Shear part joint composite structure of composite beam bridge and construction method of shear part joint composite structure

A composite structure and construction method technology, which is applied to bridge parts, bridges, bridge construction, etc., can solve problems such as low bonding performance of old and new concrete, difficulty in estimating shrinkage and creep, and poor concrete quality, so as to improve the tensile performance of the top and avoid Structural damage or even destruction, the effect of process improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

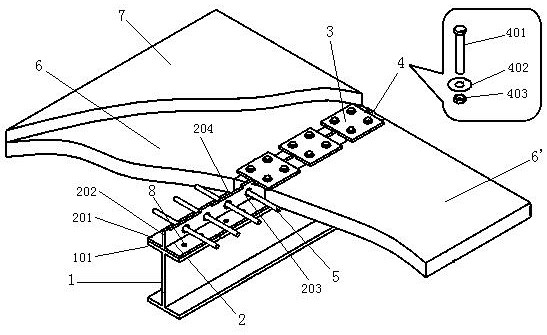

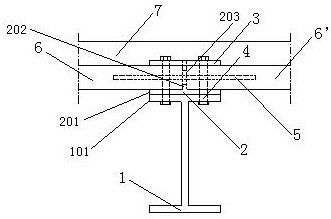

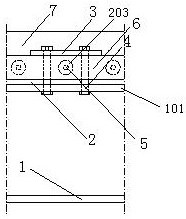

[0033] Such as figure 1 , figure 2 As shown, the shear member joint composite structure of the composite girder bridge provided by the present invention includes a steel structure composed of a steel beam and a connecting structure with left and right grooves arranged on the steel beam along the length, extending into the left and right sides of the connecting structure respectively. The left and right concrete slabs 6, 6' fixed by the bolt connector 4 in the groove, the covering layer 7 covering the connecting structure and the left and right concrete slabs 6, 6'; the length of the steel beam is determined according to the design requirements, Generally not more than 80 meters.

[0034] Between the left and right grooves of the connection structure, there are a number of transverse steel bars 5 extending into the left and right concrete slabs 6, 6'.

[0035] The connecting structure includes an inverted T-shaped lower splicing piece 2 fixed on the steel beam and several pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com