Custom pre-cured retread

A tire retreading and pre-curing technology, applied to tire parts, tire tread/tread pattern, tire, etc., can solve the problems of high initial cost, expensive, low retreading cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

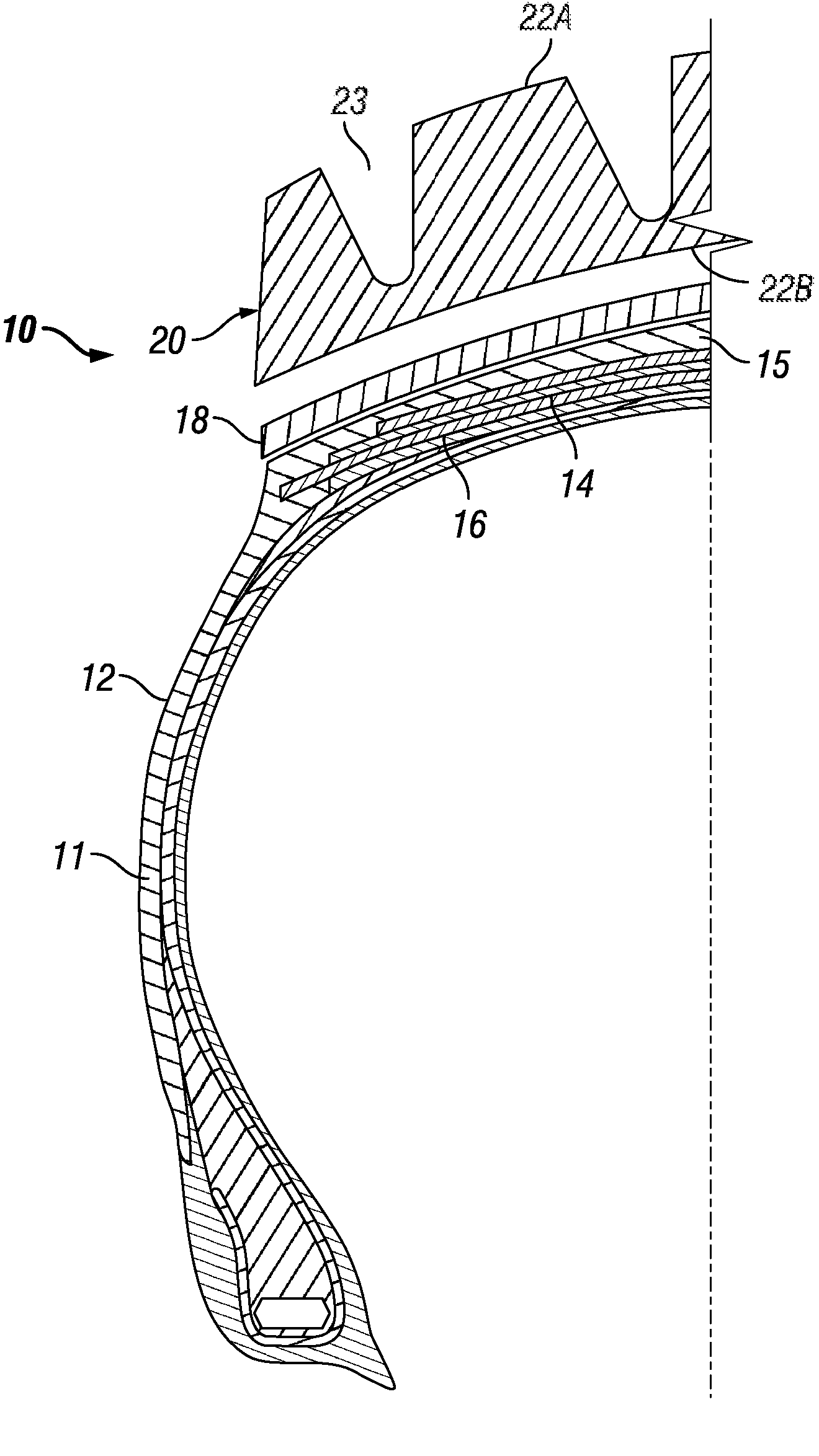

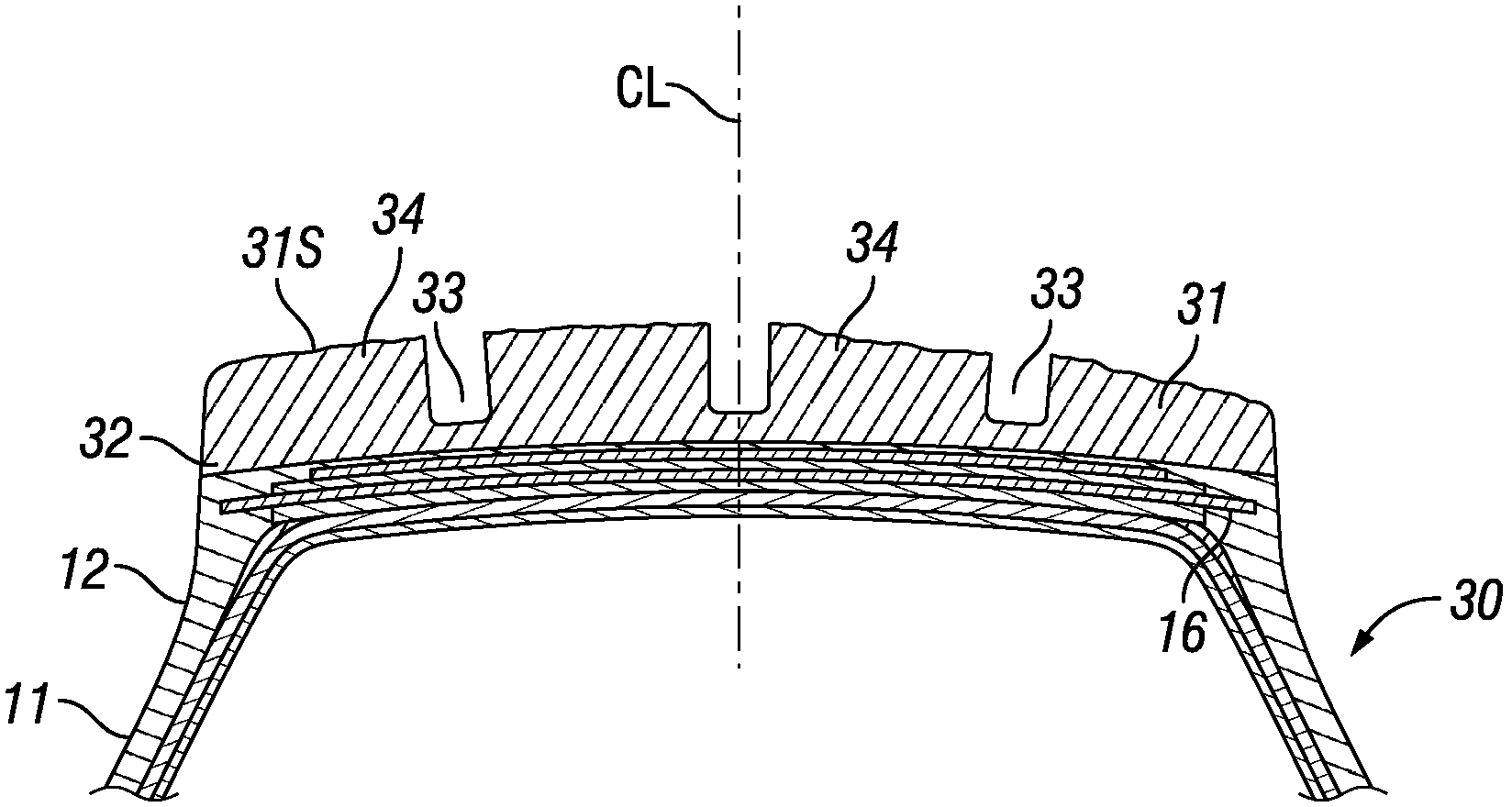

[0032] Certain embodiments of the present invention provide retreaded tires having a pre-cured tread band and, in certain embodiments, a tread band bonding surface bonded to the tire (the bonding surface is located between the thickness variations of the tire and / or on top of an asymmetric bonding layer) of a precured tread band, and a method for producing such a retreaded tire is provided. Varying thickness and / or asymmetrical bonding layers can create, for example, a varying thickness, asymmetrical base layer to bond the tread band to the tire, where a pre-existing tire's tread has experienced, for example, uneven wear or manufacturing defects Such a base layer may arise from time to time. Certain embodiments utilize a bonding layer of varying thickness to fill the area between the desired bonding location of the tread band and the bonding surface of the tire, the tread band being located at a desired distance from the bonding surface to form a retread of a particular size o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com