Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Achieve blending" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

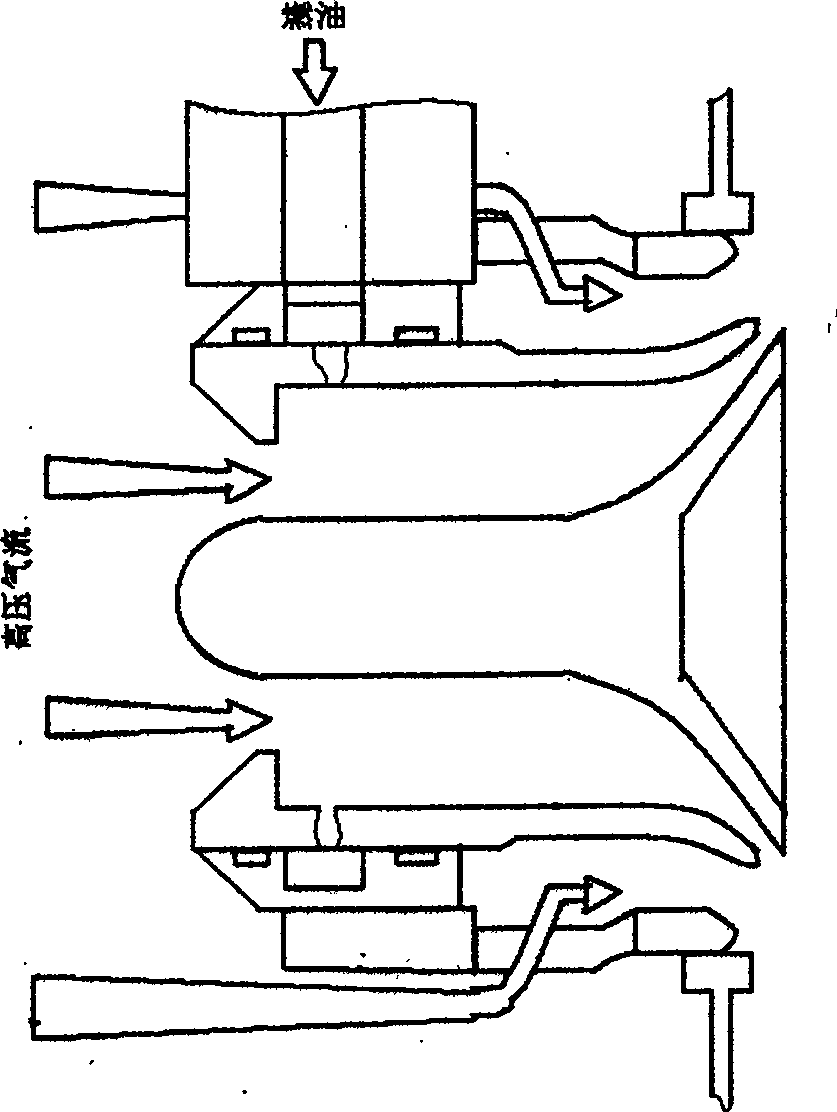

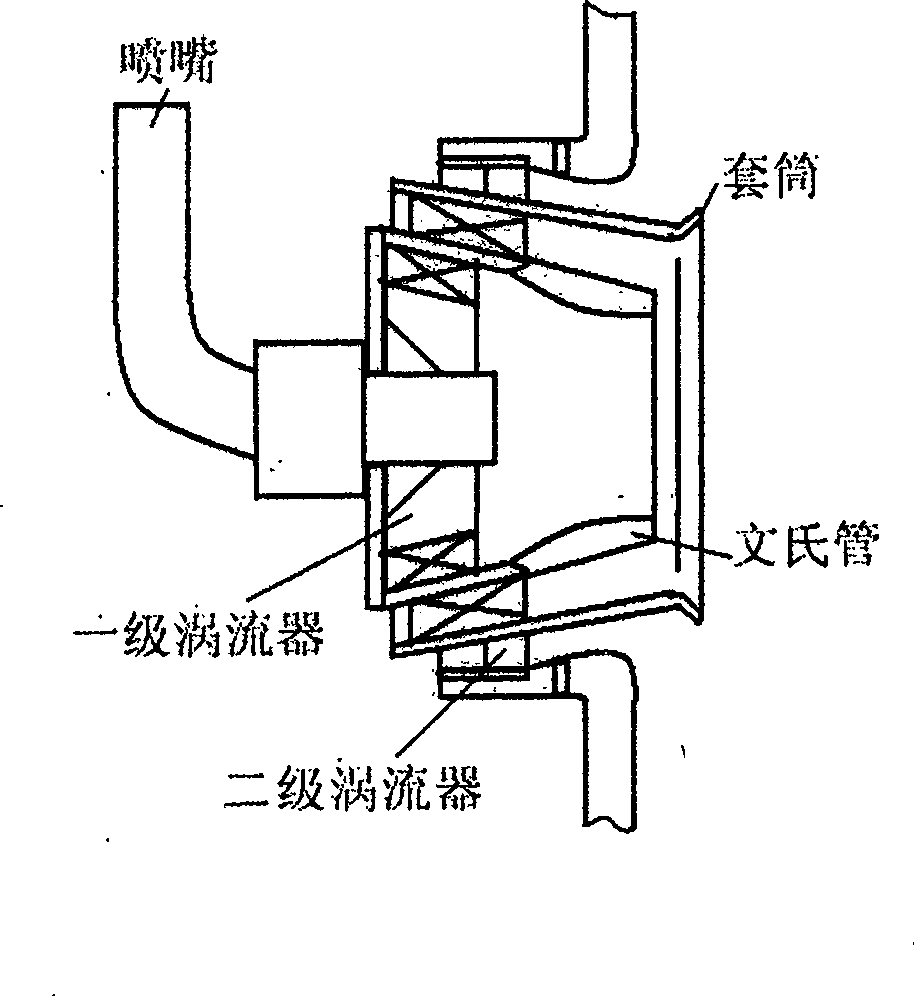

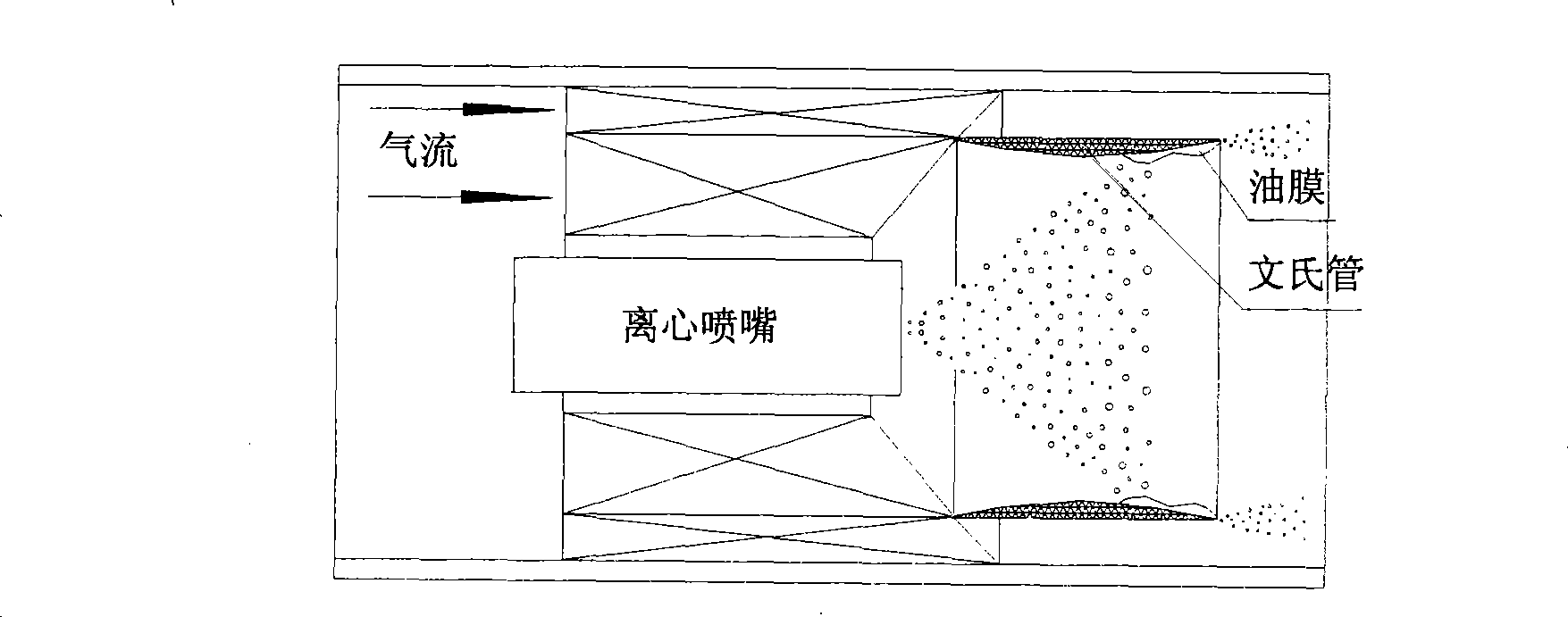

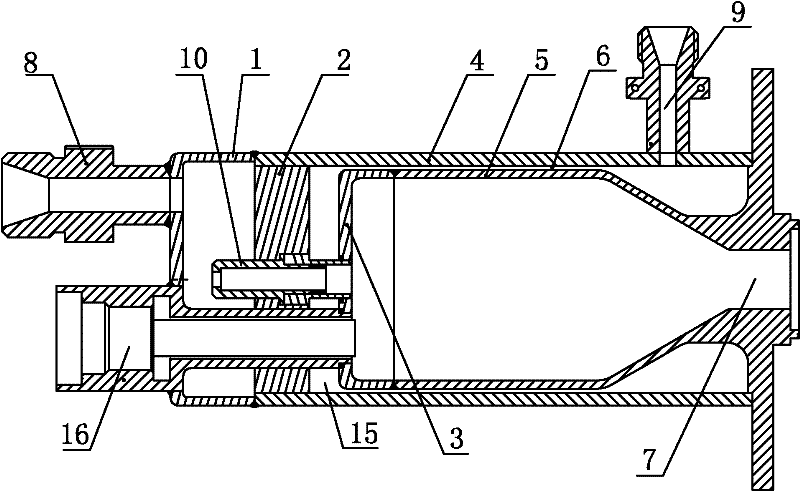

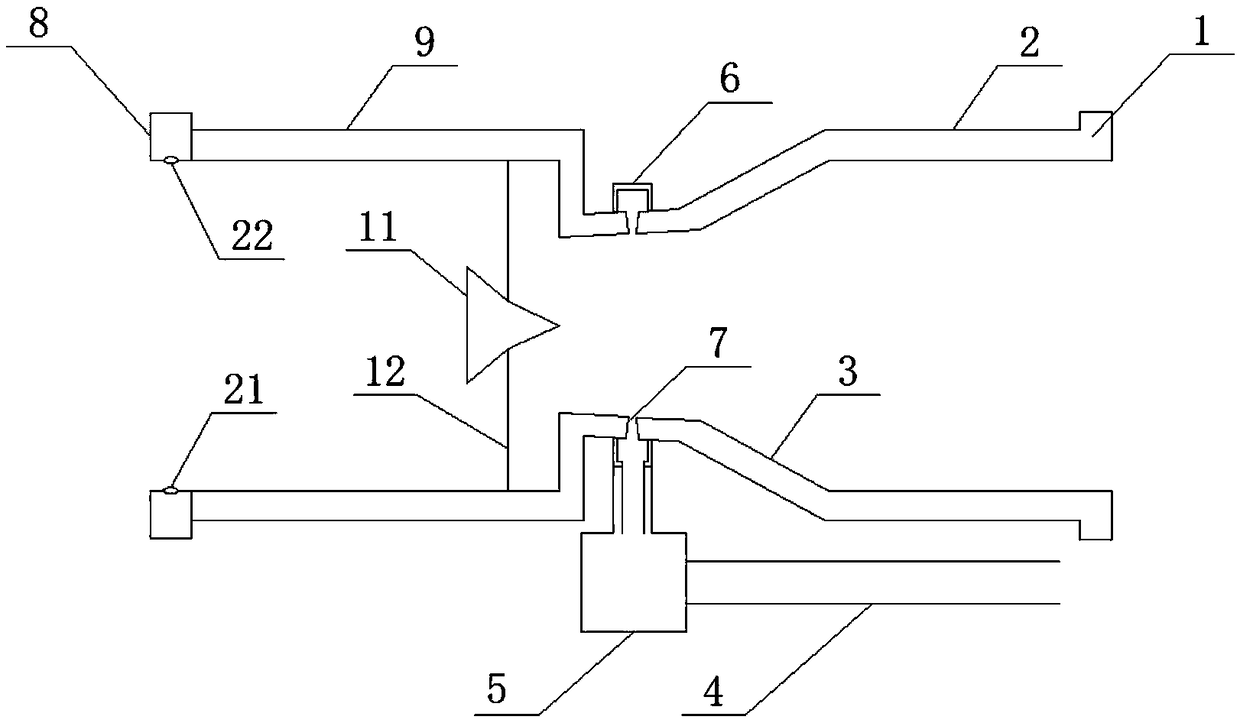

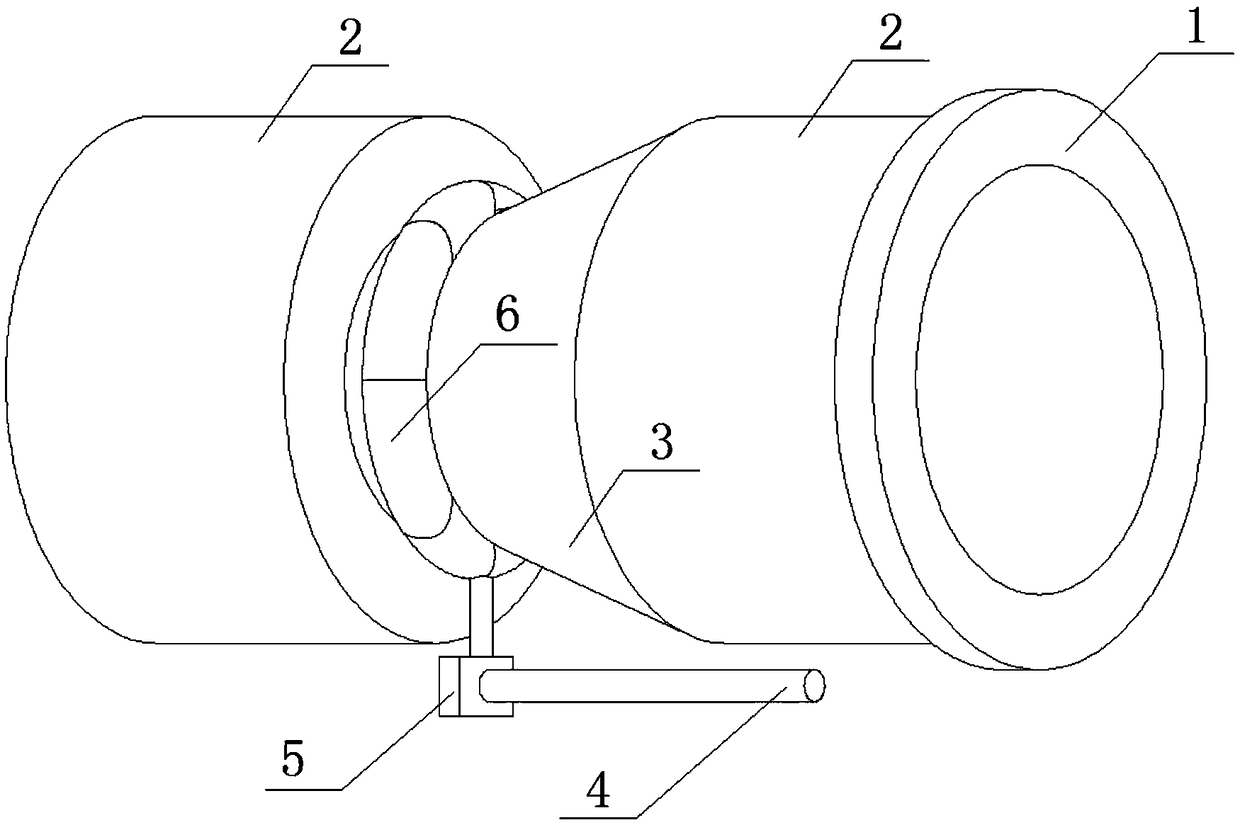

Gas turbine combined type fuel evaporating and atomizing combustion apparatus

InactiveCN101435585AIncrease the pre-mixed pre-evaporation processImprove atomization and evaporationContinuous combustion chamberAviationCyclone

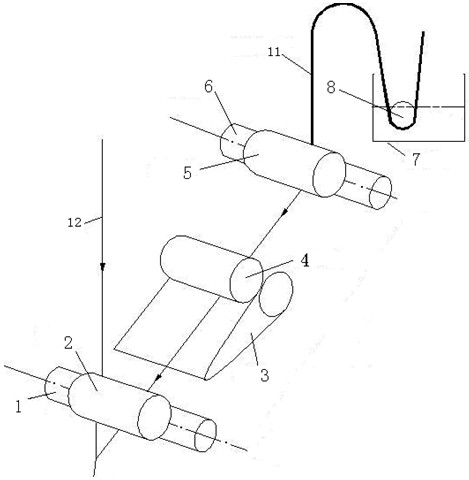

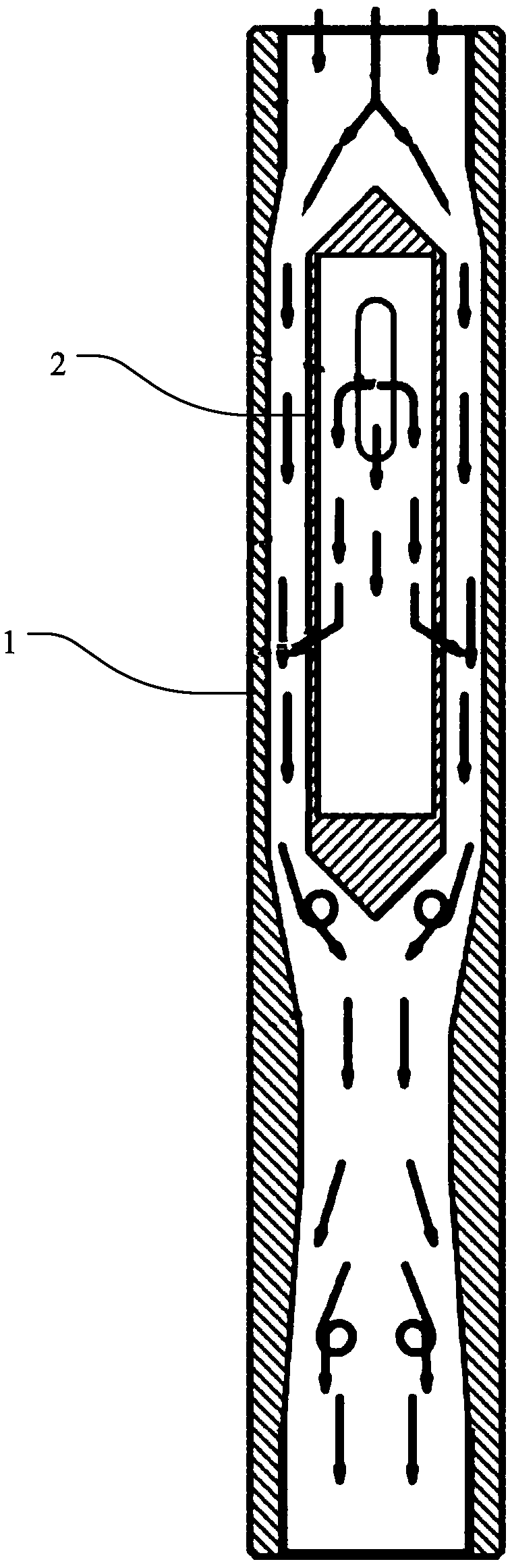

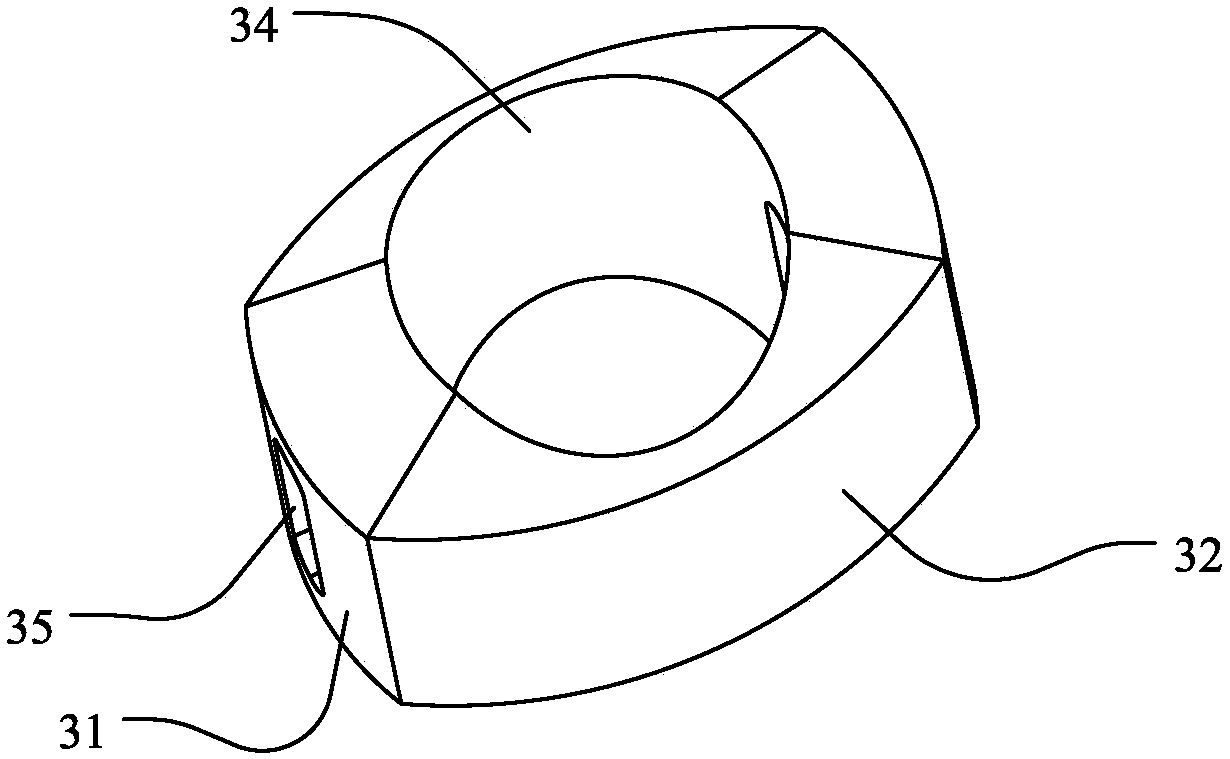

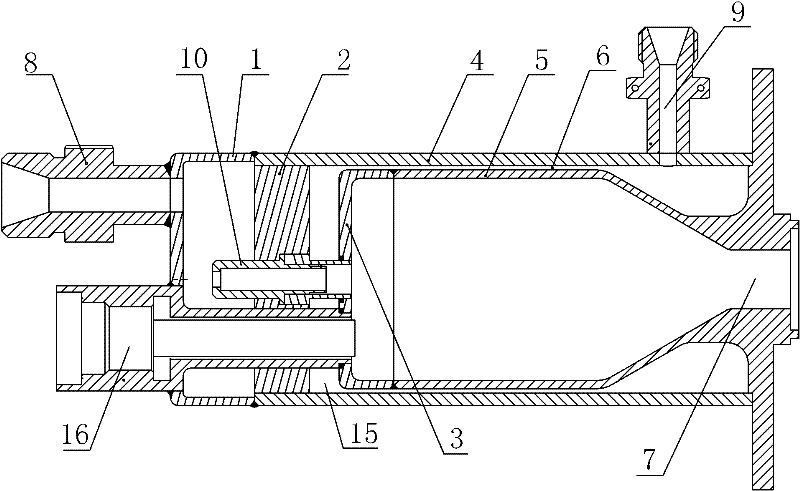

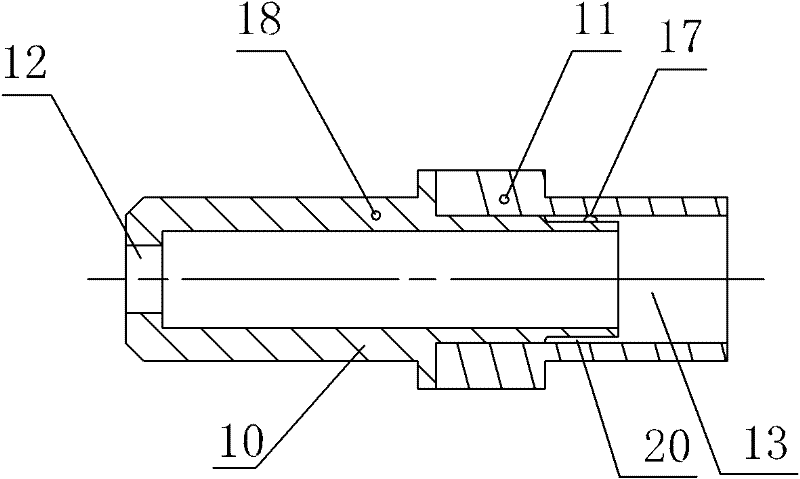

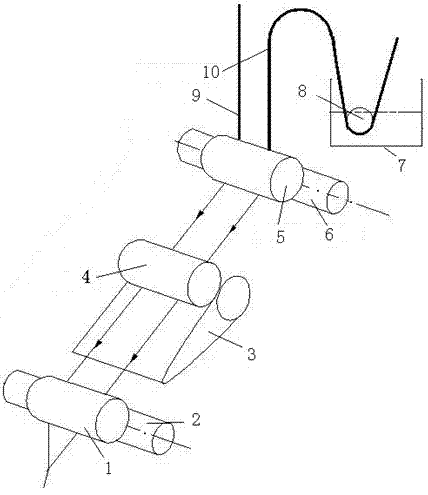

The invention provides a combined fuel oil atomizing, evaporating and combusting device for a gas turbine, relates to an air inlet device of the gas turbine, a fuel oil atomizing, evaporating and blending device, and core technology of organized combustion and stable flame, and belongs to the power field of an aeronautic power propulsion system and a ground gas turbine. A nozzle 1 is arranged at a central position of an inlet of a premixing chamber 2; an evaporator 3 is fixed in an inner cavity of the premixing chamber 2; double cyclones 4 are arranged at the inside of the outlet end of the premixing chamber 2 and connected hermetically; a centrifugal nozzle 5 is arranged at a central position of the double cyclones 4; a venturi 6 is welded at a transition position of an outlet of internal and external cyclones of the double cyclones 4; a sleeve 7 is hermetically welded with the outside of an outlet of the premixing chamber 2; and the head of a combustion chamber 8 is hermetically welded with the sleeve 7. Compared with the prior fuel oil combined nozzle, the device has the advantages of improving properties of fuel oil atomizing, evaporating and blending and evenness of oil-gas space distribution, improving combustion performance, shortening flame length and reducing discharge of pollutant, and is a comparatively ideal combined fuel oil atomizing and combusting device for a high-performance gas turbine.

Owner:PEKING UNIV

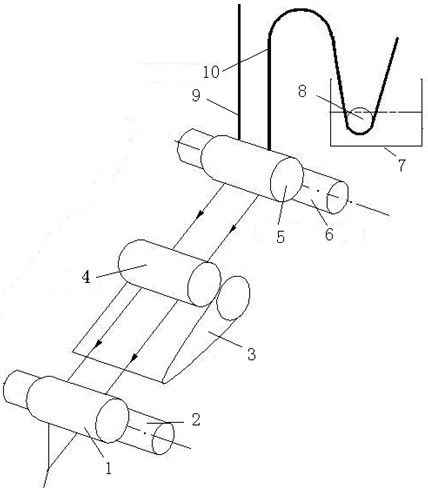

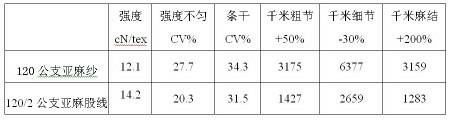

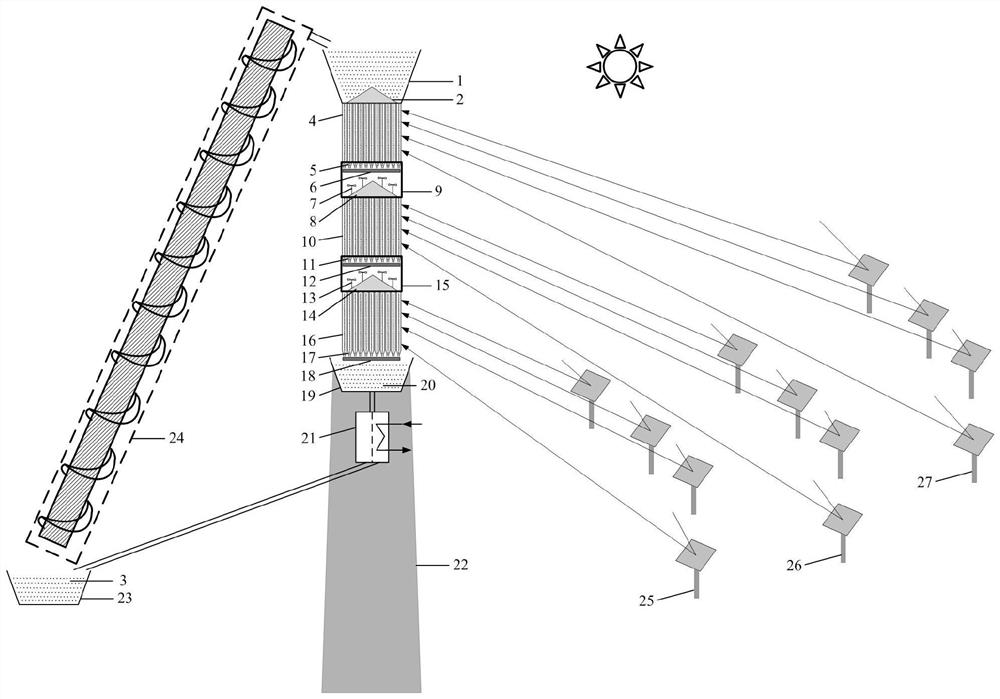

Method for producing hemp high-count yarns and folded yarns through Siro-spinning or Sirofil-spinning

The invention relates to a method for producing hemp high-count yarns and folded yarns through Siro-spinning or Sirofil-spinning. The method is characterized by comprising the following steps of: after boiling off and bleaching hemp roving, feeding the hemp roving together with water-soluble vinylon roving, a single yarn or a continuous yarn into a wet spinning frame to realize blending; after obtaining blended yarns of hemp / water-soluble vinylon, boiling and dissolving the blended yarns in aqueous solution to remove vinylon fibers so as to obtain the hemp high-count yarns; and reversely plying and twisting the blended yarns to form the folded yarns, then removing the vinylon to obtain the hemp high-count folded yarns, or reversely plying and twisting the blended yarns after removing the vinylon to obtain the hemp high-count folded yarns. The method can adopt conventional hemp fibers to spin the high-count pure hemp yarns and folded yarns, thereby solving the current problems that the conventional high-quality hemp raw materials deficient and the hemp high-count yarns are limited within 36 to 60 metric counts, and realizing the development of hemp products toward high count, high grade and species diversity.

Owner:DONGHUA UNIV

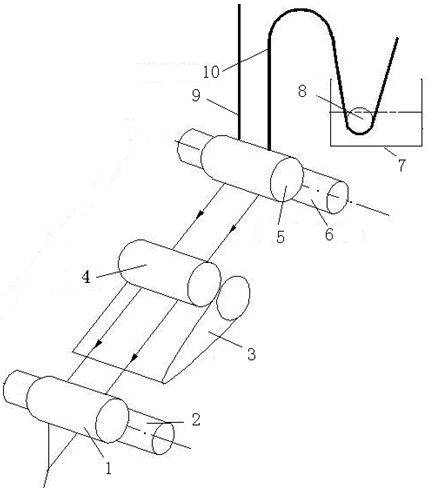

Method for producing linen wet spinning high count yarns and plied yarns

The invention provides a method for producing linen wet spinning high count yarns and plied yarns, which is characterized by comprising the following specific steps of: after boiling linen lines or linen tow rough yarns off and bleaching, feeding the processed linen lines or linen tow rough yarns and water-soluble vinylon rough yarns on a wet spinning frame jointly for mixing to obtain blended yarns of linen / water-soluble vinylon; boiling the blended yarns in aqueous solution, and dissolving and releasing vinylon fibers to obtain pure linen high count yarns; and stranding and twisting the blended yarns reversely to form plied yarns, and releasing vinylon to obtain linen high count plied yarns or releasing the vinylon of the blended yarns, and stranding and twisting to obtain the linen high count plied yarns. In the method, the pure high count linen yarns and the plied yarns can be spun by the conventional linen fibers, so the problems that the conventional high-quality linen raw materials are deficient and the linen high count yarns are limited within the range of between 36 and 60 metrical yarn counts are solved, and the development of high count, high grade and variety diversification of linen products is realized.

Owner:DONGHUA UNIV

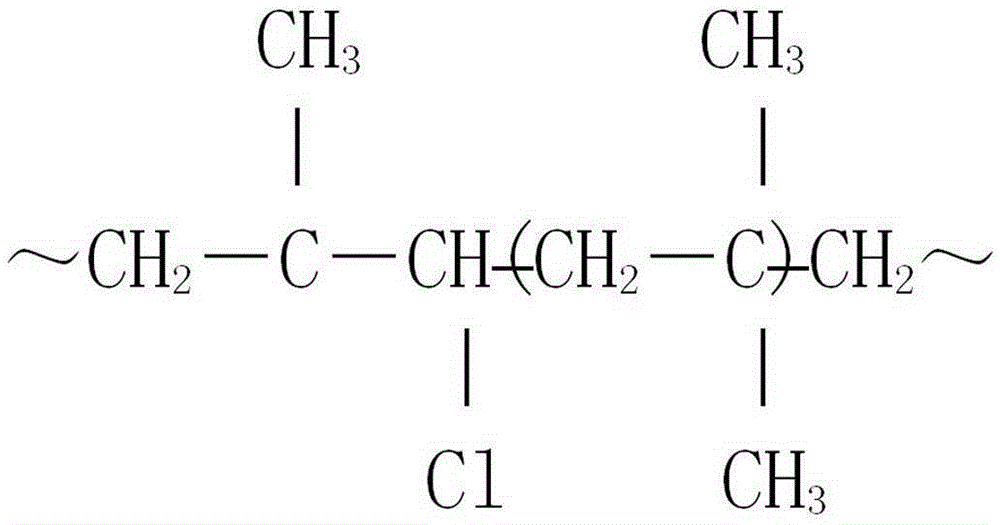

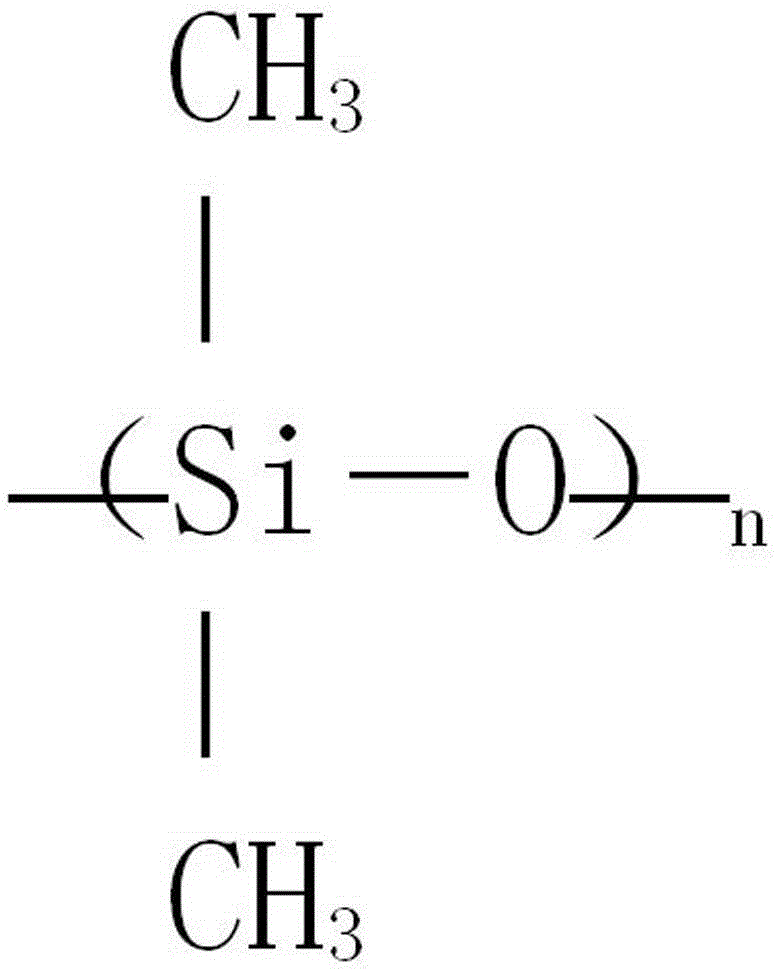

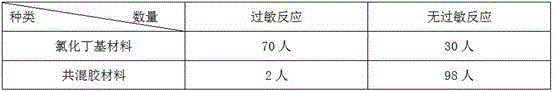

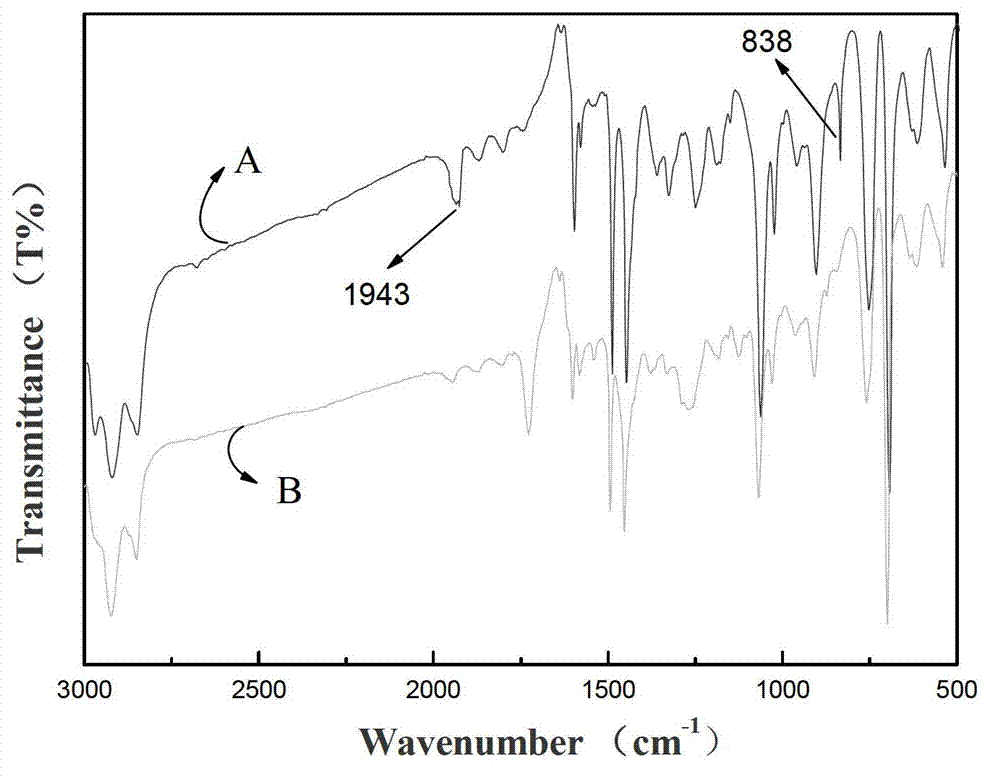

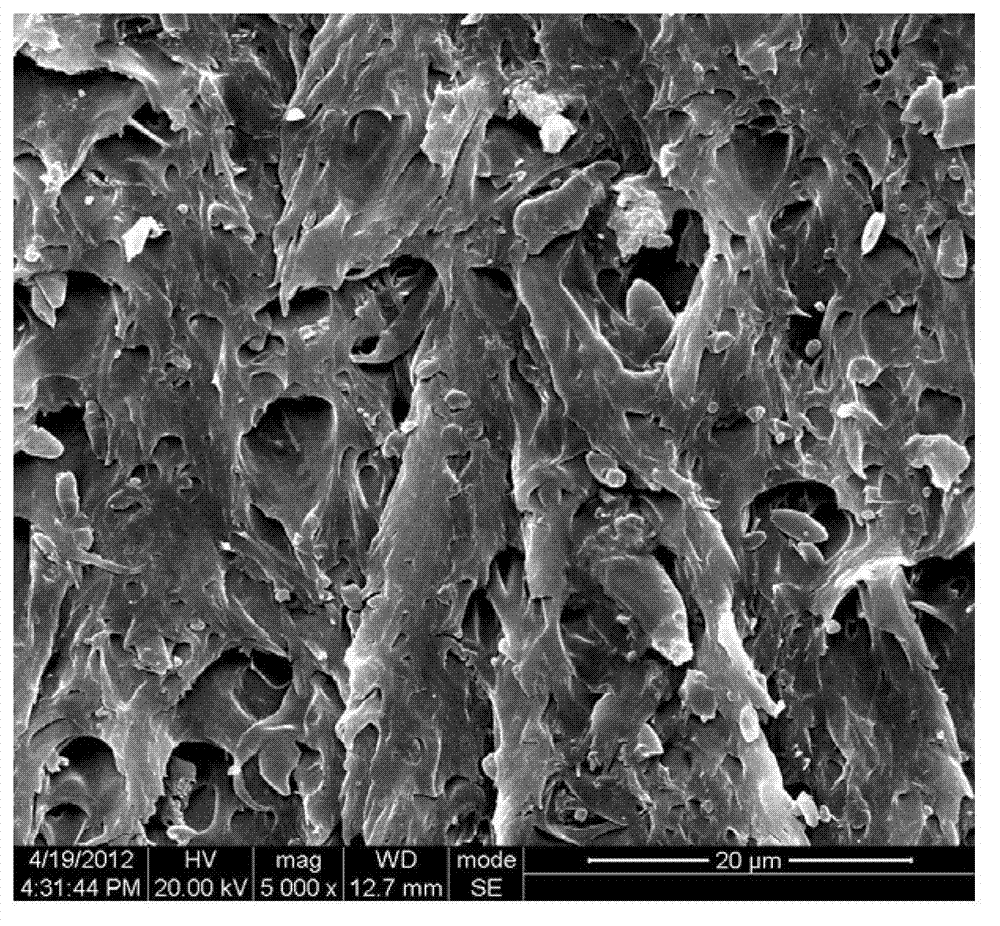

Chlorinated butyl rubber and silicone rubber blended material

The invention relates to the field of chemical materials, in particular to a chlorinated butyl rubber and silicone rubber blended material applied to a body material of a gas mask body. The chlorinated butyl rubber and silicone rubber blended material is prepared from, by weight, 50-100 parts of chlorinated butyl rubber, 5-50 parts of silicon rubber, 30-50 parts of intermediate super abrasion furnace black n220, 20-40 parts of high abrasion furnace black n330, 5-15 parts of zinc oxide, 1-10 parts of magnesium oxide, 0-10 parts of accelerator TT, 2-10 parts of accelerator ZDC, 1-10 parts of vulcanizer DCP, 2-8 parts of stearic acid, 2-12 parts of antioxidant methylene 4426 and 2-10 parts of anti-aging agents MB. The blended material has good gas defense performance, biocompatibility is improved due to the addition of silicon rubber, and the wearing comfort is improved on the premise that the protection performance is ensured.

Owner:SHANXI XINHUA CHEM

PVC (polyvinyl chloride)/styrene polymer alloy and preparation method thereof

ActiveCN102731936AAlloying is simpleImprove flame retardancyAluminum chloride anhydrousCompatibilization

The invention discloses a PVC (polyvinyl chloride) / styrene polymer alloy. The alloy is characterized by being prepared from the following raw materials in percentage by weight: 50-95% of PVC resin, 3-30% of styrene polymer, 0.2-6% of catalyst, 0-10% of addition agent and 1.5-4% of heat stabilizer. Besides, the invention also discloses a preparation method of the PVC / styrene polymer alloy. The PVC / styrene polymer alloy material has the following advantages: not only are the defects of the existing extra compatilizer overcome, but also the alloying of PVC and styrene polymer is simpler and more convenient; anhydrous aluminium chloride, anhydrous ferric chloride or anhydrous stannic tetrachloride is taken as the catalyst; the reaction mixing / extrusion in-situ compatibilization technology is adopted, thus realizing the blending of PVC and styrene polymer; and the polymer alloy material can improve the flame retardance of the styrene polymer while reinforcing and toughening the PVC, and has industrial application prospects.

Owner:XIAN UNIV OF SCI & TECH

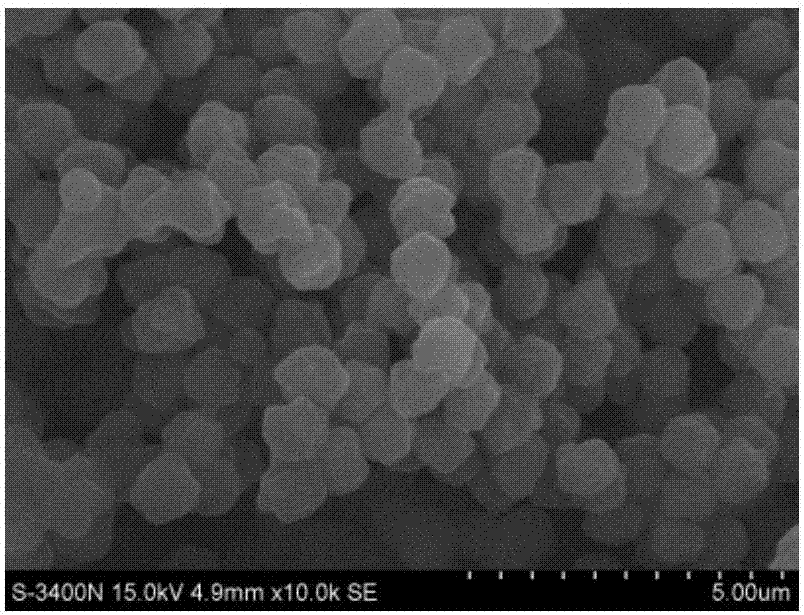

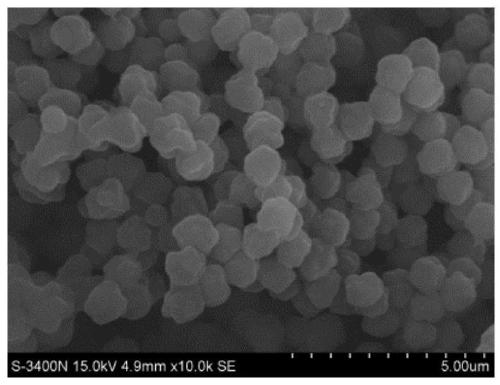

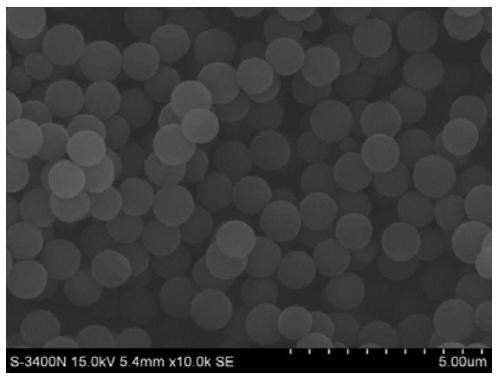

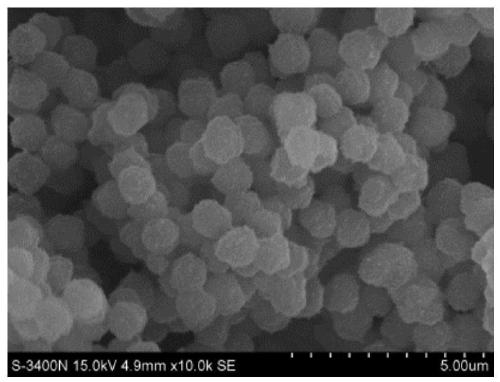

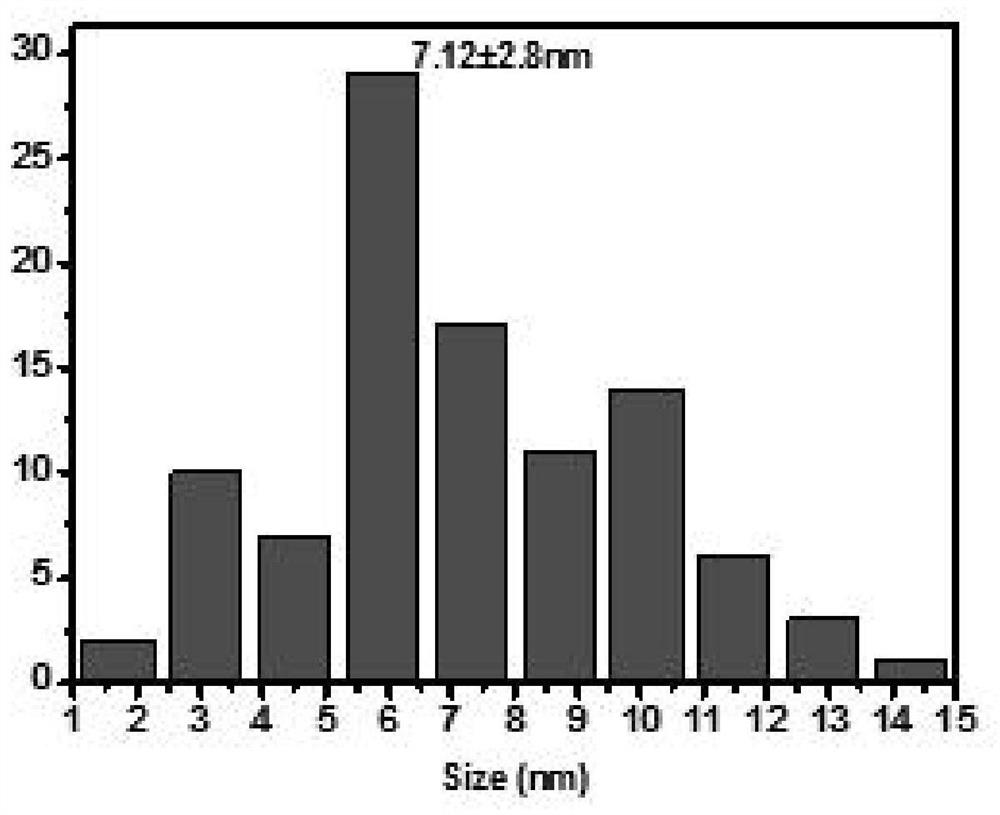

Raspberry-like shaped microsphere, super-hydrophobic coating and preparation methods thereof

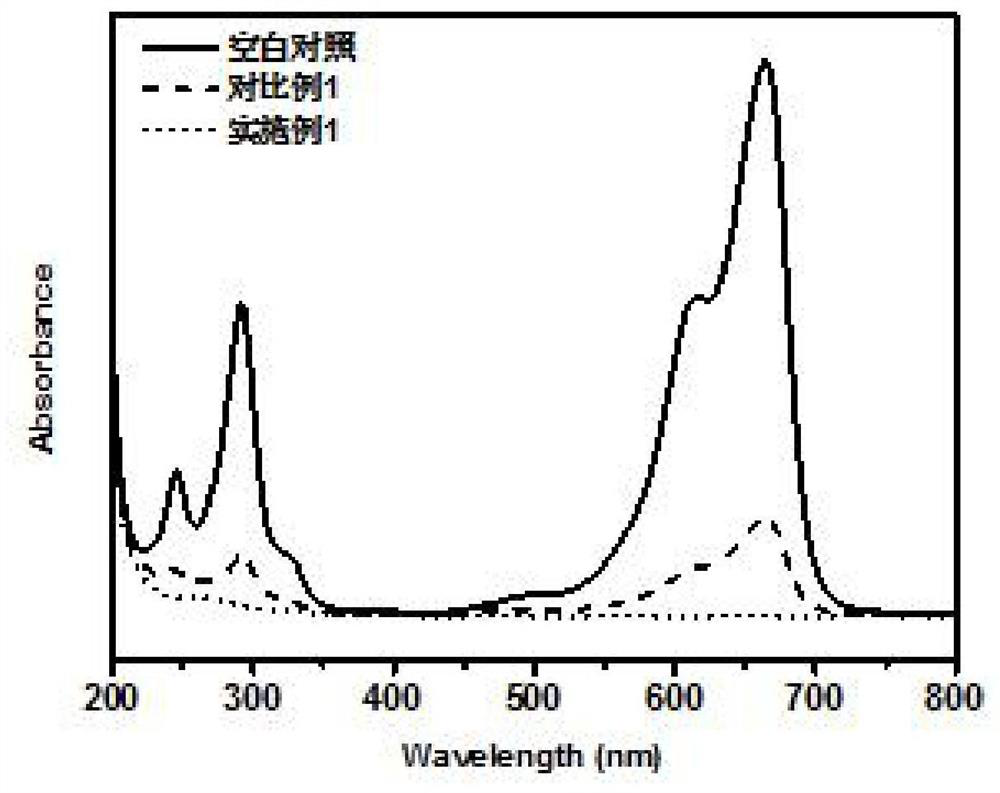

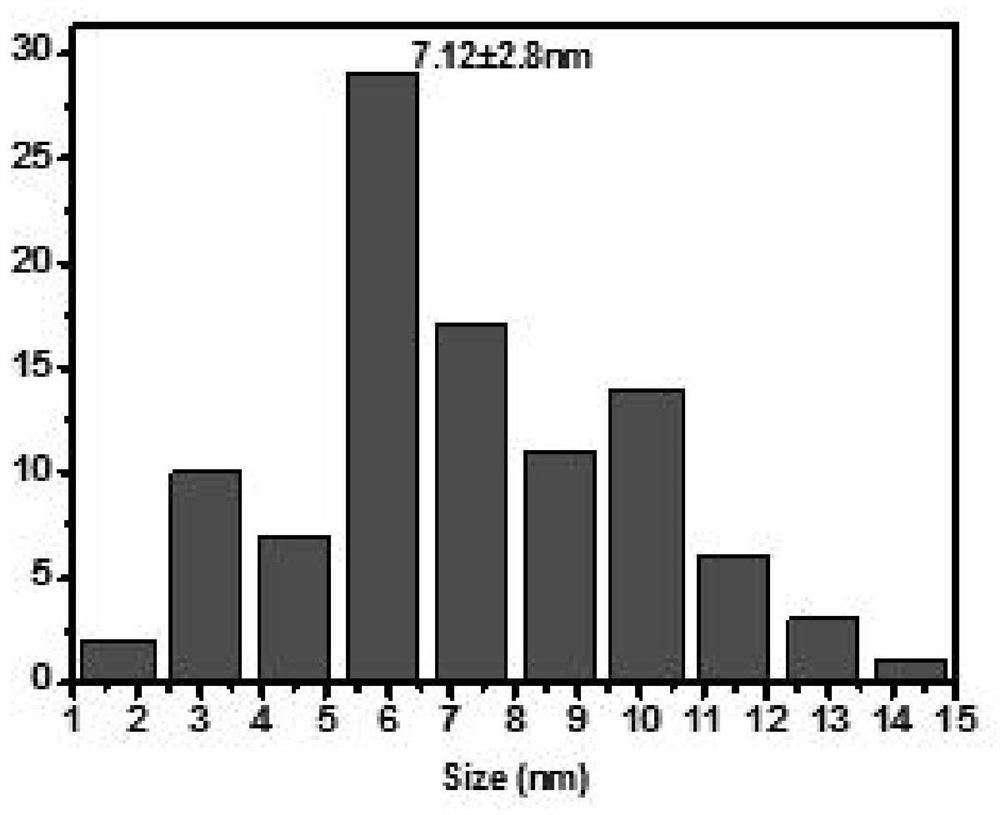

ActiveCN107998997ANarrow distributionAchieve blendingCoatingsMicroballoon preparationMicrospherePolymethyl methacrylate

The invention discloses a raspberry-like shaped microsphere, a super-hydrophobic coating and preparation methods thereof. The preparation method comprises the following steps: (1) synthesizing a polymethyl methacrylate microsphere through a dispersion polymerization method; (2) taking the polymethyl methacrylate microsphere, adding an ethanol solution of tetraethoxysilane as a silicon dioxide precursor, adopting a sol-gel process to react, and synthesizing the raspberry-like shaped microsphere which takes polymethyl methacrylate as a core and takes silicon dioxide as a shell. The preparation method is simple, the prepared raspberry-like shaped microsphere is controllable in dimension, and the super-hydrophobic coating has very good chemical stability, very good acid and alkaline resistanceand a very good hydrophobic property, has a surface contact angle of 151 degrees, and can be used for glass, building outer walls, fabric surfaces, metal surfaces and the like.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI +2

Method of using glufocinate byproduct waste residue to prepare aluminum hypophosphite

InactiveCN106986318ASmall particle sizeImprove lipophilicityHypophosphorous acidReaction ratePhosphoric acid

The invention discloses a method of using glufocinate byproduct waste residue to prepare aluminum hypophosphite. The method includes following steps: (1), slowly adding a glufocinate industrial byproduct into water, sufficiently stirring, filtering to remove filter residue, and taking filtrate for standby use; dissolving sodium hypophosphite in water to prepare a sodium hypophosphite solution, and adding hydrochloric acid to adjust pH value of the sodium hypophosphite solution to 3-6; (2), taking the filtrate and the sodium hypophosphite solution according to a reactant molar feeding ratio of sodium hypophosphite to aluminum chloride being (4-5):1; (3), putting the sodium hypophosphite solution in a container provided with a snake-shaped condensing pipe, heating to 30-50 DEG C, and dropwise adding the filtrate while stirring at a high speed; after dripping of the filtrate is finished, finishing reaction while slowly stirring; (4), subjecting a reaction product obtained in the step (3) sequentially to separating, washing and drying to obtain powdery white solid which is a product containing aluminum hypophosphite. Therefore, by optimizing the process of using the glufocinate byproduct waste residue to prepare aluminum hypophosphite, a reaction system has the advantages of mild reaction and high reaction rate.

Owner:SICHUAN FOURSTAR BIOTECH RANDD CORP

Method for preparing galactose homopolymer/polyacrylonitrile composite nanofiber membrane

InactiveCN102828346AImprove non-specific adsorptionGood biocompatibilityNon-woven fabricsAlkaline proteaseComposite nanofibers

The invention discloses a method for preparing a galactose homopolymer / polyacrylonitrile composite nanofiber membrane, which comprises the following steps that: (1) diacid divinyl ester and galactose are dissolved in anhydrous pyridine, and alkaline protease is added to synthesize galactose vinyl ester; (2) ammonium persulfate is added into the galactose to serve as an initiator, H2O or oil is added to serve as solvent, and after the polymerization reaction, Poly-OVSEGA is obtained; (3) polyacrylonitrile is dissolved in DMF (dimethyl formamide), the Poly-OVSEGA is then added to be mixed until complete dissolving, and the mixture is stood to obtain PAN (polyacrylonitrile) / Poly-OVSEGA spinning solution; and (4) the PAN / Poly-OVSEGA spinning solution is subjected to electrostatic spinning, and is finally dried, so the galactose homopolymer / polyacrylonitrile composite nanofiber membrane is obtained. The method for producing the galactose homopolymer / polyacrylonitrile composite nanofiber membrane is simple to operate, and the product is easy to processs, is economic and environment-friendly; and the membrane contains abundant functional groups which can reflect the hydrophic activity, can be used for protein separation and purification, and is low in cost.

Owner:DONGHUA UNIV

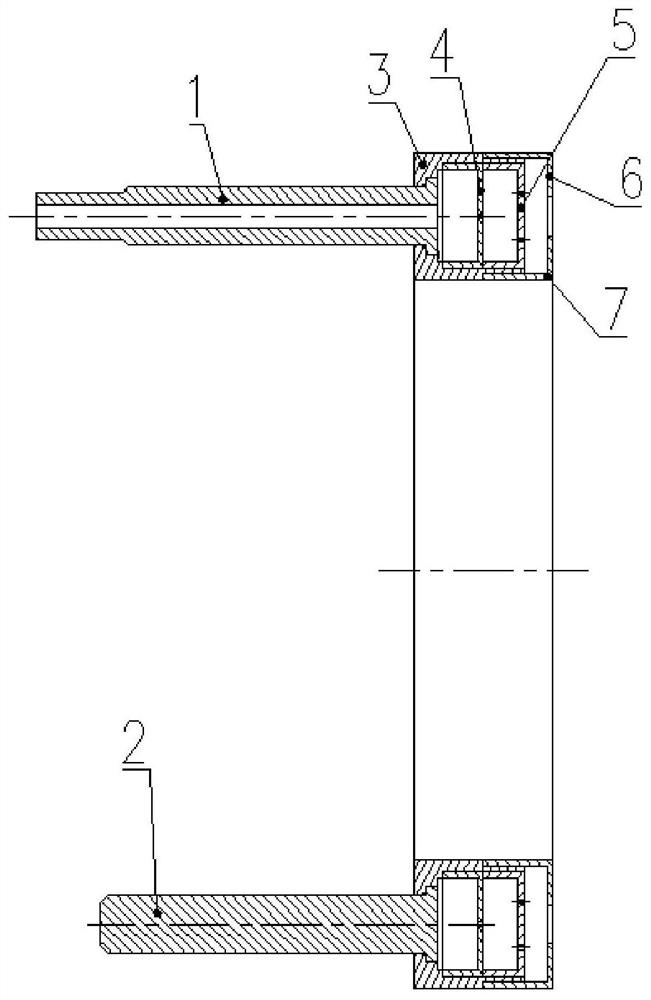

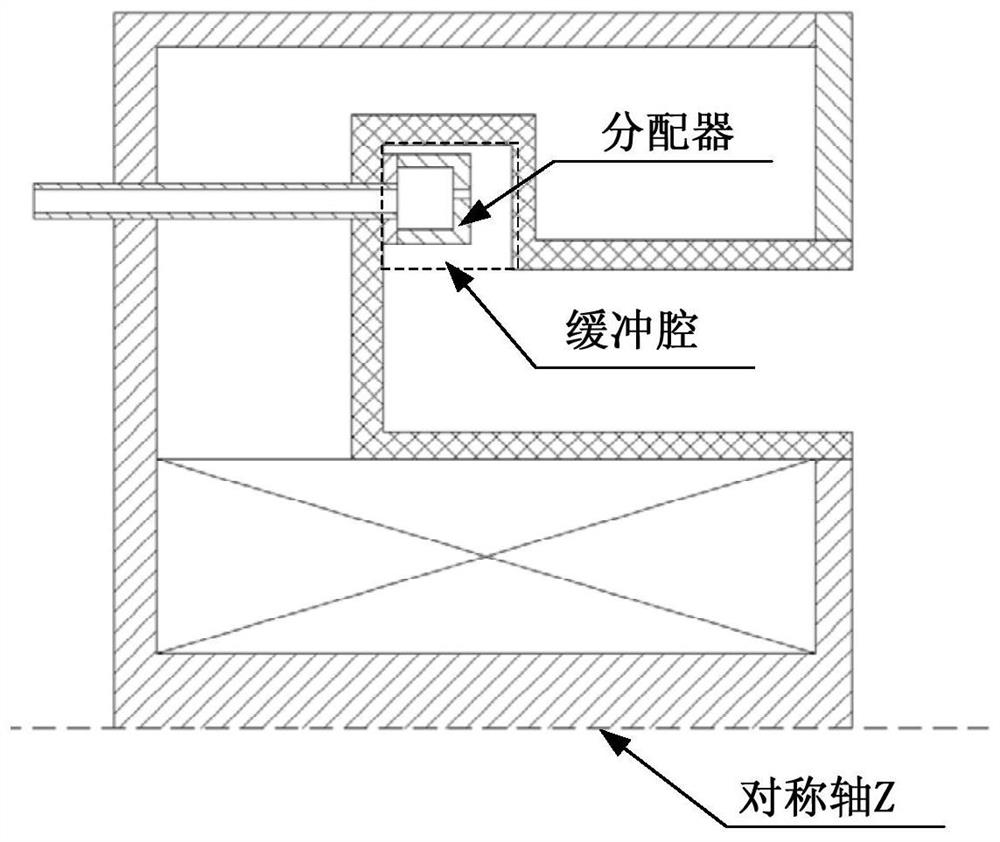

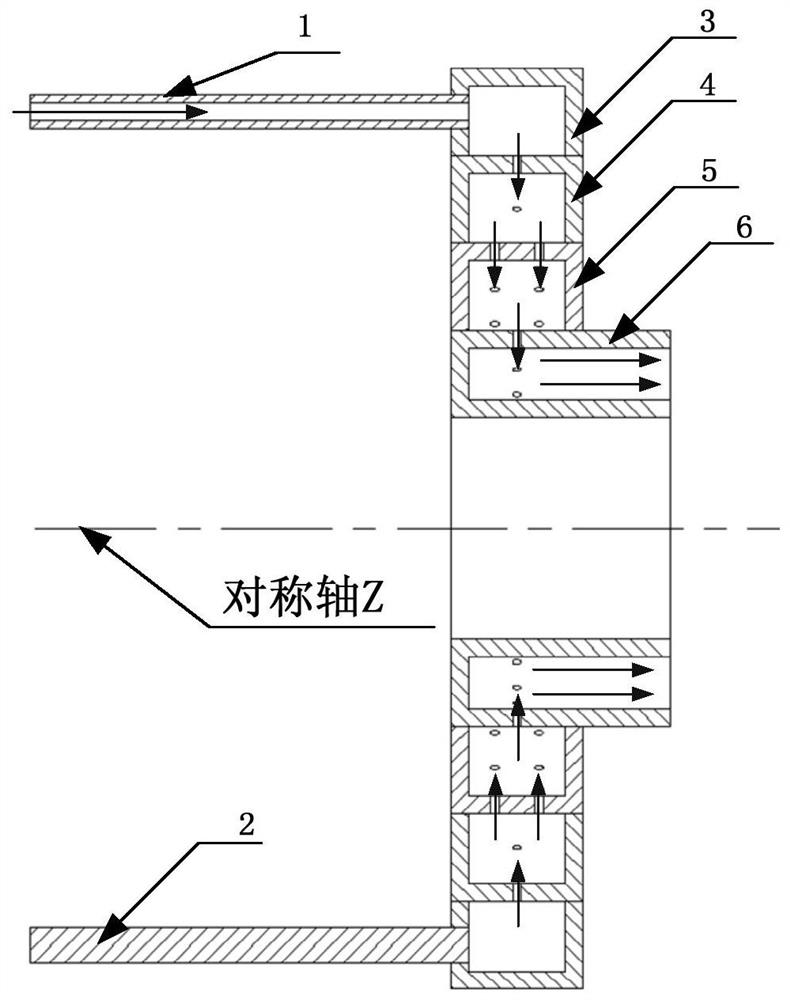

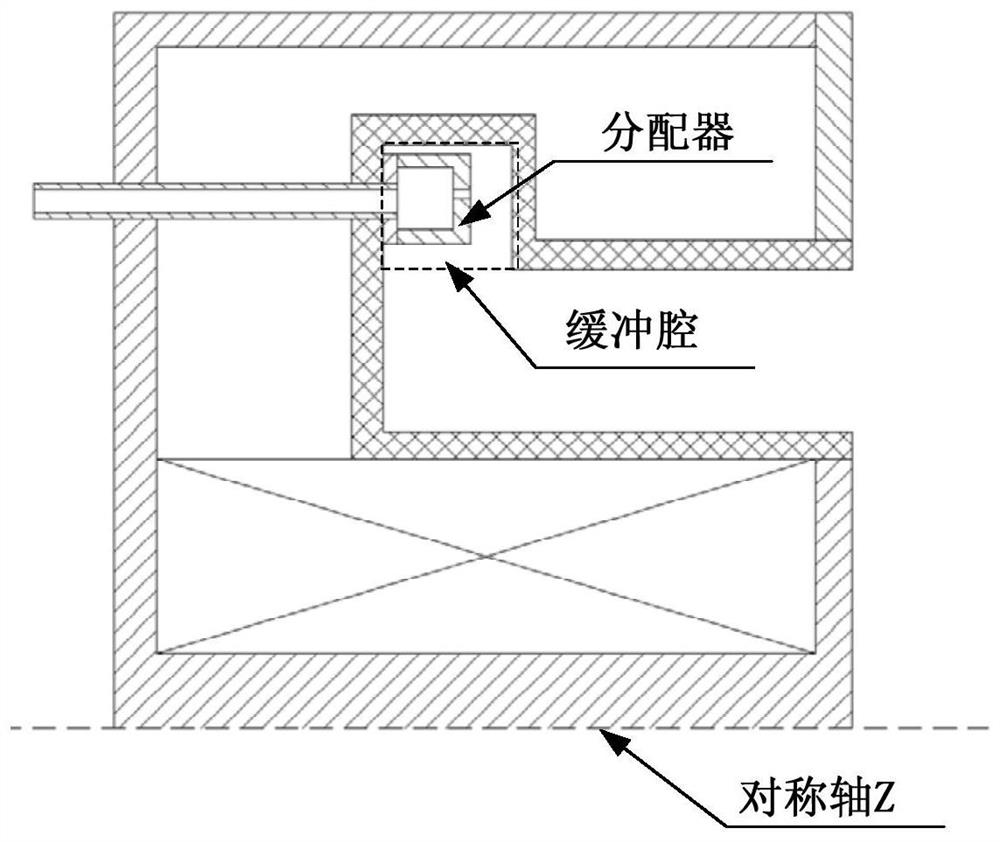

Channel external type distributor anode integrated structure for low-power hall thruster

The invention discloses a channel external type distributor anode integrated structure for a low-power hall thruster. The channel external type distributor anode integrated structure comprises a gas guide column, a fixing column, a gas inlet chamber, a single-row hole chamber, a double-row hole chamber and a channel chamber. The gas guide column is inserted into a through hole in the gas inlet chamber, and the gas guide column is stably connected with the gas inlet chamber in an electron beam welding mode. The fixing column is inserted into a through hole in the gas inlet chamber, and the fixing column is stably connected with the gas inlet chamber in an electron beam welding mode. The single-row hole chamber is inserted into the gas inlet cavity, and the stable connection between the gasinlet cavity and the single-row hole chamber is achieved in an electron beam welding mode. The double-row hole chamber is inserted into the single-row hole chamber, and the stable connection between the single-row hole chamber and the double-row hole chamber is achieved in an electron beam welding mode. The channel chamber is inserted into the double-row hole chamber, and the stable connection between the double-row hole chamber and the channel chamber is achieved in an electron beam welding mode.

Owner:BEIJING INST OF CONTROL ENG

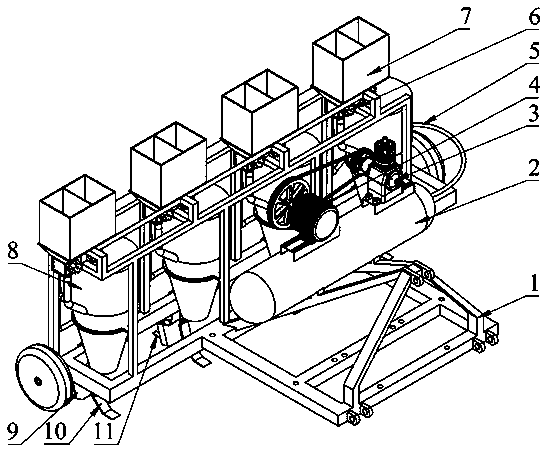

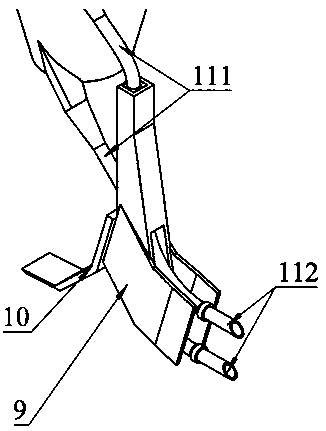

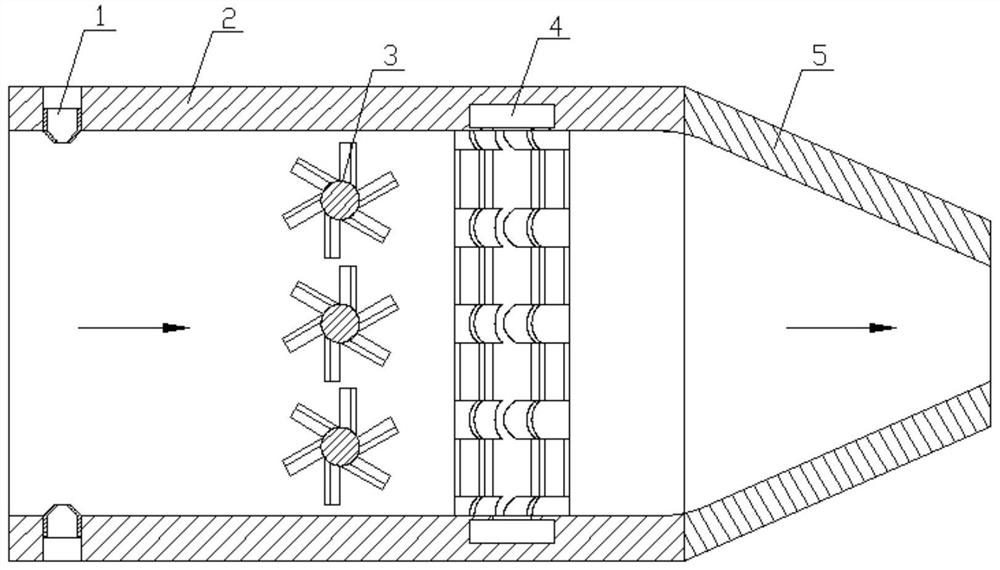

Gas-assisted layered deep fertilizing machine and using method

PendingCN110402645AAchieve blendingIncrease profitPlantingFertiliser distributersAgricultural engineeringFailure causes

The invention relates to a gas-assisted layered deep fertilizing machine and a using method. The gas-assisted layered deep fertilizing machine comprises a rack, furrow openers, layered deep fertilizing devices and a gas-assisted fertilizer discharging device, wherein the furrow openers, the layered deep fertilizing devices and the gas-assisted fertilizer discharging device are installed on the rack; each layered deep fertilizing device comprises a material discharging device, a cylinder fixedly connected with the rack and a fertilizer discharging auger installed in the cylinder, a closed passage is formed between each fertilizer discharging auger and the corresponding cylinder, a discharging port of each closed passage is communicated with at least two fertilizer discharging pipes, and thedischarging end of each fertilizer discharging pipe faces backwards and is located behind the furrow openers. By means of the gas-assisted layered deep fertilizing machine, fertilizer granules fall into the soil which is crushed by the furrow openers and then restored, the layered deep fertilizing precision is effectively improved, and the layering failure caused when the fertilizer granules fallto the bottoms of furrows is avoided; the fertilizer discharging augers adopt fixed-screw-pitch and variable-radius design so that the fertilizer granules can achieve spiral downward acceleration with the assistance of gas pressure, the initial speed of discharging the fertilizer granules is increased, and meanwhile the fertilizer granules are blended in the acceleration process and discharged more uniformly.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Polrvinyl chloride alloy material and preparation method

InactiveCN103073813AImprove mechanical propertiesAchieve blendingDioctyl terephthalateMagnesium stearate

The invention discloses a polrvinyl chloride alloy material, which comprises the following components by weight: 30-80 parts of polrvinyl chloride, 10-50 parts of ABS resin, 0.2-0.8 parts of manganese dioxide, 0.2-0.8 parts of anhydrous calcium chloride, 1-5 parts of dioctyl terephthalate, 10-20 parts of magnesium stearate and 10-20 parts of potassium stearate. The polrvinyl chloride alloy material has good comprehensive mechanical properties, has large enhancement of tensile strength, elongation at break and shock strength, and has important industrial application prospect.

Owner:无锡常安通用金属制品有限公司

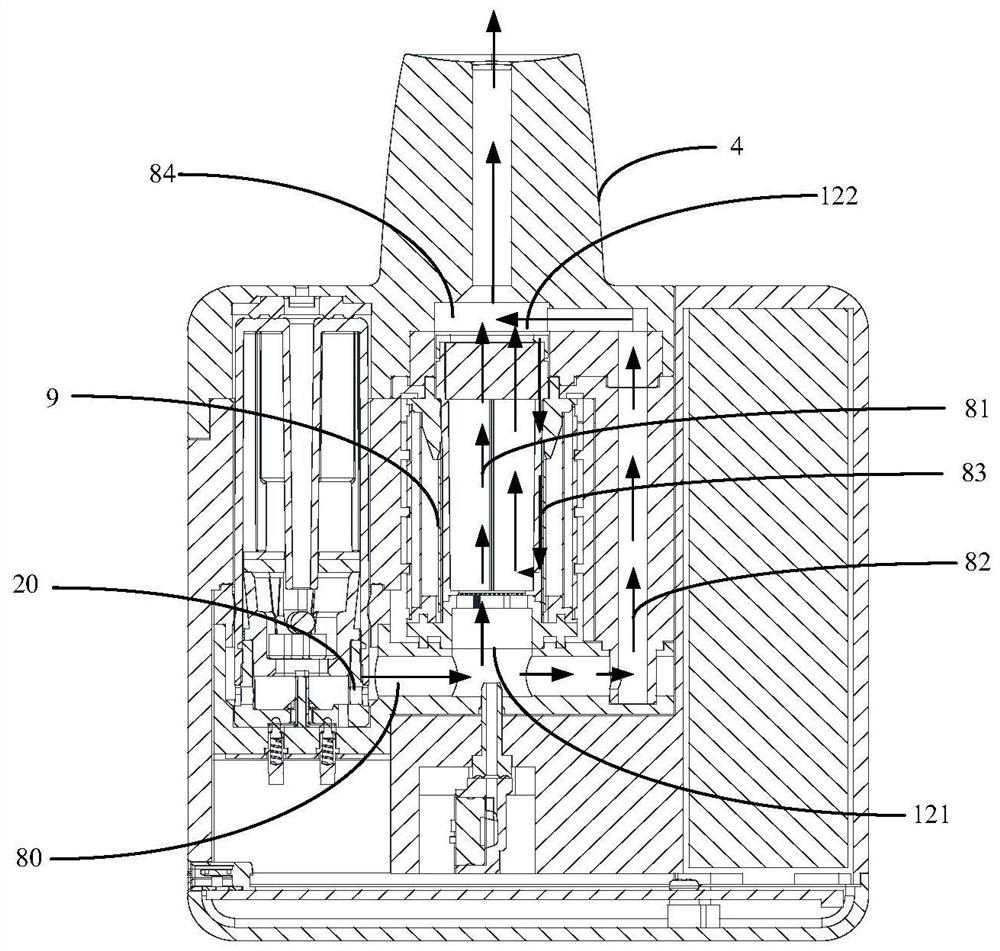

Electronic atomization device

The invention provides an electronic atomization device. The electronic atomization device is provided with a first containing cavity used for containing an atomizer and a second containing cavity used for containing an aerosol generating substrate. The second containing cavity is provided with a first end and a second end opposite to the first end; the first containing cavity is connected with a first aerosol channel, and aerosol generated by the atomizer flows through the first aerosol channel when the electronic atomization device is in a working state; the first aerosol channel is communicated with the second containing cavity through a first end in an air guiding mode, the first aerosol channel is communicated with the second containing cavity through a second end in an air guiding mode, and in the working state of the electronic atomization device, a first part of aerosol generated by the atomizer enters the second containing cavity through the first aerosol channel and the first end; and a second part of the aerosol generated by the atomizer enters the second containing cavity through the first aerosol channel and the second end. By means of the arrangement, the flow dividing air channel is provided, the taste of aerosol sucked by a user can be adjusted, and the requirement of the user for the taste is met.

Owner:SHENZHEN SMOORE TECH LTD

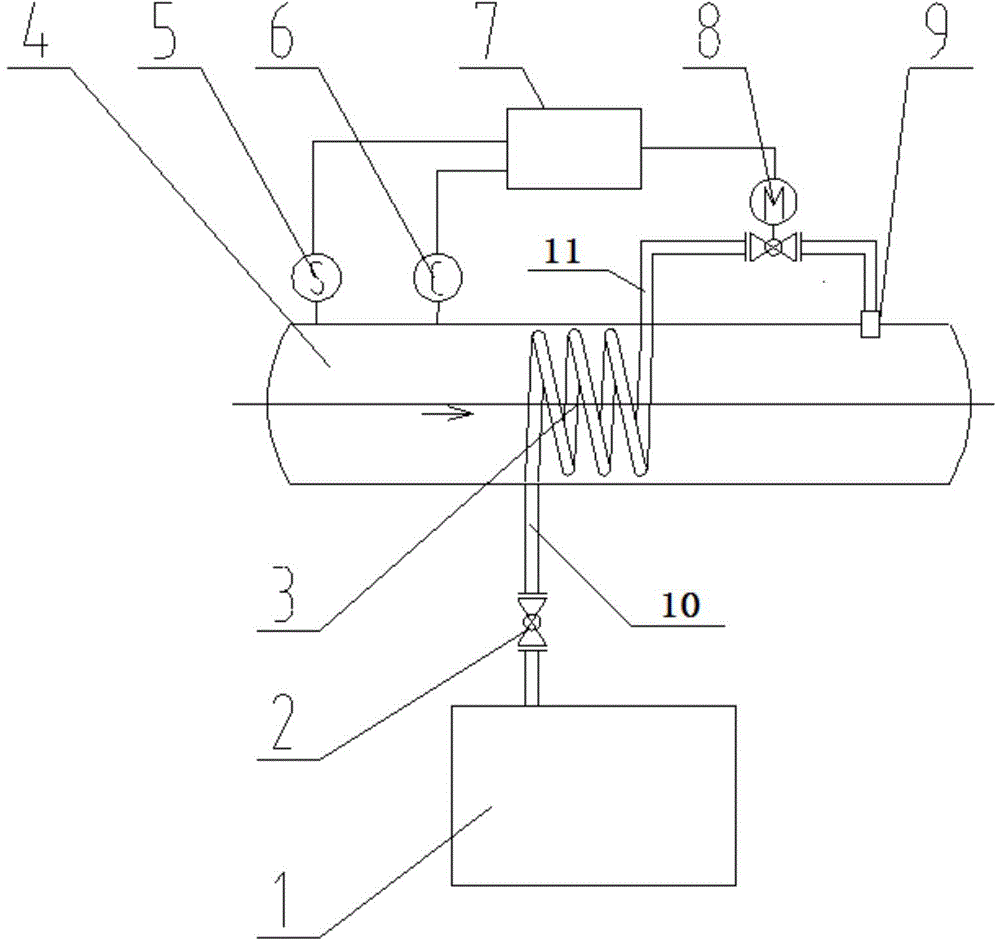

Device and method for mixing LNG fuel into methane electric generator set

ActiveCN104912696AAchieve blendingTake advantage ofInternal combustion piston enginesFuel supply apparatusFree stateProcess engineering

The invention relates to a device for mixing LNG fuel into a methane electric generator set. The device comprises a main methane conveying pipe, an LNG storage tank, a heat exchanger and an LNG gasification device. The heat exchanger is arranged inside the main methane conveying pipe. The heat exchanger is provided with an LNG inlet and an LNG outlet. The LNG inlet is communicated with the LNG storage tank through a first pipeline. The LNG outlet is communicated with the LNG gasification device through a second pipeline. The LNG gasification device is arranged on the main methane conveying pipe. The LNG fuel mixing can be achieved. When the methane concentration is fluctuated around 8%, the existing methane electric generator set can be fully utilized, and the utilization ratio of the device is improved. When the methane concentration is lower than 8%, the methane can be fully utilized, and the utilization space and the utilization ratio of the fuel are improved. Meanwhile, deep separating can be carried out on water which is in a free state and inside methane gas by the heat exchanger, and the electric generating efficiency of the electric generator set is favorable to be improved.

Owner:北京扬德环保能源科技股份有限公司

Hydraulic self-driven drag reduction slime diluting and releasing device

ActiveCN111729530AGuaranteed concealmentNo breakageFlow mixersRotary stirring mixersInterference fitEngineering

The invention discloses a hydraulic self-driven anti-drag slime diluting and releasing device which is composed of a slime nozzle, a diluting and mixing cavity, a stirring rod and a releasing nozzle.The electromagnetic flowmeter is mounted on the water inlet pipe; the dilution mixing cavity is positioned at the rear part of the water inlet pipe; the diluting and mixing cavity and the release nozzle are connected into an integrated structure; the release nozzle is of a reducing section, wherein the stirring rod is located in the diluting and mixing cavity and connected to the diluting and mixing cavity through a bearing, the slime nozzle is fixed in a through hole in the front portion of the diluting and mixing cavity and is in interference fit with the through hole, and the slime nozzle is used for spraying resistance-reducing thick slime to be mixed and diluted with inflow water. The diluting and mixing cavity is self-driven by inflow water force to realize uniform mixing, the designof the stirring rod prevents the macromolecular chain of the drag reduction slime from being broken during stirring and mixing, and the drag reduction effect is lasting and effective. The anti-drag slime diluting and releasing device can realize dilution, blending and spraying of the anti-drag slime by sharing one diluting and blending cavity, is simple in structure and has relatively high engineering application value.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

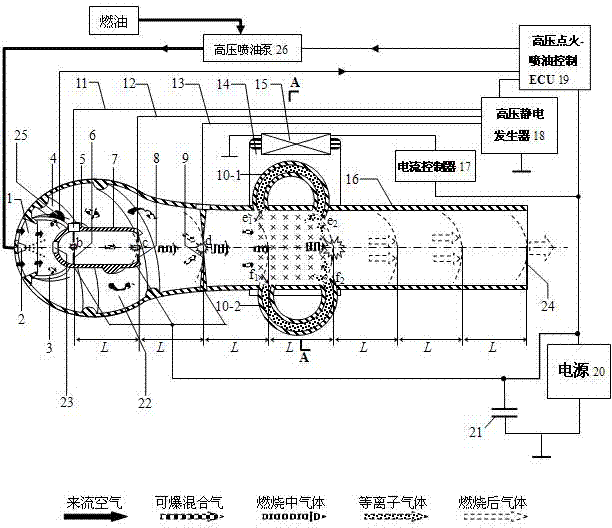

Detonation-wave-front high-voltage electric plasma gas relay coupling ignition detonation engine

The invention relates to a detonation-wave-front high-voltage electric plasma gas relay coupling ignition detonation engine which is formed by a pre-detonation burning pipe (7), a high-voltage ignition head c (8), a high-voltage ignition head, a plasma flow guide pipe (10), an annular face magnetic pole plate (14), a field coil (15), a detonation spraying pipe (16), a current controller (17), a high-voltage ignition-oil injection control ECU (19), a fuel and air premixing chamber (22), an air velocity transducer (25) and a high pressure oil spraying pump (26). Through multi-stage high-voltage ignition and plasma gas discharge, after a tiny pulse detonation wave is subject to three-stage relay coupling ignition, energy is amplified continuously, the best energy is achieved finally, the energy is sprayed out from a fuel gas spraying opening (24), and generation of detonation is guaranteed. The detonation-wave-front high-voltage electric plasma gas relay coupling ignition detonation engine has the beneficial effects that (1) the detonation, control and quick holding of the knock can be solved, and the pulse detonation wave can be gradually amplified; (2) atomization, jetting and doping of liquid fuel and an oxidizing agent can be achieved; (3) stable pushing force can be generated, low frequency to high-frequency continuous work can be achieved; and (4) pulse knock engine power adjustment can be achieved.

Owner:江苏知聚知识产权服务有限公司

Thickened oil blending-light mixed tool

The invention discloses a thickened oil blending-light mixed tool. The thickened oil blending-light mixed tool includes an outer tube, an injection pipe, a support block, a first joint and a second joint; the first joint and the second joint are separately connected to two ends of the outer tube, the outer tube is sleeved with the injection pipe, and two ends of the injection pipe is closed; the perimeter wall, close to the first joint, of the injection pipe is provided with a thin oil inlet which is used for passing of thin oil into the injection pipe, the perimeter wall, close to one end ofthe second joint, of the injection pipe is provided with a jet hole which is an annular gap formed between an outer tube and an inner tube, and the gap allows the thickened oil to enter from the firstjoint and to flow in the direction of the second joint; the thin oil enters the injection tube from the thin oil inlet and flows in the direction of the jet hole to be ejected from the jet hole, a first-time mixing of the thin oil and the flowed thickened oil is carried out, and mixed oil enters the second joint for a second-time mixing. According to the thickened oil blending-light mixed tool, the thin oil and the thickened oil can be fully mixed, the thin oil consumption is reduced, so that the effect of reducing the energy consumption can be achieved.

Owner:CHINA PETROLEUM & CHEM CORP

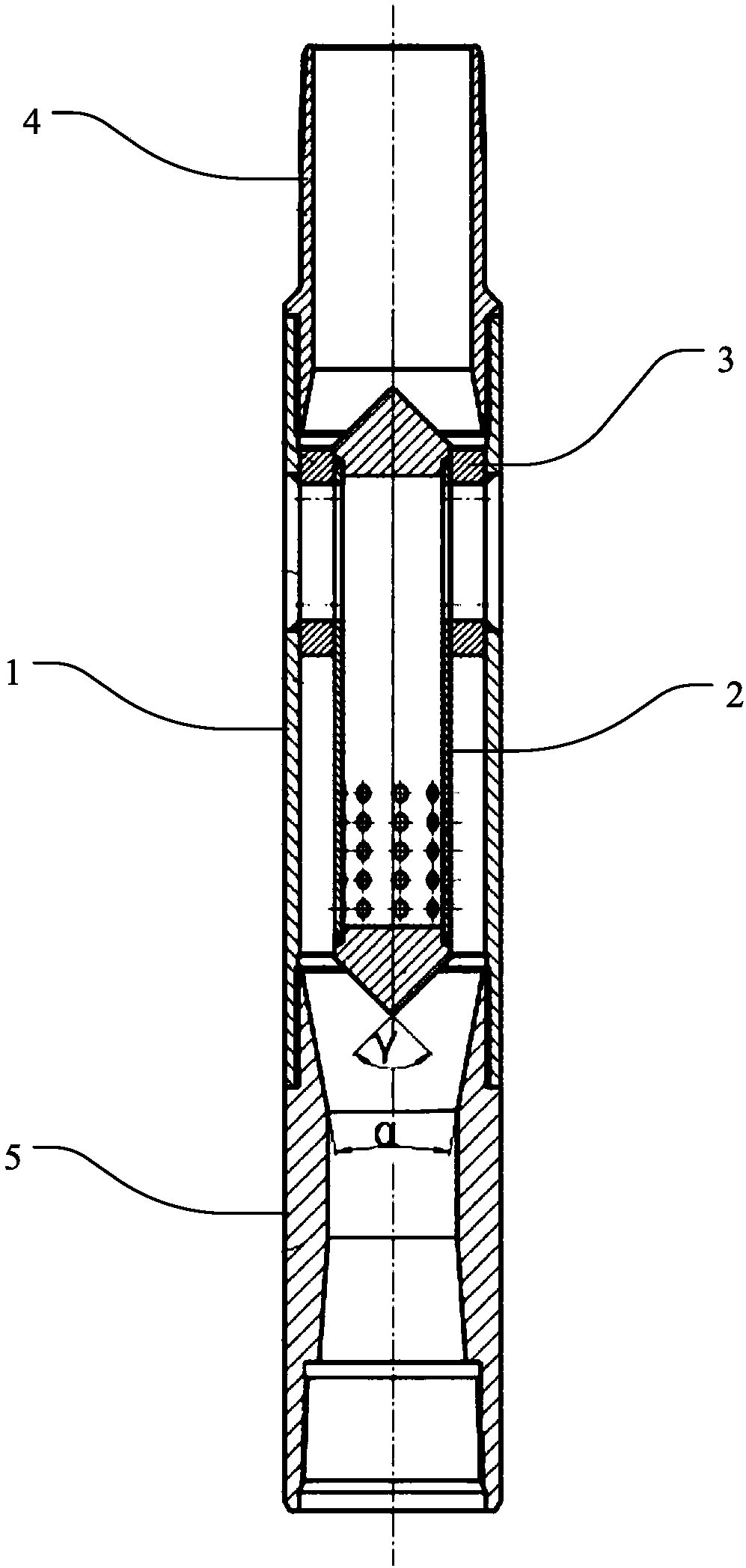

Dividing wall type regenerative cooling air oxygen alcohol torch type igniter

ActiveCN102175041BGuaranteed cooling reliabilityMeet ignition requirementsIncandescent ignitionRocket engine plantsAlcoholCombustion chamber

The invention discloses a dividing wall type regenerative cooling air oxygen alcohol torch type igniter which comprises an oxidant shell, a middle bottom, an inner bottom, a cooling jacket, a combustion chamber, a nozzle, a sparking plug, an oxidant inlet pipe mouth and a fuel inlet pipe mouth, wherein oxygen and alcohol are adopted as a propellent, and ignition is carried out by adopting the electric sparking plug. The nozzle comprises a straight-flow nozzle and an eccentric type nozzle, the straight-flow nozzle is an oxidant nozzle, the eccentric nozzle is a fuel nozzle, a cavity from the outlet of the straight-flow nozzle to the outlet of the eccentric nozzle is a reducing chamber; oxidant enters the reducing chamber from the straight-flow nozzle, fuel enters a fuel before-spraying liquid collecting cavity through a regenerating cooling chamber and then rotates through eccentric nozzle tangential holes and enters the reducing chamber, and the oxidant and the fuel are atomized and mixed in the reducing chamber and stably combusted at the outlets of the nozzles. High-temperature fuel is uniformly mixed in the combustion chamber and then sprayed through the throat part of the combustion chamber to form a stable torch. The invention ensures ignition and cooling reliability of an igniter and stable combustion of the torch at the outlet.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

Mohair blended stocking yarn and technique for processing same

The invention relates to an mohair blended knitting yarn and processing technology thereof, wherein the yarn is 82NM / 2 strands, comprising 60% of mohair, 40% of silkete Australian wool. The process includes: (1) pre-spinning: wool moisture regaining for 36 hours, with a moisture regaining rate of 24%, adding a fearnaughting oil to make the oil content in wool at 1%, the fearnaughting oil having proportion of antistatic agent:oil:water:cohesive force reinforcing agent at 0.5:1:8:1; (2) spinning: drafting for 19 times, with the speed of the fly frame at 7000r / min, single twist at 880T / M; (3) post-spinning, wherein an electronic yarn cleaner is provided for the winding, and yarns are spliced under air pressure between 0.6-0.8 Mpa. Advantages of the invention is that: (1) blended knitting of mohair with other fibers is implemented, and technological guarantee is provided for expanding application scope of mohair; (2) the product combines excellent characteristics of the two fibers, lowers cost, and enhances performance / cost ratio thereof in the mean time; (3) the product is suitable for manufacturing high class clothing and ornament, having great cost advantage and market prospect.

Owner:TIANJIN TEXTILE ENG RES INST

A kind of raspberry-like microsphere, superhydrophobic coating and preparation method thereof

ActiveCN107998997BNarrow distributionAchieve blendingCoatingsMicroballoon preparationPolymer scienceMicrosphere

The invention discloses a raspberry-like shaped microsphere, a super-hydrophobic coating and preparation methods thereof. The preparation method comprises the following steps: (1) synthesizing a polymethyl methacrylate microsphere through a dispersion polymerization method; (2) taking the polymethyl methacrylate microsphere, adding an ethanol solution of tetraethoxysilane as a silicon dioxide precursor, adopting a sol-gel process to react, and synthesizing the raspberry-like shaped microsphere which takes polymethyl methacrylate as a core and takes silicon dioxide as a shell. The preparation method is simple, the prepared raspberry-like shaped microsphere is controllable in dimension, and the super-hydrophobic coating has very good chemical stability, very good acid and alkaline resistanceand a very good hydrophobic property, has a surface contact angle of 151 degrees, and can be used for glass, building outer walls, fabric surfaces, metal surfaces and the like.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI +2

Method for producing hemp high-count yarns and folded yarns through Siro-spinning or Sirofil-spinning

InactiveCN101979733BEasy to achieve blendingAchieve blendingDrafting machinesYarnEngineeringWater soluble

Owner:DONGHUA UNIV

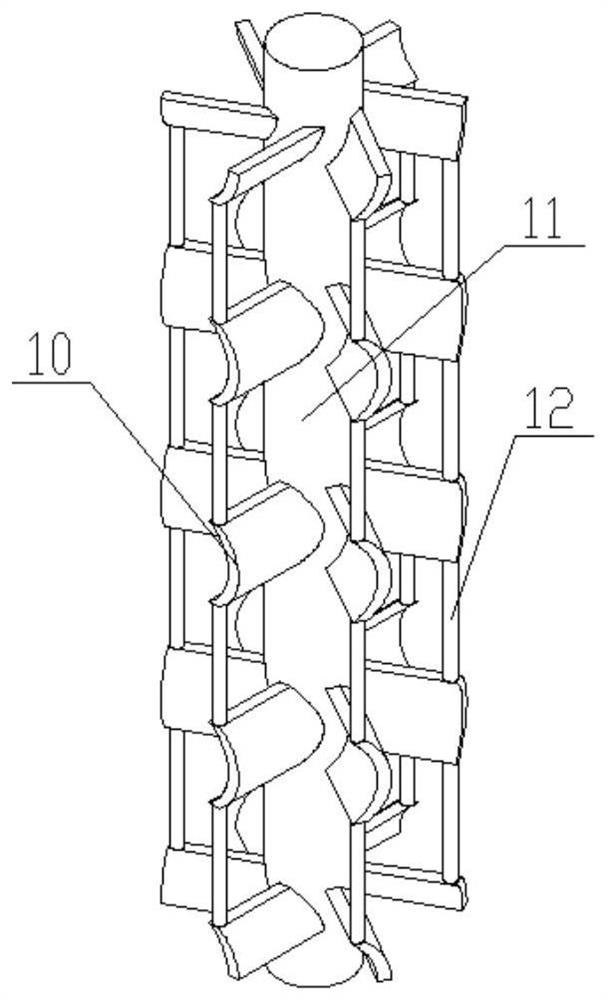

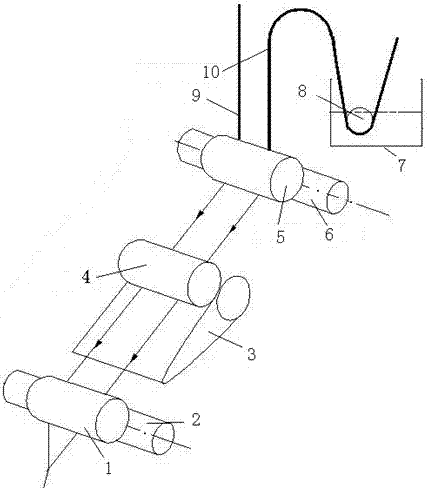

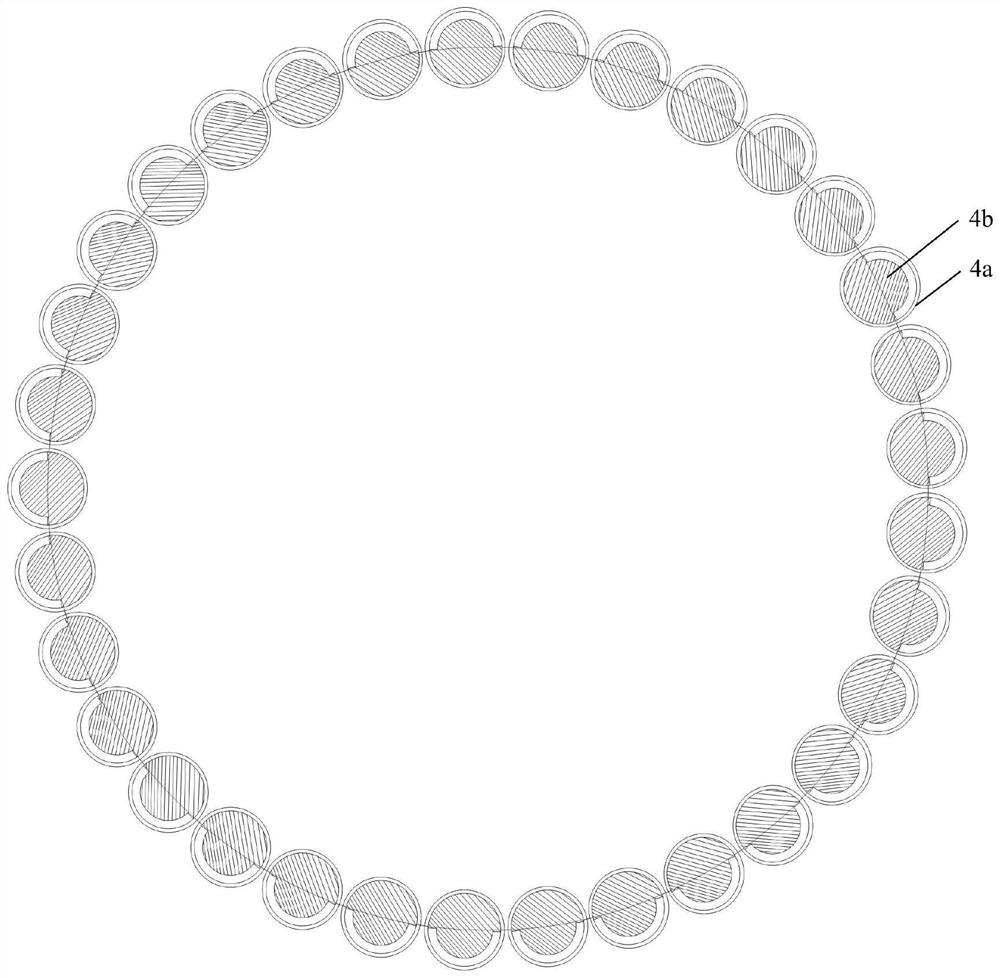

A multi-stage solid particle heat absorber for tower solar thermal power generation

ActiveCN109668341BUniform density distributionAdjust the flow rateSolar heating energySolar heat storageThermodynamicsHeliostat

A multi-stage solid particle heat absorber for solar thermal power generation is characterized in that heliostat fields (25, 26, 27) are used for correspondingly supplying radiation energy to a third-stage heat absorbing section (16), a second-stage heat absorbing section (10) and a first-stage heat absorbing section (4) which are annularly arranged at the upper part of a heat absorbing tower (22); low-temperature solid particles (3) in a low-temperature solid particle storing tank (23) are conveyed to a particle distributor (1) through a spiral lifting machine (24); the low-temperature solidparticles (3) flow into the first-stage heat absorbing section (4) for heating under the flow guide effect of a tapered insert (2) at the bottom part of the particle distributor (1); the heated low-temperature solid particles (3) enter a first-stage particle mixing chamber (9) and then enter the heat absorbing section at the next stage after temperature equalization; the low-temperature solid particles (3) flow into a high-temperature solid particle storing tank (20) through a tapered funnel (17) under the effect of a final-stage flow rate adjusting mechanism (18); after transferring heat to apower generation working medium, high-temperature solid particles (19) are transformed into the low-temperature solid particles (3) and then flow into the low-temperature solid particle storing tank(23).

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Starch-base foam material and preparing method thereof

The invention discloses a starch-base foam material and a preparing method thereof. Compared with an extrusion foaming preparing technology of a starch-base foam material, a mold pressing foaming technology is simple, a surface layer has the high density, multiple holes exist in the starch-base foam material, and the starch-base foam material with the complex shape can be prepared; in addition, starch plastifying, component blending and material forming are achieved through an internal mixer and an open mill with the technology method for preparing the foam material through rubber, the novel preparing method for the starch-base foam material is researched and obtained, and the application range of the starch-base foam material is widened.

Owner:SHAANXI UNIV OF SCI & TECH

Superfine mercerization Australian wool blended stocking yarn and processing technique thereof

The invention relates to an ultra-thin silkete Australian wool blended knitting yarn and processing technology thereof, wherein the yarn is 82NM / 2 strands, comprising 60% of ultra-thin silkete Australian wool, 40% of mohair. The process includes: (1) pre-spinning: wool moisture regaining for 24-36 hours, with a moisture regaining rate of 24%, adding a fearnaughting oil to make the oil content in wool at 1%, the fearnaughting oil having proportion of antistatic agent:oil:water:cohesive force reinforcing agent at 0.5:1:8:0.5; (2) spinning: drafting for 19 times, with the speed of the fly frame at 8000r / min, single twist at 860T / M; (3) post-spinning, wherein the twist is designed to be 510T / mm. Advantages of the invention is that: (1) ultra-thin silkete Australian wool and mohair blended knitting is implemented, and difficulty in the process is overcome; (2) the product combines excellent characteristics of the two fibers, lowers cost and enhances performance / cost ratio thereof in the mean time; (3) the product is suitable for manufacturing high class clothing and ornament, having great cost advantage and market prospect.

Owner:TIANJIN TEXTILE ENG RES INST

Equipment and method for blending LNG fuel in a gas generating set

ActiveCN104912696BAchieve blendingTake advantage ofInternal combustion piston enginesFuel supply apparatusFree stateProcess engineering

The invention relates to a device for mixing LNG fuel into a methane electric generator set. The device comprises a main methane conveying pipe, an LNG storage tank, a heat exchanger and an LNG gasification device. The heat exchanger is arranged inside the main methane conveying pipe. The heat exchanger is provided with an LNG inlet and an LNG outlet. The LNG inlet is communicated with the LNG storage tank through a first pipeline. The LNG outlet is communicated with the LNG gasification device through a second pipeline. The LNG gasification device is arranged on the main methane conveying pipe. The LNG fuel mixing can be achieved. When the methane concentration is fluctuated around 8%, the existing methane electric generator set can be fully utilized, and the utilization ratio of the device is improved. When the methane concentration is lower than 8%, the methane can be fully utilized, and the utilization space and the utilization ratio of the fuel are improved. Meanwhile, deep separating can be carried out on water which is in a free state and inside methane gas by the heat exchanger, and the electric generating efficiency of the electric generator set is favorable to be improved.

Owner:北京扬德环保能源科技股份有限公司

Ultra-low concentration gas safety mixing device and method

The invention relates to ultra-low concentration gas safety mixing device and method. The device comprises an inlet flange, an inlet pipeline, a narrow-down pipeline, an outlet pipeline and an outletflange which are communicated in turn, wherein the inlet pipeline and the outlet pipeline are conventional pipelines with equal diameter; the diameter of one side, connected with the inlet pipeline, of the narrow-down pipeline is the same as that of the inlet pipeline, and the diameter of one side connected with the outlet pipeline is small; the diameter of the pipeline at the joint between the narrow-down pipeline and the outlet pipeline changes suddenly; a circle of annular pipeline is arranged on the outer wall of the narrow-down pipeline; a circle of gap communicated with an inner cavity of the annular pipeline and an inner cavity of the narrow-down pipeline is arranged at the sealing joint between the annular pipeline and the narrow-down pipeline; the gap sprays high-concentration gasinto the flowing low-concentration gas for mixing. The invention provides a method for adjusting the mixing proportion according to the output gas concentration; according to the method, the concentration of the gas output by the mixing is stabilized at about 1.2%, and explosion is prevented; moreover, regular accuracy correction can be performed on the system.

Owner:PINGAN KAICHENG INTELLIGENT SAFETY EQUIP

An integrated anode structure of channel external distributor for low power Hall thruster

ActiveCN112012898BImprove scalabilitySimple structureShielding materialsMachines/enginesEngineeringMechanical engineering

The present invention is an integrated anode structure of channel external distributor for low-power Hall thruster, which includes air guide column, fixed column, air intake chamber, single-row hole chamber, double-row hole chamber, and channel chamber; The air column is inserted into the through hole in the air intake chamber, and the air guide column is stably connected with the air intake chamber by electron beam welding; the fixed column is inserted into the through hole in the air intake chamber, and the fixed column is connected to the air intake chamber by electron beam welding. The air inlet chamber is stably connected; the single-row hole chamber is inserted into the air inlet chamber, and the inlet chamber and the single-row hole chamber are stably connected by electron beam welding; the double-row hole chamber is inserted into the single-row hole chamber , using electron beam welding to achieve a stable connection between the single-row hole chamber and the double-row hole chamber; insert the channel chamber into the double-row hole chamber, and use electron beam welding to realize the double-row hole chamber and the channel chamber stable connection.

Owner:BEIJING INST OF CONTROL ENG

Thick Oil Mixed Thin Mixing Tool

The invention discloses a thickened oil blending-light mixed tool. The thickened oil blending-light mixed tool includes an outer tube, an injection pipe, a support block, a first joint and a second joint; the first joint and the second joint are separately connected to two ends of the outer tube, the outer tube is sleeved with the injection pipe, and two ends of the injection pipe is closed; the perimeter wall, close to the first joint, of the injection pipe is provided with a thin oil inlet which is used for passing of thin oil into the injection pipe, the perimeter wall, close to one end ofthe second joint, of the injection pipe is provided with a jet hole which is an annular gap formed between an outer tube and an inner tube, and the gap allows the thickened oil to enter from the firstjoint and to flow in the direction of the second joint; the thin oil enters the injection tube from the thin oil inlet and flows in the direction of the jet hole to be ejected from the jet hole, a first-time mixing of the thin oil and the flowed thickened oil is carried out, and mixed oil enters the second joint for a second-time mixing. According to the thickened oil blending-light mixed tool, the thin oil and the thickened oil can be fully mixed, the thin oil consumption is reduced, so that the effect of reducing the energy consumption can be achieved.

Owner:CHINA PETROLEUM & CHEM CORP

Preparation method of nylon 6/chitosan/noble metal nanofiber

ActiveCN112962216BReduce viscosityImprove degradation efficiencyElectro-spinningConjugated synthetic polymer artificial filamentsFiberPolymer science

The preparation method of nylon 6 / chitosan / noble metal nanofiber, concrete preparation steps are as follows: (1) nylon 6 is dissolved in formic acid and prepare mother liquor; (2) add chitosan in mother liquor, obtain nylon 6 / chitosan Mixed solution; (3) add metal salt in nylon 6 / chitosan mixed solution, after stirring and static, obtain nylon 6 / chitosan / metal salt mixed solution; (4) above-mentioned nylon 6 / chitosan / Put the metal salt mixed solution into the syringe of the electrospinning device, and carry out electrospinning to obtain the nylon 6 / chitosan / noble metal nanofiber membrane; using the easy phase separation and surface migration characteristics of chitosan and nylon 6, the noble metal Under the action of a high-voltage electric field, the nanoparticles break through the energy constraints of the surface of the nanofiber and migrate to the surface of the fiber, which is beneficial to improving the degradation efficiency of the dye; and the above method is a low-cost, clean, green and efficient method.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Preparation method of nylon 6/chitosan/noble metal nanofibers

ActiveCN112962216AReduce viscosityImprove degradation efficiencyElectro-spinningConjugated synthetic polymer artificial filamentsFiberPolymer science

The invention relates to a preparation method of nylon 6 / chitosan / noble metal nanofibers. The preparation method comprises the following specific preparation steps of (1) dissolving nylon 6 in formic acid to prepare mother liquor; (2) adding chitosan into the mother liquor to obtain a nylon 6 / chitosan mixed solution; (3) adding metal salt into the nylon 6 / chitosan mixed solution, stirring and standing to obtain a nylon 6 / chitosan / metal salt mixed solution; and (4) filling the nylon 6 / chitosan / metal salt mixed solution into an injector of an electrostatic spinning device, and performing electrostatic spinning to obtain a nylon 6 / chitosan / noble metal nanofiber membrane. By utilizing the characteristics of easy phase splitting and surface migration of chitosan and nylon 6, noble metal nanoparticles can break through the surface energy constraint of nanofibers and migrate to the surfaces of the fibers under the action of a high-voltage electric field, so that the dye degradation efficiency can be improved; and the method is low in cost, clean, green and efficient.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

A kind of preparation method of pva/cellulose composite fiber

ActiveCN107090607BAchieve blendingImprove water resistanceRadio/micro wave fibre treatmentConjugated cellulose/protein artificial filamentsCelluloseFiber

The invention provides a preparation method of a PVA / cellulose composite fiber. The preparation method comprises the following steps: preparing a spinning solution, performing spinning moulding, carrying out damp and hot drawing, carrying out tow treatment, carrying out tow drying, carrying out dry and hot drawing, carrying out heat treatment type approval, and simply crosslinking. The preparation method provided by the invention has the advantages that PVA solution precrosslinking and further crosslinking bath are eliminated; the prepared PVA / cellulose composite fiber not only can enable advantages of two components to be complementary, but also can realize blending of the two components in structure, dry strength of the prepared PVA / cellulose composite fiber is more than or equal to 2.12cN / dtex, and wet strength is more than or equal to 1.08cN / dtex; and the prepared composite fiber has high water tolerance, good textile processing property and moisture absorption rate of 7.6-12.0%.

Owner:潍坊欣龙生物材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com