Basalt fiber impregnating compound and preparation method thereof

A technology of basalt fiber and wetting agent, applied in the field of materials, can solve the problems of lack of public reports on wetting agent, and achieve the effects of convenient subsequent processing, good permeability and good hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

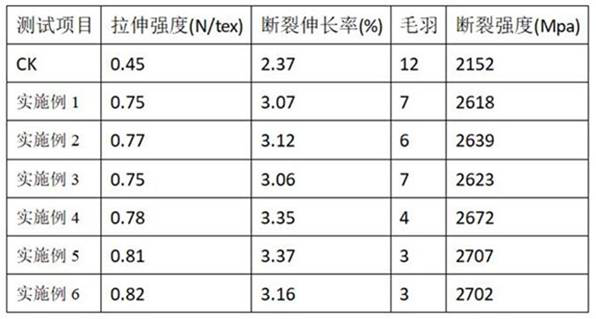

Examples

Embodiment 1

[0050] In this implementation, the preparation steps of the basalt fiber sizing agent are as follows.

[0051] (1) Feed

[0052] Weigh each component according to the following mass ratio: 7g alkylphenoxypolyoxyethylene methyldiethoxysilane, 55g glycerol triglycidyl ether, 700g deionized water, 2.7g acetic acid, 90g absolute ethanol , 12g glucomannan, 0.9g ammonium chloride, 9g polyethylene glycol (molecular weight 200~500), set aside.

[0053] (2) Prepare Solution A

[0054] Dissolve the weighed alkylphenoxypolyoxyethylene methyldiethoxysilane in deionized water, then add acetic acid, adjust the pH value to 3, and make it hydrolyze. The hydrolysis time is 1.2h; then, add Add glycerol triglycidyl ether, stir evenly, and react for 1.5 hours to obtain solution A.

[0055] (3) Prepare Solution B

[0056]Dissolve the weighed glucomannan in absolute ethanol, stir evenly, and let stand for 2.5 hours to obtain solution B.

[0057] (4) Preparation of wetting agent

[0058] Add t...

Embodiment 2

[0060] In this implementation, the preparation steps of the basalt fiber sizing agent are as follows.

[0061] (1) Feed

[0062] Each component was weighed according to the following mass ratio: 5g vinyl triperoxy tert-butylsilane, 35g sorbitol glycidyl ether, 500g deionized water, 1.8g acetic acid, 70g absolute ethanol, 20g glucomannan, 0.6g ammonium chloride, 4g polyethylene glycol (molecular weight 300~500), set aside.

[0063] (2) Prepare Solution A

[0064] Dissolve the weighed vinyl triperoxy-tert-butylsilane in deionized water, then add acetic acid, adjust the pH value to 6, and make it hydrolyze, the hydrolysis time is 2.0h; then, add sorbitol glycidol to it Ether, stirred evenly, and reacted for 0.8h to obtain solution A.

[0065] (3) Prepare Solution B

[0066] Dissolve the weighed glucomannan in absolute ethanol, stir evenly, and let stand for 1.2 hours to obtain solution B.

[0067] (4) Preparation of wetting agent

Embodiment 3

[0070] In this implementation, the preparation steps of the basalt fiber sizing agent are as follows.

[0071] (1) Feed

[0072] Weigh each component according to the following mass ratio: 9g γ-glycidyl etheroxypropyl trimethoxysilane, 50g glycerol triglycidyl ether, 900g deionized water, 2.6g acetic acid, 80g absolute ethanol, 15g glucomannan Polysaccharide, 0.8g ammonium chloride, 7g polyethylene glycol (molecular weight 200~500), set aside.

[0073] (2) Prepare Solution A

[0074] Dissolve the weighed γ-glycidyl etheroxypropyltrimethoxysilane in deionized water, then add acetic acid, adjust the pH value to 5, and make it hydrolyze. The hydrolysis time is 1.2h; then, add glycerine to it Alcohol triglycidyl ether, stirred evenly, and reacted for 2.5 hours to obtain solution A.

[0075] (3) Prepare Solution B

[0076] Dissolve the weighed glucomannan in absolute ethanol, stir evenly, and let stand for 2.0 hours to obtain solution B.

[0077] (4) Preparation of wetting age...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com