Detonation-wave-front high-voltage electric plasma gas relay coupling ignition detonation engine

A detonation engine and plasma gas technology, applied in the field of aviation power, can solve problems such as huge noise, unstable thrust, strong vibration, etc., and achieve good market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

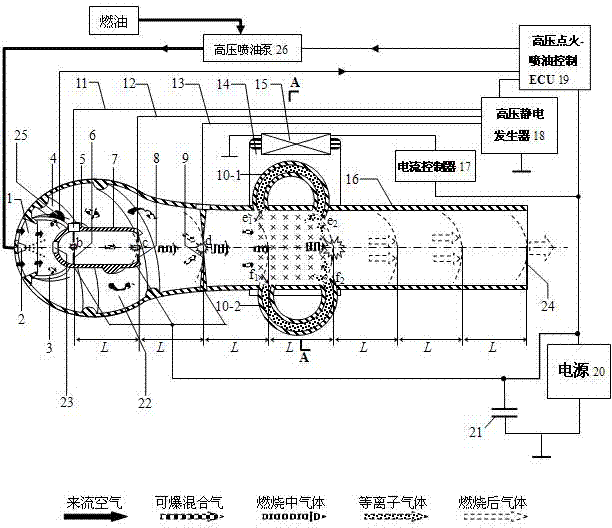

[0016] Attached below figure 1 And embodiment further illustrate the present invention.

[0017] The present invention consists of a pre-mixing indoor spiral guide bar (4), a pre-detonation combustion tube outer spiral guide bar (5), a high-pressure ignition head b (6), a pre-detonation combustion tube (7), a high-pressure ignition head c (8) , high-voltage ignition head d (9), upper plasma guide tube (10-1), lower plasma guide tube (10-2), ignition head b high-voltage ignition wire (11), ignition head c high-voltage ignition wire (12) , ignition head c high-voltage ignition wire (13), toroidal magnetic pole plate (14), magnetic field coil (15), detonation nozzle (16), current controller (17), high-voltage ignition-fuel injection control ECU (19) , fuel air premix chamber (22), pre-detonation combustion tube air inlet (23), wind speed sensor (25), high-pressure fuel injection pump (26);

[0018] The technical solution adopted in the present invention is: an air inlet (1) is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com