Health-care wadding and production method and use method thereof

A technology of health-care fleece and graphene, which is applied in the field of health-care fleece, can solve problems such as difficult cleaning, antibacterial resistance, and decline in thermal performance, and achieve the effects of increasing the body's oxygen content, promoting metabolism, and compensating for heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

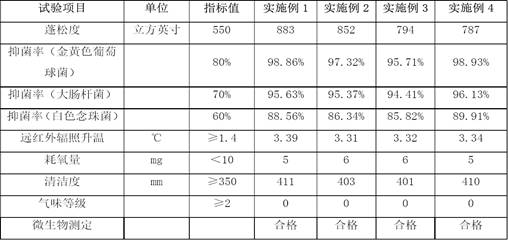

Embodiment 1

[0037] Health fleece includes the following components by weight percentage:

[0038] Graphene short fiber 20%;

[0039] Filling material 80%,

[0040] The graphene short fiber is made of biomass graphene, and the graphene short fiber is in a two-dimensional curved shape, and the filler is 90% down and 10% feather flakes.

[0041] The method for producing above-mentioned health care cashmere, it may further comprise the steps:

[0042] a. Prepare graphene short fibers, the graphene short fiber specification is 1.22D / 20mm two-dimensional crimp;

[0043] B. Graphene short fiber and filler are mixed by 2:8 to form compound;

[0044] c. Send the mixed mixture into the carding machine for carding;

[0045] d. Send the carded mixture into the mixer, and stir until the mixture forms small balls to form health-care down; the two-dimensional curly graphene short fibers can more fully realize the support between the down and down and improve its bulkiness.

Embodiment 2

[0047] Health fleece includes the following components by weight percentage:

[0048] Graphene short fiber 15%;

[0049] Filling material 85%,

[0050] The graphene short fiber is made of biomass graphene

[0051] The graphene short fiber is two-dimensional curved, and the filler is feather flakes with 90% cashmere and 10%.

[0052] The method for producing above-mentioned health care cashmere, it may further comprise the steps:

[0053] a. Prepare graphene short fibers, the graphene short fiber specification is 1.22D / 20mm two-dimensional crimp;

[0054] b. Mix graphene short fibers and fillers at 1.5:8.5 to form a mixture; down

[0055] c. Send the mixed mixture into the carding machine for carding;

[0056] d. Send the combed mixture into the blender, and stir until the mixture forms fluff and then becomes health-care fleece.

[0057]The difference between the present embodiment and the first embodiment is that the components of the health-care fleece and other conditi...

Embodiment 3

[0059] Health fleece includes the following components by weight percentage:

[0060] Graphene short fiber 20%;

[0061] Filling material 80%,

[0062] The graphene short fiber is made of biomass graphene, and the graphene short fiber is in a two-dimensional curved shape, and the filler is 90% down and 10% feather flakes.

[0063] The method for producing above-mentioned health care cashmere, it may further comprise the steps:

[0064] a. Prepare graphene short fibers, the graphene short fiber specification is 1.22D / 20mm two-dimensional crimp;

[0065] B. Graphene short fiber and filler are mixed by 1:9 to form compound;

[0066] c. Send the mixed mixture into the carding machine for carding;

[0067] d. Send the combed mixture into the blender, and stir until the mixture forms fluff and then becomes health-care fleece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com