Composite phase-change heat-storage heating method and heating apparatus

A technology of phase change heat storage and composite phase change, which is applied to heating methods and central heating, can solve the problems of large heat storage equipment and insufficient heat storage capacity, and achieve the effect of improving heat storage capacity and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0030] Example 1: Thermal storage electric heater

[0031] The specific structure of the electric heating device of the regenerative electric heater can be seen in Fig. 6 to Fig. 8 . An electric heating plate 18 is arranged at the bottom of the heat storage device to provide heat. The electric wires of the electric heating plate 18 pass through from the airflow channel 15 and the insulation layer 14, and the electric wires are covered with insulating sleeves 19 outside.

[0032] The heat storage device is composed of three parts: an insulation layer 14 , a heat storage chamber 22 , and a packed bed containing a phase-change heat storage medium and a heat medium 12 . The thermal insulation layer 14 covers the heat storage cavity 22 and the air flow channel 15, and its function is to reduce heat loss during the heat storage process. The heat medium 12 generally uses heat-conducting oil, because it has a large thermal conductivity, good heat transfer performance, and has a cert...

example 2

[0035] Example 2: Regenerative heating tube in floor electric heating

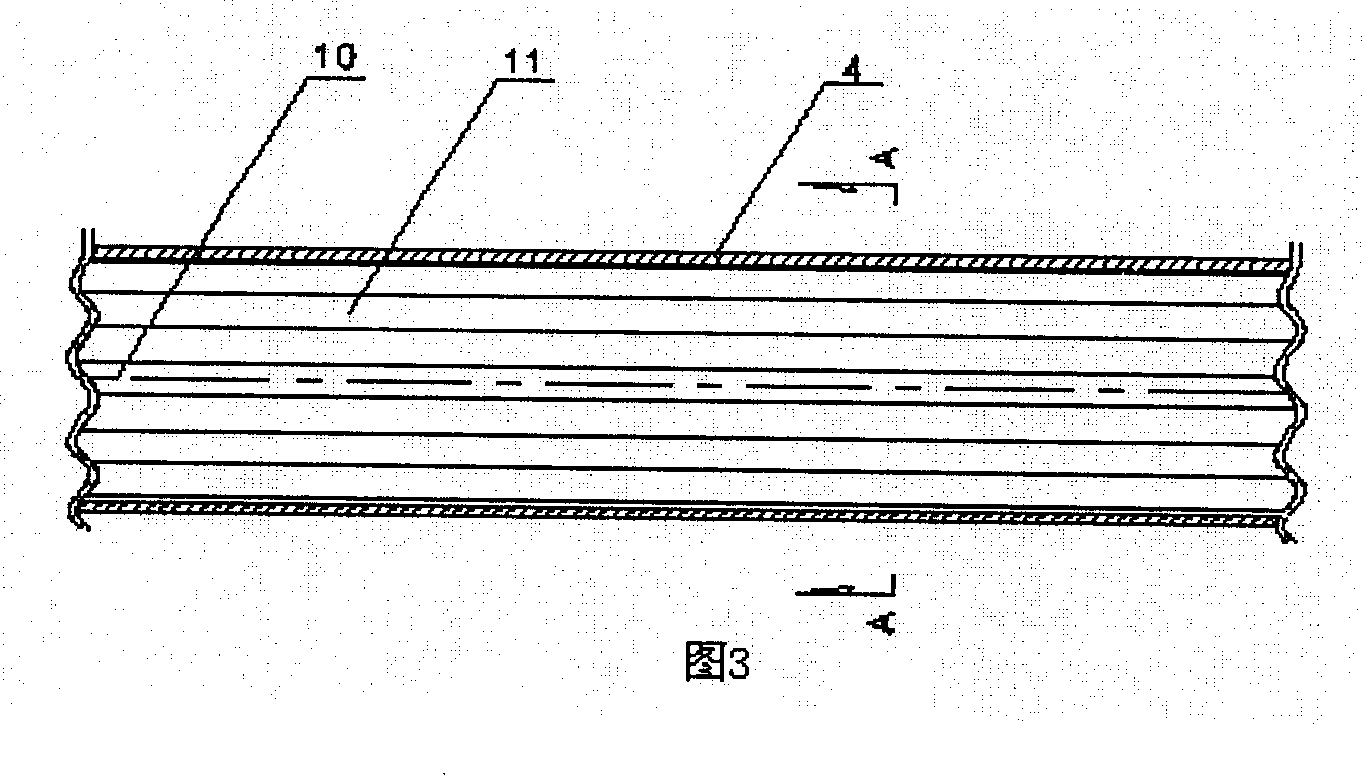

[0036] First of all, when manufacturing heat storage tubes and heat storage capsules filled with phase change heat storage medium, a certain amount of space margin should be reserved when filling the heat storage medium, so as to avoid volume expansion when the phase change heat storage medium melts and cause expansion of the tube. After filling, it should be strictly sealed to prevent the phase change material from seeping out after long-term use, which will greatly reduce the heat storage effect. The phase change thermal storage medium can be selected from organic or inorganic phase change materials with a phase change temperature between 40 and 45 degrees Celsius. Then, install the heating cable in the center of the outsourcing pipe. In the next step, the remaining space in the tube is filled with the fabricated heat storage tube or capsule. Its specific structure can be seen in Figure 3-Figure 5. Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com