Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50 results about "Retread" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Retread, also known as "recap", or a "remold" is a re-manufacturing process for tires that replace the tread on worn tires. Retreading is applied to casings of spent tires that have been inspected and repaired. It preserves about 90% of the material in spent tires and the material cost is about 20% compared to manufacturing a new one.

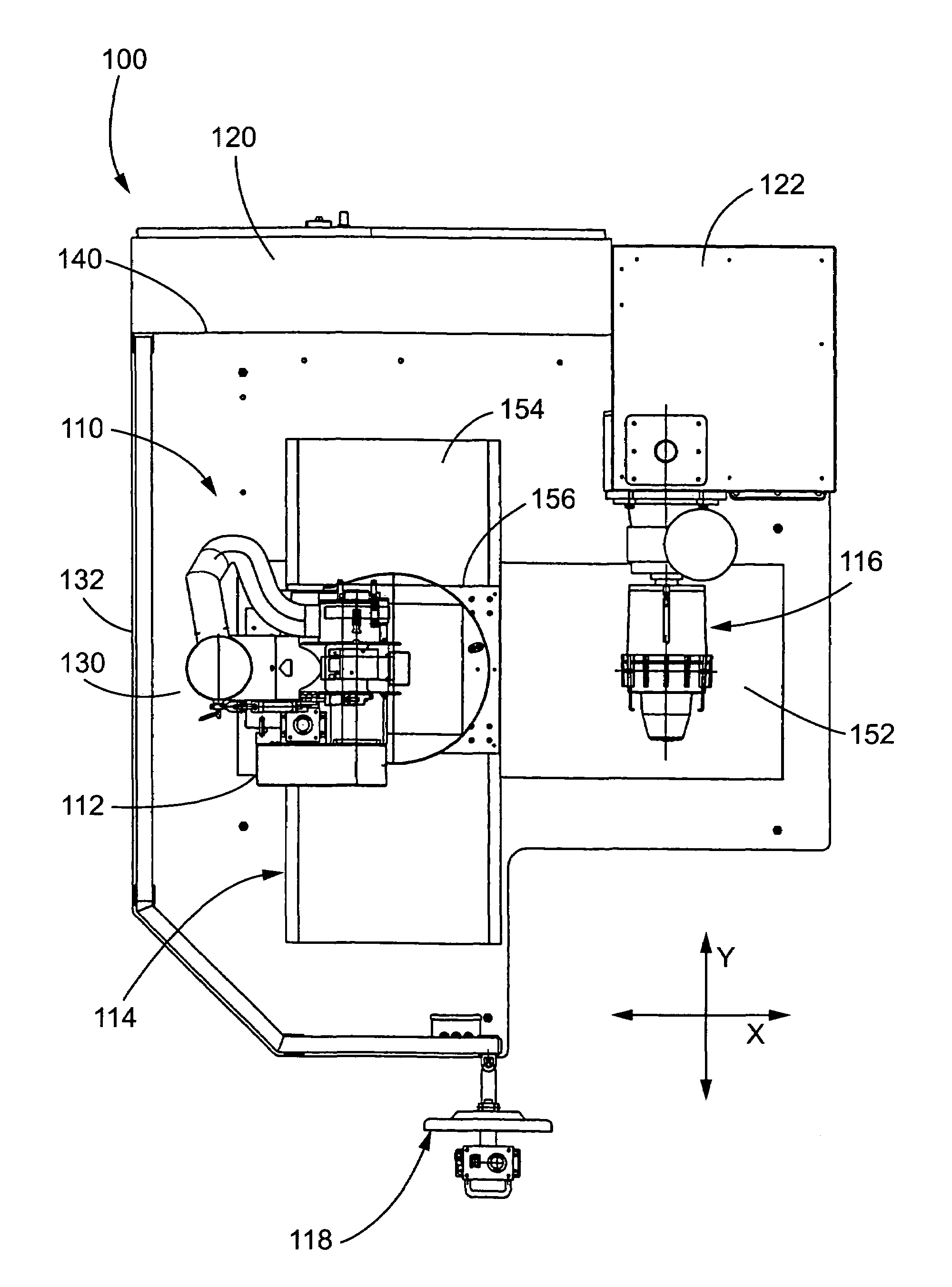

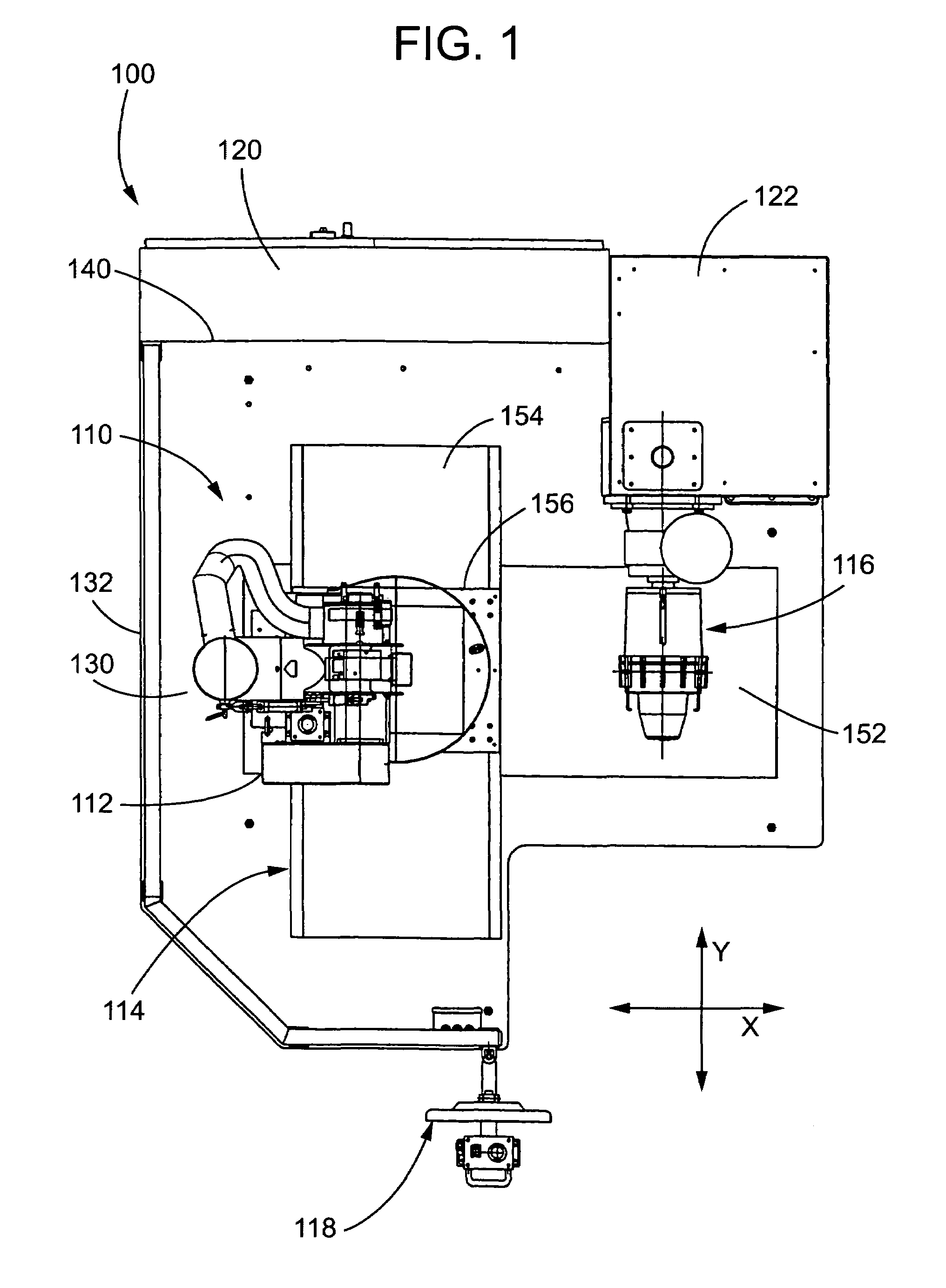

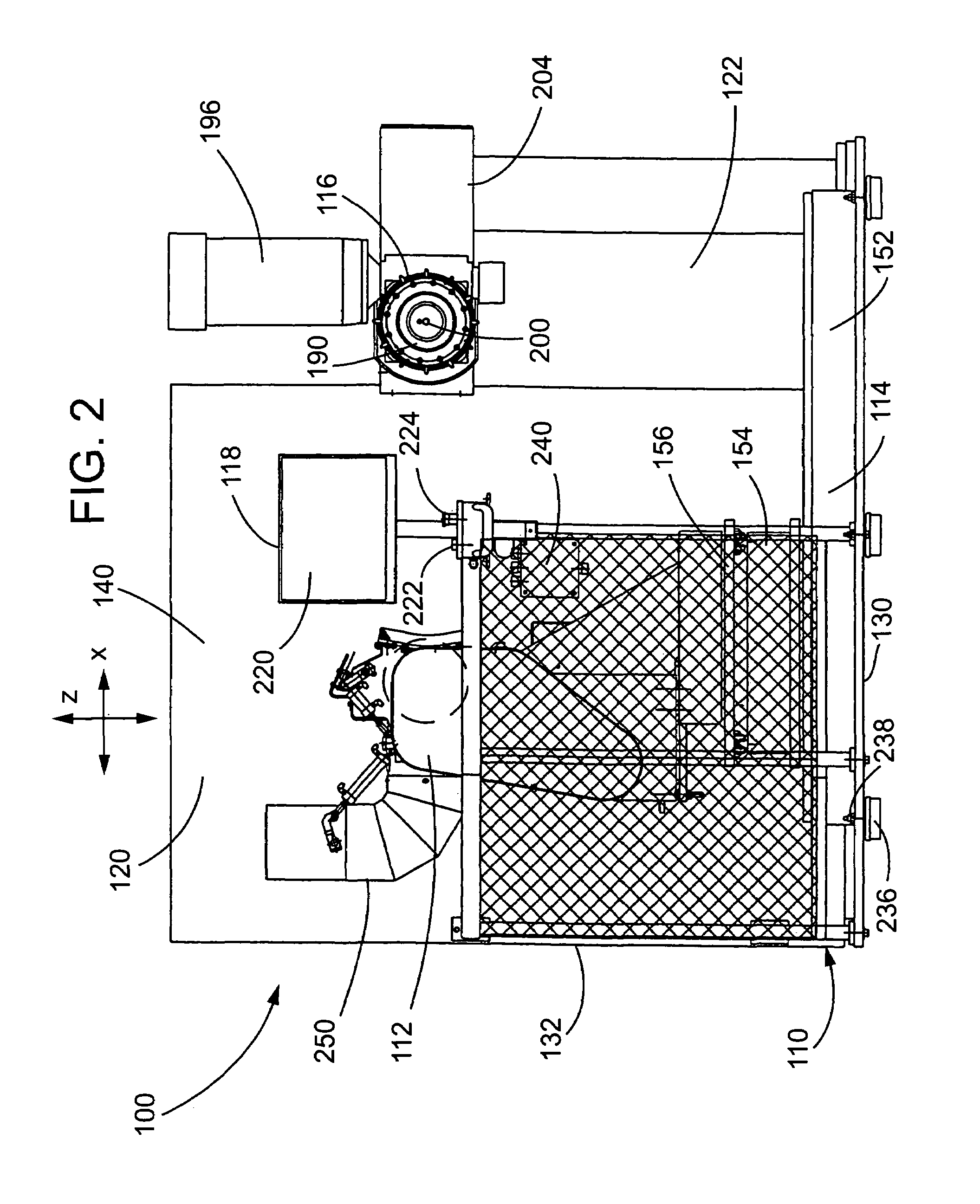

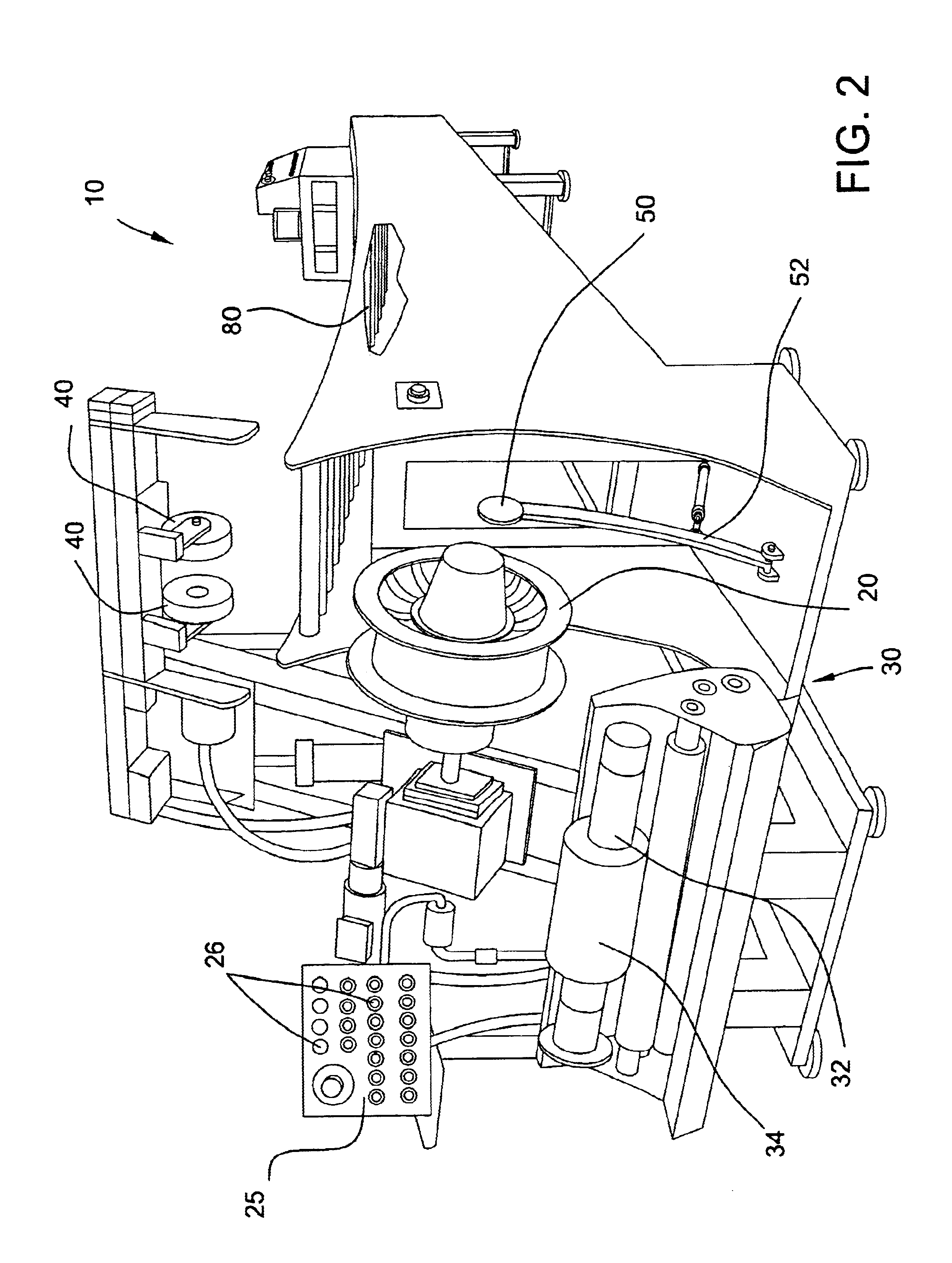

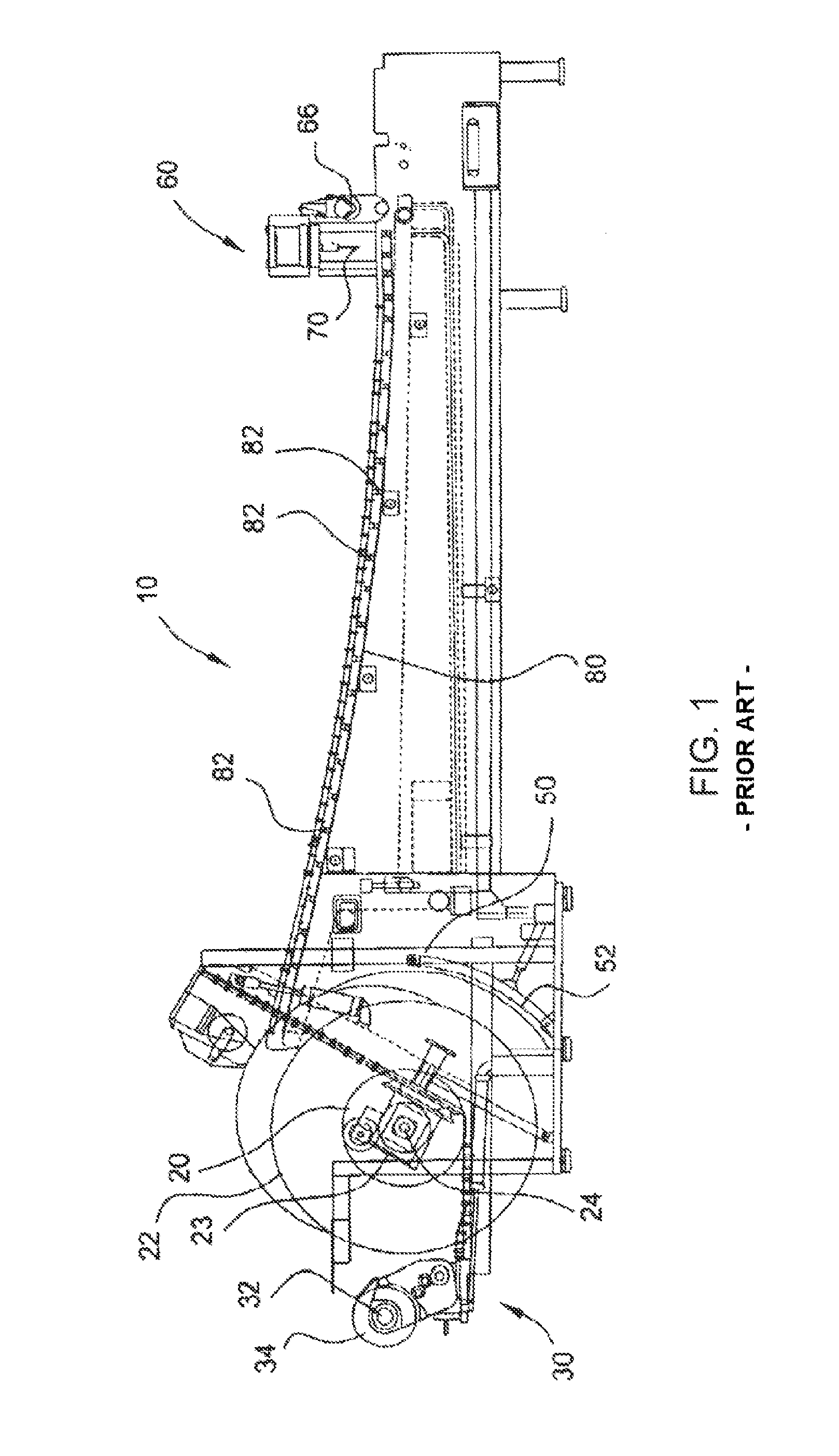

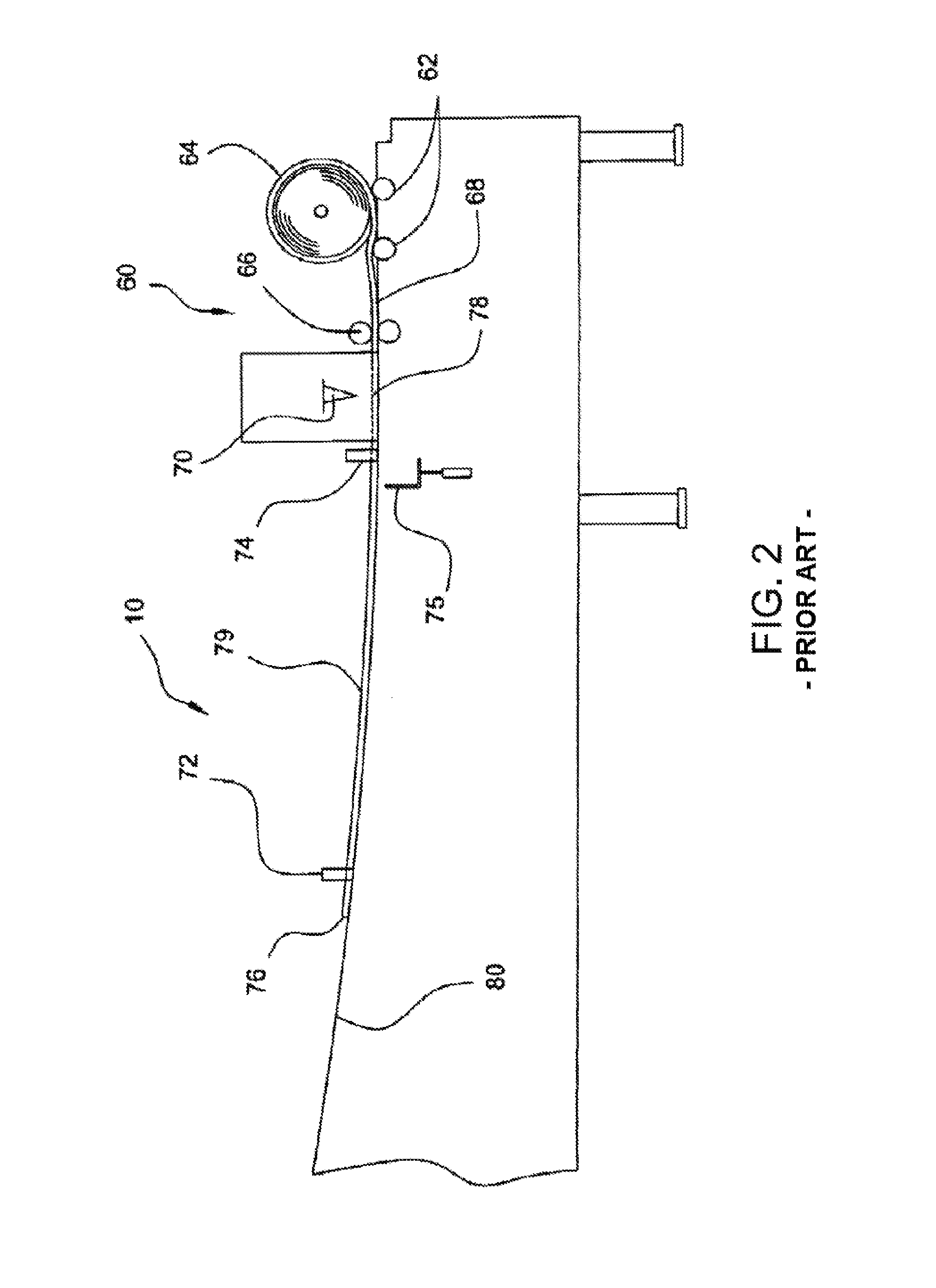

Tire buffing apparatus

InactiveUS7040371B2Consistent texture profileIncrease productionRevolution surface grinding machinesTyresRaspEngineering

A tire buffer for buffing a tire casing as part of a retread operation can include a rasp pedestal having a rasp head and a texturing device. A moving assembly can be connected to the rasp pedestal for selectively moving the rasp pedestal along a pair of perpendicular axes. The rasp pedestal can rotate about a vertical axis. A tire hub assembly can be included for rotating the tire casing. The tire buffer can be operated at an operator station by interfacing with a control unit. The tire buffer can automatically buff a tire casing to achieve a predetermined tire casing profile and impart a texture thereto. The tire buffer includes a tire location mechanism and a tire measurement mechanism mounted to the rasp pedestal. The control unit can monitor an operating parameter of the rasp pedestal or the tire hub assembly during the buffing sequence, compare the actual value of the operating parameter to a predetermined target value of the parameter, and adjust an operating characteristic of the rasp pedestal, the tire hub assembly, or both such that the actual value of the operating parameter is urged toward the calculated target value of the operating parameter.

Owner:BANDAG INC

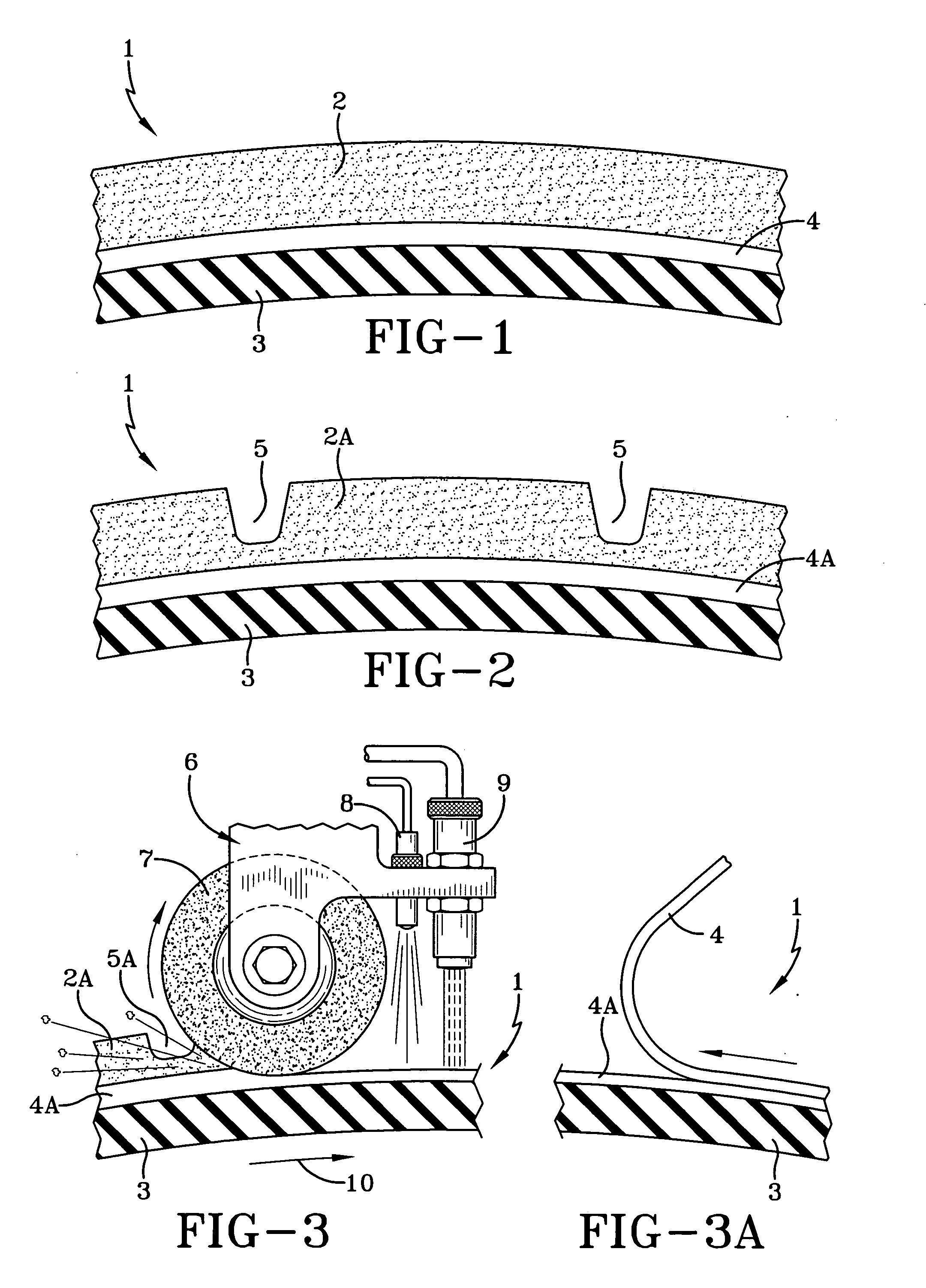

Tire with detectable carcass cushion layer and use thereof to facilitate tire carcass retreading

InactiveUS20050211351A1Thorough removalLamination ancillary operationsSpecial tyresAdhesiveEngineering

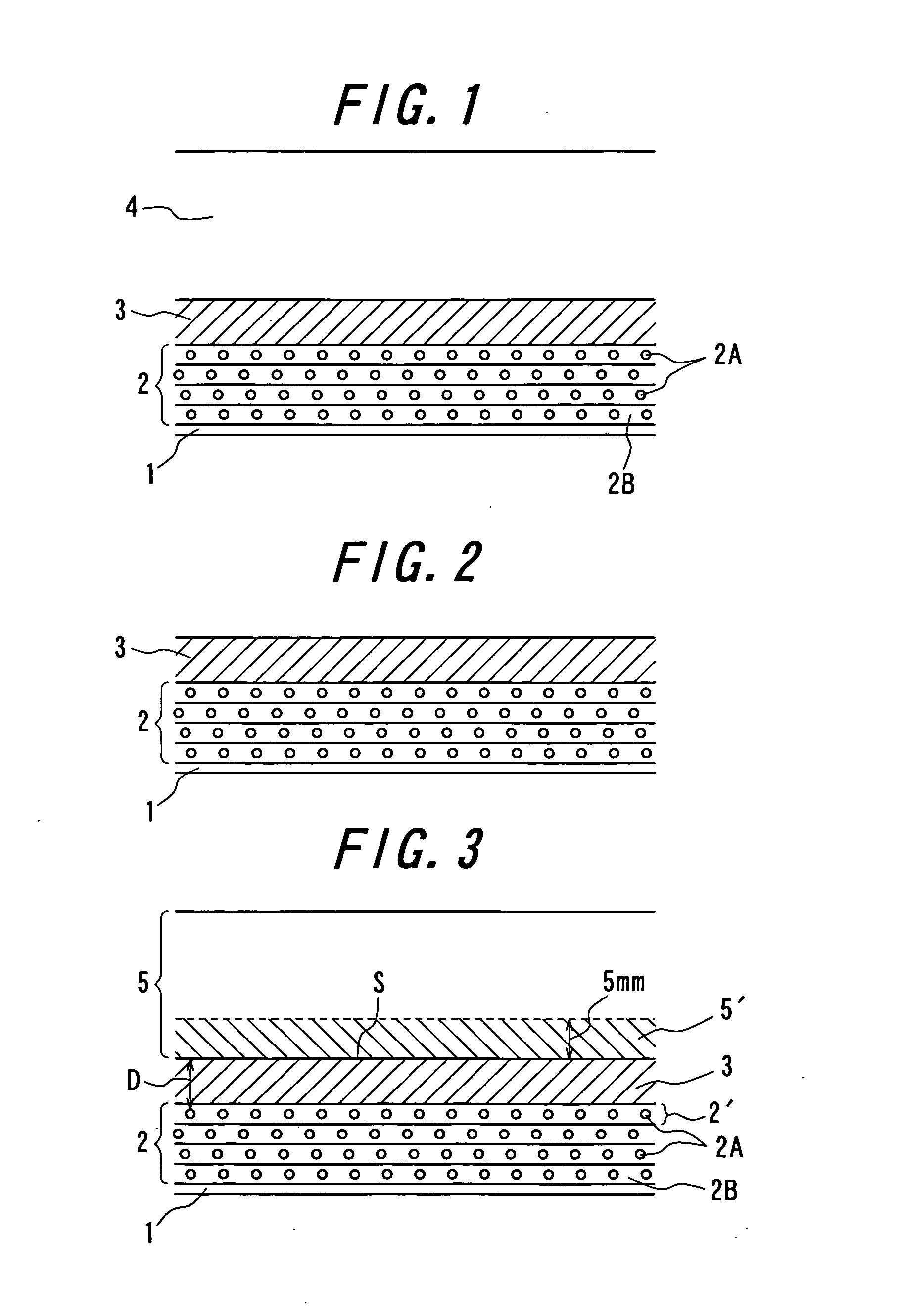

This invention relates to a retreadable tire which contains a non-black colored rubber carcass cushion layer sandwiched between its tire tread and tire casing. The non-black colored rubber carcass cushion layer acts both as an adhesive and transition layer for adhering a cured or uncured tire tread to the cured tire carcass. Such carcass cushion layer also acts as a detectable color indictor for indexing and monitoring a complete removal (e.g. by buffing, abrading, or cutting) of the circumferential rubber tire tread and partial removal of the carcass cushion layer without removing the entire carcass cushion layer. The invention also relates to a method of retreading a cured rubber tire carcass by completely removing a circumferential, carbon black reinforced (and therefor a black colored) tire rubber tread together with a partial removal of the contrastingly colored cured rubber carcass cushion layer to a depth indexed and / or determined by an automated rubber cushion layer color sensing means, or apparatus, followed by applying a non-black colored uncured circumferential rubber carcass cushion layer and carbon black reinforced (therefore black colored) tire tread thereon to form an assembly thereof and vulcanizing the assembly in a suitable mold to form a retread tire.

Owner:MAJUMDAR RAMENDRA NATH +2

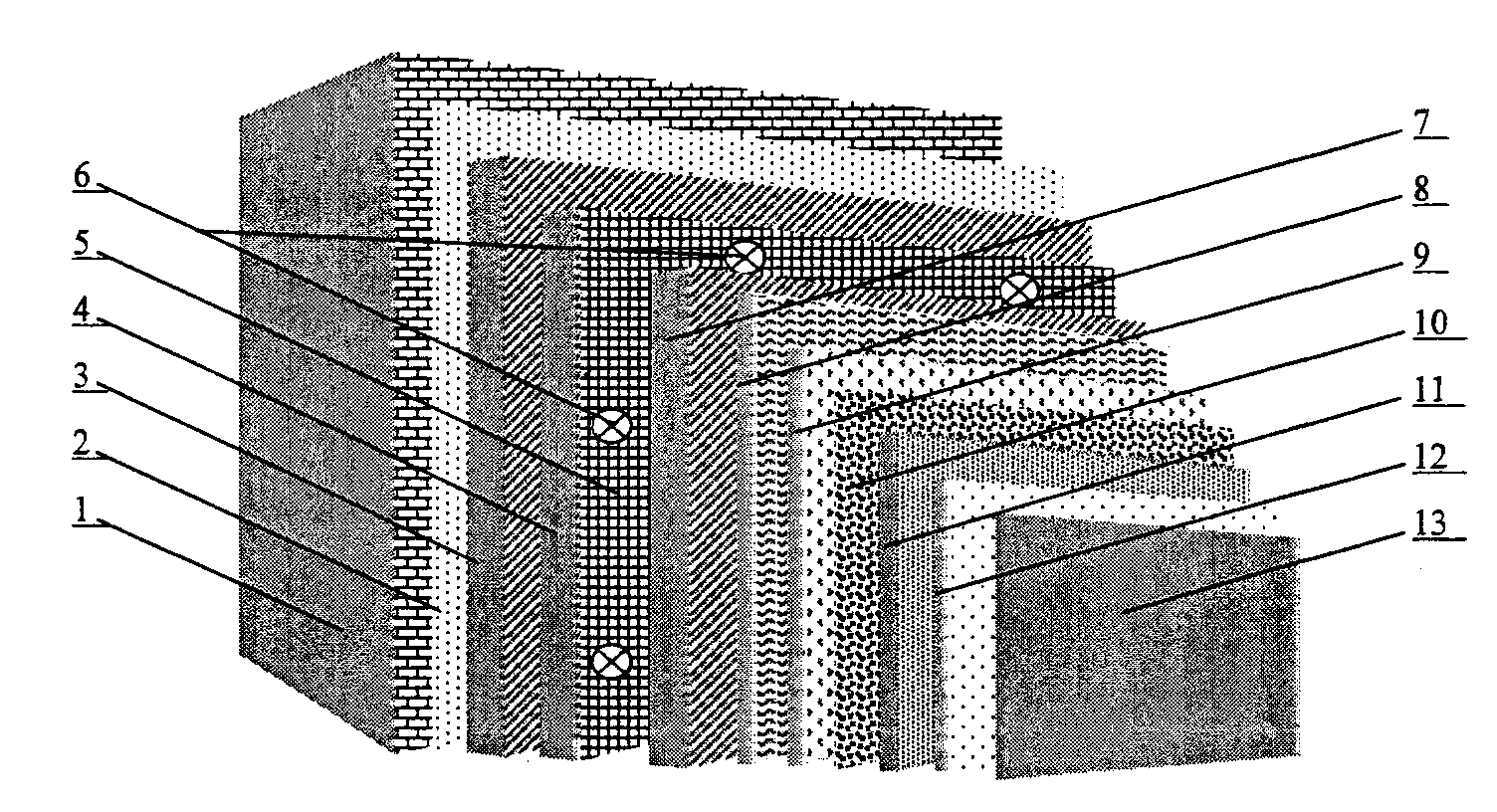

Method for retreading old porcelain brick wall by paint

InactiveCN101586401AAvoid crackingImprove water resistanceCovering/liningsBuilding repairsGlass fiberBrick

The invention relates to a method for retreading the old porcelain brick wall by the paint, a retreading decorative layer composed of a interface binder layer (2), a first polymer cracking-resistant putty layer (3), a second polymer cracking-resistant putty layer (4), a glass fiber girding cloth (5), a third polymer cracking-resistant putty layer (7), a double-component flexible putty layer (9), a smooth surface putty layer (9), a seal coat layer (10), a middle coating layer (11), a flexible silicone-acrylate latex paint layer (12) and a fluoric-carbon coating varnish layer (13) is formed on the old wall surface porcelain brick of the old wall (1), an anchor nail (6) passes through the glass fiber gridding cloth (5), the second polymer cracking-resistant putty layer (4) and the first polymer cracking-resistant putty layer (3) and is embedded in the old wall (1) for the mechanical reinforcement, all layers above are dried and solidified and are integrated with the old wall (1) firmly to complete the retread of the old wall surface. The construction cost and the labor strength are low, the old porcelain brick on the wall surface can not fall off, the decorative is high.

Owner:CHINA NAT OFFSHORE OIL CORP +2

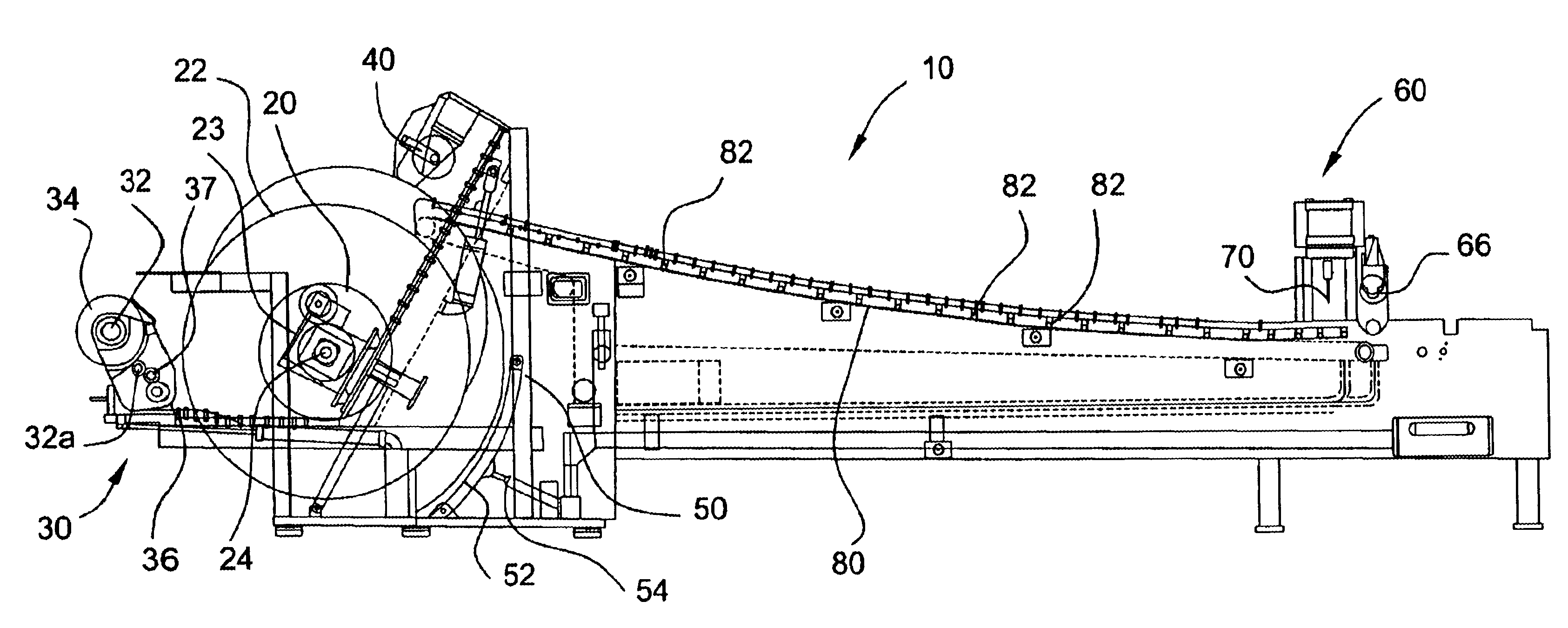

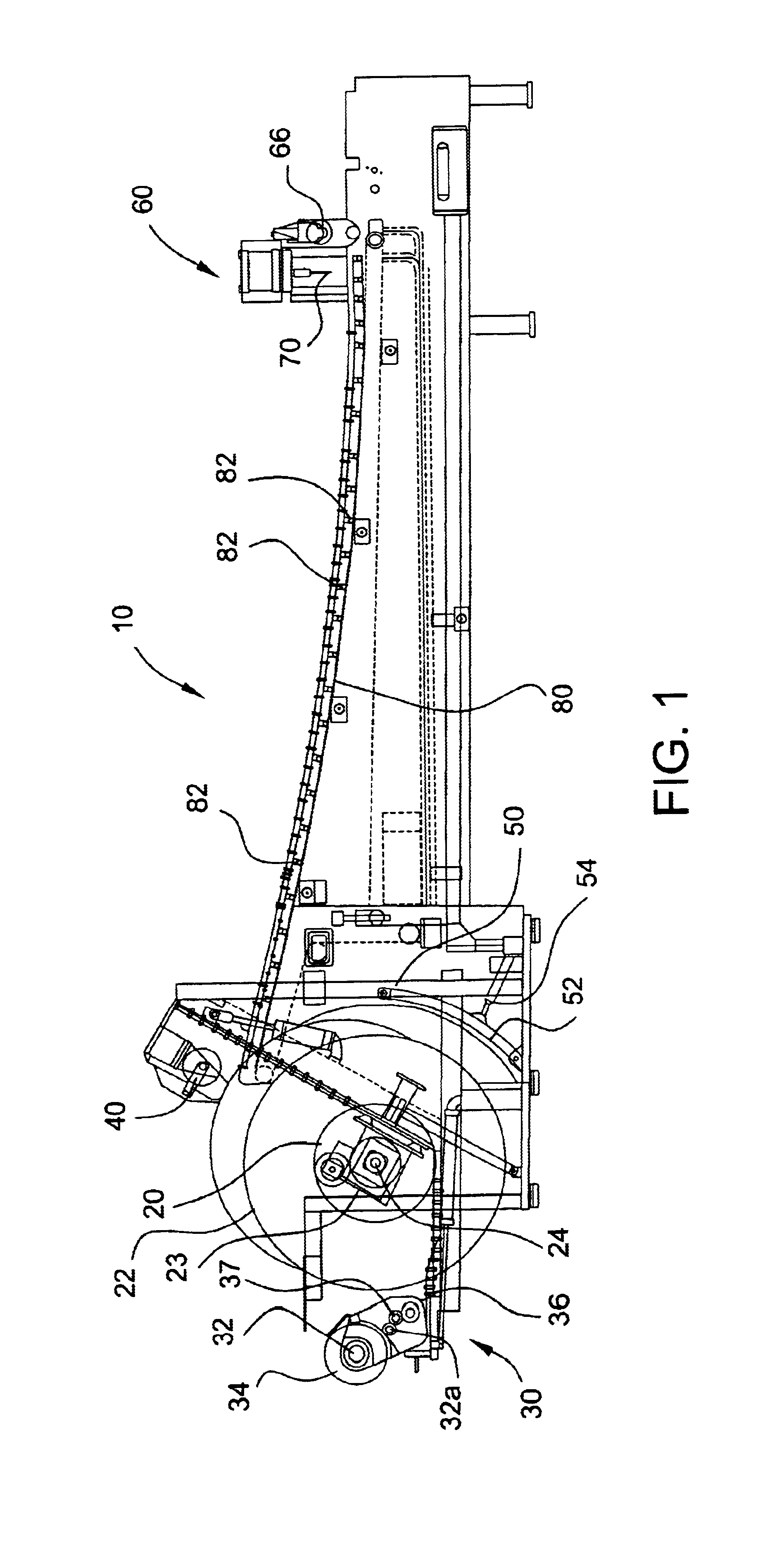

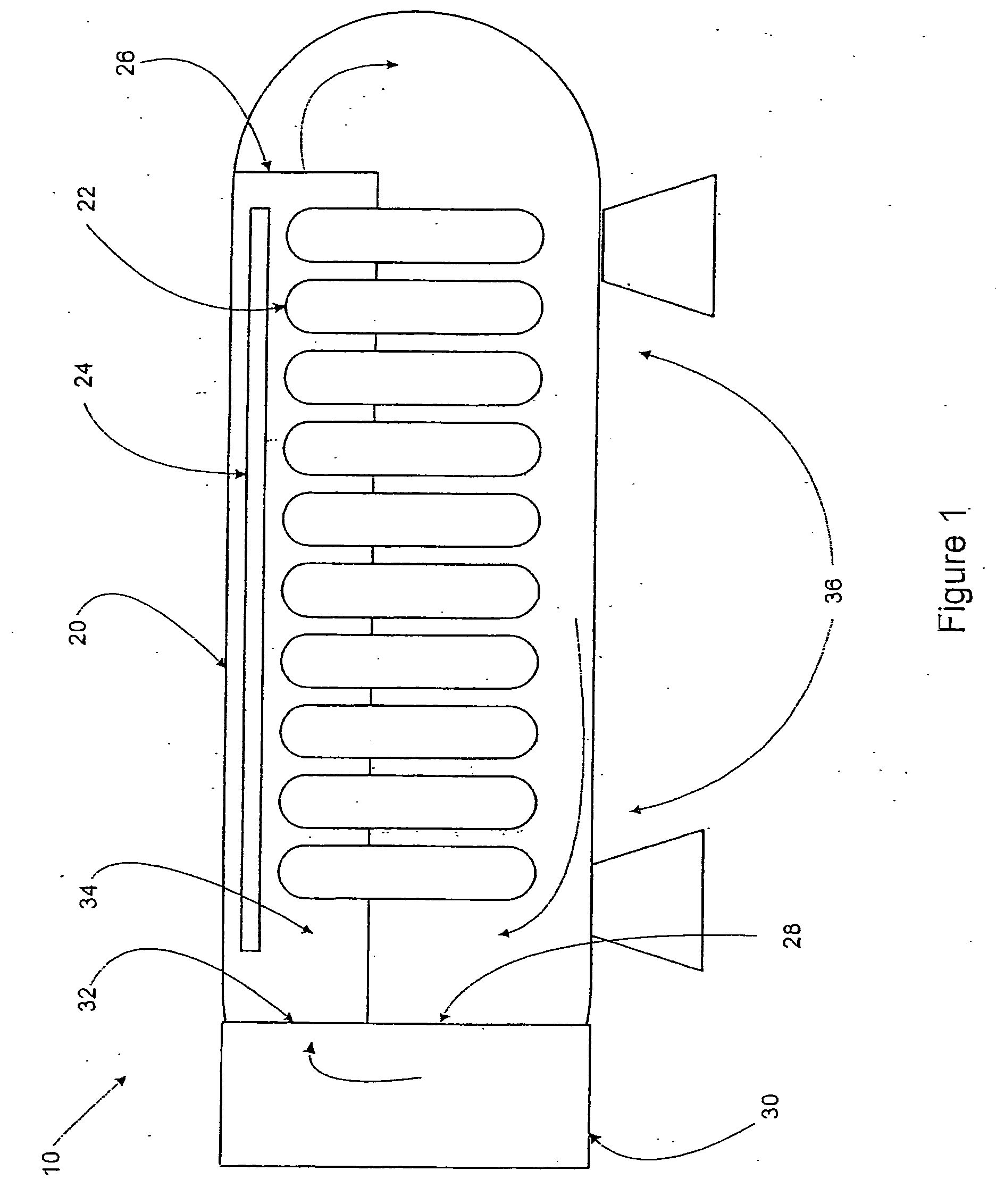

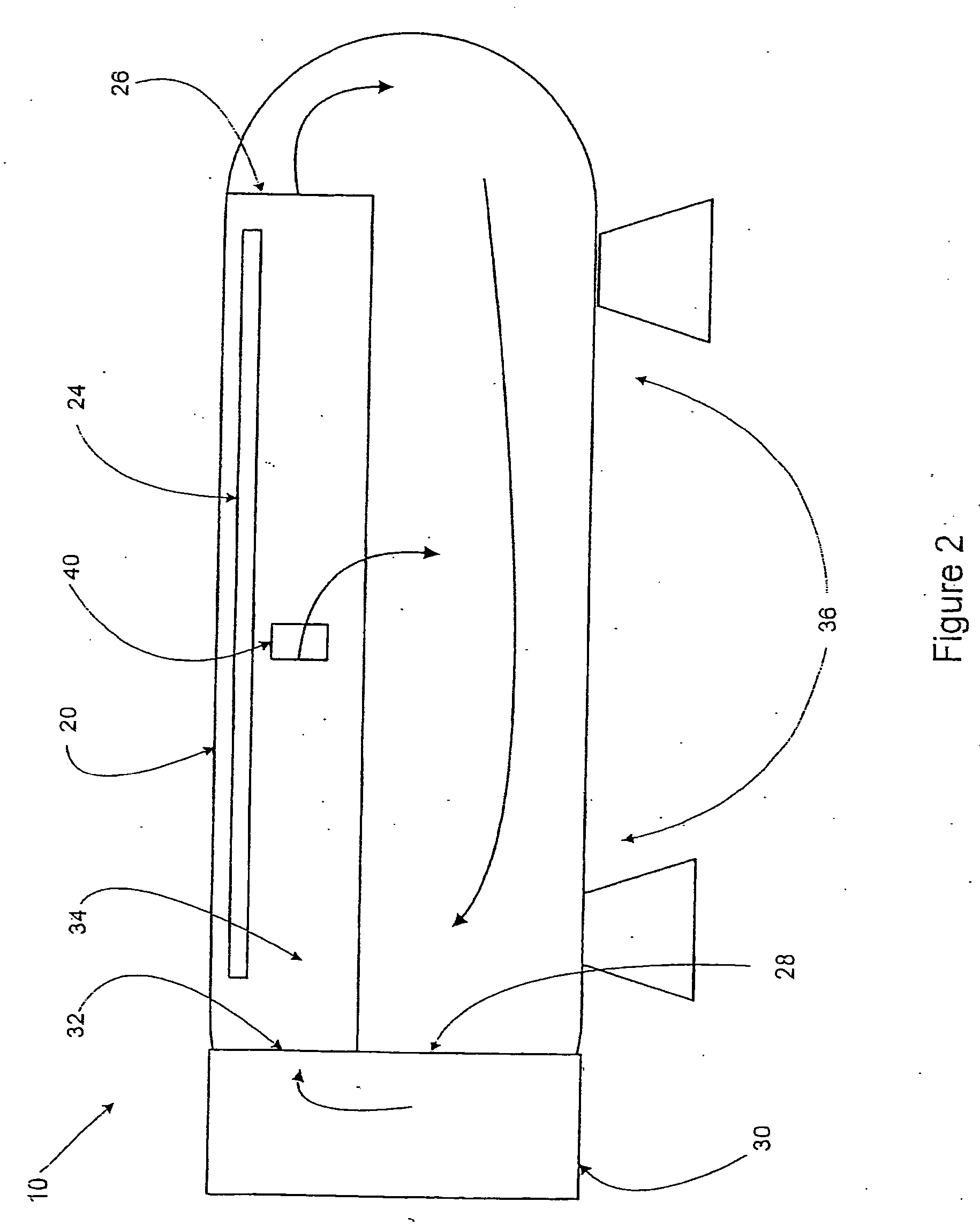

Method and apparatus for preparing tire tread for a retread tire

An apparatus for retreading tires is disclosed. The apparatus has a rotatable hub for the mounting of a buffed tire casing. The apparatus also has a cushion gum applicator that is configured to stretch a length of cushion gum onto a tire casing. Further, the apparatus has a tread dispenser that is configured to automatically dispense a length of tire tread based on the circumference of at least one of the tire casing and the tire casing plus the cushion gum. Further still, the apparatus includes a tread applicator that is configured to stretch the length of tire tread onto the cushion gum. The entire apparatus including the cushion gum applicator, the tread dispenser, and the tread applicator are integrated into a single tire bench machine.

Owner:BANDAG INC

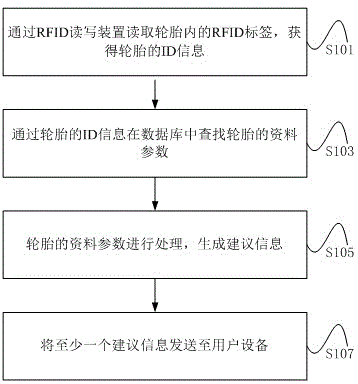

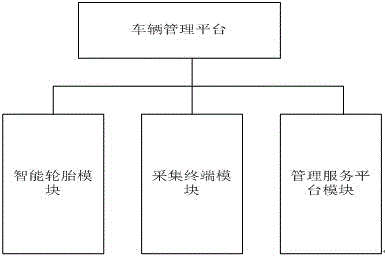

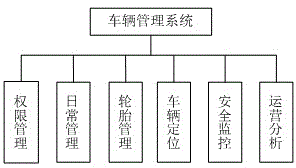

Vehicle tyre management method and device for internet of vehicles

The invention discloses a vehicle tyre management method and a device for the internet of vehicles. The method comprises the steps of reading an RFID tag inside a tyre by an RFID read-write device to acquire the ID information of the tyre; based on the ID information of the tyre, searching the data parameters of the tyre in a database, wherein the data parameters are composed of at least one of the following parameters: the basic data of the tyre, the quality condition of the tyre, the pressure of the tyre, the usage time, the driving mileage and the retread number of times; processing the data parameters of the tyre to generate the suggestion information, wherein the suggestion information is composed of at least one of the following parameters: the retread time of the tyre, the maximum retread number of times of the tyre, the suitable road surface of the tyre, the service life of the tyre, and the maximum safety driving mileage of the tyre; and sending the at least one suggestion information to user equipment. According to the technical scheme of the invention, the problem in the prior art that since a tyre cannot be effectively monitored, the tyre is excessively utilized to be shortened in service life can be solved. Meanwhile, the problems in the prior art that the resource is wasted due to the unreasonable replacement of the tyre and the occurrence of traffic accidents due to the non-timely replacement of the tyre are also solved.

Owner:MESNAC

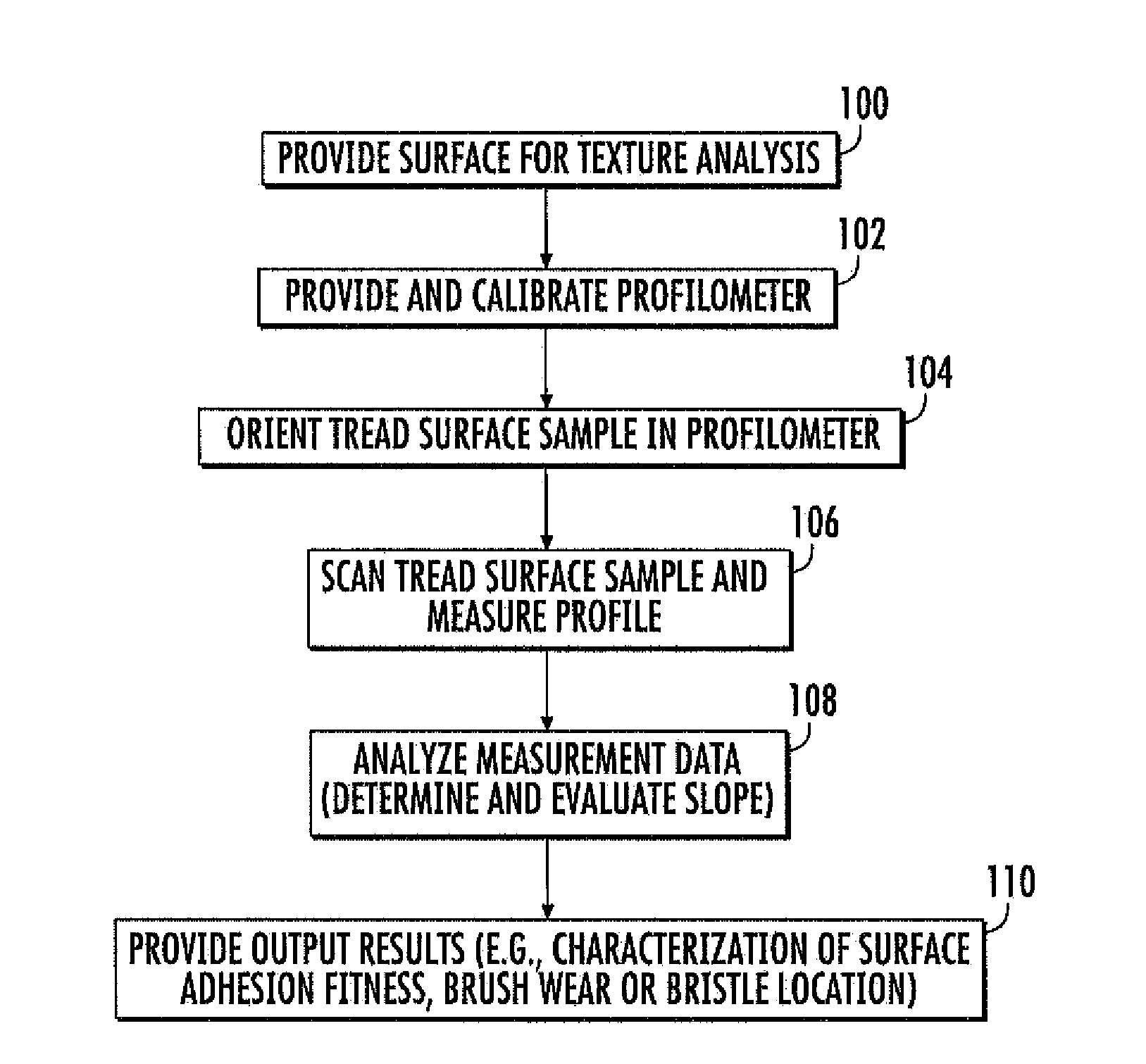

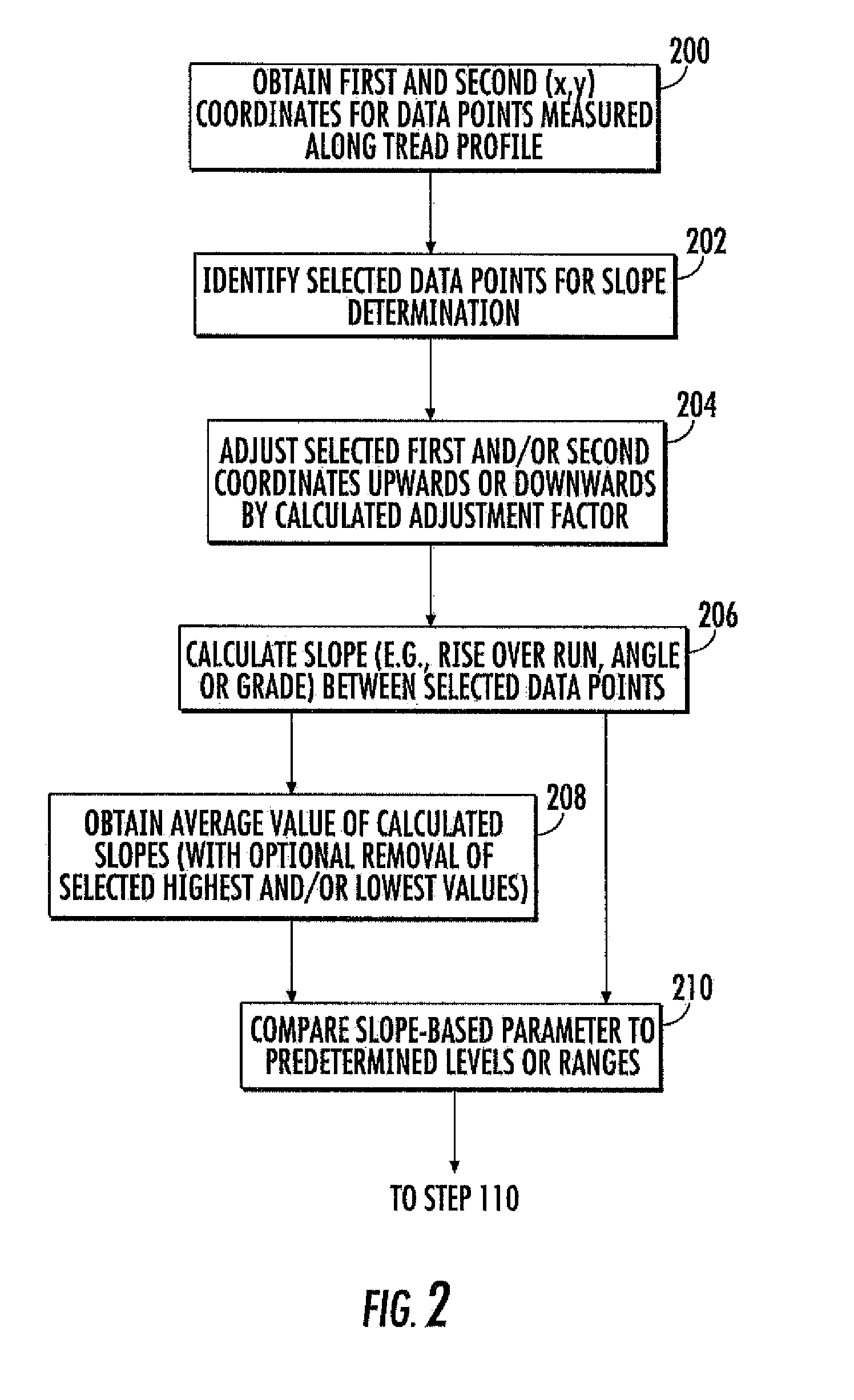

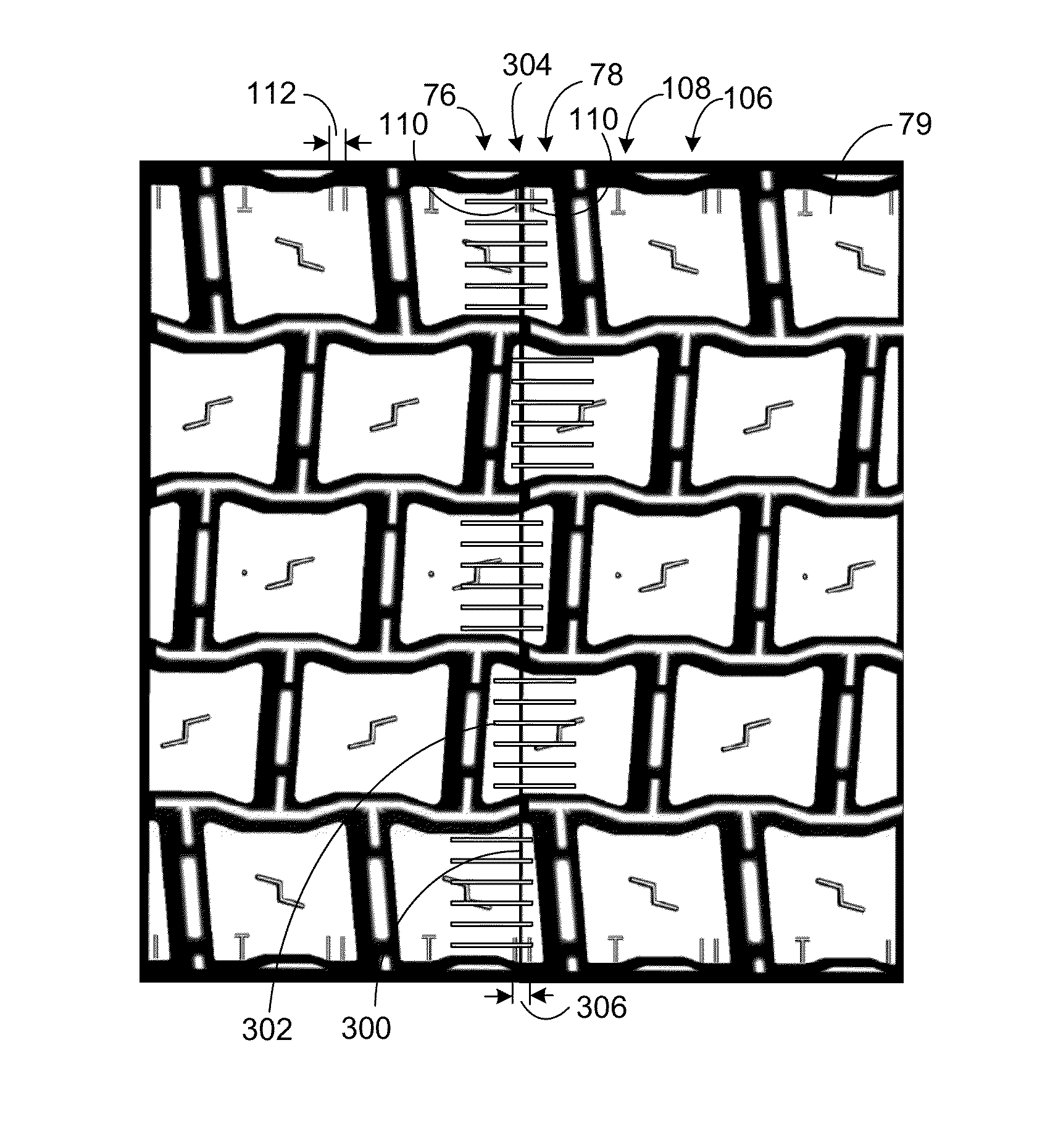

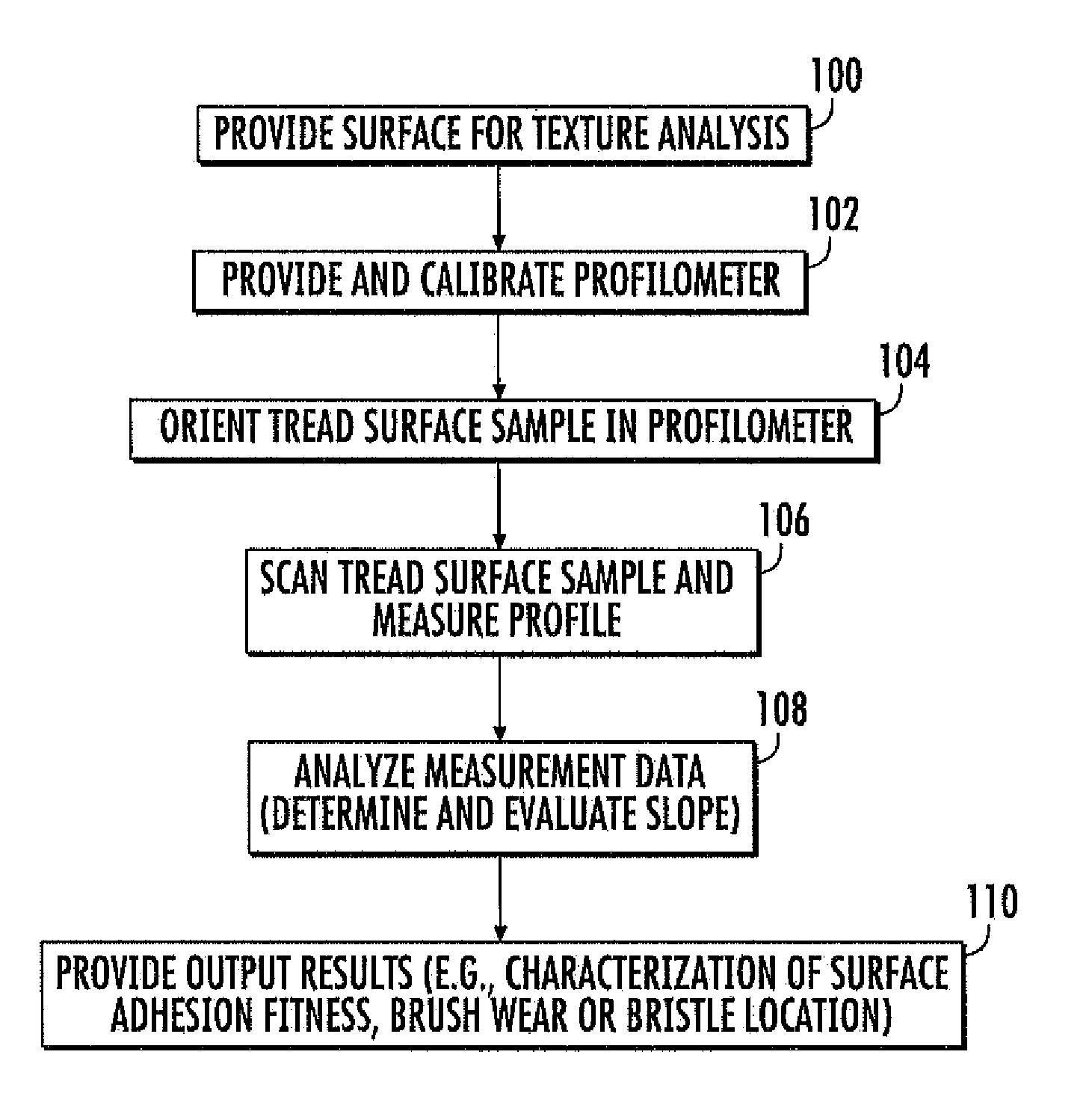

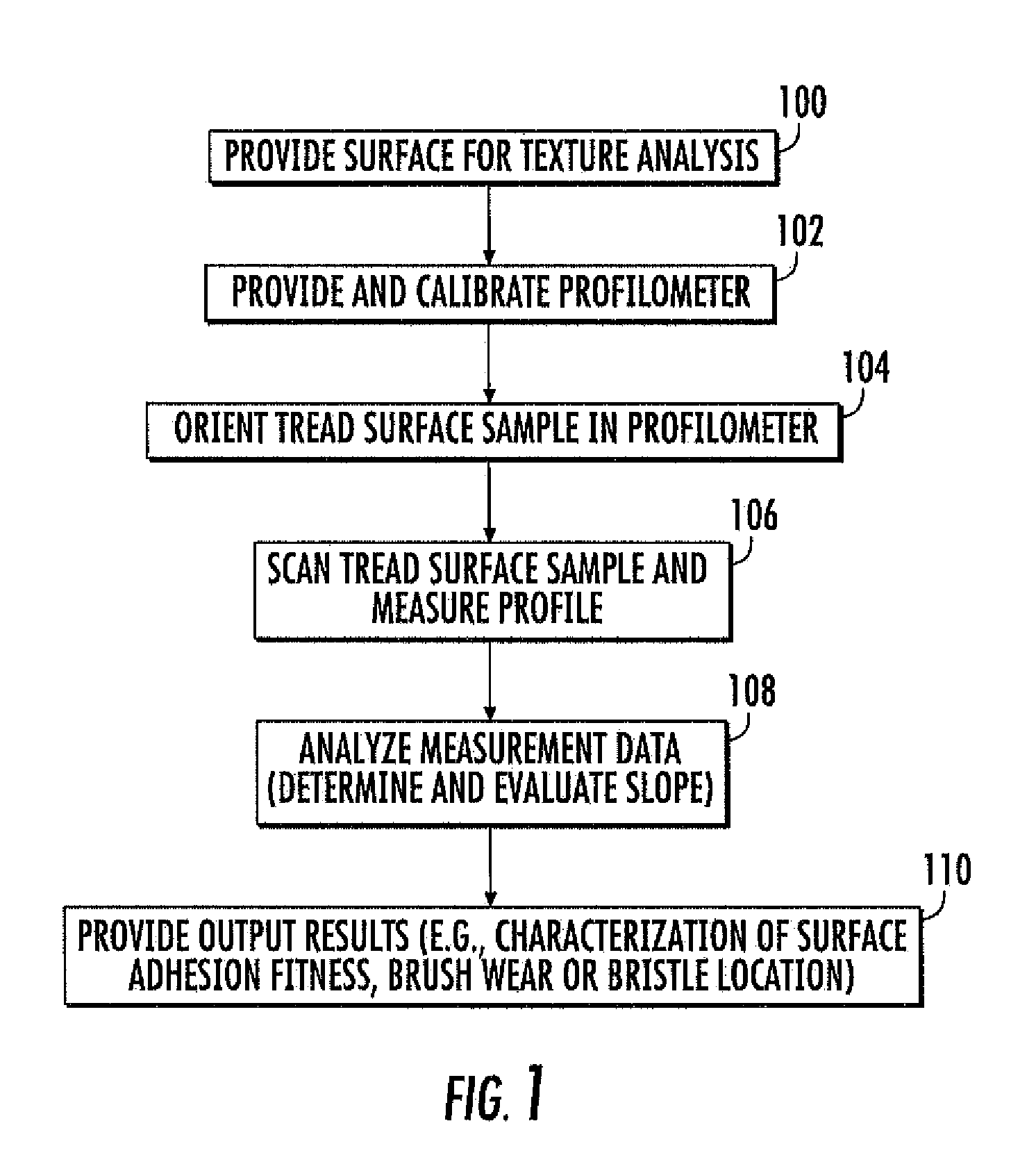

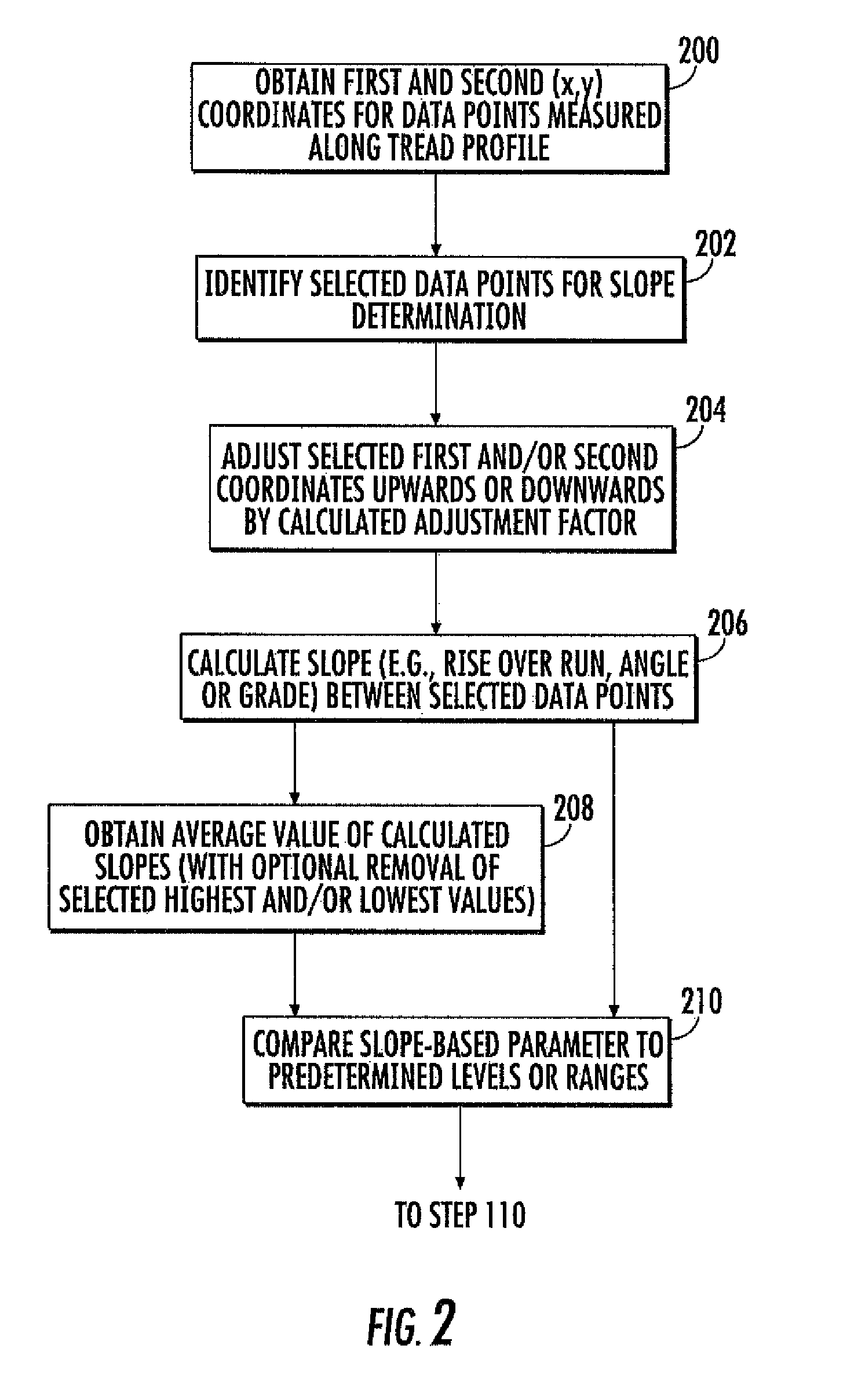

System and method for evaluating surface finish of tire retread

A measurement system scans the given surface of a tire component (e.g., a brush-finished tread or buffed tire casing) to electronically measure data points corresponding to vertical and horizontal coordinates along the given surface. Associated computer processors electronically calculate the slope at a plurality of different locations by determining the degree of steepness (e.g., rise over run, angle or grade) between selected ones of the first and second coordinates and electronically comparing at least one slope-based parameter to one or more predetermined levels to determine a characterization defining one or more of surface adhesion fitness, finishing brush wear level and brush bristle placement location. Slope may be determined between every adjacent pair of data points or between selected data points (e.g., identified local maximum and minimum). The at least one-slope based parameter compared to the predetermined levels may correspond to the slopes themselves or to a calculated average slope value.

Owner:MICHELIN RECH & TECH SA +1

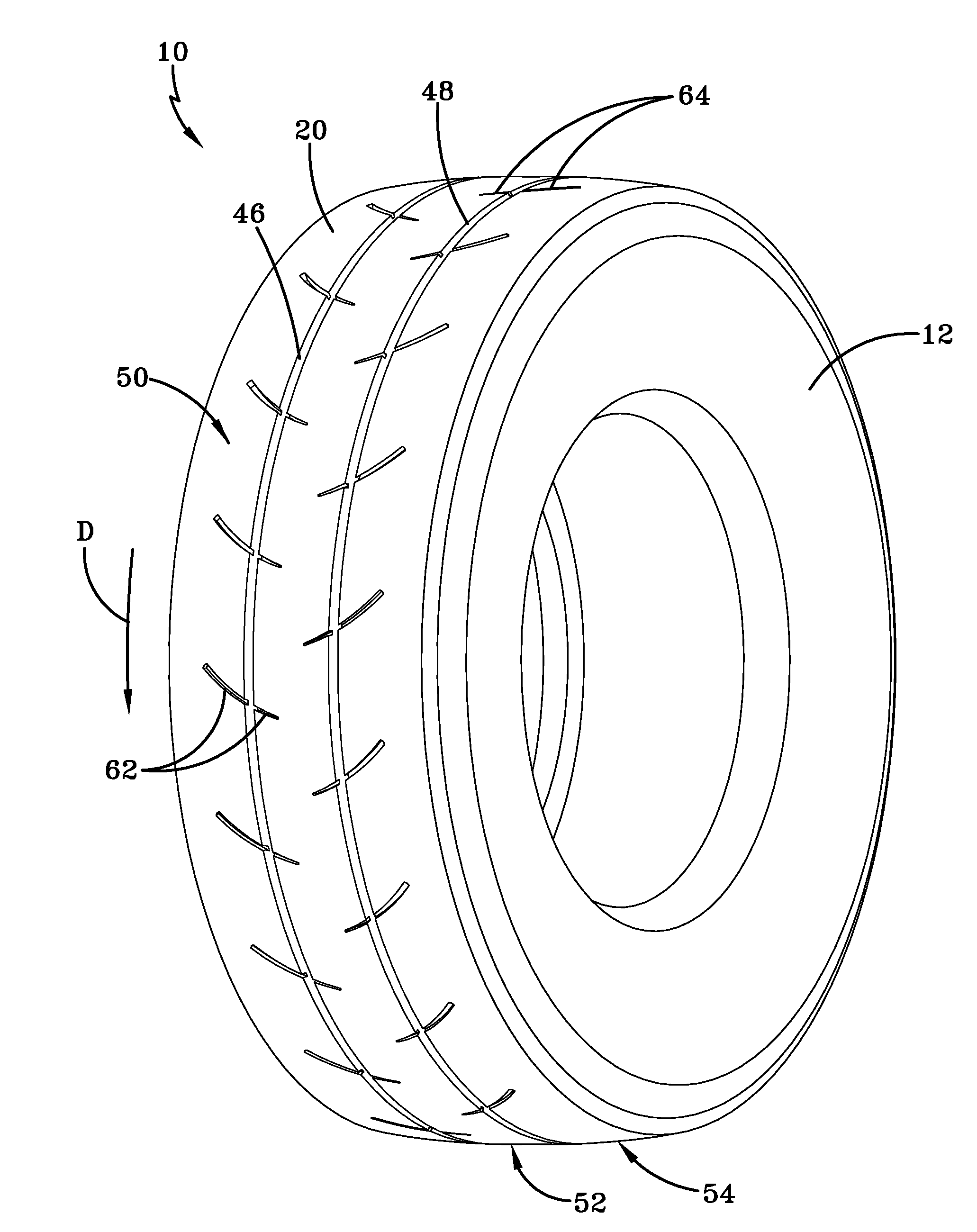

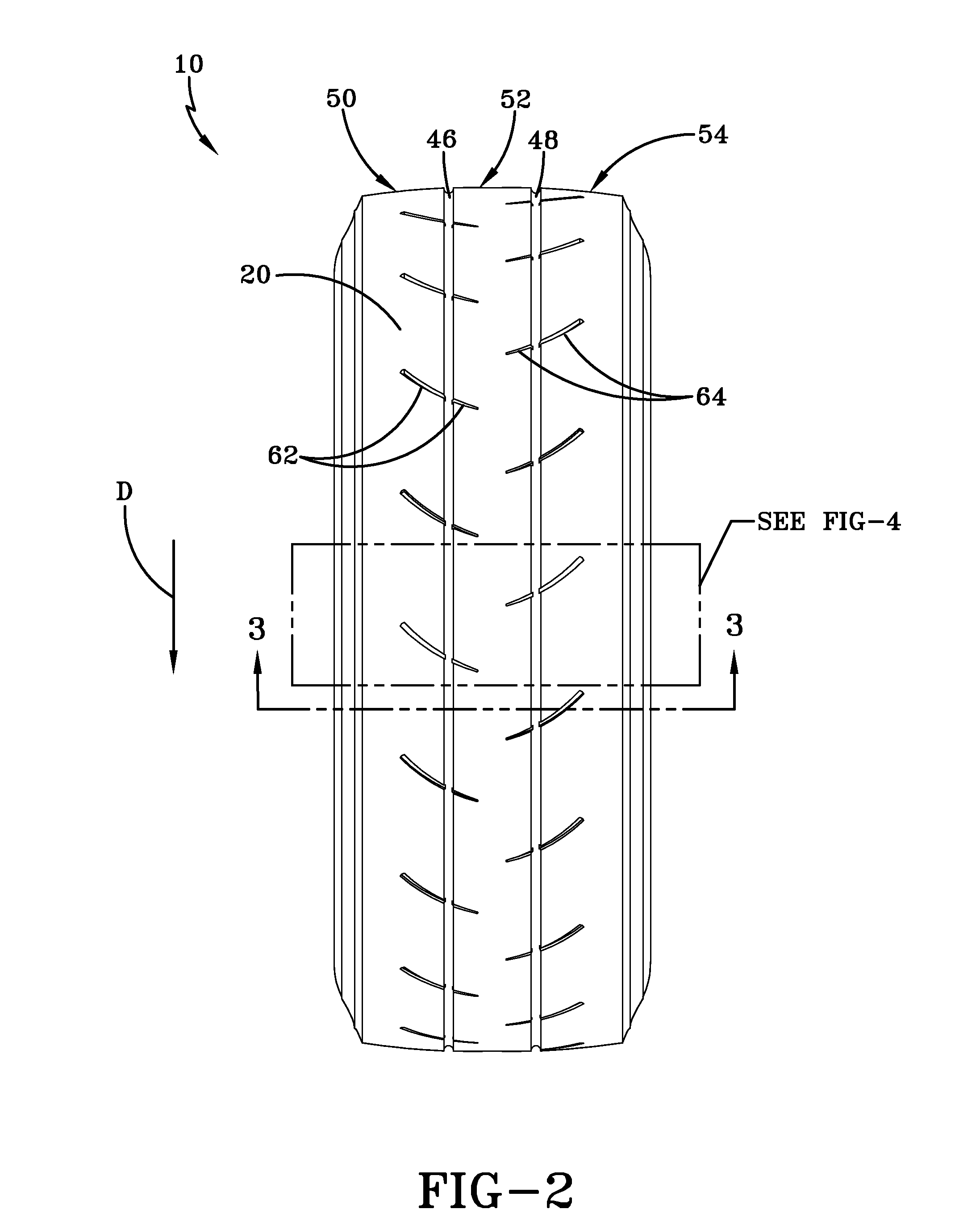

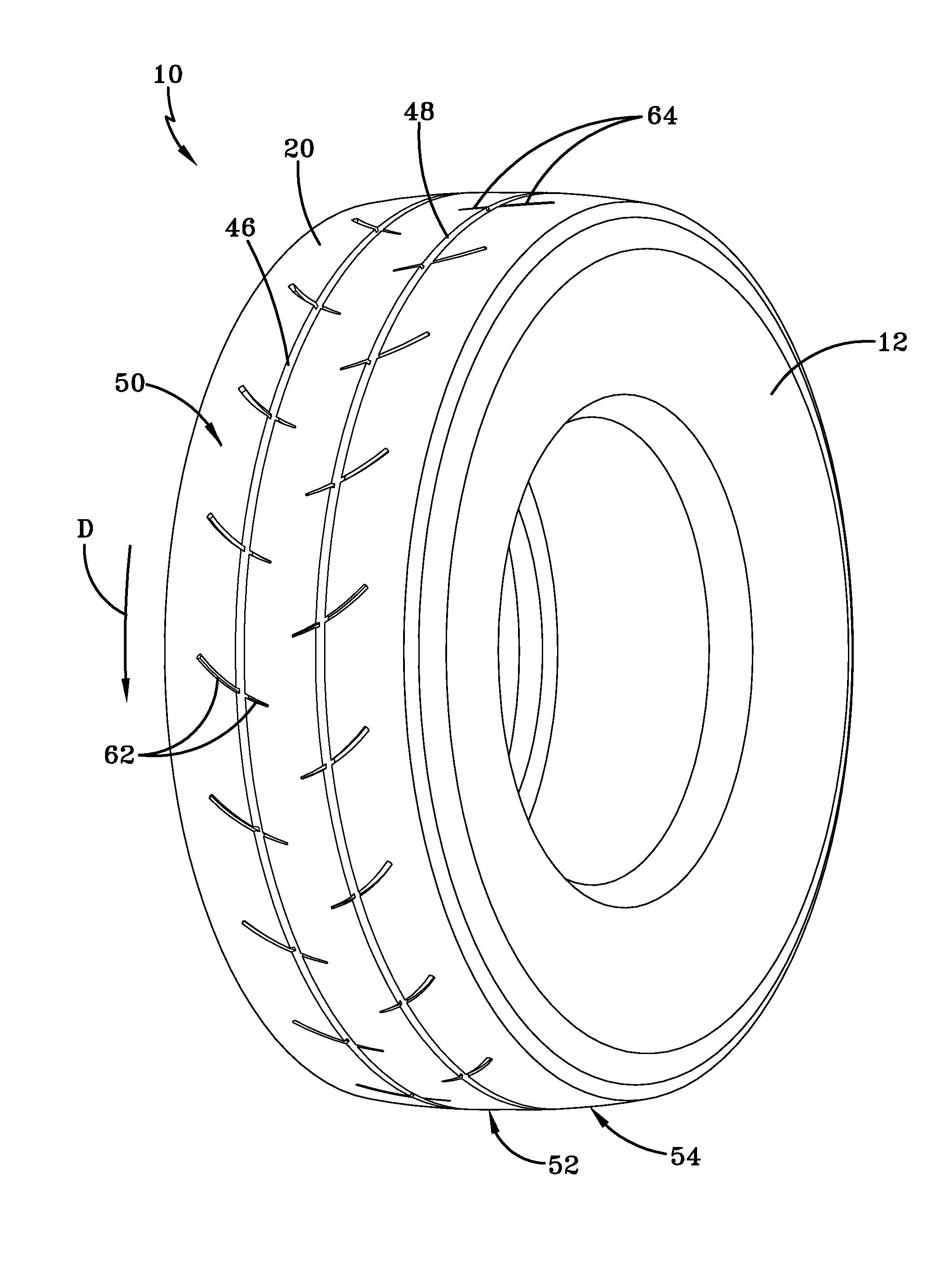

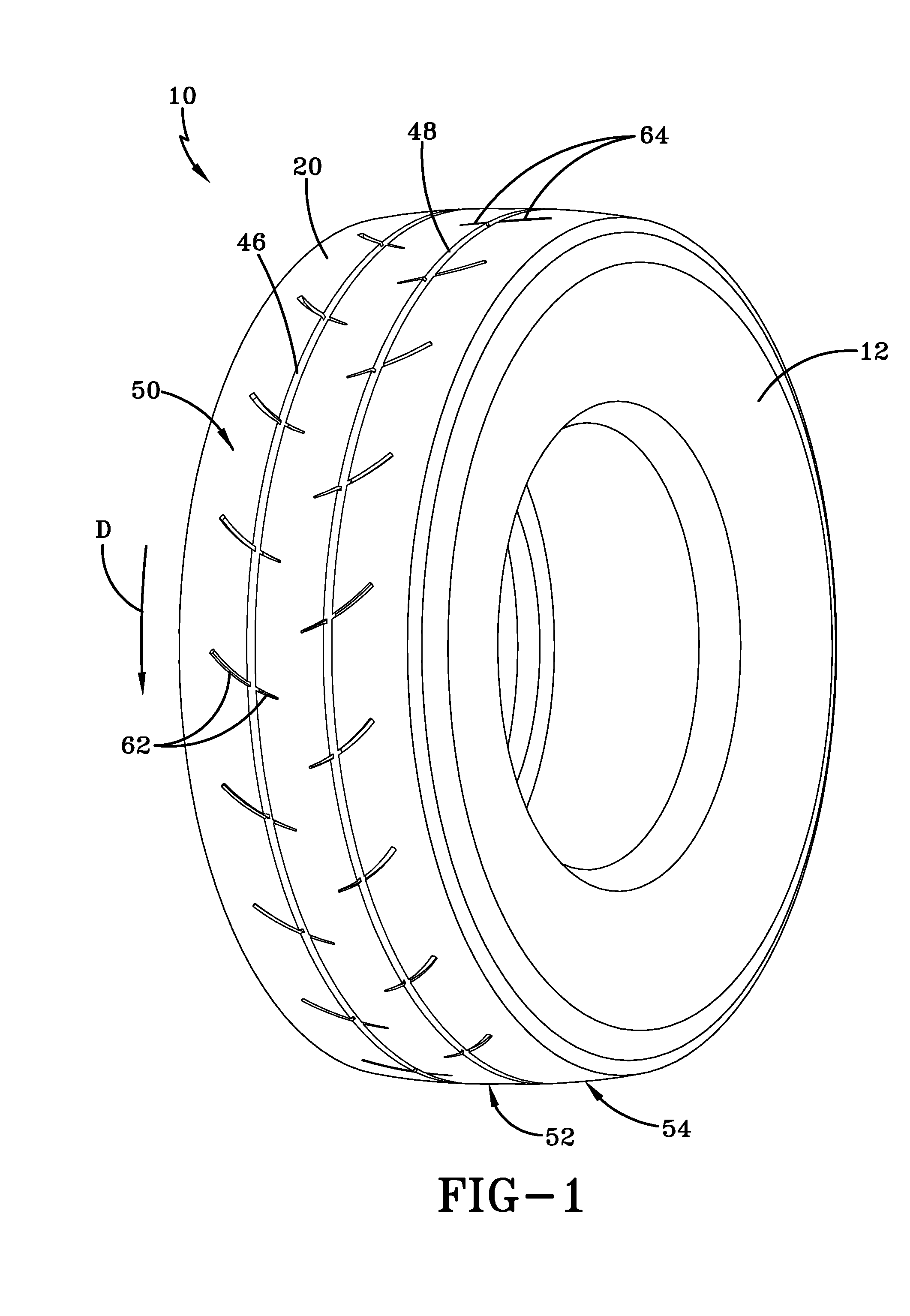

Replacement tread for a truck racing tire

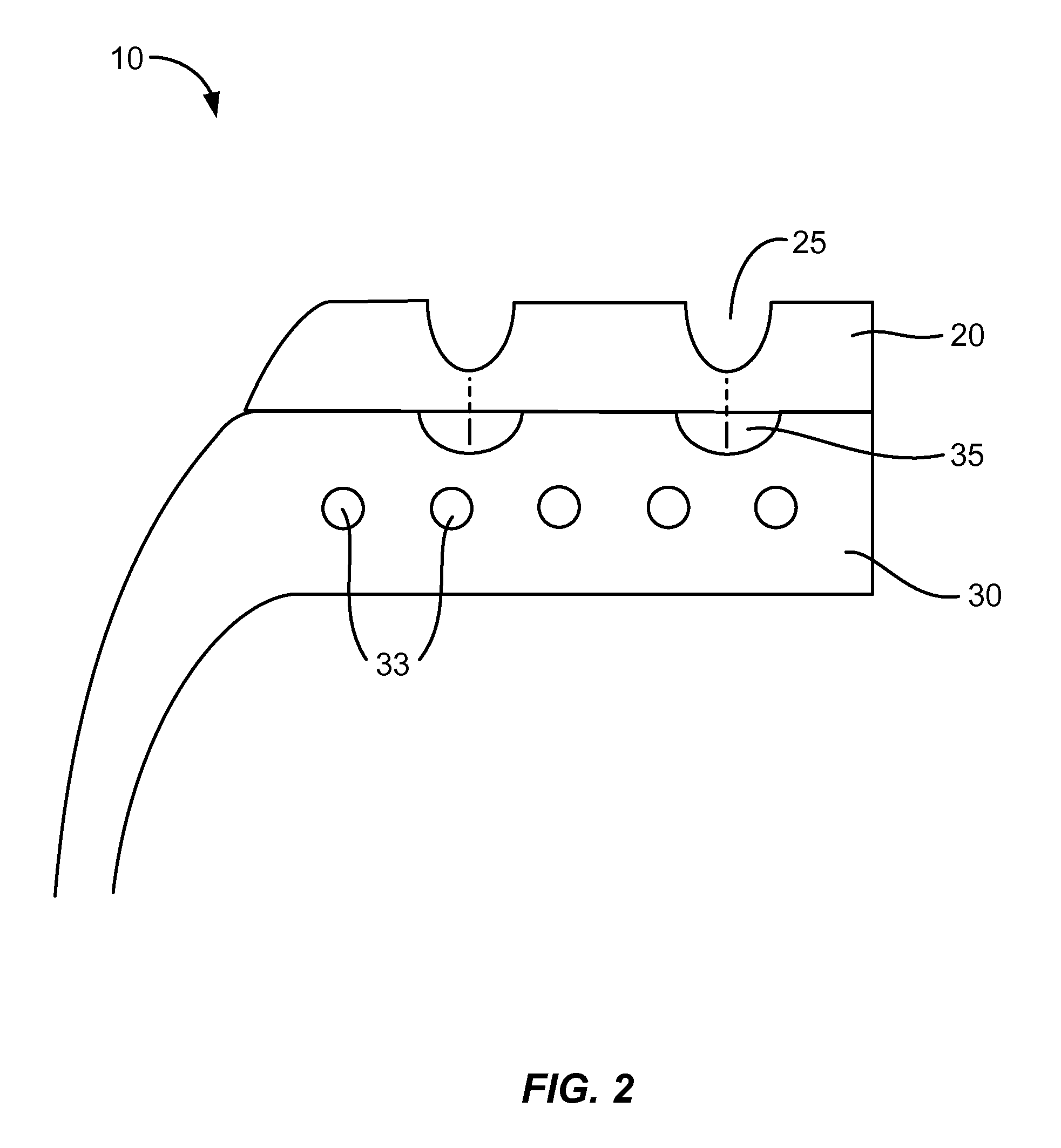

InactiveUS20090229719A1Optimizing handlingImprove vehicle stabilityNon-inflatable tyresTyresEngineeringTruck

A retreaded pneumatic truck tire includes a used carcass having a uniform annular attachment area and a retread element. The retread element secures to the attachment area of the used carcass. The retread element has a tread pattern comprising a first circumferential groove separating the tread pattern into a first shoulder rib and an intermediate rib and a second circumferential groove separating the tread pattern into the intermediate rib and a second shoulder rib. The tread pattern further comprises a first plurality of identical arcuate notches extending axially and circumferentially across the first circumferential groove and a second plurality of identical arcuate notches extending axially and circumferentially across the second circumferential groove. The first plurality of arcuate notches are offset circumferentially from the second plurality of arcuate notches.

Owner:THE GOODYEAR TIRE & RUBBER CO

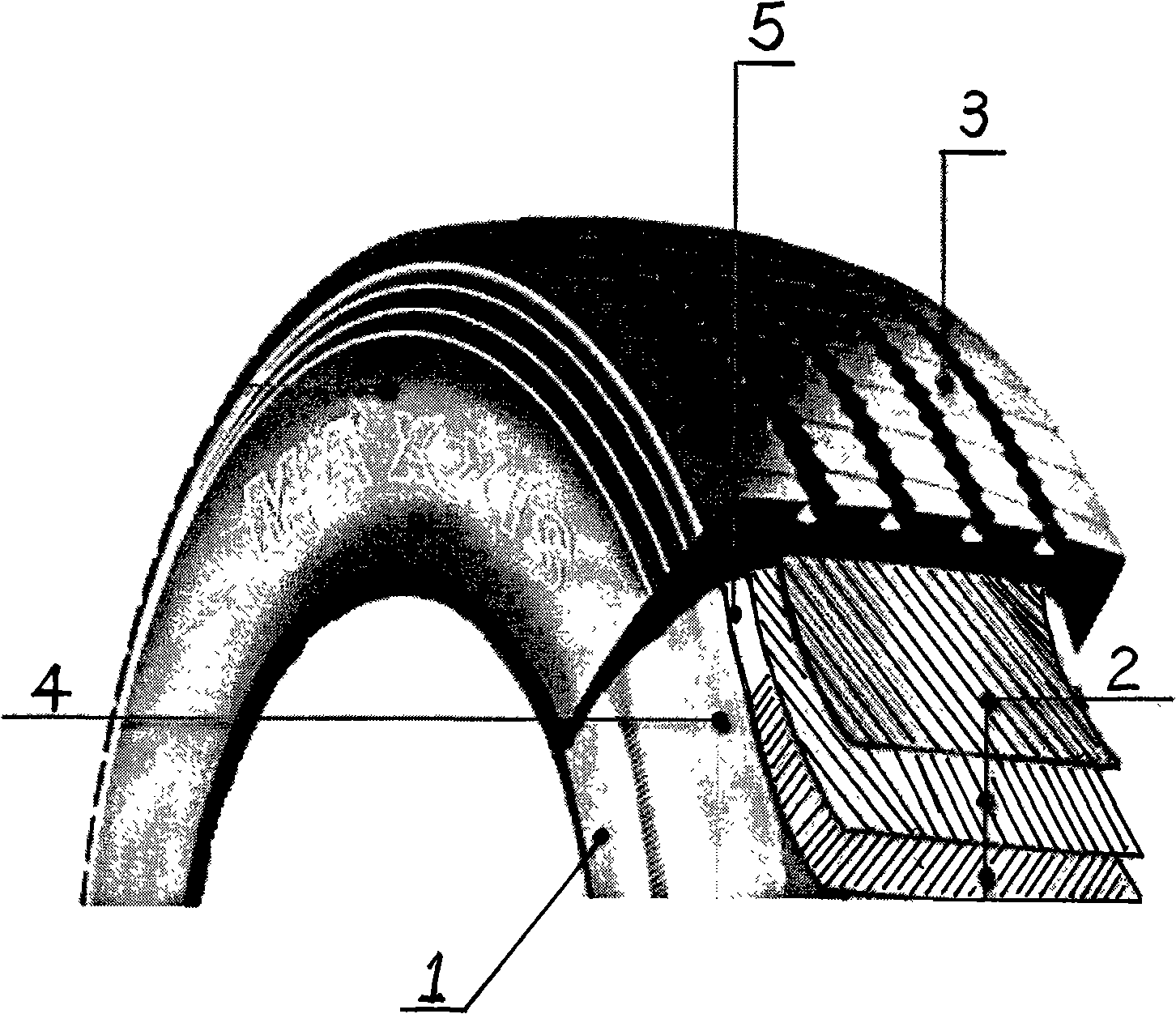

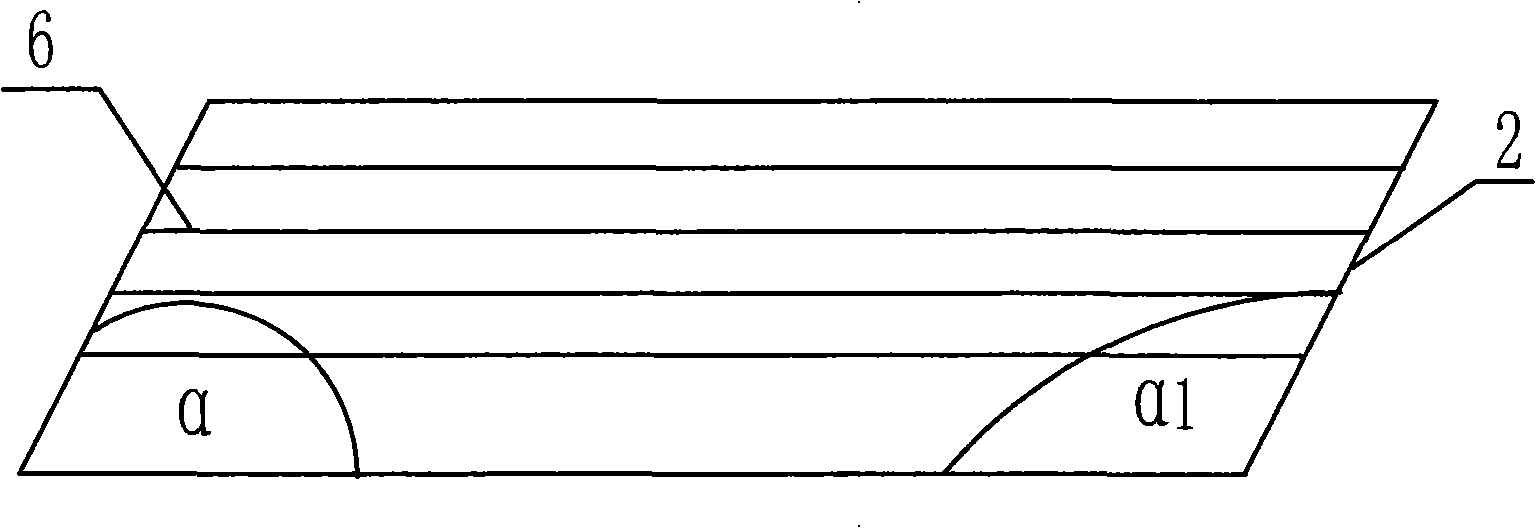

Renewing preparation method for radial tire steel wire cord layer fracture

The invention relates to the repair of a tire, in particular to a method for retreading and preparing the broken retread of the steel cord layer of a radial ply tire, which is characterized in that: recombination is carried out to carcass compound 4 is brushed on the polished coarse and cottony pitting surface of the tire body 1 in the first step; heads and ends of an Alpha angle and Alpha 1 of the first steel cord layer 2 are connected with each other to complete a bonding of the steel cord layer 2; the steel cord layer 2 is pressed layer by layer; each two steel cord layers 2 are bonded with each other by middle glue 3. The method has the advantages of simple operation, low cost, waste utilization and energy saving, can raise the utilization rate of the used tire by from 10 percent to above 20 percent, raise the service life of the retread from original 70 percent of the new tire to above 90 percent and save the energy consumption by 30 percent and the utilized materials are only 20 to 30 percent of the new tire. The cost is not increased on the basis of the original retread. The price for using the retread can be saved by above 50 percent compared with the price of the new tire.

Owner:惠树良

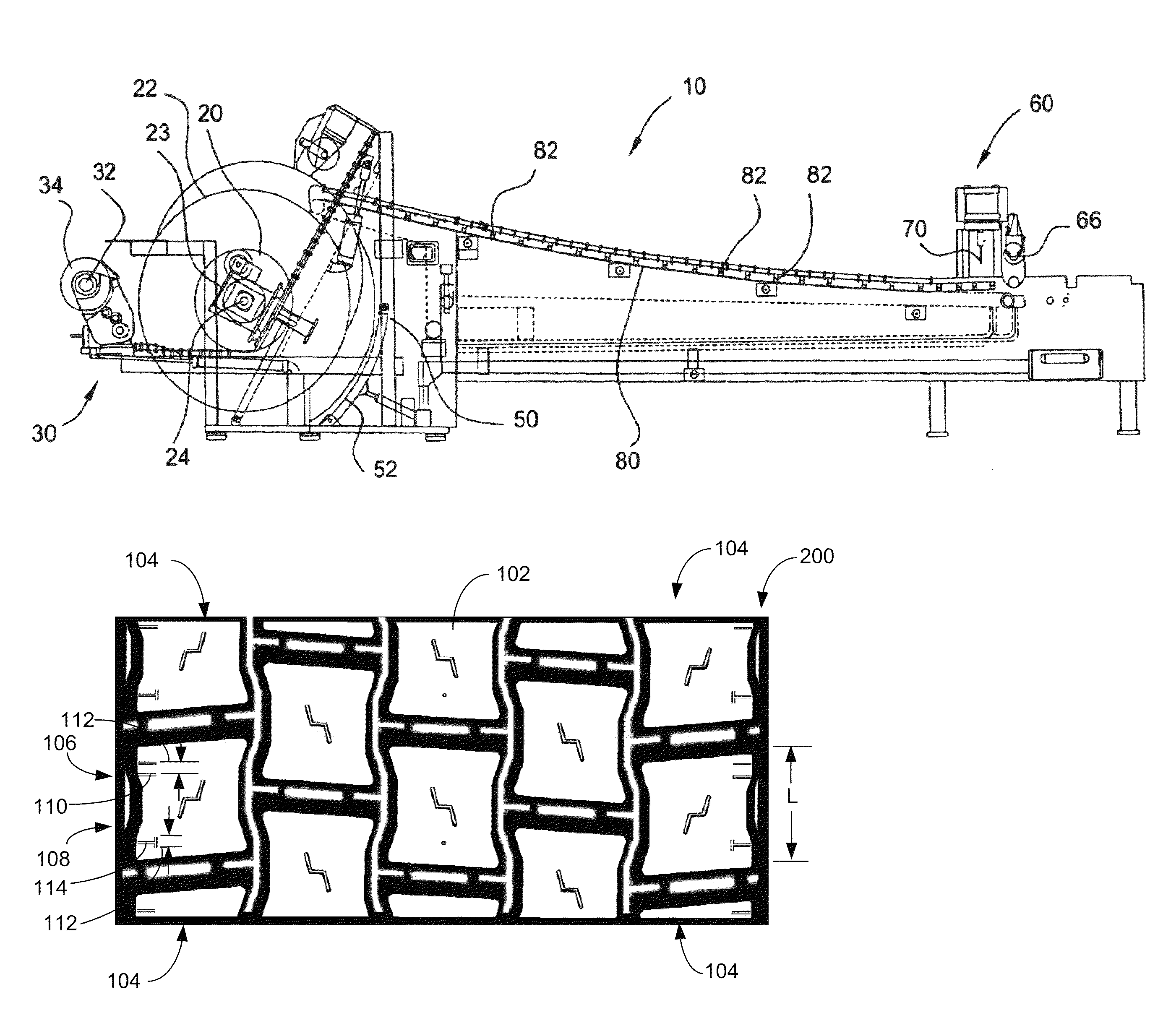

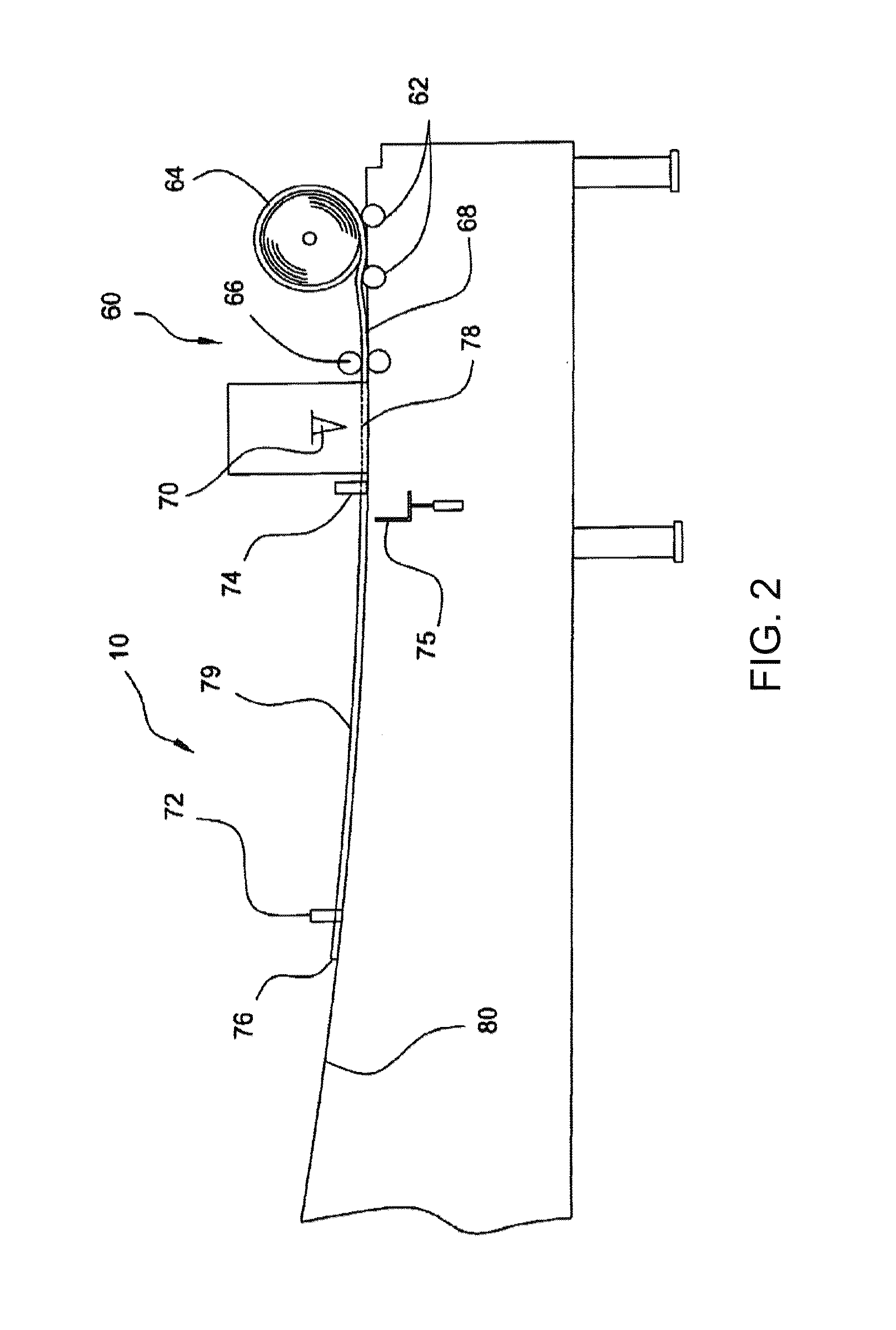

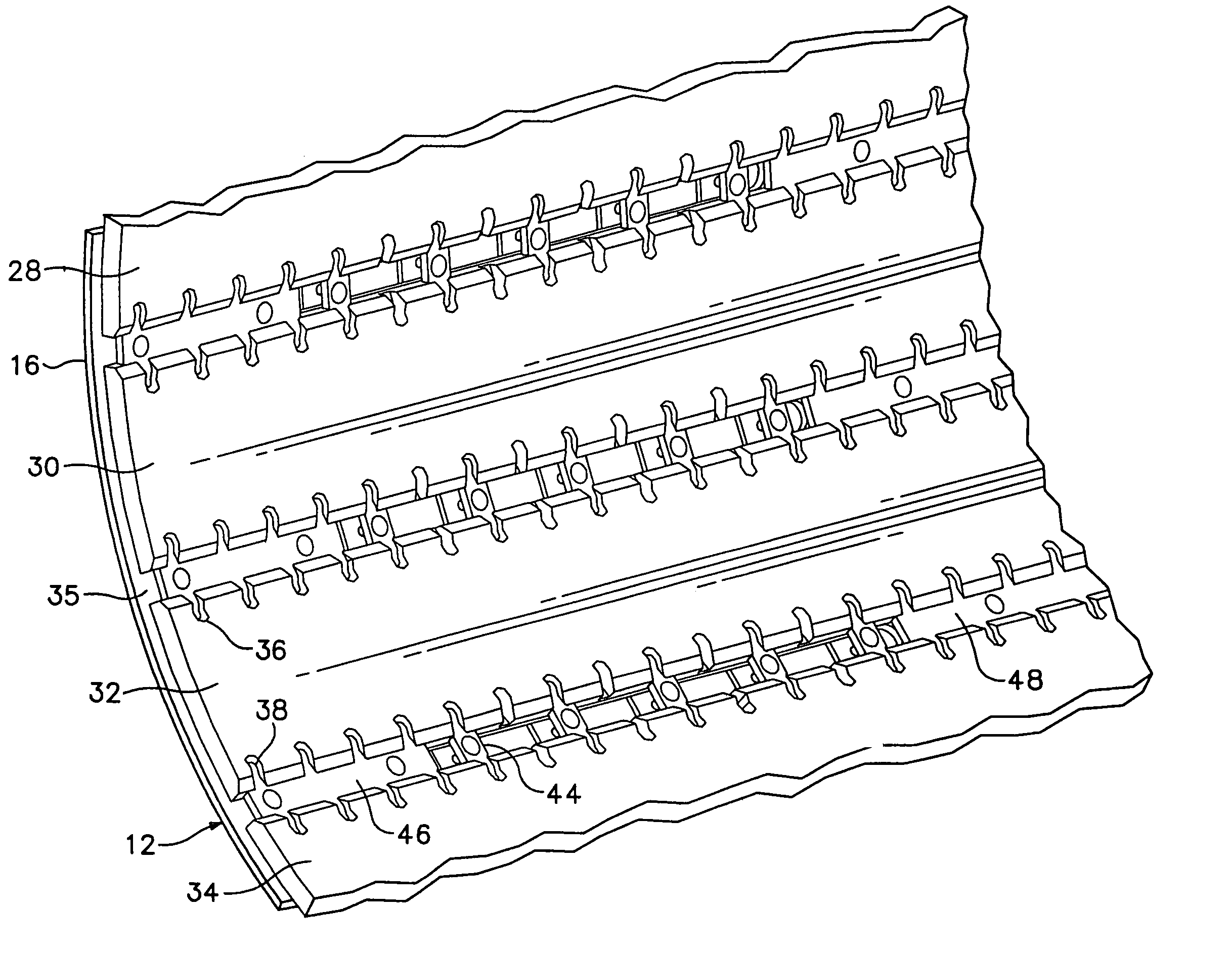

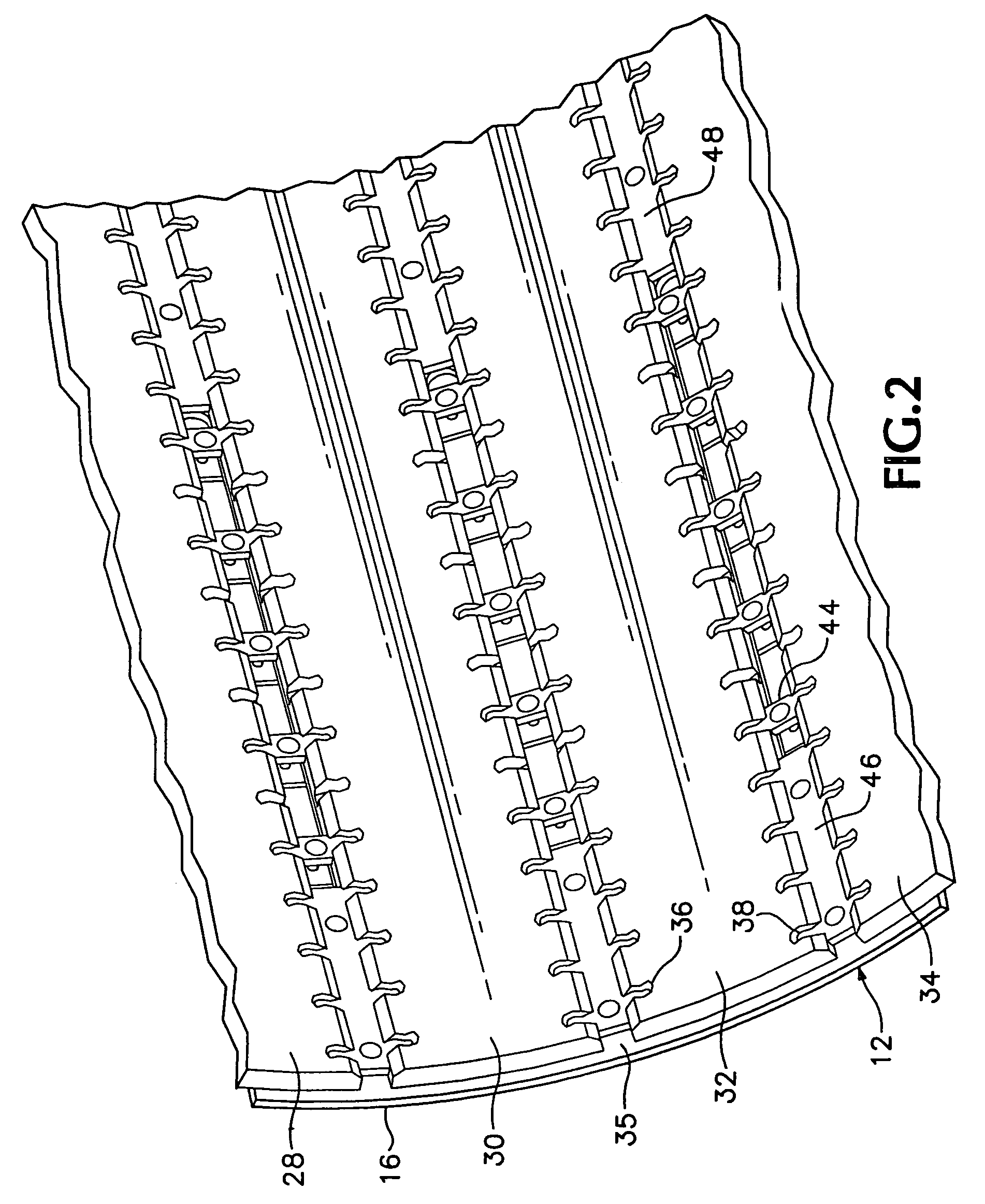

Method and apparatus for improved tread splicing

ActiveUS20110186198A1Low variabilityIncreasing retread tire performanceLamination ancillary operationsLaminationRetreadCushion

A method of cutting a length of tire tread for a retread tire includes measuring a circumference of the tire casing and cushion gum, and dispensing a length of tire tread from a roll based on the measured circumference. The length of tire tread relative to a tread cutter is adjusted so that the tire tread design at the point where the tread may be cut is between a set of marks formed in the periodically repeating tread design. The tread is then cut along a linear length of the tread disposed within the marks so that the periodically repeating tread pattern appears substantially continuous across a seam defined when the section of tire tread is wrapped around the casing such that the first and second ends meet in abutting relationship.

Owner:BRIDGESTONE BANDAG LLC

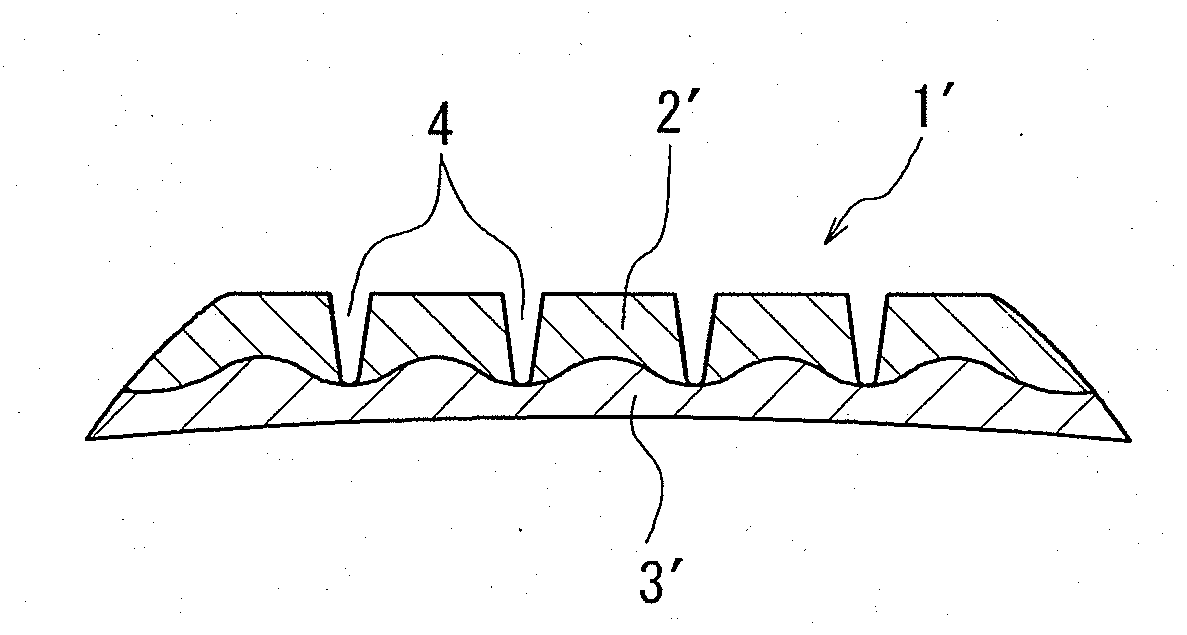

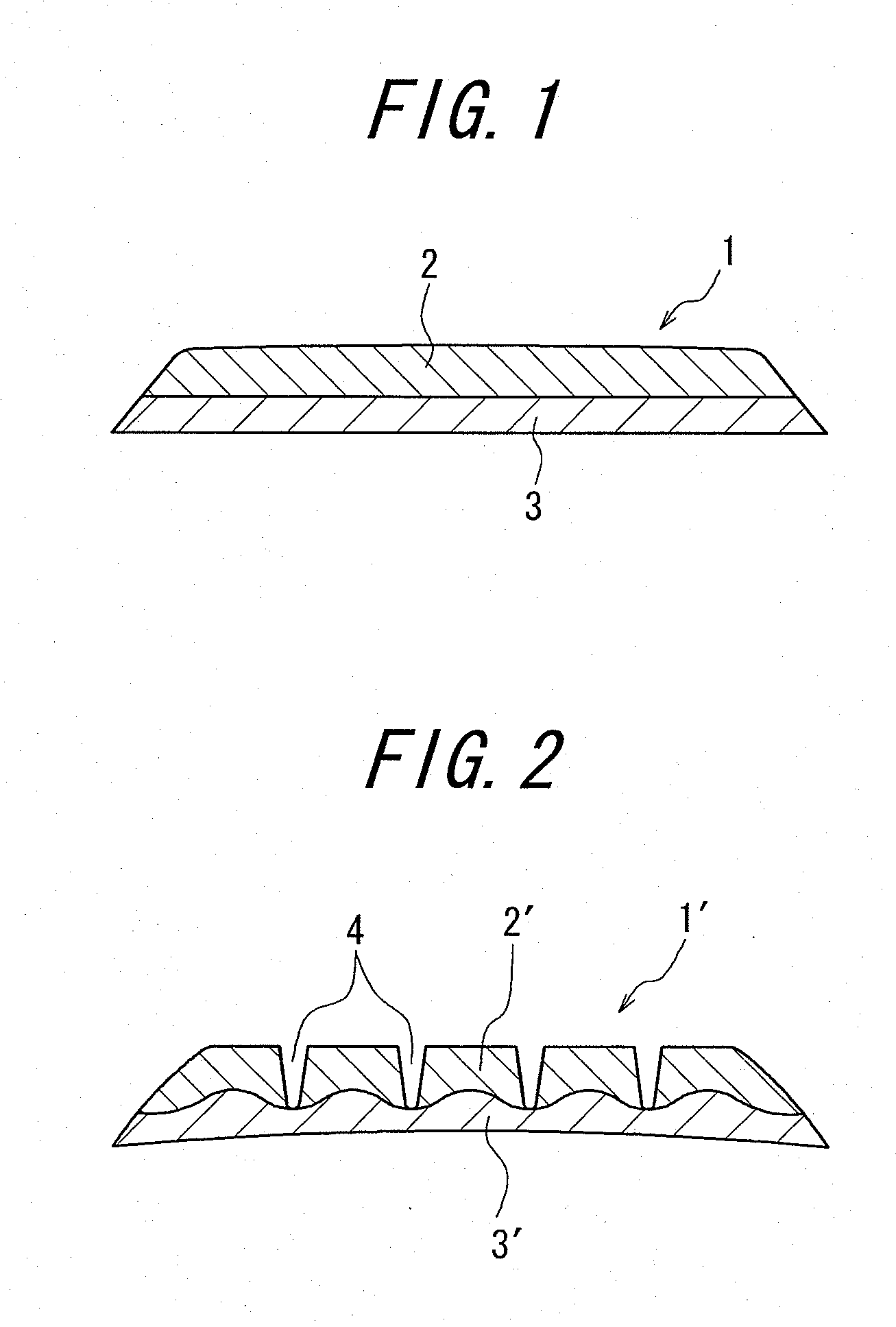

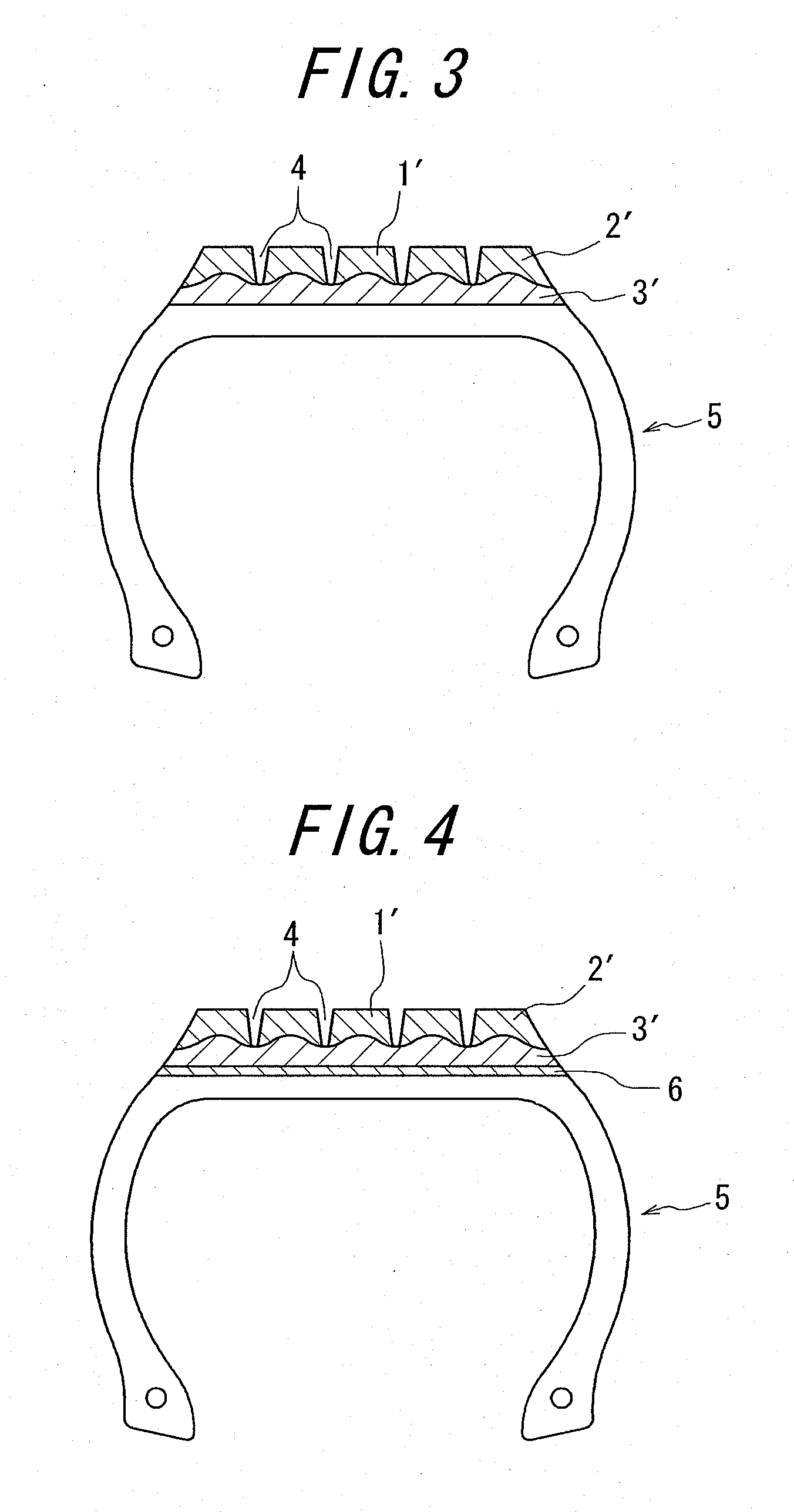

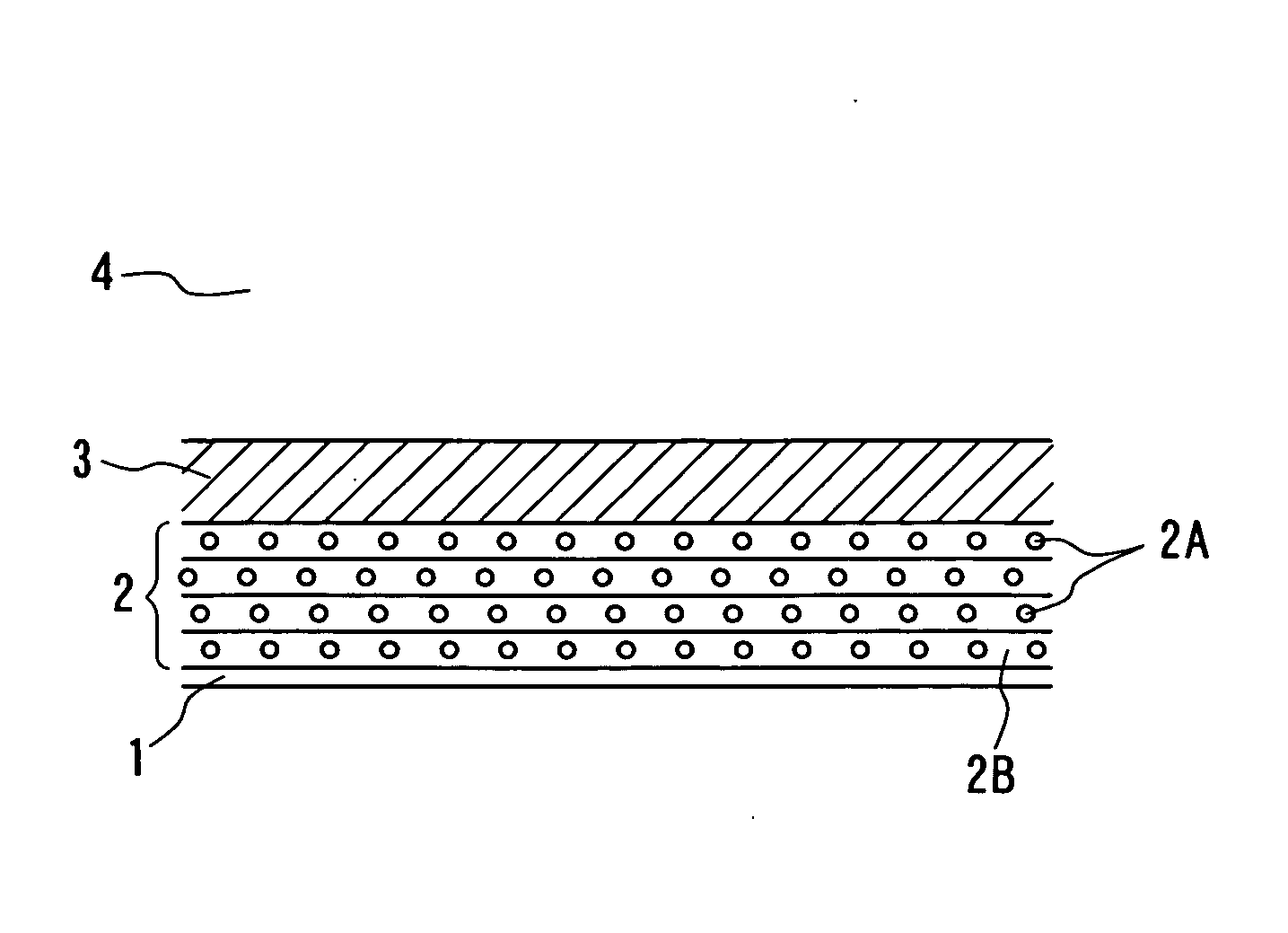

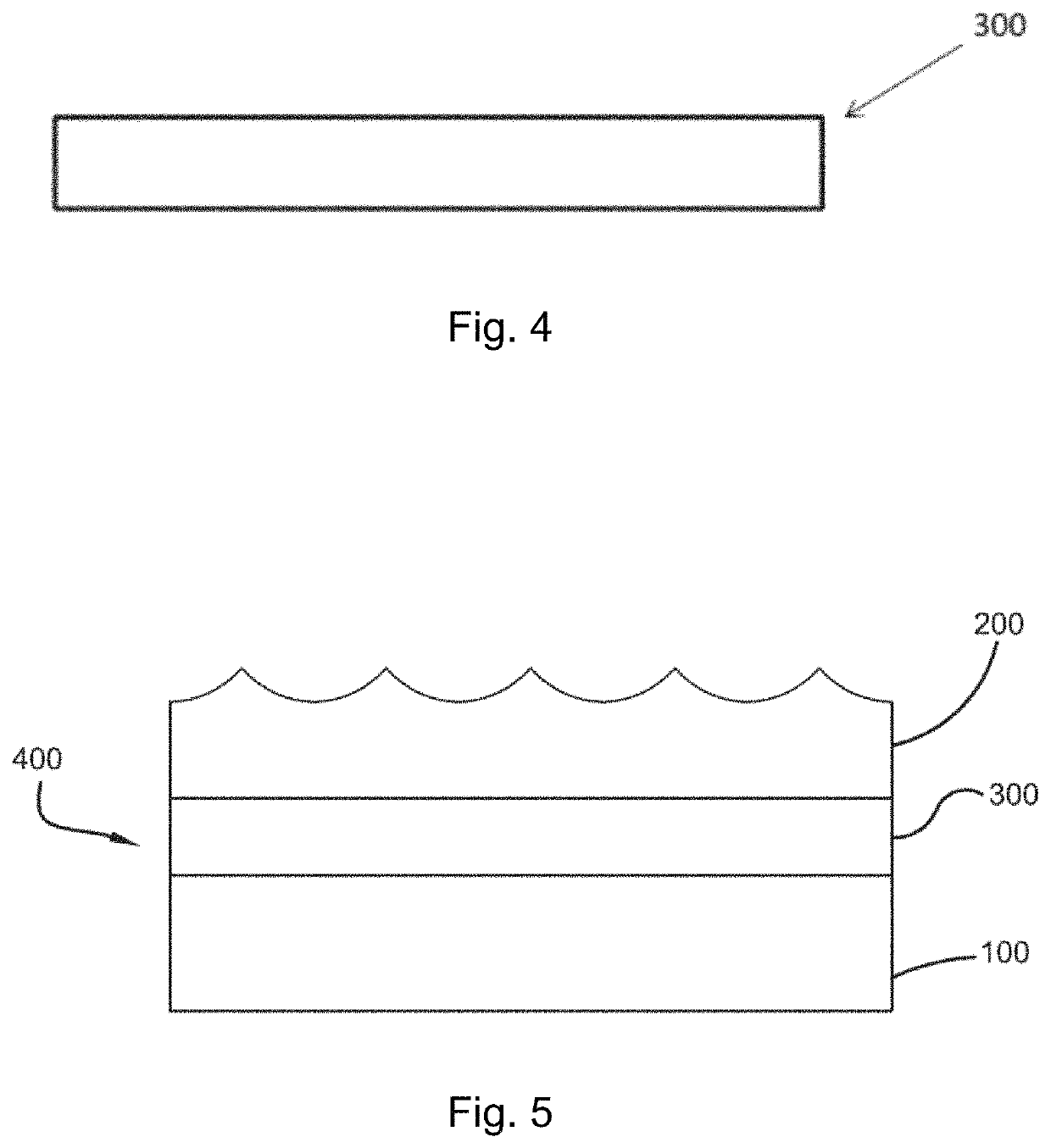

Tread for retread tire and retread tire

InactiveUS20100224295A1Improve adhesionLower operating temperatureSpecial tyresTyre tread bands/patternsTear resistanceEngineering

This invention provides a tread for retread tire capable of lowering a running temperature to suppress deterioration of peel strength at a retreading face between a tread and a base tire and further obtaining a good peel strength without sacrificing a tear resistance. In a tread 1 for retread tire comprising a cap rubber 2 located side a front surface of the tread and a base rubber 3 located side a bottom surface of the tread, a loss tangent (tan δ) of the base rubber 3 at 25° C. and 2% strain is not more than 0.10 and an elongation at break (Eb) of the base rubber 3 is not less than 460%. Also, this invention provides a retread tire comprising such a tread for retread tire.

Owner:BRIDGESTONE CORP

Replacement tread for a truck racing tire

InactiveUS8047243B2Optimizing vehicle stability and handlingNon-inflatable tyresTyresEngineeringTruck

Owner:THE GOODYEAR TIRE & RUBBER CO

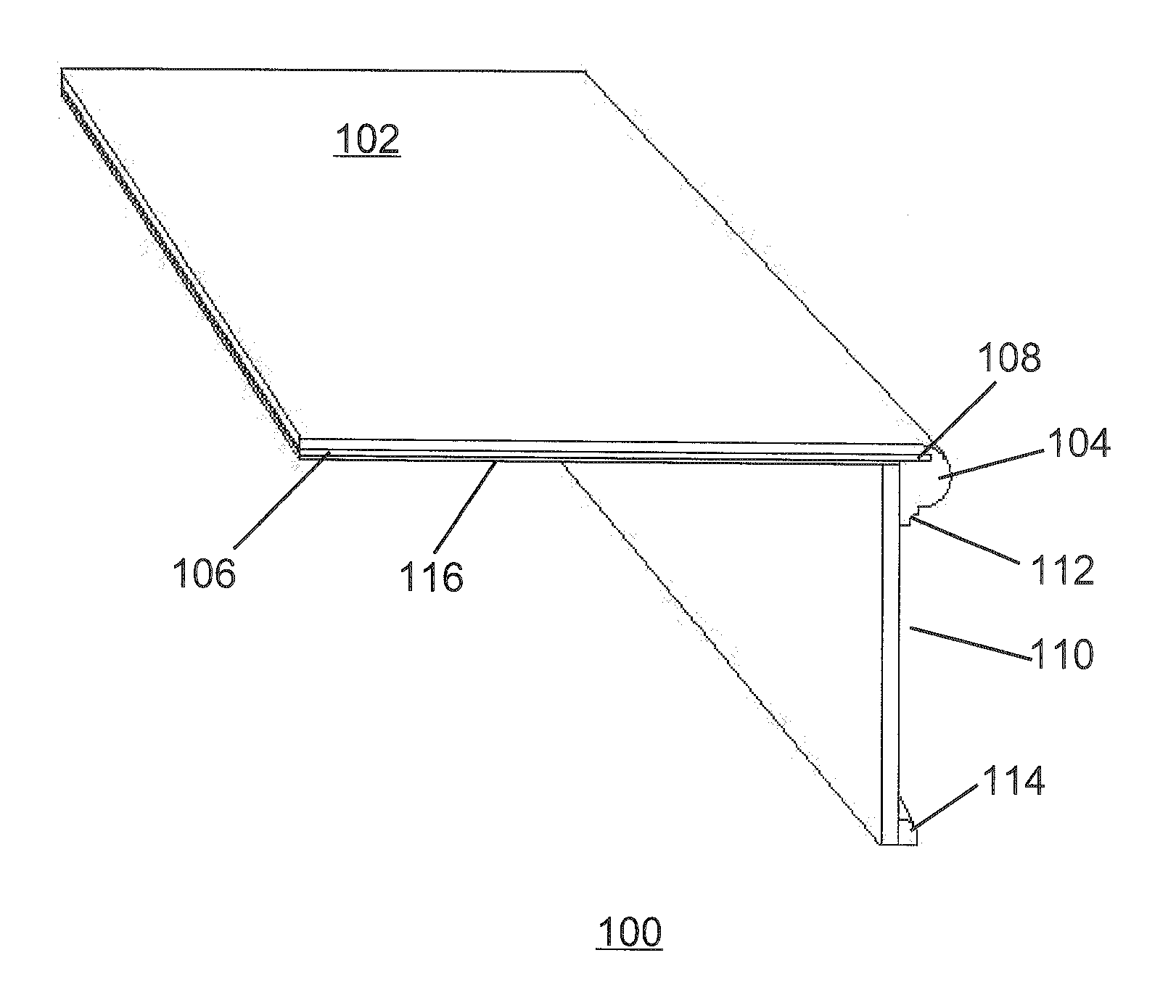

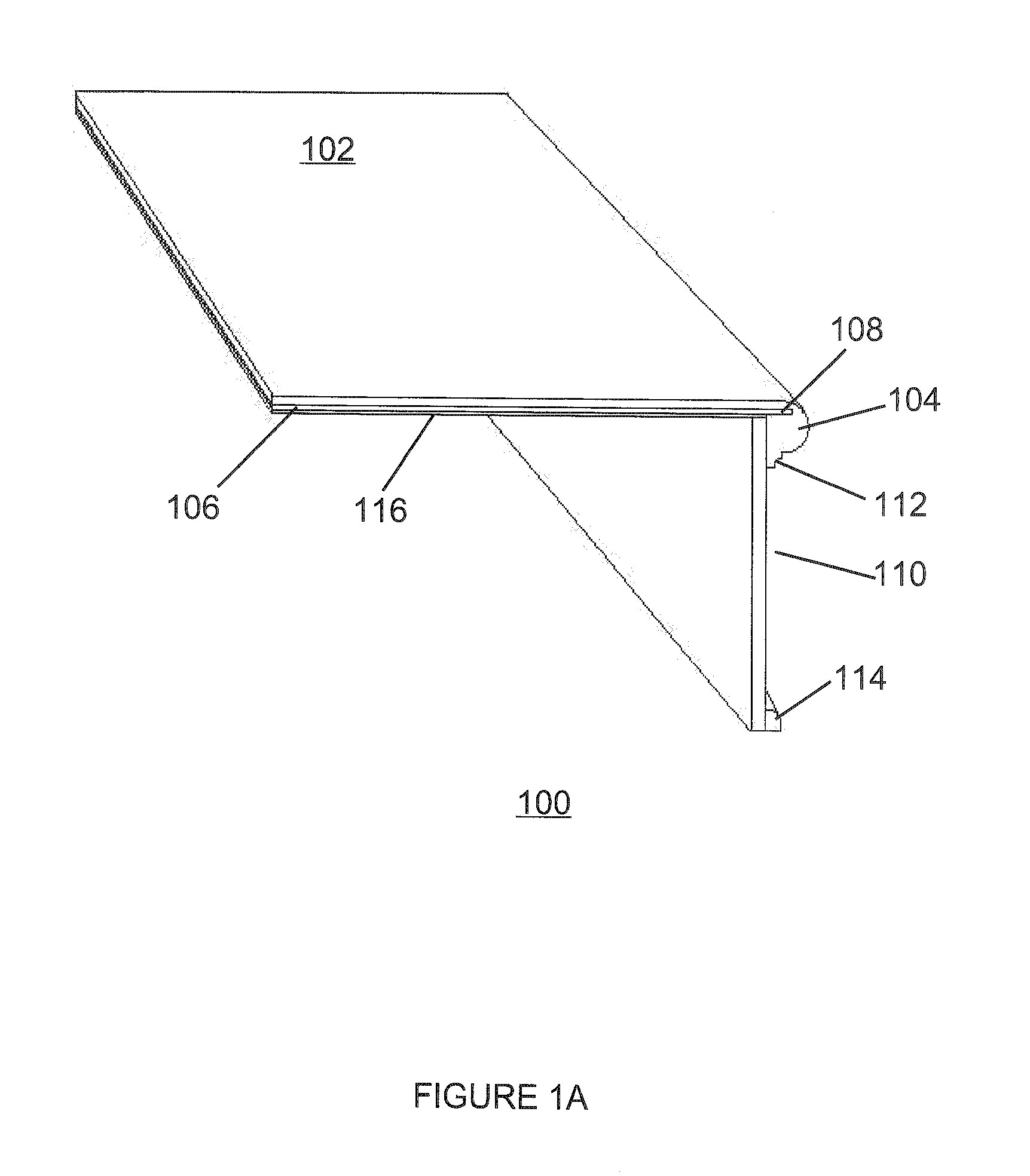

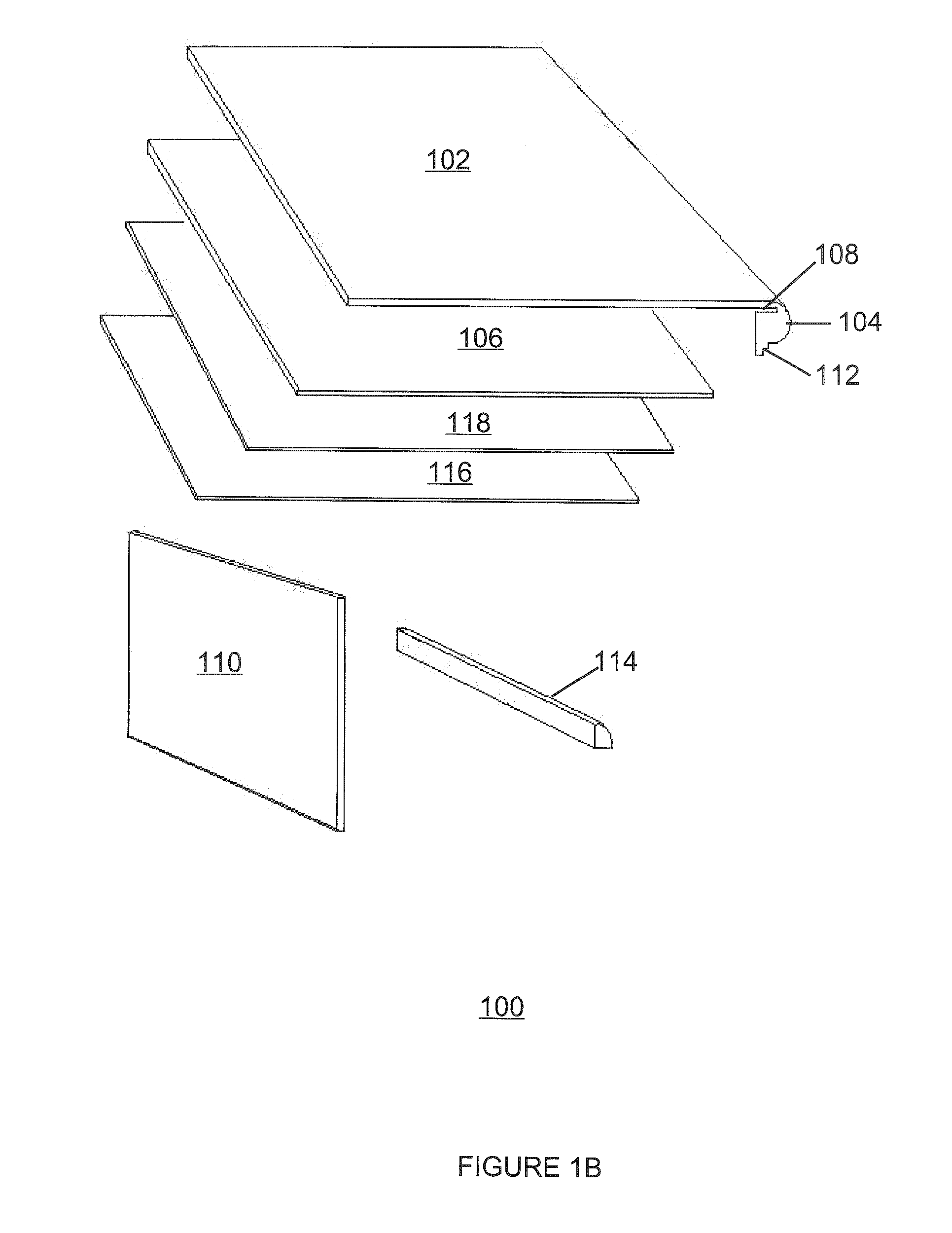

Step re-tread system and apparatus

A system for refacing an existing set of stairs without having to remove the existing set in its entirety or cause destruction to the existing set of stairs and surrounding structure including a stringer refacing component, a stringer cap, a stair tread, a nosing, a cove moulding, a riser cap, and a shoe moulding. The stair retread system may be placed over a set of stairs without removing or destroying the staircase as is common with typical staircase refinishing processes.

Owner:LOPEZ MICHAEL

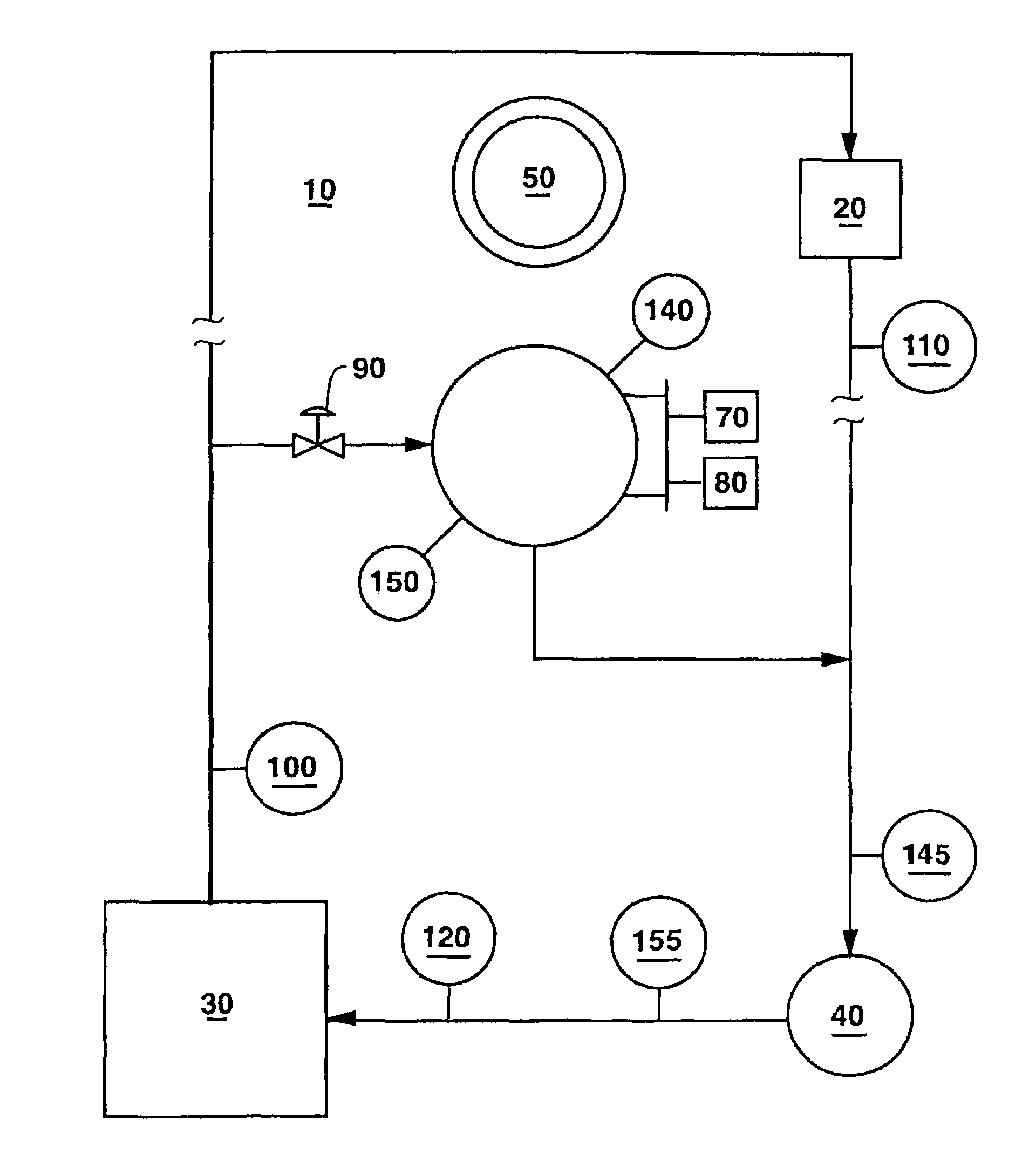

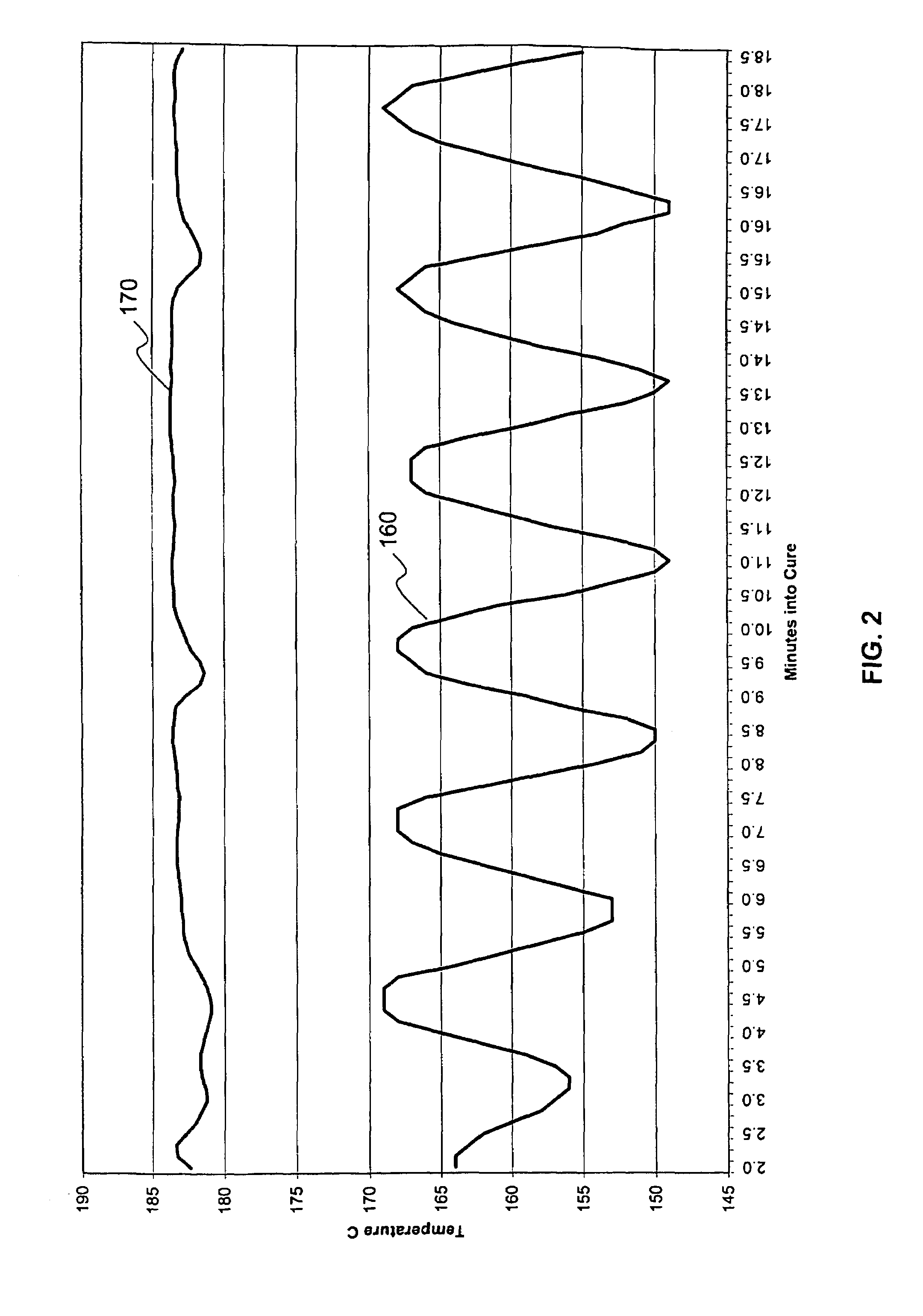

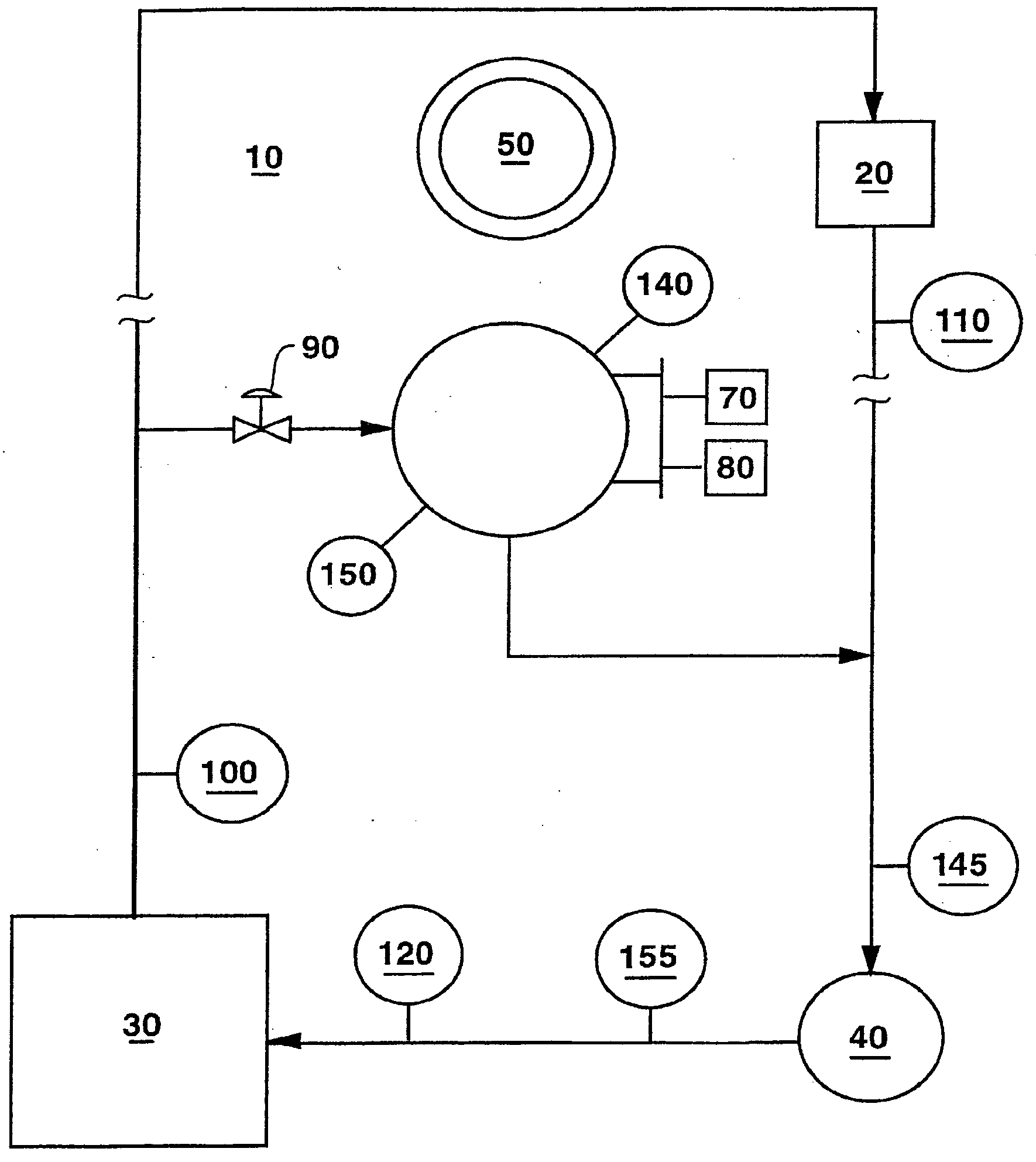

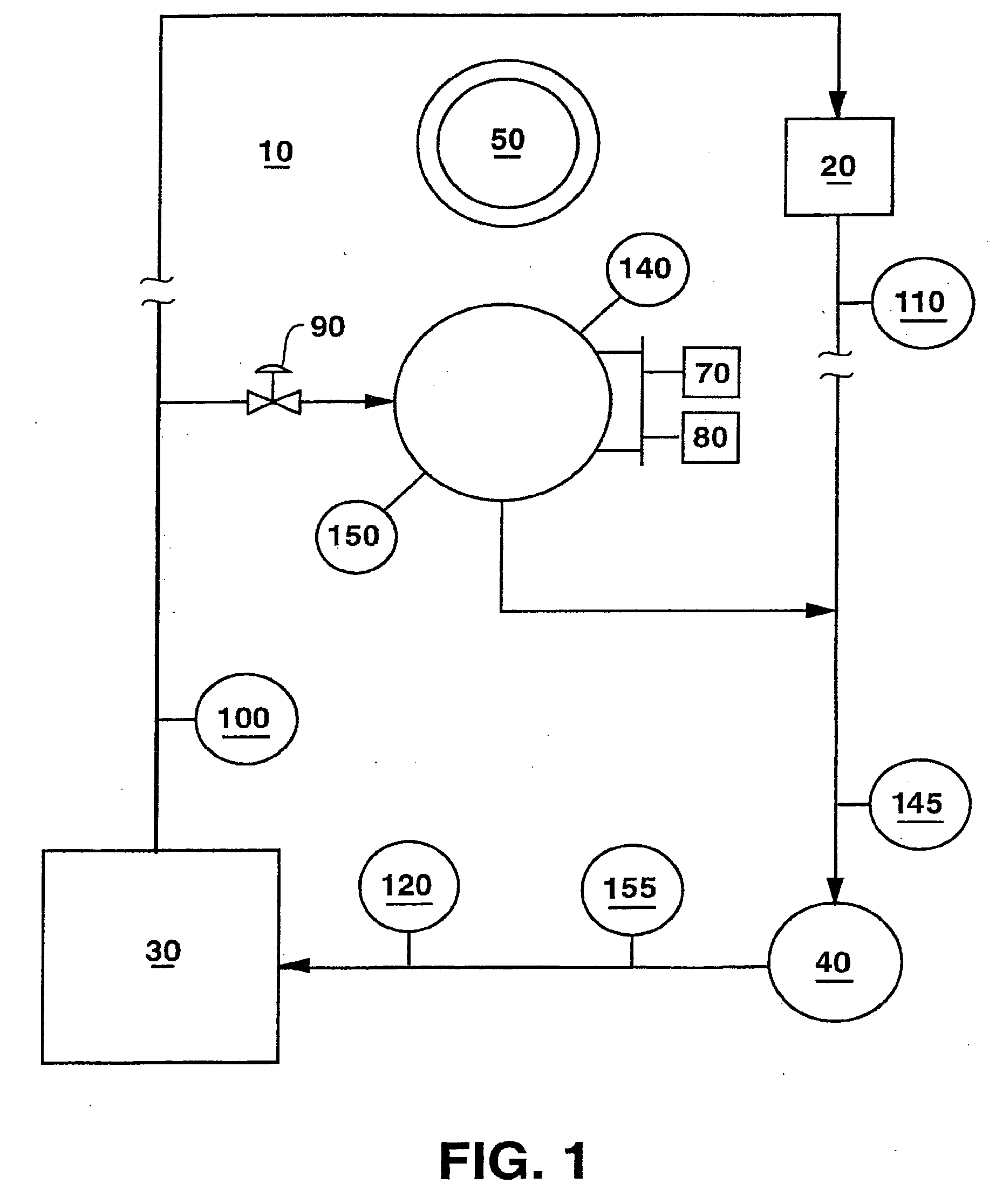

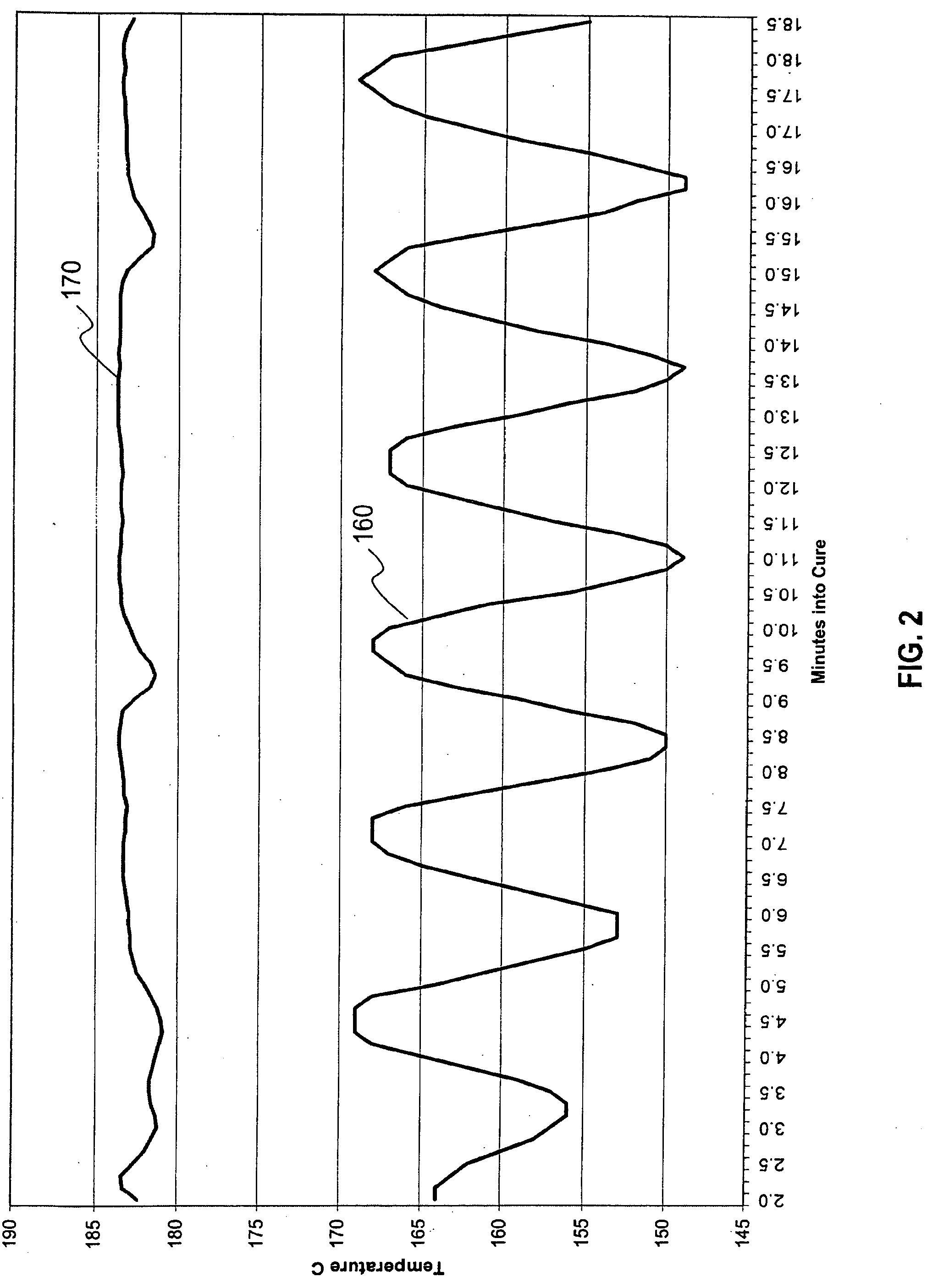

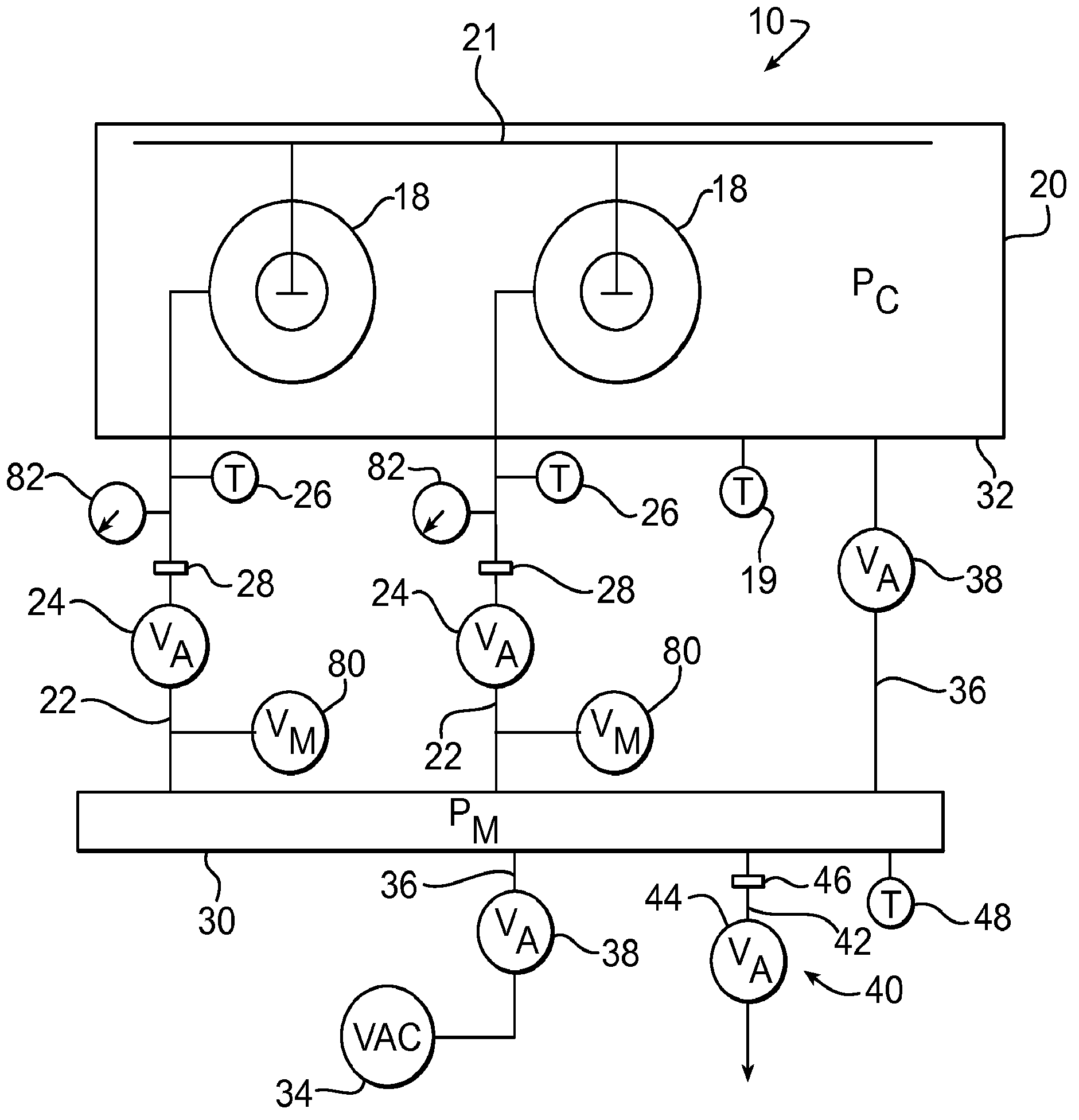

Automatic pressure and temperature control apparatus and method for curing tire assemblies

An automatic pressure and temperature control apparatus and method for use in curing tire assemblies including retread tire assemblies is provided. Using water as a heating medium, a new process control method and apparatus is described that allows a more precise control of process variables during steady state conditions such that heat transfer is improved and the undesirable formation of steam is eliminated. Existing processes and equipment for curing tire assemblies can be modified, using the teaching disclosed herein, to implement and achieve the benefits of the present invention.

Owner:MICHELIN RECH & TECH SA

Automatic pressure and temperature control apparatus and method for curing tire assemblies

An automatic pressure and temperature control apparatus and method for use in curing tire assemblies including retread tire assemblies is provided. Using water as a heating medium, a new process control method and apparatus is described that allows a more precise control of process variables during steady state conditions such that heat transfer is improved and the undesirable formation of steam is eliminated. Existing processes and equipment for curing tire assemblies can be modified, using the teaching disclosed herein, to implement and achieve the benefits of the present invention.

Owner:MICHELIN RECH & TECH SA

Retreaded tire

ActiveUS20120308793A1Excellently maintaining adhesionAvoid layeringSynthetic resin layered productsTyresHigh intensityEngineering

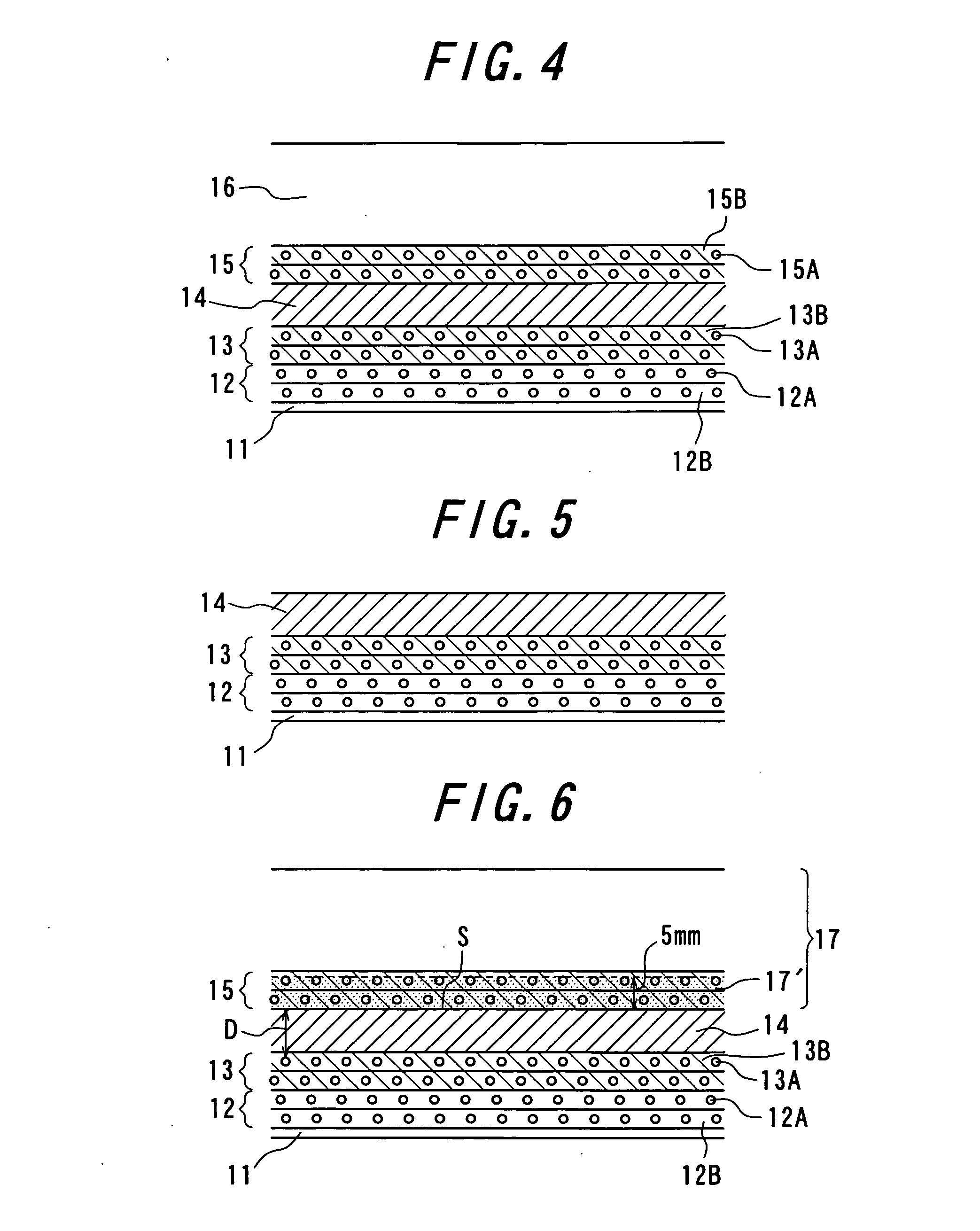

Provided is a retreaded tire that uses cushion rubber for retread that is able to further improve the prevention of separation failure while effectively suppressing blowout within the cushion rubber layer. The retreaded tire includes cushion rubber for retread, a base tire, and precured tread rubber formed of at least one rubber layer, and is characterized by: the aforementioned cushion rubber for retreaded tires being formed from a rubber composition containing specific quantities of a highly reinforcing carbon black of at least HAF grade, and natural rubber and / or synthetic polyisoprene rubber; the 100% modulus (AM) of the rubber layer (A) that comprises the aforementioned cushion rubber for retread being at least 3.0 MPa and less than 6.0 MPa; and the outermost layer (B) of the aforementioned base tire and the innermost layer (C) of the aforementioned precured tread rubber being formed from a rubber composition containing specific quantities of natural rubber and / or synthetic polyisoprene rubber.

Owner:BRIDGESTONE CORP

Retreaded tire

ActiveUS9573423B2Excellently maintaining adhesionIncreased durabilitySynthetic resin layered productsSpecial tyresHigh intensityEngineering

Provided is a retreaded tire that uses cushion rubber for retread that is able to further improve the prevention of separation failure while effectively suppressing blowout within the cushion rubber layer. The retreaded tire includes cushion rubber for retread, a base tire, and precured tread rubber formed of at least one rubber layer, and is characterized by: the aforementioned cushion rubber for retreaded tires being formed from a rubber composition containing specific quantities of a highly reinforcing carbon black of at least HAF grade, and natural rubber and / or synthetic polyisoprene rubber; the 100% modulus (AM) of the rubber layer (A) that comprises the aforementioned cushion rubber for retread being at least 3.0 MPa and less than 6.0 MPa; and the outermost layer (B) of the aforementioned base tire and the innermost layer (C) of the aforementioned precured tread rubber being formed from a rubber composition containing specific quantities of natural rubber and / or synthetic polyisoprene rubber.

Owner:BRIDGESTONE CORP

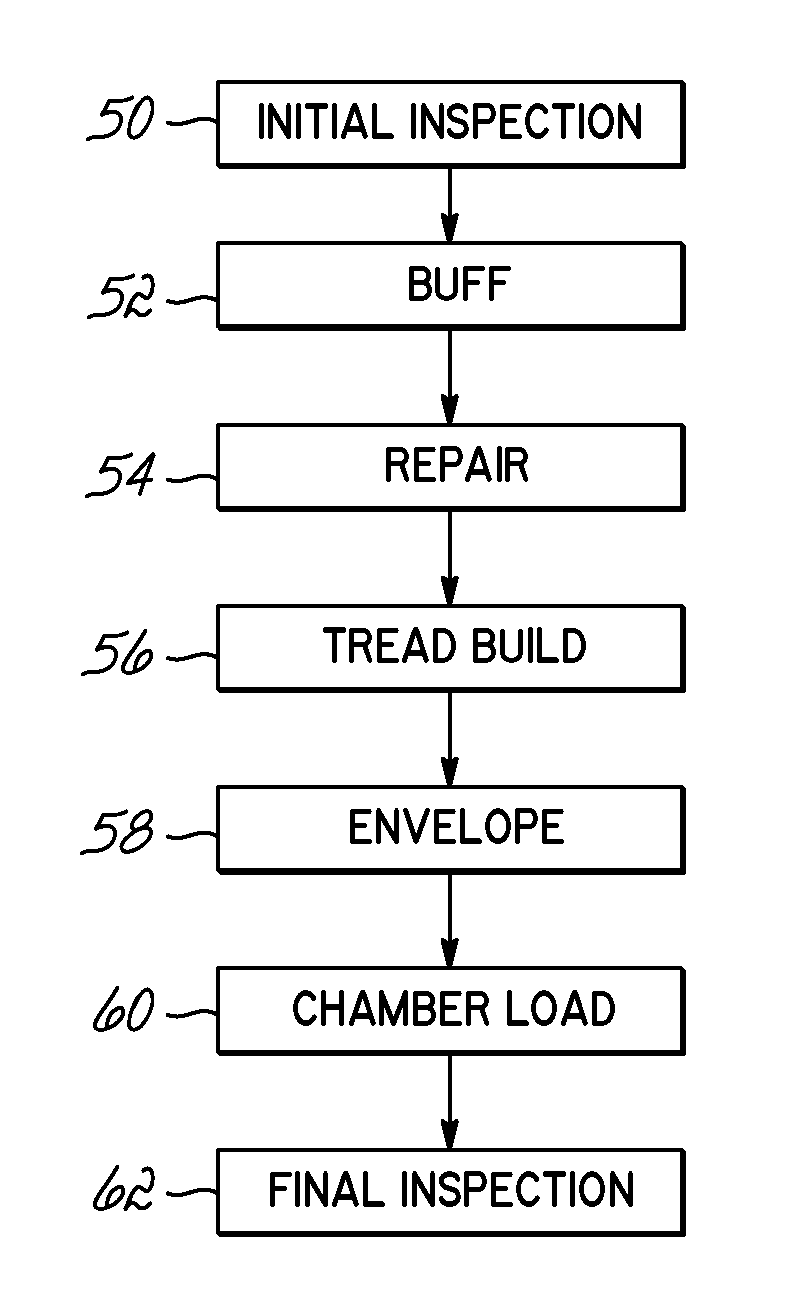

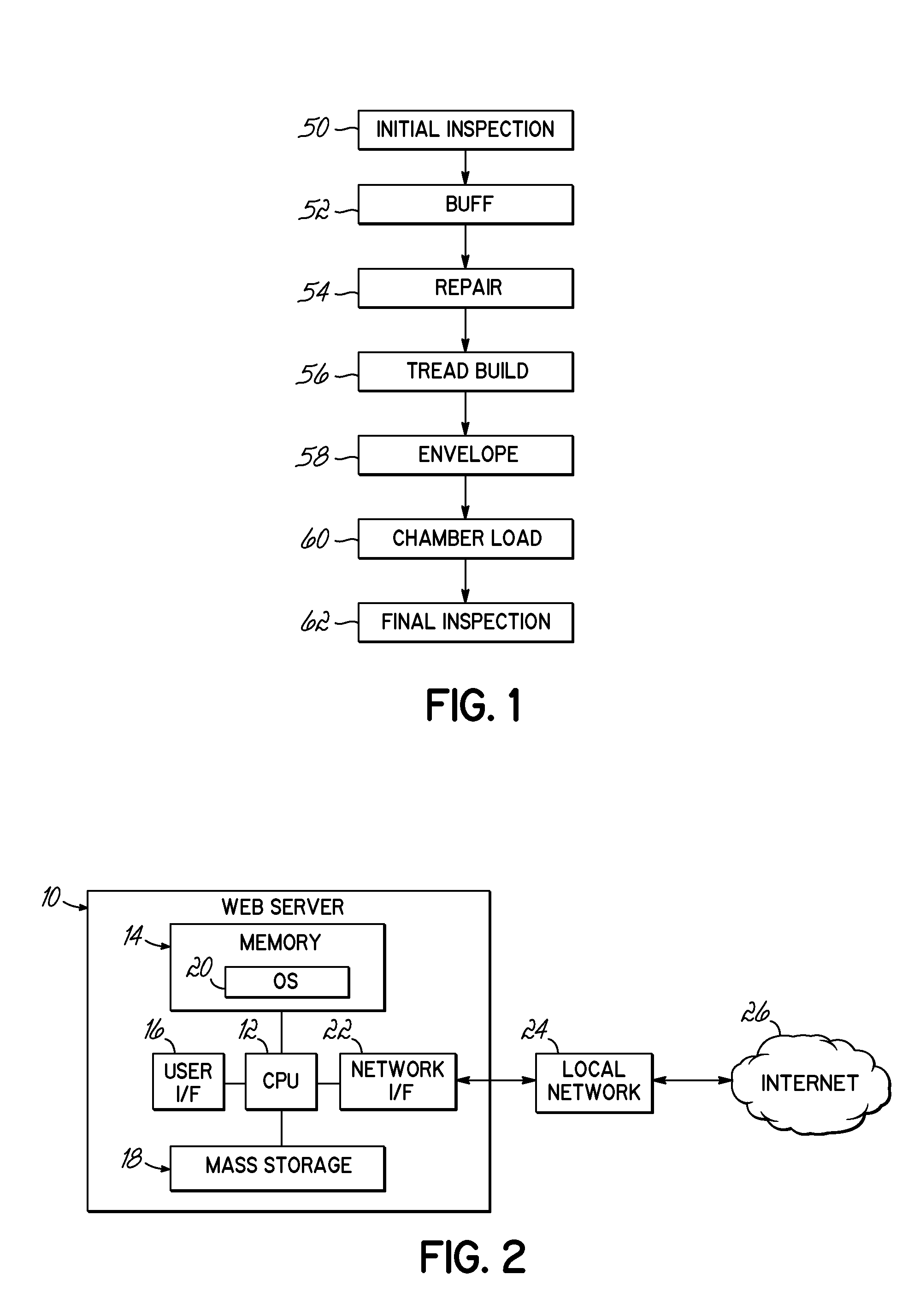

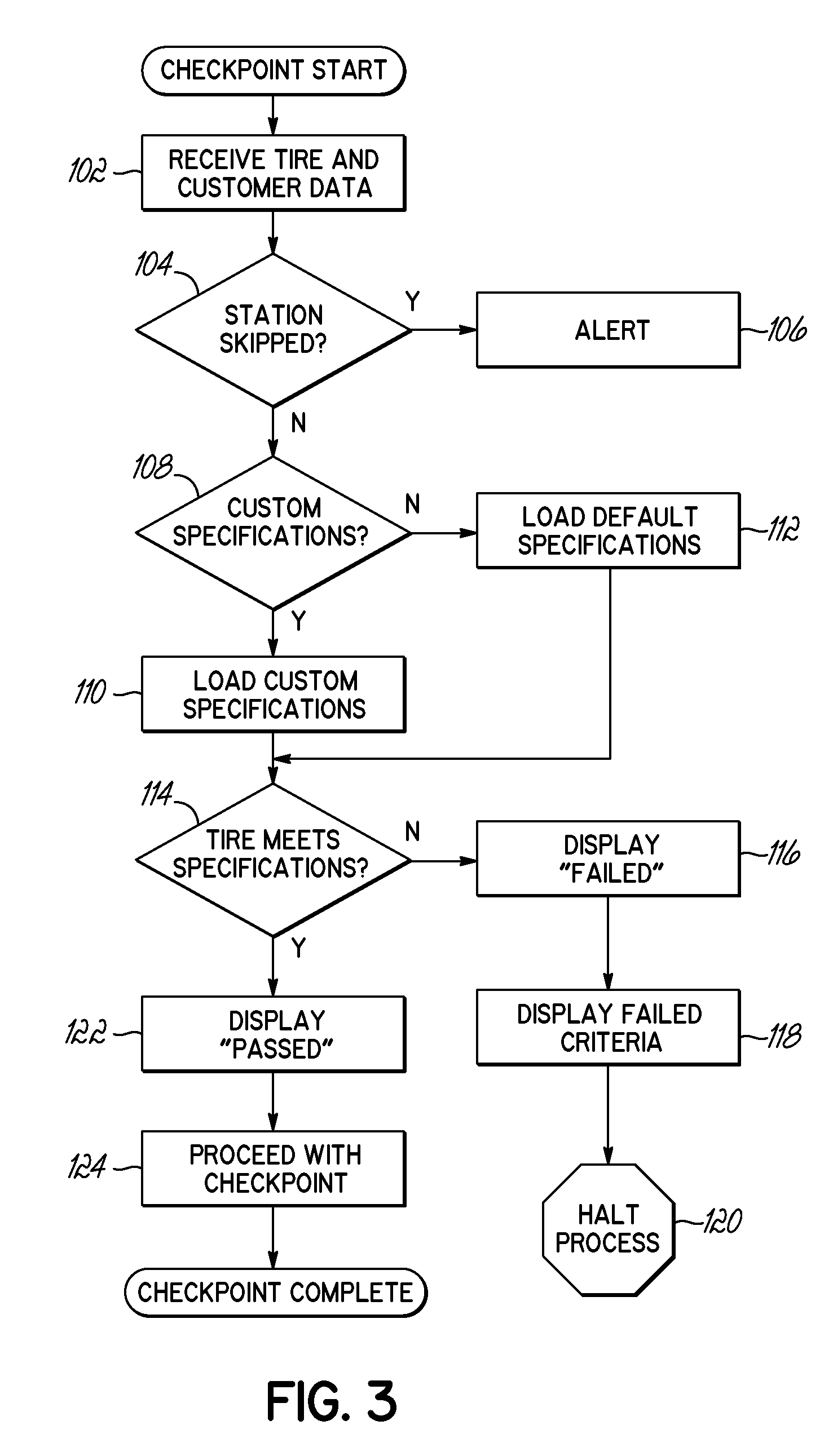

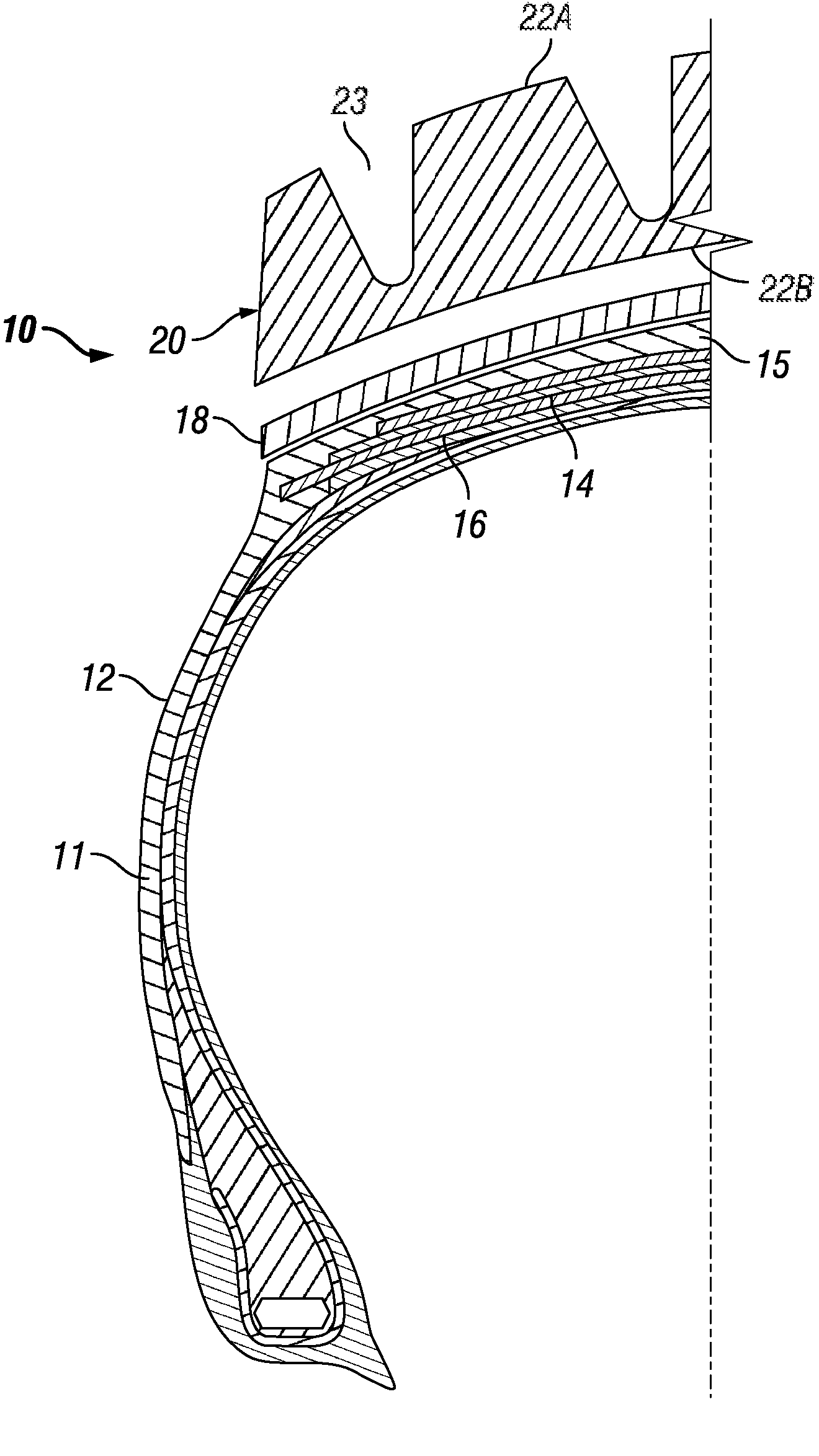

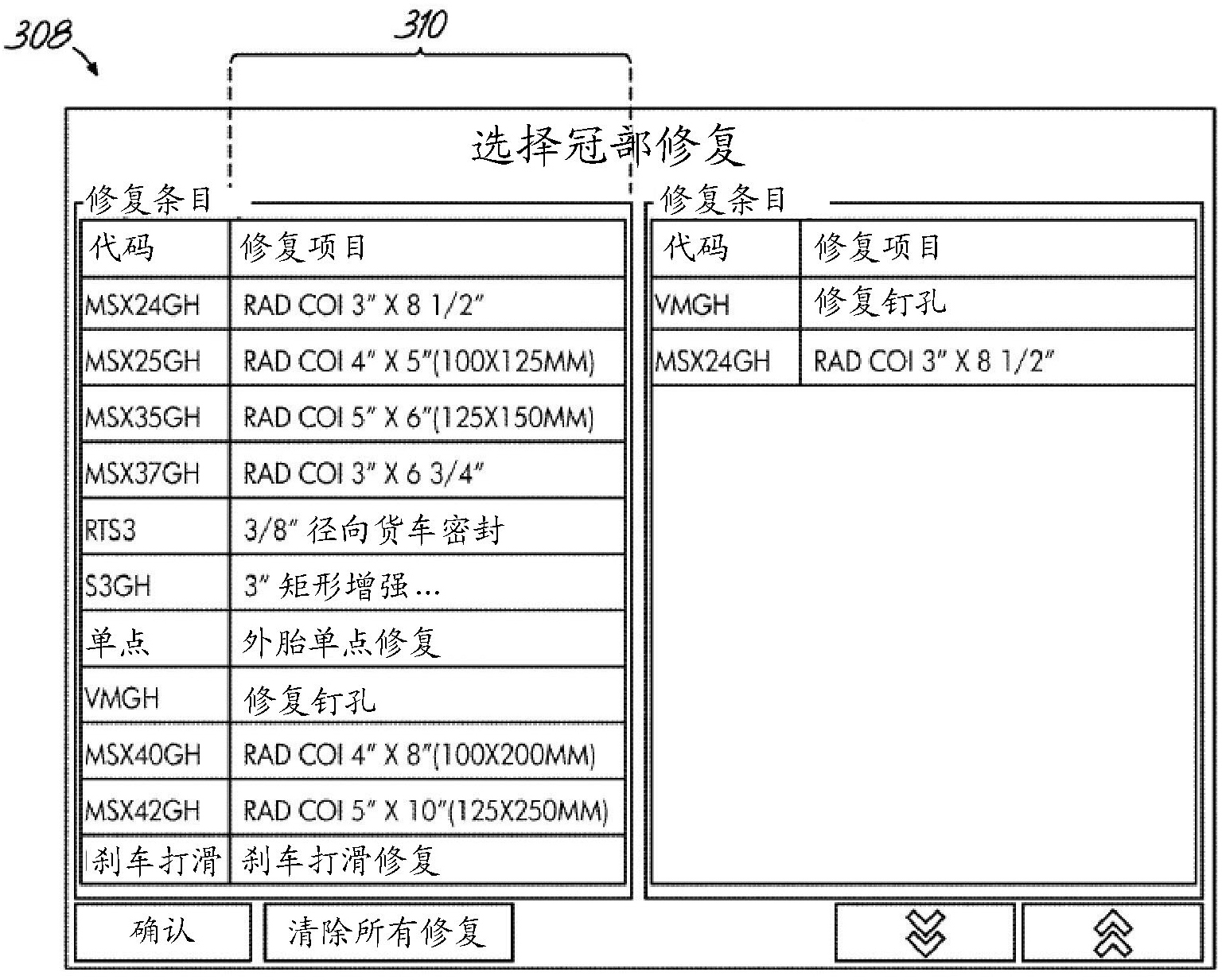

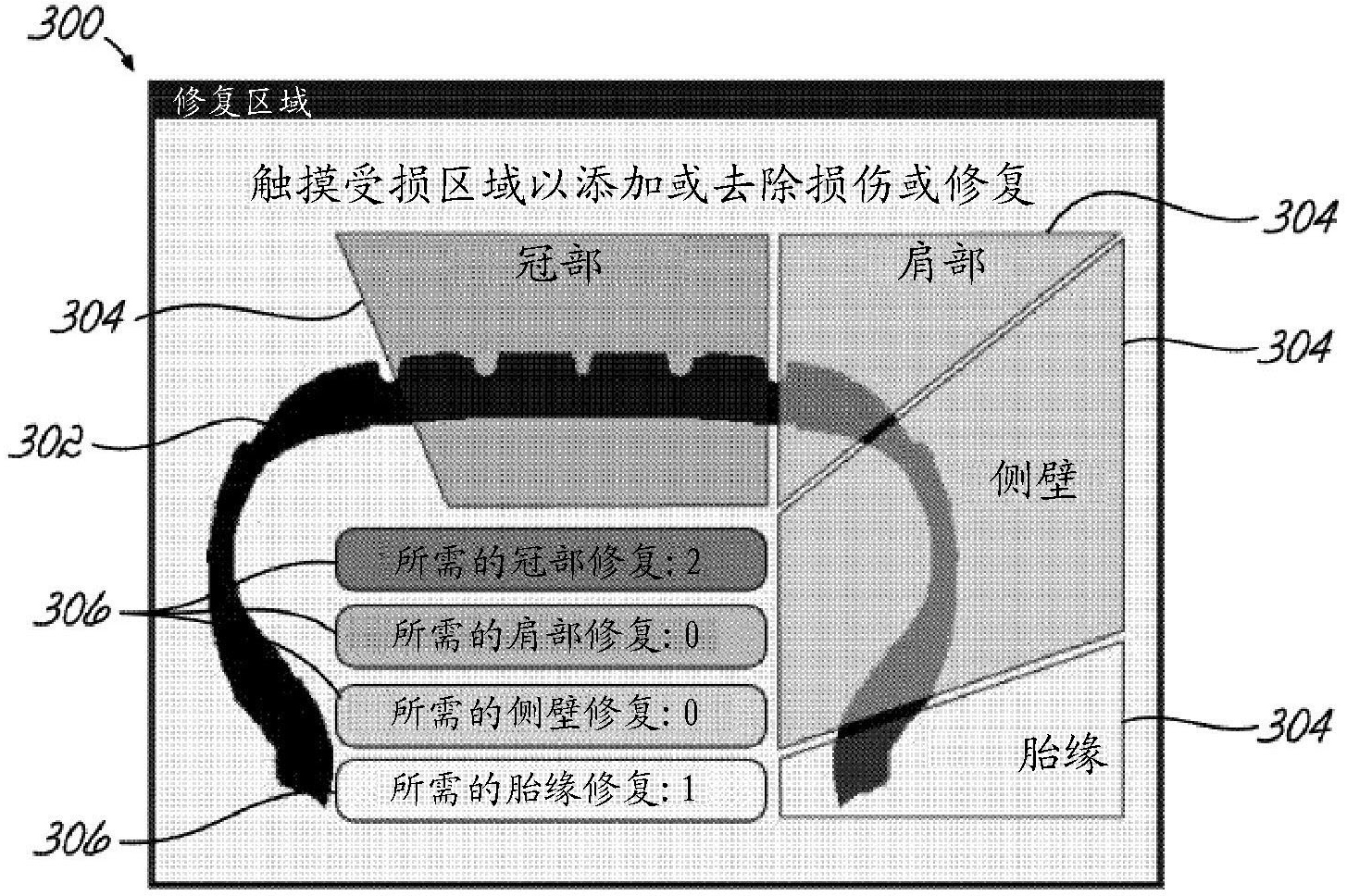

System and method for tracking a tire retread process

InactiveUS20120191617A1Sustainable waste treatmentData processing applicationsEmbedded systemRetread

A system and method for tracking a tire through a retread process include various checkpoints with networked touch screen computers at each checkpoint. At certain inspection and repair checkpoints the touch screen computers display tire cross section images with multiple different regions. Selecting a region allows a technician to change injury or repair data associated with that region of the tire. The computer automatically checks entered information against customer retread specifications and alerts the technician if the tire does not fit the customer's requirements for repairing or retreading the tire.

Owner:THE GOODYEAR TIRE & RUBBER CO

Process for repairing and coating automobile rim

InactiveCN102167014AHigh hardnessStrong adhesionPretreated surfacesVehicle servicing/repairingLacquerAgricultural engineering

The invention discloses a process for repairing and coating an automobile rim, relating to the technical field of automobile beautifying and caring. An operation flow comprises the following steps of: checking the situation of the rim; detaching the rim; checking the damage situation of the rim; checking the polishing situation; sealing edges; spraying priming paint and colored paint; spraying rim coating liquid; pouring the rim coating liquid back to the original position of the rim coating liquid is not used up, sealing and storing at a dark and shady place for later use; checking the rim; and installing. By adopting the process, gaps, scratches, retreads and the like on the rim can be repaired, the original glossiness of the rim can be quickly and effectively recovered after repairing and coating, and the original automobile hardness is enhanced. A rim repairing stick has high adhesion, and is made of the same material as an aluminum ring; a surface rim coating agent is protected; and no difference exists between a repaired rim and a new rim.

Owner:涂绍华

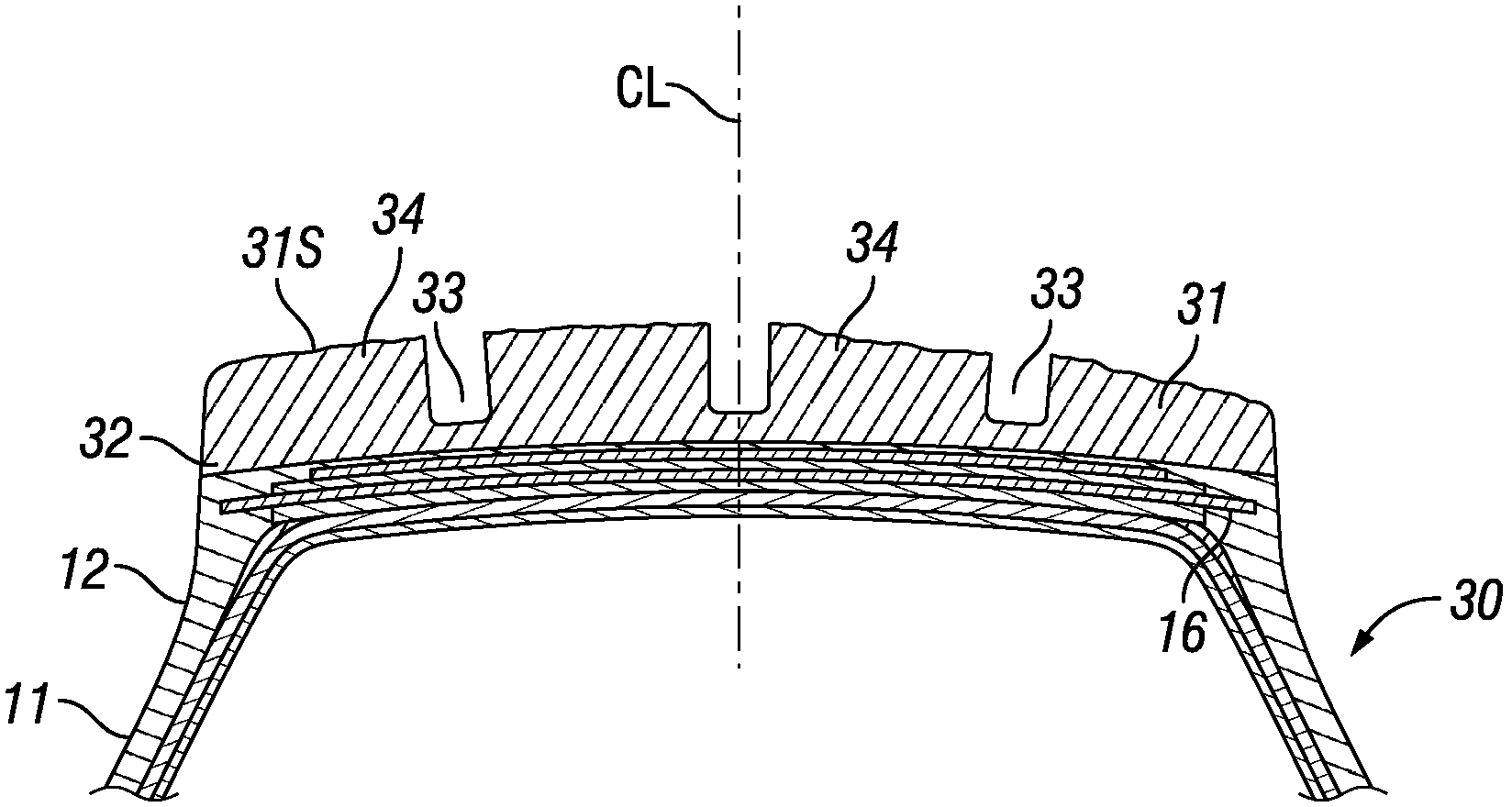

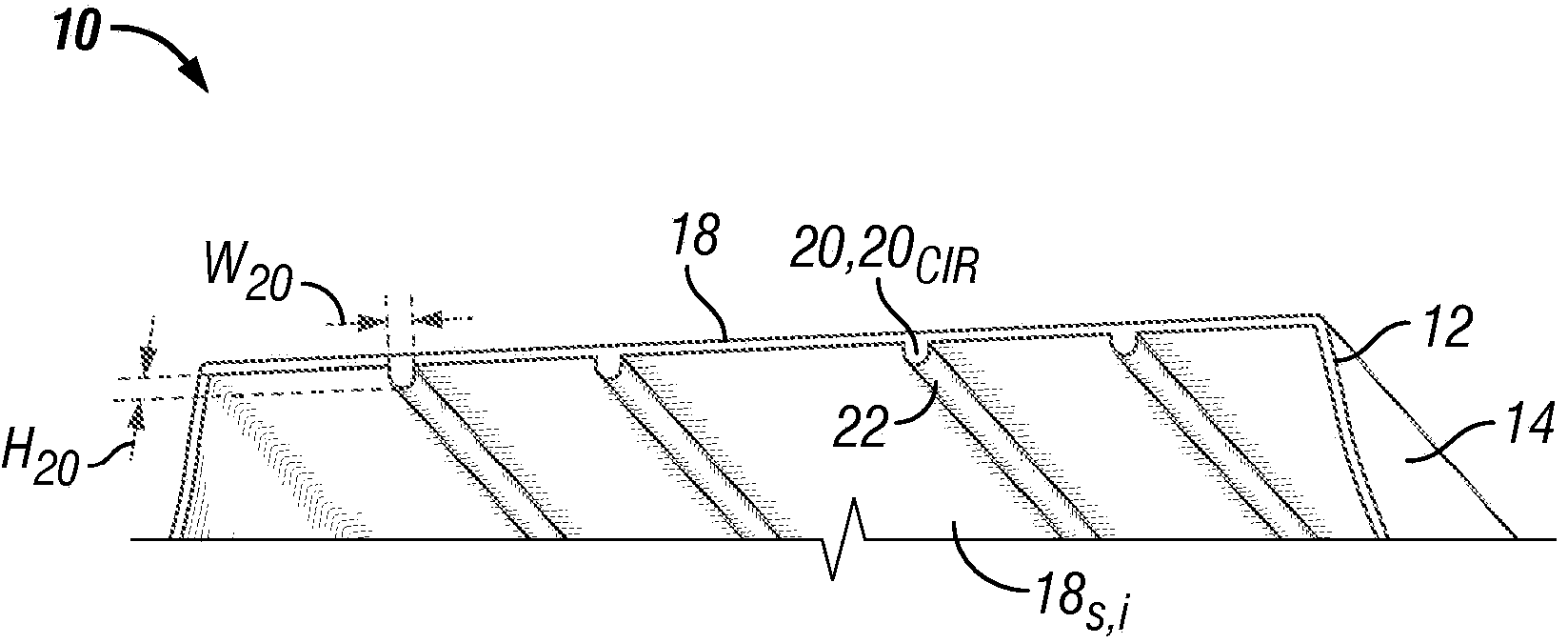

Custom pre-cured retread

The invention includes a retread tire and methods and apparatus for its manufacture, the retread tire including: a tire carcass having a bonding surface arranged along a base layer, the base layer being positioned between the bonding surface and a belt reinforcement package and including at least one base groove open to the bonding surface and a thickness that is variable and asymmetrical; a bonding layer having a thickness that is variable and asymmetrical; and a precured tread band bonded to the tire carcass, the precured tread band comprising a back face bonded to the bonding layer, a front face forming a ground-engaging surface and at least one tread groove extending through at least a portion of the tread band thickness and the back face having a discontinuity associated with the at least one tread groove, which is aligned with one of the at least one base groove.

Owner:MICHELIN RECH & TECH SA +1

Apparatus for tumbling concrete products

InactiveUS7198217B2Edge grinding machinesRotating receptacle mixersEngineeringMechanical engineering

Owner:KORONBIA MACH

Method and apparatus for improved tread splicing

ActiveUS8357254B2Improve performanceGood flexibilityLamination ancillary operationsLaminationEngineeringMechanical engineering

A method of cutting a length of tire tread for a retread tire includes measuring a circumference of the tire casing and cushion gum, and dispensing a length of tire tread from a roll based on the measured circumference. The length of tire tread relative to a tread cutter is adjusted so that the tire tread design at the point where the tread may be cut is between a set of marks formed in the periodically repeating tread design. The tread is then cut along a linear length of the tread disposed within the marks so that the periodically repeating tread pattern appears substantially continuous across a seam defined when the section of tire tread is wrapped around the casing such that the first and second ends meet in abutting relationship.

Owner:BRIDGESTONE BANDAG LLC

Automatic envelope leak detection during tire curing

The present invention includes methods and apparatus for curing retread tires, which includes detecting and controlling a leak in a tire-membrane assembly during such curing operations. The steps of the method include placing a plurality of tire-membrane assemblies within a tire curing chamber; connecting a membrane fluid passage to each curing membrane of each tire-membrane assembly where each passage extends in fluid communication between one of the curing membranes and a pressure source and / or a vacuum source, each membrane fluid passage including a transducer for measuring pressure within the passage and a flow restrictor, in particular embodiments; initiating a curing process; receiving a one or more signal responses from each transducer generated as a function of the fluid pressure within the membrane fluid passages; and determining through a controller whether the signal responses received in the prior step indicate an undesired change in pressure in each curing membrane.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Methods and apparatus for curing retreaded tires

Embodiments of the invention include methods and apparatus for constraining a tread in a desired arrangement about a tire carcass during retreading operations. Such methods include the steps of providing an annular tire carcass configured for receiving a tread. Such methods also include the step of arranging a tread annularly about the precured tire carcass in a desired position to form an assembled retreaded tire. Such methods further include the step of arranging a retread curing membrane about an outer side of the tread, the curing membrane including an interior surface arranged to engage the outer side of the tread and including one or more protrusions extending from the membrane interior surface and into a void of the outer side of the tread. In other embodiments, a separate insert containing protrusions is arranged between a curing membrane and a tire tread for retread curing operations.

Owner:MICHELIN RECH & TECH SA +1

Tire, retread tire and method of producing the same

InactiveUS20070039674A1Less in deterioration of durabilityIncreased durabilitySpecial tyresTyresEngineeringRetread

A tire comprises at least a bias carcass, a cushion rubber and a tread rubber viewing from an inside of a tread center zone in a radial direction of the tire, in which a sulfur content in the cushion rubber is 0.75-1.60% by mass. Also, a tire comprises at least a radial carcass, a belt, and, if necessary, a cushion rubber and a tread rubber viewing from an inside of a tread center zone in a radial direction of the tire, in which the belt is comprised of one or more belt layers each containing plural cords covered with a coating rubber and a sulfur content in the coating rubber and / or the cushion rubber is 0.75-1.80% by mass. Furthermore, a retread tire is formed from these tires by repetitive retreading.

Owner:BRIDGESTONE CORP

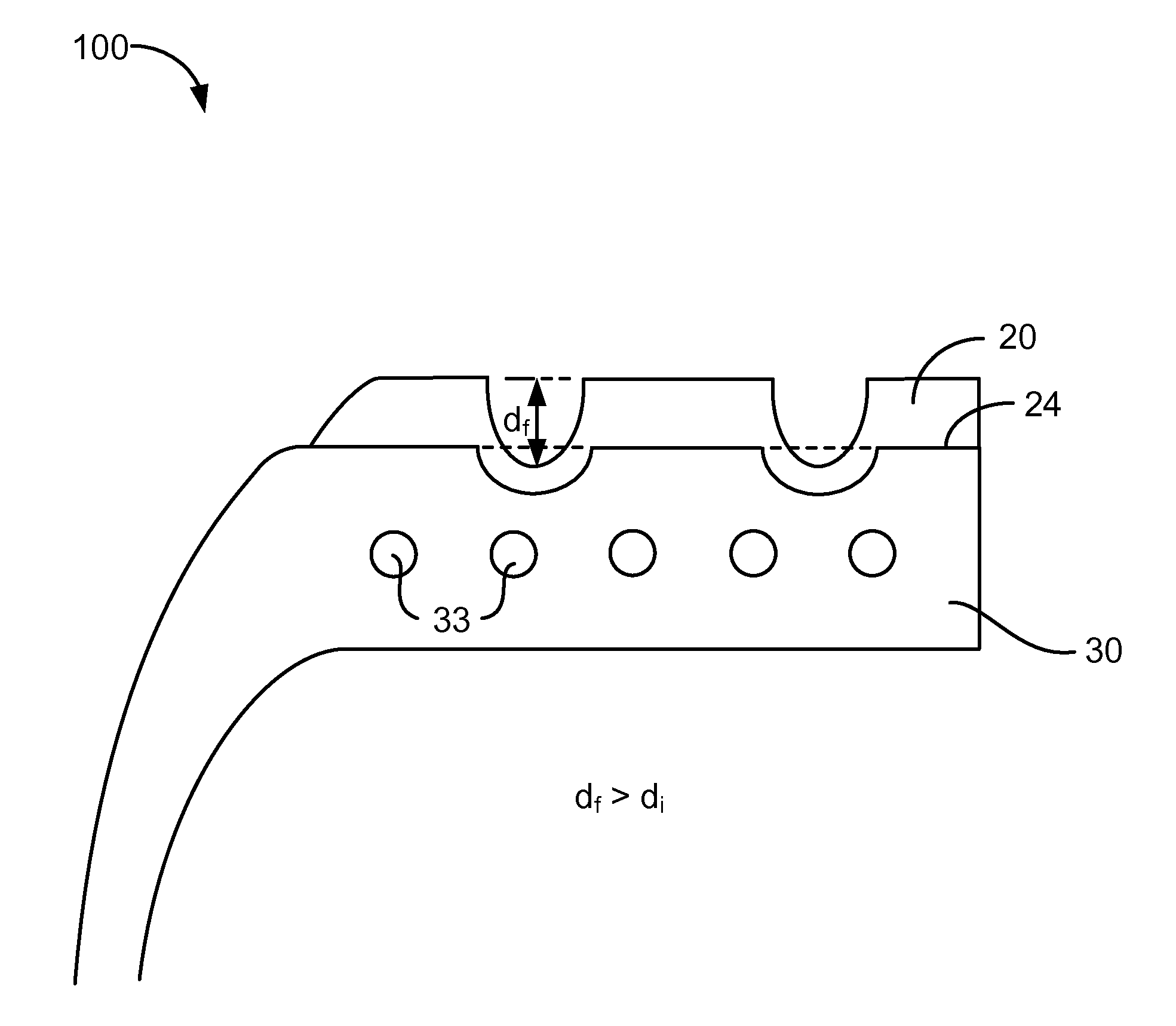

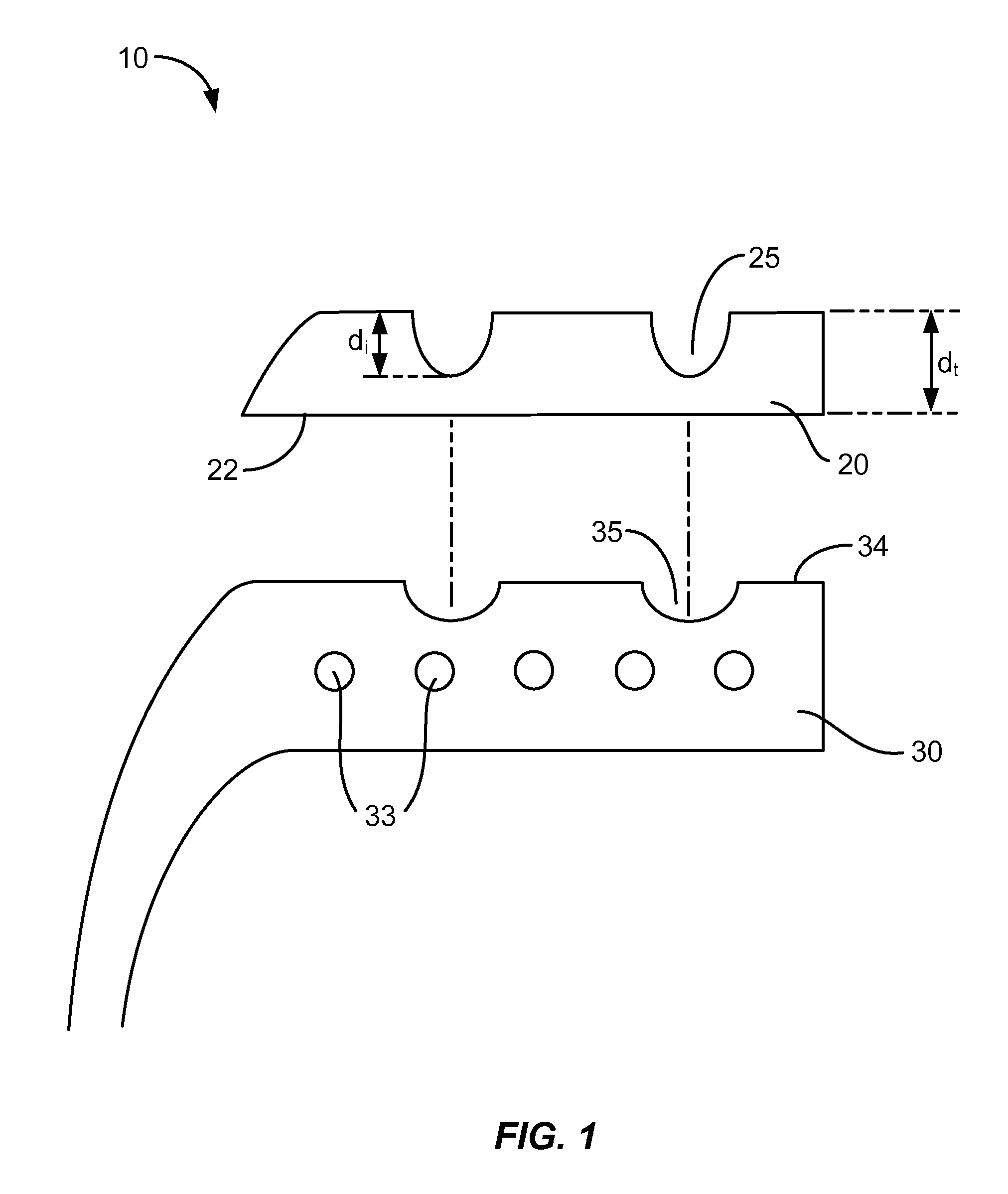

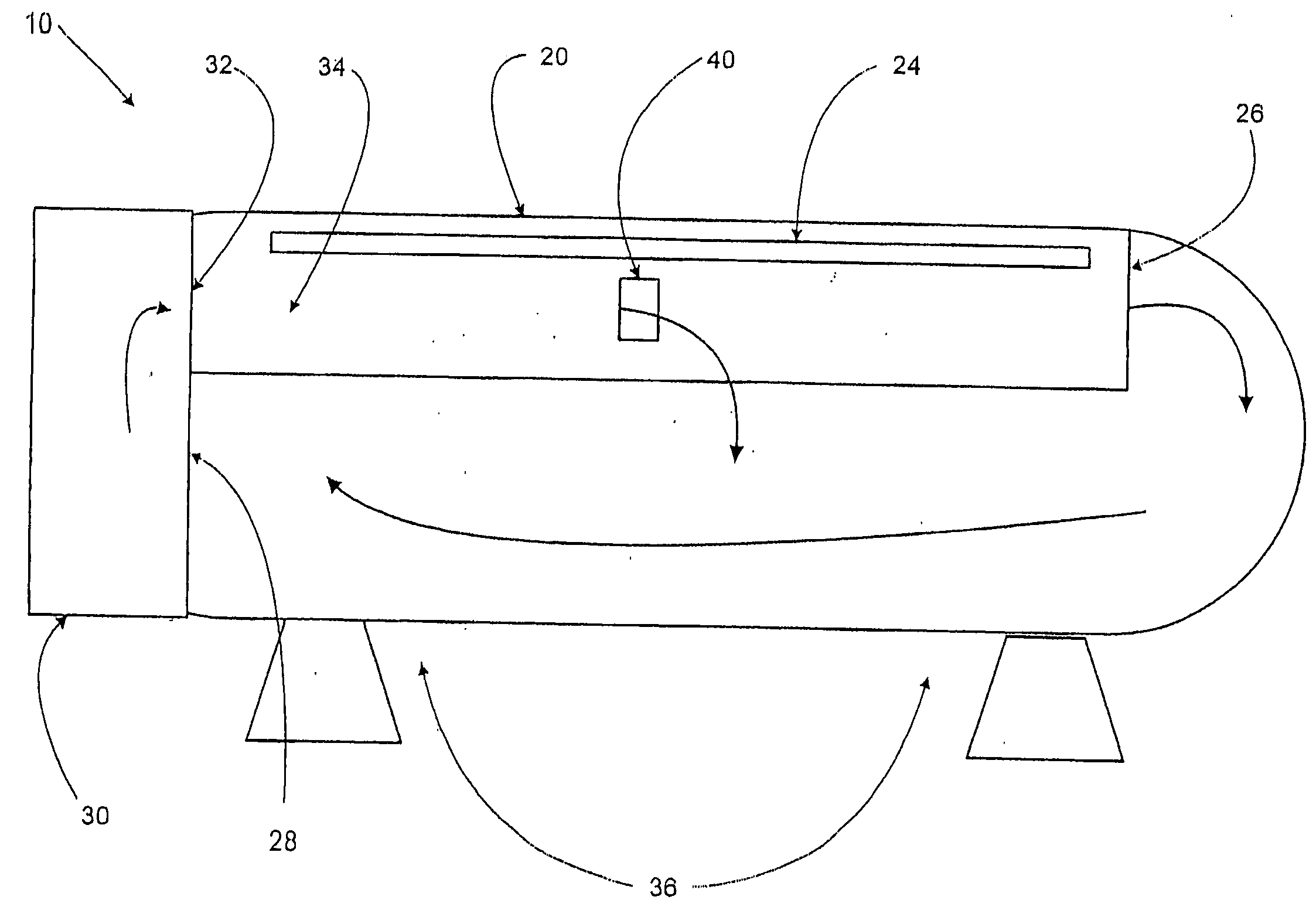

Systems and Methods for Forming Retread Tires Using Flat Backed Tread

Retreaded tires and methods for manufacturing the same. A tire is retreaded with a pre-cured tread band having a smooth back face and one or more tread grooves with compliant skid base gauge on a front face. The grooves in the pre-cured tread band align with grooves in a tire casing and upon curing conform to the shape of the casing grooves. The tire tread depths are greater than the original tire tread depth of the pre-cured tread band, thereby increasing the wear volume of the tire tread.

Owner:BRIDGESTONE BANDAG LLC

System and method for tracking a tire retread process

A system and method for tracking a tire through a retread process include various checkpoints with networked touch screen computers at each checkpoint. At certain inspection and repair checkpoints the touch screen computers display tire cross section images with multiple different regions. Selecting a region allows a technician to change injury or repair data associated with that region of the tire. The computer automatically checks entered information against customer retread specifications and alerts the technician if the tire does not fit the customer's requirements for repairing or retreading the tire.

Owner:THE GOODYEAR TIRE & RUBBER CO

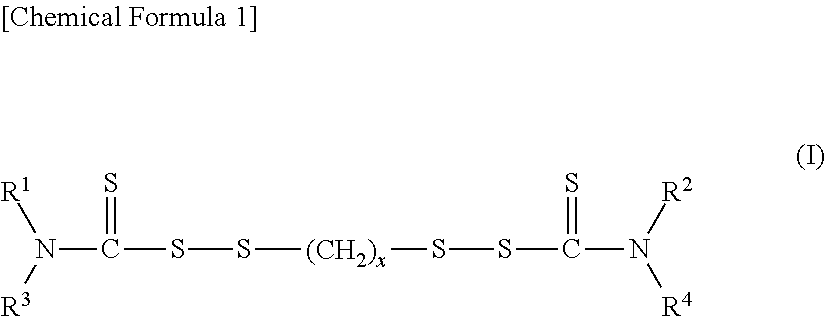

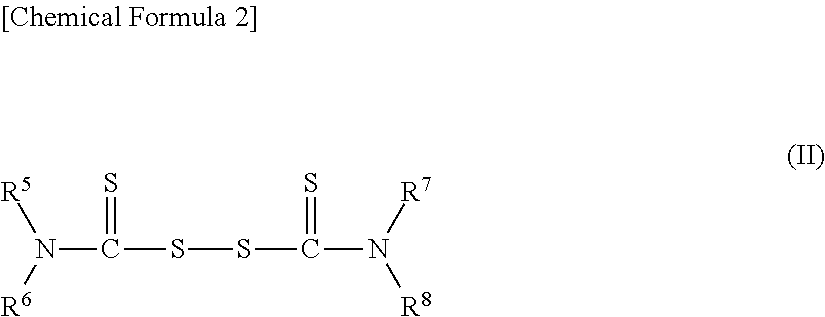

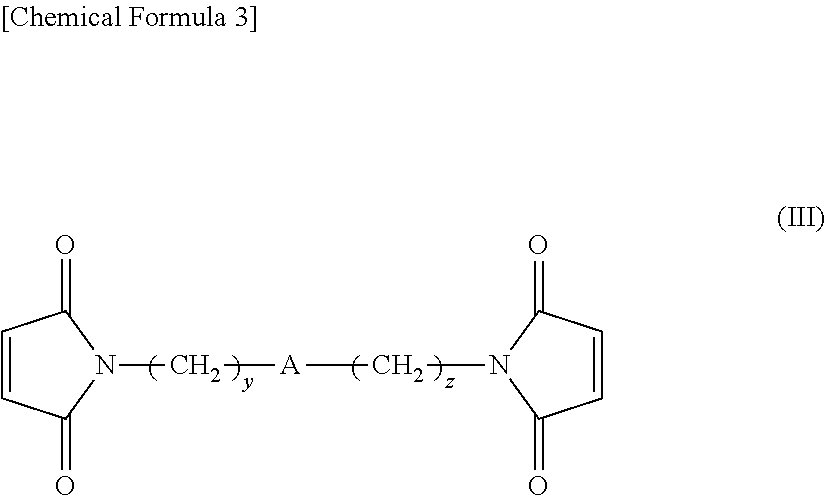

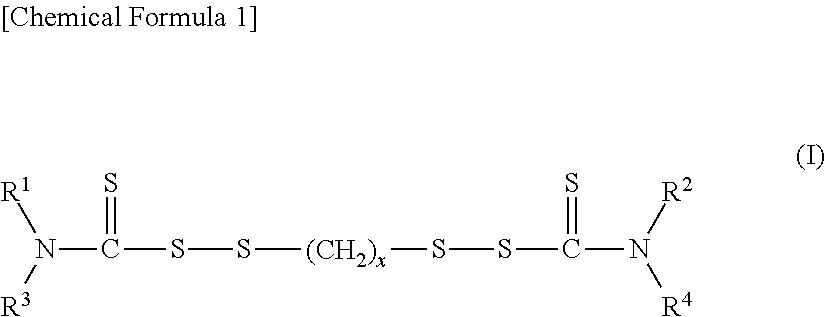

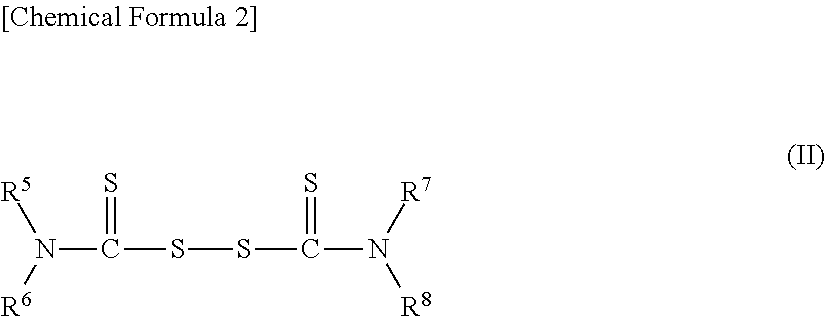

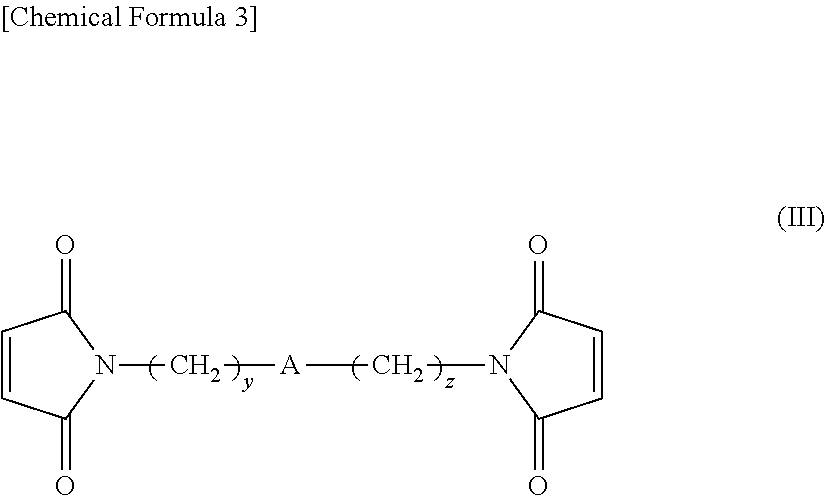

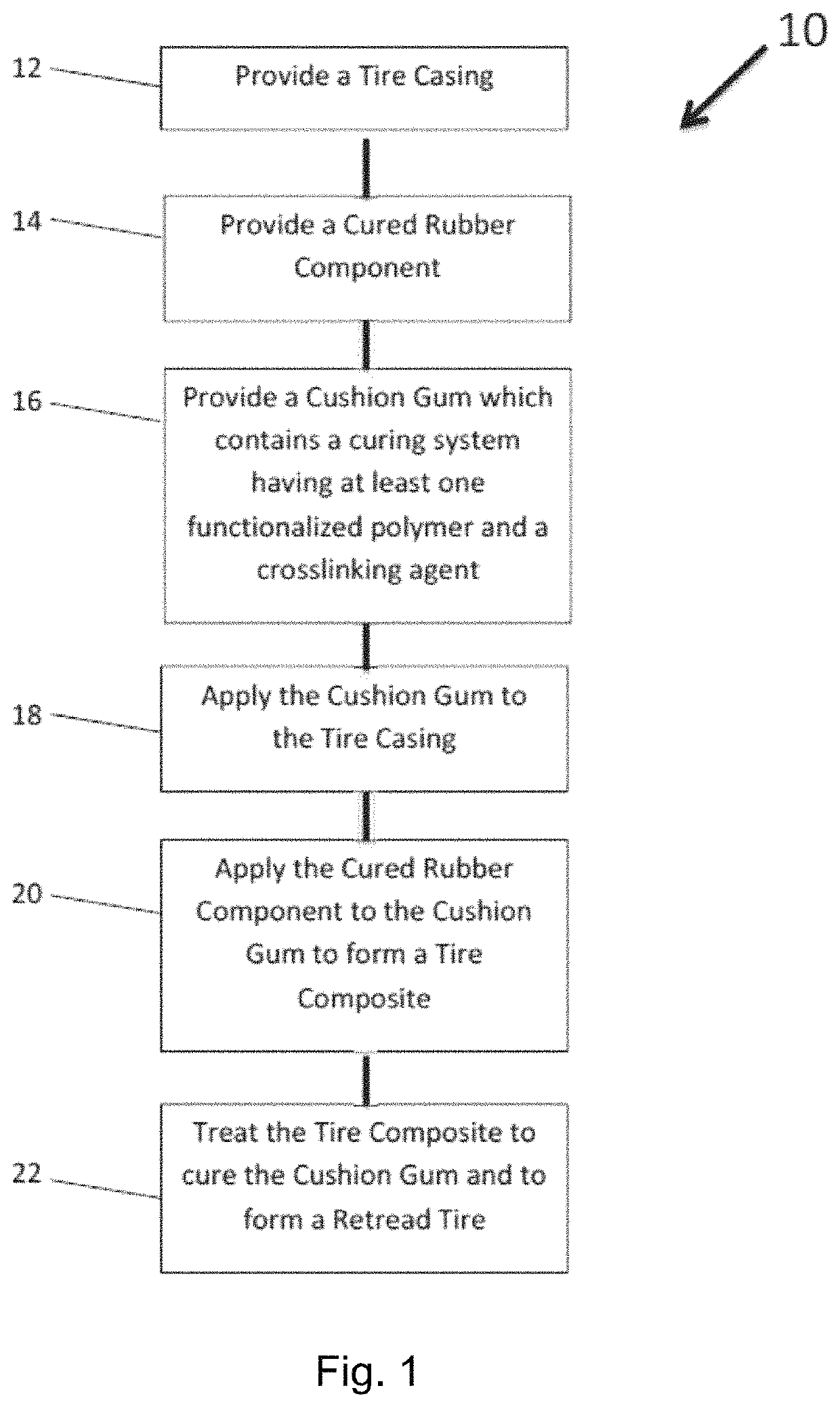

Methods for retreading tires

A process for retreading a tire, the process comprising the steps of providing a tire casing; providing a cured rubber component having first and second planar surfaces, where the first planar surface includes a tread pattern; providing a cushion gum, wherein the cushion gum is a composition including a functional polymer including at least one functional group, and a crosslinking agent including at least two moieties that will react with the functional group of the functional elastomer; applying the cushion gum to the tire casing; applying the second planar surface of the cured rubber to the cushion gum to form a tire composite; and treating the tire composite to thereby form a retread tire.

Owner:BRIDGESTONE AMERICAS TIRE OPERATIONS LLC

Autoclave for curing retreaded tires

InactiveUS20070079937A1Less-efficient heat transferImprove heat transfer performanceMuffle furnacesLaminationRetreadAutoclave

An improved autoclave for curing retread tires includes a chamber with circulating air flow having turbulence generating devices located in a middle length-wise portion of the chamber. The turbulence generating devices include apertures to guide air from a supply duct into the chamber, and / or wedge-shaped elements or fins mounted on the interior wall of the chamber to disrupt the air flow and cause turbulence.

Owner:MICHELIN RECH & TECH SA

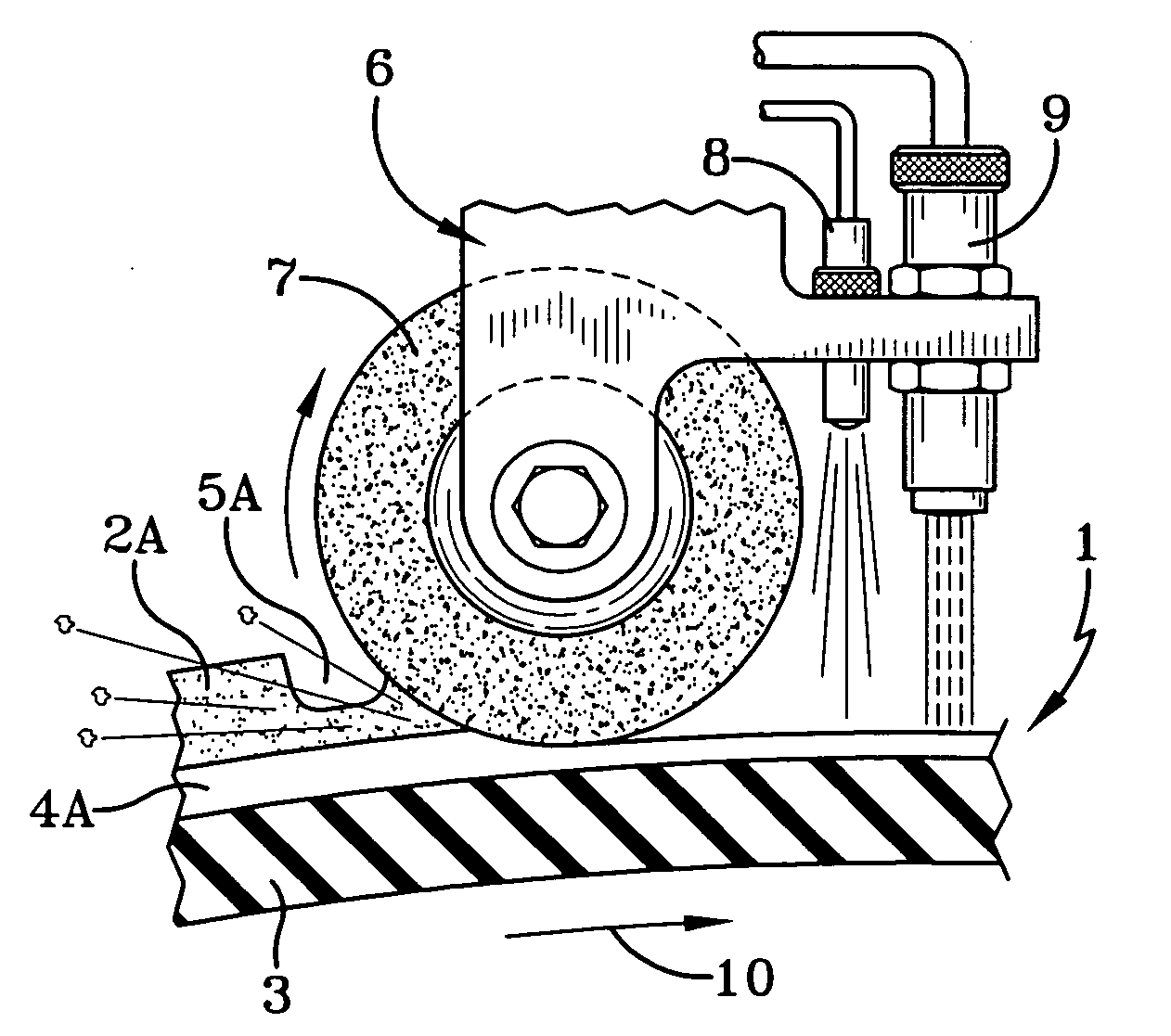

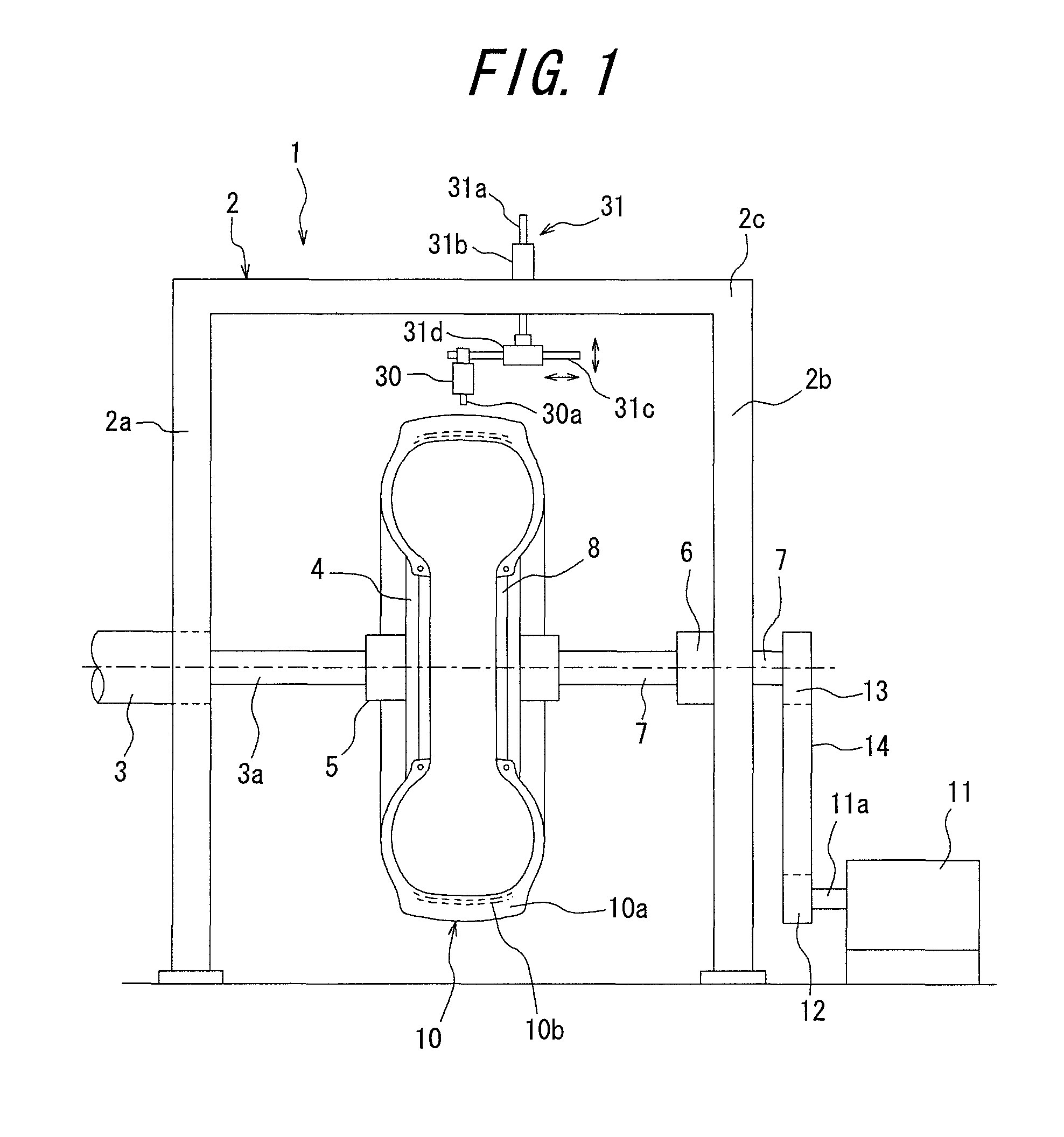

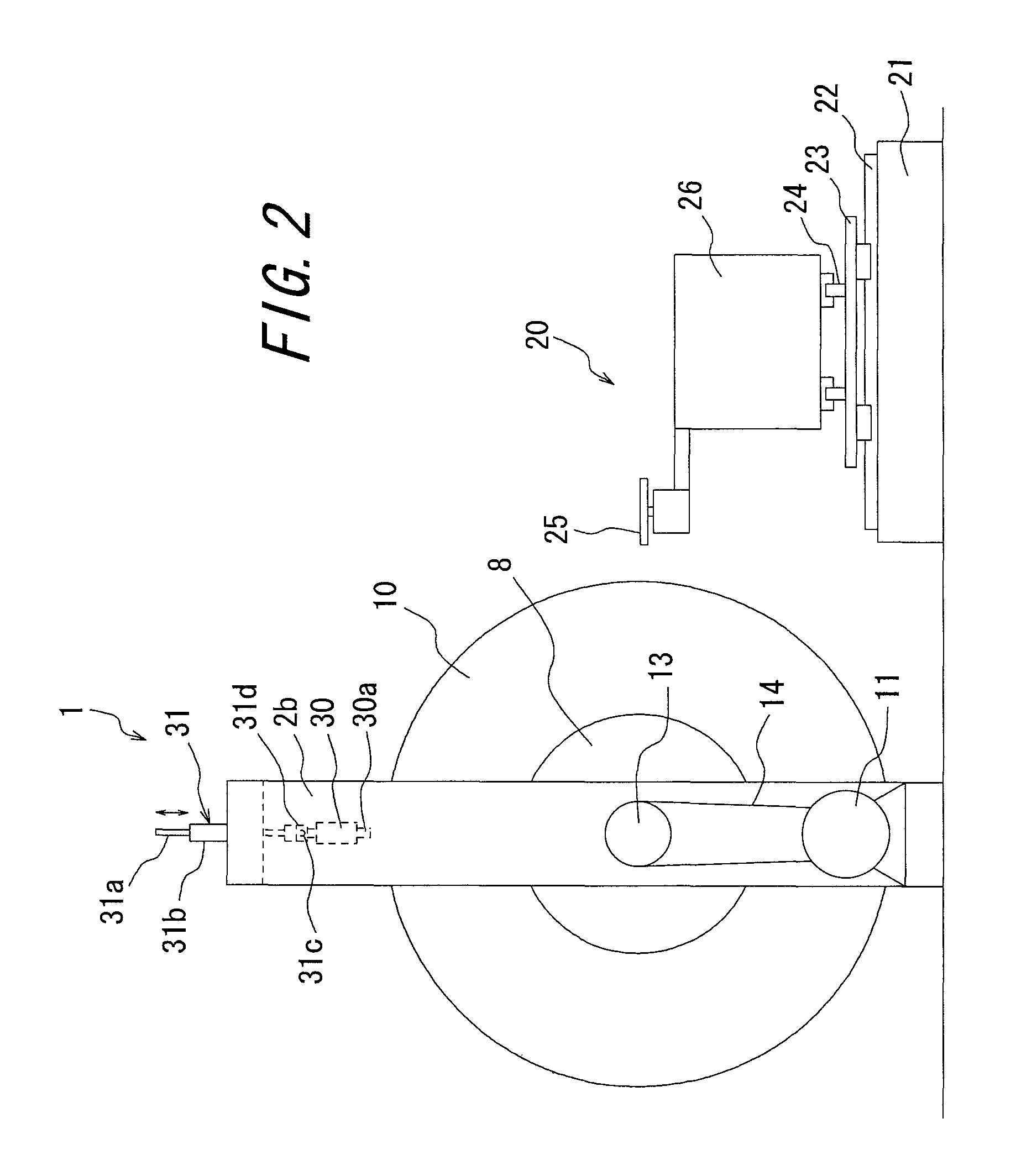

Method of producing retread tire and grinding apparatus for used tire

Owner:BRIDGESTONE CORP

System and method for evaluating surface finish of tire retread

A measurement system scans the given surface of a tire component (e.g., a brush-finished tread or buffed tire casing) to electronically measure data points corresponding to vertical and horizontal coordinates along the given surface. Associated computer processors electronically calculate the slope at a plurality of different locations by determining the degree of steepness (e.g., rise over run, angle or grade) between selected ones of the first and second coordinates and electronically comparing at least one slope-based parameter to one or more predetermined levels to determine a characterization defining one or more of surface adhesion fitness, finishing brush wear level and brush bristle placement location. Slope may be determined between every adjacent pair of data points or between selected data points (e.g., identified local maximum and minimum). The at least one-slope based parameter compared to the predetermined levels may correspond to the slopes themselves or to a calculated average slope value.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com