All-steel radial tubeless tire and preparation method thereof

A radial and tire technology, applied in the field of all-steel radial tubeless tires, can solve the problems of not being able to effectively improve the adhesive force between the crown and the belt layer, not being able to prevent the separation of the belt layer and the crown, and technical difficulties. , to achieve the effect of easy implementation, enhanced rigidity, economical and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

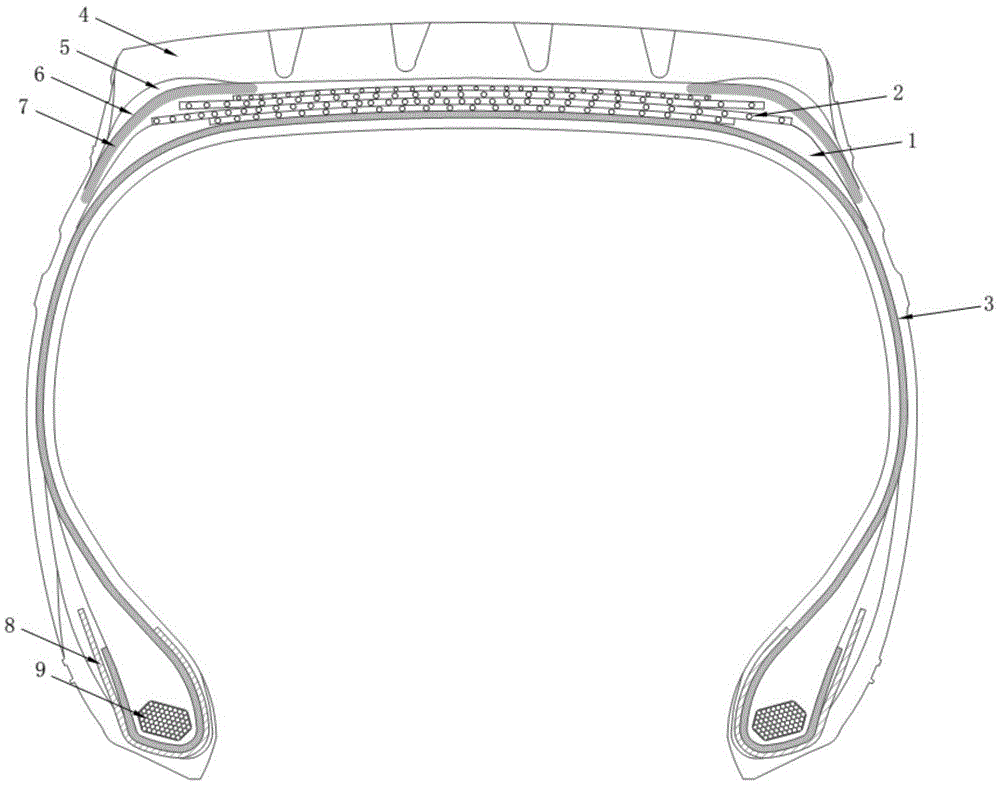

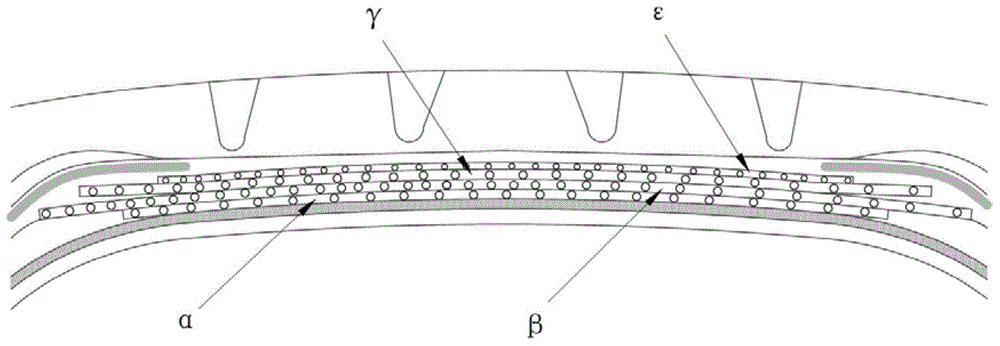

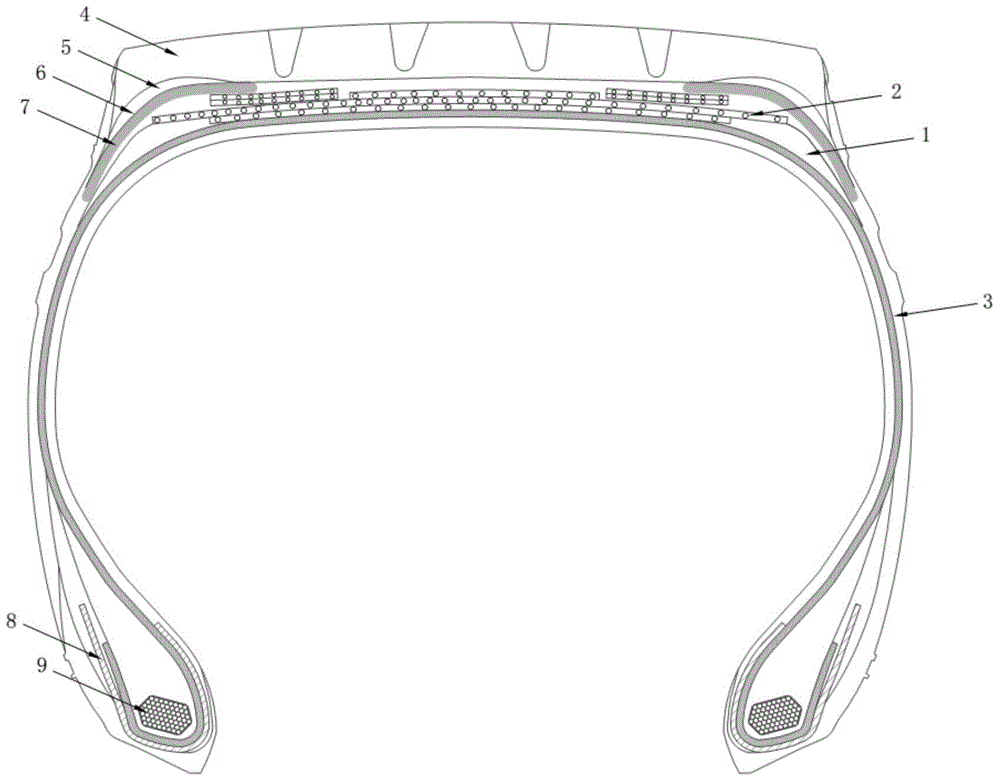

[0021] An all-steel radial tire with a new type of crown structure with an under-cap film, the structure of which comprises a crown compound, a shoulder pad rubber (1), a belt layer (2), a carcass ply, an inner liner, a tire The side (3) and bead; the structure of the crown composite part from the outside to the inside is the tread rubber (4), the base rubber (5), the buffer film (6) and the under-cap film (7). The tire is characterized in that: the sidewall (3) is close to the ladle cord (8) and turns up the wire ring (9) to the tire shoulder (1); the outer end point of the under-cap film (7) is located on the sidewall ( 3) Between the inner side and the tire shoulder (1), the inner end point is located between the crown buffer film (6) and the No. 4 belt layer, and the end points of the No. 2, 3, and No. 4 belt layers are closed. The thickness of film (7) under the crown is 2mm, and width is 60mm. The distance from the outer edge of the film (7) under the crown to the edge ...

Embodiment 2

[0028] An all-steel radial tire with a new type of crown structure with an under-cap film, the structure of which comprises a crown compound, a shoulder pad rubber (1), a belt layer (2), a carcass ply, an inner liner, a tire The side (3) and bead; the structure of the crown composite part from the outside to the inside is the tread rubber (4), the base rubber (5), the buffer film (6) and the under-cap film (7). The tire is characterized in that: the sidewall (3) is close to the ladle cord (8) and turns up the wire ring (9) to the tire shoulder (1); the outer end point of the under-cap film (7) is located on the sidewall ( 3) Between the inner side and the tire shoulder (1), the inner end point is located between the crown buffer film (6) and the 0° belt layer, and the end points of No. 2, No. 3 and 0° belt layer are closed. The thickness of film (7) under the crown is 1mm, and width is 80mm. The distance from the outer edge of the film (7) under the crown to the edge of the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com