Black sanitary towel

A sanitary napkin, black technology, applied in the field of sanitary napkins, can solve the problems of poor antibacterial, safety, and degradable effects of sanitary napkins, and achieve the effect of consistent bacterial growth and good moisture conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

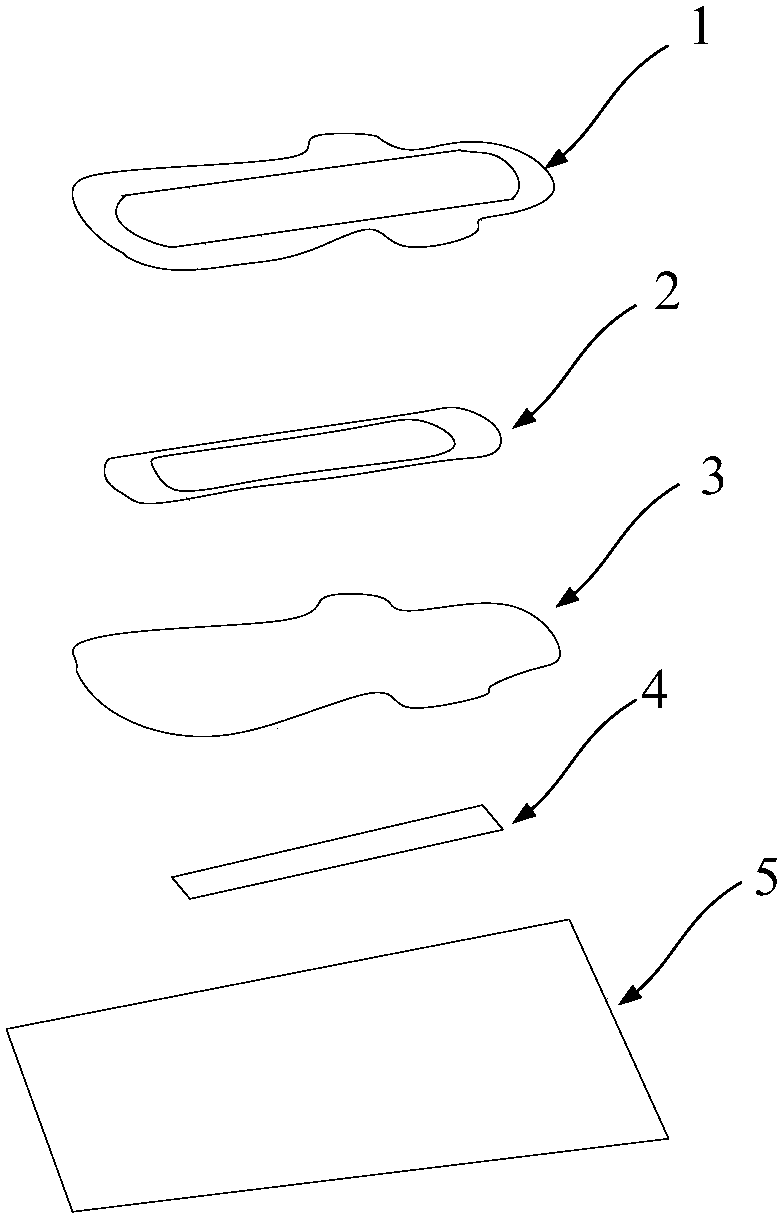

[0055] Such as figure 1 and figure 2 As shown, a black sanitary napkin is provided in the embodiment of the present invention. The black sanitary napkin includes a sanitary napkin body, and the sanitary napkin body includes a surface non-woven fabric layer 1, an absorbent core 2, a bottom layer of anti-woven fabric from top to bottom. Permeable membrane 3; the surface layer of non-woven fabric comprises an intermediate sheet 11, retaining wall 12 and side wings 13; 3 Cooperate and completely cover the absorbent core 2; the side wings 13 are arranged on both sides of the surface non-woven fabric layer 1 for fixing the sanitary napkin body; both sides of the middle sheet are provided with the The retaining wall 12, the retaining wall 12 is used to block the side leakage of the absorbents by the intermediate sheet 11 or the absorbent core 2; the side wings 13 and the intermediate sheet 11 are fixedly connected by the retaining wall 12; the surface layer has no Both the woven f...

Embodiment 2

[0070] This embodiment discloses a specific material and preparation method of the surface non-woven fabric layer in the black sanitary napkin.

[0071] 30wt% of black polylactic acid fiber and 70wt% of black viscose fiber are used as raw material fibers to be prepared through a hydroentangling process. The spunlace process includes the following steps. The raw material fibers are opened, mixed, and carded to form a fiber web layer with a thickness of 1.0-1.2 mm, and then the fiber web layer is sprayed with high-pressure and high-speed fine water flow to form a certain thickness. and strong non-woven fabrics, and perform water-repellent treatment on non-woven fabrics. In the spunlace process, the FLLBG-250 spunlace machine is used, the number of spunlace passes is 6, and the number of spunlace nozzles is 6 groups. There are six spunlaces in the spunlace step; the pressure of the first spunlace head is 40bar; the pressure of the second spunlace head is 35bar; the pressure of t...

Embodiment 3

[0076] This embodiment discloses a specific surface non-woven fabric layer material in a black sanitary napkin and a preparation method thereof.

[0077]Using 50wt% black polylactic acid fiber and 50wt% binchotan fiber as raw material fibers, it is prepared through a hydroentangling process. The spunlace process includes the following steps: raw material fibers are opened, mixed, and carded to form a fiber web layer with a thickness of 1.0 to 1.5 mm, and then the fiber web layer is sprayed with high-pressure and high-speed fine water flow to form a certain thickness. and strong non-woven fabrics, and perform water-repellent treatment on non-woven fabrics. In the spunlace process, the FLLBG-250 spunlace machine is used, the number of spunlace passes is 6, and the number of spunlace nozzles is 6 groups. There are six spunlaces in the spunlace step; the pressure of the first spunlace head is 42bar; the pressure of the second spunlace head is 38bar; the pressure of the third spun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com