Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Heat storage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coffee carbon fiber plush printed blanket and preparation method thereof

InactiveCN102162170AIncrease weaving densityReduce stretch deformationCarbon fibresWarp knittingEngineeringAcrylic fiber

The invention discloses a coffee carbon fiber plush printed blanket and a preparation method thereof. The blanket is knitted by a double-needle-bed warp knitting machine; and the plush yarn of the blanket is a yarn obtained by blended knitting of coffee carbon fibers and acrylic fibers, wherein the double-yarn specification of the yarn obtained by the blended knitting is 28-36s; the base material terylene is warped, and then the coiled head is used as the knitting yarn and weft insertion yarn of the blanket. The preparation method comprises the following steps: starching and high-temperature setting of a white grey cloth, fuzzing, lustering, shearing, flat screen printing, aging and fixation, washing, dehydrating and drying, carding, fuzzing, lustering, shearing, binding and packaging and warehousing. The coffee carbon fiber plush printed blanket disclosed by the invention has the characteristics of bright color, soft handfeel, heat accumulation, warm keeping and the like, special healthcare functions of dehumidification, anion release, antibacterium and the like, and advantages of economy and environmental protection.

Owner:JIANGSU QIYING HOME TEXTILE

Respirable high-flame-retardance outer-wall facing material

The invention discloses a respirable high-flame-retardance outer-wall facing material, which comprises redispersible latex powder, an organic-silicon water repellent, methylcellulose ether, a defoaming agent, an air-entraining agent, lignocellulose, a thixotropic lubricant, silicate cement, heavy calcium powder, fly ash, calcium hydroxide, starch ether, calcium formate and colored quartz sand. The respirable high-flame-retardance outer-wall facing material has the advantages of reasonable proportion, energy saving and environmental protection, and not only are the quality and the service lifeof an outer-wall heat-preserving system ensured, and heat-preserving heat-absorbing heat-storing performances are enhanced, but also the service life of a building wall body is greatly prolonged.

Owner:SHANDONG FENGYU ENERGY SAVING MATERIAL MFG

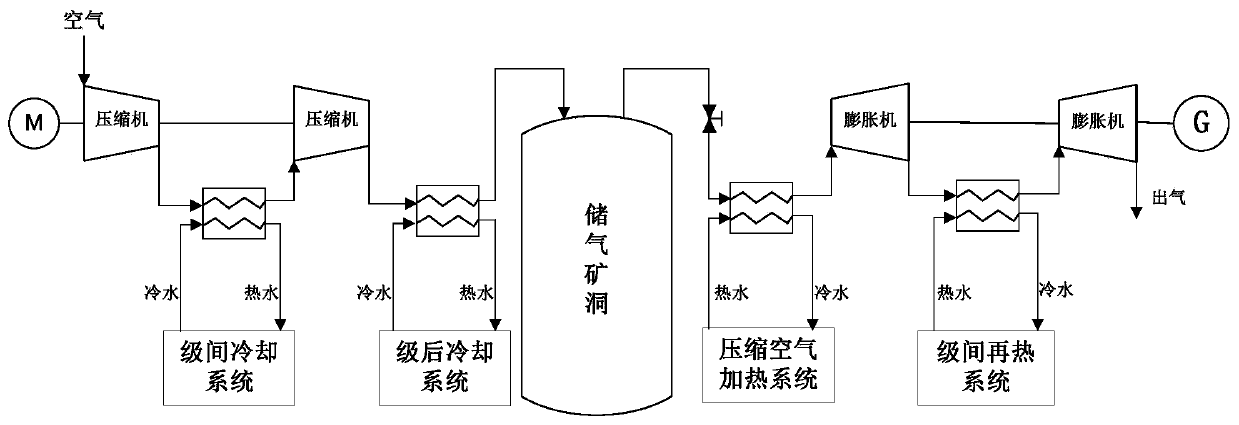

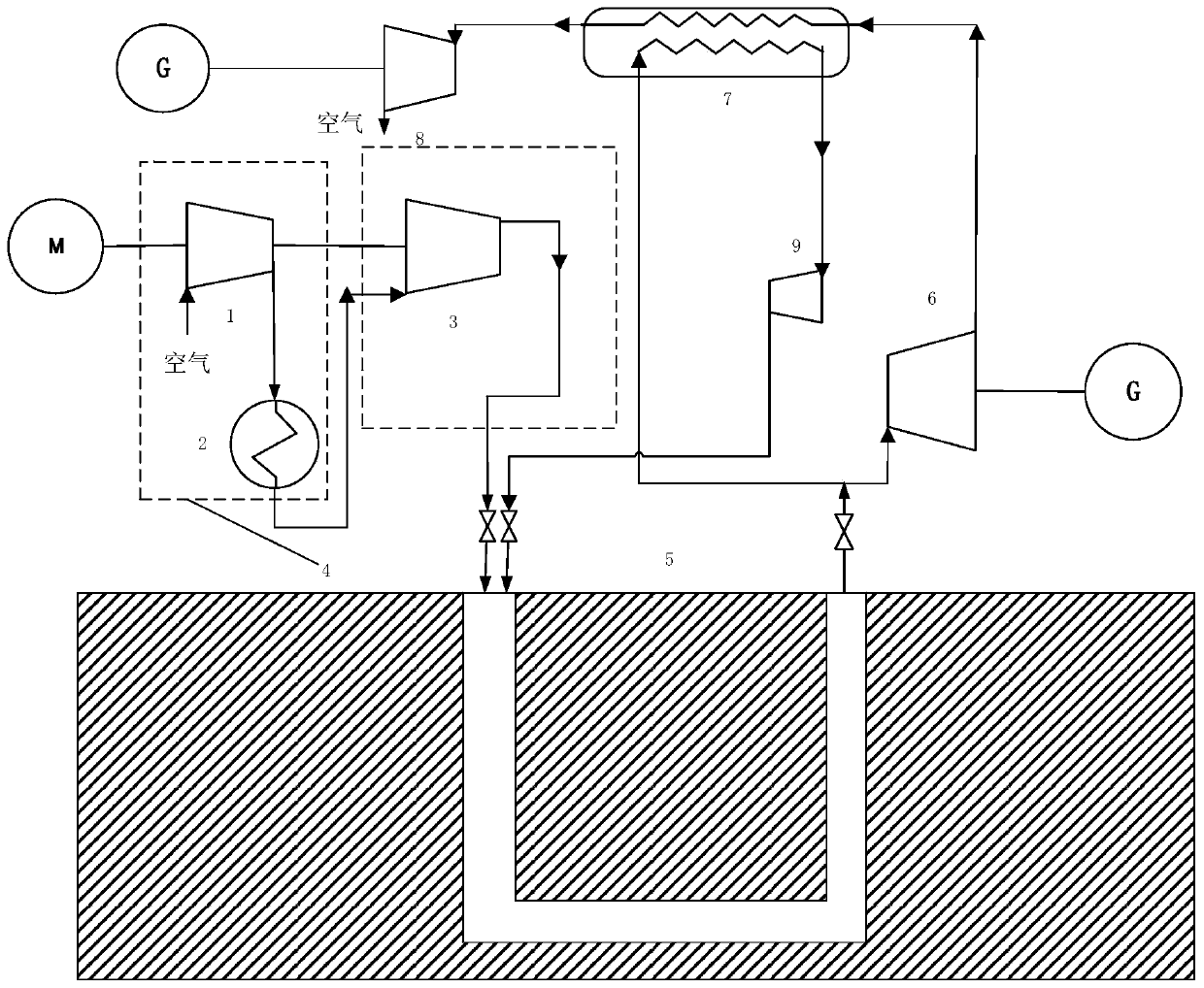

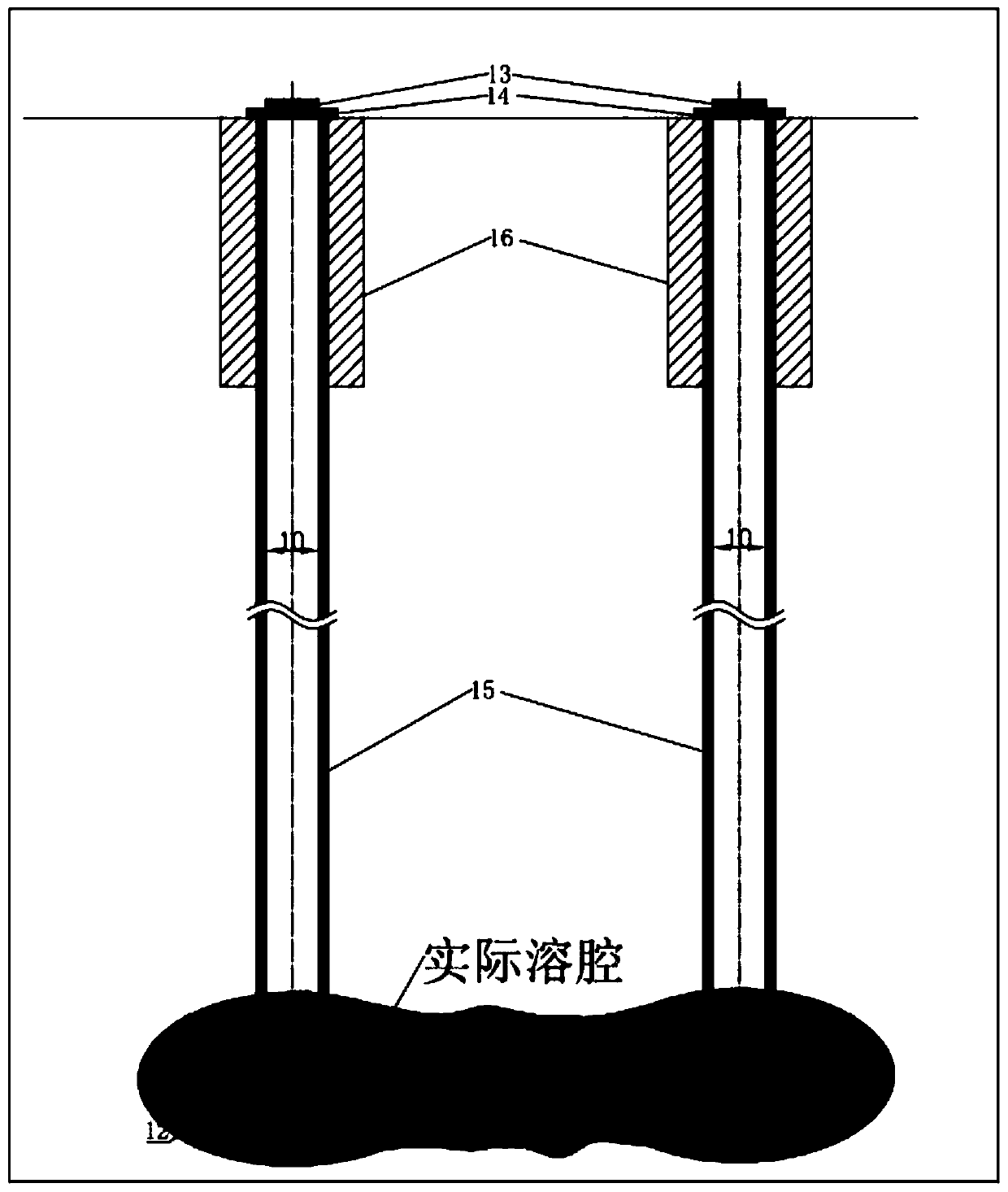

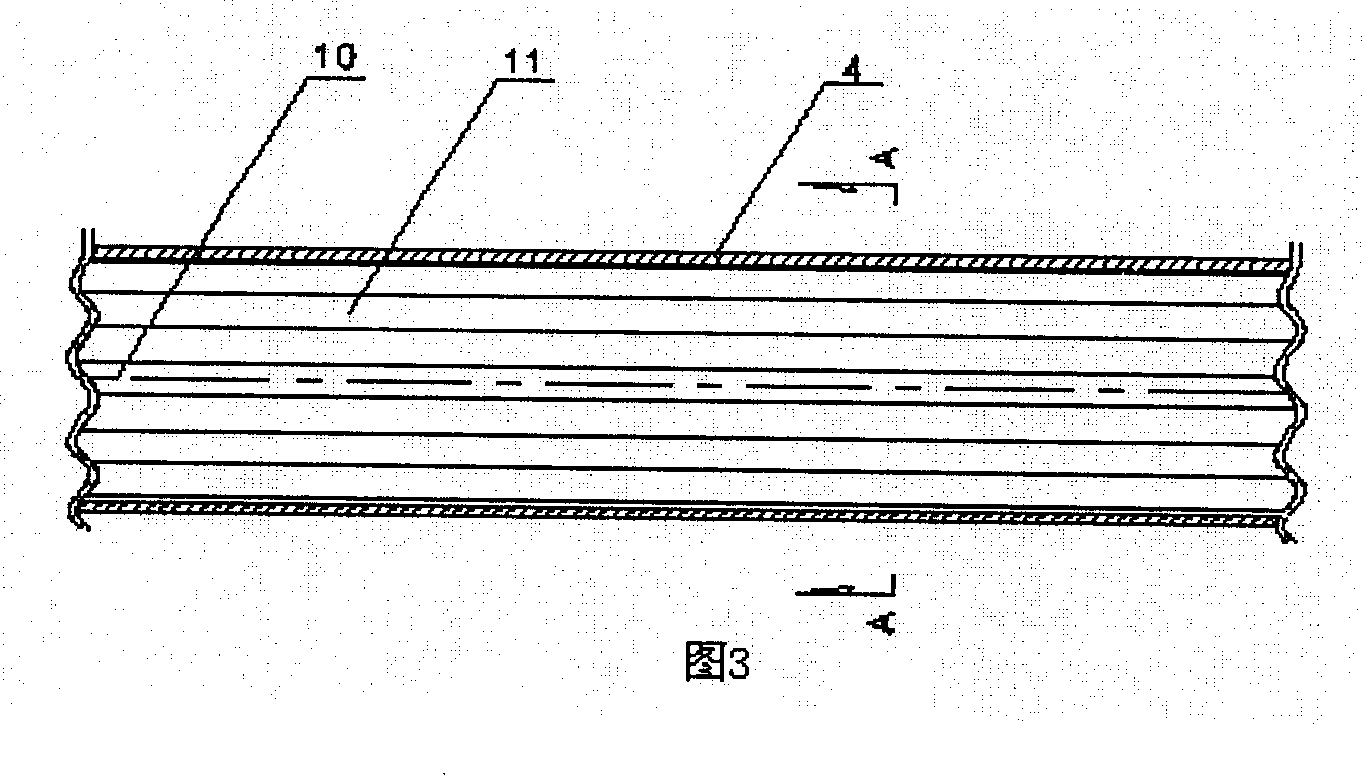

Auxiliary pressurizing reheating type compressed air energy storage system and method based on double-well structure hot salt well

ActiveCN110259662AImprove efficiencyHeatingGeothermal energy generationInsulationAir compressionThermal energy storage

The invention discloses an auxiliary pressurizing reheating type compressed air energy storage system and method based on a double-well structure hot salt well. Usage of a heat storage device is eliminated, the situation that fuel is consumed for heating is avoided, and cost and pollution are reduced. The system comprises a progressive compression unit used for being connected with a motor for energy storage, the double-well structure hot salt well for gas storage, an expansion unit used for being connected with a power generator for energy releasing, and an auxiliary pressurizing reheating loop for expansion gas heating. The double-well structure hot salt well comprises two vertical wells and a horizontal well communicating with the two vertical wells from the bottom. A top end opening in one vertical well serves as a salt well gas storage inlet, and a top end opening in the other vertical well serves as a salt well exhaust outlet. The progressive compression unit comprises two levels of air compression units which are sequentially connected, and the power input end of at least one level of air compression unit is connected with the output end of the motor. An air outlet of the progressive compression unit is connected with the salt well gas storage inlet. The auxiliary pressurizing reheating loop comprises a heat exchanger and a pressurizing machine which are sequentially connected with air as acting media.

Owner:XI AN JIAOTONG UNIV

Composite phase-change heat-storage heating method and heating apparatus

InactiveCN1731028AImprove heat storage capacityReduce volumeCentral heating with accumulated heatLighting and heating apparatusElectricityPhase change

The new composite phase changing heat accumulating heating technology includes adding heat accumulating pipe and heat accumulating capsule into traditional electric heating set and filling heat medium in the gaps. The heat accumulating medium takes phase change while being heated and cooled to form one latent heat accumulating process. The heat medium acts as the fluid medium for heat transfer between the heated surface and the heat accumulating medium to strengthen the heat transfer inside the heat accumulating medium on one hand, and takes temperature change as one sensible heat process accompanying the heat accumulating and releasing on the other hand. The technology of the present invention can strengthen the heat transfer process inside heat accumulating medium, raise heat accumulating capacity and decrease size of heat accumulating apparatus.

Owner:BEIJING UNIV OF TECH

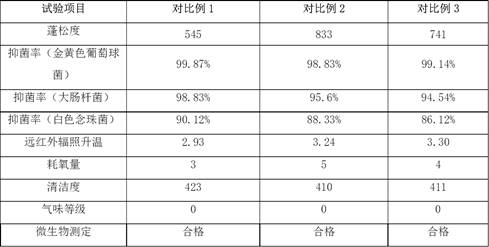

Heat-insulating fluffy down quilt and preparation process thereof

ActiveCN109911837AGood anti-felting performanceReduce damage rateBlanketBed linenPre treatmentAnti bacterial

The invention discloses a heat-insulating fluffy down quilt and a preparation process thereof. The heat-insulating fluffy down quilt comprises a down quilt cover and an inner core, wherein the inner core is coated with the down quilt cover; the inner core is filled with bamboo charcoal fibers and pretreated wool and down feather. The heat-insulating fluffy down quilt is prepared by the following steps: 1) pretreatment of down feather: sterilizing-stem removal of raw materials-removal of sand dust-refining-primary cleaning-washing-dehydration-drying; 2) pretreatment of wool; 3) preparation of the down quilt: uniformly mixing the bamboo charcoal fibers and the pretreated wool and down feather, and then filling an inner core sleeve of the down quilt with the mixture. According to the heat-insulating fluffy down quilt disclosed by the invention, the down feather, wool and bamboo charcoal fibers are taken as the raw materials, the down feather is screened twice through a down feather screening machine to select high-quality large down feather, and then mixed with the wool and bamboo charcoal fibers for filling, and the mixture is treated with an anti-bacterial agent, so that the prepared down quilt has a good anti-bacterial effect, heat-insulating performance and fluffiness.

Owner:宁波博洋家纺集团有限公司

Artificial wig fibers containing peacock feather and having heat accumulation effect

InactiveCN105887236ADoes not damage the structureDoes not destroy colorConjugated cellulose/protein artificial filamentsGrip property fibresBiocompatibility TestingCarbon nanotube

The invention discloses artificial wig fibers containing peacock feather and having a heat accumulation effect. The wig fibers have the following steps of: (1) mixing polyacrylonitrile and collagen as a spinning raw solution, wherein composite fibers prepared from the spinning solution have good biocompatibility and excellent skin-friendly experience; (2) the peacock feather is treated into nanometer-magnitude fillers, so that natural biological structure and color of the peacock feather are not damaged and the natural feeling of the fibers is improved; nano bamboo charcoal powder and carbon nanotubes are added so that the fibers have the effects of accumulating heat, preserving heat, adjusting humidity and the like; and (3) the wig fibers prepared by the invention have the advantages of smooth hand feeling and skin friendliness, softness and dropping, heat accumulation and heat preservation and humidity elimination and foreign odor removal, and the quality and grade of synthetic fiber type wigs are remarkably improved.

Owner:ANHUI PEACOCK PRINCESS ARTS & CRAFTS CO LTD

Bamboo-charcoal wet guide type polyester fiber and preparation method and application thereof

InactiveCN102560727ADeodorizingHeat storageMelt spinning methodsFilament-forming treatmentPolyresinBamboo charcoal

The invention discloses a bamboo-charcoal wet guide type polyester fiber and a preparation method and application thereof. The bamboo-charcoal wet guide type polyester fiber is prepared by the following raw materials in part by weight: 10 to 20 parts of active carbon masterbatch and 80 to 90 parts of polyester fiber forming resin, wherein the section of the fiber is abnormally shaped. The polyester fiber has high adsorption, deodorization, bacteriostatic and mildewproof functions; a pre-oriented yarn is prepared by an abnormally-shaped spinning plate; a low-elasticity textured filament yarn is prepared by elastic deformation; and the multifunctional polyester fiber with a wet guide function is obtained, and has a wide application range. The method for preparing the bamboo-charcoal wet guide type polyester fiber is high in operability, rational in process and high in production efficiency, and industrial production can be realized.

Owner:WUJIANG SANHUI TEXTILE

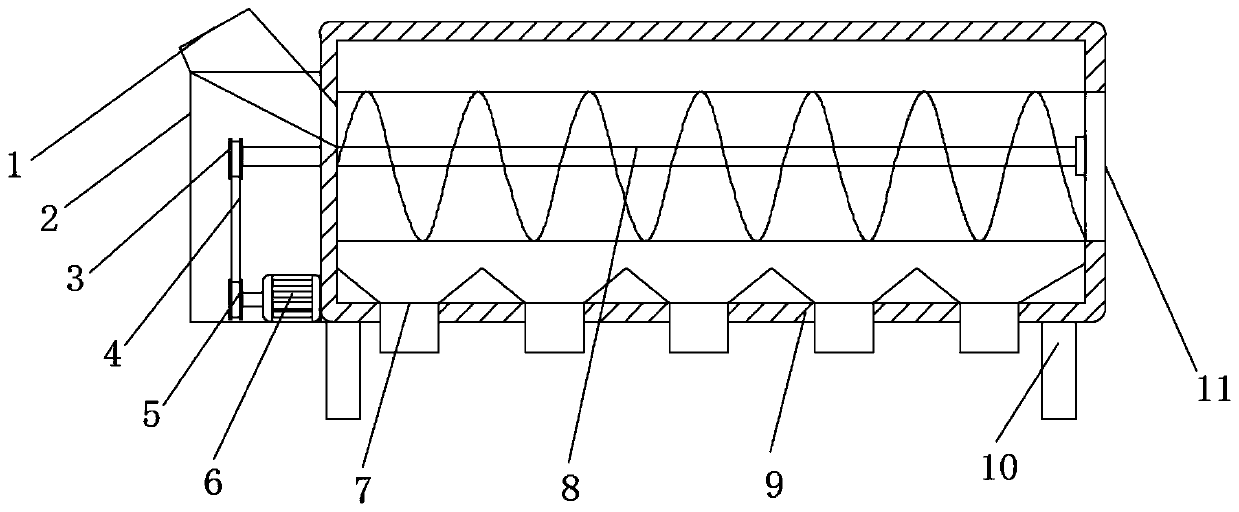

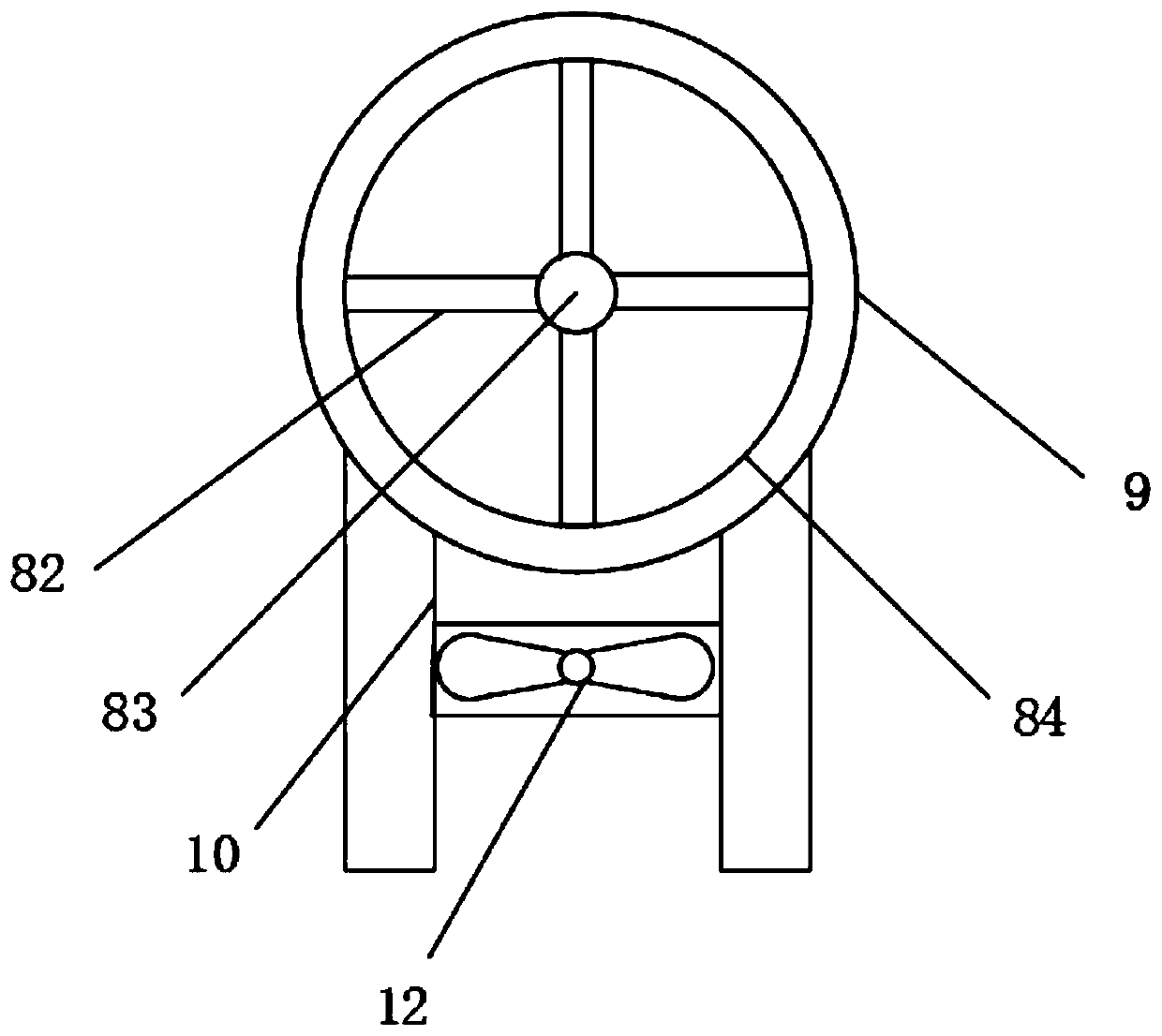

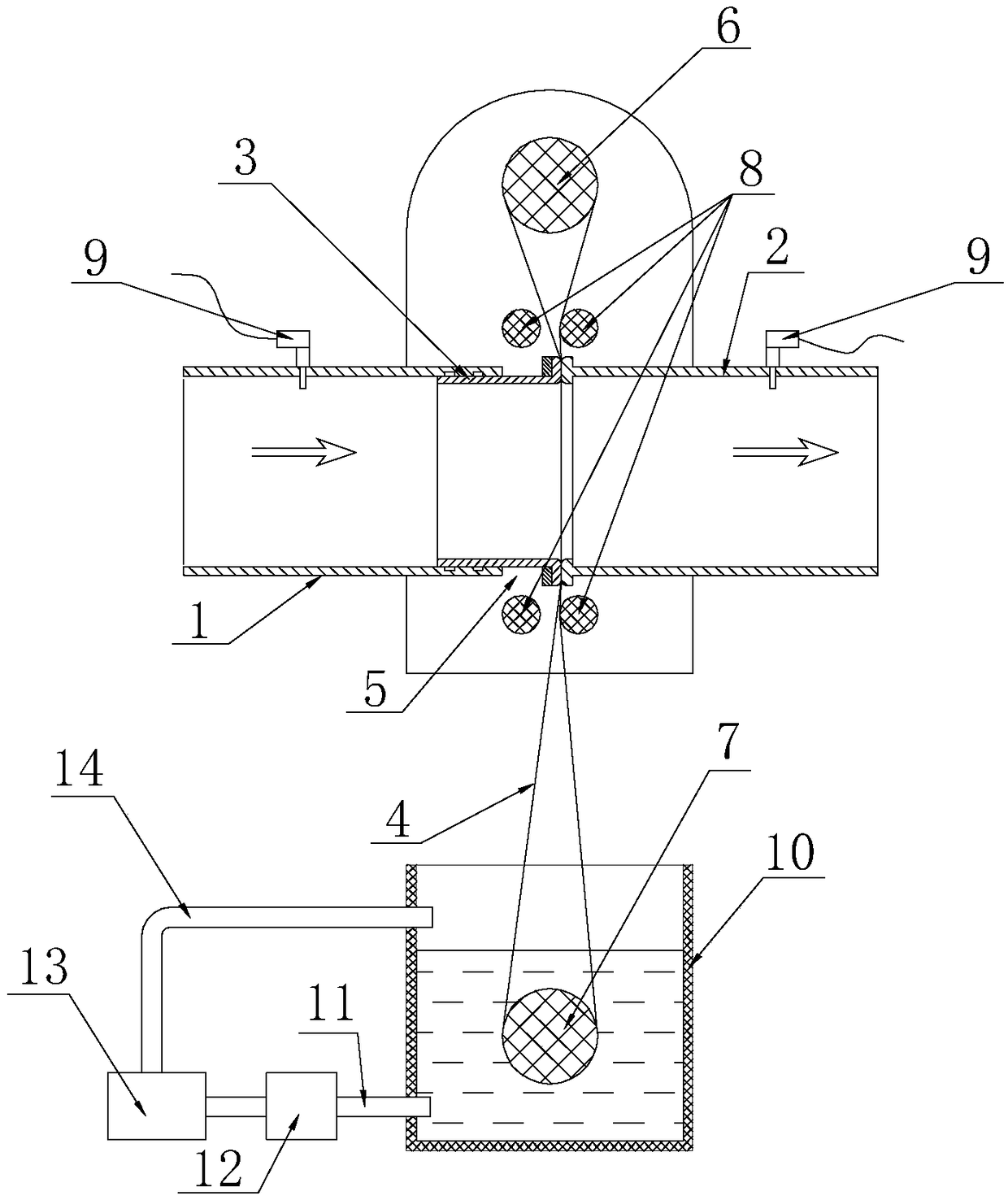

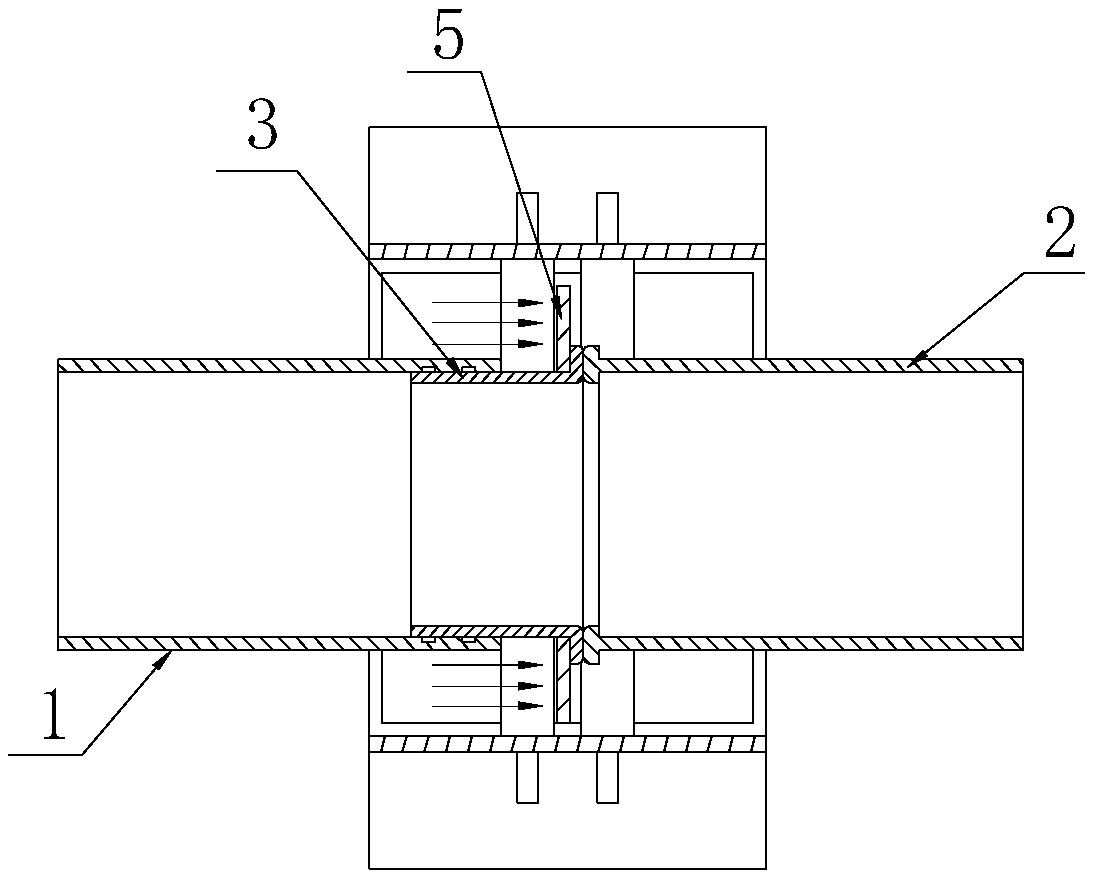

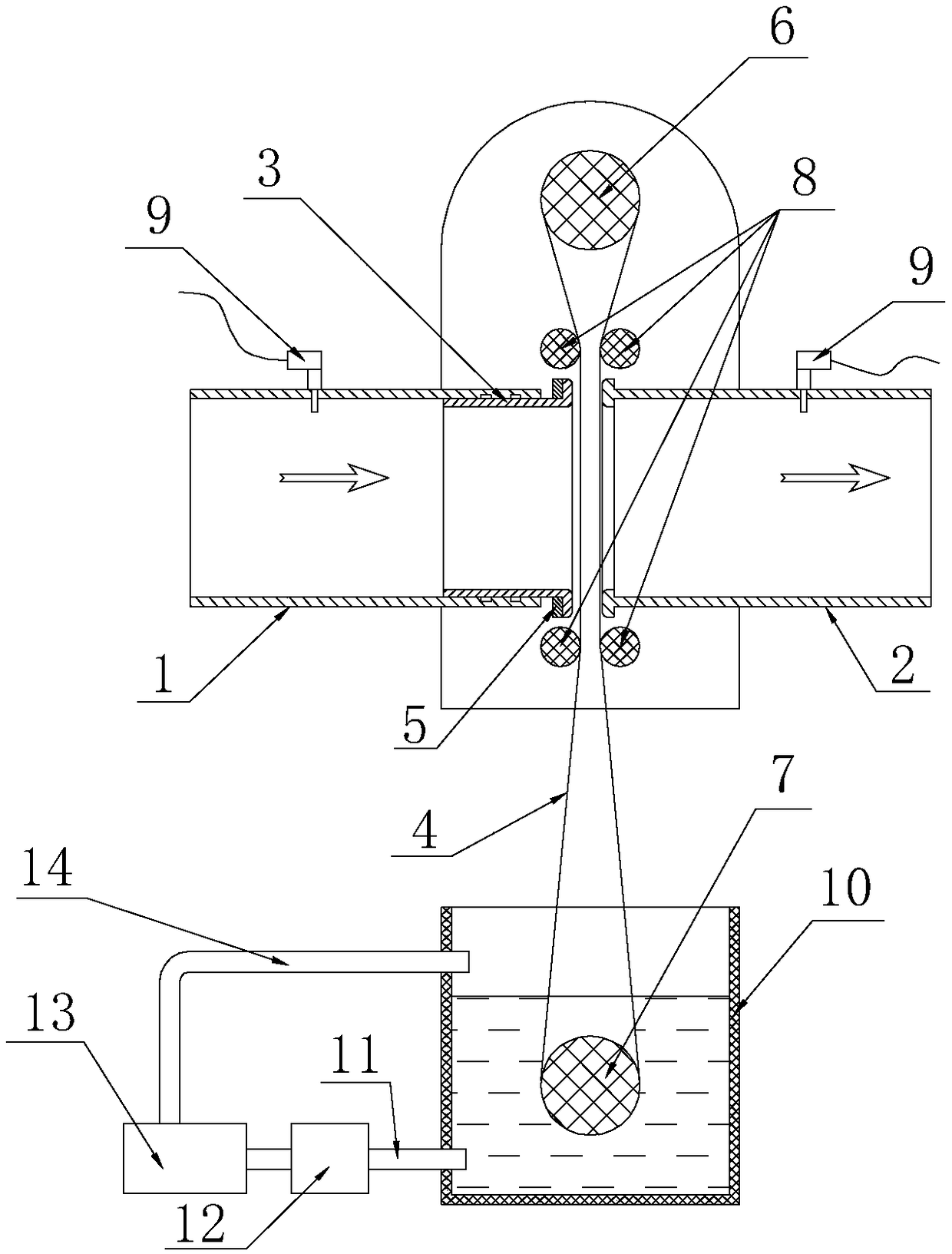

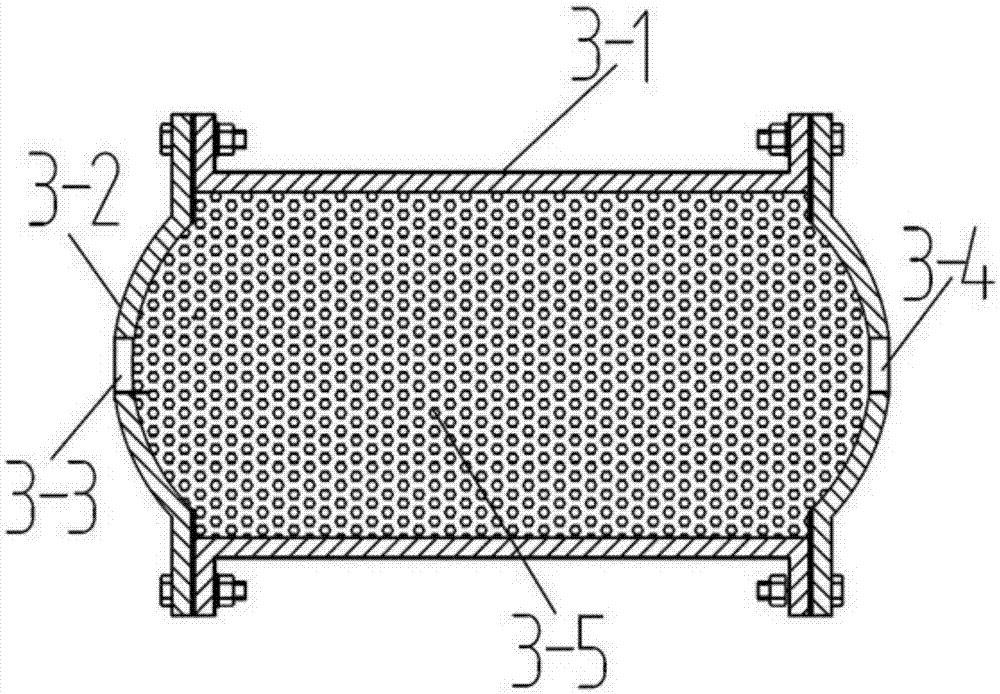

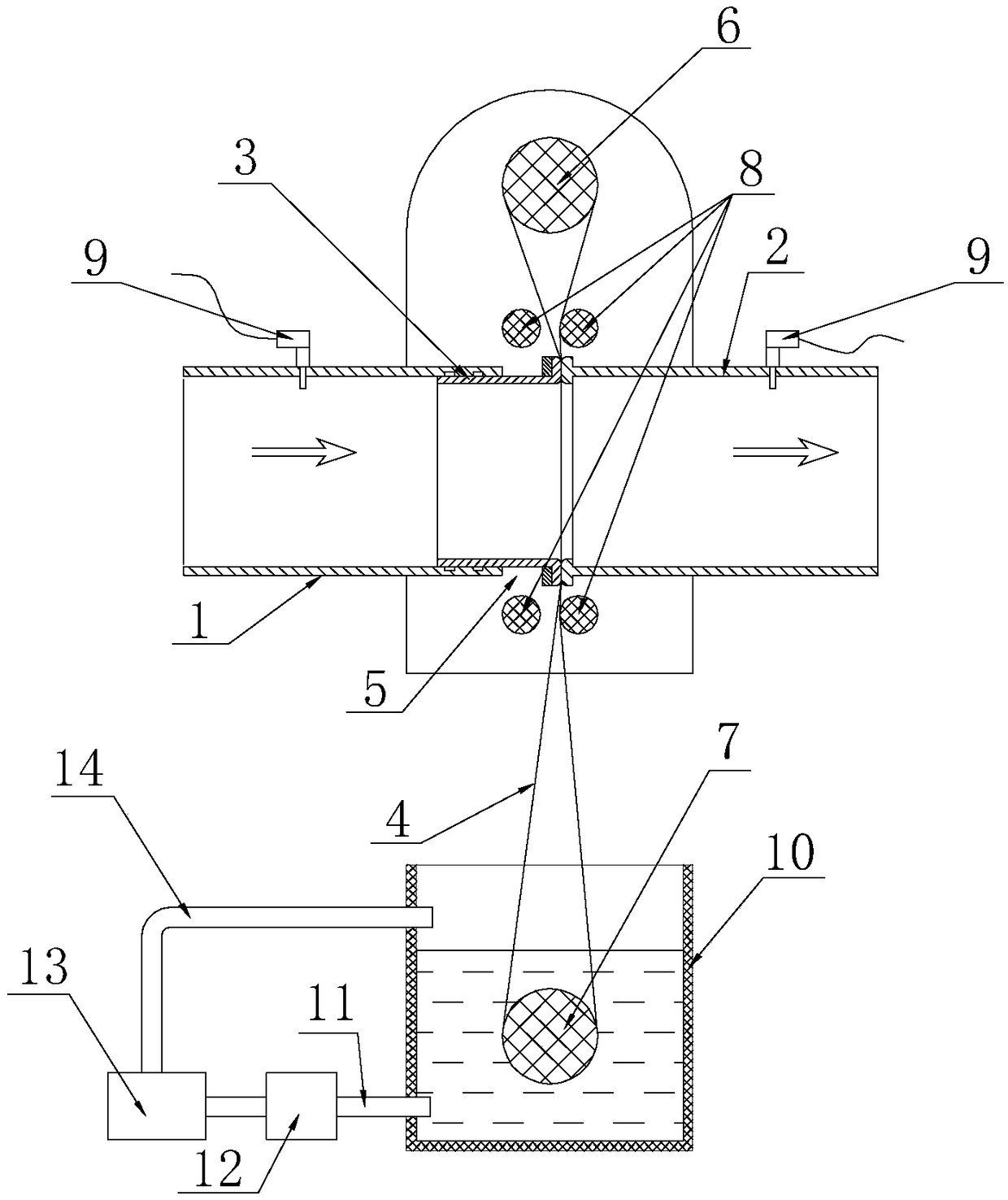

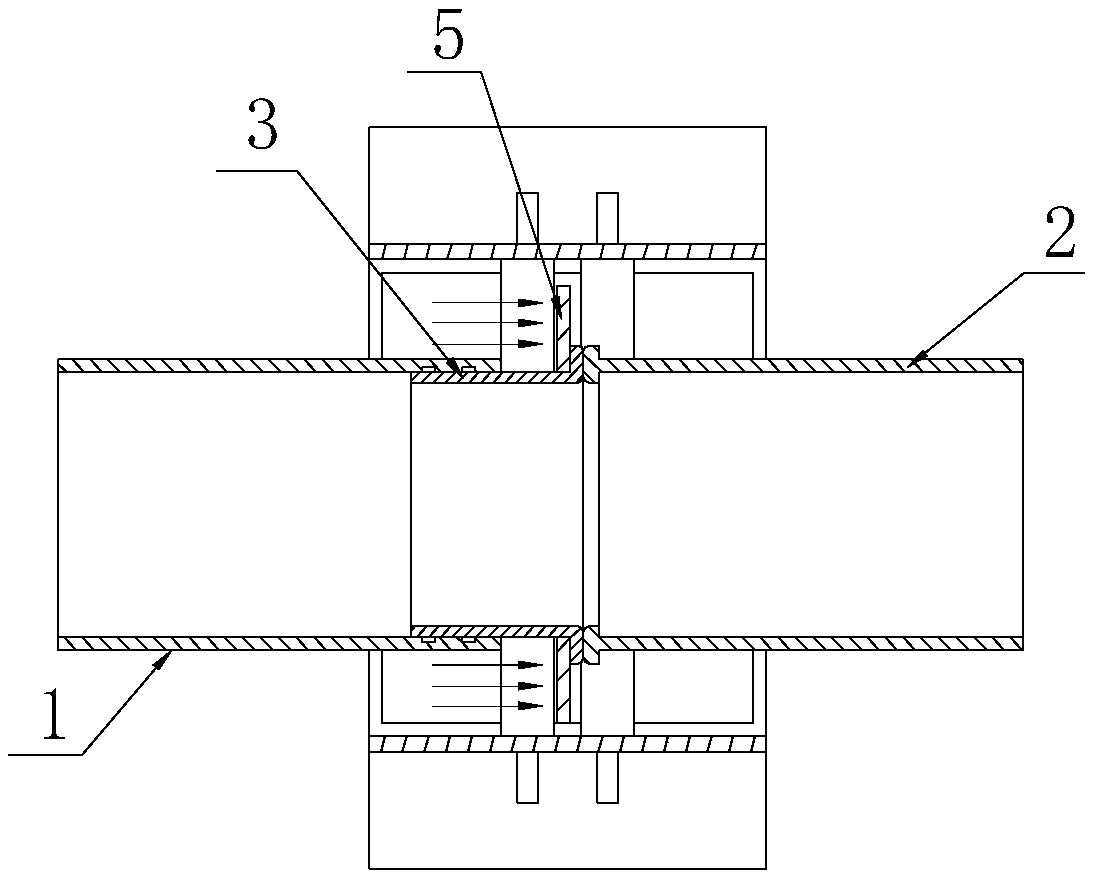

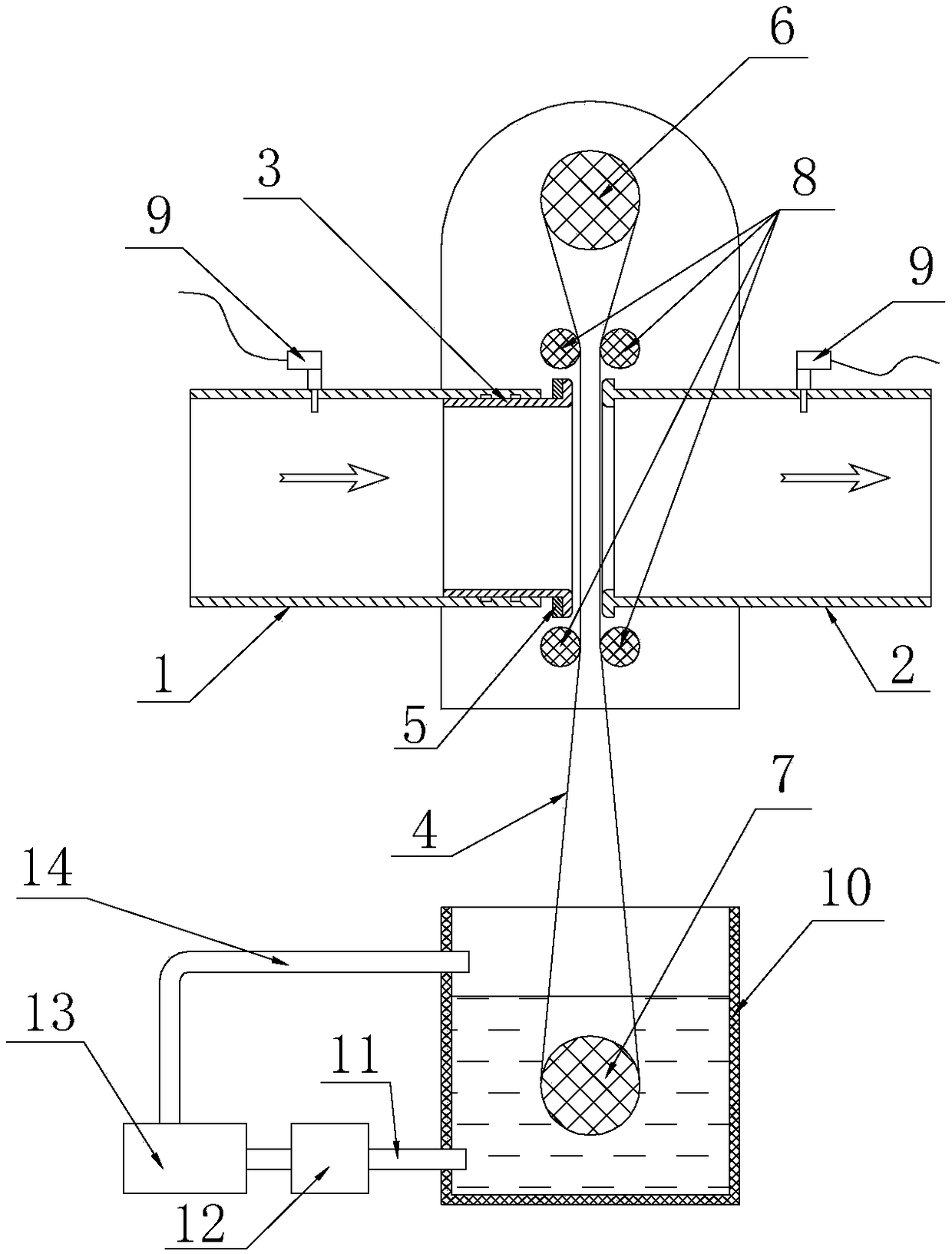

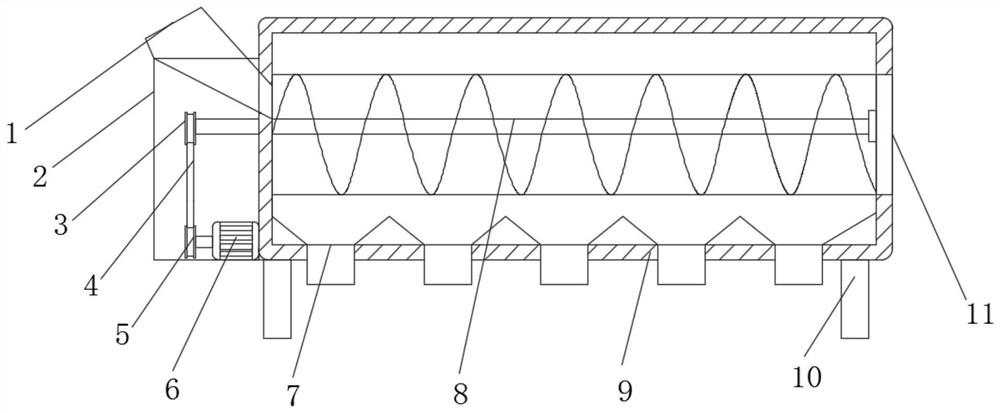

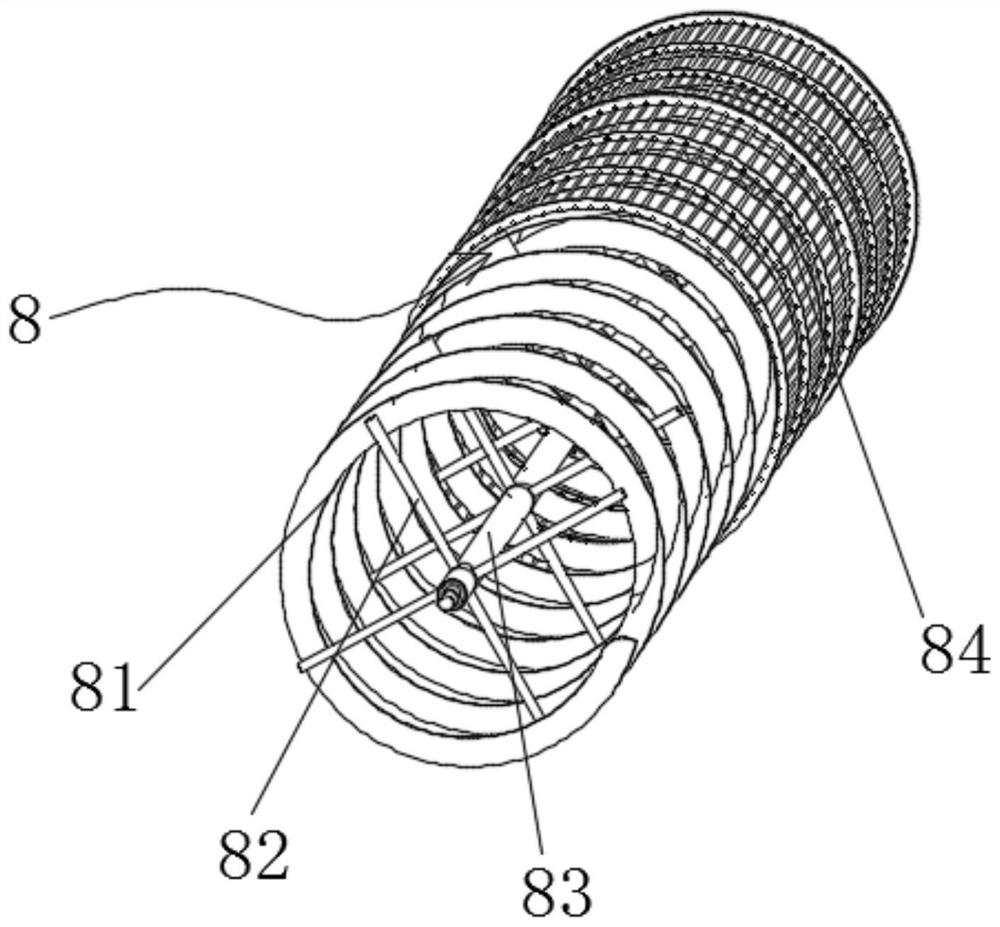

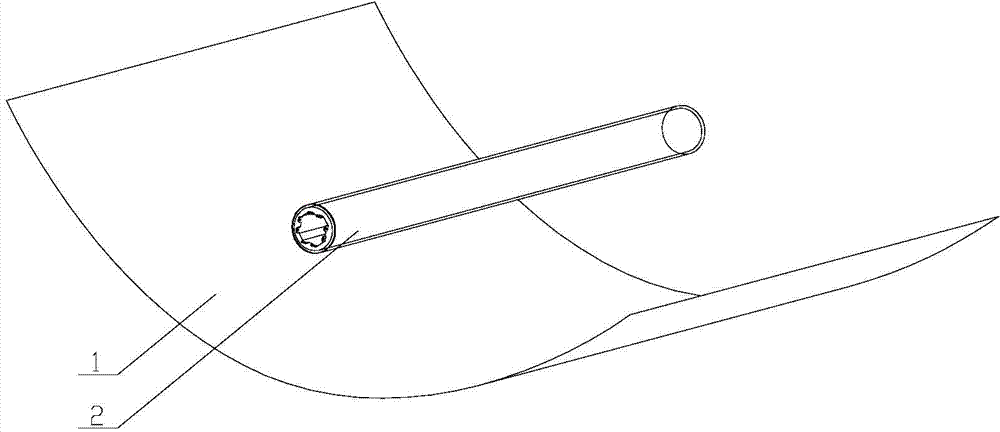

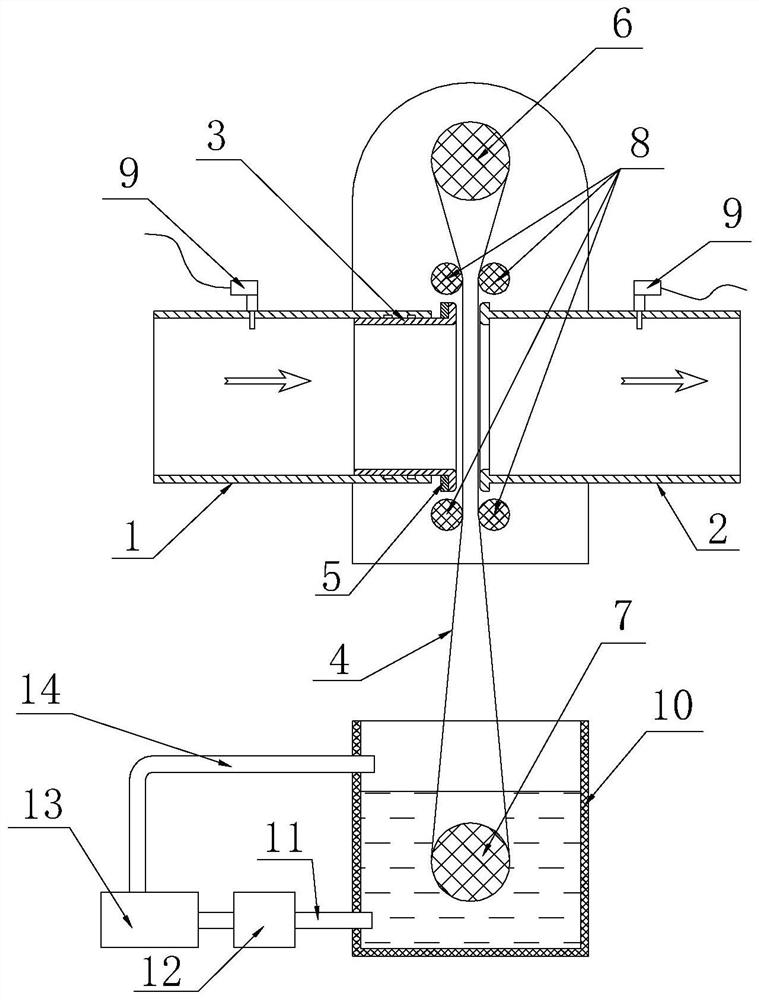

Dust-laden flue gas classification purification waste heat recovery system and dedusting heat storage and exchange device

InactiveCN109489460AHeat storageReduce wearGas treatmentDispersed particle filtrationProcess engineeringFlue gas

The invention discloses a dust-laden flue gas classification purification waste heat recovery system and a dedusting heat storage and exchange device. The dust-laden flue gas classification purification waste heat recovery system comprises a shell which is of an empty cuboid structure, and the middle part of the shell is provided with a separating plate; the shell is divided into an upper chamberand lower chamber by the separating plate; the waste heat recovery system is characterized in that the lower chamber is a flue gas channel, and the upper chamber is a cooling medium channel; the leftend of the flue gas channel is provided with a flue gas inlet, and the right end of the flue gas channel is provided with a flue gas outlet; the lower end of the flue gas channel is provided with a terraced cleanout door; the left end of the cooling medium channel is provided with a cooling medium outlet, and the right end of the cooling medium channel is provided with a first cooling medium inlet; the flue gas channel is internally provided with the dedusting heat storage and exchange device and an ash remover; the dedusting heat storage and exchange device is composed of a plurality of dedusting heat storage and exchange units arranged side by side transversely; each dedusting heat storage and exchange unit comprises a foam metal block, a filter screen and a plurality of three-dimensional ribbed heat pipe; and the waste heat recovery system can be widely applied to waste heat recovery of industrial flue gas.

Owner:CHONGQING UNIV

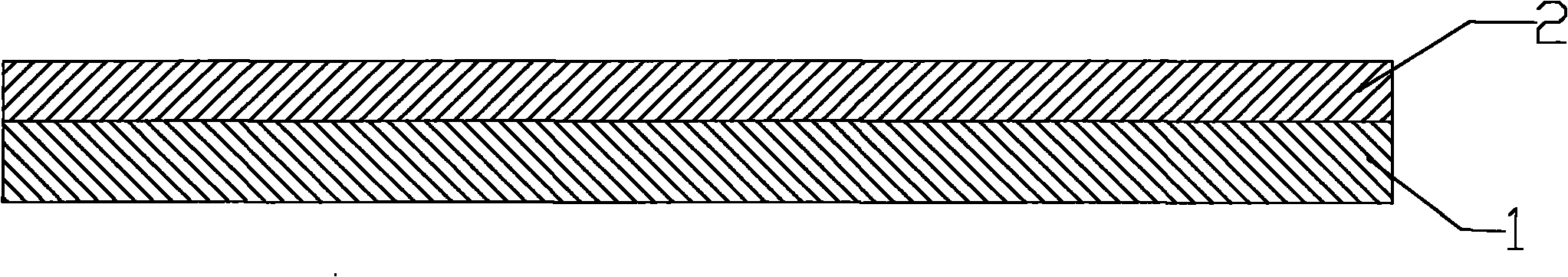

Composite wool knitted fabric

InactiveCN102092154ADehumidifyingHigh emissivitySynthetic resin layered productsCarbon fibersPhysical well being

The invention discloses a composite wool knitted fabric. The inner layer of the fabric is an antimicrobial and skin-kindly layer made of bamboo charcoal fibers, and the outer layer is a heat insulating layer made of wool fibers. The composite wool knitted fabric has the effects of dehumidifying and insulating heat as well as degerming and eliminating smell, is beneficial to the health of bodies and is suitable for being worn close to the skin.

Owner:WUJIANG YUANMING PRINTING FACTORY

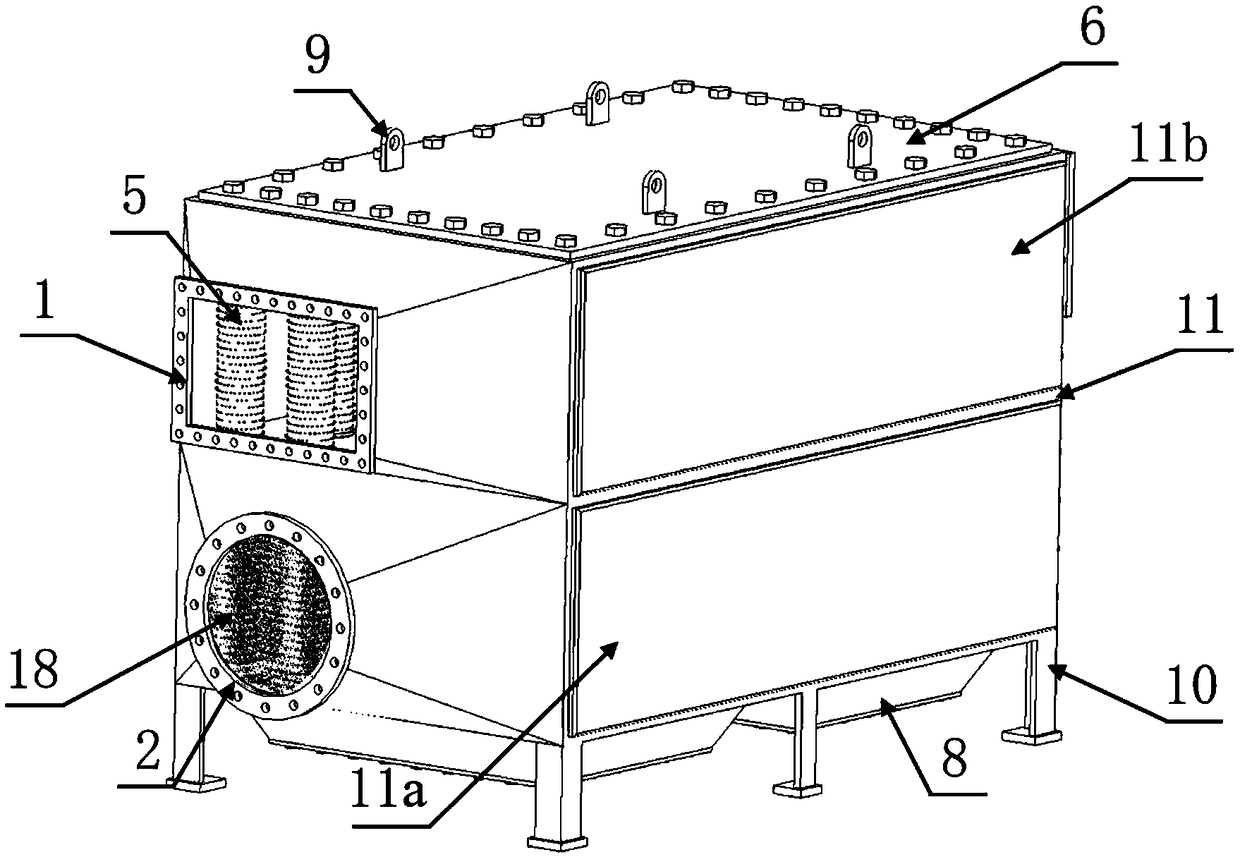

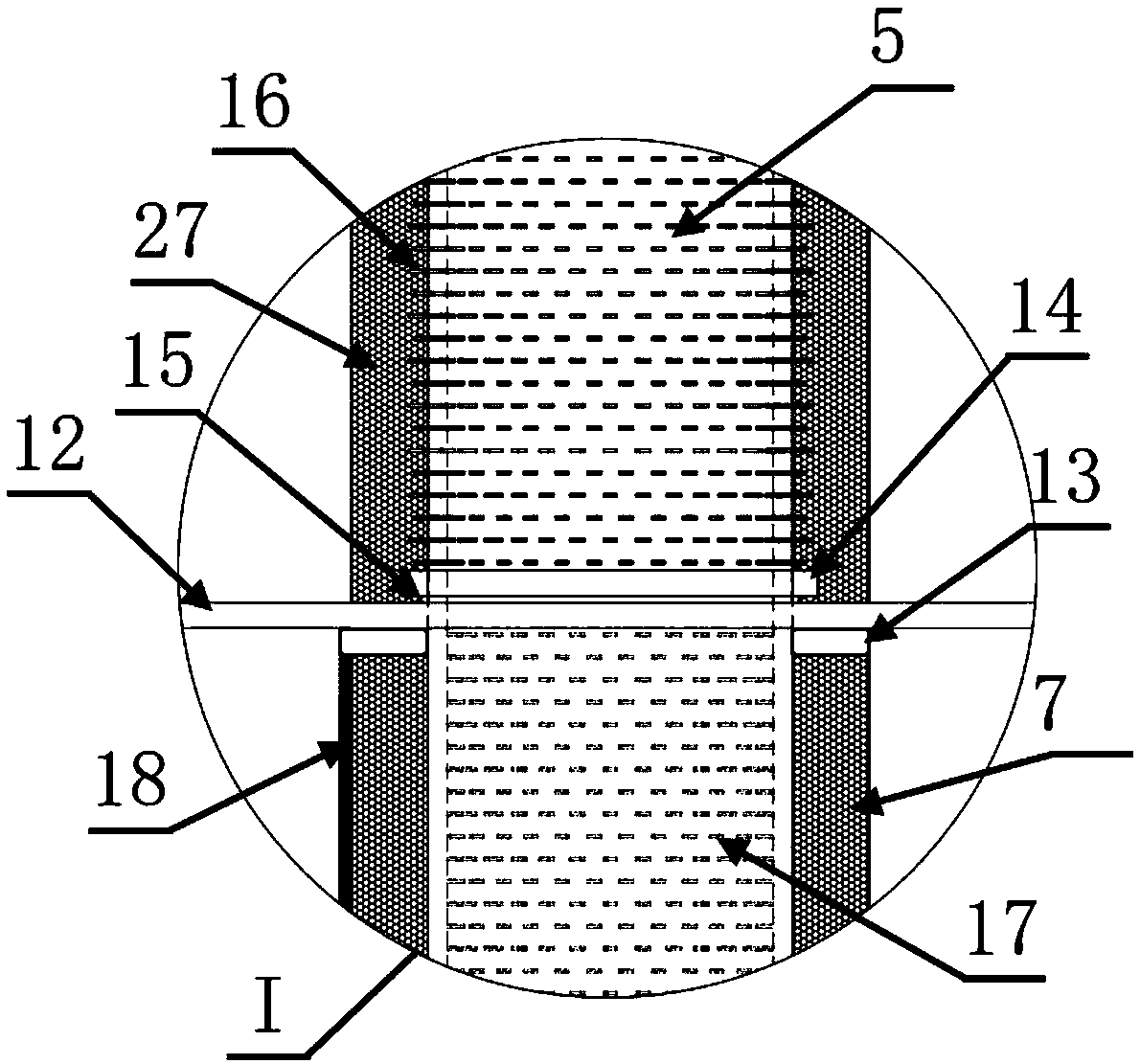

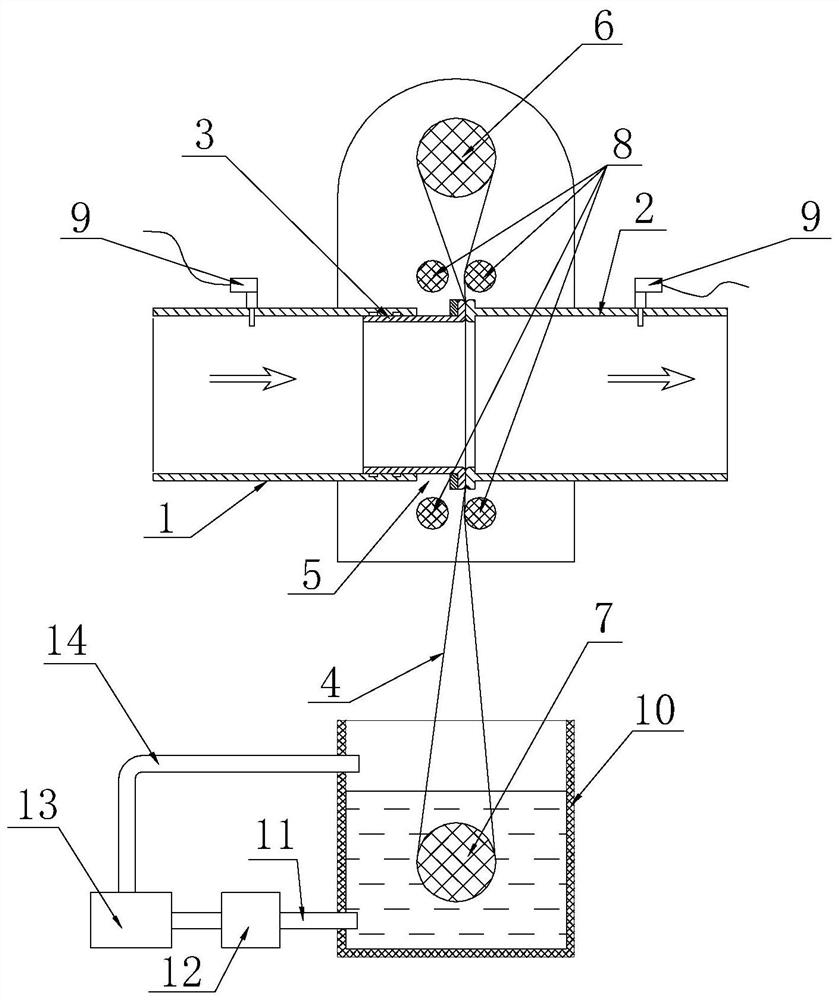

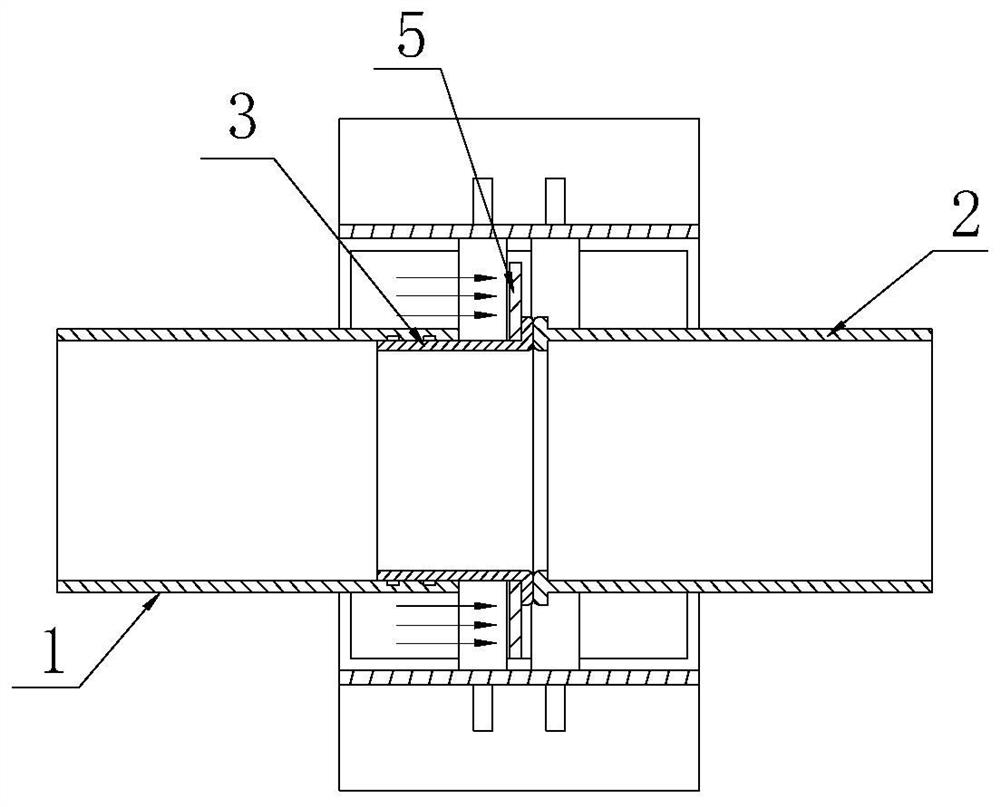

Device for composite adsorption microwave recovery or pyrolysis treatment of organic waste gas

ActiveCN109331564AEfficient removalImprove cleanlinessGas treatmentDispersed particle filtrationMicrowaveSorbent

The invention relates to an environmental protection device, and discloses a device for composite adsorption microwave recovery or pyrolysis treatment of organic waste gas. The device comprises a pretreatment unit and a plurality of parallel microwave treatment units; wherein the microwave treatment unit comprises a reaction box, an inlet tube, ceramic tubes, a microwave generator, a connecting tube, an outlet tube and a heat exchanger; the ceramic tubes are arranged in parallel in the reaction box; and the ceramic tubes are filled with active carbon layers and zeolite layers at intervals. Thepretreatment unit can automatically clean a filter medium contaminated. The microwave treatment units have high recovery and pyrolysis efficiency for organic pollutants, and the adsorbent can be repeatedly regenerated for use; and the device is simple, energy-saving, and low in operating cost. The device has great advantages in small and medium-sized volatile organic waste gas recovery and treatment projects.

Owner:义乌市爱釜义自动化科技有限公司

Energy-saving environment-friendly low-pressure die-casting machine heat-preserving furnace

The invention discloses an energy-saving environment-friendly low-pressure die-casting machine heat-preserving furnace. The die-casting machine heat-preserving furnace is provided with a furnace body air inlet / outlet hole, wherein the furnace body air inlet / outlet hole communicates with a regenerative chamber, a compressed air switch valve and a compressed air source in sequence through a pipeline; the furnace body air inlet / outlet hole also communicates with the regenerative chamber, an exhaust valve and the atmosphere in sequence through the pipeline; the regenerative chamber comprises a closed housing; a regenerator is arranged in the closed housing; and the closed housing is provided with a hot-end connection hole communicating with the furnace body air inlet / outlet hole, a hole communicating with the compressed air switch valve and a hole communicating with the exhaust valve. The die-casting machine heat-preserving furnace has the characteristics of energy conservation, emission reduction, consumption reduction and the like.

Owner:保定安保能冶金设备有限公司

Warming protection blend fiber

InactiveCN105256427AHeat storageMoisture-absorbing and breathableYarnMohairPolyethylene terephthalate

The present invention discloses a warming protection blend fiber. The warming protection blend fiber is blended and knitted by polytrimethylene terephthalate fiber, kapok fiber, ceramic thermal storage warming fiber and mohair fiber. The warming protection blend fiber comprises the components of, by weight, 17%-20% of polytrimethylene terephthalate fiber, 29%-38% of kapok fiber, 13%-16% of ceramic thermal storage warming fiber, and 32%-35% of mohair fiber. The warming protection blend fiber is blended and knitted by various fibers, has the characteristics of thermal storage and warming, health protection, moisture absorption and air permeability, and is comfortable to wear and is soft.

Owner:太仓市雄瑞化纺有限公司

Production method of bamboo charcoal polyester filament yarn

InactiveCN103184562AImprove performanceQuality improvementFilament/thread formingMonocomponent polyesters artificial filamentPolymer scienceSpinning

The invention provides a production method of bamboo charcoal polyester filament yarn. PET fondant and nanometer-stage bamboo charcoal master batch are taken as raw materials. The method comprises the following steps of: respectively transmitting and drying the two material materials, passing through an injection molding machine, extruding in a fusing way, spinning, forming in a cooling way by cross air blowing, applying oil to an oil mouth, previously stitching, discharging by a draw-off godet, stitching and forming in a coiling way, wherein the content of the nanometer-stage bamboo charcoal master batch is 23-27%. The production method of the bamboo charcoal polyester filament yarn has the following technical effects: the produced bamboo charcoal filament yarn is good in performance and stable in quality, wherein the linear density is 138dtex, the breaking strength is 2.1cN / dtex, the elongation at break is 136.8%, and the yarn unevenness is 0.8%.

Owner:JIANGSU TONGHAI THREAD

Antibacterial warm-keeping yarn and spinning process thereof

The invention relates to an antibacterial warm-keeping yarn and a spinning process thereof. The yarn contains the following components in percentage by weight: 35%-45% of bamboo charcoal modified polyester fibers, 35%-45% of polyurethane and 25%-35% of cotton fibers. The yarn has the strong antistatic and moisture absorption functions and the like, has no special requirement on washing, is not influenced by the environment and can be processed into four-season sportswear which is comfortable to wear and excellent in performance.

Owner:JIANGYIN XIANGFEI APPAREL

Antibacterial warm-keeping yarn and spinning process thereof

The invention relates to an antibacterial warm-keeping yarn and a spinning process thereof. The yarn is prepared from, by weight, 35%-45% of bamboo charcoal modified polyester fiber, 35%-45% of spandex and 25%-35% of cotton fiber. The yarn has the functions of static resistance, high moisture absorption and the like and has no special requirements for washing and is not affected by the environmentand can be used for processing four-season sportswear and is comfortable to wear and excellent in performance.

Owner:JIANGSU YUNFU FASHION CO LTD

Method for composite adsorption microwave recovery or pyrolysis treatment of organic waste gas

ActiveCN109331565AEfficient removalImprove cleanlinessGas treatmentDispersed particle filtrationActivated carbonHigh concentration

The invention relates to an environmental protection device, and discloses a method for composite adsorption microwave recovery or pyrolysis treatment of organic waste gas. Volatile organic pollutantsin the waste gas are adsorbed by a composite adsorbent loaded in a ceramic tube, so that the method is suitable for the treatment of both low-concentration large-volume organic waste gas and high-concentration organic waste gas. The low-concentration organic waste gas can be firstly adsorbed, enriched, then desorbed and pyrolyzed (or recovered); and the high-concentration organic waste gas can beadsorbed, desorbed and pyrolyzed simultaneously, in order to achieve the highest efficiency with the lowest energy consumption. Active carbon and zeolite are arranged at intervals, thereby avoiding the disadvantage that the radiation depth of microwave is affected by the fact that the single active carbon used at present absorbs the microwave, and improving the efficiency of the microwave.

Owner:义乌市爱釜义自动化科技有限公司

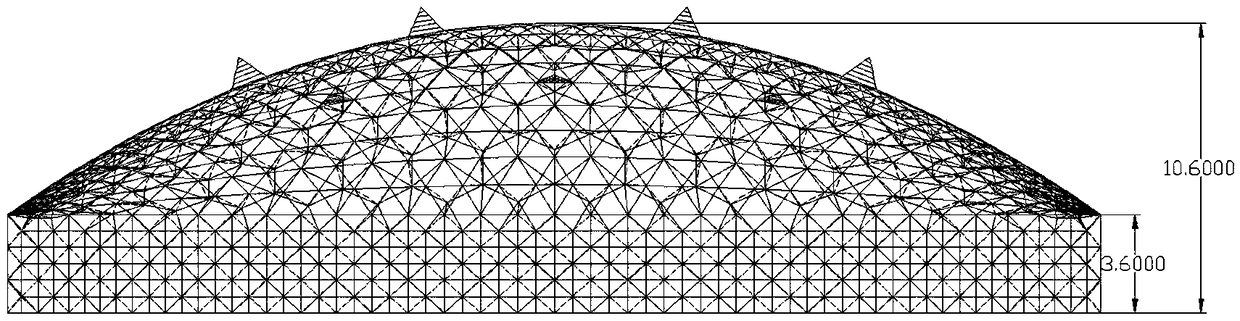

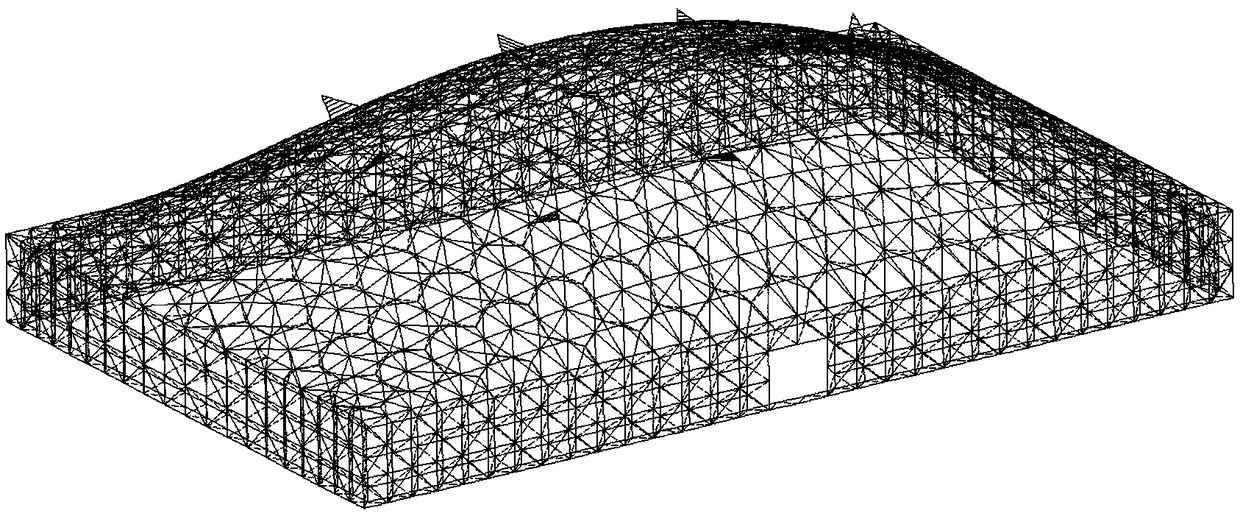

Wire-frame-type large-span supporting-column-free moment-type doom energy-saving green house construction method

ActiveCN108849090AImprove insulation effectAchieve insulation effectClimate change adaptationSaving energy measuresCold seasonGreenhouse

The invention discloses a wire-frame-type large-span supporting-column-free moment-type doom energy-saving green house construction method suitable for annual restless production, and belongs to the technical field of green houses. According to the method, the top is constructed as a doom by using a steel-structured wire frame, the ground edge is a moment-type large-span supporting-column-free green house steel structure, a green house internal wire frame platform is utilized to implement heat preserving quilt covering to achieve heat preserving effect in cold seasons, a green house internal water wall heat reserving technology is combined, dynamic controllable heat preserving, heat reserving and heat dissipating are achieved, and therefore restless production of vegetables and fruits in the cold seasons without heating is achieved. The moment-type configurations of wet curtains and fans at two ends are combined, ventilation temperature reduction culturing on high-temperature summer days is achieved to ensure the annual restless production of green house crops no matter in cold areas or in warm areas, and the method is an integrated innovation of a structure technology and a regulating technology in the field of green houses.

Owner:LISHUI AGRI SCI

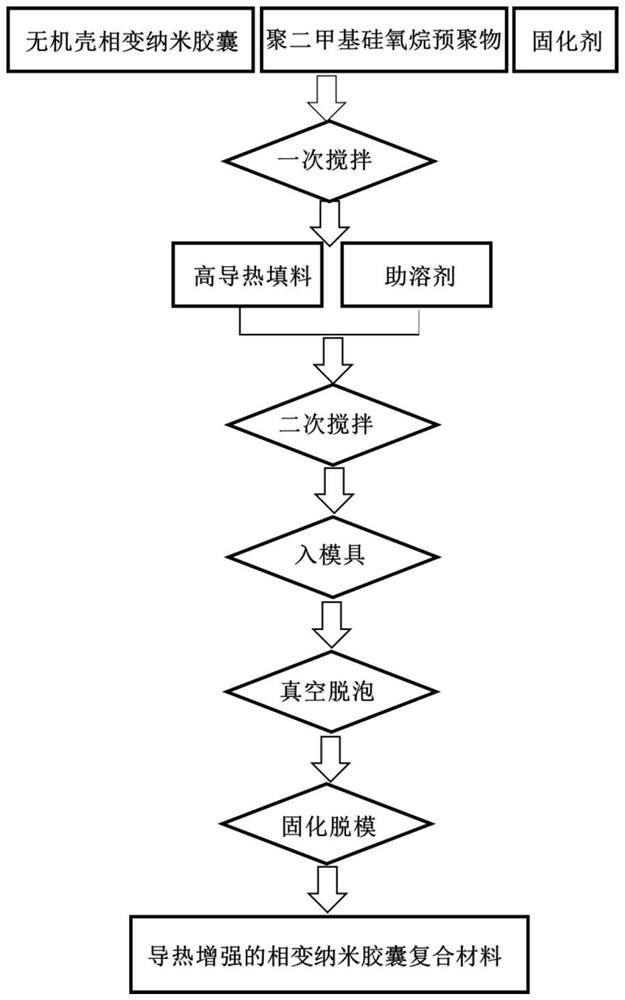

Phase-change nanocapsule composite material with enhanced heat conductivity as well as preparation method and application of phase-change nanocapsule composite material

PendingCN114774086ALarge heat transfer specific surface areaHeat storageHeat-exchange elementsNanocapsulesPrepolymer

The invention discloses a heat-conduction-enhanced phase-change nanocapsule composite material as well as a preparation method and application thereof. The heat conduction enhanced phase change nanocapsule composite material is prepared from the following raw materials in percentage by mass: 10.53 percent to 26.09 percent of inorganic shell phase change nanocapsules, 26.09 percent to 31.58 percent of high heat conduction filler, 43.47 percent to 52.63 percent of polydimethylsiloxane prepolymer and 4.35 percent to 5.26 percent of a curing agent. Dispersibility of the phase-change nanocapsule and the high-thermal-conductivity filler in a matrix is enhanced jointly through solvent assisted dispersion and intermittent feeding, so that the material has higher thermal conductivity and thermal storage capacity. The inorganic shell phase change nanocapsule enables the hardness of the polydimethylsiloxane-based composite material to be reduced, so that the composite material is more favorable for being attached to an interface. The material is used as a thermal interface material and is expected to fill air gaps, relieve thermal shock of a chip under high heat flux density and help the chip, an electronic device and the like to dissipate heat better.

Owner:SOUTH CHINA UNIV OF TECH

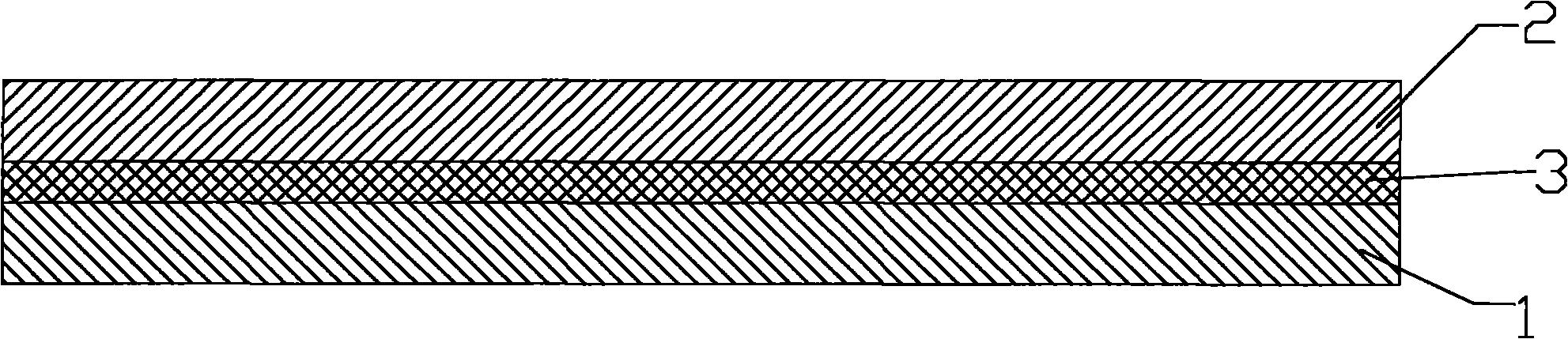

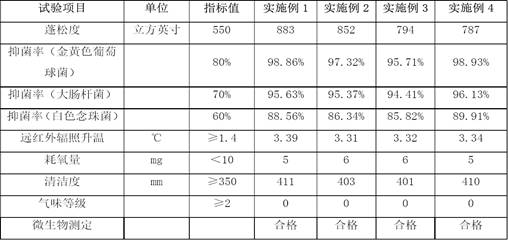

Down fabric

ActiveCN110561843APrevent drill out effectImprove breathabilitySynthetic resin layered productsCellulosic plastic layered productsWeather resistanceEngineering

The invention discloses a down fabric, which sequentially comprises a fabric outer layer, a down layer and an inner lining layer from top to bottom, wherein the fabric outer layer and the down layer as well as the down layer and the inner lining layer are respectively and independently adhered by adhesion layers, the fabric outer layer is prepared from the following raw materials by weight: 50-70parts of polypyrazolo[1,5-A]-1,3,5-triazine-2,4(1H,3H)-dione 3-(tert-butyldimethylsiloxy)glutarate, 20-30 parts of poly bis(carboxyethylgermanium sesquioxide) polytetrahydrofuran glycol ester, and 10-15 parts of graphene oxide. According to the present invention, the down fabric has advantages of excellent gas permeability, excellent down penetration prevention effect, excellent water resistance,excellent cold resistance, excellent weather resistance, excellent flame retardancy and good hand feeling, and further has health-care function of blood circulation promoting.

Owner:合肥乖米熊科技有限公司

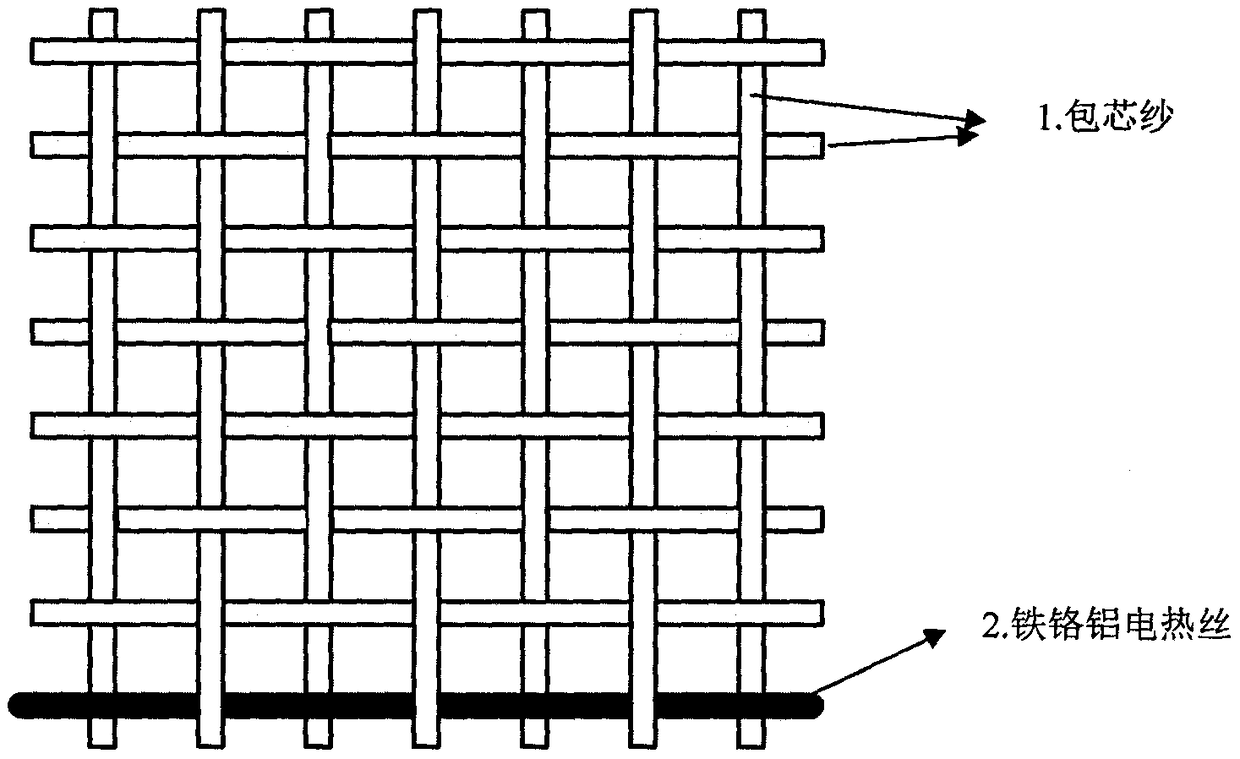

Preparation method of thermal-insulation moisture-permeable electric heating fabric

The invention discloses a preparation method of a thermal-insulation moisture-permeable electric heating fabric. The preparation method is characterized by comprising the following steps that firstly,a core spun yarn is prepared; secondly, the plain weave electric heating fabric is prepared, wherein the core spun yarn integrating advantages of three kinds of yarn is obtained through a fancy twister, the core spun yarn and iron-chromium-aluminum electric heating wires serve as raw materials, and a plain weave weaving technology is used for obtaining the fabric. The core spun yarn serves as warp, and the core spun yarn and the electric heating wires are woven into the fabric as weft at the density of 7:1. According to the method, the metal electric heating wires serve as the weft to be woven into the fabric in a circuit form, and when the distribution density of the core spun yarn and the electric heating wires is 7:1, the fabric has a good heating effect and proper softness. The electric heating fabric prepared with the metal electric heating wires as the material has better comprehensive performance than heating fabrics made of other materials, and has the advantages of being quick in heating, safe to use, high in heating efficiency, breathable and permeable to moisture.

Owner:TIANJIN POLYTECHNIC UNIV

A kind of warm fluffy duvet and its preparation process

ActiveCN109911837BGood antibacterialEasy to keep warmBlanketBed linenAnti bacterialAntibacterial agent

The invention discloses a heat-insulating fluffy down quilt and a preparation process thereof. The heat-insulating fluffy down quilt comprises a down quilt cover and an inner core, wherein the inner core is coated with the down quilt cover; the inner core is filled with bamboo charcoal fibers and pretreated wool and down feather. The heat-insulating fluffy down quilt is prepared by the following steps: 1) pretreatment of down feather: sterilizing-stem removal of raw materials-removal of sand dust-refining-primary cleaning-washing-dehydration-drying; 2) pretreatment of wool; 3) preparation of the down quilt: uniformly mixing the bamboo charcoal fibers and the pretreated wool and down feather, and then filling an inner core sleeve of the down quilt with the mixture. According to the heat-insulating fluffy down quilt disclosed by the invention, the down feather, wool and bamboo charcoal fibers are taken as the raw materials, the down feather is screened twice through a down feather screening machine to select high-quality large down feather, and then mixed with the wool and bamboo charcoal fibers for filling, and the mixture is treated with an anti-bacterial agent, so that the prepared down quilt has a good anti-bacterial effect, heat-insulating performance and fluffiness.

Owner:宁波博洋家纺集团有限公司

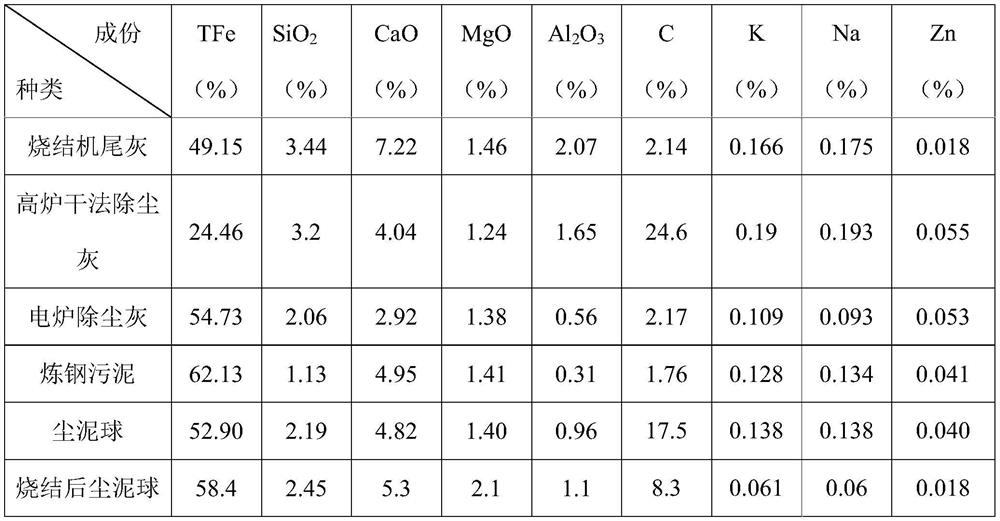

Sintering method of harmful dust and sludge in iron and steel plant

The invention discloses a sintering method of harmful dust and sludge in an iron and steel plant. The sintering method comprises the following steps of: (1) mixing various dust and sludge in the iron and steel plant to obtain a dust and sludge mixture, and adding coal powder according to the contents of TFe, K, Na, Zn and C elements in the dust and sludge mixture to obtain a dust and sludge uniform mixture; (2) carrying out double-roller ball pressing on the dust and sludge uniform mixture obtained in the step (1) to obtain dust and sludge balls; and (3) sequentially distributing a bedding material, the dust and sludge balls obtained in the step (2) and a sintering raw material on a sintering trolley, and igniting and sintering. According to the sintering method, the harmful dust and sludge in the iron and steel plant are collected, after reasonable carbon distribution and full mixing are carried out, double-roller high-pressure ball pressing is carried out to obtain the high-strength dust and sludge balls, and then the bedding material, the high-strength dust and sludge balls and the sintering raw material are sequentially distributed into the sintering trolley for ignition and sintering.

Owner:SHANDONG IRON & STEEL CO LTD

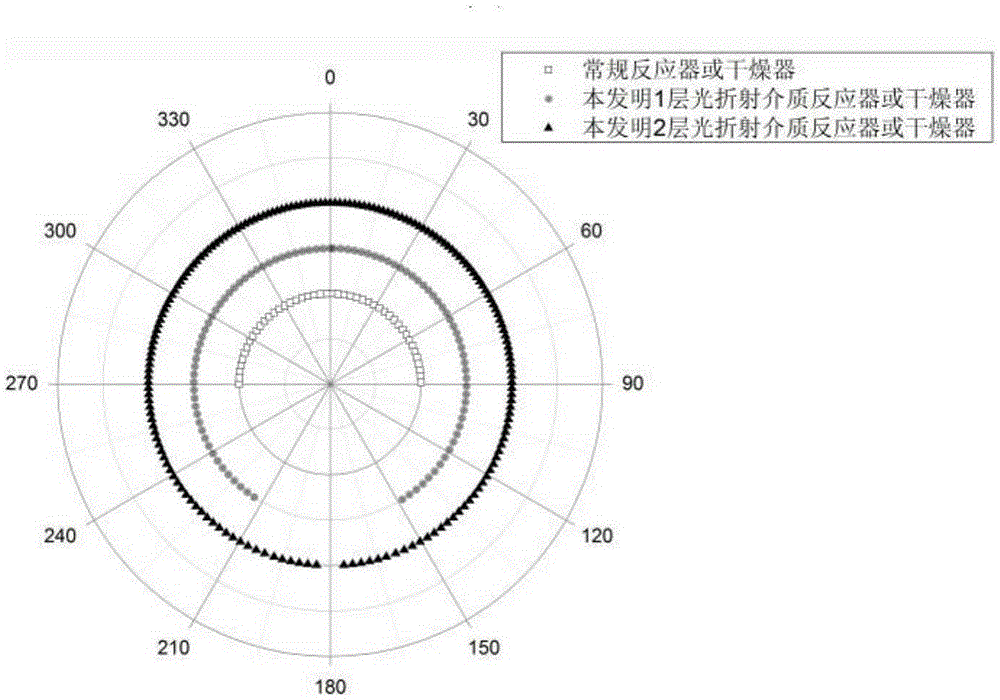

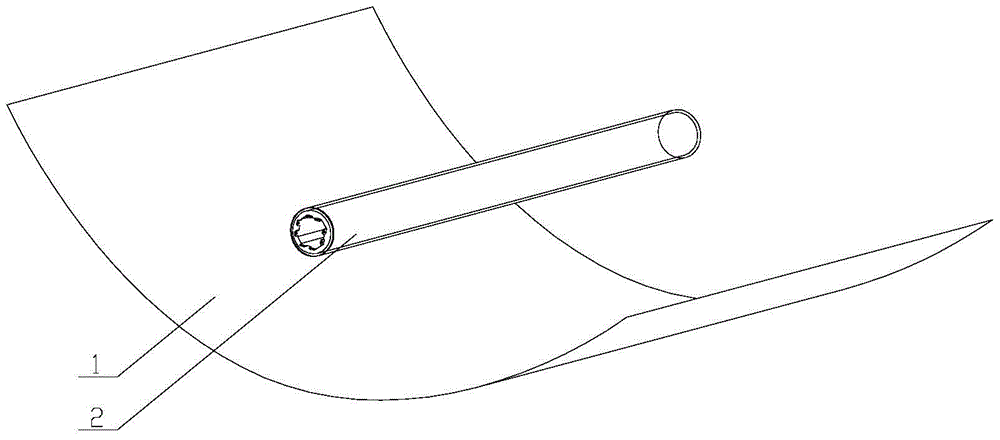

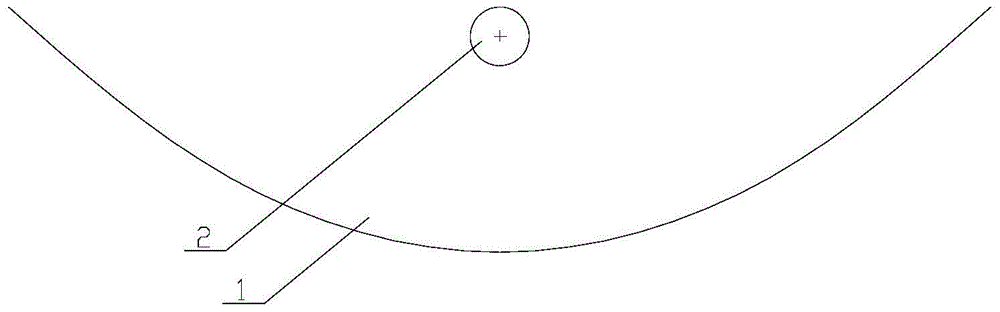

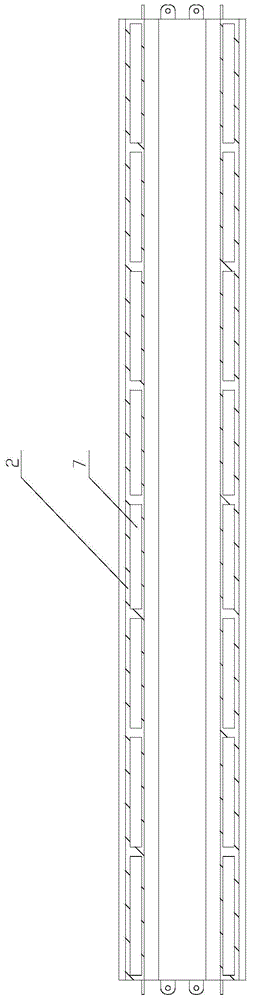

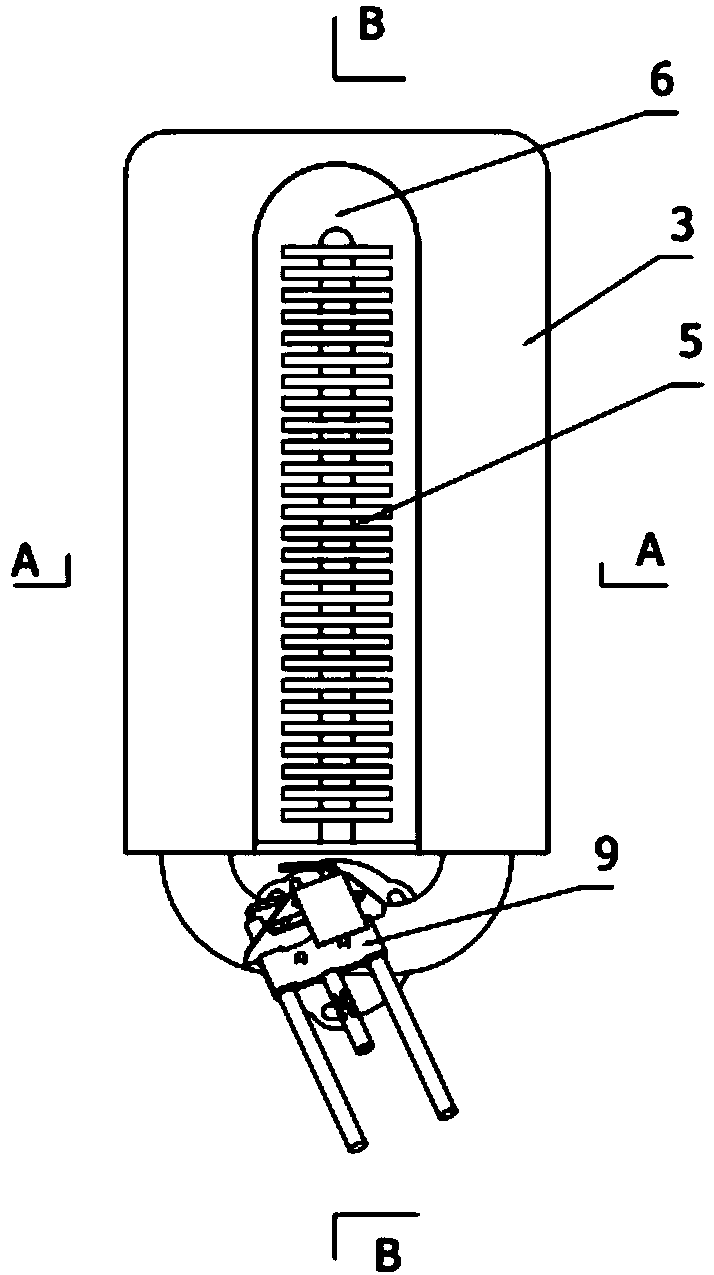

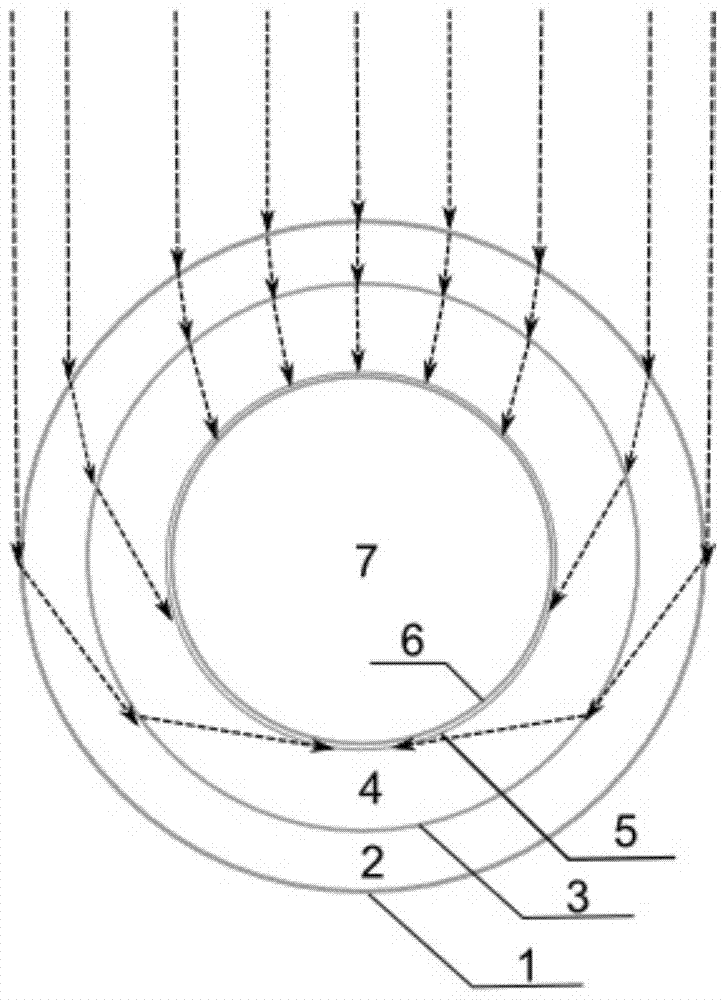

Refraction-based solar light homogenizing tube type reactor or dryer and design method thereof

ActiveCN105258364AMany layers of designEvenly distributed around the circumferenceSolar heating energySolar heat devicesSolar lightRelative refractive index

The invention relates to a refraction-based solar light homogenizing tube type reactor or dryer and a design method thereof. The reactor or dryer is composed of a plurality of cylindrical transparent hollow light refraction media with a certain refractive index and a certain thickness in a fit manner. The position between the outer surface of the cylindrical transparent hollow light refraction medium on the outmost layer and the cylindrical transparent hollow light refraction medium adjacent to the cylindrical transparent hollow light refraction medium on the outmost layer is covered with an antireflection film used for reducing light reflection losses. The relative index of refraction of the cylindrical transparent hollow light refraction media and air is increased in sequence from outside to inside. The design method for the reactor or dryer is further provided. According to the solar tube type reactor or dryer designed through the method, light reflecting losses can be effectively reduced, meanwhile, the peripheral light receiving angle of the solar tube type reactor or dryer can be effectively increased, the area of the backlight side can effectively receive light, then light distribution on the reactor or dryer is optimized, and the distribution uniformity of light in the peripheral direction of the reactor or dryer is further improved.

Owner:XI AN JIAOTONG UNIV

A trough-type concentrated solar thermoelectric generator

The invention discloses a trough type light-condensing solar thermoelectric generator which comprises a trough type light-condensing device and a receiving tube. The receiving tube is opposite to the inner cambered surface of the trough type light-condensing device and comprises an inner wall and an outer wall, the inner wall defines a hollow cavity penetrating two ends of the receiving tube, the cavity between the inner wall and the outer wall is divided into multiple sealed filling cavities through metal heat-conducting units, each sealed filling cavity is full of heat-conducting oil, thermoelectric power generation pieces are installed on the side close to the hollow cavity, in the inner wall, in the linear direction, and covers the inner wall partially or wholly, and water-cooling pieces are installed on the cooling face of the thermoelectric power generation pieces. The interlayer cavity of the receiving tube is filled with heat-conducting oil, the heat-conducting oil has certain heat storage effect, and even if sunlight is interrupted, power generation can be also sustained for a period of time. The fluctuation changing with sunlight during electric energy output is reduced, the cavity between the inner wall and the outer wall is discontinuous, the inner wall and the outer wall are still partially connected through the metal heat-conducting units made of aluminum alloy and the like, and the problem that external heat cannot be transferred to the inner wall due to poor heat-conducting performance of the heat-conducting oil is avoided.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

a down fabric

ActiveCN110561843BPrevent drill out effectImprove breathabilitySynthetic resin layered productsCellulosic plastic layered productsPolymer scienceEngineering

Owner:合肥乖米熊科技有限公司

Health-care wadding and production method and use method thereof

PendingCN111850814AWith far-infrared light wavesWith antibacterial and mite removalNon-woven fabricsFiberMedicine

The invention discloses a health-care wadding and production method and use method thereof. The health-care wadding comprises the following components in percentage by weight: 10%-50% of graphene short fibers and 50%-90% of a filler, wherein the graphene short fibers are refined from graphite ore. The production method of the health-care wadding includes the following steps that a, the graphene short fibers are prepared; b, the graphene short fibers and the filler are mixed into a mixed material at a ratio of 1:9 to 5:5; c, the mixed material is sent to a carding machine for carding; and d, the carded mixed material is fed into a mixer, and stirring is carried out until the mixed material forms clusters and then becomes the health-care wadding. The health-care wadding is used as a fillingmaterial for down jackets, down pants and duvets. The health-care wadding has the effects of far-infrared light wave, antibacterial and mites removal, heat storage and warm keeping and antistatic effect.

Owner:常熟市杰鼎服饰有限公司

Trough type light-condensing solar thermoelectric generator

The invention discloses a trough type light-condensing solar thermoelectric generator which comprises a trough type light-condensing device and a receiving tube. The receiving tube is opposite to the inner cambered surface of the trough type light-condensing device and comprises an inner wall and an outer wall, the inner wall defines a hollow cavity penetrating two ends of the receiving tube, the cavity between the inner wall and the outer wall is divided into multiple sealed filling cavities through metal heat-conducting units, each sealed filling cavity is full of heat-conducting oil, thermoelectric power generation pieces are installed on the side close to the hollow cavity, in the inner wall, in the linear direction, and covers the inner wall partially or wholly, and water-cooling pieces are installed on the cooling face of the thermoelectric power generation pieces. The interlayer cavity of the receiving tube is filled with heat-conducting oil, the heat-conducting oil has certain heat storage effect, and even if sunlight is interrupted, power generation can be also sustained for a period of time. The fluctuation changing with sunlight during electric energy output is reduced, the cavity between the inner wall and the outer wall is discontinuous, the inner wall and the outer wall are still partially connected through the metal heat-conducting units made of aluminum alloy and the like, and the problem that external heat cannot be transferred to the inner wall due to poor heat-conducting performance of the heat-conducting oil is avoided.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

Gas burner and gas steam generator thereof

InactiveCN108375069AEasy to replacePlay a role in gathering energyBurner safety arrangementsSteam generation heating methodsCombustion chamberButt joint

The invention relates to the technical field of gas devices, in particular to a gas burner. The gas burner comprises a rectangular chamber, a gas mesh enclosure, a U-shaped cover plate and a combustion chamber base, wherein the top of the rectangular chamber is open, the bottom of the rectangular chamber is provided with a mounting recess, the combustion chamber base is inserted in the mounting recess, the gas mesh enclosure is of a U-shaped trough structure, the front end of which is open, the bottom edge of the gas mesh enclosure is inserted between a bottom flat surface and the mounting recess, heat-uniforming rib plates are also evenly distributed in parallel on a top flat surface of the combustion chamber base, and the cover plate is mounted on the top of the rectangular chamber. Theinvention further discloses a gas steam generator, which comprises a stove body and heat exchange smoke tubes, wherein the heat exchange smoke tubes are symmetrically arranged on the left and the right in the stove body, the middle of the lower part of the stove body is provided with a long chamber type combustion chamber along a front-rear direction, and the gas steam generator further comprisesthe gas burner in butt joint to the lower part of the combustion chamber. The gas burner has the beneficial effects as follows: the heat gathering performance of the gas mesh enclosure is sufficientlyutilized, burning is stable, flame is stable, and the thermal efficiency is high.

Owner:赵乐

A refraction-based solar homogeneous tube reactor or dryer

ActiveCN105276838BImprove photothermal efficiencyEfficient dryingSolar heating energySolar heat storageSolar lightRelative refractive index

A refraction-based solar homogeneous tube reactor or dryer, which is composed of a plurality of cylindrical transparent hollow photorefractive media with a certain refractive index and a certain thickness. The surface, the inner surface of the innermost cylindrical transparent hollow light refraction medium and the adjacent cylindrical transparent hollow light refraction medium are covered with an anti-reflection film to reduce light reflection loss; the innermost cylindrical transparent hollow light refraction The inside of the anti-reflection film on the inner surface of the medium is the inner wall, and the inner wall is the inner reaction or drying cavity; from the outside to the inside, the relative refractive index of the cylindrical transparent hollow light refraction medium and air increases sequentially; When propagating in a hollow transparent cylinder, it is constantly deflected due to refraction, so that the circumferential light receiving angle is significantly increased, and the light distribution in the circumferential direction of the reactor or dryer is more uniform.

Owner:XI AN JIAOTONG UNIV

A device for composite adsorption microwave recovery or pyrolysis treatment of organic waste gas

ActiveCN109331564BRealize automatic controlAvoid foulingGas treatmentDispersed particle filtrationActivated carbonSorbent

The invention relates to an environmental protection device, and discloses a device for composite adsorption microwave recovery or pyrolysis treatment of organic waste gas. The device comprises a pretreatment unit and a plurality of parallel microwave treatment units; wherein the microwave treatment unit comprises a reaction box, an inlet tube, ceramic tubes, a microwave generator, a connecting tube, an outlet tube and a heat exchanger; the ceramic tubes are arranged in parallel in the reaction box; and the ceramic tubes are filled with active carbon layers and zeolite layers at intervals. Thepretreatment unit can automatically clean a filter medium contaminated. The microwave treatment units have high recovery and pyrolysis efficiency for organic pollutants, and the adsorbent can be repeatedly regenerated for use; and the device is simple, energy-saving, and low in operating cost. The device has great advantages in small and medium-sized volatile organic waste gas recovery and treatment projects.

Owner:义乌市爱釜义自动化科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com