Method for producing linen wet spinning high count yarns and plied yarns

A production method and high-count yarn technology, applied in textiles, papermaking, yarn and other directions, can solve the problem of difficulty in producing high-count, high-grade products, restricting the development of flax and water-soluble vinylon blending or companion spinning, and unfavorable development of linen product variety. and other problems, to achieve the effect of good uniformity, uniform strength and less lint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Utilize the technology of the present invention, produce 50 public support pure linen yarns and 50 / 2 public support flax strands. The process is as follows: Feed flax long hemp roving (90 wt %) and water-soluble vinylon roving (10 wt %) at a certain interval (14 mm) on the wet spinning frame of long hemp after the boiling and bleaching process, to achieve two Mixing of the former, and twisting the sliver output by the front roller into a yarn, the metric twist coefficient is 0.8, spinning out a linen / vinylon blended yarn with a fineness of 45 metric counts, and then putting the blended yarn into the de-dimensional In the aqueous solution used (bath ratio 1:10), after boiling and washing for 0.5 hours, the vinylon fibers were dissolved (removed), and 50 metric pieces of pure linen yarn were obtained.

[0023] Such as figure 1 As shown, it is a schematic diagram of mixing flax roving and water-soluble vinylon roving. The mixing method of flax roving and vinylon rovi...

Embodiment 2

[0028] Utilize the technology of the present invention, produce 50 public support pure linen yarns and 50 / 2 public support flax strands. The process is as follows: the flax short linen roving 9 accounting for 70 wt% after the boiling and bleaching process is fed to the short linen wet spinning spinning frame and the water-soluble vinylon roving 10 accounting for 30 wt% is kept at a certain distance (10mm) at the same time to realize The two are mixed, and the sliver output by the front roller is twisted into yarn, the metric twist coefficient is 0.9, and the fineness is 35 metric counts of flax / vinylon blended yarn, and then the blended yarn is put into the backing machine. In the aqueous solution for maintenance (bath ratio 1:15), after 2 hours of boiling and washing, the vinylon fiber is dissolved (removed), and 50 metric pieces of pure linen yarn are obtained.

[0029] The flax / vinylon blended yarn of obtained 35 public counts is carried out reverse plying, the ratio o...

Embodiment 3

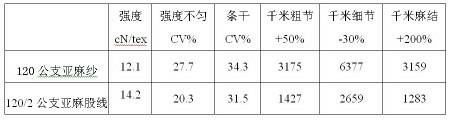

[0033] Adopt the present invention to spin the strands of the pure linen yarn of 120 public support and 120 / 2 public support. The process is as follows: in the long linen wet spinning frame, 50 wt% of the boiled and bleached flax long linen roving and 50 wt% of the vinylon roving are kept at a distance of 6mm and fed to the rear roller 6 together, drawn by the wet spinning frame, and added After the twist coefficient is 0.9, the flax / vinylon blended yarn of 60 metric counts is prepared, and then put into the aqueous solution for weaving (bath ratio 1:20), boiled for 4.5 hours, washed and dissolved After dropping the vinylon fiber therein, the pure linen high-count yarn of 120 metric counts is obtained.

[0034] The flax / vinylon blended yarn of 60 public counts obtained is reversely plyed, the ratio of the twist coefficient of the strands to the twist coefficient of the single yarn is 1.1, and a double-strand yarn of 60 / 2 public counts can be obtained, and then the strands...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com