Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Dry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermosetting reflection thermal insulation coating and preparation method thereof

InactiveCN102533011AGood chemical resistanceHigh temperature resistanceReflecting/signal paintsWeather resistanceAcrylic resin

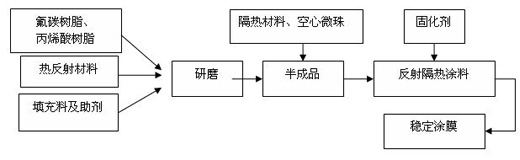

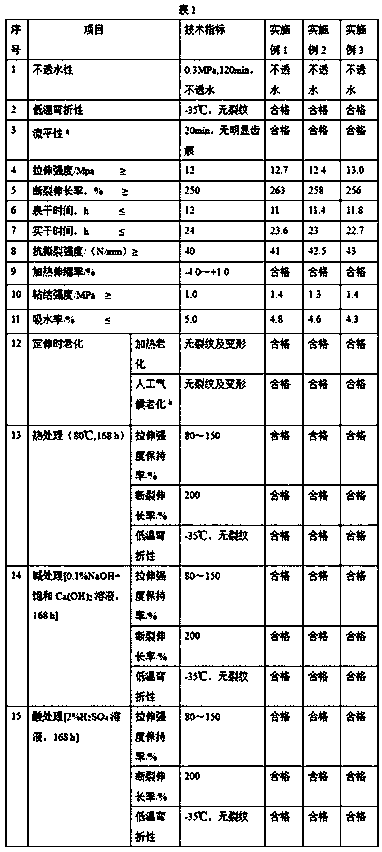

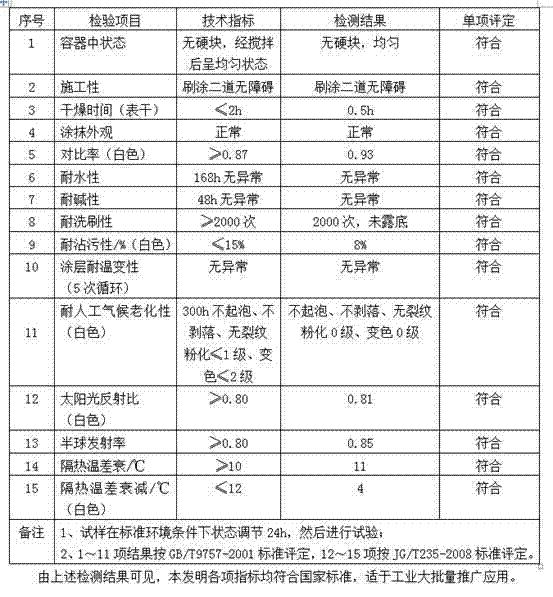

The invention discloses a thermosetting reflection thermal insulation coating. The thermosetting reflection thermal insulation coating is characterized by being prepared from the following components in part by weight: 100 to 150 parts of thermosetting fluorocarbon resin, 30 to 40 parts of thermosetting acrylic resin, 10 to 20 parts of cenosphere, 40 to 60 parts of titanium dioxide, 20 to 30 parts of silicon dioxide, 30 to 40 parts of aid, and 20 to 30 parts of curing agent; and the thermosetting reflection thermal insulation coating has the characteristics of high chemical resistance, high temperature resistance, weather resistance, and stain resistance, good self-cleaning property, long service life of a coating and the like. Moreover, the appearance of a building can be beautified and decorated by color mixing, and the effects of reflection and thermal insulation can be fully exerted.

Owner:南宁市金双龙涂料有限公司

Hollow fancy loop multifunctional health-care yarn and preparation method thereof

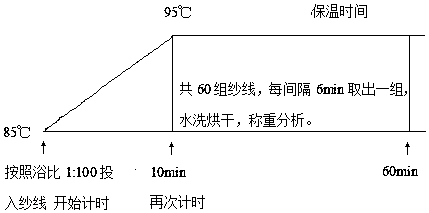

The invention provides hollow fancy loop multifunctional health-care yarn and a preparation method thereof. The yarn comprises lotus root fibers, lyocell fibers, bamboo charcoal fibers, Clean cool fibers, water-soluble vinylon fiber filaments, PTT shape memory fiber filaments, anti-ultraviolet polyester fiber filaments, cashmere fibers and mohair fibers, or comprises stainless steel fiber filaments, mint fibers, long stapled cotton fibers, water-soluble vinylon filaments, colorful negative ion multifunctional viscose filaments, bamboo charcoal fibers and coconut carbon fibers. The yarn prepared through the preparation method has excellent in hygroscopicity, natural, antibacterial, resistant to odor and capable of absorbing moisture and discharging sweat, has deodorization and anti-aging functions and the like, also has excellent radiation resistance, anti-static performance and a negative ion emission function, enhances the immune function, activates cells, promotes metabolism, has deodorizing performance, prevents mites, odor and insects, generates negative ion characteristic and is resistant to water, oil and dirt, and fabrics are prevented from being influenced by various harmful bacteria and pollution.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Waterborne polyurethane thermal-insulating sound-absorbing coating and preparation method thereof

InactiveCN104789107AExtend your lifeLow shrinkagePolyurea/polyurethane coatingsSolventAbsorption effect

The invention discloses waterborne polyurethane thermal-insulating sound-absorbing coating and a preparation method thereof. The waterborne polyurethane thermal-insulating sound-absorbing coating comprises a polyurethane prepolymer, N-hydroxymethyl acrylamide, phthalic acid dibutyl ester, a zirconium-aluminic acid ester coupling agent, rutile titanium dioxide, methylsilicone oil, a mixed solvent and a sound-absorbing material. The preparation method comprises the following steps: dissolving every 1 kg by weight of N-hydroxymethyl acrylamide in 2 kg of 50-70% ethanol in volume concentration, mixing with the polyurethane prepolymer in a reaction kettle, enabling the components to react for 1 hour at 80-150 DEG C, and adding the zirconium-aluminic acid ester coupling agent to continuously react for 2-5 hours; subsequently adding the phthalic acid dibutyl ester, rutile titanium dioxide, methylsilicone oil, mixed solvent and sound-absorbing material, and uniformly mixing, thereby obtaining a waterborne polyurethane thermal-insulating sound-absorbing coating product. The waterborne polyurethane thermal-insulating sound-absorbing coating can insulate heat and absorb sound, and is good in chemical resistance, good in temperature resistance, good in weather resistance, long in film service life, free of toxicity or smell, safe and environment-friendly and good in sound absorption effect.

Owner:GUANGXI CHAOXING SOLAR ENERGY TECH +1

Acetate synthetic fabric and manufacturing method thereof

The invention relates to a method for preparing a fabric, in particular to an acetate synthetic fabric and a preparation method thereof. The invention mainly solves technical problems in the prior art that cotton, real silk and the like fabrics are susceptible to wrinkles when in a blank state and fading when washed by water, insufficient in drape and narrow in application range, and that hemp, chemical fiber, terylene and the like materials are unqualified in environmental protection and other performance and effects and the like due to small application range and requirements for supports from agents of various chemicals for achieving a certain purpose. The fabric comprises the following components: artificial fibers, acetate fibers, a natural plant solvent and colorants. The manufacturing method comprises the following steps: carding the acetate fibers and adding the colorants and the natural plant solvent into the carded acetate fibers; spinning warps through rotor spinning; subjecting the warps to warping, slashing, warp rebeaming, drafting and buckling and weaving; looming the warps to obtain finished warps; spinning dyed yarns into wefts through jet weaving; and weaving the warps and the wefts into a fabric of a required type to obtain the finished acetate synthetic fabric.

Owner:HANGZHOU HAND MADE HOME FASHIONS

Water-soluble polyurethane external-wall thermal-insulation waterproof paint and preparation method thereof

InactiveCN104762013AGood flexibilityLow shrinkageAntifouling/underwater paintsAnti-corrosive paintsPrepolymerWeather resistance

The invention relates to a water-soluble polyurethane external-wall thermal-insulation waterproof paint and a preparation method thereof. The paint comprises a polyurethane prepolymer, N-hydroxymethyl acrylamide, dibutyl phthalate, vinyl trichlorosilane, titanium white, methyl silicone oil, superfine calcium carbonate and a mixed solvent. The preparation method comprises the following steps: adding 2 kilos of 50-70 vol% ethanol into every kilo of N-hydroxymethyl acrylamide for dissolution, mixing with the polyurethane prepolymer in a reaction kettle, reacting at 80-150 DEG C for 1 hour, and adding vinyl trichlorosilane; continuing reacting for 2-5 hours; and adding the dibutyl phthalate, rutile titanium white, methyl silicone oil, superfine calcium carbonate and mixed solvent, and uniformly mixing to obtain the water-soluble polyurethane external-wall thermal-insulation waterproof paint product. The water-soluble polyurethane external-wall thermal-insulation waterproof paint has the characteristics of high chemical resistance, high temperature resistance, favorable weather resistance favorable pollution resistance, high glossiness, long service life of the coated film and the like.

Owner:GUANGXI JIKUAN SOLAR ENERGY EQUIP +1

Polyurethane modified asphalt waterproof paint and preparation method thereof

InactiveCN108047948AEliminate coagulationEvenly dispersedFireproof paintsAntifouling/underwater paintsBituminous waterproofingGas phase

The invention relates to a polyurethane modified asphalt waterproof paint and a preparation method thereof. The paint is prepared from a polyurethane prepolymer, 90# petroleum asphalt, modified nano calcium carbonate, vinyl trichlorosilane, a tackifier, n-butyl acetate, citric acid, dibutyltin dilaurate, polyoxyethylene polyoxypropylene ether and fumed silica. The preparation method includes: modifying the 90# petroleum asphalt with the polyurethane prepolymer and modified nano calcium carbonate; then adding vinyl trichlorosilane, citric acid and n-butyl acetate into a reaction kettle, and stirring the substances evenly; then adding fumed silica, the tackifier and dibutyltin dilaurate, and stirring the substances evenly; then adding polyoxyethylene polyoxypropylene ether; further performing stirring till no powder flotation; shearing all the materials in the reaction kettle on a high speed shearing machine again until the 90# petroleum asphalt and other materials are evenly dispersed,thus obtaining the polyurethane modified asphalt waterproof paint. The product provided by the invention has the advantages of high bonding strength, high tensile strength and good dispersibility.

Owner:GUANGXI WUXUAN JINPAI WATERPROOF MATERIAL SCI & TECH CO LTD

Warm, breathable and down-proof garment fabric

InactiveCN104473360AGood flexibilityStrong hygroscopicityWoven fabricsVegetal fibresAnti bacterialWeft yarn

The invention discloses a warm, breathable and down-proof garment fabric. The warm, breathable and down-proof garment fabric comprises a base fabric body and a down-proof coating, wherein the base fabric body is interwoven by warp yarns and weft yarns; the warp yarns are twisted by 45-50 mass percent cotton fibers and 15-20 mass percent modal fiber; the weft yarns are twisted by 25-30 mass percent anti-bacterial moisture-guiding acrylic fibers and 10-15 mass percent bamboo carbon fibers; and the down-proof coating is an organic silicon high-elasticity coating. By the mode, the fabric is fine and compact in texture, has high heat retention property, high down-proof property and high breathability, has an anti-bacterial effect, and is non-toxic, harmless, environment-friendly and safe.

Owner:常熟市董浜镇徐市晨晨针织服装厂

Polyurethane external-wall thermal-insulation paint and preparation method thereof

InactiveCN104744981AExtend your lifeImprove drynessAntifouling/underwater paintsPaints with biocidesMeth-Hydroxymethyl

The invention relates to a water-soluble polyurethane external-wall thermal-insulation paint and a preparation method thereof. The paint comprises a polyurethane prepolymer, N-hydroxymethyl acrylamide, dibutyl phthalate, vinyl trichlorosilane, titanium white, methyl silicone oil, superfine calcium carbonate and a mixed solvent. The preparation method comprises the following steps: adding 2 kilos of 50-70 vol% ethanol into every kilo of N-hydroxymethyl acrylamide for dissolution, mixing with the polyurethane prepolymer in a reaction kettle, reacting at 80-150 DEG C for 1 hour, and adding vinyl trichlorosilane; continuing reacting for 2-5 hours; and adding the dibutyl phthalate, rutile titanium white, methyl silicone oil, superfine calcium carbonate and mixed solvent, and uniformly mixing to obtain the water-soluble polyurethane external-wall thermal-insulation paint product. The water-soluble polyurethane external-wall thermal-insulation paint has the characteristics of high chemical resistance, high temperature resistance, favorable weather resistance, favorable pollution resistance, high glossiness, long service life of the coated film and the like.

Owner:GUANGXI CHAOXING SOLAR ENERGY TECH +1

Water-soluble polyurethane flame-retardant coating and preparation method thereof

InactiveCN104789106AImprove self-cleaning abilityExtend your lifeFireproof paintsAntifouling/underwater paintsPolymer scienceMeth-

The invention discloses water-soluble polyurethane flame-retardant coating and a preparation method thereof. The water-soluble polyurethane flame-retardant coating comprises a polyurethane prepolymer, N-hydroxymethyl acrylamide, phthalic acid dibutyl ester, a titanate coupling agent, talcum powder, light calcium carbonate, tributyl phosphate, isopropanol, a mixed solvent and a flame-retardant material. The preparation method comprises the following steps: dissolving every 1 kg by weight of N-hydroxymethyl acrylamide in 2 kg of 50-70% ethanol in volume concentration, mixing with the polyurethane prepolymer in a reaction kettle, enabling the components to react for 1 hour at 80-150 DEG C, and adding a mixture of isopropanol and a titanate coupling agent in a weight ratio of 1:1 to continuously react for 2-5 hours; subsequently adding phthalic acid dibutyl ester, talcum powder, light calcium carbonate, tributyl phosphate, the mixed solvent and the flame-retardant material, and uniformly mixing, thereby obtaining a water-soluble polyurethane flame-retardant coating product. The water-soluble polyurethane flame-retardant coating has the characteristics of good chemical resistance, good temperature resistance, good weather resistance, good stain resistance, high glossiness, long film service life and the like.

Owner:GUANGXI JIKUAN SOLAR ENERGY EQUIP +1

Preparation method for skin care diapers

ActiveCN111420111ABacteriostaticDryLiquid repellent fibresAbsorbent padsWoven fabricHamamelis virginica

The invention relates to the technical field of disposable sanitary products, provides a preparation method for skin care diapers, and solves the problem of insufficient antibacterial properties and easy skin discomfort of diapers in the prior art. The method includes the steps of preparation of a liquid-permeable surface layer, preparation of an absorbent layer and preparation of a leakage-proofbottom layer, the liquid-permeable surface layer is sequentially provided with an upper layer non-woven fabric, an antibacterial layer and a lower layer non-woven fabric from the top to the bottom ina laminated manner, the upper layer non-woven fabric is a polylactic acid non-woven fabric, the lower layer non-woven fabric is an ES non-woven fabric, the antibacterial layer is a microcapsule, the microcapsule is prepared by using chitosan and gum Arabic as wall materials, and tea oil, hamamelis virginiana extract, and dandelion extract as core materials, and the liquid-permeable surface layer is obtained by the steps of spraying a hydrophilic finishing liquid to one side of the ES non-woven fabric, uniformly spraying the microcapsules on the side, having no hydrophilic finishing liquid, ofthe ES non-woven fabric, covering the microcapsules with the polylactic acid non-woven fabric, and performing adhesion by using a hot melt adhesive.

Owner:CHIAUS FUJIAN IND DEV

Human umbilical cord mesenchymal stem cell serum-free culture medium and preparation method and application thereof

InactiveCN110699317ASuitable for growthSuitable for dry maintenanceCulture processSkeletal/connective tissue cellsPancreatic hormoneGlutamine

The invention discloses a human umbilical cord mesenchymal stem cell serum-free culture medium and a preparation method and application thereof. The human umbilical cord mesenchymal stem cell serum-free culture medium comprises a basic culture medium, amino acid substances, trace elements, recombinant human serum albumin, transferrin, recombinant human insulin, recombinant human epidermal growth factors, alkaline fibroblast growth factors and buffer salt, wherein the amino acid substances comprise glycine, alanine, asparagine, aspartic acid, glutamic acid, proline, serine and glutamine. The serum-free culture medium is clear in components, stable in batch, free of serum, antibiotics and other serum analogues, and free of heterogeneous pollution and immunological rejection risks and safe touse; by the serum-free culture medium, normal cell adherence and good cell growth state can be kept; the serum-free culture medium has stemness and is suitable for the growth and stemness maintenanceof human umbilical cord mesenchymal stem cells.

Owner:湖南丰晖生物科技有限公司

Talcum powder with disinfecting effect

The invention discloses a bactericidal well-feeling powder, containing boracic acid, talcum powder, zinc oxide, magnesium carbonate, taibai powder (natural amylum), etc. using the talcum powder, etc., as the hygroscopic and dry component and adding in magnesium carbonate as the intensifier, and in addition because the boracic acid and the zinc oxide have the characters of sterilizing and inhibiting the biological growth and the taibai powder has the character of strong adhesivity, permanence and uneasily flying away, the invention has efficacies of tenderly sterilizing permanence, good quality, etc.

Owner:胡世珍

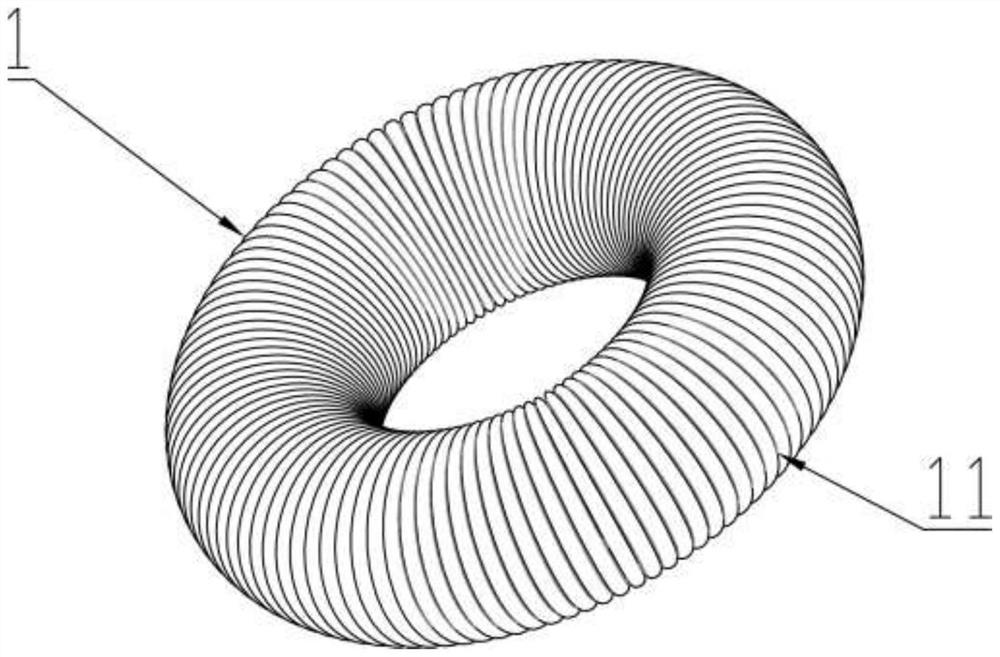

Male sanitary ring

The invention discloses a male sanitary ring. The male sanitary ring comprises a ring body and an elastic band arranged in the ring body in a penetrating mode; the ring body is made of paper, medicine components are loaded on the ring body, and wrinkles are arranged on the ring body; and the ring body is made of paper, has good hygroscopicity and can prevent the male coronary sulcus from being moist. Meanwhile, the multiple layers of wrinkled structures on the ring body can improve the air permeability of the ring body, the surface area of the ring body is increased, more medicine components can be loaded, and the cleaning and disinfecting effects are improved. The telescopic design of the ring body can adapt to coronary sulcus of different sizes and different states, the wrinkle design on the ring body can enable the ring body to stretch and retract along with the elastic band, the constraint feeling of the sanitary ring on the coronary sulcus is reduced, and the wearing comfort is improved.

Owner:郭庆和

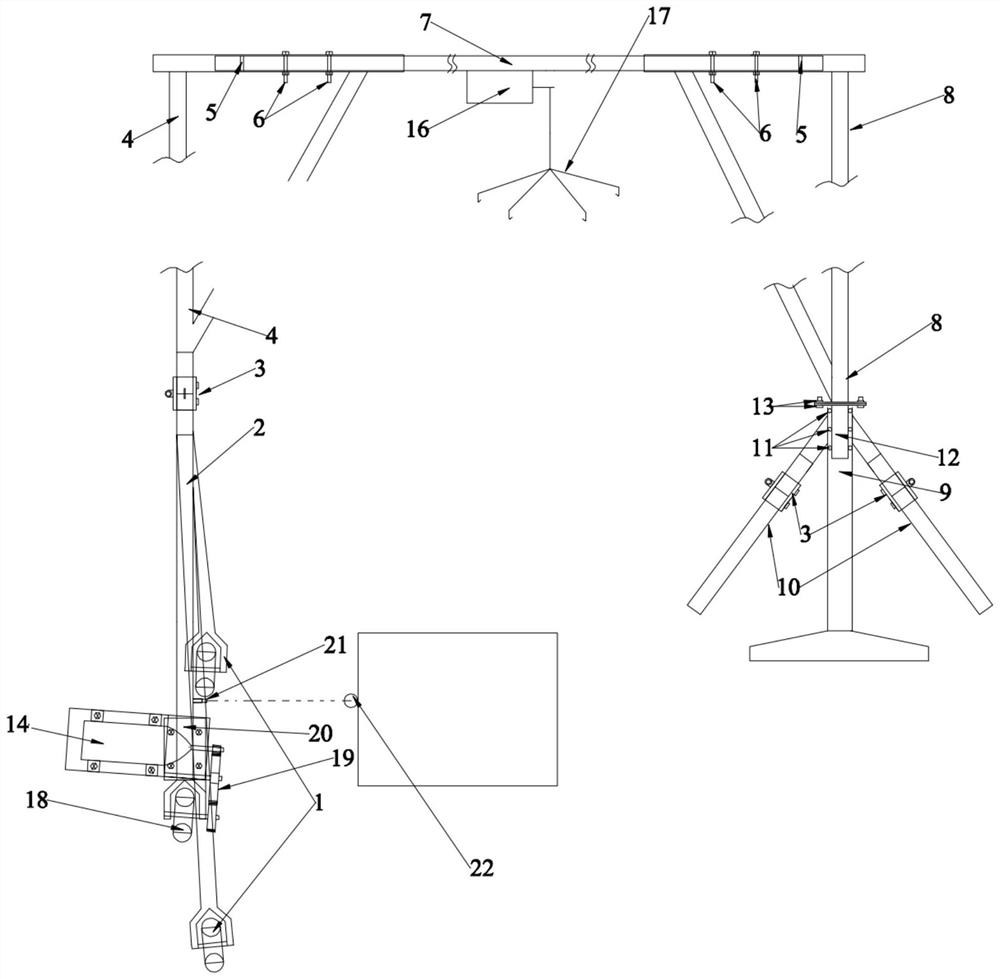

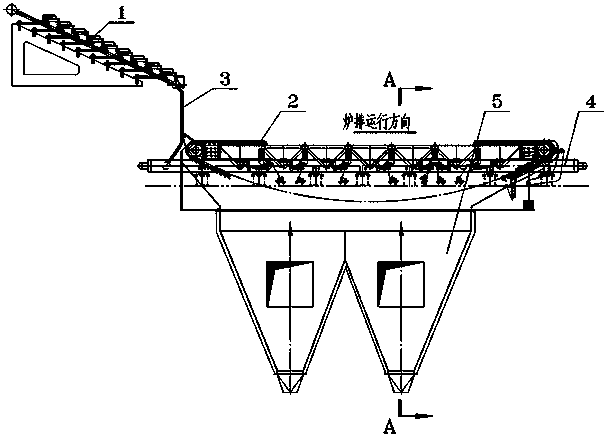

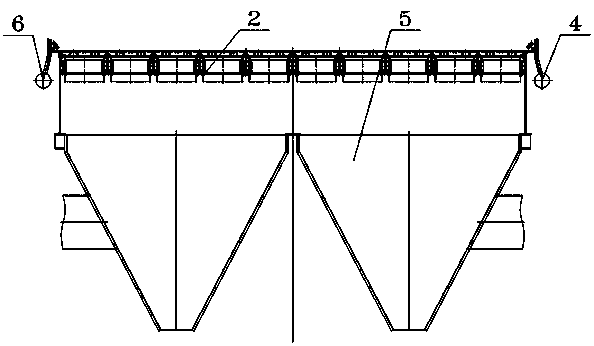

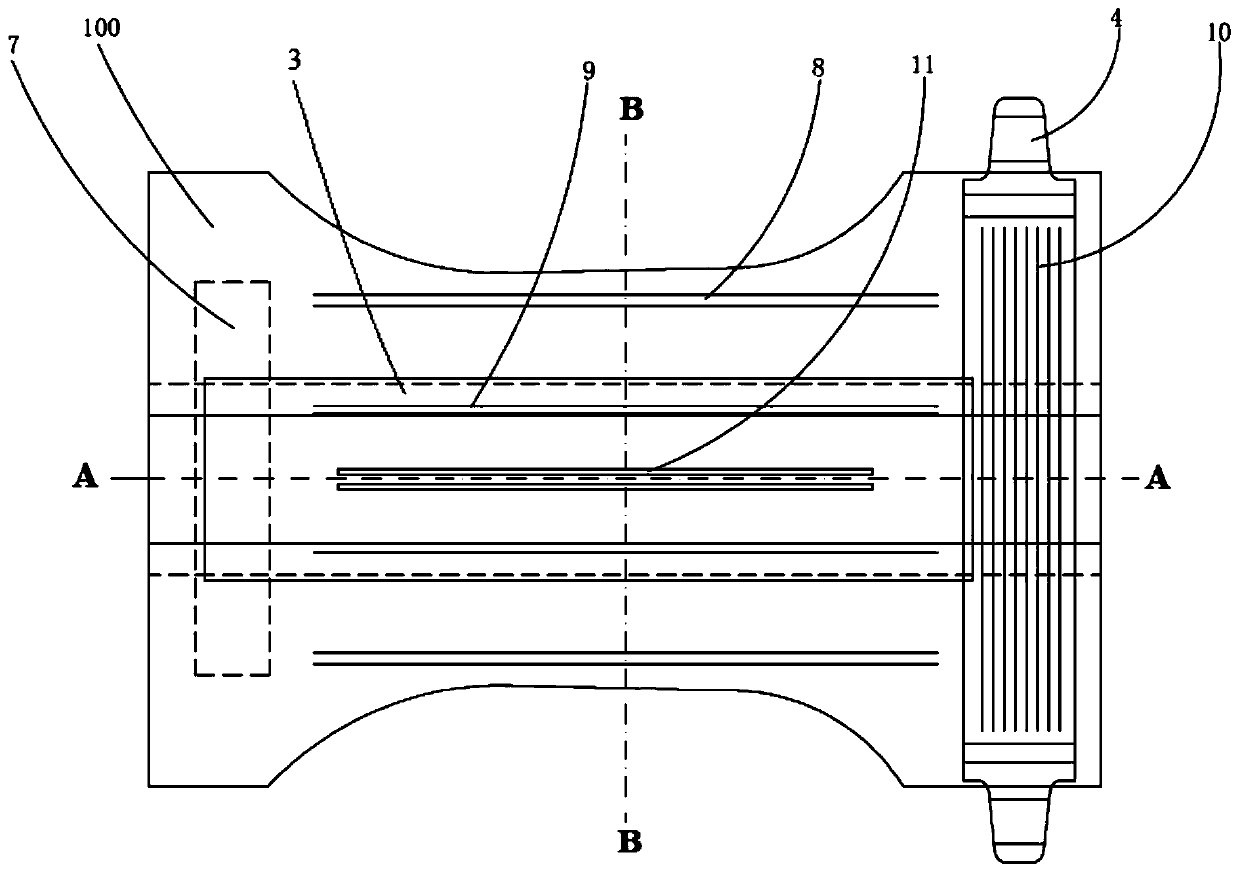

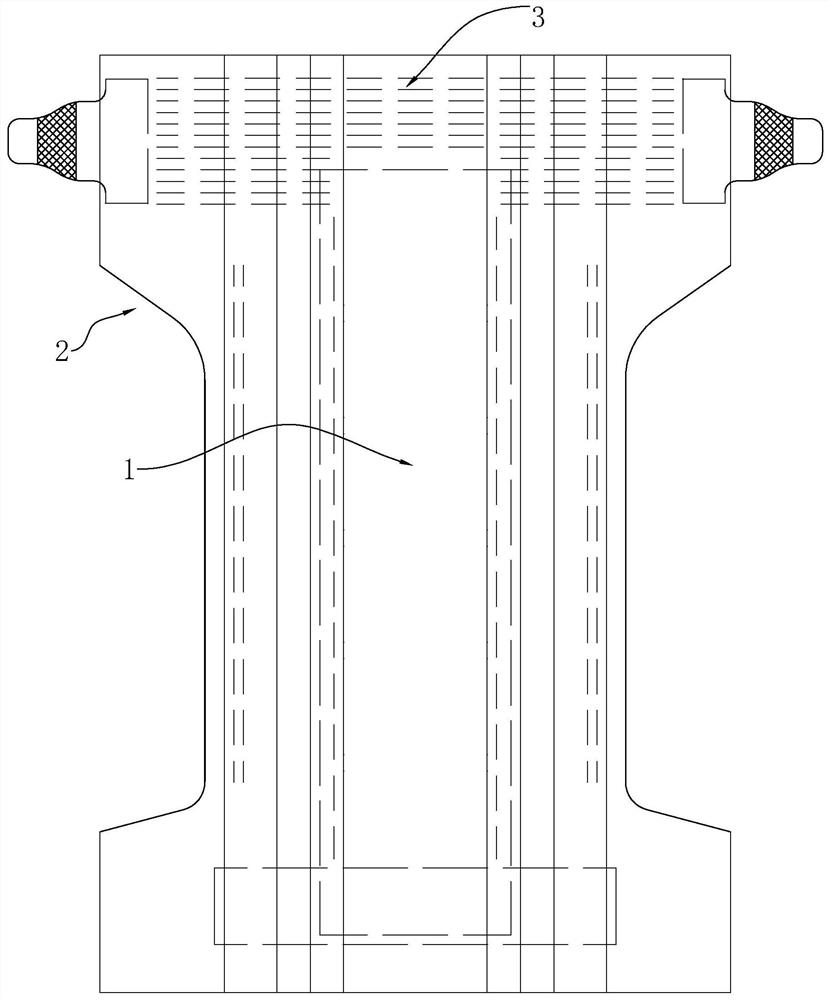

Cleaning system and cleaning process for heat exchange module in air preheater

PendingCN113566645ACompact structureSmall footprintCombustion processVibration cleaningAir preheaterSmall footprint

The invention relates to a cleaning system and a cleaning process for a heat exchange module in an air preheater. The cleaning system comprises a hanging bracket, a center support, a softening cylinder, a first ultrasonic cleaning unit, a second ultrasonic cleaning unit, a purging unit and a drying unit, wherein the softening cylinder, the first ultrasonic cleaning unit, the second ultrasonic cleaning unit, the purging unit and the drying unit are sequentially arranged around the center support; the hanging bracket comprises a walking mechanism, a first support, a cross beam and a second support which are fixedly connected in sequence, and the lower end of the second support is rotationally connected with the central support, so that the hanging bracket can do circular motion in the horizontal plane around the central axis of the central support; the softening cylinder, the first ultrasonic cleaning unit, the second ultrasonic cleaning unit, the purging unit and the drying unit are all located between the walking mechanism and the center support; and a lifting mechanism is arranged on the cross beam. The cleaning system is compact in structure and small in occupied area, and the cleaning efficiency of the air preheater can be effectively improved.

Owner:王春卉 +1

Weather-proof simulation tree bark and preparation method thereof

The invention discloses a weather-proof simulation tree bark and a preparation method thereof. The bark is prepared from the following raw materials: epoxy resin, polyaniline, carboxyl polysiloxane, ground calcium carbonate, fumed silica, pigment printing paste, glass fiber, a curing agent, an antioxidant, an ultraviolet absorber, dibutyl phthalate and a mixed solvent. The preparation method comprises the following steps: adding the epoxy resin into a reaction kettle; adding the mixed solvent and dissolving; adding the polyaniline and epoxy resin into the reaction kettle and mixing; stirring at a high speed; controlling the pH value of the reaction to 1 and the reaction temperature to 20-25 DEG C; after 1 hour of reaction, adding the carboxyl polysiloxane, and further reacting for 2-5 hours at room temperature-50 DEG C; adding the dibutyl phthalate, ground calcium carbonate, fumed silica, pigment printing paste, glass fiber, curing agent, antioxidant and ultraviolet absorber, mixing and stirring uniformly and pouring into a pre-placed bark mould; and performing micro-pressure standing to obtain a finished product of the weather-proof simulation tree bark which has good weather-proof property.

Owner:广西凯威铁塔有限公司

Composite grate combustion equipment

The invention discloses composite grate combustion equipment and relates to the technical field of biomass fuel boilers. Bilateral sides of a grate of the composite grate combustion equipment are respectively provided with water cooling headers; the grate is formed by a reciprocating grate at the front section and a catenary chain tensioning type chain grate at the rear section; the reciprocating grate which is inclined downward along the movement direction of fuel is higher than the catenary chain tensioning type chain grate. The fuel is fed into the inclined type reciprocating grate through a feeder to be preheated and dried and then is driven by the reciprocating grate to move in a downward roll mode step by step and a rolling falling effect through the height difference at a stair position of the two grates is achieved, the time for staying in the air of the fuel is prolonged, the fuel permeability is increased, and the fuel and the combustion-supporting oxygen are fully mixed. The inclined reciprocating grate plays a role in preheating and drying and the catenary chain tensioning type chain grate plays a role in discharging and burning out. According to the composite grate combustion equipment, when various biomass fuel and high-moisture fuel are combusted, the height difference between the two grates are utilized, fuel combustion is facilitated, the combustion is full, the burn-off rate of the fuel is greatly improved, and the combustion efficiency of the equipment is improved.

Owner:JINAN BOILER GRP

Absorbent article

The invention discloses an absorbent article, which comprises a water-permeable surface layer, an absorber and a water-repellent back layer. The permeable surface is in direct contact with the skin. From the proximal side to the distal side, the water-permeable surface layer is successively provided with an upper water-permeable surface layer and a lower water-permeable surface layer, wherein thefibers of the lower water-permeable surface layer are arranged to extend roughly in the length direction of the absorbent article, and the hydrophilicity of the lower water-permeable surface layer isgreater than the hydrophilicity of the upper water-permeable surface layer. As a result of the above structure, it may be ensured that liquid impurities including urine rapidly penetrate through the water-permeable surface layer, to ensure that a diaper has the characteristics of being dry and smooth.

Owner:贝亲母婴用品(常州)有限公司

Yarn containing China hemp viscose

The invention belongs to the technical field of textile, and particularly provides a yarn containing China hemp viscose. Textile fabric woven from the yarn, clothing and bags prepared from the textilefabric and the like all have the functional advantages of being soft, dry and comfortable, breathable, comfortable, antibacterial, antistatic, green and natural, absorbing sweat, resisting ultraviolet radiation and the like.

Owner:WUHAN HEMP BIOLOGICAL TECH CO LTD

Thermal, breathable and down-proof garment fabric

InactiveCN105054424AGood warmth retentionImprove the anti-drilling effectFibre treatmentWoven fabricsEngineeringMoisture

The invention discloses a thermal, breathable and down-proof garment fabric which comprises a base-layer fabric and a down-proof coating. The base-layer fabric is made of warp yarns and weft yarns by means of interweaving, the warp yarns are made of, by weight, 45%-50% of cotton fibers and 15%-20% of modal fibers by means of twisting, and the weft yarns are made of, by weight, 25%-30% of antibacterial moisture-conductive acrylic fibers and 10%-15% of bamboo charcoal fibers by means of twisting; the down-proof coating is an organic silicon high-elasticity coating. Owing to the mode, the thermal, breathable and down-proof garment fabric has the advantages that the thermal, breathable and down-proof garment coating is fine and firm in texture and excellent in thermal protection, down-proof property and breathability, and is nontoxic, harmless, environmental friendly and safe, and bacterial inhibition and antibacterial effects can be realized.

Owner:ANHUI GUIGU E COMMERCE

Anti-aging simulation tree bark and preparation method thereof

InactiveCN106010116ADryLow shrinkageAnti-corrosive paintsEpoxy resin coatingsChemistryAging property

The invention discloses an anti-aging simulation tree bark and a preparation method thereof. The bark is prepared from the following raw materials: epoxy resin, polyaniline, carboxyl polysiloxane, ground calcium carbonate, fumed silica, pigment printing paste, glass fiber, a curing agent, dibutyl phthalate, an anti-ultraviolet agent and a mixed solvent. The preparation method comprises the following steps: adding the epoxy resin into a reaction kettle; adding the mixed solvent and dissolving; adding the polyaniline and epoxy resin into the reaction kettle and mixing; stirring at a high speed; controlling the pH value of the reaction to 1 and the reaction temperature to 20-25 DEG C; after 1 hour of reaction, adding the carboxyl polysiloxane, and further reacting for 2-5 hours at room temperature-50 DEG C; adding the dibutyl phthalate, ground calcium carbonate, fumed silica, pigment printing paste, glass fiber, curing agent and anti-ultraviolet agent, mixing and stirring uniformly and pouring into a pre-placed bark mould; and performing micro-pressure standing to obtain a finished product of the anti-aging simulation tree bark. The simulation tree bark disclosed by the invention is soft and safe and has good anti-aging property.

Owner:广西凯威铁塔有限公司

A kind of flame-retardant simulated tree bark and preparation method thereof

The invention provides a flame-retardant bark of an artificial tree and a making method thereof. The bark is prepared from the following raw materials: epoxy resin, polyaniline, carboxyl polysiloxane, heavy calcium carbonate powder, fumed silica, pigment printing paste, glass fiber, a curing agent, a fire retardant, dibutyl phthalate and a mixed solvent. The making method comprises the following steps: adding epoxy resin into a reaction vessel, then adding the mixed solvent for dissolving, adding polyaniline into the reaction vessel, mixing polyaniline with mixing under high-speed stirring, carrying out a reaction at 20 to 25 DEG C for 1 h with a pH value controlled to be 1 and then adding carboxyl polysiloxane; continuing the reaction at a temperature in a range of room temperature to 50 DEG C for 2 to 5 h; and then adding dibutyl phthalate, heavy calcium carbonate powder, fumed silica, pigment printing paste, glass fiber, the curing agent and the fire retardant, carrying out uniformly mixing under stirring, pouring the obtained mixture into a bark die placed in advance and carrying out micro-pressure standing so as to eventually obtain the flame-retardant bark of the artificial tree. The bark of the artificial tree has lifelike texture and flame retardation effect.

Owner:广西凯威铁塔有限公司

Pear and avocado wine and preparation method thereof

InactiveCN109797070ABalanced wineFruityAlcoholic beverage preparationRespiratory disorderChemistryPEAR

The invention discloses pear and avocado wine. Each ton of the pear and avocado wine is prepared from, by weight, 150-250kg of pears, 150-250kg of avocados, 700-800kg of pure rice wine and 15-50kg ofhoney. The invention also provides a preparation method of the pear and avocado wine. The pear and avocado wine has strong fruit flavor, stable color and mellow mouthfeel, and has the effects of relieving cough, reducing phlegm and clearing dryness.

Owner:刘俊声

A kind of moisture-proof simulated tree bark and preparation method thereof

The invention relates to a moistureproof simulated tree bark and a manufacturing method thereof. The bark is prepared from an epoxy resin, polyaniline, carboxyl polysiloxane, heavy calcium carbonate powder, vapor-phase white carbon black, a paint color paste, glass fibers, a solidifying agent, a desiccant, dibutyl phthalate and a mixed solvent. The manufacturing method comprises the following steps: adding the epoxy resin into a reaction kettle, adding the mixed solvent to dissolve the epoxy resin, adding the polyaniline into the reaction kettle, mixing, stirring at high speed, reacting at 20-25 DEG C for 1 hour while controlling the reaction pH value at 1, and adding the carboxyl polysiloxane; continuing reacting at ambient temperature to 50 DEG C for 2-5 hours; and adding the dibutyl phthalate, heavy calcium carbonate powder, vapor-phase white carbon black, paint color paste, glass fibers, solidifying agent and desiccant, mixing and stirring uniformly, pouring the mixture into a preset bark mold, and carrying out micropressure standing to finally obtain the moistureproof simulated tree bark finished product. The simulated tree bark is flexible and safe, and has the advantages of favorable moisture resistance and high water resistance.

Owner:广西凯威铁塔有限公司

A kind of preparation method of skin care paper diaper

ActiveCN111420111BBacteriostaticDryLiquid repellent fibresAbsorbent padsPolymer scienceHamamelis virginiana

The invention relates to the technical field of disposable sanitary products, and provides a preparation method of skin care diapers, which solves the problem of insufficient antibacterial properties of diapers in the prior art and easily causes skin discomfort. The preparation of the leaky bottom layer, the liquid-permeable surface layer is sequentially stacked from top to bottom with an upper layer of non-woven fabric, an antibacterial layer and a lower layer of non-woven fabric, the upper layer of non-woven fabric is a polylactic acid non-woven fabric, and the lower layer The non-woven fabric is ES non-woven fabric, the antibacterial layer is a microcapsule, and the microcapsule is made of chitosan and gum arabic as wall materials, tea oil, witch hazel extract, and dandelion extract as core materials, One side of the ES non-woven fabric is sprayed with a hydrophilic finishing solution, and then the microcapsules are evenly sprayed on the side of the ES non-woven fabric that is not sprayed with a hydrophilic finishing solution, and the microcapsules are covered with a polylactic acid non-woven fabric, hot-melt adhesive After combining, a liquid-permeable surface layer is obtained.

Owner:CHIAUS FUJIAN IND DEV

A kind of hollow fancy loop multifunctional health care yarn

The invention provides hollow fancy loop multifunctional health-care yarn and a preparation method thereof. The yarn comprises lotus root fibers, lyocell fibers, bamboo charcoal fibers, Clean cool fibers, water-soluble vinylon fiber filaments, PTT shape memory fiber filaments, anti-ultraviolet polyester fiber filaments, cashmere fibers and mohair fibers, or comprises stainless steel fiber filaments, mint fibers, long stapled cotton fibers, water-soluble vinylon filaments, colorful negative ion multifunctional viscose filaments, bamboo charcoal fibers and coconut carbon fibers. The yarn prepared through the preparation method has excellent in hygroscopicity, natural, antibacterial, resistant to odor and capable of absorbing moisture and discharging sweat, has deodorization and anti-aging functions and the like, also has excellent radiation resistance, anti-static performance and a negative ion emission function, enhances the immune function, activates cells, promotes metabolism, has deodorizing performance, prevents mites, odor and insects, generates negative ion characteristic and is resistant to water, oil and dirt, and fabrics are prevented from being influenced by various harmful bacteria and pollution.

Owner:ZHONGYUAN ENGINEERING COLLEGE

A kind of anti-aging artificial tree bark and preparation method thereof

InactiveCN106010116BDryLow shrinkageAnti-corrosive paintsEpoxy resin coatingsEpoxyReaction temperature

The invention discloses an anti-aging simulation tree bark and a preparation method thereof. The bark is prepared from the following raw materials: epoxy resin, polyaniline, carboxyl polysiloxane, ground calcium carbonate, fumed silica, pigment printing paste, glass fiber, a curing agent, dibutyl phthalate, an anti-ultraviolet agent and a mixed solvent. The preparation method comprises the following steps: adding the epoxy resin into a reaction kettle; adding the mixed solvent and dissolving; adding the polyaniline and epoxy resin into the reaction kettle and mixing; stirring at a high speed; controlling the pH value of the reaction to 1 and the reaction temperature to 20-25 DEG C; after 1 hour of reaction, adding the carboxyl polysiloxane, and further reacting for 2-5 hours at room temperature-50 DEG C; adding the dibutyl phthalate, ground calcium carbonate, fumed silica, pigment printing paste, glass fiber, curing agent and anti-ultraviolet agent, mixing and stirring uniformly and pouring into a pre-placed bark mould; and performing micro-pressure standing to obtain a finished product of the anti-aging simulation tree bark. The simulation tree bark disclosed by the invention is soft and safe and has good anti-aging property.

Owner:广西凯威铁塔有限公司

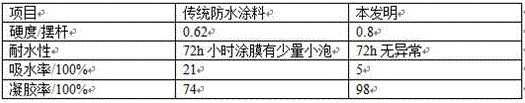

Waterborne polyurethane waterproof coating and preparation method thereof

ActiveCN104774551BAvoiding Amine ProblemsAvoiding MOCA ProblemsAnti-corrosive paintsPolyurea/polyurethane coatingsCross-linkPlasticizer

The invention provides an aqueous polyurethane waterproof paint and a preparation method thereof. The paint comprises a component A and a component B, wherein the component A is composed of polyurethane performed polymer, N-methylolacrylamide and citric acid, and the component B is composed of an inorganic filling material, a plasticizer, a cross-linking agent, an emulsifier, an antifoaming agent, a catalyst, pigment and water. The preparation method comprises the following steps: successively adding N-methylolacrylamide and citric acid according to desired weight parts, carrying out stirring and heating, adding the polyurethane performed polymer in one shot before temperature rises to 62 DEG C, then carrying out heating to 82 DEG C, carrying out a reaction at a constant temperature of 83 to 85 DEG C for 2 to 3 h and then carrying out cooling to 52 to 54 DEG C so as to obtain the component A; successively adding raw materials of the component B into a reaction vessel stirrer according to desired weight parts, carrying out uniform mixing through stirring and grinding the mixed materials to a fineness of 51 to 55 [mu]m in a three-roller machine so as to obtain the component B; and uniformly mixing the component A with the component B according to a weight ratio of 1: 2 so as to obtain the aqueous polyurethane waterproof paint. The aqueous polyurethane waterproof paint has the characteristics of high temperature resistance, good weatherability, good waterproof performance, etc.

Owner:北京奥克兰防水工程有限责任公司

A dry and breathable paper diaper and its production process

ActiveCN110215350BImprove the liquid absorption effectBreathableAbsorbent padsBaby linensPolymer scienceEngineering

The invention discloses a dry and breathable diaper and its production process. The diaper comprises a diaper body, a composite core layer and a cladding structure coated on the outside of the composite core layer; The outer core of the inner layer is wrapped with non-woven fabric; the inner layer of the core includes the upper core air-permeable cloth, the middle fluffy fiber net, the lower core air-permeable cloth, between the upper non-woven fabric and the middle fluffy fiber net, the middle fluffy fiber net and the There is a layer of water-absorbing particles between the breathable cloth on the lower layer of the core; the covering structure includes the upper layer of non-woven fabric, the lower layer of non-woven fabric, the breathable waterproof membrane and the bottom layer of non-woven fabric, and the lower layer of non-woven fabric is bonded to the composite core layer. Then, the lower non-woven fabric is bonded to the breathable waterproof membrane, and the breathable waterproof membrane is bonded to the bottom non-woven fabric. The paper diaper has the advantages of good water absorption effect, dryness and breathability, and is not easy to cause the baby to have red buttocks.

Owner:杭州贝高母婴用品有限公司

Multifunctional automobile protective wax and preparation method thereof

The invention discloses a multifunctional automobile protective wax, which comprises the following components: 19.6-30% of original wax formed by microcrystalline wax and paraffin, 10-13% of emulsifier formed by stearic acid and triethanolamine, 4.1-6.3% of assistant formed by diatomite, ethylene glycol monomethyl ether and methylsiliconeoil, and the balance water. In the invention, the multifunction automobile wax can be prepared by compounding the rigid microcrystalline wax and the soft paraffin and organically integrating the characteristics of high melting point, good radiance and strong adhesion of the rigid wax with the characteristics of low melting point, good toughness and favorable rust protection of the soft wax through adopting a dispersing emulsion method and controlling the fixed acid value in the emulsion process, and the multifunctional automobile protective wax has the functions of corrosion and rust resistance as well as polishing and beautifying.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

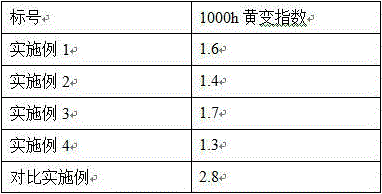

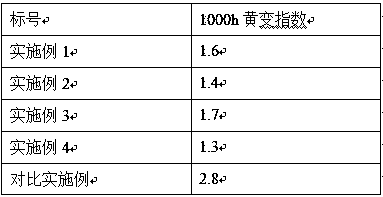

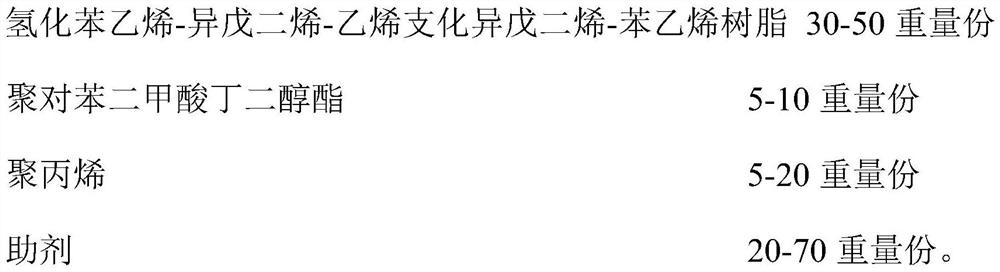

Coating material as well as preparation method and application thereof

The invention relates to a coating material as well as a preparation method and application thereof. The coating material comprises the following components in parts by weight: 30-50 parts of hydrogenated styrene-isoprene-ethylene branched isoprene-styrene resin; 5-10 parts by weight of polybutylene terephthalate; 5-20 parts by weight of polypropylene; and 20-70 parts by weight of an auxiliary agent. According to the invention, hydrogenated styrene-isoprene-ethylene branched isoprene-styrene resin and polybutylene terephthalate are introduced into the formula of the coating material at the same time, and are matched with other components in the formula according to a specific proportion, so that the obtained coating material has the characteristics of super softness, scratch resistance, fine and smooth hand feeling, dryness and chemical resistance. Moreover, the raw materials adopted by the invention are environment-friendly and non-toxic raw materials, the recycling rate is high, the production mode is clean and efficient, and no pollution is caused to the environment.

Owner:江西博硕电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com