Hollow fancy loop multifunctional health-care yarn and preparation method thereof

A multi-functional, yarn technology, applied in the field of textiles, can solve the problems of high sugar content, high price of long-staple cotton fibers, and high difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

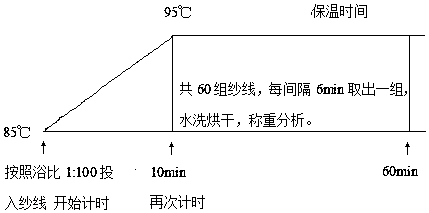

Method used

Image

Examples

Embodiment 1

[0137] What the present embodiment prepared was the hollow fancy intermittent loop yarn, and the loop yarn was made up of core yarn, fixed yarn and decorative yarn, and the core yarn was 70% of lotus root silk fiber, 10% of bamboo fiber, bamboo charcoal fiber 10%, Conlon fiber 10%, core-spun yarn processed by water-soluble vinylon filament, fixed yarn is PTT shape memory fiber filament and anti-ultraviolet polyester fiber filament, decorative yarn is 75% cashmere fiber and 25% and a half mohair fiber Spun yarn made from worsted spinning.

[0138] Core yarn preparation: opening and cleaning → carding → drawing (three passes) → roving → spun yarn → post-processing.

[0139] Among them, the process parameters of opening and cleaning cotton: use a comb beater, and the speed of the comb beater is controlled at 400 rpm, and the single beater roll machine also uses a comb beater, and the speed of the comb beater is controlled at 550 rpm; the speed of the fan is 1120 rpm, lap roller ...

Embodiment 2

[0151] What the present embodiment prepared was the hollow fancy intermittent loop yarn, and the loop yarn was made up of core yarn, fixed yarn and decorative yarn, and the core yarn was 10% of lotus root silk fiber, 70% of bamboo fiber, bamboo charcoal fiber 10%, Conlon fiber 10%, core-spun yarn processed by water-soluble vinylon filament, fixed yarn is PTT shape memory fiber filament and anti-ultraviolet polyester fiber filament, decorative yarn is 10% cashmere fiber and 90% and a half mohair fiber Spun yarn made from worsted spinning.

[0152] Core yarn preparation: opening and cleaning → carding → drawing (three passes) → roving → spun yarn → post-processing.

[0153] Among them, the process parameters of opening and cleaning cotton: use a comb beater, and the speed of the comb beater is controlled at 500 rpm, and the single beater roll machine also uses a comb beater, and the speed of the comb beater is controlled at 650 rpm; the speed of the fan is 1200 rpm, lap roller ...

Embodiment 3

[0165]What the present embodiment prepared was the hollow fancy intermittent loop yarn, and the loop yarn was made up of core yarn, fixed yarn and decorative yarn, and the core yarn was 10% of lotus root silk fiber, 10% of bamboo fiber, and bamboo charcoal fiber. 70%, Conlon fiber 10%, core-spun yarn processed by water-soluble vinylon filament, fixed yarn is PTT shape memory fiber filament and anti-ultraviolet polyester fiber filament, decorative yarn is 40% cashmere fiber and 60% and a half mohair fiber Spun yarn made from worsted spinning.

[0166] Core yarn preparation: opening and cleaning → carding → drawing (three passes) → roving → spun yarn → post-processing.

[0167] Among them, the process parameters of opening and cleaning cotton: use the comb beater, the speed of which is controlled at 595 rpm, and the single beater roll machine also uses comb beater, the speed of which is controlled at 765 rpm; the speed of the fan is 1270 RPM, lap roller speed 12.0 RPM; generall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com