Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

679 results about "One shot" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Drug container and drug infusion device comprising the same (as amended)

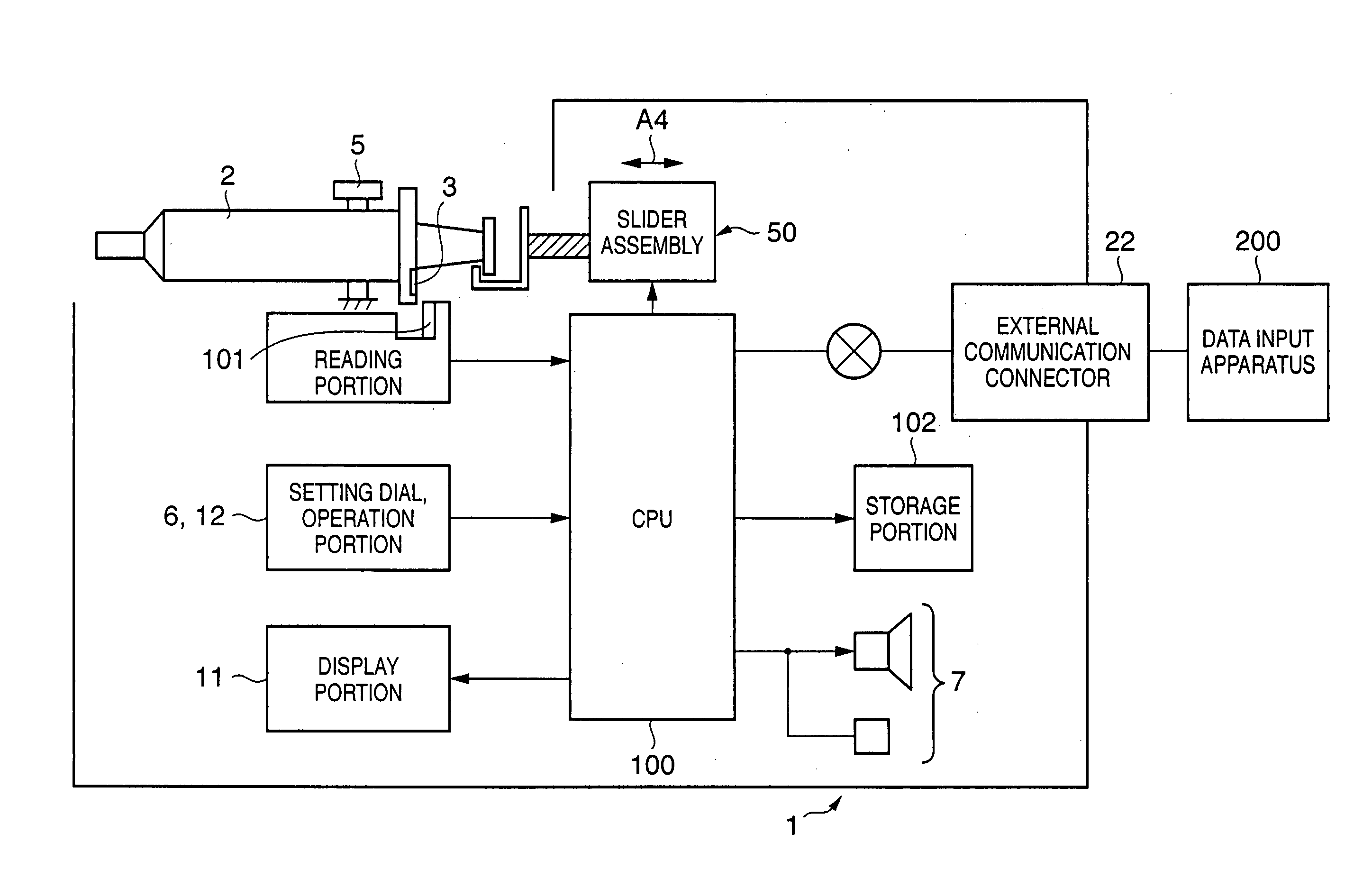

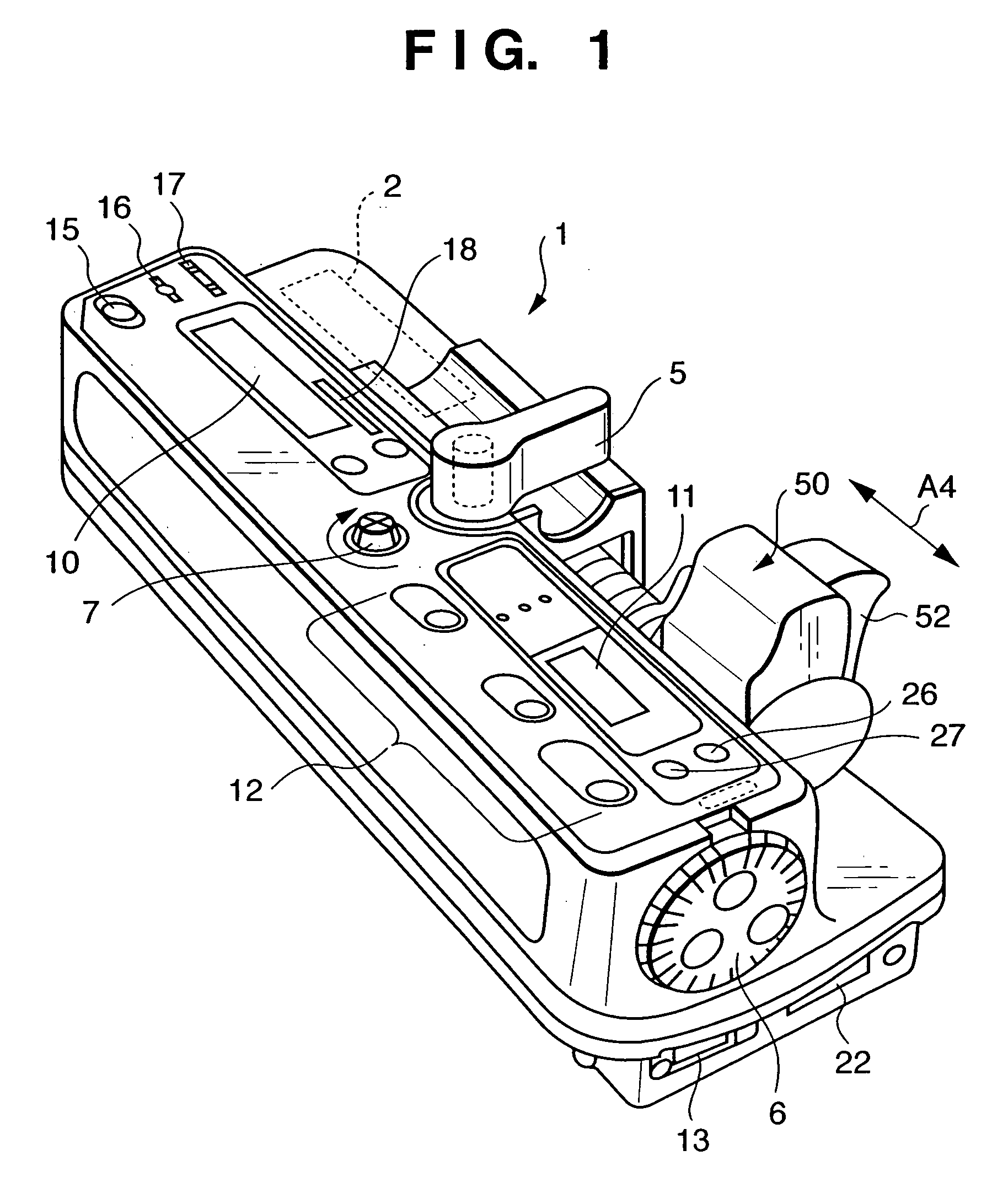

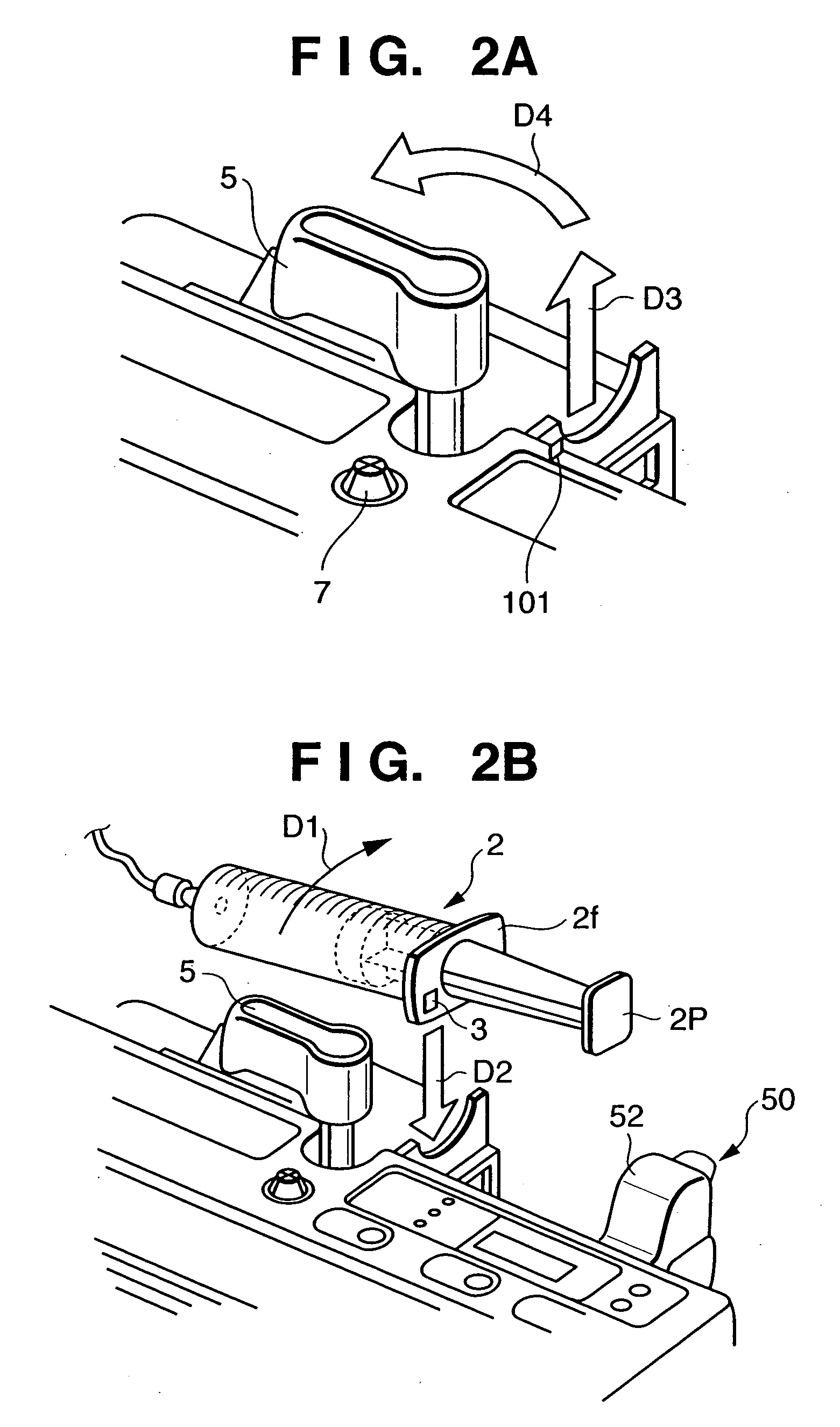

When using a drug container having an identification tag fixed or detachably provided at a predetermined position of the container, the tag having drug data on a kind and a concentration of a drug and both or one of upper and lower limits of a flow rate on a continuous infusion and the upper and lower limits, time and flow rate on a one-shot administration recorded thereon, it is possible to ensure safety by prompting for a stop of injection by a warning when a setting beyond the upper and lower limits is performed and rewrite a liquid infusing time and a flow rate and so on required to be set according to symptoms of a patient.

Owner:TERUMO KK

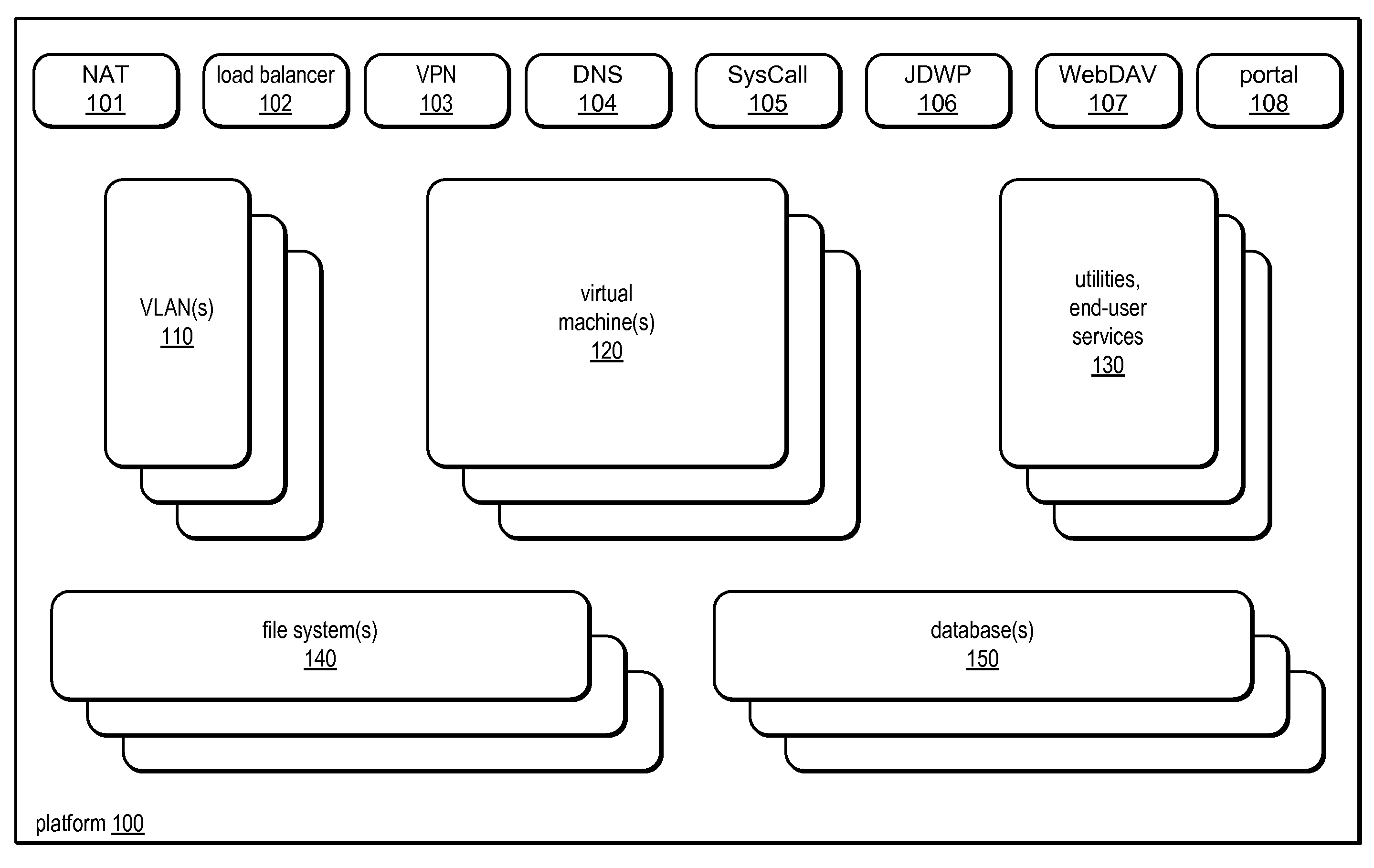

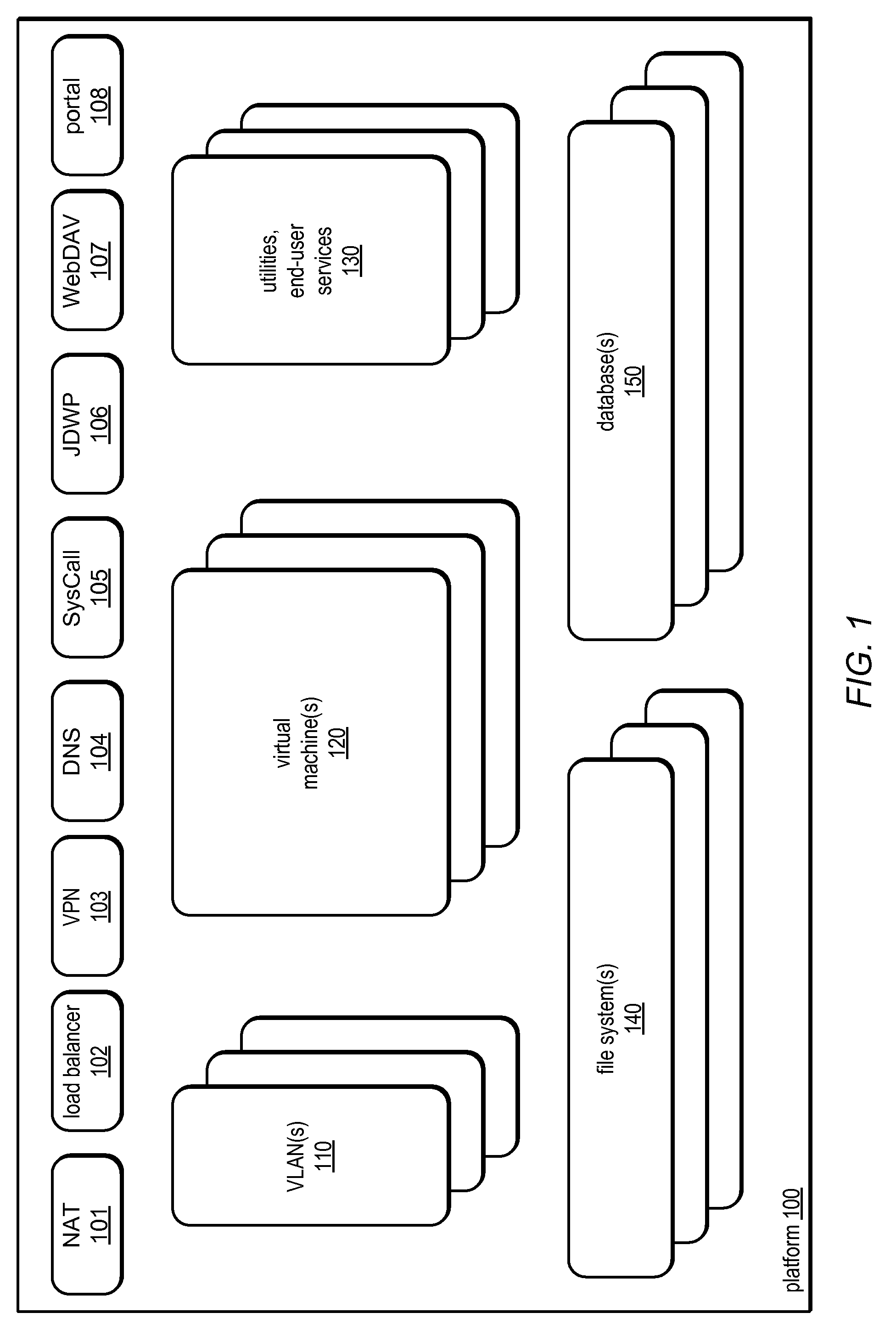

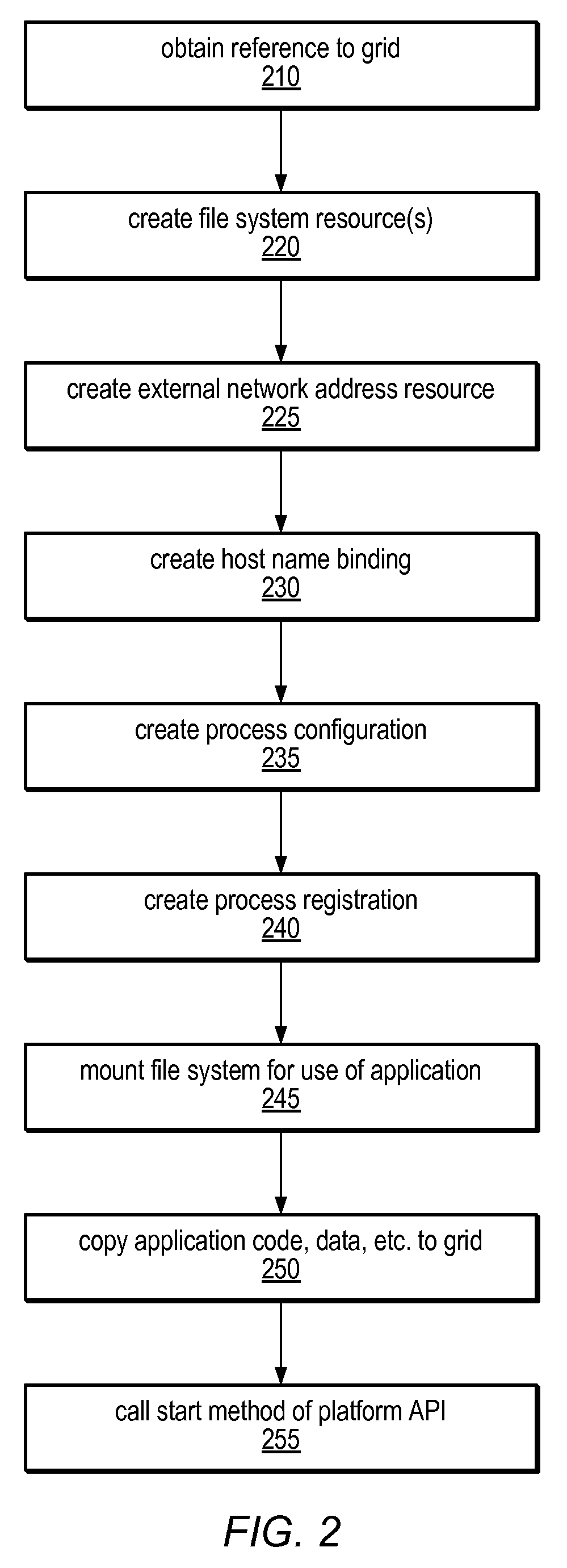

System and method for programmatic management of distributed computing resources

ActiveUS7886021B2Speed up developmentSpeeding up deliveryMultiple digital computer combinationsProgram controlWeb serviceStructure of Management Information

Systems and methods for providing a development and deployment platform for Software as a Service (SaaS) providers are disclosed. The platform may provide an application programming interface (API) through which customers may configure virtualized grids of language-level virtual machines (VMs), networks, and storage resources. A grid may be horizontally scalable and programmatically configurable by a customer and / or customer code. The platform may allow dynamic scaling of resources (up and down) to match changing demands, by allowing customers and / or customer code to programmatically alter their own system level structure at runtime, through the API. The grid may be accessed by both on-grid and off-grid processes, through internal and external connectivity resources provided by the platform. The platform may provide common utilities for end-user services, deployment operations, and development tasks (e.g., debugging), and may include frameworks and macro-components (e.g. web servers). The platform may host long-running Internet-based services and / or one-shot computational services.

Owner:ORACLE INT CORP

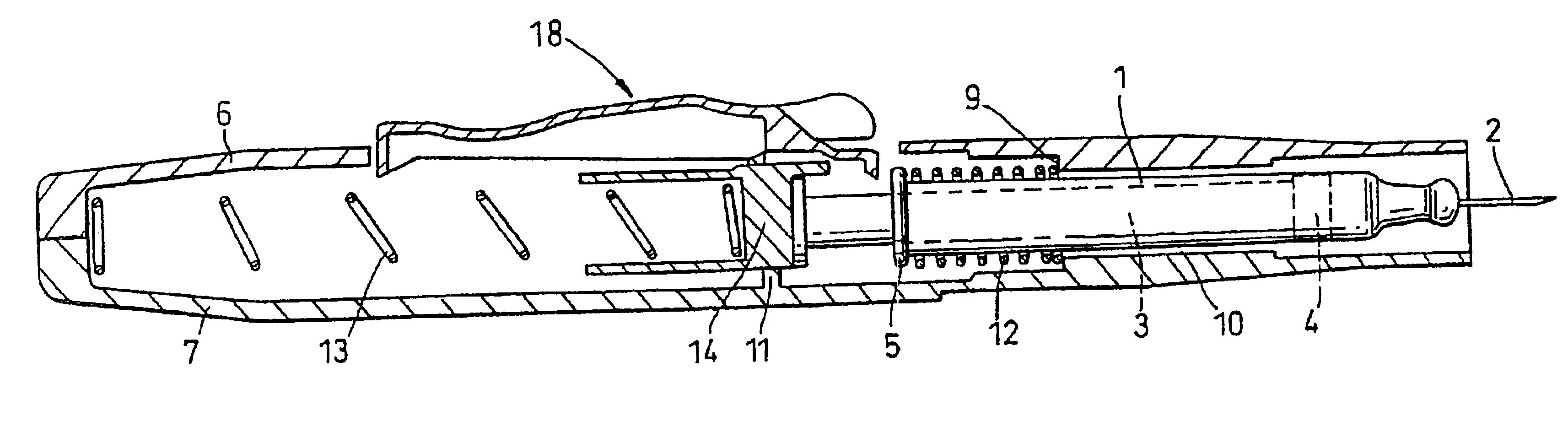

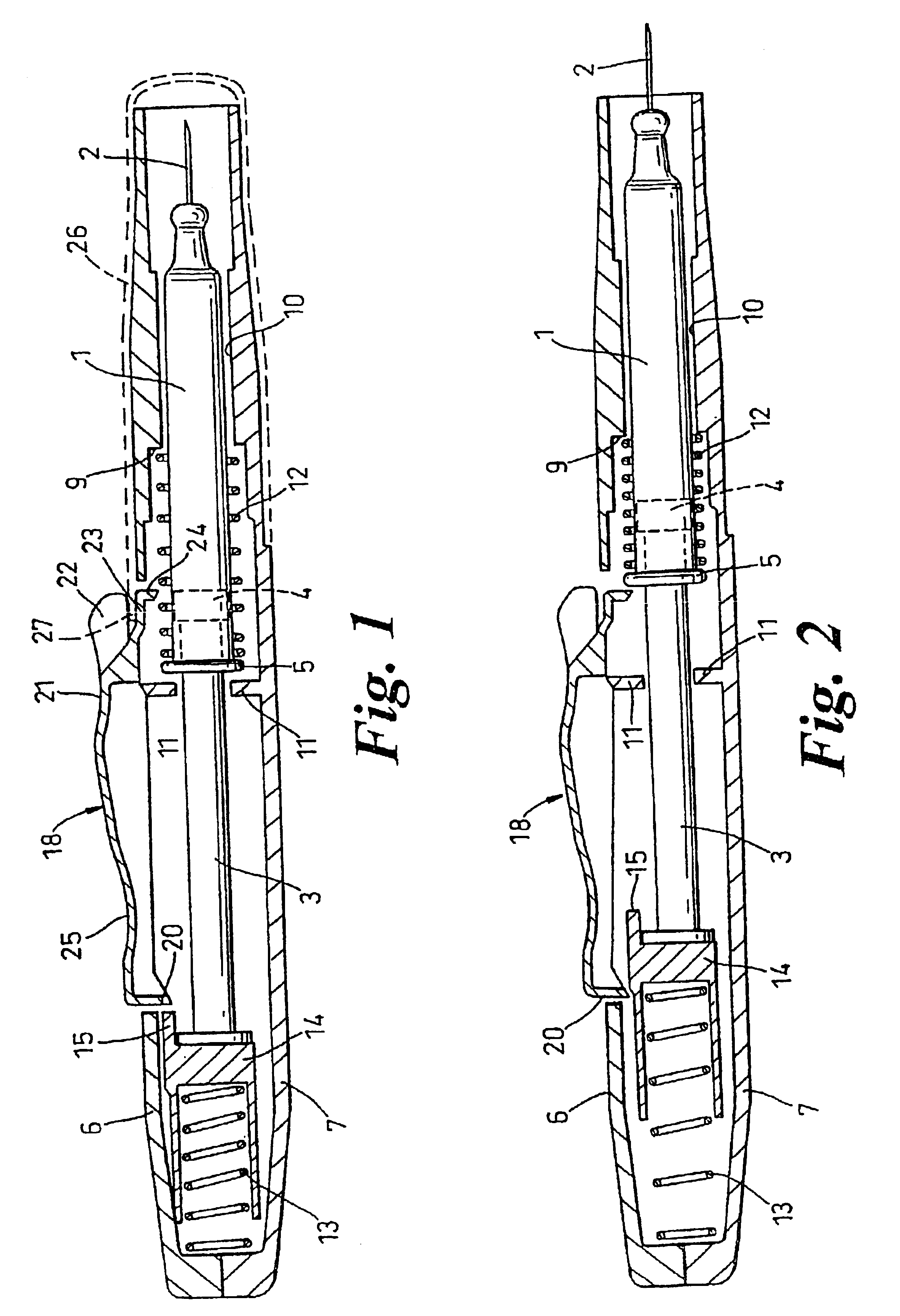

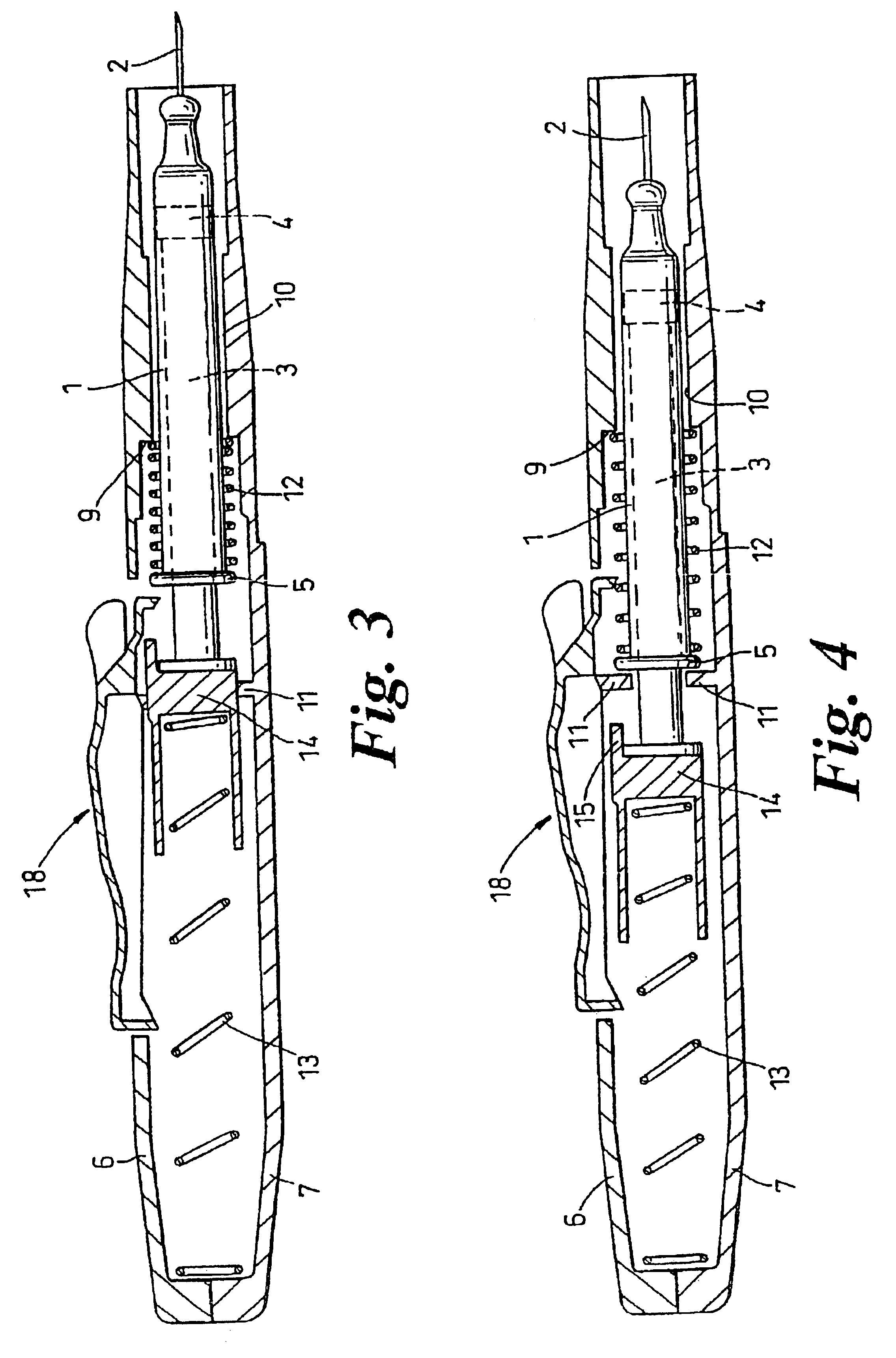

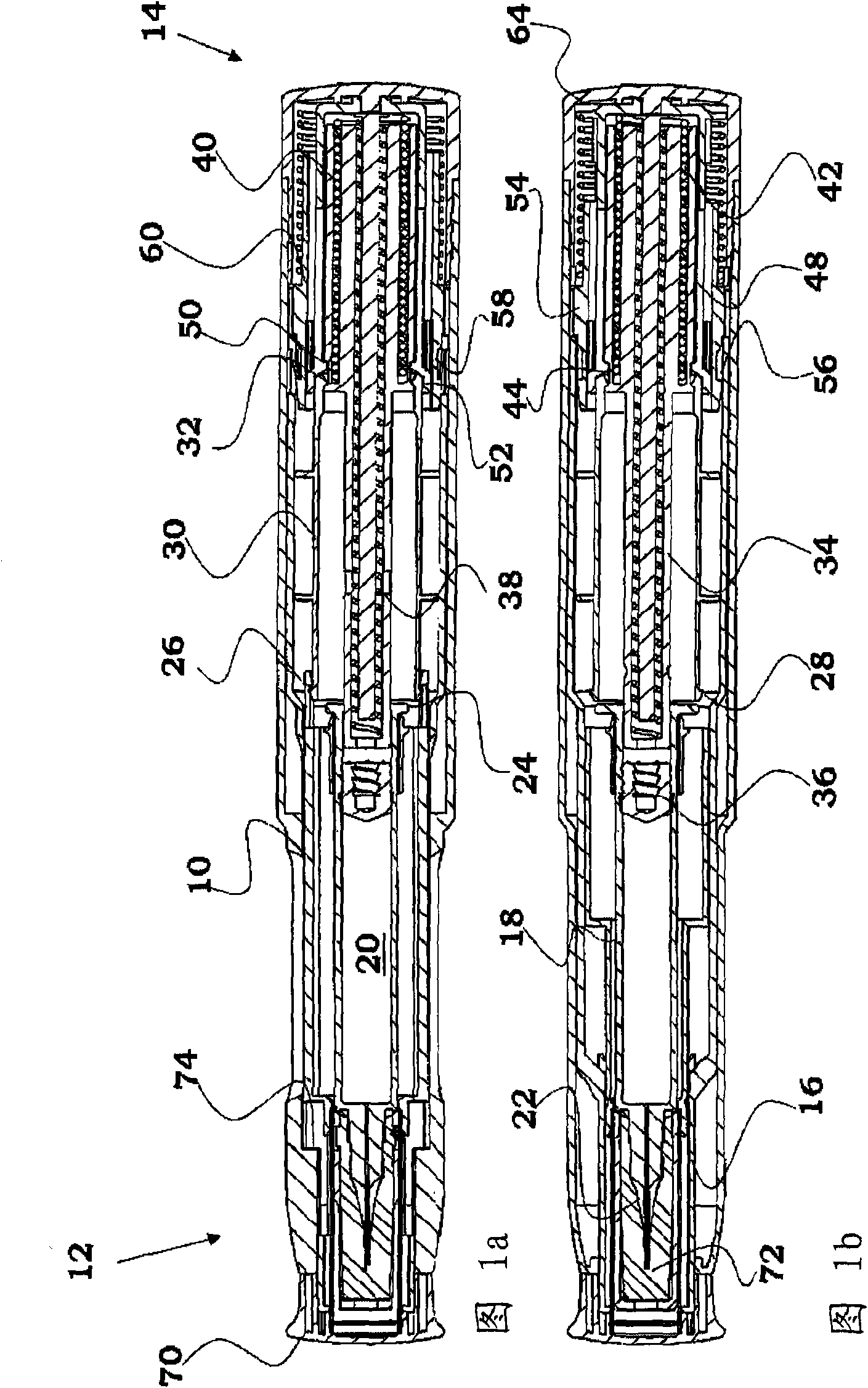

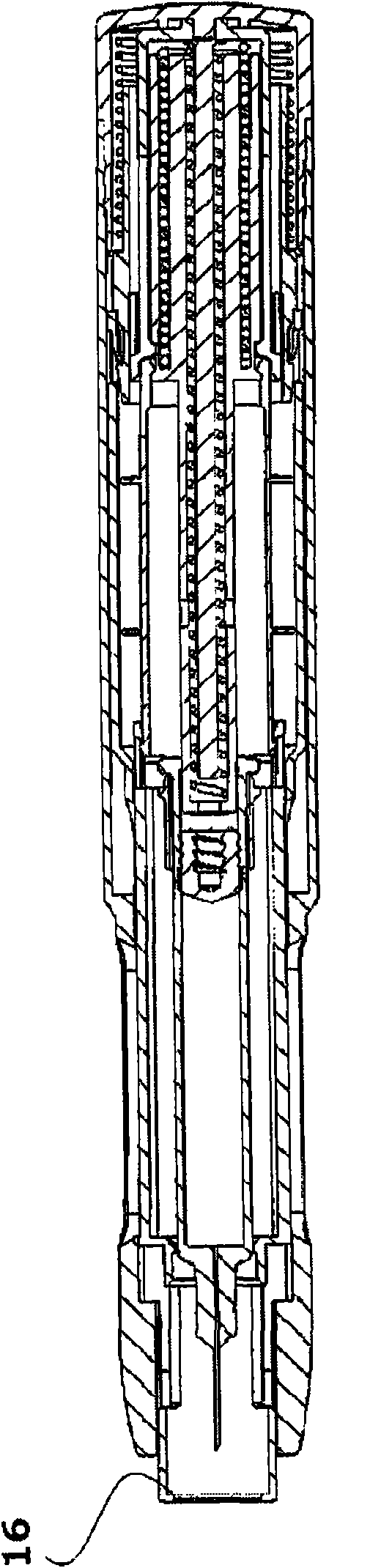

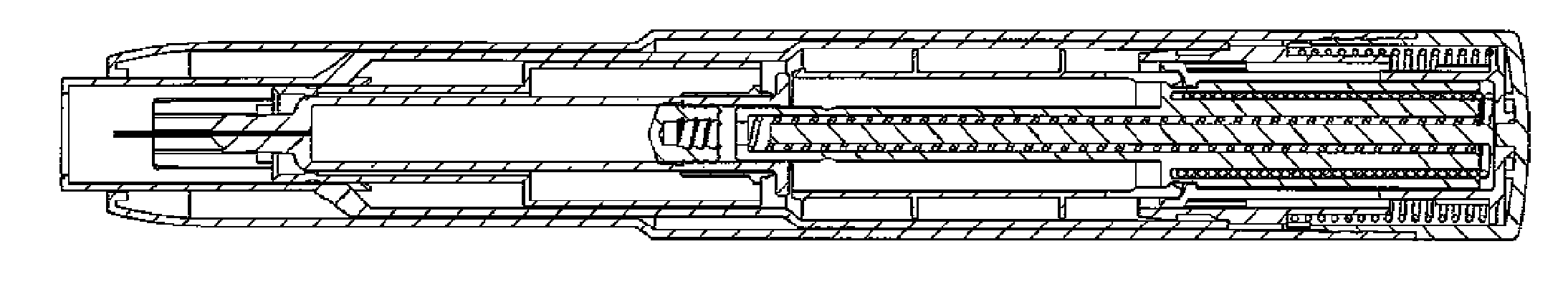

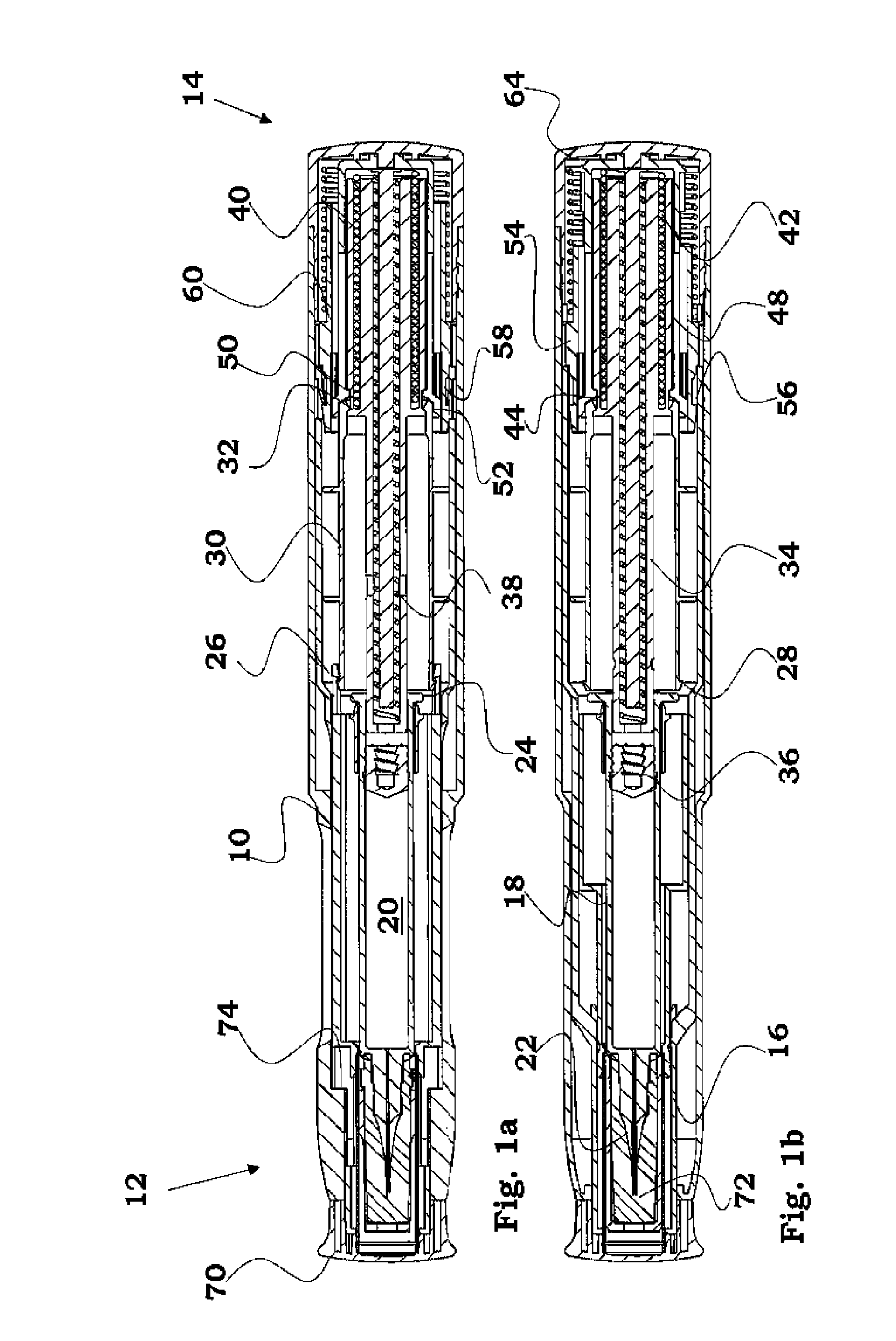

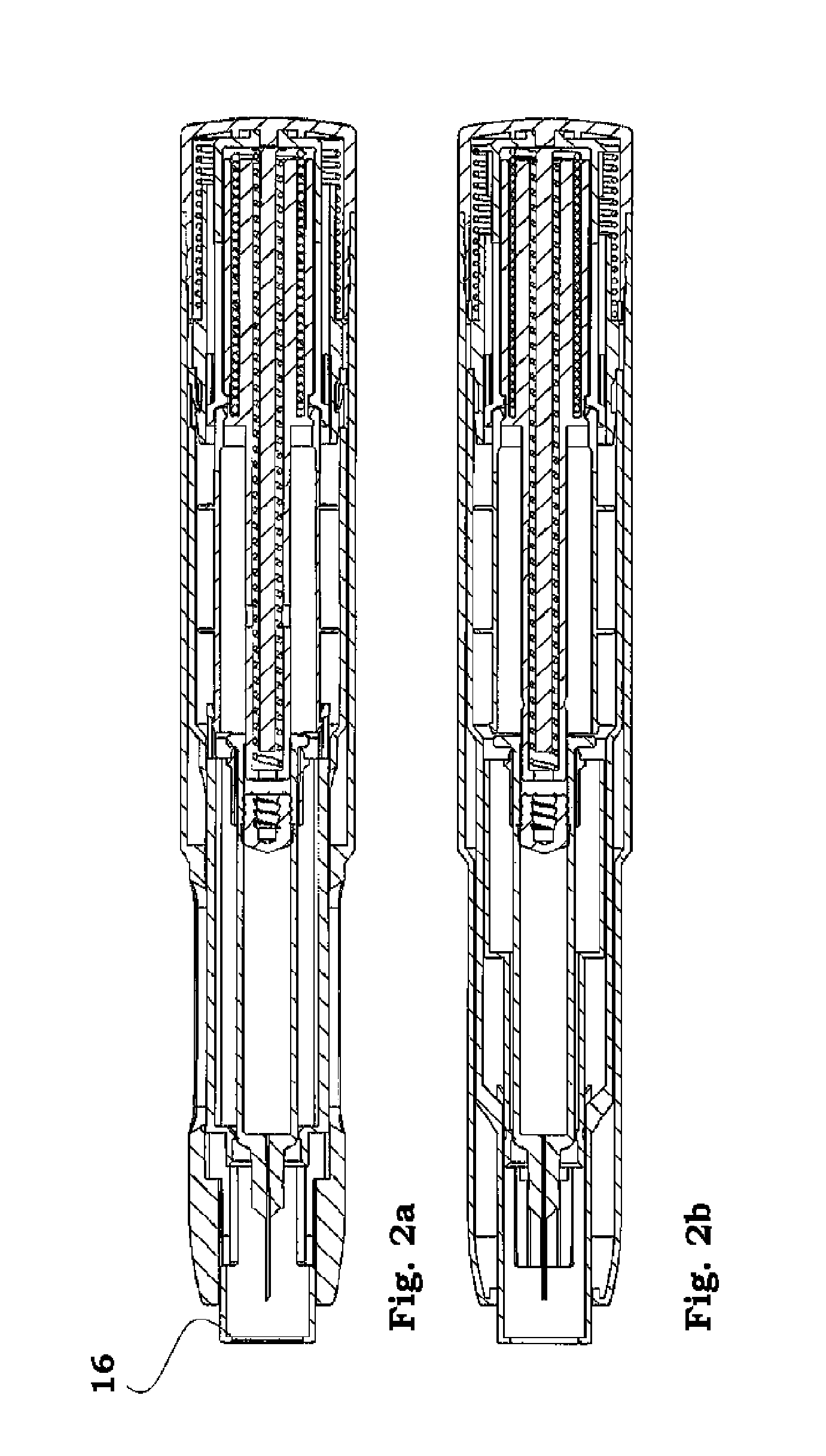

Injection devices

A one-shot throwaway injection device has a barrel that houses a syringe initially in a retracted state held back by a trigger against a drive spring. Actuation of the trigger causes the syringe to be thrust forwards by the spring acting on its plunger until the needle is fully projecting, and then the dose is ejected by the final expansion of the spring. Release of the trigger allows a return spring to urge the syringe back and retract the needle. The barrel is a unitary plastics moulding of two longitudinally split halves hinged together with the trigger integrally formed with one of these halves. The other components and the syringe are positioned in one half which is then closed up and fastened to the other half to complete the barrel.

Owner:OWEN MUMFORD

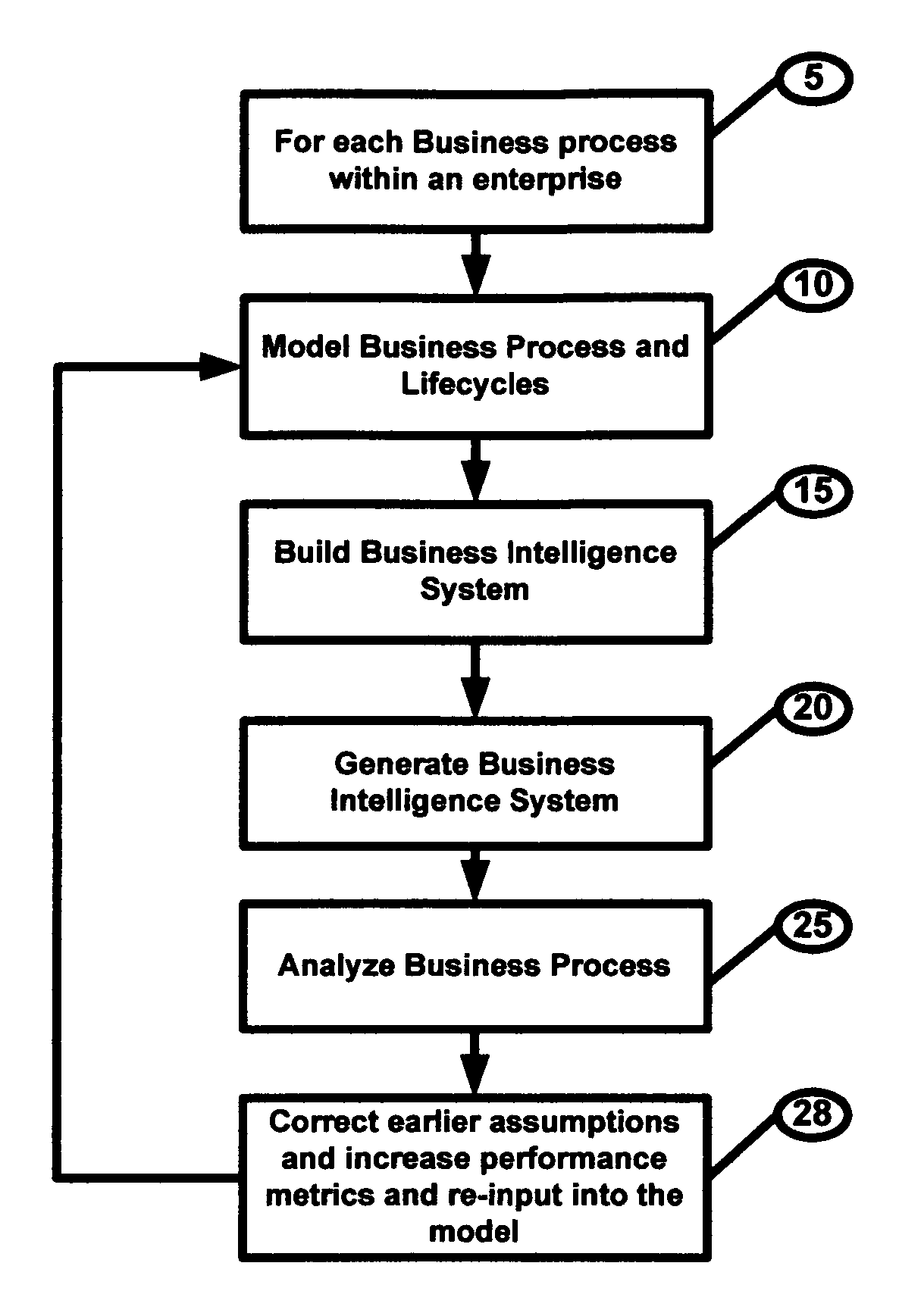

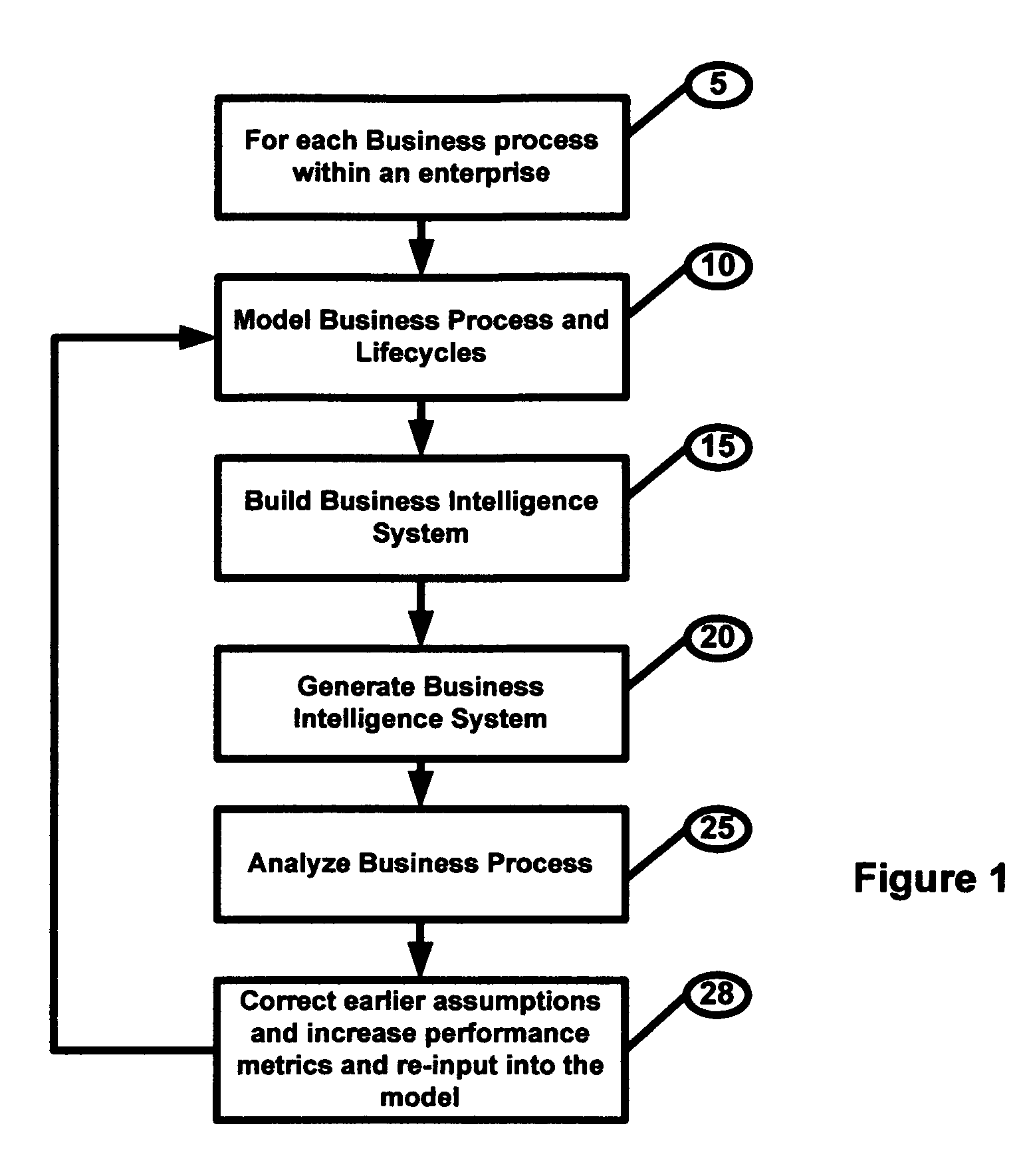

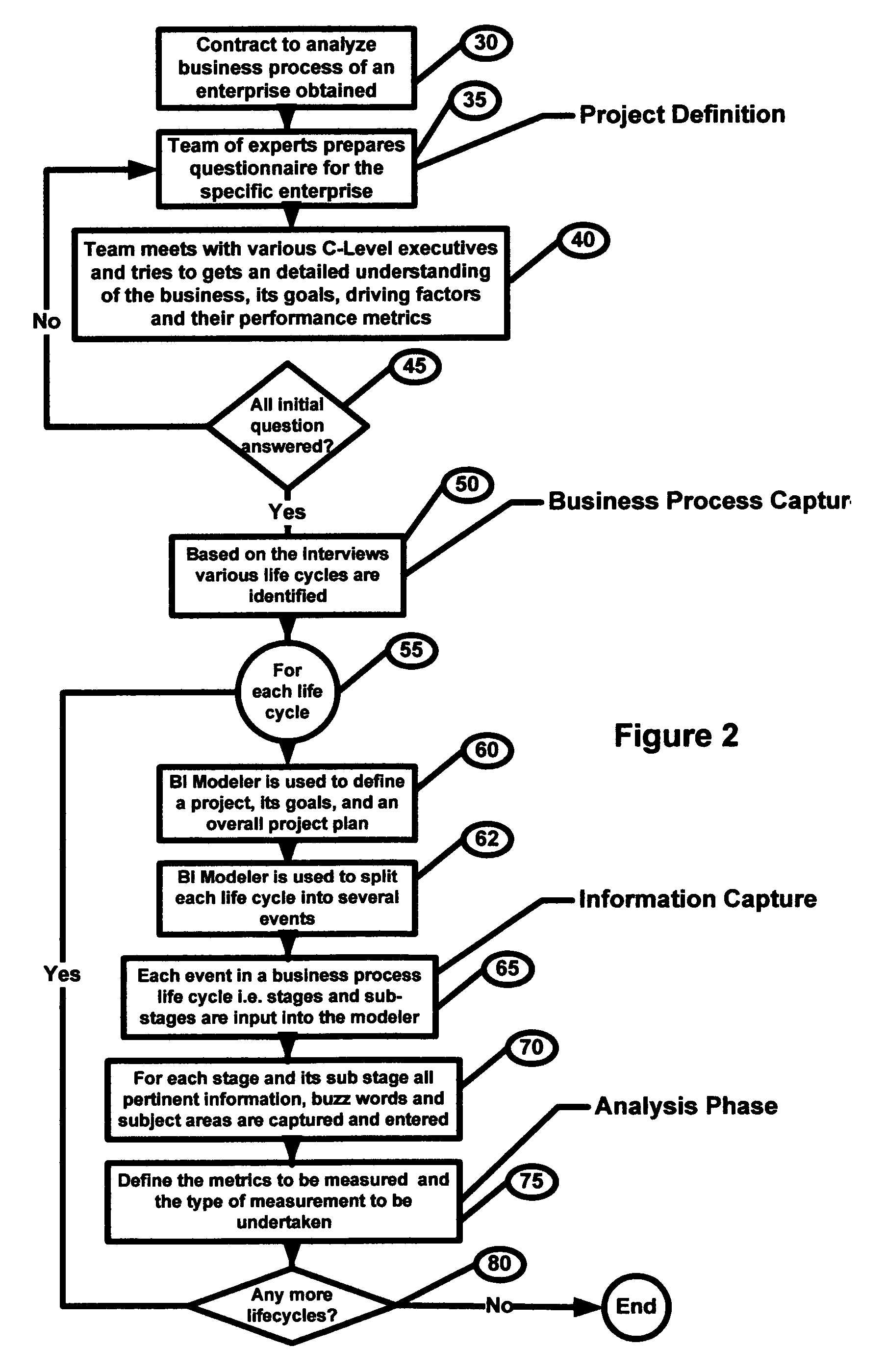

Method and system for generating a business intelligence system based on individual life cycles within a business process

InactiveUS20070021992A1Increase valueImprove efficiencyFinanceForecastingInterconnectivityProgram planning

The present invention relates to a method and system for generating a comprehensive Business Intelligence system based on a lifecycle approach that comprises of the steps of: modeling, building, generating and analyzing in order to analyze a business process end to end. In accordance with the present invention, modeling comprises the steps of defining a business process life cycle and its metrics and splitting each Business process lifecycle into several events or stages. This step also includes facilitating gathering of business requirements and developing a project plan based on them. The step of building comprises building the Business Intelligence system by interconnecting events or stages of BP lifecycles within the business process. The step of generating comprises the step of generating the Business Intelligence system in one shot by displaying the interconnectivity of various Business process lifecycles within the business process. The step of analyzing provides an easy to use web interlace to analyze business process life cycles based on the metrics and dimensions defined by business users.

Owner:KONAKALLA SRINIVAS

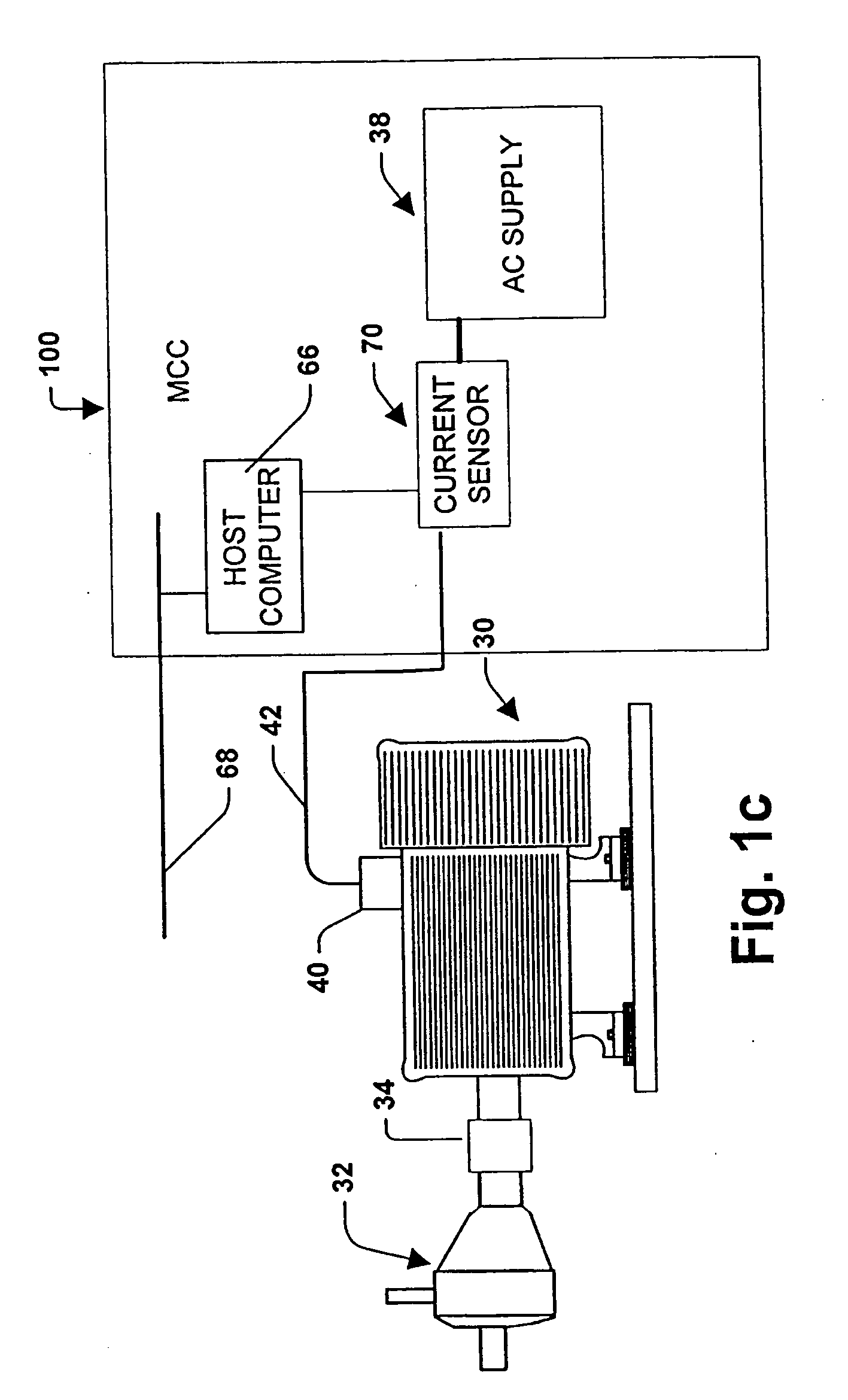

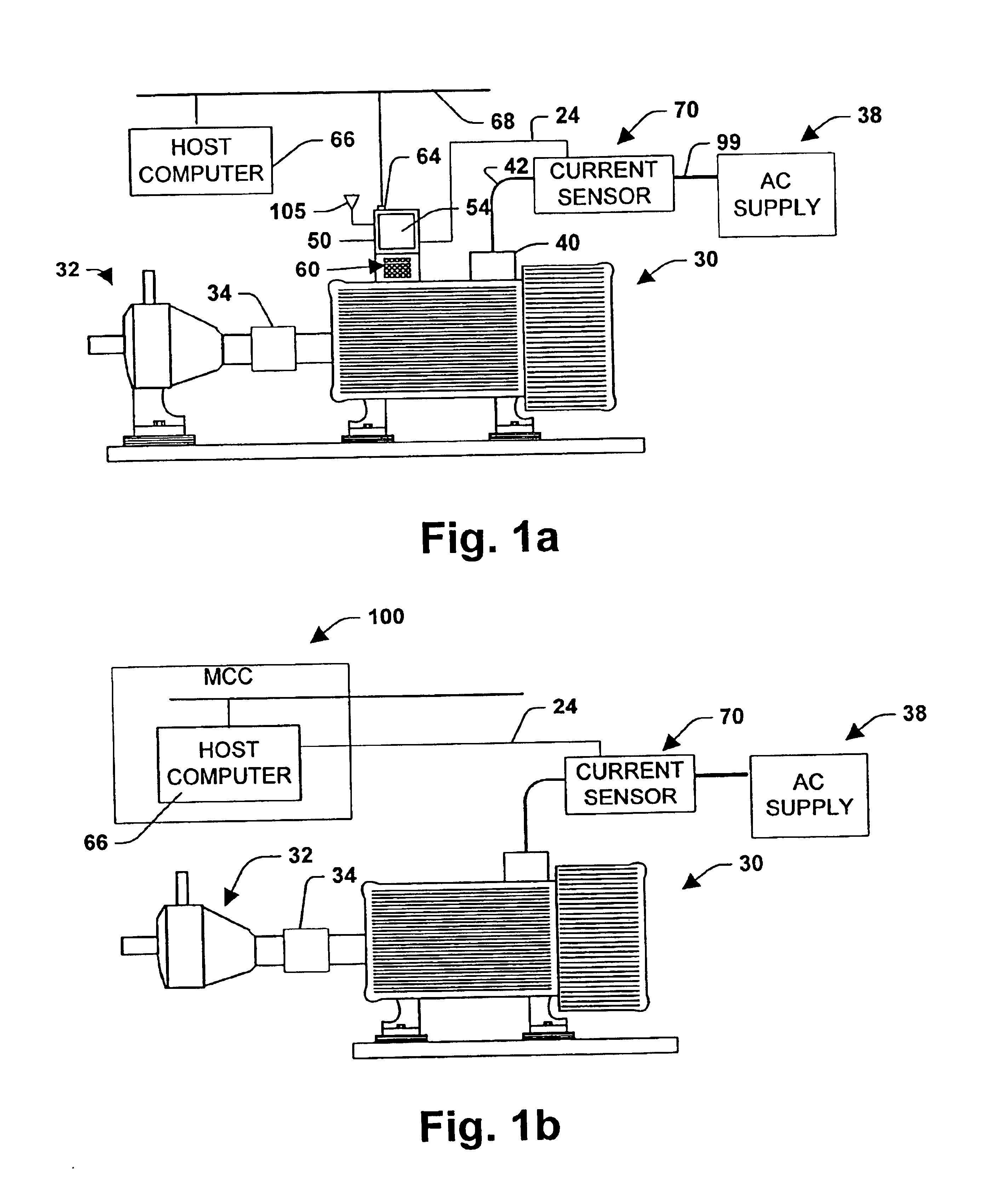

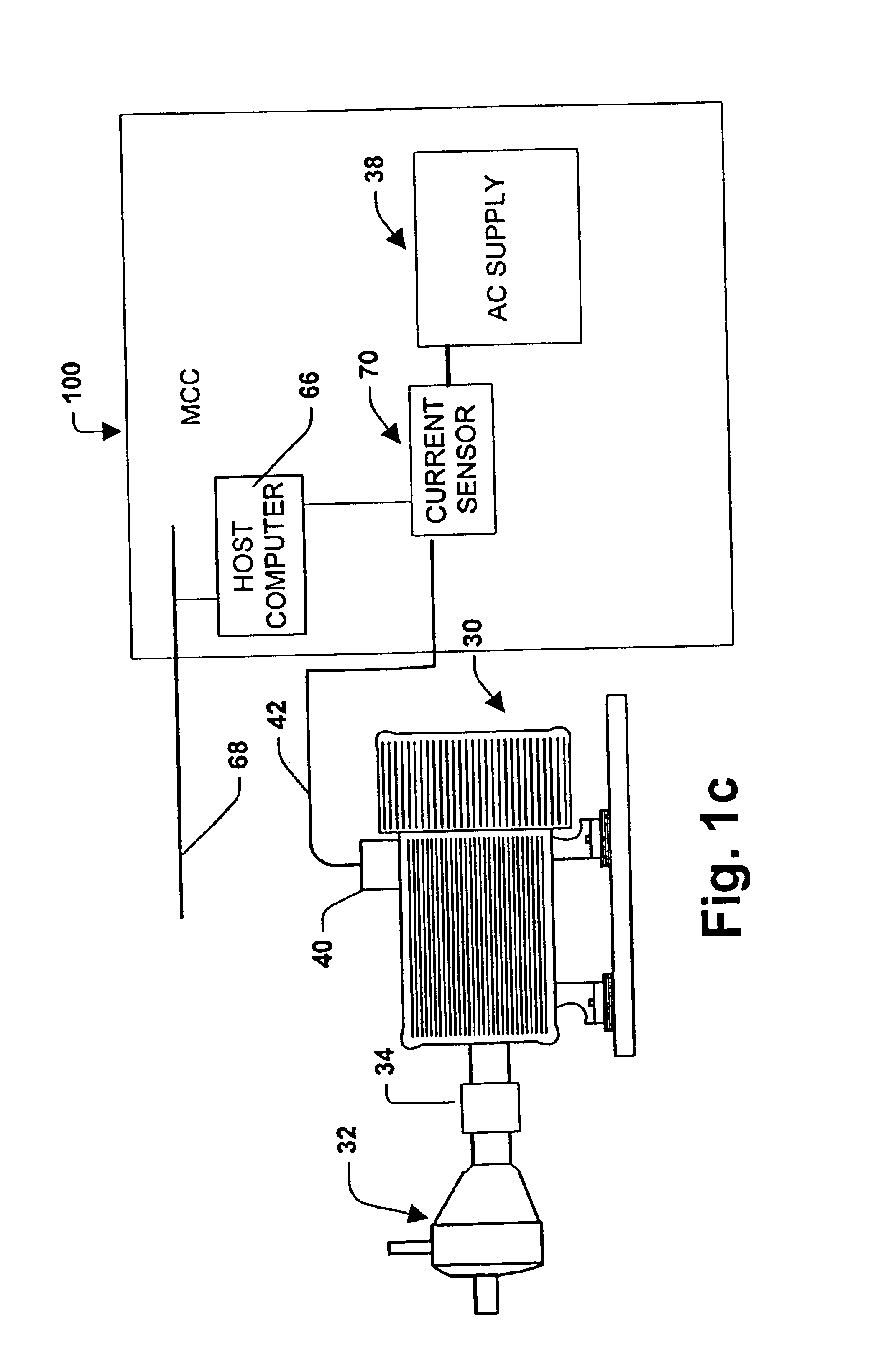

Detection of pump cavitation/blockage and seal failure via current signature analysis

InactiveUS20060071666A1Low costLower average currentLevel controlElectrical testingCavitationFrequency spectrum

A system and method is provided for monitoring the operating condition of a pump by evaluating fault data encoded in the instantaneous current of the motor driving the pump. The data is converted to a frequency spectrum which is analyzed to create a fault signature having fault attributes relating to various fault conditions associated with the pump. The fault signature is then input to a neural network that operates in conjunction with a preprocessing and post processing module to perform decisions and output those decisions to a user interface. A stand alone module is also provided that includes an adaptive preprocessing module, a one-shot unsupervised neural network and a fuzzy based expert system to provide a decision making module that operates with limited human supervision.

Owner:ROCKWELL AUTOMATION TECH

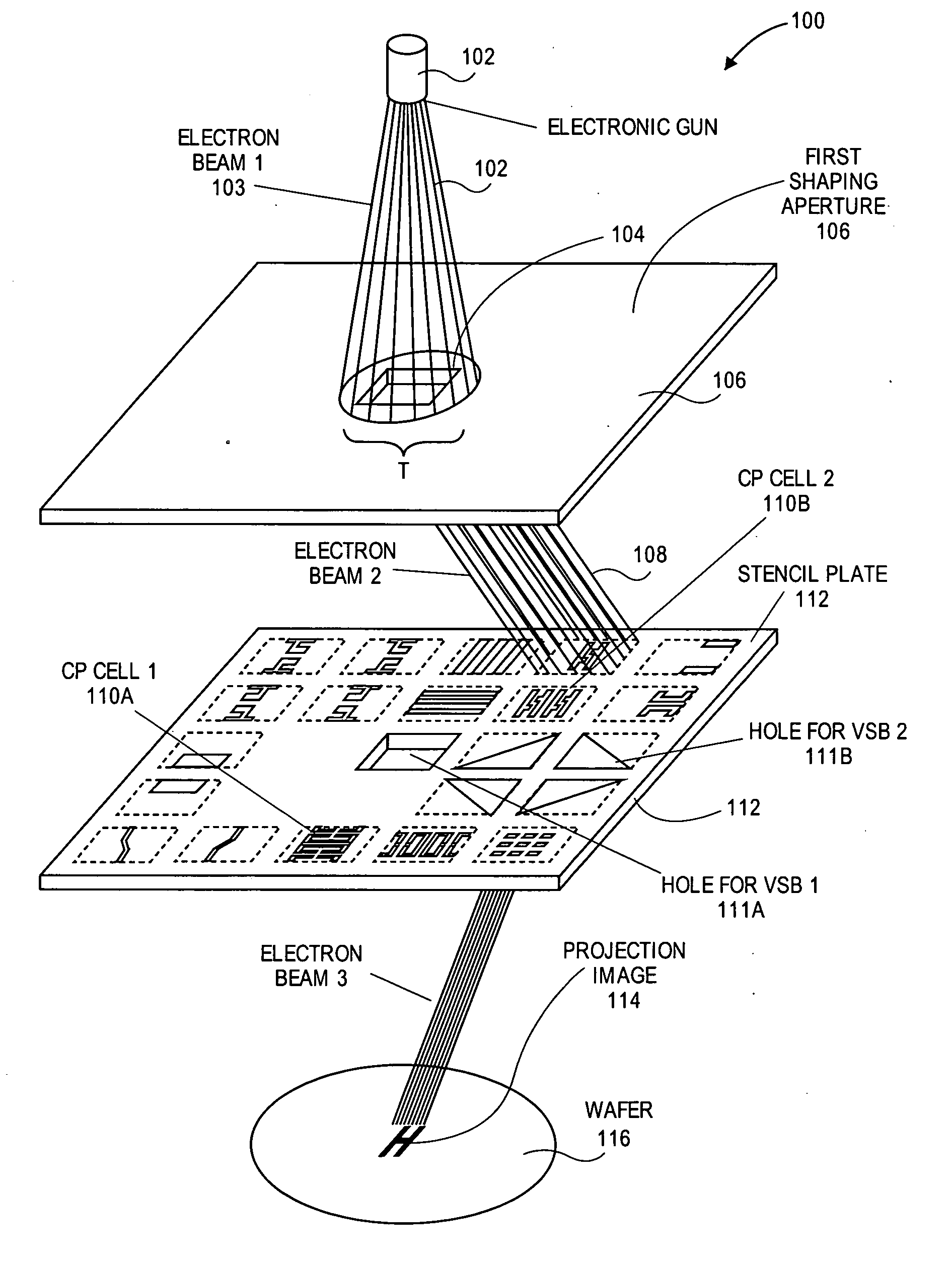

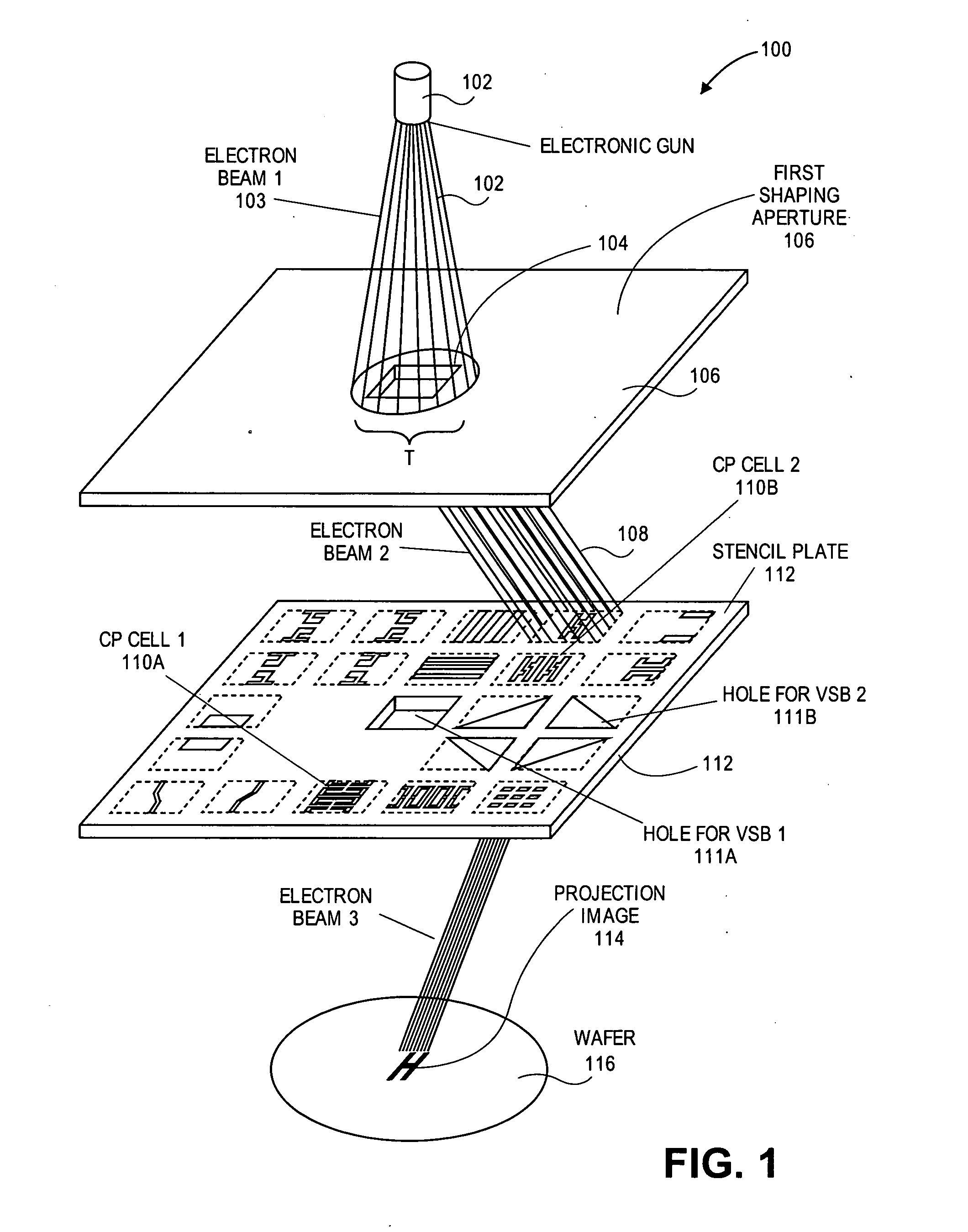

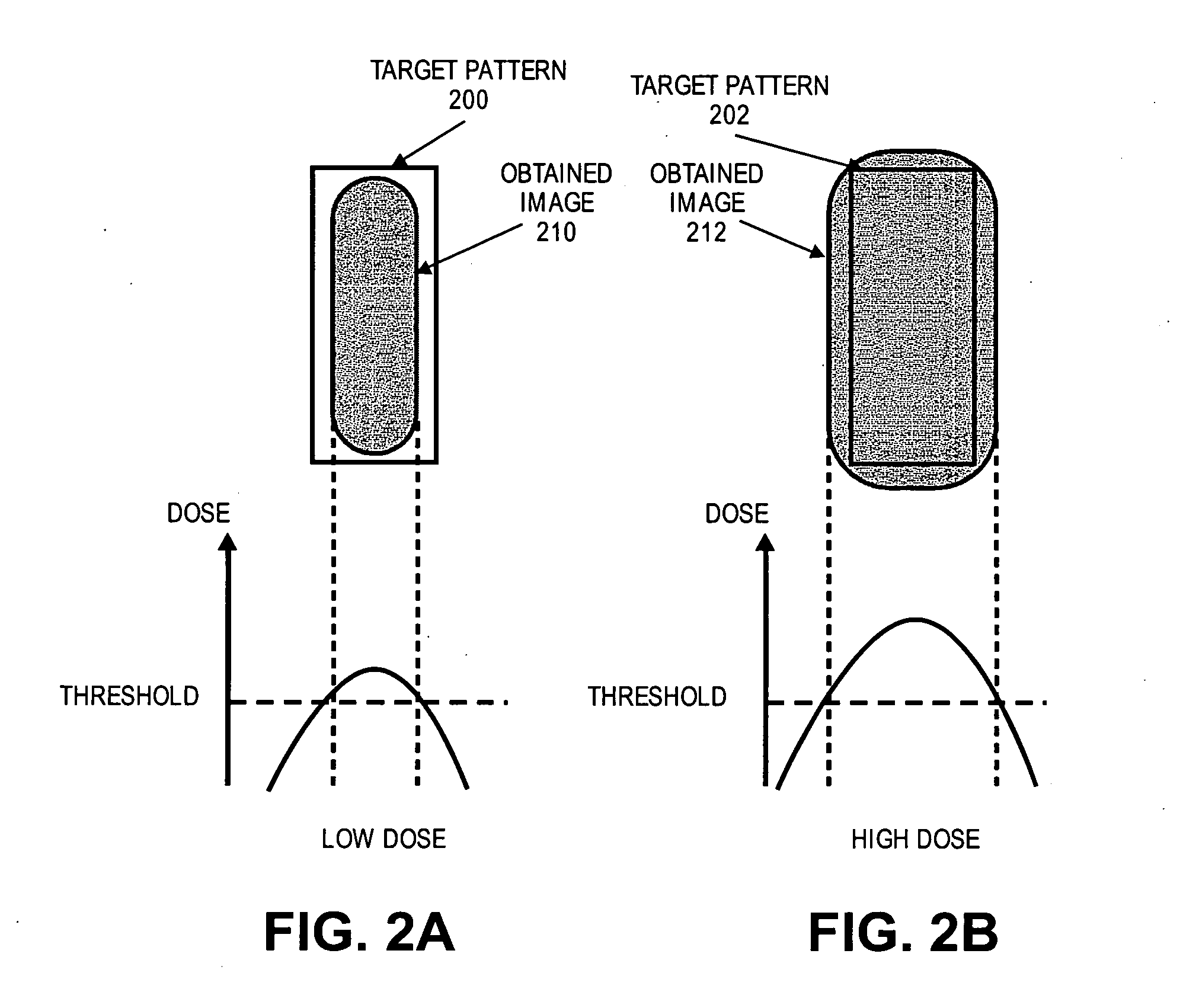

Method and system for proximity effect and dose correction for a particle beam writing device

InactiveUS20080116398A1Reduce image qualityEffective estimateElectric discharge tubesRadiation applicationsCell patternLithographic artist

A method of particle beam lithography includes selecting at least two cell patterns from a stencil, correcting proximity effect by dose control and by pattern modification for the at least two cell patterns, and writing the at least cell two patterns by one shot of the particle beam after proximity effect correction (PEC).

Owner:CADENCE DESIGN SYST INC

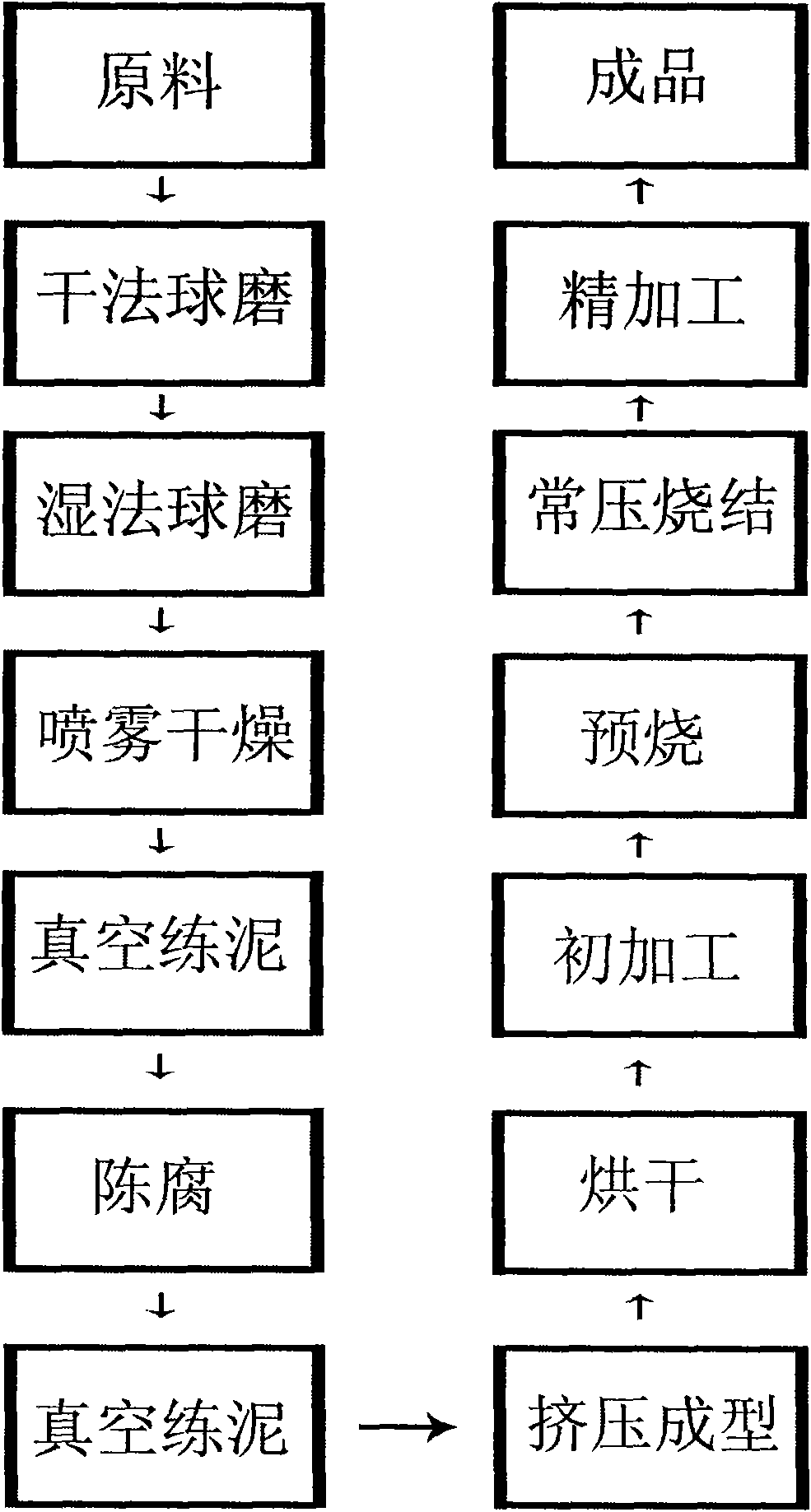

Preparation method for silicon carbide ceramic tube or rod

ActiveCN101560104AEvenly dispersedUniform moisture contentCeramic shaping apparatusClay processing apparatusShielding gasSlurry

The invention relates to a preparation method for a silicon carbide ceramic tube or rod. An extrusion moulding method is adopted to form a blank body; a normal pressure sintering method is adopted for sintering; and submicron level silicon carbide powder and additives are taken as main raw materials. The preparation method comprises the following steps: 1) carrying out ball milling on the main raw materials by a dry method, adding water, a dispersant, a plasticizer, a lubricant and a liquid state binder, and then carrying out ball milling by a wet method; 2) adopting a spray granulation process to granulate silicon carbide slurry; 3) extruding the blank body by a one-shot direct extrusion moulding method after vacuum pug, corrosion, and vacuum pug; 4) drying the molded blank body by a stage drying mechanism; and 5) placing the blank body of the silicon carbide ceramic tube or rod in a vacuum furnace and carrying out sintering for two times by taking argon gas as protective gas. The high temperature resisting strength and the corrosion resistance of the silicon carbide ceramic tube or rod prepared by the method are both better than those of a reactive sintered product. Compared with a hot press sintering method, the method has lower limit on the product shape and size, and lower cost. The method is suitable for the industrialized production.

Owner:宁波欧翔精细陶瓷技术有限公司

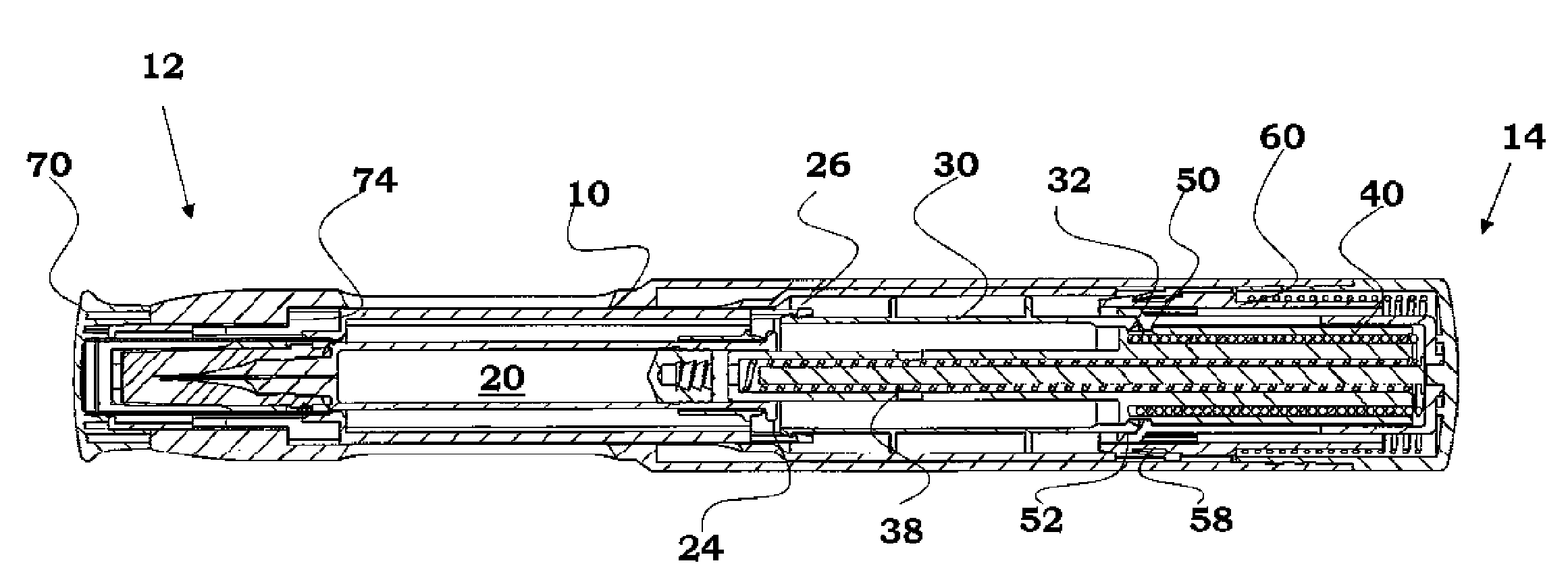

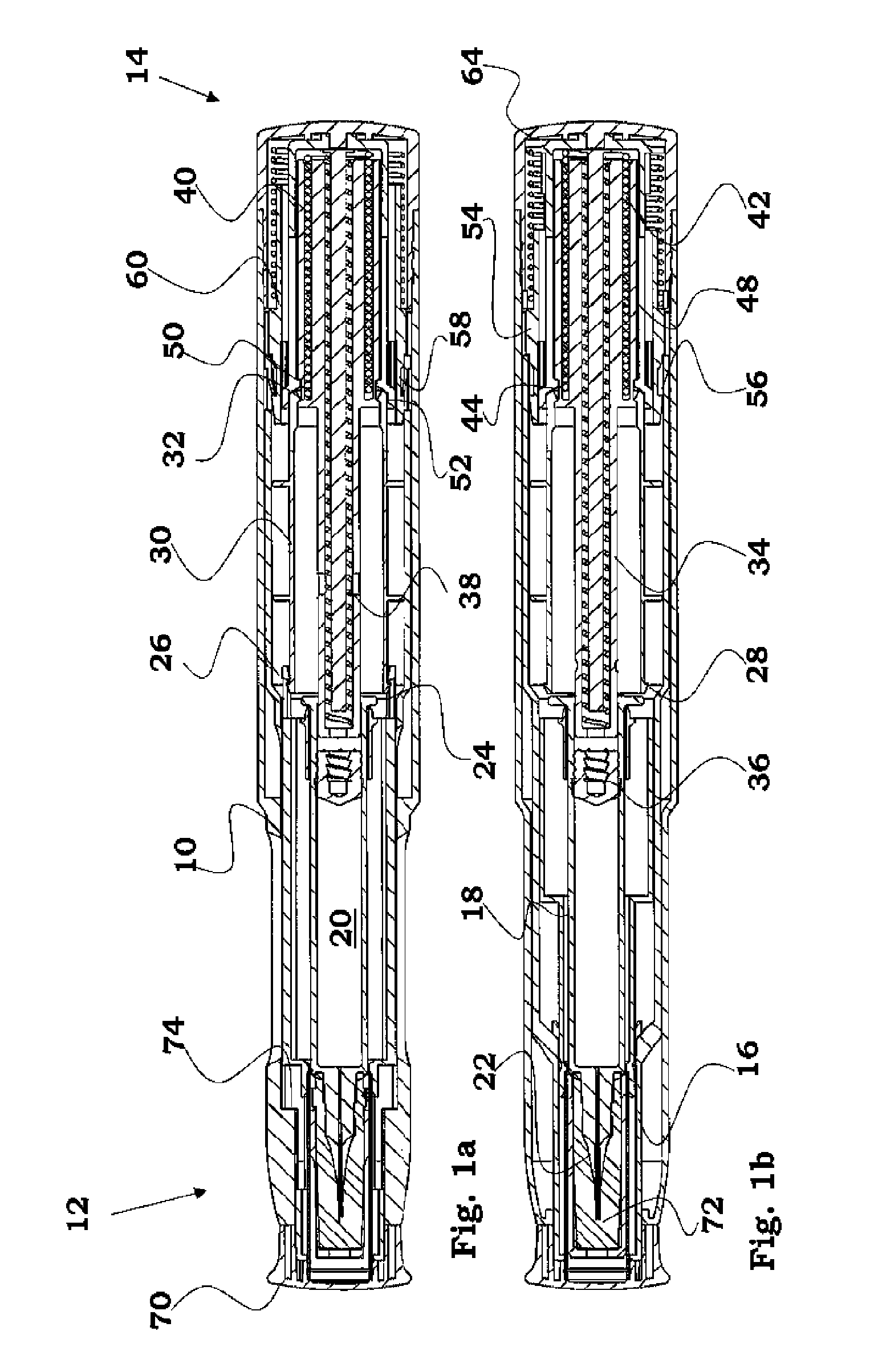

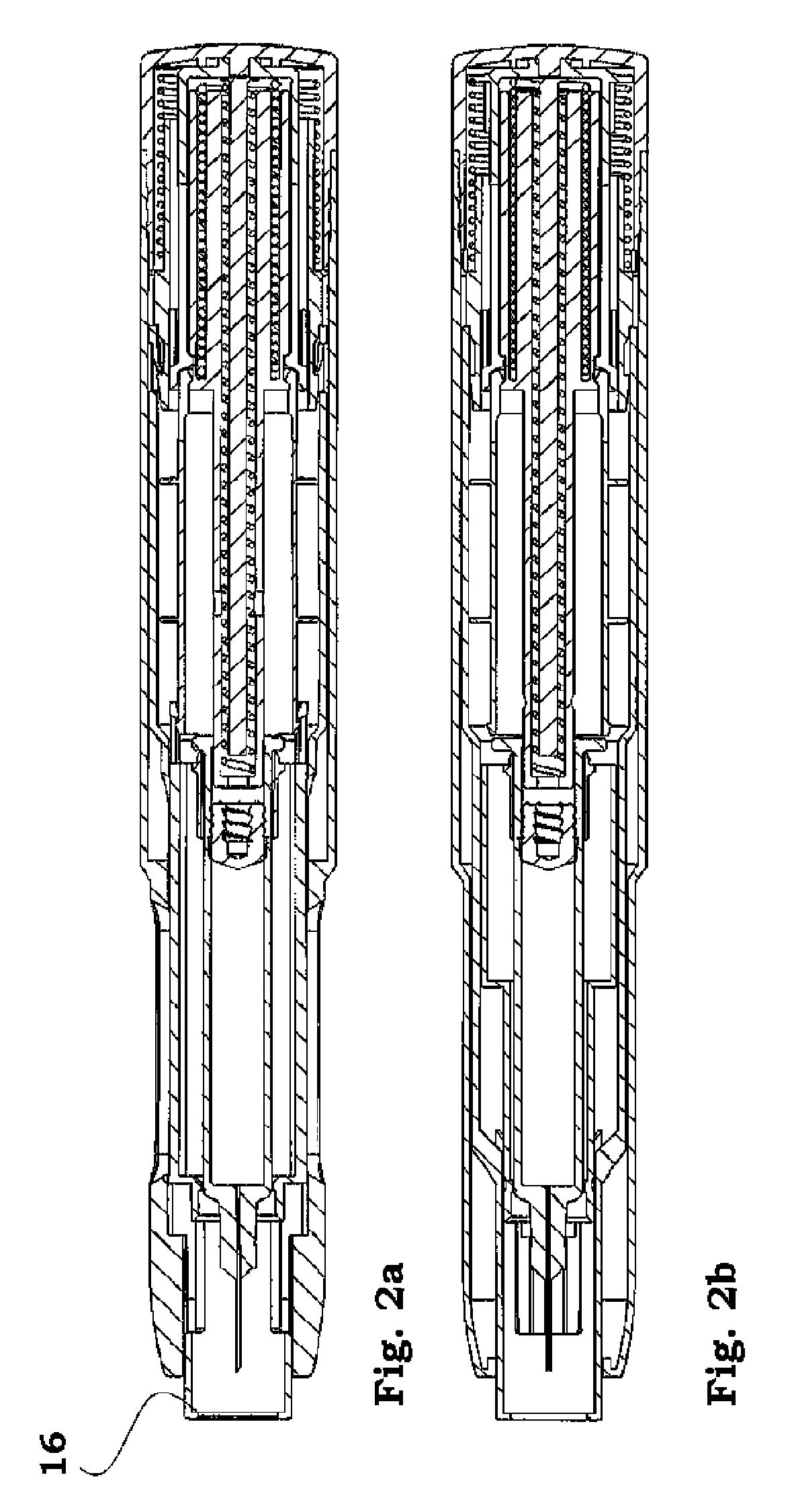

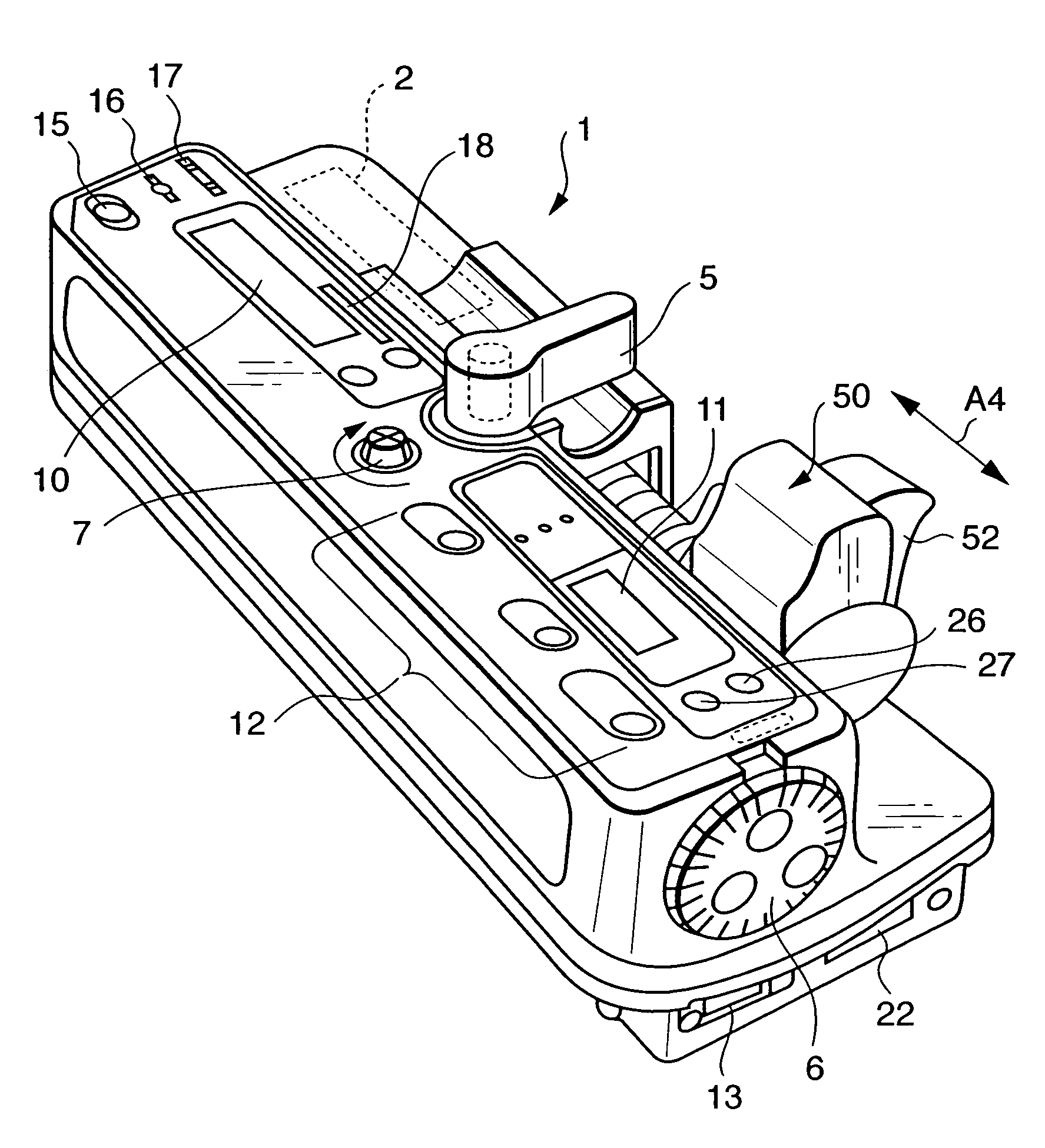

One shot injector with dual springs

ActiveUS8277412B2High viscosityIncrease in sizeAutomatic syringesIntravenous devicesOne shotMedical treatment

Owner:SHL MEDICAL AG

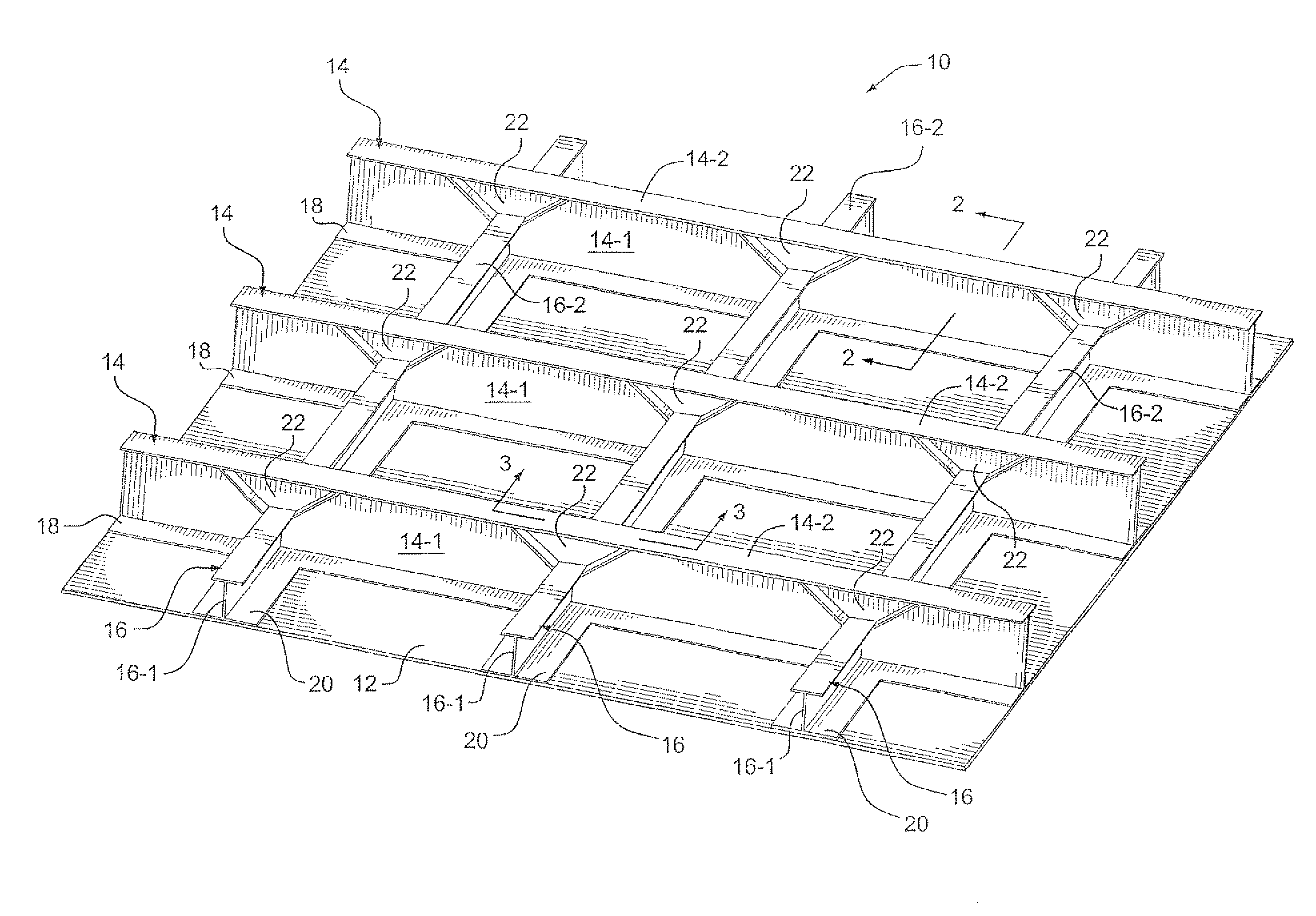

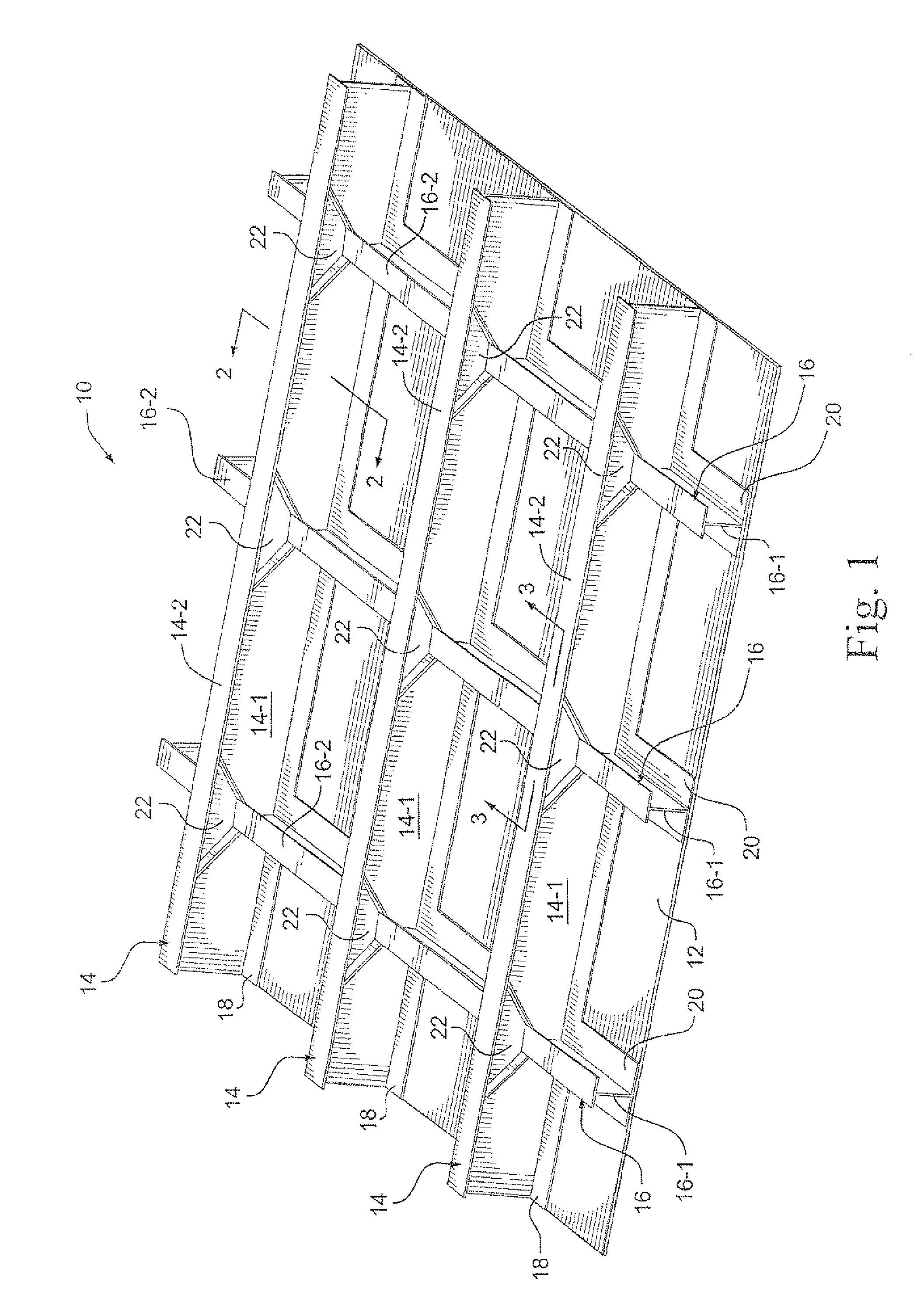

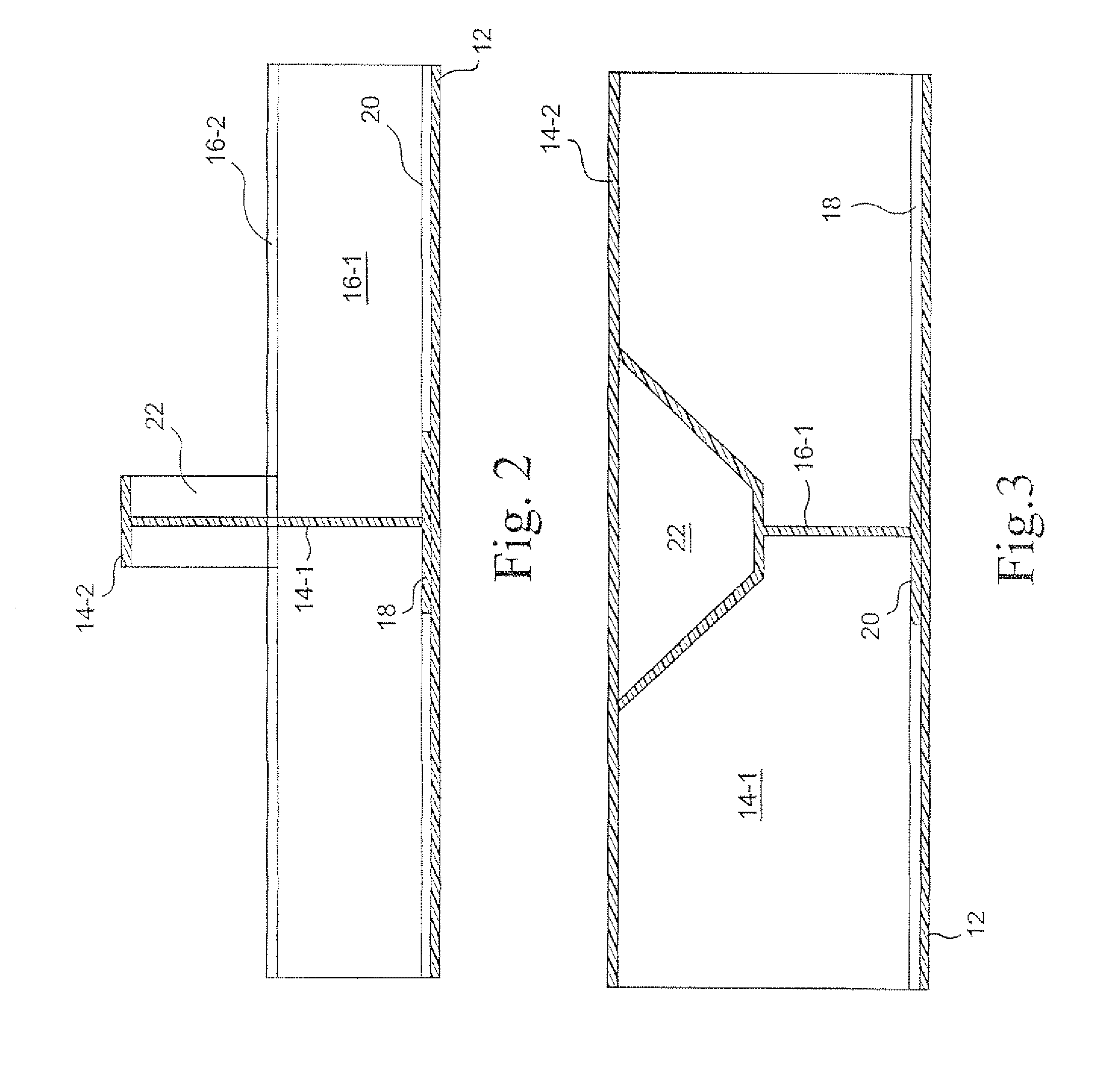

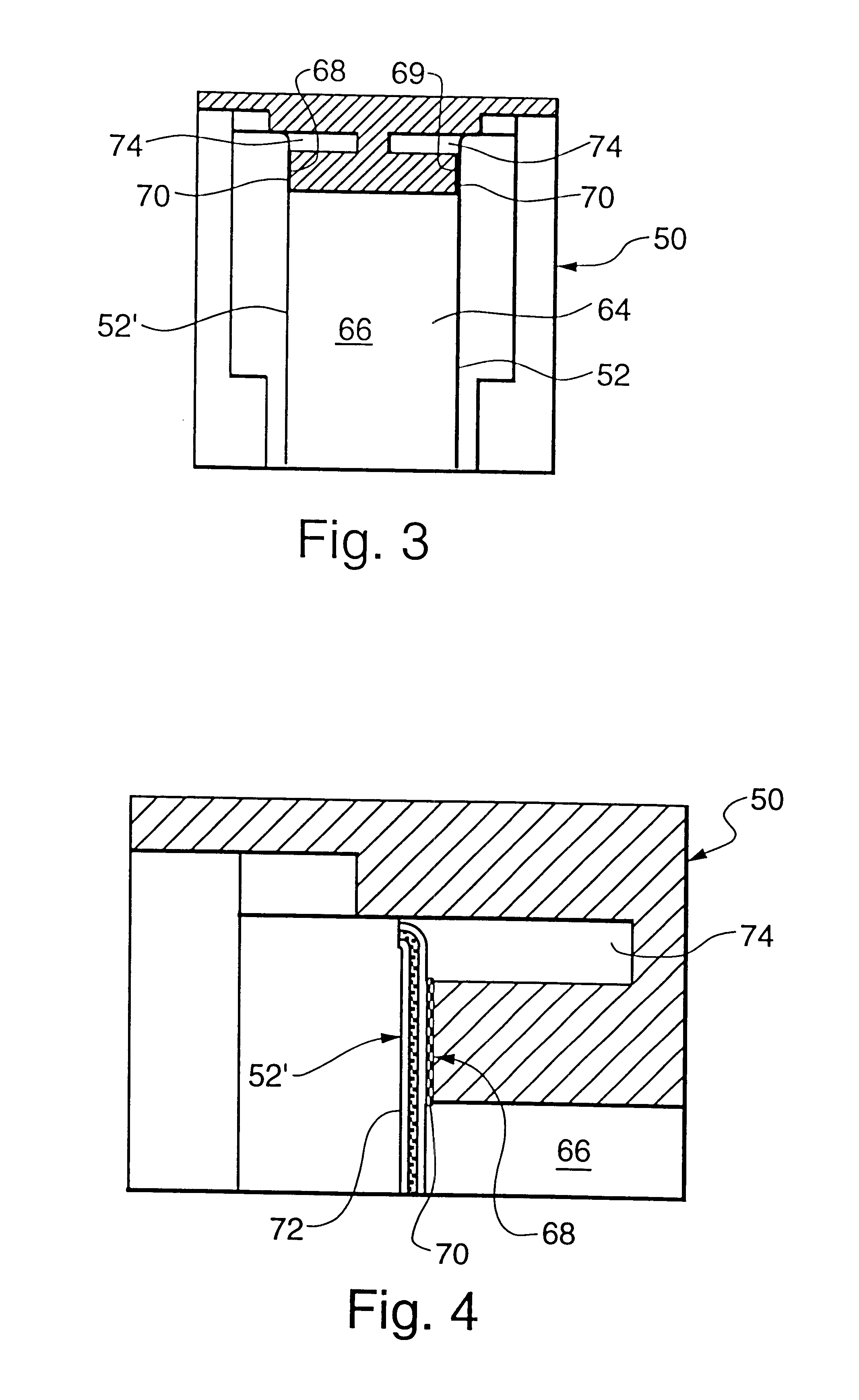

Monolithic integrated structural panels especially useful for aircraft structures and methods of making the same

Structural panels for use in manufacturing fuselage bodies and other aircraft structures are disclosed herein. In one embodiment, a monolithic integrated structural panel is configured to include a skin, an array of stiffeners and an array of frames which are preferably arranged in a mutually orthogonal layout, without the need of cut-outs in any of the crossing elements. One advantage of the disclosed embodiments is that the frame and stringer members have continuous flanges and spliced webs. The disclosed embodiments herein are compatible with composite materials technology, offering another advantage, namely the possibility of manufacturing integrated products in a single cure (“one-shot”) cycle. A structure of composite materials, e.g. carbon fiber reinforced plastics, typically comprises a skin panel, reinforced by frame and stringer members. A monolithic integrated structure constructed in accordance with the disclosed embodiments is well-suited for use as a portion of an aircraft structure, for example an aircraft fuselage, wing or empennage.

Owner:EMBRAER SA

One shot injector with dual springs

InactiveCN101687078AIncrease attractivenessAutomatic syringesIntravenous devicesOne shotMedical treatment

Owner:SHL GRP AB

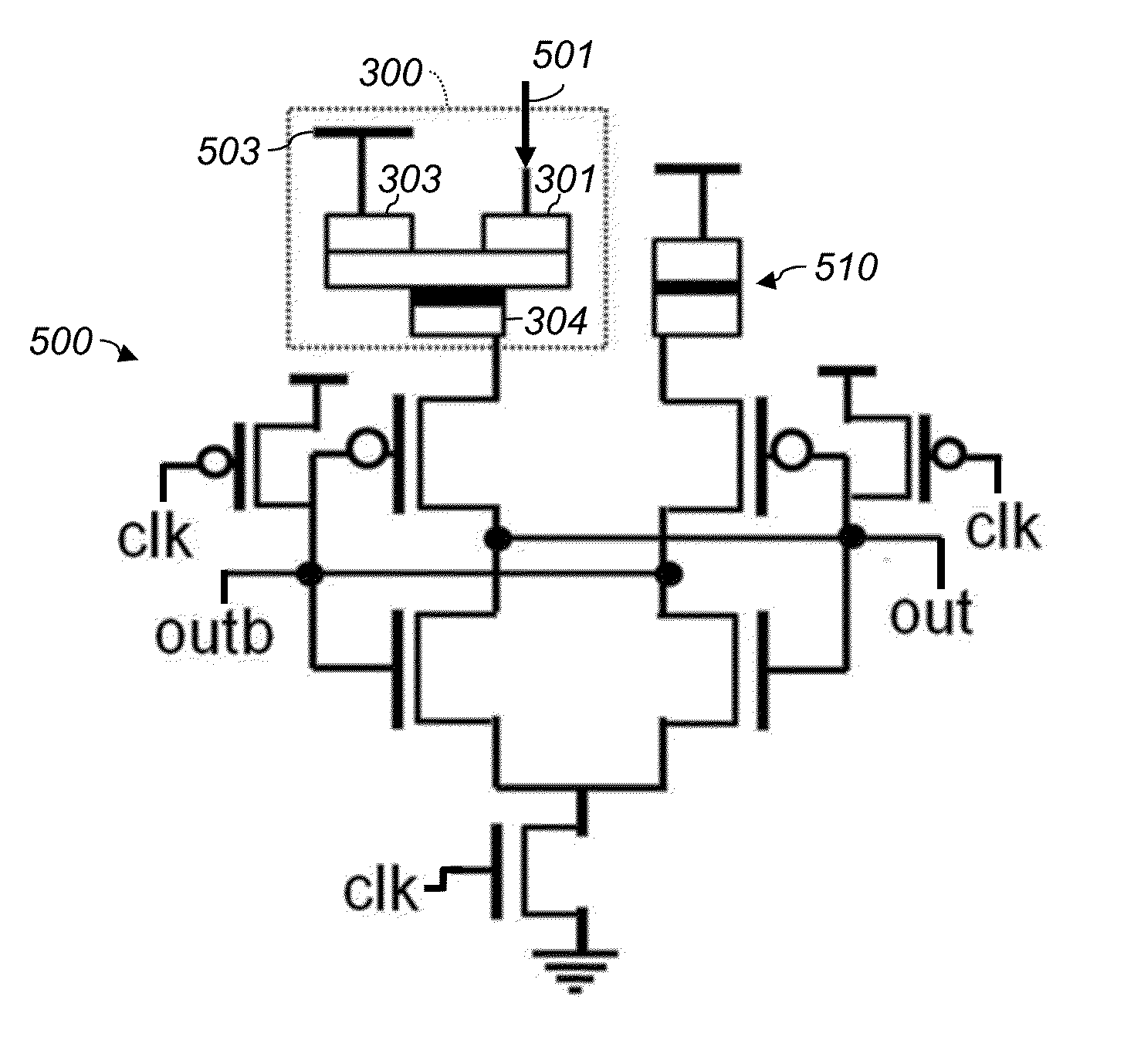

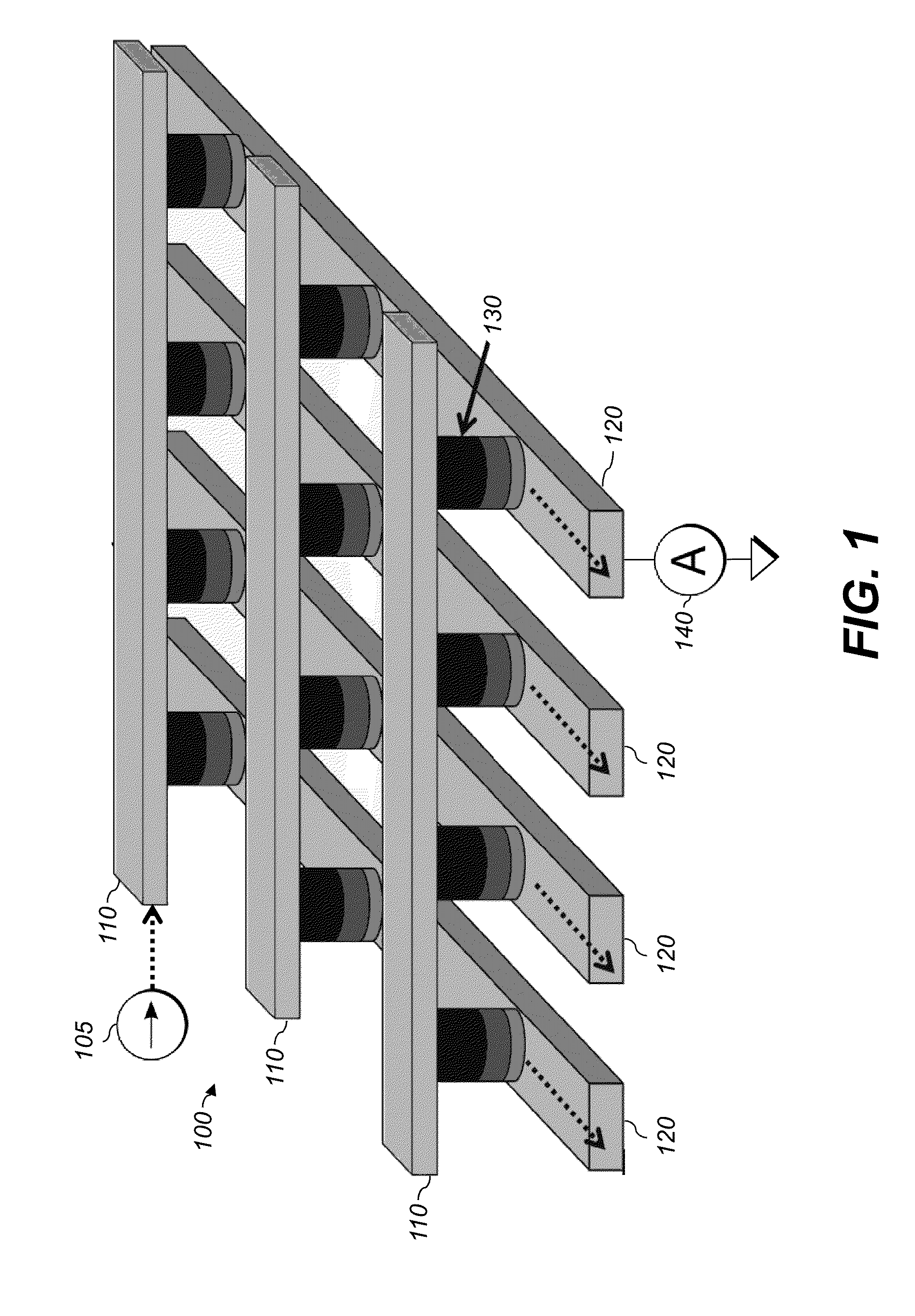

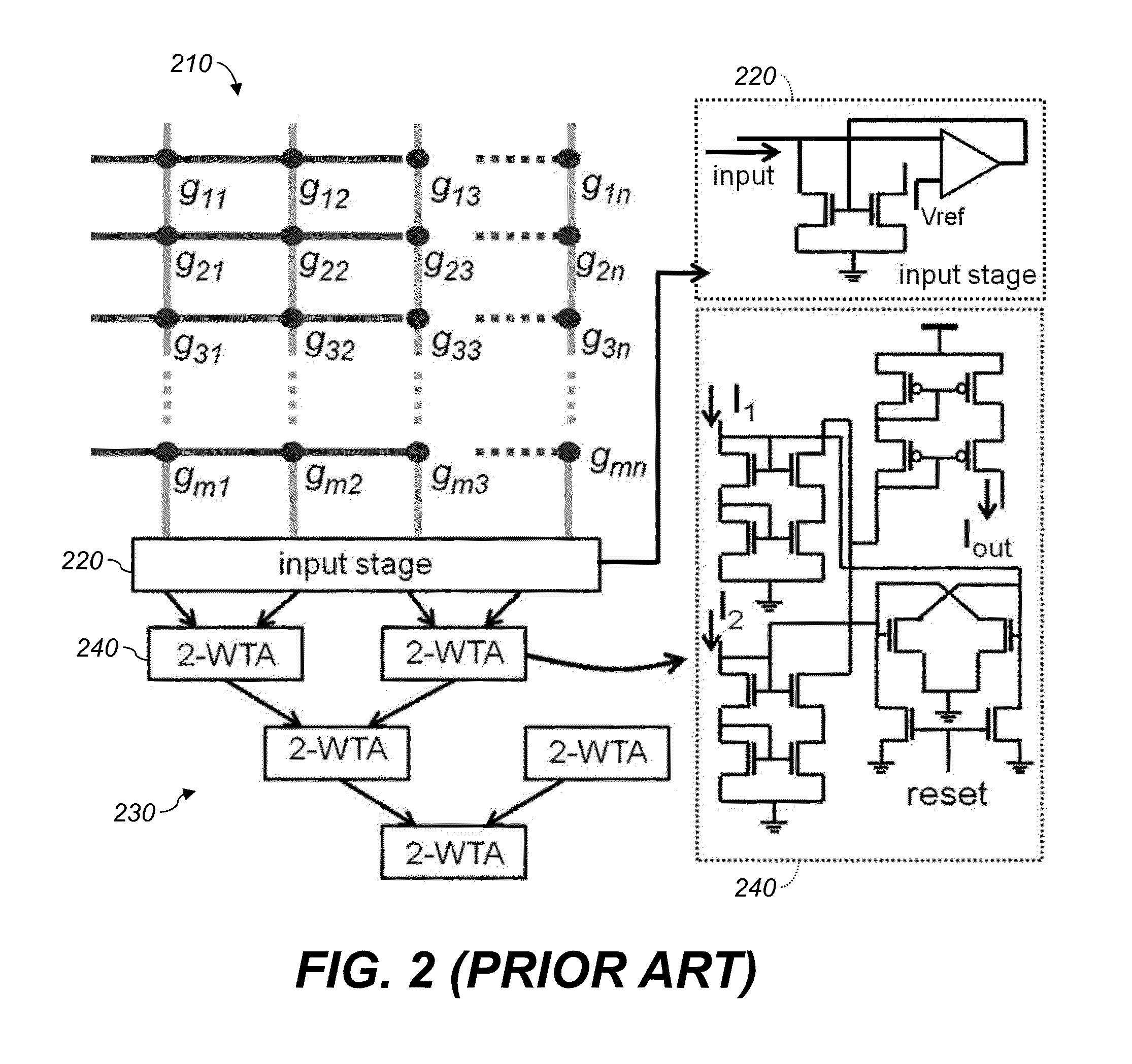

Electronic comparison systems

ActiveUS20150347896A1Easy to optimizeReduce consumptionAnalogue/digital conversionElectric signal transmission systemsCMOSNeural network system

An electronic comparison system includes input stages that successively provide bits of code words. One-shots connected to respective stages successively provide a first bit value until receiving a bit having a non-preferred value concurrently with an enable signal, and then provide a second, different bit value. An enable circuit provides the enable signal if at least one of the one-shots is providing the first bit value. A neural network system includes a crossbar with row and column electrodes and resistive memory elements at their intersections. A writing circuit stores weights in the elements. A signal source applies signals to the row electrodes. Comparators compare signals on the column electrodes to corresponding references using domain-wall neurons and store bit values in CMOS latches by comparison with a threshold.

Owner:PURDUE RES FOUND INC

Detection of pump cavitation/blockage and seal failure via current signature analysis

InactiveUS7099852B2Lower average currentRemove outliersElectrical testingDigital dataFrequency spectrumCavitation

A system and method is provided for monitoring the operating condition of a pump by evaluating fault data encoded in the instantaneous current of the motor driving the pump. The data is converted to a frequency spectrum which is analyzed to create a fault signature having fault attributes relating to various fault conditions associated with the pump. The fault signature is then input to a neural network that operates in conjunction with a preprocessing and post processing module to perform decisions and output those decisions to a user interface. A stand alone module is also provided that includes an adaptive preprocessing module, a one-shot unsupervised neural network and a fuzzy based expert system to provide a decision making module that operates with limited human supervision.

Owner:ROCKWELL AUTOMATION TECH

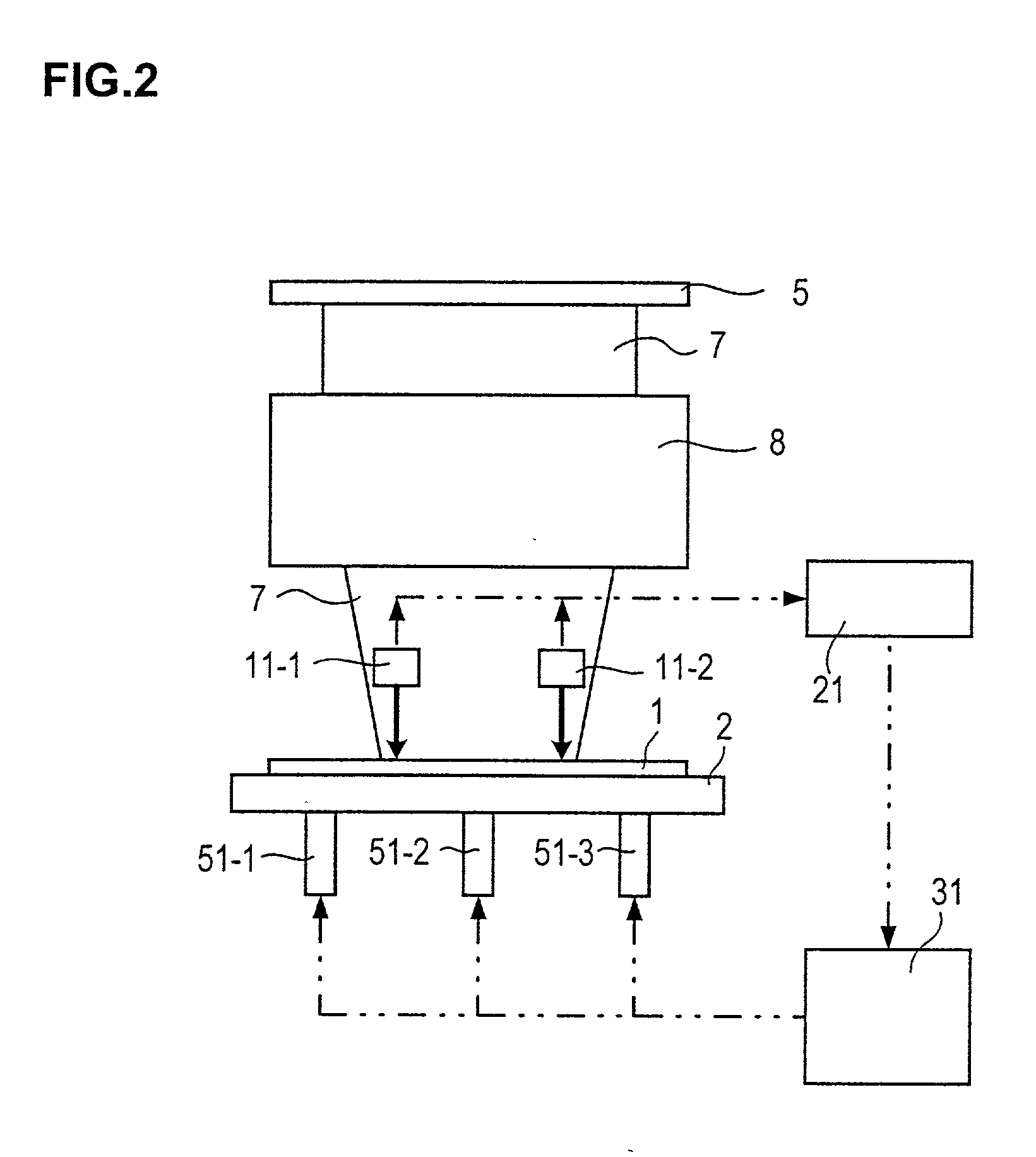

Exposure apparatus and exposure method

InactiveUS20030011771A1Small measurement errorHigh leveling accuracyInvestigating moving sheetsSemiconductor/solid-state device manufacturingCamera lensMeasurement point

An exposure apparatus and an exposure method that minimize the range over which exposing light becomes defocused even when a non-level portion is present within each shot are provided. One shot is selected from a plurality of shots (exposure unit areas) set on a wafer (S 50). 49 measurement points are set in the selected shot and the three-dimensional coordinates of each measurement point are determined (S 70). Next, an arithmetic operation is performed using the 49 sets of three-dimensional coordinate data to ascertain an "in-shot focus plane" (S 90). This arithmetic operation may be performed through, for instance, the method of least squares. The extents of positional deviation between the surface of the selected shot and the in-shot focus plane is ascertained and the extents of deviation are stored in memory as "adjustment values" (S 110). An exposure shot to undergo exposure processing is selected and the surface level variation manifesting at the exposure shot is measured. The adjustment values are subtracted from the results of the measurement and exposing light is irradiated on the exposure shot while moving the wafer along the vertical direction in conformance to the result of the subtraction (S 130).

Owner:LAPIS SEMICON CO LTD

Polyurethane elastomers having improved physical properties and a process for the production thereof

InactiveUS7045650B2Excellent characteristicsMaintain good propertiesUrea derivatives preparationIsocyanic acid derivatives preparationPolyurethane elastomerPolyol

A polyol composition having a number average molecular weight of from about 1,000 to about 3,000 Daltons is made up of (1) at least 60% by weight of a low monol polyoxypropylene polyol having a number average molecular weight of from about 2,000 to 12,000 Da and a degree of unsaturation less than or equal to 0.02 meq / g and (2) no more than 40% by weight of a polyol having a number average molecular weight of from about 400 to about 1,000 Da and a polydispersity index greater than 1.1. This polyol composition is reacted with a diisocyanate, a polyisocyanate, an isocyanate-terminated prepolymer or an isocyanate-terminated quasi-prepolymer to produce polyurethane elastomers having good physical and mechanical properties. Any of the known processes for producing polyurethane elastomers, including one-shot processes, may be used to produce elastomers in accordance with the present invention.

Owner:COVESTRO LLC

Drug container and drug infusion device comprising the same

When using a drug container having an identification tag fixed or detachably provided at a predetermined position of the container, the tag having drug data on a kind and a concentration of a drug and both or one of upper and lower limits of a flow rate on a continuous infusion and the upper and lower limits, time and flow rate on a one-shot administration recorded thereon, it is possible to ensure safety by prompting for a stop of injection by a warning when a setting beyond the upper and lower limits is performed and rewrite a liquid infusing time and a flow rate and so on required to be set according to symptoms of a patient.

Owner:TERUMO KK

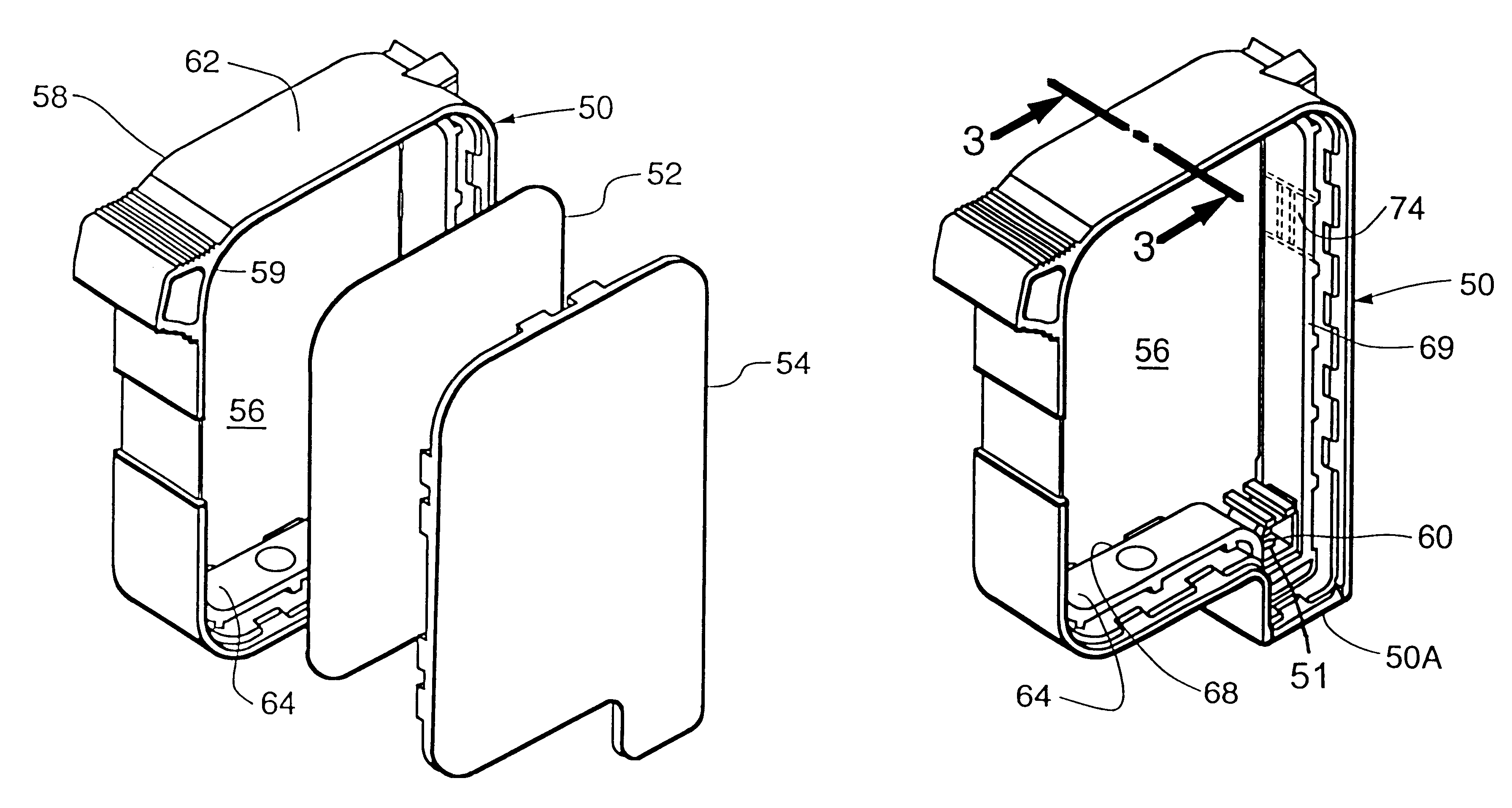

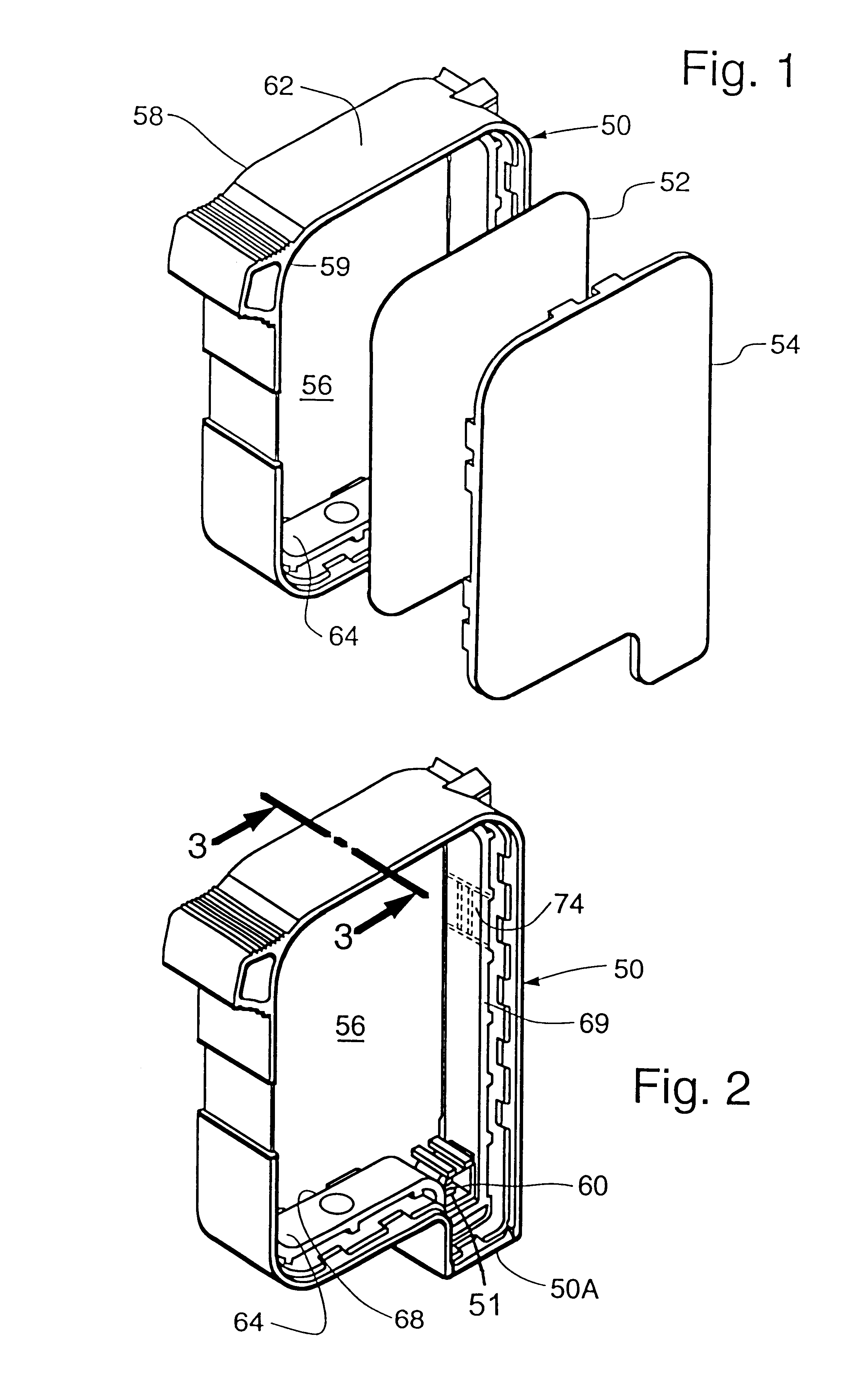

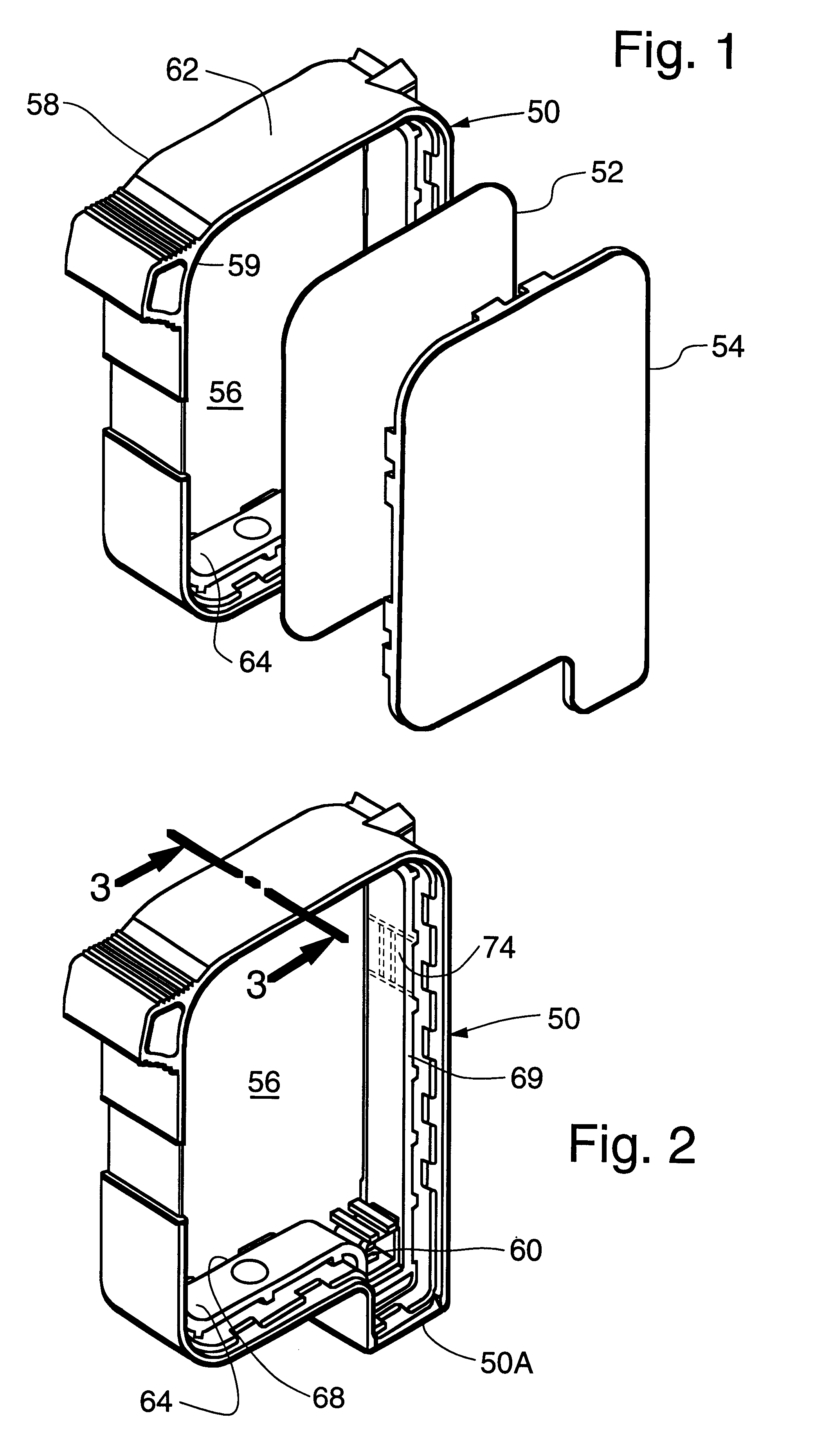

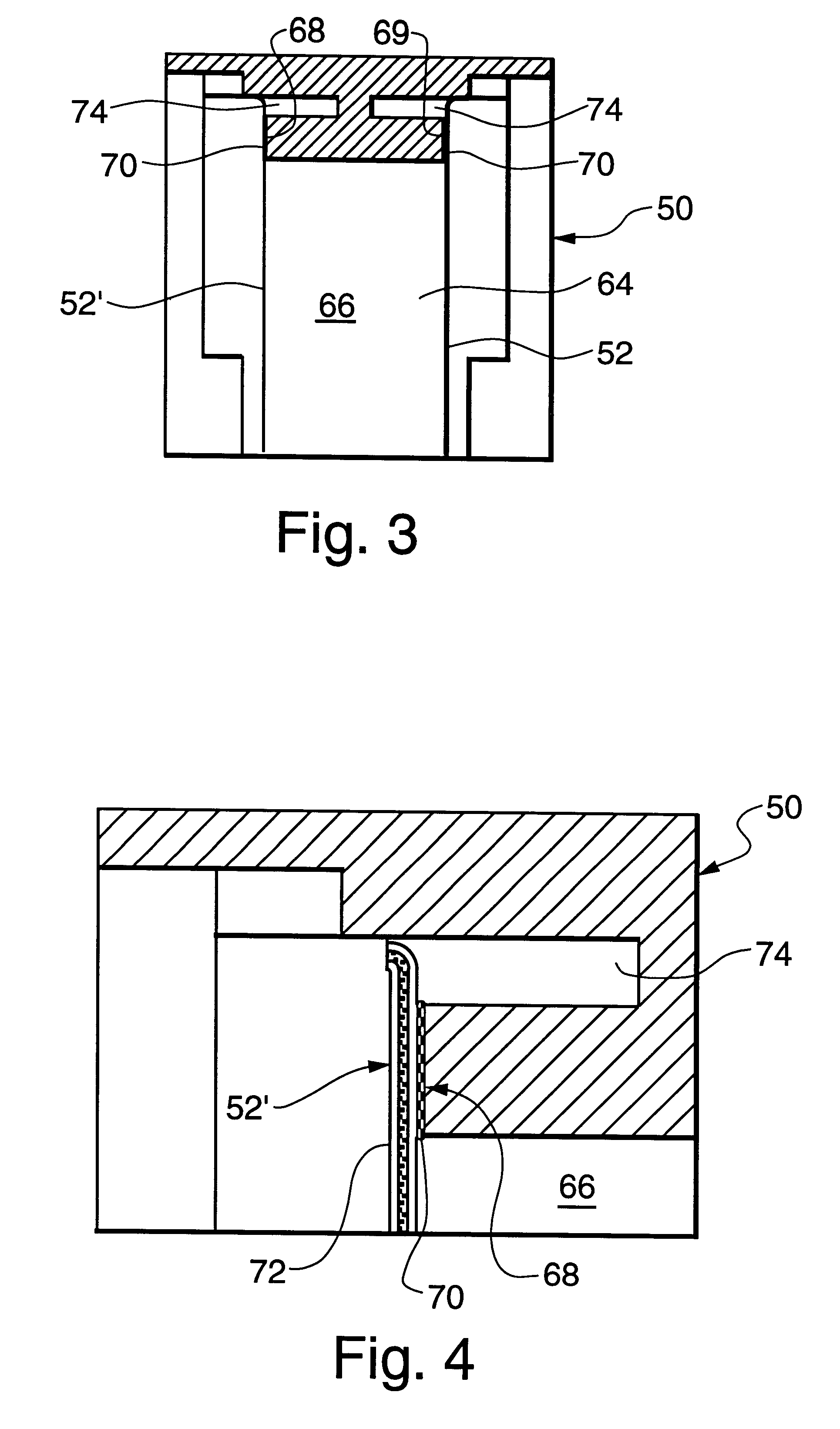

Print head cartridge made with jointless one-piece frame consisting of a single material throughout

A print head having an ink reservoir therein is made by forming, in a one-shot plastic injection molding step, a rigid monolithic frame including high melt temperature material having an opening therein extending from a first side to a second side, and first and second bonding surfaces surrounding the opening and facing the first and second sides, respectively. First and second thin flexible films are adhesively secured to the first and second bonding surfaces, respectively. The adhesive material may be a hot melt adhesive or dry adhesive films pre-formed to the shape of the bonding surfaces. By securing the flexible films to the bonding surfaces adhesively, rather than by heat staking, it is not necessary to form the frame of different materials during two separate molding steps.

Owner:FUNAI ELECTRIC CO LTD

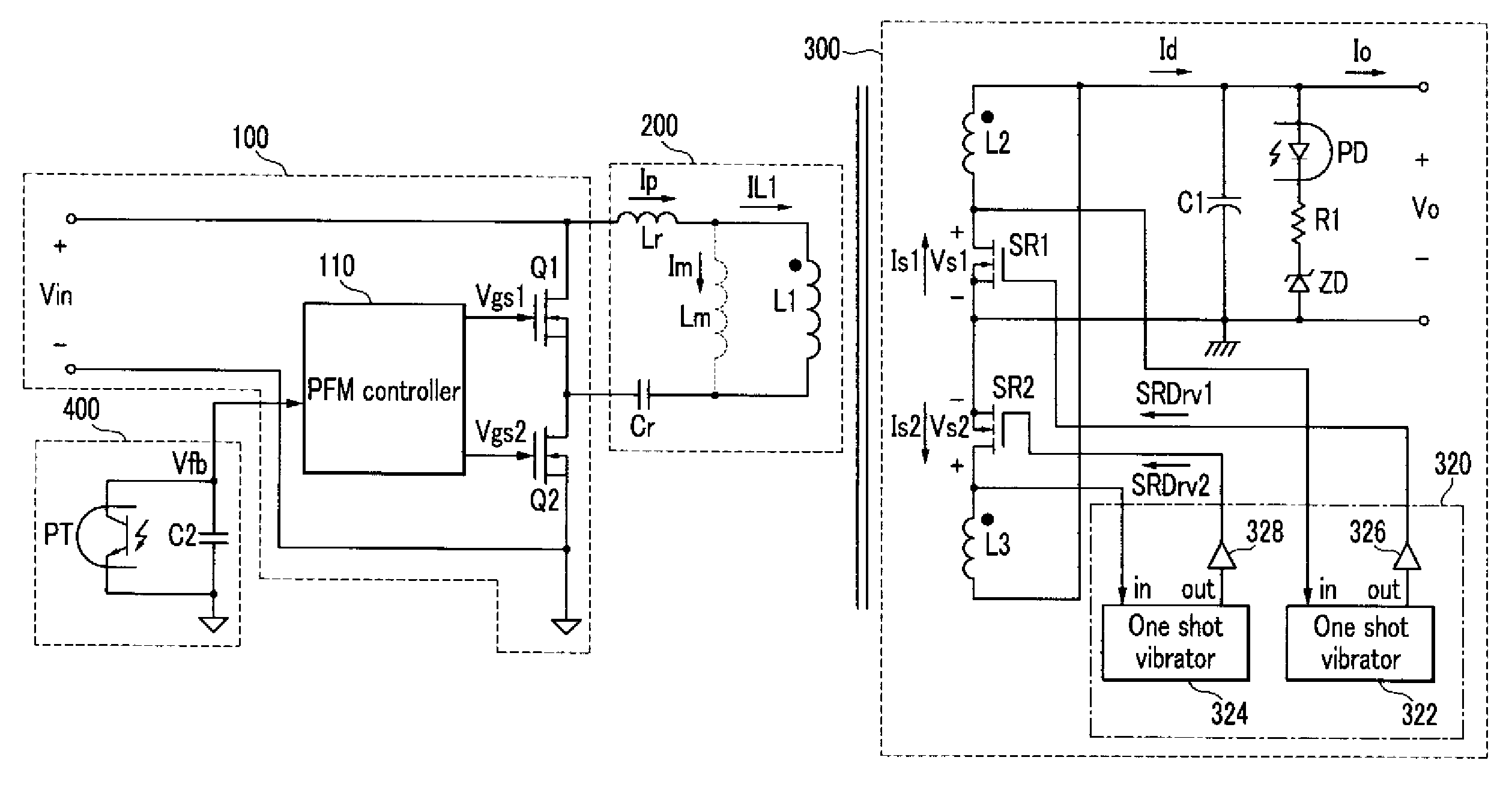

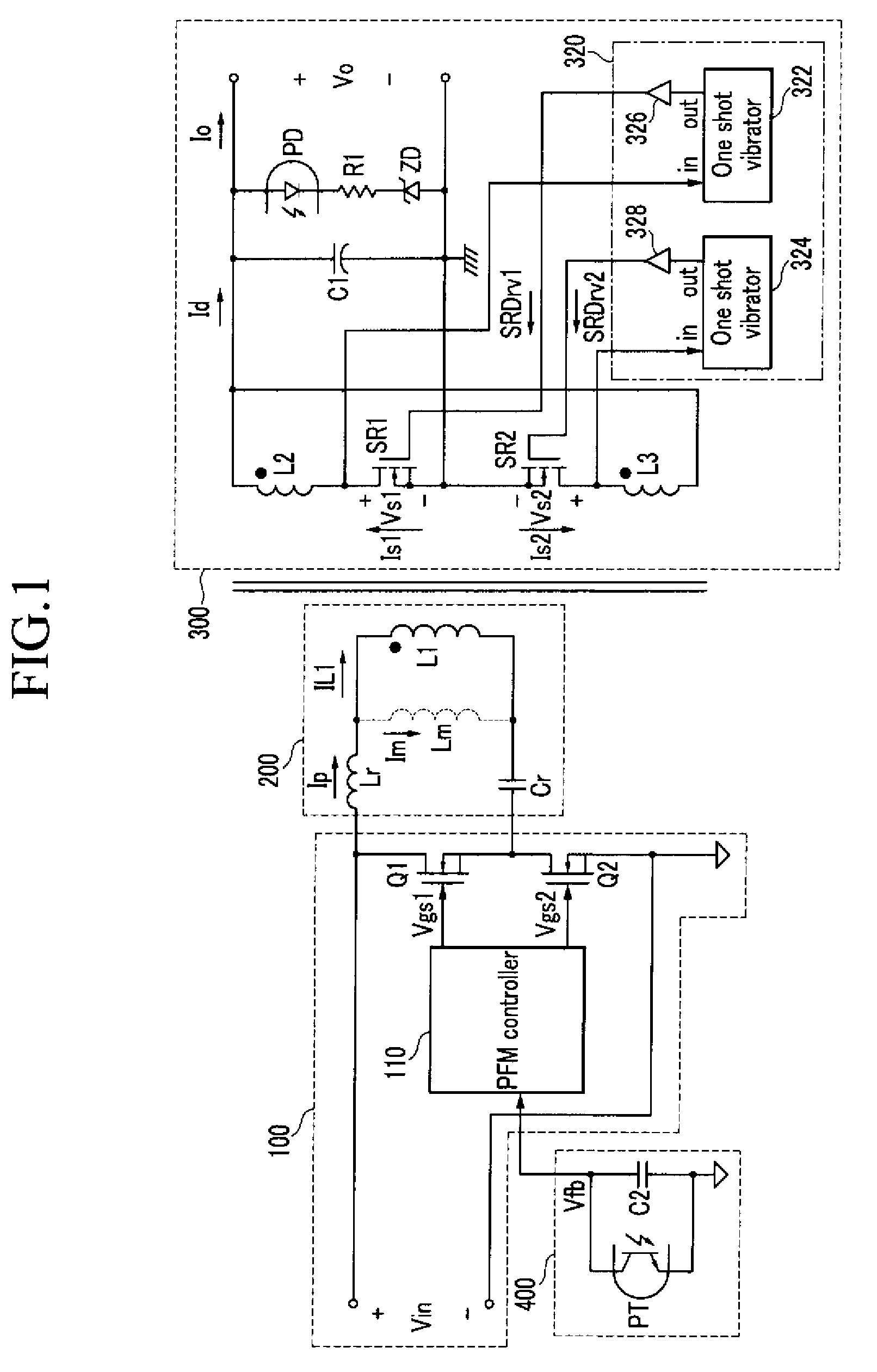

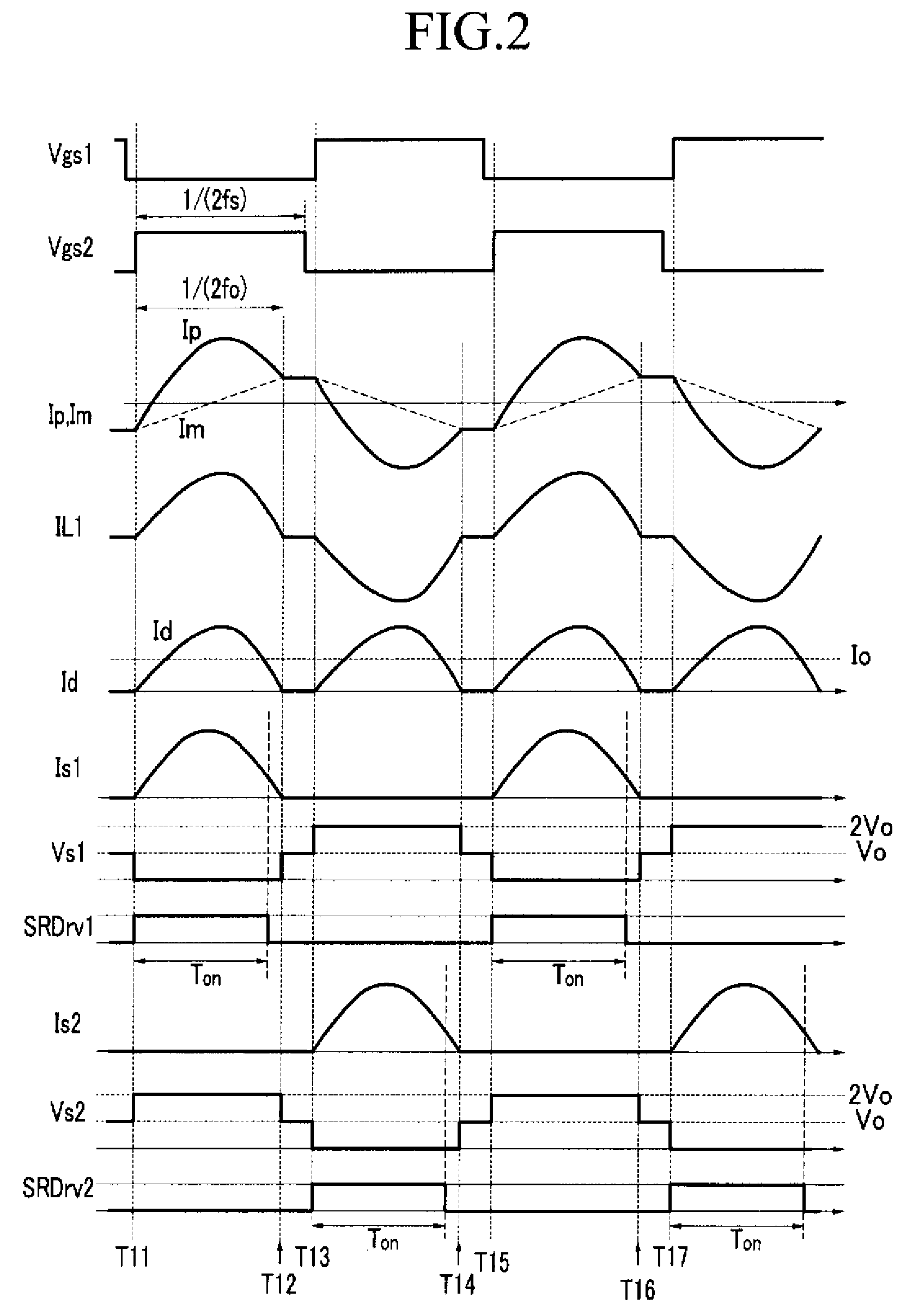

Synchronous Rectifier

ActiveUS20090175056A1Low costSolve the stability is not highAc-dc conversion without reversalEfficient power electronics conversionMOSFETEngineering

This invention relates to a synchronous rectifier for LLC resonant converter. This method allows simple drive method for the synchronous rectifier MOSFETS by using the transformer secondary winding voltage and one-shot vibrator. The synchronous rectifier MOSFETs are turned on by being triggered to the transformer secondary side winding voltage and turned off after predetermined time set by one shot vibrator. The predetermined time is set by the resonant period of the resonant network.

Owner:SEMICON COMPONENTS IND LLC

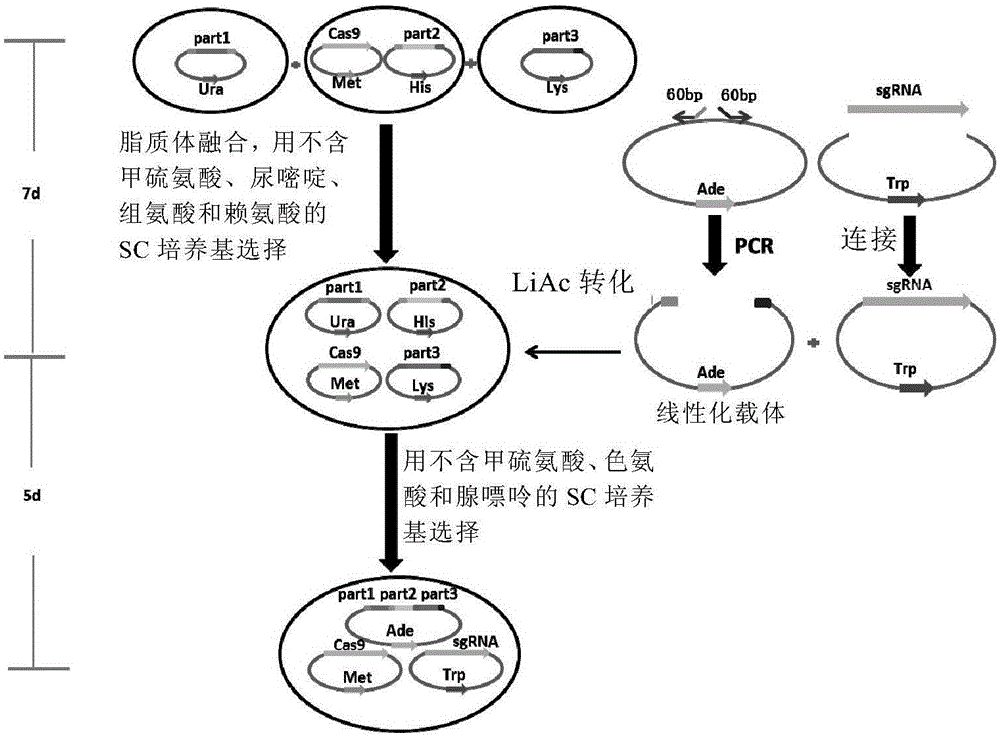

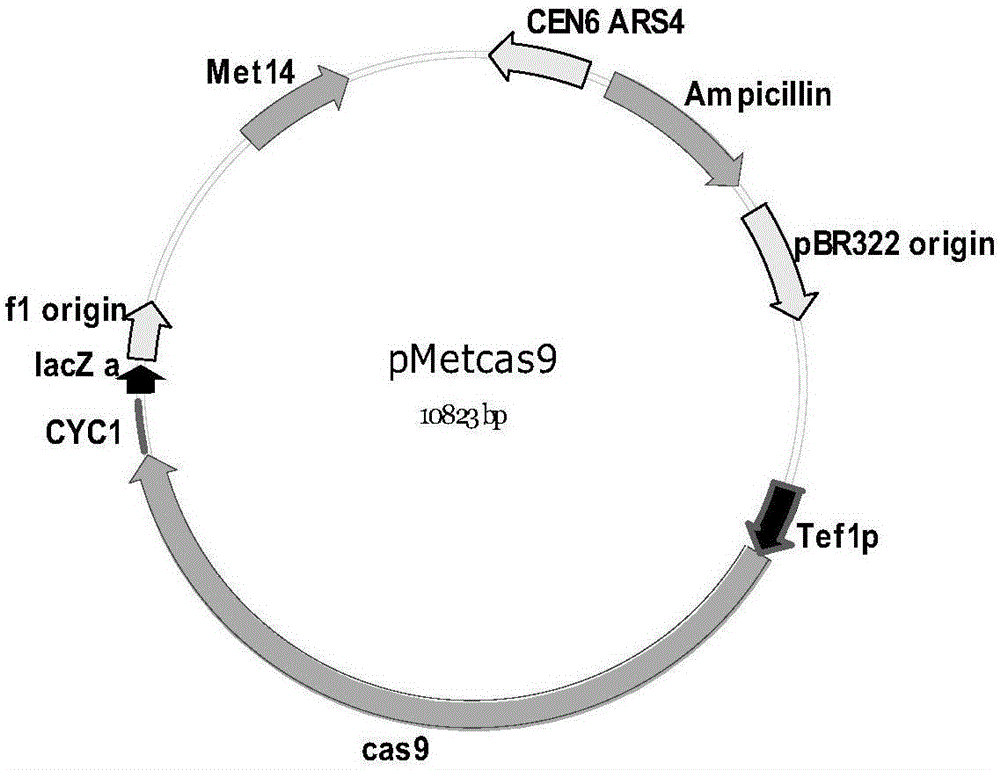

CRISPR/Cas9-mediated large DNA fragment assembling method

The invention discloses a CRISPR / Cas9-mediated large DNA fragment assembling method. Specifically, the invention provides a nucleic acid construct capable of carrying out constitutive expression of Cas9 in yeast; the nucleic acid construct contains a yeast Tef1 promoter operationally connected with a Cas9 gene, a replication origin from pBR322 and a screening mark thereof, and a replication region from CEN6ARS4 and a screening mark thereof; and the nucleic acid construct is in the form of single-copy replication in the yeast and in the form of high-copy replication in Escherichia coli. The invention also provides a nucleic acid construct capable of carrying out constitutive expression of sgRNA in yeast, a nucleic acid construct used as a receptor vector and a DNA assembling method. According to the invention, two or more to-be-assembled large DNA fragments are successfully assembled in microzyme to form a large plasmid in one shot; so low-efficiency in-vitro digestion recovery, genetic transformation and the like of large DNA fragments are avoided, and the method provided by the invention is more convenient and efficient compared with traditional methods.

Owner:CAS CENT FOR EXCELLENCE IN MOLECULAR PLANT SCI

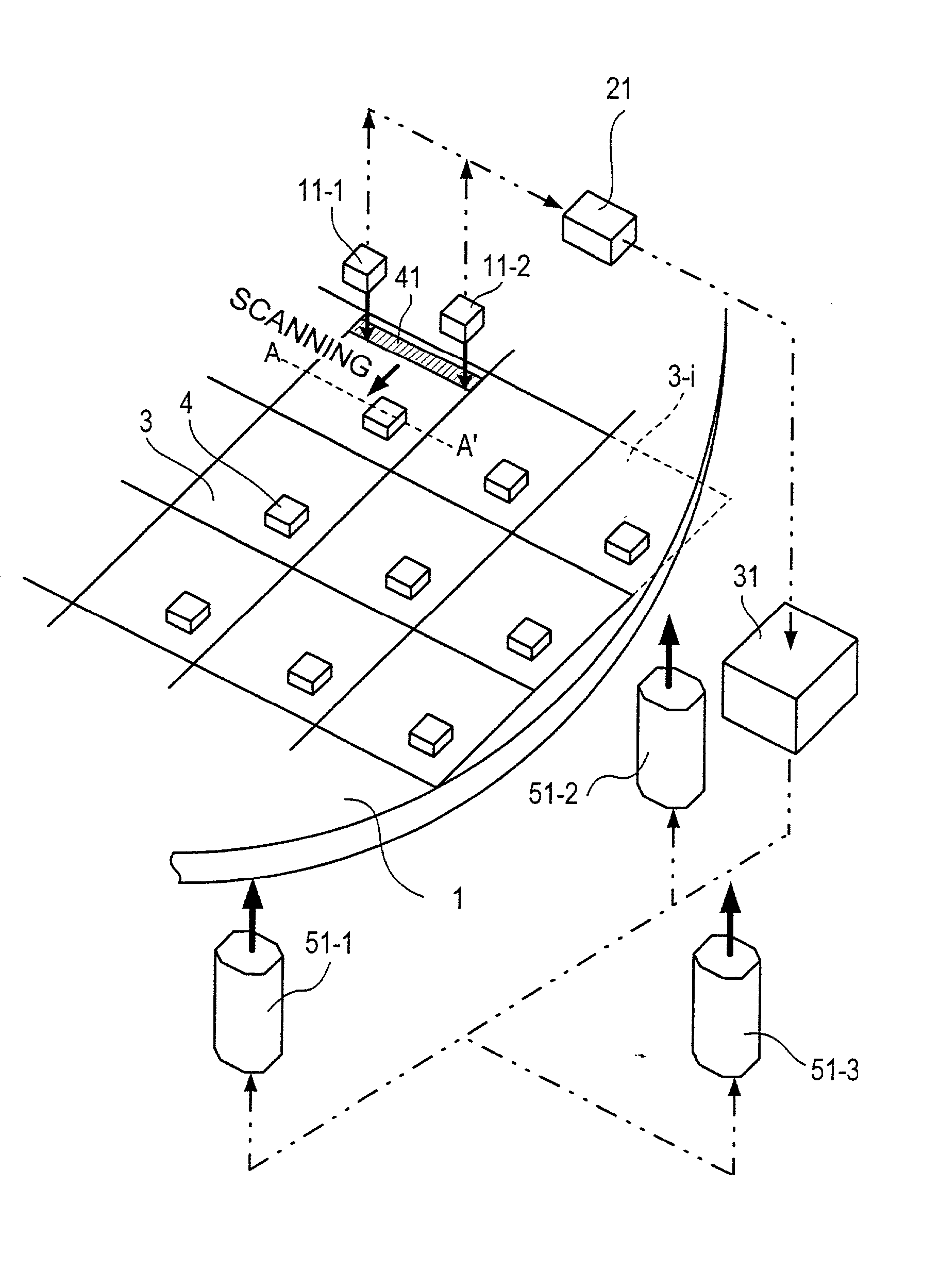

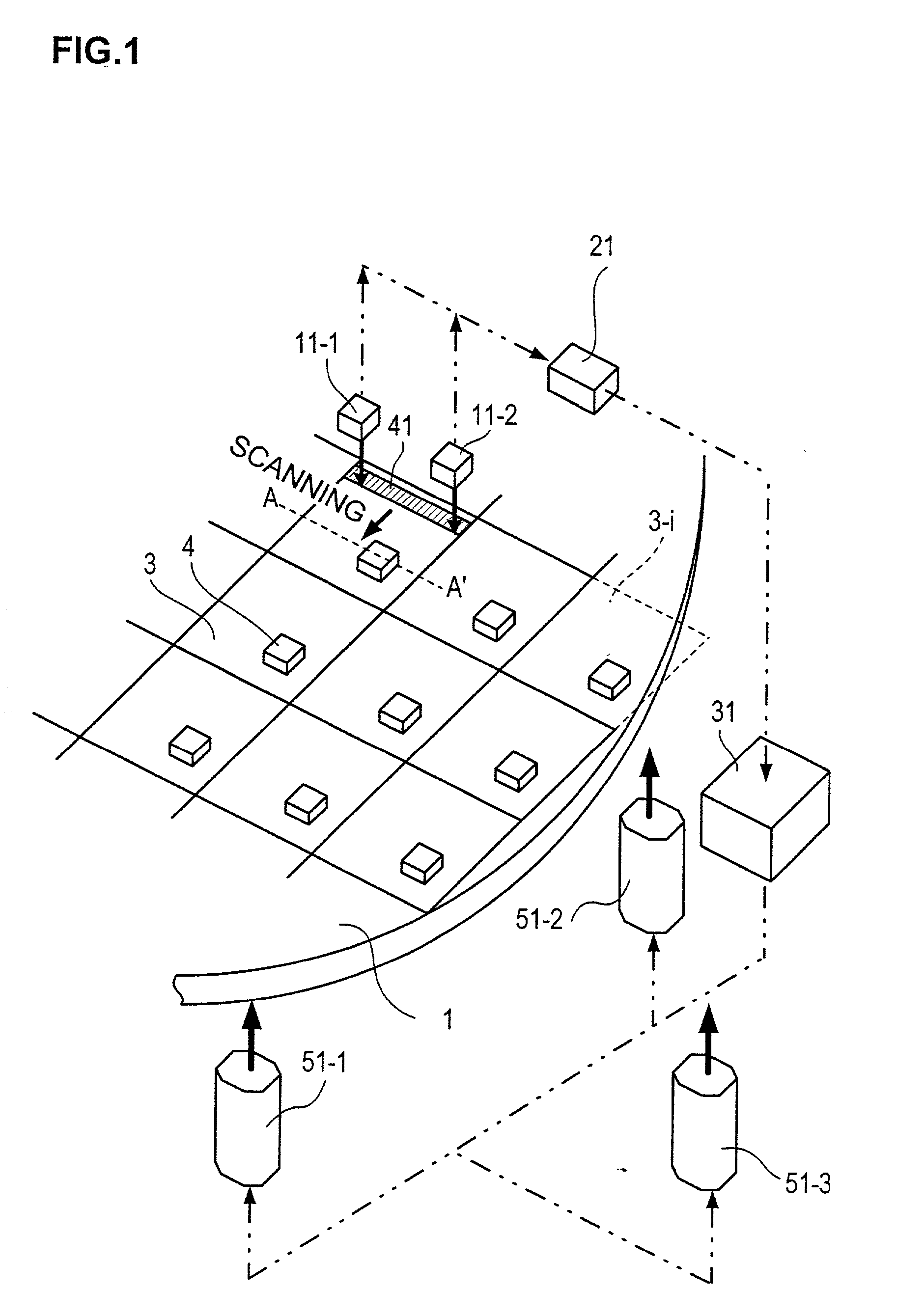

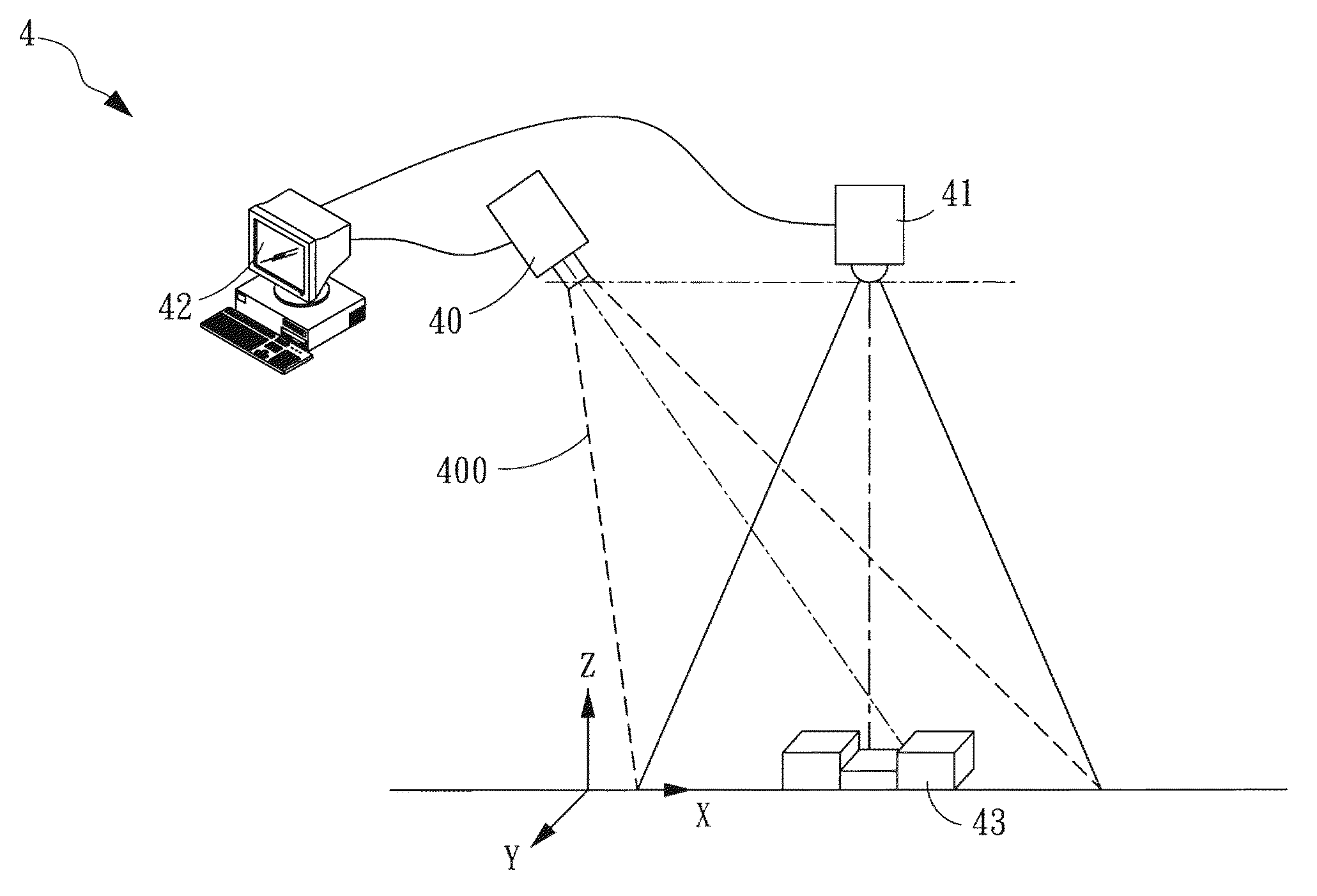

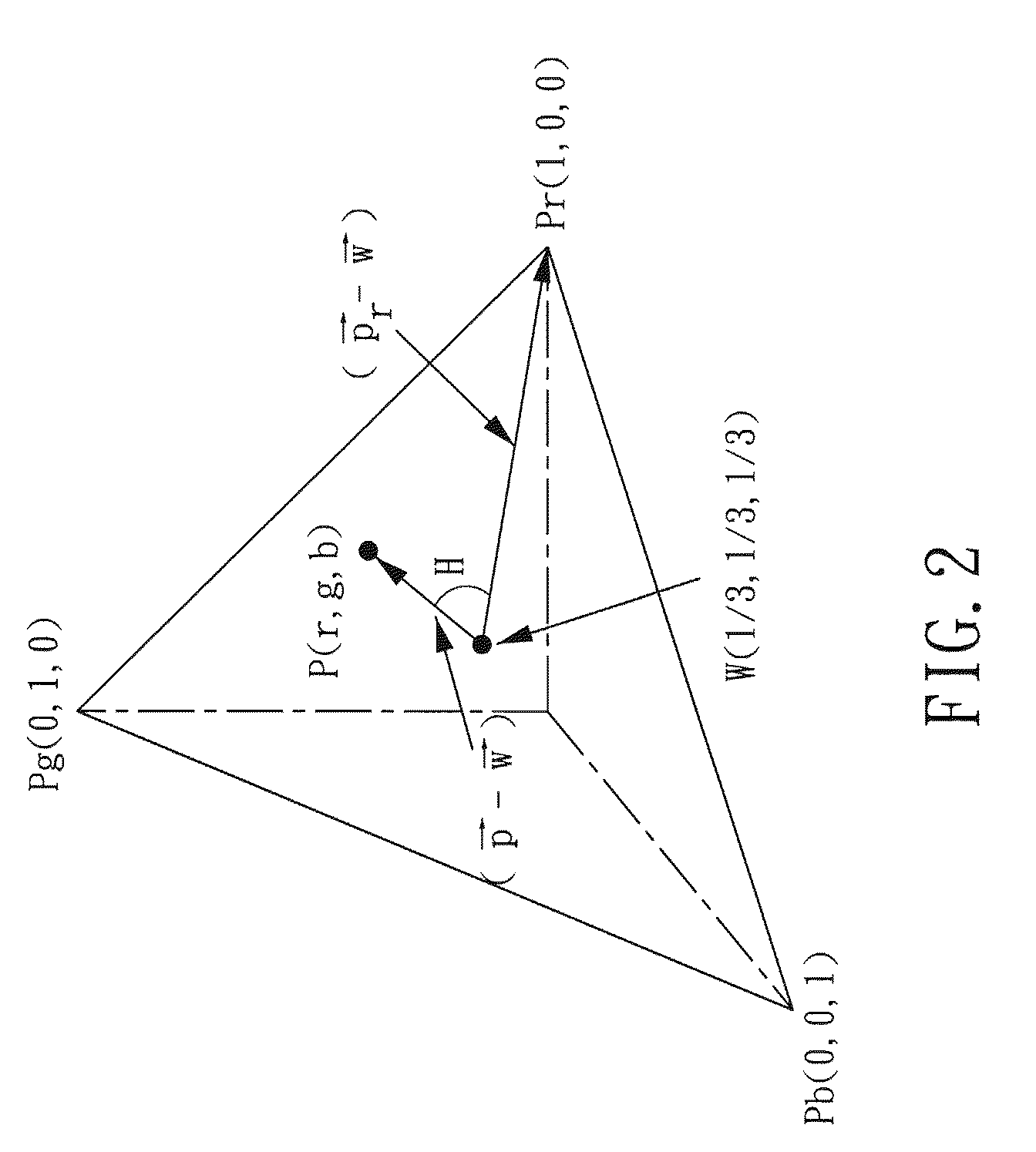

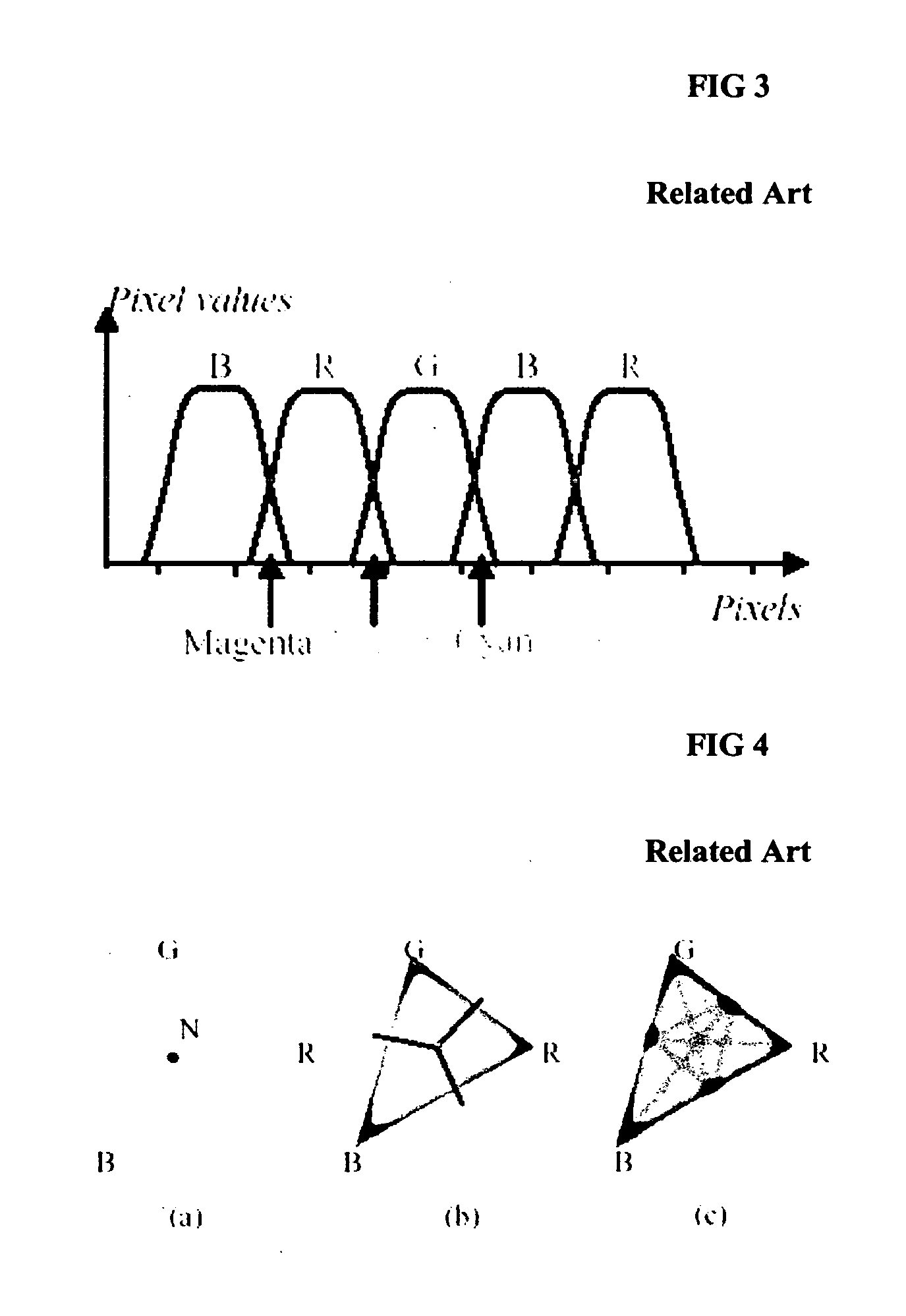

Method for simultaneous hue phase-shifting and system for 3-d surface profilometry using the same

InactiveUS20100188400A1Minimizing undesired effectShorten the timeTelevision system detailsImage analysisColor imagePhase shifted

The present invention provides a method for simultaneous hue phase-shifting and a system for 3-D surface profilometry, wherein a single structured-light fringe pattern with encoded multiple trapezoidal color fringes is projected on an object so as to obtain a color image having deformed fringe patterns and then a hue information extracted from a HSI color model associated with the fringe pattern is transformed into a hue phase-shifting information for restructuring the 3-D surface profile of the object. Since the color structured light is composed of a plurality of colorful light having phase shifts with each other in spatial domain, the single structured-light pattern comprises multiple hue phase-shifting information so that the phase shifting and unwrapping can be performed by one-shot 3-D surface reconstruction process without needs of traditional conventional phase wrapping and Euler's transformation procedures such that the efficiency of phase shifting and 3-D surface measurement can be improved.

Owner:NAT TAIPEI UNIV OF TECH

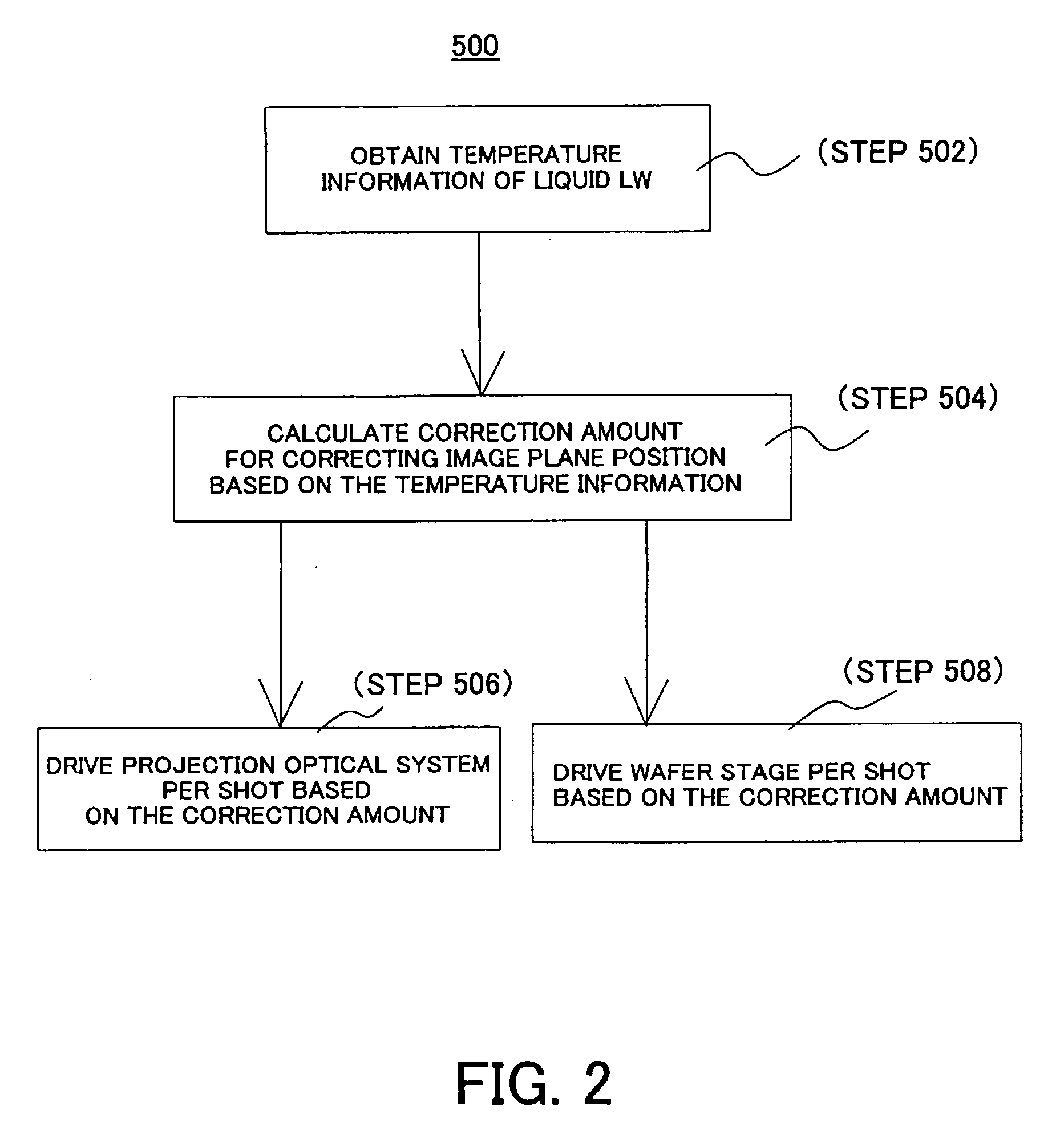

Exposure method and apparatus

InactiveUS20060197930A1High-quality exposurePhotomechanical apparatusPhotographic printingOne shotImage based

An exposure method for exposing an image of a pattern of a mask onto a plate while immersing, in liquid, a space between a final lens of a projection optical system and the plate includes the steps of obtaining temperature information of the liquid, determining a correction amount for correcting a focus position of the image based on the temperature information, and correcting the focus position of the image in synchronization with a scan position for one shot based on the correction amount.

Owner:CANON KK

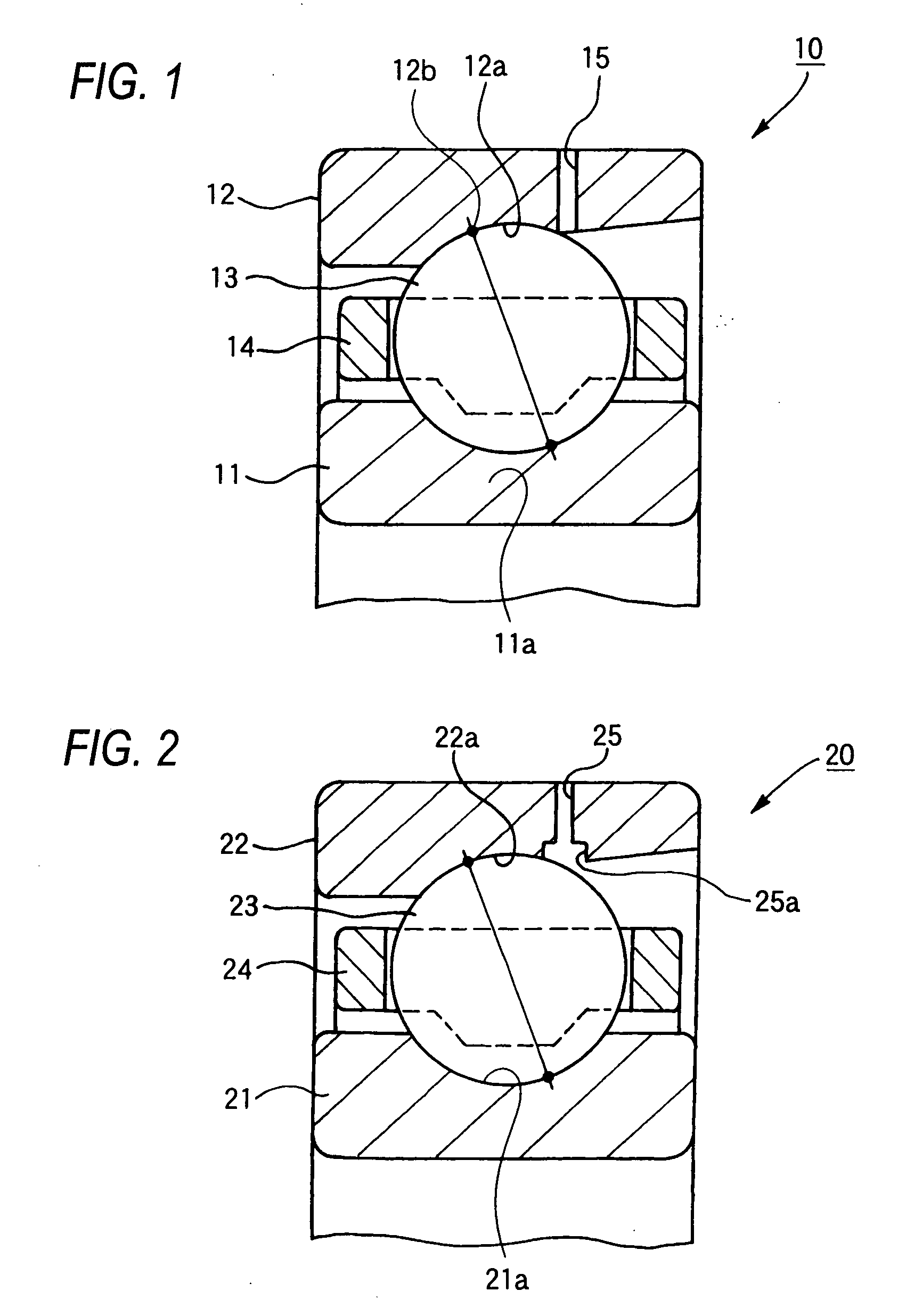

Rolling bearing, grease supply system, sprindle unit, grease supply method, and grease supply program

A spindle unit comprises a rolling bearing including an outer ring having an outer ring raceway on an inner peripheral surface, an inner ring having an inner ring raceway on an outer peripheral surface, and rolling elements provided rollably between the outer ring raceway and the inner ring raceway, whereby a spindle is borne rotatably in a housing, and a grease supply system for supplying a grease to an inside of the rolling bearing, wherein the grease supply system supplies the grease such that a supply amount in one shot is set to 0.004 cc to 0.1 cc.

Owner:NSK LTD

Mould-closing bag-moulding one-shot forming technique for composite material

The invention relates to a process, in particular to a hollow structure composite material closed die bag pressure one-step molding process. In the process, a part higher than a joint part and an upper die composite material decreasing part are preserved during the plastering of a lower die and are integrated to be one close and united body in overlapping and pressuring way under the function of an airbag. Composite materials can be added on the outside of the airbag to achieve higher strength. Meanwhile, multi-airbag external auxiliary composite materials can be adopted to be prepared into stiffened fasting products during the hollow preparation to obtain higher strength. The composite material closed die bag pressure one-step molding process has the advantages of simple equipment, time and labor saving performance, no waste materials, pollution-free, manufactured products with high strength, hollow one-step molding, hollow stiffened one-step molding, and the like, and is an ideal process for manufacturing tower tanks, wind blades, helicopter rotary blades, airplane empennages, etc.

Owner:BEIJING CAIHONG YUXING TECH DEV

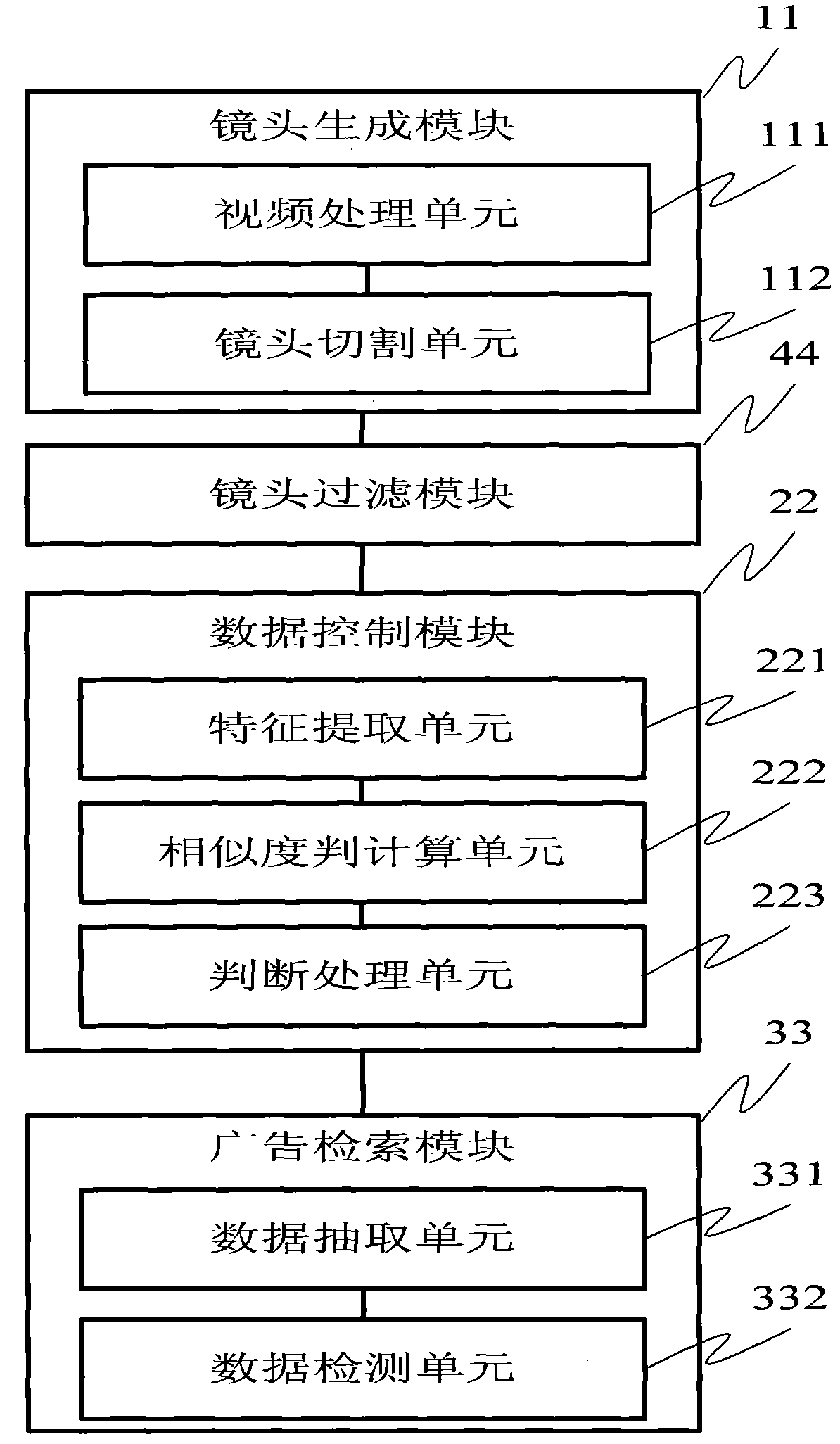

Method and device for detecting television advertisements

InactiveCN101650740AAddresses the shortcoming of not being able to detect ad shot samples that are not pre-stored in the databaseImage analysisSpecial data processing applicationsData controlRelevant information

The invention discloses a method and a device for detecting television advertisements, wherein the method adopts the technical schemes comprising the following steps: generating at least one shot according to a video to be detected; extracting image features of the shot and establishing a database by using the image features, wherein the database stores advertisement shots and corresponding related information; and searching the related information stored in the database so as to detect the television advertisements that appear repeatedly. The device for detecting the television advertisementscomprises a shot generating module, a data control module and an advertisement searching module. By adopting the technical schemes, the invention can detect repeated advertisements in the video and improves the experiences of users.

Owner:UNIV OF SCI & TECH OF CHINA

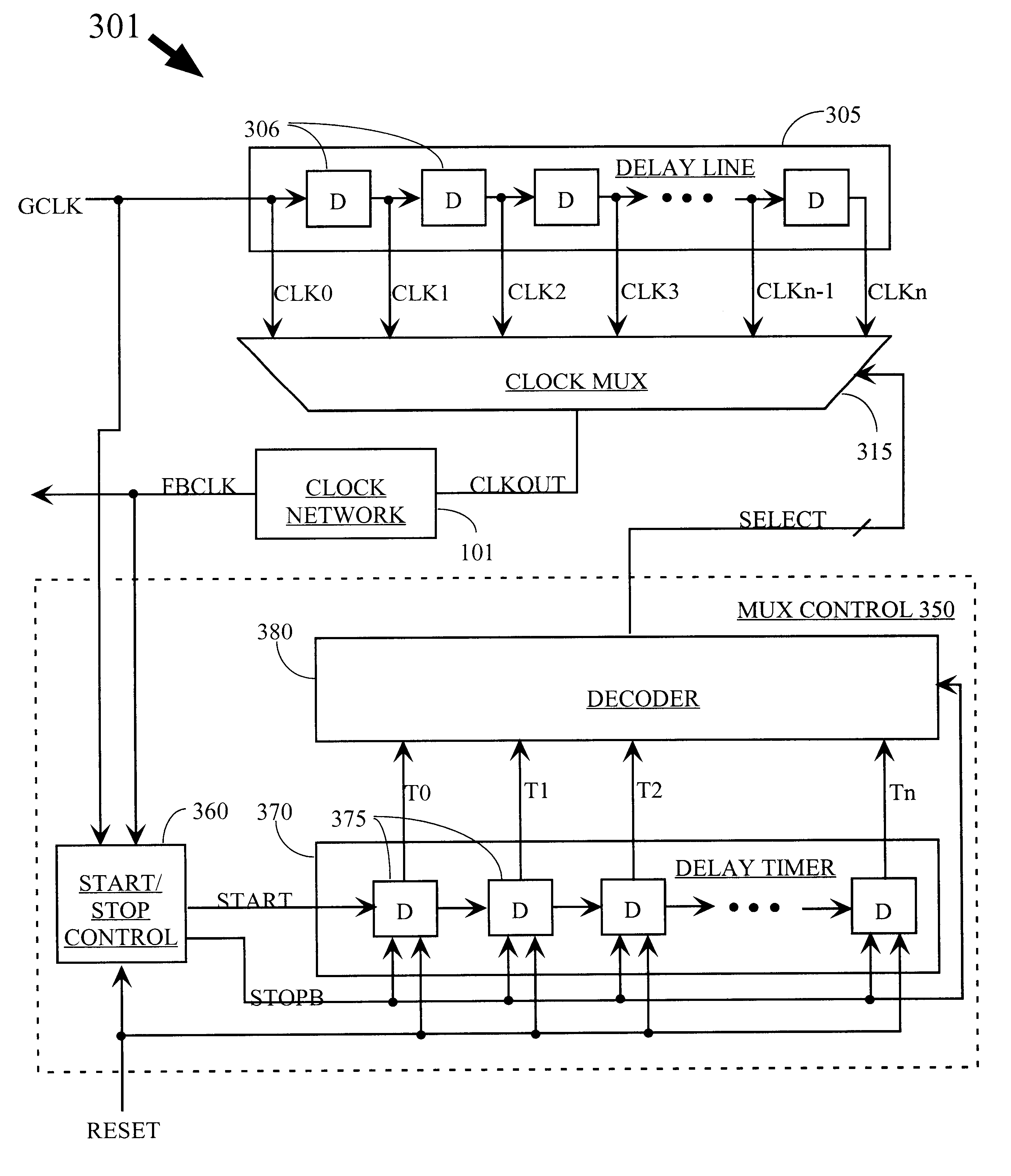

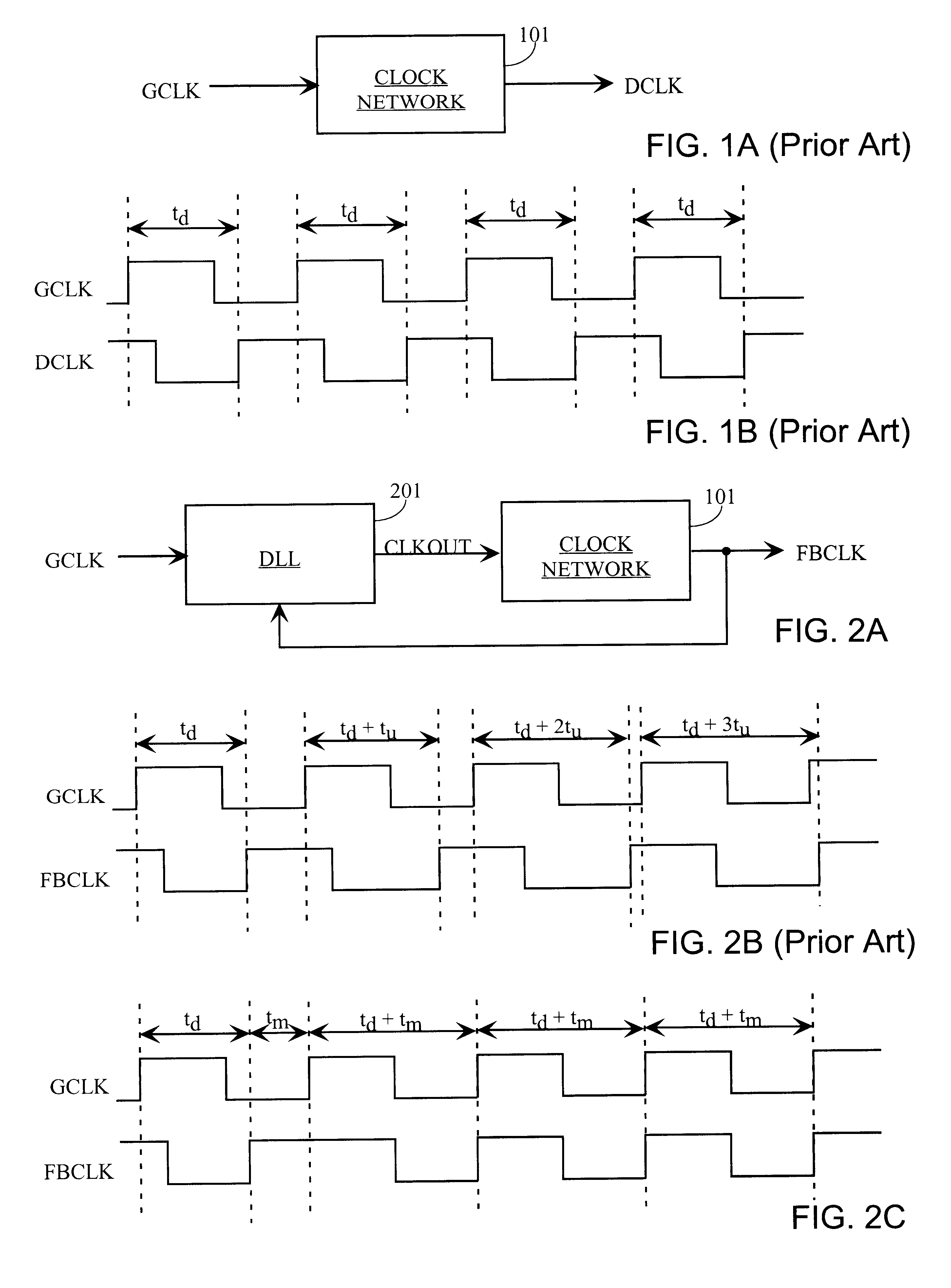

One-shot DLL circuit and method

InactiveUS6255880B1Reduce noiseHigh simulationPulse automatic controlTime-division multiplexMultiplexerDelay-locked loop

A delay-lock loop (DLL) circuit and method that accept an input clock signal and a feedback clock signal, and provide the necessary additional delay to synchronize the feedback clock signal to the input clock signal. Unlike previous circuits and methods, a single synchronization step is sufficient, provided that the frequency of the input clock signal is stable. A circuit according to the invention includes an input clock terminal supplying an input clock signal, and a delay line driven by the input clock signal and supplying a plurality of intermediate clock signals delayed from the input clock signal by incremental unit delays. A clock multiplexer selects from among these intermediate clock signals, under control of a multiplexer control circuit, the clock signal that provides the necessary additional delay to synchronize the feedback clock signal to the input clock signal. The output clock signal from the clock multiplexer is distributed through the clock network to provide the distributed clock signal as well as the feedback clock signal.

Owner:XILINX INC

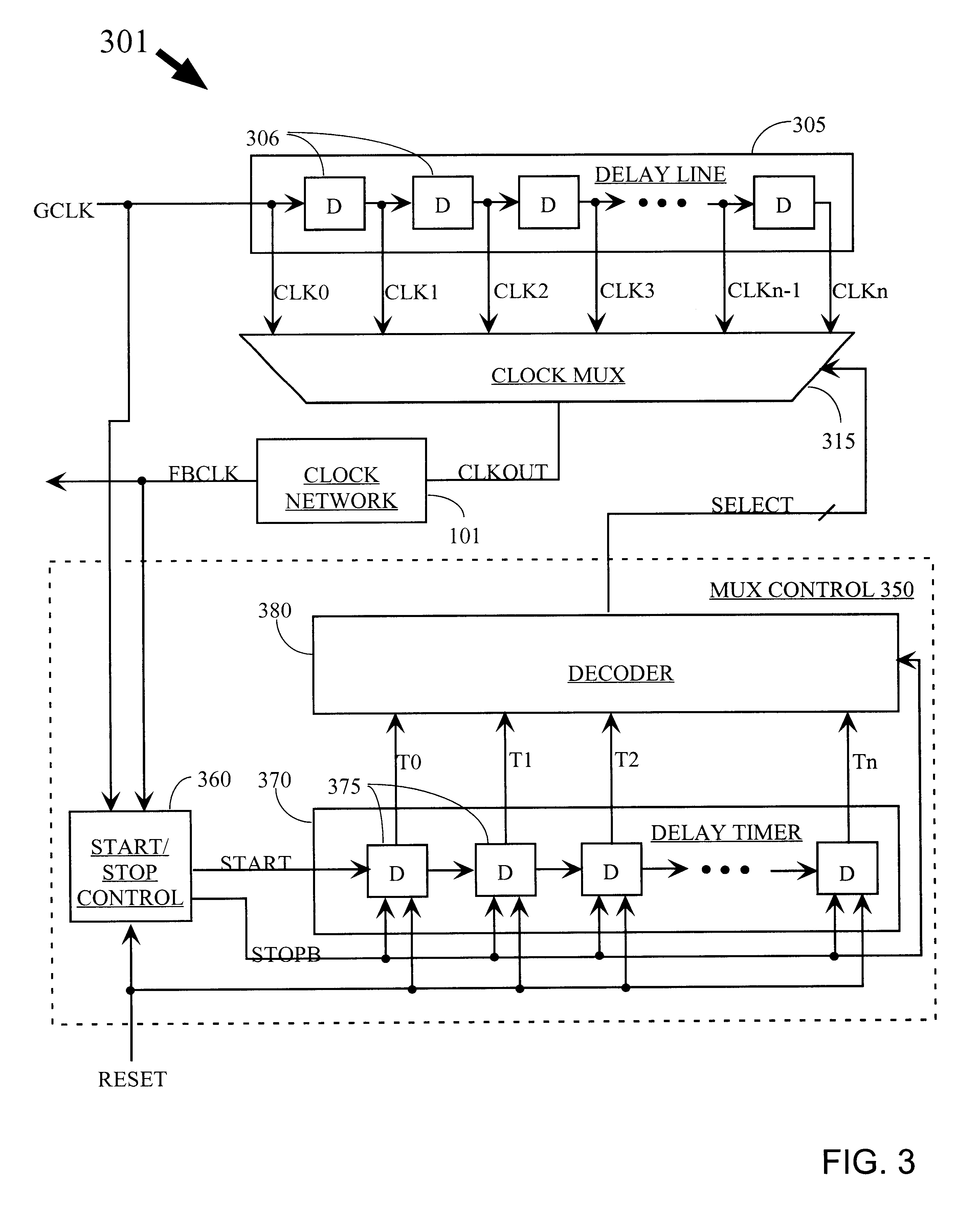

DC-DC converter

ActiveUS20080024104A1Reduce current consumptionReduce switching frequencyDc-dc conversionElectric variable regulationSwitching frequencyEngineering

A DC-DC converter performing pulse frequency modulation (PFM) control with a fixed ON time, having a control circuit performing PFM control of the ON time for a switch, including an error amplifier amplifying the difference between an output voltage and a target voltage, a voltage controlled oscillator increasing and decreasing in frequency and outputting an error signal, and a one-shot circuit generating the ON time based on a trigger signal output from the VCO, where ON time is linked to an input voltage and / or an output voltage. The switching frequency decreases under light loads and current consumption is reduced, and the switching frequency is made to be approximately constant under heavy loads.

Owner:FUJI ELECTRIC CO LTD

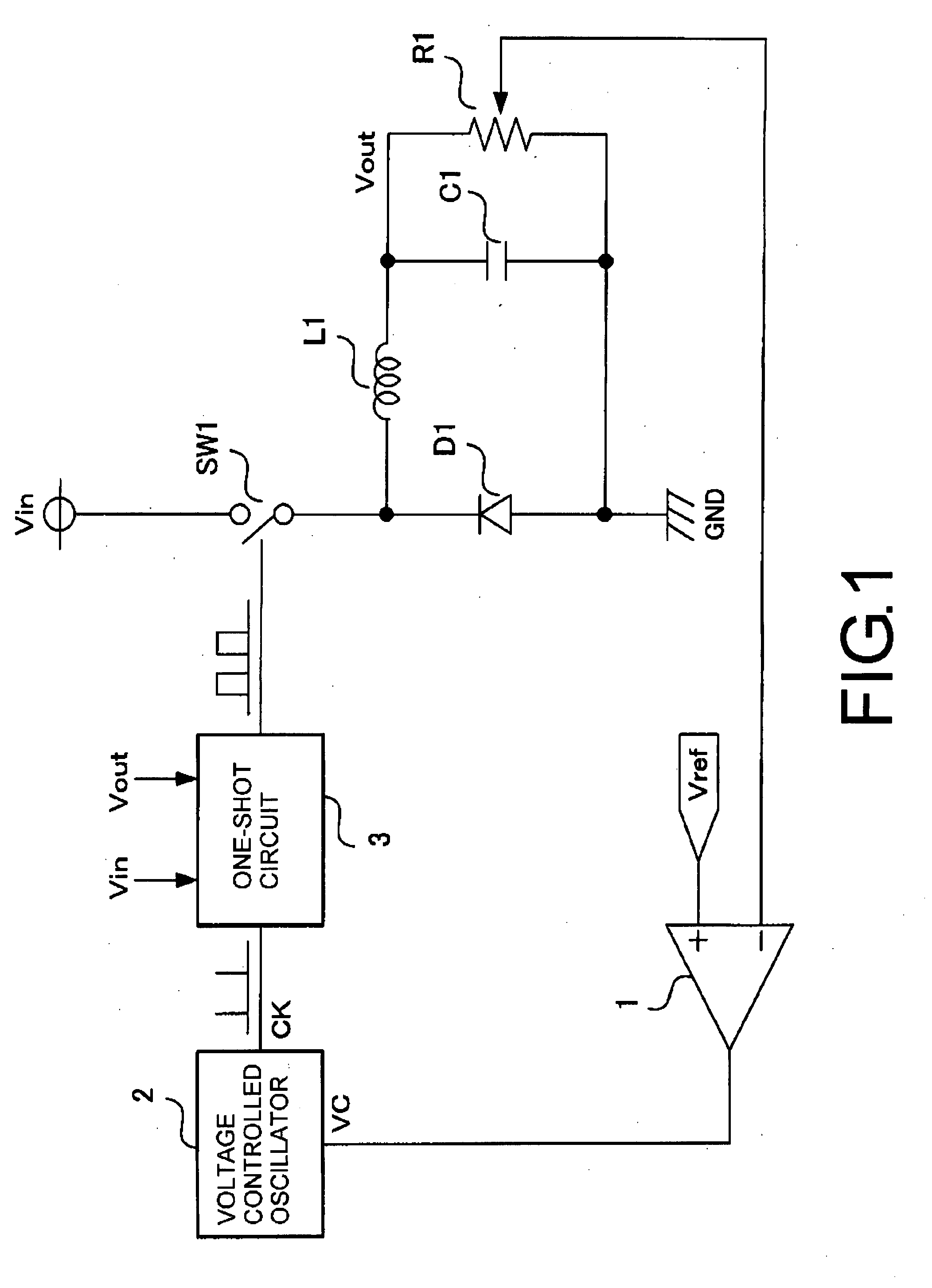

Print head cartridge and method of making a print head cartridge by one-shot injection molding

A print head having an ink reservoir therein is made by forming, in a one-shot plastic injection molding step, a rigid monolithic frame comprising high melt temperature material having an opening therein extending from a first side to a second side, and first and second bonding surfaces surrounding the opening and facing the first and second sides, respectively. First and second thin flexible films are adhesively secured to the first and second bonding surfaces, respectively. The adhesive material may be a hot melt adhesive or dry adhesive films pre-formed to the shape of the bonding surfaces. By securing the flexible films to the bonding surfaces adhesively, rather than by heat staking, it is not necessary to form the frame of different materials during two separate molding steps.

Owner:FUNAI ELECTRIC CO LTD

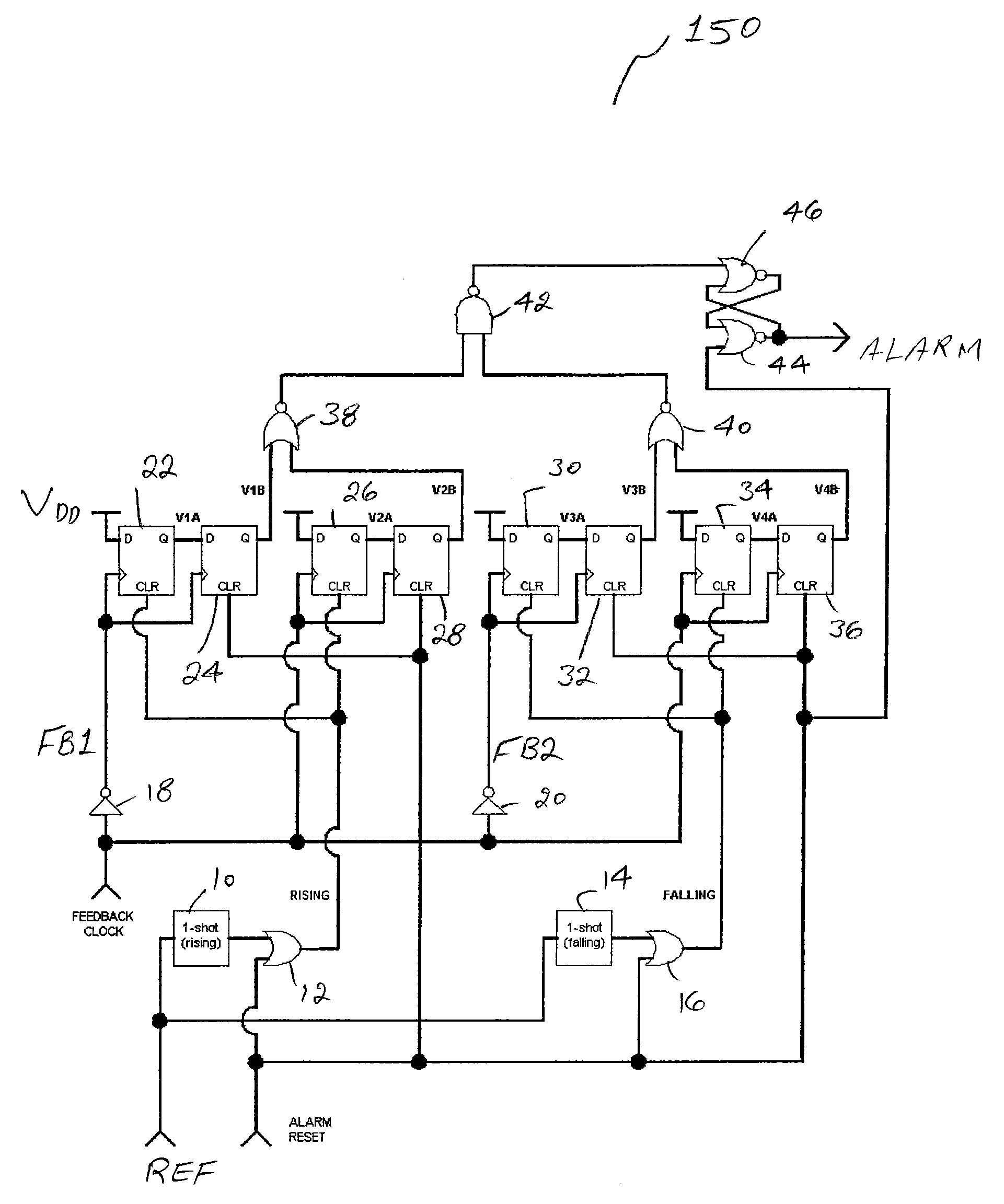

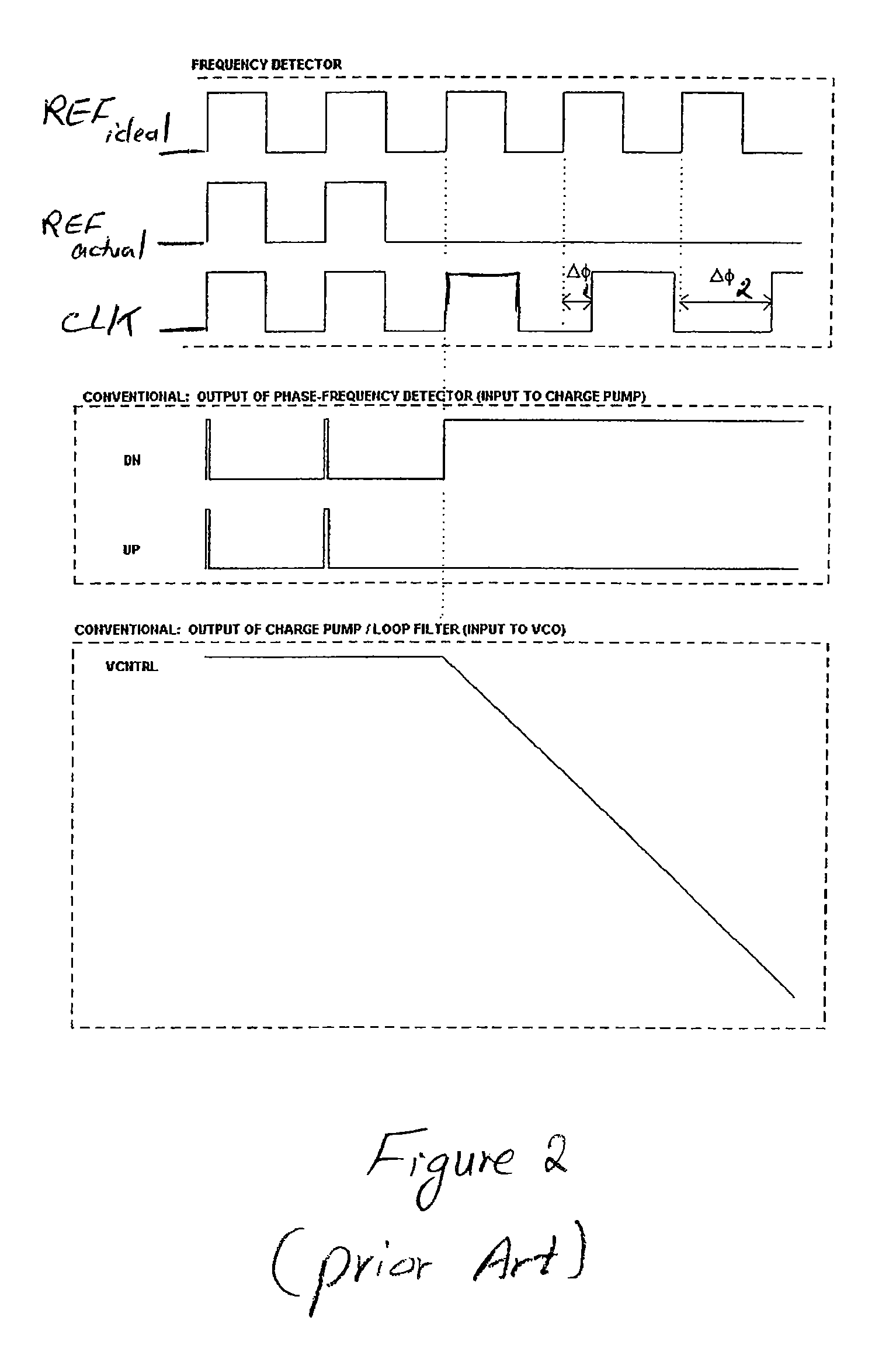

Means to detect a missing pulse and reduce the associated PLL phase bump

A phase / frequency locked loop (PLL) includes circuitry adapted to detect missing pulses of a reference clock and to control the phase bump of the PLL. The circuitry includes, in part, first and second flip-flops, as well as a one-shot block. The first flip-flop has a data input terminal responsive to a voltage supply, and a clock terminal responsive to an inverse of feedback clock. The second flip-flop has a data input terminal responsive to an output of the first flip-flop, and a clock terminal responsive to the inverse of the feedback clock. The one-shot block generates a pulse in response to a rising edge of the reference clock that is used to generate the feedback clock. The one-shot block generates an output signal applied to a reset terminal of the first flip-flop.

Owner:EXAR CORP

Method for generating structured-light pattern

InactiveUS20050116952A1Character and pattern recognitionCathode-ray tube indicatorsColor transformationAmbiguity

A method for generating a structured-light pattern is disclosed, wherein high-resolution real-time three-dimensional (3D) data can be obtained by using a single frame (or one-shot) imaging or double frames (or two-shot) imaging methods. The structured-light pattern for the one-shot imaging is formed of a multiple-stripe color pattern using a color selection scheme and a sequence principle. The proposed color selection scheme reduces the ambiguity in stripe labeling in one-shot imaging, and the proposed sequence principle increases the number of distinguishable stripe codes. The structured-light pattern for two-shot imaging is formed so that three-dimensional (3D) data can be obtained even for objects having strong surface colors with ambient lights, wherein the first two-shot pattern is synthesized, thereby forming a multiple-stripe color pattern using sign codes and a sequence principle under a condition that prevents color-transitions in more than one channels from occurring. Subsequently, the second two-shot pattern is formed by reversing the first two-shot pattern. Accordingly, high-resolution real-time three-dimensional (3D) data, which is insensitive to object shape and surface color, system noise and nonlinearity, can be obtained.

Owner:IND UNIV COOP FOUND SOGANG UNIV +1

One Shot Injector with Dual Springs

ActiveUS20100249705A1High viscosityIncrease in sizeAutomatic syringesIntravenous devicesEngineeringOne shot

Owner:SHL MEDICAL AG

Method and apparatus for improving image transfer in liquid electrostatic printing

A method for improving image transfer in one-shot liquid electrostatic printing, comprising providing at least one layer of toner to an intermediate transfer member, and selectively applying a wetting substance to said at least one toner layer, prior to transfer of said image to a final substrate.

Owner:HEWLETT PACKARD DEV CO LP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com