Method for producing hemp high-count yarns and folded yarns through Siro-spinning or Sirofil-spinning

A technology of sirofil spinning and high-count yarn, applied in spinning machine, textile and papermaking, yarn and other directions, can solve the problem of difficulty in producing high-count, high-grade products, restricting the blending or companion spinning of hemp and water-soluble vinylon, Restrict the development of the cannabis industry and other issues, and achieve the effects of good uniformity, uniform strength, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

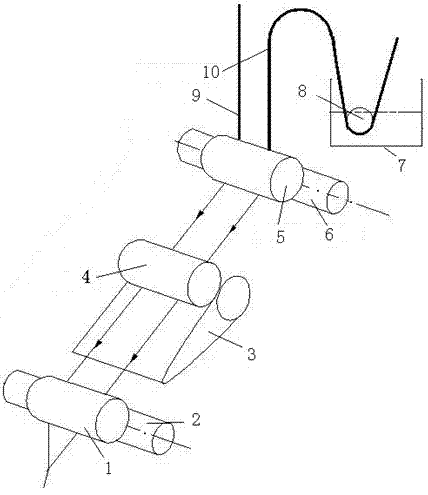

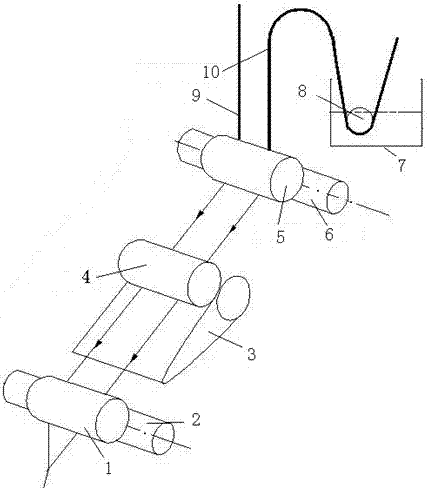

[0024] Using the technology of the present invention, 50 public hemp yarns and 50 / 2 public hemp strands are produced. like figure 1 Shown, it is the mixed schematic diagram of siro spinning of hemp roving and water-soluble vinylon roving, and its technology is: the hemp long hemp roving 9 after the scouring and bleaching process is passed through the water tank 7 (90 wt%) of the built-in yarn guide roller 8 in the wet On the spinning frame, the water-soluble vinylon roving 10 (10wt%) is kept at a certain interval of 4mm and fed at the same time. After 1 draft, it is mixed at the output, and the sliver output from the front roller is twisted into a yarn with a metric twist coefficient of 0.80, and a hemp / vinylon blended yarn with a fineness of 45 metric counts is spun out. The blended yarn is put into the aqueous solution for dimension reduction (1:10 liquor ratio), and after 0.5 hours of boiling and washing, the vinylon fiber is dissolved (receded), and the pure hemp yar...

Embodiment 2

[0029] Using the technology of the present invention, 50 public hemp yarns and 50 / 2 public hemp strands are produced. like figure 2 As shown, it is the mixed schematic diagram of the sirofil spinning of hemp roving and water-soluble vinylon single yarn or filament, and its technology is: the hemp roving 11 (67wt%) after the scouring and bleaching process is fed into wet spinning after passing through the water tank 7 Spinning frame, after drafting, the front roller 2 is mixed with 10tex water-soluble vinylon yarn (33wt%) with an interval of 12mm and twisted. The metric twist coefficient is 0.85, and the hemp with a fineness of 33 m / Vinylon blended yarn, and then put the blended yarn into the aqueous solution for dimensional reduction (bath ratio 1:10), after 2 hours of boiling, washing, and dissolving (removing) the vinylon fiber, a 50-mesh yarn was obtained. Pure hemp yarn.

[0030] The obtained 35 public hemp / vinylon blended yarn is reversely plied, and the ratio of th...

Embodiment 3

[0034] The pure hemp yarn of 150 public counts and the hemp strands of 150 / 2 public counts are spun by the present invention. First, 30wt% hemp roving and 70% vinylon roving are fed into the wet spinning frame (the spacing of the rovings is 0), and after drafting and twisting, 50 metric hemp / vinylon blends with a twist coefficient of 1.2 are obtained yarn. Then put it into the aqueous solution for dimension reduction (bath ratio 1:25), after 6 hours of boiling and washing, after dissolving the vinylon fiber in it, a pure hemp yarn of 150 metric counts is obtained.

[0035]The blended yarn produced by the above-mentioned method is reversely plyed and twisted, and the ratio of the twist coefficient of the strand to the single yarn twist coefficient is 1.3 to obtain a 50 / 2 public hemp / vinylon blended strand, and then put it in. After 6 hours of boiling and washing in the aqueous solution for dimension reduction (bath ratio 1:25), after dissolving the vinylon fiber in it, 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com