Hydraulic self-driven drag reduction slime diluting and releasing device

A release device and self-driven technology, which is applied to mixers with rotating stirring devices, transportation and packaging, mixers, etc., can solve the problems of not being suitable for carrying drag-reducing mucus, difficulty in releasing drag-reducing mucus, and large bending range. Large engineering application value, good dilution ability, and the effect of reducing mechanical noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

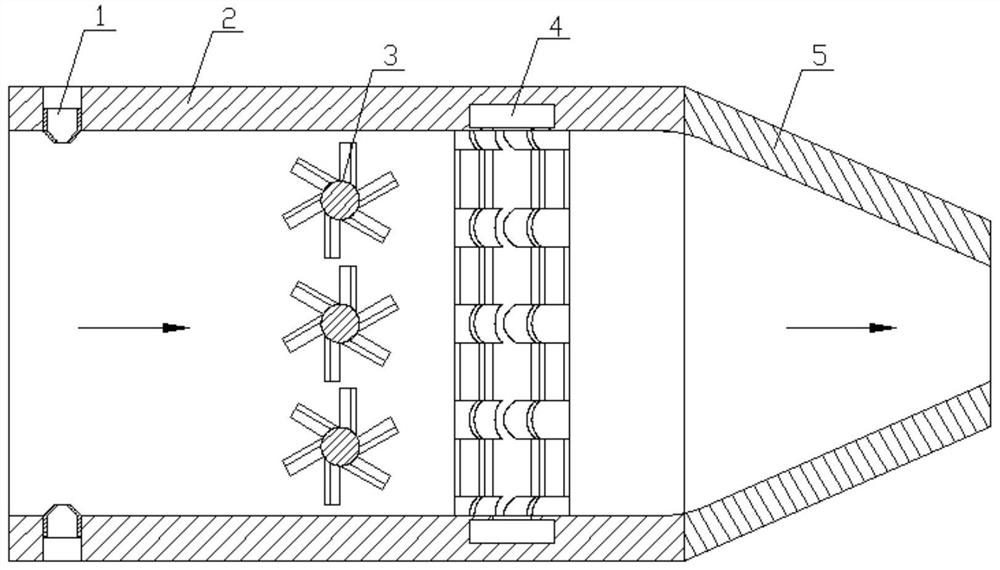

[0022] This embodiment is a hydraulic self-driven drag-reducing mucus dilution release device.

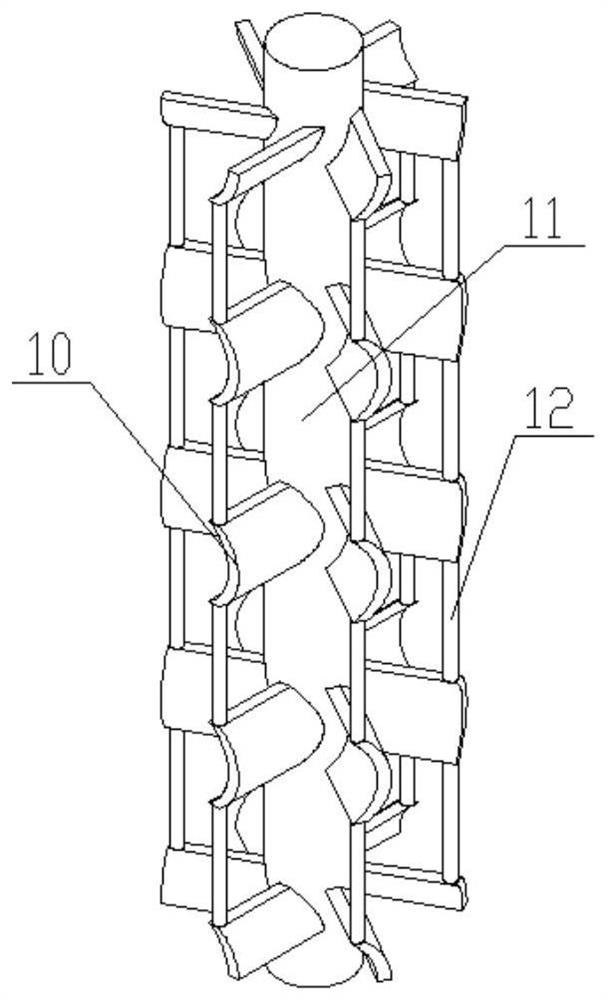

[0023] refer to Figure 1 ~ Figure 3 , figure 1 The middle arrow is the direction of water flow; figure 2 The arrows in the middle horizontal direction are the direction of water flow, and the arrows in the vertical direction are the direction of mucus flow.

[0024] In this embodiment, the hydraulic self-driven drag-reducing mucus dilution release device consists of a mucus nozzle 1, a dilution and mixing chamber 2, a stirring rod 3, a release nozzle 5, a water inlet pipe 6, an electromagnetic flowmeter 7, a mucus delivery pipeline 8, and a mucus dilution Release device 9, hydraulic turbine 10, support rod 11, stirring round rod 12; electromagnetic flowmeter 7 is installed on water inlet pipe 6, and dilution and mixing chamber 2 is located at the rear of water inlet pipe 6. Wherein, the dilution and blending chamber is a hollow cuboid with open ends, the rear of the dilution a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com