Polyurethane modified asphalt waterproof paint and preparation method thereof

A technology of asphalt waterproof coating and polyurethane modification, applied in asphalt coatings, antifouling/underwater coatings, fire-retardant coatings, etc., can solve the problem of poor binding force between calcium carbonate and coating body, deterioration of coating material performance, and difficult processing and use of products and other problems, to achieve the effect of improving mechanical properties, oil resistance and flexural resistance, and uniform distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

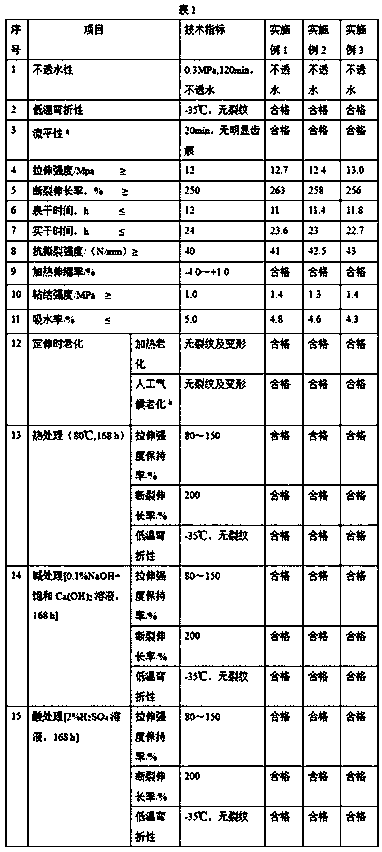

Examples

Embodiment 1

[0043] A polyurethane-modified asphalt waterproof coating made of the following raw materials by weight:

[0044] 80 parts of polyurethane prepolymer;

[0045] 90# petroleum asphalt 90 parts;

[0046] 10 parts of modified nano calcium carbonate;

[0047] 5 parts of vinyl trichlorosilane;

[0048] Tackifier 3 parts;

[0049] 5 parts of n-butyl acetate;

[0050] 3 parts of citric acid;

[0051] 4 parts of dibutyltin dilaurate;

[0052] 0.5 part of polyoxyethylene polyoxypropanolamine ether;

[0053] 3 parts of fumed silica.

[0054] The method for preparing the modified nano-calcium carbonate is: dehydrating and drying the nano-calcium carbonate powder at 115-120°C, then adding it to a high-speed mixer, stirring and raising the temperature, stopping heating at 90°C, and adding 2.0% of the nano-calcium carbonate mass The chelating titanate coupling agent KR-201 was modified at 90℃ for 10 minutes; then 2.0% stearic acid, 0.5% coconut oil and 1% industrial white oil were added to the nano-calcium...

Embodiment 2

[0064] A polyurethane-modified asphalt waterproof coating made of the following raw materials by weight:

[0065] 85 parts of polyurethane prepolymer;

[0066] 90# petroleum asphalt 95 parts;

[0067] 15 parts of modified nano calcium carbonate;

[0068] 7 parts of vinyl trichlorosilane;

[0069] Tackifier 4 parts;

[0070] 7 parts of n-butyl acetate;

[0071] 5 parts of citric acid;

[0072] 5 parts of dibutyltin dilaurate;

[0073] Polyoxyethylene polyoxypropanolamine ether 1 part;

[0074] 4 parts of fumed silica.

[0075] The method for preparing the modified nano-calcium carbonate is: dehydrating and drying the nano-calcium carbonate powder at 115-120°C, then adding it to a high-speed mixer, stirring and raising the temperature, stopping the heating at 90°C, and adding 2.0% of the nano-calcium carbonate mass The chelating titanate coupling agent KR-201 was modified at 90℃ for 10 minutes; then 2.0% stearic acid, 0.5% coconut oil and 1% industrial white oil were added to the nano-calcium ...

Embodiment 3

[0085] A polyurethane-modified asphalt waterproof coating made of the following raw materials by weight:

[0086] 90 parts of polyurethane prepolymer;

[0087] 90# petroleum asphalt 100 parts;

[0088] 20 parts of modified nano calcium carbonate;

[0089] 8 parts of vinyl trichlorosilane;

[0090] Tackifier 5 parts;

[0091] 9 parts of n-butyl acetate;

[0092] 6 parts of citric acid;

[0093] 6 parts of dibutyltin dilaurate;

[0094] 2 parts of polyoxyethylene polyoxypropanolamine ether;

[0095] 5 parts of fumed silica.

[0096] The method for preparing the modified nano-calcium carbonate is: dehydrating and drying the nano-calcium carbonate powder at 115-120°C, then adding it to a high-speed mixer, stirring and raising the temperature, stopping the heating at 90°C, and adding 2.0% of the nano-calcium carbonate mass The chelating titanate coupling agent KR-201 was modified at 90℃ for 10 minutes; then 2.0% stearic acid, 0.5% coconut oil and 1% industrial white oil were added to the nano-cal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com