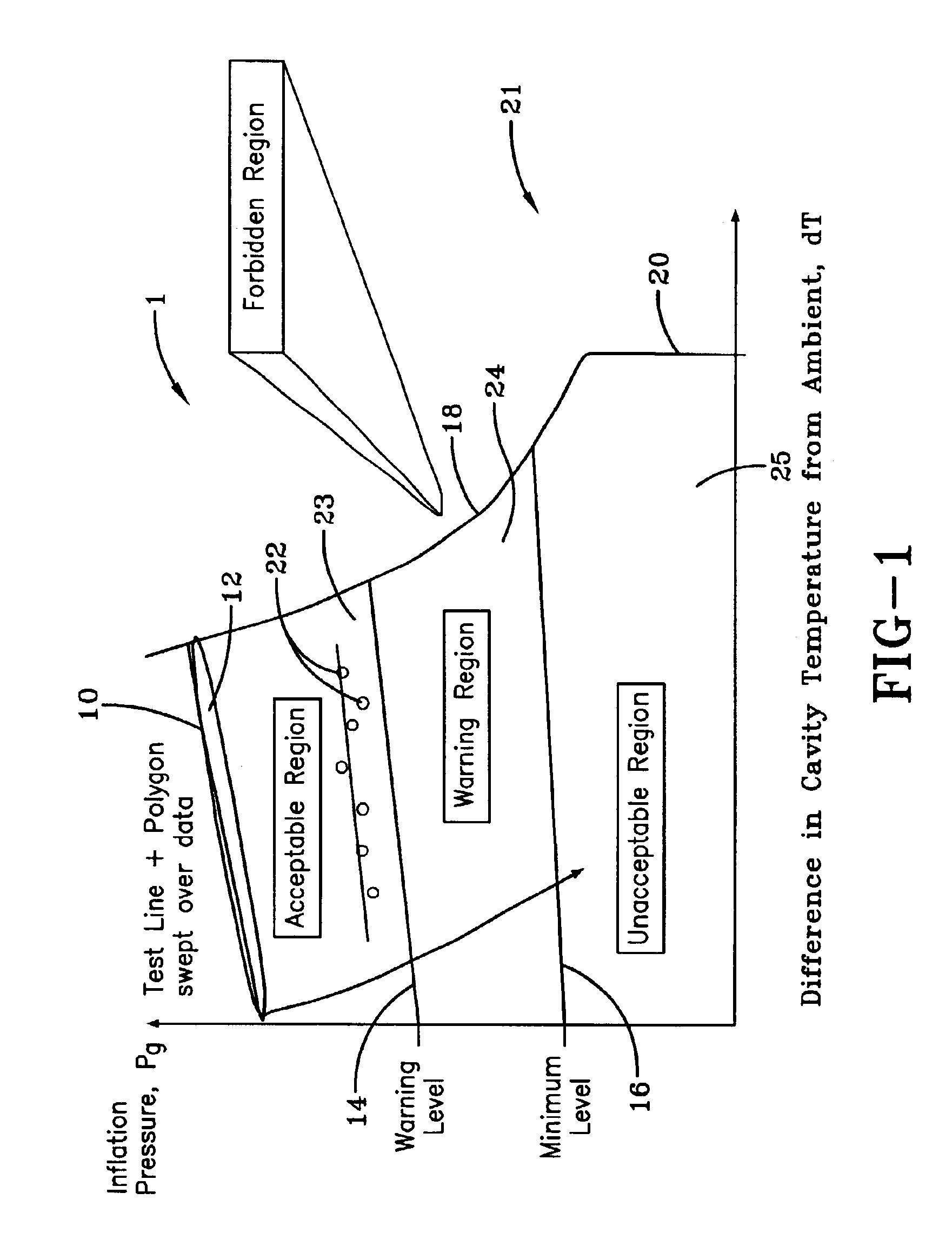

Method for processing information in a tire pressure monitoring system

InactiveUS6868358B2Improve utilizationAccurate detectionInflated body pressure measurementRegistering/indicating working of vehiclesEngineeringTire-pressure monitoring system

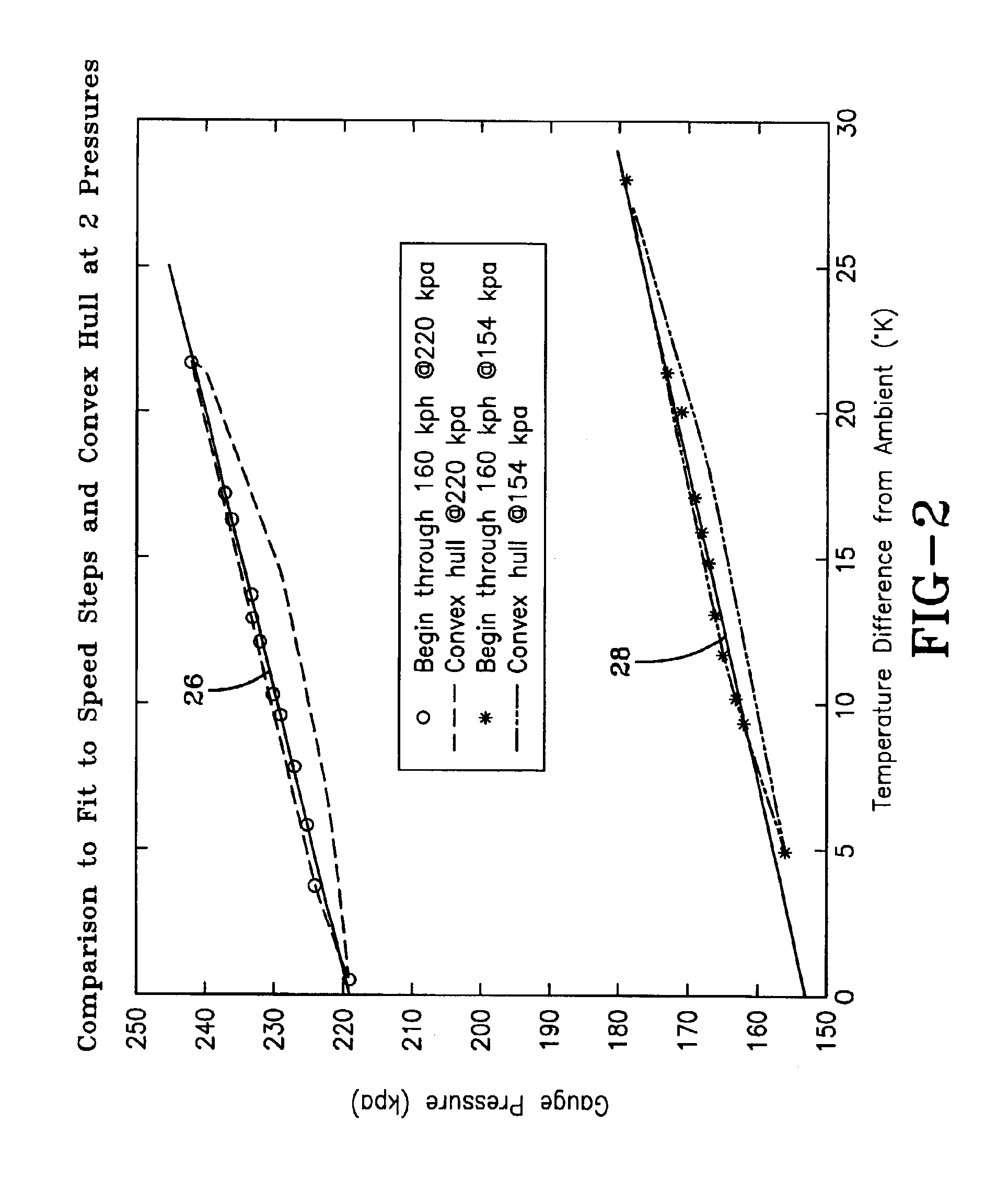

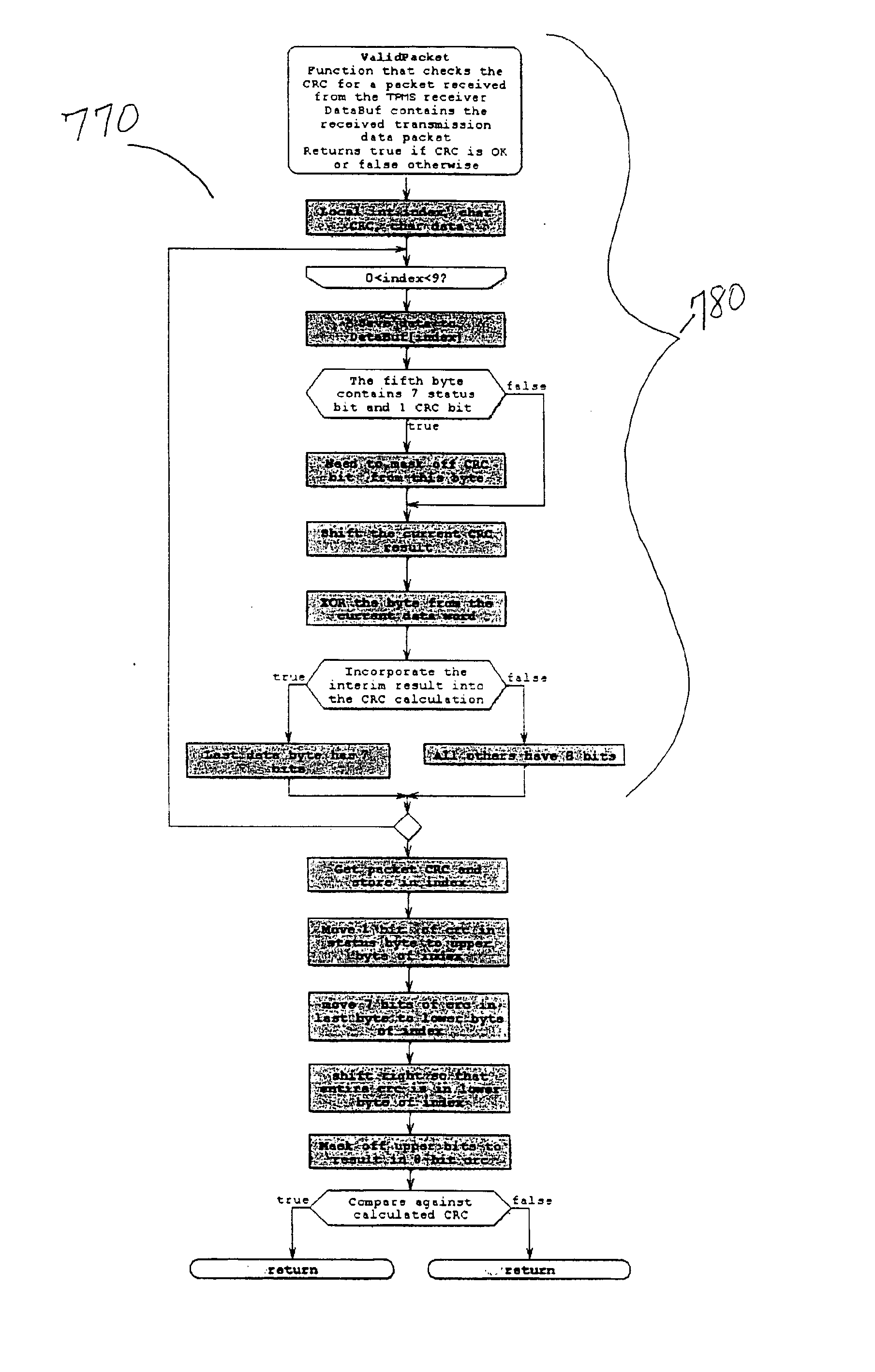

A method of processing information in a tire pressure monitoring system includes the steps of: establishing a reference temperature; determining a pressure warning threshold at the reference temperature; measuring gauge pressure and gauge temperature within a tire cavity; correcting the gauge pressure to a filtered pressure value at the reference temperature using the Ideal Gas Law; and comparing the filtered pressure value against the pressure warning threshold to determine the necessity for a warning signal. In an advanced form of the invention, the method includes determining a pressure leak rate; predicting the time interval that the filtered pressure value will cross the pressure warning threshold at the leak rate and generating progressive warnings to the driver over the time interval. Fuzzy logic is used to quantify the probability of a warning state for each data point, allow for measurement error; and report the state of maximum probability to minimize the occurrence of false warning. A warning utility function is derived based upon a combination of the filtered pressure and leak rate.

Owner:THE GOODYEAR TIRE & RUBBER CO

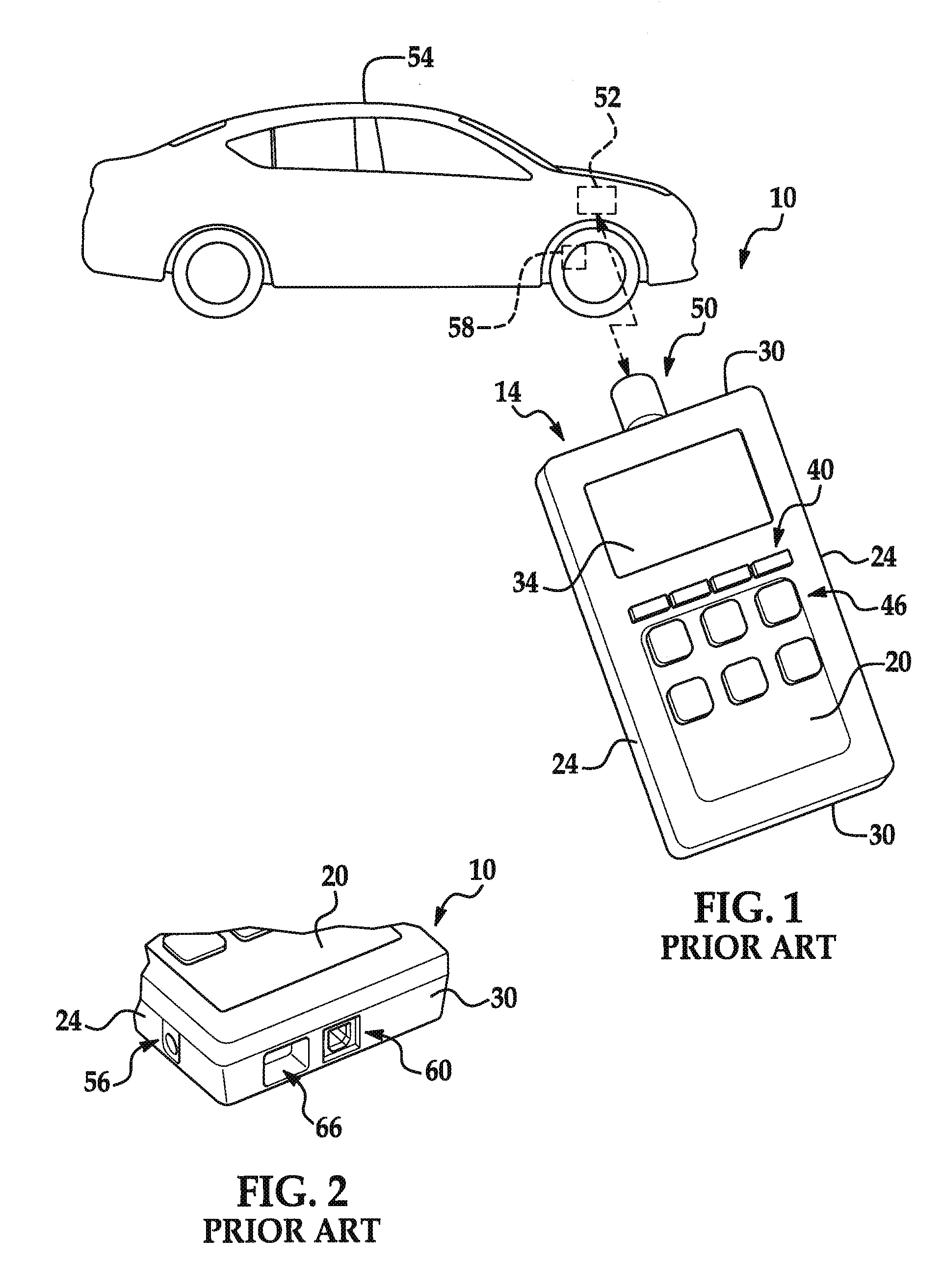

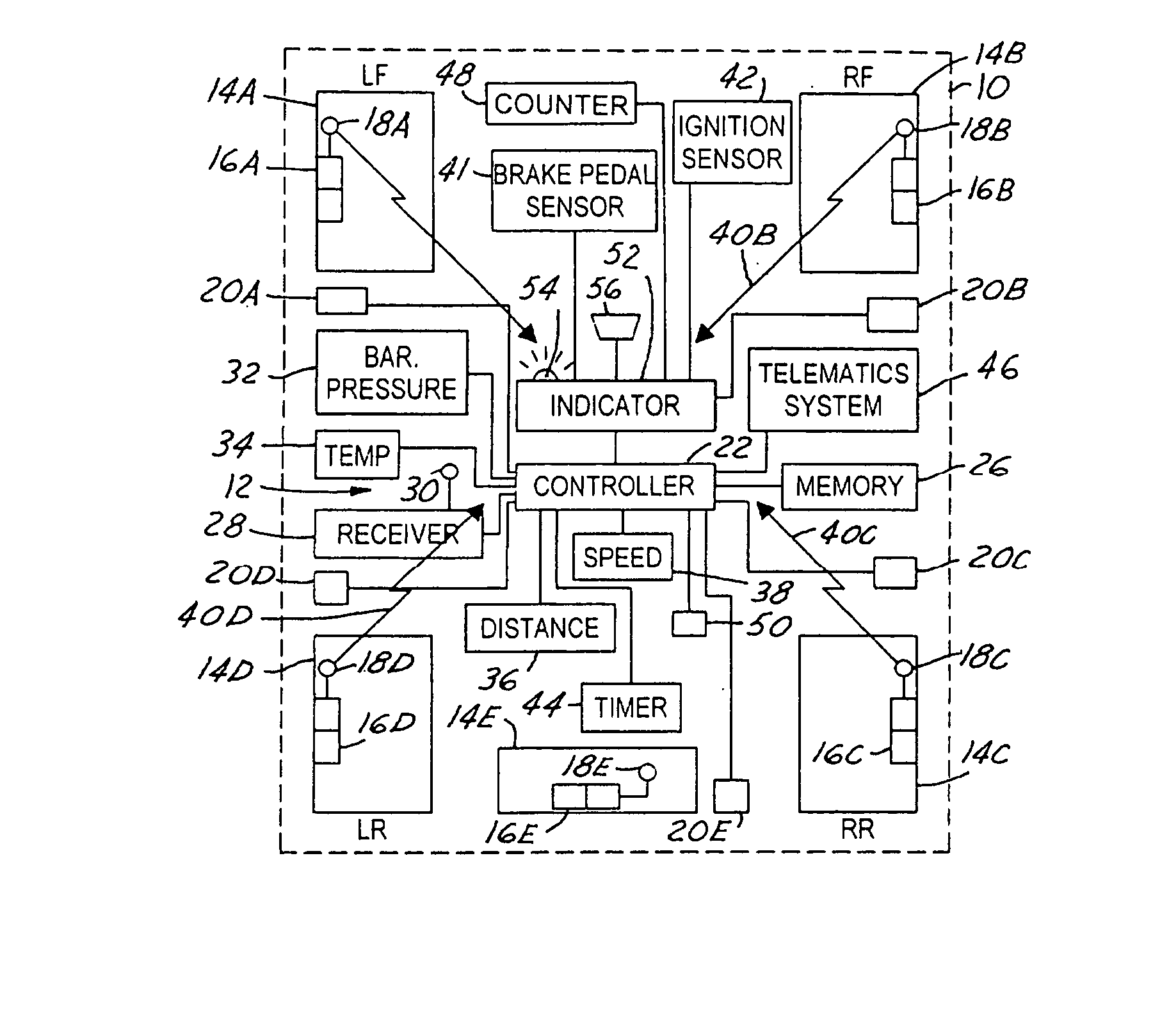

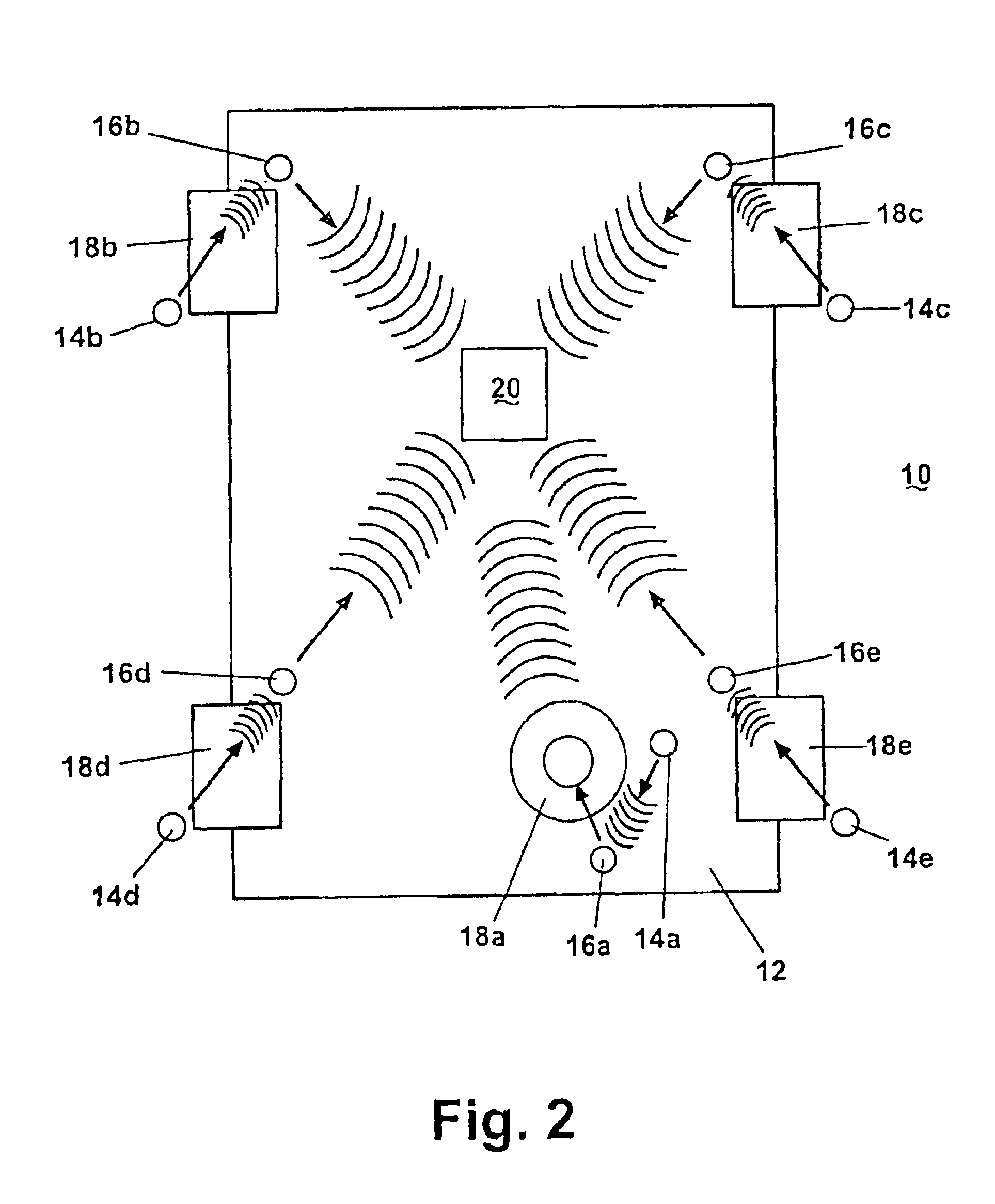

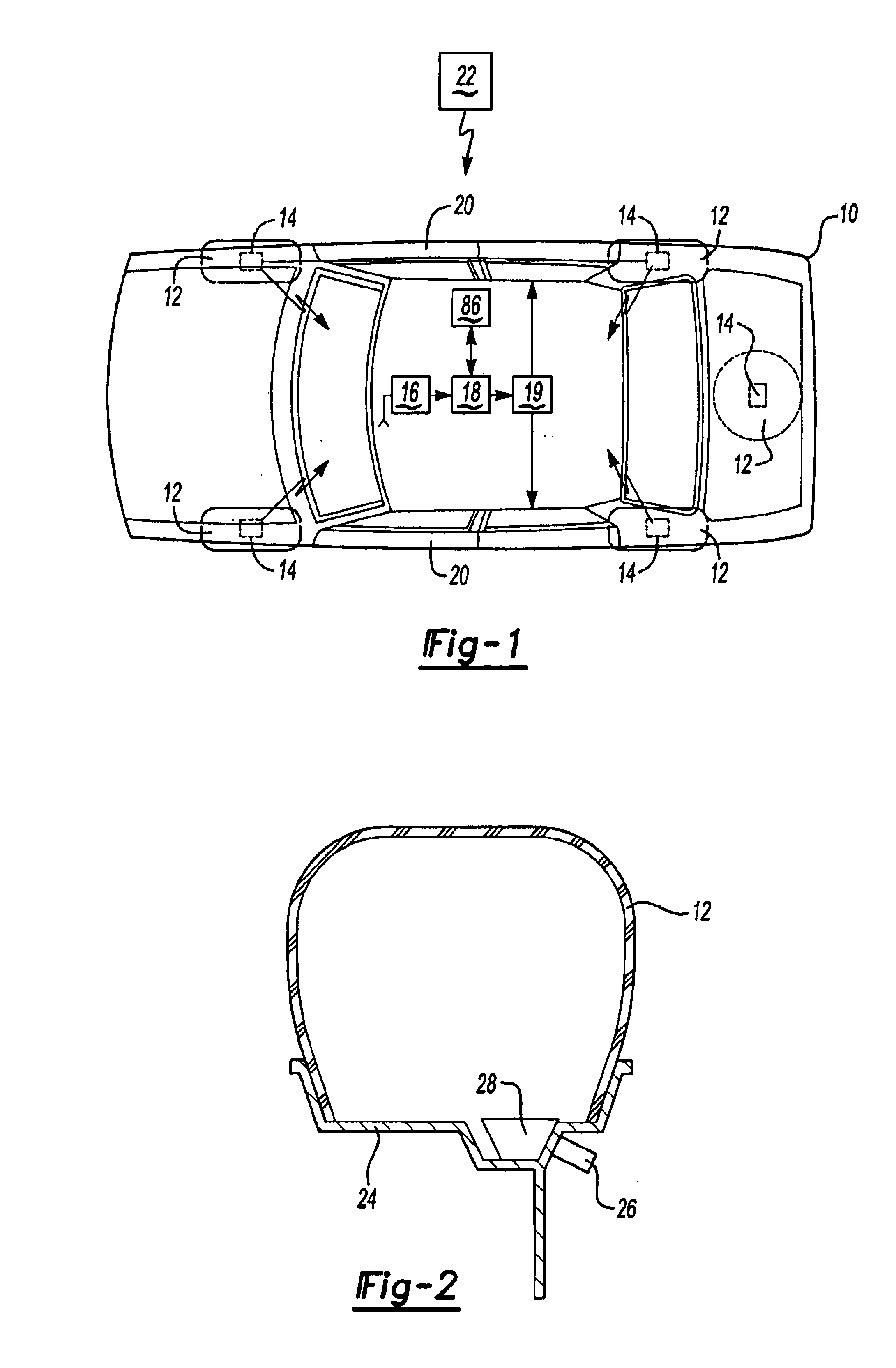

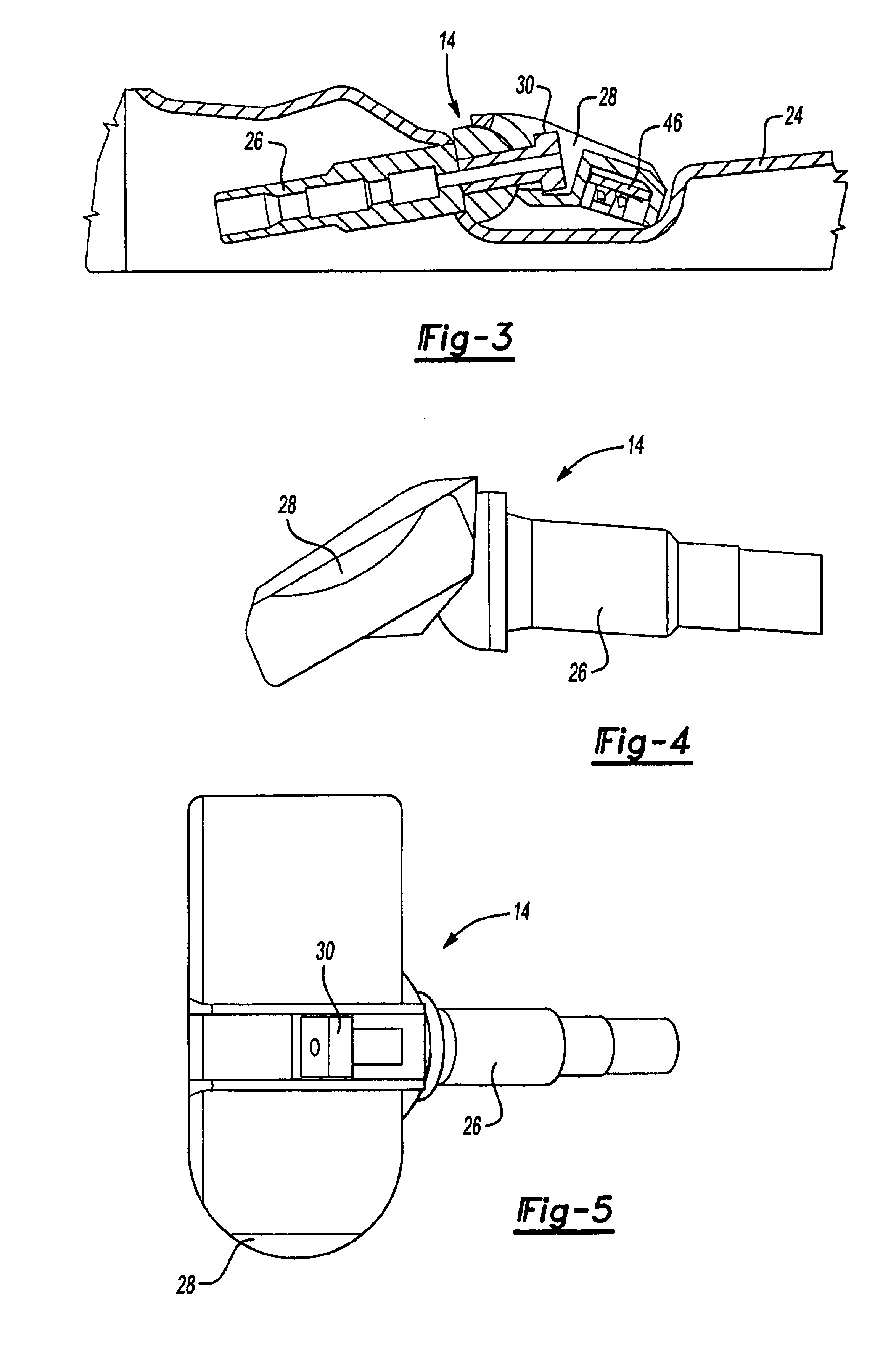

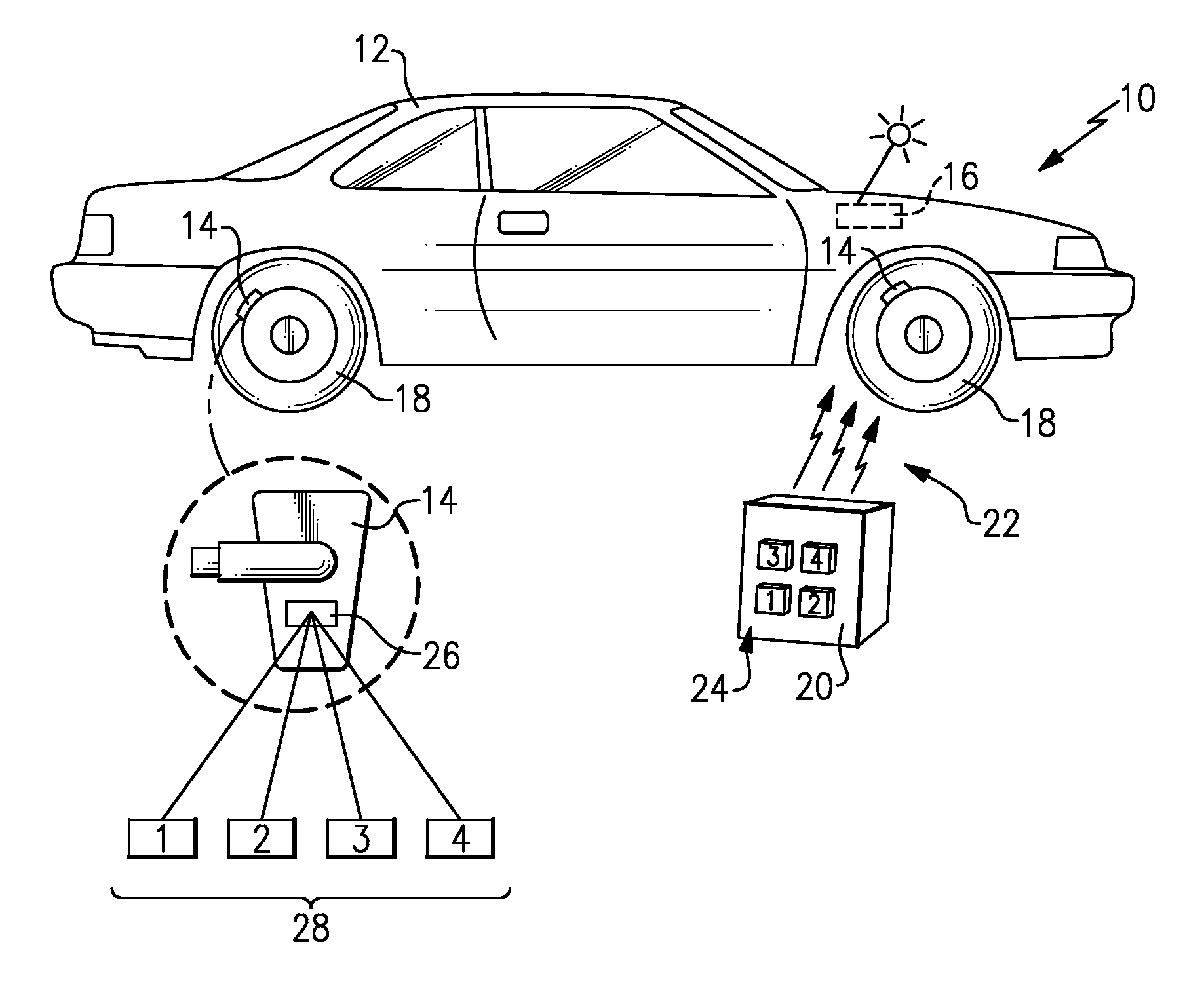

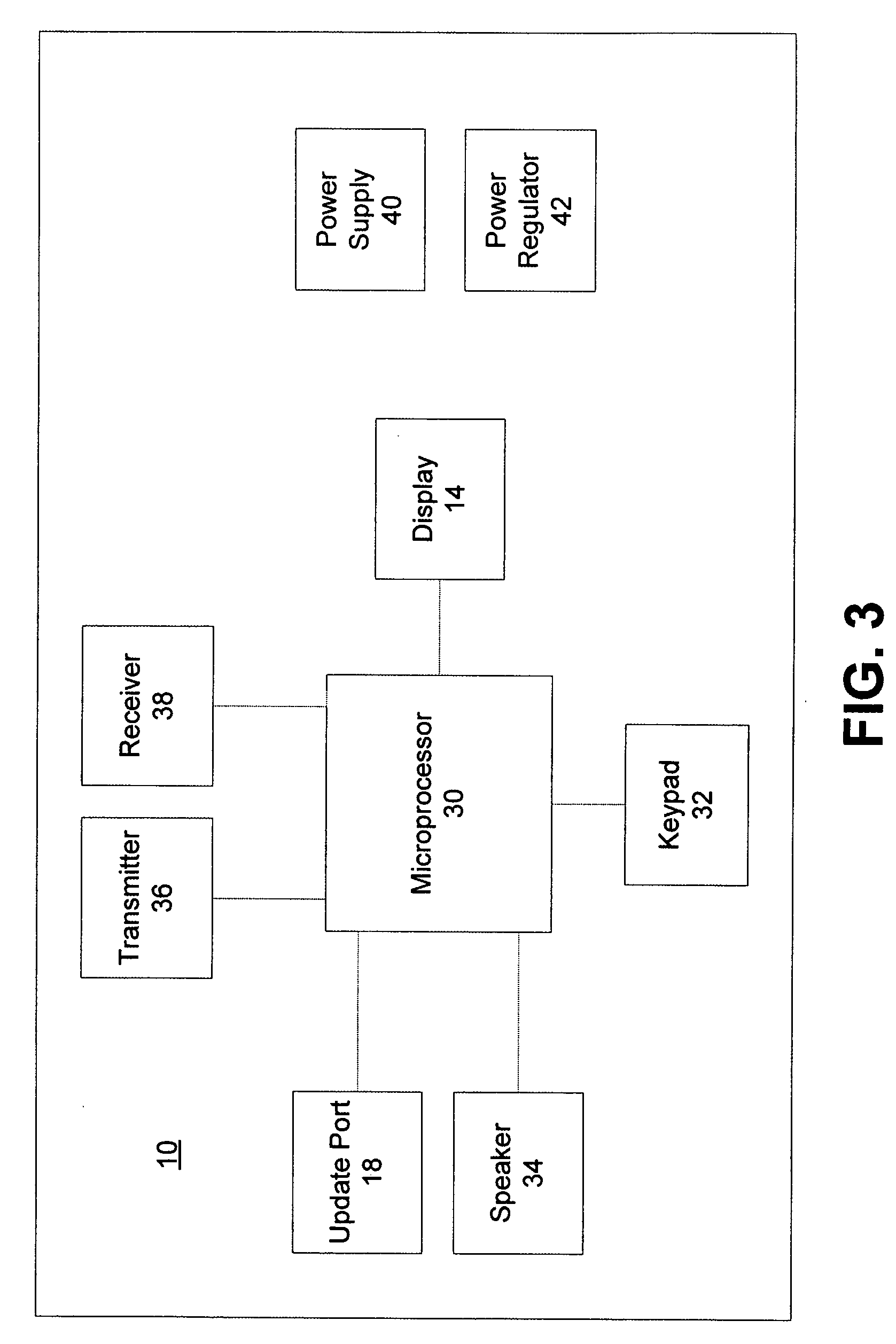

Method and system for calibrating a tire pressure sensing system for an automotive vehicle

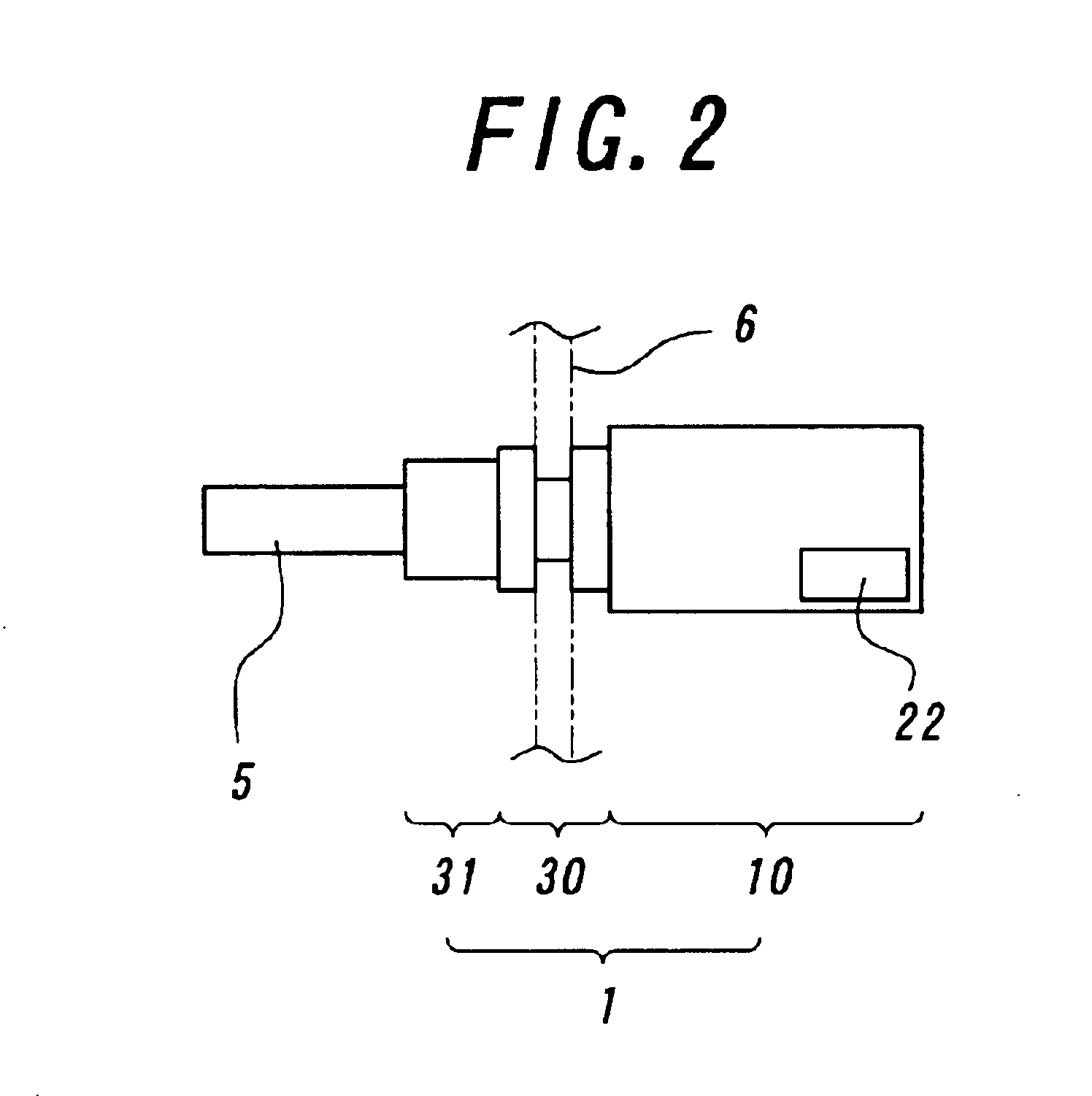

InactiveUS6945087B2Eliminate the problemNot subject to easy lossFluid pressure measurementTyre measurementsMobile vehicleEm coupling

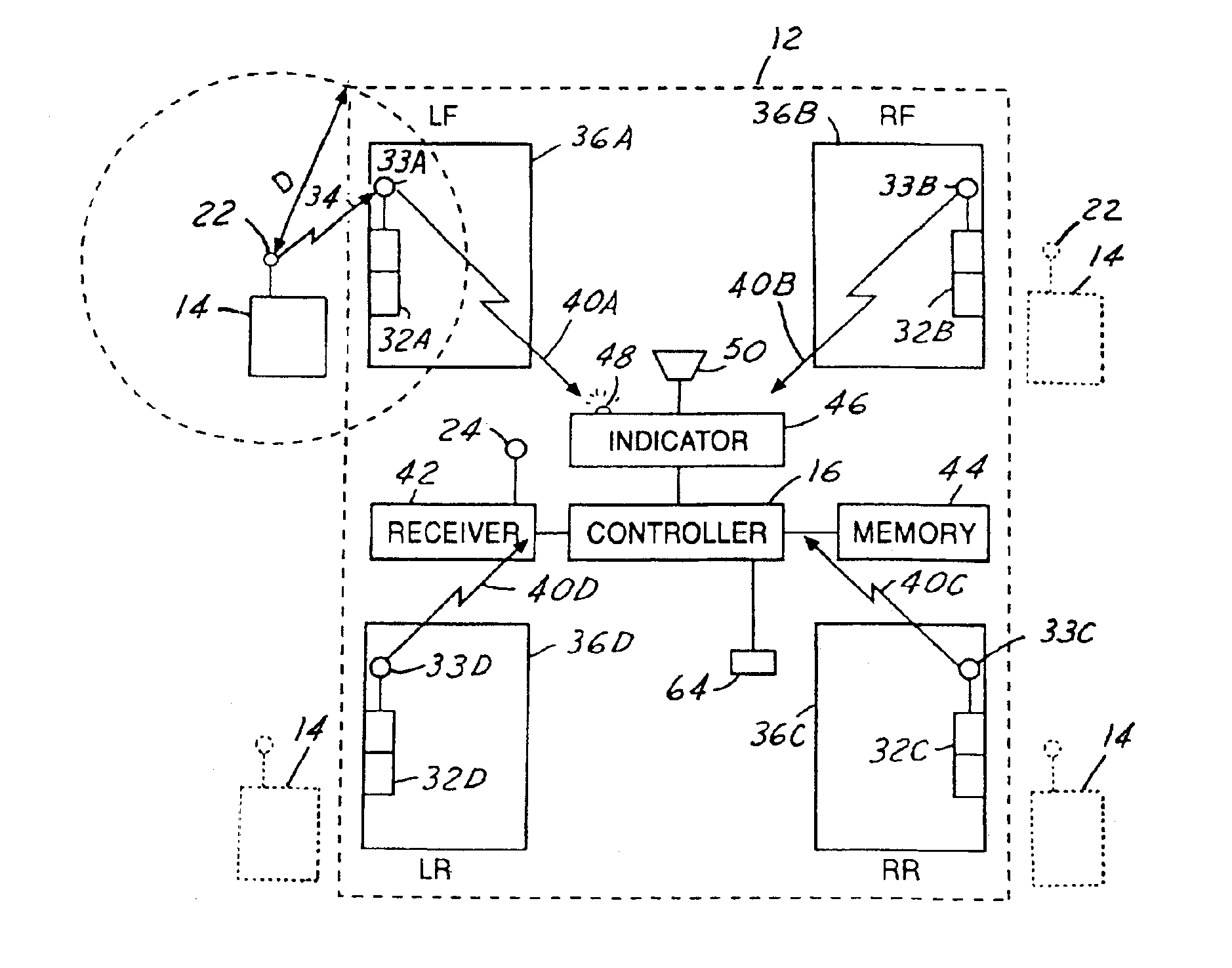

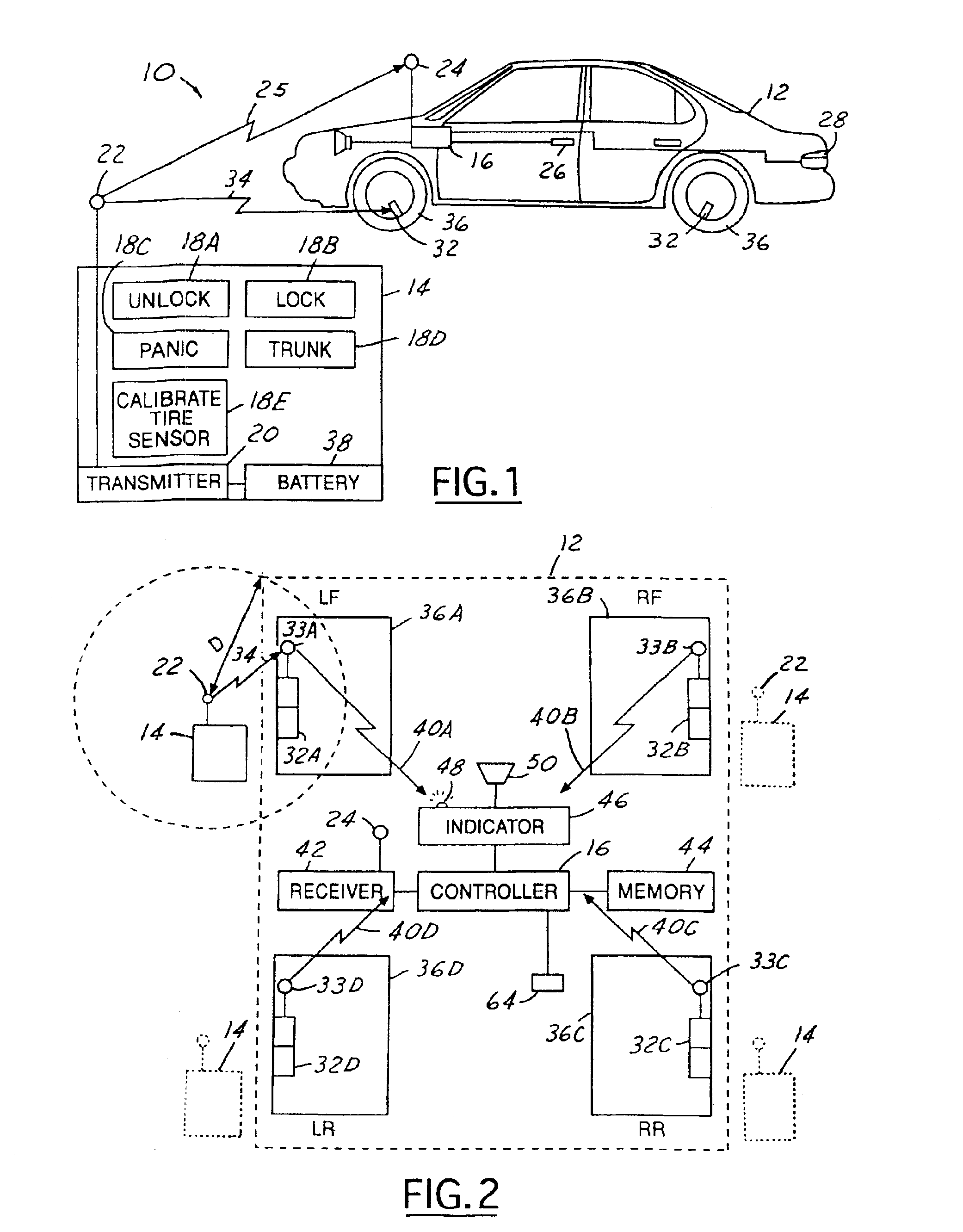

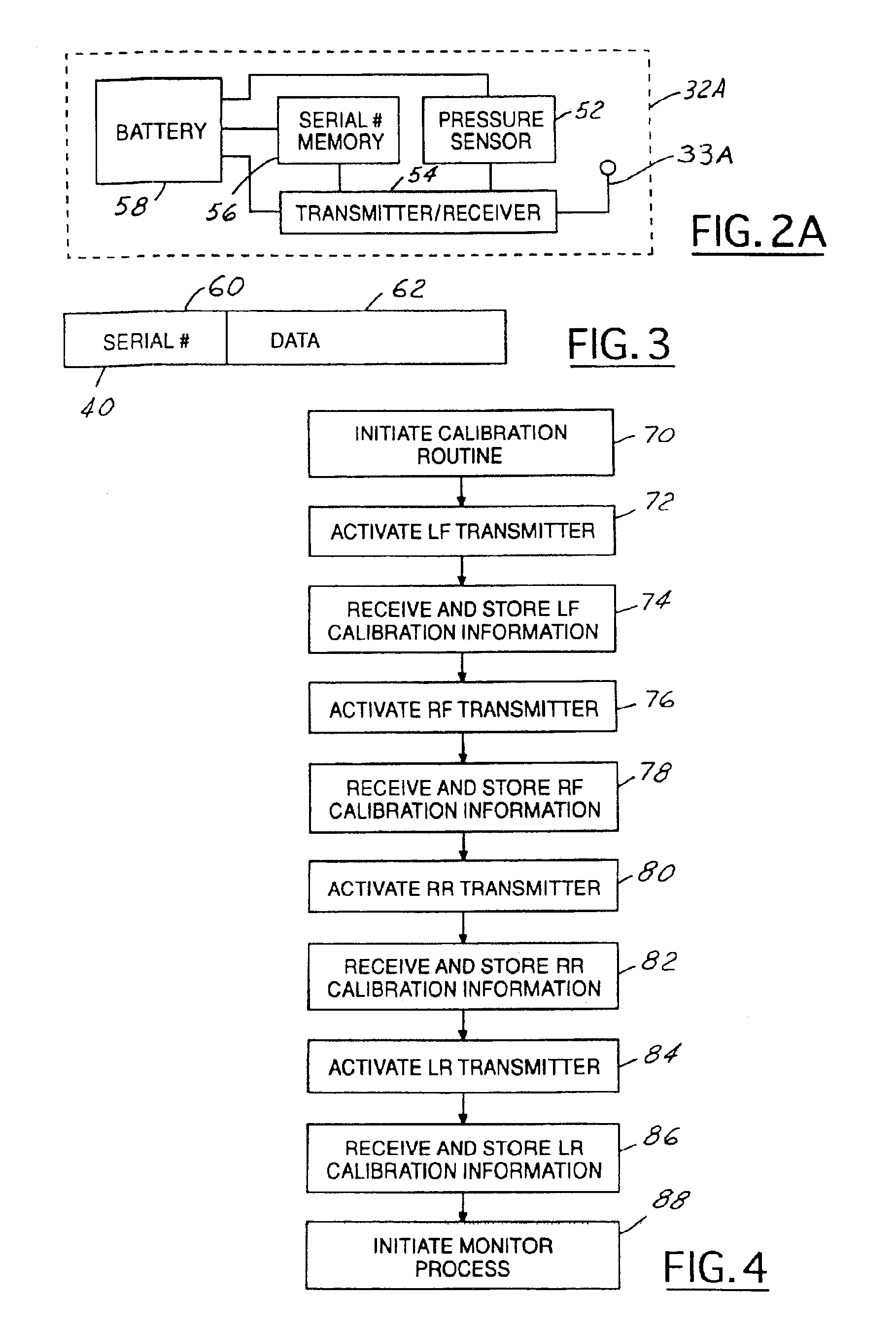

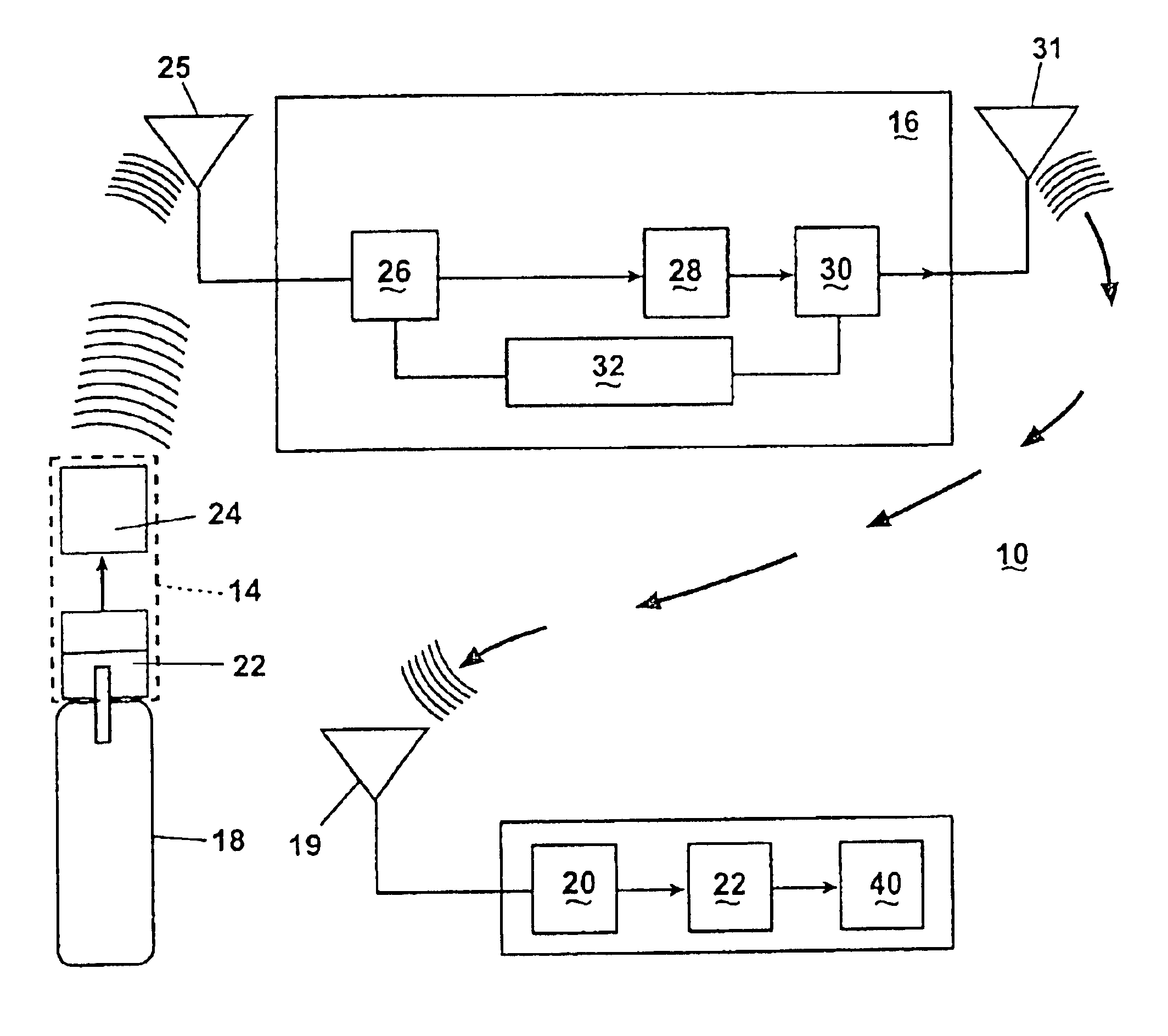

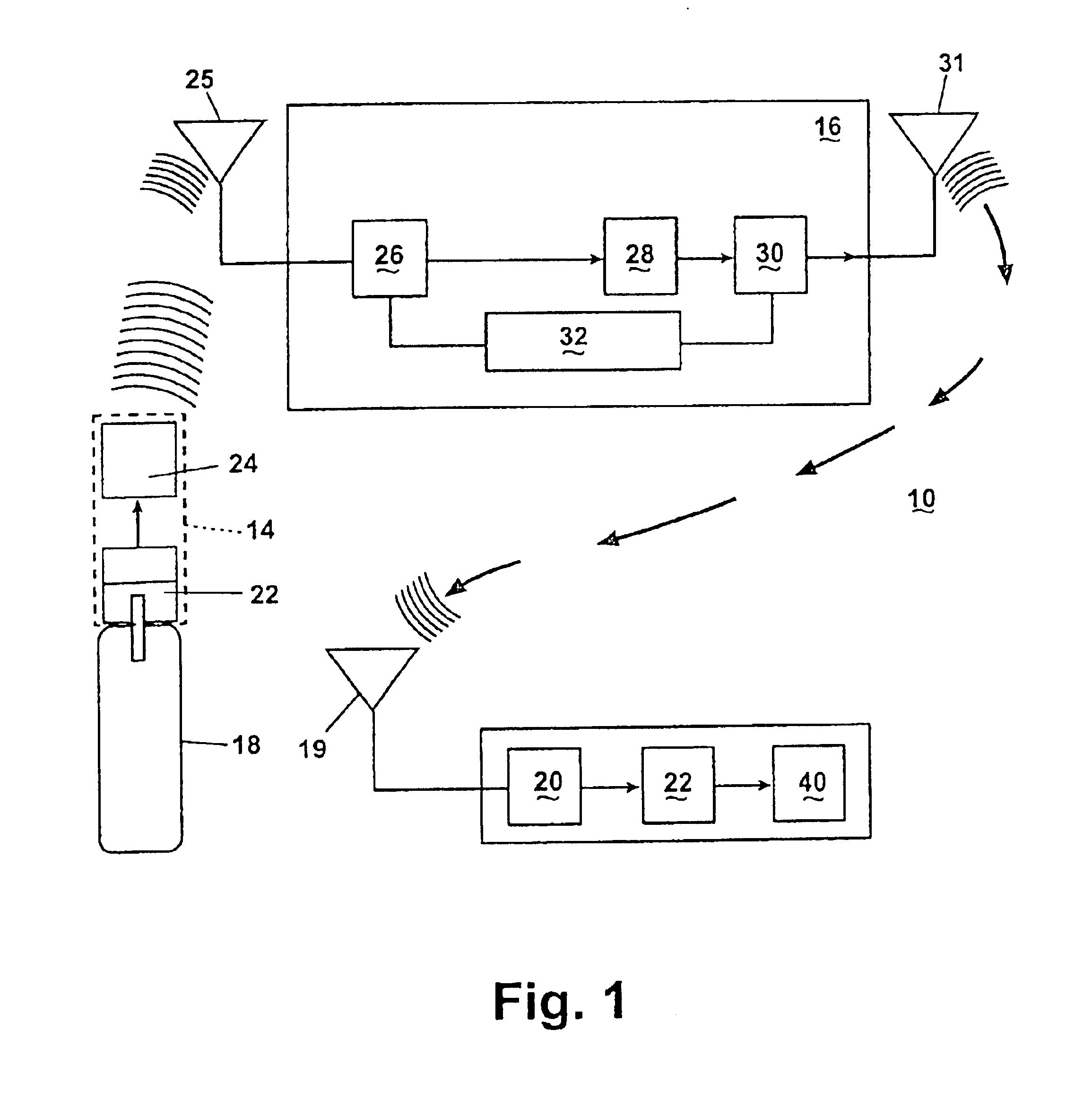

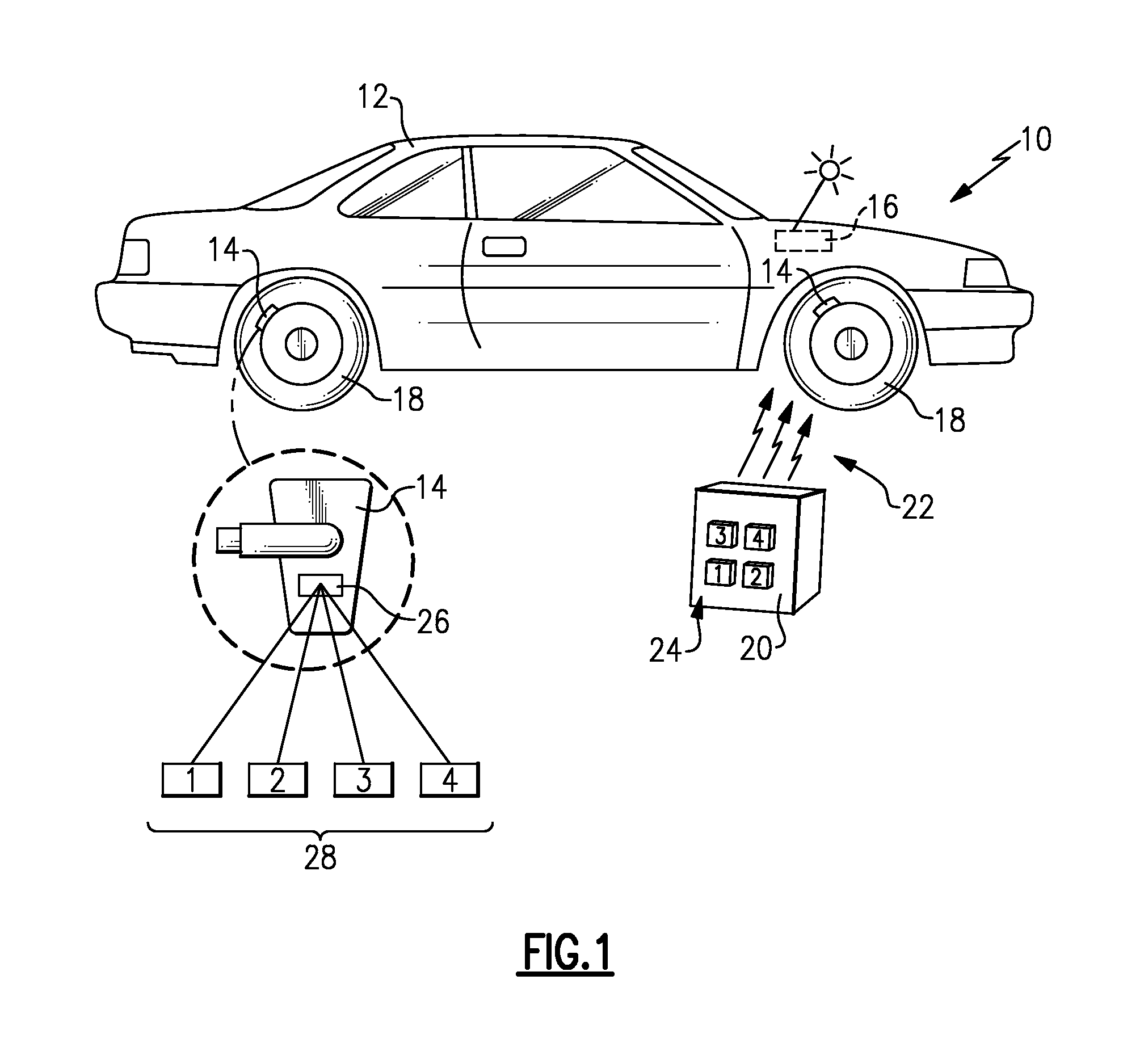

A system (10) and method is provided for calibrating a tire pressure monitoring system using an EM transmitter (14). The present invention includes a first pressure sensor coupled to a wheel of an automotive vehicle (12). The EM pressure transmitter (14) is coupled to the pressure sensor (32). The transmitter (14) has a serial number associated therewith. An EM calibration device has a transmitting range. The EM transmitter device has an actuator. When the actuator is activated, a calibration signal (34) is transmitted within the transmitting range. The calibration signal causes the EM pressure transmitter (32) to transmit a serial number. A controller (16) is EM coupled to the pressure transmitter. The controller (16) receives the serial number and associates the serial number with a tire location of the vehicle.

Owner:FORD GLOBAL TECH LLC

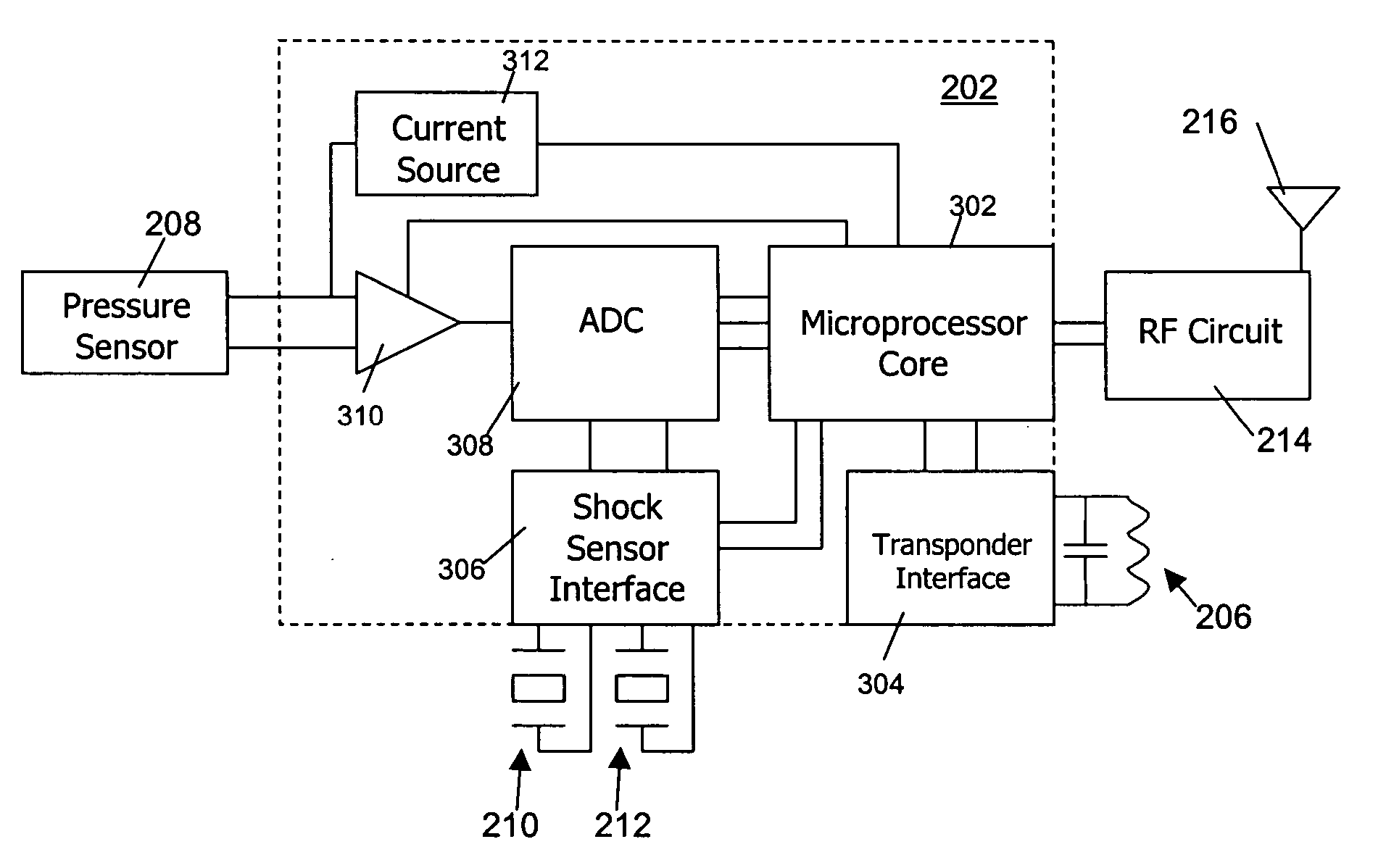

Motion detection using a shock sensor in a remote tire pressure monitoring system

ActiveUS20050156722A1Tyre measurementsRoads maintainenceMonitoring systemTire-pressure monitoring system

A tire monitor for mounting to a vehicle as part of a remote tire monitoring system includes a tire condition sensor to produce a tire condition signal, a controller coupled to the tire condition sensor to control operation of the tire monitor, and a radio circuit coupled to the controller to transmit radio signals based at least in part on the tire condition signal. A shock sensor is coupled to the controller of the tire monitor to produce a motion signal indicating motion of the tire monitor.

Owner:SENSATA TECHNOLOGIES INC

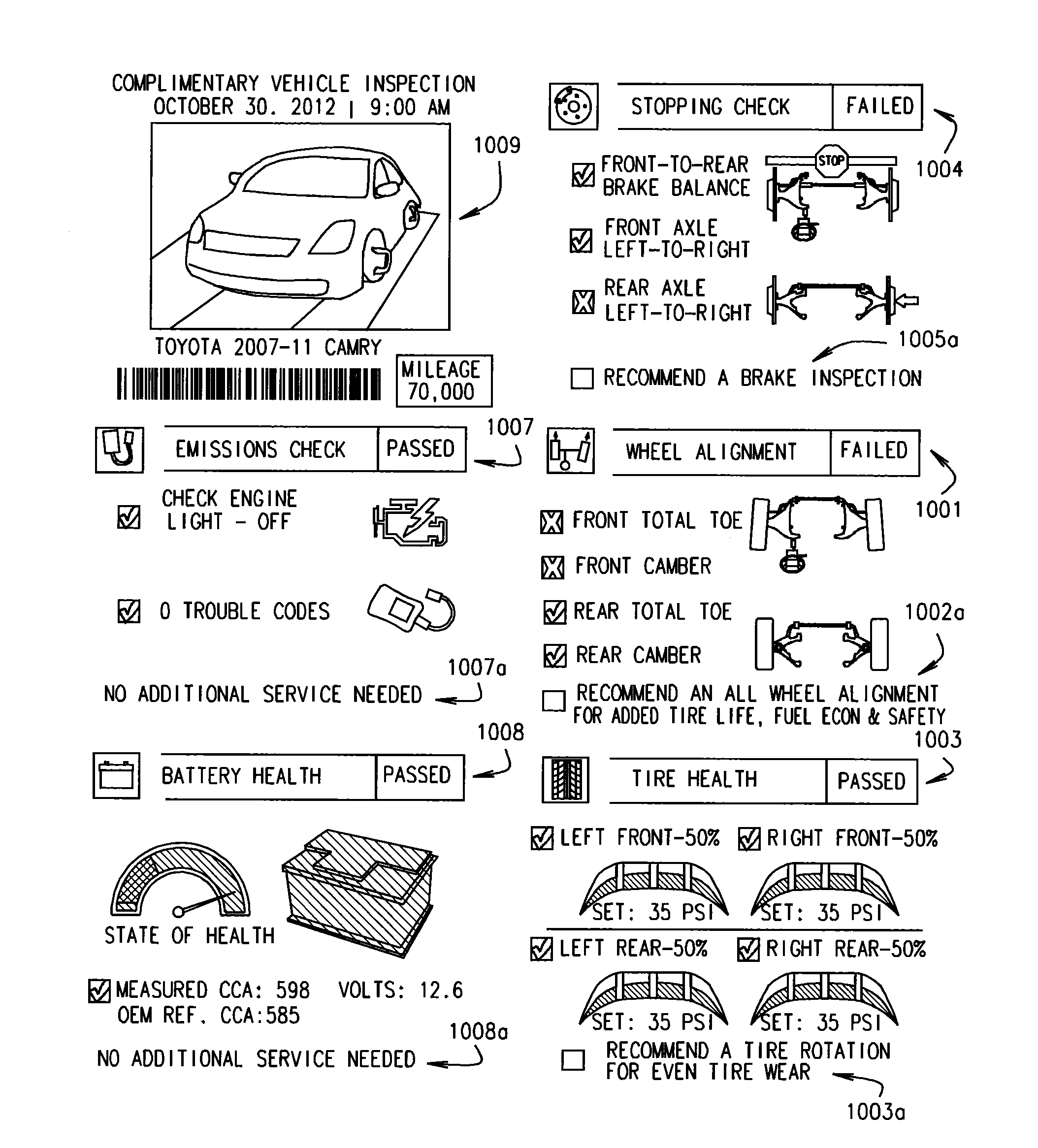

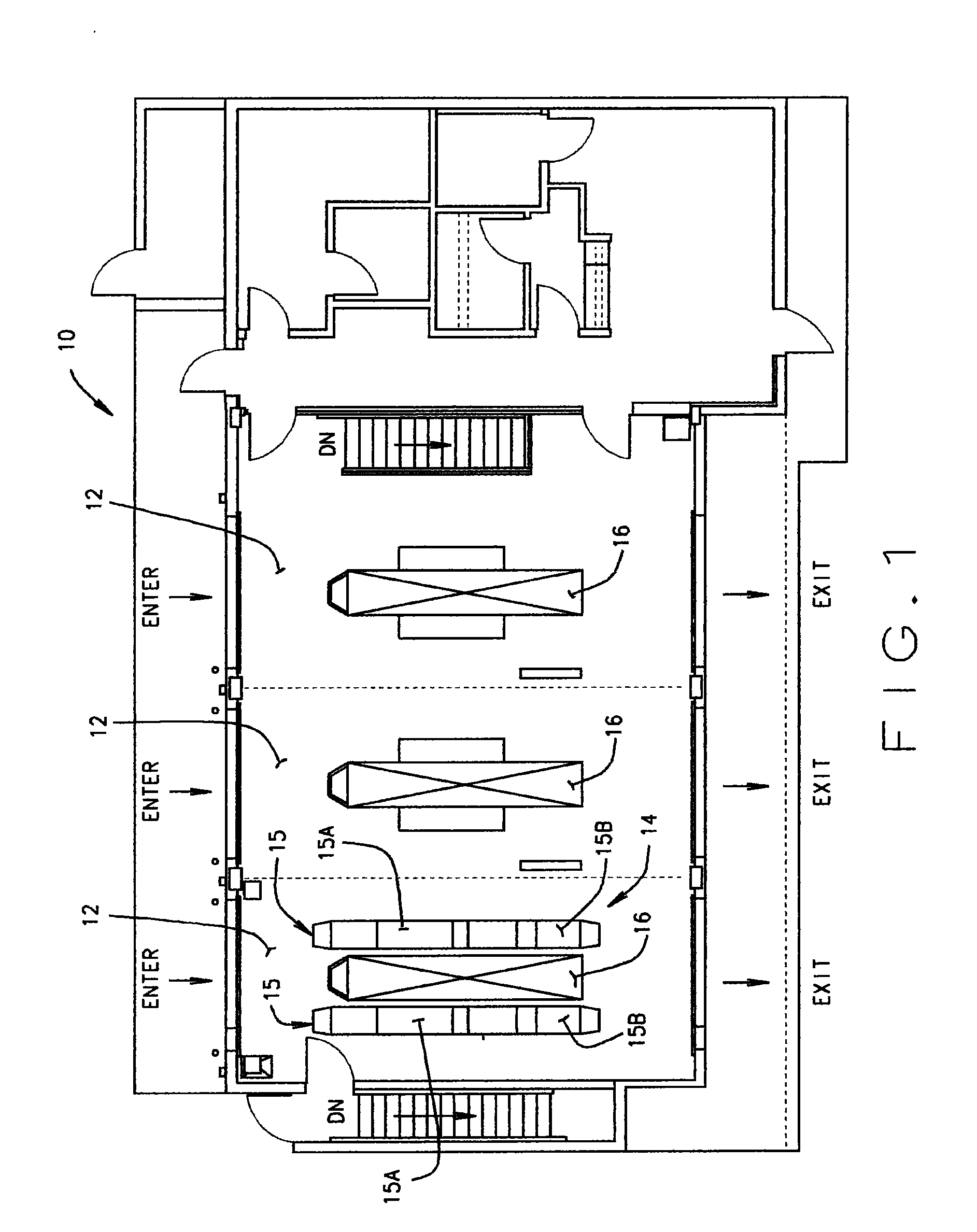

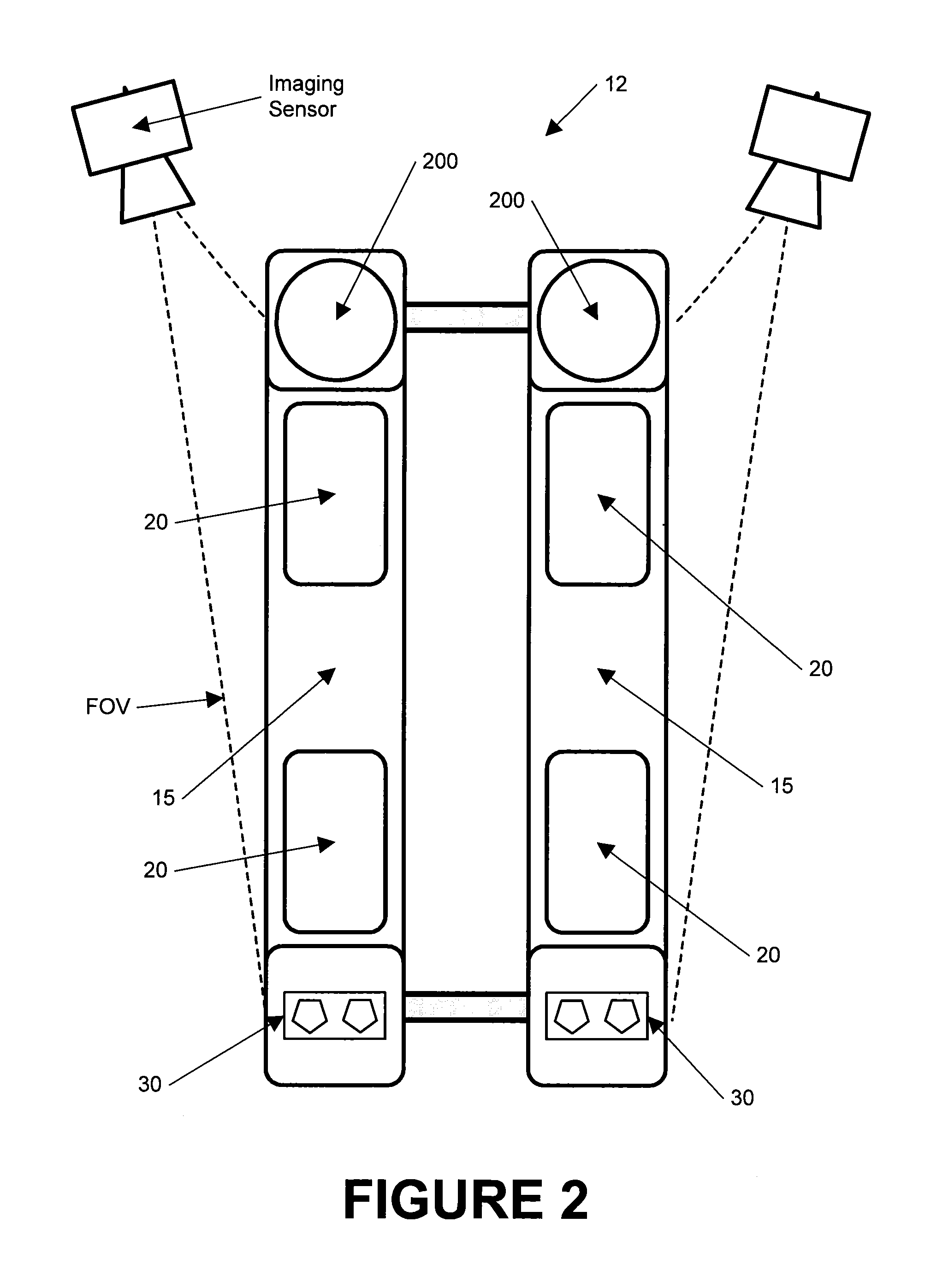

Vehicle Service Procedures

ActiveUS20130158777A1Fast resultsEasy to completeVehicle testingRegistering/indicating working of vehiclesVisual inspectionSingle vehicle

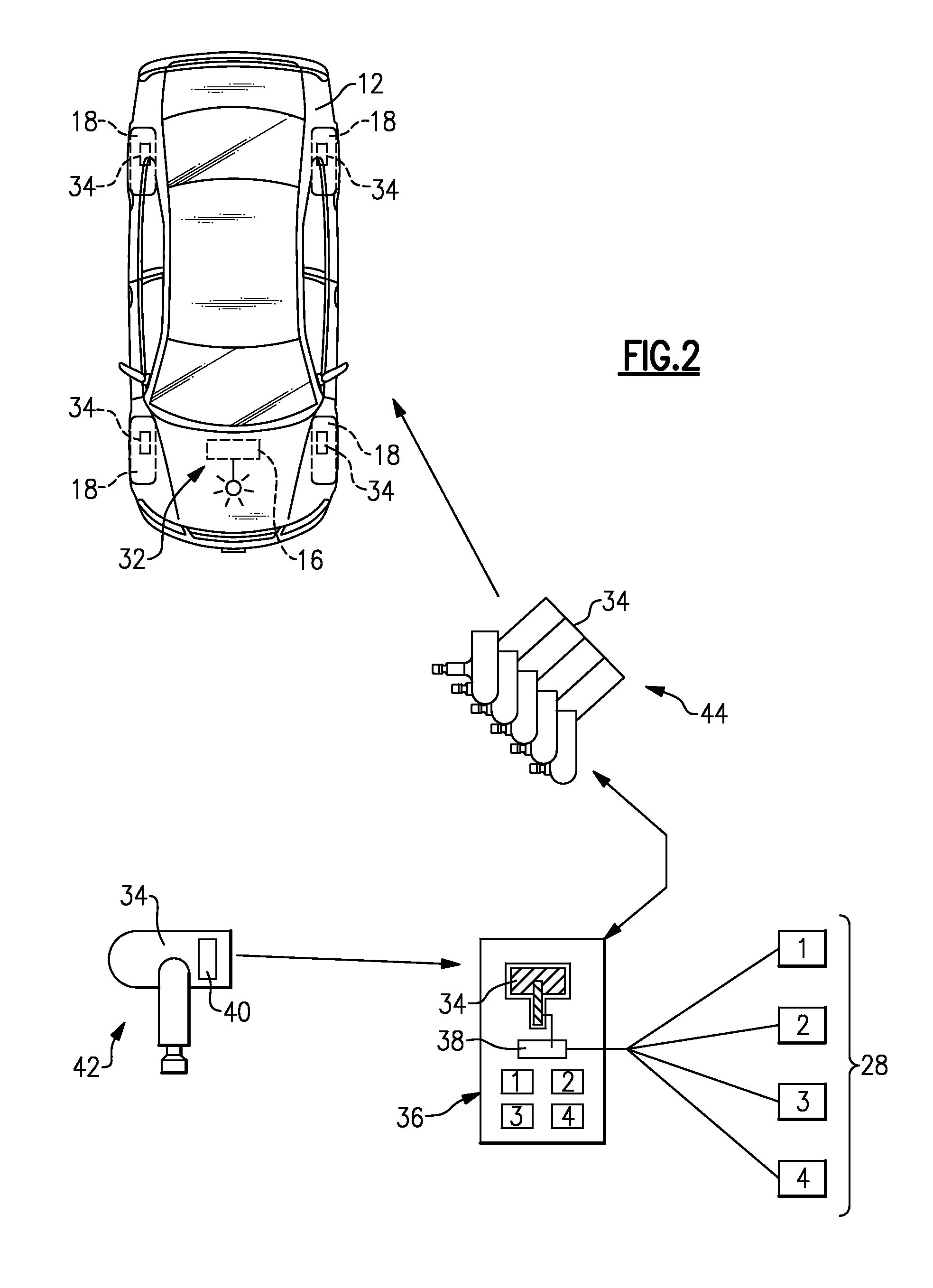

A method and apparatus for carrying out a set of vehicle inspections including, but not limited to, wheel alignment measurement, brake testing, tire tread depth measurement, tire pressure monitoring, vehicle battery testing, and a review of vehicle diagnostic trouble codes in an efficient manner using a multi-function vehicle service system and a single vehicle service bay or inspection lane. Results of the vehicle inspections are incorporated into customized reports generated for a customer or for a technician, and which may be utilized to obtain approval from the customer to conduct necessary repairs and / or provide beneficial vehicle services.

Owner:HUNTER ENG

Autonomous power source

InactiveUS7009310B2Reduce frictionHigh sensitivityBearing componentsMachines/enginesElectrical batteryEngineering

Owner:TELEDYNE SCI & IMAGING

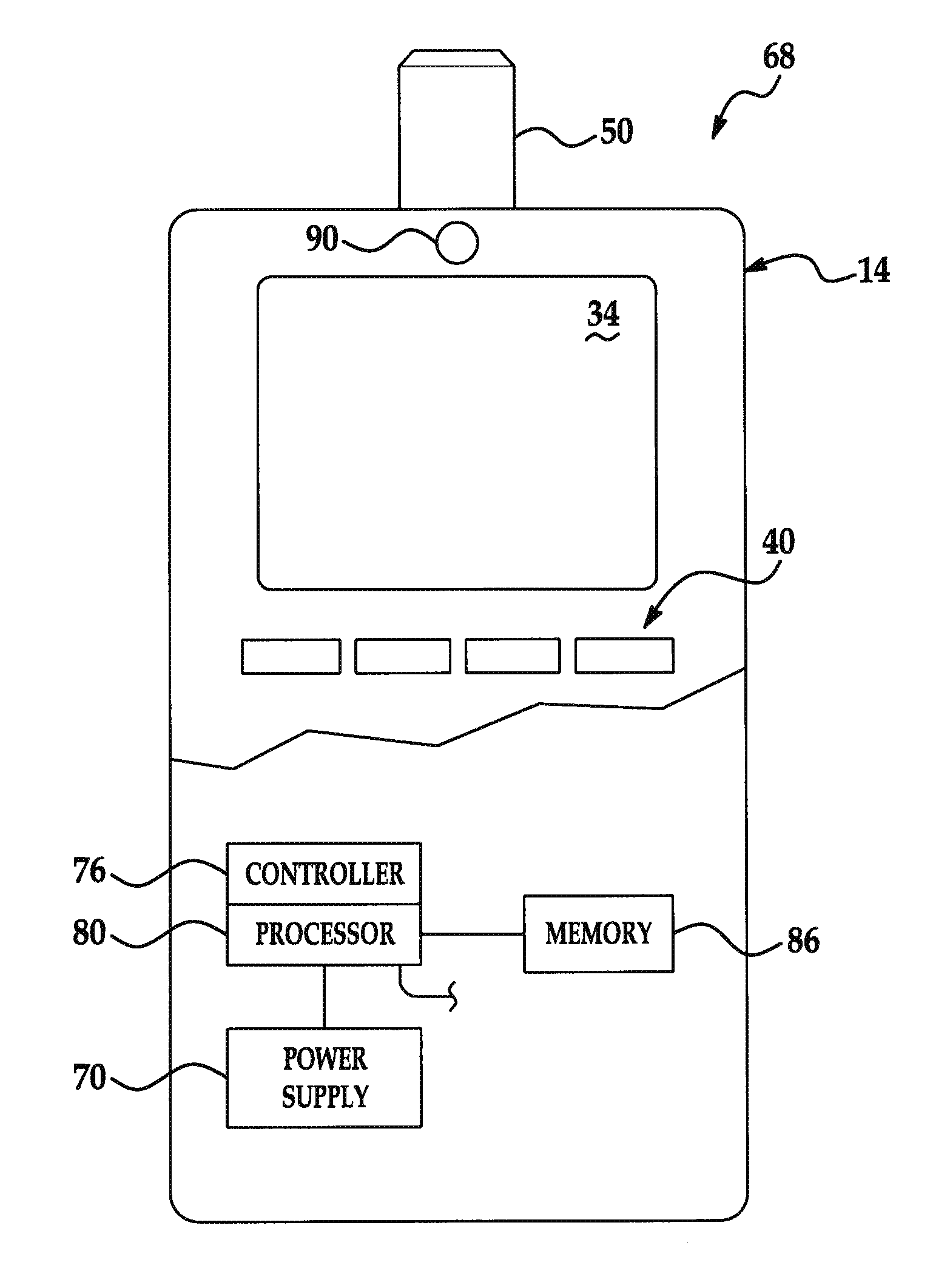

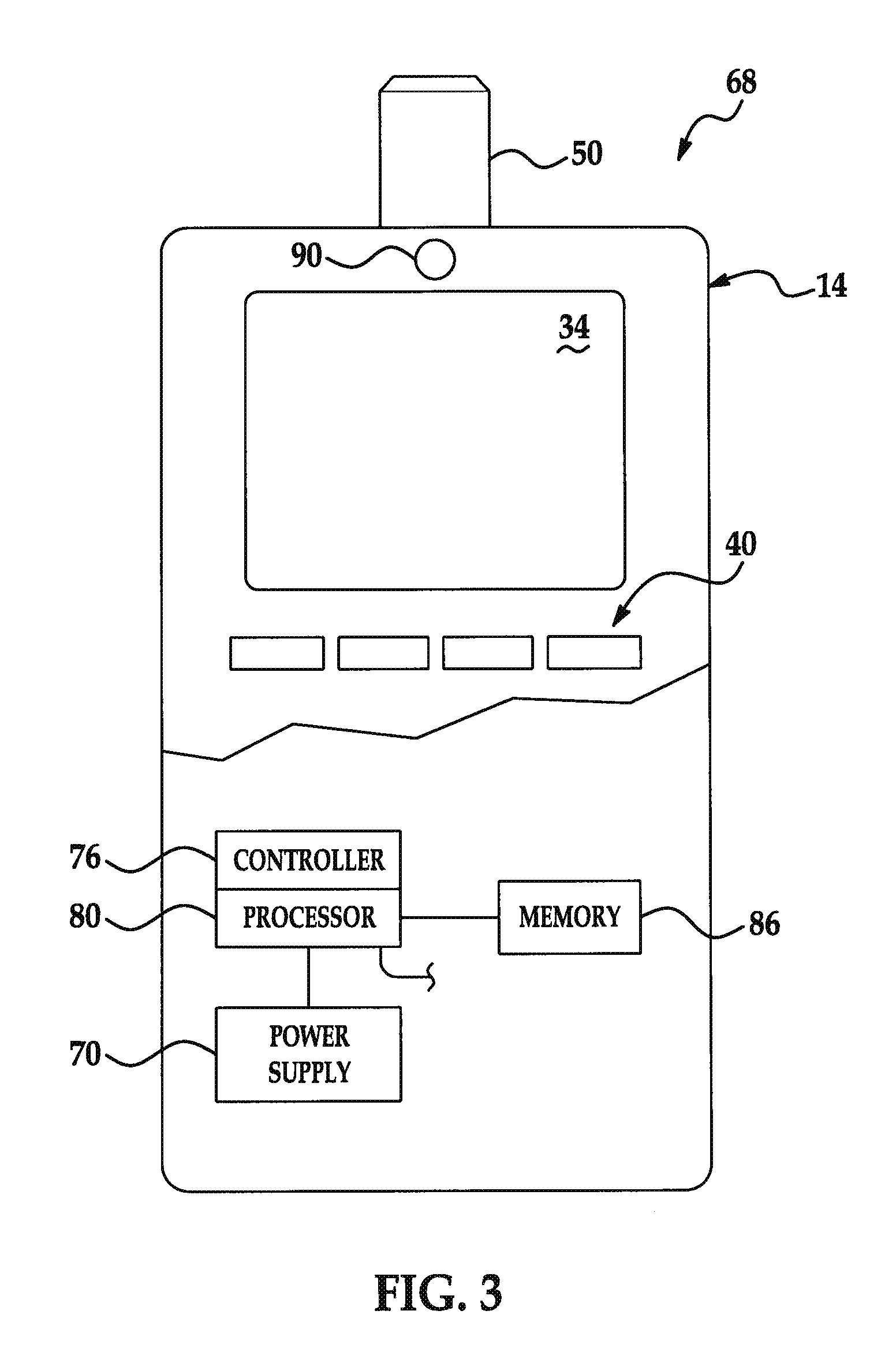

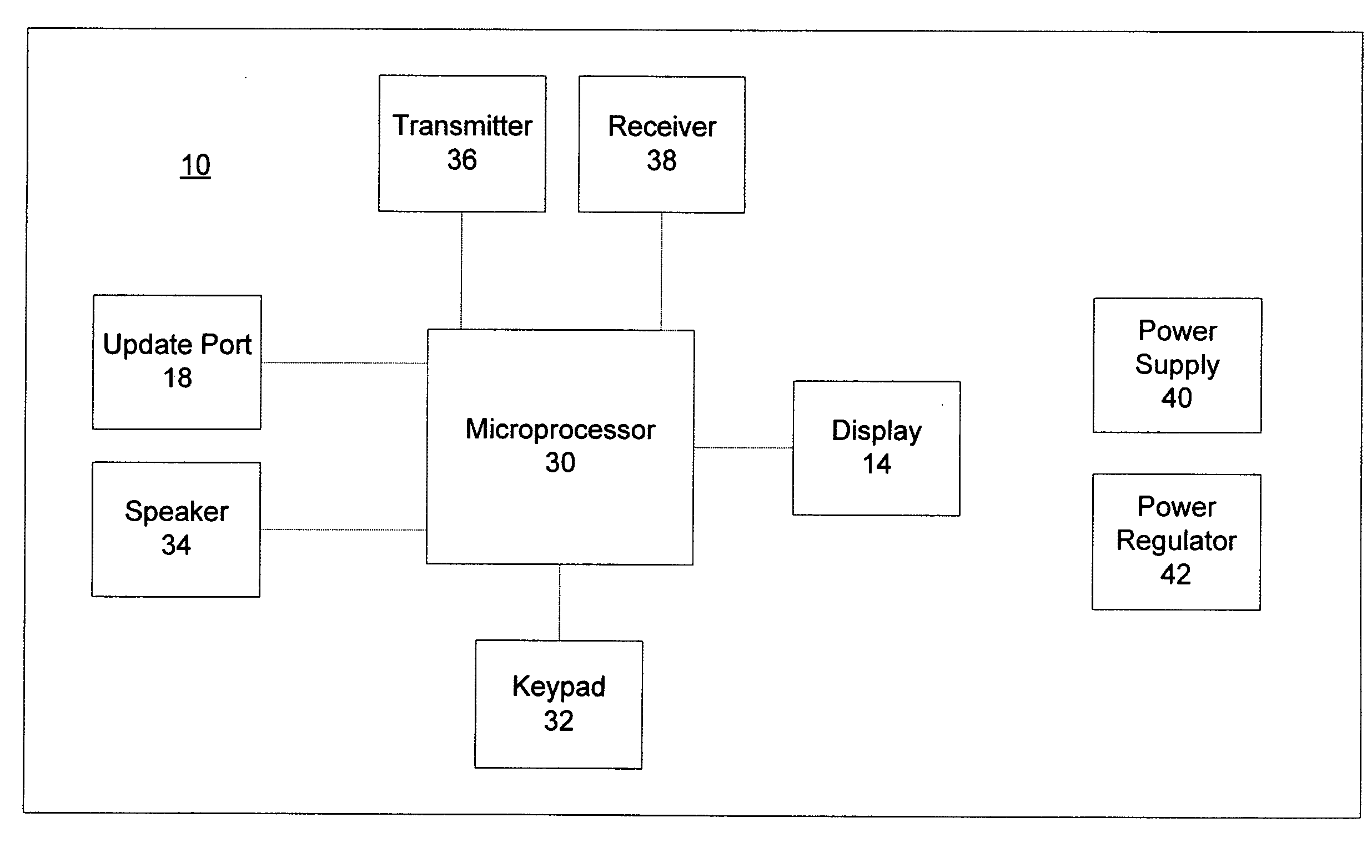

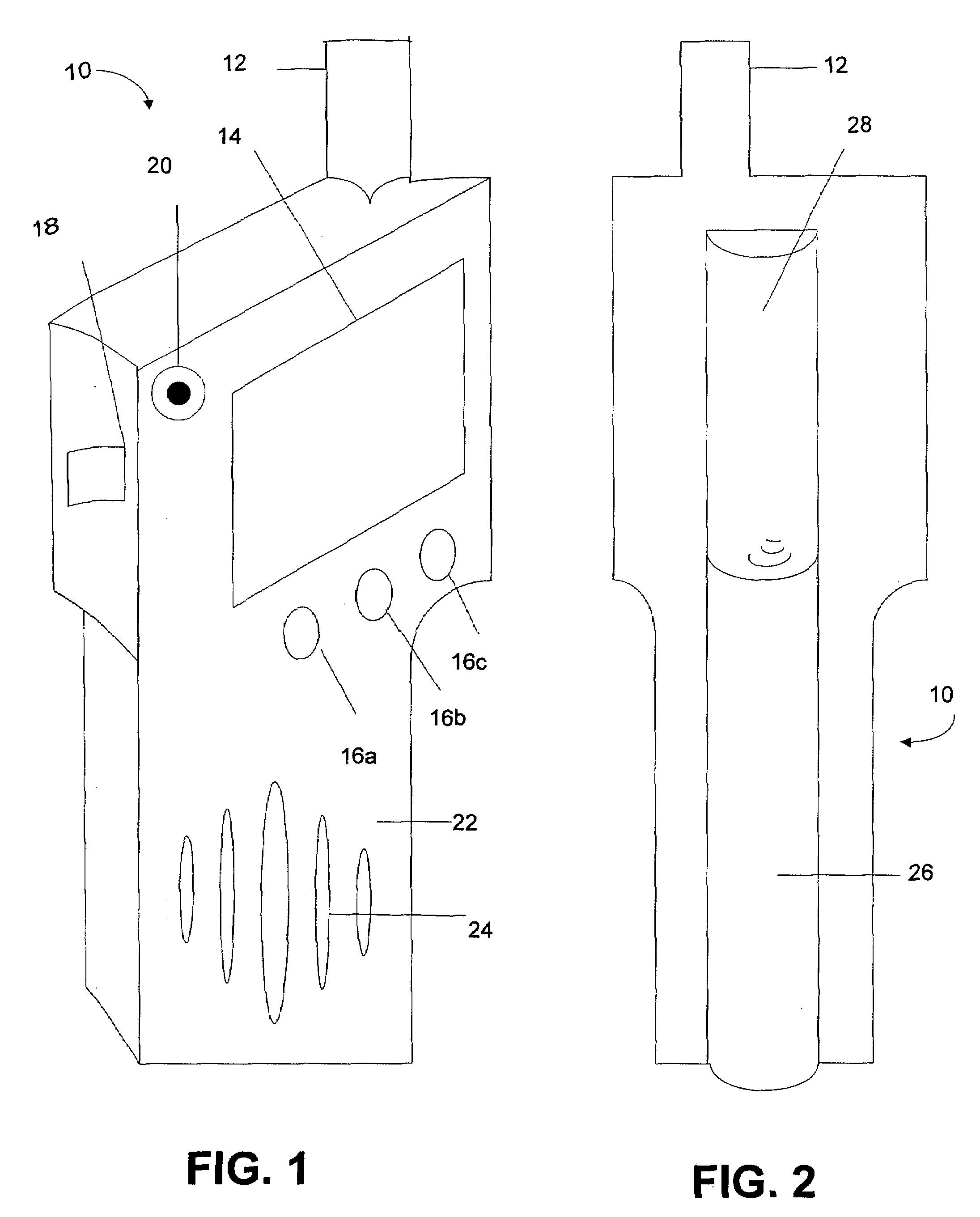

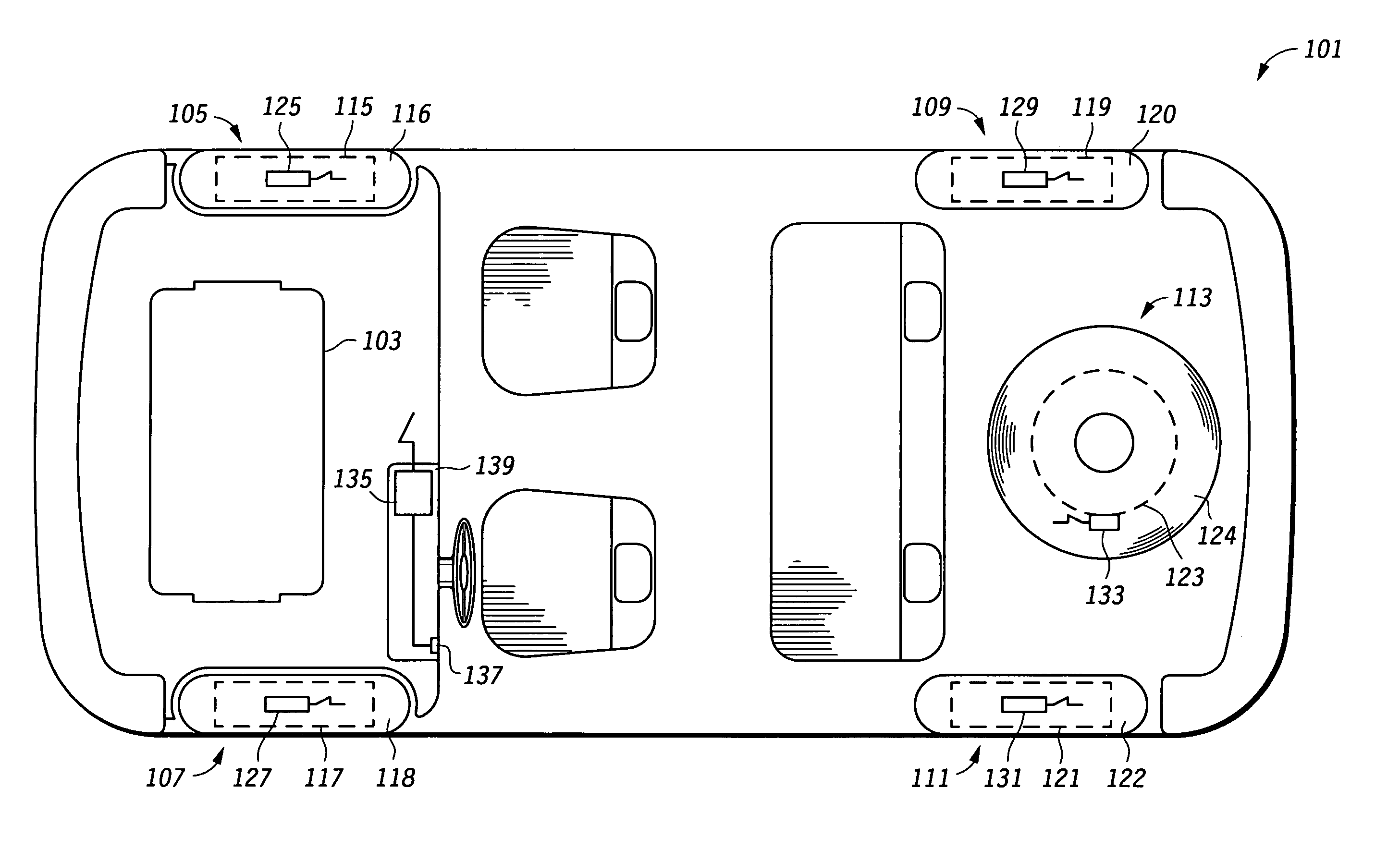

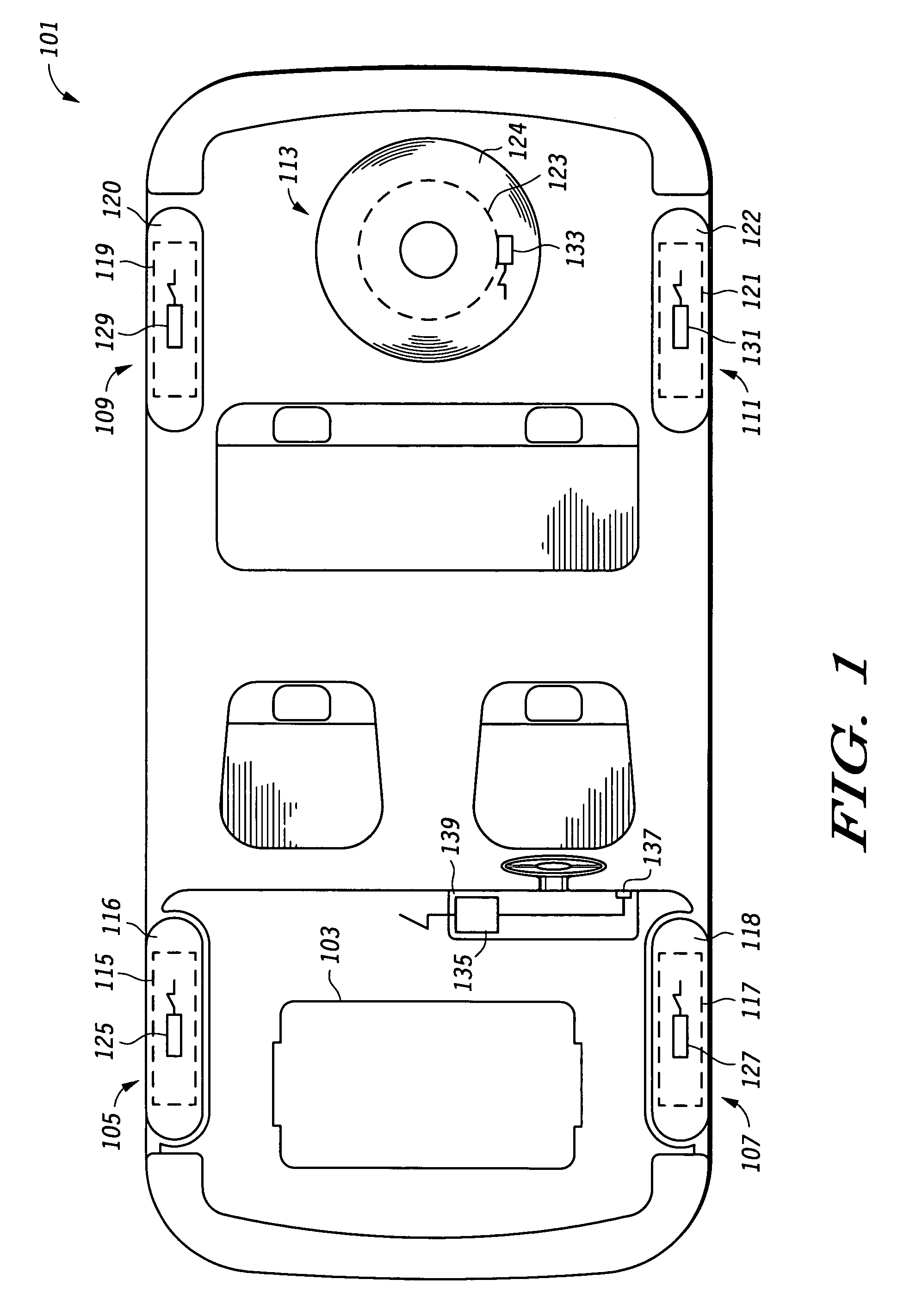

Universal tire pressure monitoring system tool and methods

ActiveUS20130106596A1Reduce the risk of lossRegistering/indicating working of vehiclesTyre measurementsElectronic communicationOptical scanners

Disclosed herein is an improved universal TPMS tool. According to one aspect of the tool, the tool can include a housing and a processor and a memory storage device positioned within the housing. The tool can optionally include a key pad positioned on the housing in communication with the processor for input of commands from a user, an electronic communication port positioned on the housing in communication with the processor, and an antenna for transmission and receipt of electronic information from the plurality of TPMS tire sensors. The tool can also include an optical scanner for reading indicia connected to the vehicle.

Owner:ATEQ CORP

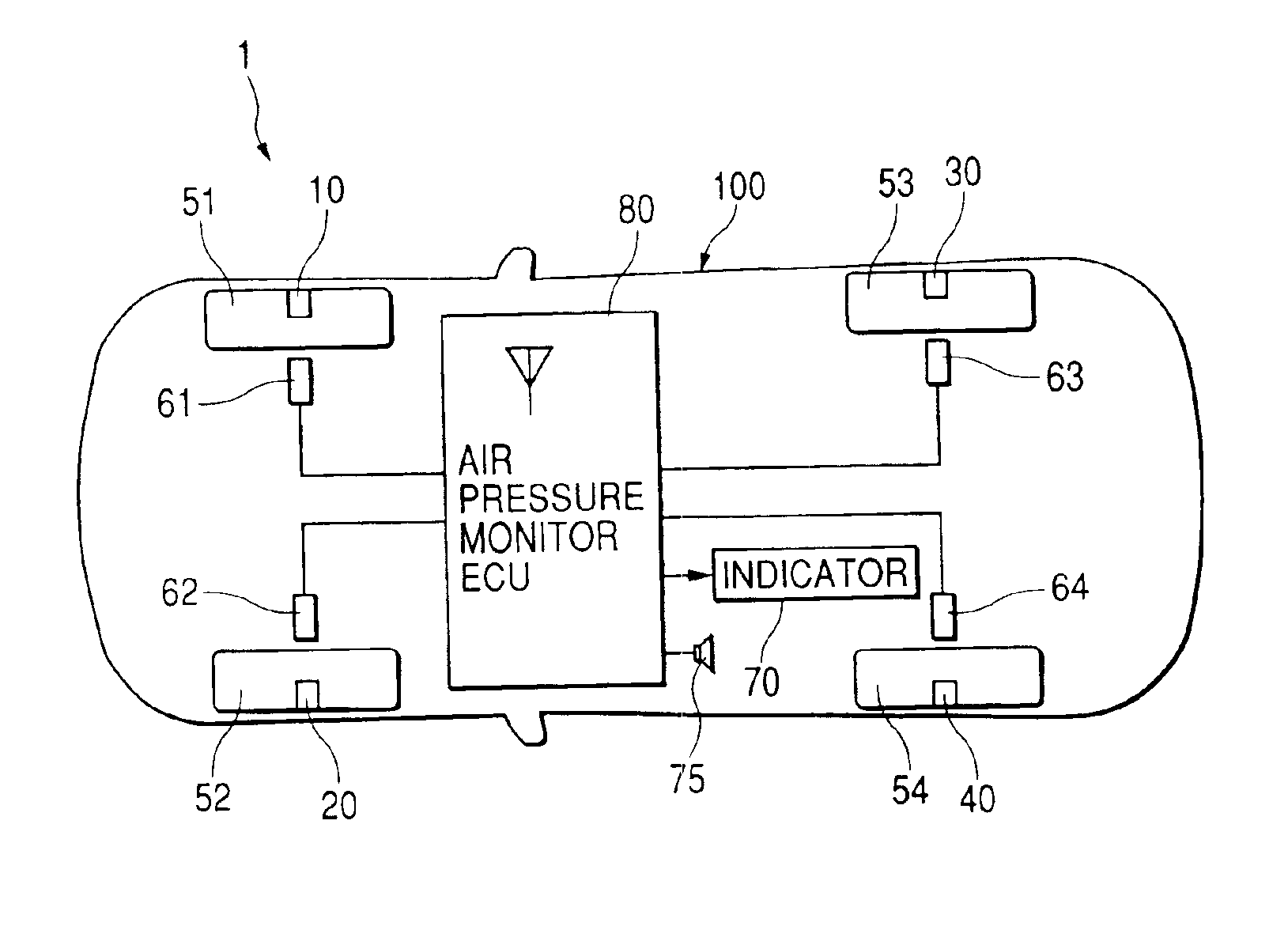

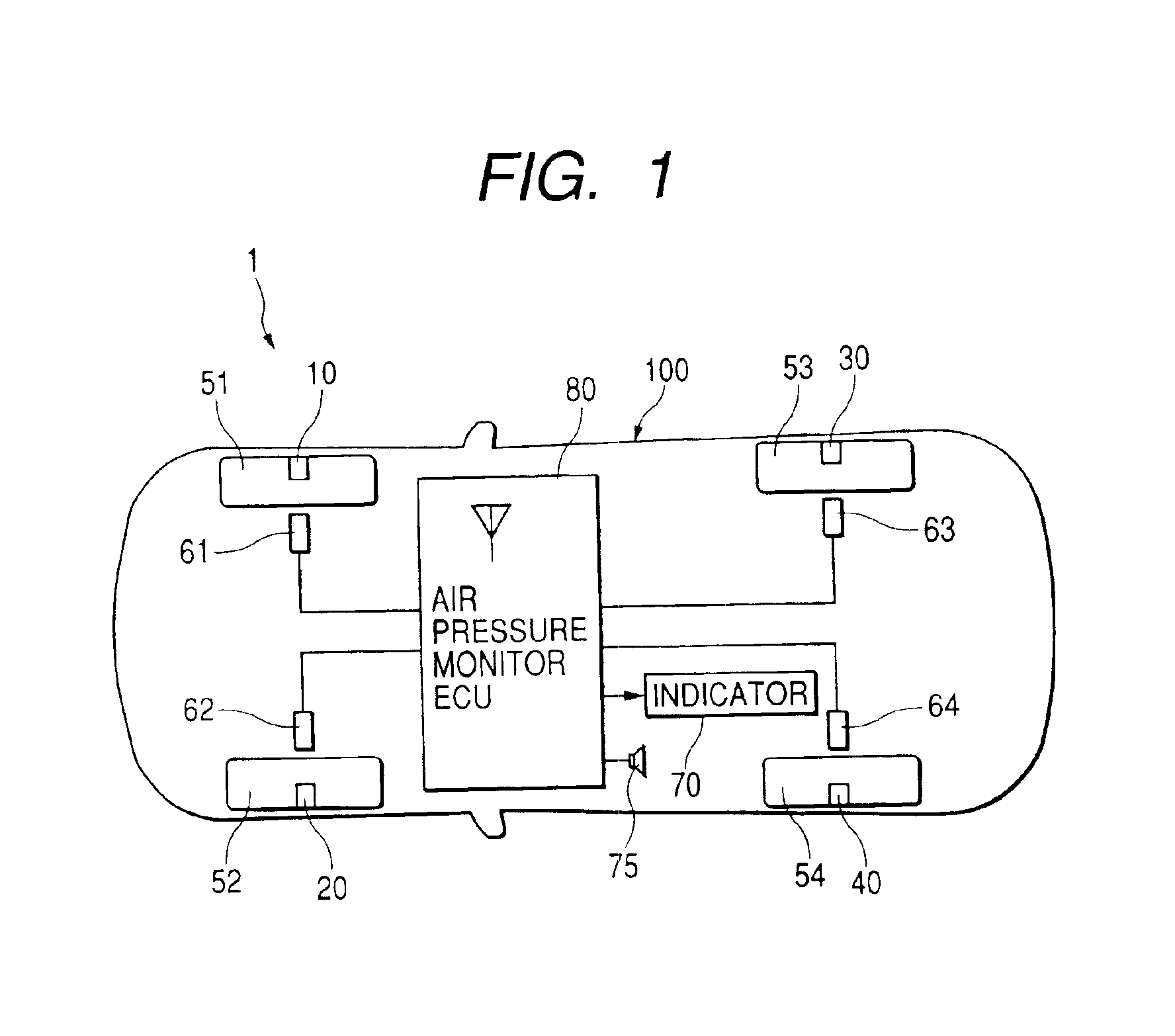

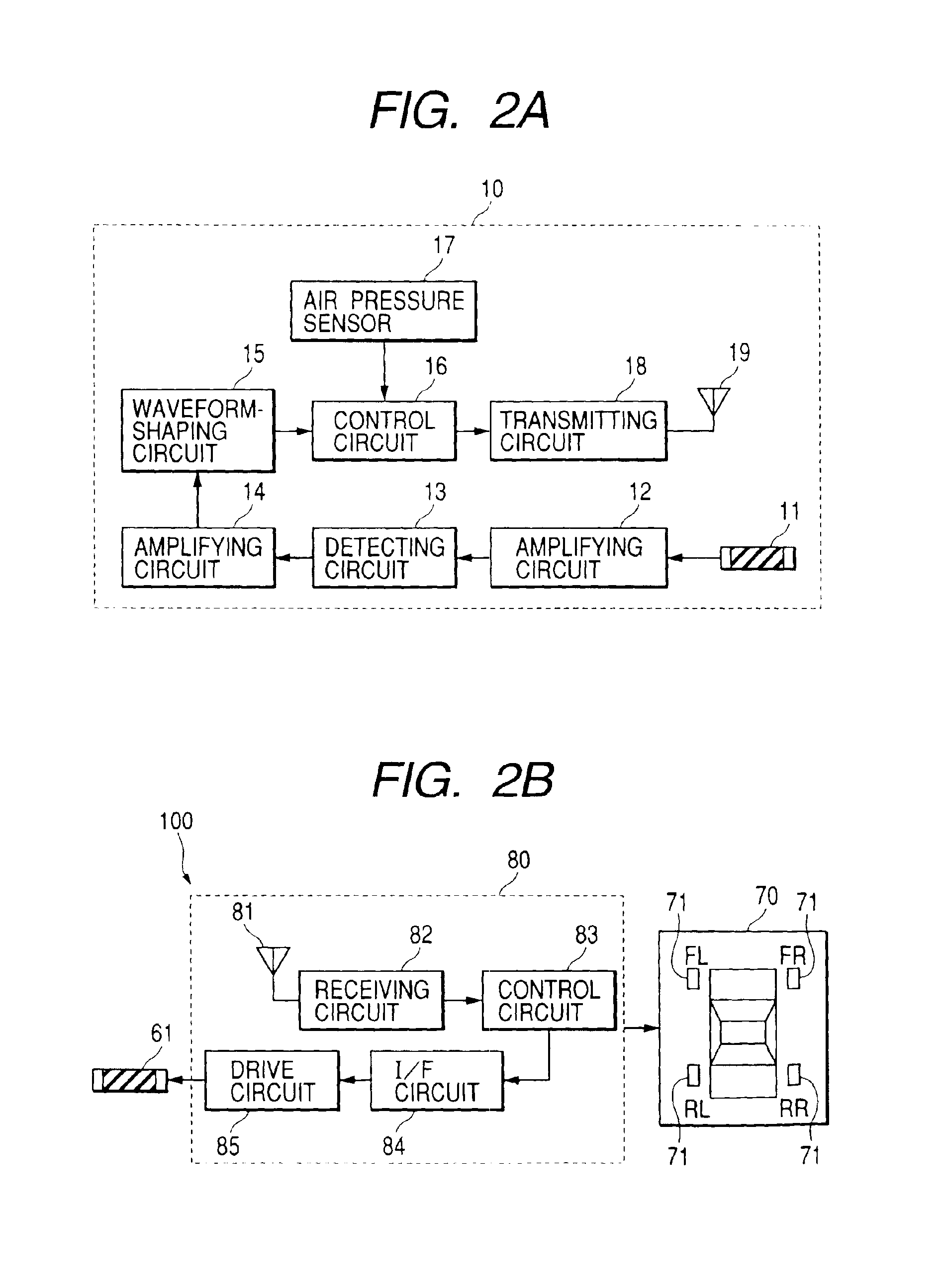

Tire air pressure monitoring system

ActiveUS6885293B2Reduce power consumptionInflated body pressure measurementTransmission systemsMonitoring systemTire rotation

Provided is a tire air pressure monitoring system capable of grasping the tire positions where there are sensor units even in the case of tire rotation. In the tire air pressure monitoring system, a trigger signal is transmitted from a transmission coil antenna to only the corresponding sensor unit in a manner such that a magnetic field is used as a medium and, upon receipt of the trigger signal, the sensor unit measures a tire air pressure and others and transmits a transmission signal including the measurement values to a monitoring unit. The monitoring unit makes a decision on the tire position where there is the sensor unit on the basis of the transmission signal from the sensor unit.

Owner:DENSO CORP

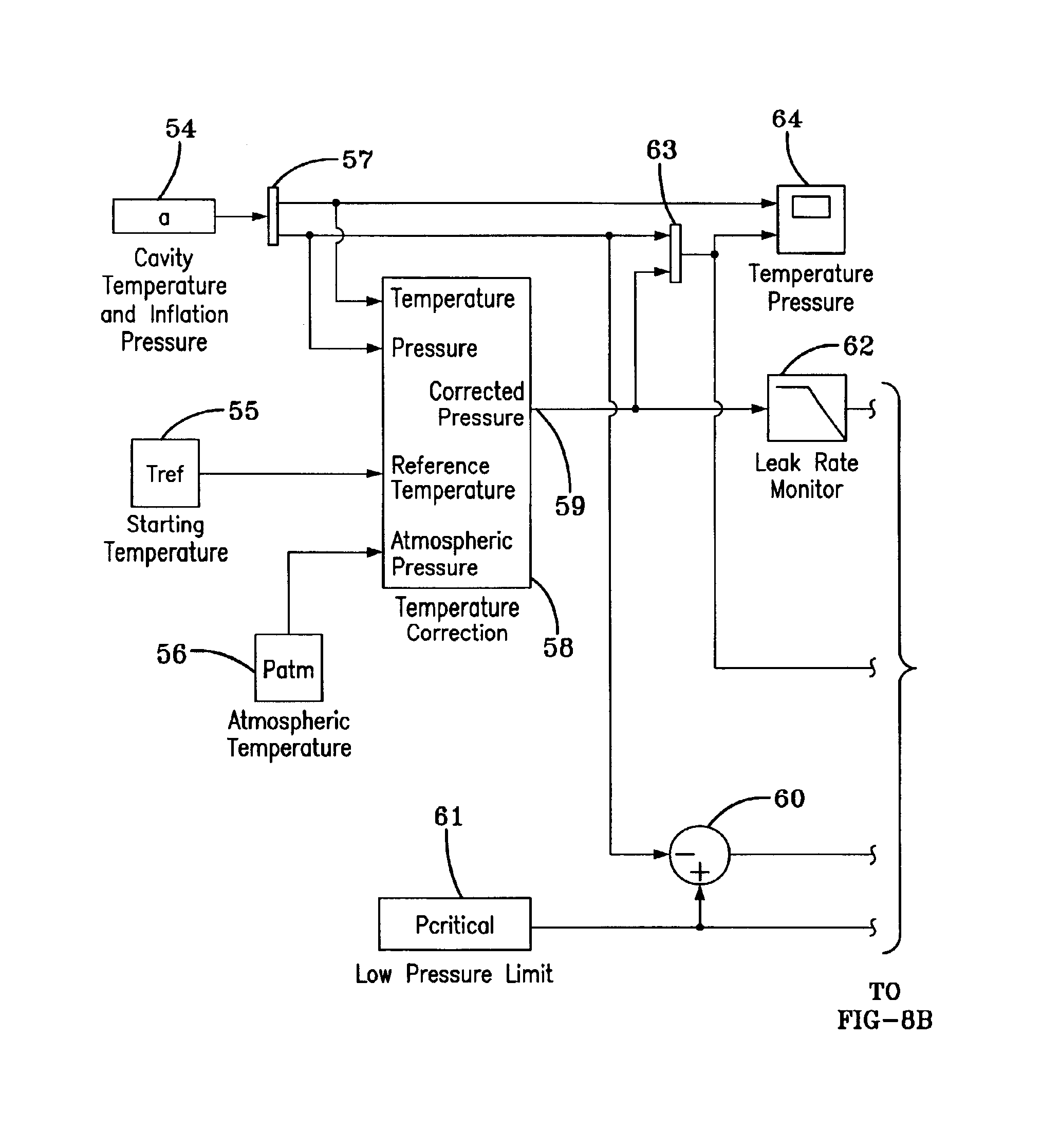

Method and apparatus for detecting leakage rate in a tire pressure monitoring system

InactiveUS20060010961A1Quickly alertedDetection of fluid at leakage pointTyre measurementsEngineeringTire-pressure monitoring system

A tire pressure monitoring system for a vehicle has been disclosed that can detect an excessive leakage rate of a tire. The system utilizes the starting pressure and starting temperature of a tire and the current pressure and current temperature of that tire with the time lapsed to determine the leakage rate of the tire. This leakage rate is compared to a leakage rate threshold. If the leakage rate is greater than the leakage rate threshold, an excessive leakage rate alert is generated.

Owner:FORD GLOBAL TECH LLC

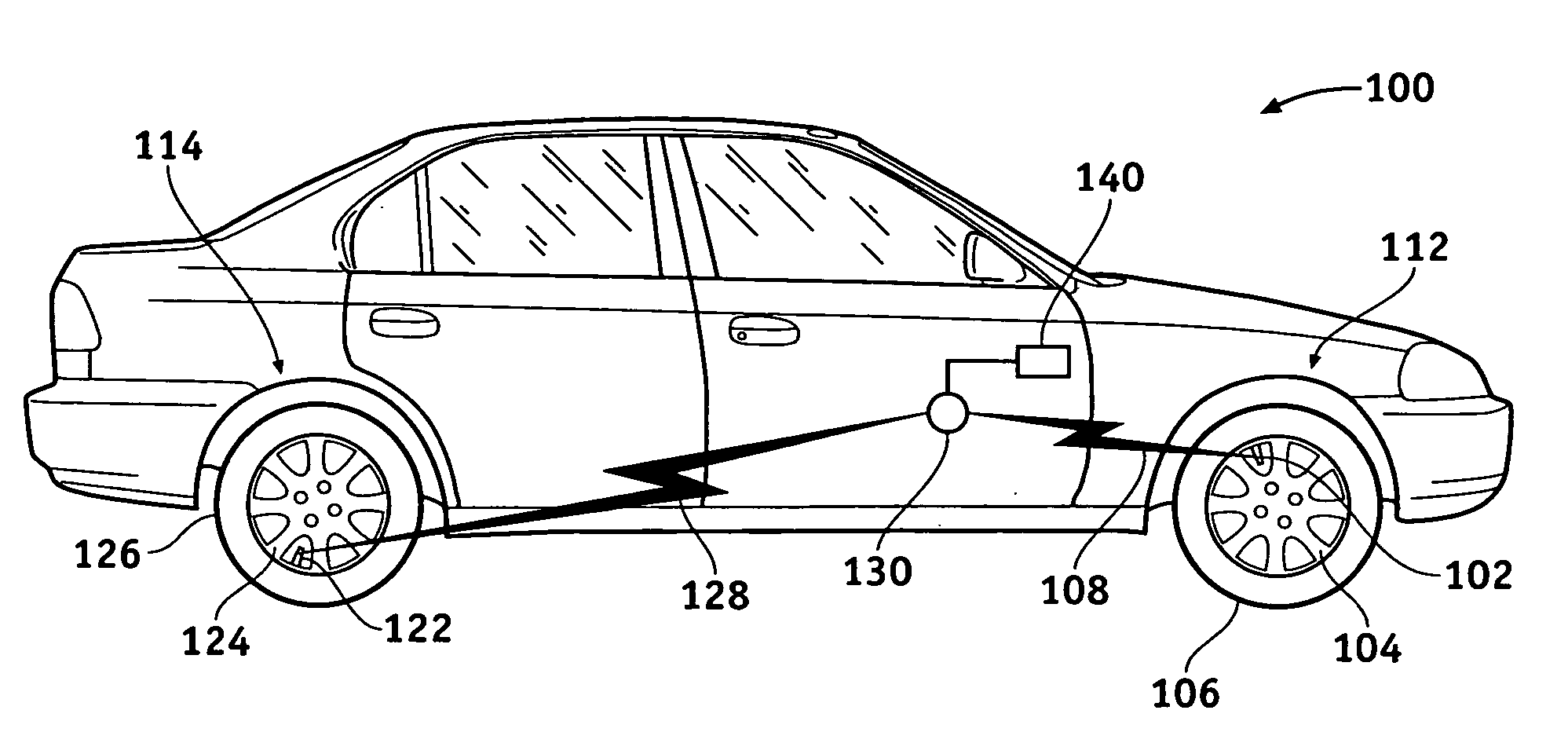

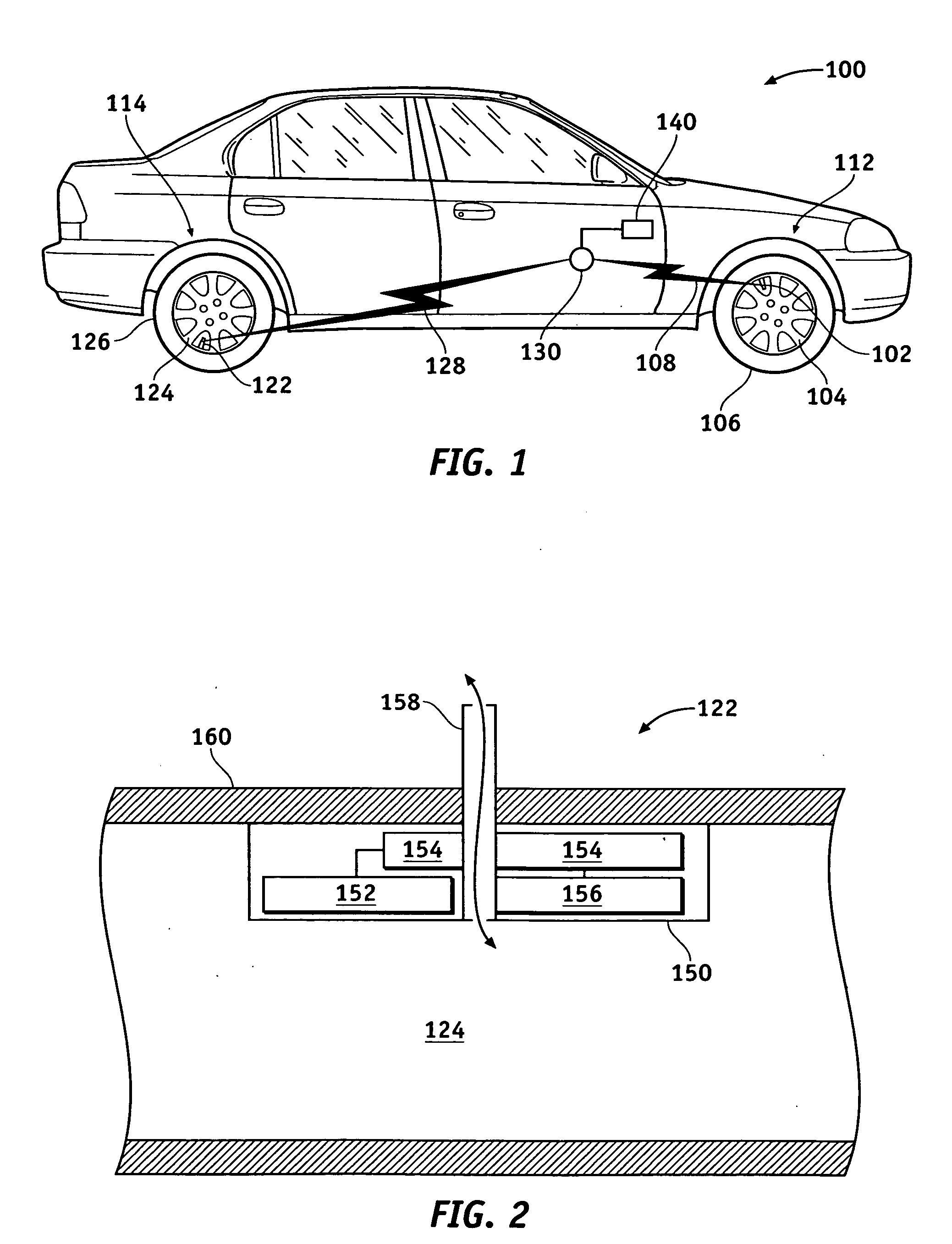

Tire pressure monitor and location identification system and method

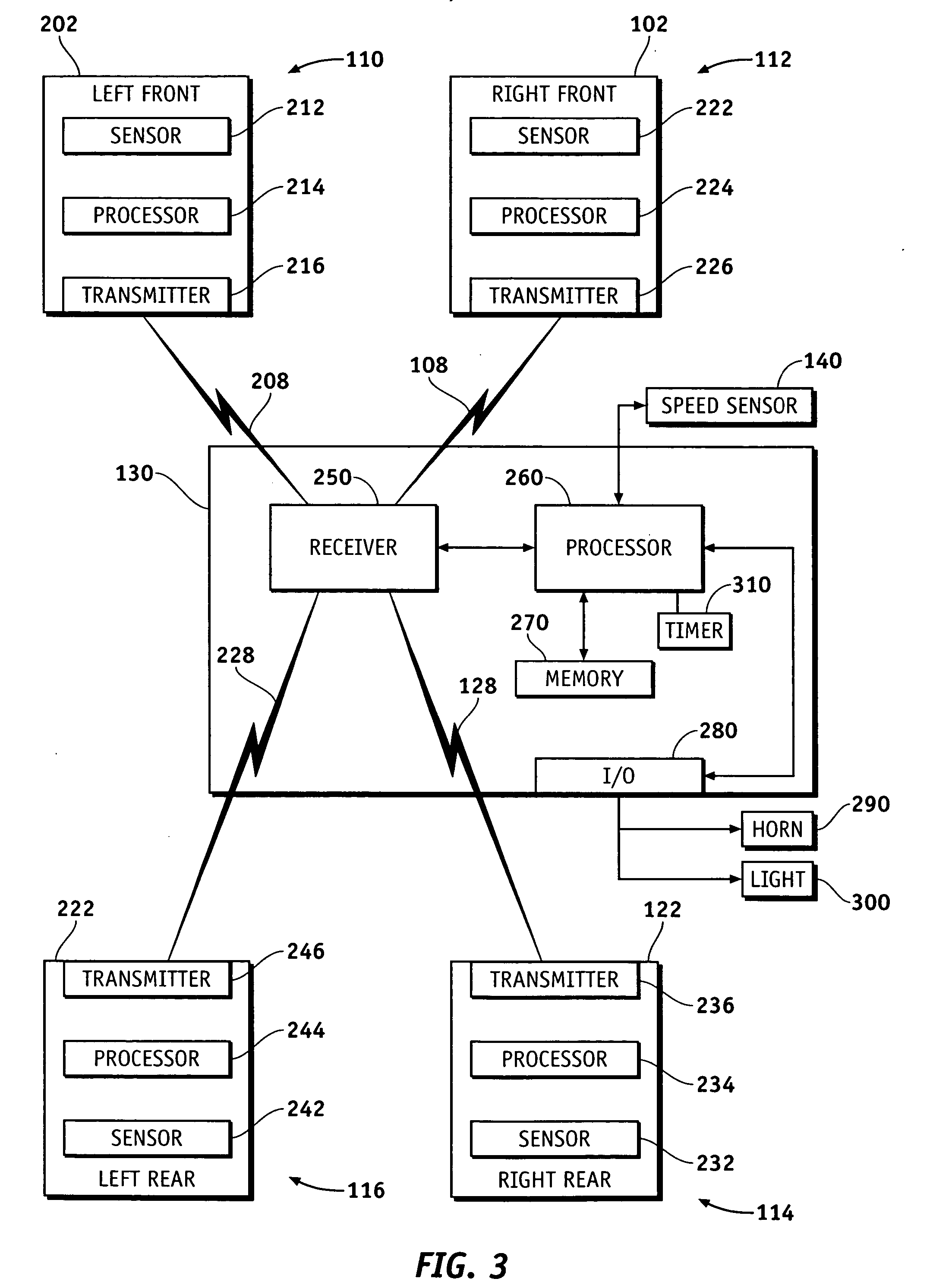

InactiveUS6897770B2Electric signal transmission systemsTyre measurementsTire-pressure monitoring systemSystem controller

A method and system for monitoring and reporting vehicle tire pressure information. The system includes tire pressure monitors mounted to the tires of a vehicle. The tire pressure monitors detect tire pressure information from their respective tires and transmit that information to transponders that are fixedly-mounted to the vehicle. Each tire pressure monitor corresponds to a single transponder. When a tire pressure monitor transmits tire pressure information, the corresponding transponder receives the signal and transmits the tire pressure signal along with a unique transponder identification code to a vehicle central system controller. Based upon the transponder identification code, the central controller associates the tire pressure information with a particular tire location. However, under certain conditions, a transmitted tire pressure signal is received by one or more of the non-corresponding transponders as well as the corresponding transponder. To filter out the stray tire pressure signals, each of the receiving transponders detects the strength of the received tire pressure signal. The system then determines which of the receiving transponders is the corresponding transponder based upon the respective signal strengths.

Owner:APTIV TECH LTD

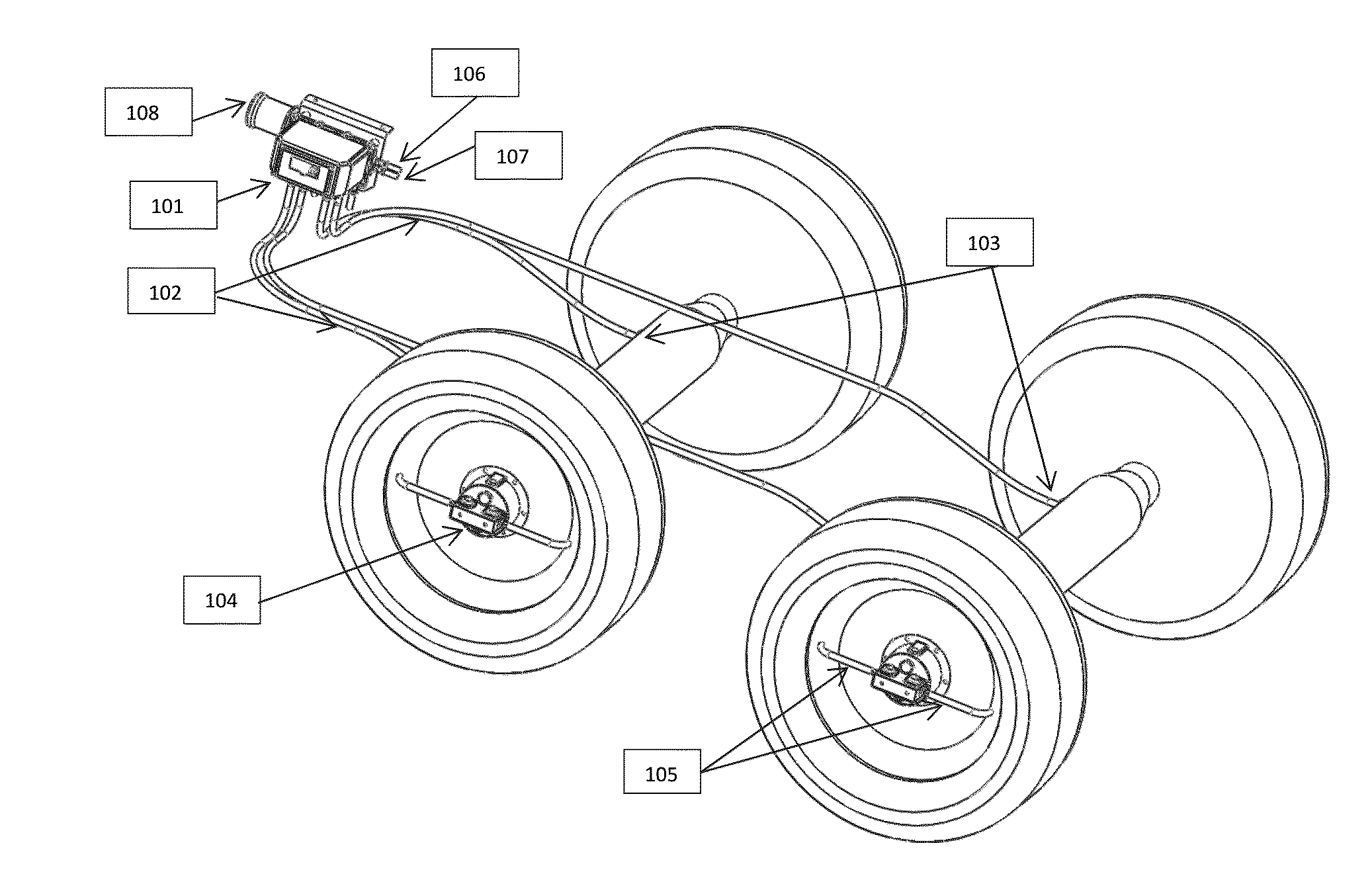

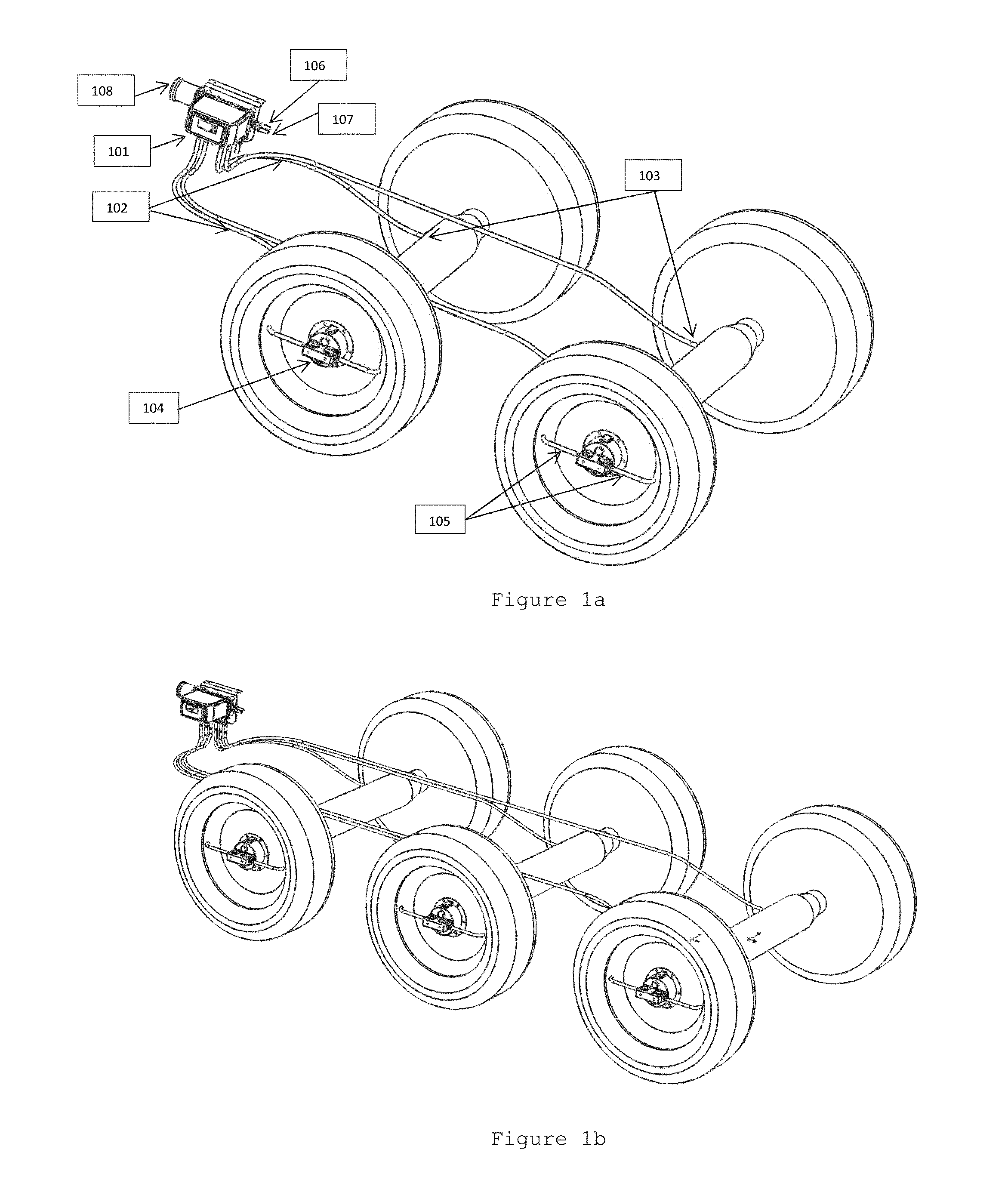

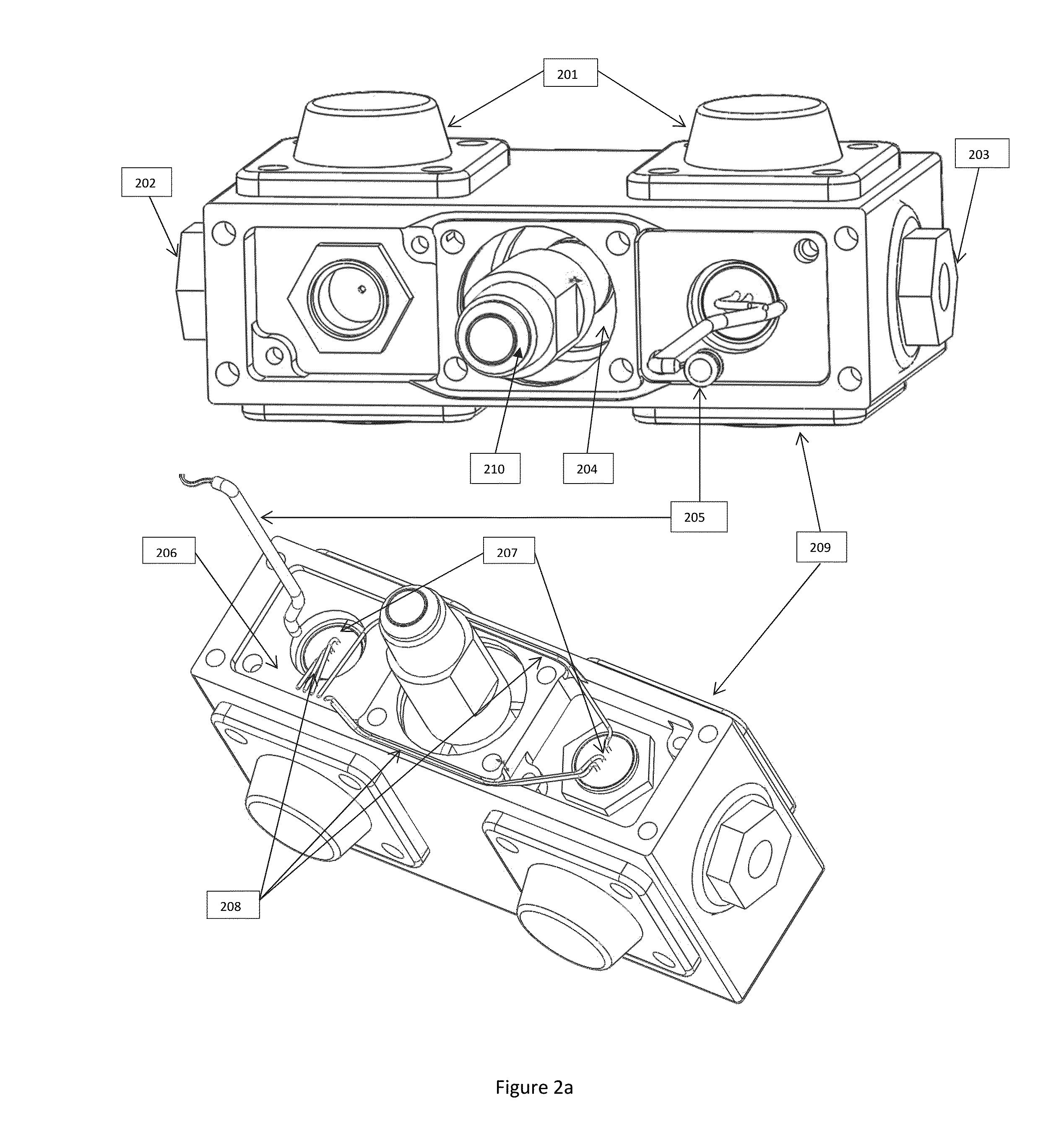

Intelligent Tire Inflation and Deflation System Apparatus

ActiveUS20150174972A1Sure easyFacilitating regular tire maintenanceTyre measurementsDistance measurementTire rotationTire-pressure monitoring system

An intelligent tire pressure management system capable of real-time tire pressure monitoring, vehicle load detection, and automatic tire inflation and deflation for maintaining optimal tire pressure in a commercial vehicle. Additional functions include counting tire rotations for calculating and recording distance travelled for each tire, and detecting wheel sliding due to locked-up tires. The system includes a chassis-mounted control box connecting to the vehicle air supply, a hubcap-mounted dual wheel valve apparatus integrated with a rotary union assembly that connects through the vehicle hollowed axles to the air tubes from the control box. The inflation / deflation supporting dual wheel valve apparatus has an embedded electronic unit that monitors individual tire pressure and temperature in real time, and communicates with the control box over the power line. Furthermore a load sensor integrated with the control box provides the system with the current vehicle load information. With readily available real time tire pressure data and current vehicle load information, this system can intelligently adjusts tire pressure to the desired level when necessary and, as a result, prolongs tire life, improves fuel economy, reduces the vehicle maintenance costs, and promptly alerts the driver of low, leaky or flat tire conditions for enabling the driver to take immediate corrective actions.

Owner:ZHOU JOE HUAYUE +1

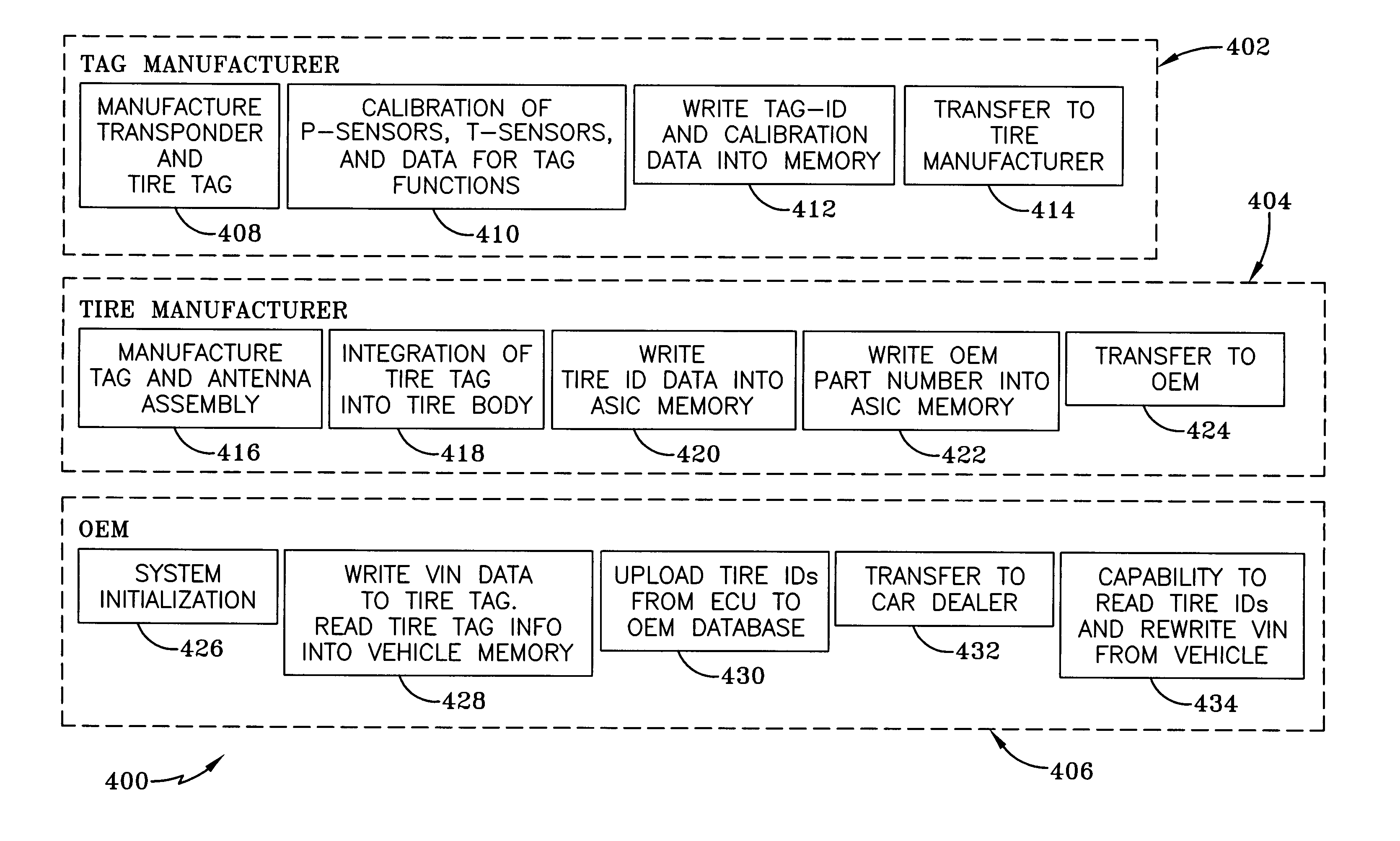

Method of integrating tire identification into a vehicle information system

InactiveUS7104438B2Ticket-issuing apparatusInflated body pressure measurementData connectionProduction line

Owner:THE GOODYEAR TIRE & RUBBER CO

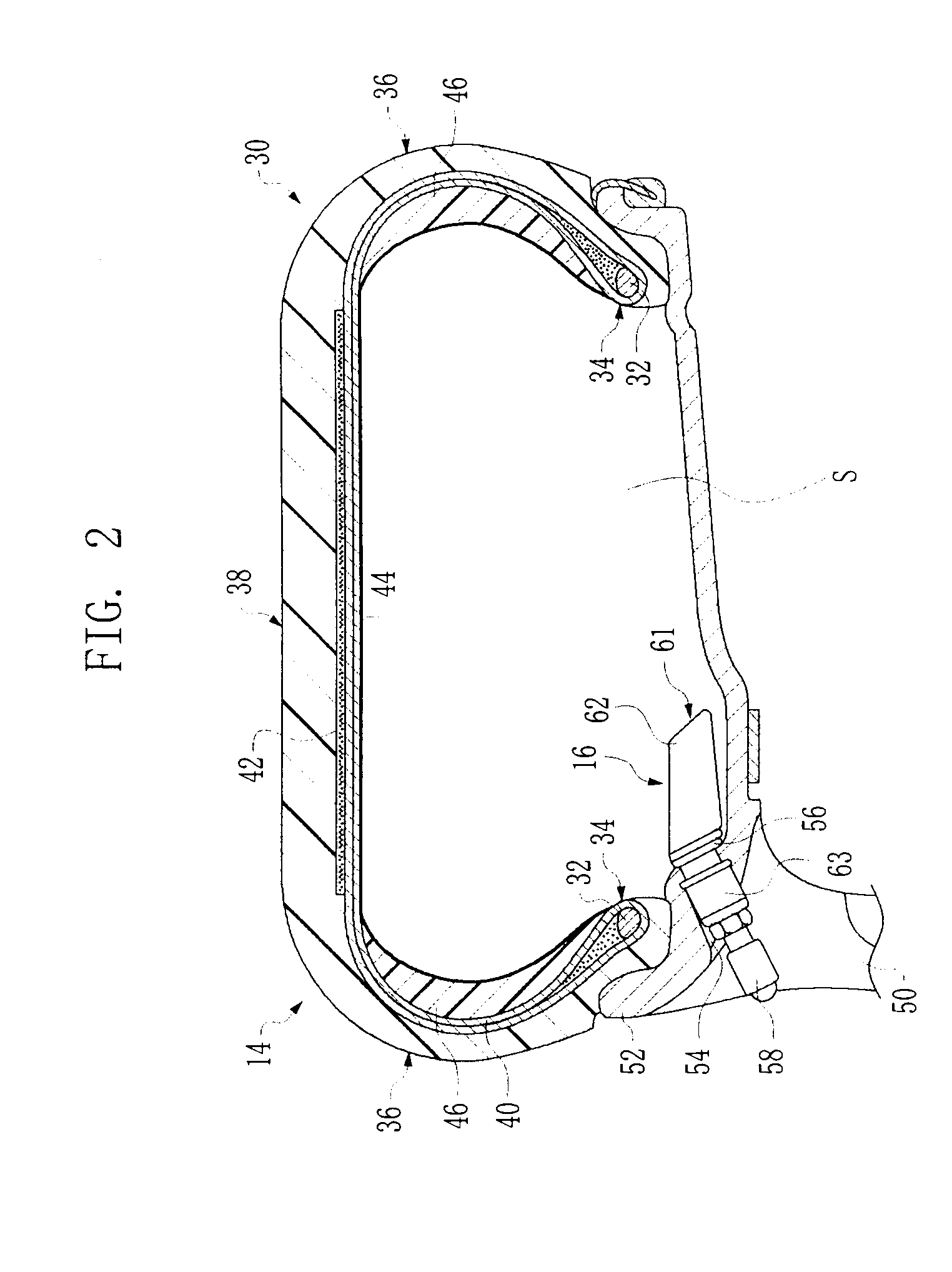

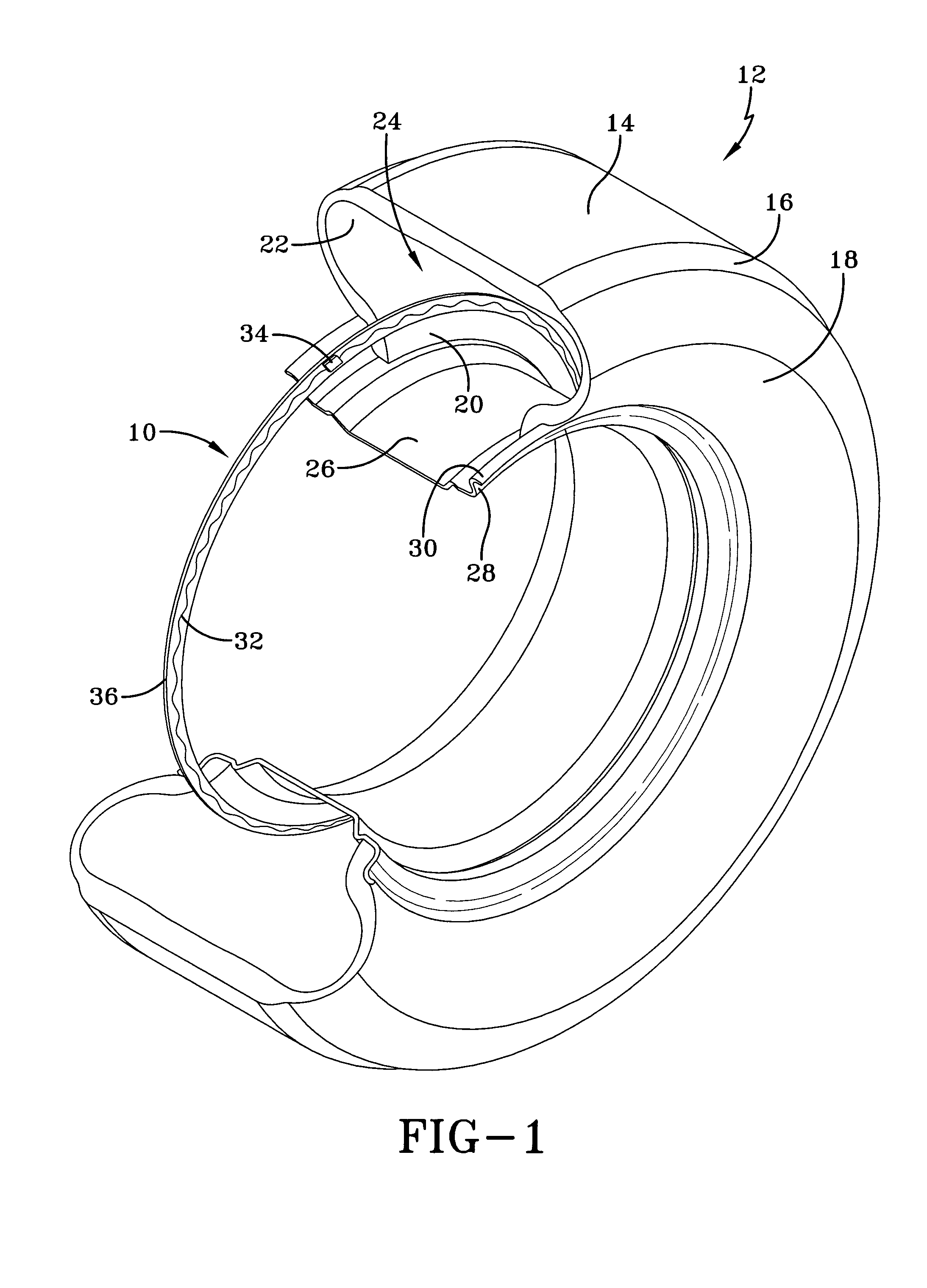

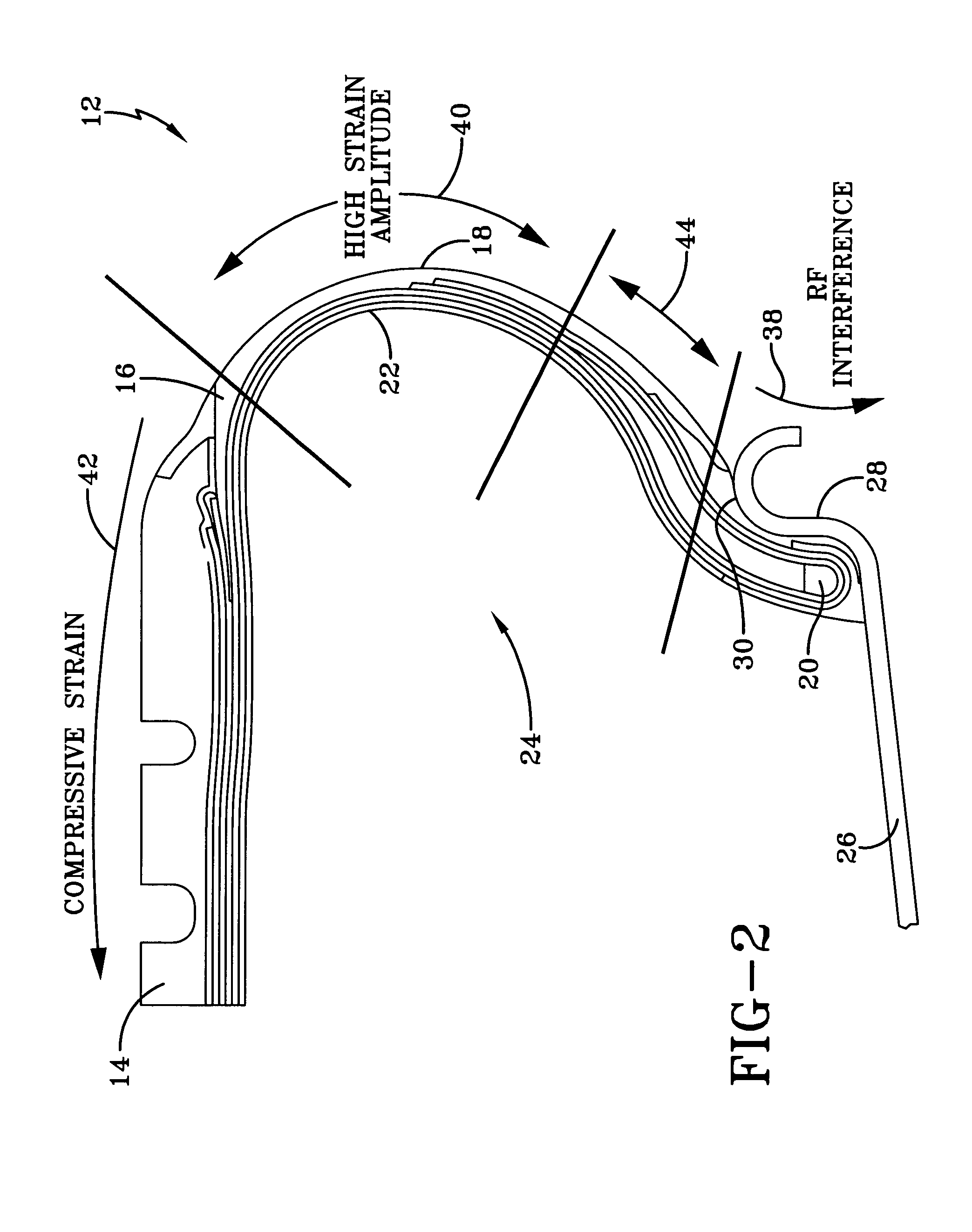

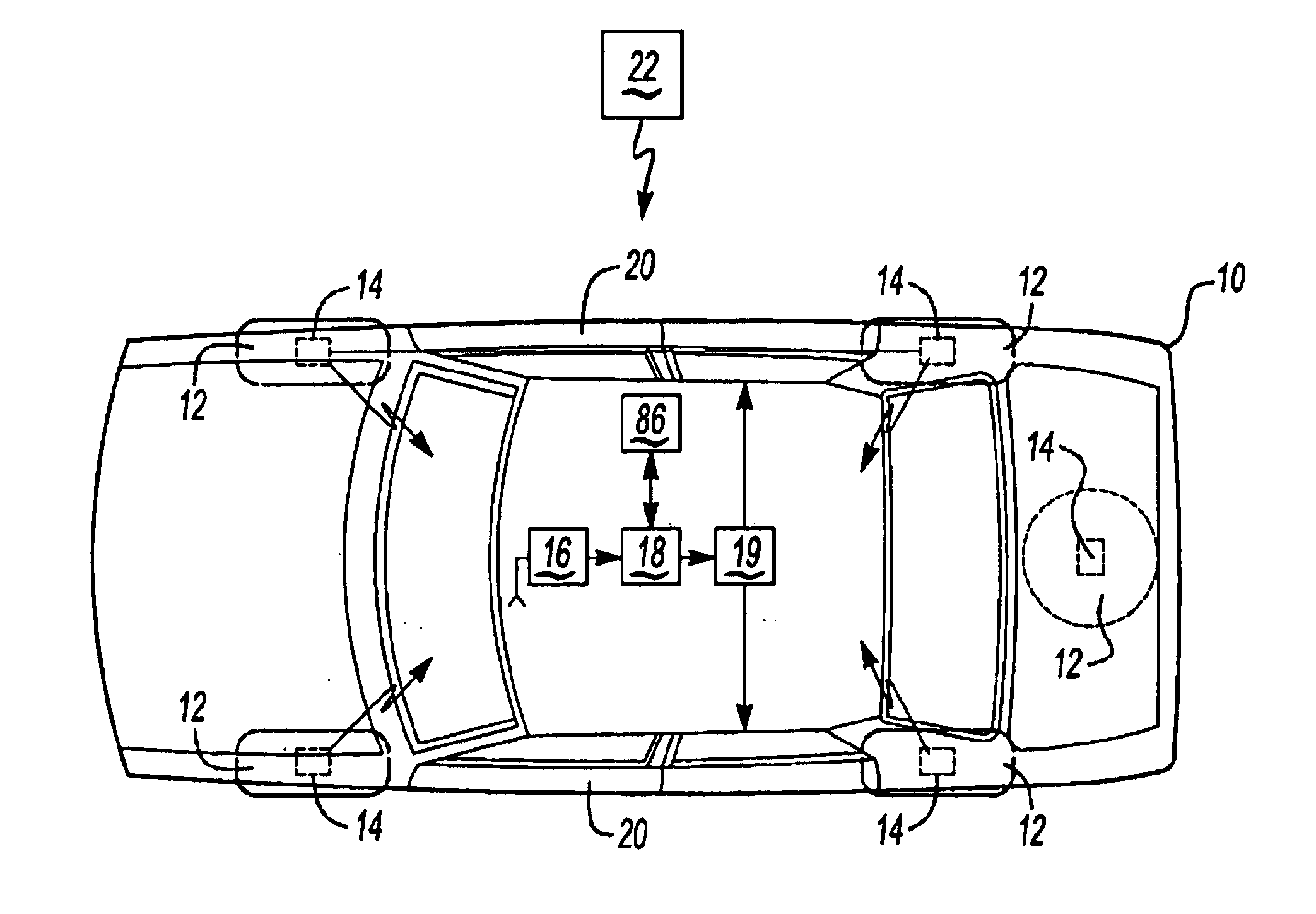

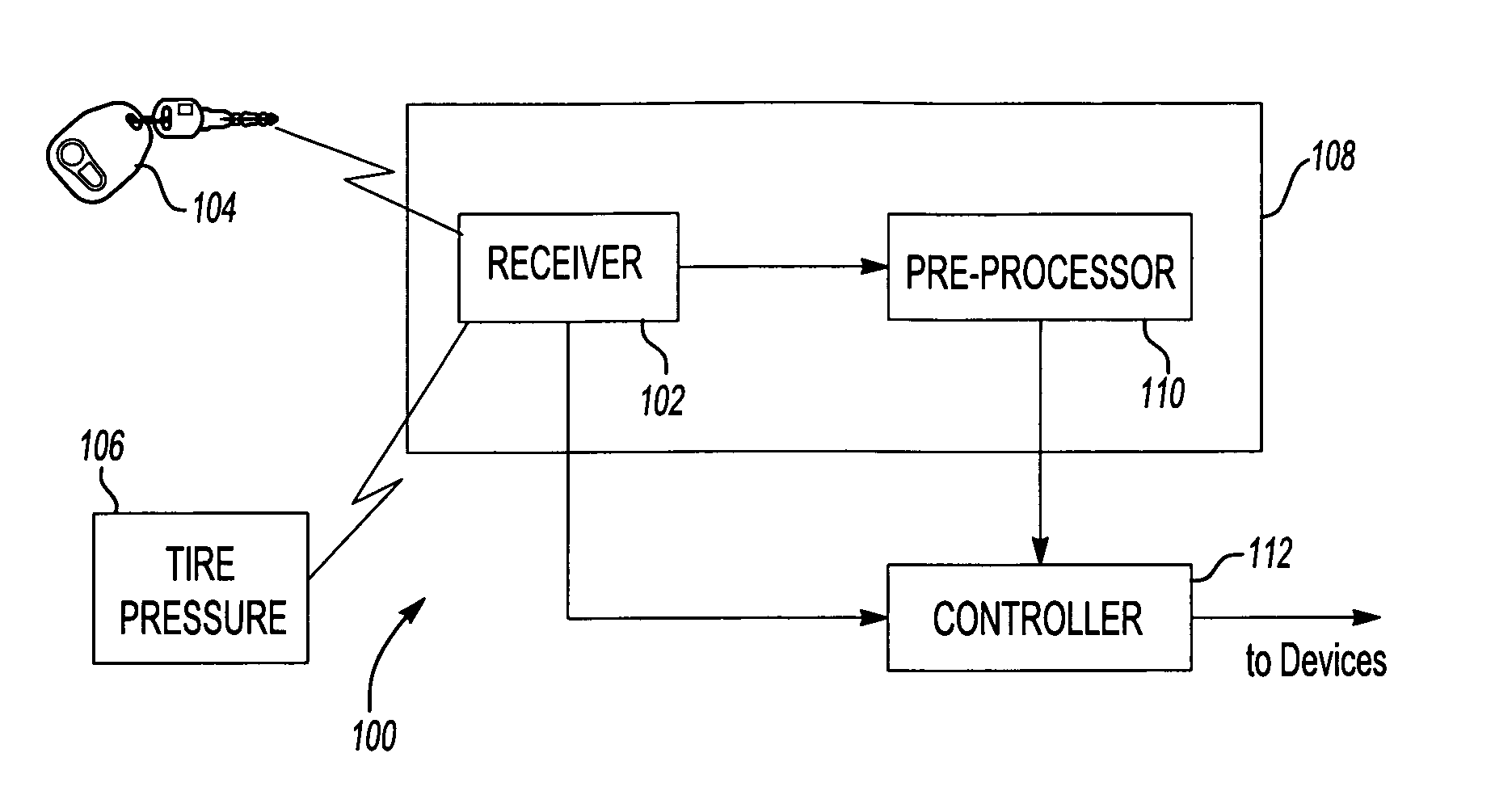

Combined tire pressure monitoring and keyless entry receiver

InactiveUS6885282B2Eliminates errant receptionReduce probabilityElectric signal transmission systemsMultiple keys/algorithms usageAccelerometerMonitoring system

A system for monitoring conditions within a tire (12) including a sensor assembly (14) including a pressure sensor (36), an accelerometer (34), a temperature sensor (32), and a transmitter (40) to transmit signals indicative of current tire conditions. A remote transmitter (22) for actuating a remote keyless entry system (19) emits a signal to actuate a function of the keyless entry system (19) such as unlocking doors (20) of the motor vehicle (10). A receiver assembly (16) includes an amplitude shift keyed receiver (52) and a frequency shift keyed receiver (58) selectively engagable to receive radio frequency transmissions from the tire monitoring system or the remote keyless entry system (19).

Owner:CONTINENTAL AUTOMOTIVE SYST INC

Method and apparatus for determining correct tire pressure inflation during adjustment

ActiveUS20060220813A1Tyre measurementsRoads maintainencePressure thresholdTire-pressure monitoring system

A method and apparatus are provided for determining pressure within a tire mounted to a vehicle, wherein the tire is coupled to a tire pressure monitoring system including a sensor coupled to a transmitter, the sensor configured to sense tire pressure and the transmitter configured to transmit the sensed tire pressure to a receiver. First, a first tire pressure is sensed. Then, a calculation is made as to whether the sensed first tire pressure is greater than a predetermined pressure threshold, equal to the predetermined pressure threshold, or less than the predetermined pressure threshold. Next, an indication is provided external to the vehicle that the sensed first tire pressure is greater than a predetermined pressure range, within the predetermined pressure range, or less than the predetermined pressure range.

Owner:GM GLOBAL TECH OPERATIONS LLC

Method and system for mitigating false alarms in a tire pressure monitoring system for an automotive vehicle

InactiveUS6982636B1Quick responseShorten the timeHydrodynamic testingVessel partsTire-pressure monitoring systemPressure threshold

A pressure monitoring system (12) for a tire (14a) of an automotive vehicle includes a first pressure sensor (94) coupled to the wheel, a pressure transmitter (90) coupled to the pressure sensor (94) whereby the transmitter generates a pressure signal. A controller (22) is coupled to the pressure transmitter. The controller (22) receives the pressure signal and in a first stage, compares the pressure signal to a pressure threshold to obtain a sensor status. In a second stage, the controller (22) qualifies the sensor status signal by generating a warning status in response to the sensor status.

Owner:FORD GLOBAL TECH LLC

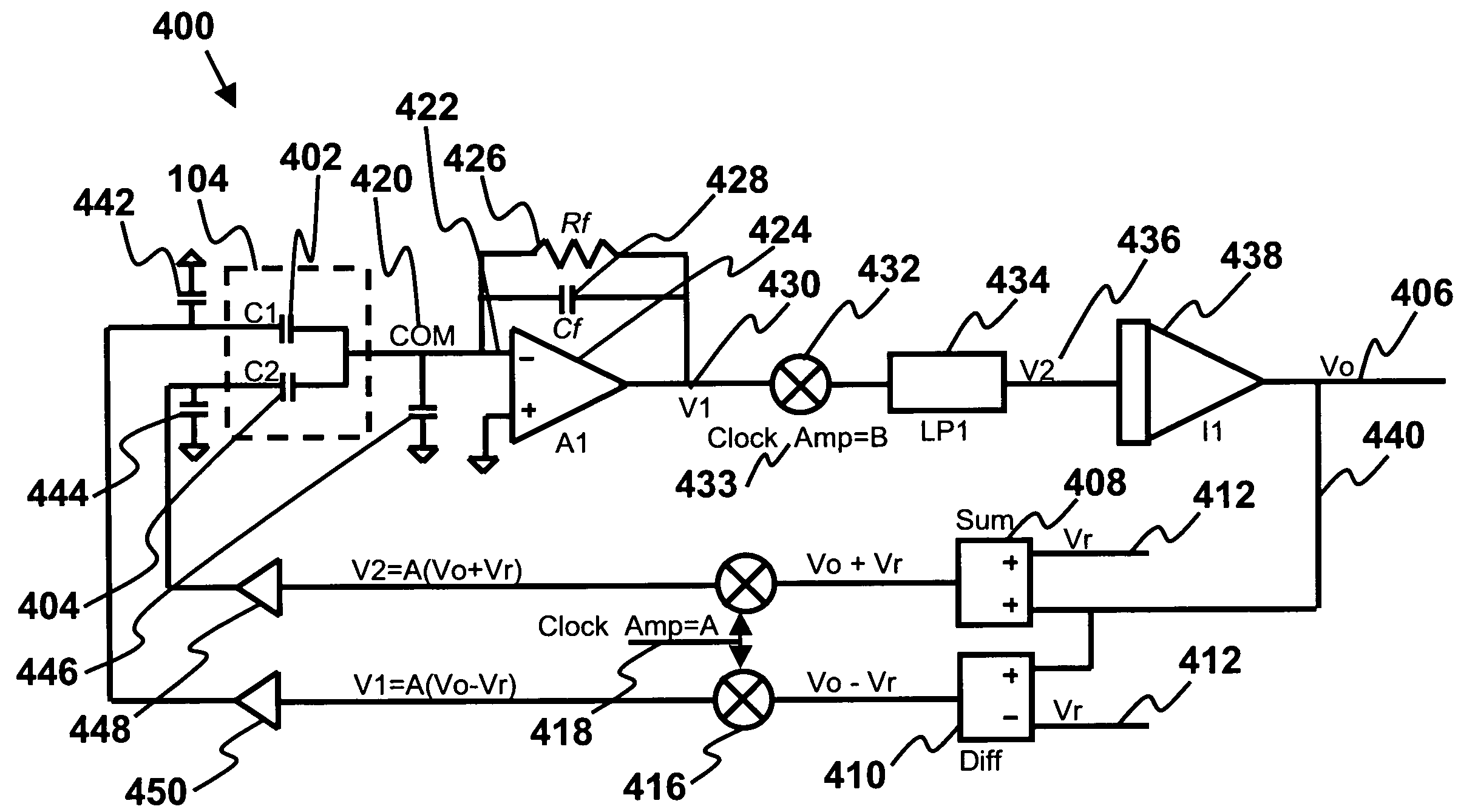

Signal conditioning methods and circuits for a capacitive sensing integrated tire pressure sensor

A tire pressure monitoring system is provided that includes a switched capacitor circuit having a clock with two non-overlapping clock phases that control a state of analog switches of the switched capacitor circuit. The system uses tire pressure sensor MEMS capacitors that are measured differentially. A capacitance-to-voltage converter is connected to the MEMS sense capacitor, and a sigma-delta converter having a comparator with a first digital output state and a second digital output state is used. The first output state is a sum of reference voltages and the second output state is a difference of the reference voltages. An average value of the capacitance-to-voltage converter output is driven to a zero value and a digital output is provided of the average output states that is equal to a difference between the MEMS capacitors divided by their sum multiplied by a ratio of the reference voltages.

Owner:SAMSUNG ELECTRONICS CO LTD

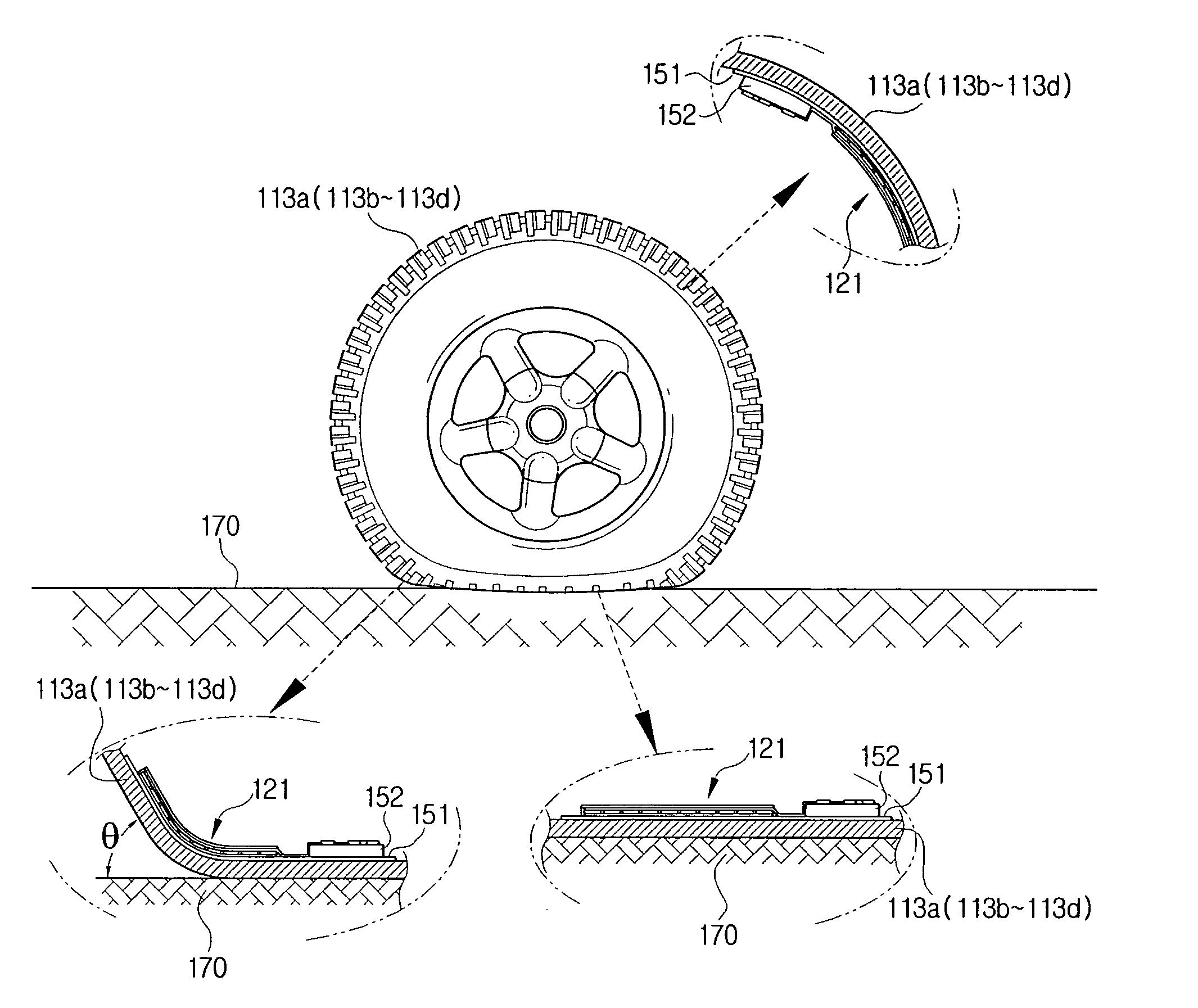

Self-powered sensing module and tire pressure monitoring system using the same

InactiveUS20050134444A1Reduce maintenance costsElectric signal transmission systemsInflated body pressure measurementElectrical batteryTire-pressure monitoring system

A tire pressure monitoring system (TPMS) having a self-powered sensing module having a sensor unit with at least one sensor for measuring at least one of a temperature, a pressure, and an acceleration in the tire, and a power unit generating a power by being deformed mechanically according to a rotation of the tire and supplying the sensor with a power required for actuating the sensor. The self-powered sensing module and the TPMS using the same are powered by the power unit generating the power owing to the mechanical deformation, without using a separate power supply. Hence, there is no need to replace a battery of the sensing module and maintenance costs are reduced.

Owner:SAMSUNG ELECTRONICS CO LTD

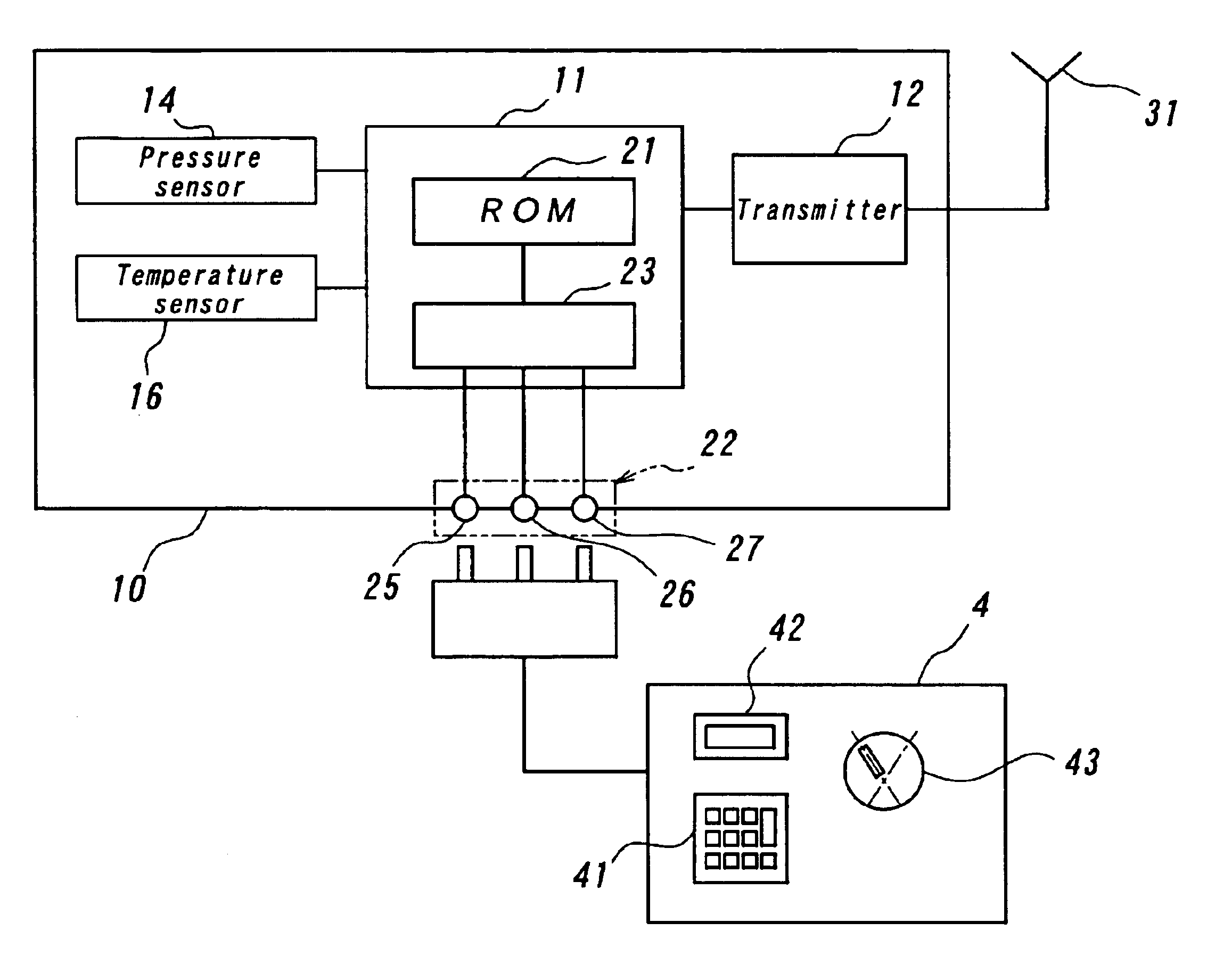

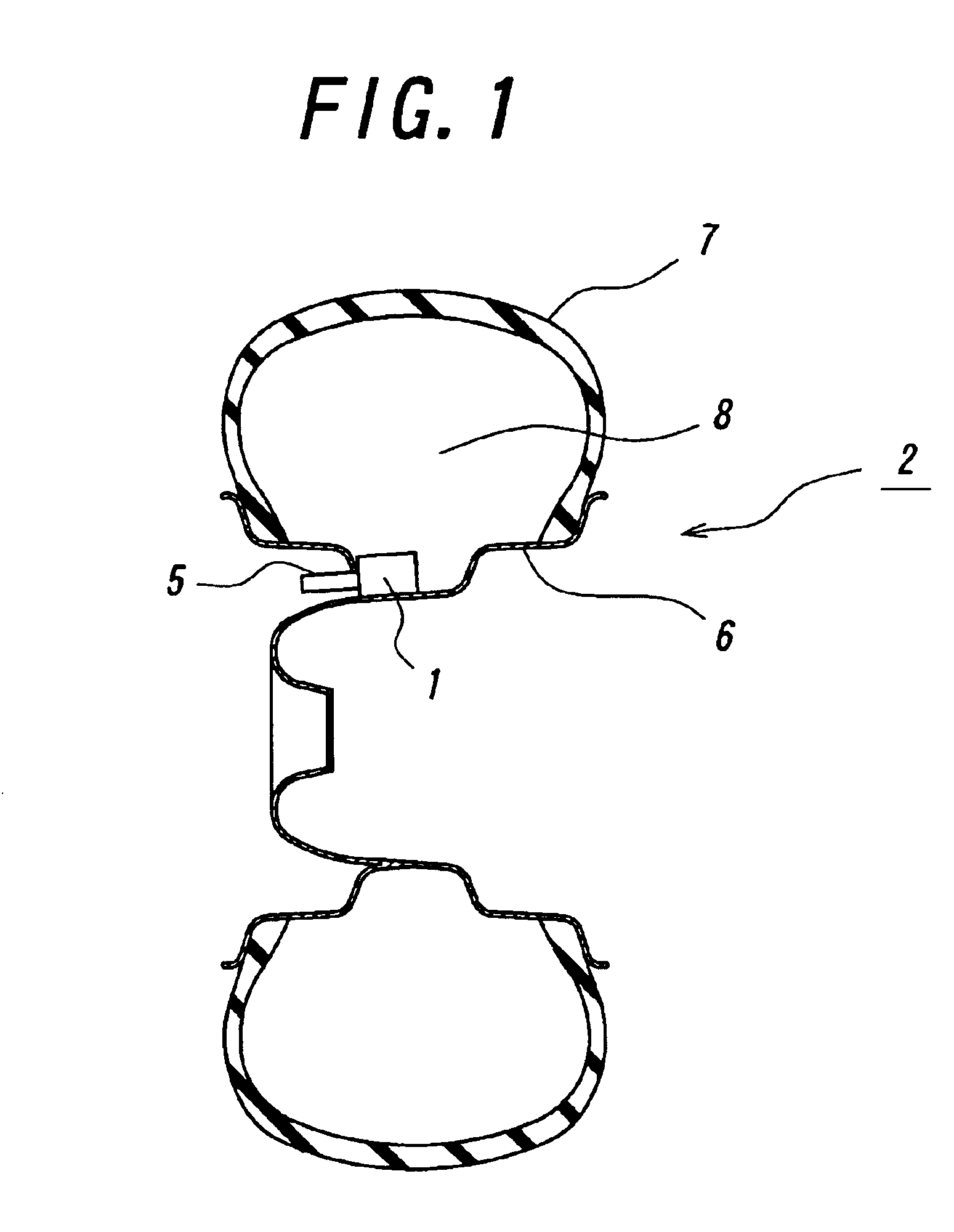

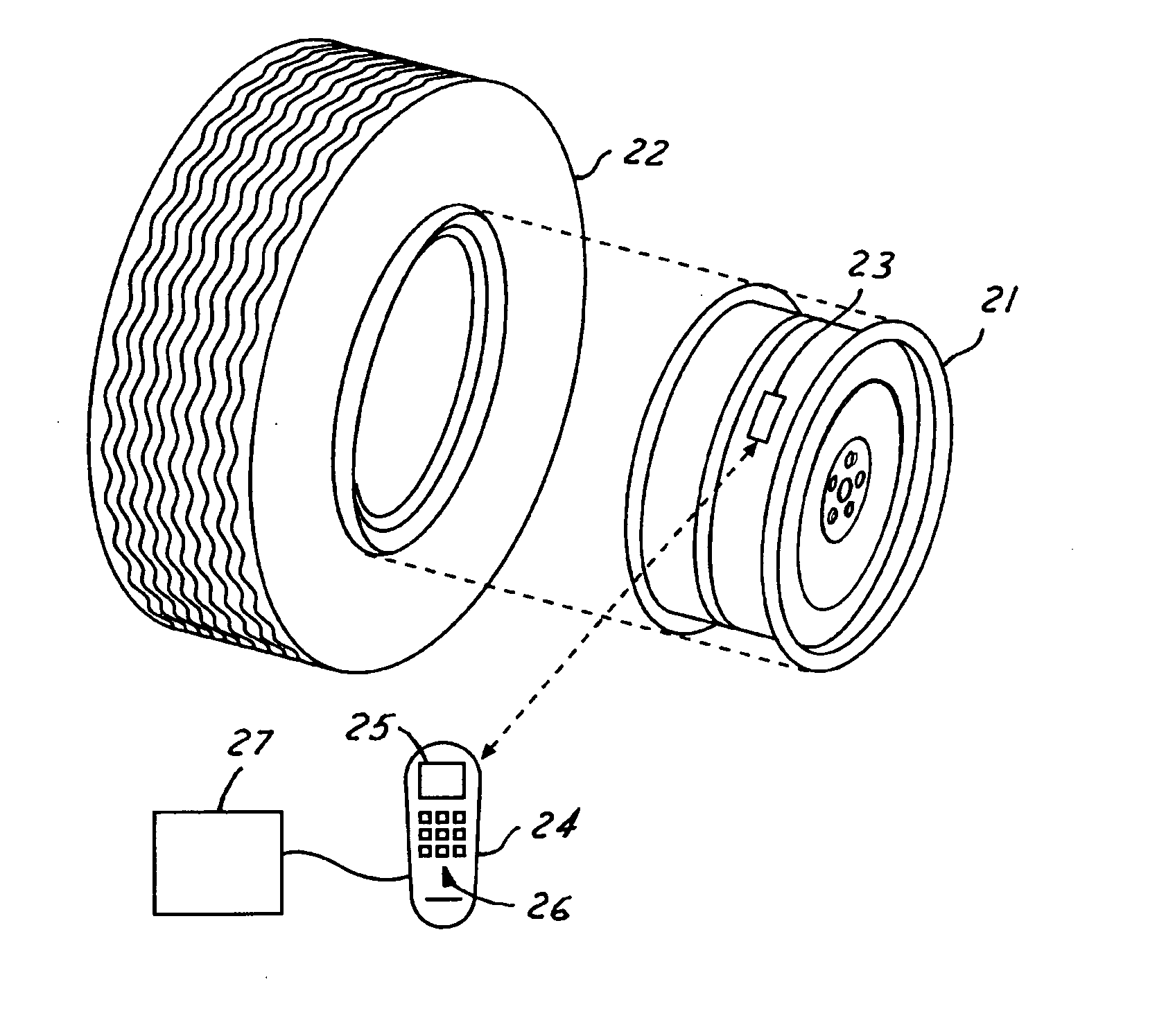

Tire pressure sensor unit, tire pressure monitoring system, and method of registering identification code of tire pressure sensor unit

InactiveUS6920785B2Easy to specifyOvercomes drawbackTyre measurementsRoads maintainenceTire-pressure monitoring systemForce sensor

A sensor unit body 10 of a tire pressure sensor unit 1 is provided with external signal-importing terminals 22 for rewriting data of self-identification code stored in a ROM 21, so that a complex operation of associating the self-identification code of the sensor unit with its mounting position in the vehicle is eliminated by rewriting the self-identification code of the sensor unit 1 after the replacement to be identical to the self-identification code of the sensor unit 1 before the replacement, when a tire wheel is replaced due to a breakdown of the tire unit or a replacement between a summer tire and a winter tire.

Owner:BRIDGESTONE CORP

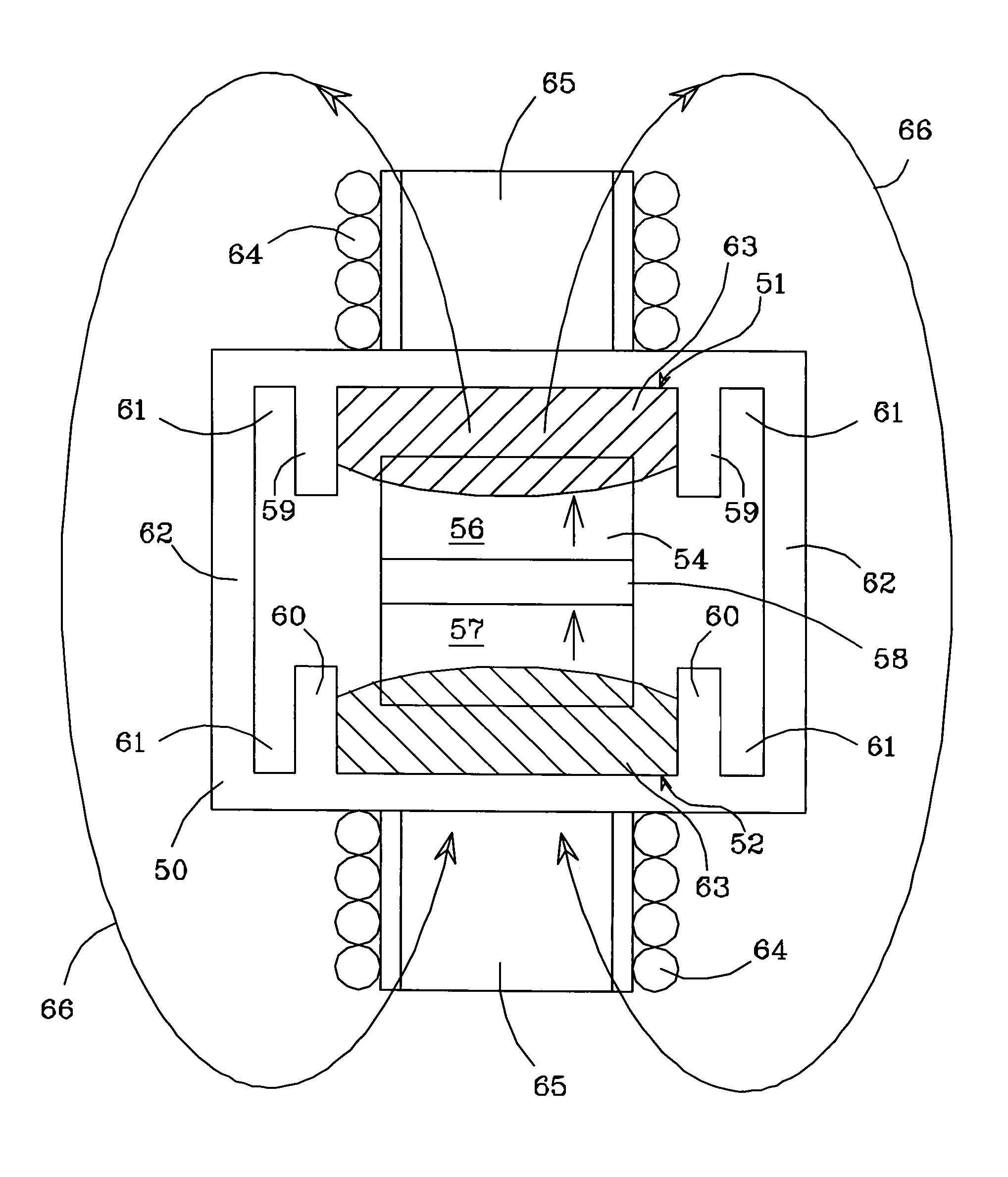

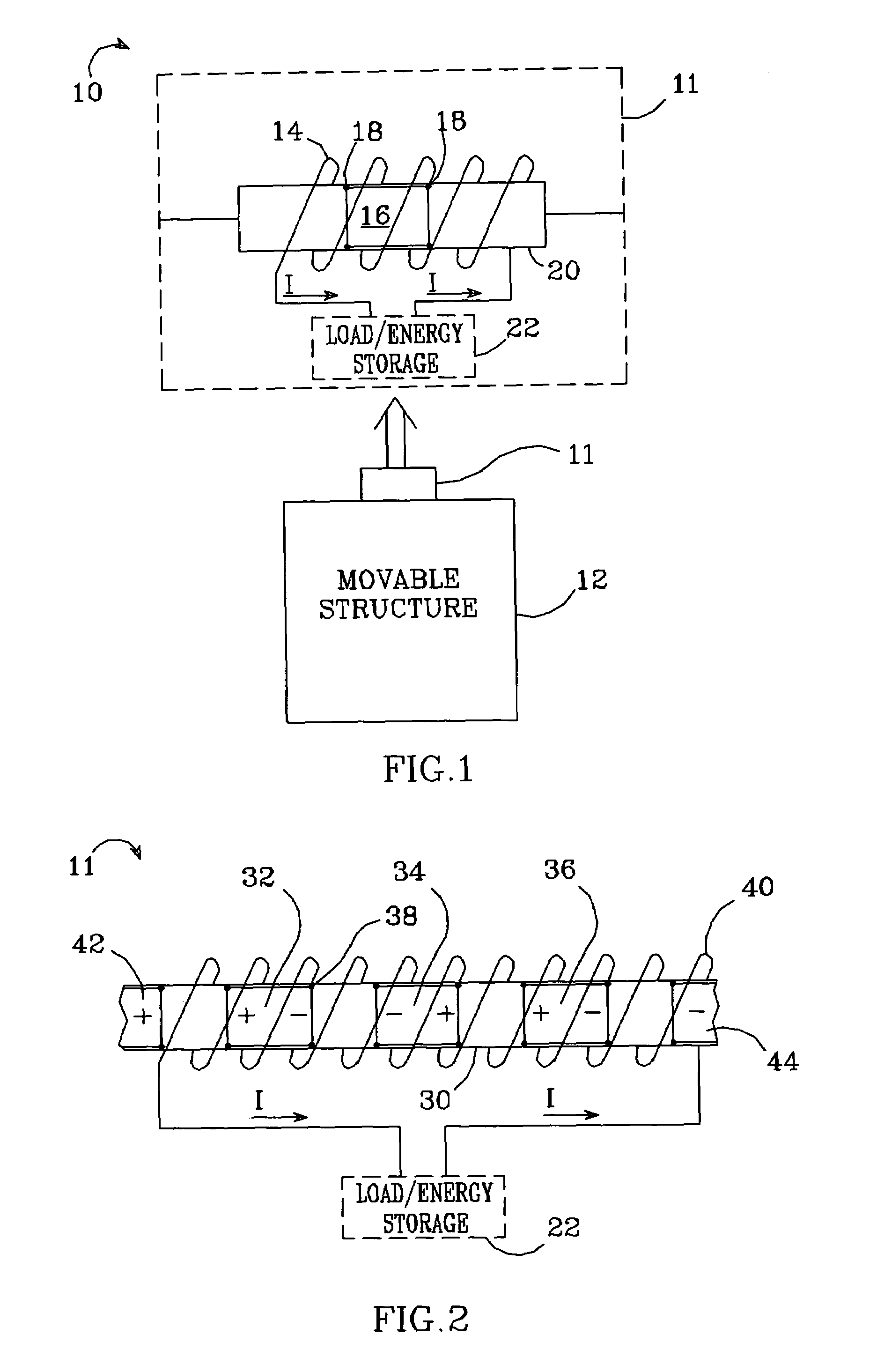

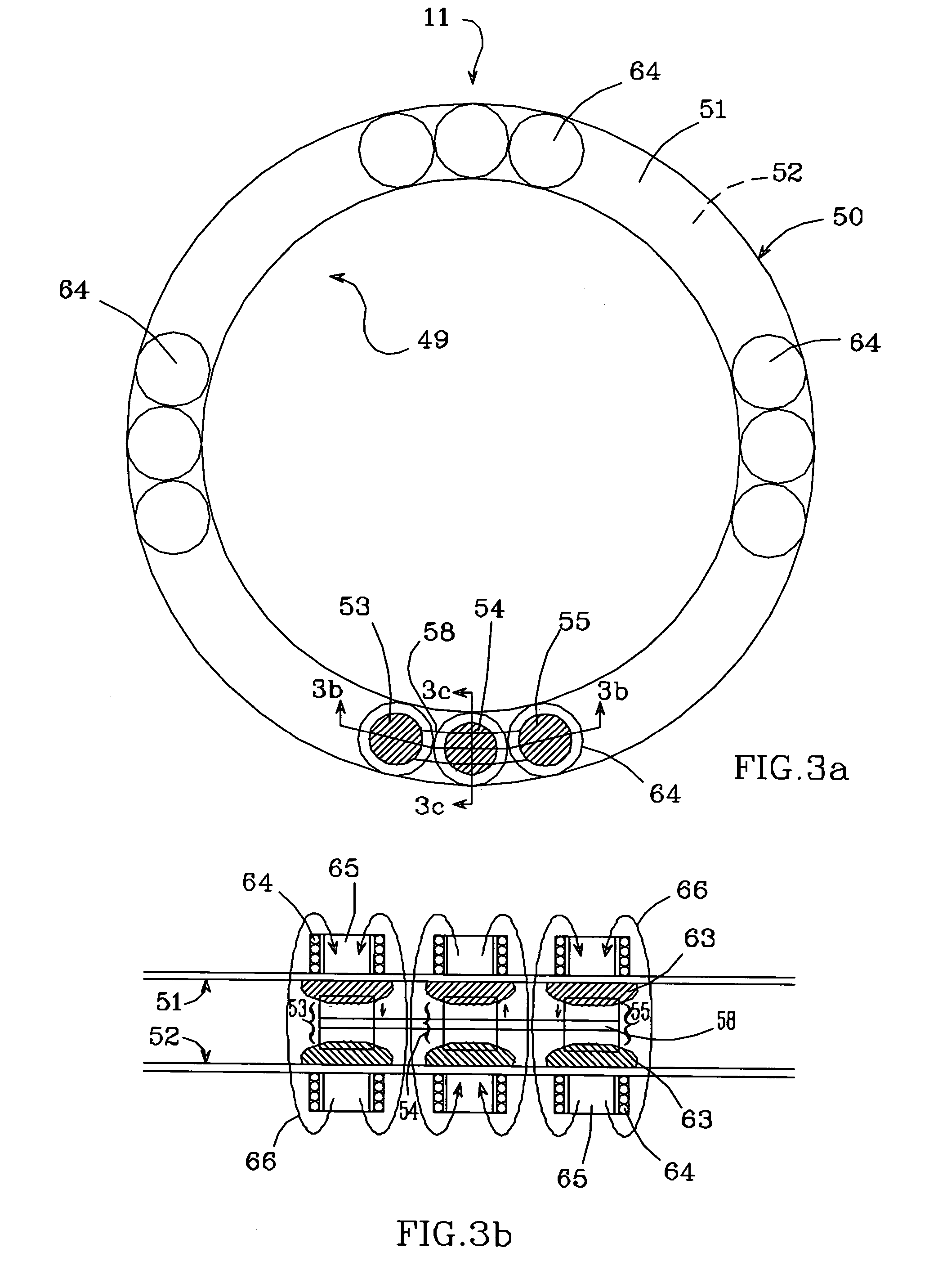

Autonomous power source

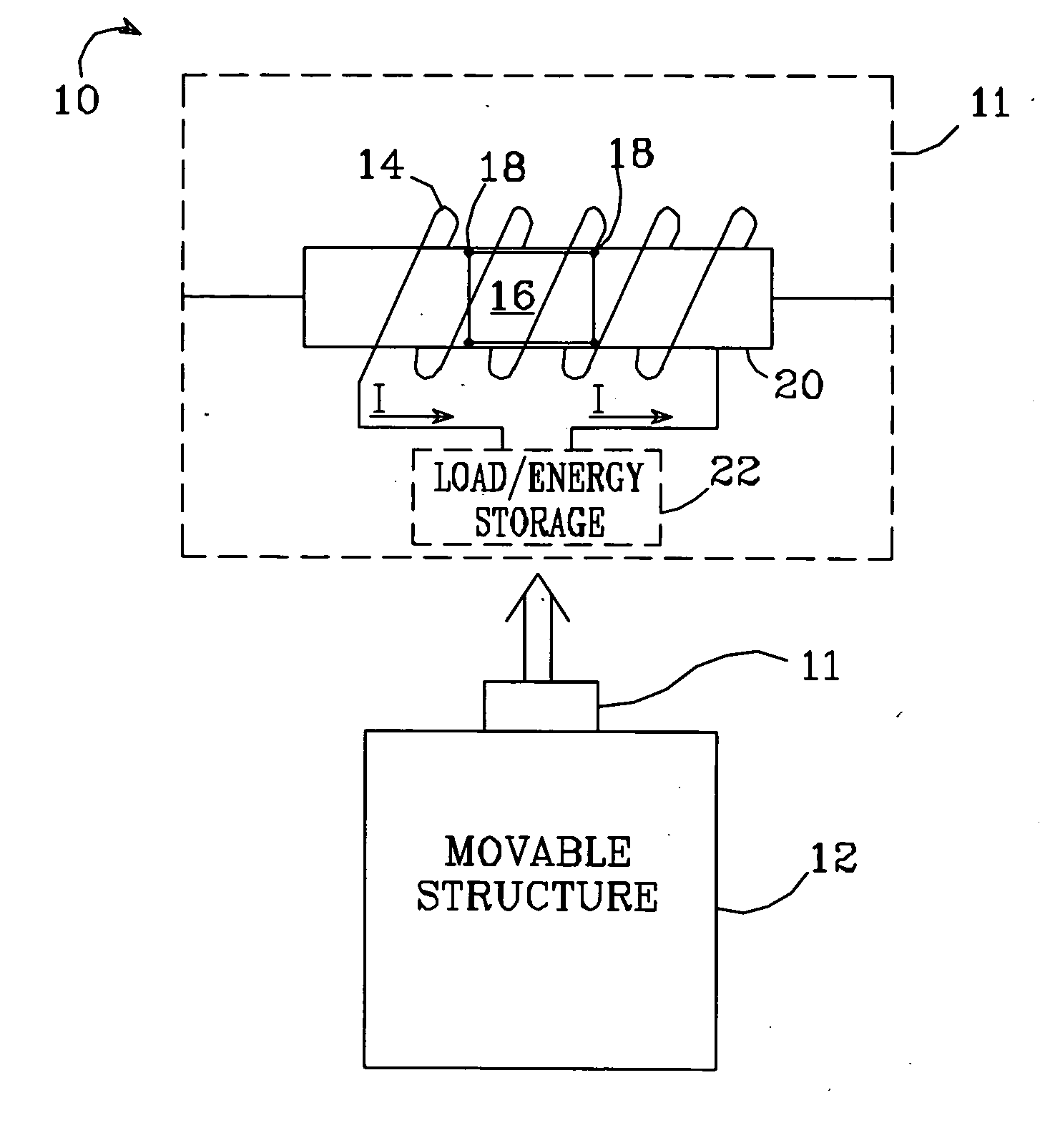

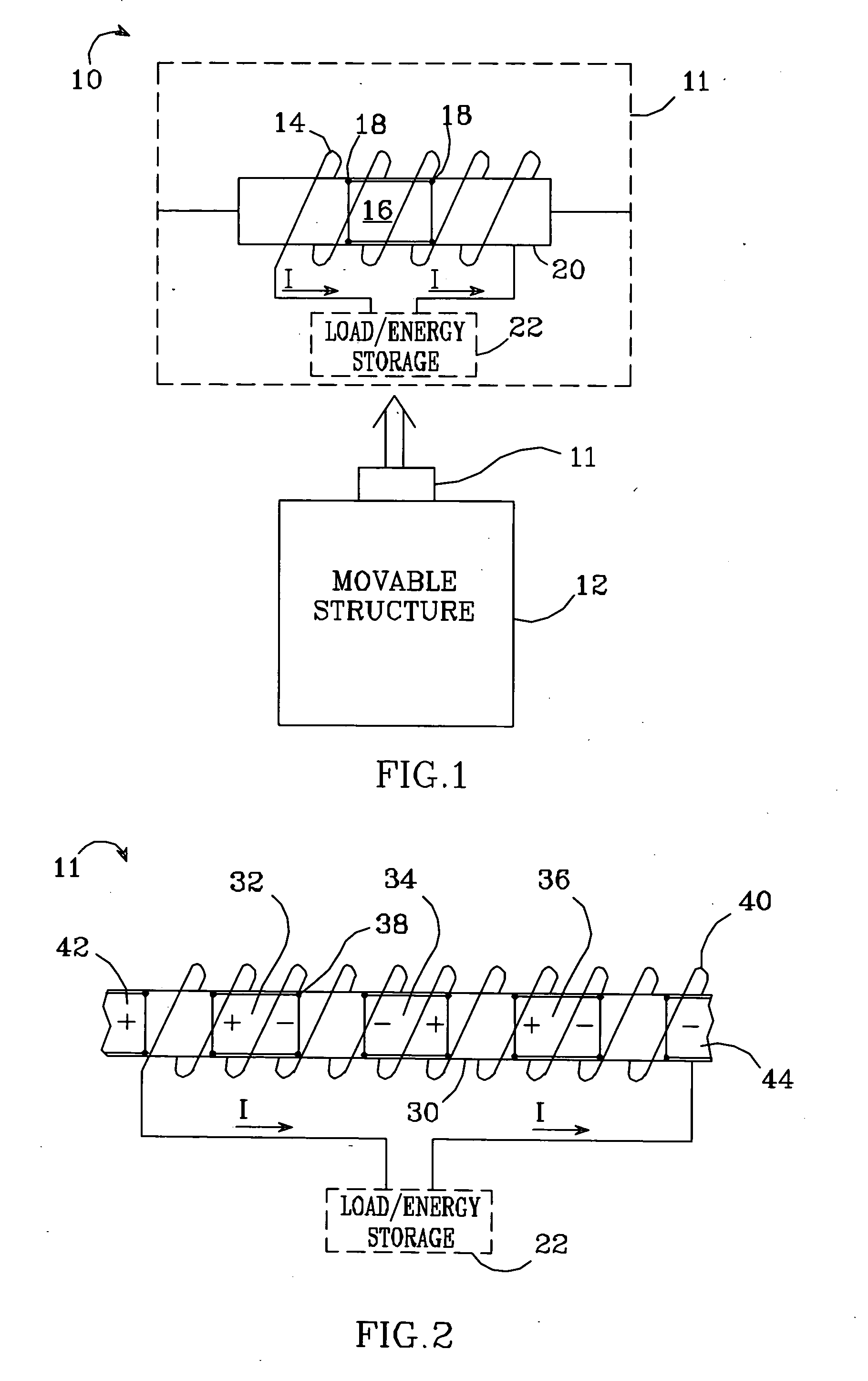

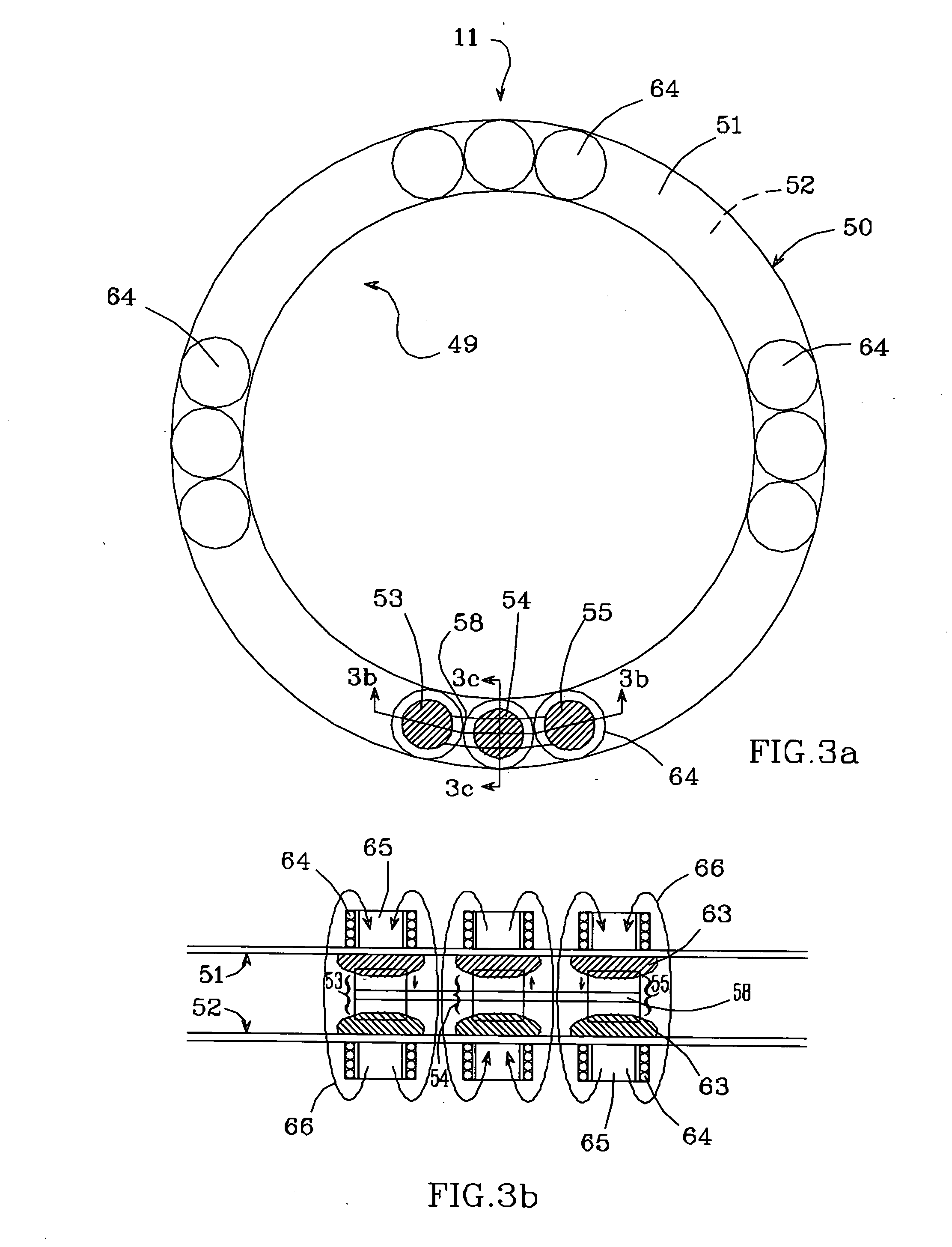

InactiveUS20050151375A1Reduce frictionHigh sensitivityBearing componentsMachines/enginesElectrical batteryEngineering

An autonomous power source comprises a power harvester mounted on a movable structure. The power harvester includes a coil, a magnet, and a low-friction ferrofluidic bearing in contact with the magnet, arranged such that the magnet and coil move with respect to each other when the structure is in motion such that an electrical current is produced in the coil. This current is converted to power and stored in an energy storage system and is thus available to power electronic circuitry. The magnet and bearing are preferably enclosed within a closed linear or circular tube, with the coil mounted around the exterior of the tube. The power harvester and battery are combined with one or more sensors and a wireless transmitter to form a tire pressure monitoring system.

Owner:TELEDYNE SCI & IMAGING

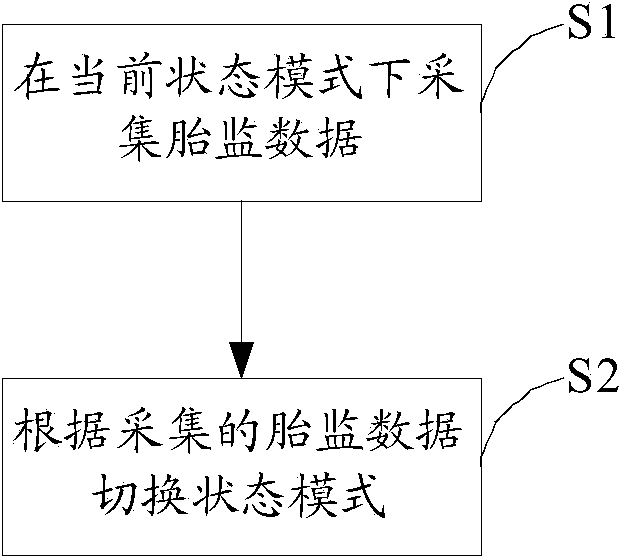

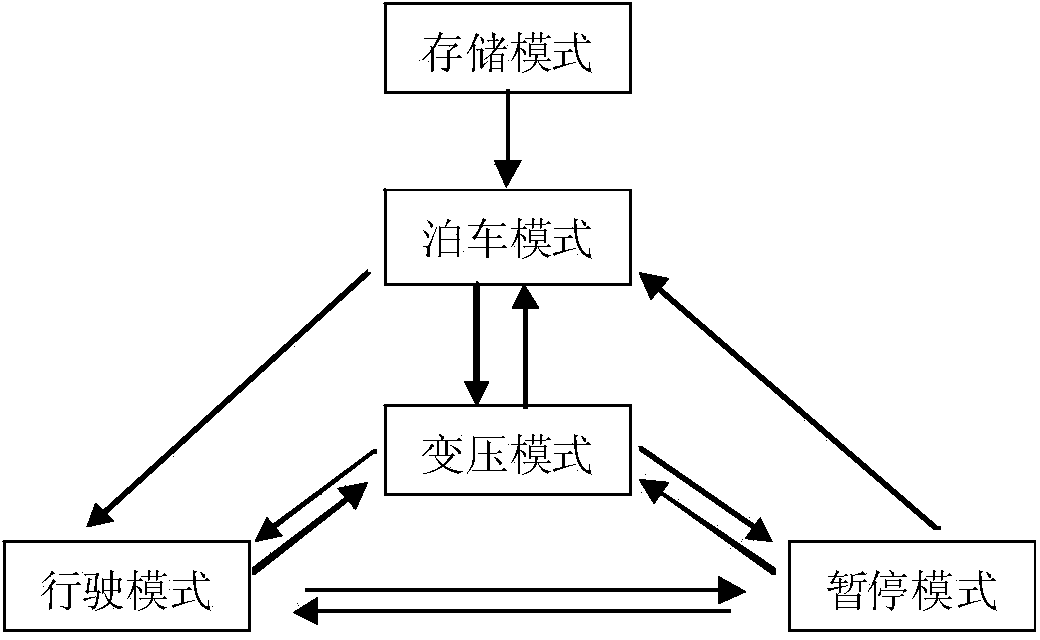

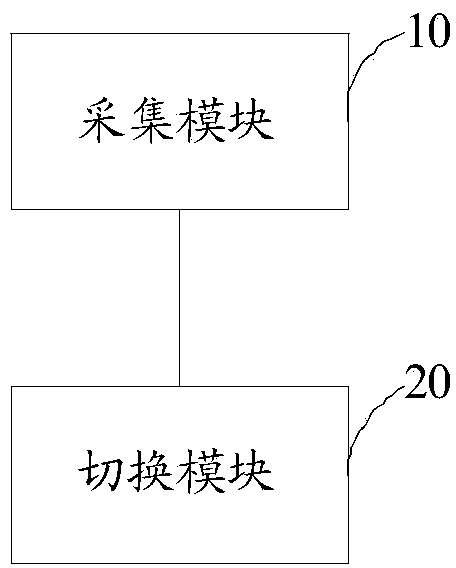

Method and device for tire pressure monitoring

InactiveCN103818204AGuaranteed validityGuaranteed reliabilityTyre measurementsState modelDependability

The invention is applicable in the field of communications and provides a method and a device for tire pressure monitoring. The method comprises the following steps: tire pressure monitoring data is collected in a current state; the state model is switched according to the collected tire pressure monitoring data. According to the method and the device provided by the invention, the validity, reliability and accuracy of the tire pressure monitoring are guaranteed; simultaneously, the power dissipation is effectively reduced; the service life of a battery is prolonged.

Owner:AUTEL INTELLIGENT TECHNOLOGY CORP LTD

Universal tire pressure monitoring sensor

A tire pressure monitoring device includes a memory that includes a plurality of selectable communication protocols to govern communication and operation.

Owner:CONTINENTAL AUTOMOTIVE SYST INC +1

Universal Tire Pressure Monitoring System and Wireless Receiver

InactiveUS20080024287A1Easy to analyzeEfficient and optimized movement and transmissionVehicle testingRegistering/indicating working of vehiclesInformation processingEngineering

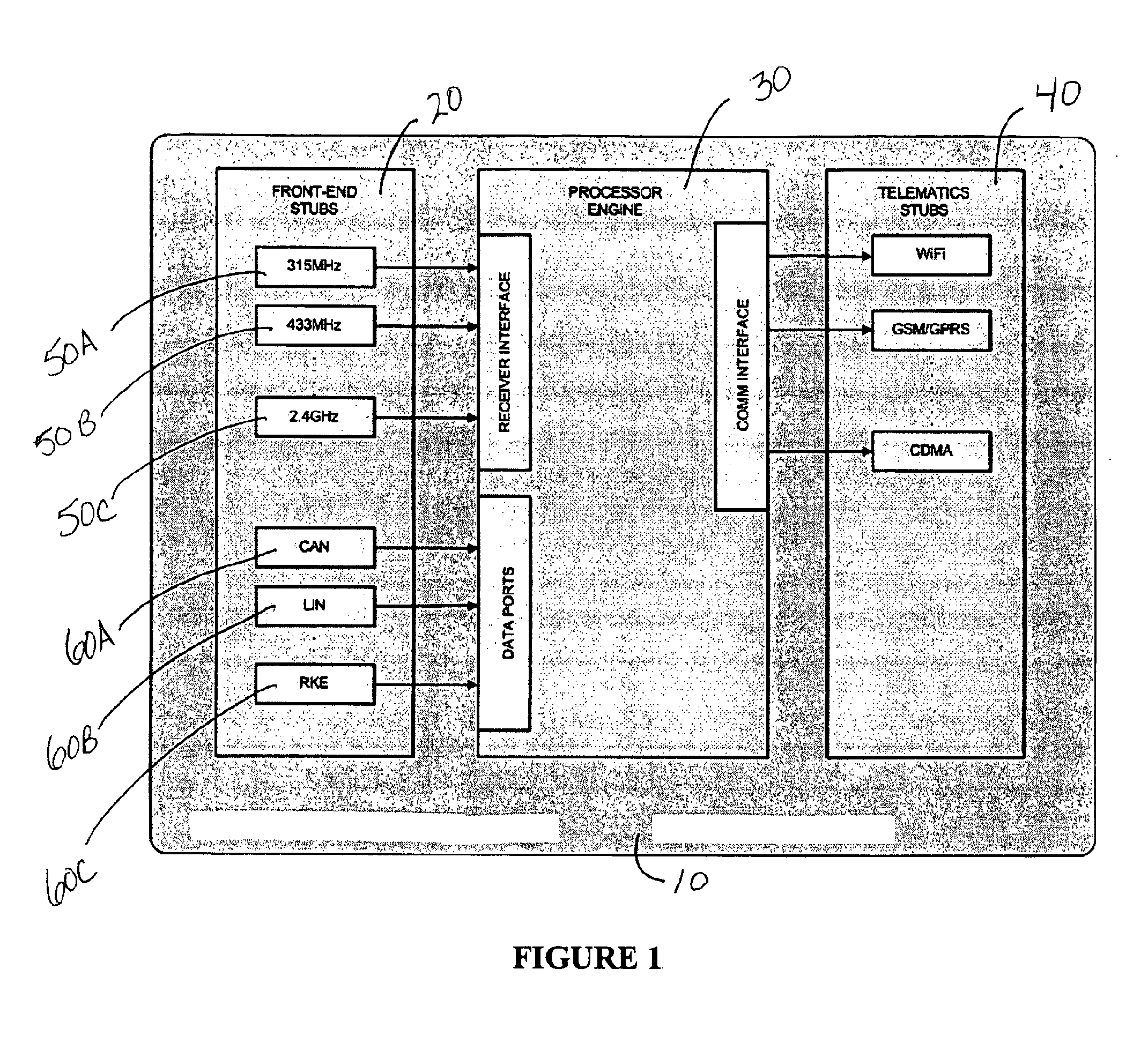

The present invention provides a universal receiver (OTR) device which functions within a vehicle in the “under-the-hood” (UTH) environment such that various types of tire pressure management system (TPMS) device, located within, upon or near a vehicle's tires can transmit tire information, such as the transmitter identification number (TIN), the tire unique identifier (TUID), the vehicle identification number (VIN), tire pressure, tire temperature, tire rotation, and other tire relevant data, to the OTR for further processing regardless of frequency, data transfer speed, or data format of the TPMS device. The OTR device in sequence: identifies the TPMS device, receives the tire information from the TPMS device, and processes the tire information into date records for efficient and optimized transmission of such data records for future analysis both within and off a vehicle. The OTR also interfaces with various types of telematics devices, regardless of the type of transmission or protocol used, by identifying the type of telematics device. The OTR also stores or retrieves information related to various telematics and TPMS devices in order to identify these devices. For example, an automotive manufacturer, dealership, or tire distributor would be able to select various manufacturers' TPMS and telematics devices for installation within the vehicle and with the OTR collect previously captured TPMS data for further analysis.

Owner:BOYLE SEAN ROBERT +2

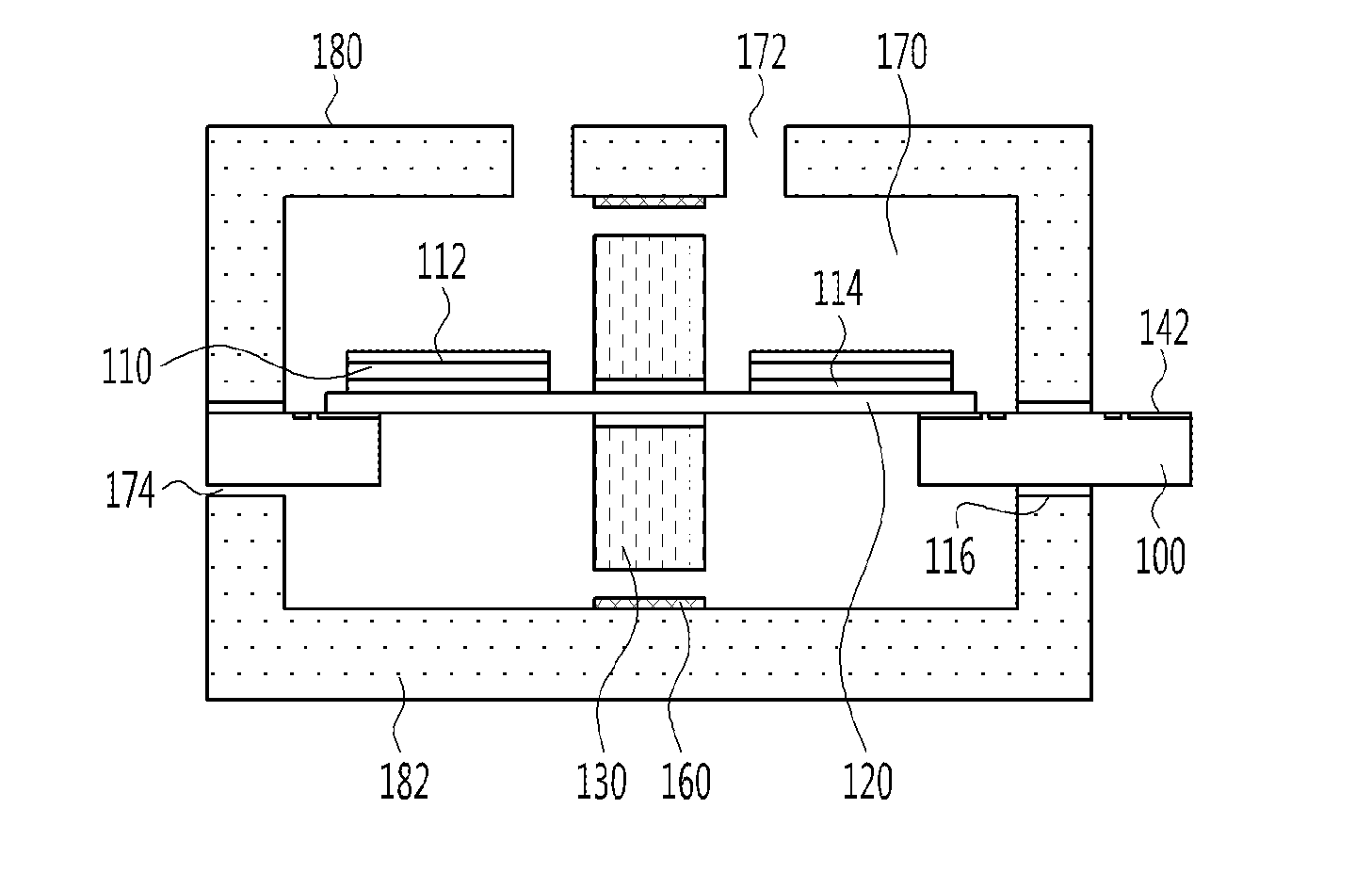

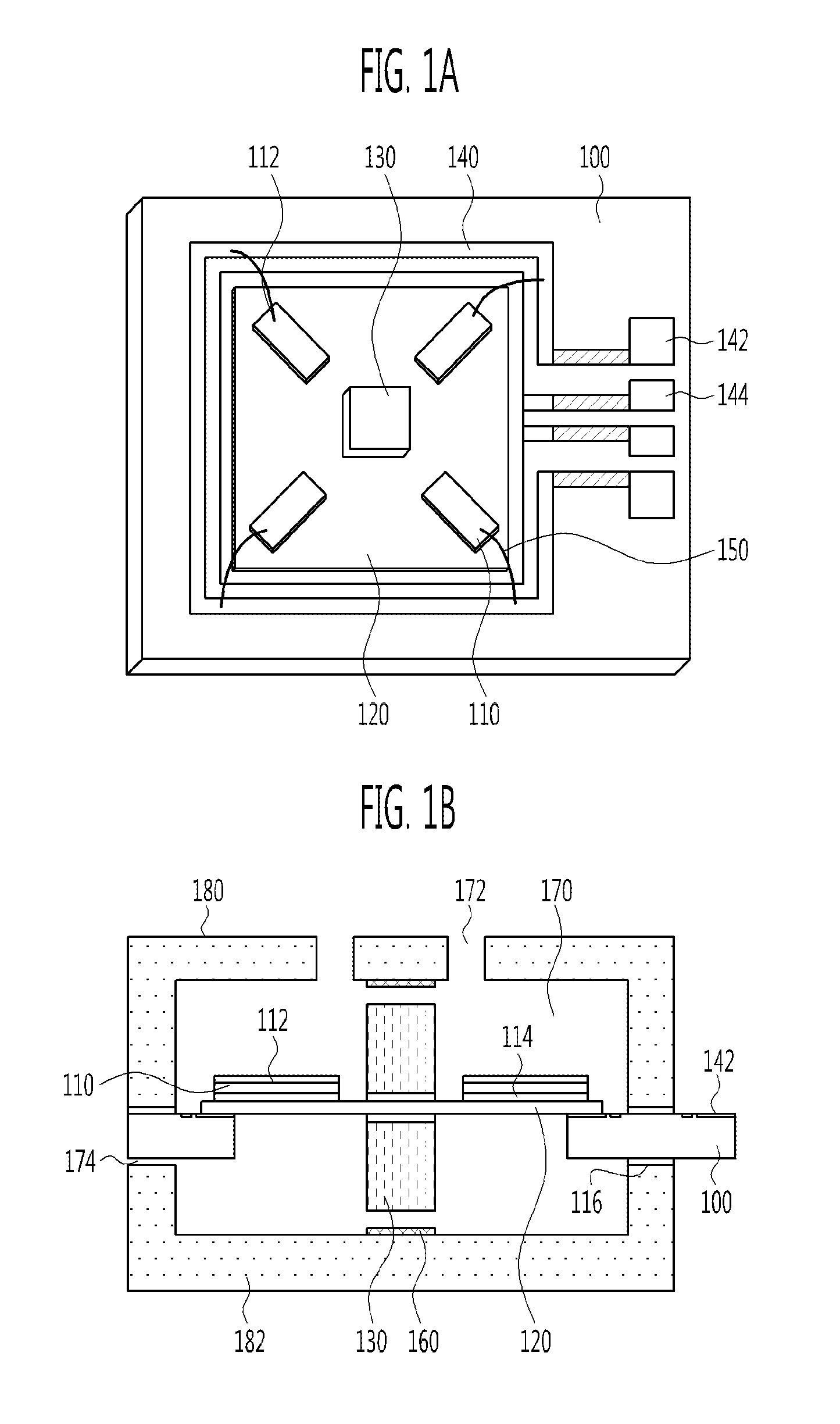

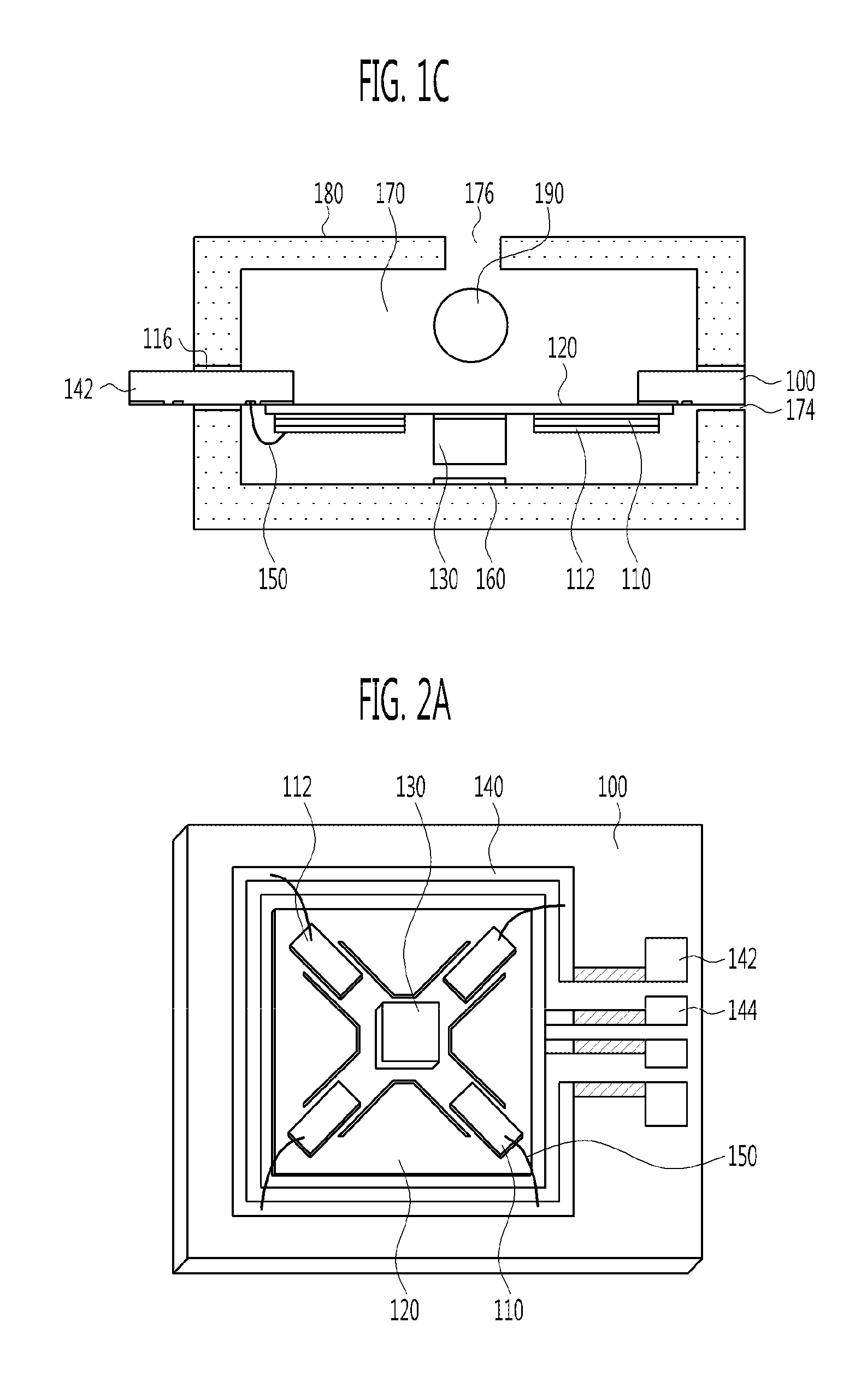

Piezoelectric power generator

InactiveUS20110140578A1Increased deformation rangeAvoid deformationPiezoelectric/electrostriction/magnetostriction machinesTyre measurementsElectric power transmissionTransmitted power

Provided is a small piezoelectric power generator applied to a wireless sensor network system of a tire pressure monitoring system (TPMS) for monitoring an internal environment of a tire such as variation in air pressure in the tire. In particular, when the system, in which air pressure, temperature and acceleration sensors are mounted, installed in the tire is operated in the TPMS for an automobile, a small piezoelectric power generator for the TPMS can be used as a power source in place of a conventional battery. The piezoelectric power generator includes a substrate having an electrode for transmitting power to the exterior, a metal plate formed on the substrate, and a piezoelectric body disposed on the metal plate and transmitting the power generated by a piezoelectric material to the electrode.

Owner:ELECTRONICS & TELECOMM RES INST

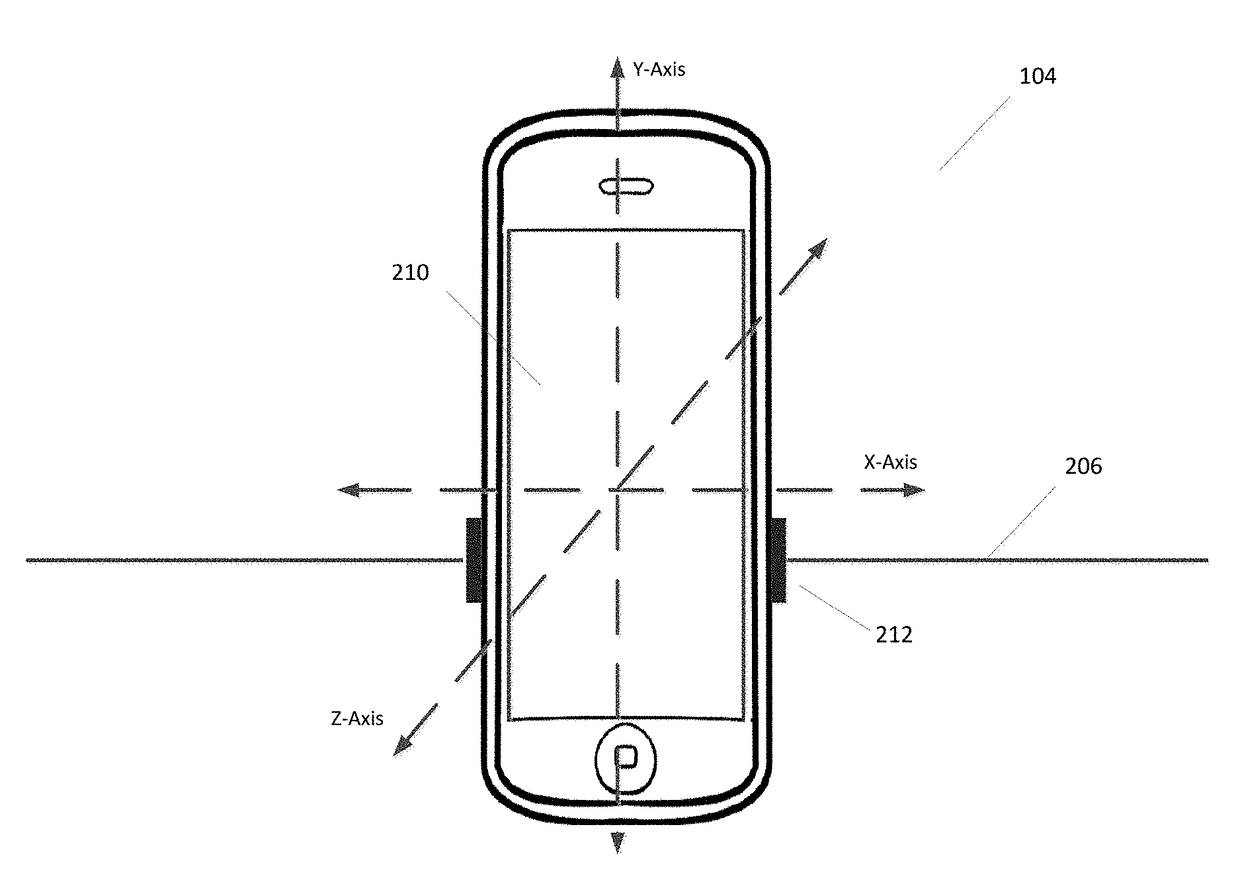

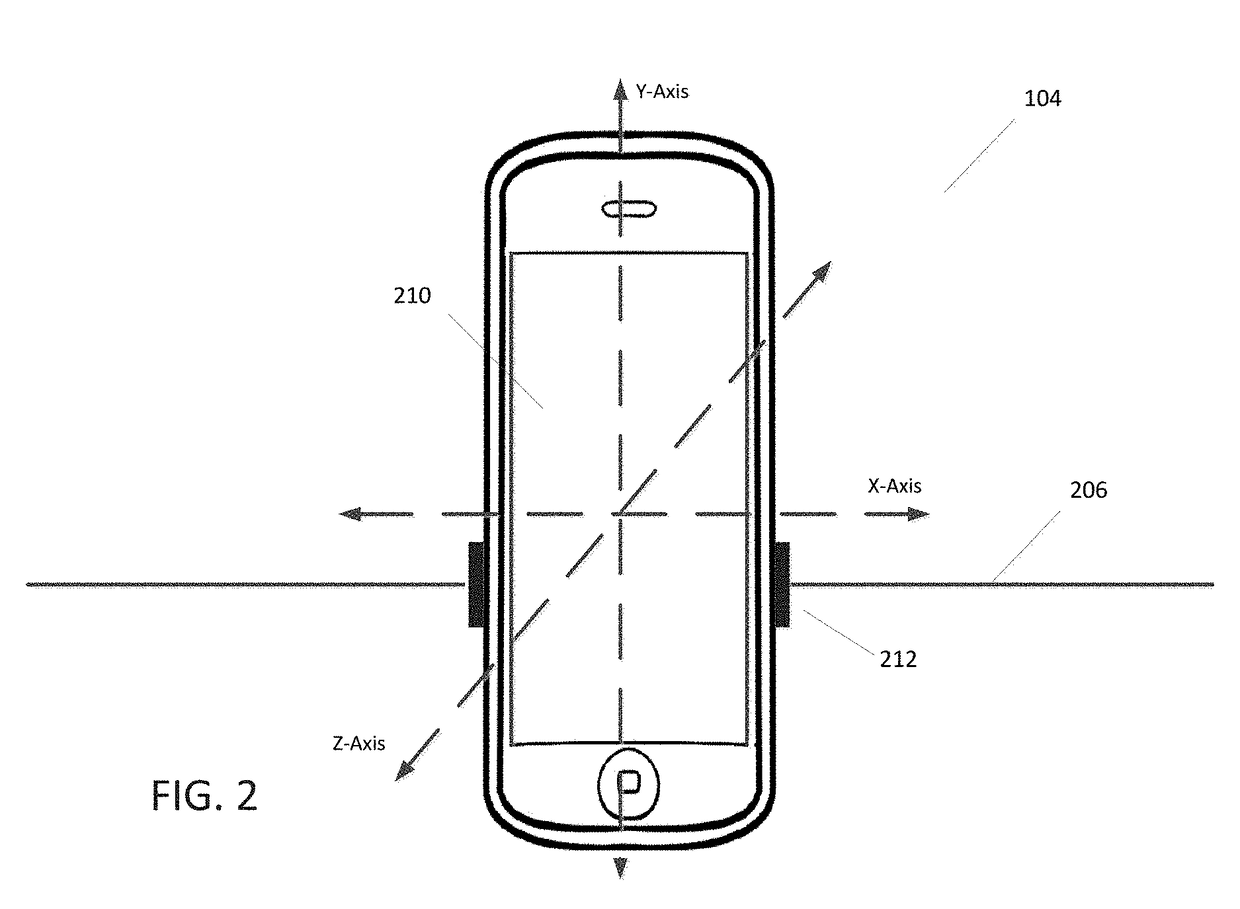

Applying motion sensor data to wheel imbalance detection, tire pressure monitoring, and/or tread depth measurement

ActiveUS20180003593A1Improve securityReduce fuel consumptionVibration measurement in solidsSubsonic/sonic/ultrasonic wave measurementMobile vehicleAccelerometer

A computer-based method to facilitate detecting wheel imbalance, a tire pressure problem, or excessive tread wear on tires of a moving vehicle is disclosed. The method includes collecting (e.g., from an accelerometer of a mobile personal computing device) data that represents vibration that results, at least in part, from the vehicle's motion, and determining, with a computer-based processor, whether the moving vehicle has wheel imbalance, a tire pressure problem, and / or excessive tire tread wear based at least in part on the vibration data produced by the accelerometer (and, possibly other data), where the mobile personal computing device and the accelerometer are moving with the vehicle when the data is being collected.

Owner:MASSACHUSETTS INST OF TECH

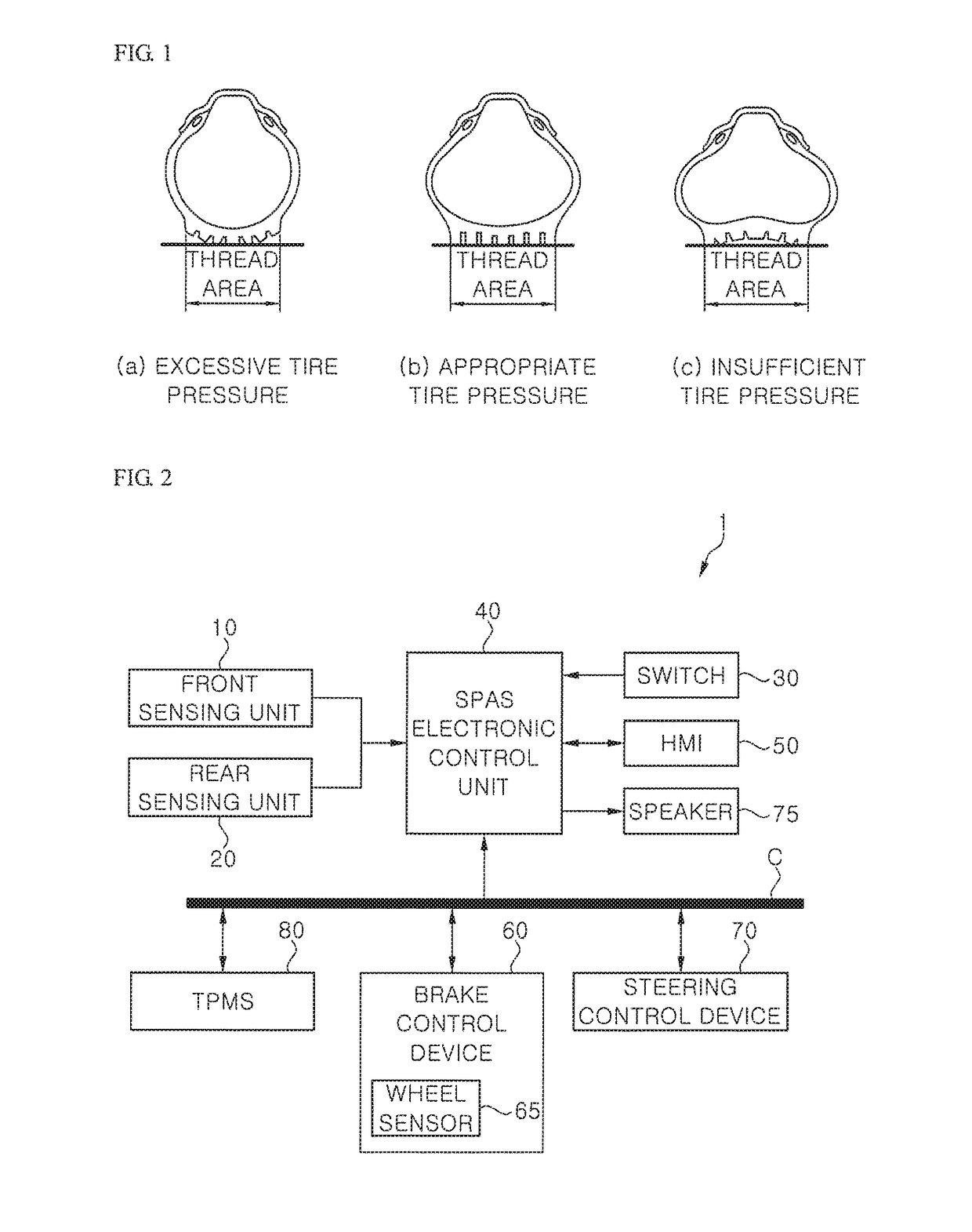

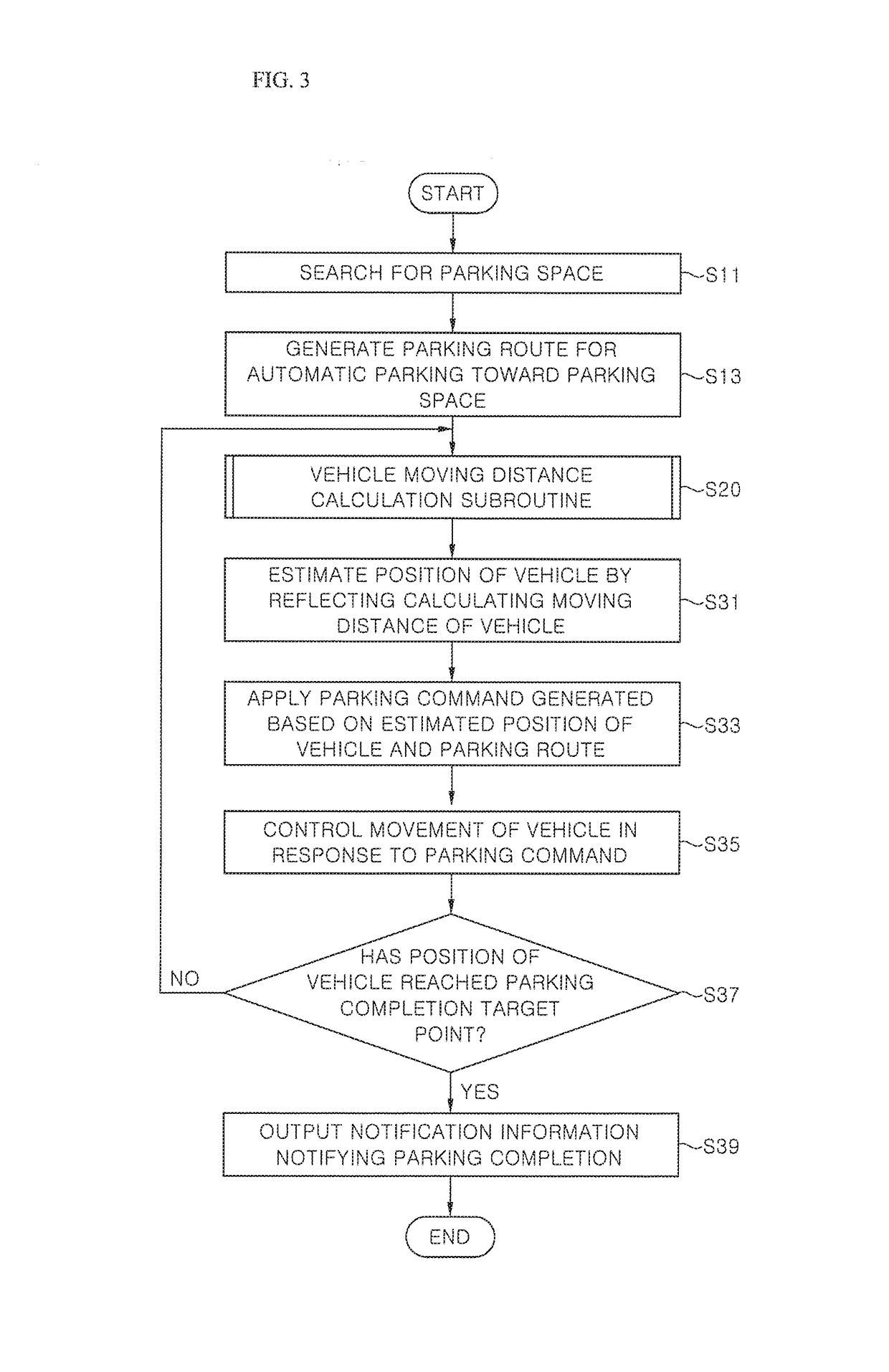

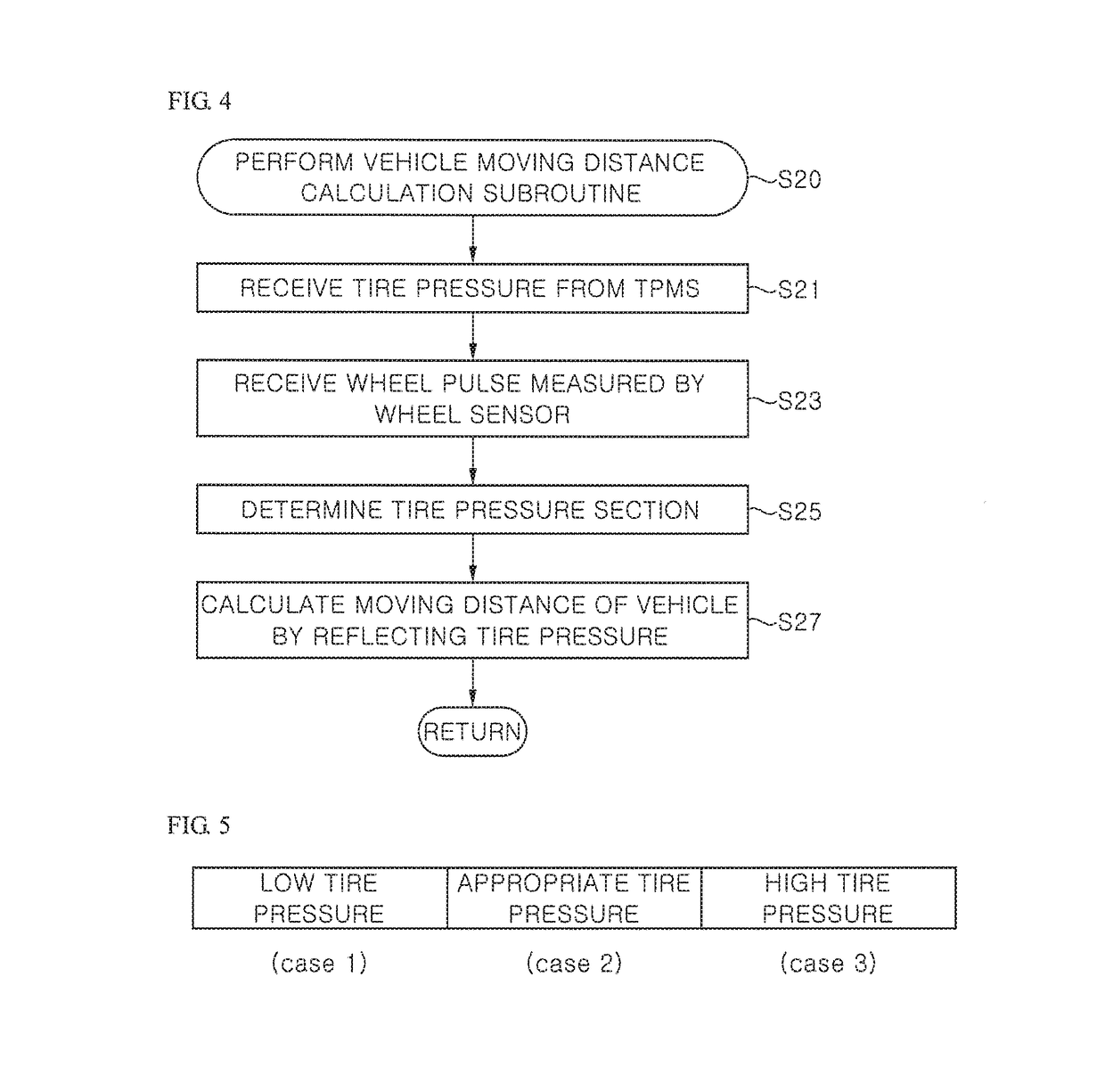

Parking assistance device using tire pressure monitoring system

ActiveUS20170297385A1Improve vehicle performanceImproving automatic parking performance of vehicleInstruments for road network navigationSteering partsParking spaceTire-pressure monitoring system

Provided is a parking assistance device using a tire pressure monitoring system (TPMS), which accurately calculates a moving distance of a vehicle by reflecting a tire pressure received from the TPMS and performs parking control in response to a parking command generated by using a parking route and a position of the vehicle estimated by the calculated moving distance of the vehicle, thereby improving automatic parking performance of the vehicle to a parking space. The parking assistance device calculates a moving distance of a vehicle moving to a found parking space around the vehicle according to a tire pressure of the vehicle, estimates a position of the vehicle by using the calculated moving distance, and generates a parking command. The moving distance of the vehicle is calculated by using a moving distance per revolution of a tire measured and set according to a tire pressure range to which the tire pressure of the vehicle belongs, a wheel pulse of the tire of the vehicle, and a reference wheel pulse per revolution of the tire.

Owner:HL KLEMOVE CORP

Tire pressure monitoring and remote keyless entry system using asynchronous duty cycling

InactiveUS20050104715A1Total current dropMinimizing false controller wakeupsElectric signal transmission systemsDigital data processing detailsTire-pressure monitoring systemEmbedded system

A device and method detects two different types of data, such as tire pressure monitoring system (TPMS) data and remote keyless entry (RKE) data and reduces current draw by duty cycling a receiver in the device asynchronously to intersperse multiple RKE sniffing periods in between consecutive, longer TPMS / RKE sniffing periods. The asynchronous duty cycle ensures that the sniffing periods conform to the actual length of the RKE data and TPMS data periods more closely, minimizing the likelihood of false wakeups caused by noise output by the receiver.

Owner:CONTINENTAL AUTOMOTIVE SYST INC

Tire pressure monitoring system

ActiveUS20050132792A1Simple and efficient processAvoid controlOptical signallingTyre measurementsTire-pressure monitoring systemAutomotive engineering

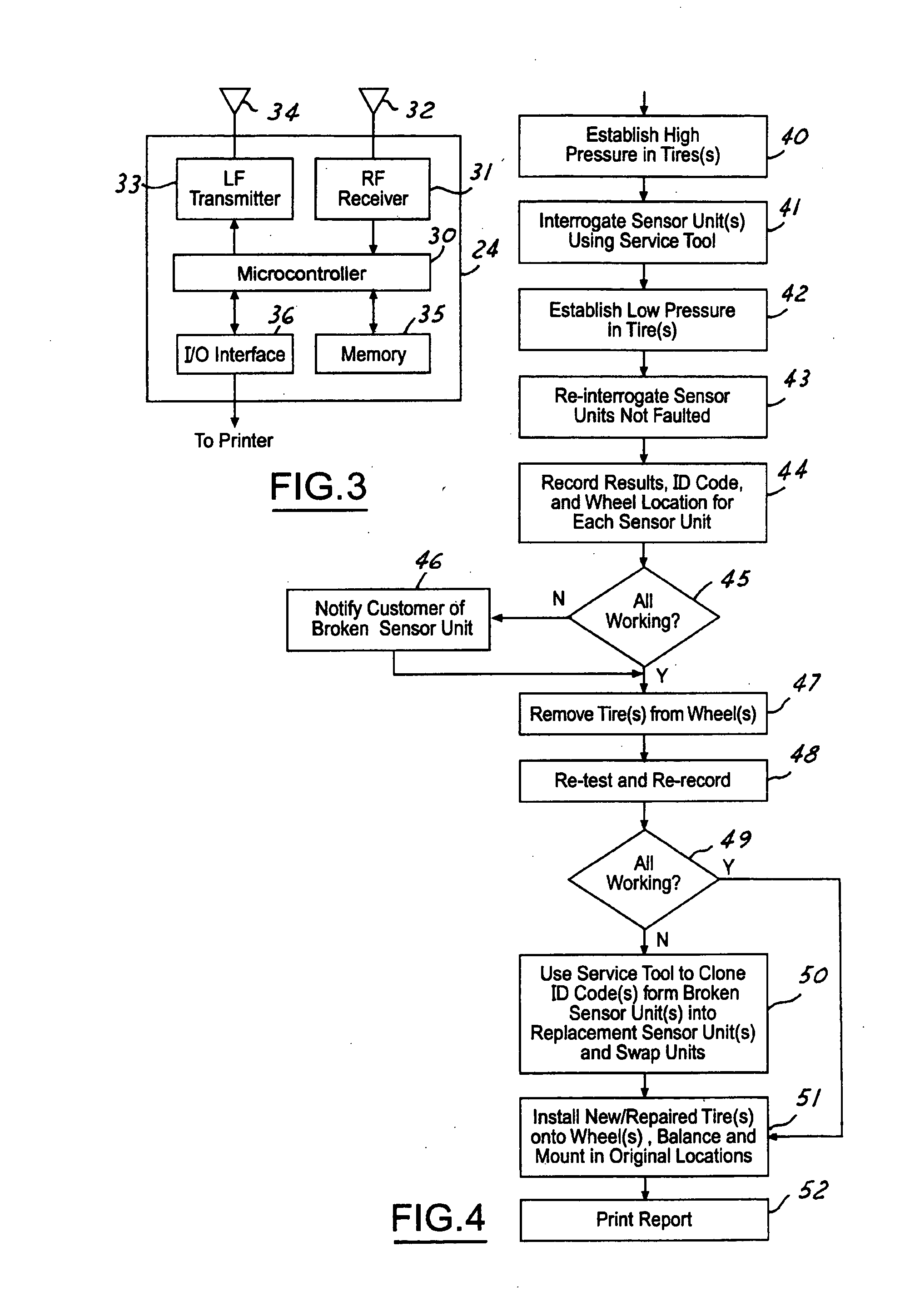

A method is provided for replacing at least one tire of a vehicle on a first wheel in a first wheel position, the vehicle having a tire pressure monitoring system with a first sensor unit having a first ID code mounted to the first wheel. The first sensor unit is interrogated. Either a nominal result or a faulted result of the interrogation is detected. The at least one tire is removed from the first wheel. If the nominal result is detected during the interrogating step, then the first sensor unit is re-interrogated. Either a nominal result or a faulted result of the re-interrogation is detected. If either of the interrogation or the re-interrogation provide a faulted result then the first ID code is cloned into a replacement sensor unit and then the replacement sensor unit is swapped for the first sensor unit on the first wheel. A new tire is installed onto the first wheel. The first wheel is installed onto the vehicle in the first wheel position.

Owner:SENSATA TECHNOLOGIES INC

Tire pressure monitor system tool with vehicle entry system

A tire pressure monitor system tool is capable of communicating with a plurality of tire pressure monitor systems. The tool includes a storing module that stores a plurality of communication protocols that are used for enabling the tool to communicate with a tire pressure monitor system. The tool enables a user to input vehicle data for identifying a vehicle having a tire pressure monitor system with which to communicate. Based on the vehicle data input, the tool determines a tire pressure monitor system installed on the vehicle using information stored by the tool. The tool determines a tire pressure monitor system installed on the vehicle. Based on the tire pressure monitor system installed on the vehicle, the tool determines a protocol used by the tire pressure monitor system to communicate with, for example, the tool and an electronic control unit of a vehicle.

Owner:BOSCH AUTOMOTIVE SERVICE SOLUTIONS

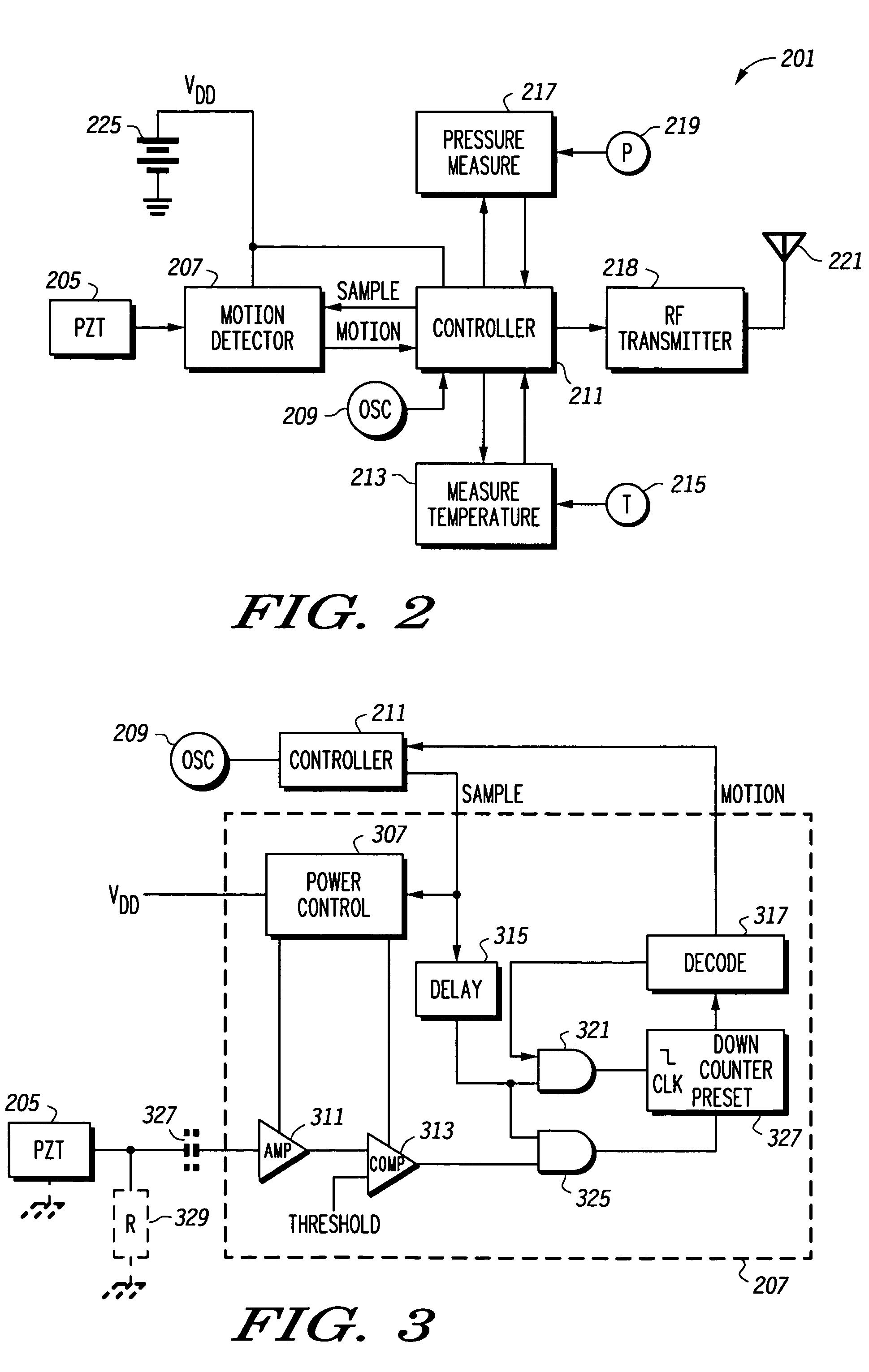

Motion sensing for tire pressure monitoring

ActiveUS7040154B2Fluid pressure measurement by mechanical elementsTyre measurementsElectricityHigh rate

Owner:NXP USA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com